44 minute read

Brake, Clutch & Driveline: All the latest on brake, clutch & driveline

NEW FROM KELPRO

Brake and clutch hydraulics range launched

Kelpro, a brand specialising in high quality rubber and hard parts, says it is proud to launch a full line of braking and clutch hydraulics to the market. The new range, which is now available, consists of Brake Master, Clutch Master, Clutch Slave and Wheel Cylinders to suit popular applications. The Kelpro Hydraulic range is sourced from an ISO 9001 and TS accredited “world leading” factory which specialises in manufacturing automotive hydraulic cylinders and uses Critical Rubber Seals from a Japanese OE supplier. Established in 1982, the factory operates with more than 180 Employees and has a production capacity of over 17,000 pieces per day. To ensure the quality of every part manufactured, Kelpro says its manufacturing partner offers a full suite of Testing and in-House Lab Facilities including ambient high and low temp testing; bore hardness and roughness testing; and 100 percent on line pressure testing.

The range spans more than 1300 parts and includes a recent expansion catering for an additional 5,000 applications and 15,00,000 vehicles on road, covering popular light commercial applications such as the Ford PX Ranger/Mazda BT-50 and Isuzu MU-X. Now available exclusively through Repco and NAPA Auto Parts, the Kelpro brake and clutch hydraulic range offers the following key features: • Made from superior-quality and durable materials (cast-iron or aluminium, weight reduced). • Superior quality materials used for longer service life. • Improved cylinder surfaces to minimise cup abrasion, to help maintain long term reliability. • Has tight tolerance specifications to ensure functioning and freedom from leaks. • Pressure and dust-protection sleeves made from EPDM (where applicable) to ensure optimal functioning and leak-tightness, and prevent the ingress of dirt, air and moisture.

For more information, visit www.repco.com.au

REPLACEMENT FLYWHEELS

Clutch Industries says: why grind when you can replace?

Traditionally when a clutch kit is replaced, the flywheel must be ground to ensure the surface finish is correct. Clutch Industries says it has surveyed workshops and found that on average, 4.5 hours of hoist time is wasted due to this process, and in addition, the trade price for a grind is on average $70 plus the delivery cost. Financially to workshops this is a massive cost when the cost of the grind, delivery time/cost and lost hoist time is considered. Clutch Industries say its new single mass flywheel range will revolutionise the clutch replacement process by offering a range of OE style replacement flywheels at an affordable price. Previously, to buy an OE spec replacement flywheel there were very limited options, says Clutch Industries, which meant if a replacement flywheel was needed a workshop would have to purchase a second-hand unit from a wrecker. Generally, the only option to buy new was through an OEM which in most cases is not stocked locally and the price can be several times more than the price of the clutch kit. “This flywheel range will change the way a clutch replacement is done, in the same way as replacement rotors did with brakes,” Clutch Industries Senior Product Manager, David Talbot, said. “Eventually as the range extends, replacing the flywheel will be a common practise for every clutch replacement.” Clutch Industries say there is a multitude of reasons why you would replace a flywheel instead of grinding one, including: • Faster installation time; less hoist time wasted. • In most cases the price is comparable to a grind. • Eliminates issues related to a poor grind like shudder, noise and slipping. • Restores correct stack height, reducing the chance of disengagement issues after installation. • Stick out from the competition; offer your customer new instead of old. Clutch Industries says that the range currently covers around 50 percent of the common clutch kits sold (where the OE flywheel is single mass), with the range being expanding regularly. It says the range is available in major Repco or NAPA branches, meaning “you’re able to buy everything you need to get the clutch job done in one place.” Clutch Industries say its OE style replacement flywheels are available in the CI range which comes with a two-year or 40,000km warranty and also offers other advantages such as: • 1045 grade steel, exceeding Australian standards. • Manufactured by quality assured factories. • Includes a ring-gear. • Engineered and manufactured to OE specifications. “We’re excited about the range and wanted to have a bit of fun by offering a promotion for customers purchasing a flywheel in the month of March from Repco or NAPA,” Clutch Industries Sales and Marketing Manager, Justin Batten, said. “Basically, if you purchase a flywheel in the range you will go into the chance to win two virtual reality Ifly experiences which is a great way to experience skydiving while staying on the ground (or close to the ground). “There is an Ifly location in most major cities and (the prize) is valid for three years, so you will have plenty of time to muster up the courage to give it a go.” The competition concludes at the end of March and is a lucky draw, so the more flywheels you purchase from Repco or NAPA, the more chances you have to win.

For more information, contact your local Repco or NAPA branch or visit www.clutchindustries.com.au

TRAKRYDER DUAL DIAPHRAGM BRAKE BOOSTER

From Pedders for Toyota Landcruiser 70 Series

Pedders Suspension and Brakes has just released an “exciting product to enhance the braking performance of the Landcruiser 70 series.” Following extensive Australian development and engineering, Pedders says it is proud to offer its TrakRyder brake booster to the suit Landcruiser 70 series (VDJ76, VDJ78, VDJ79) ABS models from 2012 to current and Non-ABS models from 2007 to 2012. With a significant increase in braking performance by up to 30 percent, Pedders says its TrakRyder dual diaphragm brake boosters are a must have for those that tow and carry loads. The TrakRyder dual diaphragm brake boosters have been designed and engineered in Australia to full ADR35/05 compliant brake testing. Pedders says these units are ideal for load carrying and towing vehicles with a GVM of up to 4380kgs (ABS) and 4310kgs (Non-ABS). All units come with a two-year/40,000km nationwide warranty.

Key features and benefits:

• Increase braking performance by up to 30 percent. • Designed and engineered in Australia. • Reduced pedal effort and improved stopping power. • Direct bolt on replacement. • Includes fitting instructions. • Includes engineering compliance letter and

QLD LG1design code approval number. • Full ADR35/05 compliant brake test available to

Engineers or Transport Authorities for sign off. • Ideal for load carrying and towing vehicles with GVM of up to 4380kgs (ABS) and 4310 (Non-ABS), • Two-Year/40,000km Nationwide Warranty.

For more information, check in with your local Pedders outlet on www.pedders.com.au

BRAIDED BRAKE HOSES

Bendix says braided brake hoses offer many advantages for 4WD vehicles

Braided brake hoses included in the Bendix Ultimate 4WD Upgrade Kits are now available in a range for individual purchase and Bendix says they offer a number of advantages over the factory fitted hoses fitted to the vehicle. By upgrading a vehicle’s brake hoses, Bendix says drivers will experience a vastly improved firm brake pedal feel as the new stainless steel braided hoses do not expand under high pressure and can withstand severe damage from stones and obstacles experienced in off-road conditions. The Bendix 4WD brake hoses are available for standard ride height vehicles and also in longer lengths to suit two-inch and four-inch raised suspensions requiring longer length hoses. Bendix explains that fitting the Ultimate 4WD hoses poses no problem as they are designed to fit without any modification. Bendix braided hoses meet SAE J1401 and are fully compliant to international design standards and as such will not impact on the vehicle warranty. They are constructed from PTFE (Teflon) tubing covered by woven stainless 304 braiding with a Bendix blue protective sheath to protect the braid from dirt, grease and road grime. The hoses are terminated with 12L14 steel chrome plated fittings and also feature rubber overmoulded sleeves designed to minimise coupling to hose fatigue for long life in tough conditions. Bendix states that its Ultimate 4WD Brake Hoses are available from leading automotive and specialist 4WD outlets nationwide.

