for long format packaging. same

premise as our manufacturing clients on-site and take them y and streamline production as

JUNE 2023

AIP: PEAK PROFESSIONAL BODY FOR PACKAGING EDUCATION & TRAINING IN AUSTRALASIA

Single Polymer PE Recyclable Films

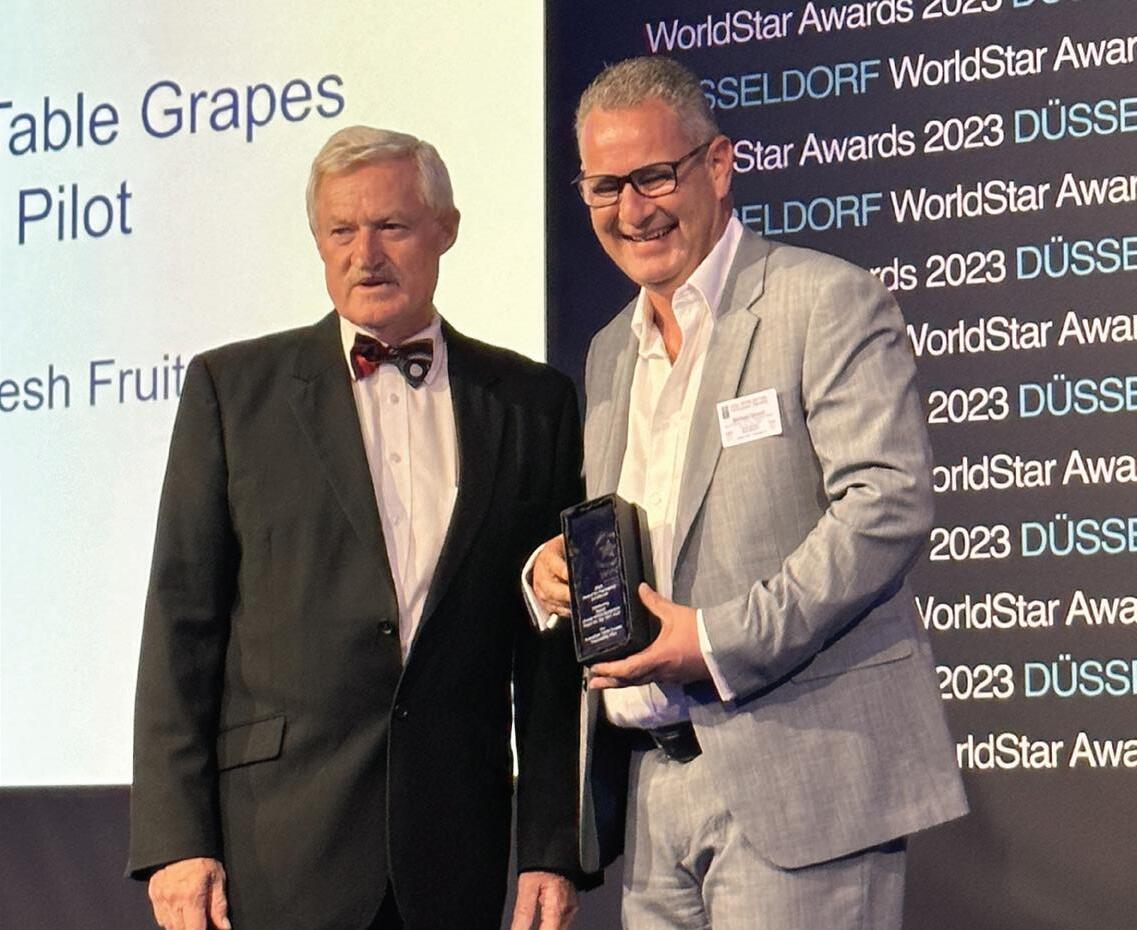

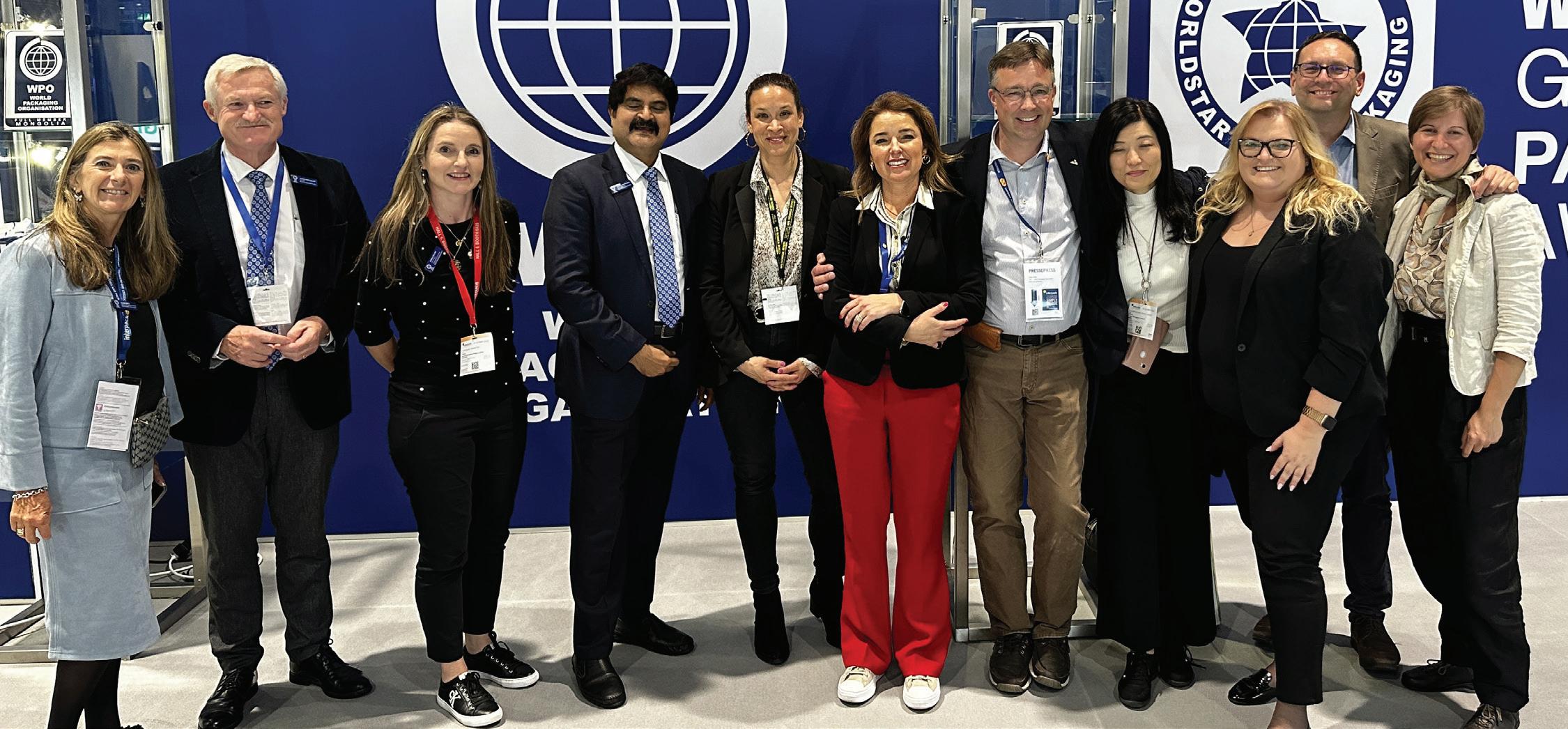

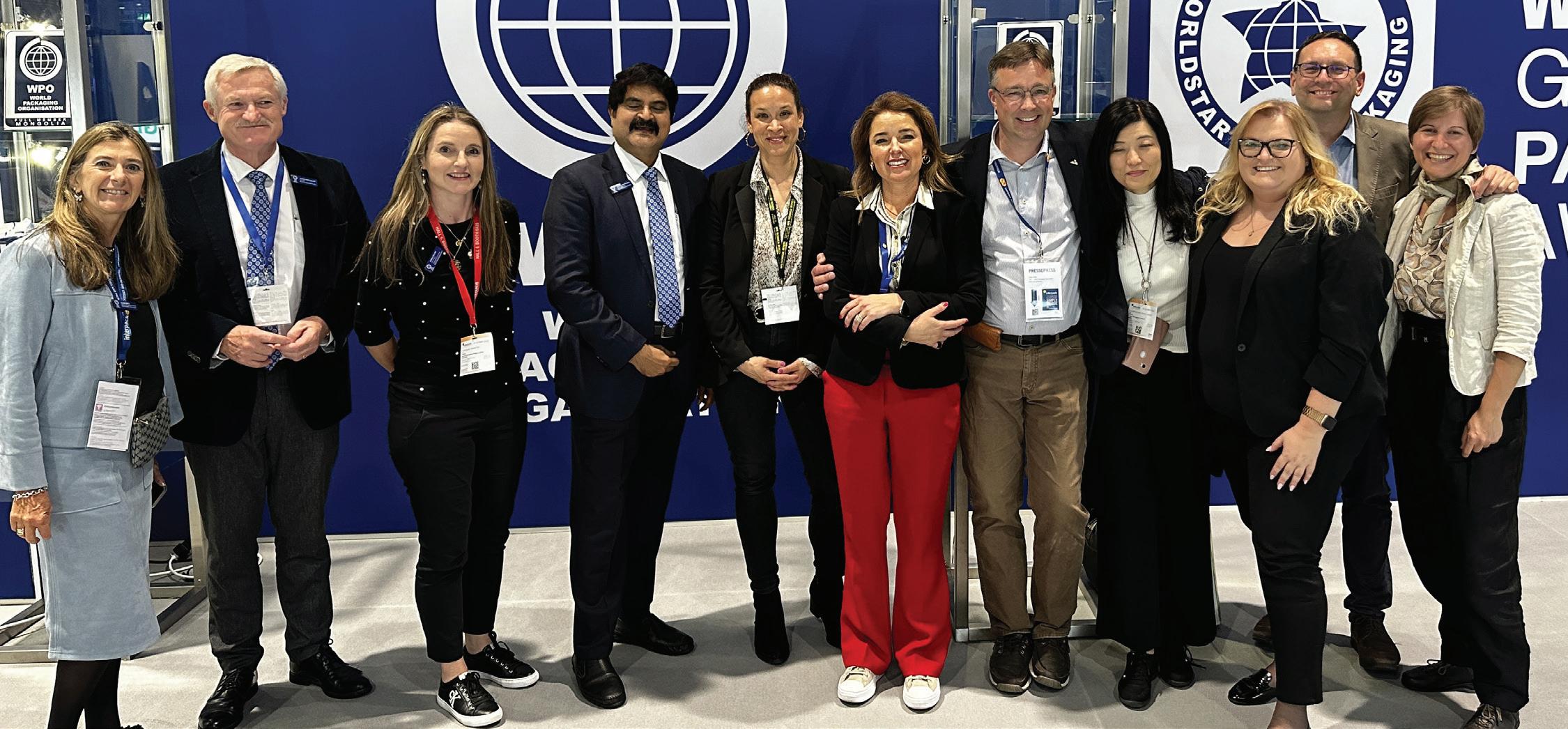

ANZ winners celebrated at 2023 WorldStar Packaging ceremony in Düsseldorf, Germany.

Inaugural Women in Packaging Forum @ interpack Page 79

Page 11 & 12

Packaging Sessions to be held alongside

Flexible Packaging: Now & Into The Future Training Course - 24 July

Page 12

POSITIONS VACANT Available

AIP to take 2x training courses & 2x packaging sessions to FoodPro - 23-26 July

Packaging Job Vacancies available

AIP NEWS

MEMBER FULL MEMBER SUPPORTING SIGNATORY CORE PARTICIPANT FOUNDING PARTNER SUPPORTER

* = 12.5 CPP PTS Page

Circular & Sustainable Packaging Design - 26 July Page 15

11

To be held alongside

* = 12.5 CPP PTS

be held

AIP packaging sessions at AWRE - 26-27 July * =1 CPP PT

Introduction to Active & Intelligent Packaging Training Course - 24 July Page

To

alongside

To be held alongside

19

interpack

25

A Balanced Approach between Packaging Waste & Food Waste - 27 July Australasian Recycling Label (ARL) - 27 July

AIP to run packaging sessions at Foodtech Packtech - 19 September

2023 Page

Page 61

Page 3-5

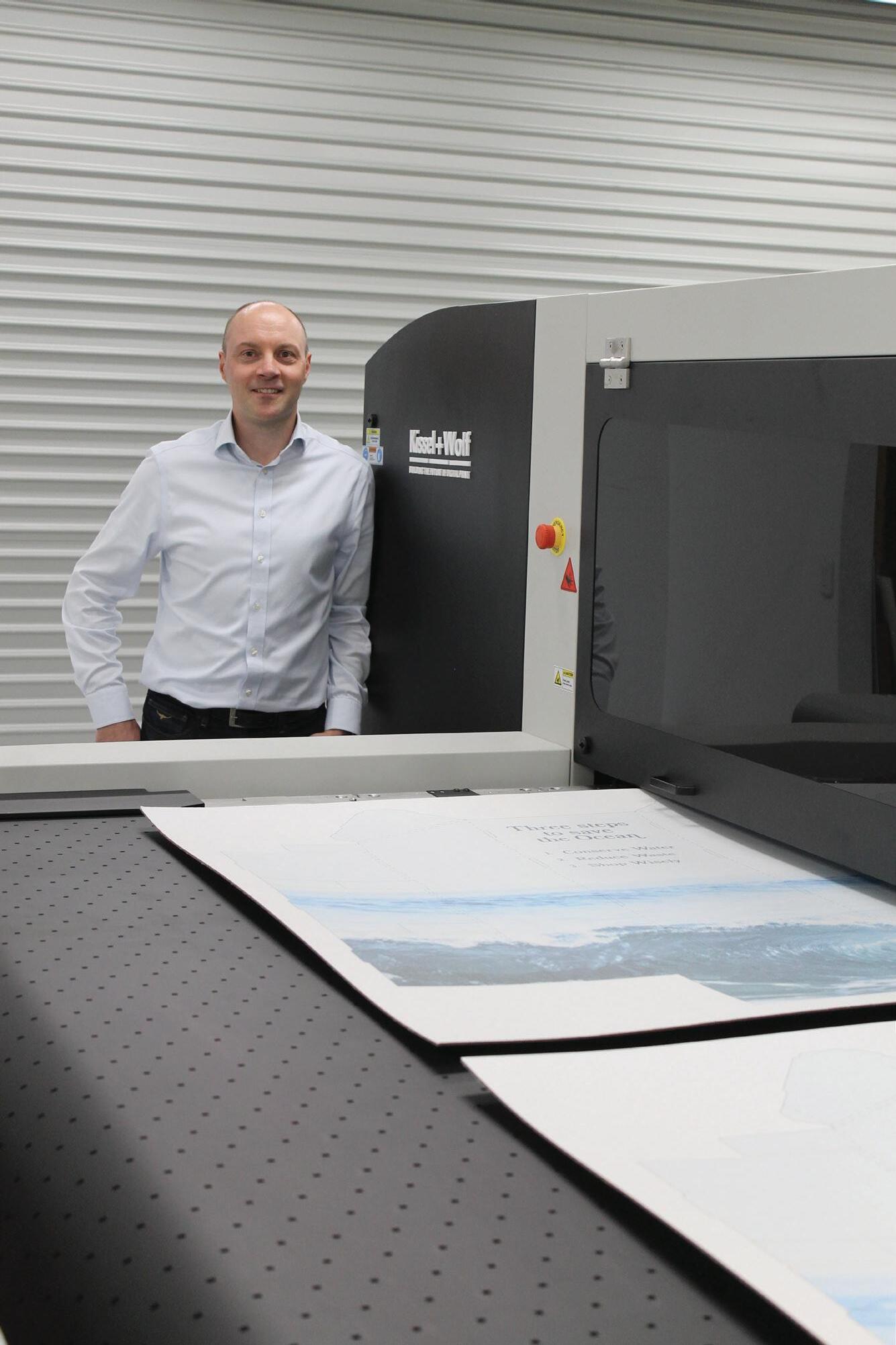

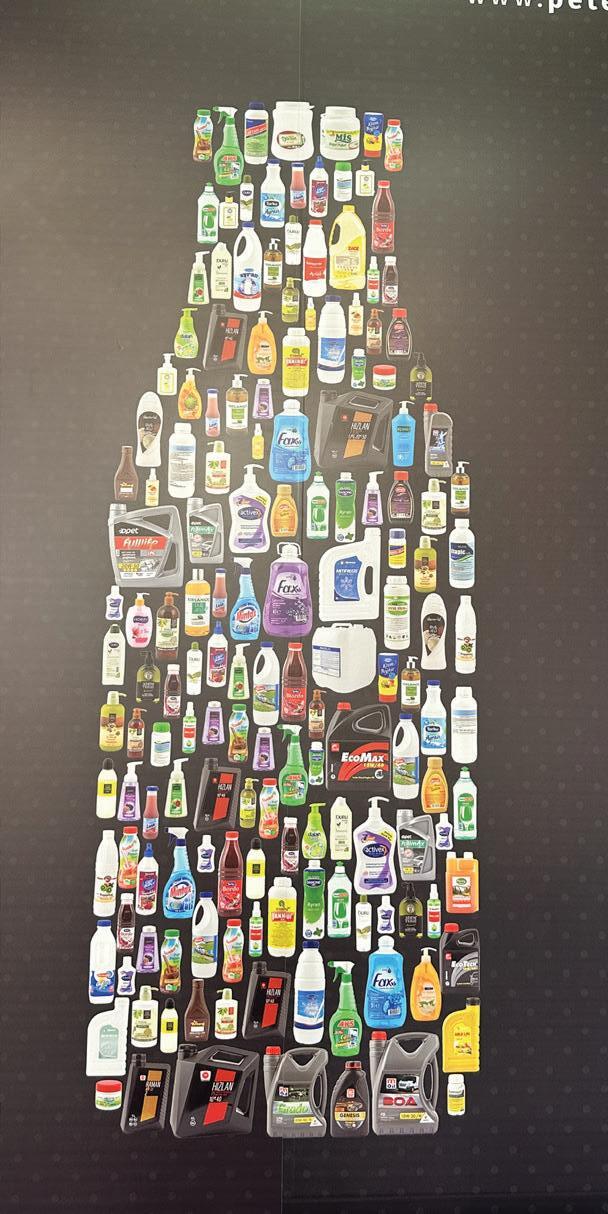

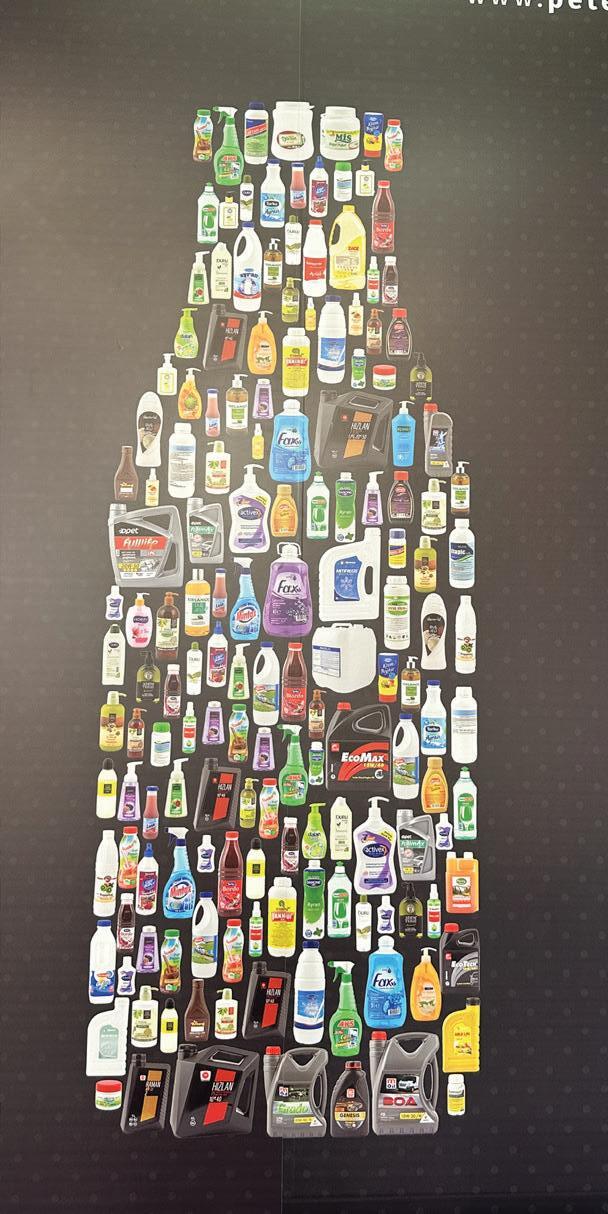

Many Plasticover clients use 100% Polyethylene (PE) films as both print and sealing layers, which allows us to craf t single polymer bags that are bet ter suited to sof t plastic ecycling than complex multiple -laminates. ds simpler packaging structures to lessen the impact onment, PE films will be eclaimed and recycled for use in om a pe ecycled plastics.

Position Vacant O F Packaging: Sales Director

Are you ready to take your career to new heights? Do you have a passion for driving sales and leading a high-performing team?

O F Packaging have an exciting opportunity for an experienced Sales Manager to join their dynamic and rapidly growing company.

Why join them?

• A competitive salary package with attractive incentives and benefits.

• Exciting growth opportunities in a fast-paced and innovative environment.

• Collaborative and supportive work culture that values teamwork and individual contributions.

