www.trayak.com

www.trayak.com

We know that maximizing your sustainability efforts and reducing your environmental footprint is key. Trayak can help. We would like to introduce you to EcoImpact COMPASS, the foremost Life Cycle Assessment solution for products and packaging. It is designed to help companies like yours embed sustainability directly into your workflow to make decisions with confidence.

• Trusted Companion Animal Care portfolio.

• Specialist Packaging Role – Project management.

• Sydney NSW preferred, but flexible.

As a marketer, wholesaler and distributor of healthcare, medical, pharmaceutical, consumer products and animal care brands, their client is a large, diversified and market leading group. The Animal Care Division manufactures, markets and distributes a diverse range of branded companion animal care and veterinary products. With core values including obsessing about their customers, taking care of each other, doing what’s right, courageously speaking up and always searching for innovation, they are dedicated to providing quality products, services and education that people need for their pets to live long and healthy lives.

A new role, Sustainable Packaging Technologist , has been created within the R&D and Veterinary Technical Services team of the Animal Care Division, to support the implementation of sustainable packaging transformation initiatives. Working closely with, and reporting to the Sustainable Packaging Manager (ANZ) you will be assisting in delivering all activities of the group’s Sustainable Packaging Strategy. This includes developing new packaging options and solutions for a broad range of products/- brands across many animal species and countries especially Australia and New Zealand, within a limited timeframe.

Your responsibilities in this role include assisting with:

• Project management and execution – timely transition to sustainable packaging solutions to meet group strategy targets.

• Packaging related testing for new product developments in the R&D pipeline.

• New packaging launches.

• Managing compliance with OHS, WHS and APCO guidelines.

• Working closely with cross functional project teams and supporting other consumer goods business units within the larger corporate group.

To be successful in this role you will have:

• Packaging experience in FMCG – packaging development across different markets with variable challenges, and demonstrated delivery of sustainable packaging initiatives.

• Good communication and stakeholder engagement skills with ability to negotiate and influence.

• Understanding of R&D and regulatory requirements with an investigative, problem solving mindset.

• Relevant tertiary qualifications (Bachelor, Master or PhD) in disciplines such as packaging, chemical/ food engineering or materials science.

You will be a packaging specialist, familiar with the environment, sustainable packaging requirements and involved in transitioning a large, trusted product portfolio to sustainable packaging solutions within a limited timeframe. There is some domestic (regional VIC & NSW) and international travel (NZ, Asia especially China and Thailand) in the role.

You may currently be in a similar Packaging Technologist role in either food, FMCG, animal health/ nutrition or pharmaceutical industries, however are up for more of a challenge, perhaps with more variety. Come and be a key member of the R&D team involved in the successful packaging transition, sharing your expertise. Join a diverse business at an exciting time which is growing, providing career progression scope. Sydney is the preferred location where the head office team is based, however there is location flexibility for the right person. A generous salary package is on offer.

For more than 30 years Caspak has maintained their position at the forefront of food packaging development in Australia & New Zealand to maximise quality and increase the shelf life of fresh food in over 14 different markets. With a focus on evolution and staying ahead of the curve, they are entering the next phase of packaging solutions with their eyes firmly on sustainability. Caspak invite you to join their team and lead their packaging evolution towards 2025 targets and beyond, to inspire and create sustainable solutions for Caspak’s existing and new markets Share.

Lead their quality assurance for the compliance of Quality and Barrier Food Packaging.

• Implement GSFI via ISO22000/FSSC22000.

• Ensuring their network of suppliers have correct and current accreditations.

• Assist with inspection, testing and analysis with all inwards receiving inventory, for compliance to specifications.

• Manage and implement effective non-conformance and corrective action systems. Lead, report on and action non-conformance root cause and corrective action as required.

• Oversee development and maintenance of all quality documentation appropriate to ISO, HACCP, FSC and audits.

• Assuming a leadership role in all relevant audits –(ISO, HACCP, GMP, FSC), conduct all internal Audits.

• Be the first point of contact for all external parties on all matters pertaining to quality control, ISO, HACCP, FSC and GMP.

• Ensuring cost of quality is actively measured and reduced over time.

• Lead and support the quality control team.

• Record, manage and submit obligatory reports in a timely manner to APCO and REDcycle and other third parties as required.

• Promote a food safety culture.

• Ensuring that Caspak is a good global citizen, with continuing improvements & policy in sustainability, human rights etc.

• Provide support to the QC, product development & sales teams, to bench marking, product & system efficiency improvement.

To achieve these outcomes, they believe you will have.

• Tertiary qualifications in Food Technology, Applied Science, etc, or alternatively a food packaging industry background to well round an alternative formal education.

• The ideal candidate will have a minimum of 2 –3 years QA industry experience. Experience in FSSC22000 and/or ISO22000 and FSC highly regarded. Some experience in the packaging/food industry would also complement the role.

• An understanding of barrier packaging for shelf-life extension of protein and other food types.

• A demonstrated ability to work across multiple market disciplines, managing multiple projects across the country.

• A strong technical understanding and capability of food processing, manufacturing, and packaging.

• Familiarity with APCO National packaging targets, AIP etc.

• A background in Quality Control as it applies to the food and food packaging industry.

• Tertiary qualification (bachelor’s degree or higher) in a Science/ Engineering/ Food Technology.

• A practical education and training in quality management and quality management systems, with a hands-on approach.

• Relevant industry experience to food packaging, but you are not at your pinnacle yet. You are striving for the next step; you want to lead, and you are ready.

Caspak is Braeside located, in new modern purposebuilt premises. The surroundings make it a pleasure to attend each day, as is required. This is not a work from home role. Its practical, its hands on, it’s here, it’s in Braeside.

The Diploma in PackagingTechnology is designed for thosewishing to pursue a career in thepackaging industry, or who are alreadyworking in the industry and wish to extendtheir knowledge and expertise. The Diplomain Packaging Technology prepares students totake responsibility for packaging operations at anylevel through the supply chain. The qualification iscomprehensive and provides an opportunity to study theprinciples of packaging, packaging materials and packaging processes.

Completion of the Diploma in Packaging Technologydemonstrates your commitment to your career and to the industry.

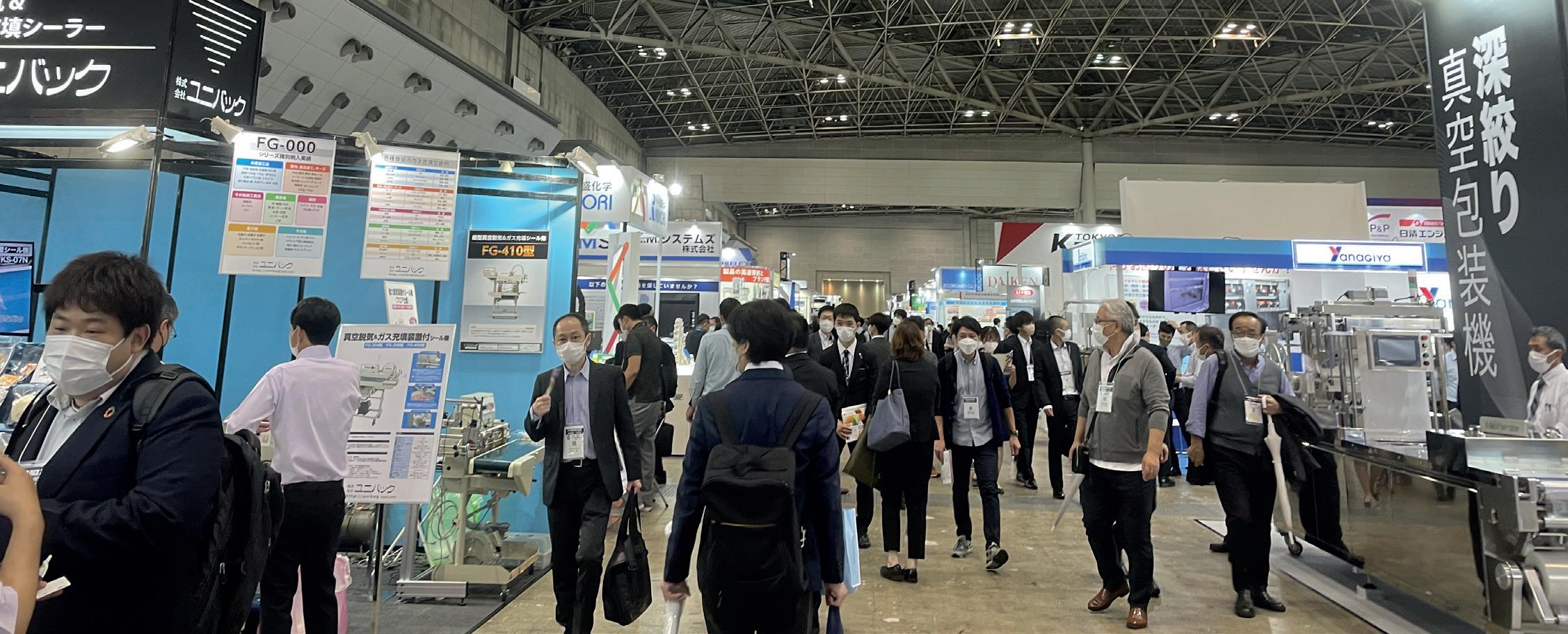

As the ANZ Board Member for the World Packaging Organisation, our very own Executive Director recently attended the biannual board meetings alongside Tokyo Pack. Tokyo Pack is the largest international packaging show in the Asian region and over 54,000 visitors attended the show including 20 x country representatives from the WPO Board.

