SER VICE MANUAL

P2350, P3440, P3550 , P4460, P4580, P4760, P4950

Contents

INTRODUCTION

Front axle system

[25.400] Non-powered front axle

Rear axle system

rear axle

Brakes and controls

[33.202] Hydraulic service brakes

Hydraulic systems

Hydraulic systems

Hydraulic seeding fan system

Seeding and planting hydraulic circuits

Auxiliary tank fill system hydraulic control

Frames and ballasting

[39.1 10] Drawbar and hitch assembly

Wheels

Rear wheels

[44.901] Caster wheels

[55.000] Electrical system

[55.100]

[55.301]

[55.302] Battery

[55.404]

[55.516]

[55.517] Cab seeding

[55.545] Auger

Electronic modules

Precision farming system

Metering system

[61.904] Product metering

Seeding

Product handling and delivery drive system

Seeding fan system

Auxiliary tank fill system

Air distribution system

[90.108] Decals and plates

[90.1 10] Operator platform less cab

[90.1 18] Protections and footboards

Safety signs

Safety signs

Basic instructions - Shop and assembly

Liquid fertilizer system - T orque - Fasteners (*)

T orque - Hydraulic tubes and fittings (*)

Basic instructions - Measuring voltages (*)

Basic instructions - Electrical testing - Connector inspection

Basic instructions - Electrical testing - Measuring voltage

Basic instructions - Electrical testing - Measuring resistance

Basic instructions - Electrical testing - Measuring continuity (resistance)

Basic instructions - Electrical testing - Short circuit ground

Basic instructions - Electrical testing - Short circuit high - Unwanted power

Basic instructions - Electrical testing - Short circuit pin pin

Basic instructions - Electrical testing - T esting voltage

Basic instructions - Electrical testing - Continuity test - Open circuit

Basic instructions - Important notice regarding equipment servicing

Basic instructions

Auger - Basic instructions

Auger - Basic instructions Hydraulic contamination

Auger - General specification

Foreword

T echnical information

This information this manual has been structured using a unique coding environment. This the way which technical information and retrieved the T echnical Information The coding has aligned locations with the warranty

All hydraulic information now Section All Electrical / Electronic information now Section Mechanical information now the section for that part

P Series Air Carts

Foreword - Important notice regarding equipment servicing

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special

Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution chain, including - without limitationnational, regional, local reject any responsibility for damages caused parts and / components not approved the facturer , including those used for the servicing repair the product manufactured marketed the manufacturer any case, warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer

The manufacturer reserves the right make improvements design and changes specifications any time without notice and without incurring any obligation install them units previously and illustrative material herein are accurate known time publication but are subject change without notice. case refer your NEW HOLLAND Sales and Service

Safety rules

P Series Air Carts

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury .

Throughout this manual you will find the signal words W and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation that, not avoided, could result minor moderate injury . F AILURE T O FOLLOW DANGER, W ARNING, AND CAUTION MESSAGES COULD RESUL T DEA SERIOUS INJUR Y .

Machine safety

NOTICE: Notice indicates a situation not could result machine property

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property The word Notice used address practices not related personal safety

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a other information the The word Note not intended address personal safety property

Safety rules

W ARNING

Chemical hazard!

W ear protective clothing and a face shield when working with not allow chemicals contact skin eyes. Always follow the chemical instructions.

Failure comply could result death serious injury

W ARNING

Unexpected machine movement!

Disengage power , shut down the tractor , and sure that all moving parts have stopped before vicing, adjusting, cleaning, unclogging the equipment.

Failure comply could result death serious injury .

CAUTION

Escaping fluid!

Hydraulic fluid diesel fuel leaking under pressure can penetrate the skin and cause infection other injury T o prevent personal injury: Relieve all pressure before disconnecting fluid lines performing work the hydraulic system. Before applying pressure, make sure all connections are tight and all components are good condition. Never use your hand check for suspected leaks under Use a piece cardboard wood for this injured leaking see your doctor immediately .

Failure comply could result minor moderate injury

General safety rules

Use caution when operating the machine Raised full tanks and other loads will change the center gravity the The machine can tip roll over when near ditches and embankments uneven

Never permit anyone ride the

Never operate the machine under the influence alcohol, drugs while otherwise impaired.

Pay attention overhead power lines and hanging High voltage lines may require significant clearance for safety

Hydraulic oil diesel fuel leaking under pressure can penetrate the skin, causing serious injury infection.

