Page

Page

Page

Page

Page

Page

Page

Page

The UK’s Morris Leslie Plant Hire is kicking off its 50th birthday celebrations in style

The UK’s Morris Leslie Plant Hire is kicking off its 50th birthday celebrations in style by placing an order for a huge fleet of new JCB machines worth 68 million.

The machines will all be supplied throughout 2024 in an expression of confidence in the UK’s housebuilding and construction market.

The substantial order - to be supplied by dealer Scot JCB - includes Loadall telescopic handlers, X Series excavators, mini excavators, compaction rollers and site dumpers. Significantly, the deal also includes 50 JCB backhoe loaders – one for every year Morris Leslie Plant Hire has been in business and a product on which the success of the company was built.

JCB Chairman Anthony

Bamford handed over the keys to one of the backhoes to Founder Morris Leslie –a special Platinum Edition machine produced to mark the JCB backhoe’s 70th birthday. Lord Bamford said: “We are very proud of our long association with Morris Leslie Plant Hire. Like many of our customers, the company has grown from very small beginnings into a force to be reckoned with in the plant hire sector. From one family company to another, we wish Morris Leslie Plant Hire a very happy 50th birthday.”

Morris Leslie said: “Over the years we have bought more than 7,000 JCB machines, so our success over the past half century is very much intertwined with that of JCB and we look forward to building on our partnership in the years to come.”

Scot JCB Sales Director David Park added: “This significant order for new JCB machines in the company’s 50th anniversary year underlines Morris Leslie’s commitment and confidence in the construction industry.”

Perth-based Morris Leslie has 15 depots across the UK with nationwide coverage, and prides itself in having one of the youngest fleets of machines available. The deal comes less than a year after Morris Leslie Plant Hire ordered 87.5 million worth of JCB machines. Morris Leslie founded his company on his parents’ farm in 1974 in the Carse of Gowrie, near Perth, where he began buying and selling construction equipment. Today the company has a fleet of more than 5,000 machines.

Discover a new way of cutting grass with our electric lawn tractors. An unprecedented experience that combines excellent cutting performance.

Discover a new way of cutting grass with our electric lawn tractors. An unprecedented experience that combines excellent cutting performance, easy maintenance, smart handling and a new way of mowing grass. From user-friendly controls to smoother, more comfortable driving over large areas, discover the joy of easy, emission-free lawn care.

Revolutionizing Lawn Care with Innovative and Eco-Friendly Solutions

STIGA has been at the forefront of introducing electric-powered garden equipment, ranging from small machines for home gardens to more complex ones for larger areas. We strive to change the way people approach lawn maintenance, by offering cutting-edge and eco-friendly alternatives.

Explore the benefits of choosing a STIGA electric tractor for your lawn care needs.

1. Designed for very large lawns

Thanks to large cutting decks of up to 108 cm and integrated ePower batteries, our lawn tractors can effortlessly cover areas of 3000 to 7500 m² on a single charge.

Discover the joy of mowing large lawns without interruption thanks

Southam Agricultural Fields Farm, Station Rd, Southam CV47 2DH

t: 01926 813426

www.southamagri.co.uk

to STIGA's advanced ePower battery technology.

Next month we will take a closer look at STIGA ePower technology, so stay tuned!

2. A better cutting experience

Innovation Meets Power: Our Electric Tractors

Years of experience in designing petrol garden machines have culminated in our electric tractors, which offer unparalleled cutting and collection performance, as well as an enhanced gardening experience. Our battery-powered machines have been improved to meet and exceed your expectations.

Eco-friendly Gardening: An improved experience for you, the environment, and the people around you.

Manoeuvrable and precise, they offer a smooth driving experience with no exhaust fumes, less noise, and less arm vibration, guaranteeing a comfortable cutting session. Additionally, with the One Pedal Drive system and the STIGA electric drive, you can control all functions with just one foot, accelerating and decelerating effortlessly and with maximum control. Explore our range of ePower garden tractors and find out more here. Man that is

mowing the lawn with a STIGA electric tractor

Get more power and cutting performance from your batterypowered tractor with less maintenance. In fact, with STIGA electric tractors, you will never have to change spark plugs, air filters, oil, or engine parts again!

3. Smart and intuitive management

Make the most out of your lawn care routine by going hightech. Attach your smartphone to the steering wheel to create a dynamic dashboard, and open the STIGA.GO app. Get real-time advice on how to adjust your mowing to suit your lawn's condition, and receive maintenance alerts to stay informed about your tractor's status. You can even contact your dealer directly through the app in case you need any help.

The Long-term Benefits of Switching to an Electric Lawn Tractor

Choosing an electric lawn tractor is a smart investment in both environmental and economic terms. By opting for battery power, you can help reduce greenhouse gas emissions while mowing your lawn. This is especially important as we transition to more eco-friendly solutions. Plus, electric tractors often have lower running costs due to reduced maintenance.

A Massey Ferguson 8735 has received a specially commissioned wrap and cab modifications to match new trailed woodchipper

AMassey Ferguson 8735 has received a specially commissioned wrap and cab modifications to match its new trailed woodchipper and continue raising funds for two cancer charities.

The MF tractor and Mus-Max chipper have been purchased by Martin Wiles, who owns CFTS Ltd, a utility, forestry and clearance company based in the Midlands. He commissioned his dealer, KO Machines in Coven, to colour match his new tractor to the distinctive blue and pink livery of his recently purchased chipper.

The original colour scheme of the chipper was added by Mus-Max dealer Ben Price in 2021 and, after Martin purchased the MF 8735 to run the chipper, he wanted to continue Ben’s work in raising awareness for Cancer Research UK and Young Lives vs Cancer.

grills from red to black, will continue raising awareness and donations, and it is nice to see a Massey Ferguson in a forestry environment.”

controls.

“When in the rear position, the armrest and screen are folded back into place and the chipper controls are lowered down towards the operator for comfortable use. It proves that although forestry operations aren’t a common choice for MF machines, with some modifications, these tractors can be equipped to offer users long term reliability and a comfortable working environment.”

Martin explains why he wanted to do it. “Cancer affects everyone, and my business wouldn’t be where it is now without my Nan, who passed away from cancer. We need the chipper for most of our clearance sites across the country, and I didn’t want to just put any tractor on the front of it. Getting the tractor wrapped, and changing the colour of the bonnet

Although the tractor had the required power to run the chipper, the cab controls required a fundamental redesign. Darren Winstanley, sales manager at KO Machines, describes the modifications:

“We installed a new 360º seat base so the user can turn to face the rear of the cab and operate the chipper. The multifunction armrest and screen turn with the seat and fold up as the seat turns. The major change in the cab has been replacing the small rear window that is used to view the pick-up hitch and install a solid box allowing space for the operator’s feet and foot

Martin is delighted with the final outcome and says the project wouldn’t have been possible without several other companies being involved. “OCS Group UK Ltd, Ben Price, KO Machines, and Allan James Financial Services have all supported the project from the moment I told them about it, and it proves what can be done when working together.”

The value of the woodchip from the combinations first job in Cambridge for OCS Group UK Ltd is being donated to the charities. Landowners on future sites where Martin is working are encouraged to donate some or all the value of the chip, after chipping and haulage costs, to the two charities. Further donations can be made by scanning the QR code on the chipper or via this Just Giving link.

Under the theme of onwards 2024, Develon held the company’s first European Dealer Conference

Under the theme of ONWARDS 2024, Develon held the company’s first European Dealer Conference in Valencia in Spain in late February 2024. This was also the first European conference under the Develon name since rebranding from Doosan Construction Equipment last year. The company normally organises these meetings every two years and the last one was held in Barcelona in April 2022.

The 2024 event had an audience of 161 attendees, 116 of which were personnel from Develon European dealers from 23 countries. These were joined by several members of the HD Hyundai Infracore executive team from Korea, as well as managers from various areas of the company.

Mr Seunghyun Oh, CEO of HD Hyundai Infracore, opened the meeting with a keynote speech about Develon‘s strong performance since rebranding in 2023. He spoke about the company's achievements, new product and engine introductions and the continuing expansion of the company facilities and its dealer network in Europe. Alongside these

developments, Develon continues to produce new innovative technologies designed to shape the future of the construction industry and how work is done.

Mr Oh also described the global market outlook and the strategic direction of the company. He confirmed record high global production levels in 2023 for Develon excavators and wheel loaders plus record high sales of mini-excavators in Europe.

Since the brand’s launch last year, Develon has expanded its product portfolio and invested in extensive dealership facility rebranding which has further strengthened the established sales network throughout Europe. The collaboration and hard work of dealers ensured the brand transition has been a smooth process without any major disruption to operations.

The Valencia conference provided a platform for invaluable insights, collaboration and opportunities to continue the collective success of both dealers and the manufacturer within a very competitive construction equipment industry.

In recognition of their

achievements in 2023, a number of performance awards for dealers across Europe were presented including:

Best Customer Care Grausch y Grausch(Poland)

Best PioneerSomatec MTPI (France)

Top Sales Performer Centrocar (Iberia)

Top Compact Performer Kellands Plant Sales (UK)

Best Brand AmbassadorReal Machinery (Finland)

Special Achievement AwardAtlas Hamburg & Ebag (Germany)

Best Product Expert Garnea(Czech Republic)

Best Aftermarket Enhancement Anema Arum (Netherlands)

The conference was followed by a gala dinner with the third day involving a regatta sailing event on the Valencian coast with 13 yachts taking part, providing a very positive contribution for team-building and motivation among all of the participants.

