WILDLAND URBAN INTERFACE BASICS

After the fire in Slave Lake in 2011, provincial funds were allocated to the Lesser Slave Regional Fire Service to focus on the 7 disciplines of FireSmart. This included cross training and inter-agency cooperation. As part of this, a 4-person full-time crew was assembled and began researching, training, and going on wildland fire deployments through contract Helitack work with Alberta Agriculture and Forestry (known at the time as SRD). As the program grew, we began responding to many WUI fires across Alberta and BC as a structure protection and Engine crew. Since 2011, your instructors have been on dozens of WUI events including: Slave Lake 2011, High Level 2015, Fort McMurray 2016, BC 2017, Chuckegg Creek 2019, BC 2021 and multiple others.

Through the years we began to compile the lessons learned and together with our own observations we started to build these courses. Currently there is minimal training in the way of WUI incidents. The S115 and S215 provide some awareness to these events but lack adequate time for hands on training. Although the theory is relevant, we found that a theory-based course does not prepare the responders for what they will actually encounter at a WUI Incident.

At many events we found a general lack of organization, know how, and skills required to action these events safely. The WUI Basic is one day of in class theory followed by 3 days of field skills and scenarios.

This course was designed to provide hands-on training to fire personnel responding to Wildland Urban Interface (WUI) events. The course is designed to focus on the current lack of hands-on best practice training and address the issues faced when responding to such a dynamic and boundary crossing event.

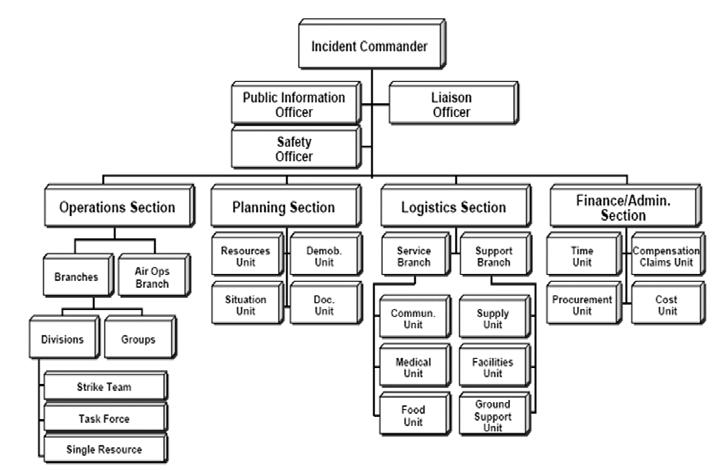

It will better prepare the responders to know what to expect, how to fall into the command structure, and function as an efficient single resource/strike team/task force at an event. It focuses on structure protection using site prep, sprinkler system set ups, burnouts, and various other protection methods. Engine operations at the strategy and tactics level is also a large component of the training.

The Basic is the first of 3 urban interface courses that have been developed by the Lesser Slave Regional Fire Service and its partners.

The following is an overview of what is included in the four-day WUI Basic course.

This section covers fire behavior, weather, fuel, topography, fire weather index (FWI), head fire intensity (HFI), parts and types of fire as well as common terminology. The theory portion goes into detail on each topic, while the activity is an opportunity to discuss and detail the skills necessary.

In this section, we will cover the phases of fire, impingement, responding to incidents and sizing up including dispatch and hazards.

Both Alberta and British Columbia structure triage will be discussed, as well as information about interface priority zones, building construction and mapping.

Here we will go over remote areas, helicopter safety, heavy equipment, as well as interactions with First Nations, the public and politicians. Included will be special considerations such as working on First Nations lands, industry, and remote site access and planning.

Covering all types of sprinkler system set ups, including set-up, pros and cons for each system, trunk line lay, structure/site prep, mounting, testing and trouble shooting, For the practical sessions, the students will set up multiple different systems, use various types of portable water pumps, learn the benefits and when to use certain types of systems over others, and efficient use of equipment.

This section focuses mainly on resources, engine, truck and tender types and operations. We will also go in-depth about safety concerns, methods of attack, and engine actions. The end of this section covers the incident command system, general staff, crew responsibilities by position and equipment maintenance.

DAY 1 In class theory learning, tabletop exercises, hands-on structure triage,and equipment familiarization

DAY 2 Hands on work in Pump site set ups, and sprinkler system deployments and scenarios

DAY 3 In class theory learning (morning), Engine operation strategy and tactics (afternoon)

DAY 4 Engine operations scenarios (morning), Full WUI scenario (afternoon)

Students will be given an incident with a time frame to prepare for and protect given structures from an impinging wildfire.

Once time frame is complete, students will assemble into strike teams and task forces to conduct a live fire impingement scenario (live fires will be hay bale and pallets outside of spring, during the spring grass hazard pre-burns of selected areas will occur beforehand to “guard” in places where small grass fires can be lit without chance of escape.

Students will then have to operate together to prioritize given fires and suppress as necessary, following chain of command and proper safety precautions.

We feel like this is needed training in Western Canada, as there is little in the way of training to prepare our people for what they will face on the ground out there.

This course was built on experiences of not only the Slave Lake crews but in coordination with multiple departments. and stakeholders involved with these events. The other two courses in this program are WUI Advanced (for leadership at WUI events) and Hazard Reduction Burning (controlled burning of grass fuel types for prevention and as a tactic in the field).

1. Identify & Mitigate Hazards in the Wildland Urban Interface Upon completion of this course, students should be able to:

2. Complete a size up and structure triage

3. Identify equipment in a sprinkler trailer

4. Select, set up, and troubleshoot an adequate pump site

5. Select, set up, and troubleshoot a working sprinkler system

6. Understand and perform engine operation strategies and tactics

7. Work efficiently and safely as a crew member in the Wildland Urban Interface

The instructors for this course are qualified individuals who have years of municipal and forestry deployments under their belts.

As mentioned earlier, this is the team that has responded to over 21 WUI deployments in various capacities such as engine/tender crew members/leaders, structure protection specialists, operation section chiefs, and incident commanders across Western Canada. We encourage you to ask questions, share your experiences and learn from the experiences of your instructors and fellow students. This is a casual learning environment intended to share best practices and build relationships to better our responses to WUI events.

The material is a combination of years of trial and error, mistakes made, and lessons learned.

This course and the ones following it have been developed by firefighters for firefighters. Varying experiences, best practices, and lessons learned have blended into a concise format to provide the most up to date training known to exist on interface fires. The environment for delivering these courses is a casual one, intended to generate discussion and share experiences of the group. Therefore, it is a casual adult learning environment, ask questions when you have them, be respectful and learn from everyone you can, and do your best to keep an open mind. The content in the course may contradict past practices, or they are implemented in a new way. This is not meant to discredit the other material out there; it is rather an evolution of that material and years of trial and error in finding the most effective and efficient ways of protecting structures.

Be courteous, keep an open mind, learn from everyone you can, and build relationships with each other. You never know who may be standing next to you when faced with an interface event.

Radiation

Radiant heat spreads ahead, to the sides, above, below, and behind the heat source. Radiant heat dries fuels out ahead or near the fire and can lower relative humidity’s in the area of the fire, further drying out the air used in combustion and adding to fire intensity.

Conduction

Ground heat warming up the duff layer which in turn dries it out and allows fire to penetrate the organic ground layer.

Convection

Uses heat and smoke to rise and preheat fuels upslope, the air above (influencing atmospheric conditions), and reduce relative humidity’s in proximity to the fire.

OXYGEN: fire needs oxygen to sustain itself. Removal of oxygen stops combustion.

WILDFIRE TRIANGLE

TOPOGRAPHY: slope, aspect, and layout of the land contribute to spread rates and direction.

HEAT: fire needs a heat source to ignite and sustain itself. Removal of the heat (cooling) extinguishes the fire.

FUEL: fire needs the proper amount of fuel dried to the right amount arranged in a way that supports burning

WEATHER: wind, temperature, relative humidity, and precipitation all contribute to fire spread.

FUEL: the amount, arrangement, and moisture content of fuels contribute to fire spread and intensity.

The measure of the amount of moisture in a given parcel of air expressed as a percentage. In English this is the amount of moisture in the air. Rule of thumbs are if RH is below 30% it is low, and you can expect to see increased fire behavior. Humidity plays a direct role in the drying of fuels by allowing them to evaporate their moisture quickly in drier air.

Temperature

Temperature speeds the drying of fuels by heating them throughout the day and increasing the amount of moisture they evaporate. As daytime heating increases, the fuels dry out more, leading to a part of the day known as “peak burn”. Peak burn is when the temperatures are usually the highest and are paired with the lowest relative humidity’s of the day. This time frame typically is from 16001800 each day. During this time period you can expect to see the highest fire behavior of the day and have the most control difficulties.

The point at which the relative humidity is equal to or less than the temperature. This is a known benchmark to expect extreme fire behavior. For example, if the temperature is 27°C and the RH is 24%, you have crossover. The greater the spread apart (higher temp, lower the RH) the more extreme behavior can be observed.

Wind

Measured in kilometers per hour, wind is the biggest factor in the fire’s rate of spread. The higher the wind, the faster the spread. The more volatile, fine, or flashy the fuel is, the greater effect wind has on its spread rate. Wind also speeds up the drying of fuels by blowing away the moisture that is evaporating on the fuel’s surface. Wind is stated as a direction and speed. For example, winds to today are Northwest at 45kms/hr. Wind direction is ALWAYS stated from the direction the wind is coming from. So, a Northwest wind means it is blowing FROM the Northwest TO the Southeast.

Precipitation determines fuel moisture content. Immediate precipitation may have a limited effect on large fuels which take time to absorb moisture but can immediately saturate finer fuels. A long slow drizzle throughout the day does more to saturate fuels than a quick, hard downpour. Light precipitation has a very limited effect on fire behavior. It may slow fire progress, but only for a short time. Long steady rains are needed to impede fire growth.

The amount of moisture in fuel is the major element that will determine how much of the fuel will burn (available fuel). According to how much moisture is in the fuel, all will burn, only part will burn or, if wet enough, none will burn. Of the fuels that do burn (the available fuel), the moisture that is in them affects the behavior of the fire. When the available fuels are moist, combustion is slow because much of the heat is expended in converting moisture in the fuel to steam. Fuel will not enter the combustion process and burn until the moisture is driven out of that particular particle of fuel and it has reached ignition temperature. As fuels become drier, the rate of combustion is increased because less heat is required to drive off the moisture that is left. Fuel moisture content is one of the important factors that determine ignition probability and fire behavior in forest ecosystems.

