Your Job:

You are not the person who will settle for just any role Neither are Kimberly-Clark Because they are out to create Better Care for a Better World, and that takes a certain kind of person and teams who care about making a difference At Kimberly-Clark, you will bring your professional expertise, talent, and drive to building and managing their portfolio of iconic, ground-breaking brands

They now have an excellent opportunity for two Packaging Specialists to join the Packaging team within their Marketing Division They are hiring for both a permanent position and also a 6 month fixed term contract�

In these roles, you will be responsible for managing packaging development for innovation & renovation projects, support their sustainability strategy and develop, maintain & review technical specifications

• You will project manage the packaging component of marketing innovation & renovation projects, support our Millicent Mill facility and 3rd party projects

• Implement packaging with an expectation of delivering functional & safe packaging with improved sustainable credentials whilst remaining commercially viable & meeting agreed timeline

• Develop, maintain & review technical specifications (including sustainability data)

• Work in a centre of expertise for packaging materials, artwork, pallet design, emerging technologies, and cost saving ideation�

In your role, you will help them deliver better care for billions of people around the world� It starts with YOU�

About Kimberly-Clark

People have looked to Kimberly-Clark brands for more than 150 years and today they are proud to help over a billion people around the world cope, laugh, love and live every day� From the best nappies and baby wipes to the softest tissues, to the best supplies for business, they are constantly searching for new ways to make life better for their consumers, their customers and their planet

Their leading consumer brands like the Kleenex, Huggies, VIVA, U by Kotex, Poise, Depend brands improve the lives of people around the world� Kimberly-Clark proudly leads the way in providing better care for a better world�

Led by Purpose. Driven by You.

About You:

• To be successful in this role, you will bring forward demonstrated experience (~5 years) leading packaging development for projects with cross functional teams, ideally within an FMCG and manufacturing environment�

• You can demonstrate Project Management skills, ability to handle multiple & varied project types (marketing innovation, renovation, correction, cost reduction, new technologies, manufacturing optimisation, new product source) with cross functional teams�

• Prior Experience in packaging development methods, and knowledge of print technology & artwork approval

• Experience in Sustainable packaging technologies, understanding of Australia’s packaging targets (APCO) and ARL will be highly regarded

• Exposure to manufacturing environment, sustainable packaging technologies, awareness of Australia packaging targets�

• Well versed in the use of Microsoft Office: Adobe, SAP, pallet design software & PREP systems

• You have demonstrated experience in working with cross-functional teams – you are able to liaise with multiple stakeholders cross functionally, and are able to articulate and identify business priorities, drivers, risks and opportunities�

• You love what you do, especially when the work you do makes a difference

At Kimberly-Clark, they are constantly exploring new ideas on how, when, and where they can best achieve results� When you join their team, you will experience Flex That Works: flexible (hybrid) work arrangements that empower you to have purposeful time in the office and partner with your leader to make flexibility work for both you and the business

Their Kimberly-Clark employees receive a competitive salary and incentives as well as access to a fantastic range of benefits including superannuation, career development opportunities, free health & well-being activities, volunteering leave and much more

Finalists for the 2024 round of the annual Australasian Packaging Innovation & Design (PIDA) Awards have been announced with a significant number of outstanding innovations being recognised across 15 categories.

Coordinated by the Australian Institute of Packaging (AIP), the PIDA awards are designed to recognise companies and individuals who are making a significant difference in their field across Australia and New Zealand�

The Packaging Innovation & Design of the Year company awards recognise organisations that have designed innovative packaging within six categories:

There

The PIDA Awards are also the exclusive feeder program for Australia and New Zealand for the prestigious WorldStar Packaging Awards run by the World Packaging Organisation (WPO)� All 2024 PIDA winners will be automatically eligible for entry into the 2025 WorldStar Packaging Awards competition

The Food Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, within food packaging and processing including fresh, frozen or other. This is a WorldStar Packaging General award category.

The finalists are Amorette Premium Mandarins Paper Bag (Costa Group & The Packaging Hippie), Bars To Paper Wrap (Mars Wrigley Australia), Deli Cuts (Dons Smallgoods), Gippsland Dairy Twist Yoghurt 160g (Chobani), koor (koor - JeanFrancois Roiron), Masterfoods Squeezy PET Sauce bottles (Wellman Packaging & Mars Food), Prime100 pet food in Tetra Recart (Tetra Pak), and Woolworths Pad-free rPET Trays with ‘Leave Attached’ Film for kerbside recycling (Pact Group/Woolworths/Hilton Foods)�

The Beverage Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, within packaging and processing for liquid or dry tea, coffee, water and soft drinks including wine, beer and spirits. This is a WorldStar Packaging General award category.

PACKAGING FINALIST BEVERAGE PACKAGIN G FINALIST

The finalists are Aqueous Ripple Paper Coffee Cup - Truly Eco (Pinnacle Packaging), Elephant in the Room 1 � 5L Bagnum Range (Fourth Wave Wine & Auspouch), Fleurieu Milk Company - Refillable Glass Bottle (Cutler Brands), IMH (Integrally Moulded Handle) Bottle (Integrated Plastics), Plastic-Free Plant Fibre Sipper Lid & Reclosable Lid (BioPak), Starward Nova (Starward) and Thermocup ™ (Wellman Packaging)�

The Health, Beauty & Wellness Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, within cosmetics, toiletries, personal hygiene, supplements, vitamins, perfumes, hair body and oral care. This award also covers packaging of all medicines including over the counter medicines, medical equipment packaging. This is a WorldStar Packaging General award category.

The finalists are 100% Paper Sachet for BrocShot (Close the Loop), Ezylug + Coconut Oil (Melrose + Caps & Closures), Ezypour + Refill (Thankyou + Caps & Closures) and Only Good Hand & Body Wash (Apex Brands)

The Domestic & Household Packaging Design of the Year award recognises organisations that have designed innovative packaging and/or materials, packaging within domestic and household items, toys, stationary, gifts, clothing, garden equipment, decorating. This is a WorldStar Packaging General award category.

The finalists are EzyLug + Coconut Oil (Melrose + Caps & Closures), Ezypour + Refill (Thankyou + Caps & Closures), Frankie & Friends (Platypus Print Packaging), Green Action® Dishwashing Liquid 500ml (TrendPac), koor (koor - Jean-Francois Roiron), rPet Bottles Balnea Body Wash & Shine Dishwashing Liquid (Woolworths FCR), Whistler - Avian Intelligence Birdfood Range for Fibrecycle (Zipform Packaging) and Zero Triple Strike Garden Weedkiller Concentrate (Yates)

The Labelling & Decoration Design of the Year award is designed to recognise the addition of content to a pack which creates a unique or innovative appearance, function or communication. This may include labels, sleeves, tags, coding/markings, etching, directly applied inks or by any other similar process. This is a WorldStar Packaging General award category.

The finalists are A’kin (Katie McManus + McPherson’s), Art Series and Indigenous Art Series BioCups (BioPak), Sealed Air Personalised Smart Pouch (Sealed Air New Zealand) and Whistler - Avian Intelligence Birdfood Range for Fibrecycle (Zipform Packaging)

LABELLING & DECORATION FINALIST

The Outside of the Box Design of the Year Award has been established for miscellaneous packs and materials that are not included in any other category. This is a WorldStar Packaging General award category.

The finalists are Bouncee - Reusable Insulating Crates (ICEE Technology Group) and PPI Coffee Tray (Production Packaging Innovations - Azadeh Yousefi- Karl Joyce)

Packaging can elicit emotional responses in consumers and should be seen as your best form of marketing. The right packaging design and eye-catching aesthetics can create emotional stimuli that ensures a brand is purchased. The Marketing Design of the Year award considers not only primary packaging but also secondary and tertiary packaging designs. This is a WorldStar Packaging Special Award category.

The finalists are EzyPour + Refill (Thankyou + Caps & Closures) and Premium Grapes Paper Bunch Bag (Costa Group & The Packaging Hippie)

OUTSIDE OF THE BOX FINALIST

MARKETING DESIGN FINALIST

The Accessible & Inclusive Packaging Design Special Award is designed to recognise packaging that is accessible, intuitive, easy-to-open and innovative. Accessible & Inclusive Packaging Design needs to include measuring techniques, understanding injuries caused by packaging and consumer satisfaction levels with packaging accessibility. This is a WorldStar Packaging Special Award Category.