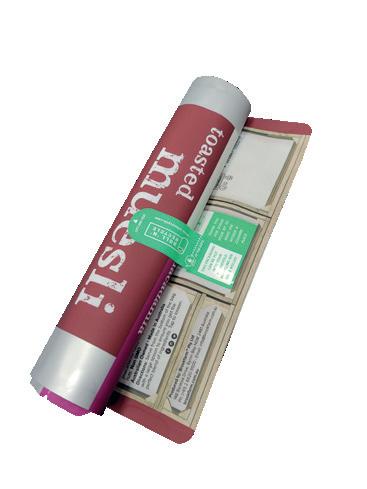

The WPO had an exhibition booth at the show and also an area for 2022 WorldStar Packaging Award winners. The ANZ winners that were showcased included Zero Co, Brookfarm, O F Packaging, Colgate, Coles, Wellman Packaging, rPUMP Zipform Packaging, Pana Organic, Cove and Chobani.

The World Packaging Organisation had an area at Tokyo Pack to showcase some of the 2022 WorldStar Packaging Award winners.

The ANZ PIDA award winners that were showcased in the pavilion included Bookfarm, Cove, Chobani, Pana Organic, the ZipForm Packaging rPump, Wellman Packaging, Coles, Colgate, O F Packaging and Zero Co showcased in the well-attended WorldStar awards pavilion.

The World Packaging Organisation held a conference at Tokyo Pack that saw five speakers fom across the globe discussing trends and innovations in their regions.

Wearing her VP for Sustainability & Save Food hat Nerida Kelton spoke about global sustainabilty trends and challenges. Nerida also surprised the audience by presenting in Japanese for the first section of the discussion. Her presentation was very well-received.

Our very own Executive Director chaired the Sustainability & Food Waste Working Group meeting at Tokyo Pack. During the week long meetings the working group held a four hour meeting covering the last 6 months of updates, regulations, inititiaves and programs that are happening across the corners of the globe. 25 country reports and a global report were tabled and discussed at the meeting.

Two highlights that were discussed was the on-going success of the Global Packaging Design for Recycling Guide and the number of countries that are busy translating the guide into their own languages and the well-supported international day of awareness of Food Loss & Waste.

The second meeting for the World Packaging Organisation was held as a hybrid and saw over 12 countries repesented in person and another 20 odd on-line.

The Managing Director of the Japan Packaging Organisation Koshino San retired and the WPO had the opportunity to meet the new MD Sonoyama San during the meeting. Nerida presented the new MD with a gift from the AIP. She also presented her Sustainability report for the world and discussed the key inititiaves that sit in the portfolio including the Global Packaging Design for Recycling guide, the waste stream mapping tools and the projects focussed on food loss and waste.

The AIP exhibited at Waste Expo 2023 for the first time and the stand became the hub for the twoday event for all of our Members. Many of our Members had not seen each other in real life in close to three years, so it was a great opportunity for networking and catching up.

In addition, the AIP joined the panel discussion with AFGC, NRA and APCO to formally launch the new SME Australasian Recycling Labelling program. Ralph Moyle moderated the session with Sally Williams and many of the AIP Members were in attendance.

One of our AIP Members, Anhely Milan MAIP has published a new book called ‘The World Behind Recycling’ which is an educational book for young children that talks about how recyclability helps to protect our planet. The AIP took the book to the Waste Expo and it was extremely well-received by all.

The book answers all of the hard questions from a young child’s perspective: Have they ever looked at a product and wondered whether it is recyclable? Do they know what happens after they throw their waste away and how this waste is sorted and repurposed? Mr. Bin will travel with the child through the recycling world to discover all the secrets behind recyclability. The child will learn how to recycle at home, the different materials that can be recycled, and the wonderful recycling processes. After embarking on this journey, they will no longer see waste in the same way. They will make changes to their day-to-day activities that can change the world, help create a better and cleaner planet, and most importantly, protect our future. Recycling is just one simple thing we all can do. A wonderful tool for schools and your own children and grandchildren (42 pages).

Order your copies today through the AIP.

The AIP, AFGC, NRA and APCO came together at Waste Expo to formally launch the new SME ARL program.

The attendees heard from a consortium of leading industry associations about how they are working on a new campaign to empower small to medium-sized enterprises (SMEs) to start using the Australasian Recycling Label (ARL) on their packaging which will in turn guide their customers how to recycle correctly and help push Australia towards achieving the 2025 National Packaging Targets. The program is being delivered in a four-way partnership with the Australian Institute of Packaging (AIP), the National Retail Association (NRA), and the Australian Food and Grocery Council (AFGC) and the Australian Packaging Covenant Organisation (APCO). This project received grant funding from the Australian Government, which is committed to helping all SMEs put the ARL on their packaging and help customers recycle correctly. To find out more about the program visit the ARL marketplace page on the AIP website.

UltraGuard™ Solutions by Milliken is a line of performance additives that brings value to polyethylene parts by improving barrier properties. It can be used in films, and in injection molded, compression molded, and blow molded parts.

These additives cut by up to 50% the transmission rate of any substance (such as moisture or oxygen) that pass es through the polyethylene bottle.

White opaque HDPE bottles are com monly used for OTC (over-the-counter) drugs, prescription drugs and nutra ceutical products because they have good moisture barrier and light protec tion properties. Barrier enhancement in HDPE pharma bottles is particularly valuable because it can help to extend the potency of drugs toward the end of their shelf life.

As an added benefit, UltraGuard Solu tions also provide sustainability ben efits. To meet the barrier requirements, pharma bottles typically have much thicker walls than needed from a purely functional point of view. PE resin for mulated with these additives enables bottle makers to reduce the weight of these bottles by up to 20% while still providing enhanced barrier properties. These lighter-weight bottles, therefore, use significantly less material and less en their overall impact on the environ ment.

Polyethylene with UltraGuard Solutions provides controlled crystallization allowing for enhanced properties.

For more details and information please contact us at asiachem@milliken.com or visit us online at chemical.milliken.com

up to

improved barrier

downgauging increased shelf lifeReduced (20%) Wall Thickness

Anew education campaign has launched which will raise awareness among small businesses about the benefits of adopting the Australasian Recycling Label (ARL) and taking action to improve the sustainability of their packaging.

The new initiative will be delivered by the Australian Institute of Packaging (AIP), the Australian Packaging Covenant Organisation (APCO), the National Retail Association (NRA), and the Australian Food and Grocery Council (AFGC).

The education campaign aims to educate 20,000 small businesses about the benefits of using the ARL on-pack, and is the first part of a series of initiatives under the SME ARL Program to support SMEs adopt the ARL on their packaging.

“We understand that sustainability is an important issue for small businesses, but with so many competing priorities, getting started can be difficult,” said Chris Foley, CEO of APCO.

“Through this campaign, we are excited to provide the tools and resources Australia’s small businesses need to start improving the sustainability of their packaging today.

“These organisations play an important role in the Australian business community. By helping them get the ARL on-pack and start working towards the 2025 National Packaging Targets, this campaign can provide a powerful step forward in Australia’s collective journey towards a more sustainable and circular packaging future.”

SMEs will receive access to a range of free educational tools, resources and events designed to cut through confusion and empower them to take action to improve the sustainability of their packaging.

“The AIP is extremely proud to be one of the four partners in the new campaign, which is a very important initiative funded by the federal government,” said Nerida Kelton, executive director at the AIP.

“The AIP strongly encourages all SMEs to start implementing the ARL on all of their packaging to ensure that their customers honestly know what can and cannot be collected, sorted, recovered and recycled in their region.

“The ARL is an effective and intuitive on-pack labelling program that can help guide all Australians to accurately dispose of the materials and packaging into the right bins every time. Consumer engagement in the process is critical to improve collection and recycling rates in the region.