For more information, visit www.bendix.com.au

ACS ADDS TO CLASSIC CLUTCH HYDRAULICS RANGE

New components are now available for early Jaguar models

Australian Clutch Services’ specialist classic and vintage brand, Classic Clutch, has recently added several new hydraulic components to its range to suit early Jaguar models. These brand-new components include slave cylinders to suit series I and II XJ6, XK150, S-Type, MKII and the legendary E-Type as well as a new master cylinder to suit the XK150. These components have been designed to meet OE quality and are direct fit replacement for the originals. “We are continually evaluating the market to ensure we add in the necessary components for classic and vintage vehicle applications,” ACS Business Development Manager, Colin Jevons, said. “These new additions to the Jaguar range will be helpful for specialists around the country who are looking to replace the hydraulics with high quality components when fitting a new clutch kit in the vehicle.” Classic Clutch offers a range of rare or obsolete clutch kits and components for classic and vintage cars, trucks, buses, boats and even military tanks. With a highly experienced technical team, Classic Clutch can provide new clutch components or rebuild original clutch kits to new or improved specification. They also offer performance upgrades for classic vehicles being used in motorsport. “We cover all types of classic vehicles and equipment including everything from classic boats through to the custom servicing requirements for older Formula One cars,” Colin said. “We can either offer brand new components, or if these are no longer available, we can rebuild the clutch in our state-of-the-art workshop facility.”

For more information, visit www.australianclutch.com.au

BOSCH ENV6 BRAKE FLUID

Developed to cope with the high strains caused by modern and future brake systems

The performance of modern brake systems is being continuously improved while the reaction times of ABS and ESP are getting faster and faster. As a developer of modern vehicle safety systems, Bosch says it also focuses on the brake fluids used. With ENV6, Bosch says it provides a particularly powerful and reliable brake fluid meeting the growing demands of modern and future brake systems.

A unique combination of characteristics: low viscosity and high wet boiling point

Bosch says ENV6 stands out for being the first brake fluid ever developed to combine both a very low viscosity – ie: very high fluidity – and a very high wet boiling point in comparison with conventional brake fluids. The lower the viscosity, the shorter the reaction times of ESP systems, for instance, while the high wet boiling point reduces the risk of formation of vapor bubbles – the main cause of brake failure. So far, Bosch says this combination of both of these features is absolutely unique and makes ENV6 particularly reliable and safe. As a result, Bosch says ENV6 can be used to replace several different brake fluids such as DOT3, DOT4 or DOT5.1; stating that only “very rarely used brake fluids based on mineral oils (LHM) or containing silicones (DOT5)” are the only ones not compatible.

Significantly increased replacement intervals

Bosch says that thanks to its very good technical characteristics, the replacement intervals of this high-performance brake fluid have been significantly increased as well. It states that while standard DOT4 brake fluids need to be replaced every two years, the ENV6 replacement interval comprises three years. Bosch explains that its high lubricity prevents noises and protects the brake system against wear and corrosion. At the workshop, ENV6 can thus be used to replace several different conventional brake fluids. Bosch says this reduces the risk of filling the brake system with inappropriate brake fluids or mixing different ones and also reduces the required storage space at the workshops. Bosch supplies ENV6 in 500ml bottles in Australia. Distributors include Stopmaster, CoolDrive Auto Parts, Burson Auto Parts, Specialised Brake and Clutch, Fry Auto Parts and Automotive Superstore.

For more information, visit www.boschaftermarket.com.au

AEROFLOW PERFORMANCE DRIVELINE COMPONENTS

Available from Rocket Industries

Aeroflow Performance manufactures a range of driveline components including engine plates, billet SFI rated flex plates, transmission yokes for GM and Ford transmissions and a range of replacement Ford 9” differential components. Rocket Industries says “as with all Aeroflow parts, these quality components represent great value for money that give workshops and mechanics the ability to make good margin while keeping prices competitive.” The Ford 9” range includes diff housings, axle tubes, axles, billet tube ends, wheel studs, nodular iron cases, full spools, limited slip style PowerTrax assemblies, shim kits, seals and bearing kits, diff breathers, axle perches and universal joints. Rocket Industries says these parts are perfect for replacing and upgrading all old school cars running Ford 9” diffs and for building custom 9” differentials for most street machines. Diff housings are available in standard and competition spec which utilise thicker steel and CNC housing flanges that allow the axle’s tubes to be welded in two places for extra strength. Thick (4.77mm) axle tubes and billet axle tube ends to suit small, big and early model Ford bearings complete your 9” housing which would be at home on the street or race track. Cut-to-fit 9” axles are available in 28 and 31 spline in different lengths with four inches of spline so they can be cut to your requirements. 31 spline axles are drilled for 4.5 and 4.75 stud patterns to suit Ford, Chrysler and Chevy. Aeroflow also offers two options for your diff centre. It says the Powertrax assembly is the latest design in traction control, utilising three x two spiral gear technology for smooth, dependable operation that combines limited-slip characteristics from gears contained in a machined, forged steel centre housing. The Powertrax reportedly delivers progressive and variable traction releasing tension on the centre to turn corners while locking up to put the power down through both wheels in a straight line. And for the more competition-oriented diff, Aeroflow’s full spools come in 28 and 31 spline lightweight steel. The Ford 9” CNC forged aluminium Daytona style pinion support is said to be a great upgrade from the cast iron models. This pinion support uses a standard Ford 9” front pinion bearing and the Daytona style pinion bearing on the rear. The latest addition to the Aeroflow Performance range are billet flexplates. Rocket Industries says the lightweight one-piece design is stronger and more durable than any twopiece style of flex plate. Machined from 4340 round bar with precise tolerances and with a chamfered gear teeth for better engagement with the least amount of runout, Rocket Industries says all of its Aeroflow billet flexplates are certified to SFI 29.2 and are available for many different models. Rocket Industries explains that Aeroflow offers a comprehensive range of bearings, studs, seals and gaskets to build and overhaul your 9” differential and a massive array of performance parts.

For more information visit www.aeroflowperformance.com or contact Rocket Industries on 02 88251 900 via www.rocketind.com

BRAKE SHUDDER

In this article, ZF Aftermarket provides important information on this common problem

Brake shudder is essentially rotational vibration of the steering wheel which can occur during braking and is usually accompanied by a booming noise. Depending on the cause, it can be divided into thermal shudder, which occurs during deceleration from high speeds, and cold shudder, which can occur at any speed.

Hot/Thermal Shudder

“Thermal shudder” is marked by a booming noise in a frequency range between 100 and 250 Hz. The intensity of the booming can vary during deceleration but does not affect braking. It is normally accompanied by vibrations in the steering wheel and a pulsation in the brake pedal. The effects of hot shudder can usually be identified by a circular arrangement of spots on the friction surfaces of the brake disc. This martensite formation is harder than the basic structure of the disc material and can be removed only by machining. When repairing a disc with martensitic spots, ZF Aftermarket encourages you to make sure you completely remove the hardened areas without reaching or falling short of the minimum thickness of the brake disc.

Cold Shudder

“Cold shudder” occurs during normal braking and can be identified by pulsation in the brake pedal, torque fluctuations in the steering wheel and/or vibration of axle and chassis components. Cold shudder can occur virtually every time the brake is applied, regardless of temperature, and has a much lower frequency range (about 5 to 50 HZ) than thermal shudder. These noises can be louder or quieter depending on the speed. The main cause of cold shudder is the thickness variation in the brake discs. Defective bearing parts and wheel imbalances can also increase the effect, as with thermal shuddering.