The finalists are Deli Cuts (Don Smallgoods) and EzyLug + Coconut Oil (Melrose + Caps & Closures)

ACCESSIBLE & INCLUSIVE PACKAGING FINALIST

The Save Food Packaging Design Special Award is designed to recognise companies that are working to minimise or prevent food waste from paddock to plate using innovative and intuitive design features that can contain & protect, preserve and extend shelf life; all the while meeting global sustainable packaging targets. This is a WorldStar Packaging Special Award category.

SAVE FOOD PACKAGING FINALIST

The finalists are Cryovac Flexprep Portion Dispensing Pouches for McDonald`s Australia (Sealed Air), Deli Cuts (Dons Smallgoods), Dutch Cream Potatoes Red Gem (Red Gem Packers & Growers + The Packaging Hippie), Ezylug + Coconut Oil (Melrose + Caps & Closures) and Naked Rivals

The Sustainable Packaging Design of the Year award is designed to recognise companies that have developed innovative packaging or processing solutions that incorporates sustainability considerations. Elements include Social, Material, Source Reduction, Energy and Recovery. This is a WorldStar Packaging Special Award category.

The finalists are Australian-Made Post-Consumer Recycled Content Postage Satchel (Close the Loop), Birds Eye Steamfresh 750g (Simplot Australia), Bunzl Workwear Packaging (Bunzl Safety and Lifting), Don Smallgoods 100% rPET Tray (VERIX & Martogg Group), EPS Replacement Prawn Carton (Tassal Group + Visy Industries), Green Action® Dishwashing Liquid 500ml (TrendPac), Home Compostable Container Range (BioPak), Korrvu Retention for Australia Post (Sealed Air + Australia Post), Liquipure Ultra for The Muse Wine Company (Sealed Air), Maggi Mug Noodles 4 Pack - Chicken And Beef Flavour (Nestlé Australia), Masterfoods Squeezy Pet Sauce Bottles (Mars Food + Wellman Packaging), PREP - Designing For The Circular Economy (PREP Design), Purex (Essity New Zealand + TC Transcontinental New Zealand), QV Face Range (Ego Pharmaceuticals), Starward Nova (Starward), Strike Pro Cleaner refill pods (Woolworths), Thermocup™ (Wellman Packaging), Woolworths Pad-free rPET Trays with ‘Leave Attached” Film for kerbside recycling (Pact Group/Woolworths/Hilton Foods), Woolworths Spring Water Bottles 600ml X 24 Pack (Nu-Pure Beverages + Woolworths Food Company) and Woolworths uncoloured milk lids�

2024 Industry Packaging Professional of the Year award is designed to recognise and acknowledge the outstanding achievements and contribution by an individual currently working within the Packaging industry in Australia and New Zealand. The judges look for individuals who have demonstrated vision and leadership, shows innovation and not afraid to take risks. This award is for significant and continued contribution of an Individual to the industry over a minimum period of 20 years.

The finalists are Barton Porter FAIP, Business Manager – Packaging, HBM Plastics & Packaging Technologies, Bryan McKay FAIP, Head of Packaging, Woolworths Group, Gary Smith, Chief Executive Officer, BioPak, George Sofocleous, Managing Director, Pinnacle Packaging and Mark Kerr FAIP, Packaging Manager, Don KRC

The purpose of the Young Packaging Professional of the Year Award is to provide incentive and recognition to young professionals who are both currently working in and wish to continue their career path within the Packaging industry in both Australia and New Zealand. This can be within any industries such as Food, Beverage, Health, Beauty & Wellness, Domestic & Household.

The finalists are Curtis Wakeley, Structural Designer, Blue Star New Zealand, Hamish Hingston, Chief Executive Officer, ICEE Technology Group, Pippa Corry MAIP, Founder & Director, Philo & Co and Dr Ruby Chan AAIP, Project Researcher, RMIT�

The Packaging Technologist of the Year Award is designed to recognise and acknowledge the outstanding achievements and contribution by an individual currently working within the Packaging industry across Australia, New Zealand & Asia.

The finalists are Christopher Cester MAIP, Packaging Specialist, Flavour Makers, Conny Gibson MAIP, Packaging Specialist, Woolworths, Nicholas Campbell MAIP, General Manager Operations & Technical, Wellman Packaging and Rebecca Kersey AAIP, Senior Packaging Technologist, APCO

The Australasian Bioplastics Association (ABA), in partnership with the Australian Institute of Packaging (AIP), is pleased to offer an annual Scholarship program for Australia and New Zealand. The Scholarship program will enable one eligible candidate the opportunity to undertake a Diploma in Packaging Technology and a second person the opportunity to undertake a Certificate in Packaging.

PACKAGING TECHNOLOGIST OF THE YEAR FINALIST

ABA SCHOLARSHIP PROGRA M FINALIST

The finalists are Donve Viljoen, Packaging Coordinator, Carman’s Kitchen, Manpreet Kaur Grewal, Product Technologist, MSAC Solutions, Renata Daudt AAIP, Director, AWEN Packaging Consulting, Angela Hanson AAIP, Packaging Technologist, Tip Top, Cristiam Camilo Serrano Gonzalez MAIP, Packaging Engineer, Don KRC, Ola Wicik, Packaging Engineer, Opal Fibre ANZ and Rhys Blakemore, Sustainable Materials Lead, Officeworks�

The AIP would like to take this opportunity to welcome Sudhir Singh MAIP, Senior Packaging Technologist, The Arnott's Group to the Institute and share a little bit about who he is and what he does in the industry. Please join with us in welcoming Sudhir to the AIP.

1. Why did you join the AIP? What benefits do you believe the AIP offers all their members?

Sudhir: I believe that the AIP is a good platform to be part of a larger packaging community in Australia and to stay connected with other packaging professionals to gain more knowledge and confidence in career The AIP provides an identity to individual professionals which will be helpful for my personal and professional development By becoming an AIP Member I will be able to keep up-to-date with latest trends in packaging industry, attend webinars and seminars to gain more knowledge on latest packaging technologies

2. How long have you been in the industry? What are your areas of expertise?

Sudhir: I have been in the industry for more than 10 years now, below are some major areas of expertise I have:

• New Packaging Development

• Packaging Materials

• Packaging Designing - ARTIOS CAD, CAPE Pack and TOPS�

• Printing Technology and Processes

• Project Management

• Value Methodology

• Value Engineering and Value analysis�

• Supplier Development�

• Should Costing

• 3D modelling - Solid works and Creo

• Artwork Management

• Print Proofing

• Root cause Analysis

• Packaging Troubleshooting

Sudhir Singh MAIP Senior Packaging Technologist

The Arnott's Group

3. What is your current job role and what are your responsibilities?

Sudhir: I am currently working as Senior Packaging Technologist with The Arnott's Group, I am responsible for:

• New Packaging Design & DevelopmentManaging projects of new packaging developments

• Driving the agenda of sustainability for existing products to improve packaging

• Support and coordinate all relevant Packaging trials�

• Co-ordination with Cross functional teams for Packaging projects�

• Support supply chain and procurement initiatives including product transfer�

• Packaging Testing & Validation

• Artwork approvals�

• Maintain Packaging system – Specs, BOM, Artworks, test and Trial�

• Provide leadership, coaching, performance management and development opportunities to team members

• Troubleshooting packaging issues at line�

• New Supplier development

Internationally recognised as the premier qualification in the packaging industry.

The Diploma in Packaging Technology is a Level 5 PIABC, 51-credit foundation degree-level qualification that prepares students to take responsibility for packaging operations at any level through the supply chain and can also lead to higher level study.

What’s in it for me?

Completion of the Diploma in Packaging Technology demonstrates your commitment to your career and to the industry. Students who successfully complete the course and achieve the qualification are equipping themselves for senior positions within the packaging industry.