NOT use your hand check for Use a piece cardboard paper

Stop remove key and relieve the pressure before connecting disconnecting fluid

Make sure all components are good condition and tighten all connections before starting the engine pressurizing the

hydraulic fluid diesel penetrates the seek medical attention immediately

Continuous long term contact with hydraulic fluid may cause skin cancer A void long term contact and wash the skin promptly with soap and water

Keep clear moving Loose jewelry , long hair and other loose hanging items can become entangled moving

W ear protective equipment when

NOT attempt remove material from any part the machine while being operated components are

Make sure all shields and handrails are good condition and properly installed before operating Never operate the machine with shields removed. Always close access doors panels before operating the machine.

Dirty slippery walkways and platforms can cause Make sure these surfaces remain clean and clear

A person pet within the operating area a machine can struck crushed the machine its equipment. NOT allow anyone enter the work

Raised equipment and / loads can fall unexpectedly and crush persons underneath. Never allow anyone enter the area underneath raised equipment during

Review this manual before each season

Never allow anyone unfamiliar , untrained, complacent operate the implement.

Use extreme care when adjusting the

NOT enter tank unless another person

NOT work around rotating Loose may get caught and cause serious injury

Air and air hoses

COMPRESSOR HOSES may move unexpectedly when suddenly

USE PROPER air

Never use compressed air clean f clothes otherwise direct toward

General maintenance safety

Keep area used for servicing the machine clean and dry Clean spilled

Service machine a firm level

Install guards and shields after servicing the

Close all access doors and install all panels after servicing the

not attempt clean, lubricate, clear obstructions make adjustments the machine while motion while the engine

Always make sure working area clear tools, parts, other persons and pets before you start operating the machine.

Unsupported hydraulic cylinders can lose pressure and drop the equipment causing a crushing not leave equipment a raised position while parked during unless securely

Incorrect towing procedures can cause When towing a disabled machine follow the procedure this Use only rigid tow

Stop the remove key and relieve the pressure before disconnecting connecting fluid

Stop the engine and remove key before disconnecting connecting electrical

Replace damage worn tubes, electrical

When welding follow the instructions the Always disconnect battery before welding Always wash your hands after handling battery

Wheels and tires

Make sure tires are correctly not exceed recommended load Follow instruction the manual for proper tire

T ires are heavy Handling tires without the proper equipment could cause death serious injury

Never weld a wheel rim with a tire Always remove tire completely from rim prior

Always have a qualified tire technician service the tires and a tire has lost all take the tire and rim a tire shop your dealer for service. Explosive separation the tire can cause serious injury .

DANGER

Explosion hazard!

W elding a wheel can create explosive air and gas mixture. Removing air from the tire loosening the tire the wheel (breaking the bead) will NOT eliminate the W A remove the tire completely from the wheel before welding. Failure comply will result death serious injury .

The Slow Moving V ehicle (SMV) sign must located the rear the

Comply with local laws and

Use appropriate lighting meet local

Driving public roads and general transportation safety

Make sure Slow Moving V ehicle (SMV) emblem and / Speed Indicator Symbol (SIS)

Use safety chains for trailed equipment when provided with machine equipment.

Lift implements and attachments high enough above ground prevent accidental contact with

When transporting equipment machine a transport trailer , make sure properly sure the SMV SIS the equipment machine covered while being transported a trailer .

aware overhead structures power lines and make sure the machine and / attachments can pass safely under

T ravel speed should such that complete control and machine stability maintained all

Slow down and signal before

Pull over allow faster traf fic

Follow correct towing procedure for equipment with without

Fire and explosion prevention

Fuel and oil that leaked spilled hot surfaces electrical components can cause a

Crop materials, trash, debris, bird nests flammable material can ignite hot surfaces.

Always have a fire extinguisher near the

Make sure the fire extinguisher(s) maintained and serviced according the manufacturer ’ s

least once each day and the end the day remove all trash and debris from the machine especially around hot components such battery , More frequent cleaning your machine may necessary depending the operating environment and conditions.

least once each day , remove debris accumulation around moving components such gears cleaning More frequent cleaning your machine may necessary depending the operating environment and

Inspect the electrical system for loose connections frayed Repair replace loose damaged not expose the machine burning brush

Promptly investigate any unusual smells odors that may occur during operation the machine.

General battery safety

Always wear eye protection when working with not create sparks have open flame near battery

V entilate when charging using enclosed

Disconnect Negative ( ‐ ) first and reconnect Negative ( ‐ )

When welding the disconnect both terminals the battery not grind smoke near a battery

Follow manufacturer ’ s instructions when storing and handling

CALIFORNIA Proposition W arning Diesel engine exhaust and some its constituents are known the State California cause cancer , birth and other reproductive Battery terminals and related accessories contain lead and lead compounds. W ash hands after handling.

