AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

MachinelearningsystemsbasedonxgBoost andMLPneuralnetworkappliedinsatellite lithium-ionbatterysetsimpedanceestimation

ThiagoH.R.DonatoandMarcosG.Quiles

DepartmentofAppliedComputation,NationalSpaceResearchInstitute, SaoJosedosCampos,P.0Box12227-010,Brazil InstituteofScienceandTechnology,FederalUniversityofSaoPaulo, SaoJosedosCampos,P.0Box12231-280,Brazil

Abstract. Inthiswork,theinternalimpedanceofthelithium-ionbatterypack(importantmeasureofthedegradationlevelofthebatteries)isestimatedbymeansofmachinelearningsystems basedonsupervisedlearningtechniquesMLP-MultiLayerPerceptron-neuralnetworkandxgBoost-GradientTreeBoosting.Therefore,characteristicsoftheelectricpowersystem,inwhich thebatterypackisinserted,areextractedandusedintheconstructionofsupervisedmodels throughtheapplicationoftwodifferenttechniquesbasedonGradientTreeBoostingandMulti LayerPerceptronneuralnetwork.Finally,withtheapplicationofstatisticalvalidationtechniques, theaccuracyofbothmodelsarecalculatedandusedforthecomparisonbetweenthemandthe feasibilityanalysisregardingtheuseofsuchmodelsinrealsystems.

Keywords: Lithium-ionbattery,Internalimpedance,Stateofcharge,MultiLayerPerceptron, GradientTreeBoosting,xgBoost

1Introduction

Thechoiceforthetechnologytobeappliedintheelectricalpowersystem(EPS)is importanttothesuccessofasatellitemissionsinceitrepresentsaround20to30 percentofasatellitetotalmass.

Forouterspaceapplications,lithium-ionbatterieshavelessthanonehalfofthe massofnickelhydrogenbatteriesforthesamestoredenergy[6]and,forthisreason, canreducethesystemweightofaspacecraft,thusimprovingtheloadefficiencyof satellites.Asaresult,lithium-ionbatteriesarehighlyadoptedinthesatellitesof theUnitedStatesandEuropeanSpaceAgency(ESA)[17].Inaddition,lithium-ion batteriesareexpectedtobecomethethirdgenerationofsatellitepowerstorage batteriesforChinasfuturespaceplatforminsteadofNiMHbatteriesandNiCd batteries.

ThereliabilityofLi-ionbatteriesisanimportantissuesduetothefactthat failuresofLi-ionbatterynotonlyresultinseriousinconvenienceandenormousreplacement/repaircosts,butalsocancauseoverheatingandshortcircuitingwhich DOI:10.5121/acii.2018.51011

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

canleadtocatastrophicconsequences,suchasexplosion.Inordertopreventseverefailuresfromoccurring,andtooptimizeLi-ionbatterymaintenanceschedules, breakthroughsinprognosticsandhealthmonitoringofLi-ionbatteries,withan emphasisonfaultdetection,correctionandremaining-useful-lifeprediction,must beachieved[20].

BatteryPHMhasawidevarietyofmeaning,rangingfromirregularmanual measurementsofvoltageandelectrolytespecificcharacteristicstofullyautomated onlineobservationofvariousmeasuredandestimatedbatteryparameters.AnimportantbatteryPHManalysisconsistsofthemeasurementofitsstateofcharge (SOC).Thestateofcharge(SOC)ofLi-ionbatterysetsisafunctionofitsinternalimpedance.Therefore,thestateofcharge(SOC)canbeestimatedthroughthe methodsdescribedonSection2ordeterminedbythebatteryinternalimpedance measurementorestimationalongtheoperatingcycles,asproposedinthisstudy.

2Li-ionbatterystateofcharge(SOC)estimation

Stateofchargeestimationhasalwaysbeenabigconcernforallbatterydriven devicesbutitsdefinitionpresentsmanydifferentissues[3].Ingeneral,theSOC ofabatteryisdefinedastheratioofitscurrentcapacity(Qt)tothenominal capacity(Qn).Thenominalcapacityisgivenbythemanufacturerandrepresents themaximumamountofchargethatcanbestoredinthebattery.TheSOCcan bedefinedasfollows:

SOCt = Qt Qn (1)

Therefore,oncethenominalcapacityisalreadydefined,themethodsdescribed belowintendtoestimatetheactualbatterycapacityaftercharge/dischargecycles.

Thevariousmathematicalmethodsofestimationareclassifiedaccordingto methodology.TheclassificationoftheseSOCestimationmethodsisdifferentinthe variousliteratures.Oneapproachisaccordingtothefollowingcategories[18]:

2.1Directmeasurements

Directmeasurementmethodsrefertosomephysicalbatterypropertiessuchas theterminalvoltageandimpedance.Manydifferentdirectmethodshavebeen employed:opencircuitvoltagemethod,terminalvoltagemethod,impedancemeasurementmethod,andimpedancespectroscopymethod.

Opencircuitvoltagemethod Thereisapproximatelyalinearrelationshipbetweenthe SOC ofthelead-acidbatteryanditsopencircuitvoltage(OCV )given by:

OCV (t)= a1 ∗ SOC(t)+ a0. (2)

Where SOC(t)istheSOCofthebatteryat t, a0 isthebatteryterminalvoltage when SOC =0,and a1 isobtainedfromknowingthevalueof a0 and OCV (t)at SOC =1.Unlikethelead-acidbattery,theLi-ionbatterydoesnothavealinear relationshipbetweenthe OCV and SOC [4].

