43 minute read

Garage Equipment - The latest in tools and equipment for your workshop

GIULIANO S835 WHEEL BALANCER

From Interequip

Interequip says the Giuliano S835 Wheel Balancer has Italian quality but has not compromised on price. It has been designed at the Giuliano Italian headquarters and produced by Giuliano’s own factory, located in China. Interequip says the Giuliano S835 Wheel Balancer comes from a very long and distinguished line of wheel balancers designed in Italy. It explains the S835 is the end result of continuous improvement and fine tuning, stating that “when you get good at something, you stick to it.”

“The S835 is a great example,” Interequip Sales Director, Alex Visser, said. “It features all of the things that a high-volume tyre store or dealership needs, but its price isn’t burdened with sales features and hyped-up addons which most operators just won’t use. “It is however, a very sturdy and accurate wheel balancer made for all day, everyday use. “One of its greatest benefits is ease of use and the minimal training required.”

Key features:

• 19” TFT LCD Monitor • Automatic start and stop • Automatic measuring of wheel diameter and distance • Line laser indicator to point to where the alloy stick on weight needs to be positioned • Automatic wheel width measurement by

SONAR • LED light in working area

For more information, contact Interequip on 18000 EQUIP (1800 037 847) or visit www.interequip.com.au

OzSwiss European Tools is proud to present to the market the new Hazet 3/4” Drive Impact Gun. It says this new gun offers maximum efficiency due to its ground-breaking ‘Hazet Twin-Turbo Technology’ with an extremely high torque of up to 4100 Nm loosening torque and 2170 Nm tightening torque despite its compact design (subject to adequate air supply, value based on M32 screw size). OzSwiss European Tools say it is a ‘must have’ for any workshop, stating that its other key features include: • innovative eight slat air motor with 25 percent higher impact performance; • long service life and high efficiency for work on trucks and heavy vehicles; • up to 2 x faster work compared to standard 3/4” drive wrenches; • exhaust air is guided downwards through the handle; • reduced vibrations (10.69 m/s²); • extra short design, only 184 mm (without anvil); • two stage forward, single stage reverse;

NEW HAZET 3/4” DRIVE IMPACT GUN

With “massive” 4100 Nm undoing torque

• rotation speed 5200 rpm; • 4.5 kg weight; • air requirement 147.2 l/min (2.5 l/sec) – important to achieve best performance; • sound power level 99.5 db(A) Lp A (at working pressure); • supplied with practical handle to attach to front of wrench. The new Hazet impact gun is available from OzSwiss European Tools, the exclusive Hazet importers, as well as authorised resellers across Australia.

For more information, visit www.europeantools.com.au or contact 02 9807 9322 or info@europeantools.com.au

ALEMLUBE AUTOMOTIVE 3D WHEEL ALIGNER

Delivering “European design, without the price tag”

Alemlube has introduced to the market its new Alemlube Automotive 3D Wheel Aligner, an advanced wheel aligner which utilises “leading European hardware and software technology.”

The perfect balance

Alemlube says this aligner offers “the perfect balance of convenience while being easy to use and featuring quality guided procedures suitable for any technician, to guarantee performance and efficiency.” The monitor has simple, intuitive graphics with rapid selection keys and icons and quick, precise measurements with value adjustments in real time. The Alemlube Automotive 3D wheel aligner is supplied complete with cabinet, computer with Windows 10 operating system, 27” TFT monitor, colour printer, USB keyboard, mouse, wi-fi pen drive, four four-point clamps 12”-24” with universal grips and targets and camera support with manual control. Also included are two mechanical turntables, brake pedal lock, steering lock, wheel alignment inbuilt software and database for popular vehicles. Alemlube Automotive says it is renowned for its top aftersales service. It states that as a family company, it has built a reputation for excellence in distribution, sales, and the total support of all automotive workshop servicing products. Alemlube says a very distinct and unique advantage of purchasing wheel servicing equipment from Alemlube is the country wide installation, service and support network coupled to real industry experienced people. The Alemlube team says it delivers “unequalled product service and certainly offers an industry leading approach to product knowledge, advice and after sales support.” Alemube has offices throughout Australia.

For more information, visit www.alemlube.com.au

BIG IMPACT. SMALL SIZE

Milwaukee’s M18 Fuel 1/2” Compact and Mid-Torque Impact Wrenches pack a big punch in a small package

Milwaukee Tool says it continues to transform cordless expectations with your new go-to impact wrench solutions for accessing tight spaces. The M18 Fuel 1/2” Compact and Mid-Torque Impact Wrenches are engineered to give you next-level versatility and performance to tackle the most challenging mechanical work, whether it’s small engine or heavy vehicle maintenance. Measuring at only 124.5mm in length and delivering up to 339Nm of nut-busting torque, Milwaukee Tool says the next generation of Milwaukee M18 Fuel Compact Impact Wrenches deliver the performance needed in tight applications where larger impact wrenches cannot fit. “We’ve been able to remove 30mm of length in our third generation of M18 Fuel Compact Impact Wrenches, all while increasing power,” Milwaukee Tool Australia and New Zealand Product Manager, Michael Di Iorio, said. “Users now have more access in tighter spaces, and they don’t have to spend time dismantling surrounding components to get to fasteners.” Packing up to 881Nm of nut-busting torque while weighing in at only 1.58kg, Milwaukee Tool says the Milwaukee M18 Fuel Mid-Torque Impact Wrenches offer the best power-to-weight ratio in their class for the most access in tight spaces and fast bolt removal. While up to 0.12kg lighter than the previous generation of Milwaukee mid-torque impact wrenches, M18 Fuel Mid-Torque Impact Wrenches reportedly generate the torque and speed needed to perform many of the same tasks, such as removing large bolts or lug nuts. “What’s going to surprise most users’ when using M18 Fuel Mid-Torque Impact Wrenches is their ability to tackle more than 90 percent of the work they do each day,” Michael said. “These mid-torque wrenches will be our users go-to solution. They’ll only reach for their high torque impacts when absolutely necessary.” True to all M18 Fuel solutions, the new M18 Fuel Compact and Mid-Torque Impact Wrenches combine three exclusive innovations. Milwaukee Tool explains that the PowerState Brushless Motor delivers the power to remove stubborn fasteners, while RedLink Plus Intelligence ensures maximum performance and protects the tool against overloads, overheating, and overdischarge; while the M18 RedLithium-Ion battery pack ensures these tools provide more work per charge and more work over the life of the pack. The M18 Fuel 1/2” Compact and Mid-Torque Impact Wrenches are part of the growing range of Milwaukee impact wrenches that further Milwaukee Tools’ commitment to a cordless, hose-free future, with powerful alternatives to pneumatic tools.