• Chance to make a significant impact and be part of a company driving industry transformation.

About the Company

O F Packaging P/L (O F Pack) is a distinguished division within Close the Loop Group (CLG), an esteemed and successful company listed on the ASX. With a strong focus on environmental responsibility, O F Pack aligns its operations with CLG’s mission of creating a circular economy.

At O F Pack, they pride themselves on being at the forefront of innovation in the industry. As a leading provider of sustainable packaging, they are committed to delivering exceptional solutions to their valued clients. To further enhance their market presence and drive revenue growth in Melbourne, they are currently seeking a talented and driven Sales Director.

About the Role

The Sales Director plays a pivotal role in developing and executing sales strategies, managing key accounts, expanding their customer base, and building strong customer relationships in addition to leading the Sales and Sales Support Teams to achieve revenue targets.

Key Responsibilities include but are not limited to:

• Developing and executing strategic sales plans to achieve targets and increase market share.

• Leading and motivating a team of sales professionals, providing guidance, training, and support to maximise their potential.

• Fostering a customer-centric culture within the sales team, ensuring exceptional customer service and satisfaction.

• Identifying new business opportunities, building strong relationships with clients, and negotiating contracts.

• Monitoring market trends and competitor activities to stay ahead of the competition.

• Collaborating with cross-functional teams to ensure seamless delivery of products/services and excellent customer satisfaction.

• Analysing sales data, preparing reports, and presenting findings to senior management.

• Staying updated with industry developments, emerging trends, and regulatory requirements related to the packaging industry.

Requirements

• Excellent communication, negotiation, and interpersonal skills.

• Proven experience as a Sales Director or in a similar senior sales leadership role within the packaging industry.

• Demonstrated success in driving sales growth and achieving revenue targets.

• Exceptional leadership abilities with the aptitude to inspire and guide a team to achieve and exceed targets.

• Strong business acumen and the ability to analyse market trends and customer needs effectively.

• Results-driven mindset with a focus on delivering outstanding customer experiences.

If you are a passionate sales professional with a proven track record and the desire to be part of a dynamic team, O F Packaging want to hear from you! Take the next step in your career and seize this opportunity to join their thriving organisation.

Join us and let’s achieve remarkable success together!

AIP NEWSLETTER JUNE 2023 3

PLEASE APPLY TODAY

Position Vacant Driscoll’s Australia: Packaging Specialist

Apply Now

• Key touch point for all business packaging requirements

• Be part of a cross-functional team environment

• Newly created role

The Opportunity

Driscoll's have an exciting newly created role for an experienced Packaging Specialist to join their team based in their HQ. Reporting directly to the National Supply Chain Manager, you will be responsible for designing, developing, and implementing packaging solutions for their fresh produce products. You will work collaboratively with cross-functional teams to ensure that packaging solutions meet product requirements, quality standards, and regulatory compliance. Your key duties will include:

• Developing the businesses packaging strategies and develop sustainable packaging solutions aligning with the business’ sustainability initiatives.

• Providing oversight, review and coordination of the company’s packaging supply chain working closely with key stakeholders including growers, regional teams, suppliers and DC’s.

• Conducting testing and validation of packaging materials to ensure they meet product and quality requirements.

• Collaborating with cross-functional teams, including product development, manufacturing, logistics, and quality assurance, to ensure packaging solutions meet business goals and objectives.

• Efficient coordination of packaging supply chain activities including order management, inventory and stock control.

• Identifying efficiency improvement initiatives through packaging innovation.

• Running PREP reports via the APCO tools.

Skills & Experience

To be considered for this role, applicants will need to demonstrate capabilities in the following:

• Tertiary Qualifications and previous experience in packaging design, solutions engineering and sustainability is essential.

• Previous experience with project management, including timeline management, budgeting, and vendor management.

• Experience in Heat Sealing not essential but highly regarded.

• Proficient in the use of Microsoft Suite.

• Strong analytical and problem-solving skills.

• Valid Australian working rights.

About Driscoll's

Driscoll’s Australia is an exciting joint venture company owned by Costa Group – Australia’s leading integrated growing and marketer of premium quality fresh produce and Driscoll’s (USA) – the world’s market leader in berries. Partnering with a broad grower base across a national footprint, Driscoll’s Australia supplies year round delicious, branded berries to consumers using exclusively patented varieties developed by their joint venture partners breeding programs. Since their inception they have successfully achieved significant yearly growth and market share, enabling them to become the market leader in their category.

Benefits

At Driscoll’s, they are passionate about berries and their people. They take the time to nurture and invest in their people capabilities to help them grow and prosper. If this role is suitable for you, they would encourage you to apply.

Driscoll's have recently introduced their Employee Reward & Recognition Program. Employees have access to many benefits, discounts, perks and more! At Driscoll’s, employee engagement and recognition is something they believe is key to maintaining a good company culture and happy workplace!

AIP NEWSLETTER JUNE 2023 4

TODAY

PLEASE APPLY

Position Vacant JBS Australia: Packaging Technologist

Apply Now

From humble beginnings as a butcher shop, Primo is now a household name on a journey to being a purposeful food brand. They hold market leading positions, across a house of brands, in multiple categories from Smallgoods to Cheese Snacking.

Primo are truly local for local, dedicated to serving their Customers and Consumers without politics: strategy, production and execution starts and ends there, and they are not burdened by the overbearing processes and approvals that often constrain companies of their size.

And last but not least, they are building a culture to match the ambition and they are proud to be part of the JBS Group.

Primo Foods has a rare opportunity for a Packaging Technologist to join the team, based at their Chullora facility. This role will assist in the Implementation of the Company’s Innovation & Sustainability strategy and deliver projects. These projects may involve new packaging development, value engineering, packaging sustainability, quality improvements and technical assistance to internal departments.

Responsibilities include (but are not limited to):

• Work closely with the Packaging Development Manager and the Lead Product Developers to assist in delivering and commercialising packaging requirements for projects to meet business objectives & goals using a Stage & Gate approach.

• Work with key stakeholders (Operations, Quality, Innovations, Procurement & packaging suppliers) to identify, develop, validate & commercialise cost optimised packaging solutions to improve efficiency, cost, quality, safety and shelf life of products.

• Manage packaging timelines for projects. Prioritise work schedule to ensure that tasks are completed within agreed timeframes and within project timelines.

• Stay abreast of packaging trends, legal & regulatory requirements that apply to the relevant/applicable packaging and packaging/product interface.

• Perform packaging line trials autonomously at company owned and contract manufacturing locations as needed.

• Conduct relevant package performance testing on packaging materials & components.

• Write and maintain accurate project trial and testing reports.

• Conduct PREP assessments & understanding ARL artwork requirements.

• Develop and maintain current and accurate specifications for all packaging.

About you:

• Degree or diploma qualified in food science/ technology and/or Packaging Technology.

• Previous experience working in packaging development and packaging related role, ideally in the meat or smallgoods industry.

• A drive and passion for everything Packaging.

• Good communication and relationship management skills.

• Ability to manage several projects and tasks simultaneously.

• Knowledge of products, process and packaging.

• Able to work with all types of meat and meat products.

Benefits include (but not limited to):

• Heavily discounted Primo/meat products.

• Retail discounts with national partners.

• Health insurance discounts on Bupa Health and Medibank Private.

What's next?

If you’re passionate and want to be a part of the largest meat, pork and salmon manufacturer and producer in Australia, this opportunity may be for you. Apply now!

AIP NEWSLETTER JUNE 2023 5

PLEASE APPLY TODAY

THE AIP WANTS TO HEAR FROM ALL OF OUR MEMBERS

The Australian Institute of Packaging (AIP) is celebrating 60 years as the peak professional body for packaging training and education in Australasia

Celebrating 60 years

2023 is a very special year for the Australian Institute of Packaging (AIP) as we will be celebrating 60 years as the peak professional body for packaging training and education in Australasia.

We are inviting all of our Members and industry colleagues to help us celebrate by finding out what you have seen change in the industry, what you have learned along the way and more.

We ask that you please complete the survey using the link below.

Should you have any photos from over the years that you would be able to share please scan them and send them as well to info@aipack.com.au.

Thank you in advance

https://forms.gle/58hQKuCziZbR4Qz26

60th Anniversary dinner to be held in Melbourne

SEPTEMBER Friday

Mark this date in your calendar

AIP NEWSLETTER JUNE 2023 6

Bunzl becomes AIP Corporate Partner

The AIP would like to take this opportunity to welcome our latest Corporate Partner, Bunzl. Bunzl’s operations in Australia & New Zealand are part of the Bunzl plc group of companies, operating across four continents in 29 countries.

Bunzl reliably sources, consolidates and delivers an extensive range of quality products and services to businesses across all market sectors. Through specialist knowledge, strong supply chain and logistical capabilities, Bunzl ensures the right products are sourced and arrive at the right time, allowing customers to focus on their core businesses - achieving purchasing efficiencies and savings.

The business’s sustainability program extends throughout the entire supply chain; from sourcing practices, operations and the value Bunzl provides its customers.

Bunzl is proud to announce they are a corporate partner of the Australian Institute of Packaging.

Contact: Felicity Kelly, Felicity.Kelly@bunzl.com.au

As a business, we have always appreciated the work AIP has been doing, particularly around more sustainable packaging. Our Bunzl values align with AIP goals, and working with like-minded people and businesses has, and will always be, core to how Bunzl operates.

Up until now, most of our engagement has been directly through our individual professional AIP memberships. Joining AIP as a company member made sense to us – to take our partnership with AIP forward. Having access to technical expertise, networking with industry experts, keeping abreast of industry trends, and staying ahead of the curve is a must – and AIP enables us to do that. Being a corporate member also gives us the opportunity to give back to a terrific organisation.

Felicity Kelly MAIP, Head of Sustainability

Calling

AIP NEWSLETTER JUNE 2023 7

Watch today: arlmarketplace.org.au/resources all SMEs: New training course developed by the AIP: Introduction to circular and sustainable packaging design.

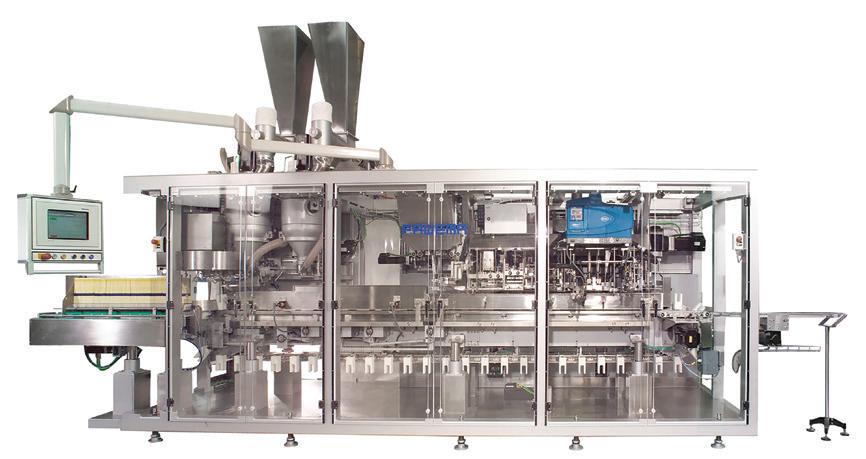

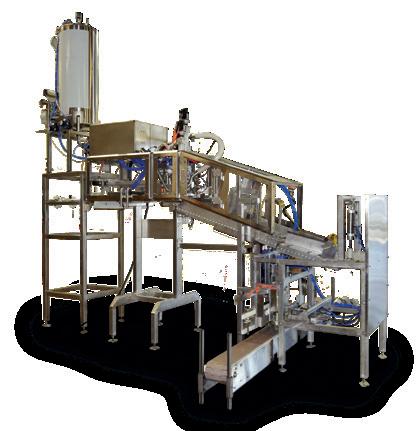

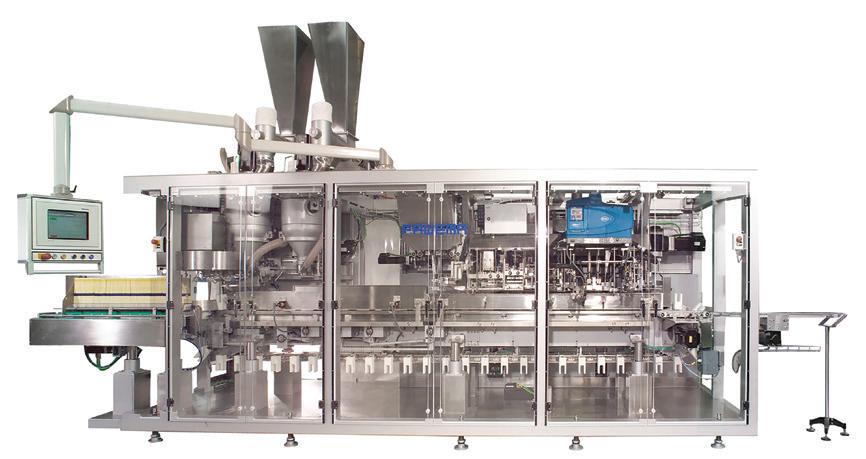

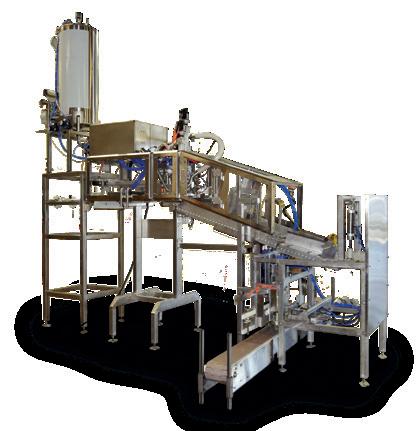

LIQUID FILLING SYSTEMS

FILL BAG-IN-BOX FROM 1.5 TO 20 LITERS

FILL STAND-UP POUCHES FROM 0.175 TO 3 LITERS

TOOLING FOR ALL TAPS, CAPS & CONNECTORS

FILL RATES FROM 60 TO 1500 BAGS PER HOUR

From small to large scale production. We have the filling solutions to meet your production requirements.

AUTOMATIC WEB FILLERS FOR BAG IN BOX

180

A unique twin fill head assembly with a single bag infeed and box loader provides reliable and consistent filling of 3-liter bags at up to 1500 bags per hour. Servo powered.

145B

Features the same servo powered fill head as the TORRfiller 150. Production rate is up to 900 3-LT bags per hour. Separates bags after fill.

140H

Semi automatic pouch and bag filler. Optional Vacuum & Nitrogen purge. Rates up to 480 bags per hour. Fills from 1 to 20 liter.

150

A single head version of the TORRfiller 180. Production rate is up to 960 3- LT bags per hour. Separates bags from the web before filling. Servo powered.

140W

An economy automatic web feed filler with air operated fill head. The operator separates the filled bag from the web and hand loads into a box or onto a conveyor. The filler paces the operator. Production rates up to 720 bags per hour.

SEMI - AUTOMATIC WEB FILLERS FOR BAG IN BOX

110

Semi manual bag and pouch filler with turbine flowmeter. Manual uncap and recap. Optional Vacuum & Nitrogen purge. Rates up to 200 bags per hour. Fills from 1 to 20 liter.

TORR Industries products are supported in Oceania by AUSPOUCH’s locally based Engineering and Sales team.

Victorian Contact: 0412 597 178

NSW Contact: 0480 254 400

130

Semi manual pouch and bag filler. Automatic uncap and recap. Optional Vacuum & Nitrogen purge. Rates up to 240 bags per hour. Fills from 1 to 20 liter.

Head Office : 02 8852 2660

4, 9 Salisbury Rd Castle Hill NSW 2154

www.auspouch.com.au

AIP NEWSLETTER JUNE 2023 8 INDUSTRIES

Up-Coming Courses, Webinars & Tradeshows

Foodpro 2023

WHEN: 23 - 26 July 2023

JULY 2023

AIP to host training course & more alongside

WHERE: Melbourne Convention & Exhibition Centre

WHAT: foodpro, Australia's most trusted and proven trade event in the food manufacturing industry, is back for the first time in 6 years.

Returning 23-26 July 2023 at the Melbourne Convention & Exhibition Centre, foodpro provides the first opportunity for the industry to celebrate the contribution of Australian food producers, distributors, and manufacturers. Showcasing the latest packaging and processing solutions, foodpro is where the food industry gathers to make big business deals, network and explore ways to create an efficient future for manufacturing. Generate leads and close deals at an action packed four day gathering attracting premium and qualified buyers.

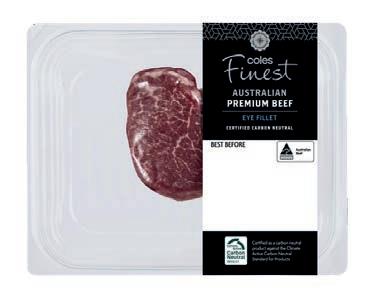

AIP Sustainable Packaging Session for the Meat & Proteins Industry

WHEN: 23 July 2023

WHERE: Smart Food Lounge, Foodpro 2023, Melbourne Convention & Exhibition Centre

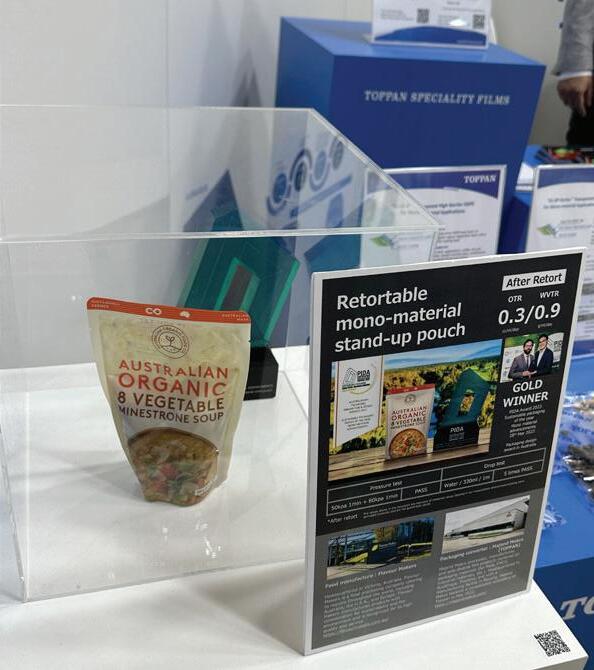

WHAT: AIP Sustainable Packaging Session for the Meat Industry: Showcasing innovative award-winning sustainable and circular packaging solutions that have won PIDA Awards and WorldStar Packaging Awards for the meat/proteins side of the industry. This session will bring together a number of experts in this field that have recently been recognised for their unique, innovative and sustainable packs.

Active & Intelligent Packaging: Training Course NEW COURSE

WHEN: 24 July 2023

WHERE: Alongside Foodpro 2023, Melbourne Convention & Exhibition Centre

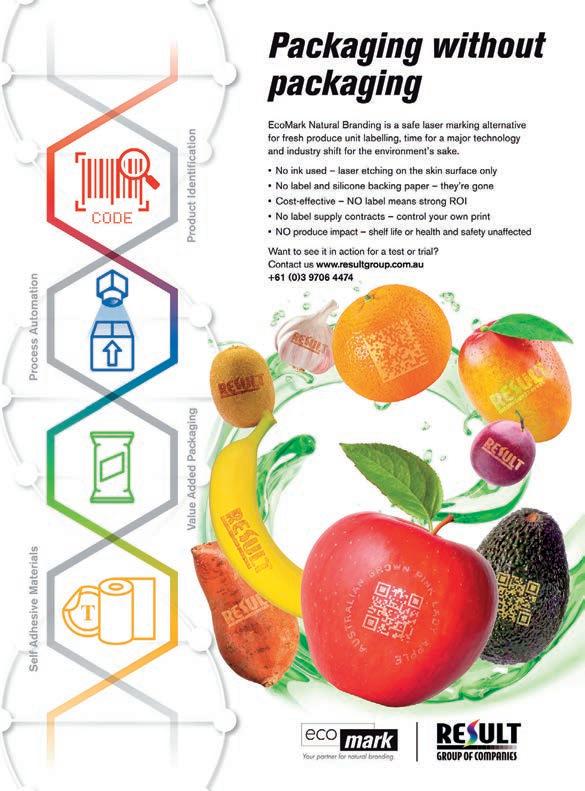

WHAT: Printed Packaging will NEVER be replaced even though nearly every other printed medium has shifted to digital and now sits on a smartphone or PC. Likewise, email and social media platforms are a crowded space where it is difficult to stand out.

To be held alongside

To be held alongside

We use smartphones and smart appliances, drive smart cars, and we increasingly purchase consumer goods that are supplied and transported in smart packages. So, what makes all those things ‘smart’ and how can 'smart packaging' be implemented?

This course is designed to assist anyone who is responsible for packaging, marketing, operations, logistics in the consumer goods and broader supply chain seeking to stay relevant in their consumers lives by using smart packaging solutions that offer out-of-the-box business value.

The course will provide attendees with a better understanding of the smart packaging solutions currently available to transform the way they package, deliver and market their products and connect directly with consumer or offer value that will ensure customers ‘come back for more’. Best Practice examples of award-winning packs from the PIDA awards and WorldStar Awards across Active & Intelligent Packaging will also be discussed in the course.

Discussions will cover Active & Intelligent Packaging in easy to understand terms, and will highlight applications being embraced by brands across various industries who are trying to leverage the benefits of smart packaging solutions to enhance their operations whilst at the same time providing an unparalleled customer experience. Is your business prepared for such transformations?

Course Objectives:

• Develop a better understanding of Active & Intelligent Packaging solutions and the core technologies involved in their delivery.