Terminalvoltagemethod

Theterminalvoltagemethodisbasedontheterminal voltagedropsbecauseoftheinternalimpedanceswhenthebatteryisdischarging, sotheelectromotiveforce(EMF )ofbatteryisproportionaltotheterminalvoltage. Sincethe EMF ofbatteryisapproximatelylinearproportionaltothe SOC,the terminalvoltageofbatteryisalsoapproximatelylinearproportionaltotheSOC [15].Theterminalvoltagemethodhasbeenemployedatdifferentdischargecurrentsandtemperaturesbut,attheendofbatterydischarge,theestimatederrorof terminalvoltagemethodislarge,becausetheterminalvoltageofbatterysuddenly dropsattheendofdischarge.

OncetheLi-ionbatterydoesnothavealinearrelationshipbetweenthe VOC and SOC,thismethodisnotindicatedduetotheestimationerror.

Impedancespectroscopymethod Theimpedancespectroscopymethodmeasuresbatteryimpedancesoverawiderangeofacfrequenciesatdifferentchargeand dischargecurrents.Thevaluesofthemodelimpedancesarefoundbyleast-squares fittingtomeasuredimpedancevalues. SOC maybeindirectlyinferredbymeasuringpresentbatteryimpedancesandcorrelatingthemwithknownimpedancesat various SOC levels[10].

Coulombcountingmethod TheCoulombcountingmethodmeasuresthedischargingcurrentofabatteryandintegratesthedischargingcurrentovertimein ordertoestimate SOC.Coulombcountingmethodisdonetoestimatethe SOC(t) whichisestimatedfromthedischargingcurrent, I(t)andpreviouslyestimated SOC values, SOC(t 1). SOC iscalculatedbythefollowingequation: SOC(t)= SOC(t 1)+ I(t) Qn ∗ ∆t (3)

2.2Machinelearningsystems

Machinelearningsystemconsistsofanapproachwhichusespatternrecognition andmachinelearningtechniquestodetectchangesinsystemstates[12].Withthis approach,fewinformationregardingtotheanalyzedsystemisnecessaryinorder tobuildprognosticmodelsduetothefactthatonlythemonitoreddataitselfis

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

necessarytoelaboratethem.Forthisreason,machinelearningsystemsareadequateto EPS systemswhicharesufficientlycomplexsuchthatdevelopingan accuratephysicalmodelisprohibitivelyexpensive.Asbatterieshavebeenaffected bymanychemicalfactorsandhavenonlinear SOC,machinelearningsystemsoffer goodsolutionfor SOC estimation.However,thisapproachimpliesinwiderconfidenceintervalsthanotherapproachesandrequiresasubstantialamountofdata fortraining.

Afterthedatapreparation,amachinelearningalgorithmshallbeselectedin ordertobuildthemachinelearningsystem.Theselectionofaproperalgorithm foraspecificapplicationisachallengingfactorinapplyingdatadrivenprognostics methods.Examplesofmachinelearningalgorithmsappliedinmachinelearning systemstoestimateSOC:backpropagationMultiLayerPerceptronneuralnetwork (MLP ),gradientboosting(xgBoost),radialbasisfunction(RBF ),fuzzylogic methods,supportvectormachine(SVM ),fuzzyneuralnetwork,andKalmanfilter [16].

Inthisstudy,twomachinelearningsystemswereapplied:MLPneuralnetwork (Section2.2)andgradientboosting(Section2.3)

MultiLayerPerceptron Inordertobuildanalgorithmcapableofclassifyinga labelattribute,theMultiLayerPerceptron(MLP )neuralnetworkcanbeapplied. The MLP consistsofafeedforwardartificialneuralnetworkmodelthatcanbe usedinclassificationorprognosticissues.

TheMultiLayerPerceptronnetworkcontainsthreeormorelayers(aninputand anoutputlayerwithoneormorehiddenlayers)ofnonlinearly-activatingneurons. Eachneuroncombinetheinputsmultipliedbytheircorrespondentweightsand applyanactivationfunctionwhichoutputisdeliveredasinputofneuronsofthe followinglayer[8,Chapter4].

Inmanypracticalapplicationsofartificialneuralnetworks(ANN),thereexistnaturalconstraintsonthemodelsuchasmonotonicrelationsbetweeninputs andoutputsthatareknowninadvance.Itisadvantageoustoincorporatethese constraintsintotheANNstructure[19].ThemonotonicMultiLayerPerceptron network(MONMLP)isanapproachformulti-dimensionalfunctionapproximation ensuringmonotonicityforselectedinput-outputrelations.Moreover,wedetermine therequirementsforthenetworkstructureregardinguniversalapproximationcapabilities.

2.3GradientTreeBoosting

Gradienttreeboostingistypicallyusedwithdecisiontrees(especiallyCARTtrees) ofafixedsizeasbaselearners.ForthisspecialcaseFriedmanproposesamodificationtogradientboostingmethodwhichimprovesthequalityoffitofeachbase learner.