Fuel size is dependent on surface area and mass. The more surface area and less mass the fuel has, the finer it is. The LESS surface area and MORE mass a fuel has, the heavier it is. Lighter, smaller fuels tend to ignite easily and be more “flashy” while larger, heavier fuels tend to take more to ignite, and burn slower. Compare this to starting a campfire. You wouldn’t start with the largest pieces of wood; you start it with finer fuels to get the larger fuels going.

Dead trees absorb moisture quickly, but they do not retain it for as long as live trees. Therefore, dead fuels dry out quickly and are more susceptible to drying days and preheating. Live fuels retain their moisture for longer and are more affected by long-term precipitation. Live fuels that are dry burn intensely, but live fuels that receive precipitation, or have a higher moisture content from previous days of precipitation, do not burn as intense.

Quantity

Refers to “how much” fuel there is. Think of this as a grass field, is it sparse in amounts of grass? Or loaded with grass? Quantity determines “fuel load” in an area and has a direct impact on control difficulty.

Arrangement

Describes where the fuels are placed on the landscape. Are they spaced tightly? Or sparse? Arrangement contributes to the “type” of wildfire you may encounter (ground, surface, crown)

Continuity

Speaks to how distributed the fuels are on the landscape. Is the fuel thick and continuous? Or does it change fuel types rapidly and unevenly? Think of a mixed wood fuel type, where coniferous and deciduous fuels are mixed and may vary in amounts grouped together.

C1 SPRUCE/LICHEN WOODLAND

C2 BOREAL SPRUCE

C3 MATURE JACK OR LODGEPOLE PINE

C4 IMMATURE JACK OR LODGEPOLE PINE

C7 PONDEROSA PINE/DOUGLAS FIR

01A MATTED GRASS

01B STANDING GRASS

M1 BOREAL MIXED WOOD LEAFLESS (EXPRESSED AS A %, EX. 50/50)

M2 BOREAL MIXED WOOD GREEN (EXPRESSED AS A %, EX. 50/50)

D1 LEAFLESS ASPEN

S1 JACK OR LODGEPOLE PINE SLASH

S2 WHITE SPRUCE/BALSAM SLASH

C1—SPRUCE/LICHEN WOODLAND

C2—BOREAL SPRUCE

C3—MATURE JACK OR LODGEPOLE PINE

C4—IMMATURE JACK OR LODGEPOLE PINE

C7—PONDEROSA PINE/DOUGLAS FIR

01A—MATTED GRASS

01B—STANDING GRASS

M1—BOREAL MIXED WOOD LEAFLESS (expressed as a %, ex. 50/50)

M2—BOREAL MIXED WOOD GREEN (expressed as a %, ex. 50/50)

D1—LEAFLESS ASPEN

S1—JACK OR LODGEPOLE PINE SLASH

S2—WHITE SPRUCE/BALSAM SLASH

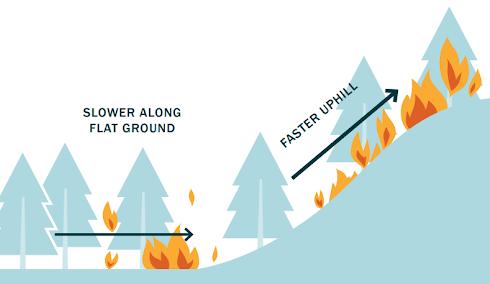

Slopes play a critical factor in predicting fire spread and direction. Fire tends to spread faster uphill than downhill, so valleys and chutes can be expected to create fire “runs”. This is due to fuels being preheated by convective heat rising upslope and flame lengths being closer to the fuels as they burn up hill. If wind is added to this equation the effects are multiplied and extreme spread rates can be observed. At the top of slopes winds will “eddy” and roll over the top. As a safety factor, refrain from being upslope of an active fire front.

The direction the slope faces. As far as fire behavior goes, this is important to understand how a slope gets heated, what fuels tend to be on different aspects, and how they will react to fire. South facing slopes get more sunlight and tend to dry out quicker while north facing slopes are more shaded and hold more fuel moisture. South facing slopes tend to have more finer, flashier fuels as a rule while north facing slopes tend to have more heavier dense fuels. The farther south you travel the more prevalent this becomes. East slopes receive the cooler morning sun while west slopes get the hotter afternoon heating. As peak burn approaches, the Eastern slopes tend to become shaded and can be expected to have lower fire intensity than West slopes during peak burn.

The layout of the landscape will affect fire behavior by channeling winds, changing fuel types, and providing natural barriers. Ridges, mountains, saddles, draws, valleys, and barriers all affect the wind patterns and fire spread. Winds move like water across the landscape. Picturing how water would flow across the landscape can help you identify how winds will behave.

Elevation plays a factor as elevation increases; humidity’s tend to increase. The caveat is that wind speeds tend to increase with elevation. At higher elevations temperatures are reduced and finer fuels become more prevalent than heavier fuels.

During normal days, air near the surface warms and begins to rise. As the air rises it hits cooler air and begins to cool. With inversion, cooler air at the surface gets trapped below a layer of warm air. This generally occurs in the morning hours and can trap smoke close to the ground hampering aircraft and reducing visibility. This can also limit fire behavior to an extent, but it can prevent aircraft from flying. As the ground starts to heat up, the cool air at the surface warms and becomes warmer than the air above it, lifting the inversion.

The FWI system is a numerical rating system for fuel moisture and fire behavior predictions. It is made up of six calculations, three being fuel moisture codes and three being fire behavior codes. These are calculated by using data collected throughout forest protection areas and calculated daily to provide inputs into the index system. Fire weather observations track temperature, relative humidity, wind speeds, and 24hr rain fall. These observations provide the data for the index system.

Fine Fuel Moisture (FFMC)

A numeric rating of the moisture content of litter and other cured fine fuels. This code is an indicator of the relative ease of ignition and the flammability of fine fuel. FFMC needs minimum of 0.6mm of precipitation to effect it. Benchmarks for the FFMC is above 80 will support free burning and above 90 is high probability of spot fires.

A numeric rating of the average moisture content of loosely compacted organic layers of moderate depth. This code gives an indication of fuel consumption in moderate duff layers and medium-size woody material. The DMC is an indicator for the potential of holdover lighting fires. Benchmarks for the DMC would be above 20 holdover lighting fires may occur.

A numeric rating of the average moisture content of deep, compact organic layers. This code is a useful indicator of seasonal drought effects on forest fuels and the amount of smoldering in deep duff layers and large logs. This is a long-term buildup indicator, benchmarks being 15 – ground saturation, 300 – persistent fire, and 500 – significant ground fire activity and mop up difficulty.

Initial Spread Index (ISI)

A numeric rating of the expected rate of fire spread. It is based on wind speed and FFMC. Like the rest of the FWI system components, ISI does not take fuel type into account. ISI can change throughout the burning period. Benchmark is above 10 cured grass burns intensely and spruce stands crown.

Buildup Index (BUI)

A numeric rating of the total amount of fuel available for combustion. It is based on the DMC and the DC. The BUI is an indicator of fuel consumption, mop up issues, and a factor in fire intensity. Fuel driven fires tend to have high BUIs. Benchmark is above 60 will have increased mop up difficulty.

A numeric rating of fire intensity. It is based on the ISI and the BUI and is used as a general index of fire danger throughout the forested areas of Canada. A high BUI and low ISI will give the same rating as a low BUI and a high ISI, but they are two very different burning days. A high BUI and low ISI will indicate it is very dry but not windy. A low BUI and high ISI are common in the spring when winds can be high, but the ground is still saturated.

Wind Driven

A high ISI value will result in a wind-driven fire. These are fueled by wind speed and direction. Fire is “pushed” by the wind and is very noticeable in flashy fuels. Fuels may not completely burn but will carry the fire spread. Potentially rapidly spreading, these can be patchy-incomplete burns.

Fuel driven

A high BUI will result in a fuel-driven fire. These are fueled by the “dryness” of the fuels. Fuels with substantially low moisture content add to the intensity of the fire by having more fuel available to burn than moisture rich fuels. Fuels burn more completely and intensely. Fuels may burn slower but release more heat. Fuel driven fires will see high numbers of spot fires associated with them.

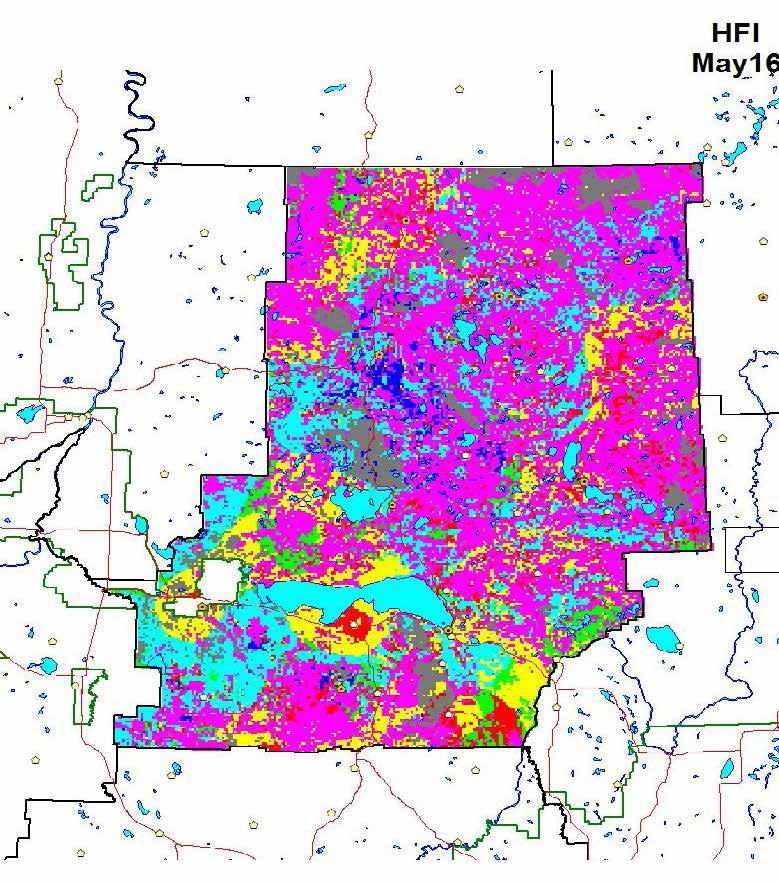

HFI is a ranking system for fire behavior. It measures energy released and flame lengths to determine a class of fire intensity. Each class (1-6) has recommended firefighting strategies tied to them. A rule of thumb to follow is to anchor at HFI 4 or greater. HFI rank can also be used in a size up to describe the fire behavior being observed to incoming resources.