The AIP would like to congratulate our latest Diploma in Packaging Technology Graduate, Nicole Roy MAIP, Business Development Manager for Temperature Assurance ANZ & Rollstock, Sealed Air. Internationally recognised as the premier qualification in the packaging industry the Diploma in Packaging Technology is a Level 5 PIABC, 51-credit foundation degree-level qualification that prepares students to take responsibility for packaging operations at any level through the supply chain and can also lead to higher level study. Nicole kindly shared with the AIP what she learnt during her studies...

1. What is your current role? What are your areas of responsibility?

Nicole: I work for Sealed Air in New Business Development� I scope out new opportunities with new and existing customers Sometimes this can mean finding new products or using existing products in new markets

2. What does graduating from the Diploma in Packaging Technology mean to you?

Nicole: I have worked in the printing and packaging industry since I left school I initially undertook a NZCS while I was Lab Supervisor in NZ, but life got in the way and I never finished it � Achieving my Diploma in Packaging Technology was really important in validating my career choice to stay in packaging � I love learning and this has given me skills to evaluate other packaging materials and outcomes that can directly or indirectly affect my proposals

3. How will you apply this knowledge moving forward?

Nicole: The Diploma in Packaging Technology has enabled me to see the bigger picture on projects� The world of packaging is changing every day, we are being challenged to find smarter and more sustainable options � The Diploma has given me a good base and I feel more confident now than ever at being able to help my customers understand why we choose materials and guide them on their sustainability journey� I have done a number of AIP courses as well as The Diploma in Packaging Technology and they are all relatable and provide valuable information for a professional packaging technologist�

4. Do you have any advice on why other people should complete the Diploma in Packaging Technology?

Nicole: The benefits from learning and being supported by a world class team at the AIP is invaluable to anyone who wants to pursue a rewarding career in packaging technology.

5. So where to from here for your career?

Nicole: To infinity and beyond!

6. Will you consider applying to become a Certified Packaging Professional as your next professional development stage?

Nicole: I will consider it now, especially as I know I will be supported by the team at AIP!

The Diploma in Packaging Technology has been designed to take in to account the experiences of training through the pandemic and the results of research undertaken on the ideal learner journey The course is comprised of short, bite-sized modules that you can study at a time and pace to suit you on a variety of devices �

Completion of the Diploma in Packaging Technology demonstrates your commitment to your career and to the industry�

Students who successfully complete the Diploma in Packaging Technology are equipping themselves for progression within the packaging industry to a position where they can assume responsibility for packaging in a company at any point in the supply chain

If you get the spec right, the rest follows.

Do you struggle with easily finding your data? Are your packaging and product specifications scattered in spreadsheets, emails, and legacy systems?

It‘s crucial to have easy access to your specification data – whether you’re developing a new product, building a new version of an existing product, or assessing a quality assurance certificate against a specification.

Accelerate the entire product development life cycle, from ideation to production, in the first patented, cloud-based Specification Management platform.

Learn More:

Majans’ partnership with TNA solutions delivers 140% throughput increase in 12 months with the tna ropac® 5

Building on its ongoing relationship with TNA solutions, Majans leveraged the all new tna ropac® 5 technology to automate its case packing operations. At a capacity of 200 bags per minute, and featuring a bag conditioner, case packer, case erector and checkweigher, it is the fastest case packing system on the market today, with the smallest footprint. Since its deployment it has helped to deliver an impressive 140% throughput increase in just 12 months.

Established in 1984, Majans produces over 2 million cases of snacks each year across a range of 53 products� The company has ambitious growth plans, and with a tough labour market and volatile supply chains to navigate, it needed a trusted partner to help increase throughput and reliability, enhance uptime and mitigate risk Manufacturing Manager Andrew McManus had already experienced TNA solutions in operation during his time at Mars and was reassured when Majans’ owner, Kam Raniga, selected the company to help future-proof operations

“I’d seen TNA baggers working perfectly after 40 years of service, and I knew we were on track when we made the decision to partner with TNA at Majans. With a TNA flavouring system and tna robag® baggers already in place, we knew we would benefit from the interchangeable aspects of a TNA solution for case packing - particularly from an electronics perspective, and also the consistency of the HMI interface for our technicians. Introducing tna ropac ® 5 systems has enabled us to improve operational efficiency, redistribute manpower and future-proof our operations as we look to continue our growth path."

Majans currently uses around 70% of the tna ropac ® capacity of 200 bags per minute, but through working with TNA solutions the company has ensured that future increases have been firmly factored into the equation Since its introduction in February 2023, throughput performance has increased by 140% and uptime by 15% From a sustainability perspective, the tna ropac ® 5 is also able to accommodate the company’s plans to move to paper-based packaging in 2024, supporting its sustainable development plans without impacting production speeds

“Just five years ago, Majans regularly had between 28 and 35 people on a single shift, bagging, mixing and case packing,” continued Andrew� “Today, with the help of TNA solutions, that same factory operates with just 10-11 people per shift at outputs up to 6.9 times greater than before the automation process began. Casual jobs have been transformed into stable, full-time employment contracts, and technicians and maintenance crews have also been upskilled to effectively service and support these systems at a higher technology level.”

Speaking about the strategic partnership between the two companies, Thiago Roriz, Chief Operating Officer at TNA solutions said: “In recent years, we have further strengthened our market leadership through sustained innovations, delivering true business value to our valued customers, such as Majans. We are extremely grateful to Majans for choosing us as their trusted partner, to support their goals as they focus on their expansion strategy."

To read the full case study on TNA solutions’ partnership with Majans, click here.

Visit www.tnasolutions.com or contact tnateam@tnasolutions.com to learn more.

TNA’s case packing systems has enabled us to improve operational efficiency, redistribute manpower and future-proof our operations. Andrew McManus, Manufacturing Manager - Majans

In the bustling environments of supermarkets and distribution centres, efficient waste management is crucial for optimising operations and reducing costs. Strautmann’s AutoLoadBaler offers a game-changing solution tailored specifically for these settings, delivering substantial labour and time savings while enhancing OH&S measures.

The AutoLoadBaler mobile cart simplifies waste collection by eliminating manual handling, with no pre-compaction required Automation, including bale ejection, expedites the process and enhances workplace safety� This efficiency allows employees to focus on core tasks that boost productivity The baler's vertical compression maximises space utilisation and the compact design seamlessly integrates into existing workflows without disruption� User-friendly operation requires minimal training, empowering staff and streamlining shift work

Mr� Bruns, manager of EDEKA Bruns store in Friedrichsfehn, part of Germany’s biggest supermarket chain, shares insights into how this innovative solution is transforming waste management at his store "What used to be done manually with a lot of time spent waiting at the press and a lot of running around is now done by the AutoLoadBaler."

"In the past, cardboard packaging was collected on trolleys. The employees had to walk long distances to the press container," he recalls "The cardboard often fell off the trolleys on the way to the press container and had to be picked up again."

In search of a better solution, they came across the AutoLoadBaler "We were able to place it directly behind the door in the warehouse," Mr Bruns says

Regarding his experiences with the AutoLoadBaler, Mr Bruns has nothing but praise "The AutoLoadBaler solves the problems of cardboard disposal in one fell swoop," he exclaims "No more shredding the cardboard, the customer is not disturbed by cardboard scraps lying around, and we have a clean appearance." Return on investment can be as short as eight months, depending on throughput Bruns highlights the efficiency of the AutoLoadBaler at EDEKA, stating, "Sensationally, the cardboard only has to be picked up once. The AutoLoadBaler has already paid for itself… A better return on investment is unimaginable." Mr Bruns also appreciates the additional benefits of the AutoLoadBaler� "My personal highlight is when I come in in the morning… there is nothing left in the warehouse, everything has been compressed," he says "The AutoLoadBaler brings us three major advantages: short distances, clean aisles, and, thanks to the automatic filling system, more time for highquality activities, such as putting away merchandise, providing advice, and sales. After all, we want to take care of our customers and not our cardboard." For more information please contact

AIP & The Packaging Forum NZ State of Industry Update Webinar

WHEN: 16 July 2024

WHERE: On-line via Zoom

WHAT: This State of Industry Webinar with Packaging Forum NZ will provide an updated view of what is happening in New Zealand in terms of kerbside collection regulations, new product stewardship programs such as Caps & Lids, Food & Beverage Carton Recycling (FBCRS), the expansion of soft plastics recycling and more�

SPEAKER:

Rob Langford Chief Executive Officer

The Packaging Forum

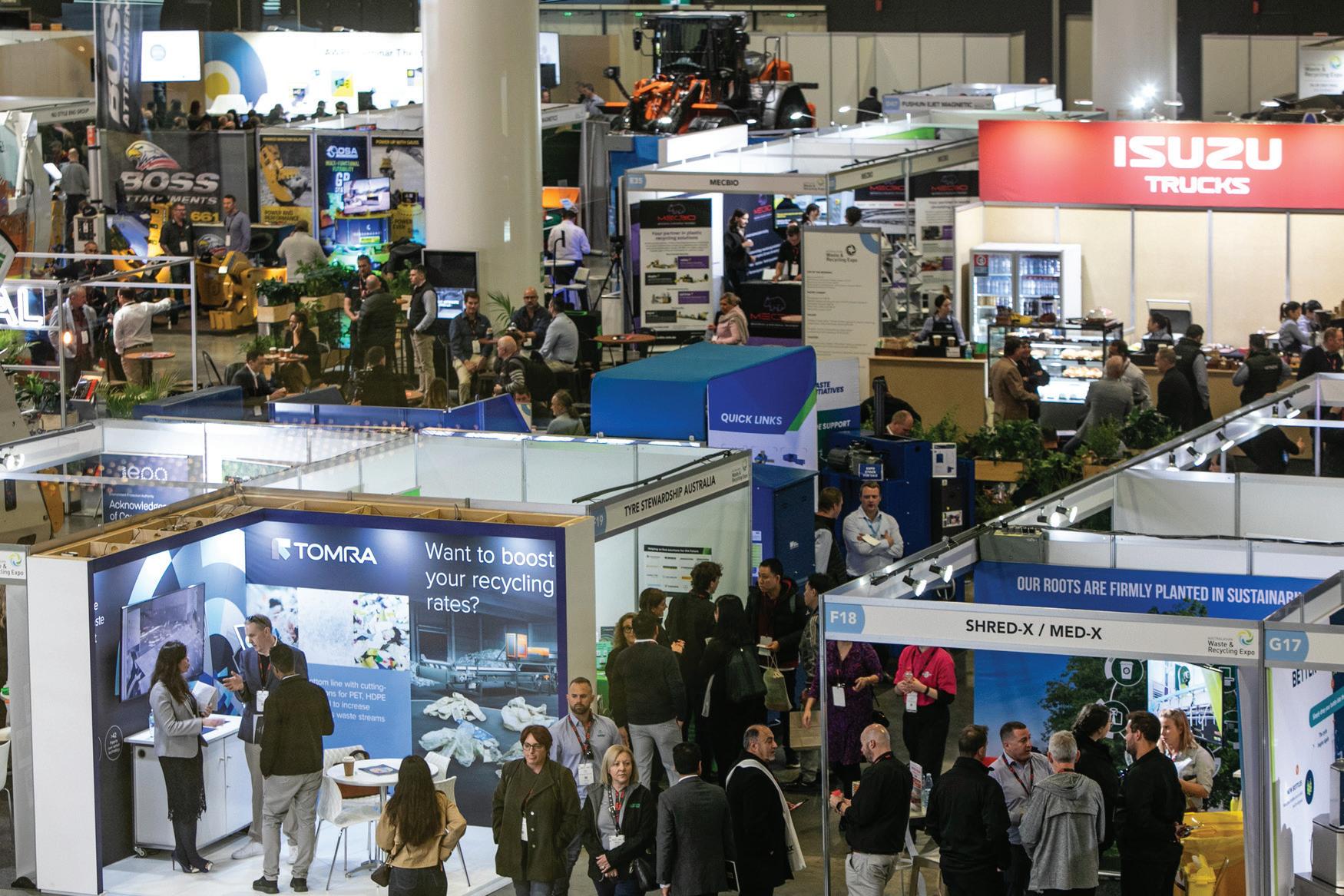

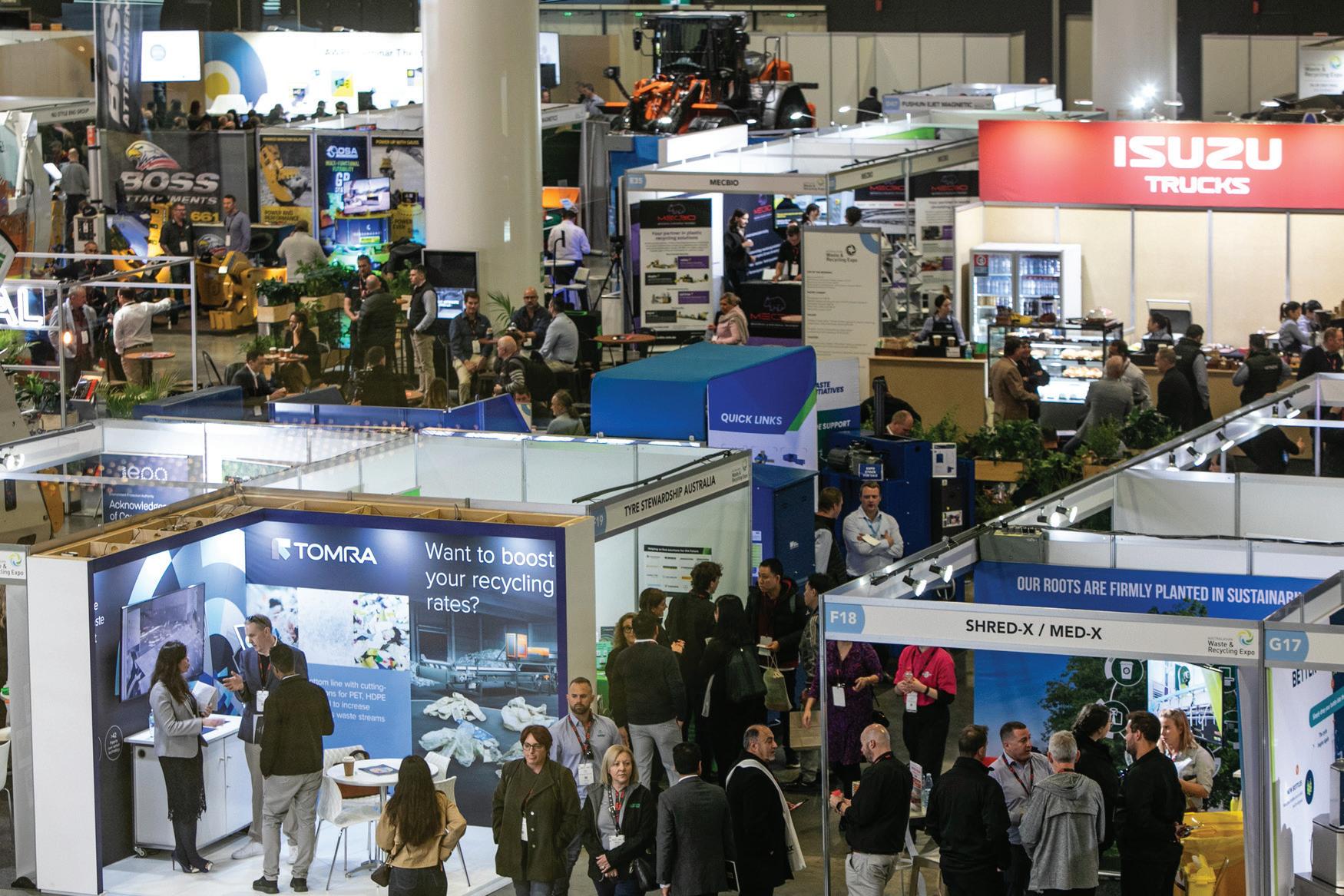

WHEN: 24 & 25 July 2024

WHERE: International Convention Centre Sydney

WHAT: Discover an exciting showcase of full circle innovative products and sustainable solutions to collect, process and recycle waste more smartly Future critical areas include Machinery & Equipment, Software & Services, Bins, Vehicles, Food & Organics and more� Connect with an influential community of waste and recycling professionals, suppliers/service providers, government departments, public sector bodies and special interest groups to successfully drive change throughout your specialist area�

WHEN: 24 & 25 July 2024

WHERE: International Convention Centre Sydney

WHAT: The AIP are pleased to continue our strong partnership with AWRE with 2x free packaging forums, a new mini training course and an exhibition stand in the new Packaging Pavilion.

