Part number 47969434

1st edition English November 2016

Replaces part number 47866576

Engine and crankcase

Pan and covers

V alve drive and gears

Cylinder heads

Connecting rods and pistons

[10.103] Crankshaft and flywheel

[10.210] Lift pump and lines

[10.206] Fuel filters

[10.218] Fuel injection system

[10.202] Air cleaners and lines

[10.250] T urbocharger and lines

[10.400] Engine cooling system

[10.414] Fan and drive

[10.310] Aftercooler

[10.408] Oil cooler and lines

10] Clutch and components

ransmission

[21.1 14] Mechanical transmission

[21.1 12] Power shuttle

10] Master clutch housing

Power shuttle transmission external controls

Gearbox external controls

Gearbox internal components

Creeper

Reverser unit

[21.200] Dropbox

Front axle system

Powered front axle

Front bevel gear set and dif ferential

Final drive steering and shafts

[25.400] Non-powered front axle

Rear axle system

[27.100] Powered rear axle

[27.106] Rear bevel gear set and dif ferential

Planetary and final drives

Power T f (PT

[31.1 14] T wo-speed rear Power T ake-Of f (PT

Brakes and controls

Mechanical service brakes

Hydraulic service brakes

10] Parking brake parking lock

Hydraulic systems

[35.000]

[35.104] Fixed displacement pump

Remote control valves

Main lift system

Steering

Steering control

Hydraulic control components

Cylinders

Wheels

Front wheels

Electrical systems

Electrical system

Harnesses and connectors

Engine starting system

Alternator

Battery

Electronic modules

External lighting

W arning and instruments

cab, and decals

[90.1 18] Protections and footboards

[90.1 14] Operator protections

Engine hood and panels

16] Fenders and guards

[10.001] Engine and crankcase .

Pan and covers

V alve drive and gears

[10.101] Cylinder heads

[10.105] Connecting rods and pistons

Crankshaft and flywheel

Lift pump and lines

Fuel filters

[10.218] Fuel injection system

Air cleaners and lines

[10.250] T urbocharger and lines .

and drive

[10.310] Aftercooler

Engine lubrication system

Oil cooler and lines

Engine - General specification

GENERAL SPECIFICA TIONS

V alve lift

T iner - Internal Exhaust Gas

opening (After BDC, during exhaust stroke)

valve closing (Before during Exhaust stroke)

cam lobe lift

valve lift (tiner)

V alve springs

V alve timing

Intake opening (before top dead centre)

Intake closing (after bottom dead centre)

opening (before bottom dead centre)

closing (after top dead centre)

V alve inserts

V alve guide

V alve guide oversize

V alve guide interference fit housing cylinder head

V alve guide fitted after reaming

V alve stem clearance guide

Crank gear

Crankshaft - Bearings

Crank pin diameter

Crank pin undersize

Crank pin clearance big end bearing

Width main bearing housing over thrust washers

Maximum main journal and crank pin ovality taper after grinding

Maximum main journal and crankpin ovality taper due wear taper due wear

Maximum main journal misalignment

Crankshaft resting end journals

Maximum misalignment crank pins relative main journals(in either direction) 0.25

T olerance from outer crankpin edge crank ‐ shaft center line ±0.10

Maximum crankshaft flange run ‐ out with gauge, over 108 (4.25”) diameter (total gauge reading)

Maximum flywheel seat eccentricity relative main journals (total gauge reading)

Connecting rods

Small end bore diameter

Small end bushing outer diameter

Bushing interference fit small end

Small end bushing

Maximum connecting rod axis misalignment 125 ±

Maximum connecting rod weight dif ference over a complete set from the same engine g