Battery acid causes Batteries contain sulfuric A void contact with eyes Antidote ternal): Flush with water . Antidote (eyes): flush with water for minutes and seek medical attention immediately . Antidote (internal): Drink large quantities water not induce Seek medical attention immediately

Keep out reach children and other unauthorized

Reflectors and warning lamps

Flashing amber warning lamps must used when operating the public

Personal Protection Equipment (PPE)

W ear personal protective equipment such hard safety glasses heavy hearing protective clothing, etc.

not operate tag

Before you start servicing the machine, attach a Not warning tag the machine area that will

Hazardous chemicals

you are exposed come contact with hazardous chemicals you can seriously The paints, adhesives, coolant, etc. required for the function your machine can hazardous. They may attractive and harmful domestic animals well

Material Safety Data Sheets (MSDS) provide information about the chemical substances within a safe dling and storage first aid measures and procedures taken the event a spill accidental release. MSDS are available from your dealer .

Before you service your machine check the MSDS for each used this This information indicates the associated risks and will help you service the machine safely Follow the information the manufacturer well the information this manual when servicing the

Dispose all filters and containers environmentally safe manner according local laws and Check with local environmental and recycling centers your dealer for correct disposal

Store fluids and filters accordance with local laws and Use only appropriate containers for the storage chemicals petrochemical Keep out reach children other unauthorized

Additional precautions are required for applied chemicals. Obtain complete information from the manufacturer distributor the chemicals before using

Utility safety

When digging using ground engaging aware buried cables and other Contact your local utilities appropriate determine the locations

Make sure the machine has suf ficient clearance pass all Pay special attention overhead power lines and hanging High voltage lines may require significant clearance for safety Contact local authorities utilities obtain safe clearance distances from high voltage power

Retract raised extended components, necessary . Remove lower radio antennas other accessories. Should a contact between the machine and electric power source occur the following precautions must taken: Stop the machine movement immediately Apply the park stop the engine and remove the key Check you can safely leave the cab your actual position without contact with electrical stay your position and call for you can leave your position without touching jump clear the machine make sure you not make contact with the ground and the machine the same time. not permit anyone touch the machine until power has been shut f the power

Electrical storm safety

not operate machine during electrical

you are the ground during electrical stay away from machinery and Seek shelter a protected

electrical storm should strike during remain the not leave the cab operator ’ s not make contact with the ground objects outside the

Mounting and dismounting

Mount and dismount the machine only designated locations that have steps not jump f the

Make sure ladders and platforms remain clean and clear debris and foreign Injury may result from slippery

Face the machine when mounting and

Maintain a three ‐ point contact with steps, ladders and

Never mount dismount from a moving machine.

W orking heights

When the normal use and maintenance the machine requires working heights: Correctly use installed ladders and Never use steps railings while the machine not stand surfaces which are not designed steps

not use the machine a ladder platform for working

Implement safety

Make sure the implement connected a stable device when activating the hydraulics fold and unfold the

Always make sure the work area within the radius the wings clear other persons before operating the wing lift

Safety rules - Ecology and the environment

Soil, air , and water quality important for all industries and life general. When legislation does not yet rule the treatment some the substances that advanced technology sound judgment should govern the use and disposal products a chemical and petrochemical

Familiarize yourself with the relative legislation applicable your country , and make sure that you understand this Where legislation obtain information from suppliers anticleaning agents, etc., with regard the fect these substances man and nature and how safely store, use, and dispose these

Helpful hints

• A void the use cans other inappropriate pressurized fuel delivery systems fill Such delivery systems may cause considerable

• avoid skin contact with all Most these products contain substances that may harmful your

• Modern oils contain not burn contaminated fuels and waste oils ordinary heating

• A void spillage when you drain fluids such used engine coolant engine hydraulic brake etc. not mix drained brake fluids fuels with lubricants. Store all drained fluids safely until you can dispose the fluids a proper way that complies with all local legislation and available

• not allow coolant mixtures get into the soil. Collect and dispose coolant mixtures properly .