Starting in July 2024 the AIP have created an innovative packaging pavilion for our Member companies to come and join us.

The package is tailored for AIP and the package costs are reduced for our Members as a way to showcase packaging solutions to a much wider industry, such a councils, government and the waste and recycling industry. Contact the AIP for details on the package for your consideration if this is something of interest please. There are limited stands available this year so please let us know if this sounds like an opportunity for your business to meet a new audience.

WHEN: 24 July 2024

WHERE: 11�15 am - 12�15 pm, NSW EPA Theatre, International Convention Centre Sydney

WHAT: This session will provide guidance on how to design your packaging to consider the implications of the up-coming Federal Government mandated National Packaging Design Standards, the new EU Packaging & Packaging Waste Regulations, the Sustainable Packaging Design Guidelines and also utilising global design guides that are intuitive and easy to use such as the WPO Global Packaging Design for Recycling Guide in your business

This session will also showcase best practice global and local award-winning sustainable packaging designs that have won WorldStar and PIDA awards for their innovative packaging�

SPEAKERS:

Pippa Corry MAIP Founder Phil & Co

Ralph Moyle FAIP, CPP Education Coordinator

WHEN: 25 July 2024

WHERE: 2�30 pm - 3�30 pm, NSW EPA Theatre, International Convention Centre Sydney

WHAT: Over 500,000 SKU’s across Australia and New Zealand are now using the Australasian Recycling Labelling on their packaging in Australia and New Zealand� This session will discuss the changes and updates to the ARL program, the ARL Marketplace and consumer insights into the ARL program� This session will be panel discussion with a number of key experts in the ARL program

SPEAKERS:

Ralph Moyle FAIP, CPP Education Coordinator

Sarah Sannen Head of Operations APCO

WHEN: 25 July 2024

WHERE: 10 30 am - 12 30 pm, Meeting Room on Level 3

International Convention Centre Sydney

WHAT: With the packaging industry evolving at such a rapid pace so is the Australasian Recycling Labelling (ARL) Program for Australia and New Zealand If brands moved to incorporating the ARL on all packaging across Australia and New Zealand the more chance we have to increase the recovery of recyclable materials and reduce contamination in the waste stream

The Australasian Recycling Labelling (ARL) program provides packaging technologists, designers and marketers with the tools to inform responsible packaging design It is an evidence-based program that can provide consumers with easy-to-understand instructions about how to correctly dispose of a product’s packaging

This new version of the Introduction to Australasian Recycling Labelling (ARL) training course has evolved to cover both Australia and New Zealand and includes:

• Guides on how to use ARL logos

• Changes to soft plastics thresholds

• The new Check Locally program

• Intersections between ARL and Away from Home collection programs

• ARL & Container Deposit Schemes

WHO SHOULD ATTEND:

• ARL & RecycleMate APP

• ARL & QR codes

• ARL Consumer Insights

• ARL Marketplace for SME’s

• Best Practice Award-winning examples

• Interactive session with attendees and their own packs

This training course will help guide companies that have never applied the ARL to their packaging and also update those who already use the ARL This course is suitable for SME’s and multinational businesses to attend� We would strongly recommend that packaging technologists and specialists, designers, marketing teams, sustainability experts, packaging consultants and design agencies all attend this course so that everyone can better understand the true value that the ARL program offers your business

LECTURER:

Ralph Moyle FAIP, CPP Education Coordinator AIP

NEW Packaging Pavillion at AWRE in Partnership with the Australian Institute of Packaging (AIP)

A partnership with the Australasian Waste and Recycling Expo (AWRE) and Australian Institute of Packaging (AIP)

AIP invites materials & packaging companies to join us at AWRE 2024

Each year, as a key association partner of the Australasian Waste & Recycling Expo (AWRE), the AIP is delighted to announce the creation of a unique packaging pavilion for our members, industry partners, and aligned businesses.

If you've been eager to showcase your solutions and programs to the waste & recycling industries, councils, and government agencies, then the packaging pavilion is tailor-made for you The AIP invites all materials & packaging companies to join us at AWRE 2024 and unlock the ultimate showcase opportunity with an exclusive package.

The Packaging Pavilion has been designed as a walk-on package that includes:

Your company brand artwork is featured across a 2.5-meter back wall.

$5,535 + GST per participant

Premium furniture setup including 2 x white high stools, 1 x high table counter, and a stand number signage.

Customised digital print panel on a hanging board.

Power and lighting set up that includes 2 x LED on the arm and 1 x 4-amp power outlet.

Stylish carpet tiles for a high-quality flooring finish.

Eye-catching signage: 1 x panel strategically positioned in the middle of your stand.

Materials manufacturers

Materials suppliers

Packaging suppliers

Packaging manufacturers

Packaging manufacturers

Design agencies

Lifecycle assessment companies

Product stewardship programs Consultants

Join forces with AWRE and AIP to elevate your brand presence and connect with key stakeholders in the industry. Reach out today to secure your spot in the Packaging Pavilion and let your innovation shine!

Ready to book your stand?

Quote “AIP2024” when booking to receive a discount

T: +61 2 9158 6610

E: tmugliett@divcom.net.au W: awre.com.au

Secure your spot today in this limited-space opportunity!

WHEN: 24 & 25 July 2024

WHERE: MCEC Melbourne

WHAT: AIP Members to receive discount to attend the 2024 National Food Waste Summit

As a core participant of End Food Waste Australia Cooperative Research Centre and a founding association of End Food Waste Australia AIP are being offered a special discount and code for our Members to attend the two-day 2024 National Food Waste Summit

End Food Waste Australia is proud to host Australia’s biggest gathering dedicated to halving food waste by 2030� The third National Food Waste Summit brings together delegates and exhibitors from across the food industry, government, NGO and research sectors as we work to create a more productive, sustainable and resilient Australian food system by ending food waste and food insecurity

Hear from Experts about:

• The scale of opportunity: how action on food waste delivers high impact

• Changing behaviours: around food waste and food insecurity�

• Research and technology: how innovation is changing food waste�

• Measuring and monitoring: what gets measured and what is the impact

• The policy landscape: how innovation is changing food waste

• Industry commitment: critical role of private sector in halving food waste� ENDING FOOD WASTE STARTS WITH ALL OF US.

SIMPLY USE THE CODE ‘NFWSEOFY’ WHEN YOU REGISTER TO RECEIVE $200 OFF.

AIP to moderate a panel at the 2024 National Food Waste Summit

WHEN: 25 July 2024, at 2:15pm - Main Stage

WHERE: MCEC Melbourne

WHAT: The AIP is pleased to advise that our very own Executive Director Nerida Kelton FAIP will be moderating a panel discussing Save Food Packaging on the 25th of July at the 2024 National Food Waste Summit

The fireside chat will be with Lukas Parker, Associate Professor – School of Media and Communication, RMIT, Sophie Sumner, Marketing Communications Manager, Sealed Air and Michael Dossor, General Manger, Result Group, and will discuss how to 'Food waste proof your products: unlock the possibilities of save food packaging and consumer touch points "

The discussion will also cover Innovation design, creative approaches to information sharing, utilisation of new technologies, and getting to know your consumer behaviours are critical ingredients to cooking up save food packaging and consumer touch points that can help reduce food waste Please come and join us for a masterclass in fresh ideas to save food and prevent waste�

SPEAKERS:

SIMPLY USE THE CODE ‘NFWSEOFY’ WHEN YOU REGISTER TO RECEIVE $200 OFF.

IAIP Virtual Site Tour: Herma & Result Group

n these uncertain times, many of our clients are looking for answers, insights and solutions to the issues raised by COVID-19.