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

Genericgradientboostingatthe m th stepwouldfitadecisiontree hm(x) topseudo-residuals.Let Jm bethenumberofitsleaves.Thetreepartitionsthe inputspaceinto Jm disjointregions R1m,...,RJmm andpredictsaconstantvalue ineachregion.Usingtheindicatornotation,theoutputof hm(x)forinputxcan bewrittenasthesum:

hm(x)= Jm j=1 bjmI(x ∈ Rjm), (4)

where bjm isthevaluepredictedintheregion Rjm Thenthecoefficients bjm aremultipliedbysomevalue γm,chosenusingline searchsoastominimizethelossfunction,andthemodelisupdatedasfollows:

Fm(x)= Fm 1(x)+ γmhm(x),γm = γargmin n i=1 L(yi,Fm 1(xi)+ γhm(xi))(5)

Friedmanproposestomodifythisalgorithmsothatitchoosesaseparateoptimal value γjm foreachofthetree’sregions,insteadofasingle γm forthewholetree. Hecallsthemodifiedalgorithm”TreeBoost”[7].Thecoefficients bjm fromthetreefittingprocedurecanbethensimplydiscardedandthemodelupdaterulebecomes:

Fm(x)= Fm 1(x)+ Jm j=1 γjmI(x ∈ Rjm),γjm = γargmin xi∈Rjm

L(yi,Fm 1(xi)+γ) (6)

RootMeanSquareError Machinelearningsystemsapplymachinelearning techniquesinasupervisedapproach.Consideringanumericlabelattributeinthe estimativeofthebatterysetimpedance,eachobservedvaluecanbecomparedwith thepredictedone.Thisindividualdeviationiscalledaresidualandtheaggregation ofalltheresidualsisdenominatedtheRootMeanSquareError(RMSE),obtained asfollows[9]:

RMSE = n t=1(ˆ yt yt)2 n (7)

Where:

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

2.4Li-ionbatterystateofcharge(SOC)basedonbatteryinternal impedance

AccordingtothedefinitionoftheSOC,thefunctionwhichprovidesthebattery stateofchargebasedonbatteryinternalimpedanceisobtainedasfollows:

SOCt = SOCt0 + t t0 ( η · I Ct ) dt (8)

Where: – SOCt0:estimatedSOCattime t0,whentheestimationprocessstarts

– SOCt:estimatedSOCattime t – η:currentefficiency

– I:current-assumedtobepositivewhencharging – Cn:capacityofthebatteryattime t

Inthisstudy,thebatteryimpedanceisobtainedthroughthemachinelearning systems(seeSection2.2)whichcanbeappliedinthedeterminationofbatterystate ofcharge(SOC).

Baggingoptimization

Accordingtobaggingoptimizationmethod,atraining set Dofsizen isdividedinto m newtrainingsets Di,eachofsizen,bysampling fromDuniformlyandwithreplacement.Samplingthe m newtrainingsetswith replacement,impliesthatsomeobservationsmayberepeatedineach Di[1].

Thiskindofsampleisalsoknownasbootstrapsample.Inordertoobtainthe resultingensembleofmodels,the m modelsarefittedusingtheabove m bootstrap samples.Finally,allthemodelsareappliedtothescoringsetandthelabelsare combinedbyaveragingtheoutput(forregression)orvoting(forclassification).

3MachinelearningsystemsforLi-ionbatteryimpedance estimation

Thisstudyappliestwomachinelearningsystems(MLPneuralnetwork-Section 2.2andgradientboosting-Section2.3)inordertoestimatethebatteryinternal impedanceandcomparestheobtainedresults.

Toperformthecomparisonbetweenthetwomachinelearningsystems,abattery testingdatabaseprovidedbyNASAAmesResearchCenter[14]wasusedasdata set.ThedatabasecomprisessensormonitoringdataofLi-ionbatteriesmountedin batchesof4andrunningthrough3differentoperationalprofiles(charge,discharge andimpedance)atambienttemperaturesof4,24and44Celsiusdegrees(seeSection 4).

Fromtheanalyzeddataset,featureswereselectedtocharacterizethebattery conditionduringacertainperiodoftime(seeSection5).Afterthedevelopment

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

ofthedataset,machinelearningsystemsaretrained(seeSection6),RootMean SquareError(RMSE)performancemetricisusedtoevaluatetheobtainedmachine learningsystems(seeSection9)and,iftheperformancecriteriaareachieved,they canbeconsideredfeasiblesolutionstoestimatethebatteryinternalimpedancein anonlinebasis.

4DatapreparationforLi-ionbatteryimpedanceestimation

Batteryimpedance,whichdecreasesovertheworkingtimeofabattery,isanimportantanddirectindicatorforestimatingbatterystateofcharge(SOC).Inonline orin-orbitapplications,suchaselectricvehiclesandsatellites,thebatteryinternalimpedancemeasurementormonitoringisdifficult[11].Itcanbeusedcharge transferresistanceandelectrolyteresistanceextractedfromEIStoestimatebattery capacity[14].However,thesefeaturescanonlybeobtainedviaofflinetestsunder theoptimalmeasuringconditionsandbyusingspecializedandexpensiveequipmentforEISmeasurements[5].Theresultsoftheagingexperimentshowedthat increaseinbatterycapacitylossorresistanceinalifetimeisrelatedtooperating conditions,suchasvoltage,current,andtemperature.However,inpracticalapplications,severalcharacteristics,suchascurrentandvoltage,arecontrolledtomeet theloadrequirementsofanassociatedcircuitandthuscannotrepresentbattery aging[13].

