March 2023

ZEROING IN ON TIMBER PILES

How timber piles can be deployed in the UK to help achieve Net Zero targets being set

Image Credit: Peter Alheid of Hercules, Sweden

A REFRESHER ON CLEAN COVER SYSTEMS

Existing guidance, the advantages, and disadvantages.

COAL TAR: ANALYSIS AND DETECTION

Standardising laboratories approaches to detection and analysis of coal tar.

INSIDE: JACOBS

Q & A with Solenn Le Pense, Senior Geo-digital Engineer at Jacobs.

Chair’s Foreword

As we launch into Spring and hopefully more manageable underfoot conditions for us all on site, I welcome you to the March issue of the AGS Magazine.

I very much look forward to seeing many of you at the AGS Annual Conference next month, to be held at the Barbican Centre in London, and we have been working hard to secure interesting speakers and sponsors for your benefit. You can read more about the programme in this issue.

In the meantime, in this edition we focus very much on geoenvironmental issues facing our industry. Please read on to refresh your knowledge of cover systems for containing contaminated ground and to learn more about the benefits, limitations, and suitability of using timber piles in the UK. Our Laboratories Working Group leader advises us on considerations regarding the analysis of and detection of coal tar, and we feature an article by our Loss Prevention Working Group leader on COP27 and how the AGS will be supporting its members in initiatives to support limiting climate change. In the ‘Inside’

article this month, Solenn Le Pense tells us what makes an interesting career as a Senior Geo-digital Engineer with Jacobs.

It’s also time to get your cameras out and send in your entries to our Photography Competition for a chance to win a tasty food hamper and to have your images features in future AGS publications. I look forward to seeing recent images reflecting your work from the usual high standard of entries.

We are always on the lookout for additional, informative content for the magazine, so if you have a case study or technical article that you think the wider geotechnical and geoenvironmental public would find beneficial, please do get in touch.

We would be interested in your feedback on the magazine and our future plans. Please contact ags@ags.org.uk if you have any comments.

Sally Hudson AGS Chair

ABOUT THE AGS

The Association of Geotechnical and Geoenvironmental Specialists (AGS) is a not-for-profit trade association established to improve the profile and quality of geotechnical and geoenvironmental engineering. The membership comprises UK organisations and individuals having a common interest in the business of ground investigation, geotechnics, geoenvironmental engineering, engineering geology, geochemistry, hydrogeology, and other related disciplines.

EDITORIAL BOARD

Sally Hudson, AGS Chair

Caroline Kratz, Forum Court Associates (FCA)

Katie Kennedy, FCA

Julian Lovell, Equipe Group

Calum Spires, Equipe Group

David Entwisle, BGS

Chris Vincett, Hydrock

Lauren Hunt, Arcadis

Adam Latimer, Ian Farmer Associates

Dimitris Xirouchakis, Structural Soils

Emma Anderson, HaskoningDHV UK

Daniele Fornelli, Geotechnical Observations

EDITORIAL STORY

If you have a news story or event which you’d like to tell our editorial team about, please contact the AGS on 020 8658 8212 or ags@ags.org.uk. Please note that articles should act as opinion pieces and not directly advertise a company. The AGS is under no obligation to feature articles or events received.

CONTACT US

AGS

Forum Court, Office 2FF, Saphir House, 5 Jubilee Way, Faversham, Kent, ME13 8GD

ags@ags.org.uk

020 8658 8212

Association of Geotechnical & Geoenvironmental Specialists

@agsgeotech

www.ags.org.uk

2 Magazine

PAGE 12

COVER STORY PAGE 16

Katharine Barker of Campbell Reith discusses how timber piles can help the UK reach Net Zero.

A refresher on clean cover systems

Over-familiarity with clean cover systems is increasingly leading to poor implementation. Andrew Tranter of RSK provides a refreshment and reminder on the existing guidance, the advantages, and disadvantages, as well as design considerations of cover systems.

AGS ANNUAL CONFERENCE

PAGE 8

The latest details and sponsorship opportunities available for the AGS Annual Conference.

COAL TAR: ANALYSIS AND DETECTION

PAGE 20

Standardising laboratories approaches to detection and analysis of coal tar.

INSIDE: JACOBS

PAGE 26

The AGS Magazine conducts a Q & A with Solenn Le Pense, Senior Geo-digital Engineer at Jacobs.

MORE INSIDE

PAGE 4

News in Short: Incl. upcoming AGS Events

PAGE 24

COP27 and a ‘Way Forward’

An AGS summary

PAGE 30

Upcoming Events & Courses

March 2023 3

Inside this month’s issue

FEATURE

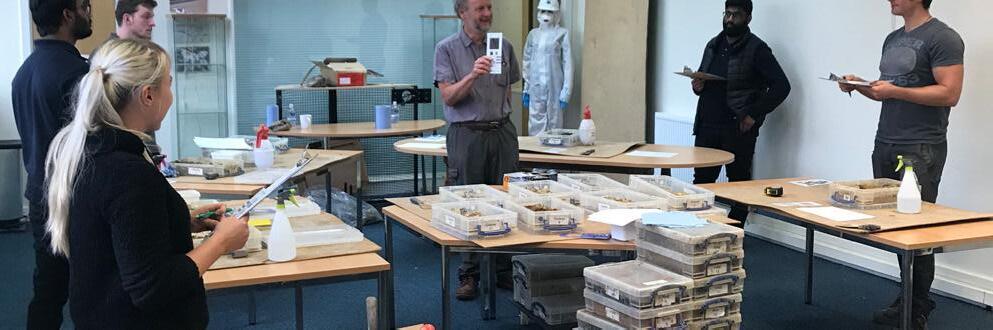

Image Credit: Andrew Tranter, RSK

News in Short

AGS Live and Virtual Events 2023

AGS Annual Conference 2023 (live event)

Î Date: 27th April 2023

Î Location: Barbican Centre, London

Î Fee: £95 for AGS Members, £160 for nonMembers and £79 for students. Prices exclude VAT. Honorary AGS members may attend the event free of charge. A limited number of delegates per AGS Member company may attend the Annual Conference free of charge, see details HERE.

Î Speakers:

∙ Nick Sartain, Head of Geotechnical Engineering at High Speed 2

∙ Luke Deamer, Group Sustainability Manager at Keller

∙ Chaido Doulala-Rigby (Yuli), Chief Civil Engineer and Business Development at Tensar International

∙ Joel Carson, CEO Executive Director at Geoprofessional Business Association (from USA)

∙ Vivien Dent, Technical Specialist: Green Growth and Delivery at the Environment Agency

∙ Edd Lewis, Data Standards Lead at British Geological Survey

∙ Additional speakers will be announced in due course

Î Sponsorship: A limited number of Emerald, Gold and Associate sponsorship packages are available. Click HERE for full details or email ags@ags.org.uk to confirm your support.

AGS Data Management Webinar

Î Date: 20th September 2023

Î Fee: TBC

Î Speakers: TBC

Î Sponsorship: Headline and Associate Sponsorship packages are available. Click HERE for full details or email ags@ags.org. uk to confirm your support.

AGS Ground Risk (live event)

Î Date: 22nd November 2023

Î Location: One Great George Street, London

Î Fee: £160 for AGS Members, £230 for NonMembers. A limited number of places are available for students, local authority and EA places for £95. All prices exclude VAT. To express an interest in attending, email ags@ ags.org.uk

Î Speakers: TBC

Î Sponsorship: A number of Headline, Diamond, Emerald, Gold and Associate sponsorship packages are available. Click HERE for full details or email ags@ags.org. uk to confirm your support.

4 Magazine

Breaking Ground Podcast: New Episode Now Live

Breaking Ground, a podcast collaboration between Ground Engineering Magazine and the Ground Forum, has released two new episodes which are available for free listening:

Î Alex Petty on Geology

Î Rebecca Penn, Martin Griffin & Gary Evans on Neurodiversity

Hosted by Steve Hadley, Breaking Ground covers a wide range of ground engineering related topics. Key themes include sustainability, design, commerce, diversity, health and safety, welfare, construction techniques, education, and industry challenges. Episodes also profile industry members' careers within the context of discussing industry issues, construction techniques and case studies.