• Understand the global standards the underpin the smart packaging revolution

• Learn how various smart packaging solutions could be implemented and developed

• Understand applications and use case examples of active and intelligent packaging from inventory management, to customer interaction as well as recycling, brand protection and product recall

• Learn how reducing food waste is possible via smart packaging

• Understand how to use data for insights and increased sales for your products

• Learn how to utilise smart packaging platforms to stay relevant in consumers lives and increase sales

• Learn how smart packaging can help mitigate loss events in the supply chain

LECTURER:

Michael Dosser MAIP Education Team Australian Institute of Packaging (AIP)

* = 12.5 CPP PTS

AIP NEWSLETTER JUNE 2023 9

Eligible for CPP Points

* = 1 CPP PT

Up-Coming Courses, Webinars & Tradeshows

JULY 2023

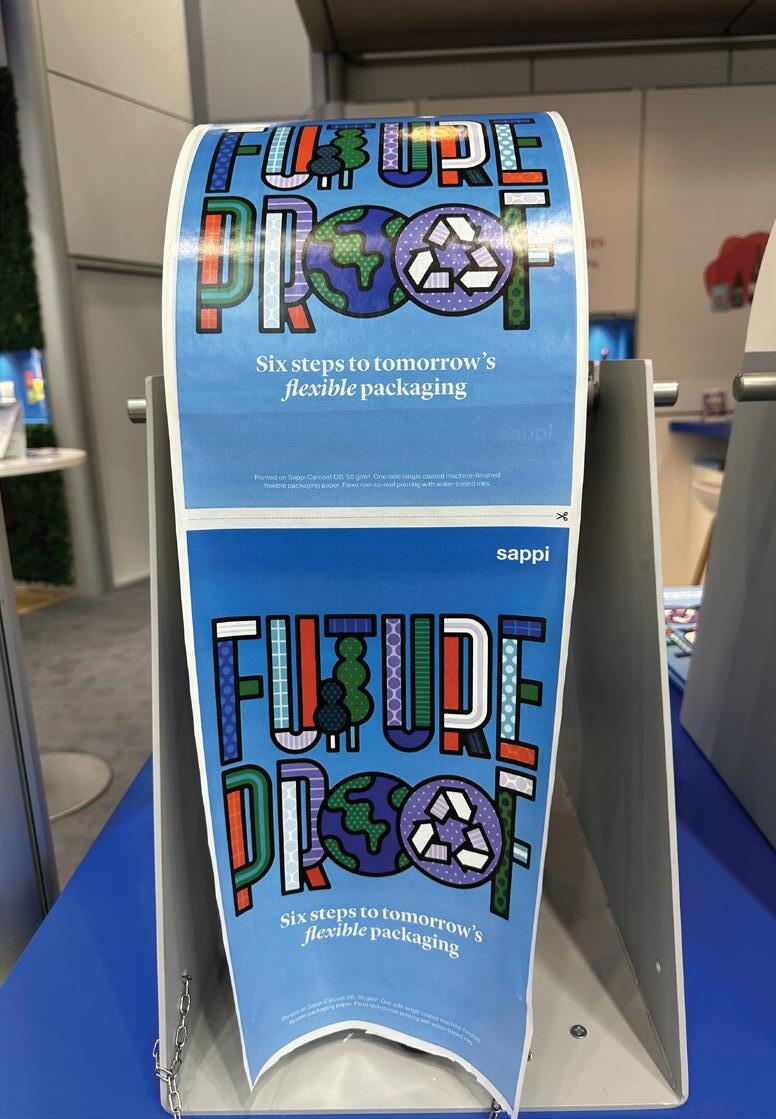

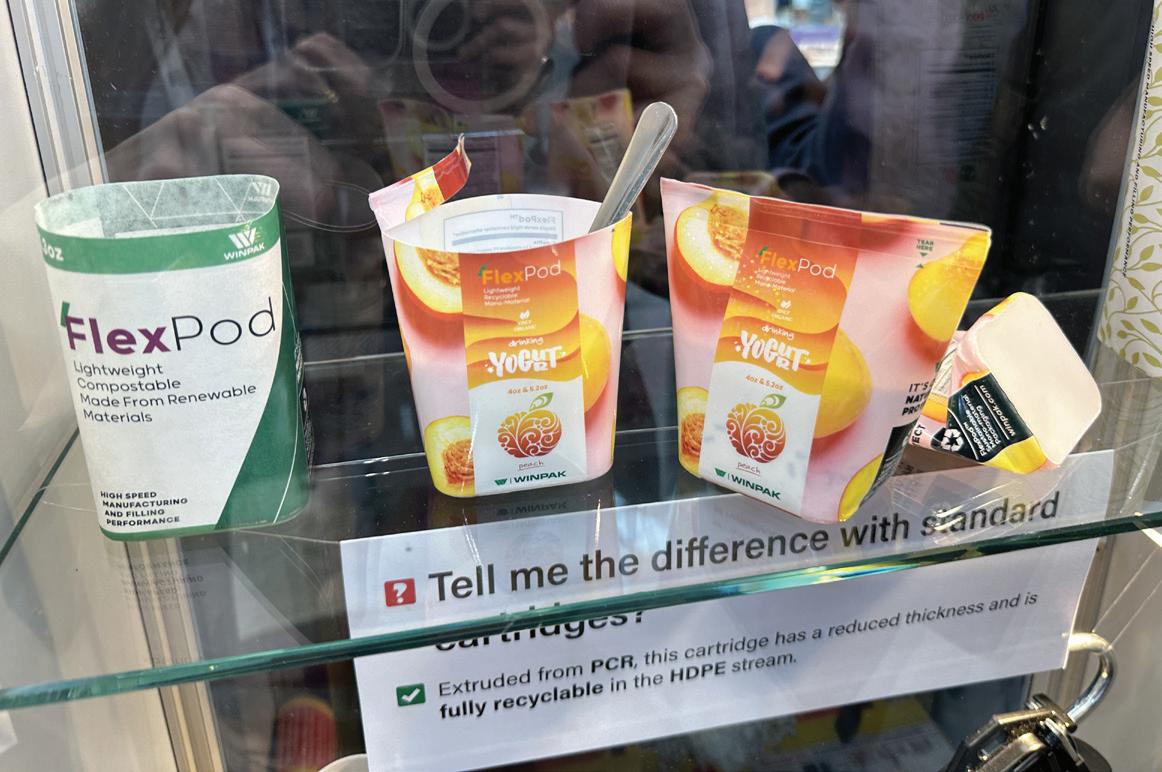

Flexible Packaging: Now & Into The Future: Training Course

WHEN: 24 July 2023

WHERE: Alongside Foodpro 2023, Melbourne Convention & Exhibition Centre

WHAT: One of the fastest growing segments of the packaging industry, flexible packaging combines the best qualities of plastic, film, paper and aluminium foil to deliver a broad range of protective properties while employing a minimum of material. Typically taking the shape of a bag, pouch, liner, or overwrap, flexible packaging is defined as any package or any part of a package whose shape can be readily changed.

Course Objectives:

The objectives of the course are to provide participants an understanding of:

• A good broad understanding of the benefits of Flexible packaging.

• The process of manufacturing.

• Where the future lies with flexible films and the changes ahead.

• Snap shot of some of the latest packaging trends and what are the driving forces.

• Understanding the challenges facing us with the sustainable packaging race toward.

LECTURER:

AIP Sustainable Packaging Session for the Food Industry

WHEN: 25 July 2023

WHERE: Smart Food Lounge, Foodpro 2023, Melbourne Convention & Exhibition Centre

WHAT: This session will showcase innovative packs that have recently award-winning PIDA Awards and WorldStar Packaging Awards including certified compostable packs, fibre based packs, packs made out of renewable materials and smart packaging. This session will bring together a number of experts in this field that have recently been recognised for their intuitive packaging that can potentially save food loss and waste across a value chain and also are more sustainable.

INTRODUCING...

4P Technical Services provides an independent technical service to the Australian manufacturing industry, with core competencies including packaging and food technology, quality management, cost minimisation and continuous improvement.

OUR SERVICES INCLUDE:

To be held alongside

To be held alongside

• Packaging design, optimisation, and cost reduction

• Packaging sustainability, convent plans, projects and reports

• Supply chain efficiencies/cost reduction

• Process continuous improvement and problem solving

• Total product and process value analysis/cost reduction

• Quality systems and HACCP auditing

• Packaging training relevant to all business levels

• Artwork management system optimisation

• Technical project management

• Expert Witness support

Please contact Greg Roberts Dip.Pkg.Tech. FAIP CPP: 0437 868 958 • greg roberts@4ptechservices.com.au • www.4ptechservices.com.au

AIP NEWSLETTER JUNE 2023 10

* = 12.5 CPP PTS

* = 1 CPP PT

Joe Foster FAIP Education Team Australian Institute of Packaging (AIP)

AIP to take 2x training courses & 2x packaging sessions to FoodPro - 23-26

July

As an Association Partner the AIP is proud to advise that it will be hosting 2x packaging sessions, 2x training courses and have an exhibition stand (K49) at FoodPro on the 23-26 of July an the Melbourne Convention & Exhibition Centre. We hope that you will join us.

Sunday 23rd of July AIP Sustainable Packaging Session for the Meat Industry:

Showcasing innovative award-winning sustainable and circular packaging solutions that have won PIDA Awards and WorldStar Packaging Awards for the meat/proteins side of the industry. This session will bring together a number of experts in this field that have recently been recognised for their unique, innovative and sustainable packs. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional designation and a certificate of attendance. Speakers will include:

Monday 24th of July Training Course #1: Flexible Packaging – Now & Into the future

The Flexible Packaging: Now & Into the Future training course will cover the basic fundamentals of flexible packaging, its benefits, how you chose the specific structures to match the product, its performance, marketing challenges and how the packaging is manufactured.

With the latest challenges facing us regarding sustainability in packaging the course will discuss the options, pros and cons of Compostability vs Recyclability, moves to mono material recyclable packaging to meet CEFLEX standards and other innovative alternative materials now available. As an add on, the course will be looking at the future plans for flexible packaging and available closed loop collection programs, kerbside collection development, advanced recycling options for circular design and many others to meet Packaging and Food Waste Targets.

Course Objectives:

The objectives of the course are to provide participants an understanding of:

• A good broad understanding of the benefits of Flexible packaging.

• The process of manufacturing.

• Where the future lies with flexible films and the changes ahead.

• Snap shot of some of the latest packaging trends and what are the driving forces.

• Understanding the challenges facing us with the sustainable packaging race toward. This course is designed for all of industry to attend so book your place today. All attendees will attain 12.5 CPD points per session towards the global Certified Packaging Professional designation and a certificate of attendance.

http://aipack.com.au/event-registration/?ee=397

AIP NEWSLETTER JUNE 2023 11

Alan Adams MAIP Sustainability Director APAC Sealed Air

Warwick Armstrong MAIP General Manager Business Development & Marketing Plantic Technologies

FREE FOR ALL TO ATTEND

Jasson Mills Director Research & Development Amcor Flexibles ANZ

* =12.5 CPP PTS

Joe Foster FAIP Education Team Australian Institute of Packaging (AIP) YOUR PLACE TODAY AS SPACES ARE LIMITED

Course Lecturer * =1 CPP PT

BOOK

AIP to take 2x training courses & 2x packaging sessions to FoodPro - 23-26 July

As an Association Partner the AIP is proud to advise that it will be hosting 2x packaging sessions, 2x training courses and have an exhibition stand (K49) at FoodPro on the 23-26 of July an the Melbourne Convention & Exhibition Centre. We hope that you will join us.

Monday 24th of July Training Course #2: Introduction to Active & Intelligent Packaging

We use smartphones and appliances, drive smart cars, and we increasingly purchase consumer goods that are supplied and transported in smart packages...So, what makes all those things ‘smart’ and how can ‘smart packaging’ be implemented?

This course is designed to assist anyone who is responsible for packaging, marketing, operations, logistics in the consumer goods and broader supply chain seeking to stay relevant in their consumers lives by using smart packaging solutions that offer out-of-the-box business value. The course will provide attendees with a better understanding of the smart packaging solutions currently available to transform the way they package, deliver and market their products and connect directly with consumer or offer value that will ensure customers ‘come back for more’. Best Practice examples of award-winning packs across Active & Intelligent Packaging will also be discussed in the course.

Discussions will cover active and intelligent packaging in easy to understand terms, and will highlight applications being embraced by brands across various industries who are trying to leverage the benefits of smart packaging solutions to enhance their operations whilst at the same time providing an unparalleled customer experience. Is your business prepared for such transformations?

This course is designed for all of industry to attend so book your place today. All attendees will attain 12.5 CPD points per session towards the global Certified Packaging Professional designation and a certificate of attendance.

http://aipack.com.au/event-registration/?ee=398

Tuesday 25th of July AIP Sustainable Packaging Session for the Food Industry:

This session will showcase innovative packs that have recently award-winning PIDA Awards and WorldStar Packaging Awards including certified compostable packs, fibre based packs, packs made out of renewable materials and smart packaging. This session will bring together a number of experts in this field that have recently been recognised for their intuitive packaging that can potentially save food loss and waste across a value chain and also are more sustainable. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional designation and a certificate of attendance.

Speakers will include:

AIP NEWSLETTER JUNE 2023 12

Michael Dossor MAIP Education Team Australian Institute of Packaging (AIP)

Course Lecturer

Richard Fernandez MAIP Business Development Manager Confoil

Gilad Sadan MAIP N.A.V.I Co. Global The Packaging Hippie

FREE FOR ALL TO ATTEND *

CPP PT BOOK YOUR PLACE TODAY AS SPACES ARE LIMITED * =12.5 CPP PTS

Felicity Kelly AAIP Head of Sustainability Bunzl Australia & New Zealand

=1

AIP NEWSLETTER JUNE 2023 13 Melbourne Convention & Exhibition Centre 23 26 JULY 2023 foodproexh.com Where big business deals happen Running for over 50 years, Australia’s largest event for food and beverage manufacturing is back. With a whole host of new additions, including Networking Drinks, an exclusive Business Lounge, an exciting new Sensory Experience Zone and product sampling opportunities, there has never been a better time to get involved. Secure a premium stand today Book your stand AIP to have a Stand, run 2x training courses and 2x packaging forums alongside FoodPro

Up-Coming Courses, Webinars & Tradeshows

JULY 2023

Australasian Waste & Recycling Expo (AWRE) 2023

WHEN: 26 - 27 July 2023

WHERE: International Convention Centre, Sydney

AIP packaging sessions alongside

WHAT: The waste, recycling and resource recovery industry is continuing to transform and has quickly become the nucleus for driving Australia towards a cleaner, more sustainable future. AWRE is THE premier national platform for waste professionals to join forces and work towards this common goal. The event will include three exciting elements for visitors and exhibitors alike.

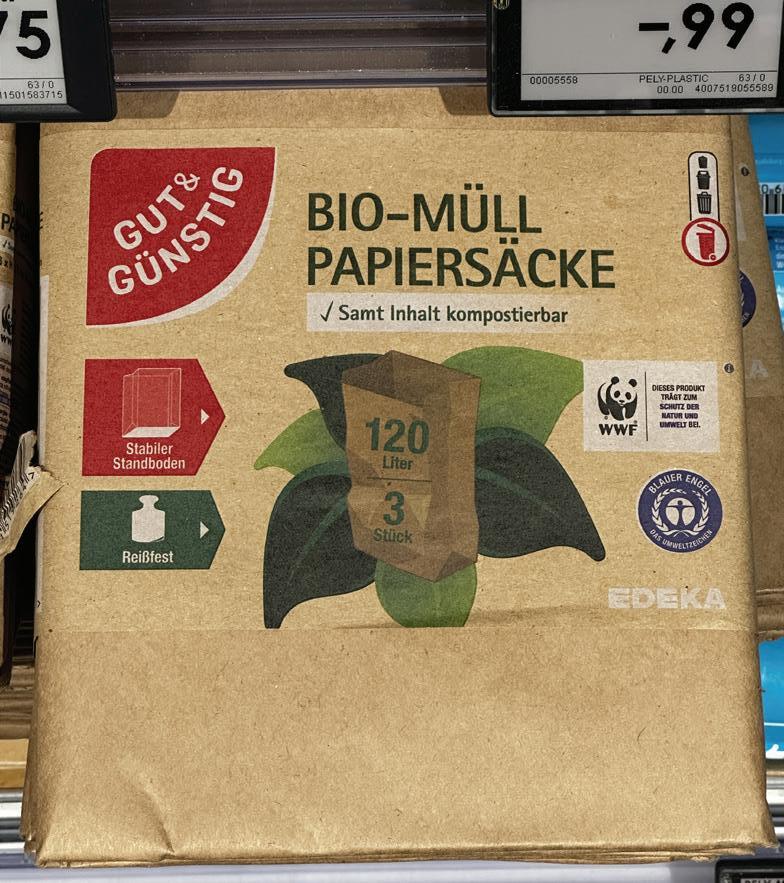

AIP AWRE Sustainable Packaging Design Session

WHEN: 26 July 2023

WHERE: Alongside AWRE 2023, International Convention Centre, Sydney

WHAT: The AIP will be running a session at AWRE that will be focussed on how to design out waste, create more circular and sustainable packaging with lower environmental impacts. The unique innovations that will be discussed in the session will be awardwinning PIDA and WorldStar examples. The Sustainable Packaging Design session is free for all of industry to attend so book your place today. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional (CPP) designation.

AIP AWRE Sustainable Packaging Design Session #2

WHEN: 27 July 2023

WHERE: Alongside AWRE 2023, International Convention Centre, Sydney

WHAT: The AIP will be running a session at AWRE that will be discussing the balance required between the environmental impacts of food waste vs packaging waste. The session will discuss the trade-offs, unintended consequences and also showcase award-winning best practice examples of intuitive and innovative Save Food Packaging Design that can minimise food loss and waste across the value chain. Speakers will be recognised designers in the field and will be discussing their most recent PIDA and WorldStar award winning packs. This Food Waste vs Packaging Waste session is free for all of industry to attend so book your place today. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional (CPP) designation.

AIP NEWSLETTER JUNE 2023 14

Eligible for CPP Points * = 1 CPP PT To be held alongside * = 1 CPP PT To be held alongside

AWRE 2023 - 26-27 July

The AIP will be continuing their support of Australasian Waste & Recycling Expo (AWRE) with an AIP stand and some packaging educational sessions that are free to attend. All of industry is invited to attend. Please book your place at the three packaging sessions and also come and see us on stand B37 during the show.

Wednesday 26 July | 12.30 pm to 1.30 pm

Circular & Sustainable Packaging Design

The AIP will be running a session at AWRE that will be focussed on how to design out waste, create more circular and sustainable packaging with lower environmental impacts. The unique innovations that will be discussed in the session will be award-winning PIDA and WorldStar examples. The Sustainable Packaging Design session is free for all of industry to attend so book your place today. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional (CPP) designation.

Speakers to include:

ATTEND

Thursday 27 July | 1.45 pm to 2.45 pm

A Balanced Approach between Packaging Waste & Food Waste

The AIP will be running a session at AWRE that will be discussing the balance required between the environmental impacts of food waste vs packaging waste. The session will discuss the trade-offs, unintended consequences and also showcase award-winning best practice examples of intuitive and innovative Save Food Packaging Design that can minimise food loss and waste across the value chain. Speakers will be recognised designers in the field and will be discussing their most recent PIDA and WorldStar award winning packs. This Food Waste vs Packaging Waste session is free for all of industry to attend so book your place today. All attendees will attain 1 CPD point per session towards the global Certified Packaging Professional (CPP) designation.

Speakers to include:

FREE TO ATTEND

Thursday

27 July | 3.00 pm to 3.30

pm

Australasian Recycling Label (ARL) and how it cuts out consumer recycling confusion

The AIP, AFGC, NRA and APCO are working together to help raise the profile of the value that the ARL brings to all sized businesses, the environment and consumers. This session will provide updates on the ARL, the Marketplace and the new tools and resources available for everyone to access to embed ARL on their packaging, one pack at a time.

Speakers to include:

FREE TO ATTEND Register to attend the show which will give you access to these free sessions

AIP NEWSLETTER JUNE 2023 15

Lars M. Ljung Sustainability Manager, Planet Protector Packaging

*

CPP PT

Brendon Holmes Managing Director, Caps & Closures

=1

Michael Dossor MAIP Managing Director, Result Group

Alan Adams MAIP Sustainability Director APAC, Sealed Air

* =1 CPP PT

FREE TO

Nerida Kelton FAIP Executive Director, Australian Institute of Packaging (AIP)

Bonnie Marshall Policy Officer, National Retail Association (NRA)

Sarah Sannen Head of Operations, Australian Packaging Covenant

* =1 CPP PT

https://register.divcom.net.au/awre-2023/visitor-registration/Site/Register?

Jack Glover Marketing Director ANZ, Accolade Wines

26-27 July 2023

ICC SYDNEY

AIP to have a stand and run 2x packaging forums alongside of AWRE

Driving a World of Solutions

The waste, recycling and resource recovery industry is continuing to transform and has quickly become the nucleus for driving Australia towards a cleaner, more sustainable future.

AWRE is THE premier national platform for waste professionals to join forces and work towards this common goal. Discover the latest innovations and solutions and connect with like-minded experts as we propel Australia to lead the charge to global and national waste targets – together.

