14 minute read

MEMBER PROFILE

Work-Life Balance

A Leap of Faith

Advertisement

BY REBECCA RENDON

If you could live anywhere in the world, where would you choose? My answer to that question comes with no hesitation: Hawaii. Th e warm, tropical waters; soft sand; picturesque mountain ranges; and the aloha spirit are unlike anything else. As I’m writing this, I’m sitting on Lanikai Beach in Kailua on the windward side of Oahu. You may be thinking, “What is she doing writing this while she’s on vacation?”

Well, I decided to take a leap of faith and move to Hawaii with my 9-year-old daughter, Kennedy, for one year of adventure. Th is wasn’t a rash decision, rather something that had a great deal of meaning and purpose behind it, which continues to evolve every day.

Th e fi rst question people ask me when they hear this is “Why?” As a single mother who loves to travel with her daughter and works remotely, the question for me becomes “Why not?”

Obviously, there were plenty of legitimate reasons for not packing up and moving 4,500 miles away to the middle of the Pacifi c. We already had a comfortable, established life in Carmel, Indiana. We had just moved into a new house, with a big yard for our dog, and Kennedy was enrolled in a top-rated elementary school. Our friends and my mother lived nearby, and that was the place I called home for the past 25 years. What more could we want? Everything was comfortable and stable— except the Indiana weather. So, why not move to a place with daily rainbows and consistently sunny, 80-degree weather?

Th e decision to move was based off more than just unfavorable Indiana weather. I had this feeling deep in my heart that there was more to life than settling for comfort and familiarity. I couldn’t help but feel like I was complacently accepting a life based on social norms and familial expectations, rather than a passionate pursuit of adventure and unchartered opportunity. At 33 years old, some people might call this a “pre-midlife crisis.” Call it what you will. I saw this as an opportunity to be brave, pursue a dream, and provide my daughter with some incredible childhood memories. So, why not take this leap of faith?

We had visited Hawaii eight months prior and fallen in love with the beauty of the land and the Hawaiian culture. However, this idea seemed like such a far-fetched dream that it posed a massive challenge. Th ankfully, I love a challenge.

Dreams are just goals without a plan, though, right? During the next month, I’d spend most evenings in deep thought, weighing the amount of eff ort and sacrifi ce required to make this happen versus the potential reward. Th is was also going to require a considerable amount of logistical planning—asking my boss for his support, deciding what to do with my house and car, transferring schools, getting our dog into Hawaii, telling friends and family, and actually making the 4,500-mile move to the middle of the Pacifi c Ocean.

If it’s meant to be, it will be. But it can never be if you don’t attempt it. Kennedy was excited and 100% on board. We’d move with our dog to the most remote chain of islands in the world, where we don’t know a soul, because why not? Th is would be a year of adventure, personal growth, and the ultimate test of faith and our own limits.

My goal was to provide us with an opportunity to embrace diversity, develop an appreciation for another culture, do good for the planet, and experience things that wouldn’t be possible in the confi nes of Carmel, Indiana.

After my boss at Kolbus gave his blessing, I started laying out a plan of action. I researched everything—best schools, safe areas to live, special Hawaii laws, etc. I felt confi dent in my plan, knowing that my daughter and I are resilient and could make it work for a year, in hopes of experiencing something wildly exciting and life-changing.

I decided to leave everything behind. We’d move with two suitcases each, bringing what is essential. Th ere’d be no room for excess. We’d be forced to evaluate what was most important to us. I sold my 4-monthold car and moved my mother into my house in Carmel for a year so we could keep our things just as they are in Indiana and return home if needed. As a single mother, I had to be logical and have a backup plan.

We visited Oahu for three weeks in May, with the goal of fi nding a place to live, buying a new car, and enrolling my

Rendon explores Black Sand Beach in Maui this past July. Photo courtesy of Rebecca Rendon.

daughter in school. Check. Check. Check. We flew home for two weeks to get our dog, say goodbye to friends, and pack our suitcases.

On July 4, we embarked on this life-changing year. I vividly remember walking out of the Honolulu airport that day, apprehensively thinking to myself, “Oh wow, we’re actually doing this!” Reality was finally hitting me. I loaded up the car, sat there for a few minutes while I cried some anxious tears, and proceeded to drive to our new home in Kailua.

As I write this, we’re in our 11th week as Hawaii residents. We are soaking up the sunshine and aloha every day and have realized how little we actually need in order to be happy.

Life during the weekdays is pretty “normal.” Due to the time difference, I wake up early, often at 3 or 4 a.m., for business meetings with colleagues in Germany and the United Kingdom. I take my daughter to school and then wrap up my workday midafternoon. Kennedy is adjusting well and is loving “island life.” She joined the swim team and has quickly developed a love for surfing and all ocean-related activities.