Breaking Ground is available for free download on channels including Spotify, Apple Podcasts and Google Podcasts. To listen to the podcast, click HERE

For further information on the podcast or for podcast sponsorship opportunities please email gforum@ground-forum.org.uk.

NQMS Myth Busters Bulletin

The National Quality Mark Scheme (NQMS) is an industry initiative led by the National Brownfield Forum to promote good practice in the preparation of land condition reports. It is endorsed by Government; it is endorsed within LCRM and many regulators now ‘signpost’ it in their planning guidance. In spite of this wider acceptance there are still unfounded myths circulating. In light of this, a myth busters bulletin has been produced and can be viewed here

AGS Publication Updates

The top three AGS publications in last month:

1. AGS Guide to Ground Investigation Reports

2. AGS Guidance on Waste Classification for Soils – A Practitioners Guide

3. Comment on the approach for classifying sites into green, yellow or red

Recent AGS publications available on the AGS website:

• A Client’s Guide: The Purpose and Use of Geoenvironmental Reports

• LPA 72 – Reminder of the Problems with Indemnities

LPA 73 – Liability for Subcontractor’s Fraud

To download the publications for free; click here.

March 2023 5

News in Short

AGS Photography Competition 2023

The AGS is pleased to announce it is holding a new photography competition for 2023.

We’re on the lookout for your most creative images which are reflective of the geotechnical and geoenvironmental industry.

If you’re a budding photographer or have a great engineering image which you’d like to enter, then we’d like to see it!

Entry into the competition is free and the winner of the competition will win a food hamper basket from luxury retailer, Fortnum and Mason, worth over £75. Three runners up will each win a bottle of Champagne.

There are no restrictions on the photography equipment used, so feel free to use a phone, computer, tablet or a traditional hand-held camera to capture your image as long as the below criteria are met.

All entries will be reviewed by select members of the AGS, who will decide on a shortlist and a potential winner. Full details will be announced in the September issue.

IMAGE REQUIREMENTS

Entries should be high resolution JPEG images (300 DPI / over 1MB image file size) of a geotechnical and geoenvironmental nature. Images can include project imagery, laboratory testing, collaborative working and more.

Photographs featuring any on-site operatives should showcase health and safety procedures

in place, if appropriate. Images should be no smaller than 4200 x 3400 pixels.

HOW TO ENTER

Please email your image with;

A short description of what it showcases and where it was taken (up to 50 words)

• Image credit information (if applicable)

• Your full name

• Company name

• Postal address

to ags@ags.org.uk with the subject ‘AGS Magazine: Photography Competition 2023’ in the email.

There is no limit to the number of images you enter. The deadline for entries is 7th July 2023. Entry into the competition is free.

TERMS AND CONDITIONS

Applicants must be aged 18 or over.

• All images must be high resolution and 300 DPI (dots per inch) / over 1MB image file size.

• Applicants must be based in the UK.

• The photographer must have full copyright and appropriate permissions from all involved parties, for all images submitted.

• All images entered may be reproduced by the AGS and used in future AGS event and marketing literature without prior notice. This may include usage across the AGS’ social media channels, inclusion in the AGS Magazine, event programmes and on the AGS website. Please note that all images used will be credited.

6 Magazine

Association of Geotechnical & Geoenvironmental Specialists

WHY BECOME AN AGS MEMBER?

Enhance your status in the industry. Make a statement about quality and good practice. Participate in the AGS Working Groups and help shape the industry and set the standards.

WHAT DO WE STAND FOR?

■ Good practice in geotechnical and geoenvironmental engineering

■ Quality companies providing a quality service

■ Health and Safety

■ AGS Data Format

For further information on the AGS and details on how to become a member visit www.ags.org.uk

Established in 1988, the Association of Geotechnical and Geoenvironmental Specialists is a not-for-profit trade association which represents over 140 leading companies specialising in site investigation, geotechnics, geoenvironmental engineering, engineering geology, geochemistry, hydrogeology, and other related disciplines.

WHAT DO WE OFFER?

■ Guidance to good practice

■ Listing in the Directory of Members

■ AGS Magazine focused on ground engineering ‘hot topics’

■ Legal helpline

■ Chemical safety helpline

■ AGS Loss Prevention Guidance Document

■ Seminars, meetings, conferences and webinars

■ Collaboration with other bodies

■ Liaison with UKAS

■ Lobbying on matters important to the sector

■ Developing and maintaining the AGS Data Format

MEMBERS CAN CONTRIBUTE BY PRODUCING SUCH DOCUMENTS AS:

■ AGS good practice guidance

■ AGS publications

■ AGS safety guidance

■ AGS client guides

MEMBERS CAN PARTICIPATE IN AGS WORKING GROUPS:

■ Laboratories

■ Contaminated Land

■ Safety

■ Business Practice

■ Loss Prevention

■ Data Management

■ Executive Committee

■ Geotechnical

■ Instrumentation and Monitoring

The AGS Annual Conference will be taking place on Thursday 27th April 2023 at the Barbican in London.

This full day, flagship, networking event will see six guest speakers present on a variety of hot topics, and short presentations from each of the AGS Working Group Leaders. Speakers confirmed to date include Nick Sartain, Head of Geotechnical Engineering (HS2), Joel Carson, CEO Executive Director (Geoprofessional Business Association) who will be flying in from America to present at the conference, Edd Lewis, Data Standards Lead (British Geological Survey), Luke Deamer, Group Sustainability Manager (Keller) and Chaido (Yuli) DoulalaRigby, Chief Civil Engineer & Business Development EH (Tensar) and Vivien Dent, Technical Specialist: Green Growth and Delivery (Environment Agency). The conference will be Chaired by AGS Chair, Sally Hudson and AGS Chair Elect, Vivien Dent.

The event is currently sponsored by Soil Engineering, Insitu Site Investigation, Geotechnical Engineering, SOCOTEC, Equipe, Geosense, Groundsure, Seequent, Dunelm, BAM Ritchies, Envirolab, Brimstone, British Geological Survey, AFITEXINOV UK, Concept Consultants and Fugro

PRESENTATIONS

Better Productivity Through Better Communication

Nick Sartain, Head of Geotechnical Engineering at HS2

Digital technologies are driving significant change within the industry and are require datadriven communication more than ever before.

This presentation will investigate what is necessary for excellent communication of digital information, what benefits this will bring, and will describe some projects underway to improve on current practice.

Building Sustainability from the Bottom Up: Embedding Sustainability throughout Geotechnical Companies

Luke Deamer, Group Sustainability Manager at Keller

Some of the most common drivers of sustainability are client demand and legislation. Both of these are important, but they can quickly be forgotten in smaller projects, or can be dismissed as a compliance exercise. In this presentation, Luke, therefore, explores the wider opportunities of sustainability to geotechnical companies.

Importantly, he also explores how every geotechnical employee has a role to play in improving sustainability. From the smallest project to the largest, from Procurement to HR, Luke identifies best practices from across our sector. Through these process-level improvements, he advocates for sustainability to be built from the bottom-up.

Environment Agency Updates

Vivien Dent, Technical Specialist: Green Growth and Delivery at the Environment Agency

The presentation will provide an update on various Environment Agency issues, projects and guidance relevant to the AGS.

8 Magazine

Learning from Others’ Pain – Loss Prevention through Lessons Learned

Joel Carson,

CEO Executive Director, Geoprofessional

Business Association (from USA)

What if we could learn from other people’s mistakes? Attend this session and learn about GBA’s library of over 110 Case Histories. Real life projects that went horribly wrong. Learn how you can avoid risk by learning from other people’s real-life losses. Most importantly learn the most common lessons learned so you can avoid them on future projects to be smarter, stronger, and more successful.