For more information or to book a visit with the Milwaukee Tool Job Site Solutions team, visit www.milwaukeetool.com.au

FIVE NUMBERS TO CHECK BEFORE YOU BUY A HOIST

Genesis Equipment says it is important that you check these vital figures before making a purchasing decision

When it comes to picking the right equipment for your workshop, Genesis Equipment says knowing five key specs will make selecting the perfect hoist easier and ensure you can get the job done safely and efficiently. They are lifting capacity; overall hoist height; concrete floor requirements; vehicle wheelbase length versus hoist runway length; and wheel track versus runway width. Genesis Equipment says it is one of Australia’s most trusted suppliers of high-quality workshop equipment and is also proud to be the exclusive Australian distributor for what it says are the world’s most reputable hoist manufacturers, including Stertil Koni and Bendpak.

1. Hoist Lifting Capacity

Lifting capacity is the maximum weight that can be supported by a hoist. You must choose a vehicle lift that can pick up and safely support the weight you need it to. Expert tip: The lifting capacity of a four-post hoist can be diminished depending on the vehicle wheelbase length (see point four), so do not review these numbers in isolation.

2. Overall Height of the Hoist

Before investing in a vehicle lift, you will want to make sure it will fit your workshop. It sounds obvious but remember to factor in your car’s combined height and lift once raised. And for two-post hoists, do not forget that you need to allow ceiling clearance for the safety bar which sits above the car. Expert tip: Stertil Koni’s mobile column lifts can be used in outdoor environments and are IP 65 rated with a splash-proof electrical system. They are also available in a wireless option.

3. Concrete Floor Requirements

Concrete floor requirements vary for different styles of hoists. Among the things you need to consider, two-post hoists must be installed on a continuous single concrete slab with specific requirements outlined for concrete thickness; spacing of rebar; and minimum compressive strength and reinforcement. It is also unacceptable to install hoists on concrete flooring which is cracked, defective or made from hand-mixed concrete.

A bigger vehicle lift is not always better - you need to select a hoist based on the wheelbase length of the vehicles you intend to lift. This one is easy to overlook but could significantly diminish your lifting capacity. Each hoist has a ‘sweet spot’ for wheelbase length, so to get the best return on investment, it is helpful to know the types and weights of the vehicles you want to lift. For example, Bendpak’s HDS-14 has a weight capacity of 6,350kg and the length of runway is 5,055mm.

5. Wheel Track (vehicle) vs Width between Runways (hoist)

On the vehicle, the wheel track is the distance from the centre of the left-hand tyre tread of the vehicle to the centre of the tyre tread on the

VEHICLE WHEELBASE

% CAPACITY LIFTING CAPACITY 3,556 – 5,055mm @ 100% Capacity 6,350kg 3,048 – 3,555mm @ 75% Capacity 4,762.50kg 2,540 – 3,047mm @ 50% Capacity 3,175kg 2,032 – 2,539mm @ 25% Capacity 3,175kg

right-hand side. On the hoist, the width between runways refers to the distance between two runways. Compare these two numbers and ensure that the vehicle’s wheel track will comfortably sit on the hoist runways. Genesis Equipment says it prides itself on providing fit for purpose workshop solutions, including helping you choose the correct hoist for your needs.

For more information, call the Genesis Equipment team on 1800 214 009.

NOLATHANE PRESS TOOL KIT

An easy-to-use tool kit for any bushing removal and replacement job

The Nolathane Press Tool Kit is a specialised tool which Nolathane says provides a safe, effective, and easy way to remove old worn bushings and install new Nolathane bushings. It is suitable for using with a press or for working directly on a vehicle. Nolathane says this kit will also provide a safer option for other workshop pressing requirements.

Key features:

• Easy enough for DIY and strong enough for workshops. • Less force required to remove/install bushings, bearings and joints; making use easy even without power tools. • 18 press tubes arranged in 2mm increments to match common bush sizes. • Mild steel construction allows them to crush instead of shatter if overloaded or be easily machined to suit specific job applications. • Individually numbered sleeves can be replaced and reordered separately. • Threaded rods in different sizes, complete with bearings. • Nuts with double washers and encapsulated lubricated ball bearings for strength and longevity (stops nut from binding and stripping thread).

Kit contents:

• 26-piece press and pull tool • 18 x Sleeves – 34mm-82mm diameter (2mm increments) • Four press plates • Four pulling spindles covering the following nut sizes: M10, M12, M14, M16. • Rolled thread on spindles

To view a video of Mark ‘Larko’ Larkham explaining how to use the press tool kit, go to https://youtu.be/h9VVAKXIiyk For more information, visit www.nolathane.com.au or call 1300 882 355 (toll free in Australia).

