18 minute read

Brake & Clutch

ENHANCE YOUR BRAKING PERFORMANCE

Pedders Suspension and Brakes has just released a new braking product

To enhance the braking performance of the Landcruiser 70 Series, Pedders Suspension and Brakes says it has released an exciting new product: The TrakRyder Brake Booster. “After extensive Australian development and engineering, we are proud to offer our TrakRyder Brake Booster to suit the Landcruiser 70 series ABS models from 2012 to current plus Non-ABS models made from 2000 to 2012,” Pedders Suspension and Brakes Managing Director, Scott Pedder, said. “With a significant increase in braking performance by up to 30 percent, the TrakRyder brake booster kits are available at your local Pedders Suspension and Brakes outlet. “We invite you to talk to us today about supply and installation of these brake booster kits to suit your Toyota Landcruiser 70 series. “These are a must-have addition for those vehicles that tow and carry loads regularly. Improve the braking feel and performance on your Landcruiser with TrakRyder today!”

Key features and benefits:

• Increasing braking performance by up to 30 percent • Designed and engineered in Australia • Reduced pedal effort and improved stopping power • Direct bolt on replacement • Includes fitting instructions • Includes engineering compliance letter and

QLD LG1 design code approval number • Full ADR35/05 compliant brake test available to Engineers or Transport Authorities for sign off • Ideal for load carrying and towing vehicles with GVM of up to 4380kgs (ABS) and 4310 (Non ABS) • Two-Year, 40,000km Nationwide Warranty

For more information, visit www.pedders.com.au

CLUTCH INDUSTRIES TALKS PERFORMANCE UPGRADES

Including the benefits of its innovative ER² design

While OE vehicles come fitted with a standard clutch, Clutch Industries explains that if an engine is modified from standard to improve performance, or if the vehicle is under a higher strain than normal (such as carrying or towing heavy weight), an upgraded clutch might be needed.

Clamp Load

Clutch Industries explains that increasing the clamp load on the cover assembly is a common way to get more torque capacity from your clutch system. It involves increasing the load exerted by the diaphragm to clamp the clutch disc between the pressure plate and the flywheel. The amount of clamp increase is limited as this can make the clutch pedal feel heavy and put strain on the clutch actuation system (hydraulics or cable etc).

Friction Material

Changing the friction material on a clutch disc can increase the torque capacity and can improve the heat properties. Common clutch disc materials include Organic, Aramid and Cerametallic/Ceramic.

Increasing surface area

Increasing the size or the surface area of a clutch increases the torque capacity of the system, however unlike brakes, you’re generally not able to simply install a larger clutch. Clutch Industries explains there are two methods that are used by performance clutch manufacturers to increase the surface area: multiple plates, and its ER² design, as described below.

Multiple Plates

Installing a twin or triple plate clutch system in most cases can be done without modifying the bellhousing and can double or triple the torque capacity without a detriment to the drivability. The Mantic Track series by Clutch Industries has a range of twin and triple plate kits which feature several different plate and friction material options for applications from street to track.

