51 minute read

Products

FLEETGUARD CABIN AIR FILTERS

A breath of fresh air

Dust! No matter how many times you clean a surface, it will not be long before you need to dust it again. The same goes for your car’s dashboard and air ducts. Dust settles everywhere, even in places you cannot see or get too. Fleetguard says its cabin air filter can filter out dust particles from your vehicle’s cabin, reducing the amount of dust you breathe in. As stated by the Victorian State Government’s health department: Commonly, particles in airborne dust tend to be coarse or non-respirable and do not pose a serious health threat to the general public. However, people with respiratory conditions, such as asthma and emphysema, may experience difficulties. Fleetguard says that is why having a Fleetguard cabin air filter is one of the easiest ways you can be sure you are looking after yourself and your passengers.

It states that every Fleetguard cabin air filter benefits from more than 60 years of research and development and the highest quality parts. It says that the standards of manufacturing are some of the highest in the world. Further, Fleetguard states that “you can find comfort in knowing you’re getting a premium product.” Fleetguard cabin air filters have a select range covering popular 4WDs, including Ford Ranger, Mitsubishi Pajero/Challenger, Nissan Navara and Toyota HiLux/Prado. Fleetguard says it has decided to extend its “already successful and world class cabin air filter systems in heavy duty trucks and light commercial application (LCA) and bring you the same quality and technology of cabin air filtration into your 4WD.” Fleetguard Cabin Air Filters are available to purchase across a range of suppliers across Australia.

For more information, visit www.cumminsfiltration.com/ south-pacific/product-releases

THE NEW EURO+ DISC ROTOR RANGE

From Bendix technology and precision engineering

With safety paramount for the Bendix engineers who collectively have a wealth of OE expertise, Bendix says it has now introduced a range of leading edge disc rotors for European vehicles that meet stringent ECE Regulation R90. Using advanced technology in proven High Carbon Metallurgy results in improved thermal stability and conductivity that reduces the chance of warping or DVT plus precision engineering, motorists can put their foot down with confidence. ‘E’ marked ECE R90 approval specifies design, construction, performance requirements and test protocols to strict European requirements. The Bendix Euro+ Disc Rotors are said to meet the highest levels of accuracy based on OE specifications for size, diameter and hole spacing for reliability and the perfect fit. Each Euro+ disc is Swiftfit coated in a protective zinc coating with corrosion inhibitors for a great look that will not degrade over time. This coating also allows for faster fitting without pre-cleaning, saving both time and money. Bendix Euro+ high quality Disc Rotors are designed for European vehicles and are engineered for optimum performance, braking synergy and driving comfort expected in a luxury vehicle’s high-end performance. Bendix says they are also perfectly matched with the Bendix Euro+ range of performance dust free brake pads. Bendix Euro+ Disc Rotors are available from leading Bendix distributors nationwide.

For more information, visit www.bendix.com.au

NULON PRODUCTS LAUNCHES ALL NEW 7L PACK

7 litre diesel engine oils launched exclusively with Supercheap Auto

Nulon Products Australia have introduced its next-generation small pack design, featuring an all-new EZY-POUR anti-glug neck design. Nulon says its new bottle design featuring its EZY-POUR neck design allows for a smoother, cleaner, and easier application. “Our all-new 7L pack design incorporates EZY-POUR anti-glug technology and a wider 50mm neck design for unrivalled pour performance,” Nulon Products Marketing Manager, Tom Murray, said. “As pack sizes have grown to meet the increasing sump sizes of many popular vehicles on Australian roads, it was critical for Nulon to develop a new larger packaging solution that not only meets the requirements of the car parc, but also helps make vehicle maintenance easier”. The sharp looking pack design also features two handles located on the top and side of the bottle for improved ergonomics and easy handling. The new 7L diesel engine oil range has been launched in the popular full synthetic 5W30 dexos2™ approved and 10W40 heavy duty diesel engine oil specifications. They are now available exclusively in Supercheap Auto stores.

For more information, please visit www.nulon.com.au

VARTA BATTERIES

For Start/Stop technology and European cars

Start/stop technology is now commonplace in Australian workshops and it is of paramount importance that workshops are familiar with the requirements of and differences in new technologies and understand the pitfalls of fitting the wrong type of battery. European cars make up 17 percent of the total of new cars registered in Australia, with 156,000 last year alone, of which the majority have start/ stop functionality. Federal Batteries, the exclusive agent of VARTA automotive batteries in Australia since 2015, explains VARTA works closely with European car manufacturers and says its batteries are now fitted to around 80 percent of manufactured cars coming from Europe with its advanced EFB and AGM technology. The VARTA brand has a history going back 125 years, manufactured in factories around Europe and reportedly found in all the leading car brands such as BMW, Golf, Audi and Volkswagen Group. The Enhanced Flooded Battery (EFB) is an advanced battery which has increased life cycles and an improved ability to accept charge, appropriate for use on basic start/stop. Federal Batteries says this battery has typically twice the cycle life of standard aftermarket batteries and improved ability to accept charge. The Absorbed Glass Mat (AGM) battery is fully sealed and reportedly offers typically three to six times the cycle life endurance at 50 percent Depth Of Discharge (DOD) compared to that of a standard aftermarket battery. It is said to also have maintenance of dynamic charge acceptance (DCA) currently up to three times that of standard flooded batteries. It is important the right battery is fitted as per manufacturers’ specifications. This may result in pressure being put on workshops to explain why the end-user might need to buy a more expensive battery, but Federal Batteries says failure to do so could very quickly lead to loss of functionality in the vehicle. It says standard batteries should not be fitted to any type of vehicle with start/stop functions nor should EFB be used on AGM applications. In some cases, AGM can be substituted, but only where this is an option given by manufacturers. Testing of these batteries can be problematic – most electronic testers used test Cold Cranking Amps (power), whereas start/stop batteries need to be tested on reserve capacity and Charge acceptance (charge quicker). Federal Batteries says the general rule is that if a charger shows “bad battery” or “good battery recharge” the battery should be replaced. Federal Batteries says has more than 30 years’ experience in the Australian market covering an extensive range of Automotive, Commercial, Marine and Deep Cycle batteries.

For more information, contact your nearest Federal Batteries branch on 1300 133 980.

HAYMAN REESE SMARTCODE

Ensuring your vehicle’s performance, comfort and safety systems are correctly enabled every time you tow a trailer

With ever-increasing technological and safety functionality being added to new vehicles, manufacturers are using this smart technology to adjust certain features when the vehicle is towing. These features can and will vary depending upon the manufacturer and model involved but include features such as ‘Blind Spot’ monitors, Adaptive Cruise Control, Lane Change warnings, Sway Mitigation (VSC/ESC) and engine and transmission mapping affecting gear shift points and power curves. Fitting a towbar, correct wiring and an electronic control unit (ECU) will not fully activate all the vehicle systems and functionality when a trailer is connected. The new Hayman Reese SmartCODE system allows the towbar installer to not only install a quality product but also ensure it is correctly recognised by the vehicle via a process called coding.

Why is individual vehicle coding important?