A LONGER LASTING CORDLESS IRON

Solder Master is perfect for small or confined spaces

Designed and engineered by the battery experts at Master Instruments, the new Solder Master soldering iron features a rapid 10 second heat-up time, LED guide light for poorly lit areas and interchangeable solder tips. The lightweight and ergonomic tool is adaptable to most environments and tasks, and is perfect for use under the bonnet, under the dashboard or even in the boot.

Boasting up to 270 minutes of run time before recharging is required, the new Lithium Ion powered soldering iron from Solder Master provides a professional grade tool for any workshop, with those behind the product exclaiming: “that is up to one month of regular daily use between recharges!” No Gas, no flame and no leaks removes potentially dangerous unwanted gasses and the accidental ignition of nearby flammable materials found with Butane powered irons, and trip hazards from extension cables used with plug-in Irons. Solder Master boasts high-quality Japanese cells and the protection found in the internal battery means safe and consistent performance for years to come, with full recharges achievable in approximately four hours. The Carbon fibre styled casing also features an easy to operate mode button with LED indication of heat level and battery state of charge and the silicon lined safety cap is capable of covering the tips, even when they’re still hot. Solder Master ESM-50WL is supplied as a full kit with AC and DC Chargers, two tips and some solder.

For more information, visit www.soldermaster.com.au

CYCLO METAL CAN HOLDERS

Putting frequently required products within easy reach

Cyclo Australia says it is excited to release its new portable workstation can holders. Cyclo explains that it is well known for its quality American-made products that save time and effort and says with this new product, it has just taken efficiency to another level. The portable workstation can holders put the right products exactly where they need to be, within the technician’s reach. Made of metal and coated in a scratch resistant coating, the can holders can be mounted onto tool boxes, rolling trollies, work benches and any other surface that is fit for purpose. This means no more searching the workshop looking for those everyday products that someone has used and left on a different bench, as everything is in its place and there is a place for everything. With more and more cost accountability required in today’s workshops, Cyclo says having each technician in charge of their own products helps with transparency for the amount of products used. The Cyclo can holders are available for free as a bonus with one of the three box packs, Breakaway, fast movers or the sampler back. The Cyclo portable can holders can also be purchased wherever you purchase your Cyclo products. The Cyclo Can holders will only be available for a short time, “but will last forever.”

For more information, please contact Cyclo Australia on 03 9702 4314 or sales@cycloaustralia.com

GEARWRENCH BOLT BITER LINE

New wheel nut extraction sockets introduced

Building on the success and popularity of the original Bolt Biter Extraction Sockets launched in 2019, GEARWRENCH is now unveiling the latest addition to its family – Bolt Biter Wheel Nut Extraction Sockets. GEARWRENCH says the new additions use the same technology that made Bolt Biter a hit, but now apply it specifically to removing worn or damaged wheel nuts. “We saw the success of the initial launch and people were immediately asking for more, so we listened and took another step further,” GEARWRENCH Product Manager, Steven Tokouzis, said. “The GEARWRENCH Bolt Biter Extraction Sockets allow auto techs, MRO techs, and DIYers to remove and reuse corroded, weathered, rounded and/or damaged wheel nuts with ease.” Bolt Biter Wheel Nut Extraction Sockets feature a tapered entry that makes it easy to seat on a damaged fastener without hammering, and the “minus-sized” sockets are designed to grip wheel nuts that are worn down substantially. The bi-directional design generates five times the gripping force of other extraction sockets and allows techs to not just remove fasteners but reuse them as well. GEARWRENCH says the sockets also have a deep design to reach the deepest wheel nuts “that others can’t.” The square drive with hex base makes Bolt Biter Wheel Nut Extraction Sockets compatible with an impact gun, ratchet, wrench, or pliers. GEARWRENCH explains that the sockets are made from chrome molybdenum for 10-times the impact life of competitors, while it states the black oxide finish provides superior corrosion resistance. As such, GEARWRENCH says they save techs time in getting the job done and money by lasting longer than the rest. Bolt Biter Wheel Nut Extraction Sockets are available in a 10-piece ½-inch drive set (86071).

For more information, visit www.gearwrench.com.au

BAC AUTOMOTIVE WORKBENCHES

Combining European standards with Australian demands

BAC Systems says it is a well-respected Australian manufacturer of refined and durable Automotive Workstations, as well as special tool and spare parts storage for vehicle service workshops. It has been manufacturing steel equipment in its Western Sydney factory since 1977 and says the modularity of its base cabinetry means that a customised configuration can always be devised to suit your individual requirements. With the boom in the luxury European car market of the last decade, Vehicle Service Workshops have seen a large take-up of the European concept of Corporate-Image compliant workshops whereby the workshop becomes a practical extension of the showroom. Part of this morph into such a professional image involves the standardisation of the technician’s toolboxes, with the European franchises now nominating the very toolboxes the mechanical technicians are supposed to use. BAC Systems says it was an integral part of this workshop transformation culture right from the beginning, stating it was quickly approached by some of the initial dealerships to adopt the European model of CI compliant workshop layout. It explains the modular BAC range made it easy to offer standardised solutions and many fruitful partnerships were forged between BAC and some of the European brands operating within Australia. It soon became evident, though, that the European approach and the Australian and New Zealand mentality didn’t quite match up. The Europeans were very clinical and minimalist in their approach. Mechanics were restricted to only holding the standard tool kit within their drawers in anticipation of all possible issues that a mechanical technician might encounter. The Australian reality, however, is that there were many variants, not within the manual, that required different tools to fix. BAC Systems says its range was able to span the gap between expectation and reality, offering the European standard of 600mm deep benches in tighter metro workshops, or instead offering the standard 800mm deep alternative to workshops where the additional 33 percent storage capacity was of the higher priority. By having both options available, BAC Systems says it is able to meet the more conservative needs of the European-influenced Australian and Asian workshops, while still having an offering for the more versatile Australian and New Zealand mechanics. BAC says it is now well established as the only major Australian manufacturer of CI compliant Workshop Furniture and has been selected by many European brands as their local preferred supplier.