Good Practice & Lessons

Learned in Constructing

Reinforced Soil Structures using Coarse, Site-Won and other Non-‘Standard’ Reinforced Fills

Chaido Doulala-Rigby (Yuli), Chief Civil Engineer and Business Development at Tensar International

A brief historic review from the origin of stabilized soil concept to today’s use of polymer geogrids in construction, sharing the ‘dos’, the ‘don’ts’ and lessons learned from around the world in construction practice, and illustrating how to effectively use site-won and other non‘standard’, unusual reinforced soil fills.

Subsurface Data Sharing and The Geospatial Commission’s Construction Playbook; BGS improved AGS data ingestion and delivery and What’s next for the National Geotechnical Properties Database?

Edward Lewis, Data Standards

Lead at British Geological Survey

The Construction Playbook recommends the use of “boilerplate” model clauses in contracts, including the recently published “HMG Model

Clause – Subsurface Data Sharing” which states that JCT and NEC3/NEC4 contracted projects require the AGS data from these to be submitted to the National Geoscience Data Centre (the “NGDC”) of the British Geological Survey (the “BGS”), “to become part of the UK repository of subsurface data for re-access and longevity.” We will outline the data ingestion, storage & delivery process for the data you’ve collected, including new tools we’re developing to make the data, including the BGS National Geotechnical Properties Database, more Q-FAIR (Quality, Findable, Accessible, Interoperable and Reusable).

TICKETS

Tickets are priced at £95 for AGS Members and £160 for non-Members. Students may attend the conference for a reduced rate of £79 by emailing ags@ags.org.uk. All prices exclude VAT. Registration closes on Monday 17th April.

A limited number of delegates per AGS Member company may attend the Annual Conference free of charge. The number of complimentary tickets provided is dependent on the number of specialists in your company. To claim your complimentary tickets, please complete the form found on the AGS website HERE and return it to ags@ags.org.uk before Monday 17th April. Terms and conditions apply; please see form for full details.

EVENT SPONSORS

March 2023 9

SPONSORSHIP

Associate Sponsorship packages are available for companies who wish to be featured in our programme and marketing of the event. Please see details below:

ASSOCIATE SPONSOR (AGS Member

Rate: £550 Non-Member Rate: £700)

Î Free entry for one delegate into the event

Î Company directory in AGS magazine (worth £50, over 5,500 subscribers)

Î Company logo on event PowerPoint Presentation holding slide

Î Company logo on the event programme

Î Company overview on the AGS website

Î Company logo to feature on promo emails

Î Announcement of your company’s involvement on the AGS Twitter page (over 3420 followers)

Î Announcement of your company’s involvement on the AGS’ LinkedIn page (over 6900 followers)

Î Company mention in pre and post-event articles in AGS Magazine

If you’d like to confirm your interest in sponsoring the event, please contact Caroline Kratz or Angharad LambourneWade on ags@ags.org.uk before Friday 31st March. Please note that packages are limited and are offered on a first come, first served basis.

Preserving our natural capital by providing environmental testing solutions

We offer a wide range of analytical services for the environmental, construction, waste, fuel and engineering industries and are accredited to ISO 17025 and MCERTS for soils and waters.

Our dedicated team can provide bespoke reports such as AGS, HWOL and CSV to help you process your analytical data.

10 Magazine

Find us on SUEZ.COM/UK

SOCOTEC GEOTECHNICAL SERVICES

SOCOTEC is the UK’s market leading provider of site investigations, drawing on over 80 years’ experience in delivering high quality services. With expert field operations, backed up by UKAS accredited analytical testing and proven technical support, we help our clients to minimise ground related uncertainty and risk, as well as maximising efficiencies.

We provide a complete, integrated package of services, covering the whole project lifecycle from the pre-build phase through to site investigation, design, construction and the built stages. As part of this service, we accurately investigate, test and advise on ground, geological and structural conditions.

Our services include:

› Ground Investigation

› Drilling and Sampling

› In Situ (Field) Testing

› Monitoring

› Cone Penetration Testing (CPT)

› Pressuremeter Testing

› Geotechnical Services

› Site Surveys

› Topographic Surveys

› Geophysical Surveys

› Underground Utility Surveys

› Contaminated Land Investigation

› Environmental Chemistry Testing

› Materials Testing

March 2023 11 01283 554 400 www.socotec.co.uk

–

A refresher on clean cover systems

Clean cover systems are one of the most commonly applied remediation techniques deployed by developers within the UK. They are used to reduce the risk of exposure to soils potentially harmful to health and or to reduce contaminant mobilisation by presenting a low permeability barrier to infiltration. Consequently, they can provide both a viable and sustainable solution for mitigating risks. Yet over-familiarity is increasingly leading to poor implementation. A refreshment and reminder on the existing guidance, the advantages, and disadvantages, as well as design considerations of cover systems, are consequently presented below.

A cover system is composed of a single or multiple layers of ‘clean’ materials, which are placed above soils that are considered to be potentially harmful to a particular receptor, typically site users on a development site.

Their main purpose is usually to remove or reduce the pathway in the source-pathwayreceptor conceptual model. However, one or more layers can, as already noted, have other uses, for instance, concerning landfills, a cover or capping layer may also be used to limit surface water infiltration.

Technical guidance on the use of cover systems as a remedial technique was first included within CIRIA special publication 104, ‘Remediation Treatment for Contaminated Land Volume IV’ published in 1995, and CIRIA special publication SP124, ‘Barrier lines and cover systems for containment and control of contaminated land’ published in 1996. However, the use of this technique for the restoration of landfills or mineral extraction sites predated any specific contaminated land guidance. Both of these CIRIA guidance documents outlined some of the factors that should be considered when designing an engineered cover system, for example, the selection of appropriate materials to guard against the upward movement of contaminants through anthropogenic activities, burrowing animals, and capillary

12 Magazine

Article contributed by Andrew Tranter, Principal Environmental Consultant at RSK

Photo Credit: Andrew Tranter, RSK Laying subsoil at Barking Riverside

action. However, there was no actual guidance given on the appropriate thickness of the cover layer to be required. This was left to the discretion of the designer, increasing the risk of an inconsistent approach between sites and geographies arising.

The British Research Establishment (BRE) subsequently published guidance document BRE465 in 2004. This sought to provide some consistency in the approach to designing cover systems. The document divided cover systems into two distinct types; an engineered covered layer designed to completely break the pathway between the contaminated soils and receptor (as discussed in the CIRIA guidance), and a simple cover layer that reduces the exposure to a receptor. The detail of this BRE guidance was, however, only to focus its content on simple cover system design.

A key question considered within this BRE guidance was to be the level of intermixing between soil layers that could be considered to arise within a domestic setting. The research was to state that disturbance from anthropogenic activities (digging) and intermixing due to natural processes, such as burrowing animals, earthworm activity, and plant roots, was unlikely to exceed 600mm.

Based on these findings, this guidance contained a method for calculating the thickness of the cover, which used 600mm to be the default mixing zone. For a given contaminant of concern (COC), the BRE equation determined how much cover would be required to reduce the concentrations to a pre-determined target concentration/ assessment criterion. As a conservative approach, the equation considered that all mixing would occur uniformly across the

whole of the mixing zone, but in reality, disturbance (impacted soils being brought to the surface) was likely to be localised. Finally, the maximum depth of the cover was set at 600mm, but this could be altered if there was reasonable justification.

An Excel spreadsheet was provided with the BRE guidance and a simple check graph enabled the user to determine whether a simple cover system was appropriate. If the concentration of the COC was too high, then this would be highlighted by the graph. Advice against the deployment of a simple cover system was also made under conditions where:

Non-threshold contaminants (i.e. those that pose a risk at any concentration, such as asbestos) were present,

• other contaminant pathways were present, such as the inhalation of vapours/ gas, direct contact with rising groundwater, etc.,

• if there was a risk to groundwaterand and the need to reduce leachability,

• where sloping ground was present i.e. where a consistent thickness of cover could not be maintained, and

• where in areas deeper excavations were required for ponds, tree planting, fencing, etc.

