12 minute read

Suspension & Handling

BOOST YOUR SUSPENSION KNOWLEDGE

With Mark Larkham and Nolathane

For more than three years, Nolathane and Mark Larkham have enhanced the suspension knowledge of in excess of 3000 industry members via the Nolathane Academy. The primary objective of the online learning portal is to improve the suspension category knowledge base at all levels of the industry; be it mechanics, apprentices, call centres, counter and field sales, purchasing through to category management.

A big part of this initiative was the use of Mark Larkham, who has proven very effective for Nolathane since coming on board as the Technical Ambassador three years ago. “Try and find a better technical expert who can simplify and explain complex designs, terminology and the application of a product than Mark Larkham,” Nolathane Marketing Manager, Andrew Nolan, said. “The guy continues to be highly regarded firstly among motorsport fans but even more so among the industry where mechanics, parts interpreters and technicians are needing continual learning to support their careers.” The modules are short one-to-two-minute videos followed by a multiple-choice question and answer format. “We have certainly taken on board the time pressures of the market, so we have developed very short and to the point content that delivers the key information we wish those completing to retain. The first module ‘Introduction to Nolathane’ can be completed in 15 minutes, so we are not talking hours to complete,” Andrew said. “On successful completion, Nolathane proudly issues a personalised certificate that we hope becomes part of any individual’s key learning achievements.”

For more information, visit www.nolathane.com.au/academy.php

Toperformance Products is the sole Australian importer of KONI shock absorbers. It distributes KONI through a number of interstate distributors and directly to the trade in Victoria. Toperformance Products explains that KONI is “about people’s mobility.” It states KONI has been a pioneer in this field since 1857, providing leading, durable and experience-improving technology. It says KONI has established itself as the brand of choice for high quality products and has been producing telescopic shock absorbers since 1948. “KONI helps people move comfortably at whatever speed they desire, wherever they are. KONI is everywhere from passenger cars to trains to military and industrial applications,” Toperformance Products National Sales and Operations Manager, Glenn Clemann, said. “Being used in the most extreme conditions, including the dry Sahara desert and the freezing poles, proves that KONI dampers perform when tested. “As undisputed industry leaders, KONI’s technical capabilities and skills develop, manufacture, and sell high-quality and topperforming hydraulic shock absorbers and suspension systems. “KONI’s goal is to create the best experience for everyone on the move.” In the early fifties, KONI decided to play a more prominent role in motorsports in order to enhance the company’s reputation. In 1955, KONI participated for the first time in the Tulpenrally, a Dutch organised rally with international status. Rally was just the beginning and KONI soon after began its racing career, entering Formula 1. In 1956, while at the famous Nordschleife in Germany, KONI assisted the Ferrari team in solving their suspension problems. The first Grand Prix that KONI officially participated in was in 1958 with Ferrari. After that, the business expanded quickly and in 1971, KONI achieved its first World Championship win, as Tyrrell Ford won the driver’s and constructor’s championship. Over time, KONI has not only improved ride control for rally cars and racing cars, but has also dedicated its expertise to improving the damping in various other commercial vehicles, and even for industrial projects like bridges. “Fast forward to today and KONI has a myriad of race driven achievements attributed to its name,” Glenn said. “KONI is also the industry leader in ‘value per kilometre’ dampers for heavy commercial applications and the damper of choice for anyone in the automotive aftermarket and racing scene who desires durability, adaptability and performance.” Toperformance has recently relocated to Dandenong South and welcomes any KONI enquiries.