WHEN: 5 August 2024

As businesses prepare for a range of scenarios, including those mandated by Government directives, we consider a major concern facing tenants today.

WHERE: On-line via Zoom, 10 00 am to 11 00 am

As a tenant, what are my rights under my lease? Will my lease allow me to terminate because of the COVID-19 pandemic?

Answer: Unlikely

Right to terminate: Although each lease will contain different terms, leases rarely contain an express right for a tenant to terminate a lease.

Force majeure: In Australia, there is no common law doctrine of ‘force majeure’. A tenant can only rely on this doctrine if their lease contains a force majeure clause. This is rare in commercial leases.

WHAT: Result Group is a leading supplier of innovative packaging equipment and materials, helping Australian businesses enhance efficiency in manufacturing and distribution. Among their advanced solutions is the Herma InNo Liner, a PIDA and WorldStar Awards 2024-winning labelling technology, that eliminates landfill waste by removing silicone, reducing disposal costs, lowering transport volume, and boosting material efficiency. Hanes Australasia, owner of brands like Bonds, Sheridan, Champion, and Bras N Things, is an early adopter of this system to meet its 2025 sustainability goals. Operating 24/7, the system provides labelling with no release liner, no silicone content, and zero waste disposal.

Tenants may argue that a Government ban on occupation of, or trading from, the premises frustrates the lease. Courts however, have been reluctant to enforce this doctrine in circumstances of a temporary change (eg short-term closure). It is therefore likely the lease will continue during any short-term period of forced closure.

Can I stop paying rent?

Answer: No, but that doesn’t mean you don’t have options

Non-payment of rent: This will most likely amount to a breach of the lease and entitle the landlord to terminate and seek damages.

During the virtual tour you will be invited to join Herma and Result Group on an insightful journey that starts in their Demo Room Travel to Herma's headquarters in Germany and return to Hanes Australasia in Australia Experience firsthand how the innovative Herma InNo Liner system operates in real time and uncover the substantial sustainability and efficiency benefits it brings to the business

Breach of quiet enjoyment: Tenants may consider terminating their lease on the basis that the landlord has failed to provide ‘quiet enjoyment’. If such failure is due to a Government mandated shutdown, courts are unlikely to view such closure as a breach of the landlord’s ‘quiet enjoyment’ obligation.

Frustration: Frustration brings a contract to an end. This occurs where, through no fault of either party, an intervening event makes performance of the contract impossible or radically different.

Rent abatement for inability to access premises: Most leases will contain provisions for rent abatement under certain circumstances. These typically relate to situations where the centre or premises have been damaged or destroyed. It is therefore unlikely that these provisions will be able to be relied upon by a tenant to support a claim for rent abatement.

If I am forced to close my premises due to a Government directive, will I be in breach of my lease?

Answer: No

Most leases contain an obligation for a tenant to keep their premises open. It is unlikely this obligation can be enforced where the Government orders or mandates closure. This is because leases will most likely also contain a provision requiring a tenant to comply with laws and Government directives.

This would likely trump any other conflicting tenant obligation.

The above information is provided on a general basis only. Now more than ever, the specific terms of each lease are critical and should be reviewed carefully.

Commercially: From a commercial perspective however, landlords are acutely aware in these challenging times of the difficulties they may face in replacing the tenant if they adopt an ‘aggressive’ approach, such as terminating the lease.

Tenants should consider strategically approaching landlords for an initial discussion to explore options for relief or assistance.

Businesses of all sizes are facing unprecedented challenges in light of the outbreak of COVID-19. We can see and feel the pressures and stresses that our clients face. We are here to help in any way we can and encourage tenants to contact us to clarify their contractual rights under their leases.

Gina Szwider

Bespoke, Principal gina.szwider@bespokelaw.com www.bespokelaw.com

Joshua Lipshutz

Bespoke, Associate Principal josh.lipshutz@bespokelaw.com www.bespokelaw.com

End Food Waste Australia is proud to host Australia’s biggest gathering dedicated to halving food waste by 2030.

The third National Food Waste Summit brings together delegates and exhibitors from across the food industry, government, NGO and research sectors as we work to create a more productive, sustainable and resilient Australian food system by ending food waste and food insecurity.

scale of opportunity: how action on food waste delivers high impact.

16 August 2024

Shangri-La Sydney, NSW

Product Stewardship & Away from Home Collection

WHEN: 21 August 2024

WHERE: On-line via Zoom

WHAT: The 5th AIP State of Industry Webinar will look at a wide range of successful product stewardship and Away from Home programs that actively engage the consumer with the collection. Product Stewardship Programs enable households access to recycling and safe disposal services for products once they have reached their end of life.

Many of the Product Stewardship programs have been designed to capture and reprocess packaging and materials that can not be collected through a traditional Materials Recovery Facility (MRF) ‘Away from Home’ collection and drop off points are established for these materials or packs so that they don’t end up in landfill and can have a longer lifecycle Some hazardous and flammable products require safe disposal such as paints, chemicals and batteries and Away from Home collection ensures the product is disposed of safely These programs keep valuable resources circulating in the economy for as long as possible, reduce the impact of a product on the environment and offer effective end-of-life recovery systems

Whether it is soft plastics, pharmaceutical blister packs, aseptic cartons, make up, toner and ink cartridges, batteries, paint, e-waste or coffee cups, everyone can proactively engage with numerous Product Stewardship programs across the country� Find out more about some of the unique and innovative programs that are available and how your business, and your household can get on board

SPEAKERS:

WHEN: 4-6 September 2024

WHERE: Jakarta, Indonesia

WHAT: ProPak Indonesia is the leading international processing and packaging trade event in Indonesia for Processing & Packaging technologies Powered by ProPak Asia, ProPak Indonesia is part of the event series taking part in the region showcasing a comprehensive array of innovative products to a thriving and expanding local market in Indonesia� It is the centerpiece where market trends converge, and industry networking evolve to valuable customer insight� ProPak Indonesia is the ‘must-attend’ processing and packaging event in Indonesia delivering an industry-focused platform connecting worldwide suppliers to both local and regional buyers in the food & beverage, consumer & personal goods, and pharmaceutical industrial sectors�

WHEN: 5 & 6 September 2024

WHERE: Jakarta, Indonesia

WHAT: ProPak Indonesia to launch Indonesian Packaging Forum

PT Pamerindo Indonesia, in partnership with the AIP, are pleased to launch the inaugural Indonesian Packaging Forum on the 5th & 6th of September as a part of ProPak Indonesia

Having served the industry for over 60 years the AIP are the peak professional body for packaging training & education in Australasia and have been running Packaging Forums alongside other Informa Markets trade shows successfully in Asia for many years

magazine and website provide sustainability-focused professionals with an easy-to-use, readily available source of the latest information that is crucial to help you reach your environmental, social and corporate governance (ESG) goals.

The Indonesian Packaging Forum will be held over two days and will be free for all to attend� Speakers will be local, regional and global and will discuss the current state of play and the future of packaging� The discussions will include a broad range of topics such as sustainable packaging design, trends and barriers for soft plastics and flexible packaging, how to reduce plastic pollution, how to design out waste at the start of the packaging development process, how to move towards more recyclable packaging, the balance between food waste and packaging waste, looking at environmental impacts when designing packaging, the future of fibre and renewable materials, product stewardship programs, eliminating single use plastics and problematic materials, the development of new facilities in the region for recycling, how to incorporate recycled content into packaging, the benefits of container deposit schemes, the benefit of Extended Producer Responsibility programs, active & intelligent packaging, save food packaging, trends and barriers for plastics: rigid & soft, the future of advanced and chemical recycling in the region and more…

The Indonesian Packaging Forum will be a must attend event for yourselves, your teams and the wider industry. Mark these dates in your calendar today.

Up-coming AIP supported forums, training,

Advancing Towards Sustainable Resource Recovery 23-24 Oct 2024 • MCEC, Melbourne

Waste Expo Australia serves as a cornerstone for advancing best practices in circular economy, resource recovery and sustainability initiatives, aiming to foster positive environmental and community impacts.