For more information, visit www.bacsystems.com.au

GIVE YOURSELF A TAX BREAK ON WORKSHOP EQUIPMENT

With the help of Capricorn Finance

Capricorn, Australasia’s largest automotive co-operative, says it can assist its Members to take maximum advantage of the Australian Government’s taxation incentives to purchase new equipment. For several years, the Australian Government has offered the Instant Asset Write-Off scheme that allows businesses to claim an immediate deduction for the business portion of the cost of an asset in the year the asset is first used or installed ready for use. Following the numerous COVID-19 outbreaks experienced over the past year across the country, changes have been made to the scheme to extend eligibility to more businesses, increase the threshold amount for assets and introduce Temporary Full Expensing. Without these schemes, businesses would only be able to claim depreciation on any assets purchased. That is, the reduction in value of the asset over its life span. Under that system, it may take many years before a business can recoup the full cost of any equipment purchased and installed. The changes to thresholds result in more businesses and assets being eligible for the Instant Asset Write-Off and Temporary Full Expensing to immediately claim the business portion of the cost of new and second-hand equipment purchased and installed on their next tax returns. Therefore, many workshop owners who purchase and install equipment in the lead up to the end of the financial year, will not be left out of pocket for long with their expenses being reimbursed as a tax deduction. In terms of the maximum value of equipment that can be claimed by a business, this largely depends on when the item was purchased and first used or installed. This taxation deduction has proven to be a tremendous opportunity over the past few years to purchase new hoists, spray booths, wheel balancers, diagnostic scan tools, solar panels and other workshop equipment needed to stay competitive and to ensure business growth. Of course, not every business has thousands of dollars lying around that can be easily diverted from paying wages and other regular expenses to invest in new equipment. To help Members take advantage of the incentives available and to help grow their businesses, Capricorn Finance may be available. Many Capricorn Members have been preapproved for loans up to $30,000 to fast track the application process, making it easier for them to purchase new equipment before the end of the financial year. In relation to the taxation incentives currently available and referred to in this article, there are eligibility criteria in relation to business turnover and asset value as well as exclusions and limitations in place on certain items, including a maximum value for passenger vehicles purchased. It is important for Capricorn Members to seek the advice of their taxation accountant to check whether their businesses are eligible for any of the incentives that are currently in place. For more information on Temporary Full Expensing or the Instant Asset Write-Off please refer to the Australian Tax Office website at www.ato.gov.au

Capricorn Members can find out more about the Finance available to them by visiting Capricorn online at www.capricorn.coop/eofy

WHAT DO EV WORKSHOPS LOOK LIKE?

EVUP says there are three steps to preparing yourself for an electric future

It says those steps are knowledge, equipment and Personal Protective Equipment (PPE).

Knowledge

While traditionally taught skills will still be needed for many years, e-mechanics will need additional electrical knowledge and a range of other skills to confidently work with EV high voltage systems.

Equipment

Specialist tools and equipment, such as hoisting pucks that fit Tesla models, OBD2 scan tools, multimeters and insulated tools to guard against shock should be considered for any workshop preparing for EV servicing. EV charging should also be considered, with a dedicated and mobile three phase charging unit enabling charging to come to the vehicle, rather than valuable space being allocated EV only.

There are significant and different risks to your workshop team when working with EVs versus internal combustion engine vehicles, including electrocution, gassing, burns and fire. No one should attempt to work on an EV without proper training and skills development. Insulated tools, specialist personal protective wear and additional high voltage signage around your workshop should form the basis of protection measures.

EVUp is ready to help

EVUp says it supplies high-quality, mobile workshop charging units compatible with every EV on the market which can charge up to 22kW (three phase). It has also written an online EV High Voltage Safety training course at evalliance.net.au

For more information, visit www.evup.com.au

REPCO EQUIPMENT

Ready to assist your workshop with your equipment needs

Repco Equipment has been involved in the supply, installation, training and servicing of workshop equipment for over 50 years in the Australian market. It explains that its dedicated state-based teams are factory trained and highly experienced in providing complete workshop solutions, which are tailored to suit the requirements, budget and timeline of customers. Repco Equipment’s services also include the design, delivery, installation and training of full “turn-key” workshop fit-outs. Repco can design/install oil storage bench tanks and oil/air delivery systems that fit your workshop needs. It invites you to contact its team to ask how Repco can improve the productivity, safety and profitability of your workshop while overall lifting your workshop’s image. It states that its market leading brands are backed nationwide with spares, consumables, service and technical support for your peace of mind. Further, Repco says it understands that the purchase of a piece of equipment is a serious investment, and as such it is fully committed to standing behind its products. When it comes to payment options, Repco says it offers competitive long-term and short-term financing options, which can help you breakdown the payments of your purchase (conditions apply). Repco encourages you to ask its team about the options available and states that no matter how small or large your enquiry, the Repco Equipment team is on-hand to assist.