A new education campaign has launched, which aims to assist SMEs to adopt the ARL on their packaging.

“We look forward to working with as many small businesses as possible to help train and educate them to see the true value that the ARL can offer their business, and in turn, their customers.”

Topics explored in the campaign include sustainable packaging options, the benefits of using the ARL for businesses, consumers and the environment, and important steps organisations can take to reach the 2025 National Packaging Targets.

“While businesses are highly supportive of sustainability initiatives, they often don’t have the time or resources needed to understand the technical intricacies of packaging requirements and trends,” commented David Stout, director of policy at the NRA.

“As part of our engagement, it is critical that we bring businesses and consumers along with us.”

A series of free online training topics will also be available. The training modules, along with a range of other action guides, fact sheets and toolkits will be housed on a new dedicated educational website – the ARL Marketplace.

“The ARL is an important tool that is helping consumers recycle packaging the right way and create clean streams of material ready for recycling into new products,” added Tanya Barden, CEO of the AFGC.

“Australian food and grocery manufacturers have already put the ARL on thousands of products, and the AFGC encourages all companies to take part in the program.

“Australia has an enormous opportunity to build new capacity in areas including advanced recycling of soft plastic packaging, and adopting the ARL is an important way for companies of all sizes to support the environment and a new, sustainable industry.”

The project received grant funding from the Australian government to support SMEs to improve the sustainability of their packaging and to adopt the ARL on their packaging.

To find out more visit the ARL Marketplace page on the AIP website.

WHEN: 9 - 11 November 2022

WHERE: Saigon Exhibition & Convention Center, Ho Chi Minh City

WHAT: ProPak Vietnam 2022 is the largest and most international trade event for the rapidly expanding processing and packaging industries in Vietnam and Indochina. This annual event is dedicated to technology suppliers involves in the food, drink and pharmaceutical processing and packaging, plus the printing and labelling industries, bringing together thousands of industry leaders and professionals from all segments of the supply chain under one roof.

Not only sourcing the best-of-breed products and technological solutions, visitors to ProPak Vietnam 2022 will also have the opportunity to network with over 550 high-profile exhibitors from more than 30 countries around the world, discuss potential business partnerships, as well as exchange knowledge and perspectives with a plethora of thought leaders and industry experts .

WHEN: 8 November 2022

WHERE: On-Line Via Zoom

WHAT: Australia is a standout producer of high-quality food that the world wants –yet one-third of all food produced is ultimately wasted. 7.6 Million tonnes of food is lost or wasted in Australia each year; which equates to 312 kg of food wasted per person. The Federal government is addressing this serious issue with the development of a National Food Waste Strategy to halve food that is going to landfill by 2030, the establishment of Stop Food Waste Australia and the recent launch of the Australian Food Pact. Working in collaboration with these programs is the Fight Food Waste CRC which brings together all areas of the value to chain develop, design, innovate and research ways to improve food loss and waste. The CRC provides the science-based evidence and research that the industry needs.

Stop Food Waste Australia and the Fight Food Waste Cooperative Research Centre’s vision is an Australia without food waste. This webinar will explore the key challenges and opportunities of reducing food waste in Australia, including the important role Save Food Packaging plays, the strength of industry collaboration through the Australian Food Pact, and the latest industry and research insights.

The AIP is proud to be a core participant of the Fight Food Waste CRC and has developed research and Save Food Packaging guidelines for the industry. In addition the Institute is a supporting signatory to the Australian Food Pact and a founding partner of Stop Food Waste Australia.

This webinar will help Members and industry colleagues to better understand the 2030 National Food Waste Strategy, the roadmap to meet these targets, how you can get involved in the Australian Food Pact, the Fight Food Waste CRC and Stop Food Waste Australia. The AIP will also provide an update on the projects they are involved in. Everyone in the industry has a role to play; find out what you can do.

WHEN: 10 November 2022 - Lunch Forum 1.20 pm - 4.30 pm

WHERE: State Library Victoria’s Conversation Quarter

WHAT: This year Women in Packaging will include several keynote speakers and a panel discussion, featuring women in our industry who are leaders in the sustainability movement, who are 'walking the talk' by pioneering new solutions, developing policies and industry programs, and taking authentic action that will drive true, sustainable change.

PRESENTERS:

WHEN: 23 - 24 November 2022

WHERE: Brisbane Convention & Exhibition Centre

WHAT: Will Australia rise to the challenge of halving food waste by 2030? Be part of the biggest food waste reduction event ever held in Australia at the second National Food Waste Summit and trade show in Brisbane on 23–24 November 2022. Hosted by Fight Food Waste Ltd, you'll be able to network with leading industry, government and research experts to help inspire solutions that will deliver real economic, social and environmental benefits for all Australians.

Reduce to nil: designing out food waste panel

WHEN: 24 November 2022 - 11:40 am - 12:30 pm

WHERE: Brisbane Convention & Exhibition Centre

WHAT: A panel discussion exploring zero waste technologies, innovations and initiatives disrupting Australia’s food business-as-usual. Hear from Associate Professor Simon Lockley, REDUCE Program Lead, Fight Food Waste CRC (Facilitator), Nerida Kelton, Executive Director, Australian Institute of Packaging (AIP), Katy Barfield, CEO Yume, Travis Hatton, Manager Business Solutions, Sustainability Victoria, and Brooke Donnelly, GM Sustainability Coles Group.

SPEAKERS: Assoc. Prof. Simon Lockrey REDUCE Program Leader, Fight Food Waste CRC

ProPak Philippines AIP to host training course alongside

WHEN: 1 - 3 February 2023

WHERE: World Trade Centre Metro Manila, Pasay City, Philippines

WHAT: ProPak Philippines is the leading international processing and packaging trade event for the Philippines. It is the perfect platform for market trends, investments and industry networking through product exchange and a variety of conferences, seminars and technical workshops offering sustainable solutions for the country’s enterprises.

WHEN: 4 - 10 May 2023

WHERE: Dusseldorf, Germany

WHAT: Interpack is far more than just a packaging show. As the world's leading trade fair, itis the major inspiration for the packaging industry and all related process technologies.2,700 exhibitors from more than 60 countries will present their latest ideas, innovate concepts and technological visions atinterpack - not only in equipment and machinery for packaging and processing, but also in production tools for packagingmaterials, materials themselves, and services for the entire industry.

ProPak Asia 2023

WHEN: 14 - 17 June 2023

WHERE: Bangkok, Thailand

AIP to host training course & seminars alongside

WHAT: ProPak Asia is Asia's Number One international trade event for Processing & Packaging Technology. ProPak Asia truly is the “Must-Attend” industry event in Asia for Asia, as quality and variety of products increase and expand, and productivity of operations and manufacturing standards are driven higher by consumer demands and new automation and technological advances, which will be presented at the show.

Foodpro 2023 AIP to host training course & more alongside

WHEN: 23 - 26 July 2023

WHERE: Melbourne Convention & Exhibition Centre

WHAT: Foodpro is Australia's largest, and longest running, trade event dedicated to food production, manufacturing and distribution. Industry leaders gather, make big business deals, network and explore the latest products and solutions to create an efficient future for manufacturing.

WHEN: 26 & 27 July 2023

WHERE: International Convention Centre Sydney

WHAT: Discover an exciting showcase of full circle innovative products and sustainable solutions to collect, process and recycle waste more smartly. Future critical areas include Machinery & Equipment, Software & Services, Bins, Vehicles, Food & Organics and more. Connect with an influential community of waste and recycling professionals, suppliers/ service providers, government departments, public sector bodies and special interest groups to successfully drive change throughout your specialist area.

FoodTech PackTech 2023

WHEN: 19-21 September 2023

WHERE: Auckland Showgrounds

AIP packaging sessions alongside

AIP to host training course & more alongside

WHAT: Together providing a forum for education, discussion and the sharing of knowledge and expertise, critical in the sustainability and growth of the industry. Held only once every two years FTPT is a must attend event providing visitors with the opportunity to come face-to-face with the experts and discover the freshest ideas, latest technologies and the newest developments entering the F&B manufacturing and packaging technology industries. Featuring the Materials Handling & Logistics Expo, the event will attract 250+ local and international exhibiting companies and some 4,500+ qualified visitors – a must attend event for anyone involved in one of New Zealand’s fastest growing industry sectors.

Anew era of coding and marking that will undoubtedly take the industry by storm. Here it comes, buckle up and get ready for this innovative labelling solution Result Group is ready to introduce to the Australian market.

Over the last few years, Result Group has worked hard to partner and collaborate with global companies in coding and marking space, EcoMark and Macsa in order to bring the unique technology to the Australian market.

Today, Result Group is excited to announce that Natural Branding, which has been rapidly gaining traction around the world, has now officially entered the Australian market.