Transport and machinery are the biggest contributor to the high fatality rate the agriculture endures

Transport and machinery are the biggest contributor to the high fatality rate that agriculture endures. Here are some simple ways you can reduce the risk and keep you, and others, safe.

One of the easiest ways of keeping yourself safe is by ensuring all the equipment you require is properly maintained and therefore suitable for the intended tasks. This can apply to any piece of equipment you run, for instance tractors, trailers, ATVs, towed appliances, farm vehicles, handheld machines etc.

By completing daily checks before commencing use of the machine or vehicle, you are more likely to notice any possible defects that could prevent the task being carried out safely.

In addition to this, regular maintenance checks completed by a dealership are also recommended to ensure any defects that are not highlighted on daily checks are addressed. This can ensure that small issues are repaired before they escalate and have a bigger financial and safety impact.

Maintenance. Why you should care.

Ensuring your machines and transport are well maintained will also ensure it is running efficiently and therefore likely to reduce long term costs associated with the machine, while also having the potential to increase its longevity.

A well-maintained vehicle or machine is more likely to be complaint with what is considered roadworthy. As such, if an incident should occur (that is not your fault), you are likely to be in a more favourable position if your vehicle or machine is well maintained.

Multi Industrial Doors Ltd is a family owned company founded back in 1985. We pride ourselves on providing a top quality service at an affordable price.

Transport and machinery are the biggest contributor to the high fatality rate the agriculture endures

Farm experience underlines role of early foliar nutrition in accelerating sugar beet establishment

Early applications of foliar nutrition could be key to helping this year’s sugar beet crops establish after the effects of the difficult winter.

That is the message from experienced Eastern counties agronomist, Ian Jackson of ProCam, who says slumped soils caused by heavy rainfall have caused havoc for creating good seedbeds, with poorer seedbeds, in turn, potentially delaying sugar beet emergence.

And even though emergency authorisation for neonicotinoid seed treatment use on sugar beet seed has been granted this season, early foliar nutrition could still be an important agronomic tool to help crops grow past their most vulnerable 12-leaf stage for aphid-borne virus transmission, he adds.

“It’s important that sugar beet achieves full ground cover as quickly as possible,” explains Mr Jackson, “not least to allow it to intercept maximum sunlight. But in many ways, sugar beet starts with a problem – in that it is drilled into cooler soils, which are unable to supply sufficient

nutrients in its seedling stage. “Even after an autumn maintenance application of phosphate (P) and potash (K), spring applications of these macronutrients are still required to counter the soil’s inability to supply adequate levels. However, soil-applied P can become locked onto the soil before it has achieved its goals, and K needs to be applied ahead of drilling to avoid seedling scorch, but the compaction from an extra set of wheelings can cause up to a 30% reduction in yield.”

In response, to give sugar beet crops an early boost, Mr Jackson suggests applying a multi-nutrient foliar treatment with the first two herbicide sprays, such as Pro+ NutriBio. This provides a balanced range of macro and micronutrients complimented with brown seaweed extract, he says, before switching to a polymer urea treatment, Pro+ N-Viron PCA, plus boron with the third herbicide spray, to supply a sustained release of nitrogen (N) to help expand the leaves across the rows.

“In farm observations, this approach has significantly increased the speed of ground cover over the last three years,” says Mr Jackson.

“Last year, treated crops grew through the early 30 degree heat which stopped most crops in their tracks for three

weeks. Other crops give very good responses to foliar urea polymers, but sugar beet seems to be in a different league.

“Indeed, two growers used no solid N for a second year as they were impressed with how Pro+ N-Viron had performed previously when N was uneconomical to purchase. These crops also performed slightly better than most crops in their areas with a much reduced cost and prospects of carbon reduction income in future.

“Including boron at this stage is a very pertinent consideration this season after the wet winter because it’s very leachable. Boron is needed during rapid cell division and deficiencies result in heart rot in sugar beet, something which is critical to avoid.”

Where aphicides are being applied to target virus transmission, Mr Jackson says these must be applied according to when aphid thresholds have been reached.

To maximise spray coverage, water volumes should be kept up and angled nozzles used, he notes. “Good spray coverage is needed on each leaf in order to get the best protection, and consider taking the opportunity to also

Smart, compact and featuring a front cab; the new 300m expands John Deere’s self-propelled sprayer portfolio in compact segment

Smart, compact and featuring a front cab; the new 300M expands John Deere's self-propelled sprayer portfolio in the compact segment.

Featuring the latest Precision Ag technology, a minimum turning radius and two types of boom with or without air sleeve, the 300M is the new specialist sprayer for narrow areas and high-value crops.

With the 332M and the 340M, two model variants are introduced. The 332M offers a tank size of 3200 litres and a 175 hp 4-cylinder John Deere engine. A boom width of up to 28 metres and a turning circle of 3.8 metres are ideally suited for work in narrow areas.

The 340M has a tank size of 4000 litres and a working width of up to 36 metres. This width, the 225 hp 6-cylinder John Deere engine and a turning circle of 4.2 metres facilitate high performance and compact operation at the same time.

With their compact design and all-wheel steering, both variants of the 300M are suited for narrow roads and field work in any situation.

Automatically adjustable track

width from 150-180cm, 180225cm and 225-300cm allow flexible use in all types of crops, including high-value.

The 50:50 weight distribution reduces soil compaction and makes work possible even under difficult conditions.

The John Deere 300M is equipped with the latest John Deere Precision Ag essentials, such as the StarFireTM Receiver, the G5Plus Universal Display and JDLinkTM. The new cab position provides excellent all-round and boom visibility. The suspended and heated seats provide the best comfort, and the new CAT 4 cab is equipped with the latest filter technology.

Both models of the 300M are offered with a steel boom and a stainless-steel boom with air sleeve. Both are available with Individual Nozzle Control. Particularly when used in high-value crops, the airassisted boom of the 300M provides excellent coverage of tall and leafy crops by increased penetration of the crop canopy. The air curtain opens the

Smithfield Tractors

Llanelwedd

Builth Wells, LD2 3SR

t: 01982 553221

crop and swirls the spray into the foliage making it ideal for lettuce, vegetables and strawberries.

The PowrSprayTM two-circuit liquid system design is also a key feature on the 300M. It offers fast filling of up to 600L/min and a highly precise output of 750L/min at three bars. With its unique design and fast response time of only three seconds from minimum to maximum, the centrifugal spray pump with direct rate control offers an accuracy of 98%.

PowrSprayTM technology, already used on the trailed model R700i, offers a variety of advantages such as stress-free filling thanks to ActivePause and the 50-litre PowrFill eductor.

The John Deere 300M will be available in France, Poland, Spain and the UK with the model year 2024. Other countries will follow in the next few years.

www.smithfieldtractors.co.uk

YOUR ADVANTAGES:

• Low ground pressure

• Minimum compaction

• High capacity pumps

• Heavy duty galvanised chassis

• Strong non corrosive tanks

• Wide range of distribution systems MOST EFFICIENCE AND COST EFFECTIVE

Smart, compact and featuring a front cab; the new 300m expands John Deere’s self-propelled sprayer portfolio in compact segment

KUHN Farm Machinery has introduced a 12.5m version of its Optimer disc cultivator that has been designed to work with controlled traffic farming systems (CTF).

The new 12500 L joins the existing range of Optimer cultivators, which start with the 3m mounted model. It features 100, 510mm discs arranged across two rows for working depths of 3-10cm and a Double U 550mm diameter rear roller for flexibility to cope with a wide range of soil types. Minimum power requirement is 350hp, and the new width complies with machines already working in CTF systems.

KUHN’s arable and connected services product specialist, Edd Fanshawe, says the new

models will help large scale farmers reduce compaction. “The Optimer range combines intensive mixing at high speed, with easy adjustment to suit conditions. The new 12500 L offers CTF users a stubble cultivator that can slot easily into existing systems and contribute to significantly lowering the number of wheelings during a season.”

The 12500 L is part of a new generation of Optimer machines that includes the 9000 9m model and the previous flagship, the 12m Optimer 12000. Updates comprise of a new hydraulic stand to replace the manual version, along with a new folding and unfolding sequence. This is

operated via a single user input replacing the four required on previous models. Steady Control is standard on Optimer 9000, 12000 and the new 12500 L. The system offers users an easier way to manage working depth by controlling pressure in the hydraulic cylinders across the width to guarantee a consistent disc depth.

Additional seeding options include the SH 201, SH 402 and SH 600 small seed applicator tanks, with the latter also available on Espro drills. The new Optimer 12500 L will be on KUHN’s stand at Cereals 2024.

Southam Agricultural Fields Farm, Station Rd, Southam CV47 2DH

t: 01926 813426

www.southamagri.co.uk

MSXH

SEPARATOR

PLUG

With well over 100,000 followers and growing across the key social media platforms and with links to rural policing initiatives we’re committed to alerting the rural community to ongoing crimes to help stop the criminals in their tracks.

Rural crime costs in excess of £49M per year! Join thousands of farmers, landowners and others living in rural areas to help us stamp out rural crime.

facebook.com/farmwatcher

twitter.com/FarmWatcherUK

linkedin.com/company/farmwatcheruk

#FWUKLetsWorkTogether

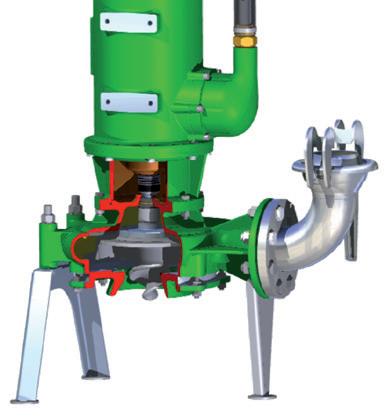

With more Separators and Green Bedding systems installed UK and Worldwide, Bauer is uniquely qualified to provide advice, products and support for your Green Bedding System

■ ECONOMICAL

■ ALWAYS AVAILABLE

■ INCREASED COW COMFORT

■ CLEANER COWS

■ NO DUST

“Cows have cleaned up no end definitely as clean as cows on sand and the number of mastitis cases has dropped dramatically.”