SHOULD ANCHOR MUST ANCHOR MUST ANCHOR

When suppressing a wildfire, it may be difficult to understand what HFI you may be actioning. A simple rule of thumb to follow is if the flames are as tall as you, it is likely an HFI of 3. Hose lines are usually sufficient to control this size of fire.

If the flames are as tall as your apparatus, it is likely an HFI of 4 or greater. Hose lines may not be sufficient to deal with this size of fire. Aircraft or indirect attack methods will likely be required. It is a good rule of thumb to always anchor, and have planned and tested escape routes when suppressing any wildfire. Always have a lookout and be mindful of wind direction and speed as well as any changes to conditions. If actioning HFI 3 or greater, feeling the wind at your back is proffered as this means you are not at the head of the fire. Feeling the wind on the back of your neck and ears can help you to notice any changes in wind before it becomes a safety concern.

Head fire intensity maps are maps forestry produces daily to show case the expected fire behavior in a forest protection area. They take fuel typing information, 24hr and long-term precipitation data, and expected HFI based on daily FWI calculations to show where the hazard is in the area. These are useful for developing pre-suppression plans (PPS) which determine how many and where the resources should be placed to match the hazard. These are useful to the municipal fire service in anticipating what fire behavior you are likely to see on the landscape.

A daily 10am briefing on expected fire weather and behavior for the day. They take forecasted weather, along with long term rainfall data and use it to make predictions on fire behavior. It notes expected HFI, spread rates in common fuel types to the area, and estimates fire size in 1 hour burning in those common fuel types. Notice the writing in RED, they show important information pertinent to the day’s conditions. Legal downs for rotary wing aircraft are also stated. For each forestry resource assigned to them (contractors included) the crews sign off on this daily and forestry gets a copy. Keep one for your records, they are good for billing if you run into issues.

Caution; Think safety before initiating fire action…..Fire intensities continue to climb as the dry weather conditions persist. All fuels available for combustion. Explosive conditions possible with gusting winds and cross over conditions. Be safe….one foot in the black

Extreme fire behaviour, serious control problems, sustained crown fire. Mid to long range spotting. > 10,000 kw/m

Flame Length: > 5.5 m

Safety Concerns:

□ Fire Environment ; EXPLOSIVE FIRE BEHAVIOUR with extreme indices

□Work Environment

□ Crew Concerns:

Duty Officer Jason Cottingham

Fire Behaviour Analyst

Aircraft Legal Down

Lake: 22:13 High Prairie : 22:21 Wab: 22:11

22:22

Crew Supervisor (print) (sign)

Crew Leader and Identifier Number (Use back of sheet if more space needed) (print) (sign)

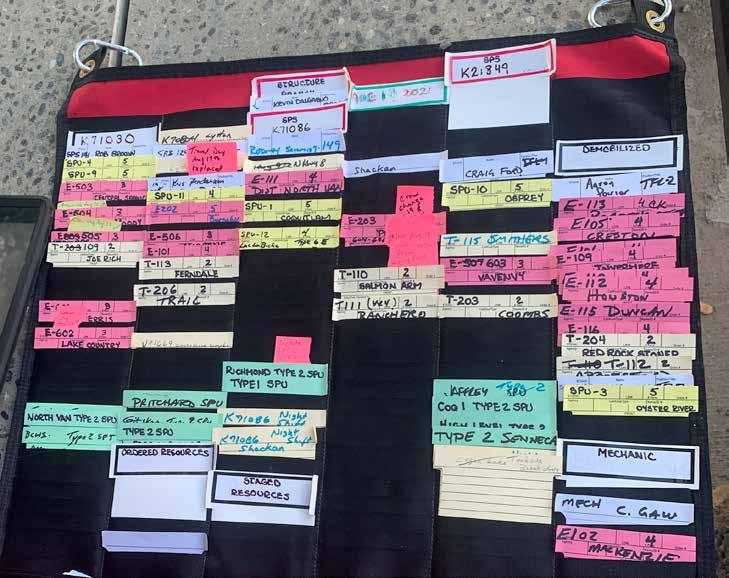

A tool forestry develops daily to assign resources, both staffed and contracted to areas within district to meet response requirements. Using a model for which resources and how many they need to meet the hazard; local duty officers develop this plan and stage resources accordingly. They are a tool not only for assigning resources, but to let every resource know who is on and where they are at for the day. During a dispatch, these resources converge on a fire based on the fire’s control needs. Initial attack (IA), support resources, overhead support, and airtanker support are all identified here. These resource allotments all change with the hazard based on the fire weather index and HFI predictions. The higher the hazard, the more resources forestry puts on to meet the threat. These can be confusing but are laid out in a way to show the resources and where they are located throughout the day as well as what time they start and finish their shift.

OVERHEAD SUPPORT

Man-up Superv sor Cou tor e le George Loon River N

Man-up Superv sor Belcourt Lance Tyle H gh Pra r e N

Man-up Supe v sor Thunder Gordon Henry Wabasca N

ndustry L ason Stegehu s Herm anus Slave Lake N

Response Of cer Jacobs Am brose M Slave Lake Y

Response Of cer Col ns Robert H gh Pra r e Y

Response Of cer Carew Ch istopher Wabasca Y

Response Of cer E uk Susan Loon R ver Y

Mapp ng Spec a st Abera Dan e S ave Lake Y

Log st cs Coord nato Bats one Ta ah S ave Lake Y

Depu y Du y O f cer DeGrazia Jam es S ave Lake Y

Warehouse Person Anderson Co e S ave Lake Y

W i d i e Invest gato McCorm ick C aig D S ave Lake Y

W i d i e Invest ga o Cha foux George K rby H gh Pra r e Y

W i d i e nvest ga or Per h B ent Chr st an Wabasca Y

W ld e nvest ga or Courtor e e Pau S H gh Pra r e Y

Adm in s rat ve Suppor Hansen S acey S ave Lake Y

W i d i e Assesso Pankratow Jason W G S ave Lake Y

Heavy Equ pm en Group Superv sor McLeod Mark Slave Lake N

Perimeter

The entire outside edge or boundary of the fire or the burned area.

Head

The fastest moving portion which is normally burning with the wind and up slope. Depending on the fuels burning, the fire usually has the greatest flame length, depth, and rate of spread.

Back/Rear

Opposite to the head, is usually the slowest spreading portion with the shortest flame lengths.

Flanks

Roughly parallel to the main direction of spread. Is less intense than the head, but more intense than the back of the fire. Flanks have less alignment with the wind and can be more fuel driven.

Finger

Long narrow extensions of fire that project from the main body of fire. Typically influenced by a more volatile fuel type tract.

Pocket/Bays

Unburned indentations in the fire edge formed by fingers or slower burning areas.

Islands

Areas where fuel was not burnt inside of the fire perimeter. Could be water, rock features, or a fuel type not carrying fire. Created when fingers close around a pocket or bay.

Fires ignited outside of the main fire perimeter by lofted embers. Referred to as spotting and can occur a few meters to kilometers in advance of the head.

The Green

Unburned fuel along the fire perimeter.

The Black

Burned area void of fuels.

One of the most important components of wildfire suppression, control lines are simply the boundaries—natural or manmade—that firefighters employ to control how and where a fire spreads. A rocky ridge or river can serve as a natural control line, or firefighters can establish a manmade one by, for example, clearing out an extended line of brush. Within this overarching definition, a fire line is when the barrier is scraped down “to mineral soil,” a scratch line is a preliminary line built in a hurry, and a wet line is when the area has had flame retardant or water applied.

Fire burning in the organic duff layers of the ground. Is typically a slow burning smoldering fire. Think sub-surface fires such as a peat moss fire.

SURFACE

A fire burning along the surface without significant movement into the understory or overstory. A fire that does not burn into the crown of the fuels. Your typical grass fire is a surface fire.

Fire that has ascended into the forest canopy. Usually ignited at first by a surface fire that grows into the crown of the fuels. Flame lengths can be small to very high depending on intensity.

Smoldering

A fire burning without open flame. Spread is slow and is lacking in oxygen.

Creeping

A low intensity fire with short flame lengths and slow rate of spread.

Running

A rapidly spreading surface fire with a well-defined head.

Torching/Candling

The ignition and flare-up of a single (candling) tree or small group of trees.

Continuous Crowning

A fire that has ascended from the ground into the forest canopy via ladder fuels. Can burn with (common) or independently (rare) of surface fuels.

Intermittent Crown

When individual or groups of trees ignite but are not sustaining continuous crown fire.

Spotting

When a fire produces sparks/embers that are carried aloft by the wind and ignite new fires outside of the fire perimeter.

The line, area, or zone where structures and other human development meet or intermingle with undeveloped wildland or vegetative fuels. The interface is the “edge” where the fuels meet the urban setting.

A type of wildland urban interface in which the home or other structures are intermixed with wildland fuels, as opposed to a distinct area of wildland fuel adjacent to a developed area. Think of remote cabins, acreages, or properties that are dotted within the wildland landscape.

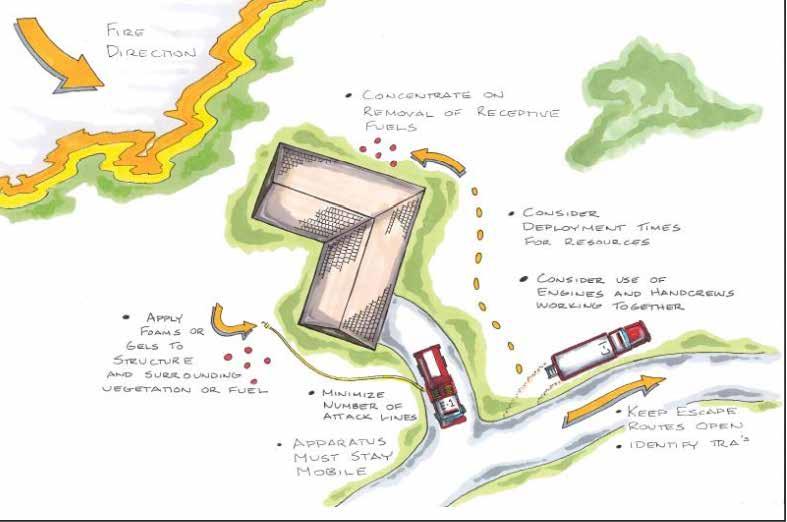

The time before a fire impacts an interface area. Could me minutes, hours, or days. The time when most structure and site prep occur including setting up sprinkler systems. The fire is in the area and threatens structures but has not impacted them yet.

