11 minute read

Heating

REDUCING THE ENVIRONMENTAL IMPACT FROM HEATING BOILERS & NOT COST THE EARTH

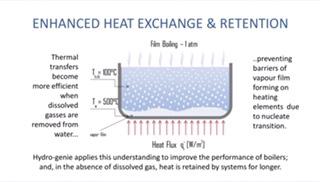

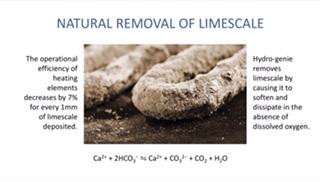

With everyone now carbon emissions. Using proven, coming out of lock patented technology, to dramatically down the Climate improve the heat transfer to the Emergency Declaration circulating heating water, this reduces made by Parliament the amount of carbon emitted and the in 2019 has still to be addressed, all fuel your boiler uses. To do this, the sectors are looking for ways to reduce hydro Genie System uses its unique fluid their environmental impact and could dynamics to induce Henry’s Law, to the also provide financial benefits. circulating water to remove the elements,

Within hospitality, industry, public which slow down the exchange of heat. sector, and at home, keeping the heating The heat that is not being absorbed into on in the colder months is essential. the circulating water, is just going up and

A warm, cosy room is expected by out the flue. The Hydro Genie System also guests, the public and staff as they work, stops rust and sludge from forming, it kills check-in to stay for the night or just at existing rust so that radiators provide up home. A cold building like a hotel, Bed to 20% more heat, Radiators which aren’t & Breakfast or home could see the giving out much heat will start to work fabrics of the building suffer or quickly again. The Hydro Genie System also has see its TripAdvisor ratings go down. onboard dirt separation, to remove any

Across all sectors with wet central magnetic and none magnetic dirt this can heating and hot water requirements be emptied manually or automatically. they all face the challenges of how to Once the Hydro Genie System has reduce carbon emissions. According to removed the elements from the heating the Carbon Trust, just the hospitality water as it passes through each of the and leisure sector accounts for over a Hydro Genie Units the fluid is slightly third of the UK’s energy consumption. compressed providing a temperature lift Heating, is so important to a guest’s of up-to 2-3 degrees, with out burning overall experience, but it contributes any fuel. The Hydro Genie System to the company’s carbon emissions. incorporates its thermal controls which Heating systems also account for up to regulate the now enhanced heat coming 60% of hotel energy bills. So, how do you out of the Hydro Genie Units, overall this keep the heating on and reduce carbon leads to lower carbon emissions, warmer emissions while still making a profit??? rooms and much lower heating bills.

A new low carbon solution recently All whilst customers, enjoy their launched to commercial and domestic buildings achieving their set temperature heat markets, The Hydro Genie System, quicker, happy in the knowledge that works with existing and new, gas, LPG they are warmer, saving money and and oil heating boilers to lower carbon doing there part for the planet. emissions & reduce fuel consumption Not only can the Hydro Genie by up to 35% 1 on commercial heating. Systems provide lower emissions and

On domestic Heat boilers by up to running costs but the commercial 45% 2 depending on the system installed. systems can be fully installed with no Retro-fitted to the flow and return up front cost with the financial savings pipe work of existing wet heating, the paying for the servitised lease.

Hydro Genie System provides lower All Domestic Hydro Genie 1 Tests carried out by Strathclyde EcoSystems and our Commercial Hydro

Innovation Unit on a large secondary school Genie Systems will have there final using a 150mm Platinum Hydro Genie System assembly and dispatch done by & recorded a reduction of 39%* in Gas used. our heroes at Scotlands Bravest 2 The Scottish Government funded SETN, in Manufacturing Company. conjunction with the University of Strathclyde Domestic Hydro Genie Systems carried out a tests on a 3 bed house recording are fully installed at 5% VAT a reduction in gas used of 49.8%* using a www.hydro-genie.co.uk 28mm platinum system.