Clutch Industries’ innovative ER² design

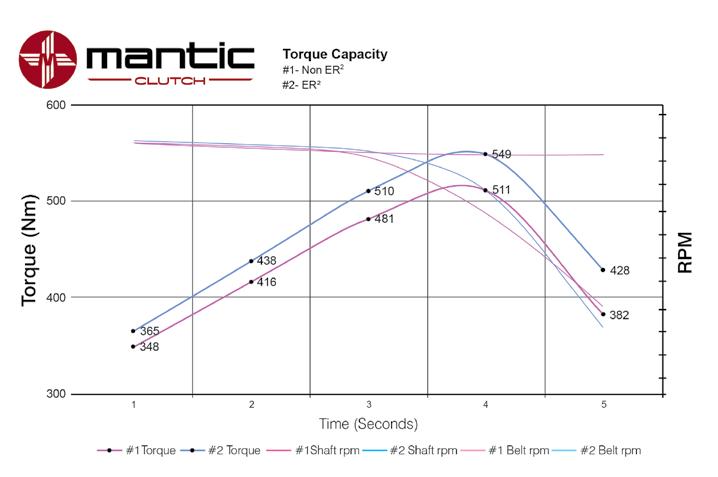

Every now and then a genuine innovation comes along for a product that has basically remained unchanged for many years. Clutch Industries says such an innovation can be found in its performance clutches with ER2 Groove Design. This groove is a patented system that has been specifically designed to increase the mean effective radius of the pressure plate and assist in heat removal. The increase in the mean effective radius of the cover assembly gives a signification increase in the torque capacity of the clutch. Clutch Industries explains that 4Terrain and Mantic Stage Cover Assemblies with the Patented ER2 Groove Design feature a unique groove pattern which is CNC machined on the friction face of the pressure plate. Clutch Industries explains that the ER2 groove has been specifically designed to increase the Mean Effective Radius of the pressure plate and assist in heat removal. The increase in the Mean Effective Radius of the cover assembly reportedly gives a significant increase in torque capacity. By adding the groove to the pressure plate, Clutch Industries explains the inside radius of the friction face has effectively been increased. It states the first 5/16 inches (7.9375mm) of the pressure plate has all but been removed and added to this, there is progressively less material removed as the radius increases. It explains the net effect of this is to move the effective inside radius further out. When comparing the Mean Effective Radius (Rm) of the ER2 version to the non ER2 version, Clutch Industries says you can see the ER2 version is further out. It explains this increases the torque capacity of the clutch, stating that torque capacity is directly related to Rm, so the greater Mean Effective Radius, the higher the torque capacity.

For more information, visit www.clutchindustries.com.au

WILWOOD BRAKE FLUIDS

Available now from Rocket Industries

Wilwood Engineering is well known for manufacturing high-performance disc brake systems and accessories. Rocket Industries here in Australia is a factory appointed distributor for the full wildwood range. Part of the Wilwood range is the following three high-quality Wilwood brake fluids.

Wilwood Brake Fluid has been specially formulated for racing applications where brake systems consistently operate at very high temperatures. In addition to guarding against vapor lock, EXP Super Hi-Temp 600 Plus Racing Brake Fluid maintains its viscosity and lubricity under extreme temperatures for maintaining brake system reliability and performance. EXP Super Hi-Temp 600 Plus Racing Brake Fluid conforms to, and exceeds US specification FMVSS No. 116 DOT 4. Its typical dry boiling point is 594° F (312°C), and its typical wet boiling point is 399° F (204°C). EXP 600 plus has reportedly been proven to “maintain firm pedal feel and quick response, long after others have failed.”

Hi-Temp° 570 Racing Brake Fluid

Wilwood’s specially formulated Hi-Temp° 570 Racing Brake Fluid has a minimum 570°F (298°C) dry boiling point to withstand the severe heat requirements of automotive racing. HiTemp° 570’s low viscosity allows easy bleeding of your brake system, eliminating aeration of the brake fluid caused by foaming due to excessive pumping of the pedal. Hi-Temp° 570 comes in convenient 12-ounce containers hermetically sealed to guarantee against unwanted absorption of moisture which can drastically lower the fluid’s boiling point (fluid from larger containers tends to become contaminated with moisture, lowering its boiling point and making it unsuitable for racing applications.

Wilwood Five Brake Fluid

Wilwood’s DOT Five is a highly refined silicone brake fluid, formulated to preserve the looks and reliability on classic vehicles and show cars. Its non-hygroscopic blend blocks moisture absorption to inhibit internal system corrosion. It is also paint friendly and will not harm most custom finishes should a spill or leak occur. Wilwood Five is said to provide superior lubrication for all brake system wear surfaces with long life from the master cylinder and caliper pistons, bores, and seals. It is a fully DOT 5 compliant fluid meeting or exceeding FMVSS 116 and MILPRF- 46176B-DOT specifications, and can be used in any vehicle that is OE specified for DOT 5 use. Wilwood does not recommend using DOT 5 fluid in any racing applications.

To purchase or for more information on all Wilwood products, please visit www.rocketind.com or call 02 8825 1900.