Hayman Reese says certain modern vehicles now require a smart solution. The Coding Process ensures the computer of the vehicle and the electronics in the vehicle are communicating correctly with the trailer module (ECU) and enable all the vehicle designed changes to be initiated when towing. The key elements to Smart CODE include: • Hardware – the towbar (physically bolted to the vehicle) • Wiring kit and trailer module (ECU) – the

Hayman Reese and vehicle specific CANbus module. • Coding – the ‘process’ carried out using the Hayman Reese Smart Code tool which ensures the vehicle recognises it has a correct towbar and wiring package installed and the vehicle specific changes required for towing are activated. Hayman Reese says SmartCODE is the first “intelligent wiring solution’ that provides a complete aftermarket solution. “What makes the Smart CODE tool and fitments unique is that for certain vehicles, installing a towbar and the correct CANbus wiring solution is only the start,” Hayman Reese Sales and Marketing Director, Gregor Brown. “Ensuring the electronics of the tow bar are

NEW RELEASES FROM ARB

A range of new products have been released by ARB recently

ARB says it is constantly working on expanding the products available in its range. Following are details of just some of ARB’s recent additions.

Recovery facelift

Heading off road generally means you are bound to find yourself stuck at one stage or another. The ARB Premium and Weekender Recovery Kits have been upgraded to a new modernised colour design with heavy-duty PVC, making them easier to clean. The ARB Recovery Kits keep your gear organised and ready for when you need it most. The Premium Recovery Kit is $499 (Australian East Coast Metro) and the Weekender Recovery Kit is $175 (Australian East Coast Metro).

Intensity AR40 V2 Light Bar

ARB says the Intensity AR40 V2 Light Bar has been updated with the latest Hyperspot technology while utilising the optimal chassis design of the popular Intensity Light Bar. Hyperspot is a refined optic used to focus and intensify the light output, driving the light down the road while maintaining the clarity and control of the beam to ensure the best performance and great natural visibility. The Intensity AR40 V2 Light Bar is $899 plus loom and accessories.

BP-51 for D-MAX

ARB invites you to take total control of your ride with what it calls the ultimate in 4WD suspension, BP-51 shock absorbers. These useradjustable internal bypass shocks are designed and manufactured in house by ARB and have now been released for the 2021 Isuzu D-MAX.

RAM 1500 Air Locker

The rear locker for the 2011+ RAM 1500 is now available. ARB Air Lockers engage instantly and at any speed, meaning you do not have to lose momentum before tackling an obstacle. The Air Locker is $1,095 (Australian East Coast Metro) and is in stock now.

D-MAX Commercial Bar

Expanding the range of bull bars to suit the new Isuzu D-MAX, the Commercial Bar is now available from ARB. ARB says Commercial Bars are frequently specified by organisations that demand strong and functional equipment but are willing to go without some of the aesthetic characteristics. The ARB Commercial Bar for D-MAX is priced from $1,745 (Australian East Coast Metro) and available now. Note: This bar is not compatible with the X-Terrain model.

integrated and coded correctly to the vehicles computer system is critical. “This means that all the ‘smart and intelligent’ functionality the vehicle has been designed with for when it tows has been activated. “Only Hayman Reese customers using the Hayman Reese SmartCODE solution can deliver this in the aftermarket.” The SmartCODE coding process is done by the SmartCODE handheld device. The device contains vehicle specific data and validated software to program or Code the vehicle to correctly recognise that the trailer module (ECU) is installed. This allows the vehicle’s embedded features to be seamlessly engaged when towing. (Note: Hayman Reese offer SmartCODE for vehicles which need the solution).

For more information, visit www.haymanreese.com.au

Compressor Switch Bracket

With each unique build comes a new idea to develop a product that can provide variety to a wider range of customers. ARB says the latest product is the Universal Switch and Air Coupling Bracket. The ARB Universal Switch and Air Coupling Bracket provides a cleaner look while allowing you to easily use your compressor and is priced at $36 (Australian East Coast Metro). It is available now.

For more information, visit www.arb.com.au

PEDDERS GAINS ISO CERTIFICATION

The Australian owned company offers a range of quality brake and suspension products

Pedders Suspension and Brakes says it is very proud to announce that it has recently been awarded ISO9001 Quality Assurance Certification. The Australian family-owned company has been operating since 1950 and boasts a 120 plus franchise and dealer store network which prides itself on offering “No Bull” aftermarket parts and tailored vehicle solutions in Shock Absorbers, Suspension, Brakes, Steering, Wheel Alignment and Towbars. Pedders explains it has been independently assessed and accredited as successfully meeting the requirements of the International Standard for Quality Management Systems – ISO9001. This standard is based on a number of quality management principles including a strong customer focus, driven and focused leadership, a process approach and evidence-based decision making, and striving for continual improvement. “ISO9001 certification provides the framework for Pedders to constantly improve our processes and outcomes for the benefit of our customers,” Pedders Managing Director, Scott Pedder, said. “At Pedders we are constantly looking at ways to improve the quality of our products and services and consistently meet our customers’ expectations. ISO certification recognises this and provides our customers with quality assurance.” The ISO certification process requires an in-depth systematic audit of all the processes and systems within an organisation. It was an intense and challenging process and Scott thanks the team, lead by Chief Product Officer Rob Davis, for undertaking the mammoth task. “Congratulations to all that have been involved here but a very special congratulations and enormous thank you to Rob Davis for driving this project,” Scott said. “This is a landmark day for Pedders and one that will continue to reap rewards for the company, our staff and our customers well into the future.” Pedders says the ISO Certification is a testament to its ongoing pursuit of both quality and innovation. “At Pedders, quality is fundamental to our products, services, and outcomes for our customers. We seek excellence in everything we do,” Scott said. “Likewise, innovation encourages us to strive for continual improvement in the way we do things and pursue new ideas and initiatives to constantly enhance our outcome. “The Pedders Quality Management System certified by ISO 9001 will continue to guide our strategy and operations at every level to continually meet and exceed our customers’ expectations.”

For more information, visit www.pedders.com.au

PEAK LUBRICANTS AND BURSON AUTO PARTS

These two businesses have been succeeding together for more than 25 years

Burson Auto Parts’ lubricant product quality and reliability came to trade customer prominence in mid-1994, when it began an association with fellow Australian lubricant product manufacturer, Peak Lubricants. Peak Lubricants Founder, Ron Shugg, established his Victorian based lubricant company in 1982 after having successfully operated a number of Esso service stations equipped with automotive workshops. The enterprising automotive businessman then expanded his operations to supply lubricants and other automotive products to local workshops and parts stores. It was at this time that Peak Lubricants embarked on a successful lubricant product manufacturing and marketing alliance with the then relatively small and solely Victorian based, Burson Auto Parts business of just 24 stores. “As Burson Auto Parts had developed an extremely loyal trade customer base, they needed their own lubricant products that needed to be high quality and able to stand out on their own against the much bigger and better-known brands,” Ron said. “The very first Burson Oil lubricant products that we manufactured were the Burson Four Litre Super 25w50 blend and the Five Litre Burson Automatic Transmission oil. “From this humble beginning, we have worked together across more than 25 years to ensure that Burson Auto Parts remains highly competitive in Australia’s incredibly diverse vehicle lubricant market with more than 300 SKUs now available in the Burson Oil product range to meet the exacting requirements of Australia’s automotive repairers and service centres.” As a smaller and completely independent operation compared to the major oil companies, Peak Lubricants has also been able to react to market requirements quickly, ensuring the timing and packaging of Burson Oil products always met the requirements of Australia’s automotive repairers. Regular product upgrades to meet and exceed ever changing OEM engine performance and fuel economy specifications have also been an important part of Burson Auto Parts’ lubricant product alliance with Peak Lubricants. Along with lubricant product manufacturing, testing and development, Peak Lubricants supports Burson Auto Parts through detailed product training for store staff provided by a team of nationally located specialists. The company also provides support to Burson Auto Parts stores and their trade customers for any lubricant product based technical questions, handling numerous technical enquiries daily; and also manages Burson Auto Parts’ engine, transmission, and industrial lubricant portfolio. Burson Auto Parts is celebrating its 50th anniversary in 2021. “Our highly successful long-term association with Ron and his team at Peak Lubricants has and continues to be an association of two great Australian companies with shared values in relation to product quality, value for money and customer support,” Burson Trade Executive General Manager, Craig Magill, said. “Over the past quarter century and moreover across the past decade, our companies have grown significantly together, and this loyal relationship continues to bring new developments into the market, such as our new Seven Litre oil packaging along with the new latest specification lubricant products being added to our Burson Oil range.”