Defra permit the use of RMS (Recycled Manure Solids) as bedding for dairy cattle. Farms using RMS must notify APHA and Red Tractor

With Europe’s agriculture sector in turmoil, as farmers stage mass protests against unworkable environmental restrictions, new breeding technologies

With Europe’s agriculture sector in turmoil, as farmers stage mass protests against unworkable environmental restrictions, new breeding technologies such as gene editing could go a long way in helping the EU achieve its sustainability goals.

Considering the bloc’s stringent, historical opposition to GMOs in agriculture, the European Parliament’s recent decision to adopt looser rules for the cultivation of NBTs is a significant step forward. But the regulatory regime being proposed is not likely to set the stage for a full-scale food revolution in the EU. Without a commitment to complete deregulation, Europe will remain a genetic engineering backwater for decades to come, argues retired international economist Steven Cerier.

It’s going to be a long and difficult journey before the fate of the European crop biotechnology reform bill passed on February 7 by the EU Parliament is known. Proponents and rejectionists are already positioning themselves for what is shaping up as an acrimonious debate that will spill over well into next year.

The fate of the measure revolves around two issues,

either of which could derail or denude the final measure: whether to allow the patenting of gene-edited crops; and whether plants engineered using what the bill calls New Genomic Techniques (NGTs), will be traced and labelled.

Claiming there is “misery ahead” for European farmers if the bill passes in its current form, Greenpeace issued its objections, claiming it will accelerate the ‘corporate takeover’ of global agriculture - a view echoed by other environmental groups who aligned with the organic industry in lobbying to water down the final bill.

Scientists, farmers and seed companies welcomed the passage of the bill. They claim the reforms are needed for the EU to participate in the agricultural genetic revolution that is creating hardier, higheryielding, more nutritious and climate resilient crops.

But reform proponents are far from enthusiastic. Yes, it’s an improvement over current statutes that all but ban the growing of transgenic GMO crops in the EU. But they claim it is filled with restrictions that would ensure Europe would remain a global crop biotechnology backwater if preserved in the final measure. At a time when many other

countries, including Nigeria, Brazil, Argentina, the US, Israel, Japan, Canada and Australia, have all recently removed the shackles from new breeding technologies (NBTs), there are many problems with the EU proposals which suggest it will not be the panacea that many had hoped for.

The EU Council of Ministers has yet to agree a common position on the NGT dossier, with Hungary, Austria, Poland and Germany likely to be among the most recalcitrant countries, where anti-GE groups have forged broad coalitions. The USDA Foreign Agricultural Service (FAS) has issued in-depth reports analysing the depths of the opposition in each country.

Although the country has no formal policy on cisgenic gene-editing, the most recent report from the USDA Foreign Agriculture Service for Hungary indicates that it is “one of the strongest opponents of transgenic engineering”, and notes that maintaining its “GE free status” is a government priority:

“Hungary does not produce genetically engineered (GE)

such as gene editing could go a long way in helping the EU to achieve its sustainability goals

crops, animals, or cloned livestock. The Government of Hungary opposes the use of GE products in agriculture. Political parties in Hungary have historically held a firm anti-GE position… Maintaining the country’s GE-free status is among the government’s highest priorities. [Hungary] does not support any initiative that would allow “NGT” products to be placed on the market without risk assessments. Additionally, it requires a mandatory labelling system.”

Austria is also a long-time genetic engineering opponent, claiming it poses “incalculable risks”, although opposition appears to be softening in certain sectors. The country has the highest percentage of agricultural land in the EU under organic management. According to the USDA, “Anti-biotech NGOs, farmer organisations, the foodprocessing sector, and the retail sector all campaign against genetically engineered agricultural food products.”

Although the government formally opposes the current NGT measure, and the public is hostile, “within informed stakeholder groups like scientists, seed breeders, seed traders, and farmer representatives, the

acceptance of innovative biotechnologies … is much higher than for traditional GE crops.”

Poland Poland formally opposes crop biotechnology. Paradoxically, it imports millions of tons of GMO corn to feed its livestock even though a ban is in place, and there is no parliamentary plan to enforce that ban. Opposition to biotechnology is slowly softening in some sectors, the USDA reports, noting that “most Polish scientists and some commercial farmers support advanced agricultural techniques.” Still, “70 percent of Poles oppose agricultural biotechnology [and] environmental organisations, and consumer groups regularly protest its use in agriculture.”

The future of gene editing in Europe may rest with Germany, which has the largest economy and is the most populous country in the EU. Without its acceptance, any major liberalisation is doomed to fail. The issue is “highly politicised”, the USDA writes, and the government is “conflicted”. While Germany is “generally open to new technology” and is home to numerous global agribusinesses.

“Biotech test plots, which are used both as a research tool and are a required part of the EU regulatory approval process, were destroyed by vandals so often that test plots are no longer attempted in Germany today. Public rejection of GE crops has been widespread for decades and still prevails. [A]round 58 percent of the German population are still in favour of strict regulation of agricultural biotechnology and oppose the European Commission’s proposal to deregulate the genetic engineering law. … In the current environment, there is still little prospect of developing a German market for GE crops or foods.”

Labelling and traceability required?

To make the deregulation of GE crops more palatable to opponents of the technology, MEPs have proposed that labelling should be required.

Pushing back, a growing coalition of scientists, farmers and agri-businesses, as well as many consumer advocates, say labelling is unnecessary and even deceptive, and that it would inhibit acceptance, used by anti-GE forces to demonise and vilify foods produced via NBTs.

Fodder beet should be a serious consideration for livestock farmers this spring

Fodder beet should be a serious consideration for livestock farmers this spring, given its potential to be the highest yielding of UKgrown forage crops and the cheapest per unit of energy produced.

So says ProCam’s Rhys Owen, who outlines a number of key management points and recent advances in agronomy that will help to ensure success.

“Achieving its typical potential of around 25 tonnes of dry matter (DM) per hectare, fodder beet can work out at as little as 5-6.5p/kg DM, which can be about a third to half of the cost of grass silage, or compares with about 8-10p/kg DM for kale,” Rhys explains. “Fodder beet is a crop that requires investment and attention to detail. However, done right, it can be the most cost effective forage crop available.

“It is a multi-purpose crop, in that it can be grazed in situ or lifted. Fed in situ, it has the potential to extend grazing seasons, or to be utilised as part of an out-wintering system for cattle or sheep.”

Fodder beet is drilled earlier than most other forage crop options, with the optimum sowing period being midMarch to the end of April, says

Rhys, so should therefore be established before the greatest risk of dry periods that can hamper later-drilled crops. In all cases, site selection is the first consideration, he says, then it’s important to prepare the right seedbed.

“Light and medium bodied soils that are free draining are best, with a pH of 6.5 or higher. For optimum establishment and crop growth, create a seedbed that’s fine and firm in the upper 5-7cm, with a more open structure below to allow root development.

“If you are intending to graze the crop in situ, it’s important to plan ahead of drilling in order to optimise the layout. If planning to transition cattle on to beet, leave a 6m headland to allow them space. Also, drill in a direction that enables the fence to be positioned along the rows, which simplifies allocation of the crop to all stock. If the field is sloping, always aim to graze downhill.”

Maximising returns from fodder beet also depends on choosing varieties based on trials performance and their suitability for the required end use, adds Rhys.

“For grazing cattle, use a proven medium DM variety like Geronimo, whereas if it’s for sheep or young cattle you’ll

achieve better utilisation by going for a variety that sits out of the ground more, with a lower DM, such as Lactimo. In all cases, I’d recommend using primed (pre-germinated) seed, as this will result in a faster and more even establishment, with the crop reaching canopy closure more quickly.

“Primed seed is an important advance in fodder beet growing. It should be used alongside a number of other significant agronomic improvements in order to achieve full potential.

“For example, where a crop is destined for grazing, fertiliser application and disease control should be geared towards maintaining green leaf growth longer into the season, boosting overall yield and protein content,” he says.

“Fodder beet has a total nitrogen (N) requirement of about 200-240kg N/ha, compared with 120-150kg N/ ha for traditional beet. But with the right inputs at the right time, fodder beet can out-perform any other forage crop and be your most cost effective autumn and winter forage.”

For the last 75 years, Amazone has been at the forefront of drilling innovation, a milestone that is being recognised for Spring 2024

For the last 75 years, AMAZONE has been at the forefront of drilling innovation, a milestone that is being recognised for Spring 2024 with a very special offer.

AMAZONE drill production goes back to the first 2 metre wide, horse drawn D1. Even back then, the use of the pioneering ‘Elite’ seed wheel which enabled the drill to sow a variety of seed sizes from clover through to cereals and legumes, without needing to change the seed wheels, was ahead of its time.

1967 saw the first seed drill combination of RE reciprocating harrow with the D4 drill bringing one-pass seedbed preparation and sowing into one operation, saving time and fuel costs as well as leaving a wheelingfree finish and an enhanced germination.

