7 minute read

GUIDANCE ON THE OPENING OF CORE AND DYNAMIC SAMPLER LINER

Article contributed by Liz Withington (Principal Engineering Geologist, CC Ground Investigations) and Adam Latimer (Director, Ian Farmer Associates).

For engineering geologists in the UK ground investigation industry, the opening of core and dynamic sampler liners to enable the logging of recovered material is a standard and often daily procedure. This operation is frequently carried out onsite, under field conditions, using a variety of tools including knives to complete the task effectively.

Statistics on accidents involving knives within the geotechnical and environmental sector aren’t readily available, however, relevant information is accessible from the UK plastics industry. Reviewing four separate plastics manufactures with online published information our research indicated;

1. A plastic film manufacturer identified that hand knife injuries contributed to over 50% of their total accidents.

2. A polyethene manufacturer indicated that over 50% of their accidents were hand injuries.

3. A plastic components manufacturer appointed a new safety manager who noticed that hand knife injuries accounted for a significant percentage of the company’s total injuries.

4. A pipe extrusion company noted that their largest category of injuries were cuts, and of these 75% were caused by knives.

Within the ground investigation industry there are many anecdotal incidents where operatives and logging engineers have caused serious harm to themselves whilst using knives, and it is more than likely that injuries involving the use of knives is more common than those instances that are reported.

The aim of this article is to explore the methods available to the engineer in the field and provide guidance on the safe cutting of core and dynamic sampler liners.

The use of knifes and other cutting devices is covered by The Provision and Use of Work Equipment Regulations 1998 (PUWER 1998), which requires work equipment to be suitable and safe for the task it is being used for.

The only focused advice from the Health and Safety Executive (HSE) is How to reduce hand knife injuries. HSE PPIS12(rev1) May 2000. However, this is not specific to the construction industry but provides practical advice to anybody involved in managing the risks of using hand knives as part of their work.

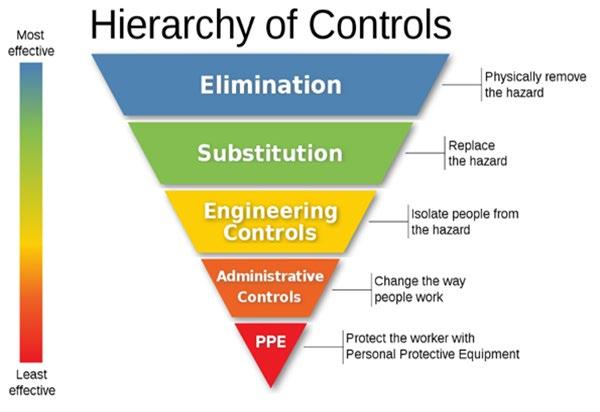

As with all risks associated with work activities, a risk assessment is required to identify the risk and put into place suitable and sufficient control measures to reduce the risk. When considering risk controls for core and dynamic sampler liner cutting it is important to select the most effective control measure, this is achieved by considering the hierarchy of controls.

As highlighted by the graphic, the most effective risk controls are elimination, substitution and engineering controls, weaknesses within administrative controls and personal protective equipment are created through the reliance on humans to follow rules. Where this reliance can be removed, more effective controls have a positive impact on reducing harm.

Considering, the hierarchy of controls application to core and dynamic sampler liner cutting mitigation, the following could be considered:

Elimination: alternatives to core liner could be identified that eliminate the use of knifes or the need to cut liners. Consideration should be given to different techniques that may eliminate the need to cut core liners or in fact not use core liners at all.

Substitution: can be applied to the core liner itself, identify alternative types of liners that are easier to cut and reduce the effort used to cut the liner improving knife control and reducing the risk of cutting. The volume of core liners produced can also potentially be reduced, through the reduction of intrusive locations, the use of other investigative methods (e.g. CPTs) or substituting some of the field work for computer modelling utilising AI based technologies.

Engineering Controls: provide significant options to reduce cutting associated with core liners, from specifying safety knifes with self-retracting or hidden blades or by the introduction of purpose-built core liner cutters, jigs for powered tools or other mechanical options.

Administrative Controls: in relation to fixed blades bans within site rules and procedures or alternative equipment detailed within method statements. These controls have weaknesses surrounding implementation, as they need greater levels of supervision and trust of the operatives and fixed blade knifes have a habit of finding their way onto site.

Personal Protective Equipment: is universally used on every project and sometimes overused, throwing PPE at a problem without taking the time to understand the holistically to begin with. Cut resistant gloves, gauntlets and other protective items have been significantly improved in recent years, providing good dexterity as well as high cut resistance.

Through the research required to write this article, consulting with people across the industry and those outside of it, methods of core and dynamic sampler liner cutting which significantly lower the risk of cuts to hands have been identified. These are not risk free, but in practice significantly reduce the risk of significant hand injuries when compared to the use of fixed blade knifes which should not be used for core and dynamic sampler liner cutting.