For more information, visit www.toperformance.com.au

KONI SHOCK ABSORBERS

Available from Toperformance Products

ROADSAFE REPLACEMENT CONTROL ARMS

Innovative new product to save workshops time and money

Roadsafe, one of Australia’s leading undercar component suppliers for the automotive aftermarket for over four decades, has introduced a suspension replacement innovation that it says will save workshop’s labour, time and money while ensuring an accurate and complete control arm and related bushings replacement. Roadsafe Replacement Control Arms are said to ensure that general automotive technicians and suspension specialists can fit a completely brand new, high quality control arm as a bolt-in replacement with no pressing required. The use of Roadsafe Replacement Control Arms reportedly reduces suspension component fitment issues, by eliminating the process of fitting new parts into unknown worn components. Roadsafe explains that whether the reason for repair is worn suspension arm bushes or a worn ball joint, the other components fitted to the arm have done exactly the same amount of work over its lifespan, so in reality while still serviceable, these components could be on borrowed time, requiring dismantling a second time in the near future. Another complication with modern vehicles is the use of what are referred to as “time positioned” bushes. This is where the centre hole is offset rather than being dead centre of the bush. Roadsafe explains the complication here is when pressing in a new bush, the positioning of the bush is absolutely critical and if pressed in only a few degrees out can lead to alignment issues, harshness, noise and most importantly, shortened service life of the bush which usually leads to a come-back job. To eliminate all of these issues and create a better result for your customers, while saving workshop time for your business, Roadsafe says you can replace the complete suspension arm and “get the job right the first time.” Available from Burson Auto Parts stores nationwide, Roadsafe says it offers a vast range coverage across almost five million vehicles for these innovative suspension repair components. Applications cover a wide variety of vehicles with the range constantly expanding to meet Australian car parc replacement requirements. The Roadsafe Replacement Control Arm range includes upper arms, lower arms, radius arms and strut rods across both front and rear replacement applications. The quality of these automotive aftermarket suspension components is backed by a 40,000-kilometre, two-year warranty. As parts of Australasia’s largest automotive aftermarket company, Bapcor Limited, Roadsafe and Burson Auto Parts say they are enhancing the proud Australian company’s commitment to automotive repairers nationwide with this new Roadsafe product range.

To find out more about the Roadsafe Replacement Control Arm range, call your local Burson Auto Parts store on 1300 BURSON (287 766) or visit www.roadsafe.com.au

MEYLE-HD CONTROL ARM

For Mercedes-Benz W205

Mercedes vehicles with complex multi-link axles are susceptible to high levels of wear and tear. The ball joints, in particular, can fail prematurely, thus impairing driving safety and causing costly repairs with relatively low mileage. Meyle says this is where Meyle-HD comes into play, offering better durability for a longer service life. The Meyle-HD control arm for Mercedes W205 models has reportedly been technically enhanced by Meyle engineers to meet the highest quality standards for the high weight load on Mercedes vehicles. The special feature is the increased ball diameter of the Meyle-HD ball pin, which reduces the surface pressure and thus wear. During the optimisation process, Meyle says its experts not only focused on the function but also on the condition, stating that an inductive heat treatment has made the ball stud even more resistant to friction and wear and therefore simply lasts longer than the OE part.

Meyle states the high-performance grease used is also designed for a long service life and supports optimum functionality while a newly designed plastic seat ensures a perfect fit. As a manufacturer of high-quality steering and suspension parts, Meyle says its products come with 25 years of technical know-how and that it offers a complete range of products for almost all aspects of steering and suspension. Meyle says that its award-winning and cleverly designed Meyle-Kits also save time and money in daily workshop business. It states that quality is not only ensured in the in-house quality and testing laboratories in Hamburg, but also in a real “stress test” on the track with renowned racing teams. Meyle-HD parts come with a four-year warranty.

For more information, visit www.meyle.com

BILSTEIN B4 DAMPMATIC

Helping Mercedes suspension ‘stay intelligent’