BRE465 remains a commonly applied reference. The NHBC published a technical extra (issue 8) in 2012 on the ‘verification of clean cover system-testing of subsoil and topsoil’. This document has clearly stated that the topsoil should meet British Standard 3882:2007 and has provided details of how

March 2023 13

“ A key question considered within this BRE guidance was to be the level of intermixing between soil layers that could be considered to arise within a domestic setting.

What is a cover system?

Cover systems fall into two categories: firstly, a simple cover layer is typically composed of one or two layers (topsoil/subsoil) of ‘clean’ material that reduces the exposure to potentially harmful substance(s) in the strata it is placed over.

Secondly, an engineered cover system comprises one or multiple layers which prevent contact within the underlying soils. Each layer may be designed for a specific purpose such as reducing infiltration, capillary break, no-dig later, etc.

Design considerations (examples)

1. Purpose of the cover system (simple or engineered)

2. Topography of the site

3. Landscaping details

4. Suitability of the cover soils

5. Drainage/groundwater

6. Depth of cover

7. Sustainability (removal of soils for off-site disposal)

many plots on a residential development should be validated. The current NHBC technical standards (2022) Chapter 10.2 (Drives, Paths and Landscapes) further positions that:

• Works should be carried out following a formal remediation statement,

• Topsoil and subsoil should be of a quality that does not pose a hazard to users,

• Old foundations, concrete bases and similar obstructions should be removed from 450mm of finished ground level,

• Appropriate action should be undertaken to restore the physical conditions and drainage characteristics of topsoil and subsoil that has been compacted during construction,

• A minimum thickness of 100mm topsoil is required.

A key message is that even if the NHBC is not involved with a development, it is now considered as ‘ordinary care', as their guidance is followed when designing and validating a

cover system as a matter of normal practice.

Of further note then with familiarity, it has almost become standard to apply a 600mm clean cover system. Sometimes, but not always, this is underlain by a marker layer in private gardens. The presence or absence of a marker layer should always be clearly and explicitly described in the remedial strategy. Such reasoning is too often absent or simply inferred. Next in regards to 600mm this may indeed be adequate to reduce the risk to an acceptable level, however, there is again often little or no justification to the design. Indeed this depth is based on the mixing zone from the BRE guidance, but the purpose of the guidance was not to set a definitive depth for a cover system. Assessment criteria derived using the Environment Agency’s contaminated land exposure assessment (CLEA) model takes into account exposure to site users within the top 1 metre of soil. Also, if a landscaped area is planted with trees then the roots will extend beyond a metre depth. The depth of the cover system should always be based on its specific setting. In summary, the thickness of a cover layer should again always be clearly and

14 Magazine

Overall, the advantages of specifying a clean cover system are that it can negate the requirement for the removal of a contamination source; is generally straightforward for a groundworker to implement, and is widely accepted by a Local Authority. The disadvantages are that to often to little consideration is given to the appropriate design of cover systems. Furthermore, where ground levels cannot be raised, the soil is excavated and removed to accommodate the cover system. The removed soil can be either disposed of off site or reused in accordance with a Materials Management Plan (MMP). Other risk assessment or remedial measures may be able to reduce the quantity of soil requiring replacement and/or disposal. Indeed, the need on occasion for some cover

In conclusion, the use of a cover system can be a very reasonable and cost-effective remedial solution to use, as long as they are documented, designed then implemented with thought and critical thinking. However, the technique is so widely used that with over-familiarity it is perhaps sometimes abused. It may be that as consultants contractors and developers we should take the opportunity to reflect and remind ourselves that we must ensure that a consistent and critical approach is applied. Lastly, let's never forget to validate!

The National Contaminated Land Officers Group (NCLOG) cover systems subgroup are currently working on a new guidance document, so please keep a look out.

March 2023 15

“ In conclusion, the use of a cover system can be a very reasonable and costeffective remedial solution to use...

Photo Credit: Andrew Tranter, RSK

Validating clean cover system – St Albans

Net Zero –The Use of Timber Piles

As the construction industry works towards a ‘Net Carbon Zero’ future, we are asked to take a hard look at current practices to find areas where the carbon cost associated with our built environment can be reduced. The cement industry is widely recognised as being one of the main producers of carbon dioxide emissions, accounting for around 7% of global emissions. Low carbon and carbon neutral concrete products are already entering the market, but the use of timber as an alternative to concrete piles provides an opportunity to use a sustainable foundation material. This brief article considers the benefits, limitations and suitability of using timber piles in the UK.

In 2009 a technical paper by Reynolds and

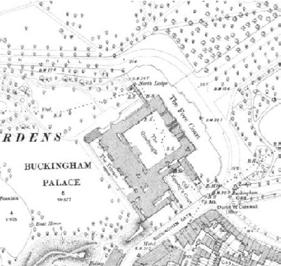

Bates was published in Ground Engineering magazine, titled “The Potential for Timber Piling in the UK”1. It explored the current global locations and circumstances in which timber piles are used and discussed the potential for UK locations with comparable ground conditions where their use could be considered. The article states that timber piles are currently widely used in the Netherlands, the United States, New Zealand, Canada and Australia, and concludes that timber piles are “an entirely viable, low cost and sustainable alternative to steel and concrete, with the potential to be used for many projects”. A notable example of timber pile use given in the article is the Cargo Terminal at John F. Kennedy Airport in the USA. BRE Digest 479 (Timber Piles and Foundations) cites a number of historic examples where timber piles have been used, including Old London Bridge in the UK, the Royal Palace in Amsterdam and the Pont Notredame bridge in Paris.

16 Magazine

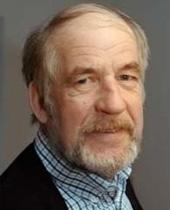

Article contributed by Katharine Barker, Associate, Campbell Reith

Photo Credit: Peter Alheid of Hercules, Sweden.

A timber pile is essentially the trunk of a tree, stripped of branches and bark. They are currently used in the UK in maritime construction, such as groynes, piers, jetties and for sea defences, where timber is favoured due to its ease of handling in overwater environments, its ability to absorb impacts and low cost.

Since timber is a renewable material it has a significantly lower carbon cost associated with its production and use than its concrete and steel counterparts. The monetary costs to produce and transport timber piles are lower than those of concrete and steel (as described in Reynolds and Bates, 2009). The placement of timber in the ground is a form of carbon sequestration, which plays an important part in ensuring the overall Net Zero compliance of a project.

One of the main drawbacks to using timber is that it is biodegradable. Decay occurs fastest when the timber is exposed to the air, which allows fungal decay and rot to occur. As such, a typical life span for timber placed in an unsaturated environment is c. 25 years.

saturated, anoxic environment, will decay at a much slower rate and can have a design life of up to 100 years depending on the timber species used. The piles can be chemically treated to provide additional resistance to biodegradation, however, the chemicals used may have the potential to introduce contamination into the gro und.

To minimise degradation, the top of the pile that extends above the water table (i.e. not in saturated ground) is typically formed of concrete. This can be a pre-cast concrete section connected to the timber or can comprise a concrete pile cap spanning several timber piles. Pre-boring the pile locations and setting the timber pile in concrete or grout can also be used to slow degradation, however this will increase the amount of concrete used and the arisings that require disposal.

Although timber, as a pile, will have a lower compressive strength compared to concrete or steel piles, it is often the case that the bearing capacity of the pile is governed by the properties of the surrounding soil rather than the strength of the pile itself. On this basis

March 2023 17

“ One of the main drawbacks to using timber is that it is biodegradable. Decay occurs fastest when the timber is exposed to the air, which allows fungal decay and rot to occur.

the use of timber piles may be equally suitable to that of concrete in certain settings.

Pile length is another design consideration that may impact the suitability of using timber piles. As timber piles are typically difficult to splice, the maximum pile length is restricted by the height to which the tree can grow, which is also dependant on the species, and by the ability to drive it to the required depth. Conversely, timber piles can easily be cut down to size as needed and the off cuts are biodegradable.