4.1Li-ionbatterytestingsetinformation

ThefollowingsectionsapplymachinelearningtechniquesinLi-ionbatteryimpedance estimationusingbatterydataprovidedbyNationalAeronauticsandSpaceAdministration(NASA)AmesPrognosticsCenterofExcellence[14],where134rechargeablelithium-ionbatteriesweretested.

ThelaboratorysetupanddatarecordingwereconductedbyNationalAeronauticsandSpaceAdministration(NASA)AmesPrognosticsCenterofExcellence [14].AccordingtoNASAexperiment,the134rechargeablelithium-ionbatteries areorganizedin34batterysets.Eachbatterysetcontainsthetestdataorganized accordingtoFigure2.

4.2Laboratorysetup

TheexperimentalsetupprimarilyconsistsofasetofLi-ioncells(whichmayreside eitherinsideoroutsideanenvironmentalchamber),chargers,loads,EISequipment forbatteryhealthmonitoring(BHM),asuiteofsensors(voltage,currentandtemperature),somecustomswitchingcircuitry,dataacquisitionsystemandacomputer forcontrolandanalysis.Figure1detailstheassemblyoftheequipment.

Fig.1. Laboratorysetup[14]

Thecellsarecycledthroughchargeanddischargecyclesunderdifferentload andenvironmentalconditionssetbytheelectronicloadandenvironmentalchamber respectively.PeriodicallyEISmeasurementswillbetakentomonitortheinternal conditionofthebatteryusingtheBHMmodule.TheDAQsystemcollectsthe externallyobservableparametersfromthesensors.Theswitchingcircuitryenables thecellstobeinthecharge,dischargeorEIShealthmonitoringstateasdictated bythealgorithmsrunningonthecontrolcomputer[14].

4.3Li-ionbatterytestingsetinformation

TheLi-ionbatteriesareorganizedinbatchesof4arerunthrough3differentoperationalprofiles(charge,dischargeandimpedance)atambienttemperaturesof4, 24and44oC[14]:

1.Chargestep:chargingwascarriedoutinaconstantcurrent(CC)modeat1.5A untilthebatteryvoltagereached4.2Vandthencontinuedinaconstantvoltage (CV)modeuntilthechargecurrentdroppedto20mA

2.Dischargestep:dischargingwasconductedinCCmodeuntilthedischargevoltagereachedapredefinedcutoffvoltage.Fixedandvariableloadcurrentsat1, 2,and4Ampswereusedandthedischargerunswerestoppedat2V,2.2V, 2.5Vor2.7V

3.Impedancemeasurement:measurementwasperformedthroughanelectrochemicalimpedancespectroscopy(EIS)frequencysweepfrom0.1Hzto5kHz

Figure2detailsthebatterydatastructureoftheoperationalprofiles.

4.4Li-ionbatteryimpedancemeasurementrectifier

Inordertoeliminatethenoisegeneratedbytime-varyingcurrentpassingthrough anelectro-chemicalcellorbatteryduetoloadfluctuation,afilteringapproachoran

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

Fig.2. Datastructure[14]

electroniccancellationtechniqueshallbeapplied.Inthelaboratorysetupdescribed above,itwasusedanelectronicdevice.

Time-varyingcurrentflowinginacircuitwhichincludesthecell/batteryis sensedexternallytothecell/batterywithamagnetically-coupledaccurrentprobe therebyproducinganinducedtime-varyingsignal.Thisinducedsignalisamplified totheleveloftheoriginaltime-varyingcurrentandappliedtothecell/battery’s terminalsinphase-oppositiontotheoriginalcurrent.Asaresult,thecomponentof time-varyingcurrentflowinginthecell/battery’sexternalleadsassumesanalternatepatharoundthecell/batteryandiseffectivelycanceledwithinthecell/battery itself[2].

5FeaturesselectionforLi-ionbatteryimpedanceestimation

Inthisstudy,the134rechargeablelithium-ionbatteriesareorganizedin34battery sets.EachbatterysetcontainsthetestdataaccordingtoFigure2.ForeachC-D (chargeanddischarge)cycle,thefollowingfeatureswereextracted[20]:

– F1:duringchargecycle,timeintervalbetweenthenominalvoltageandthe cutoffvoltage

– F2:duringchargecycle,timeintervalbetweenthenominalcurrentandthe cutoffcurrent

– F3:duringdischargecycle,timeintervalbetweentwopredefinedvoltages

– F4:averagetemperatureduringthetimeintervalF1

– F5:averagetemperatureduringthetimeintervalF2

– F6:duringdischargecycle,cutoffvoltage

Thehistoricalsetappliedinthemachinelearningsystemsmodelingincludes thesixfeatures(F1,F2,F3,F4,F5andF6)andthelabelattributewhichcorrespondstotherectifiedbatteryimpedance.Foreachmachinelearningsystem,two

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

regressionmodelsarebuiltinordertoestimatetherealandimaginarycomponents oftherectifiedimpedance.Tables1and2areextractionsofthehistoricalsets correspondingtotherealandimaginarycomponentswhichcontain20records(C-D cycles)foreachoneofthe34batterysets(684records-C-Dcycles,intotal).