For more from Burson Auto Parts, visit www.burson.com.au

CTEK PRO15S: TACKLING BATTERY TROUBLES

No matter how big or small the job

In the modern workshop, it is important to remember that no matter how big or small the job in front of you, it is vital that battery support isn’t forgotten. After all, the battery is the heart of any car, and as part of diagnostic servicing keeping it fully supported is always the best practice solution. With vehicle technology evolving, the battery continues to be put to the test. From keyless entry to the alarm system and even the digital clock, each of these uses the battery to perform. CTEK says it is the leader in battery charging technology and explains it has run extensive tests on vehicle battery usage. When testing an average BMW X5 SUV, for example, CTEK says its research data shows that central locking uses 27.1 Amps (peak), while power windows use 40.38 Amps (peak), the electric parking brake uses 30.6 Amps (peak), and lights use 27.68 Amps (peak). Even having the vehicle door open and the ignition off uses 10.5 Amps, and with the ignition on this goes up to 32.8 Amps. So, no matter how big or small the job, simply charging and conditioning batteries during a service will ensure that customers are protected against flat batteries and other battery related breakdowns. CTEK says it has a fast, safe and effective solution that will enable workshops to charge batteries without removing the battery from the vehicle or interfering with vehicle servicing procedures. It says the CTEK PRO15S is an innovative, versatile and highly efficient battery charger and power supply unit, designed around the needs of the automotive professional. Combining power and advanced technology with safety, portability and flexibility to work with any 12V vehicle battery, including lithium (12V LiFePO4), CTEK says it is the perfect solution to professional battery charging, in the workshop or the showroom. The CTEK PRO15S is available in Australia via Bainbridge and the Ashdown-Ingram network.

For more information, visit www.baintech.com.au or www.ashdown-ingram.com.au

NEW FROM GARRETT

Introducing the 2014+ 2.8L Holden Colorado PowerMax Direct Fit Turbocharger

Garrett explains that PowerMax direct fit performance turbocharger kits are engineered for increased engine performance while maintaining OEM direct fitment. With professional ECU calibration and tuning, the optimised compressor aero will increase flow and outperform the stock turbocharger. Garrett says its PowerMax turbocharger upgrade for the Duramax 2.8L engine platform is engineered to increase engine performance while maintaining OEM installation specifications. This direct drop-in stage one upgrade reportedly provides up to 20 percent more flow than OEM. Garrett explains that this creates a higher manifold air density which results in more power up to 160kW/215 BHP*. Variable turbine geometry is engineered to factory OEM specs and is controlled by the included module. Garrett states that improvements in efficiency and flow can be attributed to the lightweight forged fully machined compressor wheel with advanced aero design. It explains this turbocharger is outline interchangeable with the OE hardware, to ensure a “perfect fit every time.” The maximum allowable turbocharger speed for this PowerMax turbocharger is 213krpm. The use of this product above 213krpm is at the owner’s risk and can result in damage and premature failure. Garrett explains that to protect the turbocharger from overspeed when operating, a speed sensor port is machined into the compressor housing for the fitment of speed sensor part numbers 7813280001 (Street, includes sensor and gauge), and 781328-0002 (Pro, includes speed sensor). It says this will allow the tuner to tune the vehicle correctly for a more robust torque and horsepower settings. Speed sensors kits sold separately. Garrett’s highly engineered portfolio is rooted in more than 60-years of pioneering turbocharging systems. It states its innovations enable its customers to set new benchmarks in vehicle performance while addressing evolving fuel efficiency and exhaust emissions regulations.

For more information, visit www.garrettmmotion.com

*Performance results of this product are highly dependent upon your vehicle’s modifications and tuning/calibration. The target power representedabove has been calculated based strictly on choke flow of the compressor map (total turbo capability), which represents the potential flywheel power.