BENDIX ULTIMATE+ BRAKE PADS

For sports and high-performance vehicles

Brake specialist Bendix has developed the Ultimate+ range of high-performance disc brake pads specifically for sports and highperformance vehicles. Upgraded from the Ultimate range, Bendix says the Ultimate+ range provides even greater stopping power utilising an advanced ceramic formulation. It says this provides the added advantages of even greater resistance to brake fade at high temperatures, low braking noise, and new levels of low dust generation.

Under extreme conditions, Bendix states the new brake pads deliver consistent brake pedal feel, even after a hot lap. Incorporating the Bendix Blue Titanium Stripe for instant friction without the need for bedding in the brakes on installation, the new brake pads are designed and developed for use with slotted rotors. For ease of fitment, the Bendix Ultimate+ brake pads come complete with Bendix proprietary brake shims featuring nitrile rubber coating that absorbs noise and vibration. This latest development draws on Bendix’s latest OEM research and development experience, with Bendix stating its Australian engineers continue to bring leading edge products to the aftermarket.

For more information on the new Ultimate+ Disc Brake Pads, free call the Bendix Brake Advice Centre on 1800 819 666 or +61 3 5327 0211 from overseas (8am – 5pm Monday to Friday EST), email brakeadvicecentre@bendix.xom.au or visit www.bendix.com.au