AIP NEWSLETTER JUNE 2023 16 Up-Coming Courses, Webinars & Tradeshows Find Out More AWRE.COM.AU #AWRE2023

Up-Coming Courses, Webinars & Tradeshows

SEPTEMBER 2023

AIP 60th Anniversary Dinner

WHEN: 1 September 2023

WHERE: Aviary, Crown Promenade, Melbourne

Save the date

PACK EXPO Las Vegas 2023

WHEN: 11 - 13 September 2023

WHERE: Las Vegas Convention Center, Las Vegas, Nevada

WHAT: Every two years, PACK EXPO Las Vegas brings together all packaged goods and life sciences industries for the most productive week of the year. This is where suppliers showcase their latest innovations and end users discover game-changing solutions to packaging and processing challenges. With thousands of solutions on display, PACK EXPO Las Vegas 2023 is the one show in North America where consumer packaged goods and life sciences companies can count on finding the right solutions for their next project.

MixedoutlookforAustralianco-packingsector PACKAGINGNEWS.COM.AU

SEPTEMBER/OCTOBER 2020 Covidimpactsresultsofmajorpackagingplayers Towardsarefillablefutureforpackaging Boxsectorstandssolidintoughtimes

JUNE 2023

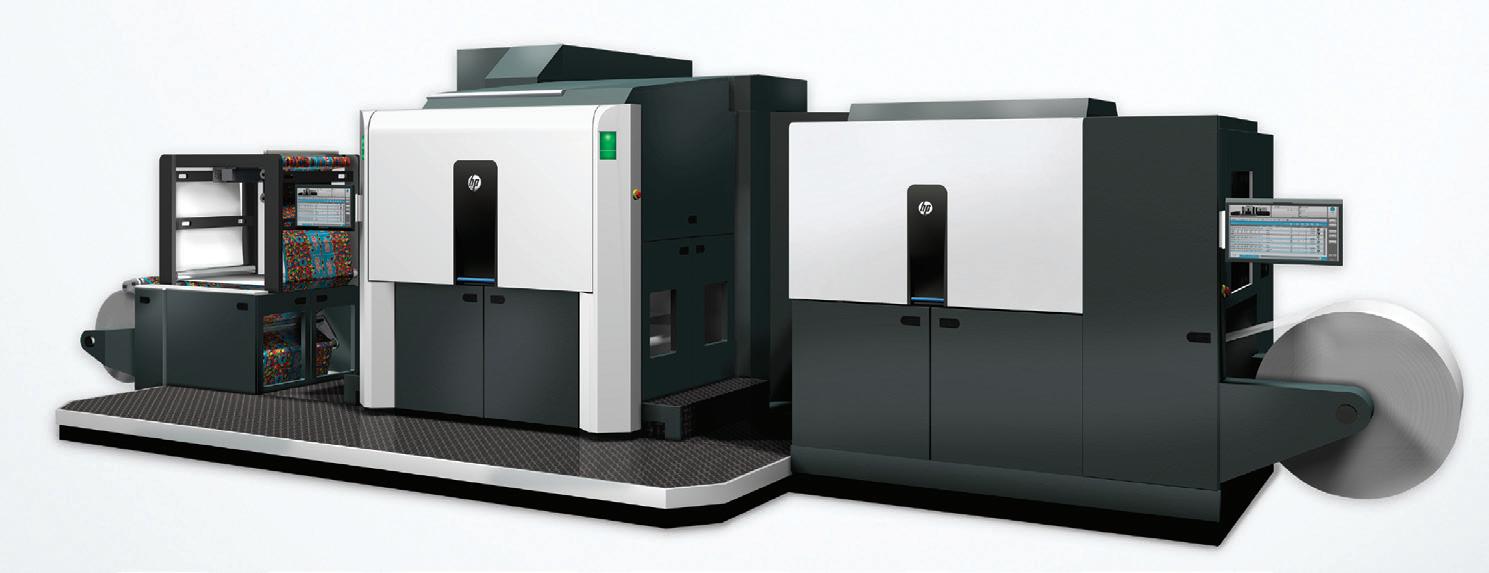

Digitalprintingdrivesbrandengagement Flexibles:thinkingoutsidethepouch celebrates50yearsofinspiringAustralian brandownersanddesigners LayoutForAd_p001_KurzAustr.indd 1 PRINT POST APPROVED 10005337 Govtinvests$100minrecycling 2025targets:plasticinAPCO’ssights Greenexpectations:biobasedupdate 2xfaster patented design 60YEARS PRINT POST APPROVED 10005337 LIGHTWEIGHT Ecolean’s lightweight packaging solutions for impact on the environment, by using less Joinourapproachtosustainablepackagingat MARCH/APRIL 2020 IndustryleadersweighinatPlastics LoopfounderTomSzakyshares ANZPACPlasticsPactsignals Transformativetechnology Beveragegrowthsupported PACKAGINGNEWS.COM.AU Cover.indd MAY/JUNE 2020 PIDA2020:AccoladesforANZinnovation Packagingindustrystepsupinpandemic OurPackagingFutureshowscircularway Digitalgrowthdriversinpackagingprint Chobanicupgetsinnovationinjection PRINT POST APPROVED 10005337 INDUSTRY DIRECTORY 2020-21 60YEARS MAY/JUNE 2020 Xxxxx Xxxxx Xxxxx Xxxxx Xxxxx PRINT POST APPROVED 10005337 XXX XXXX XXX XXXXXX 60YEARS NCI nails gold MAY/JUNE 2020 Xxxxx Xxxxx Xxxxx Xxxxx Xxxxx PRINT POST APPROVED 10005337 XXX XXXX XXX XXXXXX 60YEARS NCInailsgold Xxxxx Xxxxx PRINT POST APPROVED Cover.indd 1 25/5/20 10:38am SEPTEMBER/OCTOBER 2020 Covidimpactsresultsofmajorpackagingplayers Towardsarefillablefutureforpackaging Boxsectorstandssolidintoughtimes Craftbeerembracesthecost-effectivecan

PRINT POST APPROVED 10005337 PLUS: APPMA’S MACHINERY MATTERS 60YEARS Embrace the new normal megatrends toboostyourbrand’sbusinessthrough HP Indigo Digital Print. Cover.indd 15/9/20 11:26

Craftbeerembracesthecost-effectivecan MixedoutlookforAustralianco-packingsector PACKAGINGNEWS.COM.AU YEARS JULY/AUGUST 2020 VisybuysO-IANZinmajorindustrydeal Govtpledges$190mtomoderniserecycling Smartfactory:keystoautomationsuccess Digitalprintingdrivesbrandengagement Flexibles:thinkingoutsidethepouch PLUS: APPMA’S MACHINERY MATTERS Kurzcelebrates50yearsofinspiringAustralian brandownersanddesigners PRINT POST APPROVED 10005337 JANUARY / FEBRUARY 2020 LocalOIglassoperationsupforsale Govtinvests$100minrecycling 2025targets:plasticinAPCO’ssights Greenexpectations:biobasedupdate speed + control | ability CALL 1800 FOODMACH 2xfaster patented design Australia’smostflexibleshelfreadycasepacker. 60YEARS Cover.indd PKN Packaging News is Australia’s definitive packaging industry news source, providing in-depth coverage of industry and technology developments relevant to the entire packaging supply chain, including packaging end-users. Get the latest packaging industry news as it breaks, any time, on any device. TWITTER @pknpackagingmag LINKEDIN PKN Packaging News ENEWSLETTER packagingnews.com.au ONLINE packagingnews.com.au PODCAST PKN Packaging News: The Podcast VIDEO BULLETIN PLAY PKN STAY CONNECTED

FoodTech PackTech 2023

WHEN: 19 - 21 September 2023

WHERE: Auckland Showgrounds

Up-Coming Courses, Webinars & Tradeshows

SEPTEMBER 2023

AIP to host training course & more alongside

WHAT: New Zealand’s foremost food and packaging technology exhibition where New Zealand’s food manufacturing sector encounters new materials, processes and technology from the world’s top suppliers. FoodTech PackTech (FTPT) is New Zealand’s largest food manufacturing, packaging and processing technology trade show. Running strong for over 20 years this free to attend event brings industry professionals and decision makers together providing a forum for education, discussion and the sharing of knowledge and expertise, critical in the sustainability and growth of the industry.

The AIP are a supporting association of the FoodTech PackTech New Zealand again this year and as a part of the partnership the Institute will be hosting four hours of packaging sessions on Day One, a training course on the Future of Flexible Packaging on Day Two and an exhibition stand.

We hope that you will join us as this will be our first time in New Zealand since the pandemic started..

AIP & FoodTech PackTech Sessions

WHEN: 19 September 2023

WHERE: Alongside FoodTech PackTech 2023, Auckland Showgrounds

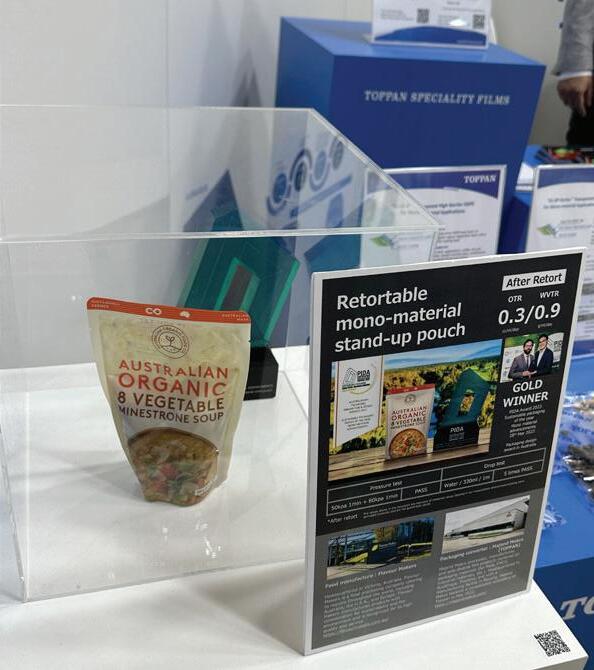

WHAT: The AIP will be running a series of packaging sessions which will be designed as panel discussions covering a broad range of topics including packaging targets, waste directives, Sustainable & Circular packaging innovations and designs, incorporating recycled content into packaging, the future of soft plastics and flexible packaging, how to embed the 10 Sustainable Packaging Design Principles into your business, the role that packaging plays in minimising food waste, the future of fibre and renewable materials, the important role that the Australasian Recycling Labelling program plays across ANZ and updates for ANZPAC. The speakers will also include a number of our NZ winners of the ANZ PIDA Awards and the WorldStar Packaging Awards.

Flexible Packaging: Now & Into The Future: Training Course

WHEN: 20 September 2023

WHERE: Alongside FoodTech PackTech 2023, Auckland Showgrounds

WHAT: The Flexible Packaging: Now & Into the Future training course will cover the basic fundamentals of flexible packaging, its benefits, how you chose the specific structures to match the product, its performance, marketing challenges and how the packaging is manufactured.

With the latest challenges facing us regarding sustainability in packaging the course will discuss the options, pros and cons of Compostability vs Recyclability, moves to mono material recyclable packaging to meet CEFLEX standards and other innovative alternative materials now available. As an add on, the course will be looking at the future plans for flexible packaging and available closed loop collection programs, kerbside collection development, advanced recycling options for circular design and many others to meet Packaging and Food Waste Targets.:

Course Objectives:

The objectives of the course are to provide participants an understanding of:

• A good broad understanding of the benefits of Flexible packaging.

• The process of manufacturing.

• Where the future lies with flexible films and the changes ahead.

• Snap shot of some of the latest packaging trends and what are the driving forces.

• Understanding the challenges facing us with the sustainable packaging race toward.

LECTURER:

Joe Foster FAIP Education Team Australian Institute of

Packaging (AIP)

* = 12.5

CPP PTS

AIP NEWSLETTER JUNE 2023 18

Eligible for CPP Points

To be held alongside To be held alongside * = 1 CPP PT per session

Up-Coming Courses, Webinars & Tradeshows

The AIP will be running a series of packaging sessions which will be designed as panel discussions covering a broad range of topics including packaging targets, waste directives, Sustainable & Circular packaging innovations and designs, incorporating recycled content into packaging, the future of soft plastics and flexible packaging, how to embed the 10 Sustainable Packaging Design Principles into your business, the role that packaging plays in minimising food waste, the future of fibre and renewable materials, the important role that the Australasian Recycling Labelling program plays across ANZ and updates for ANZPAC. The speakers will also include a number of our NZ winners of the ANZ

Awards and the WorldStar Packaging Awards.

19 September 2023 | Venue: ASB Showgrounds Auckland

AIP NEWSLETTER JUNE 2023 19

Huzaifa Mohsinally MAIP Packaging Manager Goodman Fielder New Zealand

Ben McCulloch AAIP Product Manager (rPET) Martogg

Kitty Sandoval MAIP Senior Packaging Manager Frucor Suntory Oceania

Nerida Kelton FAIP Executive Director - AIP VP Sustainability & Save Food WPO

PIDA

Alan Adams MAIP Sustainability Director APAC Sealed Air

Sarah Yanez MAIP, CPP Director Totally Wrapt Packaging

Nikki Withington MAIP NZ Co-ordinator - ARL & the ANZPAC Plastics Pact APCO

Apoorv Mehrotra AAIP Business Development Manager Oji Fibre Solutions

Florian Graichen General Manager – Forests to Biobased Products Scion

Barbara Nebel CEO thinkstep-anz

Vikas Ahuja Sustainability Director Tetra Pak

Deanne Holdsworth General Manager Sales - Pact Packaging NZ Pact Group

Joe Foster FAIP Chief Executive Officer Close the Loop Group

Chris Thomas Divisional Manager Packaging BJ Ball NZ Ltd

Just some of the Speakers confirmed thus far...

19 - 21 September 2023

Auckland Showgrounds

New Zealand’s foremost food and packaging technology exhibition where New Zealand’s food manufacturing sector encounters new materials, processes and technology from the world’s top suppliers

See us at stand 160

The AIP will have a stand, run multiple packaging sessions and a training course alongside FoodTech PackTech.

AIP NEWSLETTER JUNE 2023 20

Up-Coming Courses, Webinars & Tradeshows

OCTOBER 2023

Waste Expo Australia

WHEN: 25-26 October 2023

WHERE: Melbourne Convention and Exhibition Centre

WHAT: Waste Expo Australia is the country's largest gathering of waste management and resource recovery professionals.

Alongside their largest ever conference program, running across 4 different tracks with 60+ individual sessions and over 100 leading national and international experts, Waste Expo Australia will feature 100+ brands with presence from both local and international exhibitors, providing a platform to discover the latest breakthrough innovations shaping the future of the waste, recycling and resource recovery industry.

Attracting more than 6,000 industry professionals, Waste Expo Australia is a must-attend event in the industry's calendar. Be part of this free-to-attend exhibition and conference from 25-26 October 2023 at the Melbourne Convention and Exhibition Centre.

The AIP will have an exhibition stand and will be hosting three packaging sessions at Waste Expo.

AIP NEWSLETTER JUNE 2023 21

Eligible for CPP Points AIP to Partner

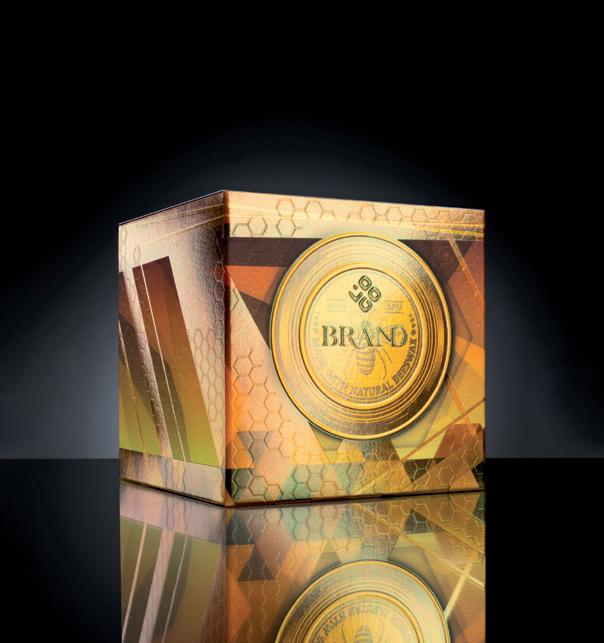

FINALIST LABELLING & DECORATIO N DESIGN OF THE YEAR Showcasing brands with progressive packaging solutions from Zipform Packaging www.zipformpackaging.com.au

Australian Institute of Packaging returns to Waste Expo Australia in 2023

Join us as we exhibit and speak at the largest gathering of waste management and resource recovery professionals in the country.

With 2700+ visitors and 100 brands+ on display in 2023, there are only a limited number of stands and sponsorship opportunities still available!

Scan the QR code or click here to enquire to exhibit today

25-26 October 2023

Melbourne Convention & Exhibition Centre

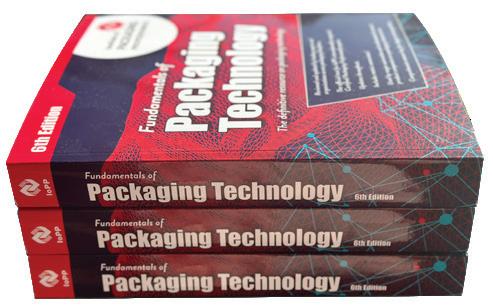

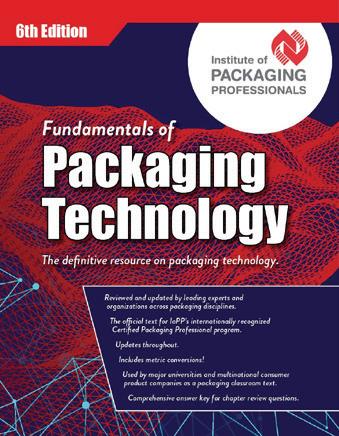

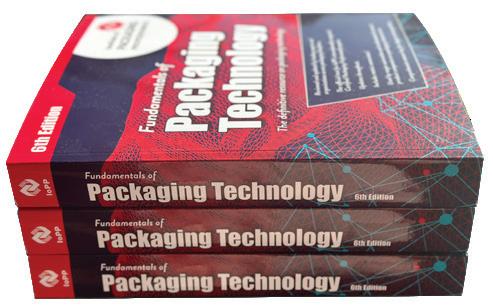

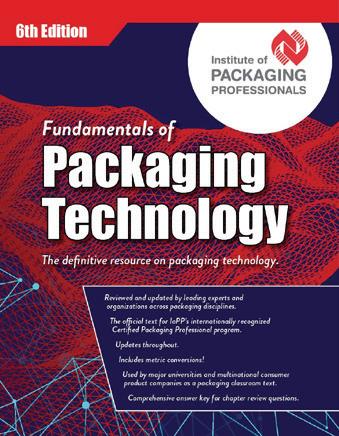

6th Edition arrives in Australasia

Order your copy of the New 6th Edition of the Fundamentals of Packaging Technology Textbook today!

Fundamentals of Packaging Technology, 6th Edition is more comprehensive and better than ever.

The newest Edition contains a reorganised and expanded discussion on sustainability, the circular economy, packaging law, a more in-depth discussion of e-commerce, additional on-line resources, and updated information on technical considerations, standards, and testing procedures!

Fundamentals of Packaging Technology, 6th Edition is peer-reviewed to add to the extensive past contributions of Walter Soroka, with fresh insights from nearly 100 packaging subject matter experts.

This revised Edition also includes a chapter review answer key and an updated look at considerations for machinery in packaging, including robotics, augmented reality, and virtual reality.

If you are thinking about starting your Certified Packaging Professional designation or undertaking modules from the Fundamentals of Packaging Technology course then this textbook is for you!