The 2024 edition will offer four comprehensive streams featuring over 120 esteemed speakers across 60 engaging sessions. And as if that weren’t enough, we’re also hosting over 100 leading suppliers, representing 12 different countries.

6th AIP State of Industry Webinar: Container Deposit Schemes

WHEN: 18 September 2024

WHERE: On-line via Zoom

WHAT: Container Deposit Schemes (CDS) are an ideal example of product stewardship programs where the brands take responsibility for the packaging they put on to market. This includes ensuring that there is an established system in place for recovery of the packaging and then the recycling scheme to support the end of life.

Container Deposit schemes for Beverage packaging provide many benefits to the country via minimising litter, keeping packaging out of the environment, providing quality feedstock for recycled content, incentivising consumers to recycle properly, supporting charities in Australia, improving recycling rates and keeping valuable resources that can be recycled out of landfill The challenge for our country is that not all State and Territories are running the same scheme and not all materials are accepted on a national basis � There is also a need for greater consumer education programs to be developed to ensure that less packaging that should be going into CDS programs is kept out of kerbside collection, or worse, landfill

This webinar will discuss the current state of Container Deposit Schemes in Australia, collection points, accepted materials, opportunities for regional areas and more� The speakers will also discuss how we can improve recovery rates and incentivise more households to utilise the CDS programs and be able to use platforms like RecycleMate to locate Away from Home collection points�

SPEAKERS:

2024

Bonnie Marshall Policy Officer National Retail Association

James Dorney Chief Executive Officer TOMRA Cleanaway

Waste Expo Australia AIP to Partner

WHEN: 23-24 October 2024

WHERE: Melbourne Convention and Exhibition Centre

Shannon Doherty MAIP

Sustainability Manager Australian Beverages Council

WHAT: Waste Expo Australia serves as a cornerstone for advancing best practices in circular economy, resource recovery and sustainability initiatives, aiming to foster positive environmental and community impacts

WHEN: 23-25 October 2024

WHERE: Tokyo International Exhibition Centre

WHAT: Held every two years and with 53,5000 visitors in 2022 TokyoPack offers a variety of exhibits from packaging materials and machinery to converting, packaging, distribution, environmental protection equipment TOKYO PACK serves as a platform for industrial solutions and international exchanges, and contribute to the development of society from an international perspective TOKYO PACK Inspires the Packaging World - A Gateway to Innovation -

WHEN: 3-6 November 2024

WHERE: Chicago, USA

WHAT: Bringing together 45,000 attendees and 2,500 exhibiting companies with packaging and processing solutions for 40+ vertical markets, PACK EXPO International is one powerful show� Experience equipment in motion, idea-sharing across vertical industries, problem-solving in real time, networking and learning at this incredible intersection of innovation� Explore the latest innovations from 2,500 exhibitors to get ahead of trends, move projects forward and solve any challenges holding you back

With large product windows for perfect sealing at high speeds, with 60% less1 power consumption, the Yamato Dataweigh OMEGA will maximise your packaging capability.

selpak.com.au

With DCCEEW set to reform Packaging Regulation & Design

Requirements to deliver a circular economy for packaging in Australia, the AIP ran a State of Industry Webinar with over 200 people in attendance to here from the Federal Government.

With the Federal Government recently announcing that DCCEEW is developing new mandatory requirements for packaging under Commonwealth regulation that will replace the current co-regulatory arrangement, all packaging technologists and designers need to start looking at how this will change the way they design their packaging going forward� Australia’s new Federal national packaging laws will provide regulatory certainty and consistency, and make businesses take responsibility for the 6�7 million tonnes of packaging they place on the Australian market� Strengthened regulation will drive investment, minimise waste and support circular economy outcomes, industries and jobs� Better packaging design makes it easier to reduce waste, and to reuse, recycle or compost packaging waste�

Creating demand for recycled content will also increase recycling rates This webinar discussed the priority pillars for DCCEEW for this reform including:

• DCCEEW to become the regulator of the new packaging regulation

• Mandatory National Packaging Design Standard�

• Eco-Modulation and Extended Producer Responsibility�

• Eliminating Chemicals of Concern (CoC)

• Establishing minimum thresholds for Recycled Content in all packaging�

• DCCEEW public consultation process and update

DID YOU KNOW THAT THE AIP IS A FOUNDING ORGANISATION OF END FOOD WASTE AUSTRALIA?

Environment Ministers’ Meetings (EMM) agreements:

October 2022: the need to reform the regulation of packaging to ensure packaging is designed to be recovered, reused, recycled and reprocessed safely in line with circular economy principles.

June 2023: to mandate obligations for packaging design based on international best practice, including removing harmful chemicals and other contaminants from packaging.

November 2023: that the regulations will be implemented under Commonwealth law and that the Australian Government will regulate the new scheme.

Through laws that establish:

• design requirements to ensure packaging is designed to minimise waste and be recovered and recycled

• recyclability assessment and labelling criteria that allow transparent and clear recycling guidance

• mandatory uptake of recycled content, underpinned by traceability and verification systems

We have an opportunity to:

• recover more packaging and improve environmental outcomes

• increase regulatory consistency across Australia

• reduce industry confusion

Principles for a circular economy for packaging in Australia

• Whole-of-supply chain approach

• Extended Producer Responsibility (EPR)

• Build on progress towards National Packaging Targets

• Mandatory requirements

• National consistency

Public consultation will be conducted in the coming months

Public consultation will be conducted in the coming months

Focus of consultation

Focus of consultation

• Visibility of reform process – steps and sequence

• Visibility of reform process – steps and sequence

• Continued engagement with industry, peak bodies, state and territory governments, NGOs and international entities

• Continued engagement with industry, peak bodies, state and territory governments, NGOs and international entities

• Public consultation on Extended Producer Responsibility approaches and proposed mandatory obligations

• Public consultation on Extended Producer Responsibility approaches and proposed mandatory obligations

Upcoming opportunities

• DCCEEW industry webinar

• DCCEEW industry webinar

• Online public consultation

• Online public consultation

Until new regulations are in place, your obligations remain the same

Until new regulations are in place, your obligations remain the same

Functional barrier papers serve as fibre-based alternatives for plastic in applications such as HFFS/VFFS.

They are engineered for recyclability and are compatible with flexo, roto, digital and other printing technologies.

Discover the versatility of functional barrier paperscustomise a barrier solution for grease, water vapor or whatever the application may be. Available in both white and brown options.

Available from National Resources Global Sourcing, for Local Manufacturing

Contact: Scott Henschke

National Sales & Marketing Manager: 0417 694 336

We partner with the world’s leading processing, filling, packaging and product inspection brands.

Building the capability of Australian and New Zealand manufactures by matching equipment to business needs and application.

J.L.Lennard are a proud Australian and Family-owned company since 1879. Working with household brands both large and small across the beverage, confectionary, food pharmecuaticals and chemical industries to access high performing machinery. Contact us today!

Auspouch

The 2024 Turning the Dial conference that was run by the Department of Primary Industries and Regional Development (DPIRD) in Western Australia was an action-packed day full of amazing and inspiring speakers.

AIP Executive Director, Nerida Kelton FAIP recently headed over to Western Australia and had the opportunity to present from both a global (WPO) and local perspective (AIP) at the annual WA DPIRD Turning the Dial conference

The AIP moderated a session with David Kilpatrick MAIP, Michael Dossor MAIP and Bonnie Marshall discussing how to find the balance between the 2025 National Packaging Targets and the 2030 Food Waste targets� IN addition Nerida joined Meri Fatin, Vikas Ahuja and Jacqueline Kay (nee Brock) on a panel discussion about sustainable packaging and closed the conference in the final panel discussion with Josh Byrne, Huia Adkins and Bonnie Marshall�

The AIP would like to take this opportunity to acknowledge the fabulous and hard working WA DPIRD team including Phil May MAIP, Greta M, Laura, Monica, Amelia De Groot, Ryan and everyone else that made the one day conference such a huge success�

The AIP hopes to be back to Western Australia more often…Now more than ever we need to collaborate across all states and look to support regional areas and States Like WA that are challenged by the tyranny of distance�

Nerida Kelton represented the World Packaging Organisation (WPO) at the inaugural ‘Role that packaging plays in minimising food loss and waste’ conference that was hosted by the Hungarian Association of Packaging & Materials Handling (CSAOSZ). She files this report for PKN.