The new EcoMark Natural Branding provides a non-contact and safe labelling technique that creates an image on the peel - a high resolution laser removes colour from the fruit or vegetable's outer layer of skin; and literally acts as a tattoo on a variety of goods, making plastic-free packaging a reality... packaging without packaging.

EcoMark Natural Branding is the new, sustainable, and cost-effective alternative to produce unit labelling, as it has the potential to completely eliminate the need for those pesky little fruit labels and the silicon liner that goes with them, and it contains zero ink. The new system, has no labeller; not to mention ridiculously good ROI - zero label cost and no lock in contracts for consumable. The advantages are endless...

The new laser technology may be used on any food with any a robust skin, including: apple, avocado, apricot, banana, grapefruit, kiwi, lemon,

lime, mandarin, pear, orange, papaya, peach, passion fruit, coconut, fig, guava, papaw, plum, pomegranate, lychee, mango, corn, capsicum, chilli, cucumber, ginger, garlic, onion, carrots, parsnip, tomato, pumpkin, zucchini, artichoke, beetroot, Brussel sprout, cabbage, eggplant, fennel, peas, potato, squash, sweet potato, asparagus, turnips, radish, cauliflower to name but a many!!!

It is fair to assume that differentiating organic products with over 40 installations already undertaken and operational are the major focus of the innovative solution, however the conventional marking and traceability coding is now a reality, especially with 2D codes use evolving in the Fresh Produce and to use in retail outlets.

Utilising a laser for the marking, the system ensures branding, SKU level identification, traceability and authenticity while producing no long-term damage barely detectable heat on fruits and vegetables. The advantage of the system is that it simply depigments the uppermost cell layer of the fruit's skin and removes the outermost layer of skin, preserving the fruit's integrity.

However, due to its adaptability and ease of production line integration, it is becoming increasingly popular for conventional goods such as bread, biscuits, chocolate, and other confectionery products, all of which can benefit from natural

branding without losing traceability; the method is absolutely exceptional for marketing promotions and branding of the product itself, as it has no effect on food quality or shelf life, providing the cheapest way to mark the product in small or large quantities.

“In over 35 years of coding and marking and spending a good part of those years exploring the world for innovation, I have seen nothing like this system, nor the potential for expansion in other markets outside of fresh produce. Put simply, this can and will re-invent coding and marking in the years to come,” said Michael Dossor, a Group General Manager at Result Group.

Laser technology is the most environmentally friendly, safe, and efficient method of labelling organic fruits and vegetables for retail sector; there is no use of plastic or paper labels or the silicon baking paper that comes with them, and only a small amount of energy is required and there are ZERO, that’s right ZERO consumables. EcoMark lasering is ideal for short-term special editions or standard seasonal product labelling.

Whatever the complexity of the coding to be marked on the product – 2D codes Datamatrix and QR, logos, certification marks, shapes, numbers, and text - the various requirements can be met with the Eco Mark machine, with the ultimate being a GS1 Datamatrix or QR code represented by the GS1 digital link standard that contains everything from the source of the product to the use by date and origin information; and is still acceptable for pointof-sale scanning and consumer engagement via any smartphone camera or app.

As a GS1 Australia Strategic Alliance Partner, Result Group sees enormous potential in leveraging innovative technology by collaborating on future projects with GS1 and the entire industry. Result Group is already working with a number of industry bodies proving the tech for growers.

The Eco Mark Natural Branding system has 4 base components;

• A Product handling system designed around the product or products being marked

•

A 3 D camera for vision and mapping locating the exact place to mark the product

• The Laser coder or coders themselves

• Software control that drives the entire system and is infinitely upgradable

Natural branding is a completely innovative approach emerging in the industry to improve traceability and assist in the reduction of label use for environmental and economic reasons.

In the process, no inks or chemical additives, packaging materials, colours, or stickers are used. The laser beam does all the marking work, fruits and vegetables remain completely intact beneath their skin or peel. The natural flavour is also preserved; consumers can simply peel or eat it with the skin or peel, and the shelf life is not impacted.

The economic benefit over plastic packaging and stickers is obvious: On average, a package weighs about 20 grams, plus a sticker for labelling. So, the packaging costs are sometimes even higher than the product costs themselves.

Absolutely! Natural Branding employs this technique to create profitable creative marketing campaigns for a variety of occasions, such as a pattern on a pumpkin for Halloween or an Easter bunny on fruits in April, as well as countless opportunities for the baking and confectionery industries... Each customer request can be handled individually and quickly without incurring additional costs. With the EcoMark software, new logos and text can be easily and quickly created, imported and printed, each user can instantly adjust and react to the ripeness of the fruit or create new products with new logos.

There are numerous possibilities for logos that include serving tips and, of course, QR codes for recipe ideas or other creative campaigns that could go directly on the product… Every time a customer touches the real thing, they might think of a use case they hadn't considered before.

There are various laser strengths available that can be fitted within the machine removing speed as a barrier to entry. The higher the laser power the faster the marking time and if necessary, multiple lasers can be installed in the one Eco Mark machine. The machine has a fast 3D camera that allows for process times of milliseconds. The technology is capable of keeping up with a modern grading or packing facility and some.

The EcoMark machine is available in two model series in terms of technical specifications: Light and Professional, both of which are very simple to operate.

The laser systems of the machines are built on a modular basis. Even the entry-level machine has a conveyor belt, allowing objects to be marked "on the fly," that is, without stopping. The products can be placed individually, in finished packs or boxes, or even put onto the conveyor belt chaotically. The integrated 3D camera detects the position and orientation of the objects to be laser markedcut automatically. There is no need for operator intervention.

The information is transmitted to the laser in a few milliseconds, and each product is marked according to pre-set criteria. Height differences are dealt with automatically with laser focal distance automatically adjusted by motors moving the lasers up or down.

EcoMark's top priority is user friendliness. With a few clicks of the user-friendly software, operators without strong PC skills can independently set up the machine for all new products and logos. The only thing the machine operator has to do is press the start button. Production can be switched over in a matter of seconds. Another product can be called up with a few clicks to keep production flexible and ensures that that the best camera and laser settings are used. As Product characteristics of fruit and vegetables change, due to ripeness, moisture content and age, the software allows you to react to these changes quickly and

The Natural Branding product line is expanding…

Apple, avocado, apricot, banana, grapefruit, kiwi, lemon, lime, mandarin, pear, orange, papaya, peach, passion fruit, coconut, fig, guava, papaw, plum, pomegranate, lychee, mango, corn, capsicum, chilli, cucumber, ginger, garlic, onion, parsnip, tomato, pumpkin, zucchini, to name a few… but not limited to fruits and vegetables only due to numerous reasons and benefits that the Natural Branding can offer…

We must acknowledge that evolving technology is unique and has the potential to have a significant impact on the future of the packaging industry as well as the greatest impact of the carbon footprint we leave. We can help our planet to some extent simply by switching to alternative packaging, natural branding which is no doubts economically more favourable and protects the environment and climate, thanks to Packaging without Packaging.

The EcoMark Natural Branding machine has arrived and been installed in the Result Group's Demo room. Please contact the Result Group to schedule a demonstration session to learn more about the technology.

Oji Fibre Solutions (OjiFS), one of Australasia’s leading producers of market pulp, paper and fibre-based packaging, with aligned logistics and paper recycling services in NZ to help it close the loop on its value chain, opened the doors to its Brisbane facility to Australian Institute of Packaging (AIP) members via a virtual tour.

OjiFS creates shared value by harnessing the strength of sustainably-managed NZ-grown radiata pine to produce quality products that are used every day in households and businesses across Australasia, as well as in 30-plus countries around the world.

Proudly part of the global Oji Group – the fifth largest pulp and paper conglomerate in the world, OjiFS has the stability, strength and support to grow in the Australasian region.

Through the virtual tour on 26 October, AIP members learnt more about the company, how its 10 packaging plants and six distribution centres across Australasia support primary industries, and witnessed how corrugated packaging is manufactured at its 5-Star Green Star-rated packaging and converting facility in Yatala.

“We capture all of our water to reuse within the facility, we’ve got solar panels on the roof to run the facility, and all the materials used in the facility are all sustainably-sourced and certified products,” explained Tim Slade, state operations manager for Queensland at OjiFS.

“The facility itself also has a number of certifications, such as the ISO 9001 Quality Management System, ISO 45001 Health and Safety Certification, FSSC 22000

Food Safety Certification, as well as having FSCcertified paper used in our products."

A few short years since its commencement in March 2018, OjiFS’ Yatala facility now delivers on average 1000 pallets from customers as far away as Coffs Harbour, to Far North Queensland, and over into Darwin.