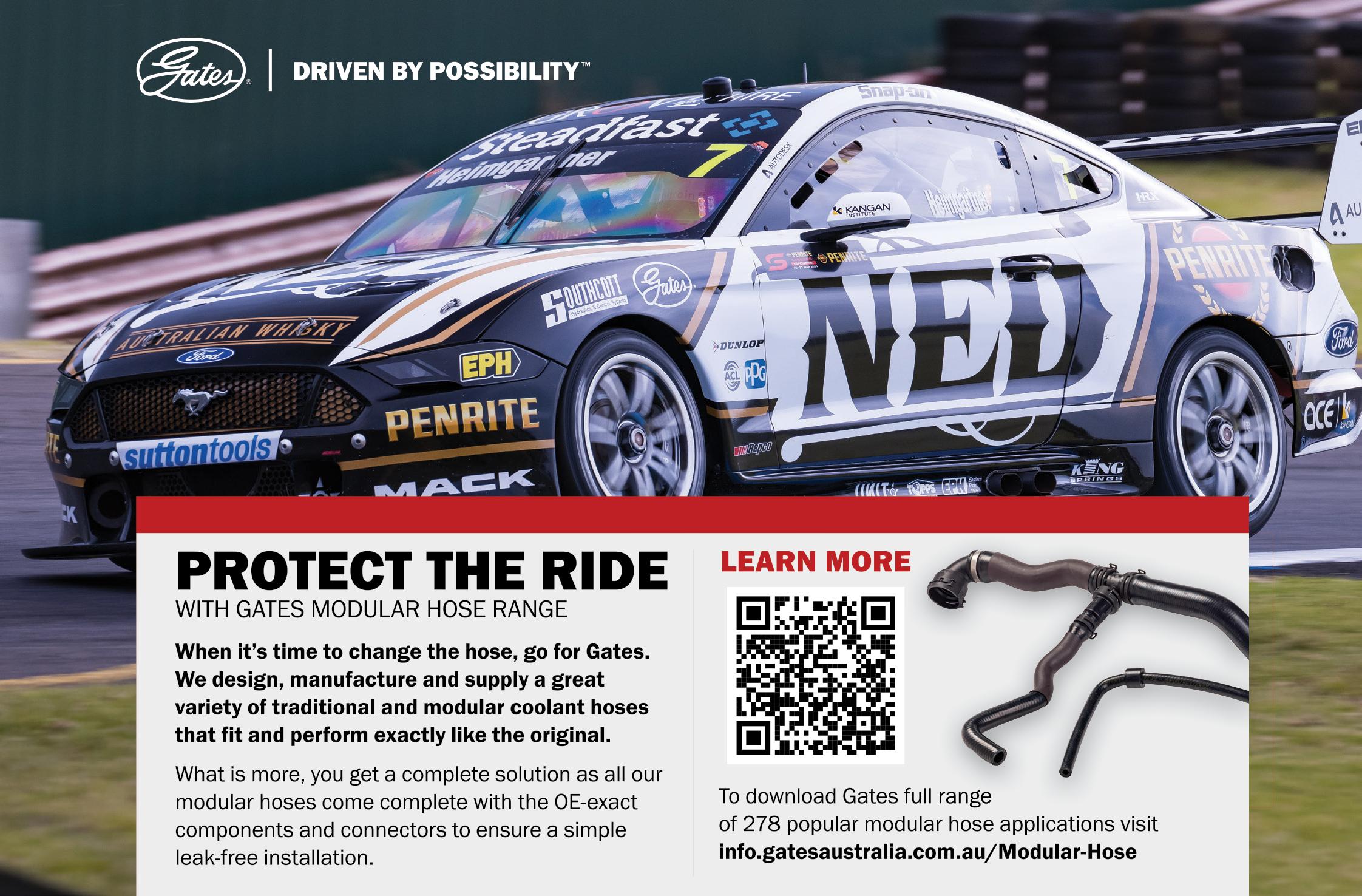

MODULAR COOLANT HOSES

From Gates Australia

Today’s car and trucks are more complicated than ever and continue to evolve. Nonetheless, all types of vehicles have a cooling system and these systems no longer just keep the engine/motors cool; they also cool and warm various components under the hood, as well as other areas of the vehicle. In order to convey coolant to these components, the “radiator hoses,” as they were once called, have become much more complicated and even contain assorted elements built into the hose to perform a wide variety of tasks. These hose assemblies are called “modular” coolant hoses, because they employ a variety of modules in their construction. A modular hose is defined as a coolant hose assembly, with one or more modules (which are built into the hose) and has coolant flowing through the modules(s). These modules can be a branching tee in the hose, quick-connect, valve, drain, air-bleeder or sensors. You will primarily see modular hoses on European vehicles, but the Asian makes are quickly following suit. Why you ask? A modular hose simplifies the plumbing of the vehicle at assembly. One hose assembly will connect to multiple components. These modules within the hoses are critical to the proper operation of the cooling system. For example, some hoses include flow-restrictors within the hose. These restrictors reduce the flow and pressure within the hose to certain components such as the heater core; and are required to maintain core integrity. Last year, Gates says it received a call from a consumer regarding the repeated failure of a heater core in a limousine. It seems the limo had a leaking modular hose and a workshop replaced it with a new, (standard) hose. Soon after, the heater core started leaking. The heater core was replaced, and after just a few months, it started leaking again. Once the consumer finished explaining the situation, they were asked by Gates if the replacement hose included a flow-restrictor; it did not. Without the restrictor, system pressure was simply too high for the core. When replaced with a Gates modular hose, Gates reports that the issue went away. Gates explains that Modular hoses are not a dealer only item, stating that you can find the same Gates aftermarket hose from a distributor/ reseller for significantly less; saving your customer substantially and making it more profitable for you. With 278 part numbers, Gates says it has the largest range in the aftermarket, and with coverage of over 3.3 million vehicles in operation in Australia and New Zealand, it says it has all the popular makes and models covered.

For more information on the Gates modular hose range, go to www.gatesaustralia.com.au/modular-hose

FUCHS CONTINUES TO EVOLVE ITS PORTFOLIO

In an ever-evolving car parc in Australia, sump sizes are changing

With many models now requiring more than 5L to complete a service, FUCHS Lubricants has introduced a number of new pack sizes to a selection of its TITAN vehicle lubricants to suit these needs. Utilising the very best in global lubricant technology, FUCHS says its new FUCHS TITAN 7L and 10L ranges deliver a flexible and reliable solution to the market. The jewel in the crown is the “game-changing” TITAN GT1 FLEX 23 SAE 5W-30. Suitable for a combined range of over three million cars in the Australian and New Zealand car parc, TITAN GT1 FLEX 23 SAE 5W-30 combines both ACEA C2 and C3 into a single product, making it broadly applicable for both diesel and petrol vehicles, including a wide range from Toyota and Holden. It also boasts a comprehensive list of OEM approvals from world class car manufacturers including Mercedes Benz and BMW. Building on this flexibility, the FUCHS TITAN range also includes the impressive TITAN GT1 FLEX 34 SAE 5W-30. Servicing vehicles requiring either ACEA C3 and/or C4, FUCHS says TITAN GT1 FLEX 34 SAE 5W-30 is the perfect solution for workshops that specialise in servicing vehicles from a number of Asian and European manufacturers including Nissan, Infiniti and Renault. With a local history spanning over 100 years, FUCHS says it is proud to be a part of, and support, the Australian vehicle aftermarket industry. Committed to is value proposition of ‘Australian Made with German Technology that pays back’, FUCHS says it has invested in two local world class plants and laboratories and is the only lubricants manufacturer to produce lubricants, coolants, greases, and additives locally.

For more information, contact 1800 1800 13 or visit www.fuchs.com.au

The TITAN range now includes the following new pack sizes: TITAN GT1 FLEX 23 SAE 5W-30 – 7L 3 10L 3 Broad application for diesel (with DPF) and petrol engines across many manufacturers TITAN GT1 FLEX 34 SAE 5W-30 – 7L 3 Designed particularly for Nissan / Renault engines with exhaust after treatment TITAN GT1 PRO C-3 SAE 5W-30 – 7L 3 10L 3 Designed particularly for VW / Audi engines including petrol and diesel TITAN GT1 SAE 5W-40 – 7L 3 Suitable for GM/Holden diesel vehicles requiring a SAE 5W-40 specification oil TITAN SuperSyn D1 SAE 5W-30 – 7L 3 Designed to provide broad dexos 1 approval for all GM petrol vehicles TITAN SuperSyn F Eco-DT SAE 5W-30 – 7L 3 10L 3 An essential engine oil for use in Ford DuraTorq-Diesel engines TITAN SuperSyn F Eco-B SAE 5W-20 – 7L 3 Extreme fuel-economy engine oil especially developed for Ford Ecoboost engines TITAN SuperSyn F Eco-FE SAE 0W-30 – 10L 3 Especially developed for modern Ford diesel engines TITAN SuperSyn Longlife SAE 5W-40 – 7L 3 10L 3 A high performance product for use in a broad spectrum of European vehicles

PROTEX ULTRA 4WD

Brakes built for anything

Protex says its Ultra 4WD range offers the ultimate in braking versatility as an upgraded braking solution for those drivers that want to be equipped for any situation. Designed to withstand the toughest driving conditions, Protex Ultra 4WD is made for enhanced durability with a raft of features, including: • Anti-Corrosion Protection: Ultracoat Z360 is

Protex’s exclusive anti-corrosion coating for faster fitting and longer life. • Eco-Friendly: Protex says it is committed to minimising environmental impact, from the production methods deployed through to the materials it uses. • High Carbon Rotors: six directional slots and unique pillar design for optimised heat dissipation. • Ceramic friction formulation on the pads: delivering ultra-quiet, stable stopping power.

Putting the spotlight on its Ultra 4WD range, Protex has recently launched a new advertising campaign, “Built for Anything.” The campaign showcases the versatility of the Ultra 4WD brake range and will be featured across radio and digital channels nationally. Protex says: “when considering their options to upgrade their brakes, consumers should go with the solution that is built for anything, Protex Ultra 4WD.” As it states in their latest campaign, it says, “whether you’re driving down the road, towing a heavy load, or exploring off-road in the outback remote, Protex 4WD are the brakes built for anything.”