Pile Construction and Suitable Locations

Installation of timber piles is predominantly carried out using driven techniques. The success of this technique will depend on the ground conditions, since the presence of dense layers, hard bands or variable strata could result in the refusal of the piles at unplanned depths. Driving through harder bands may be achieved with the inclusion of a driving shoe at the toe of the pile, therefore, a good understanding of the ground conditions present is key to ensuring the successful installation of timber piles.

Ground conditions most amenable to the installation of driven timber piles comprise soft deposits such as soft clay or peat, over a denser material such as gravel or rock, with a high water table. Reynolds and Bates identify such ground conditions to exist in numerous estuarine and river valley locations around the UK, including the Severn estuary, the Fens in East Anglia and the marshes of Dartmouth.

The seasonal variation of groundwater levels

at a site needs to be well understood if the development is to consider using timber piles, as the degradation, and consequently the design life, of a timber pile is primarily governed by whether the ground is saturated or not. This places a greater importance on groundwater monitoring and modelling to understand the existing groundwater regime as well as the impact that climate change will have on groundwater levels through the design life of a project. Understanding the groundwater regime of a site is already a key part of geotechnical design, and a requirement of Eurocodes. As such, any additional data gathering at ground investigation stage of a project may not extend significantly beyond the typical geotechnical needs of a project.

Conclusion

Ground conditions exist in the UK that may be amenable to the use of timber piles. As with any geotechnical design, the collection of relevant information at ground investigation stage is crucial, but wouldn’t necessarily require any particular measures beyond what would be expected in order to satisfy current standards. The use of timber for on-shore piling is not an impossible or unreasonable solution to reducing the carbon cost of construction and may, in due course, be driven by necessity to address the climate crisis.

References

1. https://www.geplus.co.uk/technicalpaper/technical-paper-the-potential-fortimber-piling-in-the-uk-01-01-2009/

18 Magazine

“ This places a greater importance on groundwater monitoring and modelling to understand the existing groundwater regime as well as the impact that climate change will have on groundwater levels through the design life of a project.

Groundsure Insight

The environmental data standard

The Complete View

Imagine, no add-ons – just one product for everything you need.

Groundsure Insight is the only report bundle available on the market that includes 10k geology data, MasterMap site plan, current and historical aerial imagery and Historical Land Use Data as standard. Giving you everything you need in one product.

For more information visit www.groundsure.com or contact your preferred search provider Email: info@groundsure.com Tel: +44 (0)1273 257 755

March 2023 19

Coal Tar: Analysis and Detection

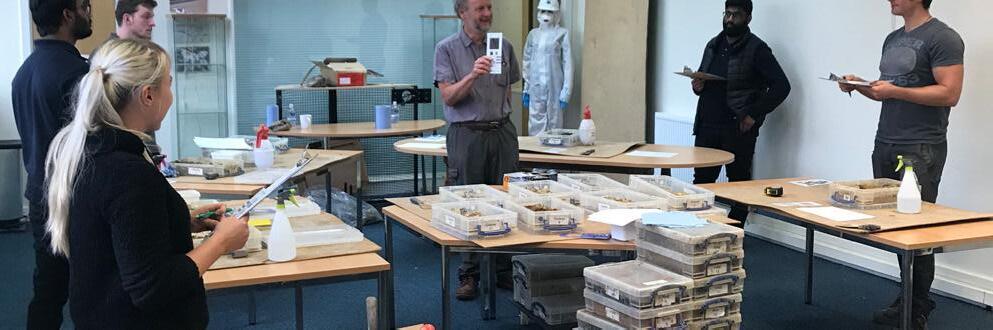

A recent review through the AGS Laboratory Working Group revealed a range of techniques, some common themes and a potentially confusing landscape for the industry to navigate in order to secure a fit for purpose and cost effective solution.

The analysis of and detection of coal tar has seen a significant increase in the last few years. This is linked, primarily, with an increased focus on thorough waste classification and some long running nationwide initiatives such as the Streetworks Project. It encompasses all the regional water companies and activities in line with the Regulatory Position Statement RPS211 relating to the excavated waste from utilities installation and repair, the withdrawal of which was delayed until April 2023 due to the scale of works underway and still requiring of completion.

One of the challenges facing laboratories is the lack of standardization in the specification of requirements from the clients and, also, the analysis itself. As an area not fully understood in terms of hazardous classification, it became beholden on the labs to put forward a range of approaches that would encapsulate the variety of client specifications, while also providing what was hoped would be sufficient levels of detail to allow for the onward use of data for a range of purposes.

The two primary sources of information that influence the testing requirements, other than the labs individual clients, are the Environment Agency (EA) WM3 (1st Edition v1.2)1 Technical Guidance and the ADEPT Guide to Managing Reclaimed Asphalt (Version 2019 revision 1)2.

From section 3.2 of WM3, we have the following, based on the knowledge that coal tar is present:

• Coal tar levels over 0.1% result in a hazardous classification to HP7,

• The total must be inclusive of all compounds, polycyclic aromatic hydrocarbons (PAH) concentration alone is not sufficient,

• If the concentration of Benzo(a)pyrene (B(a) P) is less than 0.005% of the coal tar then HP7 does not apply.

Looking specifically to Asphalt waste, already classified under 17 03 01* or 17 03 02 (bituminous mixtures that do/don’t contain

20 Magazine

Article contributed by Will Fardon (Technical Director, Chemtech Environmental Limited) on behalf of the AGS Laboratories Working Group

coal tar respectively), we also have to consider:

If B(a)P is greater or equal to 50mg/kg in the Black top alone then the amount of coal tar should be considered to be sufficient (0.1%or more) to be considered hazardous and coded 17 03 01*.

The ADEPT guidance provides more specific focus on the managing of reclaimed asphalt and provides information in to the classification of waste. It reiterates and references WM3 and the 0.1% threshold for coal tar and also the use of the 50mg/kg level for measuring B(a)P should the total coal tar concentration values not be available for measurement.

What the ADEPT guidance then gives, is a clear and defined protocol for sampling, sample preparation, sample volumes and data review with also indication of analytical requirements and basic principles.

The document gives details and refences to specific British Standards for the sampling and preparation of road plannings and road cores (BS 932 and BS 12697), and then recommends the following testing:

• PAH analysis in the laboratory by gas chromatography mass spectrometry (GCMS) for the USEPA16 suite of PAHs, though only B(a)P may be necessary. It is worth noting here that labs will test for the full suite in a single process so requesting B(a)P only will usually give no cost or speed benefit. Should further characterisation for landfill disposal be required then the USEPA17 suite inclusive of coronene should be used,

• Screening methods such as PAK marker sprays or Acrylic White sprays can be used but validated by the use of frequent ‘full’ analysis,

• Specifies the use of Monohydric Phenol (Phenol Index) testing, with a potential

requirement to speciate the individual compounds (Phenol, Cresols and Xylenols) should the levels be sufficiently high.

In terms of data review the 3 potential outcomes are:

1. Classed as Inert for the purposes of the Quality Protocol for Aggregates from Inert Waste if:

a. The guidance of sample numbers has been observed,

b. All the B(Aa)P results are below 25mg/ kg,

c. There are ≥3 results.

2. Classed as Hazardous and treated accordingly is:

a. All the B(a)P results are above 50mg/kg

Note: If there are limited results and close to the threshold then further investigation is required.

3. Full statistical analysis required to make assessment if:

a. Some or all results are above 25mg/kg and below 50mg/kg.

The incorporation of the Waste Acceptance Criteria (WAC) testing for characterization and landfill disposal is a good example of where labs adapt to meet the broader requirements of the customer. From the recent AGS LWG study, we can see a number of consistent elements:

• Quantification of PAH compounds including B(a)P

• ‘Total’ extractable material/coal tar, usually by Dichloromethane (DCM) extraction and quantification either gravimetrically or by GCMS,

• ‘Forensic’ identification of coal tar.

March 2023 21

There is little to no consistency as to the how, but the principles all involve the selective identification of one or more marker compounds (Benzothiophene was common but arrange of other phenols, heterocyclics and aromatics were used) by GCMS.