The use of drill combinations has stood the test of time with thousands of drills produced by AMAZONE each year still mounted to a PTO-driven KE rotary harrow or KG cultivator or the non-powered CombiDisc.

1970 saw the inauguration of the Hude production facility in Oldenburg, Germany as a dedicated factory for drill and harrow production which utilised metal workers

laid off by a collapse of the ship building industry in Northern Germany. Hude is still producing components for drills and harrows, but assembly has now moved down the road to a stateof-the-art facility at Altmoorhausen with its massive paint shop and 18 production lines that is able to keep pace with the constant rise in demand for AMAZONE seeding systems.

During the 1970’s, the Amazone D7 became the first commercially produced drill to offer a tramline system.

The drill featured a mechanism that deliberately left parts of the field undrilled to generate wheelings for the following crop care operations where spreader bout width was matched to the sprayer boom width in order to work on a fixed tramline width, a principle that is accepted as the norm these days.

A unique drill in the late 1970’s came in the form of the EV Garant which opened the door to up to 9 m solo seeding with a transport width of only three metres. Seed was augered up from a central, low level seed hopper into a ‘gravity’ metering roller system which then dropped the seed down the pipe to each coulter across the whole 6 m working width without the need for an air

flow.

The 1970’s also saw production of the NoTill drill being ramped up as direct drilling became commonplace.

The NoTill was a conventional gravity seed hopper feeding a chisel opener for a clean, straw-free seed slot and perfect depth control. The NoTill could be mounted in gangs for increased working widths. The production of the NT ceased with the introduction of the Primera which used the same chisel opener principle but features hydraulic folding and pneumatic seed conveyance, the Primera sells by the 100’s across the big prairie farming areas such as Eastern China, Kazakhstan, the Baltic States and Eastern Europe.

The Airstar pneumatic seeders came along in the 1990’s with a centralised metering system and a distribution head feeding each individual coulter via an air flow from the on-board fan. This then gave the ability to run the tank out to nothing, ideal for rape and small seeds where keeping a box drill covered over the full width often resulted in large seed residues. The air distribution system also offered the flexibility of using a front tank and a folding power harrow and seed rail on the back for compact.

Spreader testing as important as having a sprayer tested. With nitrogen fertiliser currently costing around £360/ tonne, a 3 tonne spreader is carrying just over £1,000 of product each time it leaves the yard. At a rate of 200kg/ha a spreader with a coefficient of variation (CV) of 20% could be costing you around £240 in lost revenue due to uneven application.

The NSTS test aims to achieve a CV of below 10% when a spreader is tray tested and an important factor is being able to achieve this by testing the

product first. Litre weight, hardness and size range of granules are checked against manufacturers recommended settings and the machine set accordingly. Settings options in spreader apps are a very good guide but variability of product from when it was first tested can mean a small tweak to the suggested settings is needed. The kit required to do the product tests is relatively cheap and can be purchased separately however some spreader manufacturers do supply the kits with new machines.

When the tray test is carried out, 47 trays (for 24 metre

tramlines) are laid out across the full width of spread and the results entered into an app to calculate CV. Adjustments can then be made if necessary but often because the product has been tested and the machine inspected, the target of below 10% can already be achieved.

Test Centres across the UK allow easy access to getting your spreader, or any pesticide application equipment, tested. For more information go to the NSTS website

www.nsts.org.uk

BouMatic introduces XpressWay 3.0, a parallel milking system with a rotating rapid exit system ensuring higher cow and milker comfort

BouMatic introduces XpressWay 3.0, a parallel milking systemwith a rotating rapid exit system ensuring higher cow and milker comfort.

BouMatic proudly unveils it’s latest marvel: the Xpressway 3.0 rapid exit parallel stall.

This innovative system incorporates a rotating reel concept, delivering the fastest and most efficient exit for animals on the market. The primary aim? To enhance comfort for both milkers and cows alike.

The XpressWay is a parallel milking system equipped with a rotary reel rapid exit system.

This remarkable technology boasts a pneumatical system with a hydraulic brake, setting it apart from conventional market offerings by eliminating electromagnetic fields thus ensuring a comfortable environment for the cows. In line with BouMatic's longstanding commitment to sustainability and innovation,the XpressWay distinguishes itself by its reliance on anon-

electrical motor, a hallmark of the company'slegacy for over 30 years. This forward-thinking approach underscores BouMatic's unwavering dedication to

environmentally responsible practices.

In a bid to prioritize the well-being of the cows, the XpressWay 3.0 has been meticulouslydesigned with widened spaces, increasing from 71 cm to 74 cm. This modification allows for more freedom of movement and expedites cow traffic.

Moreover, the gates are now devoid of springs, reducing maintenance requirements and streamlining operations.

By leveraging an optimized design and refining the

upper cabinet from the acclaimed SmartWay 90 parlour stall system, the XpressWay 3.0 guarantees superior visibility and optimal access to the udder for milkers.

This ergonomic configuration empowers operators to position themselves in close proximity to the cow, ensuring comfort and efficiency in their tasks. The XpressWay stands as a testament to BouMatic's relentless pursuit of excellence indairy farming technology. Its unique combination of precision engineering, elimination of electromagnetic fields, and eco-friendly design positions it as an unparalleled offering in the market. With the XpressWay, BouMatic reaffirms its status as an industry leader, poised to revolutionize milking practices and enhance the welfare of both dairy farmers and their herds.

The Xpressway milking system is available on the market immediately through the European BouMatic dealer network.

BouMatic launches MagStream milkmeter: the first wireless, ICAR approved free-flow milkmeter

BouMatic, a global leader in the manufacturing of milking equipment, is proud to announce the release of the MagStream Milkmeter, a milkmeter that ensures a continuous and completely free milk and air flow.

This meter has the lowest occurrence of vacuum drops and fluctuations of any meter of the market today. Thanks to advanced technologies used for power management, data communication and recording, it is the first milk

meter that is completely wireless.

Key Features of the MagStream Milkmeter:

• Easy Installation & Service: The MagStream Milkmeter's wireless design ensures easy installation and service.

It is plug-and-play, quickly calibrated (statistically) and can be fully integrated with your milking installation, farm automation systems and herd management software programs.

• Animal Friendly: With its

100% free-flow design, the MagStream Milkmeter guarantees a stable vacuum and a very low vacuum drop throughout the milking process, providing optimal comfort for the animals and resulting in consistently efficient milking sessions.

• ICAR Approved: The MagStream Milkmeter is ICAR approved, ensuring top performance when it comes to accuracy, hygiene and more.

BouMatic: Introducing the Gemini UP, a distinctive solution for any herd size

BouMatic Group (consisting of the brands BouMatic, SAC andHokofarm) introduces the next generation of Gemini, the milking robot. The firstgeneration robot was launched in 2011. Over the years the model has been optimized with new benefits to take it to the next level. Therefore, the new milking robot will be launched with the name of Gemini UP to help reinforce the new level of performance that can be achieved for milk production.

The Gemini UP has been developed with the focus on the best milking practices, cow comfort and lowering energy consumption. On top of the unrivaled, well known Gemini robot features, such as the unique rear attachment approach and the unobstructed open view, the upgrade contains a vast list of new cutting-edge features.

Optimized milk path, according to BouMatic Group milking philosophy

One of the major upgrades, at the heart of the milking robot,is the optimized milk

path, resulting in simply better milking.

The milk flows now per quarter, without any restrictions, into the milk receiver. The new quarter milk line has an internal diameter of unprecedent in the market.

BouMatic and SAC flows are milked optimally in the Gemini UP. This proves that our robotic system follows the same tried-and-true method as conventional milking.

Improved energy consumption

modular

This leads to maximum vacuum stability and a continuous milk flow without any blockages. Even cows with the highest milk Gemini UP – Double box, available from BouMatic and SAC Gemini UP – Single box, available from

Furthermore, the Gemini UP features an improved energy consumption. This is mainly due to the new mechanical circulation cleaning, which consumes less water at a lower temperature. The washing unit is placed in the external technical room and is centralized regardless

BouMatic: Introducing the Gemini UP, a distinctive solution for any herd size

of the number of robots in a dairy farm. So, in case a farm has numerous robots, one washing unit manages all cleaning cycles.

The same counts for the vacuum system and buffer tank. These are now centralized into one unit.

More Geminis can be attached to these central units. This means that the system is modular and adaptable to all kinds of configurations, from small family farms to big commercial farms.

individual cow features such as udder and teat shapes and colors leading into a quicker and more reliable milking.