HEATING BUILDINGS AND ACHIEVING NET ZERO

The recent publication of With the report urgently advocating to waste heat or centralised water, the Committee on Climate the uptake of more eco-friendly heating air or ground source heat pumps, Change’s report into the technology, Steve is advising specifiers resulting in much lower emissions UK’s net zero progress and developers to look into low-carbon when compared to gas-powered third demonstrates a pressing need solutions. “If we are to stay on track generation district heating options. for project specifiers and developers to with our goal of decarbonising the Steve concludes: “Developers need consider low-carbon heating systems. economy, the construction sector to consider both district heating and heat

The CCC’s report into what still must take action now, in line with the pumps if they are to decarbonise at the needs to be done for the UK to reach CCC report’s recommendations. It is pace outlined in the CCC’s report and net zero carbon emissions by 2050 therefore crucial that developers and produce buildings fit for the future. The – a pledge signed into law last year – specifiers evaluate the merits of more release of the Construction Leadership highlights how gas boilers remain a sustainable heating technologies. Council’s post-pandemic ‘Roadmap key obstacle for reducing emissions. By doing so, they can futureproof to Recovery’ earlier this month, which With this in mind, Steve Richmond, both residential and commercial placed net zero at the heart of any Head of Marketing and Technical for developments for years to come.” industry recovery and reinvention plan, REHAU Building Solutions, is advising Examples of more sustainable further prioritises this course of action. key construction stakeholders to further technologies include heat pumps, which “Whether used on an individual, accelerate the decarbonisation process. produce heating and hot water from house-by-house basis, or as the “The passage of the UK’s net zero the sources such as water, air, or the central source for a district heating commitment into law transformed the ground. Hydrogen is often highlighted as system heating a number of buildings, landscape in many industries, including a viable renewable heating technology, heat pumps and district heating construction,” says Steve. “Lower carbon but with workable solutions potentially represent viable options for reducing emissions are now vital concerns for any years away, specifiers should turn emissions in line with net zero targets project, and governs key specification to proven options to lower carbon as the construction sector recovers decisions. Additional legislation such emissions, such as heat pumps. from COVID-19 disruption.” as the Future Home Standard 2025 Fourth generation district heating For further information on are a step towards this goal, but as systems linked to low-carbon sources REHAU’s pre-insulated pipework the CCC’s report shows, there is more can also help markedly reduce carbon systems, and their use in heat pump work to be done – especially with the emissions. Because water flows and district heating networks, visit: current uncertainty about the future through the system at a lower, 40-60oC www.rehau.uk/districtheating renewable heat policy landscape.” flow temperature, it is ideally suited