THE STAGING OF this conference sent an extremely positive message that the wider packaging community is now discussing this important topic on a global platform. The conference speakers were of high calibre and included the Deputy State Secretary, Ministry of Agriculture, Hungary; UNIDO; WPO; the National Food Chain Safety Office; GS1 Hungary and many more stakeholders in the value chain discussing food waste, government initiatives, technology advancements and, of course, the true role packaging can play in minimising food loss and waste.

A highlight was that two hours of the program was dedicated to discussing the Save Food Packaging Design Guidelines, that were developed by the AIP & RMIT as a part of End Food Waste Australia Cooperative Research Centre, and global award-winning best practice Save Food Packaging design examples were showcased.

It is important that we must not lose sight that the true role of packaging is its functionality. Packaging needs to be designed

to ensure that a product is protected, preserved, container and transported all the way through the value chain from production until it is used in the household.

Inadequate packaging that results in wasted food defeats the whole purpose and is a much bigger waste of resources and has environmental impacts.

The challenge for packaging technologists is to be able to design optimum packaging with the lowest environmental impact at the start. It is about finding the balance between not underpacking (wasting food) and not overpacking (wasting packaging materials) and being able to meet both 2030 Packaging and Food Waste Targets. If the balance is tipped either way it will create unintended consequences.

Under the revision of the Waste Framework Directive in the European Commission, legally binding reduction targets and necessary measures will be required by EU Member States to reduce

food waste by the end of 2030. These measures include reduction of food waste by 10 per cent in processing and manufacturing, and by 30 per cent (per capita) at retail and consumption (restaurants, food services and households).

The challenge for packaging technologists is to be able to design optimum packaging with the lowest environmental impact at the start.

Food Waste in Europe is currently sitting at 58 million tonnes per year which equates to an average 131 kilograms per person. Interestingly Portugal is one of the highest countries for food waste in Europe, sitting at approximately 124 kilograms a year per person. Comparatively Australia is 7.60 million tonnes of food wasted

a year with an average of 312 kilograms per person.

In addition to the EU targets many countries like Hungary are already working on their own strategies and roadmaps to meet the 2030 food waste targets. What was interesting to learn is that Hungary is one of the more advanced countries in the EU for Food Loss and Waste measurement and targets, with a significant amount of work happening in the households.

According to a recent study Hungary produces close to two million tonnes of food waste every year. 46.59 per cent of all food wasted goes to landfill and 25 per cent goes to worm composting. 62 per cent of all food wasted in Hungary is in the processing and production stages and the remaining 38 per cent is in household consumption and retail. The top three categories are Ready Meals, Fresh Produce and Bakery, which is not dissimilar to Australia.

According to recent data, food waste generated by Hungarian households was estimated at 59.85 kilograms per capita which has seen a significant decrease since 2021 which was sitting at 66.50 kilograms per person. The food wasted in households has been decreasing each year for the last seven years in Hungary which is a great example of what can be achieved with a roadmap.

Since 2016, Project Wasteless of the National Food Chain Safety Office of Hungary (Nébih) has been measuring the quantity and distribution of food waste in Hungarian households, following a direct measurement utilising a food waste diary. 8 out of 10 households underestimate how much they waste in their homes, and 13% believe that they could see substantial financial savings if they stopped wasting as much food in their homes. 50.87% of those surveyed believe that there is too much packaging, however 43% were satisfied with the amount of packaging being used.

Measures to prevent food waste include the establishment of a public awareness program called

‘No Leftovers’ by the National Food Chain Safety Office, which provides practical advice on how to effectively reduce food waste in households. An additional education and early childhood program was launched which has reached more than 400,000 children, and more than 800 teachers.

The government agencies in Hungary have developed multiple programs including one that ensures that all bread that is about to pass its best before date is shared with those in need. The Hungarian Food Bank Association and its partner organisations distribute around 11 thousand tonnes of food with a total value of around HUF 7.5 billion to people in need. (2019)

Leaving the conference, I realised that the next step is to see every government across the world establish a food waste roadmap that is linked to the UN Sustainable Development Goals, global Food Waste regulations and targets and Environmental (ESG) policies, with a view to actively improve environmental and social impacts surrounding food waste for each country.

If each roadmap ensured that every person who suffered from food insecurity is fed, that no edible food is being ploughed back into field, that food doesn’t end up in landfill, that all edible food is being utilised and that food rescue organisations are supported in times of natural disasters, then we would be a better world.

Everyone has a role to play, and I commend the Hungarian

Association of Packaging & Materials Handling for having the foresight to be one of the first WPO member countries in Europe to discuss the intersection between food waste and packaging.

Packaging has an important role to play, and I look forward to seeing even more companies across the globe embed the Save Food Packaging Design Guidelines into their packaging development processes. The ultimate objective is for every brand to design intuitive and innovative packs that not only contain, protect, preserve and transport a product all the way to a household, but also minimise food loss and waste across the value chain; all the while offering the lowest environmental impacts.

As one of the speakers said “Packaging is just like a car. A car is designed to protect the passengers, to make sure that they don’t feel the shocks or vibrations as they travel and to ensure they arrive at their destination safely.” ■

Facing page: (From left) Aleksa Mirkovic, UNIDO; Beata Gonci, MD, CSAOZ; Miklos Nagy, general secretary, CSAOZ; Nerida Kelton, VP Sustainability & Save Food, WPO.

Below: (From left) Oksana Sapiga, Myriam Annette and Darya Aleksseva, FAO Regional Office for Europe and Central Asia with WPO’s Nerida Kelton in Budapest, Hungary.

The Certified Packaging Professional CPP® is the premier designation in the industry globally, signifying excellence as a packaging professional with the most recent IoPP salary survey revealing that CPPs® earn up to 10% more than their non-certified co-workers.

Using the CPP® program to assess and evaluate one’s professional competency validates you as internationally proficient as a packaging professional; a cut above your peers.

Hungary recently launched its deposit return system (DRS) for recycling single-use drink containers, and so Nerida Kelton ventured off to find one of the machines and see how it works. Global reverse vending leader TOMRA has partnered with MOHU, the central system administrator for the DRS, to roll out collection infrastructure to make drink container returns as convenient as possible for new recyclers. This DRS covers ready-to-drink or concentrated beverages (except milk and milk-based beverages), in single-use aluminium cans and glass/plastic bottles, ranging from 0.1 litres to 3 litres in size. Consumers pay a deposit of 50 Hungarian forint (approximately AUD\ 0.21) when purchasing an eligible drink, which is refunded when they return the empty container for recycling. Drink containers in Hungary can be returned to grocery retailers such as Aldi.

PIQET is a powerful and user-friendly LCA tool for assessing packaging sustainability.

Use it to measure and improve the performance of your packaging over a whole product life cycle.

Large and small companies across the world rely on PIQET to understand their environmental impacts.

Created 15+ years ago for the packaging industry. Led and managed by LCA experts, Lifecycles.

+ Build LCA capacity in-house

+ Make better packaging decisions with the right data at your fingertips

+ Identify hotspots quickly – see a range of impacts and their causes at a glance

ISO 14044

Built-in ISO 14044 standard LCA reports

Tracking certified materials such as Carbon Neutrality, FSC and more!

+ Generate the results you need to explain packaging options to your stakeholders

+ Speak to an LCA expert when you have queries

+ Have access to live hands-on training

With our upcoming launch, we’re making the tool more intuitive than ever.

info@piqet.com tim@piqet.com

+61 3 9417 1190

piqet.com lifecycles.com.au

linkedin.com/company/90451316

New recycling functionality Organization packaging footprint

New range of metrics including PEF indicators and packaging indicators

Join as a Partner today. The Australian Institute of Packaging (AIP) provides opportunities for your company to partner with the Institute through our on-line newsletter, website and social media sites. These communication tools will provide direct access and communication on a regular basis to our Members and wider industry colleagues on the AIP database. Ask the AIP how your business can become a partner today.