For more information, visit www.protexparts.com.au/ promotions

THE NEXT GENERATION OF ENGINE OILS

The most advanced engine oils on the market are now derived from natural gas, says Shell

Shell explains that these oils offer high performance with virtually none of the impurities found in crude oil, making them perfect for those competing at the highest level in motorsport and the everyday driver. One of the most recent innovations in motor oil comes in the form of synthetic motor oil made from natural gas. These oils are made with PurePlus technology and the Pearl gas-to-liquid (GTL) plant in Qatar is the world’s second largest source of them. Shell explains that the Pearl GTL plant is a partnership between Shell and Qatar Petroleum where they have dedicated a substantial amount of time to perfecting the GTL process. This breakthrough process converts natural gas into a crystal-clear base oil with virtually none of the impurities found in crude oil. Shell explains that base oils made from crude oil have performance limitations; they contain impurities and weaker molecular bonds that can limit performance. Shell says that its Shell Helix Ultra product, for example, is a GTL engine oil that uses ‘PurePlus Technology’, which when compared to traditional group II and group III base oils, provides enhanced viscosity, friction reduction and longlasting engine performance. Shell has long used the motorsport arena as a test bed for its engine oils. The company’s rich history in this space started with Ferrari in 1929 and has since spanned a wide variety of global competition; from F1, to MotoGP, the World Rally Championship, Supercars and Formula E. Collaboration between scientists and motorsport engineers in the competitive environments of motor racing are the perfect recipe for producing revolutionary engine, transmission, and gear oils. The learnings can then be taken from the track and applied to the development of motor oils for the everyday motorist. For instance, a Formula One power unit can exceed temperatures of 1000oC and demands on the engine are huge. The race lubricant used by Scuderia Ferrari is vital to the cleaning, protecting, lubricating, and cooling of the engine, while delivering improved performance and efficiency. The role of the engine oil developed specifically for Scuderia Ferrari is therefore identical to the role of lubricants in any car on the road, says Shell. Shell says that engine oils made with PurePlus technology have stronger molecular bonds1 when compared to base oils derived from crude oil, which makes them more resistant to extreme temperatures in the engine. The technology also reportedly offers superior cleansing and protection for today’s engines – protection that exceeds industry standards, keeping critical engine components cleaner. It is not just the testimony of Scuderia Ferrari that supports the case for this technology, says Shell, with Hyundai Motorsport also leveraging the technology to support it in the World Rally Championship (WRC). WRC offers a unique challenge for these oils with competition events taking place in an array of conditions; from snow and ice, to gravel and asphalt with temperatures ranging from -30°C to +40°C. These different environments mean that the car and engine reliability are put to the test and safeguarding against power loss is magnified. Oils made from natural gas also have qualities that help the everyday motorist as their lower viscosity at cold temperatures supports quicker engine warm up from cold starts. Shell says that with the long-lasting performance of your engine that comes with an oil like Shell Helix Ultra, your car will run and feel like new every time you use it. Shell Helix Ultra can be used for gasoline, diesel, and gas engines, and it is also suitable for biodiesel and gasoline/ethanol fueled cars. Further to the above, Shell Helix Ultra is now carbon neutral2 across Europe, Asia-Pacific, and the Middle East. Shell says this provides mechanics and consumers with a more sustainable choice of motor oil without compromising the high performance and engine protection that has made Shell Helix Ultra renowned around the world. Shell says it has been advocating for and developing PurePlus technology for some time now, not just because of its applications at the top end of motorsport, but because it is made available to motorists around the world to ensure they can reap the rewards of improved reliability and engine performance.

For more information, visit www.shell.com.au/helix

1 Based on paraffinic hydrocarbon content and significantly higher level of iso-paraffins compared to typical Group II and III base oils. 2 The CO2e lifecycle emissions of this product have been offset with verified Nature-Based Carbon Credits. CO2e (CO2 equivalent) refers to CO2, CH4, N2O.

COOLDRIVE GROWS BRAKING PORTFOLIO

Textar Commercial Brakes has joined the CoolDrive Auto Parts range

CoolDrive Auto Parts has moved into the Commercial Braking arena with the addition of the Textar brake technology range. CoolDrive Auto Parts says Textar has been a worldwide leader in vehicle brake friction supplies for over 100 years, with over 70 percent of all commercial vehicles in Europe coming equipped with Textar brake lining as standard. The brand is said to be a leading supplier to both the OE sector and the replacement aftermarket for commercial applications, with the company manufacturing a total of 1.2 million friction products a day. The Textar range available via CoolDrive features more than 135 different brake pad lines, more than 430 brake linings, and over 100 different brake disc types. Textar’s commercial vehicle range covers popular applications for truck manufacturers such as Iveco, MAN, Mercedes-Benz, Volvo, DAF, Renault, Scania and more, as well as components compatible with leading axle and system suppliers such as Meritor, Rockwell, BPW and Knorr-Bremse. Textar’s latest disc brake pads are said to combine safety and sustainability, featuring an ultrastrong construction combined in a lightweight design, contributing to lower fuel consumption and subsequently fewer emissions. This lightweight design philosophy sees pads produced geometrically identical as standard units, ensuring ease of direct replacement. Environmental consideration is also front of mind for the manufacturing processes, which sees 8,000 tonnes of abrasion material by-products recycled annually. Textar’s development timeline for a new friction product can take up to three years, including up to 300,000km of on-road testing, 2,000 hours of dynamometer testing, computerised simulations of braking performance and wear patterns, rigorous homologation testing in reallife conditions, as well as extensive NVH (Noise, Vibration, Harshness) and comfort engineering. This development and testing program yields 11 terabytes of data for the company each year. Multiple techniques are utilised to bond the friction material to the backing plate, including steel or cast plates with brass pins, cast plates with cast-on pins, steel plates with weld mesh, or lightweight plates with pins, with the different processes ensuring the permanent securing of the friction material, even under the most extreme thermal loads. When it comes to the friction material itself, Textar has developed 334 different formulations, created from 43 raw materials, for a “massive” array of applications. Outside of the commercial vehicle market, CoolDrive Auto Parts says the brand is at the forefront of new technologies, with the development of cutting edge products for electric and hybrid vehicles.

For more information, visit www.ishop.cooldrive.com.au or contact your local CoolDrive Auto Parts store.