With a total budget in excess of $100 million, the Yatala facility was designed to service all of the packaging segments across Queensland, in particular, the high-performance applications in sectors such as horticulture, meat, protein and cold chain.

“Beyond the build details themselves, the functioning of the overall site and the business comes down to the capability and dedication of our operational teams, our logistics teams, and our customer service staff,” said Wolf Lorenz, general manager for packaging Australia at OjiFS.

“Over the past two years, that team has managed to deliver products and services of the highest quality standards in the most challenging business environment that we’ve experienced.

“I’m confident that collectively, they will continue to support the business’ objectives, and our future success will be underpinned by our corporate values of partnerships, innovation and future focus.”

The facility utilises OjiFS’ fully-certified FSC papers, liners and mediums to generate packaging solutions that meet the most demanding of applications across both the domestic and export supply chains.

The 35,000sqm facility has been designed with a number of sustainability features, such as utilising stormwater harvesting and renewable energy, as well as a 100 per cent closed loop manufacturing recovery for all production waste.

The site is also fully-food service-certified with safety and food hygiene accreditations in place in order to meet the most demanding applications for direct food contact for its food service clients.

“All of our products are designed to give the optimum pallet efficiencies, so the distribution channels are maximised for ensuring optimised pallet efficiencies during the supply chain,” explained Jason Cairns Lawrence, state sales manager for Queensland at OjiFS.

“Also, the papers we use come from mill in NZ, and they give us high strength capabilities, even in lightweight-grade solutions. The strength of our papers is key to supplying a product that is fit for purpose, fit for export, fit for complicated supply chains, whether frozen or chilled.”

The team at OjiFS work closely with its customers to find out what their requirements are, in order to find a fit-forpurpose sustainable corrugated packaging solution.

“This is achieved by working closely with our skilful and experienced team at OjiFS, who have many years of experience within the packaging industry,” added Sheahan Perera, account manager at OjiFS.

“We also work on value engineering by identifying the need for improvements within the supply chain, which is then collated and analysed by our design team to deliver a better packaging solution for our clients.” http://www.packagingnews.com.au/latest/ojifs-touts-sustainability-efforts-in-site-tour?

PKN talks... Educating the global packaging industry to address sustainability and skill shortages, with Professor Pierre Pienaar, president of the World Packaging Organisation (WPO). In this episode, Lindy Hughson, managing editor & publisher of PKN Packaging News, talks with Pierre about his experiences in the industry, packaging education, achieving and recognising sustainability initiatives, and addressing skills shortages.

We start with Pierre's entry into the Packaging and Processing Hall of Fame in the United States, then look at some of the international recycling projects that are reducing waste and driving sustainable operations. We also discuss the WPO's WorldStar awards, and how the Australia and New Zealand region is regularly punching above its weight. The episode wraps with a review of the causes and impacts of the skills shortage in the industry and how this is being addressed through education programs.

LINKS: Pierre Pienaar enters US packaging Hall of Fame: www.packagingnews.com.au/latest/pierre-pienaar-enters-us-packaging-hall-of-fame WPO marks global day for food loss & waste: www.packagingnews.com.au/associations/wpo-marks-global-day-for-food-loss-and-waste

Click here to listen to the full podcast with Prof Pierre Pienaar

Ball & Doggett is Australia’s largest distributor of printable materials and press consumables.

Our Labels & Packaging division are specialists in working with brands, printers and convertors on the selection of materials for a diverse range of market sectors. Our products are backed by our specialist teams including dedicated sales and technical support.

We are a trusted partner for brands as they journey to explore more conscious materials choices for their products and how this represents them through the lens of their consumers.

Ball & Doggett are the market leader in supplying materials to the Graphics and Communications industry.

We turn big ideas into reality.

four Sherpa,” product

Brett echoed this trend by adding, “It’s something we’ve seen from the outset at Whakatane Mill, after we moved away from producing liquid packaging board back to carton board, we’ve experienced an immediate and significant increase in demand for our products.”

As Australian businesses continue to recover from the global pandemic, the challenges of supply chain remain a significant issue for SMEs with more than one in four citing supply of stock as an issue for their operations, according to new research from NAB.

comply Article by Josh Gleeson Marketing Executive

Article by Josh Gleeson Marketing Executive

Article by Josh Gleeson Marketing Executive

Formakote™ family covers four distinct board grades:

Consumers are now all too aware just how fragile supply chains can be in the face of a health crisis, natural disaster or international incident. Ball & Doggett is certainly not immune from the pressures of global supply chain disruptions when sourcing materials from offshore locations.

Whether it is packaging for Quick Service Restaurants or Supermarket shelves, Formakote™ White is the ideal choice, and has inherent grease resistance layer for food end users. For more information on our range: https://bit.ly/3OTgq9Y

Strong relationships with local suppliers can help ease the effects of global pressures and minimises supply chain disruptions. Our enduring partnership with Whakatane Mill Limited – the region’s only carton board manufacturer – has allowed us to do just that, to the benefit of our customer base.

Formakote™ Natura your everyday packaging needs, Formakote™ Natura provides great value and performance. Available as hard sized for chilled and can also be supplied with grease resistance. For more information on our full https://bit.ly/3SnqLh9

strength and stiffness are critical, Formakote™ Spectra covers all the options and supplied with grease resistance. For information on our full range: https://bit. ly/3SeJZ8V

We caught up with Brett Keen, Sales Manager ANZ, Whakatane Mill Limited, at PacPrint, during his recent visit to Melbourne, to chat all things Formakote™ – the iconic carton board range – and present him with our newly created swatch book.

Formakote™ is our safe, flexible and sustainable carton board product, manufactured with unparalleled expertise by the FSC certified mill, located on the east coast of New Zealand’s north island.

Formakote™ Sherpa name implies, Formakote™ Sherpa tough and durable for any carrier-board application. Sherpa has high wet strength attributes, important for wet or chilled environments. For more information on our full https://bit.ly/3BDDyGm

range under the Formakote™ banner, offering four board types, Natura, White, Spectra and Sherpa,” explains Brett Keen.

Doggett are continuing to see a very increase in demand for our fibre-based products as more brand owners seek substitution solutions for plastic packaging, where fibre-based alternatives are fit for purpose.

echoed this trend by adding, “It’s something seen from the outset at Whakatane Mill, we moved away from producing liquid packaging board back to carton board, we’ve experienced an immediate and significant increase in demand for our products.”

for optimal performance and the greatest product safety. It is made with a 3-layer structure that combines locally produced virgin kraft pulps and mechanical fibres. They are clay coated to meet the requirements of end users such as FMCG, beverage carrier boards and food services." with stringent food contact requirements.

The Formakote™ family covers four distinct carton board grades:

Whether it is packaging for Quick Service Restaurants or Supermarket shelves, Formakote™ White is the ideal choice, and has an inherent grease resistance layer for food service end users.

For your everyday packaging needs, Formakote™ Natura provides great value and performance. Available as hard sized for chilled food, and can also be supplied with grease resistance. For more information on our full range: https://bit. ly/3SnqLh9

The Formakote™ Swatch Book is available now through your local Ball & Doggett representative.

Formakote™ Spectra

When strength and stiffness are critical, Formakote™ Spectra covers all the options and can be supplied with grease resistance. For more information on our full range: https://bit. ly/3SeJZ8V

As the name implies, Formakote™ Sherpa is tough and durable for any carrier-board application. Sherpa has high wet strength attributes, important for wet or chilled environments. For more information on our full range: https://bit. ly/3BDDyGm

The Formakote™ Swatch Book is available now through your local Ball & Doggett representative.

The Formakote™ Swatch Book is available now through your local Ball & Doggett representative.

The Formakote™ Swatch Book is available now through your local Ball & Doggett representative.

It’s about the conversation, the collective impact and sharing important information pertaining to sustainable packaging.

As a business Ball & Doggett’s focus is on People, Products, Planet which demonstrates their commitment to sustainable business practices.

The conversation around sustainability is broad, with layers of complexity as we all come to understand within our industry how to best improve our own understanding of sustainability. As distributors they are in a position to partner with customers to support their sustainable pathways.

Welcome to ecoporium by Ball & Doggett , The Destination for Sustainable Packaging. ecoporium by Ball & Doggett is a brand that has been developed into a resource through a website platform. Created to educate and inform the market on their Labels & Packaging range and share knowledge with sustainability in focus. The Ball & Doggett team have interviewed industry and sustainability practitioners, specialists, curators of packaging brands, customers and suppliers on how they view sustainable packaging through their lens. These conversations are pertinent to share with the market as we all navigate this pathway.

The very first podcast launched was with John Bigley MAIP the CEO of Zipform Packaging who is also the Vice President of the AIP.