Analysis

In most cases, brake shudder is caused by several factors, making it difficult to clearly identify the root cause. ZF Aftermarket offers the following as some general steps to follow: • Determine whether the shudder is coming from the front or rear axle. • Check all brake components including the brake pedal, brake booster, master cylinder, brake lines, brake hoses and wheel brakes. If replacing components, make sure to replace brake pads and brake discs, brake drums and brake shoes in complete axle sets. • Check the wheels for balance, axial runout, radial runout and the condition of the tyre tread. • Check the axle settings, wheel suspension, steering components and adjust/repair as necessary.

For further information on ZF’s TRW braking range, visit www.aftermarket.zf.com/au/trw

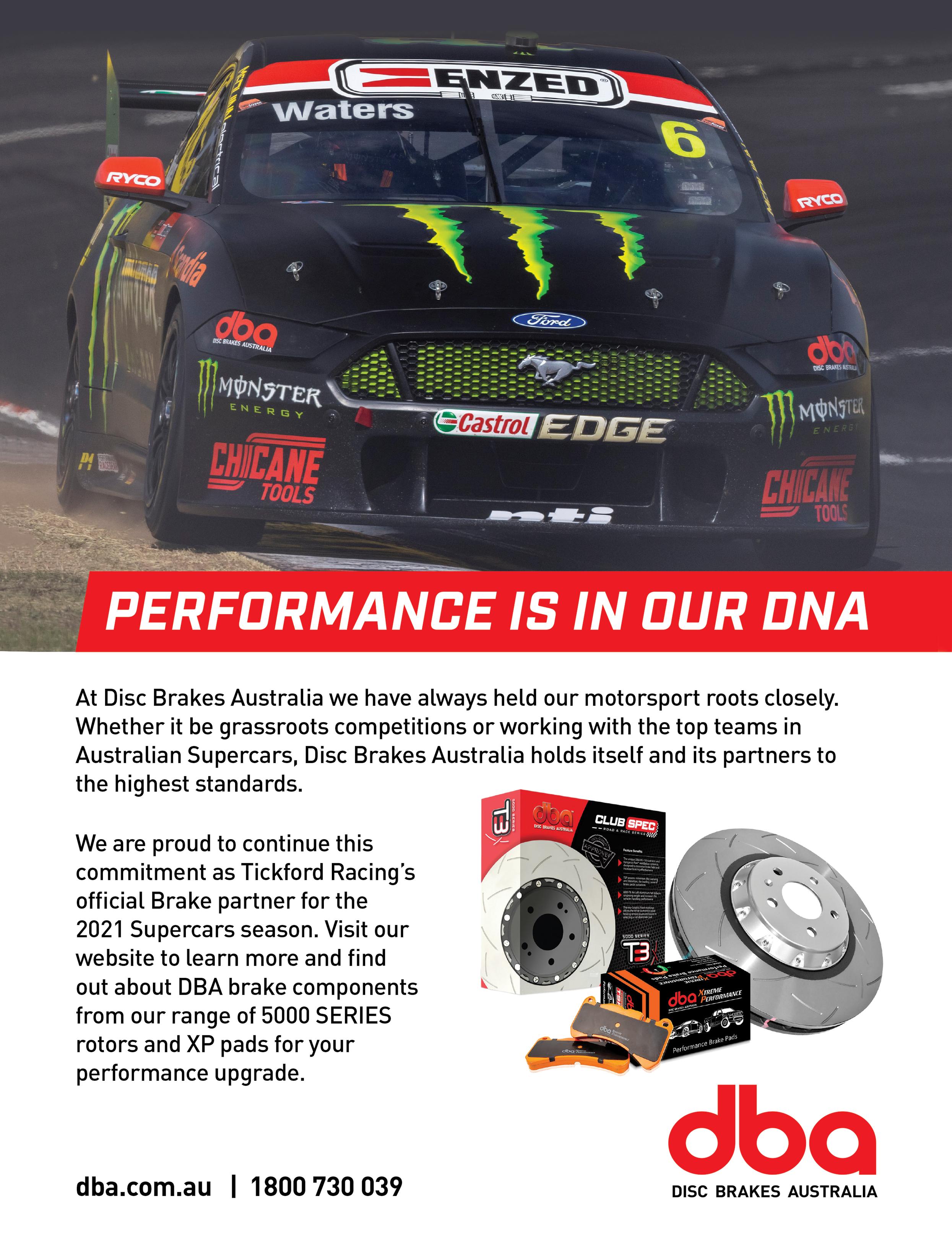

RELIABILITY IS EVERYTHING

Especially when it comes to brakes

Flexible Drive – an original equipment supplier to some of Australia’s largest and most demanding manufacturers – says it understands that in the aftermarket industry, reliability is everything. As such, it says it applies those same exacting standards to the aftermarket products it supplies with its products sourced from “the best suppliers across the globe.” When it comes to brakes, Flexible Drive says it is your reliable partner as the exclusive distributor of Remsa brakes in Australia – providing performance and reliability for over 1,300 plus parts and 24,000 Australian vehicles. Flexible Drive says it knows value for money is important, stating that “comparing like for like, our prices are better value. We are a private business, which means lower costs for you. We are in business to grow and we believe the best way to compete is by keeping our costs down and offering you a better deal than our larger competitors. We give customers like you the best value, so you can pass it on, and continue to grow your business.” Further, Flexible Drive says it is continually looking for ways to do things better and to grow. For five years, it says its range has expanded, with the hydraulics range growing by 100 percent and its Remsa brake pads range by 500 percent. It says its catalogue is constantly being updated and its new eCatalogue allows you to find the parts you need and have them delivered faster. Flexible Drive’s communications systems have also been upgraded to make ordering and tracking easier while its range and availability has reportedly increased nationwide. “At this rate, it won’t take long before we will have the best programs for parts interpreters in Australia. Constant innovation helps our business – and yours,” Flexible Drive said.

Not just brakes

Flexible Drive says brakes are just the beginning of its offering, explaining that it also specialises in cables, mounts, commercial wipers, safety systems and an ever-increasing range of control systems and replacement parts. Flexible Drive says it welcomes brake resellers of any size, so whatever your needs and whatever your scale, it invites you to get in touch.

For more information, contact Flexible Drive on 1300 363 735 or sales@flexibledrive.com.au

DAYCO HARMONIC BALANCERS

Increased power with “total reliability”

The Dayco Powerbond harmonic balancer range includes a number of precision engineered applications designed specifically for high performance and racing vehicles. Dayco says its Powerbond Street Series delivers bonded balancer technology within the budget of every performance street engine builder while also being an excellent option for heavy duty OEM balancer replacements. The bonded dampening rubber eliminates spinning and component separation, providing reliable performance in engines used to 6,500rpm, and these balancers combine new high strength SG (Nodular) Iron Balancer centres and inertia rings, which have been bonded and balanced to extremely tight tolerances. To assist automotive technicians and enthusiasts, Dayco Powerbond Street balancers also feature easy to read permanently etched timing marks on the outer ring. The Dayco Powerbond Race Series reportedly brings the advantages of bonded balancers to high revving race applications where an SFI approved balancer is required. Every Race Series Powerbond balancer features a precision CNC machined AUSI 1045 forged steel hub bonded to an equally strong steel inertia ring. Dayco says this highly advanced design ensures that Powerbond Race Series balancers are extremely light for an all-steel product and in most cases, they are only marginally heavier than the original cast iron balancer and generally much lighter than other all-steel balancers available in the aftermarket. In addition, the steel inertia ring of the Race Series models is positively protected against forward and backward movement and has the assurance of bonded rubber to eliminate spinning; and every model has easy to read laser etched timing marks. All Powerbond Race series balancers meet SFI specification 18.1. The Dayco Powerbond Underdrive balancer is a smaller and lighter harmonic balancer that acts like a lightweight flywheel which under-drives the accessory pulleys to reduce parasitic power losses from the alternator, air conditioning, water pump and power steering at high engine RPMs. Dayco Powerbond Overdrive balancers are suitable where a supercharged engine requires more boost. This is achieved by increasing the diameter of the harmonic balancer, which in turn increases the speed of the supercharger. Dayco Powerbond overdrive balancers are available five percent to 18 percent bigger in diameter and also feature an eight-rib serpentine drive for maximum belt grip. Dayco Powerbond supercharger balancers offer twin keyways for secure crank mounting and have extra bolt holes for bolting on the factory pulley or six bolt Gilmer drives. Dayco’s Powerbond range also features power pulley kits for a complete heavyduty fitment of under driven harmonic balancers. Dayco has responded to market demand and introduced a high quality Nissan Navara OEM replacement harmonic balancer (Dayco Part Number HBB1882N) for models manufactured from May 2015 onwards. This part number also suits Mercedes-Benz X220d and X250d models manufactured from December 2017.