And then also often included in the suite we can see:

A range of more traditional TPH tests, from a straightforward C10 – C40 extractable Hydrocarbons to a more thorough TPHCWG range from C5-C44 including Aliphatic and Aromatic breakdown,

• A Chromatographic interpretation of the hydrocarbon source.

Usually taken from the TPH analysis, done either as a general identification against a library of standard chromatograms to identify exactly what fuel source is present, presumably should it not be Coal Tar. A specific determination of whether the hydrocarbon source can be identified as either diesel or weathered diesel. While neither of these are specifically relevant to Coal Tar, as part of the Classification process within WM3 when considering hydrocarbon contamination then should coal tar not be the issue, varying caveats can be applied to the hazardous threshold should the contamination be of a specific type and the laboratory identification of diesel as a source is one the most prevalently used

• Phenolics

Either as a simple Monohydric Phenol (compounds containing one hydroxyl group) of a speciated output using HPLC or GCMS to identify specifically

the Phenol, Cresol and Xylenol content amongst a range of other phenolic compounds.

The running of additional testing may seem extraneous based on the specific context of your project at that stage, but consideration of any subsequent stages may give rise to a more comprehensive suite. The relative costs of laboratory testing compared to the associated site costs in holding/transporting/disposing of waste materials are low, so a comprehensive approach may present a more cost effective solution.

It is also worth revisiting the question you are trying to answer, as the specific identification of coal tar may be of secondary importance to the quantified PAH, specifically the B(a)P results, in terms of onward management.

As with any project involving lab work, the overarching recommendation would always be to consult with your lab at the outset and throughout to discuss options and define a project specific set of requirements rather than looking for a default or ‘standard’ solution, especially in an area like waste and waste classification where standard solutions are a thing we can still only imagine.

References:

1. Guidance on the classification and assessment of waste (1st Edition v1.2.GB) Technical Guidance WM3 (October 2021)

2. ADEPT Guide to Managing Reclaimed Asphalt Version 2019 Revision 1 (August 2019)

22 Magazine

“ As with any project involving lab work, the overarching recommendation would always be to consult with your lab at the outset...

+4 4 (0)8 45 862 0558

IN S ITU TESTIN G SPEC IALISTS

CONE PENETRATION TESTING (CPT)

Seismic, Shear Vane, Video Cone, Gamma Cone, Magnetometer, MOSTAP Sampling

PRESSUREMETER TESTING

Self Boring Pressuremeters (SBPs), High Pressure Dilatometers (HPDs), Ménard Pressuremeter Tests, Cone Pressuremeter, Goodman Jack Borehole Probe

ENVIRONMENTAL

Membrane Interface Probe (MIP), Hydraulic Profiling Tool (HPT), WASTAP, Optical Image Profiler (OIP)

MARINE RAIL RESTRICTED ACCESS

TAILINGS STORAGE FACILITIES PETROGRAPHY ANALYSIS SAMPLE AND CORE LOGGING

UK & WORLDWIDE

info@insitusi.com

www.insi tusi. com

COP27 and a ‘Way Forward’

Article

Article

contributed by

Jo Strange, Technical Director, CGL

Between 6-20 November 2022, the COP27 (‘27th Conference of Parties’) conference was held in Sharm El Sheikh, Egypt. This built on discussions and decisions made at the COP26 conference in Glasgow in 2021.

You may ask why is this relevant to the AGS? Simply put, the effects of global warming and climate change affect everyone and every business sector. The UK Government set a clear mandate for the UK to achieve zero carbon emissions by 2050, and for this to be achieved, all businesses need to be aware of Government policy and start the process of baselining and carbon control/ reduction. The direction of Government policy is likely to be highly influenced by the outcomes and agreements made at the COP conferences.

A summary of the headlines from COP27 is listed below. Relevant items to the geoindustry are the ‘Early Warning System’, ‘Clean technology’ and ‘Adaptation’.

Loss and damage fund - Governments agreed to establish new funding arrangements, as well as a dedicated fund, to assist developing countries in responding to loss and damage.

Brazil is back – Brazil’s president (the elect)

Luiz Inácio Lula da Silva announced that “Brazil is back”. He said: “There is no climate security for the world without a protected

24 Magazine

Amazon. We will spare no efforts to have zero deforestation and the degradation of our biomes by 2030.”

Emission commitments – The US also announced plans to cut methane emissions, leading to an 87% reduction by 2030, compared to 2005 levels. Mexico has upped its commitment to cut carbon emissions from 22% to 35% by 2030.

Indonesia Just Energy Transition Partnership

–The partnership will mobilise $20bn over the next three to five years to accelerate a just energy transition.

• Early Warning System

– An action plan for the Early Warning for All initiative was launched at COP27, which will be able to give early warnings against increasingly extreme and dangerous weather to everyone on the planet within five years.

• Clean technology –Governments representing over half of global GDP set out a 12-month action plan to help make clean technologies cheaper and more accessible everywhere, as part of the ‘Breakthrough Agenda’.

• More focus on adaptation – New pledges, totalling more than $230m, were made to an Adaptation Fund at COP27. The Global Shield Financing Facility was launched to provide funding to countries suffering climate disasters.

• Forest and Climate Leaders’ Partnership launched – This will hold annual meetings with government representatives on

progress to halt forest loss and land degradation by 2030

In a round up by Sarah Mukherjee, CEO of IEMA, who attended the COP27, she commented on COP27;

Î “Without the skills, without the training, and without education, there will be no green economy. These skills are not just for the office workers and the lattedrinking classes, but they are for technicians, for engineers, for people who are doing first and secondary jobs within the economy and are absolutely vital if we are to get where we need to go.”

Î $100 B per year required from developed countries for meaningful mitigation actions

Î The 1.5oC limit on rising global temperatures is still achievable …just.

Therefore, it appears that provided the population is educated, trained and enabled to support a ‘green economy’, which will also require adaptation and use of clean technology, the target limit on global warming is still ‘just about’ possible, but the happenings during the decade to 2030 will be crucial. Everyone and every business can be part of achieving current targets.

The AGS is looking at creating a sustainability working group, which will act across all the existing working groups to coordinate ideas, tools, innovations and guidance to support the AGS members and the geo-industry in navigating the route to carbon net zero and support minimising climate change.

March 2023 25

“ The AGS is looking at creating a sustainability working group which will act across all the existing working groups to coordinate ideas, tools, innovations and guidance to support the AGS members and the geo-industry in navigating the route to carbon net zero and support minimising climate change.

INSIDE JACOBS

globally. We have a network of 30+ offices throughout the UK and 22 offices across continental Europe.

How many people does the company employ?

We have more than 55,000 people globally, about a fifth of whom are working from UK and Europe. Our tunnel and ground engineering team includes around 800 employees globally.

How long have you worked at Jacobs?

What does the company do and what areas does it specialise in?

Jacobs is a technology-enabled global solutions provider serving several markets. We provide a full spectrum of professional services including consulting, technical, scientific and project delivery for the government and private sector. Our tunnel and ground engineering team manages ground risks and geohazards on some of the most challenging projects globally.

Where is Jacobslocated?

We operate from over 40 countries and 400 offices

I have worked at Jacobs for over two years, since March 2020

What is your career background, and what enticed you to work for Jacobs?