For more information, please call 1800 224 581 or visit www.repcotrade.com.au

RHINO LININGS ARMAFLOOR FLOOR COATING

Rhino Linings says its ArmaFloor 500AU Polyaspartic Floor Coating is the ultimate solution for workshops, garages, commercial and walking surfaces and so much more. Rhino says its polyaspartic flooring is long lasting for floors that are simple to maintain, strong and tough which look attractive too. The topcoat makes a corrosion protection coating system that is non-yellowing and has excellent overall weathering capabilities. The fast-drying feature of polyaspartic coating converts into a fast return to service, whereas the high film build decreases the number of coats required in similar coating systems. Polyaspartics reportedly improve the use of common two-component aliphatic polyurethane coating technology by providing a quicker dry time, offering a hard-wearing coating, being highly decorative with added paint flakes or quartz chip, and by being perfect for use for industrial, business and residential flooring. Rhino ArmaFloor 500AU is Rhino’s premium polyaspartic floor coating, offering highperformance and allowing for fast installation and a rapid return to service. Due to the product’s aliphatic chemistry, Rhino ArmaFloor 500AU is colour stable, which means it can withstand UV exposure without the colour shift seen with other coating systems such as epoxies. Rhino ArmaFloor 500AU can be rolled, brushed on or spray applied with Rhino Linings’ application equipment. With the addition of flake chips to add texture or quartz granules for slip resistance, you can create beautiful, unique decorative blends. Rhino Linings says ArmaFloor 500AU is fast becoming the floor coating of choice due to the many features and benefits it has to offer for virtually any interior or exterior concrete surface application.

For more information, visit www.rhinolinings.com.au

BATTERY MANAGEMENT SOLUTIONS

From Century

Being able to proactively manage battery health for customers can make a real difference to customer satisfaction and revenue for workshops. Century offers a number of tools to help workshops be on the front foot for their customers when it comes to managing their batteries.

DHC BT521A Handheld Battery Tester

Proactive battery testing using a handheld tester like the DHC BT521A from Century Yuasa provides an accurate on the spot test result in minutes. It can help identify suspect batteries before they fail and highlight problems with the vehicle’s starting and charging system. But more importantly, it helps your customers avoid the financial and emotional costs associated with a flat or faulty battery. Not only will this translate into increased battery sales, but it’ll also help maintain your reputation of offering good customer service and further cement your business in the local community.

Century Yu-Fit

With the introduction of C02 production control systems including Idle Stop Start, it is essential that vehicles have a battery of the correct type and specification installed. More importantly, several automotive manufacturers have introduced active energy management systems that require the replacement battery to be correctly configured to the vehicle following installation. This configuration is required because a brand-new replacement battery requires a very different charging strategy compared to the battery which has reached the end of its serviceable life. Applying the old charging strategy to a new battery could result in a loss of Stop Start system functionality, loss of vehicle system functionality, plus increased fuel usage and CO2 emissions. Century says that luckily, the configuration of these vehicle energy management systems can now be carried out simply and easily using its Century Yu-Fit battery configurator tool. The Yu-Fit tool can be used to configure the replacement battery to the vehicle’s active energy management system – informing the vehicle that a new battery of the correct type and performance has been installed. It will also inform the charging system of the new battery characteristics and ensure the correct charging strategy is applied right from the start. Configuring a vehicle with the Yu-Fit tool following battery replacement will reportedly ensure the vehicle’s charging, energy management and system functionalities will perform as intended, and ensure that your customer will receive the best possible performance from their battery purchase. The Century Yu-Fit tool comes pre-loaded with profiles for all common vehicle manufacturer make and models and receives regular updates to help keep pace with the latest changes to the Australian new car market – all by simply connecting the tool to your PC.

For more information, visit www.centurybatteries.com.au or contact your Century Batteries Specialist on 1300 362 287.

COOLANT TEST STRIPS AND REFRACTOMETERS

Proactive coolant testing can help you save money in equipment down time and parts replacement

Regularly testing and monitoring coolant can tell us much about the condition of the cooling system and if anything is wrong that might to lead significant problems. Every good cooling system maintenance program should include regular coolant testing to determine if the proper level of protection is present or if contaminants exist. A good coolant testing program eliminates guesswork and allows the cooling system to maintain peak performance. To assist with on-site testing, Cummins Filtration has a range of coolant test strips and refractometers that can be used on-site as a quick guide to assess the immediate health of your Fleetguard coolant and cooling system condition.

Coolant Condemnation Test Kits

• PG Platinum (Propylene Glycol based OAT coolant – premix ~50 percent. Nitrite, Amine,

Phosphate, Silicate free). Four-way coolant 50 strip test kit. - Easy to use test strips measure freeze point, molybdate, and nitrite (as a contaminant) and pH

- Results in 45-75 seconds - Designed specifically for use with PG Platinum • PG Plus (Propylene Glycol based hybrid coolant – premix ~50 percent). Nitrite/

Molybdate for cavitation protection, three-way heavy-duty coolant 50 strip bottle test kit - Measures protection against liner pitting, corrosion and coolant dilution - Easy to use test strips measure freeze point (glycol percentage) and molybdate/ nitrite - Results in 45-75 seconds - Easy to read table that indicates how much DCA4 or DCA4+ to add when these additives are low • Quick-Chek Three-Way Test Strip (contamination check) 10 Strip Bottle - Easy to use test strips measure levels of pH, sulphate and chloride for overall coolant quality - Minimises unnecessary draining of coolant still within specification

- Results in 30-70 seconds - Test twice a year - For use with PGPlus or other coolants not coloured red or orange

Coolant Refractometers

• PGPlus Refractometer and PG Platinum

Refractometer available - Determines glycol percentage (freeze point protection) for coolants - More accurate than test strips or float-type hydrometers - Durable storage case included

For more information, visit www.fleetguard.com.au or call Cummins Filtration on 1800 032 037.