The second podcast was with our very own Executive Director, Nerida Kelton MAIP who also touches on some of the work she is undertaking in her WPO role.

Sustainability is at the core of good business practices and Ball & Doggett value being part of the collective making an impact and creating shared experiences to reduce impacts on the environment. For further information about ecoporium please contact Zaidee Jackson, National Business Development Manager – Sustainable Packaging, Ball & Doggett zaidee.jackson@ballanddoggett.

All members are invited to attend any events across Australasia

The team at Martogg, along with industry partners recently conducted a bale audit on site to understand the components that make up a PCR PP bale from kerbside recycling.

WHEN: 23 Feb to 3 March 2021

WHERE: Dusseldorf, Germany

WHAT: Internationally the most important event in the packaging sector and the related process industry, interpack will be held at the Düsseldorf Exhibition Centre. Both exhibitors and visitors can look forward not only to an entirely new Hall 1 and a new Entrance Süd but they canalso benefit from an overall clearer hall structure with even more sharply focused segments. This means even shorter distances thereby making for more efficient trade fair visits.

Interpack’s unique selling point is its distinctive solutions package and coverage of entire value chains. This includes processes and machinery for the packaging and processing of packaged goods plus packaging media and materials and the manufacturing of packaging aids as well as services for the packaging business.

The last edition of interpack attracted 2,866 exhibitors and 170,899 visitors from 168 countries and thanks to busy orders from three-quarters of the decision-makers among them made for significant impulses in the sector.

WHEN: 20 to 30 April 2021

WHERE: Dusseldorf, Germany

WHAT: There is no other industry event that hassuch great international appeal as the leading trade fair forprinting technologies. More than half of its visitors cometo drupa with specific investment projects.

drupa provides crucial impulses for print, media, packagingproduction, and industrial applications – especially in thevertical markets as well. The world’s leading trade fairfor printing technologies offers outstanding networkingopportunities and potential for excellent business dealings.This is where innovations are brought into the market, newbusiness models are developed, and new partnerships areformed.

drupa is an international magnet for visitor target groupsfrom a wide variety of industries. In addition to the printingand packaging industry, there are also groups from verticalmarkets such as consumer goods, luxury goods, cosmetics,bank and safety technology, and many more. More thanhalf of its visitors come to drupa with specific investment projects. AIP Members to receive discounted visitor tickets.

Are your packaging artwork processes up to scratch? There’s a whole raft of improvements to the process that putting a digital packaging solution in can help with. Want to learn more? Talk to Esko.

www.esko.com

info.oce@esko.com

As the sun rose on Monday 3rd October, the world lost a beautiful man. Tom Hart-Davies MAIP fought cancer fiercely and with unshakeable positivity for the past 16 months.

Tom was adored by all, especially his four daughters, two grandchildren and wife, Jacky - everyone who knew him knew what an amazing man he was. He bounced out of bed every morning and lived his life for those around him. Tom loved his job, he was passionate for making change, ran a business based on family values of empathy, honesty and compassion; and his employees and clients were his friends.

Everyone who knew Tom was instantly drawn to his warm and generous nature, always witty and could certainly spin a compelling yarn. The life of every party and always there to lend a hand or give the calmest advice.

There are no words that could describe the impact Tom had on all of our lives. A role model, an anchor to all, an adoring father, the most loving husband, the wisest man we will ever know. One of a kind.

No amount of time would have ever been enough with you, Tom.

In recent months, Tom was delighted to introduce his youngest daughter Clare to the company. Tom loved nothing more than seeing his legacy live on through his family - the team at Retailquip, Clare and her family will endeavor to provide the same level of ingenuity, service and integrity that Tom was so so proud of.

The ProPack.pro Podcast: Sustainability leads the direction for Close the Loop Group

C l ose the Loop Group recently won several awards at the 2022 Australasian Packaging Innovation & Design Awards (PIDAs), which was organised by the Australian Institute of Packaging (AIP).

Close the Loop Group marketing manager Jessica Ansell AAIP sat down with ProPack.pro in our podcast to talk about how sustainability is ingrained into every one of its products and how it leads the company’s current and future direction.

Click

The Production Packaging Innovation (PPI) team finally had the oportunity to celebrate their three PIDA award wins as a team.

AIP President Scholarship winner Azadeh Yousefi AAIP has finally received her plaque.

The internationally recognised

Fundamentals of Packaging Technology

are available exclusively through the AIP in Australasia. The FPT Course is set up for the convenience of busy working professionals, and the training platform is functionally intuitive. The beauty of the FPT course is that you only have to undertake lessons as you need to fill knowledge gaps so you can complete your training when your time allows, and at your own pace. Take the complete course and learn about all the major segments of packaging or customise your packaging training for your specific needs.

Wherever you are, the course goes with you.

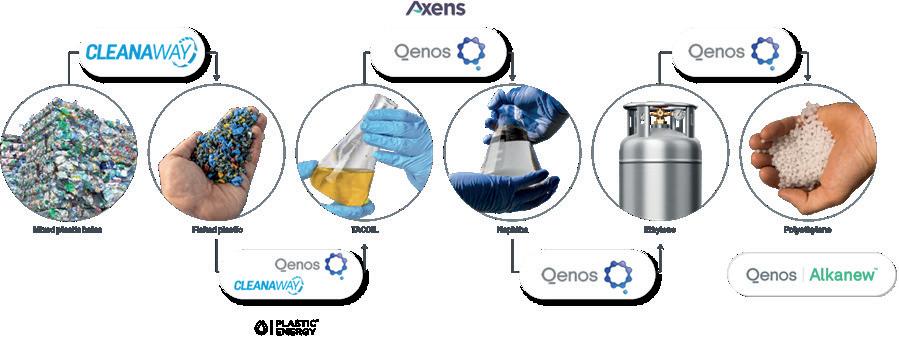

Alkanew by Qenos is the new industry solution helping Australia reach its plastics recycled content targets.

Australia’s Qenos is well down the track of creating a new advanced circular plastics recycling manufacturing chain that would be a major step change towards meeting local circular plastic packaging targets.

David Francis and Jeroen Wassenaar from Qenos were recently interviewed by John Richardson from Independent Commodity Intelligence Services (ICIS) about the Qenos Circular Plastics Project. The article here has been adapted from this interview first published in ICIS Chemical Business 22 July 2022.

The country’s only cracker operator and polyethylene (PE) producer is conducting a joint feasibility study with Cleanaway, a leading Australian waste management company, to convert 100,000 tonnes of plastic waste into circular PE.

Plastic Energy, the UK-based advanced recycling technology provider, has been chosen by Qenos to support the pyrolysis technology assessment for the proposed project. The project would cost several hundred million Australian dollars.

France’s Axens will evaluate the use of its Rewind Mix process to upgrade the pyrolysis oil from the proposed new plant to the right quality of naphtha to provide some of the feedstock for Qenos’ cracker at Botany Bay in New South Wales.

The project’s feasibility study is expected to be completed by the end of this year with a final investment decision due next year. Start-up would be in phases starting in late 2025.

It is estimated that eventually the equivalent of a total of some 60,000 tonnes/year circular PE, branded as Alkanew, would be generated by the project.

“The scale of our project is somewhat dictated by how much can we fit into our cracker without having to reject any conventional feedstock,” said Dr Jeroen Wassenaar, Circular and Renewable Plastics Manager at Qenos.

“If you back calculate from the yields, the result is about 100,000 tonnes of plastic waste feedstock per annum being fed into the cracker,” he added.

He said that there was no single Australian waste management company that had the quantity or quality of feedstock required. However, Qenos has partnered with Cleanaway to source feedstock across the wider waste management industry.

Cleanaway has local mechanical recycling joint ventures with the Pact Group, an Australian converter, and brand owners Asahi Beverages and Coca-Cola Europacific Partners.

Plastic waste fed into the pyrolysis unit would be mainly PE and polypropylene (PP) that is not suitable for mechanical recycling such as post-consumer soft plastics.

The Australian Packaging Covenant Organisation (APCO), a non-profit organisation promoting recycling, has also set targets to reduce PVC content in flexible packaging to make recycling easier.

APCO has introduced guidelines that will by 2025 reduce the use multilayer laminates that contain PET, polyamides and polyvinylidene chloride (PVDC), which is used as an oxygen and water barrier, especially by the meat and dairy industries.

“There might still be some unsuitable laminates by 2025 because there could be some applications where replacement is difficult, but we won’t be seeing the quantities we are seeing today,” said Wassenaar.

Trials for collecting soft plastic from curb sides have been carried out by Cleanaway and the City of Melbourne Council.

“Organic waste can be tolerated to some extent in the pyrolysis process, but one of the issues with organic waste is water. Most food is water. There is a drying step required during pre-processing,” he continued.

