Front

Powered front axle

Front

Powered rear axle

Rear bevel gear set and dif ferential

Final drive steering and shafts

Brakes

Fixed displacement pump

Main

[35.724]

[35.701]

[35.726]

[35.736]

[35.737]

Frames and

Steering control

Hydraulic control components

Wheels

[44.51

[44.520]

Wiper

Front

Safety rules

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury

Throughout this manual you will find the signal words W and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation not could result minor moderate injury

F AILURE T O FOLLOW DANGER, W ARNING, AND CAUTION MESSAGES COULD RESUL T DEA SERIOUS INJUR Y .

Machine safety

NOTICE: Notice indicates a situation that, not avoided, could result machine property damage.

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property damage. The word Notice used address practices not related personal safety .

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a step, other information the The word Note not intended address personal safety property

Safety rules

DANGER

Improper operation service this machine can result accident.

not operate this machine perform any lubrication, maintenance, repair until you have read and understood the operation, lubrication, maintenance, and repair information.

Failure comply will result death serious injury

W ARNING

Maintenance hazard!

D0010A

Always perform all service procedures punctually the intervals stated this This ensures optimum performance levels and maximum safety during machine operation.

Failure comply could result death serious injury .

NOTICE: Extreme working and environmental conditions require shortened service

W0132A

Use Case and filters for the best protection and performance your All and filters must disposed compliance with environmental standards and Contact your Dealer with any questions regarding the service and maintenance this machine.

Use this manual with the manual understand and perform the complete service Read the safety decals and information decals the machine. Read the Operator ’ s Manual and safety manual. Understand the operation the machine before you start any

Before you service the machine, put a Not tag the steering wheel over the key switch. Ensure the tag a location where everyone who might operate service the machine may see clearly

Plastic and resin parts

• A void using paint thinner , when cleaning plastic instrument cluster ,

• Use only water , mild and a soft cloth when you clean these

• Using can cause deformation the part being

Safety rules - Ductile iron

DANGER

Altering cast ductile iron can cause weaken

Before you weld, cut, drill holes any part this machine, make sure that the part not cast ductile iron.

Failure comply will result death serious injury .

D0148A

Altering cast ductile iron can cause weaken Unauthorized modifications cast ductile iron parts can cause death serious injury not repair , attach items cast ductile iron parts this

Before you drill holes any part this make sure the part not cast ductile See your dealer you not know a part cast ductile

The following items are examples cast ductile iron There may also other parts made cast ductile iron that are not the list below

• two - wheel drive steering link

• dump links

• front axle

• stabilizers

• extend - a - hoe

• swing tower

• bucket linkage

• Air - Conditioning / compressor mounting bracket

not make any unauthorized Consult authorized dealer before making any modifications this

Safety rules - Ductile iron

DANGER

Improper operation service this machine can result

Any unauthorized modifications made this machine can have serious consequences. Consult authorized dealer changes, additions, modifications that may required for this machine. not make any unauthorized modifications.

Failure comply will result death serious injury .

D0030A

Before you drill holes any part this make sure the part not cast ductile See your dealer you not know a part cast ductile iron. The following are cast ductile iron parts:

• two wheel drive steering link

• dump links

• front axle

• stabilizers

• extendahoe

• swing

• bucket linkage

• Air Conditioning / compressor mounting bracket

Unauthorized modifications cast ductile iron parts can cause injury W drilling can cause cast ductile iron not drill repair attach items cast ductile iron parts this

INTRODUCTION

Safety rules

Unless otherwise instructed, always perform these steps before you service the machine:

Park the machine a level

Place the backhoe the transport position with the swing lock pin installed for transport.

Place the loader bucket the with the bottom the loader bucket parallel the

Place the direction control lever and the transmission you need open the hood perform raise the loader arms and install the support

Shut down the

Place a Not tag the key switch that visible other workers remove the key

Safety rules - Ecology and the environment

Soil, air , and water are vital factors agriculture and life general. When legislation does not yet rule the treatment some the substances required advanced technology , sound judgment should govern the use and disposal products a chemical and petrochemical

NOTE: The following are recommendations that may assistance:

• Become acquainted with and ensure that you understand the relative legislation applicable your country

• Where legislation obtain information from suppliers cleaning with regard their fect man and nature and how safely and dispose these

Helpful hints

• A void filling tanks using cans inappropriate pressurized fuel delivery systems that may cause considerable spillage.