I started my career in academic research, with a PhD in geotechnical engineering that I obtained in France. My PhD included a fair amount of code and software development, for application to the mathematical and numerical modelling of soils. Pushed by curiosity, broad interests and a willingness to travel, I moved away from geotechnical engineering for a while, and moved to the UK to join Heriot-

Watt University (Edinburgh) as a Research Associate. I was part of a research project in computational biomechanics, looking at how bone porous microstructure influences its mechanical behaviour (bone looks very much like a highly porous rock!), using finite element analysis software. I then decided to try out work outside of academia and joined a small start-up whose aim was to develop a novel airborne wind energy system that generates electricity by autonomously flying a tethered aircraft. I worked there for almost three years, and was responsible for developing modelling and analysis tools, including a flight simulator. The project was very stimulating and the team very motivated, and I did learn a lot about programming and software development (as well as aerodynamics, which was a bit outside my core area of expertise to start with!). When looking for my next job, I was then looking for a bit more stability, as well as a larger company where I could be surrounded by a lot of experienced colleagues (having found that was a limitation in a-20 people company). So, when I saw Jacobs advertising for a geo-

26 Magazine

Getting to know Jacobs with Senior Geo-digital Engineer, Solenn Le Pense.

digital engineer position, I thought it was the perfect opportunity to reconnect with my original geotechnical background, while further developing my recently developed skills and interest in programming and software development. The good reputation of Jacobs, wellknown within the industry, as well as its large and experienced tunnel and ground engineering team, gave me the confidence that it would allow me to keep learning and grow as an engineer, while working on important and exciting projects.

What is your current role within Jacobs and what does a typical day entail?

I am currently a senior geodigital engineer, part of the tunnel and ground engineering team, and am based in Glasgow. The role is very varied, and I really enjoy the diversity of tasks and projects I get to work on. Part of the role can include some traditional geotechnical engineering tasks, such as geotechnical data management and analysis, or design of geotechnical structures. Some of my core responsibilities are a bit less traditional and revolve around

developing and programming design automation tools for geoscience and engineering applications. That does include a lot of programming (mainly in Python, but also C++) and software development processes. We are a team of programmers with engineering knowledge, and we can work together, or more individually depending on the size of the project. As a crossmarket discipline we get to work on projects in multiple areas, such as transportation, water or energy, which makes the job varied and interesting.

What are the company’s core values?

As a company, we have four key values: we do things right, we challenge the accepted, we aim higher, and we live

27 March 2023

“ The role is very varied, and I really enjoy the diversity of tasks and projects I get to work on.

inclusion. We try to reflect this in our everyday work, both with clients and with each other. Our values allow us to act as one company and unify us worldwide when interacting with our clients, employees, communities and shareholders.

Are there any projects or achievements which Jacobs are particularly proud to have been a part of?

We are very proud of the sustainable solutions we co-create with clients and other organizations. We look at ways to make a positive environmental, societal and economic difference for our people, businesses, governments and communities around the world. Some of our major programmes include the London 2012 Olympics and Paralympic Games, Thames Tideway and TEAM2100, where we have provided sustainable infrastructure and help leave a legacy for future generations, clean our water and environment, or protect our coastlines and communities. There are of course many other projects where we live our purpose of providing a

smarter, more connected and more sustainable world.

How important is sustainability within the company?

Sustainability is at the core of our business, and for us it means developing long-term business resilience and success, and positively contributing toward the global economy, society and the environment. It is not simply about avoiding harm, but about maximizing impact and stakeholder value, and striving to deliver a positive, fair and inclusive future for all in partnership with our clients. Our approach to sustainability is embodied by our PlanBeyondSM programme, which is our approach to integrating sustainability throughout our operations and client solutions in alignment with the United Nations Sustainable Development Goals.

How does Jacobs support graduates and early career professionals who are entering the industry?

We invest in our graduates and early career professionals. Our Graduate Development Programme (GDP) takes our graduates through a 2-year

programme of mentoring, skill building and networking to help build their careers; and professional accreditation schemes supporting staff through their chartership journeys. More widely, we implement apprenticeships to help early professionals obtain an academic qualification while working with us; drive STEAM (science, technology, engineering, arts and mathematics) engagement and leadership throughout the business, including our own Butterfly Effect programme, which is driving sustainability in decision-making for young pupils.

How has COVID-19 impacted Jacobs today? Are there any policies which were made during the pandemic that have been kept to improve employee wellbeing and productivity?

Covid-19 has been a game changer for us as an industry. For one, we’ll never go back to see the same level of travel as before as people have adjusted to hybrid working and adopted technology to collaborate and deliver work. Employee wellbeing is of course at the heart of our business decisions, including raising awareness of mental health challenges, especially in a world where perhaps we don’t see our colleagues as often and regularly as we used to. An example of the work

28 Magazine

“ Our values allow us to act as one company and unify us worldwide when interacting with our clients, employees, communities and shareholders.

Jacobs has done in this space is the roll out of our One Million Lives web app. The free mental health check-in tool was created to help enhance users’ understanding of their current state of mind and provide proactive strategies for personal mental health development.

Why do you feel the AGS is important to the industry?

The AGS Data Format has been around for over 30 years, has become the industry standard and, in our experience, increasingly used for every project regardless of size

or complexity. Comparison with other civil engineering disciplines allows us to see the benefit that this standard format provides, as our colleagues often lack an equivalent, vendor agnostic format. AGS data helps us to work with a dataorientated approach from the beginning of our projects and fits well with the BIM environment that has become more recently familiar. The AGS fulfil an important role in continuing to manage and evolve this format to suit the everchanging needs of our industry.

What are Jacobs’ future ambitions?

As a purpose-led company, Jacobs is passionate about leaving a positive legacy for generations to come. We are channelling our technologyenabled expertise and capabilities toward benefiting people and the planet, working closely with our clients to build a more sustainable, equitable future in the context of global environmental, social, and economic challenges. Launched this year, our 20222024 Boldly Moving Forward strategy responds to this and is built around three key accelerators, which we see at the heart of tomorrow’ solutions: climate response, consulting and advisory, and data solutions.

29 March 2023

“ The free mental health check-in tool was created to help enhance users’ understanding of their current state of mind and provide proactive strategies for personal mental health development.

Training Courses

Equipe Training: Specialist Geotechnical Courses

Equipe Training's specialist geotechnical training courses are delivered both in person at our dedicated training facility just outside of Banbury, Oxfordshire, and also online via Zoom!

Available upcoming dates are provided below:

Î 19th April 2023 - Professor David Norbury’s Rock Description Workshop

Î 25th April 2023 - Mastering the AGS Data Format

Î 26th April 2023 - Slope Stability Design

Î 27th April 2023 - Earthworks Design and Constructio

Î 9th May 2023 - Professor David Norbury’s Soil Description Workshop

Î 17th May 2023 - Basic Foundation Design

Places on these courses can be booked online here, or via contacting Equipe on +44 (0)1295 670990 or info@equipegroup.com

Equipe Training: Specialist Geotechnical Heath and Safety Courses

Equipe Training and their health and safety training partners RPA Safety Services and EB Safety Solutions are delighted to announce their collection of specialist health and safety courses for the geotechnical market have resumed being delivered in person, as well as being delivered online where required.

These courses are approved and certified by the Institution of Occupational Safety and Health (IOSH) and meet the requirements of UK Health and Safety regulations for working on geotechnical and land drilling sites. Upcoming courses have limited numbers of places available in order to maintain social distancing within the classroom environment. Upcoming dates include:

Î 16th March 2023 - IOSH Avoiding Danger from Underground Services

Î 4th – 6th April 2023 - IOSH Safe Supervision of Geotechnical Sites

Î 20th April 2023 - Managing and working with Asbestos Risk in Ground Investigation (MARGI)

Î 30th May 2023 - Safe Working on Geotechnical Sites

Places on these courses can be booked online here, or via contacting Equipe on +44 (0)1295 670990 or info@equipegroup.com

30 Magazine

INTERNATIONALLY RENOWNED TRAINING COURSE CONE PENETRATION TESTING

IN

GEOTECHNICAL PRACTIC E

COURSE DATE: 18TH - 19TH APRIL 2023

Speakers

Director

An essential comprehensive training course and refresher for geotechnical & geo-environmental practitioners involved in Cone Penetration Testing for Onshore and Offshore Geotechnics. The course is devoted to raising awareness of current test procedures, advances, data derived from the tests and the importance of quality control.

What delegates will learn

• Have an understanding of the importance of using CPT specialists

• Advantages and limitations of CPT tools and techniques

• An understanding of how CPT data can be used for soil interpretation

• An understanding of how CPT data can be used for design

• An appreciation of recognising suspect/erroneous data

Who should attend?