THE “ULTIMATE” IN BRAKE TESTING EQUIPMENT

Braking performance is a critical factor when considering vehicle safety

The potential damage of a couple of tonnes of steel and plastic hurtling out of control can be detrimental to property and people. Traditionally, the braking capabilities of a vehicle are tested using a physical and on-road check to verify that safety standards have been complied to. However, what about the brake’s operating performance? Are the results of the vehicle’s braking capabilities still accurate when a driver has to suddenly slam on the brakes? A Victorian based manufacturer, AutoTest Products, says it is taking an innovative approach to testing equipment to ensure a brake’s capabilities and operating performance are factored into the safety of a vehicle. AutoTest explains that it provides a range of stateof-the-art, automotive testing and diagnostic products, designed to improve the accuracy of the test results used to meet safety regulations. It says AutoTest products will also help generate business for workshops, with or without Licensed Vehicle Testers (LVT) status. AutoTest offers two main product lines: the ‘AutoStop,’ which is a range of products designed to test a vehicle’s brake performance, and the ‘AutoLight,’ which enables accurate measurements to be taken of the light transmission through vehicle windows. AutoTest also offers a range of workshop products relating to suspension, emissions, headlights, Noise, OBD, and brake fluid. AutoTest supplies workshops, regulatory authorities and service testing stations across the world, including Australia, New Zealand, USA, UK, South Africa, Malaysia, Holland, France, and Germany, with products from the AutoStop range. It says that its AutoStop Maxi brake meter is used by over 3,000 workshops in New South Wales alone.

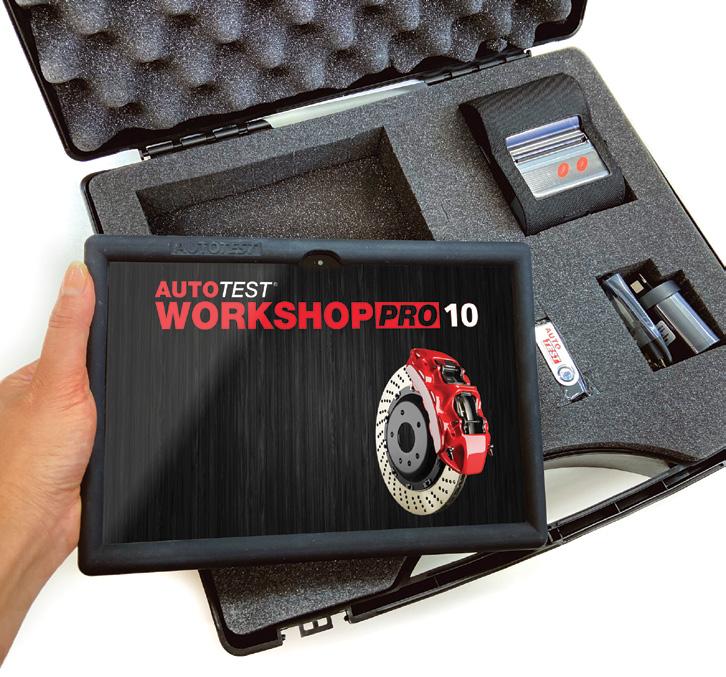

AutoTest Workshop Pro 10

AutoTest explains that its AutoTest Workshop Pro 10 is an easy to use electronic in-vehicle testing device, used to measure the deceleration required to stop a vehicle. At the end of each test, the AutoTest Workshop Pro 10 evaluates a vehicle’s brake performance and prints out or records the results of the test for future analyses. The comprehensive report includes information on vehicle speed, deceleration, stopping distance and GPS location. The AutoTest Workshop Pro 10 can print copies out for both you and your customer, if required. An advantage of the AutoTest Workshop Pro 10 for Victoria and Queensland based workshops and garages is that it reads all three VicRoads and QLD DOT specified figures, including GPS locations, average peak decelerations, stopping distances and test speeds.

For more information, visit www.autotest.net.au

KEEPING IT GREEN

By keeping it clean

Exhaust Clean Australia says it offers the ultimate emissions cleaning solutions for DPF, SCR, EGR, intake manifolds, intercoolers and EGR coolers. It says it uses state-of-the-art and industryleading machines to clean Diesel Particulate Filters and the like back to near new condition with all carcinogenic particulate matter contained inside the machine trapped in purpose-built filters which can then be disposed of safely without a threat to the environment. Regular cleaning of DPFs helps extend the life of the filter, removing all soot and ash up to 10 microns from the porous membrane of each cell which helps engines perform at optimal efficiency and peak power. Over time, ash builds up in the bottom of each cell after the vehicle performs a regeneration to remove the soot loading, eventually resulting in exhaust gas flow restriction. This restriction increases exhaust backpressure which in time reduces engine efficiency requiring more fuel and more boost from the turbo to perform at the same level. The ash loading in each cell is not removed by a regeneration whether it’s done whilst driving or forced using a scan tool, says Exhaust Clean Australia. It says a forced regeneration should never be the solution to a blocked or restricted DPF, as so many other external factors can cause DPFs to become blocked such as split intercooler hoses, faulty sensors, EGR valve failures/restrictions, worn injectors and incorrect grade of oil to name a few. While these are all contributing factors, Exhaust Clean Australia says one of the biggest contributors to a DPF issue can be driving style. It explains that consistent short trips over a long period of time will cause the DPF to become restricted in flow as this style of driving does not allow the ECU to perform a regen due to a lot of factors not being met. Further, the engine not being up to operating temperature and short timeframes of not driving at a consistent higher rpm will inhibit the system performing a regen to remove the soot loading from the filter. Exhaust Clean Australia says that fuel economy, performance and throttle response are notably improved when keeping these emissions systems clean and in a good operating manner. Turbo chargers are also put under a lot less stress with a free flowing and restriction free DPF. It says the cost of DPF cleaning versus DPF replacement is miniscule in comparison and will be recouped in lower operating costs plus reductions in wear and tear on some critical components as well. Exhaust Clean Australia services the greater Brisbane and Gold Coast areas to the New South Wales border with free DPF pick-up and delivery. It also will accept DPFs from all over Australia to receive a new lease of life, no matter your location.