We are assimilating to life in Hawaii and are making the most of every day here. There are still hard days when I miss friends and family, good Mexican food, or the comforts of home. However, those sad feelings are short-lived when I step into the warm, tropical water of Waikiki Beach to surf with my daughter, or when we come across a sea turtle or Hawaiian monk seal basking on the beach.

The biggest lesson I’ve learned so far: Be brave and take that leap of faith because there’s a chance it could turn out better than you could have ever imagined.

Rebecca Rendon is marketing and communications manager at Kolbus America Inc. She can be reached at rebecca. rendon@kolbus.com.

Arvco: The ‘Swiss Army Knife’ of the Corrugated Industry

BY STEVE YOUNG

Photos courtesy of Arvco Container Corp. Arvco President and CEO Greg Arvanigian and Maintenance Manager Chad Hawkins at the company’s Kalamazoo plant.

Arvanigian standing aside Arvco’s J&L 150" folder gluer.

COMPANY:

Arvco Container Corp.

ESTABLISHED: 1967

JOINED AICC: 1974

PHONE: 269-381-0900

WEBSITE: www.arvco.com

HEADQUARTERS:

Kalamazoo, Michigan

PRESIDENT AND CEO:

Greg Arvanigian

George B. Arvanigian founded Arvco Container Corp. in Kalamazoo, Michigan, in 1967. But his journey was not a typical entrepreneur’s path into the corrugated box business. “My dad was kind of a unicorn in the industry,” says Greg Arvanigian, president and CEO. “He’s one of the few production guys that started his own business.”

‘He Wanted His Own Thing’

George’s career path in the production side of the business began in the early 1960s in Worcester, Massachusetts, with Dowd Box. From there, he was recruited by Inland Container to run its Philadelphia plant. He eventually caught the attention of International Paper (IP), which was rapidly expanding its corrugated box operations in the 1960s in the South and Midwest. He was off ered the position of production manager at IP’s Howell, Michigan, plant, eventually joining one of his sheet customers, Grand Rapids Packaging, and its subsidiary Wolverine Packaging in Schoolcraft, Michigan, as vice president and general manager. Like many in the box industry at that time, the elder Arvanigian recognized the growing volume of available corrugated business signaled a great opportunity.

“He was at Wolverine [Packaging] about three years and got tight with a couple of sales guys and met a local banker,” Greg recalls. “He just wanted his own thing; he wanted to make corrugated boxes. Th at was in 1971.”

Th e company’s fi rst location in Kalamazoo had two Langston letterpress printer slotters, a slitter, bandsaw, and taper. In 1975, after another move to its current location near downtown Kalamazoo, George acquired a used Hooper-Swift 78" corrugator. He also opened a sheet plant in Warsaw, Indiana, in 1974 and a sheet plant in Northwood, Ohio, near Toledo, in 1978. Following the bankruptcy of Grand Rapids Packaging in 1980, Arvco picked up a number of Grand Rapids Packaging’s salespeople, expanding its market reach north and leading to the opening of a sheet plant in Cadillac, Michigan, in 1982. Th e following year, Arvco moved its Northwood plant to Delta, Ohio, and added a corrugator, a move that Greg admits was not the best one for the company. “We didn’t invest enough in the plant to keep it economically viable,” he says.

In the meantime, though, Arvco was investing heavily in its Kalamazoo facility, adding a second corrugator—an 87"—and new Hycorr (now Kolbus) rotary die cutters.

Th en in 1989, George passed away. Greg, at age 28, became president of the company. Refl ecting on the transition he had to lead at that time, Greg says, “as As happens with a lot of entrepreneurial guys

that start businesses, the business grows and outgrows their ability to run it the way they want to run it.

Greg’s fi rst task, as he described it, was to huddle with the company’s management team. “I called all the managers, and I say, ‘Guys, I’ve got a revelation for you: You’re managers; I expect you to manage. "I can’t do it the way my dad did,’” he says.

Greg taking the reins of the business in 1989 began a period of refocusing Arvco’s mission. Th e company’s capital equipment was aging, and the customer base—which was at that point largely automotive and consumer appliances—was also shifting. Arvco’s plant in Warsaw, which was built, in part, to serve the Whirlpool parts business in LaPorte, was hobbled by extensive capital equipment needs Greg in his new position could not immediately justify. “Th e big thing we looked at was our business mix at the Warsaw plant,” he remembers. “We did a lot of folding and gluing down there. Our biggest customer was Whirlpool for their parts boxes, and most of the other business we were running in Kalamazoo anyway. And Warsaw, 73 miles away, is not that far. So, we made the diffi cult decision to close that plant and put all our money back into the mother ship.”