For more information, call Dayco Australia on 03 9794 4466 or visit www.dayco.com.au

REPCO BRAKING AND CLUTCH RANGE

A wide array of solutions are on offer from Repco

Repco offers an extensive range of products, including in the areas of brake and clutch.

Repco braking range

Repco has a comprehensive braking range which consists of both branded and “market leading” exclusive programs, such as the RCT (Repco Premium Ceramic) and REX (Repco Extreme) Brake pad ranges. The extensive Repco Rotor range has recently been enhanced through the addition of the Kelpro hydraulic program. Repco says it has also expanded the Repco Extreme Brake pad offering which has had 37 new part numbers added to suit more than 2,800 applications and in excess of 500,000 vehicles. Repco explains that the Kelpro Range of Brake and Clutch Hydraulics is specifically sourced from accredited world leading factories that specialise in making automotive hydraulic cylinders. Repco says this ensures the robust quality of every Kelpro Hydraulic part manufactured, providing long service life and excellent reliability. The range spans over 1,300 parts and consists of the following to suit popular applications, Brake master, Clutch master, Clutch slave and Wheel cylinders.

Clutch Kits, Dual Mass Flywheels and Specific Tool Kits for DCT

The automatic transmission is a constantly evolving piece of technology. One of the more recent trends has been the introduction of the Dual Clutch Transmission, or DCT. These mechanical wonders are designed for fast efficient shifts and fuel efficiency. With a range spanning Volkswagen, Audi, and Skoda vehicles, fitted with the 7-speed “dry clutch” DCT unit, LuK has a comprehensive range of DCT Clutch Kits and Dual Mass Flywheels (DMF). The replacement of these clutch and DMF units is made easier with ‘all in one’ clutch kits and tech data. Repco explains that the key benefits of the LuK DCT Clutch Kits are: • OEM Product • All components including Clutch, Forks,

Bearings, and Shims contained in one box • Complete fitting / assembly instructions • Specific Tool Kits All of the products listed here are available from Repco.

For more information, visit www.repco.com.au

HELLA PAGID BRAKE SYSTEMS

Meeting the growing demand for European parts

With European brands becoming an increasingly popular choice, one of Europe’s leading Original Equipment brands, Hella Pagid Brake Systems, says it is meeting the growing demand for premium quality European parts. Hella Pagid Brake Systems is the result of a joint venture between German automotive giants Hella KGaA Hueck and Co GmbH and TMD Friction, the world’s largest manufacturer of Original Equipment brake friction and the name behind the Pagid brand. Pagid’s reputation for serious stopping power stretches back over 60 years and Pagid friction materials are still used on many current models, including performance cars such as the Porsche 911, SUVs such as the Audi Q7 and Porsche Cayenne, and city cars and utility vehicles including Volkswagen’s Golf and Amarok models. More than 50 different friction formulations, derived directly from TMD Friction’s OE programme, feature within the Hella Pagid brake pad range to meet the individual requirements and characteristics of the vehicle, ensuring the optimum balance of performance, safety, and comfort. Its extensive OE programme means many European models roll off production lines equipped with Pagid brake friction and over one million brake pads are manufactured each day at TMD Friction’s European production facilities. Pagid is also trusted by race teams competing at some of the highest levels of motorsport. The Hella Pagid Brake Systems range brings this Original Equipment expertise to the Aftermarket.

Perfect for the needs of European cars

With a high level of desirability driving the growth in sales of European cars in recent years, the popularity of marques such as Audi, BMW and Volkswagen show no sign of slowing. European styling flair, brand appeal and high levels of refinement are amongst the reasons why European cars are finding favour with Australian car buyers. However, to meet the demands of their domestic markets, typically European passenger cars are developed to offer different driving dynamics to their American and Asian counterparts too, with steering, chassis, suspension – and braking – all playing a role in shaping the vehicle’s characteristics and the driving experience. When it comes to friction components, European manufacturers favour low-metallic brake friction materials. With a lower metal content, low-metallic friction compounds are said to offer improved heat dissipation, more consistent braking performance and are kinder to discs than the semi-metallic and non-asbestos organic (NAO) friction formulations used by many Asian and American manufacturers. Hella Pagid Brake Systems states that replacing worn brake pads and shoes on European vehicles with anything other than high quality low-metallic friction components can alter the characteristics of the vehicle under braking and result in increased vibration, more noise and longer stopping distances.

A comprehensive OE disc range from Hella Pagid Brake Systems

Hella Pagid Brake Systems offers a comprehensive range of brake discs, all of which are manufactured to OE specifications and cast from high-end alloys to ensure optimum performance and life, without the issues of vibration and overheating commonly experienced with inferior products. The range includes coated discs, which use a chrome-free Geomet coating that provides extended corrosion protection and speeds up fitment by removing the need for degreasing; uncoated discs for price-conscious customers and older vehicles; high carbon discs for premium and high-performance vehicles; and two-piece composite discs for certain BMW applications. Using the same low-metallic friction materials specified by European vehicle manufacturers, Hella Pagid Brake Systems says its comprehensive range of brake pads – which covers most European vehicles – is engineered alongside the OE parts and finished to the same high standards, ensuring that these products provide the same performance, long-life and comfort characteristics as the original part.

A wide array of products

In addition to brake pads, Hella Pagid Brake Systems says it also offers high quality brake discs, available with a special Geomet coating for advanced protection from corrosion; uncoated discs for older vehicles and price-conscious customers; high carbon discs for premium and high-performance vehicles, and two-piece composite discs for certain BMW applications. The range also includes brake shoes and brake drums, as well as replacement wear indicators, ABS sensors and accessory kits.