For more information, visit www.exhaustclean.com.au or call 073382 7199.

TWO-POST LIFTS FROM MAHA

Australian workshop equipment specialist introduces innovative triple safety German-made hoist to local market

MAHA has recently brought to Australia the German-made MA Star two-post lift, which has a 3500kg load capacity. It has a triple safety feature and a 20-year plus proven spindle-nut system with self-locking thread and comes with a five-year warranty. The MA Star two-post lift comes in several models: the MA Star 3.5A Asymmetrical, the MA Star 3.5S Symmetrical, and a soon to be available 5500kg load capacity version. The MA Star 3.5A includes asymmetrical columns turned by 45 degrees for a generous door-opening angle, and asymmetrical support arms with a 180-degree range. The optional MA Star 3.5S comes with symmetrical columns for a reduced overall width and symmetrical support arms. The coming soon MA Star 5.5 has been designed to accommodate larger vehicles and long wheelbase vans and will be available in Australia in the coming months. As usual, the customer can choose from numerous additional options, including an LED lighting kit or the 5.5 specific wheel fork supports for special and electric vehicles, which allow unrestricted access to the underside of the vehicle and thus facilitate the removal and installation of vehicle batteries. MAHA says these supports are also ideal for municipal vehicles such as street sweepers, which often do not have mounting points for support arms. All models are available with variable installation width and are finished with your choice of powder coating or are supplied in standard RAL 7040 window grey on the columns and RAL 7016 anthracite grey on the support arms.

Features with standard delivery:

• Two asymmetrical columns with control panel at operating column • Four asymmetrical support arms • 80mm standard pick up pad height suitable for lowered vehicles (MA STAR 3.5 only). • Sports car arms are available for race car applications. • 50mm and 100mm extensions that can be combined to achieve 150mm for large side steps • Adjustable Cable bridge for low ceiling installation MAHA explains that its lifts are manufactured in Bavaria in Germany and hold Factory approvals with the German OEMs, stating that these approvals are only obtained be adhering to strict lift requirements across the entire range. The features of the MA Star 3.5A and MA Star 3.5S are highlighted in a YouTube video which can be found on the MAHA Australia and New Zealand YouTube Channel.

For installation costs and more information, call MAHA Australia on 1800 006 242 or visit www.maha.com.au

MAKING AN IMPACT

With Auto One

The Auto One group has been making recent headlines with the addition of new stores, but the Australian automotive retailer has started making waves with the range of products on its shelves. Auto One says the launch of its eye-catching Impact Automotive range was implemented to allow Auto One outlets to not only provide quality products to their customers but also “produce the best value for money offer for the Australian market.”

The Impact Automotive range includes garage equipment, coolants and floor mats. Auto One states the range of garage equipment is impressive, covering everything from engine cranes to vehicle dollies, right through to high lift jacks and mobile mechanic stools. The trolley jack range provides a convenient and efficient solution for everything from DIY to trade at an affordable price. The Impact Coolants range offer both premix and concentrate variations that cover everything from passenger car to light commercial applications. The red and green long-life variations are supplemented by a Corrosion Inhibitor option, giving strong car parc coverage through 15 individual SKUs. “We will continue to grow the Impact Automotive range where we see opportunities to offer quality products at a very competitive price,” said Auto One’s newly appointed Head of Marketing, Lara Galvin. “The Impact brand started with a range of trolley jacks, engine hoists and general garage equipment. “We will continue to add products to that area of the range, as well as find new opportunities to implement well-designed and excellently produced products in additional areas for our customers.”

For more information, visit www.autoone.com.au

Burg Design says the Fastback Pro allows technicians to easily and safely manoeuvre over floor grates, air hoses and even unpaved driveways. This patented garage creeper reportedly offers excellent comfort, handling and full control for an ideal working position without the user having to grab the underside of the vehicle being worked on to pull themselves up and around. The two seven-inch All Terrain wheels are both in a “positive camber” configuration and provide the capability to easily spin and manoeuvre. Further, the Fastback wheels have a dual tread tyre profile suitable for both smooth and rough surfaces. The Fastback also has dual level adjustment for low or high ground clearance and thanks to its low centre of gravity, Burg Design says a rollover is physically impossible. Burg Design explains that the Fastback features a strong and durable heavy duty blow moulded HDPE shell with a very comfortable ergonomic shape and a soft polyurethane headrest. Also featured are tool trays in the armrests, two built-in removable magnetic work lights and two magnetic small parts trays. Also available as an optional extra is a lockable wall mounted bracket. The Fastback Pro Garage Creeper is protected by a two-year warranty.