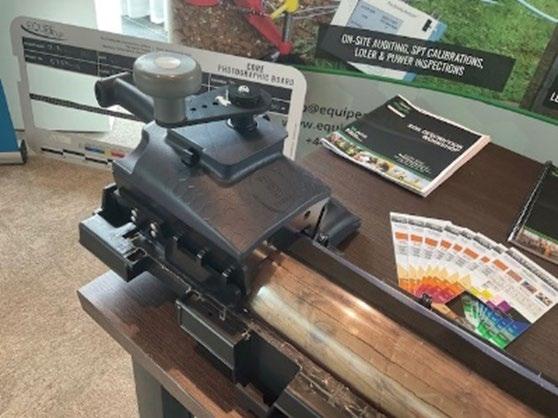

Core Line Cutting Rig

In a purpose-built logging shed core liners can be cut using a bench and cutting rig arrangement where liners are put within a rigid frame and the liners mechanically cut either by a hooked blade arrangement in a safety jig or vibratory cutter (noting that the introduction of vibrating tooling introduces vibration, noise and dust risks which need to be controlled).

In either case the cutting is carried out without the need for the technicians/geologist fingers to be anywhere near the cutting edge, reducing the risk of injury. However, with what is available on the market today, this type of set up is almost certainly prohibitive in terms of suitability of the site environment when working in the field.

height for the operator to ensure ergonomic working practices, reducing the risk of musculoskeletal injuries. This can be achieved in the field by using trestles or the open tailgate of a truck. Rechargeable battery units should be preferred to eliminate introducing the additional risk of trailing cables and electric shock.

“ In either case the cutting is carried out without the need for the technicians/geologist fingers to be anywhere near the cutting edge, reducing the risk of injury.

Using Oscillating Blades

and Smalls Grinders will introduce additional hazards that must be controlled through the introduction of suitable and sufficient controls, these include: manual handling, flying debris and dust, noise, vibration and the potential damage to the core/sample itself through overcutting.

Safety Cutters

Oscillating Blades and Smalls Grinders

The use of oscillating blades (preferred due to safer handling) and small grinders is a technique that can be beneficially used where the cores and liner can be placed in a rigid structure (such as a core box), and at a suitable

There are a number of different safety cutters available to the industry which are capable of cutting core and dynamic sampler liner. These types of cutters prevent the small surface area of the blade coming into contact with the fingers.

Unfortunately, this type of cutter is often the source of great frustration when they fail to work either due to user error or their lack of suitability for the task in hand, particularly when they were too wide to get between the core and the core liner. It is well documented that when such frustrations occur it is human nature to bypass the agreed procedures and revert to fixed blade knifes and inaccurate statements made that ‘all safety cutters will not work’.

Due to these very real risks, the selection and testing of safety cutters is imperative to ensure that the tools are fit for purpose, task and the environment which they are used in.

Safety Knives

There are a number of different safety knifes available in the marketplace. These type of knifes have an automatically retracting blade when pressure is released from the blade. These will then require resetting before the blade is re-exposed.

As safety knifes work using the same manual techniques as a fixed blade knife, their use, provided the correct knife has been selected for the task, is more widely accepted by those within the industry and they do not require controls to be introduced.

When using retractable safety knifes, if they are poorly maintained, they are susceptible to being damaged by rust and the mechanism being clogged by debris, eventually preventing it from working effectively. This, together with other maintenance and user information should be documented into administrative controls to support their effectiveness.

As with any task, training and health and safety risk assessments should be provided on how to open core liners and other samples safely, regardless to which of the above techniques are employed. This training should cover the core cutting methodology, how to replace blades on retractable knives, regular cleaning and maintenance of cutting tools.

When considering the task itself it is important to place the liner in a fixed sturdy location such as a core box or other configuration that holds the liner firmly in place, place the knife perpendicular to the core, facing away from the body at a 45o angle and ideally use two hands, pull the knife allowing slow controlled cuts, be given to the strength and dexterity of the person cutting the liner. Additionally, certain types of core liner can be prone to shattering and splintering when cut. The operator shall remain vigilant at all times when cutting liners in case they are fragile and the cutting methodology reassessed.

Other basic controls when handling knifes should be applied, even when using safety knifes, these consist of but are not limited to;

Not handing a knife to a work colleague. Instead, lay it on a flat surface for them to pick up.

Keep the thumb of the hand using the cutter away from the blade, and your other hand far enough away to avoid laceration.

• Knife blades should be kept sharp and knives maintained and checked before use.

• Any damaged or knives or blades should be disposed of in a safe manner.

• Ensure there is good lighting available where the task is being undertaken.

• When done with a knife, store it edge-down or covered.

As with all cutting activities, they should be

severity of the injury.

The right kind of cut-resistant glove to purchase is the one that best protects the user from the hazards they face. Heavy duty gloves or gloves that are too large for the individual will affect the dexterity of the user and they may be tempted to remove the gloves, which exposing them to risk. Always ensure that when selecting gloves, cut resistant and dexterity are considered.

Summary

The cutting of core and dynamic sampling liner within the geotechnical industry will remain an important part of the normal operations of field based engineers. Knives are the most commonly used hand tool for this type of activity, however, they require proper selection, application, and training in use and storage. The improper use of cutting tools and knives can lead to significant hand injuries, however, using a simple risk assessed approach, the severity and likelihood of injuries sustained can be greatly reduced if not eliminated.