AIP NEWSLETTER JUNE 2023 23

SAVE FOOD PACKAGING RESEARCH

CERTIFICATE IN PACKAGING (On-Line )

FUNDAMENTALS IN PACKAGING TECHNOLOGY (On-Line & Residential)

HELPING SHAPE THE CAREERS OF EVERYONE WHO WORKS IN AND AROUND PACKAGING aipack.com.au

AUSTRALASIAN PACKAGING INNOVATION & DESIGN (PIDA) AWARDS

MASTER OF FOOD & PACKAGING INNOVATION (Residential)

DIPLOMA IN PACKAGING TECHNOLOGY (On-Line)

30 TRAINING COURSES (Virtual & Hybrid)

WORLDSTAR PACKAGING AWARDS

SITE VISITS, SEMINARS, CONFERENCES & FORUMS

CERTIFIED PACKAGING

PROFESSIONAL DESIGNATION

ANNUAL SCHOLARSHIP PROGRAM

AIP NEWSLETTER JUNE 2023 24

MEMBER FULL MEMBER SUPPORTING SIGNATORY CORE PARTICIPANT FOUNDING PARTNER SUPPORTER AIP: PEAK PROFESSIONAL BODY FOR PACKAGING EDUCATION & TRAINING IN AUSTRALASIA

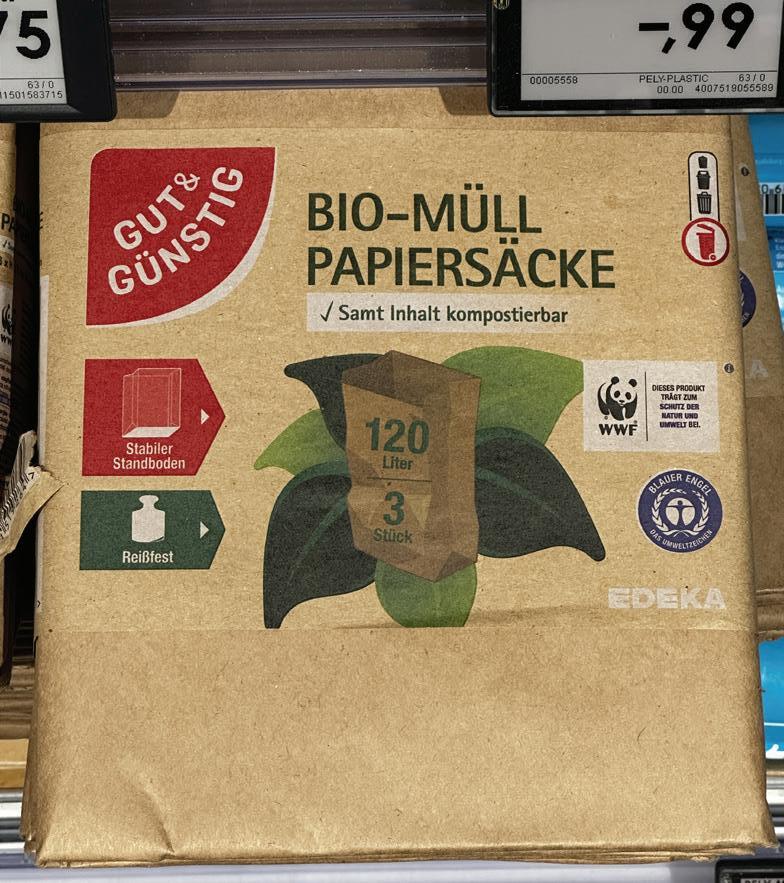

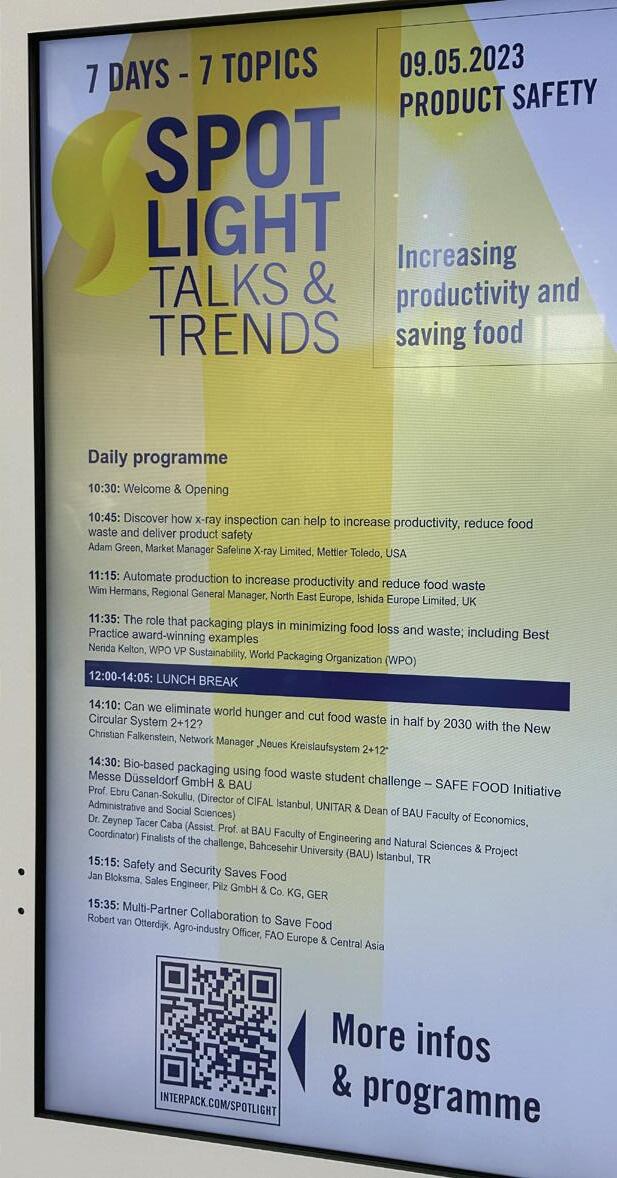

Australian delegation attends 2023 WorldStar Packaging Awards to pick up 22 awards; including 3x special awards

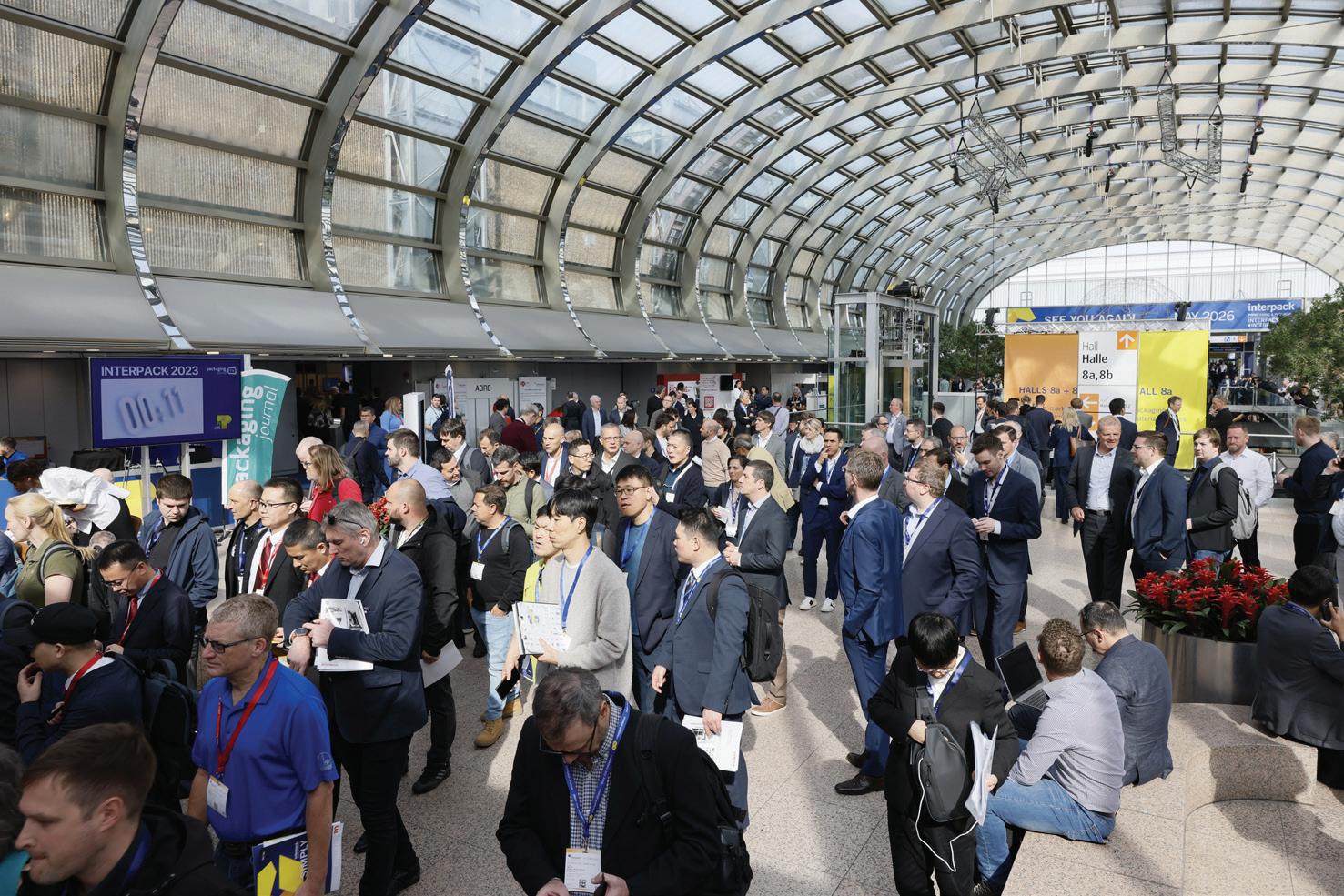

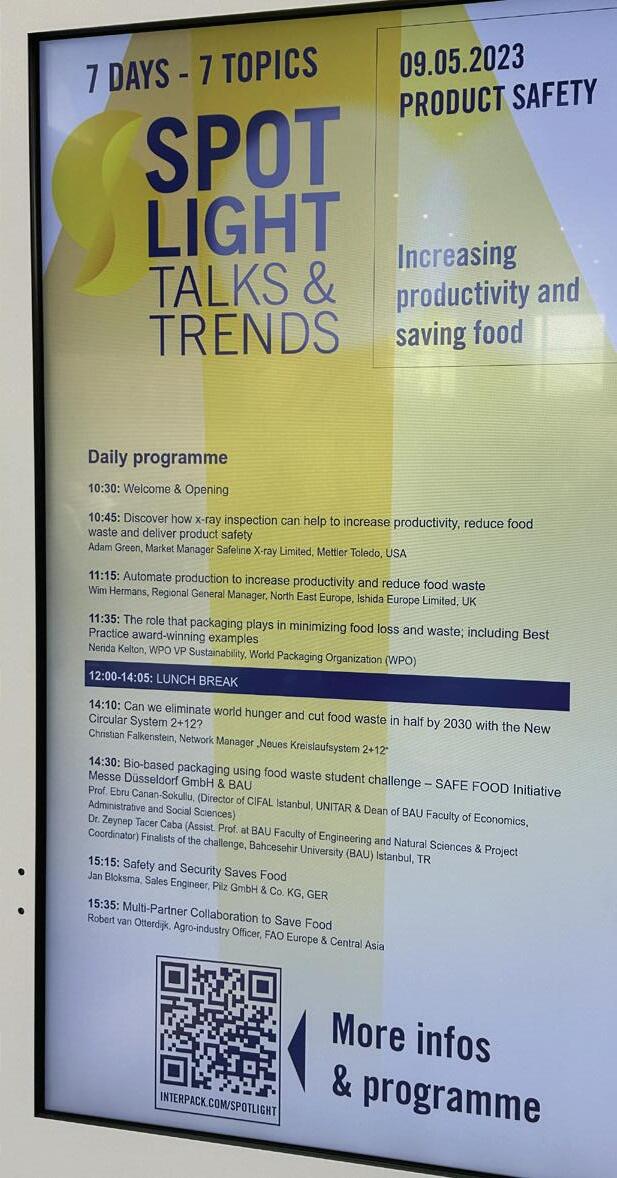

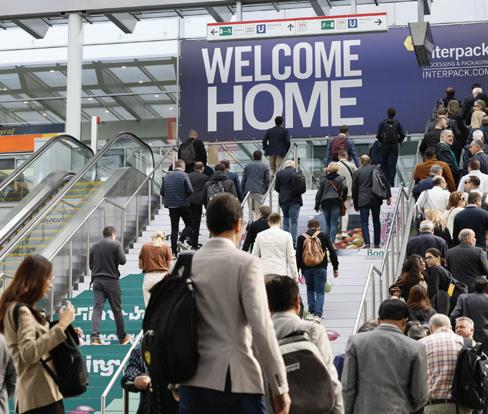

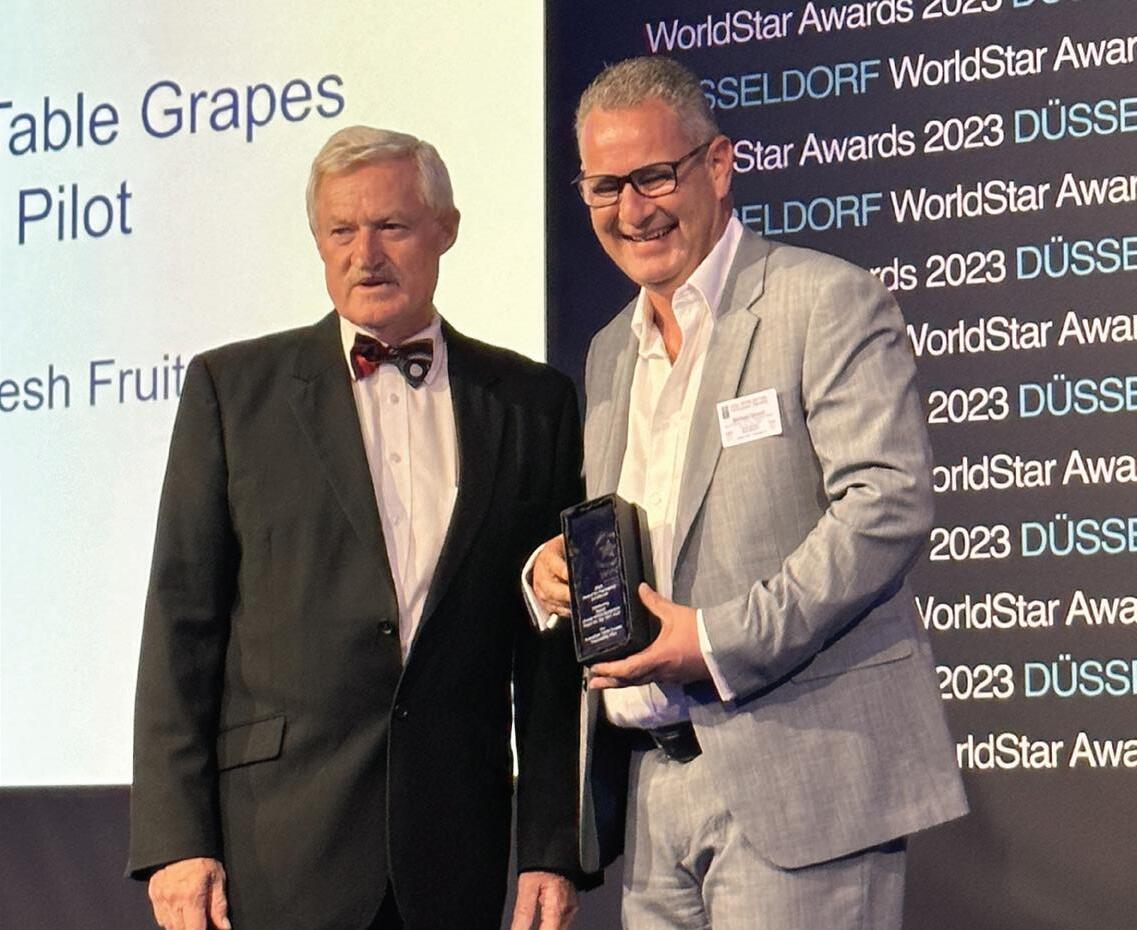

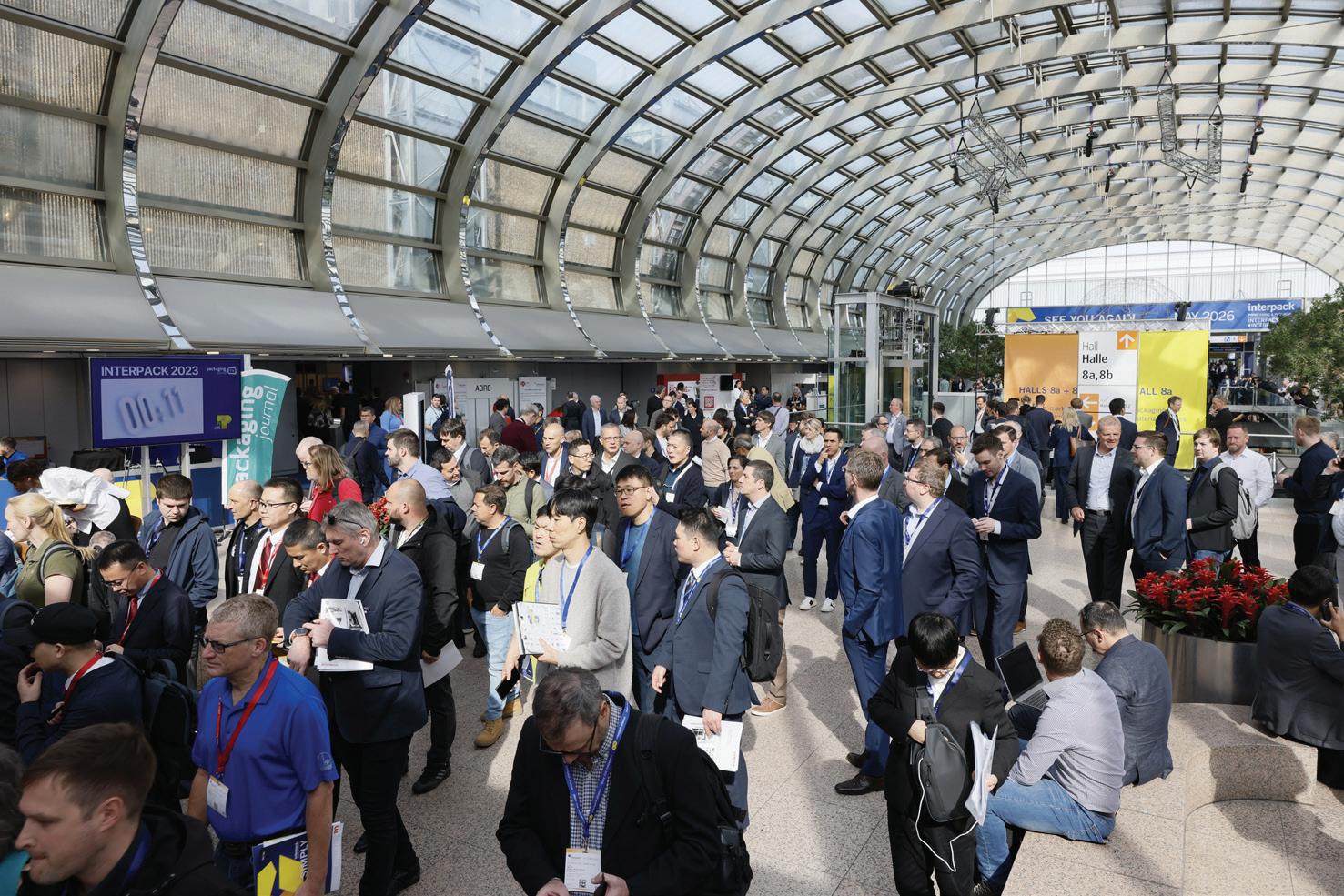

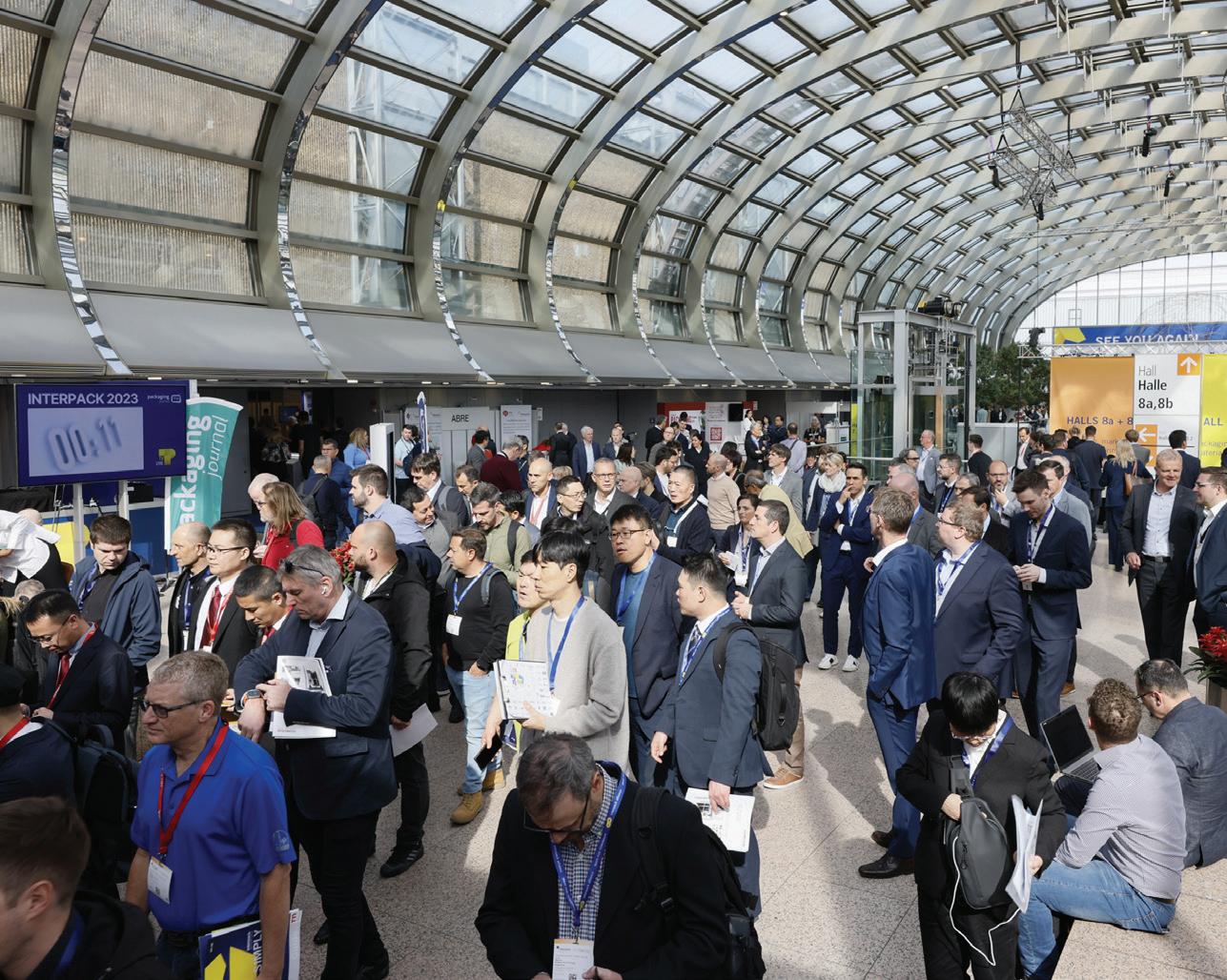

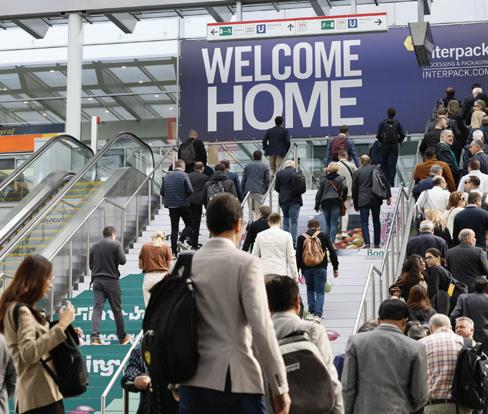

On the 8th of May the 2023 WorldStar Packaging Awards, which are run by the World Packaging Organisation, saw 300 people from over 40 countries converge at interpack in Duesseldorf, Germany.

