1 minute read

CARBON ANALYSIS GROUND FLOOR PANELS EMBODIED CARBON

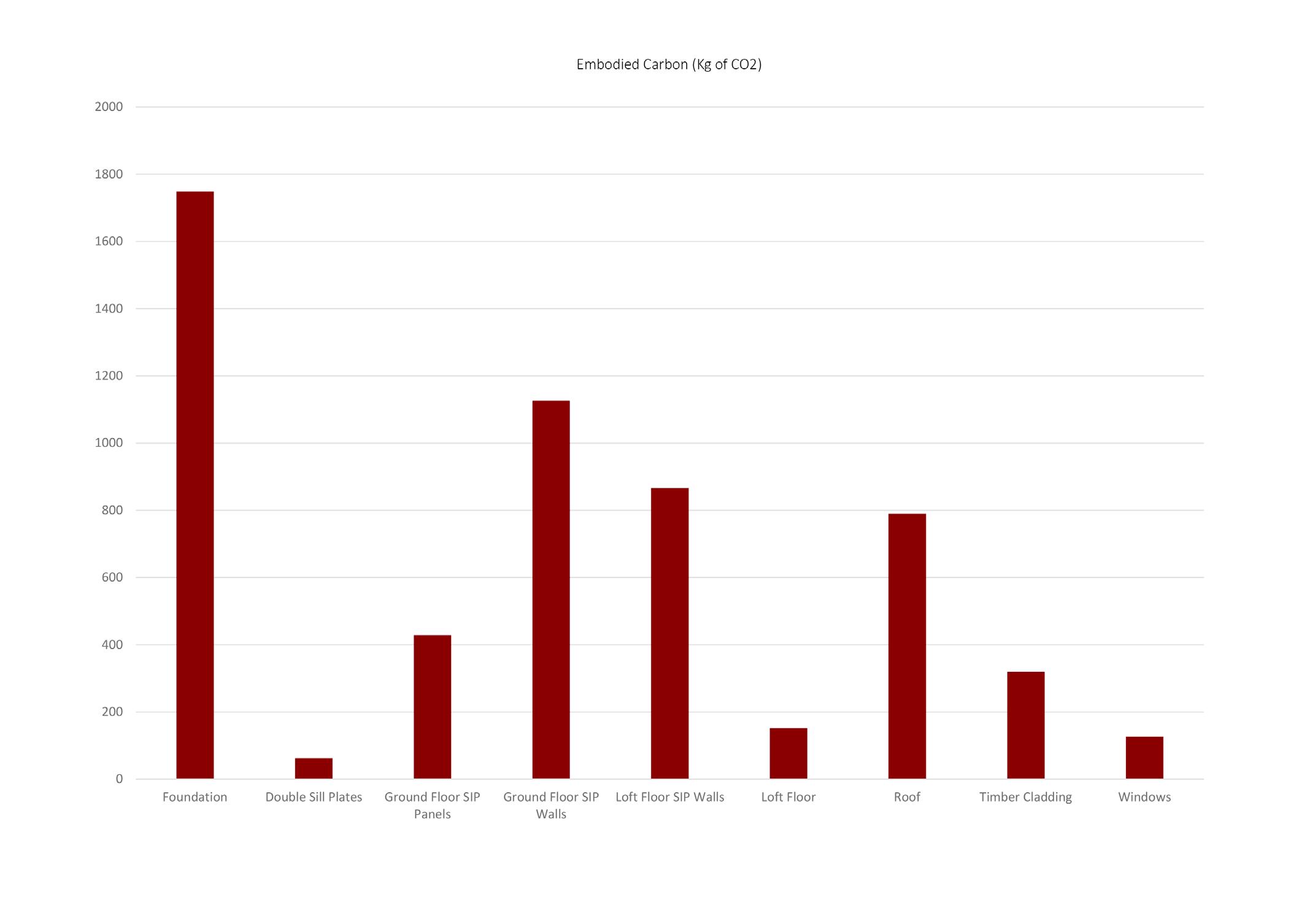

The calculations uses OSB, C16 Timber and Polyurethane Insulation for its calculations. The calculations split the ground floor SIPs into 5 seperate categories and then added the total of each category to get the total embodied carbon

The OSB of the SIPs have an embodied carbon of 90.27 KgCO2/Kg.

Advertisement

The Insulation of the SIPs have an embodied carbon of 302.25 KgCO2/Kg.

The SIP Block Splines have an embodied carbon of 18.43 KgCO2/Kg.

The top, bottom and end plates have an embodied carbon of 17.44 KgCO2/Kg.

Total embodied carbon is 428.38 Kg of C02.

In terms of timber floor construction, it would be similar to the SIP floor structure however joists would be needed to hold the floorboards and insulation. There would also be timber studs in between the insulation creating more chances of thermal bridging. Therefore a traditional timber floor structure would result in a higher embodied carbon since more parts would be needed and be less effective than a SIP floor, it would not reduce thermal bridging or be as airtight as a SIP floor would be.

If the ground floor was made from concrete with the concrete base, insulation and screed, it would already has a higher embodied carbon than the SIP flooring at 1960.04 KgC02/Kg exlcuding any other necessary parts.

Therefore using the SIP as the floor is more effective in reducing the EC of the tiny house.

Carbon Emissions Calculations

The data calculations only include material sourcing to the end of the factory processes and not the transportation.