For more information, contact Burg Design on 03 9555 9277 or sales@burgdesign.com.au

ACS TOOL HIRE PROGRAM

Australian Clutch Services (ACS) offers customers the opportunity to hire a range of specialised tools with the purchase of any applicable ACS clutch kit. The ACS tool hire range has been developed to support an evolving market with the necessary tools and technical support. This includes DCT removal and installation tools which are generally vehicle specific. “The market in which we operate is quickly evolving with dual clutch transmission technology now starting to become commonplace in the aftermarket,” ACS Business Development Manager, Colin Jevons, said. “Our distributors around the country are seeing a major increase in the demand for DCT clutch kits and components and it is important we can provide them with the tools and support required to install these components. “As part of this, we have introduced the tool hire program that allows customers to hire the required tools for the clutch installation rather than having to purchase multiple vehicle specific tools.” ACS says the hire program is proving successful and only includes a minimal fee to cover freight and logistics costs. “The feedback from the market has been very positive with many of our distributors’ customers being able to take on these jobs now they don’t have to incur the significant investment in tools required,” Colin said. “This has opened up the market to a broader range of independent workshops and we are proud to be able to support these workshops as they adjust to this new trend.” The hire program currently includes nine different tool kits including a range of DCT clutch installation and removal tools. Also included is a self-adjusting clutch tool designed to assist in the installation of kits with selfadjusting pressure plates without causing the internal mechanism to incorrectly adjust during installation. These tools cover various vehicles from Audi, Volkswagen, Hyundai, Renault, Ford, Alfa Romeo, Fiat, Jeep and Kia. ACS explains it offers a comprehensive range of DCT clutch kits, flywheels, actuators, service kits and tools for purchase; with strong stock levels for fast delivery and a comprehensive range of the latest and hard-to-find parts. The tool hire program is available through any ACS distributor with the purchase of an applicable clutch kit.

For more information, please call 1800 CLUTCH or visit www.australianclutch.com.au

FASTBACK PRO GARAGE CREEPER

New and unique to the market

BUILD YOUR OWN ROTARY HOIST

With Burson Equipment

Not all automotive workshops are the same, so it makes sense that all automotive workshop hoists should not be the same or extremely limited in design specifications. Specific vehicle specialisations for automotive or body repair work require specific lifting capacities and design options to enhance productivity and workshop safety. Burson Equipment says it provides Australian automotive workshops the opportunity to custom design their own hoists to best suit their specific automotive specialisation. Burson Equipment says that together with the world’s leading hoist manufacturer, Rotary, it exclusively provides automotive repairers with the ability to customise their hoists using the vast number of options made available from the Rotary hoist and accessory range. Australian automotive workshop owners can select a style of hoist, choose a height or length that best suits their requirements, select from an arm or frontal design, select a voltage, and consider the optional accessories that Rotary makes available. Once these selections are made, or for assistance with making these selections to best suit any specific workshop, automotive repairers or collision repairers can contact a dedicated Burson Equipment Specialist by calling 1300 287 766 to organise their own custom designed Rotary hoist. There are arm or ramp options, three overall height options (3628mm / 3873mm / 4178mm), three length options in closed front or open front design (4451mm / 5060mm / 5893mm), two voltage options (417V Three Phase / 240V Single Phase) traditional arm design or trio load arms, along with optional accessories including alignment kits, rolling jacks or the state-of-the-art Rotary Spotline and Locklight pack. Burson Equipment also offers a brand-new Rotary four post hoist range with a complete built-in Alignment Kit, enhancing workshop productivity, accuracy and additional revenue earning capacity. All Rotary hoists from Burson Equipment reportedly function to an industry best height of 2000mm, providing abundant under vehicle working space with single point operation. Burson Equipment says these premium quality, customisable Rotary hoists feature high performance steel lifting cables and a range of optional accessories to best suit exacting repairer requirements.

To find out more, contact the Burson Equipment Team on 1300 287 766 or visit www.bursonequipment.com.au

WORKSHOP EQUIPMENT

From Aeroflow Performance

Aeroflow Performance offers a wide array of tools and equipment for your workshop. Just some of the products on offer are as follows:

Professional Single and Double Flare Tool Kit

The Aeroflow Brake Flaring tool is said to be the fastest way to get a professional single or double flare, every time. This easy-to-use flare tool comes with six assorted metric and imperial dies, including the popular 3/16” brake line which requires a double flare to meet ADR standards. This flaring tool produces convex and double flares to SAE and DIN standards in seconds while the smooth die does not mark the tubing and comes with an easy carry case.

Low profile car ramps

When working with lowered cars with body kits, there isn’t the room to get a jack under the car to access a jacking point, even to simply look under the car to inspect something. Aeroflow Performance low profile car ramps solve this problem and are designed to not slide forward when driven onto, have a lip on the edge so you don’t drive off the ramp and are very lightweight.

Nine-inch diff centre assembly stand

stand to your work bench (or engine stand) to stop wrestling with the diff housing every time you need to replace a gear set or spool. It saves you time and energy, rotating 360 degrees for total access to your Ford nine-inch diff assembly.

Workshop creeper

Forget rolling around on the cold, hard, uncomfortable concrete floor and get yourself a Aeroflow Performance workshop creeper. The six swivel castor wheels make it easy to move around underneath a raised and supported vehicle with little effort. The heavy-duty steel frame holds up to 130kg (maximum) and the great design of this creeper allows it to easily turn into a seat for the ultimate in comfort when working around the workshop.

LS Series Engine Lift Plate

Aeroflow Performance’s engine lift plate is a perfect way to simplify the installation and removal of any LS engine. Remove the intake manifold and valley plate and bolt it down in place using the existing valley plate bolts. There are four holes for various chain placements for proper engine weight balance offset and it suits all GM LS engines.

Engine Lift Plate

Aeroflow Performance’s engine lift plate allows you to lift engines up by the intake manifold for easier manoeuvring. You can also use them as a manifold cover when storing an engine. These Aeroflow zinc plated carburetted engine lift plates fit standard Holley 4150/4160 and Dominator, Rochester Quadrajet, Carter, Demon, Quick Fuel, Motorcraft, Edelbrock, Edelbrock Q-Jet and Carter AFB carburettors. Also on offer in Aeroflow Performance’s workshop equipment range are a wide array of hand tools, workshop trolleys, engine support bars, Qwik lift vehicle jacks, engine levelling tools, engine cranes, chassis stands, engine stands, engine cradles and more.