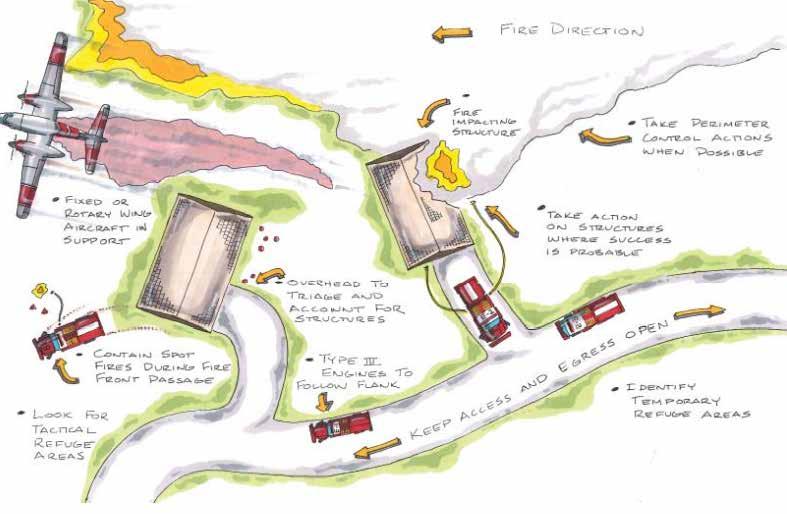

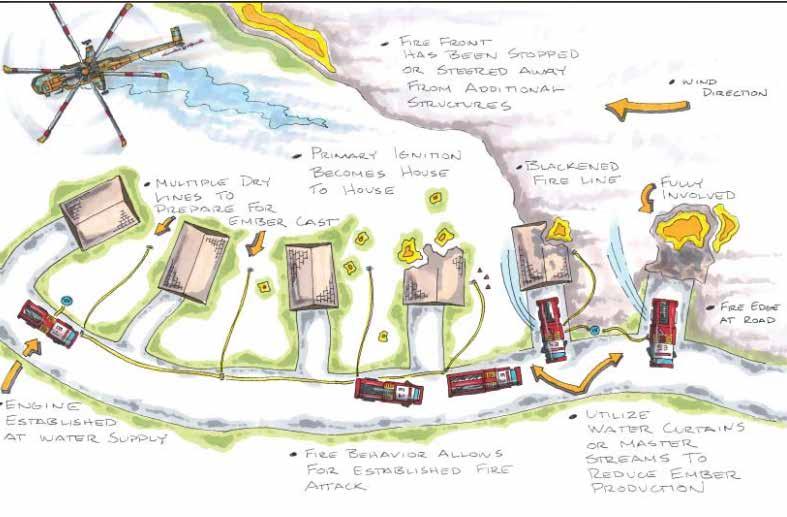

This phase is after the main fire front passes, usually leaving active fires burning throughout the interface area but the main threat of the fire front has passed. This is a critical phase in preventing structure to structure ignition. Think of structures as dominoes, to prevent a large-scale conflagration, dominoes need to be protected or “taken out of play” to prevent the rest of the dominoes from falling. Engine operations is heavily focused here as well.

When a fire impacts an interface area. Usually begins with ember showers and leads into the fire front impacting the interface area. It is when active spot fires start to occur and the time when structure ignition begins. Impingement is when the chaos usually starts. Large amounts of spot fires quickly tend to overwhelm resources unless properly planned for.

The bulk of engine operations focuses on this phase of WUI fires.

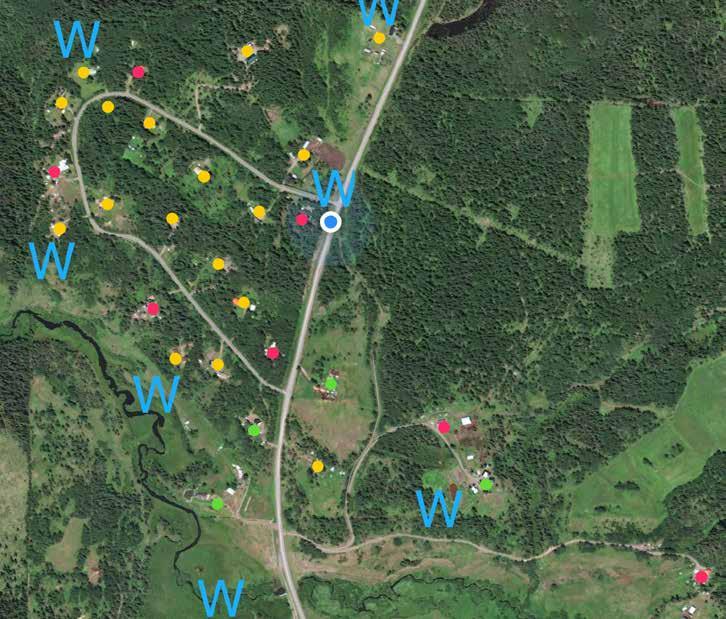

The key to ensuring preparedness for a WUI incident is proper planning. Structure protection planning can greatly improve a response should it be needed. They include critical information and procedures for handling a WUI incident. Contact information for mutual aid, provincial aid, ESS, utilities, forestry, OFC, and industry can be found there. Strategic and tactical maps may be a part of a good plan. These maps should include identified safety zones, escape routes, staging areas, water sources, and critical infrastructure. Resource planning should include the appropriate kind and type of resources to have on hand should an incident occur in the given planning area.

If time allows, crews should familiarize themselves with the response area. Make contact with the local fire service immediately if incident is outside of local response area. If the incident is located inside the Forest Protection Area (FPA), make contact with forestry early on to get the most up to date information. Identify areas of likely impact and the most at risk area. Identify critical infrastructure, water sources, access/egress routes, and resource needs. Develop a plan, refrain from running in and setting up sprinklers at random. Complete a structure triage and compare that to community layout. Where structure to structure ignition is possible, incorporate a strategy to prevent this from occurring. Prioritize what you can save in the moment and work towards a common goal.

Funding is available through government grant programs for mitigating WUI incidents. Hiring a qualified professional can help take the burden off of a stretched fire service and allow the best practices to be prescribed. If funding is a concern, starting out on your own is always a great way to increase local knowledge of at risk areas. Having a look at these areas with a different lens on can greatly change the perspective on what needs to be done during an incident. Write this information down, or better yet, map it out for future use.

Identifying water sources early in an incident will help you plan pump sites for sprinkler systems, tender fill sites, and anchor positions for strike teams and task forces. You will need to differentiate water sources for these tasks. Avoid selecting a water source for multiple applications unless it is large, has good access, and will not compromise other tasks being accomplished. Determine how reliable it is, how far from where the water is needed, and access points. For sprinkler systems try to select one closest to the structures being protected. This will reduce gear on the ground allowing you to protect more structures as well as improving flow and pressure in the systems. Types of water sources include static sources (ponds, lakes), waterways (streams, creeks, rivers), portable bladders/ drop tanks, and culvert damming or land depression filling with water tenders.

Situational awareness for the day begins with weather. Know the winds, temperatures, and relative humidity’s that are expected for the day. If the hazard is not local, where is it located and what can you expect if deployed? Ask yourself, are we ready for an interface fire today? Is the apparatus and equipment ready to respond?

Is the incident within local response areas? If so, determine where it is located and what fuels it could be burning in. Try to determine what could be threatened and gather any information you can on fire size, behavior, and spread rates. Determine if there are enough resources available to handle the incident and request more resources early if needed. If the fire is located inside of the FPA, determine what forestry is mobilizing. If the incident is outside of local response areas, ensure crews are ready to deploy and apparatus are equipped for the journey. Find out where to check in, who to report to, and what the accommodations will be.

Critical infrastructure is top priority for structure protection. Homes can be replaced but, hospitals, schools, water plants, policing and fire stations, communication buildings, and industry are difficult to bring back. These types of buildings are usually more fire-resistive but are critical to a community’s ability to recover and get back to normal.

Continually reassess information and weather on route. Try to gather as much information on the fire as possible. If you can see the column, try to determine smoke color, condition, size, and direction. If you are not the first arriving resource, listen to the initial radio report of the fire. Determine if structures are threatened and if the need to evacuate exists.

After gathering all the information you can, determine if the current resources are adequate to handle the incident. If there is doubt, ask for more resources.

Lives are top priority, evacuate the public from the area if immediately threatened. Pass information up the chain of command if you think it is time to evacuate. Evacuations take time and coordination so pull the trigger earlier rather than waiting until it will impede the response when it is really needed. The local municipality decides if/when an evacuation occurs, but they will need input from the response to make that decision. Try to establish estimated timelines (forestry can help here) and determine the risk should residents stay in place. If it is an immediate threat, you can do a site level evacuation (tactical evacuation) to remove residents from immediate danger without the municipalities blessing. The reason the municipalities need to be notified is because once displaced, they are responsible for those residents and need to set up reception centers and ensure they are cared for.

Once you arrive, size up the scene. Look closely at fire behavior, weather, and what is threatened. Determine which phase of the fire you are in (pre-impingement or impingement) and select the appropriate strategy. Given the time and resources available, prioritize what you can save and begin building a structure protection plan.

Complete an initial radio report. Describe where you are located, the size of fire, HFI, values at risk, the strategy you are employing, and establish command. Assign the next in resources BEFORE they show up. This helps crews to understand what they are going to and what is needed of them before they arrive. Note any safety concerns and have crews establish LACES.

Strive to order resources early. Think “get big quick”. You can always send resources home If they are not needed, but results can be devastating if the appropriate resources are not there when needed in time.

Each job site or typical fire scene has its own set of hazards, WUI events present a wider variety of hazards to personnel. The typical home has utilities such as power and gas hook ups that present a real danger once they are compromised. Shutting the gas off at threatened structures beforehand may be an option if impingement is imminent. Overhead power lines present a real hazard to personnel and apparatus on roadways. They can be difficult to work around when putting up sprinklers as well. Give yourself lots of room around them and plan for them to be compromised during impingement. Simple things like access can prevent or hinder egress if a situation changes, so consider and plan if you will be placing resources in these areas. Always park facing out, avoid parking on flashy fuels, and be on the lookout for things that may compromise your escape routes.