For more information, call 1800 061 729 or email info.au@hella.com

NEW CALOFFROAD DIFF DROP KIT RELEASED

For Toyota Hilux 2005-2015 on N70 and N80

CalOffroad is an Australian owned and operated company which says it is rapidly expanding its warehouse capability. Over the next 12 months, CalOffroad will be expanding its warehouse size by over double the existing floor area, and combined with the latest inventory management software, it says this will allow greater stock levels and faster dispatch times. CalOffroad says that amongst its many highend parts, it has now released a new diff drop kit for the Toyota Hilux 2005 - 2015 on N70 and N80. This diff drop kit reportedly comes immaculately presented in its own box, allowing you to see the quality of the parts and to be a part of the CalOffroad culture. CalOffroad states it has been the leader in modified suspension components, requiring the extra attention of high-end parts like its diff drop kits, upper control arms and shock absorbers. CalOffroad says it likes to add features like E Coat for first coat and then High-End Finish Powder Coat to make its components the most corrosion resistant and high quality finish for the harsh Australian conditions. CalOffroad explains that it chooses E Coat and powder coat over the older galvanised or zinc coat to be more environmentally friendly and to help keep our world cleaner. If you are running over 2.5 inches of lift, CalOffroad says you will need to correct your CV angles to help eliminate CV boot failure and early wear and tear on your CV joints. The CalOffroad Toyota Hilux Diff Drop Kit also reinforces the vulnerable drivers’ side diff mounts by adding a second mounting point to the rear cross member. Added polished Stainless Logo plates for CalOffroad Brand Identification and over 30mm of Diff Drop make it the leader in Hilux Diff Drop technology, says CalOffroad, which states that other major advantages include: • Drivers’ side bracket reinforced with side web. • Drivers’ side bracket connects to front and rear crossmembers for extra strength. • Helps restore CV angles in high lift applications. • Allows more downtravel of the front suspension with less CV joint angle. • Recommended to use the CalOffroad sump guard plate for extra diff centre clearance. The CalOffroad Diff Drops can be used with any brand of suspension and are available from any of the CalOffroad resellers around the country.

For more information, visit www.caloffroad.com.au

AUTOPRO UP BRAKE LATHES

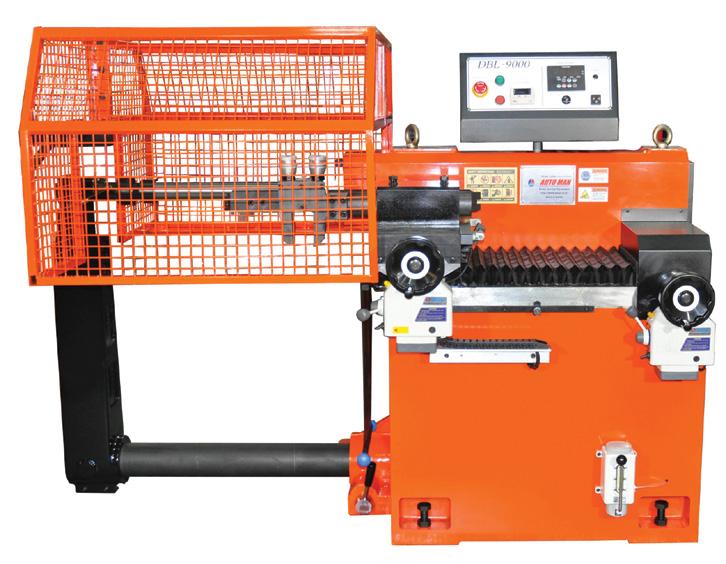

Made in Korea, available from Interequip

AutoPro Up has been established in South Korea for more than 20 years and in that time Interequip says it has been dedicated to manufacturing brake lathes and workshop presses with high precision and quality. Starting from the grass roots, AutoPro Up says it has built up its own reputation all over the world by supplying high quality equipment with very competitive prices. Interequip, its exclusive importer, explains that its team visits the AutoPro Up factory each year and reports that it is equipped with hightech manufacturing equipment including laser cutters to manufacture each component of the machines, including parts with heat treatment of tooling and cone fixtures to ensure maximum durability and precision. So, if you are in the market for a press with a spring compressor or a brake lathe, Interequip says you should look no further than AutoPro Up as it says nothing beats AutoPro up in quality and price.

The off-car brake lathes models include DBL4000 (for disc only max arbor weight 60 kg), DBLStar (for disc and drum, max rotor/drum weight 70 kg), DBL5000 (from passenger car to heavy truck, max drum/rotor weight 80 kg) and the DBL9000 (for heavy truck and bus, max drum/rotor weight 350 kg). Optional truck cones and flywheel adaptors, chuck adaptors and so on are also available for purchase and all are manufactured by AutoPro Up. AutoPro Up says it also manufactures reliable quality workshop presses with spring compressors and wall mounts “at a very good price.”

For more information, please contact Interequip on 18000EQUIP (1800 037 847).

COOLDRIVE’S BRAKES PROGRAM

An extended product range means your brake needs are covered, says CoolDrive

CoolDrive Auto Parts says it has quickly established itself as a market leader in brakes, following an extension expansion to its product range in 2020. The CoolDrive braking range features the latest products from leading global brands including Bremtec, Brembo, Bosch, Fremax, Akebono, HULK 4x4 and Stolz, covering an impressive range of street, performance and track products. Headlining the 2021 braking range at CoolDrive are the newly updated Bremtec brake pad and rotor ranges, with over 1,500 part numbers covering 21.5 million cars, offering cleaner, quieter and safer braking. Bremtec’s TRADE-LINE Ceramic+ brake pads contain a new advanced Ceramic+ formulation, reportedly offering significantly less dust, reduced brake pad and rotor wear, while still offering the optimum balance of comfort and durability. PRO-LINE Ceramic+ brake pads are Bremtec’s new Heavy-Duty brake pads, engineered for the ultimate braking performance, with the new advanced friction formulation delivering improved stopping distances and a longer life, while virtually eliminating unwanted brake dust. Born from racing technology, the newly released Bremtec Evolve F2S range of Performance rotors are engineered with unique HPC (Hyper Pillar Cooling) venting for improved air flow to resist cracking and metal fatigue. Featuring Bremtec’s hyper groove slotting for better braking consistency, the Evolve F2S rotors have a brake temperature paint applied to the edge of the rotor to easily monitor effects of driving styles. New additions to CoolDrive in 2021 were Brembo brake discs and pads, which provide coverage to an impressive 96 percent of the Australian car parc. With a reputation founded on unique working relationships developed with over 30 global automotive manufacturers, CoolDrive says Brembo’s products deliver OE-quality, resulting from years of research and development, laboratory, and road testing. Brembo brake pads are available in Low-Metallic, NAO and Xtra ranges, with Brembo reportedly matching the ideal friction material to each application, all while offering high performance and minimal noise. Also available is the Brembo high performance range of brake upgrades, which have been designed and tested specifically for track day enthusiasts, club racing and for drivers who demand the utmost performance for their cars. CoolDrive also stocks the latest offering from Bosch, headlined by the Blue-Line range of brake pads, perfect for Australian, Asian and European vehicles. The OE quality parts are available in an assortment of friction materials, including ceramic, copperfree ceramic, and low metallic, with the product line delivering benefits such as smooth, quiet stopping power, all while lowering rotor wear. Reinforcing CoolDrive’s braking reputation is the Fremax range of brake discs and drums, which have earned a solid reputation over the past 30 years of production, with the company manufacturing more than 5,000,000 pieces annually for over 1,800 applications. CoolDrive Auto Parts says Fremax components offer an ideal combination of quality, innovation and safety, with all of its brake disc rotors being High-Carbon as standard, with a patented groove on the surface face for faster bedding in. Akebono – said to be the number one choice for OEMs in Japan and North America – offers brake pads that provide up to 50 percent longer lasting wear, while virtually eliminating dust and providing a smooth and quiet ride. The four-wheel drive market is also catered for with CoolDrive’s own HULK 4x4 range, which is said to offer a big performance boost through Big Brake Upgrade Kits featuring forged six piston calipers for the front slotted and dimpled rotors, rear brake drum to disc conversions, pad and rotor upgrades and dual diaphragm brake boosters. Wrapping up the main product lines at CoolDrive are the Stolz SFZ and FEX Series premium performance braking system upgrades for a host of applications. Completing the offering for workshops is an extensive range of quality consumables that get the job done right, including brake fluids, cleaners, greases, and lubes.