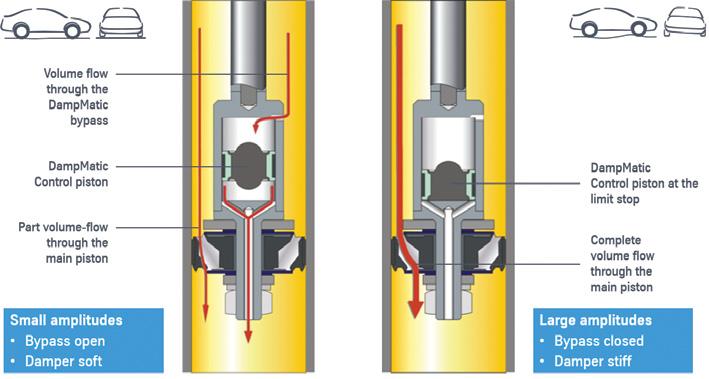

Bilstein says you should watch for DampMatic technology when replacing dampers on a Mercedes, stating that “only with Bilstein does the suspension retain its ‘intelligence.’” For more than a decade, many entry-level Mercedes-Benz models have been equipped with “intelligent suspension” based on a mechanical process. They use the DampMatic technology developed by Bilstein – an amplitude-dependent control system that is fully integrated into the shock absorber. The models concerned are A-Class W168/W169, B-Class W245, C-Class W204/W205, GLC X253 and E-Class W212/W213. However, says Bilstein, this smart feature of the factory suspension is often unknown to independent garages and is hardly recognised when it is removed. After all, no cables or other visual features draw the attention to the DampMatic system. If any aftermarket shock absorber is ordered, Bilstein says the suspension loses its “intelligence,” stating that the only exception is if the workshop has opted for the B4 series replacement shock absorber from Bilstein as it explains that along with the genuine MercedesBenz spare parts, this is the only shock absorber that offers the unique DampMatic system. Bilstein says workshops do not need to take anything else into account when ordering spare parts: if a Mercedes is already equipped ex-works with the amplitude-dependent control system, this also applies to the associated Bilstein B4 DampMatic. It states there is no need to decide between different product variants “with” and “without” and therefore no mistake can be made. So how does the DampMatic exactly work and why should motorists never do without it despite slightly higher costs? Bilstein says the reason is the large damping force spread, which is made possible by a control piston. Bilstein explains that depending on the driving situation, the shock absorber behaves more softly or more firmly. As such, on a well-developed road, the passengers can enjoy outstanding rolling comfort, while on a serpentine road, dynamic attitude and agile handling are achieved. It says the system reacts at lightning speed so that even unexpected evasive manoeuvres can be safely mastered. Driving comfort, agility and safety are thus no longer conflicting demands; rather the centre of gravity is flexibly repositioned according to the situation and necessity. Importantly for the workshop, Bilstein says the installation is just like with any other shock absorber, as no cables, sensors or even an external control unit are required for this semi-active system. The degree of complexity thus reportedly remains pleasantly low and weight is also saved. Bilstein says those who are interested in technology and want to know exactly how it works can imagine it as follows: in the “soft setting,” the damper oil flows through both the main piston and a special DampMatic bypass. If the vibration amplitude increases due to the driving situation, the control piston moves to its stop due to the sudden excitation. It thus closes the bypass, and the entire volume flow is handled by the main spool. As the flow rate is thus reduced, the shock absorber behaves “more tightly.” In the sum of its properties, Bilstein says its B4 DampMatic offers significantly more than a conventional shock absorber, despite slightly higher costs. It states it is the only aftermarket spare part that offers the full performance spectrum of the original suspension and says that when replacing shock absorbers on a Mercedes, workshops should therefore always pay attention to this small but significant difference, which is easily overlooked when ordering parts. Bilstein says if you use Bilstein components straight away, you can be sure that all the features of the original are retained in full.

For more information, visit www.bilstein.com

REVOLUTIONISING TYRE CHANGER TECH

Introducing the Corghi Uniformity – the world’s first diagnostic tyre changer

Corghi Australia says Uniformity is the world’s first ‘Diagnostic Tyre Changer,’ breaking new ground in both safety and efficiency. The Uniformity reportedly halves the number of steps it takes to fit a new tyre. As a result, it delivers “massive increases” in workshop efficiencies in addition to improved workflow and safety. But most importantly, says Corghi Australia, investing in a Uniformity will ultimately increase profitability. Corghi Australia explains that when using current technology, fitting a tyre is a four-step process of Mounting, Diagnostic, Match Mounting and Balancing. It explains that the Uniformity completes the Mounting, Diagnostics and Match Mounting tasks simultaneously, leaving only the balancing to be completed by the operator before the wheel and tyre assembly is ready to be fitted back onto the vehicle. “The Uniformity is the first Tyre Changer that allows match-mounting to be carried out directly on the tyre changer, transforming it into a real wheel diagnosis centre,” Corghi Australia General Manager, Andrew Cornwell, said. “This is essential for the professional who wants to provide clients with a first-class service.” Corghi Australia says the key is the unique variable thrust pressing roller and the precision laser sensor, which delivers a complete diagnostic evaluation of each wheel and/or the entire set of wheels. It analyses the wheel geometry in a loaded and unloaded state, simulating behaviour on the road and favouring driver comfort and safety, in addition to completing the normal tyre mounting and demounting operations. “The Uniformity resolves the vibration problem by providing the tyre fitter with suggestions about how to best mount the tyre on the rim, making it possible to reduce the actuation work time by at least 25 percent and reducing the total time by up to 50 percent when compared with traditional tyre fitters,” said Andrew. Operators are guided step-by-step through the tasks that need to be performed via a modern and intuitive graphic video interface and the machine resolves detected faults by optimising the coupling position between the rim and tyre.

For more information, visit www.corghiaustralia.com.au or call 1800 267 444.