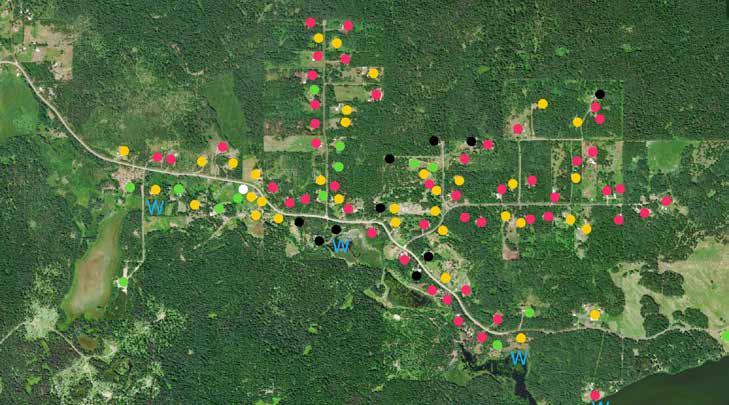

Structure triage is the process of inspecting and classifying structures based on their defensibility or non defensibility. It is based on fire behavior, location, construction, and adjacent fuels. In urban environments, structure arrangement and proximity can vastly affect triage needs. Care must be taken to triage correctly to ensure the maximum number of structures can be saved with the given resources. Too much time and resources spent on difficult to defend single properties rather than multiple, means more defensible properties can result in an inefficient operation.

Structures are prioritized based on the color rating as well as time and resources available. Firefighter safety is the largest consideration in triage, as we will not risk the lives of firefighters for property. Starting from zone 1A (0-1.5 meters) and working outward, assess the vegetation, building construction, ember traps, and areas around the structure that would be compromised during impingement. Base your triage colors on these items, not on time and resources. Priority is given to the most savable (green rocks) with limited resources. It is important to remember, that while these are family homes with memories and personal belongings attached to them, that a structure is no more than another type of tree in a wildland urban interface fire. We do not mean this to be heartless, but rather to understand that a structure itself IS FUEL. It will burn and can threaten other structures. It is important that while triaging we realize early, we cannot save them all and we certainly cannot protect them all at once. Once we break the human bond to the structures, we can do our jobs more effectively and in turn save more property. Leaving emotion out of it is important when you may know the homeowner.

Requires the most mitigation work and is likely NOT savable. It is usually the most work and unsafe for firefighters to protect. A rule of thumb for determining red rock structures is that they will receive no protection as losing gear will be highly likely. The risk to responders coupled with losing gear in a system that could compromise other structures make these structures undefended. This does not mean you will not try to save it if time and resources allow, just that it will be the last to receive protection pre-impingement and will be approached with caution during impingement.

Requires little work to prepare and is MOST LIKELY savable. These structures are safe for firefighters to action and provide good egress and have defendable space around them. These are the bulk of the sprinkler protection work and where we will engage the fire during impingement. These structures will have certain qualities that make them somewhat fire-resistive but will need some mitigation work to protect.

Requires the least amount of mitigation work and MOST LIKELY is savable with little to no mitigation work. These properties are safe for firefighters to action and provide excellent egress and defendable space. Fire resistive building construction and great zone 1A-2 maintenance make these structures green rocks. Green rocks often get no mitigation work as the homeowner has prepared the structure for fire.

ZONE 1A (non-combustible zone) 0-1.5 METERS

ZONE 1 1.5-10 METERS

ZONE 2 10-30 METERS

ZONE 3 30-100 METERS

Roof

Starting with roof materials, look at the structure from the top down. Asphalt shingles, tin, clay tile, and rubber tiles are very fire-resistive while cedar is next to impossible to protect. Cedar roofs make a structure a red rock automatically. Next look at the eaves troughing. If they are full of organics, chances are they will be dried out and need to be removed or plugged off and filled with water to prevent ignition.

Siding

Siding made of wood paneling or vinyl are not fire resistive. Log buildings, cement board, stucco, brick, and metal siding are all very resistive to fire.

Windows

Pay attention to large windows next to fuels outside of the structure. The rule of thumb is the larger the window and the less panes of glass, the more likely it is to fail under heat stress from an impinging fire. This could be from a burning vehicle, bushes, or rubbish pile.

Skirting/Openings

Look for openings in the skirting and underneath decks and close them if possible. Keep a close eye on where leaves or debris has collected around the structure. These are the same places embers will collect and they are loaded with dead, dry material.

Fences/Decks

Fences can pose an issue if they are combustible and fastened directly to the house or decking. Fences that stop and do not attach through the siding often burn but do not compromise the structure if they are installed properly. Decks that are weathered will compromise a structure quickly, while a clean, treated, and maintained deck will resist fire. Pair that with a fully skirted surround and decks are not always bad.

Landscaping

The immediate landscaping in zone 1A plays a large factor in the survivability of the structure. Mulch and other organic material are popular, but it is a structure-killer. If kept saturated these materials are not a danger but whenever there is a risk of a WUI fire, chances are the weather is hot and dry. Therefore, all organics will be dry as well unless constantly irrigated. As in the previous chapter, fine fuels dry out quickly. Mulch will hide fire, often smoldering beneath the surface, only to appear all too often when resources have moved on from the area thinking the remaining structures are safe. Public engagement in interface areas pre-incident is needed to help homeowners use noncombustible materials in zone 1A such as rock.

Any clutter or debris on deck/adjacent to house, jerry cans, propane tanks, etc.

Structures positioned mid to top slope are at an elevated risk of fire danger. As fire burns quicker and more intensely upslope, structures that are in the path of this will face higher levels of fire behavior. In more extreme cases, homes that are built on stilts or have exposed undersides are very hard to defend as they themselves will be preheated as the convective heat rises upslope. That paired with the fact that upslope is a dangerous position for firefighters, makes it likely that these structures will be hard to defend.

In groups, look at the following pictures and based on what you can see, triage the structures as Threatened Non-Defensible (Red Rock), Threatened Defensible (Yellow Rock), or Not Threatened (Green Rock). Come up with a list of reasons why you categorized them the way you did.

The arrangement of the structures is important when creating the structure protection plan. Like forest fuels, how homes are arranged, how close together they are, and how continuous they are play a large factor in how a conflagration spreads. Pair that with poor building construction and structure to structure ignition can quickly overwhelm a prepared response. Look at the community and neighborhood layout as a whole, but also individual properties and what could compromise them. Other structures or outbuildings are very susceptible to fire and those being to close or upwind of a structure could cast embers in a volume that you cannot defend. Remember the domino effect and how important it is to break the chain. Triage accordingly.

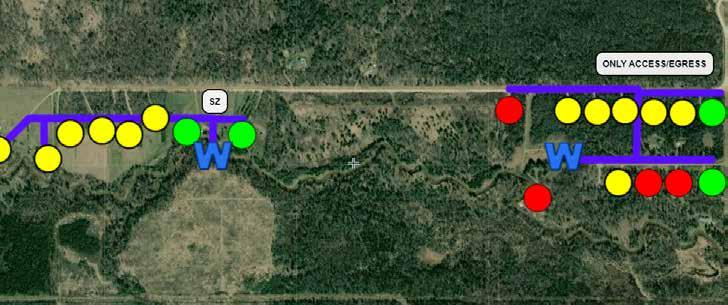

If you have time, create a map of structures triages. Place red, yellow, green, and black (black for structures lost) dots on the map to get an overall picture of the work to be done. Site check, locate water sources, and put them on the map. Digital formats are preferred because they can be shared with other resources. Currently there is no “global” input mapping program for structure protection. In the future, mapping will be available to everyone who has the training to use it. This will allow us to “triage on the fly” updating real time info with pictures and text icons dropped on properties that all resources can see. This will allow incoming resources to get a good lay of the land and when getting an address to work on, they can site check it digitally before arriving to be more efficient. For now, we just have programs such as google maps, scribble maps, or Avenza maps. While helpful, none of these programs currently meet the full needs of structure protection. If you have no access to digital systems, a paper map works well. Try to get one with satellite imagery and draw neatly on the map. Forestry can provide great paper maps in quantity, as well as geo-referenced pdf mapping. Triage mapping is very useful post-incident for the local municipality. It can give them a starting point to focus on prevention and homeowner engagement while the smoke is still in the air and they have everyone’s attention. By focusing on the yellows and reds, the municipality can help people engage in Fire smart activities.

In the province of BC, Emergency Management BC (EMBC) has identified a color system for classifying structures. This is done to speed up efficiency and accountability for every property in the interface area. Colored flagging tape will mark the property at its entrance to identify its classification.

NO GO

It is unsafe for firefighters to protect a structure and is likely nondefensible or not enough resources are available to protect.

Crews have determined the structure has a greater probability of surviving a WUI fire. Crews have completed a Structure Triage Report and requested the equipment and resources necessary to aid in protection.

PROTECTED sprinklers are in place and FireSmart principles have been implemented PUMP ON SITE A pump site exists at the property.

TENDER SITE

There is a bladder or drop tank that requires tenders to fill at the property.

DEFENSIBLE – PREP AND HOLD

DETERMINING FACTOR Safety zone is present.

SIZE UP Structure has some tactical challenges that require some mitigation.

TACTICS Firefighters needed onsite to implement structure protection tactics during ember showers and fire front contact.

DETERMINING FACTOR Safety zone is present.

SIZE UP Structure has very few tactical challenges.

TACTICS Crews may not need to be directly assigned to protect structure as it is not likely to ignite during embers showers and initial fire front contact. No structure is completely without need of mitigation or protection. Patrols following the passage of the fire front will be needed to further protect the structure.

DETERMINING FACTOR NO safety zone present.

SIZE UP Structure has some tactical challenges.

TACTICS Firefighters are not able to commit to stay and protect the structures. If time allows, rapid mitigation measures may be performed. Set trigger points for a safe retreat and patrols following the passage of the fire front will be needed.

DETERMINING FACTOR NO safety zone present.

SIZE UP Structure has significant tactical challenges.

TACTICS Firefighters are not able to commit to stay and protect the structure. If time allows, ensure people are not present in the threatened structure, especially children, elderly and the invalid. Set trigger point for a safe retreat and patrol following the fire front passage to protect the structure.