For more information or to obtain a copy of the CoolDrive Brakes Program Guide, visit www.cooldrive.com.au or contact your local CoolDrive Auto Parts branch.

CLUTCH CONVERSION SOLUTIONS

Xtreme Outback says it is the conversion clutch kit specialist

One of the most overlooked steps when converting a vehicle’s engine or gearbox is the clutch. With different dimensions often required for a conversion, it is important to ensure that a custom solution is developed to ensure the best driveability and reliability. Xtreme Outback, the heavy duty 4x4 and SUV brand from Australian Clutch Services, specialises in custom developed 4x4 clutch upgrades for those who are changing the engine or gearbox in their street, off-road or race vehicle. With a comprehensive in-house engineering team and a research and development facility at its Adelaide headquarters, Xtreme Outback can custom produce a wide range of solutions tailored to the vehicle’s use and performance levels. “We have been producing custom clutch kits for engine and gearbox conversions for decades,” Xtreme Outback Mechanical Engineer, Stewart Furze, said. “Our conversions are carefully developed whilst working closely with the customer to ensure the best solution for the vehicle. “We analyse the dimensions available within the bellhousing as well as any adaptor kits that have been used to design a clutch kit that offers the correct release characteristics for that application. “This service is easily accessible to anyone who requires a custom solution and, depending on the specific conversion, we often keep the components required on the shelf.” Building a custom clutch kit can be as simple as switching the spline hubs over in the discs through to more specialised solutions such as tailored flywheel designs. “Some conversions are a very simple change in componentry whilst others require a full custom solution,” Stewart said. “Having developed these for many years, we have provided performance solutions for many different street and Motorsport applications in Australia and around the world and have streamlined the process to ensure we can offer the ultimate solution for any vehicle.” Xtreme Outback has also recently introduced several new conversion kits for popular engine and gearbox conversions such as Nissan Patrol’s fitted with GM LS2 engines and RB Series engines as well as LandCruiser gearboxes fitted to a Nissan TB48 engine.

For more information, please visit www.xtremeoutback.com.au or call 1800 CLUTCH.

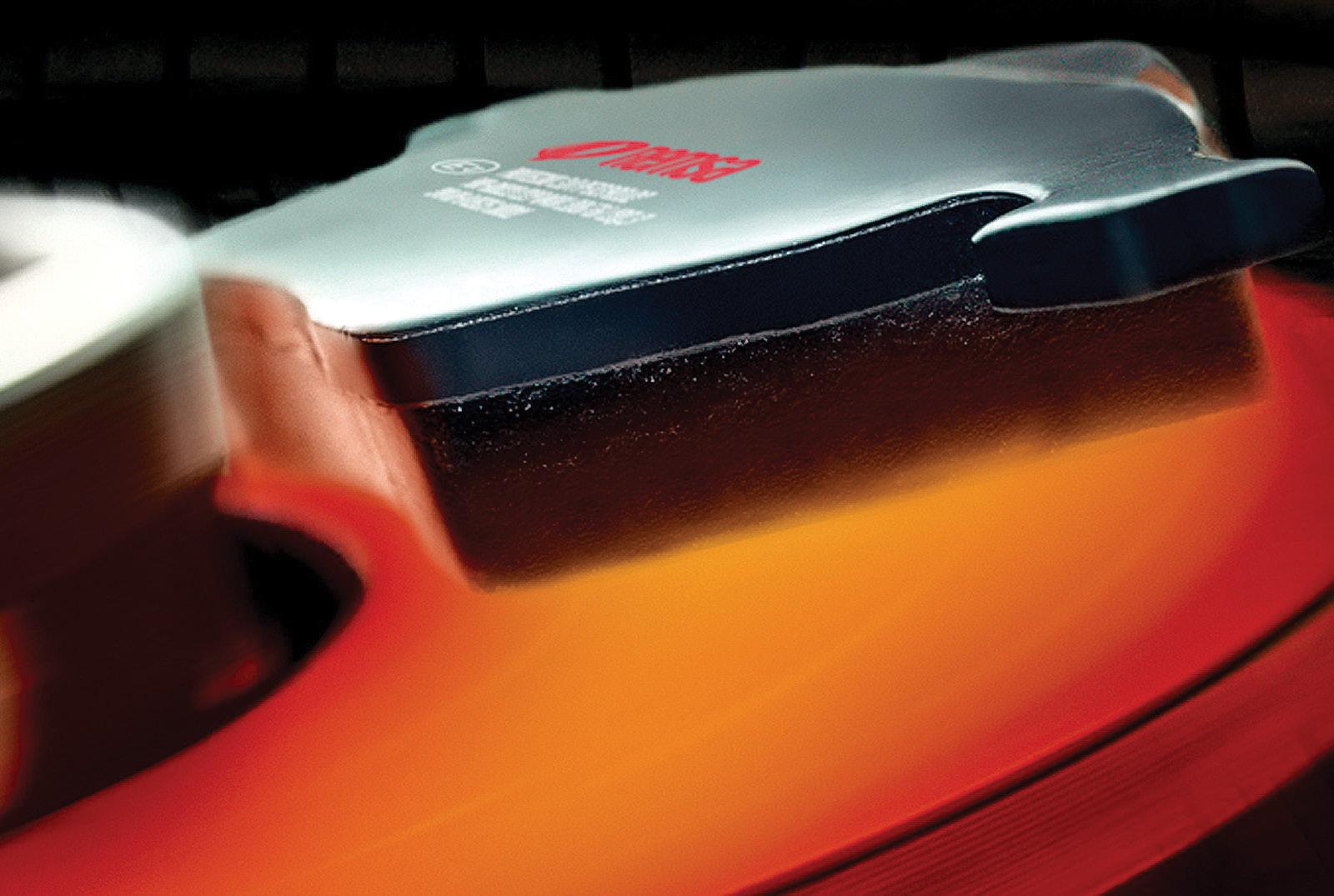

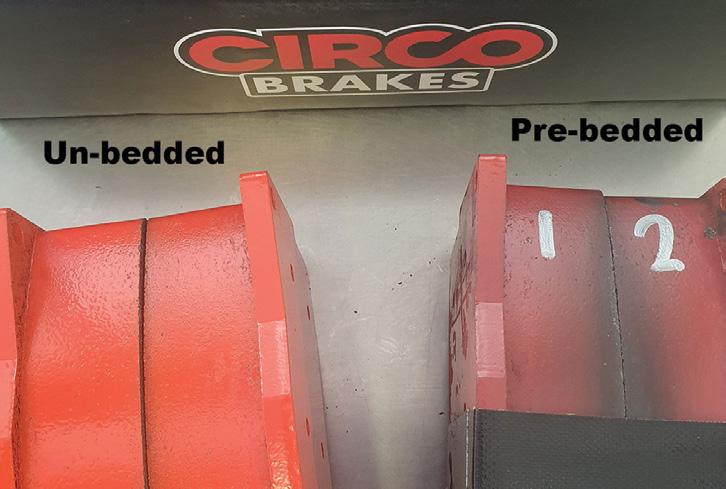

BRAKE BEDDING SERVICE

From Motorsport Brakes

Alongside a wide array of braking products, Motorsport Brakes also offers a brake bedding service to its customers. Brake ‘pre-bedding’ is a way of doing the final preparation of the pad material, prior to heavy use – normally in competition conditions. Motorsport Brakes explains that the bedding process is effectively a final heat cycle that puts enough energy into the pads to ensure they reach a point of consistency required for when the user hits the track or stage. The pre-bedding process also helps with reducing pad wear rates, and costs associated with bedding brakes at the track. “The ultimate performance, consistency and life of your brakes is much more likely when using pre-bedded brake pads,” Motorsport Brakes Director, Marty Beckton, said.