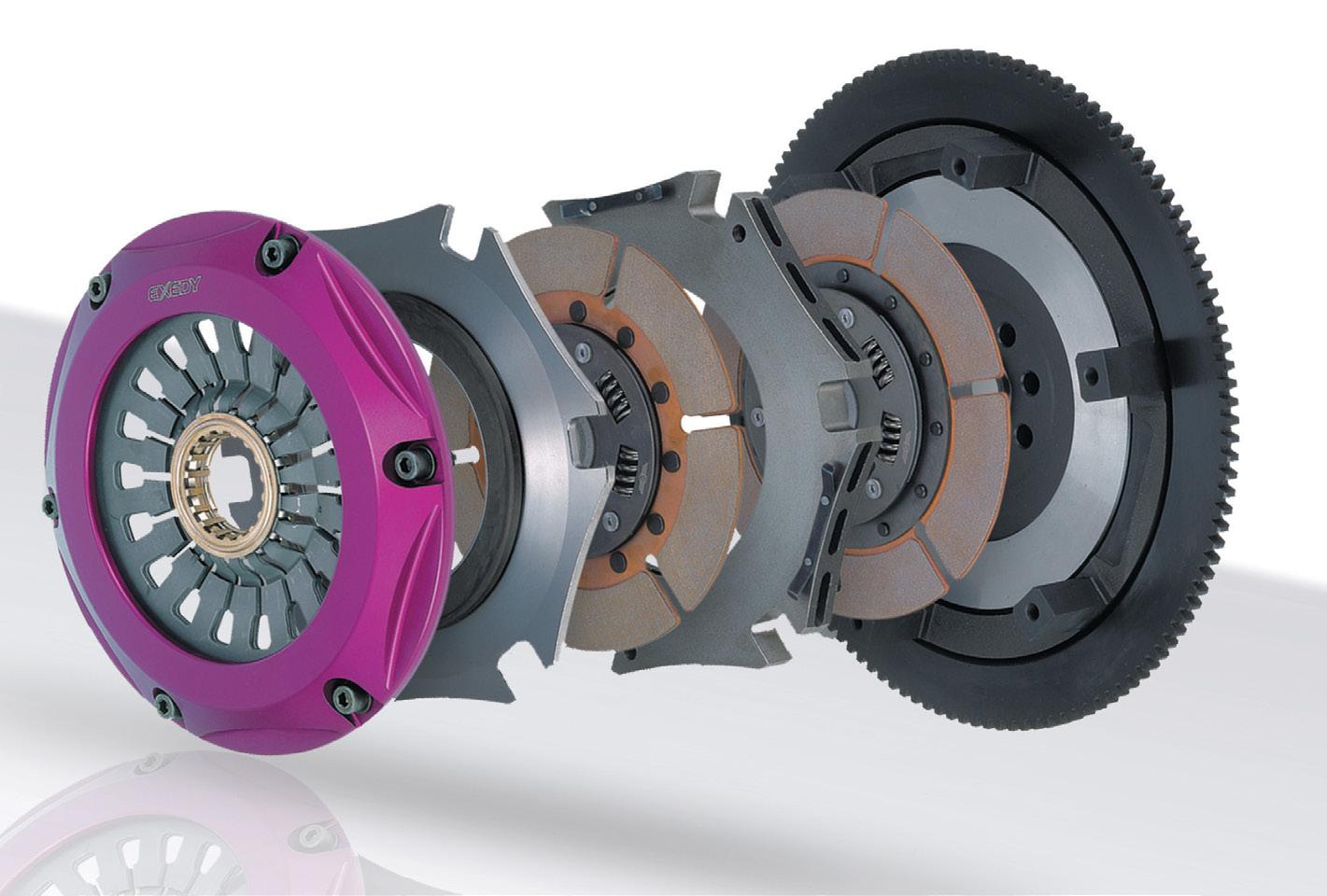

CHOOSING THE CORRECT EXEDY PERFORMANCE CLUTCH

In response to the growing popularity of bolt-on performance modifications, an extensive range of performance clutch kits are available in the market. To shed some light on selecting the correct performance clutch, Exedy says some key considerations can steer you in the right direction. Whether your customer is looking to hit the open road in a vehicle with performance upgrades, or if you are dealing with an amateur drift, circuit, rally or drag racing driver, having a full understanding of each customer’s situation plays a key role. Exedy says you should take into account the following considerations to ensure they get the right clutch for the application. • What vehicle does the customer have? You need to know manufacturer’s exact model, model year, engine size and code, upgrades or alterations. • How much torque does the vehicle make? If the torque output is unknown, investigate on vehicle modifications. Knowing the baseline torque output and basic research on how each additional performance component has affected engine torque will help you figure out the estimated total torque output. • What type of driving is the customer going to be doing? Street driving, street/strip/weekend racer or dedicated race car, serious fourwheel driving, towing a large boat or caravan? Once you know these basics, Exedy says you can recommend the right Exedy clutch-type. It explains the options from Exedy as follows: • Exedy Sports Tuff (HD) – a great option for the “street driver”. A very smooth engaging

clutch that drives similar to the OEM unit, but capable of handling moderate levels of modifications. • Exedy (SO)(SC)(RC) Cerametallic and Sports

Organic disc with sprung hub centre section – an excellent choice for the “street/strip/ weekend racer.” It handles moderate to aggressive levels of modifications and offers a very consistent operation whether being raced or daily driven. • Exedy Hyper Cerametallic disc with sprung hub centre section – Exedy says this is the right choice for the “dedicated race car” or very highly modified vehicles. It offers a very consistent operation; however, chatter and driveline vibrations may be experienced due to the upgraded disc damper and performance ceramic friction material. • Exedy Safari Tuff – ideal for 4X4 enthusiasts.

Purposely engineered to meet the demands of serious four-wheel driving, it comprises a cover assembly which boasts a minimum 25 percent increase in clamp load in comparison to standard. Made of a high-quality clutch disc which has upgraded damper springs and premium grade friction materials. • The Devil Clutch kit – designed to handle significantly higher torque loads whilst maintaining smooth engagement and low pedal effort. It is limited to a handful of popular vehicles where a requirement for a specialised clutch system exists. Exedy Australia says it is globally known for providing the broadest range of performance clutches. It says the Exedy Sports Tuff range is the first port of call for those drivers looking to upgrade clutch performance, offering a range that stands up best to the toughest challenges while delivering the best driving experience.

For more information, visit www.exedy.com.au

XTREME CLUTCH UPGRADES

For Polo GTI and Audi S1

Xtreme Clutch is now offering a motorsport inspired range of performance upgrade kits for the 2015-2018 Volkswagen Polo GTI 1.8L and 2014-2020 Audi S1 2.0L. These small performance vehicles have proven popular for aftermarket upgrades around the world and are now seeing significant increases in power and torque. The Xtreme Clutch upgrade kit has been developed around their 240mm alloy performance pressure plate which has offered a modular solution for a wide range of popular performance cars around the world. Paired to a 4140 chromoly single mass flywheel and with the choice of a sprung organic or sprung ceramic friction disc, these kits have been designed for vehicles that have had significant performance modifications. The kits also come complete with a replacement concentric slave cylinder, flywheel bolts, pressure plate bolts and alignment tool, ensuring the installer has all of the hardware required for the installation and for long term durability. The option of an organic or ceramic friction disc allows vehicle owners to choose a kit best suited to their vehicle use and performance goals. “The sprung organic single plate is ideal for vehicle owners who still drive their car on the street every day and is suitable for vehicles producing up to 600 Nm of torque at the crank,” Xtreme Clutch Mechanical Engineer, Stewart Furze, said.