Pistons

Piston diameter: measured from base skirt and right angles pin

Piston clearance liner

Piston oversize range

Piston stand ‐ out with respect head T

Piston pin diameter

Piston pin seat bore piston

Piston pin clearance piston

Piston pin clearance small end bushing

maximum wear clearance

Maximum weight dif ference between pistons same engine g

Piston ring clearance groove

• T

• 2nd

• 3rd

Maximum wear clearance

• T

• 2nd and 3rd

Piston ring gap

• T

• 2nd

• 3rd

V alve gear

wear gap

V alve timing gears T iming

Idler gear bushing fitted after reaming

Jack shaft journal clearance bushing

Bushing interference fit idler gear

Lift and power steering pump drive gear shaft

Bushing fitted after reaming

Shaft clearance bushing

Bushing interference fit housing

Pump drive gear thrust washer thickness

Camshaft

Camshaft bushing

• Front

• Intermediate

• Rear Bushing interference fit housing

Camshaft bushing fitted I.D after reaming:

‐ Front

‐ Intermediate

‐ Rear

Camshaft journal diameter:

‐

T appets

T

V

Lubrication system

Gear housing depth pump bodyDrive and driven gear end float

Relief valve spring length:

Free ‐ A T load 134.55±6.73 N ‐ A T load N

Cooling system

W ater pump drive ratio

Shaft interference fit impeller

Shaft interference fit fan hub

Face sealing bushing interference fit impeller

Opening temperature

Close f temperature

V alve travel when fully open

Radiator V ertical tube and Aluminium fins Fan 6 blades

W ater temperature gauge Three colored sectors T emperature range for each sector: ‐ white sector

green sector

sector

Fuel pump drive Shaft journal dia

Bushing fitted after reaming

Shaft clearance bushing

Bushing interference fit housing

Inner washer thickness

Outer washer thickness

Injection pump

BOSCH

, integral governor and advance device 0460423063 (with LDA) ( 0460423072 ) With KSB 0460423073 With KSB 0460423079 (without LDA) (0460423076) Without KSB (0460423077) Without KSB (0460423075) With KSB (0460423078) Without KSB

Injectors:

Nozzle holder F002 C70 567 (KBAL P 163) F002 C70 567 (KBAL P 163 ) F002 C40 750 (DSLA 142 P 5565 ) F002 C40 738 ( DSLA 145 P 5544)

(delivery connection cylinder marked with letter

Engine - T orque

Engine - Sealing

SEALANTS

T iming Gear cover Dowel pin(S5)

Starter Motor Flywheel Housing (S6)

Allen Plug Cylinder Head Thermostat Housing (S7)

Cylinder Head Exhaust Manifold Studs (S8)

® 270 Oil Sump Engine Block (S9)

5900®

Silencer mounting Studs Exhaust Manifold(S10)