Of the 300 guests, 20 were Australians who had travelled half way across the globe to receive their awards and to be recognised by their global peers for their packaging designs. Australian & New Zealand companies received the second highest amount of wins in the world behind Japan. This is the second year in a row that the region has dominated the global awards program, which is a true reflection of the innovative packaging designs being developed in the Southern Hemisphere.

AIP NEWSLETTER JUNE 2023 25

Australian delegation attends 2023 WorldStar Packaging Awards to pick up 22 awards; including 3x special awards

Not only were ANZ PIDA Award winners recognised with 19x awards across 9x categories but 2x of the companies also picked up the coveted WorldStar Special Awards which were announced live on the night.

2023 WORLDSTAR PACKAGING THAT SAVES FOOD SPECIAL AWARD SILVER WINNER

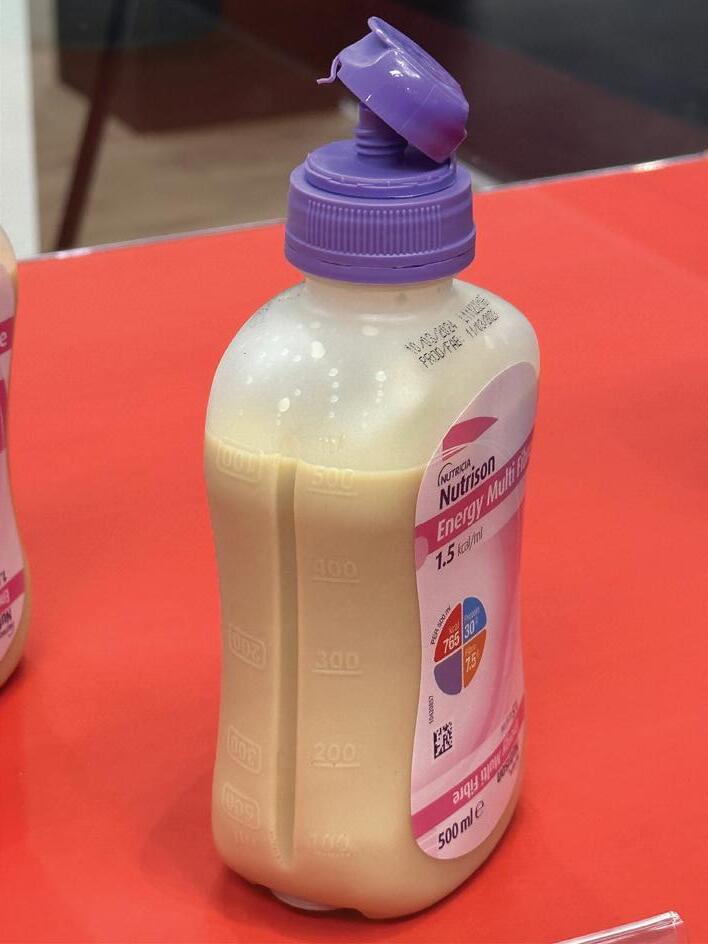

2023 WORLDSTAR ACCESSIBLE PACKAGING DESIGN SPECIAL AWARD SILVER WINNER

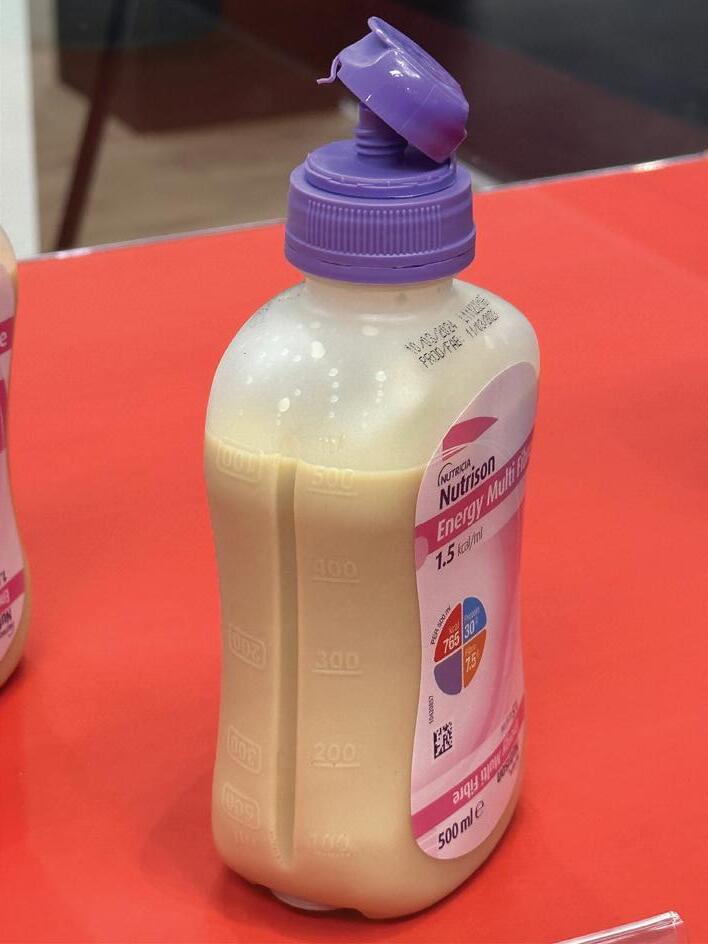

Caps & Closures was recognised with silver recognition for two different products - the NEW Accessible Packaging design special award for the EzyGrip and Packaging that Saves Food special award for the ThermoShield Temperature Monitoring System – Food. This brought the tally for Caps & Closures to 6x WorldStar awards; making them the first Australian company in history to win this amount of awards.

According to Brendon Holmes, Managing Director of Caps & Closures, “When the recognition comes from your industry peers, representing our Australia comes with immense pride. Receiving two WorldStar Special Awards recognising our efforts in Save Food Packaging and Accessible Packaging was tremendous. Our dedicated team has invested hours, weeks and months into finding solutions for challenging issues we all face as consumers. Our focus on fighting food waste, brand protection, accessibility and sustainability remains, and these awards inspire us further to continue down this path. It was good to see many companies at interpack adopting similar innovative solutions that improve the consumer experience in accessibility and functionality.”

2023 WORLDSTAR SUSTAINABILITY SPECIAL AWARD GOLD WINNER

BioPak also made history being the first Australian company to win the coveted GOLD Sustainability special award for the Sugarcane Pulp Hot & Cold Cup Lids. This brought BioPak’s tally to 3x for the 2023 edition.

Gary Smith, Chief Executive Officer, BioPak who was on a jetlag high during the evening added that, ‘Each day we come into BioPak with a passion for change and a passion for sustainable improvement in our industry. There is little focus on anything else. Working at a screen all day, working in a closed environment not understanding the impact of what we take for granted as our day-to-day, has a danger of stuffing passion. Attending the WorldStar Awards and being surrounded by so many innovators and change makers was humbling and a boost to make me excite all at our business into working harder and smarter at continual improvement and sustainable developments! We were humbled to be singled out in an evening to receive the coveted Gold for the Sustainability special award, where there is so much good in overcoming mediocrity and bad practices. Seeing so many new developments and innovations, and meeting so many talented people was a privilege!”

AIP NEWSLETTER JUNE 2023 26

Australian delegation attends 2023 WorldStar Packaging Awards to pick up 22 awards; including 3x special awards

FIRST TIME WINNERS

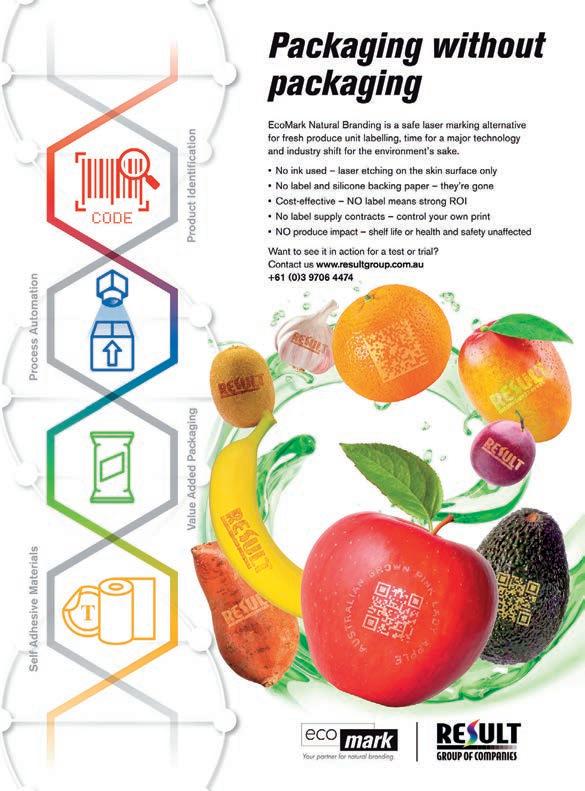

In addition ANZ had one table of firsttime winners such as Result Group, Ego Pharmaceutical, JBS and Opal which was a great moment to watch.

“Being amongst global peers and fellow Australian Worldstar award winners was one hell of an experience that’s for sure! Sharing the night itself with our project partners was sensational, but bringing the award home to the team and seeing the pride on every face is something I will never forget.” Michael Dossor MAIP, Managing Director, Result Group.

The 9x general categories where ANZ designs were recognised include Food, Fresh Fruit & Vegetables, Beverages, Household, Transit, Medical & Pharmaceutical, Health & Personal Care, Labelling & Decoration and Other.

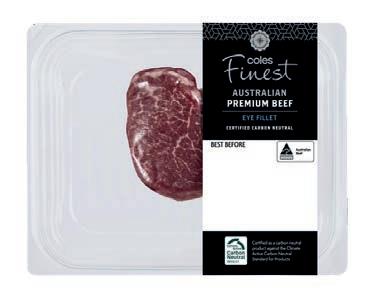

Food

• Smarties Paperisation - Nestle Australia

• Waitoa free range chicken - Ingham’s New Zealand, Sealed Air New Zealand

• Ecotite R barrier shrink bags – Amcor Flexibles

• Praise 100% rPET Mayonnaise Bottle –Goodman Fielder

• FSC Rectangle Paper Containers - BioPak

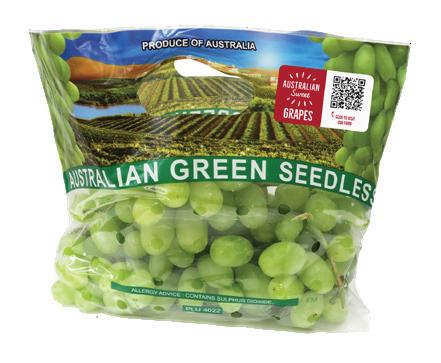

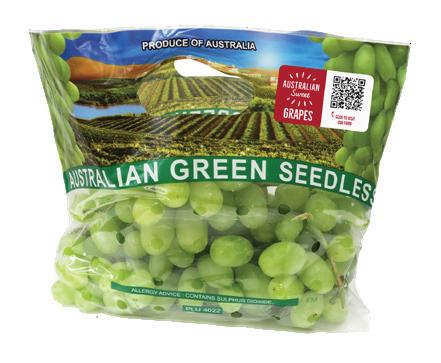

Fresh Fruit & Vegetables

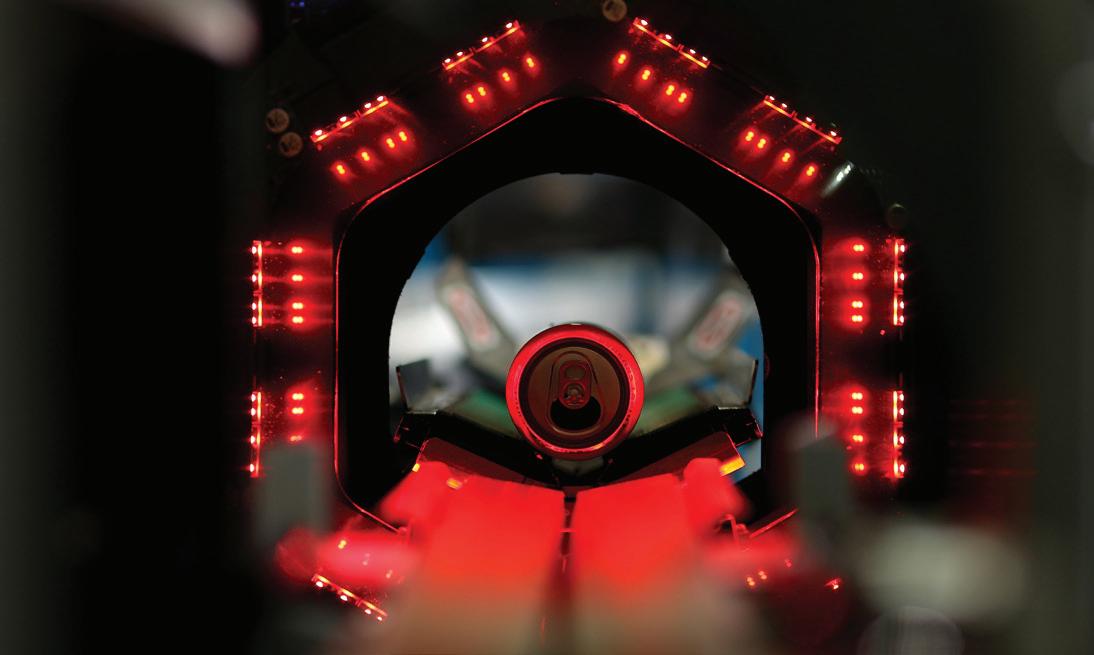

• Australian Table Grapes (ATGA) pilot – Result Group

Beverages

• Kraft Renewable Milk Carton - Brownes Dairy

• Norco 100% rPET Milk bottle – Pact Group

• Coles Home Compostable Coffee Capsules –Coles Group

• Sugarcane pulp hot and cold cup lids –BioPak

• ThermoShield Temperature Monitoring system – Caps & Closures

AIP NEWSLETTER JUNE 2023 27

Australian delegation attends 2023 WorldStar Packaging Awards to pick up 22 awards; including 3x special awards

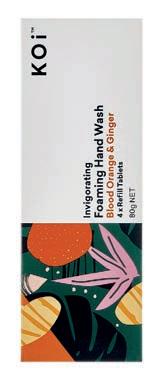

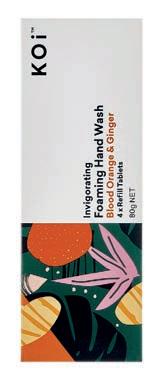

Household

• Earthwise Eco Laundry Scoop – Earthwise Group

• KOH Kerbside recyclable spout pouch refill pack – O F Packaging & Close the Loop Group

Health & Personal Care

• Etch & Ethos – EGO Pharmaceutical

Medical & Pharmaceutical

• EzyGrip – Caps & Closures

• ID Shield Anti counterfeit system – Caps & Closures

Transit

• JBS and Opal Dunnage Solution – JBS and Opal

Labelling & Decoration

• ID Shield Anti counterfeit system – Caps & Closures

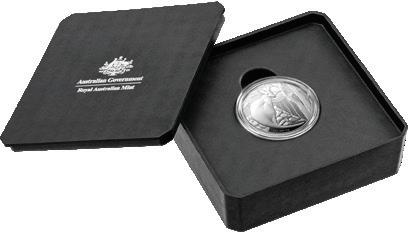

Other

• Royal Australian Mint Coin Box – Macher

The full list of 2023 WorldStar Packaging Award winners are available to view on https://www.worldstar.org/winners/

ELIGIBILITY FOR WORLDSTAR AWARDS

Coordinated by the Australian Institute of Packaging (AIP), the annual Australasian Packaging Innovation & Design (PIDA) Awards are designed to recognise companies and individuals who are making a significant difference in their field in Australia and New Zealand. The PIDA Awards are the exclusive awards program for all Australia and New Zealand entries into the prestigious WorldStar Packaging Awards. http://aipack.com.au/pida-awards-overview/

AIP NEWSLETTER JUNE 2023 28

Australian delegation attends 2023 WorldStar Packaging Awards to pick up 22 awards; including 3x special awards

ANZ Special Award Winning Packaging Designs

Caps & Closures ThermoShield – Silver Save Food Packaging Special WorldStar award winner

The core value in developing ThermoShield is to combat food loss resulting in wastage. ThermoShield is developed to be a crucial cold chain safeguard across refrigerated production, storage and distribution activities.

With the ability to account for, identify and improve the weak links in the supply chain network, Caps & Closures provides a simple yet effective solution to one of the primary causes of food waste. Clever use of ThermoShield can also improve the product brand through intuitive design that would boost consumer confidence and purchasing happiness, knowing that what is purchased has been taken care of.

Caps & Closures ThermoShield is an optical system, where the packaging will dynamically change its colour appearance at a preselected temperature switching point. ThermoShield packaging safeguards cool and cold chain products by monitoring temperature through the entire process, using thermochromic materials designed to change colour when the temperature of a product changes. This is useful in the transport and warehousing because the over temperature stock can be clearly seen. ThermoShield products are smart and ensure that there is no overheating of perishable food and temperature sensitive items in transit and in storage; which is a major cause of food spoilage, loss and waste.

BioPak Pulp Hot & Cold Lids – Gold Sustainability Special WorldStar Award winner

Switching from single-use plastic packaging derived from finite fossil resources to sugarcane packaging makes a big difference: if a large QSR swapped out 10 million conventional plastic lids to sugarcane pulp BioCane alternative they could avoid 37,400 kgs of fossilfuel plastics, offset 83,478 kgs of carbon emissions and if all were composted at home, the organic waste would create 25,900 kgs of nutrient-rich soil which in return sequesters even more carbon from the atmosphere, reversing climate change.

In comparison to other packaging products in its class BioPak maintain the ability to increase or decrease the gauge of the pulp, the density of the pulp and its composition. Their blend of wheat straw pulp with bagasse ensures a stiffer package at a reduced weight. Their production facility is certified to ISO 14001 environmental standards, their products are made from rapidly renewable plantbased agricultural byproducts designed to be compostable at the end of their life. The sugarcane pulp lids are PFAS free as drinks don’t contain grease and these lids perform well as a takeaway lid. The BioPak Sugarcane cup lids are recyclable (when not contaminated with food) and certified home compostable to AS5810 and European NF T51-800 standards, and industrially compostable to Australian AS4736 or European EN13432 standards. They are independently tested and verified to completely biodegrade within 120 days in a commercial compost facility, the end product is a non-toxic, nutrient-rich compost.

AIP NEWSLETTER JUNE 2023 29

2023 WORLDSTAR PACKAGING THAT SAVES FOOD SPECIAL AWARD SILVER WINNER

2023 WORLDSTAR SUSTAINABILITY SPECIAL AWARD GOLD WINNER

CHANGING THE WAY YOU INTERACT

Globally Recognised

4x WorldStar Awards

6x PIDA Awards

Sensory • IDShield, ThermoShield, BioShield

Ergonomic Cap • EzyGrip

We are redefining how people interact and buy their products. Dynamic visualisation of anti-counterfeit and temperature quality assurance. A passive technology that continuously protects against harmful microbes. Through our human senses, we know, and we care. Learn more at capsandclosures.com.au.

AIP NEWSLETTER JUNE 2023 30

Australian delegation attends 2023 WorldStar Packaging Awards to pick up 22 awards; including 3x special awards

ANZ Special Award Winning Packaging Designs

Caps & Closures EzyGrip – Silver Accessible Design Special WorldStar Award winner. NEW CATEGORY

Easy to grip, ergonomic design and child-safe. Thanks to medical and scientific achievements, more of us enjoy good health as we age, with longer more fruitful lives and a more active lifestyle.

Consequently, we are experiencing a global trend where national populations are ageing, and a growing number of consumers suffer reduced hand strength and dexterity. Our senior population would benefit from a better ergonomic design that makes opening a product easier. EzyGrip features large evenly distributed side lobes enhanced with mini surface ribs to improve hand grip over the standard cap significantly, reducing hand and wrist strain and allowing the adult consumer to get what they need with ease. While the enhanced grip design makes opening easy, EzyGrip can be integrated with the Caps & Closures leading child-resistant closure design, resulting in a safer product, especially in the application of prescription medicine and hazardous substances. EzyGrip has optional additional safety, hygiene and sustainability functions such as tamper-evident seals and advanced additive technology like BioShield™, EnviroShield™ and Oysterlean™. EzyGrip’s ‘senior-friendly’ design methodology gives seniors easy access while providing safety, health and sustainability benefits to our community through additive technology.