CIRCO RACING BRAKE PADS

Designed especially for motorsport use

“World class” racing brake pad brand, Circo Racing Brake Pads, is distributed by Motorsport Brakes (MSB) in Australia. MSB explains it acts on behalf of Circo in all racing category supply including for V8 Supercars, the Australian Rally Championship, TA2 Muscle Cars, Touring Car Masters, the RX8 Cup Racing Series and more. “Circo pads are 100 percent manufactured in Japan to world class standards,” Motorsport Brakes Director, Marty Beckton, said. Circo Racing Brake Pads feature proprietary compounds designed for specific applications and standards. The compound range is broad and covers all types of competition. Compounds on offer include: • Circo S83 (friction range 0.30-0.38µ; temp range 0-600°c): this lowmetallic compound is designed for rear applications for circuit use where lower friction braking is required for stability. MSB explains this pad tapers off at higher temps and has very good pad wear and disc wear properties. • Circo S88 (friction range 0.30-0.38µ; temp range 0-650°c): these brake pads feature a low-steel carbon-based compound and are suitable for heavy duty, performance and light enthusiast track day use. MSB says the low steel properties make this pad popular for those looking to upgrade to exceptional performance without compromising on too much comfort. • M119 (friction range 0.48-0.51µ; temp range 50-800°c): this carbonmetallic compound brake pad has been specially formulated for gravel and tarmac rally use, as well as circuit racing where low temperature performance is required. MSB explains the compound has been “The ceramic option has also been included for vehicles being used in motorsport applications where the clutch is likely to experience a high degree of thermal loading.” Australian Clutch Services, the owner of the Xtreme Clutch brand, also offers a range of standard replacement kits for these vehicles under its ClutchPro brand. These kits are available with the original style dual-mass flywheel and include an organic friction disc, pressure plate and concentric slave cylinder. ClutchPro also offers replacement clutch assemblies and installation tools for Dual Clutch Transmission equipped vehicles.

For more information on the Xtreme Clutch range of products, please visit www.xtremeclutch.com.au or call 1800 CLUTCH.

rigorously tested in top level machinery including WRC, S2000 and GpN as well as in historics. It says M119 displays excellent resistance to fade for those longer stages and races, whilst offering brilliant levels of low temperature friction. • M207 (friction range 0.45-0.56µ; temp range 250-920°c): this is the heavy-duty brake pad in the Circo range. MSB says this carbon metallic pad has exceptionally consistent torque characteristics at all temperatures, making it a ‘must have’ for professional circuit racing at the very highest levels. MSB states that the M207 is extremely capable at higher temperatures where other compounds “simply give up.” Motorsport Brakes (MSB) explains it was established to supply premium brake friction products to the Australian and NZ performance and competition markets. All Australian distribution of Circo products is warehoused at the MSB base in Yatala, Queensland. The business operates inventory management software which allows for B2B access by Trade and Wholesale partners for all stock and ‘overnight’ purchases.