BouMatic

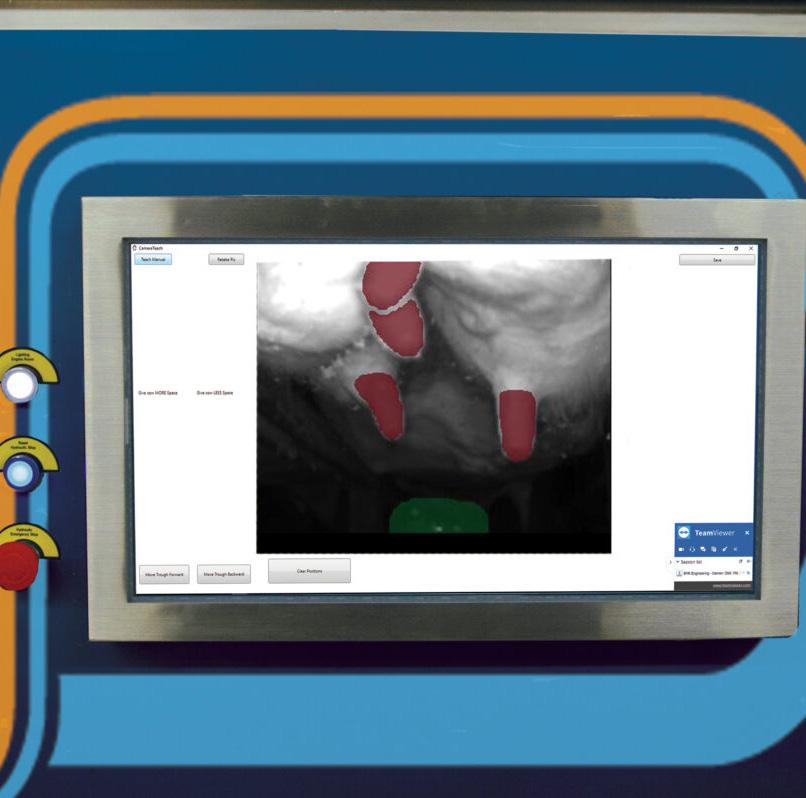

Cutting edge vision system

Gemini UP attaches cows fast and accurately thanks to machine learning technology implementation.

This breakthrough technology now looks at udder imagery gathered from a wide range of cows and has allowed attachment and ultimately the throughput to rise-up to the next level for your dairy.

The vision system helps to continuously adjust knowledge about different,

herewith introduces AI into the milking industry.

Full robotics solutions for all farm types

“Continuing development and innovation is what BouMatic Group represents.

We are always working on the optimization of our systems, taking the feedback from our customers and dealers into account. This new milking robot is thoroughly tested, and we believe it offers excellent performance and cow comfort, “says Uwe Osthues, Chief Commercial Officer at BouMatic.

“The new features are too numerous to sum up,” completes Rik Schoenmaker, Sales Director at SAC. “But one of the most important advantages is that we can now offer a full robotic solution to all types of dairy farmers, from small farms with less then 240 cows up to big commercial farms with 2000 cows. Mainly thanks to the abovementioned centralized systems and the recently added Gemini MAX, Herd milking system. In this system a group of cows are guided at fixed times to the robotic parlour”.

The Gemini UP milking robot is available on the market immediately through the worldwide BouMatic and SAC dealer network.

BouMatic Group is a global leader in the design, manufacture and supply of the highest quality milking systems and dairy farm equipment.

The Gemini UP single box milking robot is a 2-in-1 self-contained unit and, as a result, is quick and easy to install.

It has an efficient, small footprint, one integrated machine room and unique in-box selection options. It therefore offers an unrivalled automatic milking solution for every farm type.

Cow flow is smooth and easy with the Gemini Up Single Box. The integrated selection process means there is no need for extra fencing and gates. REACH YOUR PERFOMANCE GOALS WITH OUR EXCLUSIVE

Joice and Hill is helping to advance Britain’s egg-laying sector through a combination of investment and innovative thinking

Joice and Hill is helping to advance Britain’s egglaying sector through a combination of investment and innovative thinking. By Michael Barker

Britain’s egg sector is only as good as the quality of its layers, so it is reassuring to get an insight into the depth of work that is helping to take the industry to the next level.

At the forefront of that work is Joice and Hill, which won the Hatchery of the Year category at the 2023 National Egg & Poultry Awards in recognition of its sizeable investment in both its hatchery facilities and research and development, carried out in the UK and globally by its parent company Hendrix Genetics.

Peterborough-based Joice and Hill distributes the Hendrix Genetics range of egg-layer breeds in the UK and Ireland, currently supplying around 37% of market demand. The business sells a range of brown egg layers – including world-leading breed Bovans Brown – alongside the highly productive white egg layer the Dekalb White and a series of speciality hens. In addition to the hatchery, the business also manages the parent stock farms that provide

the hatching eggs, which is a key part of the operation that gives the company vital control over its own supply chain.

Managing Director Nick Bailey has been with the business since 1996, and in charge since 2008, and he says the overall combination of traits offered by the Hendrix birds, from production numbers to ease of management, robustness, and recovery from disease, give them their unique selling point. That’s down to the amount of investment that goes into genetic selection, breeding technology and field-based testing, he adds.

Beyond that, there’s one clear factor that is increasingly winning customer loyalty and market share for Joice and Hill – extended laying cycles. “Since the beginning of modern poultry breeding, geneticists have focused on hens which lay at a higher rate up to 60-70 weeks of age,” Bailey explains. “Having already extended to 80 weeks, Hendrix Genetics took the view that even testing and selecting to 80 weeks was no longer going to be sufficient, particularly with the US talking about banning forced moulting. We thought that the only reasonable way we could improve the birds more was to extend

that testing range up to 100 weeks. And that’s what we’ve ended up with now – birds that can lay reliably on a good feed conversion, with excellent shell quality, all the way to 100 weeks.”

Achieving that 100-week milestone might have seemed unrealistic a decade or two ago. Pedigree, pure line birds, such as those maintained by Hendrix Genetics in France and the Netherlands and backed up by flocks around the world, are selected to make the next generations and real progress is being made. “At the moment we are adding approximately one week of production every year from these efforts,” Bailey explains, “and the geneticists that I talk to think that within their lifetime, flocks going on one cycle to 120 weeks of age is a realistic proposition. When I first started in the industry, people were depleting at 65 to 70 weeks, so that’s a that’s an unbelievable gain.”

It is the white birds that are showing the most promise, and while 100 weeks has been achieved with brown flocks, 85-90 weeks is still more common. That inevitably leads to the question of whether the market should continue to be steered more towards white

Joice and Hill is helping to advance Britain’s egg-laying sector through a combination of investment and innovative thinking eggs, and Bailey believes the supermarkets are already “pretty sold on the white egg story”, pointing to the fact that Lidl in the Netherlands has already switched to 100% white and British retailers are starting to get on board. He believes that the UK market will ultimately see a mixture of brown and white, but with white having a growing significance over time.

There are multiple benefits to longer bird cycles, according to Bailey – not least from the sustainability angle.

“If you take a flock to 100 weeks rather than, say, 75, which has been the normal brown production length, that means in a five-year period you only have to buy or rear three lots of pullets rather than four. And that’s a huge impact on the carbon footprint of the chain, and also a massive saving to the clients who have to turn around the units one less time in five years and buy one flock less.”

Sustainability is certainly something that Hendrix Genetics as a group is putting a great deal of thought into. The company is a member of Code-EFABAR – a voluntary code of practice in support of responsible breeding – and invests time

and resource into looking at ethical breeding practices and the conservation of genetic resources. “It’s about breeding birds that are healthy and full of vigour at the end of production,” Bailey notes.

The company’s other key sustainability stream focuses on its footprint on the world, and to that end a monitoring process is in place whereby all of Hendrix’s global operations report on feed and energy consumption, as well as any antibiotic use, which is something Bailey stresses is kept to an absolute minimum.

Investment in sustainability is just one of the core focuses of attention for Hendrix Genetics, which prides itself on innovation and continuous development. One current project is HenTrack, which examines individual bird movement and location patterns to bring genetic selection of cage-free laying hens to the next level. The current phase of the project sees $2.7m of funding used to promote cage-free housing for laying hens and improve their health and welfare through new breeding approaches. The idea is that by remotely monitoring hen behavioural patterns, assessment of relevant traits can be carried out without

disturbing the birds, with data able to be collected from individual hens in large groups in a way not possible before.

There are also projects underway focused on liveability, with the company keen to improve outcomes in areas such as keel bone strength, while a further area of focus centres on in-ovo sexing. Hendrix is currently trialling two different types of technology in two of its hatcheries, in response to law changes in Germany and France banning the culling of male chicks at birth. Bailey says that “if you look at the detail, then it [the technology] is not quite there yet” but expects progress to be made going forward and for a move ultimately towards in-ovo sexing as early in the process as possible.All of that is at a group level, but back in the UK there have been investments aplenty in recent years too. The hatchery has been completely renovated over the past decade, with all the old incubation equipment replaced and updated. New, single-stage Jamesway incubators and hatchers were installed that are much more energy efficient than the old equipment and provide much better hatchability results and better chick quality.

We have recently seen an unwelcome return of Avian Influenza with a case in free-range egg unit in the North East.

By Gary Ford, chief executive, British Egg Industry Council

By Gary Ford, chief executive, British Egg Industry Council

We have recently seen an unwelcome return of AI with a case in a free-range layer unit in the North East. Whilst a set back for all, not least the producer, who we have been supporting throughout this challenging time, Defra have not changed the risk status of low for commercial poultry and medium for cases in the wild bird population. The time of the year, as we move into Spring, will hopefully help. Defra praised the site management for prompt reporting of suspicion of disease which is encouraging to hear as one of the key messages to combat AI is vigilance and prompt reporting.

We continue to engage with

the Welsh Government for a consultation on the 16week derogation. The English and Scottish consultation closed on 5 March and as a consequence it is critically important for the free-range sector in Wales that the Welsh government bring forward a consultation at some point in the coming months and certainly ahead of the AI ‘season’ later this year. My concern is that a lack of a consultation will negatively impact on consumers and have the potential to have a devastating impact on Welsh free range egg producers at a time when Welsh farming is already under enormous pressure and uncertainty.

Another area that we continue to engage on is the RSPCA amended laying hen welfare standards published in November 2023. The strength

of feeling continues and that was evidenced when I spoke at the Welsh NFU Cymru poultry conference at the end of February. Industry is as one on this and we have recently written a joint letter to the RSPCA formally asking them to pause the introduction of the new standards until they have completed proper and meaningful industry consultation. We are also calling for commercial scale trials on UK farms to ensure that it is representative of UK production and conditions and has a demonstrable welfare benefit for laying hens.