BILSTEIN B6

Bilstein says its B6 is the ideal shock absorber for caravanning

Camping holidays are more popular than ever before, with Bilstein stating that this is shown by the increased figures for caravan registration. The target group of buyers is usually very concerned about safety and are willing to invest in useful extras. However, Bilstein says many of them do not have the subject of shock absorbers in mind. As such, it says workshops would be well advised to actively inform their customers about sensible solutions in this area, such as the Bilstein B6. With this registration-free gas pressure shock absorber, the suspension manufacturer says it offers a technically convincing solution that provides a significant increase in damping force in everyday use compared to the standard part. For customers and their families, Bilstein says this means a significant increase in driving safety and comfort and by providing advice in this regard, workshops can increase customer satisfaction and generate new sales at the same time. “Due to the high drawbar loads, tractive forces and leverage forces that occur on the trailer coupling, the standard shock absorbers are quickly at their limit in dangerous situations, as they have not been optimised for this load,” Head of Bilstein Academy, Rainer Popiol, said. “In most cases, the damping force is simply no longer sufficient to ensure safe, comfortable and agile driving behaviour.” Bilstein says workshops that sell trailer hitches or find them on customer vehicles should therefore also offer the Bilstein B6. It says that even if the practical hitch has already been fitted at the factory, the standard suspension does not necessarily offer enough reserves. Here, too, Bilstein says the Bilstein B6 brings about a significant improvement in almost 100 percent of cases. “If a shock absorber replacement is due (soon) anyway, there are hardly any additional costs for the customer – not even for installation. Installation always follows the motto ‘plug and play,’ keeping the costs low,” Rainer said. “The B6 performance shock absorbers in standard length also pay off when towing other trailers or in combination with bicycle racks or heavy roof loads that shift the vehicle’s centre of gravity upwards. “This can cause the car to sway dangerously or react far too sluggishly, especially when swerving quickly or negotiating bends. “The Bilstein B6 puts a stop to these and similar problems right from the start. This means that drivers are protected from unpleasant surprises even with caravans and reach their destination safely.”

For more information, visit www.bilstein.com

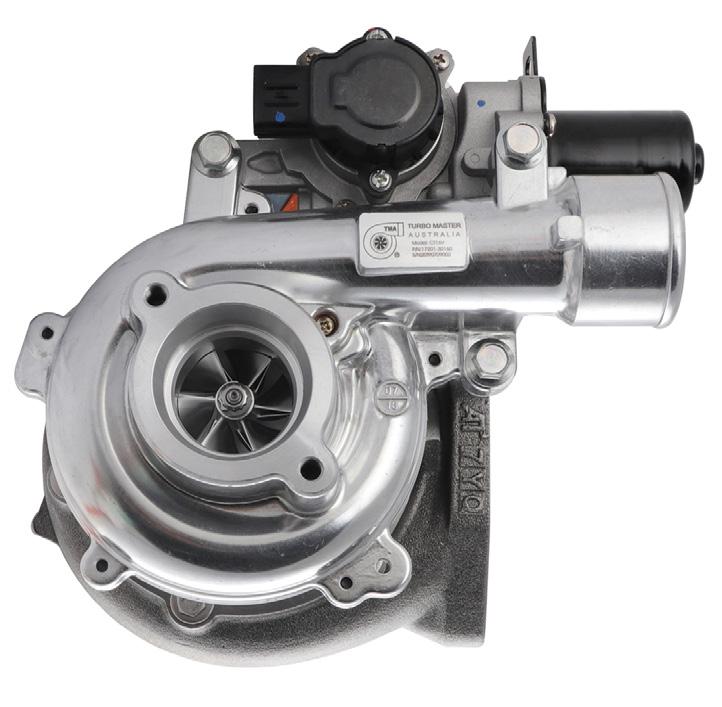

TURBO MASTER AUSTRALIA COMES TO COOLDRIVE

CoolDrive Auto Parts has boosted its offering by introducing Turbo Master Australia’s (TMA) range of turbochargers to its already extensive range of aftermarket replacement parts. With over 25 years of experience in the industry, the Australian owned and operated TMA Turbochargers are available for passenger vehicles, 4WDs, trucks and machinery, with CoolDrive initially stocking around 20 common application part numbers, which will continue to grow in time. CoolDrive says the TMA range offers a premium quality direct replacement option at a fraction of the replacement cost of an original unit. Via extensive in-house and field vehicle testing, CoolDrive says performance and durability levels have been certified to meet or exceed genuine OEM specifications. Significantly, almost all TMA turbochargers are upgraded to include a billet compressor wheel, ensuring improved performance and reliability over traditionally produced internal components, says CoolDrive. CoolDrive explains that TMA turbochargers are manufactured with only high quality, new components. Further, it says they are professionally constructed, balanced and flow checked via the latest precision testing equipment, to ensure perfect operation straight from the box. Depending on the application, wastegates and/or electronic control actuators are included, along with all gaskets, as per the original item. All TMA turbochargers come complete with a 12month, 20,000km Australia-wide warranty.

For more information, visit www.ishop.cooldrive.com.au

SHINING THE WAY

Lightforce has launched its new HTX2 driving lights

High quality aftermarket driving lights are essential to safely explore Australia off-road and to travel our long and winding roads. The team at Lightforce says it is committed to developing and manufacturing the world’s best driving light right here in Australia. Its evolved hybrid driving light, the HTX2, is said to bring a new meaning to the term, high performance. Lightforce says the unique combination of a powerful, long-distance HID and the equivalent of a 20-inch LED lightbar in one unit provides unparalleled power and light spread, and states “it’s two driving lights in one.”

New and improved design

Lightforce’s engineers, designers, product evaluators and quality assurance professionals have reportedly made dozens of enhancements to the DNA of its original HTX to enhance its famous hybrid driving lights in almost every way. Lightforce says that as a result, they are now more rugged and reliable than ever, giving you control on and off the road. Thanks to a new one-piece aluminium housing, Lightforce explains that HTX2 is fully sealed and is not just dustproof and ‘water resistant,’ but fully waterproof up to depths of one metre. With full IP68 and IP69K certification, HTX2 has been tested over 110,000 hours against dust, temperature, and water. Lightforce says it has also dramatically improved its hybrid driving light’s efficiency and reduced its power draw; stating that HTX2’s energy-saving HID bulb, advanced heatsink and domeless LEDs mean superior thermal capacity and management.

Ready for high performance

Weighing in at only 2.3 kg, Lightforce says HTX2 packs a lot into a featherweight package. It says its slimmer profile is easier to mount in small spaces and less likely to interfere with crash avoidance systems. It is also said to be simple to install and you can fully secure HTX2 with a nyloc nut and bolt to most bullbars. Both the HID and LEDs on HTX2 are calibrated for neutral white 5,000K colour temperature and a colour rendering index of 70 for maximum clarity. The Lightforce team say that its focus is on producing driving lights that reduce glare and allow you to better distinguish different objects ahead – with less eye fatigue and strain. Lightforce has also made HTX2 compatible with more accessories, including its modular filter system and using a spot or combo filter, you can change the light pattern to suit your environment.

For more information, visit www.lightforce.com.au

KONI SUSPENSION PRODUCTS

Distributed in Australia by Toperformance

Koni products are not only found in many segments of the automotive industry – from cars to 4WDs, racing, truck and bus – but also in other industries such as rail, military and even construction. Koni says these diverse applications have given it the knowledge and experience to create some of the most durable and long-lasting dampers ever produced. Of these dampers, it says the Koni 90 series is a standout. The 90 series is listed in the Koni 4WD range as the ‘Raid’ and Koni says it has become the “go to” damper for the serious off-roader. A 2.5 mm thick, 70mm diameter twin tube body with a large 42mm piston and high oil capacity ensures that not only the piston cylinder is protected from damage, but the damper also dissipates heat effectively. Coupled with Koni’s unique valving design, Koni says the Raid offers the best possible ride, no matter the conditions. It explains that having been developed through years of off-road testing in the Australian outback and the deserts of Africa, the Koni 90 series Raid “offers fastidious drivers ‘no compromise’ peace of mind.” The 90 series is also a standout for heavy vehicles, with Koni stating that in the transport industry, 90 series dampers on trucks have seen service intervals over 1,000,000 kilometres. Many Koni dampers have an adjustable rebound feature and replacement rubbers are available, further increasing the longevity of the damper. When considering the costs of downtime and replacement, Koni says the 90 series damper really is the best value per kilometre damper and states that transport industry leaders such as Kenworth, Meritor, Krueger, Dana and Hendrickson choose Koni as original equipment. For those driving a classic, Koni also has a great range of dampers. For classic vehicles, Koni says it selects the most appropriate damper technology and develops every shock absorber specifically for each application to bring out the best possible ride and handling. Koni ‘Reds’ (the off-car adjustable Special/ Classic) and ‘Yellows’ (the externally adjustable Sport) reportedly continue to be the industry standard for older performance cars. In many cases, Koni says it can offer both Special (Classic) and Sport options for early Holdens and Fords as well as Valiants and many overseas models. Toperformance Products is the Australian distributor for Koni Suspension products.