• The air - conditioning system contains gases that should not released into the Consult airtioning specialist use a special extractor recharge the system properly

• Repair any leaks defects the engine cooling system hydraulic system immediately

• not increase the pressure a pressurized circuit this may lead a component

• Protect hoses during Penetrating weld splatter may burn a hole weaken allowing the loss

Battery recycling

Batteries and electric accumulators contain several substances that can have a harmful fect the environment the batteries are not properly recycled after Improper disposal batteries can contaminate the groundwater , and NEW HOLLAND strongly recommends that you return all used batteries a NEW HOLLAND dealer , who will dispose the used batteries recycle the used batteries properly some countries, this a legal requirement.

Mandatory battery recycling

NOTE: The following requirements are mandatory

Batteries are made lead plates and a sulfuric acid solution. Because batteries contain heavy metals such lead, CONAMA Resolution 401 / 2008 requires you return all used batteries the battery dealer when you replace any not dispose batteries your household

Points sale are obliged to:

• Accept the return your used batteries

• Store the returned batteries a suitable location

• Send the returned batteries the battery manufacturer for recycling

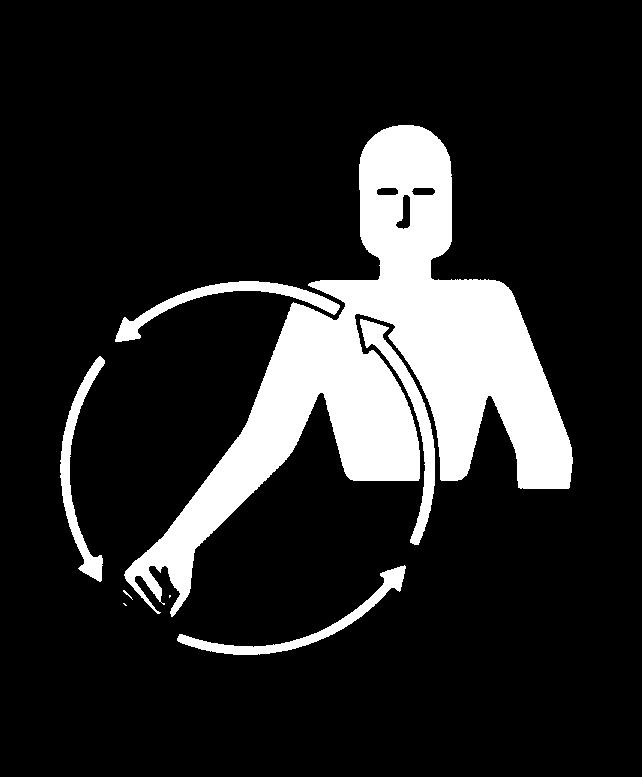

Hand signals

often necessary communicate using hand signals agricultural operations when noise distance inhibit communication The ASAE S351 standard illustrates these hand which provide easy means particularly the interest safety

THIS F AR T O - Place palms ear level facing head and move laterally inward indicate remaining distance

COME T O - Raise the arm vertically palm the and rotate large horizontal

- Raise hand upward the full extent the palm the Hold that position until the signal understood.

MOVE T ARD

FOLLOW - Point toward beckon holding the arm horizontally the palm and motioning toward the body .

SPEED , INCREASE

SLOW

SPEED - Raise the hand the shoulder , fist closed; thrust the fist upward the full extent the arm and back the shoulder rapidly several

THE ENGINE - Draw

MOVE OUT , T AKE OFFFace the desired direction movement; hold the arm extended the ear; then swing overhead and forward the direction desired movement until palm

T THE ENGINE - Simulate cranking vehicles moving arm circular motion waist

DECREASE SPEEDExtend the arm horizontally palm and wave arm downward

LOWER EQUIPMENTMake circular motion with either hand pointing the

RAISE EQUIPMENTMake circular motion with either hand head level.

right palm across the neck a motion from left

Safety signs

The following safety signs are your machine a guide for your safety and for the safety those working with you. W alk around the machine and note the content and the location all safety signs before you operate your

Keep all safety signs clean and legible. Clean safety signs with a soft cloth, water , and gentle detergent.

NOTICE: not use solvent, gasoline, other harsh chemicals. Solvents, gasoline, and other harsh chemicals may damage remove safety

Replace all safety signs that are damaged, missing, painted over , illegible. a safety sign a part you your dealer make sure that you your dealer install the safety sign the new See your dealer for replacement safety

Safety signs that display the operator ’ s symbol direct you the operator ’ s manual for further information regarding procedures for particular areas the When a safety sign displays this consult the appropriate page the operator ’ s

Safety signs that display the service symbol direct you the service you doubt your ability perform service contact your dealer

NOTE: New decals are available from your NEW HOLLAND dealer

NOTE: If there is no response to click on the link above, please download the PDF document first, and then click on it. Have any questions please