Your braking needs sorted

Motorsport Brakes (MSB) explains it was established to supply premium brake friction products to the Australian and NZ performance and competition markets. The company says it is now the world’s largest brake pad distributor for one of Japan’s most experienced manufacturers of braking products: Winmax Corp, which is a subsidiary of MK Kashiyama Group, Japan. World class racing brake pad brand, Circo Racing Brake Pads, is also distributed by MSB in Australia. MSB acts on behalf of Circo in all racing category supply including for V8 Supercars, the Australian Rally Championship, TA2 Muscle Cars, Touring Car Masters, the RX8 Cup Racing Series and more. “We distribute the Winmax and Circo world class products via a network of knowledgeable dealers which range from one-man band workshops right through to national retailers. However, MSB is also always available for personal service or back up where needed,” Marty said. “MSB is a business dealing in quality products offering personal service focused entirely on quality and rapid response to crucial requirements in specialist fields including Motorsport, street performance, OEM, Fleet and Government. “Our existing range of brake pad compounds covers almost all areas of world motorsport. We are capable of supplying categories from club level right through to FIA world championship organisations. At the same time our product range caters to every area of performance vehicles, including street, tuning, enthusiast, club, rally, circuit and also the growing Performance 4x4 Heavy Duty market. Our brake pad range covers almost 1,800 applications and counting.” All Australian distribution of Winmax and Circo products is warehoused at the MSB base in Yatala, Queensland. The business operates inventory management software which allows for B2B access by Trade and Wholesale partners for all stock and ‘overnight’ purchases.

For more information, visit www.motorsportbrakes.com.au

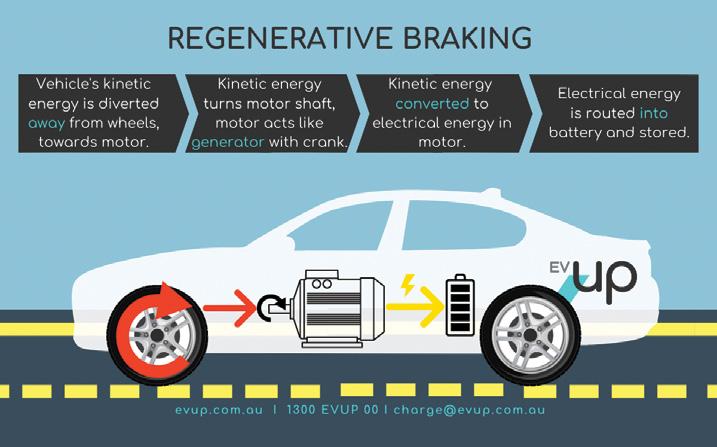

HOW TO IMPROVE THE RANGE OF AN EV BY STOPPING

Regenerative braking is a system found in both electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs) that recharges your battery by braking

EVUp explains it is a simple but effective technology which is widely used in electric vehicles and is an efficient way to mitigate the loss of energy while braking.

What is regenerative braking?

A moving vehicle creates kinetic energy and when the brakes are applied, this energy must go somewhere. In a conventional braking system, friction-based disk brakes are used to slow vehicles. The kinetic energy from the movement of the vehicle is being converted into heat via friction and dissipating into the atmosphere, resulting in a loss. Regenerative braking is when an electric vehicle’s kinetic energy is harvested through the action of slowing down and is sent back into the battery as usable power. Put simply, braking in an EV regenerates your power and gives you more range. However, not a lot of power is retrieved in this process and it is often depleted as the vehicle accelerates. While it does not fully reimburse the power expended to accelerate, regenerative braking is efficient enough to increase an EV’s overall range when compared to a similar car with conventional braking systems. Overall, regenerative braking is not designed to make a car more efficient; it is designed to make it less inefficient. The most efficient way to drive is at one constant speed, never accelerating or decelerating, but as that is not feasible in real world driving, the next best option is to mitigate energy lost with regenerative braking. (Note: EVs and PHEVs do often have disk brakes as well that serve to substitute the limitations of regen braking and act as emergency brakes for if the powered systems fail.)

How does regen braking work?

As you slow the speed of an electric vehicle, regenerative braking engages the motion of the wheels to act as a sort of crankshaft, sending energy to the motor via rotation of the motor shaft. This transfer of energy from the wheels to motor slows the vehicle down, often rapidly, and is why EV owners refer to ‘one pedal driving’; ie. they rarely use the brake pedal. The rotation that is applied from wheels to motor opposes the movement of the motor shaft and creates a counter electromotive force, or back EMF. In short, the reverse force on your motor’s magnets, converts rotational energy into electrical energy. Simply put, in this scenario, the EV motor essentially serves the role of a generator powered by a crankshaft while regenerative braking; harvesting power that is stored in the battery for later use.

Is your workshop getting enquiries about electric vehicles?

EVUp invites you to ask its Director, Emma Sutcliffe, about Australian-made three phase charging for your workshop by calling 1300 EVUP 00 or email emma@evup.com.au

For more information, visit www.evup.com.au

CLUTCH INSTALLATION TIPS

From ZF Aftermarket

ZF Aftermarket has shared the following advice for workshops, to help avoid errors when conducting clutch disc installations. Before replacing the entire unit, ZF Aftermarket advises workshops to always check the surrounding components in the event of clutch malfunctions, including the clutch actuation and the seals of the engine, flywheel, and transmission.

Examining the clutch disc before assembly

The clutch disc, also known as the drive plate, is subjected to the greatest load, because the clutch’s mode of operation results in mechanical abrasion. For this reason, the clutch disc must have high wear and temperature resistance. Before installation, workshops should double check the condition of the clutch packaging and the new part, as they could have been damaged during transport, or because of improper handling. To be completely certain of the condition of the part, workshops should make sure that the lateral run-out of the disc does not exceed the limit value of 0.5 millimeters. If it does, this can be corrected using a straightening fork.

Pay attention to the installation position and precisely center the clutch disc

When installing the clutch disc, make sure it is in the right position. Incorrect installation can result in damage to the disc itself, its hub spline, release lever, or even to the transmission. Fitting instructions can usually be found on the component side. If no indications can be found, compare the new part with the old one before installation. The new clutch disc must be precisely centered to prevent damage to the hub spline. There is a tolerance range of only a few hundredths of a millimeter between the transmission input shaft and the hub spline. Even small inaccuracies during insertion of the transmission input shaft can prevent the mobility later required for disengaging the clutch. The hub spline must slide onto the transmission shaft without resistance. ZF Aftermarket recommends greasing the hub spline with Sachs high-performance grease. It says its viscous consistency and temperature resistance means it adheres to the spline during operation without spreading. In order to prevent clutch shudder when the clutch is later disengaged, excess grease must always be removed, and care must be taken to keep the clutch linings absolutely clean.

Sachs Clutches

ZF Aftermarket offers clutches, dual-mass flywheels, and clutch actuation systems under its product brand Sachs, as well as clutch kits that include all the relevant components needed for a clutch repair.