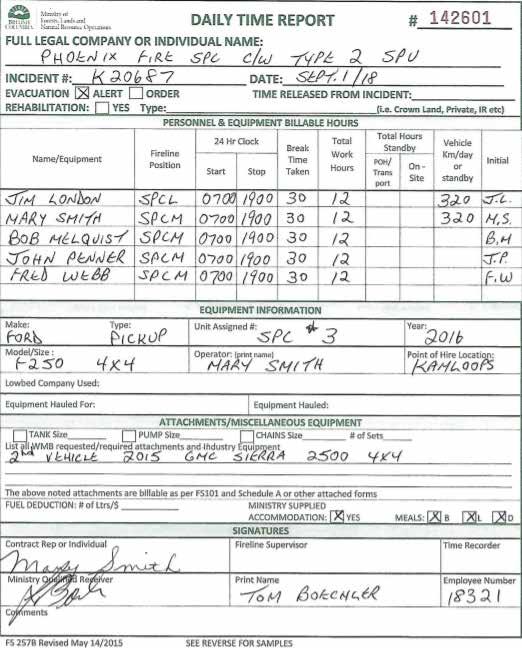

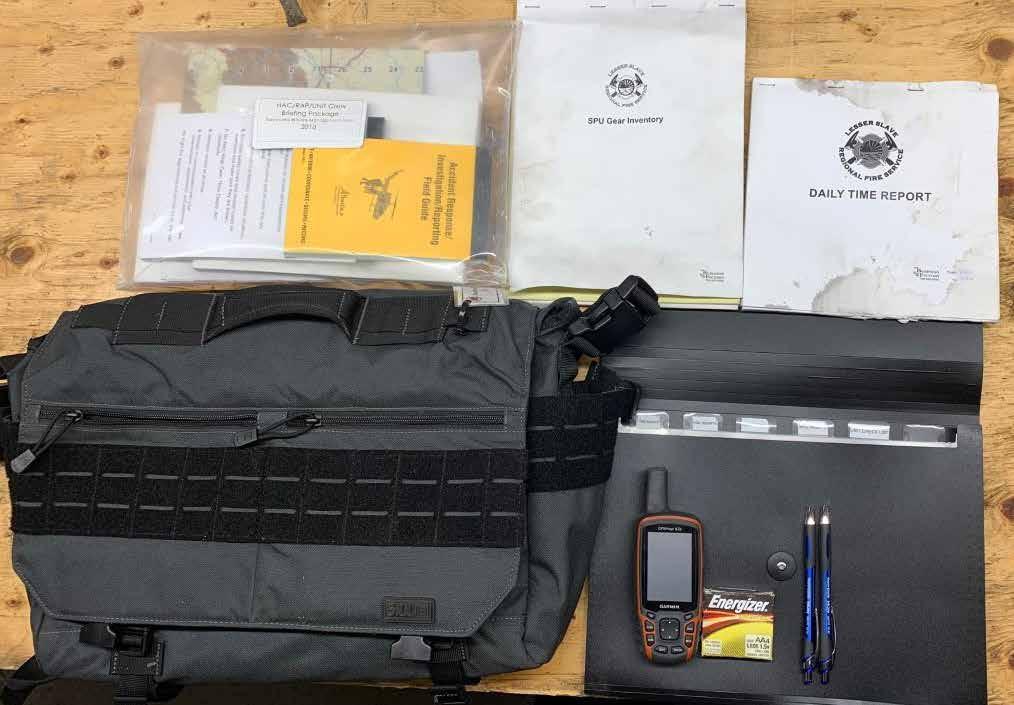

Like Alberta, a daily time report is needed for each crew daily. The DTR is signed off by the Structure Protection Specialist (SPS) at the end of the day, a position filled by experienced personnel hired by the BC Office of the Fire commissioner to oversee municipal crews engaged in structure protection. Care must be taken to fill out DTRs correctly. If filled out incorrectly, billing issues will arise and could result in prohibitions from future deployments

A British Columbia Wildfire Service (BCWS) structure triage report must be completed for each structure being assessed. It is vital that these report forms are filled out and supported by pictures with time and date stamps. Pictures must be inserted into the form and handed into the SPS daily, be sure to include status of occupants. Triage reports can be filled out by hand or with Form Connect on a tablet or iPad.

Be sure to fill out your DTRs, Structure Triage forms, and other paperwork in a timely fashion. Fill it out correctly, failing to do so will result in payment delays, headaches, and poor results from your department on deployments. Governing bodies are very driven on proper paperwork and documentation. Do your part to ensure you are filling out the required paperwork.

The Initial Fire Report is to be filled out by the first arriving resource to a new fire. The information gathered is used to determine control needs and further resources. It includes information such as location, fuel burning, estimated size, values at risk, estimated spread rates, slope, access, water sources, and recommended actions.

BC has set requirements for training to be able to go on deployments. The Structure Protection Workshop (WSPP-115) is the prerequisite for all structural firefighters to participate on structure protection crews that are deployed provincially by the OFC or BCWS. The Wildland Firefighter Level 1 (WSPP-WFF1) is a prerequisite for all structural firefighters to participate on structural protection suppression crews that are deployed provincially by the OFC or BCWS. Resources are also listed prefire season for availability for deployment throughout the province. Municipal fire services submit a list of available resources they can offer if required. Each resource (engine, tender, SPU crews, etc.) have to meet a minimum requirement of personnel and equipment which is listed by the OFC and BCWS. If resources show up lacking personnel or equipment, they will be staged until the proper requirements are met or sent home. Requirements can be found at:

https://www2.gov.bc.ca/gov/content/safety/emergency-preparedness-response-recovery/ fire-safety/wildland-urban-interface-fire-information/about-structure-protection-program

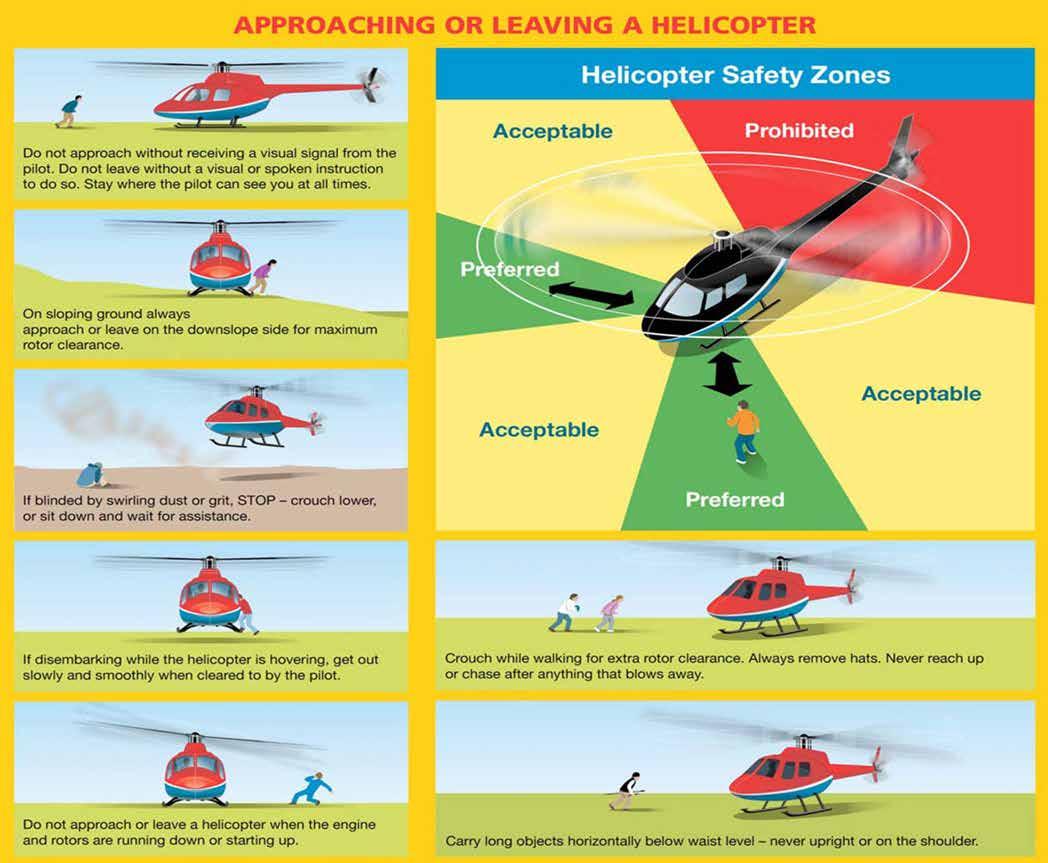

When working in remote areas many challenges that do not exist in developed areas become prevalent. Road access may be limited, cell service can be poor, and re-supply issues can be challenging. Having a good communications plan can help with some of these issues, but crews must also be as self-sufficient as possible. Some areas may need to be accessed by helicopter, so having equipment pre-weighed can help. Ensure everyone receives a safety briefing from the pilot and follow all loading and unloading procedures as per the pilot in command. Take the time to understand the hazards when working around aircraft.

When operating with rotary aircraft, care must be taken to ensure the safety of all involved. A pilot led safety briefing must be obtained before flight. This ensures the crew will operate within the safety regulations of the aircraft. The pilot has the ultimate say in who boards their aircraft, and must be listened to when recommending operations. Crew members must know their fully kitted weights, as well as the weight of their equipment. Each helicopter has a payload that cannot be exceeded. This includes helicopter fuel, crew weight, equipment weight, and pilot weights. The pilot is responsible for ensuring they do not exceed this limit. Weather and altitude also plays a factor in weights. The hotter the day and the higher the altitude you are flying in, the less weight the aircraft can carry. General rotor-wing aircraft safety rules are shown in the following picture. Take note of the approach angles and be sure to never carry tools above your waistline or throw objects near a helicopter. Always get visual or radio confirmation from the pilot before approaching a helicopter. They may not be prepared for your approach especially in a hover. Avoid being in a rush around aircraft and always think before you act.

When working around heavy equipment, use caution. Forestry commonly deploys heavy equipment to wildfires. Always make eye contact with the operator if you are going anywhere near the equipment. Use radio communication where possible and understand where they will be working. Urban heavy equipment use can be highly effective once the fire progresses to a conflagration. Careful planning and tactics must be used when deploying heavy equipment to the urban setting.

Working around industry can present safety concerns. While most oil and gas sites are inherently fireresistive, logging and mill sites may present great difficulties when trying to protect. Industry is great for knowing their site-specific hazards and they may have resources available that can help you (heavy equipment, water trucks, accommodation support). Try to build a relationship with industry and work together to help mitigate their risk to fire.

With any interface fire, politicians will be involved. Be courteous if you end up speaking with them, and direct them to your supervisor. Do not give them any fire-related information if you are not in a position to do so. Do not let them influence structure triage or the structure protection plan. Remember, you would not let a mayor or councilor tell you how to perform a vehicle extrication, so why would you let them tell you which structure to protect?’’