For more information, visit www.toperformance.com.au

MANN-FILTER FRECIOUSPLUS

For greater health and traffic safety

After the warm season with its high pollen levels, now is the time to change the cabin air filter. However, this is something car drivers often overlook when preparing their vehicle for the cold season. “Replacing the cabin air filter for the cold season is very important, because it filters harmful particles and viruses from the outside air taken into the vehicle,” MANN-FILTER Cabin Air Filter Product Manager, Jens Weine, said. “Particularly in fall and winter the cabin air filter needs to deliver peak performance for a clear view and good air quality in the vehicle. “After all, hundreds of thousands of litres of air per hour flow into the vehicle cabin through the filter, air conditioning system or heating system and fan. “As well as switching over tyres and buying antifreeze, drivers should also make sure to change the cabin air filter.” The current situation with COVID-19 and the fact that airborne transmission is one of the main ways the coronavirus spreads once more highlight the importance of clean ambient air.

MANN-FILTER FreciousPlus

MANN-FILTER says its FreciousPlus cabin air filter improves air quality thanks to its different layers. In addition to coarse particles like dust and tyre dust, it also filters viruses and deleterious particulate matter. MANN-FILTER says it virtually completely adsorbs unpleasant odors and harmful gases like nitrogen oxide and ozone from the airflow. It also states an innovative biofunctional special coating has both an anti-allergen and antimicrobial effect and verifiably reduces the growth of microorganisms like mould or bacteria on the filter. MANN-FILTER explains it supplies the FreciousPlus in customary OEM quality and for many vehicles, the filter upgrade is an easy one. When changing the filter, the mechanic inserts the FreciousPlus instead of the old cabin air filter, with no additional effort required. Like wearing a face covering, a cabin air filter does not count as “personal protective equipment.” It provides cleaner air in the vehicle cabin and thus should be regarded as an additional protective measure. To operate at full efficiency, a cabin air filter should be changed in accordance with the service schedule.

For more information, visit www.frecious-plus.com

HOW TO AVOID CLUTCH INSTALLATION ISSUES

Exedy experts explain how to avoid the ‘top three’ problems encountered with clutch installations

The most important part of any clutch system repair begins with the initial diagnosis. The primary cause of complaint must be identified correctly, along with any secondary or related concerns, before replacing or repairing any components. For example, a clutch might be slipping because it is old and excessively worn, but this phenomenon may also occur for many other reasons (such as grease or oil contamination, release mechanism problems, driver error/abuse, or an incorrect flywheel profile). If the initial diagnosis is not correct, then, despite repair work having been carried out, the vehicle will still be in a state of disrepair. The inevitable consequence of which is usually the premature failure of the replacement clutch. Exedy Australia says it always recommends following vehicle manufacturers’ individual clutch installation instructions, unless the kit selected requires a different procedure, in which case any special instructions required will be provided within the kit. As with most things in life, prevention is better than cure, so Exedy Australia explains below the top three installation errors it encounters, along with what it says are sure-fire ways to avoid them.

Incorrect or excess grease applied during installation

This is a very easy mistake to make, which can result in contamination of the friction surfaces, leading to the clutch slipping and/or juddering. You should apply a small amount of suitable high melting point grease to the input shaft, the splined hub, the fork (where it contacts with the release bearing) and the fork pivot surface. Slide the friction disc onto the input shaft then wipe off any excess grease before completing installation. Exedy Australia explains that it includes a tube of high melting point grease with every clutch kit purchased.

Misalignment of the engine and transmission

This can occur for various reasons, including hanging the gearbox during installation; forcing the gearbox input shaft during installation; a worn or missing pilot bush (spigot bearing); warping of an alloy gearbox bellhousing; damaged or missing gearbox dowel pins; interference between the gearbox and engine mating surfaces caused by dirt or grease accumulation, metal filings, or even by trapped wiring. To avoid this, it is important to degrease and inspect the gearbox bellhousing thoroughly, ensure a transmission jack is used correctly, and use the appropriate clutch alignment tool during installation.

Release bearing installation and release mechanism faults

Thoroughly inspect the gearbox bearing guide tube, the fork or lever and the cable or hydraulics system for any wear or visible faults. Always follow vehicle manufacturers’ recommendations when adjusting or replacing the bearing, the cable or any hydraulics components. Check for any clutch travel adjustment required upon clutch replacement. Exedy Australia says if you should encounter any problems or are unsure about any of the above, you should seek advice before proceeding further. It states that most vehicle manufacturers will have a technical hotline you can contact for help, or you can contact your local Exedy office for assistance.

For more information, visit www.exedy.com.au

ADRAD’S PRODUCT RANGE EXPANDS

Gas Struts have been added to the Adrad portfolio

The Adrad name has been associated with quality radiators for more than 35 years, and the company has thousands of radiator products available. So, it might be a surprise to learn that the majority of part numbers in Adrad’s range aren’t radiators at all. Adrad’s parts range has grown to include: • Intercoolers; • Air conditioning; • Oil coolers; • EGR coolers; • Belts; • Sensors and switches; • Filters; • Ignition; • Wipers; • Thermostats and housings; • Hoses and clamps; and • Tools and workshop consumables. Now another new product category has just joined the collection: gas struts. At launch, the initial range of Adrad gas struts covers more than 1,400 vehicle applications and includes bonnet, hatch, and tonneau fitments for popular vehicles. Adrad says these quality struts are built to meet or exceed OE specifications and feature Teflon seals for smooth operation and long service life. “Twice as good and half the price” might sound like a bold promise, but that’s how Adrad has described its gas strut range. Packed in matched pairs (left and right), Adrad says its gas struts are anticipated to sell for around the same price you would expect to pay for a single strut elsewhere. Adrad says it is so confident that these parts will deliver on performance and reliability, that it is backing them with a two-year, nationwide warranty. Trade account customers shopping online at Natrad Trade Online can quickly find the correct parts for a particular vehicle via the handy “REGO search” function that identifies appropriate parts based on the number plate entered. Adrad gas struts are available across Australia.