Flywheel Bolt (S1

Engine - Special tools

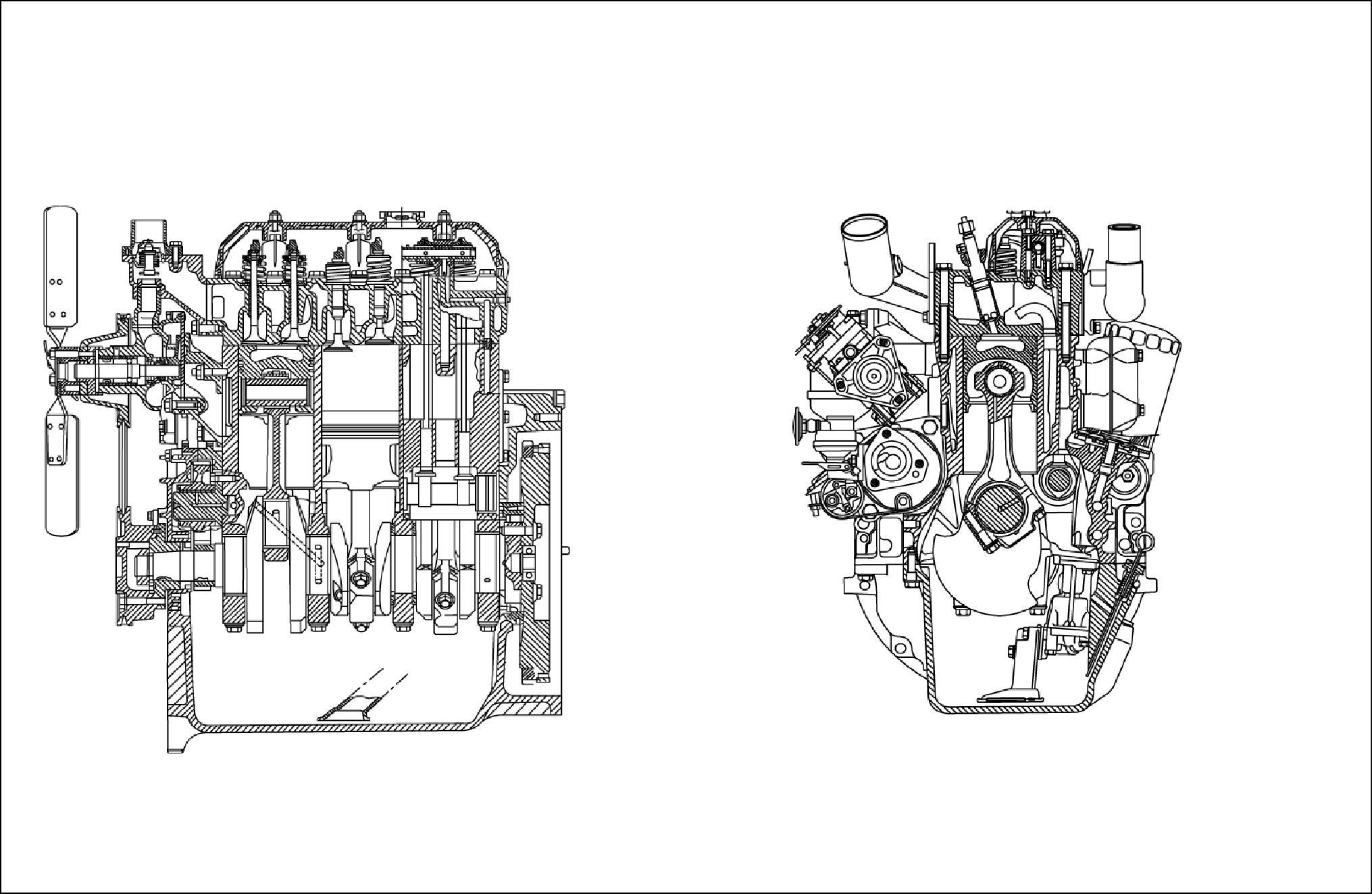

Engine - Overview DESCRIPTION AND OPERA TION

The engine a 3 cylinder engine with T urbo Charger and a inter ‐ cooler . This engine features cross flow cylinder with the inlet and exhaust manifolds opposite sides the cylinder The fuel and air combustion takes place the specially designed bowel the crown the pistons

CYLINDER HEAD ASSEMBL Y

The cylinder head consists valves and with the valve rocker arm shaft assembly bolted the cylinder block through the cylinder Cylinder head retaining bolts are evenly spaced with a six ‐ point pattern around each cylinder; this ensures even clamping load across the cylinder The intake and exhaust manifolds are bolted the head; the intake manifold mounted the right side the engine, with the diesel injectors mounted outside the rocker cover The exhaust manifold mounted the left side the W ater outlet connections and thermostat being attached the front the cylinder block directly behind the radiator V alve guides are inserted into the cylinder and Special replaceable cast alloy valve seats are pressed into each valve port during oversize valve seats guides are All valves are fitted with positive value rotators; valve clearance maintained adjustment the self locking adjusting screw , mounted each the rocker

CAMSHAFT ASSEMBL Y

The camshaft runs 3 replaceable bushes. The camshaft drive gear mesh with and driven the camshaft idler gear which driven the crankshaft timing gear Camshaft end thrust controlled a thrust plate bolted the and located between the camshaft gear and the front camshaft A helical gear integral rear cam shaft, and drives the engine oil lubrication pump mounted forward the flywheel.