Care must be taken when at events with regards to social media. It is recommended that no crew member use their personal phones for pictures, as they may be requested at the end of the event by the respective governing body. Pictures known to be taken on personal phones (crew members caught taking photos) will be confiscated. This means they can take your phone and remove the pictures. Your crew may also not get asked to leave the incident and your department may not be requested in future deployments.

Posting of any incident pictures to social media is strictly prohibited. Even through your fire departments social media. Do not risk this, there has been cases in the past of resources getting sent home and “black listed” from future deployments for this reason. The governing body or provincial wildfire agency has sole authority for pubic information.

Working on First Nations lands can present both challenges and opportunity. We stress open communication and working with First Nations to help mitigate their risks. They may have site specific concerns or limitations that need to be considered. As with all relationships, build a good working relationship that can build trust when working on these lands.

Dealing with homeowners can be challenging but try to stay calm and understand their concerns. Take the time to engage with them and they may be able to help more than hinder your operations. If you can help to educate homeowners on FireSmart principles, your site prep can be vastly reduced by having them get started on their own properties. Stay humble and respectful when interacting with the public, they are going through an experience they likely have not had before, and their livelihood may be threatened. Do not let homeowners dictate your structure triage or structure protection plan, fall back to priorities and training to make the right decisions.

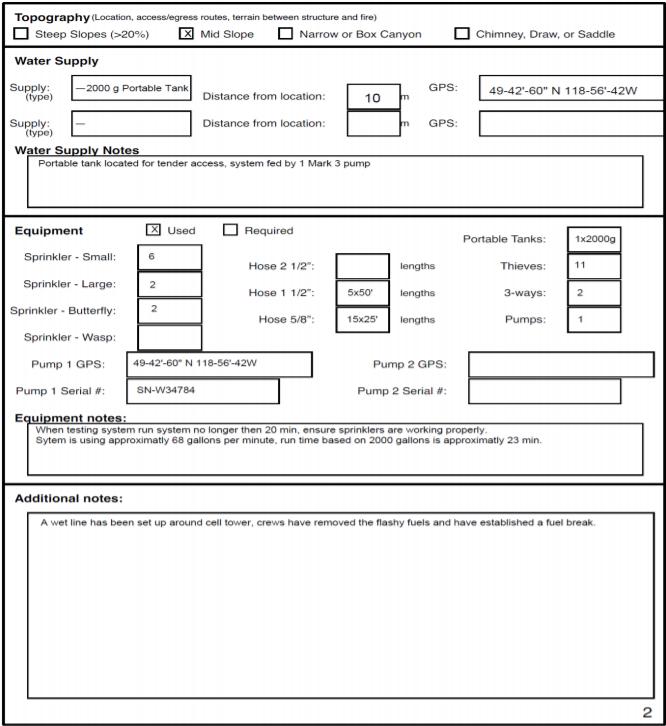

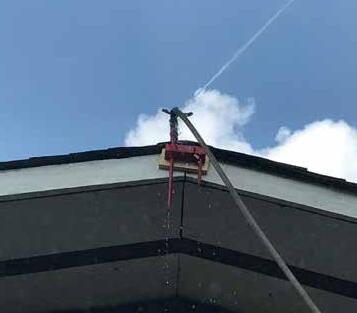

The selection of a sprinkler system begins with developing a plan. Which structures and how many you protect, water source locations, trunk line locations, critical infrastructure, and how much time is available will all need to be considered. With proper community and structure triage, we can begin to develop a plan of action to protect structures using sprinkler systems. Sprinkler systems require adequate pressure to maintain proper coverage. Reducing the amount of gear needed (waste) to protect structures reduces friction loss in the system allowing you to stretch it farther. The more larger diameter hose and the less small diameter hose you can use the better.

Dead end systems are laid out from the pump site towards the farthest structure. They branch out to protect structures as the trunk line is laid out, and dead end at the last structure. The sprinklers closest to the pump see the highest pressures, and then decrease in pressure the farther from the pump they are. Dead end systems are not always taught to be effective, but on smaller set ups it can be highly useful. A good strategy is to try a dead end first, as it saves on the most gear, then add a loop, counter pump, relay tank, parallel, or tandem if necessary. Depending on trunk line length, pump size, and number of sprinklers, a dead end can handle a standard small to medium sized set up. The biggest advantage is the extra equipment saved to protect more structures on additional systems.

For many years and is still frequent today, looping is taught as the only way to deploy sprinklers. The theory behind this is the same as what you see in a municipal water system or any type of “closed loop” fluid system. If you do not dead end the hose line and loop it back to itself either close to the pump or around a structure, you create equal pressure in the system. This is absolutely correct; however, this is a dangerous way of thinking as it is often interpreted as “it will increase the pressure” in the system. The latter is very FALSE. It ONLY EQUALIZES pressure, and that most certainly includes bad pressure. To simplify, if you have great pressure out of every sprinkler head, or only a small number of heads that need a little more pressure, looping an excellent strategy. However, if you have a lot of sprinkler heads with bad pressure and only a few with good-great pressure, looping will equalize the pressure in the system and create bad pressure on all heads. It ALWAYS makes the heads in the loop the same pressure, so you need great pressure to justify looping. A rule of thumb we have developed is that looping is only effective in a large system when AT LEAST 70% of heads have great pressure and NO MORE than 30% need a small to moderate increase in pressure. Looping also greatly increases the amount of gear deployed in the same system restricting you from protecting additional structures with the equipment available as well as increasing the friction loss in the system.

Often the solution to scenarios where the system is too big to loop is adding an additional pump at the opposite end of the system and having the pumps pumping towards each other (counter pumping). Typically, you will start by protecting what you need to in a dead-end fashion, then deciding whether to loop or counter pump. Other pumping solutions are available as described below, but all include adding an additional pump.

In current and past thinking, looping each single structure is taught. Often this is not necessary on smaller structures (typical single-family dwelling) but is effective on larger homes or structures. The other case where this could be effective is the structure is farther off of the main trunk line and is needed to equalize pressure at the individual structure. The same 70/30 rule applies to be effective. Looping every single structure uses up a large amount of hose and fittings that could be used to protect more structures. Other solutions exist that increase the effectiveness of the system while saving on gear and time.

In larger set ups, looping the trunk line around a large cluster of structures (think neighborhood) will equalize the pressure going to each structure. This works for a small to medium sized set up on a single pump. The 70/30 rule is critical here as well as a large amount of gear can be set up only to find that more pressure is needed. The heads farthest from the pump will see an increase, but closer to the pump pressure will be lost. Care must be taken to ensure using more hose and fittings is more appropriate than adding an additional pump.

Adding an additional pump can benefit the system by allowing you to protect more structures than were originally sprinklered.

Counter pumping is an excellent strategy that maximizes the number of structures you can protect with two pumps on a single system. For large set ups, pumps are on either end of the sprinkler system pumping towards each other. This is the standard go-to set up for larger numbers of structures to protect. This system can span an impressive distance with the right pumps and allows you to save on gear use. To simplify, counter pumping is used when a dead end is too large to create sufficient pressure in the system, and where a loop will only equalize bad pressure. In some cases where counter pumping is deployed, pressure in the center of the system may still lack pressure. This can be found when the system is spread too far and too many sprinklers are in play. The solution to this would be to add a “booster pump” precisely where the pressure is the lowest. This can be done by dropping a bladder or drop tank in the desired location. The only other solutions would be to cut the system up into smaller pieces or reduce the number of sprinklers or structures protected.

Parallel pumping uses the same water source and two pumps to boost pressure in the system. Both pumps flow separate hose lines for at minimum the first 100 ft or more, then Siamese into a single trunk line. Works great with larger diameter hose (65 mm) Siamesed into smaller hose (38 mm). This will have a noticeable increase in pressure, but counter-pumping should be considered if adding a second pump anyways due to being able to protect more structures farther down the line.

Center pumping is a great option when the water source is central to multiple structures in a small to moderate sized set up. A single pump is used to pump in two separate directions from the water source. Using a wye, preferably one with no valve or restriction, the trunk line splits near the pump to travel separate directions. In the end it is simply two dead end lines but the pump is in the middle of the system. Center pumping may not be a good option when there is large numbers of structures to protect over great distances.

Tandem pumping is effective when large distances or grade must be traveled. The first pump at the water source pumps as far as it can until pressure and flow starts to be lost, then a second pump is added IN-LINE to boost the pressure. This set up is effective but can be challenging to find the correct location for the second pump. Almost always, maximum pump capabilities cannot be achieved due to the variables in running both pumps through the same hose line. If the correct location is not selected, the second pump cannot run at full rpm due to the risk of cavitating the supply line from the first pump. A relay tank system is more effective here as water supply is easier to manage. Tandem pumping should be used as a last resort to all other pumping systems for this reason.

Tank relay pumping is selected when the best water source is far from the structures or there is a significant grade to overcome before reaching the structures. This is done by pumping water from the main source to a second location such as a bladder, drop tank, ditch, or depression in the land to fill and use as the second water source. At the second water source another pump is required to run the sprinkler system. This system effectively “brings water to you” and is very useful when tender shuttles are not available, or roadways are not available/accessible. Typically, you can select the location of the 2nd water source as close as possible to the structures which reduces hose and fitting requirements allowing you to protect more structures on the single system. Where grade and sloping are the issue, the primary water source pump uses its pump power to overcome the grade, so the second pump does not waste pressure trying to both overcome the grade and protect structures.

The first thing to run out on all sprinkler systems is hose, specifically 38 mm, and pump power. SPUs are limited by the amount and type of pumps they carry as well as the amount of trunk line hose they carry. Always try to think, where can we optimize? Where can we cut gear out and achieve the results we need? How can we get more out of this system? Is every structure getting the proper coverage with this system? Limiting gear use does not keep it in the SPU, it simply allows you to protect more structures with less.