• avoid skin contact with all

Most them contain substances that may harmful your health.

• Modern oils contain not burn contaminated fuels and waste oils ordinary heating

• A void spillage when draining f used engine coolant gearbox and hydraulic brake not mix drained brake fluids fuels with Store them safely until they can disposed a proper way comply with local legislation and available

• Modern coolant antifreeze and other should replaced every two They should not allowed get into the but should collected and disposed properly

• Repair any leaks defects the engine cooling hydraulic system immediately .

• not increase the pressure a pressurized circuit this may lead a component

• Protect hoses during welding penetrating weld splatter may burn a hole weaken them, allowing the loss

Basic instructions - Important notice regarding equipment servicing

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution chain, including - without limitationnational, regional, local CASE reject any responsibility for damages caused parts and / components not approved the manufacturer , including those used for the servicing repair the product manufactured marketed the manufacturer

any warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The information this manual - - date the date the the policy the manufacturer for continuous Some information could not updated due modifications a technical commercial changes the laws and regulations dif ferent

case questions, refer your Case New Holland Construction Equipments Sales and Service Networks.

Basic instructions

W ARNING

Explosive gas!

Batteries emit explosive hydrogen gas and other fumes while charging. V entilate the charging area. Keep the battery away from sparks, open flames, and other ignition sources. Never charge a frozen battery

Failure comply could result death serious injury .

W ARNING

Hazardous chemicals!

W0005A

Battery electrolyte contains sulfuric acid. Contact with skin and eyes could result severe irritation and Always wear splash - proof goggles and protective clothing (gloves and W ash hands after handling.

Failure comply could result death serious injury .

• not run the engine with the alternator wires

• Before using electric welder , disconnect the alternator instrument cluster and

• not use a steam cleaner a cleaning solvent clean the alternator

• Keep the battery vents Ensure the battery vents are not

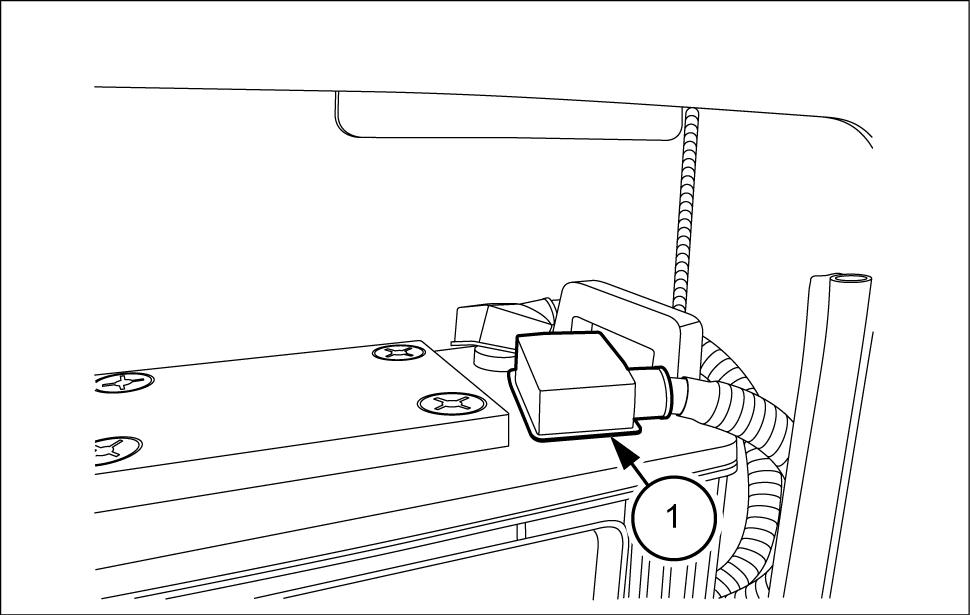

Disconnect battery

Open the battery compartment cover the right hand side step the using the key

Disconnect the negative battery cable (1) from the negative battery

W0006A

Basic instructions - Fuse and relay locations

The machine equipped with a fuse located the side

Side console box

T urn the thumb screws (1) loosen the panel cover (2) for the fuse Remove the panel cover

Remove the fuse box covers needed.

Refer the decal top the panel cover for relay , and / diode

The fuses are arranged per the 2