Table1. Historicalset-impedancerealcomponent

cycleF1F2F3F4F5F6imp re 2008 4 19966.4076422.609472.31327.007426.30082.45560.06175 2008 4 210226.3756627.891472.12525.674226.53232.63210.05989 2008 4 310635.9686528.063472.34425.675426.33252.50100.05919

Table2. Historicalset-impedanceimaginarycomponent

cycleF1F2F3F4F5F6imp img 2008 4 19966.4076422.609472.31327.007426.30082.4556-0.00096 2008 4 210226.3756627.891472.12525.674226.53232.6321-0.00112 2008 4 310635.9686528.063472.34425.675426.33252.5010-0.00105

6Li-ionbatteryimpedancedatamodeling

Afterthedatapreparation,twomachinelearningtechniques(MLPneuralnetwork -Section2.2andgradientboosting-Section2.3)areappliedinordertoestimate thebatteryinternalimpedance.Foreachappliedtechnique,afewtrainingcycles areexecutedwiththevariationofthetechniquehyperparameters.Therefore,each trainingcyclegeneratesaregressionmodelwhichcanbecomparedwiththeother obtainedregressionmodelsbytheapplicationoftheRMSE(RootMeanSquare Error)validationtechnique,accordingtoSection2.3.

7MLPneuralnetworkwithmonotonicityconstraintsmodeling

Tables1and2areusedtobuildtworegressionmodelsbasedonMLPneural networktechnique(Section2.2).

MultiLayerPerceptronneuralnetworkwithmonotonicityconstraintsimplementsonehidden-layerMultiLayerPerceptronneuralnetwork(MLP)modelsthat enforcesmonotonicrelationsondesignatedinputvariables.Eachtrainingcycleapplies10or20ensemblememberstofitand1,2,3or4hiddennodesinthehidden layer.

Theensemblememberstofitineachtrainingcycleareobtainedaccordingto Section2.4.Eachensemblemembercontainsarandomsubsetof70percentofthe

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

trainingsetand,aftergeneratingthe10or20regressionmodels(dependingon thenumberofensemblememberstofit),theresultcorrespondstothemeanvalue obtainedthroughtheapplicationofallregressionmodels.

ThesetrainingcycleswithdifferentcombinationsresultintodifferentMLPneuralnetworkswithmonotonicityconstraints.Thesedifferentcombinationsofthe hyperparametersaredescribedinTable3.

Table3. MLPneuralnetworkwithmonotonicityconstraintshyperparameters

Hyperparameter Description

Possiblevalues hidden1 numberofhiddennodesinthefirsthiddenlayer 1,2,3,4 n.ensemble numberofensemblememberstofit 10,20 monotone columnindicesofcovariatesforwhichthe monotonicityconstraintshouldhold 1 bag logicalvariableindicatingwhetherornot bootstrapaggregation(bagging)should beused TRUE iter.max maximumnumberofiterationsof theoptimizationalgorithm 500

7.1MLPneuralnetworkmodelingwithmonotonicityconstraintsand 10ensemblememberstofit

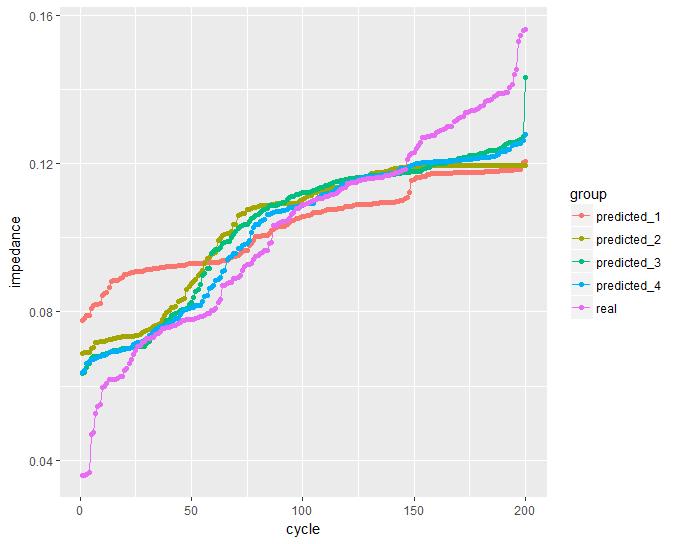

Estimativeofrealcomponentofbatterysetimpedance UsingthebackpropagationalgorithmtoupdatetheMLPneuralnetworkweights,monotonicity constraints,10ensemblememberstofitandusingdifferentnumbersofhiddennodes inthehiddenlayer(1,2,3or4),therealcomponentofthebatteryimpedance throughthecyclesisaccordingtheFigure3.

Estimativeofimaginarycomponentofbatterysetimpedance Usingthe backpropagationalgorithmtoupdatetheMLPneuralnetworkweights,monotonicityconstraints,10ensemblememberstofitandusingdifferentnumbersofhidden nodesinthehiddenlayer(1,2,3or4),theimaginarycomponentofthebattery impedancethroughthecyclesisaccordingtheFigure4.

7.2MLPneuralnetworkmodelingwithmonotonicityconstraintsand 20ensemblememberstofit

Estimativeofrealcomponentofbatterysetimpedance UsingthebackpropagationalgorithmtoupdatetheMLPneuralnetworkweights,monotonicity constraints,20ensemblememberstofitandusingdifferentnumbersofhiddennodes inthehiddenlayer(1,2,3or4),therealcomponentofthebatteryimpedance throughthecyclesisaccordingtheFigure5.