Finally, congratulations to the newly elected NFU Officeholder team led by Tom Bradshaw. We very much look forward to working with you over the next two years.

Joice and Hill is helping to advance Britain’s egg-laying sector through a combination of investment and innovative thinking

By Aimee Mahony, chief poultry advisor, NFUIn my last column I talked about the frustrations of policy making. The need for timely decisions is greater in certain circumstances but often there are many factors at play and a lengthy process before we see any fruitful results. Any frustrations do seem worth it when the desired outcomes are delivered, and this makes my line of work very rewarding.

One example of these fluctuating emotions is the ongoing work looking at fairness in the supply chain. It was therefore welcomed at the NFU conference in February when the Prime Minister –The Rt Hon Rishi Sunak MP, underlined the government’s commitment to deliver on its plan to support profitable farming businesses, improve food security and protect the British agriculture sector for generations to come.

has taken place.

The roundtable meeting with Farming Minister Mark Spencer MP offers an opportunity for representatives from the entire broiler supply chain to come together to raise any concerns related to fairness and offer solutions for any desired improvements. This will make it an important

other sectors. Their immediate aim is to ensure contracts in the dairy sector are fair and transparent and later this year they will be introducing similar regulations for the pig sector with regulations for the egg sector expected to follow on from that.

Hard work pays off. Producers will see this on farm and bringing the challenges and opportunities that they face to life makes for more effective outcomes in our ongoing lobbying efforts.

moment for the sector.

Of note was the PM’s announcement of a review which is set to improve fairness in the poultry supply chain. Further clarity has confirmed that this is a review of the broiler supply chain, and it is anticipated to take place later this year once the more imminent roundtable meeting

Thinking about the egg roundtable meeting with the Farming Minister back in December 2022, we saw further scrutiny of the way risk and reward is shared and as a result of that Defra have conducted a review of the egg supply chain.

With their ambition to build fairness in the supply chain, the government have also announced that they have delivered on their commitment to introduce regulations in

At the time of writing we are busy recruiting for the NFU national poultry board, and the successful members will play a crucial role in shaping a profitable and sustainable future for all those operating in the poultry sector.

There are other opportunities to get involved on the horizon with the next Poultry Industry Programme open for recruitment and the evolution of regional NFU poultry boards across England and Wales. Please contribute to discussions and get involved in events and meetings wherever possible. Your views are vital and appreciated and can make a huge difference and I look forward to meeting and speaking to many of you at the numerous events over the upcoming months.

Bob

www.bobgerard.co.uk

CM

David

Granada

Daventry, Northants,

NN11 6DP t: 07502 661861 Mikes

Fields Farm, Station

DG Buscombe, Saint Columb, TR9 6DE

t: 01637 880119 | www.dgbuscombe.co.uk

Marrs of Methlick, Schoolbrae Garage, Methlick, Ellon, AB41 7DS

t: 01651 806910 | www.marrsofmethlick.com

Smithfield Tractors, Llanelwedd, Builth Wells, Powys, Ls2 3SR

t: 01982 553221 | www.smithfieldtractors.co.uk

Trebor Jones & Son Ltd, Llanfyllin, SY22 5LE

t: 01691 648411

Wharfedale Tractors, Unit 1 Riffa Bus. Park, Harrogate Rd, Otley, LS21 2XB

t: 01132 841117

Polaris Off Road is pleased to announce a new and exclusive offer for customers in the UK and Ireland

Polaris Off Road is pleased to announce a new and exclusive offer for customers in the UK and Ireland: Any customer purchasing any new, mid-size Ranger 570 is eligible for a FREE half cab kit upgrade, worth £1,798.80*.

Running from 1st October 2023 until 31st December 2023, the half cab kit offer will give new Polaris Ranger 570 owners the benefits of a half cab at no extra cost, providing riders with protection from the elements leading up to the winter months. Buyers can also combine this offer with Polaris Finance 0% hire purchase, spreading the cost over two years.

The half-cab kit upgrade comprises Lock & Ride® Full Glass Windshield, Wiper and Washer System, Sport Poly Roof and Poly Rear Panel. Polaris Genuine Accessories are designed by the same people who designed the vehicle, so riders can be sure the components are built to the highest quality and standard. Buyers can choose to complete the cab with full crank window doors for just £1575 excluding VAT.

Richard Coleby, National Sales Manager for Polaris UK said:

“The Ranger 570 is a small but mighty machine, and with the unpredictable British winter just around the corner, the half cab kit offer allows our customers to add protection from the elements to their Ranger, meaning they can stay on the go for longer.”

The perfectly sealed Lock and Ride® Full Glass Windshield ensures impeccable clarity and toughness whilst protecting the rider from unpredictable weather, making for a vastly more comfortable ride. Thanks to the Lock and Ride® functionality, the windshield can be fitted and removed in a matter of minutes.

Made from optical grade, 0.6-centimetre polycarbonate, the scratch-resistant Poly Rear Panel provides riders with superior visibility and reliable protection from wind, inclement weather, off-road hazards and cargo shifting in the rear cargo box. The low-profile rear panel installs quickly and easily using Polaris’ Lock & Ride® functionality and a reliable seal is created thanks to the recessed channel design providing a professional grade fit.

The windshield and rear panel work in synergy to block dust swirling into the cab from the rear, creating greater protection from the dirt whilst out at work. Included in the half cab kit is the wiper and washer system for ultimate clarity no matter the weather.

Riders can stay warm, dry and comfortable all day thanks to the lightweight and durable Sport Poly Roof that fits perfectly, installs quickly and instantly turns the cab into a safe retreat from unpredictable UK weather.

Polaris also offers a wide range of specially-engineered accessories, including the in-

cab heater and defrost system, integrated audio systems, light bars, plows and winches, as well as hundreds of Lock&Ride storage solutions for the cargo bed.

For 2023, the Ranger SP 570 starts at £11,999 excluding VAT, and is available in Sage Green. The Ranger SP 570 is also available with EPS and in various special editions including the Hunter Edition and Nordic Pro Edition.

Polaris UK’s exclusive twoyear 0% finance offer* for business customers purchasing any Polaris model in the United Kingdom has now been extended. Running in conjunction with new finance partners, DLL, a global finance brokerage with more than 50 years of experience, this offer is available on all adult and youth products**,

Any customer who purchases a new Sportsman 570 from an authorised and eligible Polaris UK dealer can now receive a £1000 (including VAT) trade-in contribution when they trade in any make or model of ATV or SXS towards a new Sportsman 570 model until 31st March 2024

Polaris has announced that dealerships across Europe have started to receive the first shipments of the all-new Ranger XP Kinetic vehicles

Polaris has announced that dealerships across Europe have started to receive the first shipments of the all-new fully-electric RANGER XP Kinetic vehicles, ready to be collected by customers.

Homologated models specifically for European markets are manufactured at Polaris’ more than 33,000-square-metre manufacturing facility in Opole, Poland—the first Polaris factory built for the production of off-road vehicles outside of North America—with production of the fully electric model starting in August this year.

Rodrigo Lourenco, Vice President of Polaris Off-Road Vehicles EMEA, said: “Our customers are now going to be able to experience the extraordinary performance advantages that the electric powertrain in the RANGER XP Kinetic can provide. We know this vehicle is highly anticipated across our international dealer network, so we’re pleased to see the first shipments arriving in showrooms and looking forward to seeing them in action across our utility customer base.”

RANGER XP Kinetic is available as a 3-seat model

in Premium trim and top-ofthe-range Ultimate trim, which will be arriving in Europe shortly after. The Premium trim contains a single 14.9 kWh lithium-ion battery that offers an estimated range of 45 miles (70 kilometres), while the Ultimate trim delivers 29.8 kWh of battery capacity and offers an estimated range of 80 miles (130 kilometres)*.

The Ultimate trim also offers a bright 18-centimetre infotainment screen powered by RIDE COMMAND technology, offering configurable gauges to monitor ride activity, as well as camera integration, Bluetooth connectivity to wirelessly stream music and stay connected with call/ text alerts, and plow mode to make snow removal even easier by automatically lowering and raising the plow when shifting between low gear and reverse.

The RANGER XP Kinetic delivers uncompromised capability, unrivalled durability, and refined performance. With its all-electric powertrain, engineered for off-road use through Polaris’ exclusive 10-year partnership with Zero Motorcycles, the RANGER XP Kinetic offers the most

horsepower and torque ever found in a utility side-byside, with a class-leading 110 horsepower and 140 lb-ft of instantaneous torque that delivers maximum power and quick acceleration when it’s needed, including the ability to effortlessly tow up to 1,134kg and boasts an industry-best 680kg payload capacity. Thanks to being fully electric, the RANGER XP Kinetic also delivers smooth, precise control when operating at low speeds, especially useful in scenarios like towing or backing up to a trailer.

RANGER XP Kinetic also features a class-leading 35.5 centimetres of ground clearance and 25.4 centimetres of suspension travel to confidently rise over obstacles and smooth out the bumps, and is equipped with 74-centimetre, 8-ply Pro Armor X-Terrain tyres for maximum traction and durability to crawl over rocks and ruts. With regenerative braking, electric power steering, on-demand allwheel drive and VersaTrac Turf mode as standard, as well as three driving modes— ECO, Standard and Sport— riders are in complete control of their ride, depending on the terrain and task at hand.