For details of your nearest stockist, please contact Adrad on 1800 882 043 or enquire at customerservice@adrad.com.au

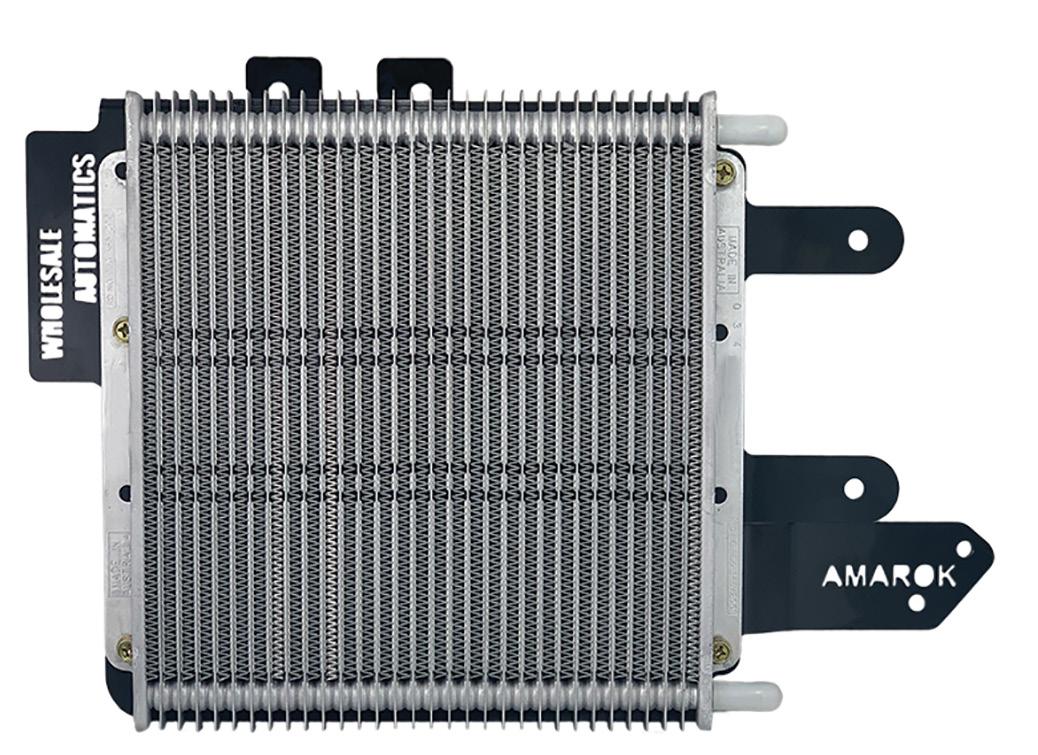

AUSTRALIAN BUILT TRANSMISSION COOLERS

Designed for Australian conditions

Wholesale Automatic Transmissions says it specialises in manufacturing a large range of auxiliary automatic transmission cooler kits, in particular for ‘tradie ute’ and 4X4 style vehicles. It says very few vehicle manufacturers can ever get it exactly right when designing their transmission cooling systems. Wholesale Automatic Transmissions says this is because manufacturers concentrate on building a vehicle for the widest possible worldwide market. However, here in Australia we have vast distances, extreme climates and a need to upgrade the vehicles for both towing and heading off-road. If you are thinking about cooler upgrades, Wholesale Automatic Transmissions asks you to consider these points: • The number one killer of automatic transmissions is heat. Using a proper transmission oil cooler increases the life and performance of your transmission and protects the longevity of your transmission oil. • Many vehicles do not come with an adequate cooling system, especially if you are planning on any engine upgrades, towing or venturing offroad. Wholesale Automatic Transmissions says its coolers are a premium Australian made product that will improve the transmission cooling significantly, with years of experience and research going into the design of its range of coolers. A wide range of coolers are available, and each is built for a specific vehicle, including the Ford Ranger/Everest, BT50, Colorado/Colorado-7/ Trailblazer, D-Max/MU-X, Triton, Hilux/Fortuner, 200 Series, FJ Cruiser, Prado, Nissan Y62, Amarok and the current model D-Max/BT50. Wholesale Automatic Transmissions says it uses a proven heavy duty one-piece mounting system that is both zinc plated and Mannex coated for maximum corrosion resistance. It cautions you against being “caught out with flimsy mounting brackets, stainless steel, or even worse, multi-piece brackets,” stating, “we cannot emphasise enough the importance of using a one-piece mount, especially on corrugated roads, where the mount must absorb all the vibrations and shock.” Wholesale Automatic Transmission says it stands behind every product it sells with “excellent technical support” and explains that each kit comes with full colour step-by-step DIY installation instructions which include every nut, bolt, hose, clamp and so on that you need to fit the cooler.

For more information, call 03 9762 8004 or visit www.automatictransmission.com.au

Trade and dealer enquiries are welcome.

PRODUCT RECALL

Trojan Australia Electric Park Leg Part #307007

Trojan Australia has issued a Product Safety recall for the return of an Electric Park Leg which contains low levels of asbestos in an internal gasket. The Electric Park Leg is used to support heavy duty trailers in a limited number of specialised applications such as fifth-wheel recreational vehicles, large horse floats with accommodation and similar low-volume situations. A gasket located underneath the electrical motor housing, inside the unit, has been found to contain low levels of asbestos. The gasket is only exposed if the unit is dismantled. The risk of any fibres being distributed is considered to be extremely low. As part of the recall process Trojan has attempted to contact all known purchasers of the product directly and is now releasing information on a broader basis to help ensure anyone who could not be contacted directly is aware of the issue.

Australian and New Zealand purchasers of these units who have not been contacted by Trojan are asked to contact Trojan Technical Services Manager, Darren Malone, on +61 3 9701 9541.

NARVA DEBUTS MK2 DRIVING LIGHTS

The new lights are a ‘brighter and bolder’ evolution of its Ultima LED driving lights

Narva gave visitors to the recent Brisbane 4x4 Show an early look at its highly anticipated and soon to be released Ultima LED MK2 driving lights. On the cusp of an official release, Narva had its new driving lights installed on multiple vehicles around the show and featured them as the centrepiece of its terrain-themed exhibit at the show. Narva says the new lights are a ‘brighter and bolder’ evolution of its popular 180mm and 215mm Ultima LED driving lights, hence the MK2 name. Both sizes of MK2 reportedly offer a substantial 30 percent increase in light output over and above the class-leading performance of current Ultima 180 and 215 lights, as well as a 20 percent longer light beam, making them a worthy upgrade for owners of the first-generation lights and “a must” for new owners. An improved colour rendering index and 5,700K colour temperature has also resulted in less glare for a clearer view of the road. “One of the things people love about Ultima 180 and 215 lamps is their bold, premium look and the personalisation they can have with the choice of bezel finish and coloured trims to suit their vehicle, whether truck or 4WD,” Narva Marketing Manager, Jake Smith, said. “The Ultima MK2 takes this concept further with a new ‘Black Edition’, which includes three bold new colour trims – Hyper Green, Electric Blue and Slate Grey (fitted) – as well as unique darktinted ‘stealth’ light covers. “The ‘Black Edition’ is also available in a twin light kit which includes Narva’s premium heavyduty ‘Plug and Play’ wiring harness, specially designed to handle the performance of Ultima LED MK2 lights.” Although Narva had participated in virtual/ online trade shows throughout 2020 under the nationwide COVID restrictions, Brisbane’s 4x4 Show marked its return to physical events following the easing of restrictions. “The response and enthusiasm from visitors has been fantastic to see and I think everyone has really missed coming out to these shows and seeing the latest gear up close,” Jake said. “The timing of the Brisbane 4x4 Show fitted in well with the launch of our new Ultima MK2 lights, so we were really keen to see what the crowds thought of them and so far it’s been overwhelmingly positive.” Narva’s new Ultima LED MK2 driving lights will soon be available in-store for purchase from leading automotive, transport and 4WD outlets.

For more information, visit www.narva.com.au