Fig.3. EstimatedrealcomponentofbatterysetimpedanceusingMLPneuralnetworkmodeling withmonotonicityconstraintsand10ensemblememberstofit

Fig.4. EstimatedimaginarycomponentofbatterysetimpedanceusingMLPneuralnetwork modelingwithmonotonicityconstraintsand10ensemblememberstofit

Estimativeofimaginarycomponentofbatterysetimpedance Usingthe backpropagationalgorithmtoupdatetheMLPneuralnetworkweights,monotonicityconstraints,20ensemblememberstofitandusingdifferentnumbersofhidden nodesinthehiddenlayer(1,2,3or4),theimaginarycomponentofthebattery impedancethroughthecyclesisaccordingtheFigure6.

ApplyingtheRMSE(RootMeanSquareError)validationtechnique,accordingto Section2.3,eachmodeldevelopedwiththeapplicationofMultiLayerPerceptron

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

Fig.5. EstimatedrealcomponentofbatterysetimpedanceusingMLPneuralnetworkmodeling withmonotonicityconstraintsand20ensemblememberstofit

Fig.6. EstimatedimaginarycomponentofbatterysetimpedanceusingMLPneuralnetwork modelingwithmonotonicityconstraintsand20ensemblememberstofit

techniqueintheestimativeofrealandimaginarycomponentsofthebatteryset impedancewasevaluatedandthecorrespondingRMSEvaluesarepresentedin Table4.

Increasingthenumberofensemblememberstofit,therewasnoimpactonthe rootsquaremeanerrorforestimatingtherealcomponentofbatterysetimpedance. However,ahighernumberofensemblememberstofitminimizedtherootsquare meanerrorforestimatingtheimaginarycomponentofbatterysetimpedance.

AccordingtoTable4,ahighernumberofhiddennodesonthehiddenlayer minimizestherootsquaremeanerrorforestimatingtherealandimaginarycomponentsofbatterysetimpedance.

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

Table4. MLPneuralnetworkwithmonotonicityconstraintsmodelvalidation

Batteryimpedance Ensemblememberstofit Hiddennodesonlayer RMSE real 20 1 0.0161220600 real 20 2 0.0124101700 real 20 3 0.0100222800 real 20 4 0.0094165090 imaginary 20 1 0.0011236520 imaginary 20 2 0.0007225610 imaginary 20 3 0.0004410664 imaginary 20 4 0.0003257367

TheMLPmodelswiththelowerrootsquaremeanerrorinestimatingthereal andimaginarycomponentsofbatterysetimpedancehavetheconfigurationof20 ensemblememberstofitand4hiddennodesonthehiddenlayerandanRMSE errorof0.0094165090and0.0003257367,respectively.

8Gradientboostingmodeling

Tables1and2areusedtobuildtworegressionmodelsbasedongradientboosting technique(Section2.3).Thetrainingsetisdividedintotrainingandvalidationsets. Thevalidationsetisusedtoevolvetheregressionmodelsduringeachgradient boostingiteration.Eachtrainingcycleappliesan’eta’equalto0.20or0.60to controlthelearningrateandasubsampleratioofthetraininginstancesof0.80, 0.85,0.90or0.95.

Thesetrainingcycleswithdifferentcombinationsresultintodifferentgradient boostingmodels.Thesedifferentcombinationsofthehyperparametersaredescribed inTable5.

Table5. Gradientboostinghyperparameters

Hyperparameter Description

Possiblevalues objective objectivefunction reg:linear max depth maximumdepthofatree 10 eta controlthelearningrate:scale contributionofeachtreebyafactor of0 <eta <1 0.20,0.60 col sample subsampleratioofcolumns whenconstructingeachtree 0.80

ss sample subsampleratioofthetraininginstance. 0.5meansthatxgboostrandomly collectedhalfofthedatatogrowtrees andthiswillpreventoverfitting 0.80,0.85,0.90,0.95

eval metric evaluationmetricpervalidationcycle rootmeansquareerror nrounds themaxnumberofvalidationcycles 200

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

Thehyperparameter’eta’hasanimportantroleinthegradientboostingmodelingsinceitcontrolsthelearningrate.Thisparameterscalesthecontributionof eachtreebyafactorbetween0and1whenitisaddedtothecurrentapproximation. Itisusedtopreventoverfittingbymakingtheboostingprocessmoreconservative. Lowervaluefor’eta’implieslargervaluefor’nrounds’:low’eta’valuemeansmodel morerobusttooverfittingbutslowertocompute.

8.1Gradientboostingmodelingwitheta=0.20

Estimatingrealcomponentofbatterysetimpedance Buildinganensemble ofdecisiontreesinwhicheachdecisiontreeisbuiltinordertominimizetheerror ofthepreviousone(gradientboostingmethod),settingthemaximumdepthofthe treesto10,applyingtherootmeansquareerrormethodasametrictoevolvethe modelwiththevalidationset,controllingthelearningratethrough’eta’of0.20 andsubsettingthetrainingsetinstanceswithdistinctratios(0.80,0.85,0.90or 0.95),therealcomponentofthebatteryimpedancethroughthecyclesisaccording theFigure7.

