1 minute read

CARBON ANALYSIS

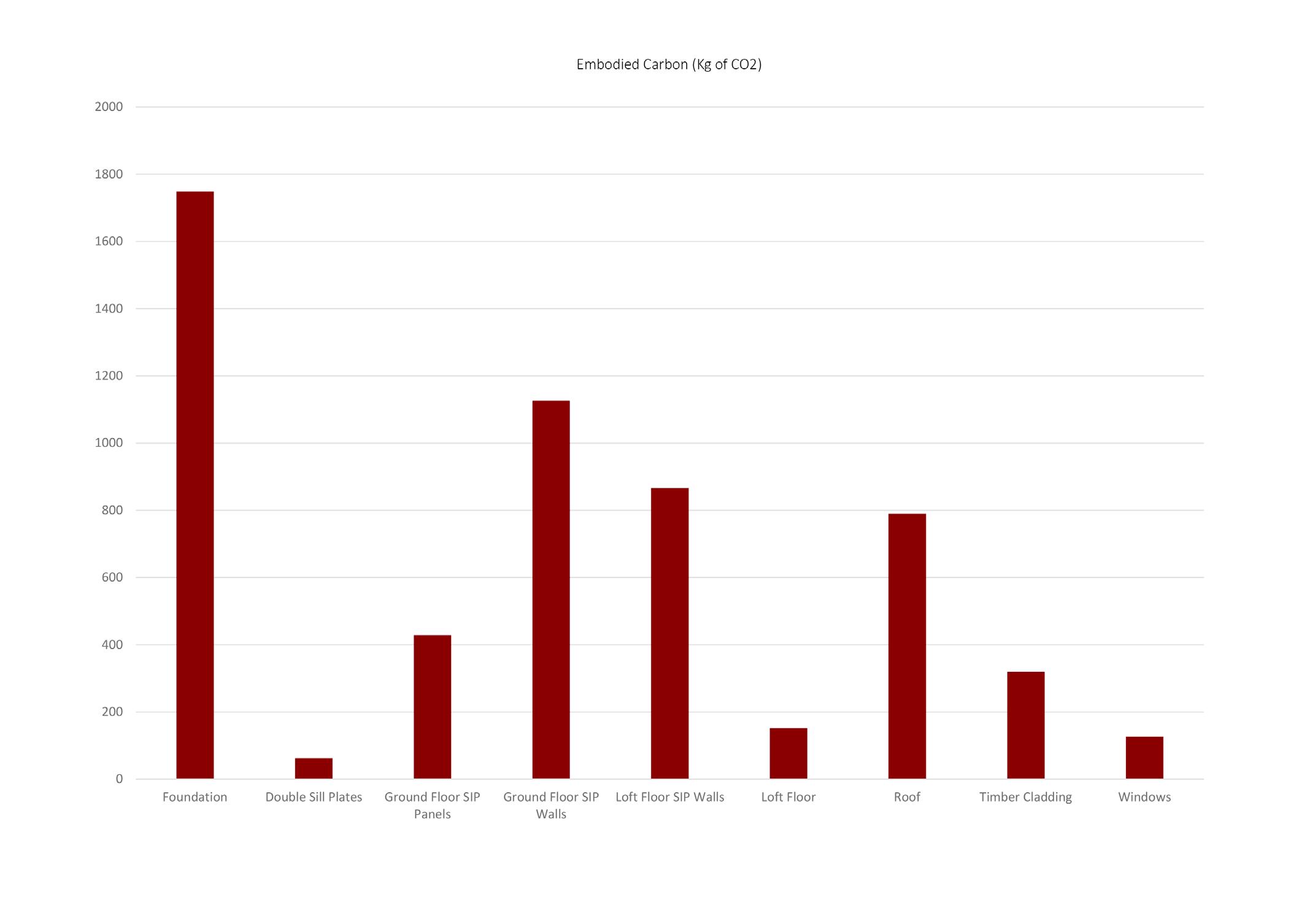

Ground Floor Walls Embodied Carbon

The calculations uses OSB, C16 and C24 Timber and Polyurethane Insulation for its calculations. The calculations split the ground floor SIP walls into 7 seperate categories and then added the total of each category to get the total embodied carbon

Advertisement

The OSB of the SIPs have an embodied carbon of 253.344 KgCO2/Kg.

The Insulation of the SIPs have an embodied carbon of 760.5378 KgCO2/Kg.

The SIP Block Splines have an embodied carbon of 46.6926 KgCO2/Kg.

The Top, Bottom and End plates have an embodied carbon of 42.0537 KgCO2/Kg.

The Door Frames have an embodied carbon of 11.046 KgCO2/Kg.

The Window Frames have an embodied Carbon of 12.3084 KgCO2/Kg.

Total embodied carbon is 1125.9825 Kg of C02.

Compared to a traditional timber frame construction, the SIP wall uses less embodied carbon, from sourcing to processing and transportation, the SIP system uses fewer variety of materials and less timber, with 11mm thick OSB covering the most surface area. The SIP walls contain only 3 materials to manufacture and can be manufacatured and transported from one location reducing the need of various sourcing locations.

The OSB uses 35% less timber used compared to traditional building methods.

Timber uses 20% of the energy needed for concrete to make a product with equal strength.

The SIPs have a U-value of 0.13 which is a Passivhaus standard.

Carbon Emissions Calculations

The data calculations only include material sourcing to the end of the factory processes and not the transportation.