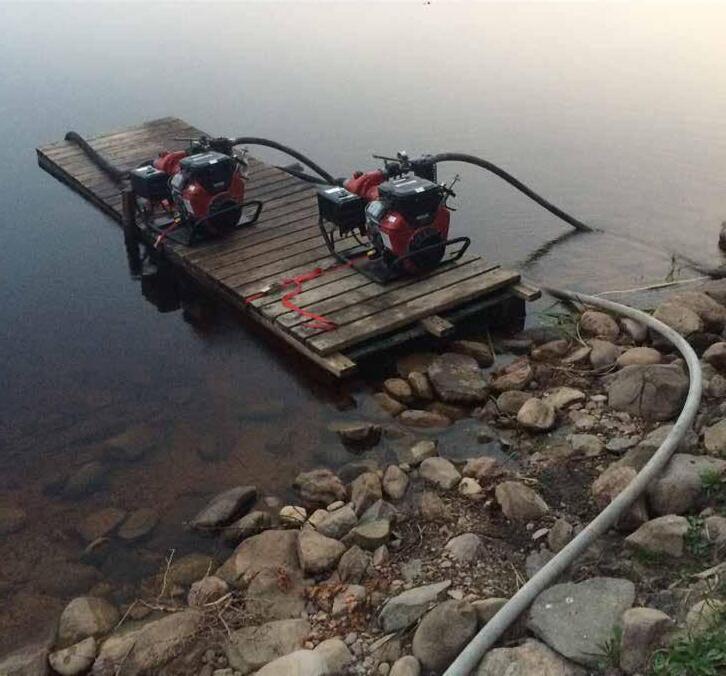

Once the plan has been made and water sources selected, you will likely begin by setting up the pump site. This can happen in tandem to the system set up given you have enough manpower and resources. This will include selecting the correct pump, securing the site, protecting the site, troubleshooting, check valve use, and testing. Use of fresh, premium, stabilized fuel is preferred as most pump issues outside of operator error involve poor fuel that has been sitting in the SPU for too long. You will need a pump, suction hose, fuel, pump kit, troubleshooting equipment, and water source to set up a pump site.

You will want to select a large, clean, and reliable water source. Natural water sources are typically the best, as they hold large amounts of water that can be supplemented with tenders or hydrants. Rivers, streams, lakes, ponds, land depressions, ditches, or damming culverts are great options for large volume reliable water. Bladders and drop tanks are great options for placing them in the preferred locations if you have access to tender shuttles or hydrants to nurse them. AVOID tying the sprinkler systems to hydrants or using the municipal water system as a source of pressure. Hydrants add more volume than pressure and come with a large number of variables rendering them unreliable. Industrial 400-barrel tanks are excellent sources of water (16 600 US Gallons) when compared to a bladder or drop tank (500-4000 US Gallons) providing you have the adaptors to use them. Another serious complication to the 400-barrel tank is that they MUST be clean inside. In industrial applications these tanks hold all kinds of hazardous materials and must be steam cleaned prior to use. Most companies that provide these tanks will say they have been cleaned but ensure you check for yourself. This was a hard lesson learned in many WUI deployments where “dirty” water was used to sprinkler homes and resulted in massive clean-up efforts. Swimming pools are another great option for water.

Bladders and drop tanks are excellent choices since you can place them directly in and amongst the structures to be protected. This is advantageous due to eliminating long trunk line lays, the pump sites are inherently protected by the sprinklers, and the locations can be set up for easy tender shuttle operations. The disadvantage to this option is they are limited to how much water they can hold. Bladders can be placed on minor slopes without affecting water capacity but drop tanks will see a large reduction in capacity when placed on a slope. Drop tanks take less manpower to set up, where as a bladder requires more personnel to set up effectively. Bladders store easier and are readily available through forestry, where drop tanks typically come on municipal fire apparatus and are limited to usually one per apparatus that have them. When placing either option for tender shuttle operations, ensure they can be easily accessed by a single operator of a tender. This includes placing them so the driver does not need to back up to it, rather they can pull up beside it and then drive away.

Pumpkins range from 300-3000 US Gallons and can be set up on low slopes without reducing capacity. They are affordable, easy to maintain, and easily drained and collapsed. They require more personnel to set up and are not easily stored on fire apparatus. These bladders may have pre-plumbed fittings at low points on it to hook a suction hose to.

Typically used by the municipal fire service and stored on fire apparatus such as tenders. They require minimal manpower to set up and take down. The disadvantage to framed drop tanks is that they have reduced capacity when set up on any kind of grade or slope. They may or may not have pre-plumbed fittings to connect to.

When running a portable pump site from a natural water source with a suction hose, try to float the hose in the water to avoid picking up debris from the very bottom. This can be done with some empty water bottles or windshield washer jugs taped approximately two feet from the foot valve. If the bottom of the water source is clean such as a rock bottom or a bladder/drop tank, floating may not be necessary. Use a low-level strainer where possible in these situations to maximize water use. Ensure the suction side of the pump is air-tight and that the foot valve is functioning properly.

When pumps are running, they vibrate and need to be secured. Floating pumps need to be tied off in the event the discharge hose becomes disengaged. This will prevent the floating pump from floating away. To secure a pump, cut stakes from trees and hammer them into the ground around the pump. Then tie the pump to the stakes. Building a level pad out of wood or dunnage in muddy areas can ensure the pump does not vibrate into the mud too far. Ratchet straps, rope, or twine work well when tying off pumps. Pumps set up on slopes face issues of sliding into the water source or away from it. Protecting the pump from the wildfire may be a concern as well, so consideration should be made to sprinkler the pump site if needed.

Pump selection is critical when planning a system. While there are many out there, the best have a pressure head or combination pressure-volume head. Standard pumps used in the interface are the Wajax (Waterax) Mark III and the BB4. Mark III’s are light, readily available, and easily serviced pumps that are widely used by forest agencies across North America. A maximum PSI of 380 with 98 GPM make them suitable pressure pumps for small to medium sized set ups. Mark III’s are 2 stroke and can be difficult to start without proper training or experience. The BB4’s have 4 stroke engines that are easy to start and can provide great pressure to a system. With 425 PSI and 105 GPM they provide a larger amount of pump power to the system, allowing you to protect more structures on a single system. Well suited for large set ups, they are heavy and usually require two people to set up.

The fuel used in pumps must be fresh, clean, and preferably premium grade. Bad or old fuel is the leading cause of pump failure or issues. Changing fuel out in the spring before the fire season can ensure readiness and reliability in the pumps. Using generic jerry cans instead of unique, quick coupler jerry cans is preferred due to the compatibility and availability with other agencies equipment. Specialty jerry cans are harder to repair and are not compatible with what forest agencies use. Fuel lines should be in good repair and fitted with filters. Keep jerry cans and fuel lines clear of hot exhaust areas. Some pumps may have on board fuel tanks with fuel source valves to select on board fuel or jerry can fed fuel lines. Engine RPM and fuel capacity dictate how long the pump will run.

If you cannot achieve prime with a running pump, the first step is to check the suction side for air leaks. Tighten all fittings on the suction side and check for proper foot valve plunger operation. The plunger should not stick closed, it must open with ease to fill the suction hose when priming and pumping. Manually prime the pump if necessary, to help achieve prime. This can be done by filling the suction hose and pump head manually through the filling cap on the pump.

The first step when a pump is not starting is to check that the ignition switch is in the “on” position. This is typically the most common mistake made when trying to start a pump. Ensure the fuel line is primed and not leaking fuel. Open the fuel tank’s cap to prevent air locking. Ensure the choke is on and throttle is at 1/3. If the pump does not start and you can smell fuel coming out of the exhaust while starting the pump it may be flooded. If this is the case, you can try a “Hail Mary” before pulling the spark plug. To do this, de-activate the choke, place the throttle at full speed, and attempt to start. If this does not work, shut the fuel off, pull the spark plug, and turn the engine over approximately 20 times. This should clear the “flood”. Check for spark by placing the spark plug against the engine block and turn the engine over. If no spark is seen, change the position of the plug on the block. If no spark is seen again, the plug may be in-operable. If spark is seen, put the plug back in and attempt to start the pump from step one.

If you are pumping up a grade, you may want to consider using a check valve. This reduces back pressure on the pump head when starting the pump. Place the check valve after the first 10ft of hose. Face the check valve in the proper direction (improper direction will cause a burst hose or no flow). Check valves help keep water in the system and keep head pressure off of the pump head to allow for easier starting. If there is a lot of head pressure on the pump it will be difficult to start at an idle as the pressure coming in may be higher than the pumps discharge pressure at idle. Only use a check valve if overcoming elevation. If there is no elevation a check valve is not needed and will only increase friction loss in the system.

When a pump site is located in the path of the fire, or is surrounded by fuel, it may be necessary to place a sprinkler near the site. Burning out around the pump is an option. Ensure jerry cans and fuel lines are clear of the exhaust and jerry cans are in a stable, upright position. If they can get knocked over by the pump vibrating away and “pulling” them by the fuel line, secure them as needed.

The rapid deploy bags are bags or backpacks that hold either rolled or flaked in hose line. Typically, in 38 mm, they feed out of the bag worn by the wearer. The advantage to this lay is that the trunk line can be surgically placed to reduce the amount of hose needed. It is a precise, accurate way to maximize the hose you have available. It can be labor intensive due to the wearer carrying 40-60 lbs. of gear and walking through uneven terrain. This is a slower way to deploy hose as it can only be deployed at walking speed but is a precise way to lay hose efficiently.

The trunk line in a sprinkler system is the main supply line that delivers water to the structures. It is the largest diameter hose that comes from the water source. Care must be taken to protect the trunk line from fire, vehicles, pinch points, and other potential hazards. Laying the trunk line through culverts when crossing roads is an excellent option but may be difficult to feed. Charging the line so you can “push” it through the culvert may be necessary. Never go over top of railway tracks, rather dig between two railway ties to feed the hose underneath the rail line. Lay the trunk line as close to the structures as possible to reduce the amount of small diameter hose in play. This will save on friction loss allowing you to protect more with that system.

The single roll method involves deploying one hose roll at a time. It allows you to accurately lay the hose lay it precisely where you want it. It is the slowest method due to the time required in rolling out a hose section, fixing tangles, and straightening the line. Deploying hose 50-100 ft at a time is manpower intensive and can add to the confusion when large numbers of people are trying to deploy the hose according to the plan.

Preparing a site for sprinkler systems requires going back to triage and why it was categorized. Standard tactics of removing combustibles such as firewood, lumber, leaves, patio furniture, flammable containers, and BBQ propane tanks from Zone 1A apply. Removing objects that can obstruct sprinkler heads and their streams should be done if possible. Burning out vegetation and dead grass may be an option if proper resources and experience is present.

Utilizing the hose bed of an apparatus is the quickest way to lay trunk line. It is quick, easy, requires little manpower, and can be beneficial in an urban setting. This method is the least accurate and can be limited by where there is road access. It will increase the amount of smaller diameter hose needed to get to the structures by not laying the trunk line directly beside them. Should be used when lack of time is a factor. When adequate time exists, more precise methods are preferred.