Fig.7. Estimatedrealcomponentofbatterysetimpedanceusinggradientboostingmodelingwith eta=0.20

Estimatingimaginarycomponentofbatterysetimpedance Buildingan ensembleofdecisiontreesinwhicheachdecisiontreeisbuiltinordertominimize theerrorofthepreviousone(gradientboostingmethod),settingthemaximum depthofthetreesto10,applyingtherootmeansquareerrormethodasametric toevolvethemodelwiththevalidationset,controllingthelearningratethrough ’eta’of0.20andsubsettingthetrainingsetinstanceswithdistinctratios(0.80,

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

0.85,0.90or0.95),theimaginarycomponentofthebatteryimpedancethroughthe cyclesisaccordingtheFigure8.

Fig.8. Estimatedimaginarycomponentofbatterysetimpedanceusinggradientboostingmodeling witheta=0.20 8.2Gradientboostingmodelingwitheta=0.60

Estimatingrealcomponentofbatterysetimpedance Buildinganensemble ofdecisiontreesinwhicheachdecisiontreeisbuiltinordertominimizetheerror ofthepreviousone(gradientboostingmethod),settingthemaximumdepthofthe treesto10,applyingtherootmeansquareerrormethodasametrictoevolvethe modelwiththevalidationset,controllingthelearningratethrough’eta’of0.60 andsubsettingthetrainingsetinstanceswithdistinctratios(0.80,0.85,0.90or 0.95),therealcomponentofthebatteryimpedancethroughthecyclesisaccording theFigure9.

Estimatingimaginarycomponentofbatterysetimpedance Buildingan ensembleofdecisiontreesinwhicheachdecisiontreeisbuiltinordertominimize theerrorofthepreviousone(gradientboostingmethod),settingthemaximum depthofthetreesto10,applyingtherootmeansquareerrormethodasametric toevolvethemodelwiththevalidationset,controllingthelearningratethrough ’eta’of0.60andsubsettingthetrainingsetinstanceswithdistinctratios(0.80, 0.85,0.90or0.95),theimaginarycomponentofthebatteryimpedancethroughthe cyclesisaccordingtheFigure10.

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

Fig.9. Estimatedrealcomponentofbatterysetimpedanceusinggradientboostingmodelingwith eta=0.60

Fig.10. Estimatedimaginarycomponentofbatterysetimpedanceusinggradientboostingmodelingwitheta=0.60

8.3Gradientboostingmodelvalidation

ApplyingtheRMSE(RootMeanSquareError)validationtechnique,accordingto Section2.3,eachmodeldevelopedwiththeapplicationofGradientboostingtechniqueintheestimatingrealandimaginarycomponentsofthebatterysetimpedance wasevaluatedandthecorrespondingRMSEvaluesarepresentedinTable6.

Alower’eta’minimizestherootsquaremeanerrorforestimatingtherealand imaginarycomponentsofbatterysetimpedance.AccordingtoTable6,increasing thenumberofinstancestobeusedinthetrainingprocess,therewasadecrease ontherootsquaremeanerrorforestimatingtherealcomponentofbatteryset impedance.However,ahighernumberofinstancestobeusedinthetrainingprocess

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

Table6. Gradientboostingmodelvalidation

Batteryimpedance ’eta’-Learningrate Subsampleratio RMSE real 0.20 0.80 0.0057317940 real 0.20 0.85 0.0044927730 real 0.20 0.90 0.0034616720 real 0.20 0.95 0.0028836380

imaginary 0.20 0.80 0.0003310718 imaginary 0.20 0.85 0.0006632989 imaginary 0.20 0.90 0.0005046742 imaginary 0.20 0.95 0.0001962272

maximizedtherootsquaremeanerrorforestimatingtheimaginarycomponentof batterysetimpedance.

TheGradientboostingmodelswiththelowerrootsquaremeanerrorinestimatingtherealandimaginarycomponentsofbatterysetimpedancehavethe configurationof’eta’=0.20andasubsampleratioof0.95andanRMSEerrorof 0.0028836380and0.0001962272,respectively.

9Li-ionbatteryimpedancemodelvalidation

AccordingtoRMSEvalidationtechnique(seeSection2.3),theMultiLayerPerceptronmodelwiththehigherperformance(20ensemblememberstofitand4 hiddennodesonthehiddenlayer)andtheGradientTreeBoostingmodelwiththe higherperformance(’eta’=0.20andasubsampleratioof0.95)arecomparedin11 regardingtheestimationoftherealandimaginarycomponentsofthebatteryset impedance.

Fig.11. RMSEStateofcharge(SOC)modelvalidation

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

10Conclusion

Inthisstudy,twodistinctmachinelearningapproacheswereappliedinorderto estimatethebatteryimpedanceofsatelliteLi-ionbatterysetswhichisusedinthe determinationoftheirstateofcharge(SOC)(seeSection2.4).TheobtainedRMSE (RootMeanSquareError)ofbothapproacheshasdemonstratedthefeasibilityof suchmachinelearningsystemsinestimatingLi-ionbatterysetsbatteryimpedance incaseswhereanerrorbelow0.10isacceptable.

However,oncetheobtainedRMSE(RootMeanSquareError)oftheGradient TreeBoostingmodelislowerinestimatingbothrealandimaginarycomponents ofthebatteryimpedance,thisapproachisrecommendedovertheMultiLayer Perceptronmodel.

Acknowledgements

M.G.QthanksFAPESP(Grant2011/18496-7)andCNPq(Grant310908/2015-9).

References

1.J.A.Aslam,R.A.Popa,andR.L.Rivest.Onestimatingthesizeandconfidenceofa statisticalaudit. ProceedingsoftheElectronicVotingTechnologyWorkshop,7,2007.