AIP NEWSLETTER JUNE 2023 31

2023 WORLDSTAR ACCESSIBLE PACKAGING DESIGN SPECIAL AWARD SILVER WINNER

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 32

ANZ PIDA Awards Winners take Second in the World with 22x WorldStar Packaging Awards

CONGRATULATIONS TO THE 2023 WORLDSTAR WINNERS FROM AUSTRALIA & NEW ZEALAND

AMCOR FLEXIBLES ASIA PACIFIC ECOTITE R BARRIER SHRINK BAGS FOR THE FOOD CATEGORY

I am delighted to share Amcor’s new PrimeSeal ™ Eco-Tite ® Recycle-Ready Shrink Bag has just won a prestigious WorldStar award at the World Packaging Organisation’s Global Packaging Awards. This international recognition continues to highlight Amcor’s position as leader in market innovation in meat packaging locally and globally, demonstrating what we can deliver for our customers. The development of the Eco-Tite ® R Shrink Bag has been no small feat for our local team, creating a new lighter, high barrier shrink bag that is free of PVdC and other contaminants that would prevent it from being recycled. It has been designed to be circular, with the ability to add local advanced recycled content by 2025. We will proudly be launching the first shrink bags in Australia in early 2023.

Mike Cash, President, Asia Pacific Flexibles

Mike Cash, President, Asia Pacific Flexibles

Opal Shapes the Future through Sustainable Packaging so winning this WorldStar award sends a strong message that OPAL is living its vision with a bias to action. Also supporting our customers on their own individual sustainability journeys and delivering real and meaningful outcomes, could not make us feel prouder.

Craig Madden, Regional Sales Manager - Industrial,

Close the Loop Group are so grateful to have the hard work and dedication that went into creating this project recognised. Forwardthinking and sustainable brands like Koh are pushing the boundaries, to ensure simpler packaging materials and less plastics are used. This award further substantiates our aim to be leaders in the sustainable packaging solutions, and we will continue our efforts towards helping achieve a more circular economy for the packaging industry.

Joe Foster FAIP, CEO, Close the Loop Group

AIP NEWSLETTER JUNE 2023 33

2023

Opal

JBS AND OPAL

JBS AND OPAL DUNNAGE SOLUTION FOR THE TRANSIT CATEGORY

O F PACKAGING/CLOSE THE LOOP GROUP

KOH KERBSIDE RECYCLABLE SPOUT POUCH REFILL PACK FOR THE HOUSEHOLD CATEGORY

ANZ PIDA Awards Winners take Second in the World with 22x WorldStar Packaging Awards

COLES GROUP

COLES HOME COMPOSTABLE COFFEE CAPSULES FOR THE BEVERAGES CATEGORY

We are thrilled to accept the WorldStar Packaging Award for our Coles Home Compostable Urban Coffee Culture Pods. At Coles we are always looking for ways to make supermarket Own Brand and Coles Liquor’s exclusive products more eco-friendly and sustainable for shoppers. We know our customers love the convenience of pod-based coffee machines and being able to make café-style coffee at home, but want a better solution for dealing with the used pods which can be difficult to recycle. We also know that very few councils accept compostable packaging in their council food and organics waste bin, which is why we have worked with our suppliers to find a coffee pod solution which customers can compost at home. Composting at home is also a great way for our customers to reduce the amount of food waste going into landfill.

The Home Compostable Urban Coffee Culture Pods allow Coles to provide coffee-lovers a more sustainable solution, while still delivering a delicious quality brew.

Natalie Shaw, Packaging Technologist, Coles Group

SMARTIES RANGE PAPERISATION FOR THE FOOD CATEGORY

Winning the prestigious WorldStar Awards is an amazing recognition for the work in the development of this packaging material. The transition from plastic bag and blocks formats to paper was a collaborative effort between Nestlé packaging experts at our Confectionery R&D Centre in the UK, the Nestlé Institute of Packaging Sciences in Switzerland, and our packaging suppliers. This award shows that there is a strong focus on sustainable packaging materials and we are proud to be leading the way in packaging sustainability. Shifting Smarties packaging to recyclable paper is an important step in realising Nestlé’s ambition to reduce our use of virgin plastics by a third by 2025. We will continue to innovate and work with industry to further our progress in developing packaging for a sustainable future. We thank the Australian Institute of Packaging and the World Packaging Organisation for this award!

Karunia Adhiputra MAIP (Adhi), Head of Packaging Oceania, Nestlé Australia

AIP NEWSLETTER JUNE 2023 34

NESTL É AUSTRALIA

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 35

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 36

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 37

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 38

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 39

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 40

Australian Delegation attend the 2023 WorldStar Awards in Germany

AIP NEWSLETTER JUNE 2023 41

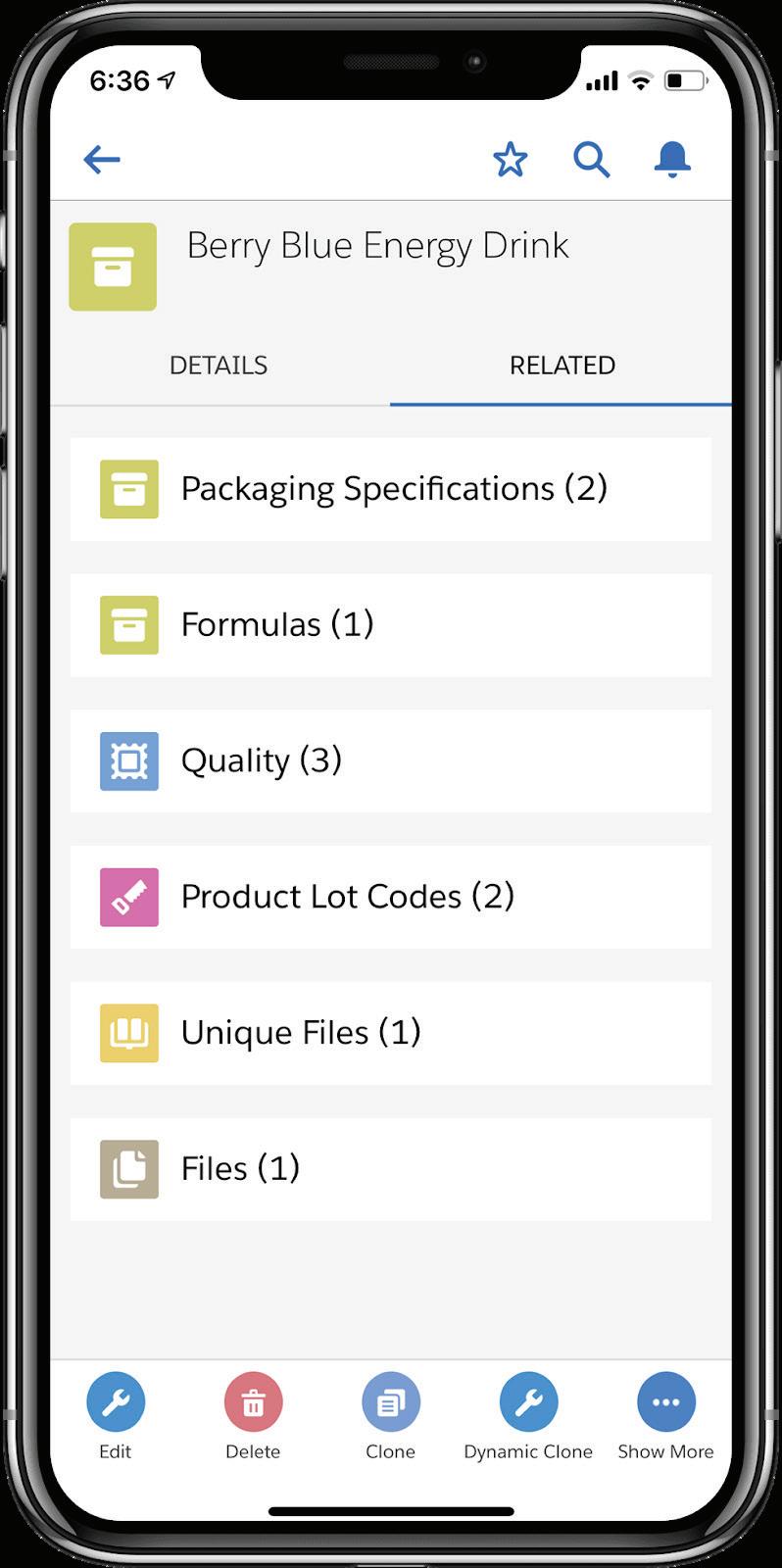

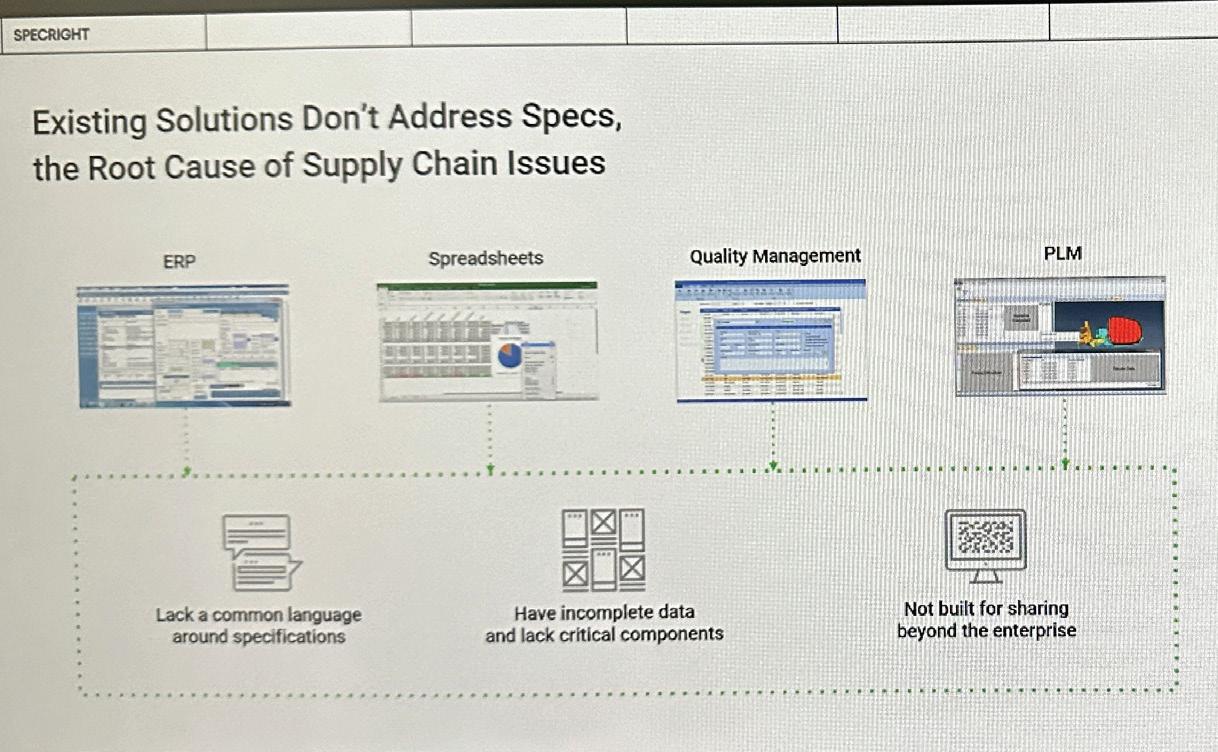

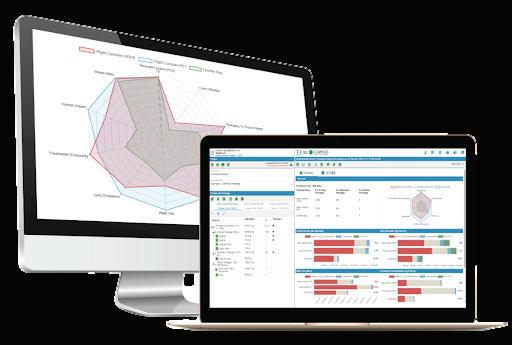

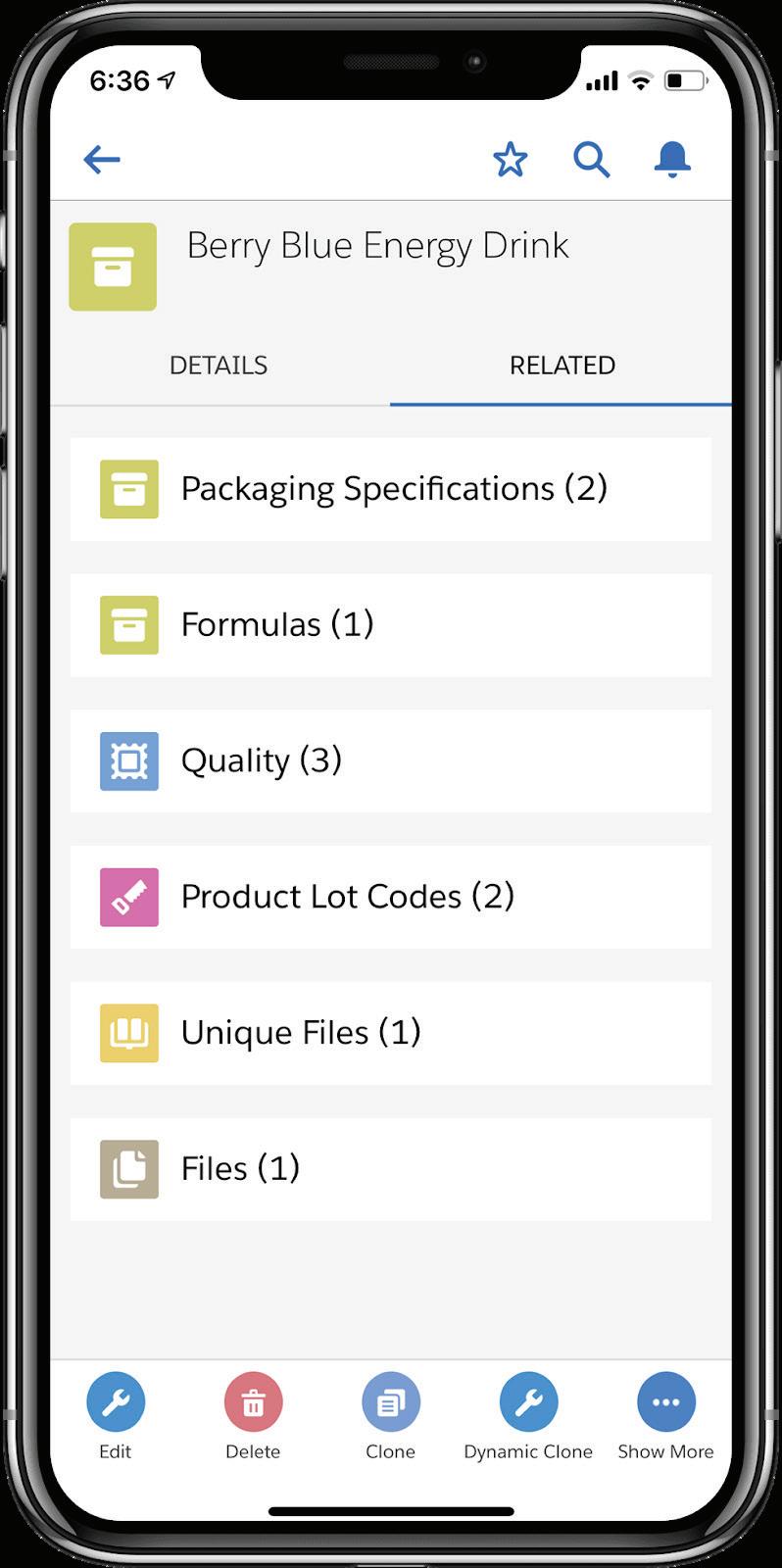

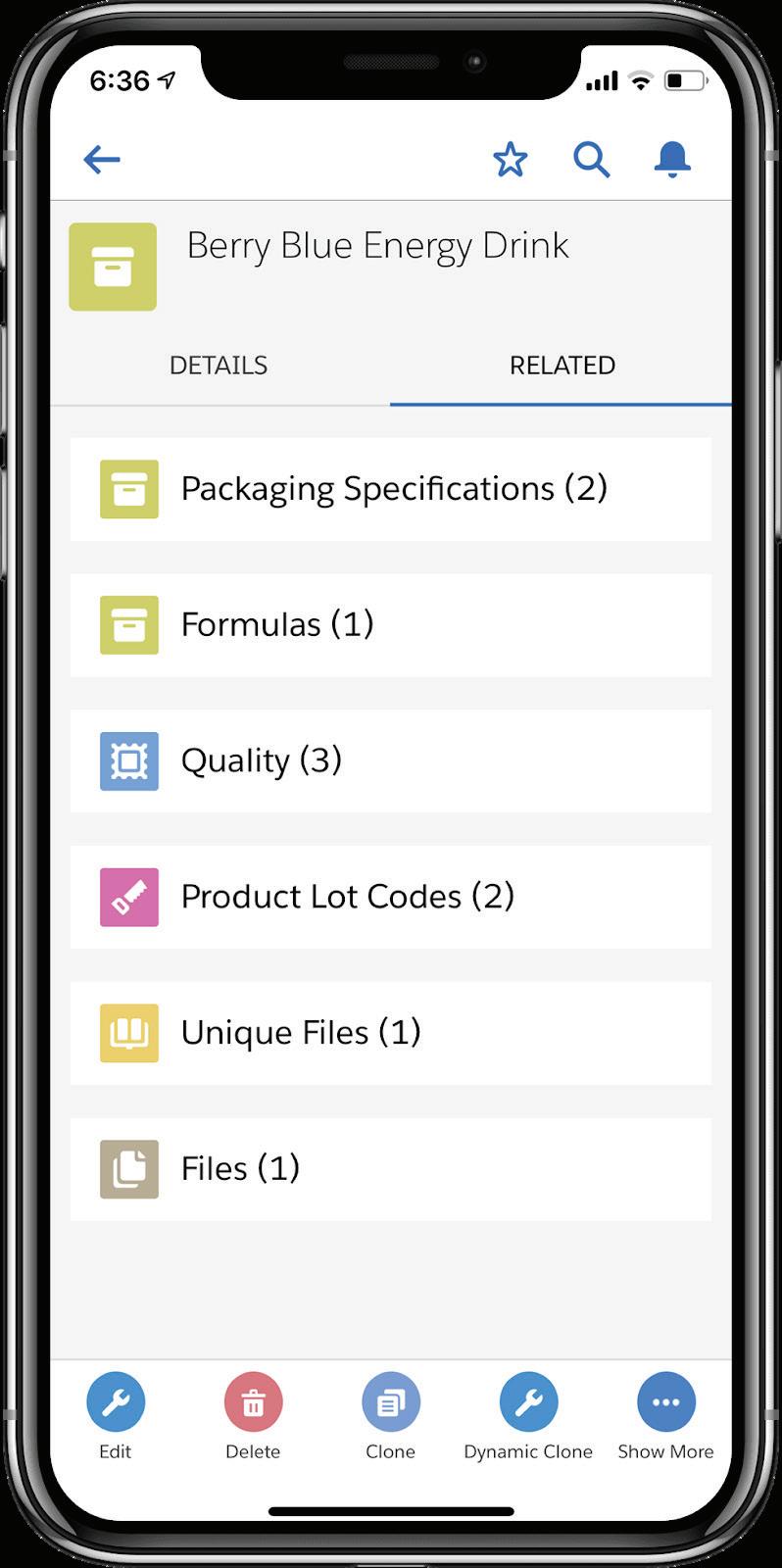

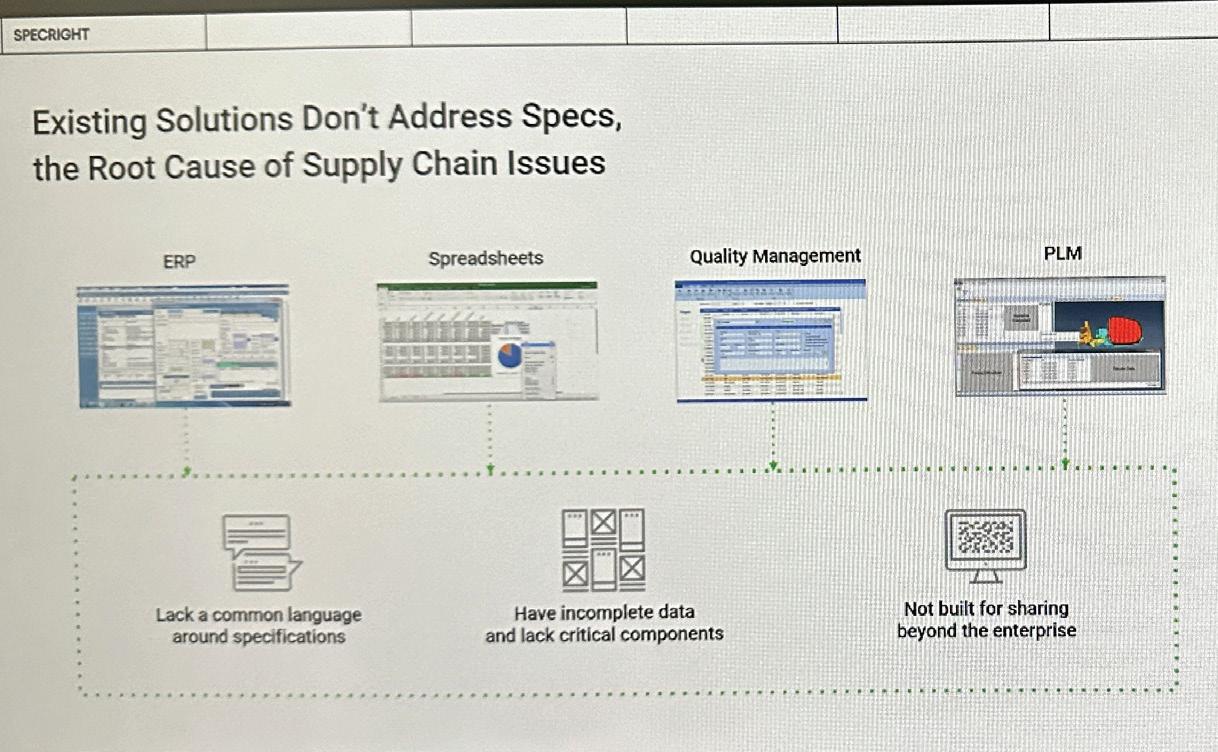

The #1 platform for Specification Management

Digitize & manage all your specification data – from raw materials, and ingredients, to packaging and finished goods – and collaborate across teams and suppliers with Specright.