Onshore and offshore specifiers, procurers and users of Cone Penetration Testing. Geotechnical Engineers, Engineering Geologists, Consulting Engineers, Civil Engineers, Designers, Developers and Clients involved in onshore and offshore ground investigations.

AFFLIATE MEMBER SUPPLIER MEMBER

Tom Lunne Expert Advisor

Dr John Powell Technical Advisor

JUST £495 + VAT REGISTER ONLINE WWW.EQUIPEGROUP.COM DELIVERED AT

ORGANISED BY

SPONSORED BY

Darren Ward Managing

The AGS, an institution of Specialist in Land Condition (SiLC) is pleased to announce the SiLC Annual Forum is taking place virtually on Wednesday

29th March 2023 between 9:30am – 13:30.

This half day event, Chaired by Tom Henman (SiLC PTP Chair), will bring together industry professionals for a stellar programme of presentations and discussions. The Annual Forum will be divided into two sessions: Climate & Sustainability and Looking into the Future.

There are a host of presentations confirmed for the event including;

• Delivering Effective and Sustainable Materials Management on National Infrastructure Projects (Carrie Rose, Associated Technical Director at Atkins and Ian Evans, Senior Technical Director at Arcadis Consulting (UK)),

• The Development and Application of Carbon Calculator Tools to Sustainable Development (Sarah Cook, Associate Director, Leap Environmental), Understanding the Relationship Between Soil Biodiversity and Soil Health (Dr Felicity Crotty, Senior Lecturer in Soil Science and Ecology at the Royal Agricultural University),

• Post-Brexit Regulation of Excavated Materials: Waste Not Want Not; Waste, Want or Not; Want, Not Waste; Not Want, Waste (Paul Nathanail, Director at LQM),

• PFAS: What the UK can Learn from Jersey and Guernsey Approach to PFAS (James Lemon, Associate Technical Director, Arcadis).

There will also be a panel discussion, Chaired by Claire Dickinson (Director, Geo-environmental Matters) on the topic, “What do land condition professionals consider they need to understand to tackle climate change and sustainability challenges?” The panel will feature Amy Juden (Associate at The Environmental Protection Group), Martin Ballard (Group Head of Environment, Wates), and Robert Tyler (Environmental Quality Officer at the Royal Borough of Kensington and Chelsea).

Further speakers will be announced in due course.

TICKETS

Tickets for the SiLC Annual Forum are priced at the following rates, all of which are inclusive of VAT:

SiLC Members: £66

Retired SiLC Members: £26.40

Non SiLCs: £105.60

Affiliate Scheme: £52.80

Local Authority & Other Public Sectors, Jobseeking/Graduates and Students may attend the Annual Forum free of charge.

To register, click HERE and complete the registration form. Payment must be received by Friday 24th March.

SPONSORS

This event is sponsored by Jackson Remediation, Vertase FLI, AECOM, Statom Group, Element, Arcadis, Evonik, and Unyte Waste.

32 Magazine

How to become a Member of the AGS

AGS Members all share a commitment to quality in the geotechnical and geoenvironmental industry. This has become widely recognised by clients, governmental bodies and other associations that touch issues to do with the ground.

We welcome both companies and individuals who want to be recognised for their quality of practice to join our growing membership of over 130 Members. We shape our industry, continually improve practice and collaborate on issues that affect us all; from clients, all the way through to the people who use the land and the buildings we help develop.

To become a Member of the AGS, please visit http://www.ags.org.uk/about/become-a-member and submit your application online. Please note that all membership applications are reviewed by the Membership Committee 6 weeks in advance of each quarterly Executive meeting. The deadline for the next round of completed applications is Tuesday 2nd May 2023

AGS Chemical and Legal Helplines

All Members of the Association of Geotechnical and Geoenvironmental Specialists are entitled to free chemical and contractual advice through the use of Loss Prevention Committee Members, Marquis & Lord and Beale & Co.

For advice on chemical safety and best practice, Marquis & Lord will provide 30 minutes of free advice to all AGS Members.

Additionally, if you’re an AGS Member and are looking for legal advice, please contact Beale & Co and quote ‘AGS Helpline’ where the first 15 minutes of legal advice will be free of charge.

CHEMICAL SAFETY HELPLINE

Marquis & Lord

Tel: +44 (0) 121 288 2386

www.marquisandlord.com

(Please quote ‘AGS Helpline’)

LEGAL HELPLINE

Beale & Co

Tel: +44 (0) 20 7469 0400

www.beale-law.com

Member Reporting Service for Industry Issues

If you have any queries regarding AGS Data Format, there is a discussion forum on the AGS Data Format website, where queries can be posted and answered by the Data Format team.

If a Member has any issues with regard to Safety, Contaminated Land, Geotechnical, Instrumentation & Monitoring or Laboratories which you think the industry should be aware of please email ags@ags.org.uk, we will then forward your email to the relevant AGS Working Group.

Disclaimer

All articles in the AGS Magazine are the opinions of the authors and are not intended to be a complete or comprehensive statement of the law, nor do they constitute legal or specialist advice. They are intended only to highlight current issues from date of publication that may be of interest. Neither the writer(s), nor the AGS, assumes any responsibility for any loss that may arise from accessing, or reliance on the material and all liability is disclaimed accordingly. Professional advice should be taken before applying the content of the articles to particular circumstances.

March 2023 33

Advertising and Rates

An online advertising campaign within the AGS Magazine will help to build and increase industry awareness of your company’s profile, initiatives and offerings.

The AGS can help build a package to suit your needs and budget; whether it’s a series of adverts across multiple issues, a combination of event sponsorship and advertising, or a single advertorial.

How to Advertise in the AGS Magazine

The AGS Magazine is a free email publication that looks at a range of topical issues, insights and concerns, whilst publishing new guidance notes, working group activities and information on upcoming industry seminars.

With 6 issues each year, our subscribers include industry professionals such as practitioners, chartered specialists, senior decision makers and managing directors

To receive a media pack or to discuss advertising rates, please contact Caroline Kratz on 0208 658 8212 or email ags@ags.org.uk

Advert Sizes and Rates

FULL PAGE

W: 210mm

H: 297mm

RATE: £400

HALF PAGE

W: 210mm

H: 145mm RATE: £250

QUARTER PAGE

W: 105mm

H: 145mm

RATE: £160

DIRECTORY

Company name, address, contact number, email and one logo.

RATE: £50

Advertising Requirements

All adverts should be sent in a PDF, PNG, JPEG, TIFF, PSD (Photoshop) or EPS (Illustrator) format.

All advertising artwork must be supplied in 114 dpi resolution.

Artwork must be delivered to the AGS using the agreed artwork specification size listed left.

Artwork should be emailed to ags@ags.org. uk no later than 10 days prior to publication.

34 Magazine

COMPANY NAME ADDRESS CONTACT NUMBER EMAIL LOGO

AECOM

Aldgate Tower, 2 Leman Street, London,E1 8FA,

+44 (0) 7425 646 339

iain.mcburnie@aecom.com

Evonik Operations

GmbHZweigniederlassung

Österreich | Active Oxygens

Center Linz, Promenade, Steingasse 6a, 4020

Linz

+43 664 1803060

Mike.mueller@evonik.com

Statom Group

Statom House, 795 London Road, West Thurrock, Essex, RM20 3LH

01708 222777

enquires@statom.co.uk

Unyte Waste

Harborough Innovation Centre, Market Harborough, Leicestershire, LE16 7WB

0161 826 9075

Waste@Unyte.co.uk

Element Unit 3 Deeside Point, Zone 3, Deeside

Industrial Park, Flintshire, Deeside, CH5 2UA, UK

+44 (0)1244 833780

contact.us@element.com

Jackson Remediation

37-41 Mortimer Street, London, W1T 3JH

+44 020 8145 5699

hello@jacksonremediation.co.uk

VertaseFLI Limited

Number One, Middle Bridge Road, Portishead, Bristol, BS20 6PN

01275 397600

mfeld@vertasefli.co.uk

March 2023 35

Directory

Article

Article