Cylinder block assembly

The cylinder block alloy cast iron with deep cylinder skirts & water jackets for cooling the The cylinder bores are machined integral with the cylinder during the manufacturing Cylinders are inline and vertical and numbered from 1 3 from front the engine the rear The oil which attached the bottom the cylinder the reservoir for the engine oil lubrication A cast iron engine front cover and front plate attached the front the engine and covers all the timing gear assembly

CRANKSHAFT ASSEMBL Y

The crankshaft supported the cylinder block 4 main The crankshaft manufactured from steel with machined finished crank webs, End thrust controlled a thrust bearing. A dynamic balancer fitted and driven crankshaft ensure smooth running Front and rear crankshaft oil sealing fected one piece seals that are designed for long and durable service

CONNECTING RODS

The shaped the small end the connecting rod has been designed reduce the reciprocating weight the piston The connecting rods have a heavy beam construction and are assembled a matched set each They are attached the means insert type They are retained position the connecting rod big end cap and secured two bolts per rod. The small end the connecting rod fitted with a replaceable bronze through which the free floating piston pin The steel pin being held place within the piston two snap

PIST ONS

Pistons are constructed aluminium silicon alloy with notch type combustion chamber being recessed the piston

Each piston has two compression rings and one oil control reduce the friction and increase positive All rings are located above the piston pin.

Manifolds

The cross flow design aluminium intake, and cast iron exhaust manifolds are opposite sides the cylinder head. This designed maintain balanced heat distribution within the cylinder The configuration the manifolds

also ensures minimum heat transfer the intake The intake manifold connected through hose air cleaner

A 1

T iming gears

The crankshaft timing gear heated and press fitted the front the a high degree accuracy during This enables precise timing being maintained during the life the The crankshaft gear drives the idler gear , which attached the front cylinder block. The idler gear then drives the camshaft and the injection pump via meshing helical gears

The camshaft gear bolted the front the shaft and keyed maintain position the gear the

LUBRICA TION SYSTEM

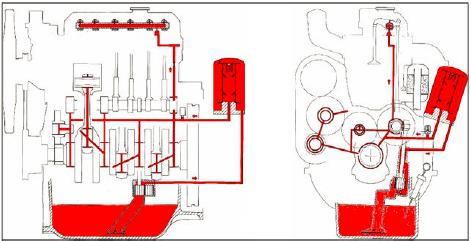

Lubrication the Figure 7 & 8 maintained a gear type oil pump mounted the rear the engine forward the flywheel the left hand side viewing from rear side the The oil pump driven from the rear the camshaft and drains oil from the engine oil sump through a tube and screen assembly

A spring loaded relief valve integral with the oil filter and prevents over pressurization the A spin type oil filter mounted externally its support housing the left hand side the engine. Oil flows from the filter the main oil gallery , which runs the length the cylinder which also intersects the camshaft follower chamber

The main gallery also supplies oil the crankshaft main connecting rods both big and small ends and timing gear The underside the pistons and pins are lubricated oil pressure

T iming gears are lubricated splashed oil from the cam follower chamber and the pressure lubricated camshaft drive gear

intermittent flow oil directed the value rocker arm shaft assembly via a drilled passage the cylinder This located vertically above 3 camshaft bearing and aligns a hole the cylinder The rotation the camshaft allows a controlled intermediate flow

COOLING SYSTEM

The function the water pump mounted the front the maintain a continuous flow water around the cooling This essential ensure engine temperature and performance within the recommended during vehicle

The W ater pump driven a ‘V’ belt the crankshaft pulley , when the engine

The cooling system for the new generation engines recirculating ‐ pass type with full length water jackets for the bottom tank the radiator the water which passes the coolant the cylinder This coolant then flows through cored passages cool the cylinder walls.

Passages the cylinder head gasket allow coolant flow from the cylinder into the cylinder head cored passages also conduct the coolant the fuel injector nozzle locations before ‐ entering the water pump below the thermostat

The thermostat located the top the water pump body , and controls the flow the water required perature

NOTE: If there is no response to click on the link above, please download the PDF document first, and then click on it. Have any questions please