Learn why more than 1 million products are on Specright at www.specright.com

AIP NEWSLETTER JUNE 2023 42

AIP Out & About

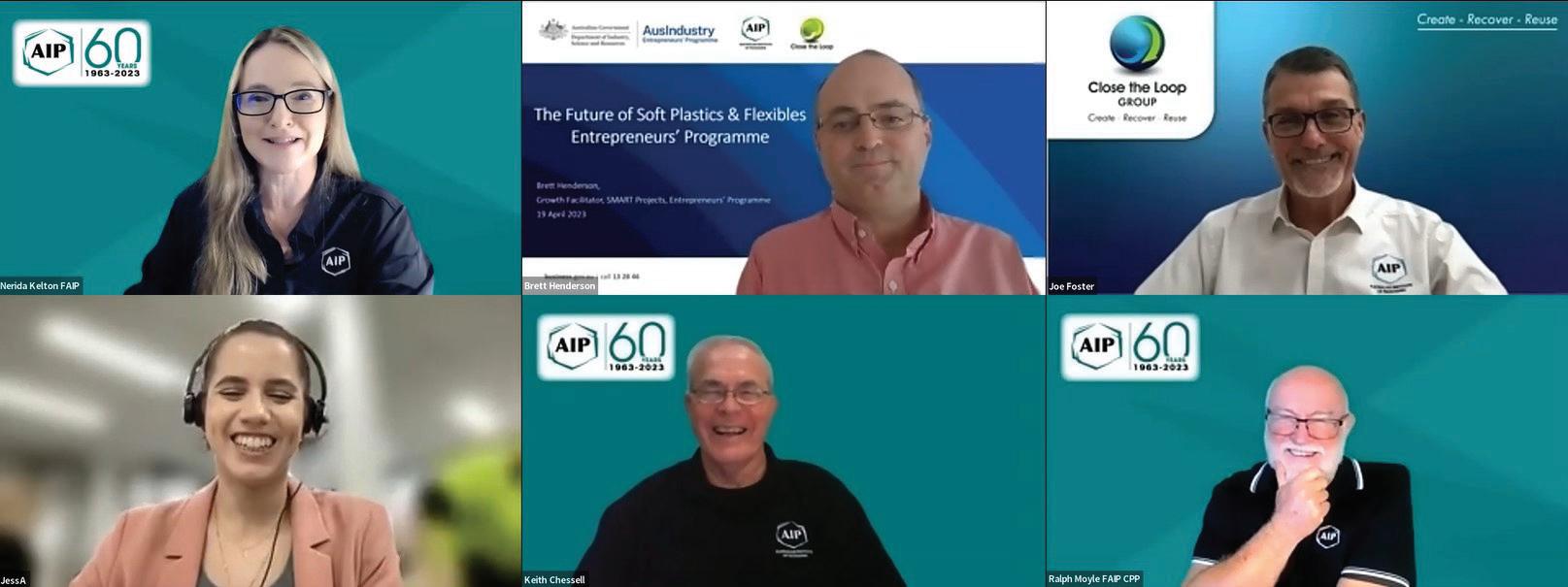

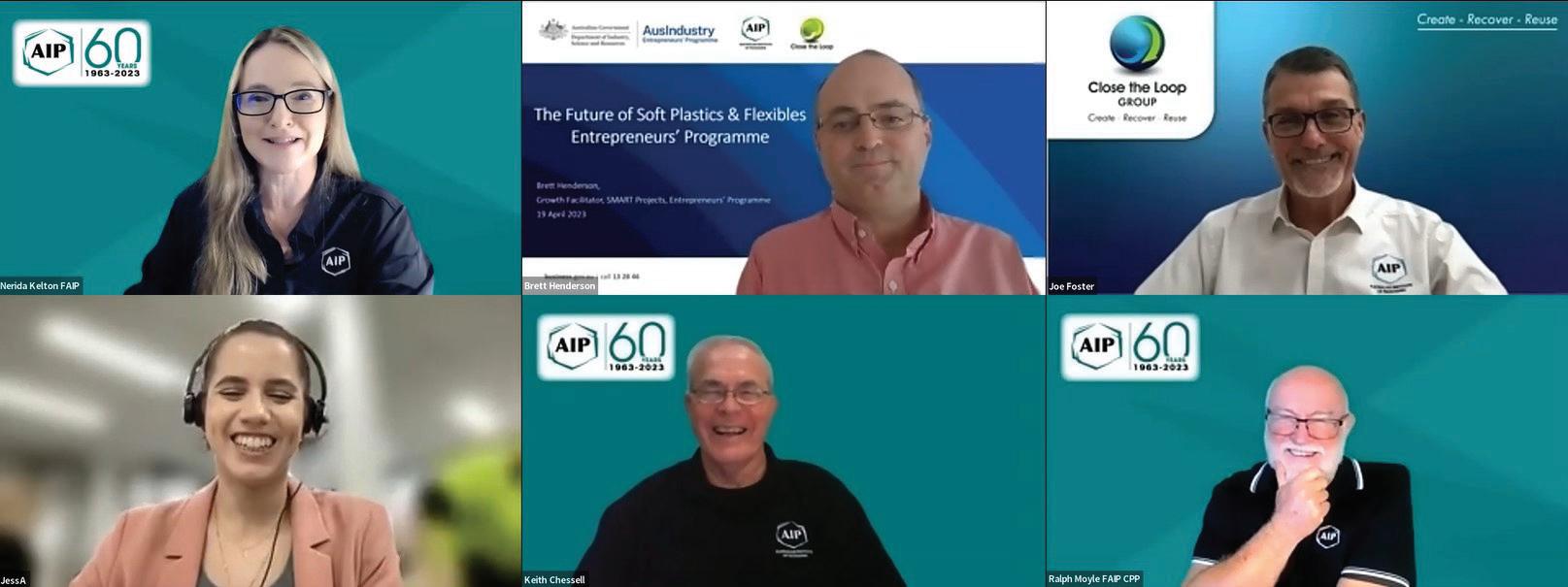

The AIP in partnership with AusIndustry hosted three webinars over two months that discussed the Future of Soft Plastics, The Future of Fibre & Renewables and How to market without Greenwashing. Close to 1200 people attended these sessions. Our very own Keith Chessell FAIP, Ralph Moyle FAIP, CPP and Joe Foster FAIP presented these webinars.

AIP NEWSLETTER JUNE 2023 43

AIP Out & About

The AIP continues to run a broad range of educational programs and webinars with many of our partners. AusIndustry has run a number of webinars with the AIP in the last two months including The Future of Fibre with Joe Foster FAIP with close to 400 people in attendance.

AIP talks to SEE about sustainability that makes lots of cents

Shining the light on SEE's sustainable packaging innovation that makes cents.

A prelude to the WorldStar Global Packaging awards, the Australian Institute of Packaging's annual Australasian Packaging Innovation and Design Awards (PIDA) awards recognise and celebrate the outstanding packaging innovation across Australia and New Zealand. If you've been watching closely, collectively across both prestigious events, SEE (formerly known as Sealed Air) and its customers are the proud owners of more than 23 awards, including 3 WorldStar Save Food special awards. Behind every prestigious award is value that's been unlocked for SEE's food and e-commerce customers. Watch this interview between Nerida Kelton (Executive Director, AIP and Vice President Sustainability & Save Food, World Packaging Organisation) and Alan Adams (Director Sustainability, APAC - SEE and 2021 Industry Professional of the year) learn what it takes to deliver award winning sustainable packaging design that makes lots of cents. Watch the full video here

AIP NEWSLETTER JUNE 2023 44

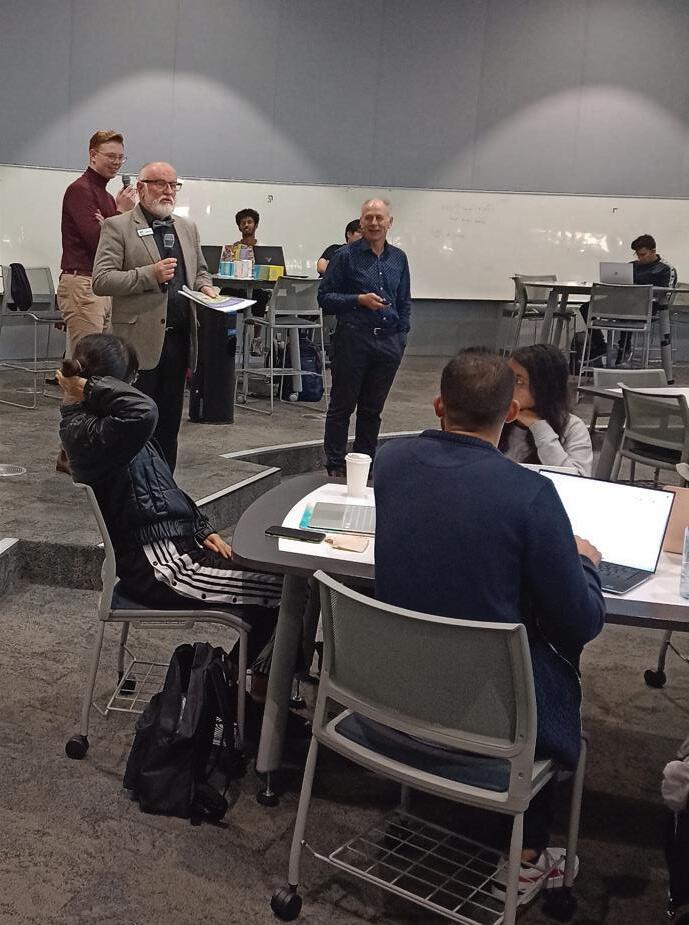

AIP Education Director, Prof Pierre Pienaar FAIP, CPP recently visited Grade 12 students at Parklands Christian College to discuss sustainability, packaging waste and recycling.

This is one of Pierre's favourite educational programs to do as he believes it is critical that the AIP educates the young people on sustainability and recycling.

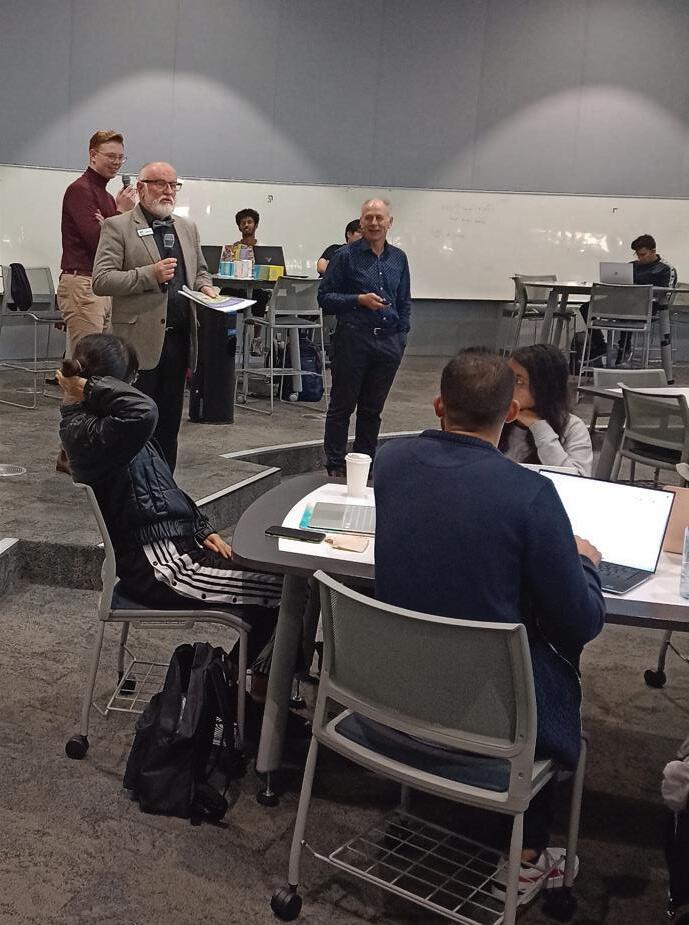

12 of our AIP Members recently supported the Monah University Supply Chain & Logistics Business School as Guest lecturers. Michael Dossor MAIP presented a lecture on Active & Intelligent Packaging to the students in person.

AIP Education Coordinator, Ralph Moyle FAIP, CPP recently lectured at the Monash University Masters of Food degree. Ralph discussed Sustainable Packaging & Circular Design and Food Safety.

AIP NEWSLETTER JUNE 2023 45 AIP Out & About

AIP Out & About

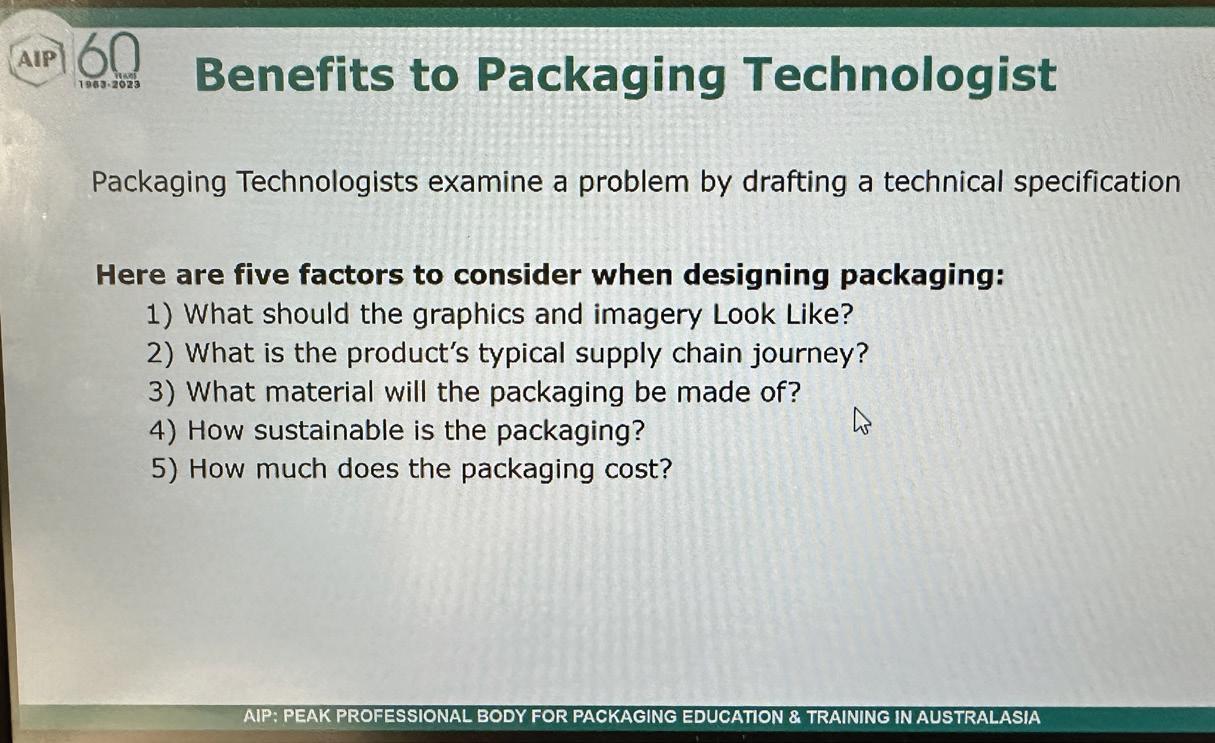

5 0 people recently attended the AIP Introduction to Packaging Specifications training course with Prof Pierre Pienaar and Matthew Wright, CEO of Specright as the lecturers.

Lear n ings from the course included:

• Who controls the data? The answer is the brand.

• Packaging Specifications allow the brand to take control.

• Without adequate packaging specifications it creates risk, slows speed to market and inhibits innovation.

• The Packaging Specification is the DNA of the product.

• The next generation of the workforce is moving rapidly towards more advanced technology and systems.

• Packaging Specifications create a common language, clarity for all, visibility and enable a brand to move to a single source of truth.

• The Packaging Specification serves as a contractual benchmark if there is a dispute.

The AIP would like to thank the team at Specright for working with the Institute on this course. We look forward to running this again soon. All attendees receive 12.5 points towards the Certified Packaging Professional designation.

The AIP will also be hosting a webinar with Specright in the next few months so stay tuned for more information.

AIP NEWSLETTER JUNE 2023 46

ANZPAC Impact Report & Recyclability Assessment Communications Support

The ANZPAC (Australia, New Zealand and Pacific Islands) Plastics Pact has today released the first ANZPAC Impact Report, which provides a crucial look at how the region is progressing towards the development of a circular economy for plastic.

The ANZPAC Impact Report contains aggregated data from ANZPAC Member Reports from 2021, the year the program was launched, and delivers on ANZPAC’s commitment to a transparent and data-driven approach towards circularity. This benchmarking data provides critical insight into the gaps and opportunities for future collective action of Members and tracks progress towards the ANZPAC Regional Plastics Targets.

Chris Foley, APCO CEO, said: “The data confirms that whilst we have a long way to go to the 2025 ANZPAC Regional Plastics Targets, Members are already undertaking upstream initiatives, and some materials have a reliable recovery pathway.

“However, collection presents a considerable issue towards increasing recovery rates in the region, while reuse systems are failing to reach significant scale. The vast distances of remote and regional geographies and data gaps across the ANZPAC region are presenting challenges that must be considered when developing up and downstream circular solutions.

“It is vital that businesses across the region continue, accelerate and expand their efforts to reduce the impact of plastic packaging. We have seen some fantastic collaboration and innovation in a very challenging space, but, put simply, more needs to be done. Cooperation across the industry and with governments across the region will be critical to driving change, particular in those areas in need of significant investment in recycling infrastructure.”

The report outlines key findings for each of the Regional Plastics Targets:

• Target 1 – Eliminate unnecessary and problematic plastic packaging through redesign, innovation and alternative (reuse) delivery models .

o Result – 2,232 tonnes of problematic and unnecessary single-use plastic packaging were eliminated by Pact Members during the reporting period.

ANNUAL

IMPACT REPORT

20 21

• Target 2 – 100% of plastic packaging to be reusable, recyclable, or compostable by 2025.

o Result – 63% of plastic packaging put on the market by ANZPAC Members is currently designed for end-of-life recoverability (reuse, recycling, or composting).

• Target 3 – Increase plastic packaging collected and effectively recycled by at least 25% for each geography within the ANZPAC region.

o Result – 16% recovery rate recovery of plastic packaging placed onto the market across the ANZPAC region

– 25.8% recovery rate of plastic packaging placed onto the market in New Zealand.

– 15.9% recovery rate of plastic packaging placed onto the market in Australia.

– 0.1% recovery rate of plastic packaging placed onto the market in Pacific Island Countries.

• Target 4 – Average of 25% recycled content in plastic packaging across the region.

o Result – 7.5% average of recycled content included in plastic packaging across ANZPAC brand owner and retailers.

The report can be accessed here.

AIP NEWSLETTER JUNE 2023 47

SUPPORTED BY

VERSION 1: MAY 2023

Establishing a baseline for the 2025 Regional Plastics Packaging Targets

THE ANZPAC PLASTICS PACT

Australian Institute of Packaging Helping small to medium-sized enterprises adopt the Australasian Recycling Label

The AIP is proud to be partnering on a new campaign helping SMEs to put the ARL on their packaging.

Small businesses can access:

The ARL Marketplace: new educational hub featuring free AIP training videos and the Packaging Impact Calculator.

Expertise from four campaign partners: the Australian Packaging Covenant Organisation, the National Retail Association, and the Australian Food and Grocery Council.

Weekly ARL drop-in session: Register for the online sustainable packaging discussion.

COMING SOON: a new online directory of approved packaging that’s ready to label with the ARL.

To find out more register* today at arlmarketplace.org.au

AIP NEWSLETTER JUNE 2023 48

1. 2.

3. 4.

*Please tick the AIP from the drop-down box when you indicate where you heard about this program on the registration link.

How the ARL helps businesses prioritise sustainability

Every business has a part to play in safeguarding our environment – even SMEs. With 80% of supermarket goods set to feature the Australasian Recycling Label (ARL) by the end of 2023 under the Federal Government’s National Plastic Plan, it’s worth understanding how your business can make a stand for responsible packaging.

In their SmartCompany webinar with the Australian Packaging Covenant Organisation (APCO), host David Adams explores the power of the ARL, the role of SMEs in sustainable packaging, consumer demands in recycling and the businesses making the change. Joining Adams is Bonnie Marshall, Policy Officer, National Retail Association; Nerida Kelton, Executive Director, Australian Institute of Packaging; and Alison Appleby, Engagement and Capability Manager, APCO.

A uniform labelling scheme

For businesses, displaying the ARL is an easy way to inform consumers on how to dispose of their packaging correctly.