Park Farm Industrial Estate

Wellingborough

NN8 6UW Tel 01933 673 900 www.dayandcoles.co.uk

Derbyshire Quads Wild Park Lane Brailsford Ashbourne Derbyshire

3BN Tel 01335 361 349 www.derbyshirequads.co.uk

Halls of Bromyard

K

Copplestone

Devon EX17 5NW

* 5 Year Manufacturer Limited Warranty *

The Blade series has been sold worldwide now for over 20 years. The 520SL is the latest edition to the agricultural lineup. A combination of elements developed over a decade of hard work within the agricultural industry, the 520SL boasts a long list of key features. This workhorse ATV is ideal for any agricultural situation.

Powered by the tried and tested TGB 503cc high torque engine, but now equipped with Electronic fuel injection.The Blade 520SL is T3 homologated so can be registered for road use.

A1 Tractor Parts, West View, Cumbria, CA7 3NL | t: 07873 737538

www.a1tractorparts.co.uk

CMS Exeter, Venny Bridge, Exeter, EX4 8JJ | t: 01392 467700

Fairoak Machinery, Yew Tree Garden Centre, Hatt Common, Ball Hill, Newbury, Berkshire, RG20 0NG

www.keewaymotorcycles.com

Fairoak Machinery, Hatt Common, Berks, RG20 0NG | t: 01635 254533

t: 01635 254533

www.fairoakmachinery.com

www.fairoakmachinery.co.uk

H & H Vehicle Services, Unit J2, Holmfirth, HD9 4DS | t: 01484 859322

www.hhvehicleservices.co.uk

NG Quads & Moto (Covering Devon & Cornwall), 2 New Road, Brixham, TQ5 8Lz t: 01803 883555 | www.ngmoto.com

R.O Davies, Garthmyl, Llangernyw, Abergele, LL22 8RG

New Forest Garden Machinery, Southampton, SO40 3ND | t: 02380 871764

t: Rhys - 07879 016798

www.nfgmltd.co.uk

www.rodavies.co.uk

Taylors Tools LTD, Primrose Hill, Herts, WD4 8HX | t: 01923 260699

www.taylorstools.co.uk

BOMFORD HEDGE CUTTER B578 3PL MTD, 1.30 CUTTING HEAD £4,500 + VAT

DAVID BROWN 1490, 2WD 1983 A REG C/W ECON HEDGEMASTER NEEDS TLC £4,775 + VAT Congratulations

TIPPING TRAILER 3-4 TONS £950.00 + VAT

BARTON MUCK FORK, GOOD CONDITION, £350.00 + VAT

WALK BEHIND ROLLER, £675.00 +VAT

McCONNEL FLAIL HEAD, £325.00 + VAT

DAVID BROWN 1490 1983, 2WD TRACTOR NEEDS TLC £POA

TEAGLE TOMAHAWK STRAW CHOPPER 2008, (SPARES) 3 POINT LINKAGE, GOOD CONDITION £POA

TEAGLE 510 PASTURE TOPPER IN GOOD WORKING ORDER £1250.00 +VAT

1982 DAVUD BRIWN 1490 2WD TRACTOR THREE POINT LINKER ON 14 X 34 REAR

7.50-16 FRONT, NEEDS TLC £3,375 ++ VAT

1968BDAVID BROWN 990 FRONT LOADER BUCKET ROLL BAR £2,535.00 + VAT

1999 T REG LDV HORSEBOX LORRY £3,500 COMPLETE, OR JUST BOX OFF £1,750 + VAT – HAS NO TEST

KUBOTA KH51 MINI DIGGER ON STEEL TRACKS OFFERS AROUND £3,275.00 + VAT

BARTON MUCK FORK V.G.C. TRIP MODEL £275.00 + VAT

3 TON TIPPER TRAILER (NEEDS REBUILD) £525.00

MF 50B DITCHING BUCKET £325.00 + VAT

MF FRONT WEIGHTS £325.00 + VAT

GEAR BOX & PUMP TO FIT ECON UNDER TANK £475.00 + VAT

IH FRONT WEIGHTS FOUR ONLY £225.00 VAT

SNOW PLOUGHS GRAY FRONT OR BACK £535.00 + VAT

SNOW PLOUGH BOUNCE FRONT ONLY £875.00 + VAT

LINER SAW BENCH WITH ENGINE ON SMALL WHEELS £135.00 + VAT

DOWDESWELL DP7 4 FUR REV PLOUGH £1,100.00 + VAT

DOWDESWELL DP7D 4 FUR PLOUGH £1,950 + VAT

PARMITER POST RAMMER £1,325.00 + VAT

MF CHISEL PLOUGH 8FT WIDE 3 TINES £765.00 + VAT

BOMFORD CHISEL PLOUGH 8FT WIDE 9 TINES £790.00 + VAT

BAMFORD 4 FUR PLOUGH DISC £425.00 + VAT

IFOR WILLIAMS 2 TON TRAILER WITH SIDES £1,750.00 + VAT

1988 KRAMER 312SE LOADING SHOVEL £4,450.00 + VAT

BOBCAT 313 SKID STEER LOADER NEEDS TLC £POA

McCONNEL HEDGE TRIMMER 1.2M £655.00 + VAT

LELY 3.5 TO 4M POWER HARROW FROM £895.00 TO £1,750.00 + VAT

MF 30 DRILL PIPES SHORT AND LONG £POA

WELD ON POINTS FOR LELY POWER HARROW, TOTAL 72 £POA

PUMPS TO FIT ECON HM1 & HM2 ECON HEADS £POA

LOWER LINKAGE HOOK TO FIT MF 2640/2680/2720 £POA

PLOUGH PART FOR DOWDESWELL AND RANSOMES £POA

MUIR HILL 4000 2WD LOADING SHOVEL SPARES OR REPAIRS £625.00 + VAT

SANDERSON 50 2WD FORKLIFT NEEDS ENGINE REBUILD £1,550 + VAT

SHELBOURNE REYNOLDS RAPE MACHINE TYPE 302/302-13 SPARE OR REPAIR

£1,475.00 + VAT

DUAL STOCKS AND BETTERSON 18.4X38 £POA

ECON HM1 & HM2 HEDGE TRIMMER GOT BRACKET £1.050 TO £1,650 + VAT

ECON HM1 BOOM WITH RAMS £465.00 + VAT

MF DRAW BAR TO FIT 135 TO 165 TRACTOR £175.00 + VAT

WHEELS AND TYRES FROM 14,0-16 10 PLY £325.00 + VAT

RIMS AND TYRES TO FIT MF OR FORD ETC., SIZE 12.5/80=18 10 PLY £325.00 + VAT

THE PAIR PLUS

11.00 = 16 10 PLY

MUCK FORK WITH GRAB TO FIT 4FT BOBCAT £425.00 + VAT

BOMFORD MODEL 90, 18461, 1957 K99 HEDGE TRIMMER 3 POINT LINKAGE CABLE

CONTROL 1.3M

HEAD £4,250 + VAT

SPEARHEAD MK6 HEDGE TRIMMER £POA

BOMFORD HYDRO MOWER HEDGE CUTTER £625.00 + VAT

FERGUSON CULTIVATOR FOR GREY FERG £195.00 + VAT

FERGUSON EARTH SCOOP ON THREE POINT LINK £325.00 + VAT

NUFFIELD OR LEYLAND SMALL WHEELS FOR FRONT £135.00 + VAT

TANCO BALE GRAB UP AND OVER MODEL £545.00 + VAT

PERKINS DIESEL 4CLD ENGINE TO FIT LANDROVER ETC., £345.00 + VAT

POWER PACK TO RUN WRAPPER ETC., NEEDS TLC £425.00 + VAT

DOWDESWELL SKIMS TO FIT DP1 PLOUGH £210.00 = VAT

NEXEN ROADIAN AT P245/70 R17 TO FIT TOYOTA OR ISUZU ETC., 6 STUDS £425.00 + VAT

TOP TO FIT TOYOTA PICK UP SINGLE CAB £135.00 + VAT

*PLEASE NOTE: ALL PRICES ARE PLUS VAT

£1,500

SUBARU DEPOSIT CONTRIBUTION*

APR 5.9% REPRESENTATIVE†

3 YRS

SERVICING FOR £299**

3 YRS ROADSIDE ASSISTANCE#

STOCK AVAILABLE FOR IMMEDIATE DELIVERY

SUBARU OUTBACK fuel economy and CO2 results (WLTP): Combined 33.0mpg, CO2 emissions 193g/km. MPG figures are real life conditions & CO2 produced depends on a number of factors including accessories fitted (post-registration), variations

Offers available until 31.12.23. Stock subject to availability. Subaru reserves the right to amend or withdraw offers at any time without prior notice. Private customers only. *£1,500 Subaru Deposit Contribution (incl. VAT) on a 2.5i Outback Limited, Field or Touring. †Credit is subject to status. Must be 18+. This credit offer is only for £299.00 (incl. VAT) offer applicable when you purchase a brand-new Subaru Forester e-BOXER, XV e-BOXER or Outback. All services should be taken at the The customer’s failure to redeem the services within the designated mileage or time will void the manufacturer’s warranty. Available to retail customer only. Does and Assistance Programme is included, valid in the UK and Europe.