For more information, visit www.motorsportbrakes.com.au

NEW CHAPTER FOR DBA

Disc Brakes Australia has become the official Brake Partner for Tickford Racing

The leading Australian brake technology company has opened a new chapter in its motorsport history by becoming the Official Brake Partner for Supercars outfit Tickford Racing in 2021, with the brand to feature prominently on all three Mustangs. “We’re excited to increase our involvement in motorsport, working closely with the drivers and the whole team at Tickford Racing,” Disc Brakes Australia (DBA) Marketing Manager, Lars Mehlan, said. “Particularly Cam Waters, who will also be sporting our colours on his race suit in 2021, had an incredible season last year. “We believe there is a lot of potential in this team, and its professionalism and commitment to success make this partnership a great fit for our brand.” It is a reunion of sorts between the two companies. “This collaboration is a continuation of our history as an engineering partner and manufacturer for Tickford performance cars, which started back in the 1990s and saw DBA supply the brake rotors for the Falcon TE50, amongst others,” Lars said. “More broadly, it underlines our long-standing commitment to Supercars, the pinnacle of Australian motor racing.” Tickford Racing Chief Executive Officer and Team Principal, Tim Edwards, welcomed DBA as the team’s newest addition. “We are delighted to welcome DBA into the Tickford family. DBA’s desire to remain on the cutting edge is no different from our own as a race team,” Tim said. “This is why they lead the industry with technical innovations and numerous awards to their credit. In a year that many of us are looking to embrace Australia, it is exciting to join forces with an Australian brand that has gained worldwide recognition, and we’re looking forward to achieving success together in 2021.” Along with support of the race team, Tickford and DBA will also explore opportunities to include DBA brake pads and rotors in future Tickford vehicle enhancement packages. “An exciting part of this partnership is the opportunity to build on our historic engineering and manufacturing relationship and work towards putting DBA products into the road cars we work on,” Tim said. “DBA offers a variety of premium braking products that are in line with the premium quality vehicle enhancements we provide, so we see a lot of potential here for the future.”

For more information on the DBA range of aftermarket performance products, contact DBA on 1800 730 039, email marketing@dba.com.au, or visit www.dba.com.au

SAFETY AND PERFORMANCE

With TRW Brake Fluids

Amongst the latest developments in automotive manufacturing is the inclusion of advanced braking systems in most new cars, including electronic stability programmes (ESP). As ESP technology develops, brake fluid needs to act quickly to maximise the performance of the system and prevent the car from skidding. Whenever drivers use their brakes, the brake fluid heats up and, as brake hoses get older, the amount of moisture that gets into the system increases, resulting in a lowering of the brake fluid boiling point. If the brake fluid reaches boiling point through the use of the brakes, ‘vapour lock’ will occur, which can result in brake failure. This is why it is important to change the brake fluid of a vehicle on a regular basis, with ZF Services Australia recommending workshops regularly check a vehicle’s brake fluid, with annual changes advised. Available through ZF Services Australia is TRW’s extensive range of brake fluids, which cater for a wide range of vehicles, including those with drum brakes through to high-performance vehicles with ESPs. Driven by safety, all TRW brake fluids are tested to the extreme and exceed international DOT specifications. ZF Services Australia says this means that all TRW brake fluids deliver higher performance in safety critical areas including boiling points and viscosity performance, as well as offering better anti-corrosion and rubber performance. TRW’s brake fluids reportedly incorporate the latest technology to make vehicles safer, with a blend of advanced lubricants, stabilisers, antioxidants and corrosion inhibitors to help minimise wear and maximise performance. The range includes: • DOT 3: DOT 3 brake fluid from TRW is designed for vehicles with front and rear drum brakes, as well as hydraulic clutch systems. Additionally, some Japanese car manufacturers recommend DOT 3 brake fluid for their vehicles with ABS and ESP. • DOT 4: TRW recommends the DOT 4 brake fluid for vehicles with disc brakes on the front and drum brakes on the rear. DOT 4 is also suited for vehicles with disc brakes all round as well as those fitted with ABS. The special

DOT 4 ESP has been added to the TRW range to offer support for vehicles fitted with ESP and ABS. While for high-performance vehicles, TRW recommends the DOT 4

GT brake fluid, which has been designed specifically for racing applications. • DOT 5.1: The latest in brake fluid innovation from TRW, the DOT 5.1 ESP is ideal for heavy, high performance cars, providing an extra level of safety, which can cope with ambient temperatures from -50oC up to +50oC. DOT 5.1 ESP has been designed to complement the very latest ESP, with the low viscosity of the brake fluid allowing for a faster increase and decrease of the pressure needed for varying braking demands.

For more information, visit www.trwaftermarket.com or contact ZF Aftermarket via +61 (2) 9679 5555.