2.K.S.Champlin.Methodandapparatusforsuppressingtime-varyingsignalsinbatteries undergoingchargingordischarging,111992.

3.Y.Chang,W.Thestateofchargeestimatingmethodsforbattery:Areview. International ScholarlyResearchNoticesAppliedMathematics,2013:1–7,2013.

4.M.Coleman,C.K.Lee,C.Zhu,andW.G.Hurley.Stateof-chargedeterminationfromemf voltageestimation:usingimpedance,terminalvoltage,andcurrentforlead-acidandlithiumionbatteries. IEEETransactionsonIndustrialElectronics,54:25502557,2007.

5.M.Dalal,J.Ma,andD.He.Lithium-ionbatterylifeprognostichealthmanagementsystem usingparticlefilteringframework. Proc.Inst.Mech.Eng.PartOJ.Risk,225:8190,2011.

6.G.J.Dudley.Lithium-ionbatteriesforspace. ProceedingsoftheFifthEuropeanSpacePower Conference,page17,1998.

7.T.Hastie,R.Tibshirani,andJ.H.Friedman. Theelementsofstatisticallearning:datamining, inference,andprediction,volume02.Springer,USA,2009.

8.S.Haykin. Neuralnetworks-Acomprehensivefoundation,volume02.CambridgeUniversity Press,USA,1999.

9.R.J.HyndmanandA.B.Koehler.Anotherlookatmeasuresofforecastaccuracy. InternationalJournalofForecasting,04:679688,2006.

10.R.Li,J.F.Wu,H.Y.Wang,andG.C.Li.Predictionofstateofchargeoflithium-ion rechargeablebatterywithelectrochemicalimpedancespectroscopytheory. Proceedingsofthe 5thIEEEConferenceonIndustrialElectronicsandApplications,page684688,2010.

11.D.Liu,H.Wang,Y.Peng,W.Xie,andH.Liao.Satellitelithium-ionbatteryremainingcycle lifepredictionwithnovelindirecthealthindicatorextraction. Energies,6:36543668,2013.

12.J.LiuandG.Wang.Amulti-steppredictorwithavariableinputpatternforsystemstate forecasting. MechanicalSystemsandSignalProcessing,23:15861599,2009.

13.M.ParvizandS.Moin.Boostingapproachforscorelevelfusioninmultimodalbiometrics basedonaucmaximization. J.Inf.HidingMultimed.SignalProcess,2:5159,2011.

AdvancedComputationalIntelligence:AnInternationalJournal,Vol.5,No.1,January2018

14.B.SahaandK.Goebel.Batterydataset,2007.NASAAmesResearchCenter,MoffettField, CA.

15.S.SatoandA.Kawamura.Anewestimationmethodofstateofchargeusingterminalvoltage andinternalresistanceforleadacidbattery. ProceedingsofthePowerConversionConference, page565570,2002.

16.M.Schwabacher.Asurveyofdata-drivenprognostics. AIAAMeetingPapers,2005.

17.D.Wang,G.Li,andY.Pan.Thetechnologyoflithium-ionbatteriesforspacecraftapplication. AerospaceShanghai,4:5459,2000.

18.N.Watrin,B.Blunier,andA.Miraoui.Reviewofadaptivesystemsforlithiumbatteriesstateof-chargeandstate-of-healthestimation. ProceedingsofIEEETransportationElectrification ConferenceandExpo,pages1–6,2012.

19.H.ZhangandZ.Zhang.Feedforwardnetworkswithmonotoneconstraints. InternationalJoint ConferenceonNeuralNetworks,03:1820–1823,1999.

20.J.ZhangandJ.Lee.Areviewonprognosticsandhealthmonitoringofli-ionbattery. Journal ofPowerSources,196:60076014,2011.

Authors

ThiagoDonatograduatedatElectricalEngineeringfromFederalUniversityofItajub-UNIFEI(2006)andhasworkedduringfiveyearsinprivatecompanies(EMBRAER-aircraftmanufacturercompany-andTOTVS-softwarecompany)developingsolutionswhichapplymachinelearningtechniquesinthe resolutionofmajorissues.Donatoisenrolledinmaster’sat ComputerSciencefromNationalSpaceResearchInstituteINPE(2018).HasexperienceinMachineLearning,actingon thefollowingsubjects:dataandtextpreparationandmining, neuralnetworkandothermachinelearningclassificationtechniques.

MarcosG.QuilesisanAssociateProfessorattheDepartmentofScienceandTechnology,FederalUniversityofSoPaulo, Brazil.HereceivedtheBSdegree,withhonors,in2003fromthe StateUniversityofLondrina,Brazil,andaPh.D.degreefrom theUniversityofSoPaulo,Brazil,in2009,bothinComputer Science.FromJanuarytoJulyof2008,QuileswasaVisiting ScholarinthePerceptionandNeurodynamicsLabatTheOhio StateUniversity.FromJanuarytoDecemberof2017,Quiles wasanAcademicVisitorattheUniversityofYork,York-UK. HewasawardedaBrazilianresearchproductivityfellowship fromtheBrazilianNationalResearchCouncil(CNPq).Hisresearchinterestsincludenature-inspiredcomputing,machinelearning,complexnetworks,andtheirapplicationsininterdisciplinaryproblems.