‘Invert the Bell Curve’

Th e consolidation of Arvco’s production assets and the reinvestment in capital equipment began in earnest in 1994 with the retirement of its older 78" and 87" corrugating capacity and the acquisition and installation of its 98" Agnati/Fosber corrugator. “I say, ‘We’re going all-in, and we’re going to put in a new corrugator,’” Greg says. “It was the best thing we could have ever done.”

Arvco’s corrugator capacity serves a broad waterfront, with fl ute profi les A, B, C, E, F, and K in single-face and single-, double-, and triple-wall board. As Greg explains it, Arvco’s business mix at the time was heavyweight-based, with triple-wall applications and heavier containerboard grades. But its broadening reach into the food and beverage business—Arvco manufactures 265 food packaging items and holds 10 food-related patents—required a machine with fl exibility in emerging microfl utes like E and F. “We were already in the food business, and so I needed a corrugator that could make triple-wall as well as lighter-weight microfl utes,” he says. “Th e Europeans had a lot of experience with microfl utes, so it’s one of the reasons I was steering toward Agnati.”

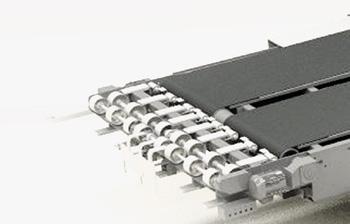

Th e company’s converting and fi nishing capabilities have mirrored the fl exibility and diversity of the 98" corrugator. Arvco’s Kalamazoo plant maintains an impressive large-box and triple-wall capacity in its jumbo Flexoline 86" x 212", two-color fl exo folder gluer, and its J&L 150" specialty folder gluer.

Th e company also maintains a stable of equipment suitable to the industrial box market, with its Langston Saturn III threecolor mini fl exo and its Post 84" specialty folder gluer. In between is a complement of workhorse machines: Ward and Hycorr (Kolbus) rotary die cutters as well as enhanced-graphics rotary die cutters in Arvco’s two Apstar 66" x 110" four-color and its Hycorr 66" x 85" four-color. In Cadillac, a similar machine footprint can be seen in its Langston 50" two-color fl exo folder gluer, Ward 66" x 85" two-color die cutter, and Hycorr 66" x 85" three-color rotary die cutters. Rounding out the equipment mix are a Göpfert MAXI boxmaker, a Bahmüller stitcher, and a DPI three-color digital printer.

About Arvco’s broad business mix, Greg says, “We want to sell the stuff that nobody else wants to sell. If you were to look at our mix, take the bell curve of the corrugated industry where ultralightweight is on one end and super heavy triple-wall is on the other end. Invert that bell curve, and you have an Arvco. “When it comes to doing something with a corrugated box,” he adds, “we do more stuff on-site than anybody else in the world. I don’t know anybody else that does what we do. And we’re constantly trying to move that along.”

Trying to move that along requires continual investment, and Kyle Baldwin, Arvco’s chief fi nancial offi cer (CFO), attributes the company’s success at procuring the right equipment to Greg’s gut feel for what will work. Says Baldwin, “He defi nitely has more of that entrepreneurial spirit when it comes to capital expenditures and investments.”

“I make educated guesses,” counters Greg.

Greg’s “educated guesses” serve a unique but evolving mix of business. Th e company’s market has ebbed and fl owed through an eclectic mix of government, automotive and industrial, and food and beverage. “We’re very diversifi ed,” he says. “We actually do a fair number of government contract boxes like weather resistant, Class-2 triple-wall, etc. We’ve always done government work.”

Arvco is also a principal player in the pizza box business, a piece of the market brought to the company in the 1970s by Steve France, one of the company’s sales representatives at the time. Today, that business represents 45% of Arvco’s production. “Steve basically focused on selling pizza boxes,” Greg recalls. “He went out and bought cutting dies. We did a couple of marketing pieces, and we trademarked the name, ‘Pizza-tainer.’”

As Greg explains, Arvco’s focus on the food business balanced the highs and lows of industrial and automotive sectors. “Th e food business—it’s a hedge,” he says. “When the economy changes, the food business gets good when the industrial business doesn’t. People realize they can feed a family of four for $20 when they order a pizza. Where else can you do that? So, that helps us get through a lot of these downturns.”

Arvco’s specialization in pizza has expanded into other styles of convenience packaging for other kinds of fast-food outlets selling chicken and sandwiches. Giving one specifi c example, Greg described the on-site packaging space savings they