UNDERFLOOR HEATING INDUSTRY— A BILLION-DOLLAR BUSINESS

Once seen as a luxury investment UFH systems are easily being combined UNDERFLOOR HEATING – underfloor heating – has with heat pumps, gas condensing boilers, BECOMES “SMART” gone mainstream and UFH is now perceived as one of the fastest growing areas in the heating landscape, partly due to soaring energy bills and environmental concerns. With the industry witnessing an unprecedented focus on comfort and efficiency, manufacturers have upped their investments in underfloor heating systems to keep up with requirements of both new-build and refurbishment projects. While the principles of UFH are almost same as they were during the Romans circa 500 B.C., the development in technology pertaining to UFH pipes and in low temperature renewable sources has been grabbing headlines across Europe. UFH, as such, is being designed within the fabric of the building. The trend towards “greener” building systems in advanced economies such as the U.K. and the U.S. has witnessed underfloor heating popularity soar in numerous and thermal solar power systems. A notable uptick in the high net worth individuals in the U.S. and the U.K. may well play a huge role in the adoption of underfloor heating. Countries such as Germany, the U.K., France, the U.S. have been leading the way in terms of installation of UFH systems. HYDRONICS SYSTEM BOOSTS SUSTAINABILITY The year 2020 and the following years are slated to be replete with investments in hydronic UFH systems. Hydronic underfloor heating systems have become popular as a sustainable and energy efficient heating solution. The system is an attractive revenue stream and allegedly works better under several floor surfaces such as stone, marble, carpet, timber and slate. With no dust and cost-effective attributes and ideal for large open areas, hydronics UFH industry outlook is up for a robust projection. Manufacturers of underfloor heating Smart thermostat is also being adopted to offer a cost-effective, optimal, and energy-efficient electric underfloor heating systems. To put things in perspective, smart underfloor heating WiFi thermostat has been making headlines in the U.K and the U.S. and is gradually gaining pace in China, Japan, and Australia. An app controlled WiFi UFH thermostat boosting energy-efficiency of a floor heating system may be the business strategy to woo new consumers. There are unwavering efforts being undertaken by companies to combine underfloor heating with smart intuitive control of heating. Expanding penetration of UFH in the global scale has a lot to do with easier installation in retrofit landscape in electric systems. This will help to rev up installation and reduce disruption. As such, low profile UFH systems that boost flexibility and reduce the impact on floor height have become massively popular. sectors, including residential, commercial have been using sophisticated designs DIY KITS GAIN PROMINENCE and industrial. Mega-trends favouring the and in-screed to boost the quality of UFH WITH RISING RENOVATION expansion of underfloor heating are the use of better thermal insulation within buildings and the transition towards condensing boilers. Underfloor heating has become the next big thing as a highly efficient form of space heating which stems heat via hydronic and electric heating elements embedded beneath the surface of the floor. SCREED AND NO-SCREED SYSTEM Demand for good quality screed, especially in-screed system has surged in the UFH ecosystem as these systems are said to ramp up installation and conduct the heat evenly across the surface of the floor. Installation of a top-quality screed helps to retain the heat for longer hours, thereby improving the energy efficiency and reducing the energy required at the source of the UFH system. Dry fit system, or no screed system that allows UFH to keep up with the heating system and end user’s comfort, has been gaining momentum. Radiant heating systems have become a major revenue generating stream as they are believed to be a quiet, clean, efficient, cost-effective, and dependable way to heat buildings. When it comes to promoting energy efficiency across the value chain, underfloor heating has become second to none, thanks to comfort and energy efficiency that it offers to the consumer. As these systems have high heating capacity even with low flow temperatures, systems. Hydronic radiant heat has become the most sought-after and cost-effective heating system for heating dominated areas. Besides, advanced hydronic systems have been allowing for zoned heating that tends to control temperature in various parts of the buildings. Amidst critics claiming that hydronics cost more than electric UFH systems, it is worth noting that cost of installing a hydronic UFH system depends upon floor covering, the type of installation, location, and size of the home. TRENDY ELECTRIC UFH SYSTEM In retrospect, electric UFH systems were perceived as an expensive and inefficient; however, they have come through the ranks, and have evolved as an efficient and quick responding system. Electric UFH systems have become an ideal choice for single zone renovation and wet rooms. Underfloor electric heating has become a top-notch solution as it does not compromise on any design features and does not emit VOCs. Some of the upsides such as easy installation, adding value to properties, and reducing dust and allergens have augured well for stakeholders vying to expand their portfolios As there is no distribution manifold, electric UFH has become apt for single room refits. Moreover, they provide a low temperature as compared to standard baseboards or radiators, thereby reducing the heating costs. DIY sector for underfloor heating has been gaining momentum in residential sector as high percentage of UFH is being used in new build housing. Further, custom build housing remains a lucrative sector for UFH manufacturers. With renovation witnessing an upward trend in North America, Europe, and APAC, demand for DIY underfloor heating systems has surged drastically in recent years. Consumers are opting for a low-profile UFH system that will help reduce any disruption to fittings and fixtures. Besides, rising trend for DIY UFH has compelled manufacturers to introduce lightweight systems. In areas where space is at a premium, UFH has become an apt choice. Business outlook for UFH industry remains intact as there is a sense of optimism and recovery in the housing market is likely to be witnessed after world turns corner from COVID-19 pandemic. With thermal comfort, environmentally friendly, and energy saving attributes, underfloor heating technologies have become a go-to-solution for stakeholders eyeing to expand their portfolios. UFH has become one of the fastest growing business in the Europe and North America as these systems are being retrofitted; spreading heat consistently; and manage energy usage without compromising on comfort. Billions beckon underfloor heating makers as they have scaled up efforts to mass produce the systems. www.gminsights.com