For more information, visit www.zf.com/sachs

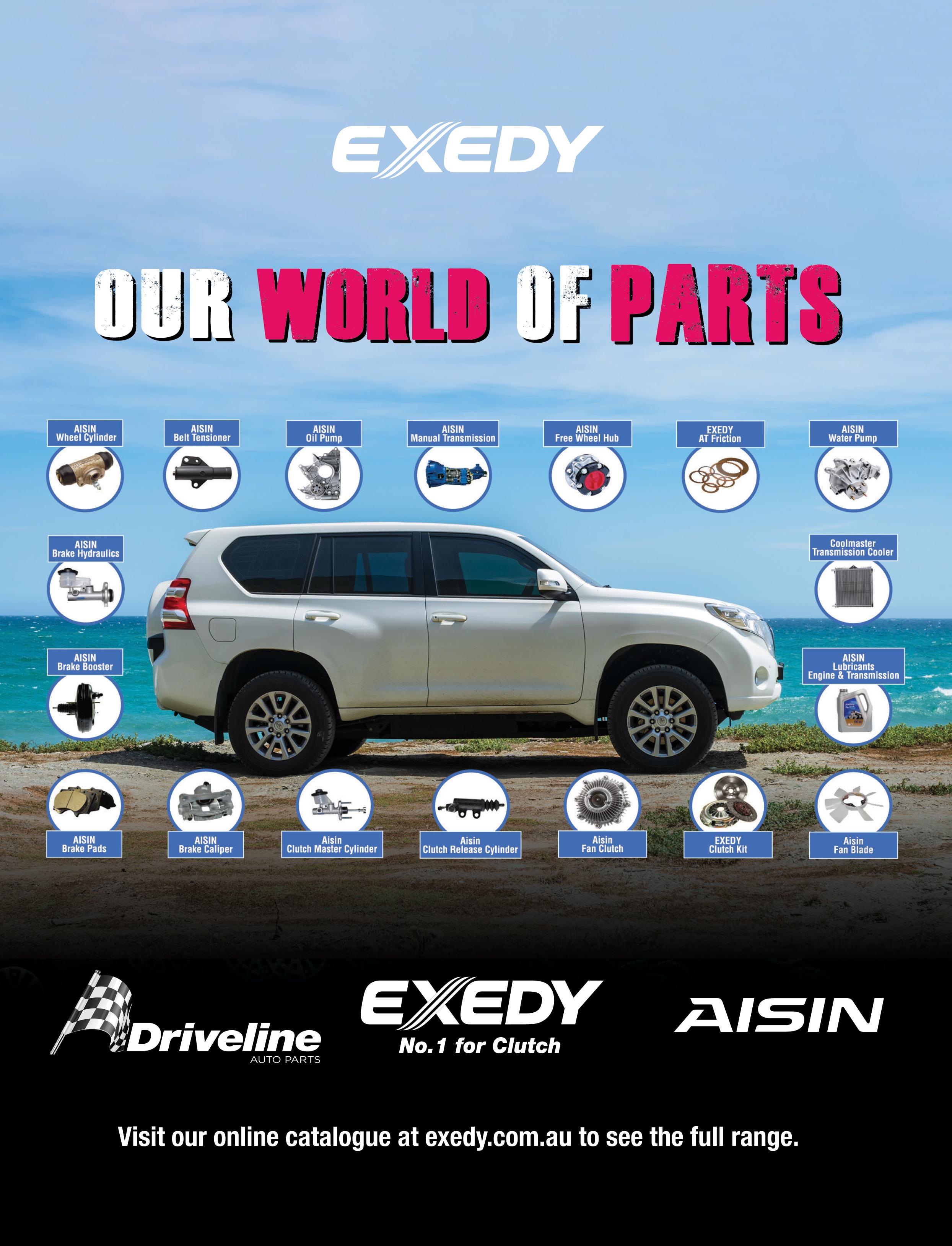

AISIN BRAKING SYSTEM

Stopping you reliably and safely

Exedy says that Aisin is one of the world’s leading manufacturers for Japanese, European and American vehicles. Aisin/Advics braking products are available in Australia through Exedy’s vast network of dealers and distributors.

Brake Booster

• Delivers optimal air pressure to the brake master cylinder. • Provides precise pedal feel to help prevent driver fatigue. • Manufactured with the highest quality materials to ensure safe operation. • Engineered to exacting OE specifications. • Maximises durability.

Brake Pads

• Consistent braking performance using carbon ceramic friction material. • Designed and manufactured under OE specifications assuring superior quality. • Quiet, smooth, and low dust operation under all braking conditions.

Brake Caliper

Compared to drum brakes, Exedy says disc brakes offer better stopping performance due to improvements in cooling efficiency. Therefore, discs are less prone to the brake fade caused by overheating. Features include: • OE quality. • Offers improved stiffness and brake noise and vibration performance. • Quiet and smooth operation under all braking conditions. • Lighter weight and greater resilience using mono-body design.

Brake Rotors

Constructed with expert machining to achieve tight, precise tolerances that eliminate judder, vibration, distortion and assure smoother stops, Exedy says Aisin Rotors are engineered to provide high heat dissipation for maximum friction and overall high braking performance. Features include: • High carbon evenly distributed through steel for consistent heat diffusion and better fade. • Resistant to higher temperatures. • Ensures thermal stability and optimised friction characteristics for durability and long life.

For more information, visit www.exedy.com.au

TUFF CLUTCHES FOR SERIOUS PERFORMANCE

Exedy says its Sports Tuff Clutches are great all rounders

The Sports Tuff range of performance clutches from Exedy are said to be perfect for applications requiring extra torque capacity. “Our extensive Sports Tuff range has been designed for drivers who have modified their engines to deliver more performance with the confidence they need to get the torque to the ground reliably,” Exedy Senior Product Manager, Mark Davis, said. Exedy’s extensive Sports Tuff Range offers solutions to for a wide variety of applications. “The Sports Tuff range is one of our largest. It includes clutch kits covering the full spectrum of uses and performance requirements, for those who just need additional torque capacity for towing, right though to the driver who has seriously increased their engine torque output,” Mark said. Exedy’s Sports Tuff range offers three levels of performance: HD Sports Tuff, with the HD suffix indicating that they are suitable for Heavy Duty applications; the Heavy Duty Cushion Button selection; and the Heavy Duty Button range which boasts the highest torque capacity of Exedy’s Sports Tuff performance range. With three levels of performance, Exedy says its Sports Tuff range is certainly the first point of call for those drivers looking to upgrade clutch performance. To leverage the growing popularity of bolt on performance modifications, Exedy also offers the Devil Clutch. Designed to handle significantly higher torque loads whilst maintaining smooth engagement and low pedal effort, the Devil Clutch range is limited to a handful of popular vehicles where a requirement for a specialised clutch system exists. “It is super tough and delivers a massive increase in clutch cover clamp load, which is vital in any vehicle with performance upgrades.” Mark said. “The inclusion of a dual friction design clutch disc results in a significant increase in clutch torque capacity.” Exedy has taken its “No 1 for Clutch” message to the racing circuits of Europe and The United States through professional Drift driver Karolina Pilarczyk who hails from Poland and was a double champion of Queen of Europe in 2016 and 2017. In 2019, Karolina took part in more than 20 Motorsports events and 17 rounds around the world. She closed an intense season by conquering ninth position among almost 100 of the best drivers in Europe in the European Vce Championship in the women’s league. Besides, Karolina was the only woman from Europe taking part in Formula Drift in the United States. “While I am drifting, I use many techniques that require using a clutch that is strong, reliable and durable. Our choice is Exedy clutch,” Karolina said.

For more information, visit www.exedy.com.au