We

are official EU test figures for comparative purposes & may not reflect real driving results. Fuel consumption achieved in variations in weather, driving styles & vehicle load.

customers only, not available in conjunction with any other offers. Excludes Personal Contract Hire and Business Contract Hire. Available at participating dealers only available through Subaru Finance provided by International Motors Finance Limited, St William House, Tresillian Terrace, Cardiff, CF10 5BH. **3 services the relevant service intervals - either 12,000 miles or 12 months, whichever comes sooner. All services must be completed by an authorised Subaru Retailer. Does not cover any non-service related parts or repairs or general wear and tear. Servicing is transferable with the vehicle. #A comprehensive 3-Year Recovery

David

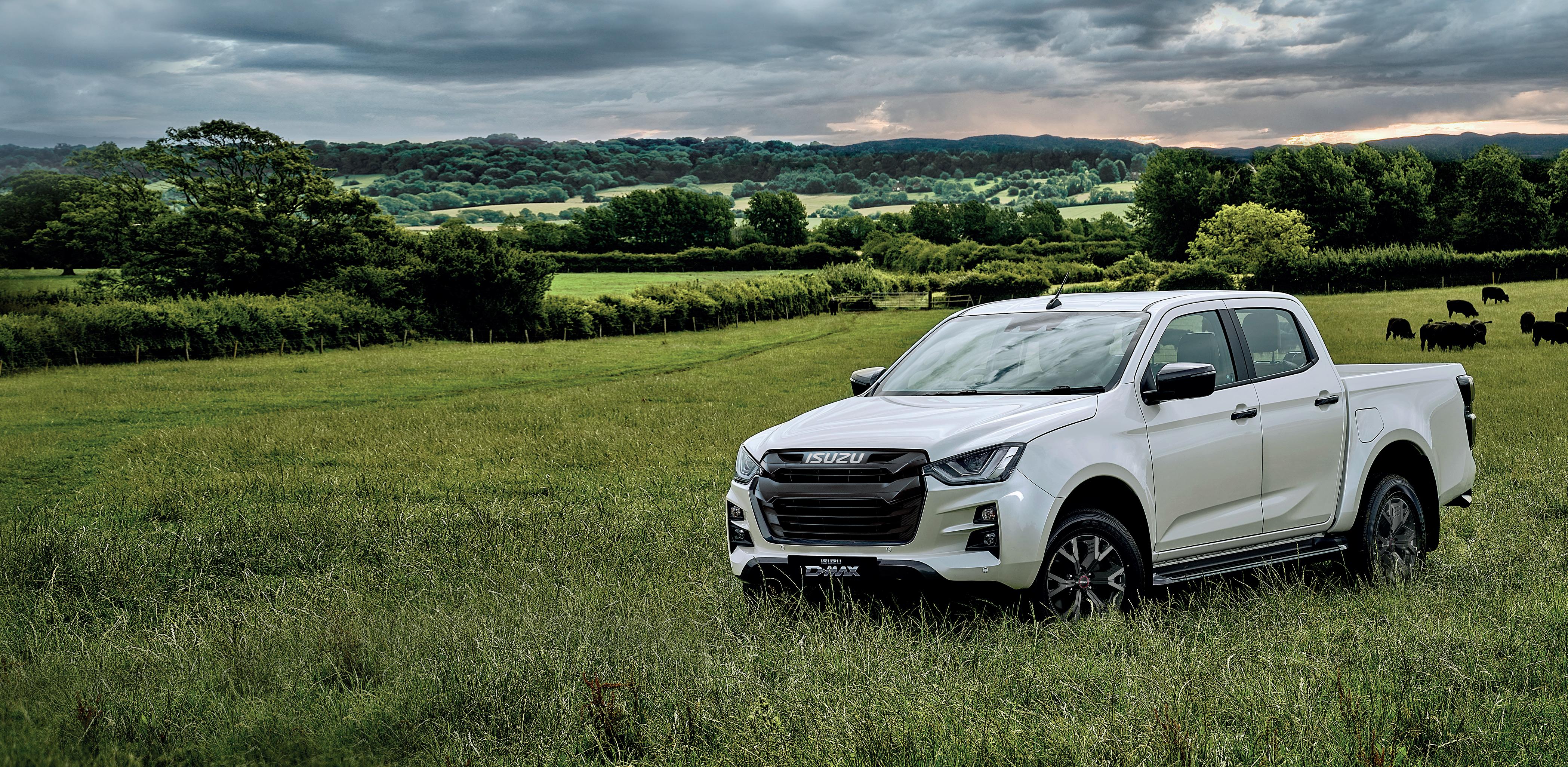

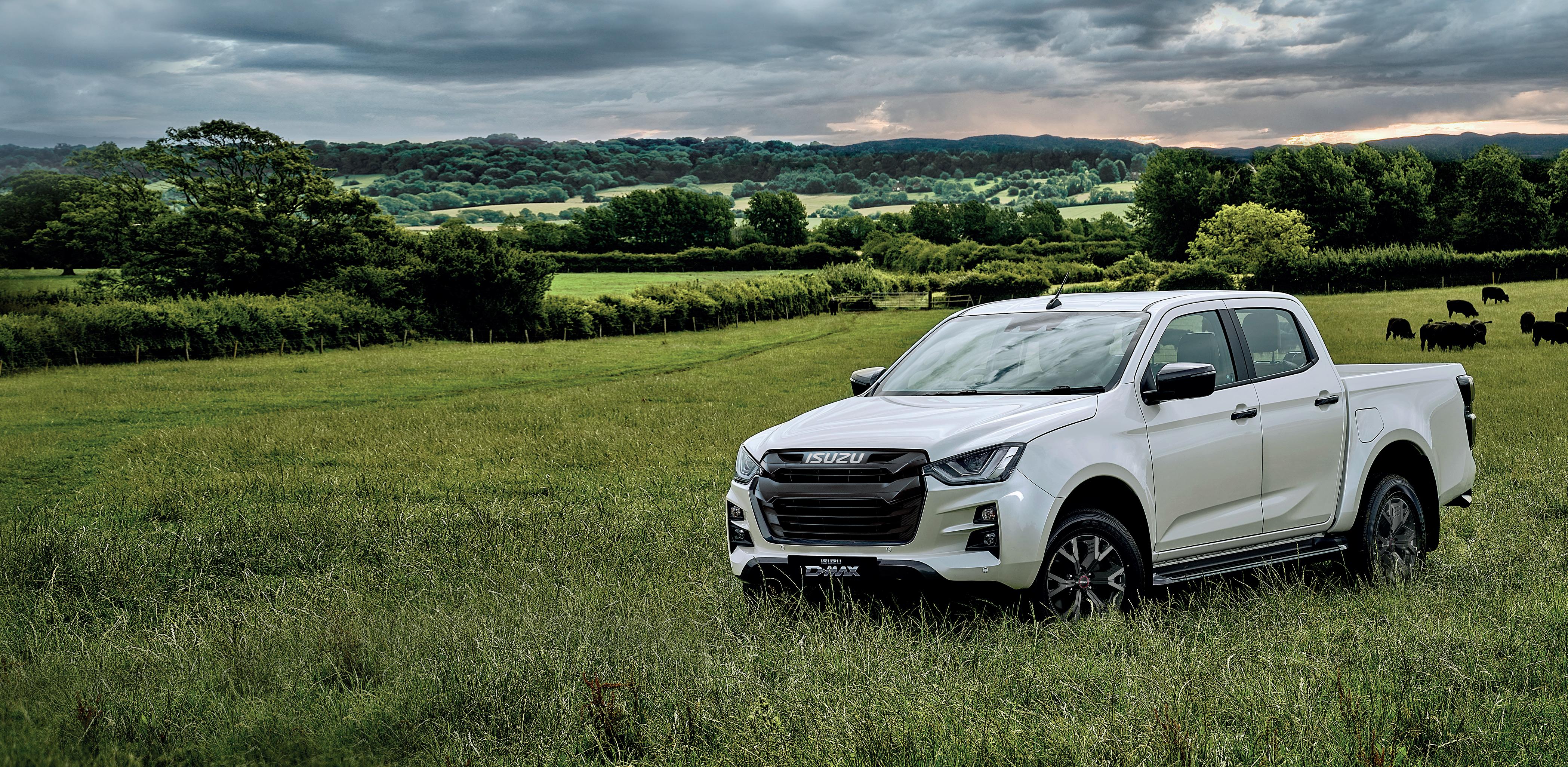

That’s the multi-award-winning Isuzu D-Max. With a 3.5 tonne towing capacity, 1.1 tonne payload, trailer sway control, hill start assist and descent control, it’s the pick-up as driven to do as you are.

01873 810304

Granada Park

Bob

David

www.bobgerard.co.uk

www.davidtaylorgarages.co.uk

Slip End

www.davidtaylorgarages.co.uk

, Crickhowell, Powys NP8 1HW

Luton, Bedfordshire, LU1 4BU: t: 01582 456888

www.slipendgarage.co.uk

All fuel consumption and emission values are based on the new WLTP (Worldwide Harmonised Light standard Isuzu D-Max range in MPG (l/100km): Low 25.1–27.6 (10.2–11.2). Mid 31.4–36.4 (7.8–9.0).

emissions 220–241 g/km.

Visit Isuzu.co.uk or contact your local Isuzu dealership for more information.

MJ Fews, Wotton-under-Edge GL12 8SR | t: 01453 844131

www.mjfews-isuzu.co.uk

Westaway Motors, Northampton, NN16 8JE t: 01604 847245

www.westawaymotors.co.uk

Light Vehicle Test Procedure) test cycle which uses real-world driving data. Official fuel economy for the (7.8–9.0). High 36.0–39.4 (7.2–7.8). Extra-High 29.0–30.8 (9.2–9.7). Combined 30.7–33.6 (8.4–9.2). CO2