Cleanaway is designing an end-of-life plastics treatment facility to make sure Qenos ends up with the specifications it needs.

On the Australia eastern seaboard alone, there is probably around 1m tonnes/year of suitable plastic waste.

“Because of losses in the feedstock preparation process, you will probably have to source 150-200,000 tonnes of plastic waste a year to get the targeted 100,000 tonnes/year of actual feedstock,” said Wassenaar.

Another challenge is that there is currently no source separation at kerbside for difficult to recycle plastics such as soft plastics, which means they largely end up in landfill. Recent announcements by the Victorian government to include soft plastics in commingled kerbside collection and the National Plastics Recycling Scheme (NPRS) spearheaded by the Australian Food and Grocery Council, provide confidence that the required feedstock volume will be available by the time the Qenos project is ready for start-up.

Some advanced recycling technologies are geared toward the production of transportation fuels that obviously end up generating carbon when they are combusted in engines.

But Qenos says that the Plastic Energy process produces a single fraction of pyrolysis oil that can be upgraded, using the Axens technology to 100% naphtha.

One of the other criticisms of chemical recycling is that it is energy and therefore carbon intensive.

But Qenos contends that life-cycle analyses by BASF, Plastic Energy and the Consumer Goods Forum, show that the project will be relatively carbon efficient.

“The studies are all consistent. Compared with producing virgin PE, the reduction in the carbon impact is about 50%,” said David Francis, General Manager Sales, Marketing, Product Technology, Strategy at Qenos.

“Because you are not producing fossil feedstock, with all the connected carbon output, this provides carbon credits,” he added.

“The big message we are trying to communicate on this project is that we’re looking for complete circularity.”

There is also the contribution that the project would obviously make in reducing plastic waste.

In July last year, Australia banned exports of plastic waste, leading to a bigger local disposal problem.

National Packaging Targets have been set by industry and the government with a target date of 2025. APCO has been given the responsibility of helping ensure the targets are met, which are as follows:

• 100% reusable, recyclable or compostable packaging.

• 70% of plastic packaging being recycled or composted.

• 50% of average recycled content included in packaging (revised from 30% in 2020).

• The phase out of problematic and unnecessary single-use plastics packaging.

But Francis contends that individual brand owner targets recycled content are a bigger challenge which cannot be met by mechanical recycling alone – hence, the need for circular plastics.

“You cannot provide all the food-grade materials required by brand owners from mechanical recycling alone if you have, say, pledged to do 30% recycled content in your packaging and your business is packaging food,” he said.

“The biggest challenge is getting access to feedstock that’s on-spec. The second challenge is accessing technology that works and integrating the feedstock into our plant to deliver the yields we are looking for,” said Francis.

The third challenge was getting customers to commit to buying the product which would not be sold regular PE prices, but instead a multiple higher, he said.

“This is a new ecosystem, a new industry and a new product which will remain scarce at least for a decade or so. Our proposal to our customers is around a fixed price not linked to oil, with committed offtakes ,” added Francis.

Qenos has held numerous discussions with government officials at the state and federal levels on the benefits of the project, and the Victorian state government is partly sponsoring the feasibility study.

“We certainly have backing, and we are confident we have a solid business case that is worthy of government support,” said Wassenaar.

Australia’s manufacturing industry has long struggled against cheap overseas competition, often heavily subsidised by governments, and high labour and energy costs.

The eastern states are in the middle of an energy cost and supply crisis.

This is the result of the surge in natural gas costs and tight global supply resulting from the Russia-Ukraine conflict, along with insufficient gas reserved for local supply from the country’s LNG projects. The Qenos project therefore represents a bold, imaginative and very smart attempt to add economic value in a difficult competitive environment.

Given the well documented limitations of mechanical recycling in providing food-grade material, beyond the PET resins sector, a local circular plastics value chain would help local brand owners hit their recycling targets.

With a diminishingly small chance that brand owners will back away from their targets because of strong legislative and public pressure, solutions need to be found.

It estimated that the Qenos project would over the long term generate $350m of annual revenues across the whole of this new manufacturing chain and 3,100 new jobs.

Foodloss and waste statistics in Australia are simply staggering.

A total of 7.6 million tonnes of food is wasted across the supply and consumption chain each year, costing the economy $36.6 billion. This waste equates to 312kg per person, one in five bags of groceries, or between $2,000 and $2,500 a year dumped in the bin and ending up in landfill.

These issues involve all parts of the value chain, from paddock to plate, so everyone needs to play a role.

There are many ways food and beverage manufacturers can play a role, but a key contribution is through the packaging they design and use.

Packaging has always played a critical role in containing, protecting, preserving and transporting a product from point of production to the household. But now more than ever it needs to ensure health and safety, extension of shelf life, tamper evidence, traceability, recall capabilities, temperature monitoring and the ability to minimise food loss and waste wherever possible across the value chain.

The good news is that we are starting to see more packaging that is intelligent, intuitive, accessible, inclusive, sustainable and offering lower environmental impacts.

So many of the winners in the 2022 Australasian Packaging Innovation & Design Award (PIDA) have designed

packaging that can provide significant benefits to minimise food loss and waste from paddock to plate. It is extremely encouraging to see that Save Food Packaging is increasingly on a packaging technologist’s radar and that food and beverage manufacturers are now designing packaging that can minimise or prevent food waste.

Thermochromic dye technology, temperature monitoring systems for food and beverage, 2DBarcodes for meat, traceability systems for exported premium grapes, accessible and inclusive ready meals for chicken and dunnage for exporting meat are just some of the new Save Food Packaging designs that stood out at the 2022 PIDA Awards.

ThermoShield, developed by Caps and Closures, is an optical system, meaning the packaging will dynamically change its colour appearance at a preselected temperature switching point.

Based on thermochromic dye technology that changes colour as the environment changes, the system allows for more than two colour changes (eg, black to orange to red) as the packaging gets warmer, and the reverse as the temperature drops through the selected switch

temperatures. The design can also allow for ‘locking’ of the colour when the temperature rises above a set temperature, changing colour permanently.

This feature finds applications where a particular temperature renders the contents unusable. This can be especially useful in tracking cold chain (refrigeration required), perishable food or beverage, to extend retail display and home refrigerator shelf life, which ultimately reduces food waste. ThermoShield is useful in transport and warehousing because the over-temperature stock can clearly be seen.

ThermoShield ensures that the packaging can alert logistics managers, warehouse staff and consumers to instances where temperature sensitive products are being, or have been, exposed

to higher or lower than acceptable temperatures.

Traceability of any product is enhanced when temperature excursions are detected, and the level of resolution can be from the macro level (transport container temperature), down to discrete (the individual product) packaging. Using the locking function available, a record of overheating is permanent and will be identified after a long road or sea shipment.

Stock can easily be sorted to remove damaged product prior to warehousing or stocking shelves. This innovative technology has the potential to significantly reduce food loss and waste due to incorrect temperature control at various stages of the logistics path from paddock to plate.

The community of farmers behind the Waitoa brand are at the forefront of free range, Toitu Carbonzero™ certified chicken farming in New Zealand. Here, respect for nature comes naturally and sustainability drives decisions.

The Inghams Waitoa Free Range Butterflied Chicken is a pre-marinated product that transforms the consumer experience and eliminates the need for consumers to handle raw chicken and marinate themselves, which can often be a source of food waste. The pre-marinated range comes with an easy open tear notch, a user-friendly cooking experience and the ability to

freeze the product. These features mitigate waste in households which accounts for approximately 50% of all food waste.

Additional consumer engagement and information is included on the pack via instructions for storage and cooking, a callout that the chicken can be frozen, and scannable QR code accesses meal inspiration ideas.

The packaging has been developed in partnership with Sealed Air NZ using Cryovac technology that increases shelf life by 40% to 14 days. The packaging incorporates 80% recycled content and is Australasian Recycling Label (ARL) return to store recyclable.

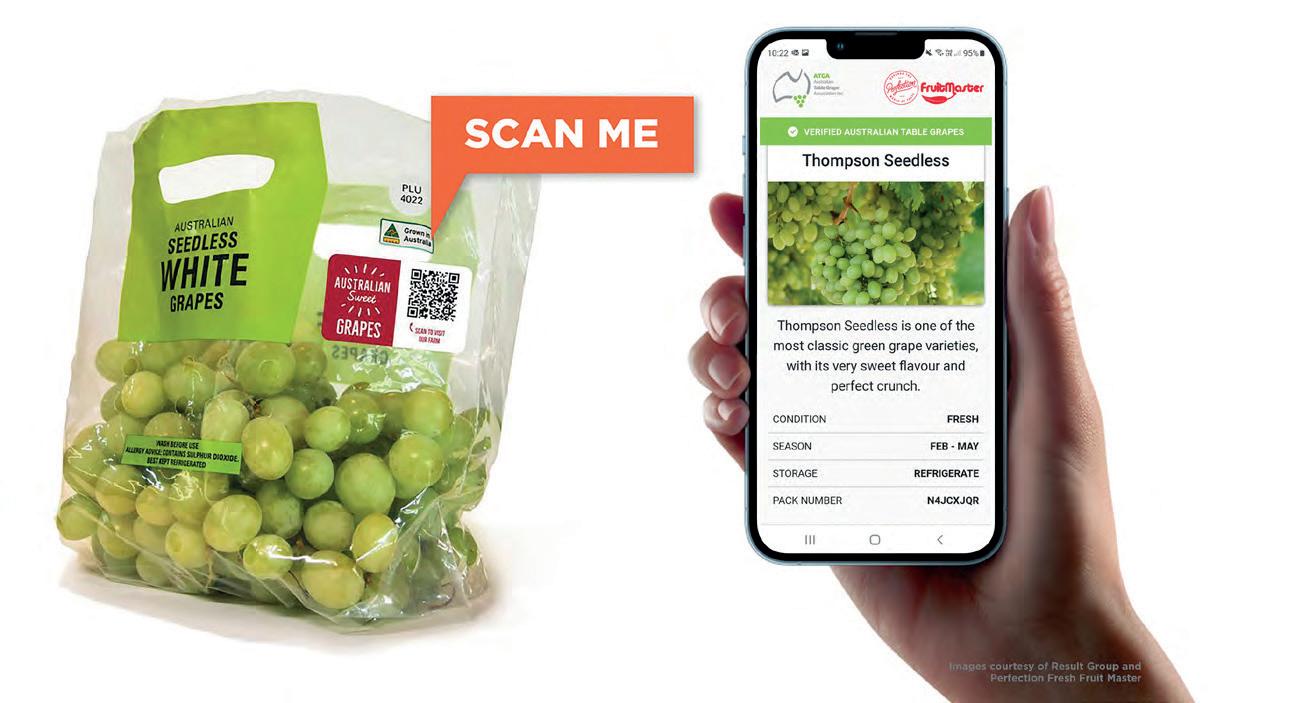

To address the need for greater transparency within the industry, the Australian Table Grape Association (ATGA) worked with Result Group and Perfection Fresh to launch a new traceability system for export table grapes.

Since grapes are highly sensitive to impact due to their relatively thin skins, they must be handled with appropriate care. High temperatures and low humidity cause water loss from the grapes and stems, which ultimately increases the rate of deterioration which in turn reduces shelf life.

Maintaining the cold chain with proper cooling, storage and monitoring can extend the shelf life of grapes and ensures minimal product waste. In addition, active packaging was developed that comprises releasing/ emitting properties to inhibit spoilage

caused by microbes. The packaging not only protects the table grapes but also extends shelf life.

Each pack has a unique identifier QR code that provides a convenient and actionable way for consumers to access real-time information about the product. The code can be scanned by a smartphone and provide information about the product’s origin. The applied unique serialised GS1 Digital Link-enabled QR code allows the automated collection of data from paddock to plate. The Active Digital Identity (ADI) embedded in the QR code label ensures each item is unique and traceable; an important innovation in combatting food fraud. Each label carries critical international traceability data, based on GS1 standards, covering consumer pack units, cases and pallet codes, as well as time and temperature logging, which are captured through the EVRYTHNG Product Cloud database. Using GS1 standards future proofs the table grape industry for evolving traceability regulations in export countries.

Real-time temperature sensors are placed in all cartons and shipping containers for temperature monitoring. With a temperature monitoring system, Perfection Fresh can easily track, control and regulate a product’s temperature in a specific environment. The sensors log temperature levels at every step of the way during transport from farm to overseas retail outlet, and alert the brand owner whenever temperatures are registered outside preset levels.

During the shipping process quick action can occur to correct temperature levels and avoid product waste. The setup alerts included temperature, humidity and location.

Traceability is at the heart of the ATGA Table Grapes project which effectively manages product beyond the loading process, enhances tracking of produce through the supply chain and takes the consumer along the journey with the brand.

Chilled meat products are typically vacuum sealed and placed in boxes that are stacked in export shipping containers. Without the necessary dunnage support, these boxes frequently move in the containers during transportation and can lead to product spoilage and food waste, which is costly for meat and food processors. Whilst current solutions in the market are designed to limit box movement, they tend to be constructed from Expanded Polystyrene (EPS) material, which is not ideal from a sustainability and recyclability perspective at point of destination.

The JBS & Opal Dunnage Solution is a column-like corrugated structure to limit product movement during container transportation of meat exports and offers a direct replacement for the non-recyclable EPS version. The JBS dunnage solution is made using corrugated cardboard that consists of 64% kraft paper and 36% recycled cardboard

content and is fully recyclable. JBS export customers can easily recycle with the rest of their used cardboard packaging. The cardboard dunnage can also be assembled at JBS in less than 30 seconds from a flat sheet.

Woolworths are the first Australian Retailer to invest in 2DBarcode labelling and, with 20 million customers shopping every week, the technology can offer significant efficiencies that minimise food waste.

The 2DBarcodes are currently applied to 50% of the Woolworths meat range in more than 1,000 stores across the country and the program has seen a 40% waste reduction in this category.

Having the best before date in the 2DBarcode enables store teams to easily and quickly identify if a product is approaching its expiry date and mark it down, so the product can be sold without having to be disposed of. The technology also allows for more targeted and accurate product recalls, saving food from unnecessarily being sent to landfill.

2DBarcodes provide operational benefits in the areas of quality assurance and traceability, by encoding information such as confirmation of production time, the line food was produced on, the carton number the food was assigned to, the pallet number and inventory location of the food and when the food was shipped.

The encoding of a product’s batch,

lot and/or serial number into a 2DBarcode can assist in identifying any products that need to be recalled or withdrawn from shelf. The beauty of the 2DBarcode is that it can quickly and easily track and trace the items anywhere within the value chain. This benefit ensures that any unaffected products can be saved from the recall and remain on shelf for sale.

Since implementing the program, Woolworths has seen improved date code management so food can be sold without having to be disposed of, a 44% improvement in out-of-code dumps and stock adjustment and a 21% improvement in productivity.

Whilst all of the Save Food Packaging innovations mentioned are designed differently, they offer commonality in intuitiveness, intelligence and outcomes that can potentially minimise food loss and waste across the value chain. The environmental benefits of designing Save Food Packaging can be significant and measurable, and we encourage all food and beverage manufacturers to consider what changes they can make to their packaging at the start to ultimately reduce food loss and waste across the value chain. Every design change can make a difference.

Nerida Kelton MAIP is Executive Director of the Australian Institute of Packaging (AIP) and Vice President – Sustainability & Save Food of the World Packaging Organisation (WPO). f

Incorporating Renewable Materials is just one of the ten principles within the Sustainable Packaging Design Guidelines that help companies and packaging technologists to design sustainable packaging that will meet the 2025 National Packaging Targets.

So what are Renewable Materials?

Well, they are materials made of natural resources, composed of a biomass from a living source, that can be sustainably grown and replenished continuously. There are a number of renewable materials available for packaging including sugarcane, bagasse, corn starch, wood fibres, bamboo, cotton, straw or biopolymers from a sustainable source.

Renewable materials, if sustainably grown and certified in the country in which the packaging is sold, can potentially offer lower environmental impacts than non-renewable alternatives. Undertaking a Lifecycle Assessment before you shift your packaging to renewable materials is paramount to ensure that the choice of material is an appropriate alternative. Another important factor in selecting renewable materials is the End of Use (EoU) of the packaging. i.e., will the packaging be able to be reused, recycled, or composted?

In addition, it is recommended that all renewable material packaging is verified to local and international certifications such as Forest Stewardship Council (FSC); the Program for the Endorsement of Forest Certification (PEFC) for timber/cellulose-based materials. Other renewable fibre and biobased materials will need to be certified either home compostable AS58102010 or commercially compostable AS4736-2006. It is also important

that renewable fibre-based packaging is certified to have ‘no added PFAS’, as this treatment is commonly used for water and grease proofing. Packaging that is certified to these standards will confirm to consumers that there are no forever chemicals or potential toxins in the material and that the pack can be reused, recycled, and/or composted in the correct environmental conditions.

Some of the recent winners of the Australasian Packaging Innovation & Design (PIDA) Awards are using renewable materials in the packaging including Australia’s Most Sustainable Milk Cartons (Brownes Dairy) and FSC Rectangle Paper Containers (BioPak).