5 minute read

Drive Aviation maintenance efficiencies with SAASbased fleet planner.

Case Study of

— which will be essential to realizing our objectives. You cannot rely on just the primary Plan A, but IFS Fleet Planner enables users to simulate various plans by changing parameters.

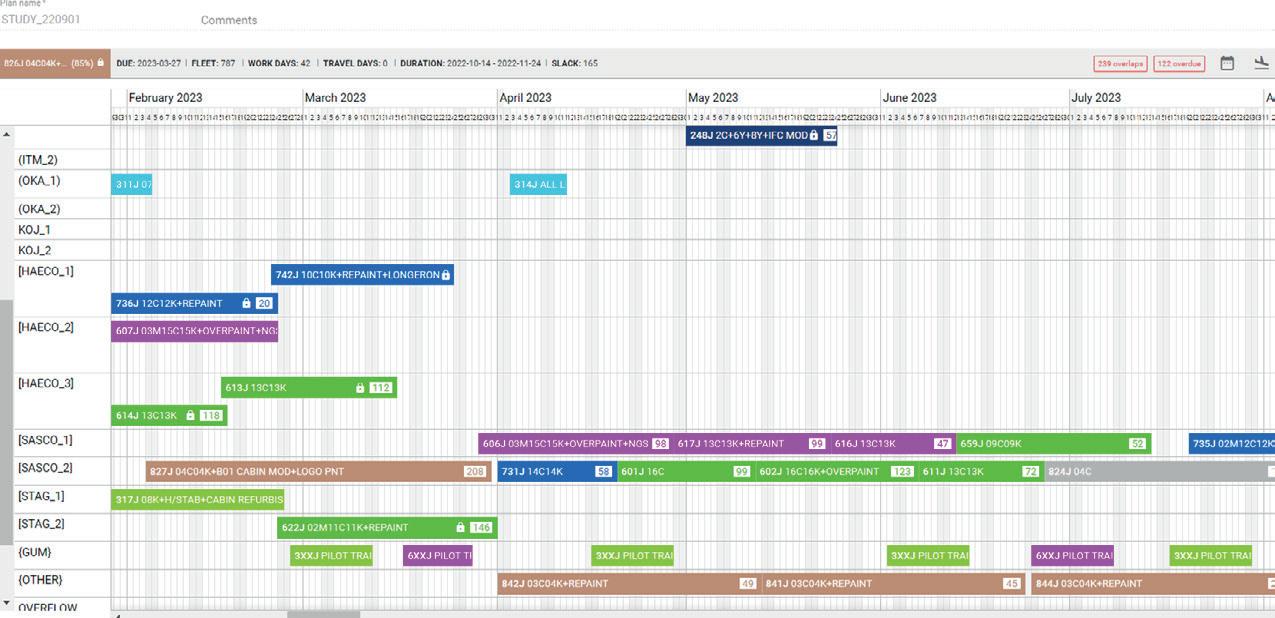

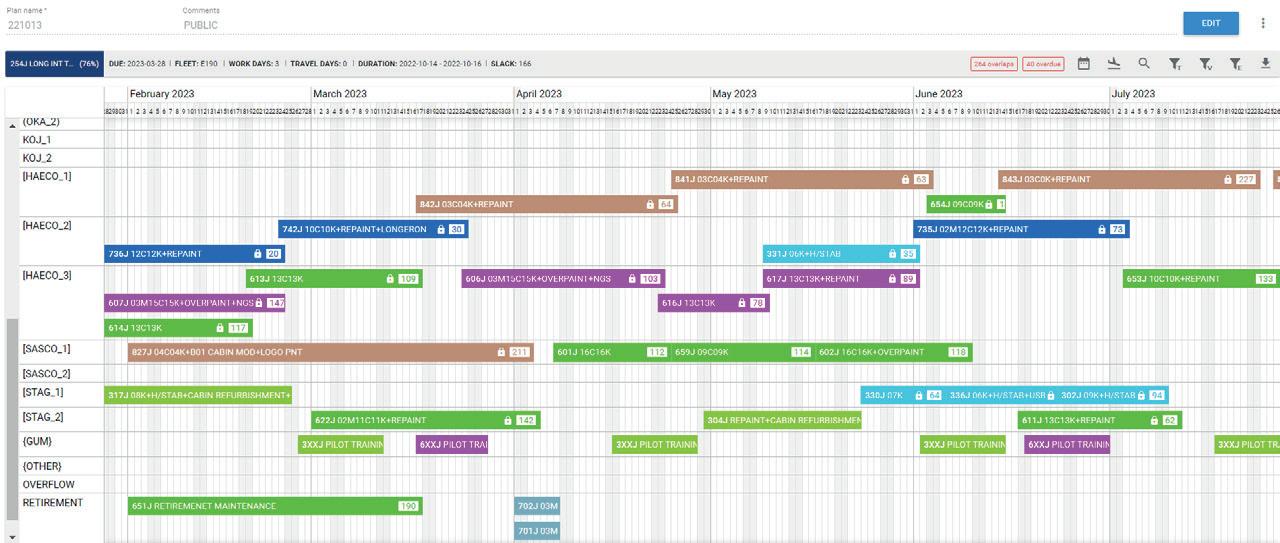

In figure 5.1 you can see a primary plan or Plan A which is the optimized plan.

Case Study of JALEC

Primary Plan ”A” ~Optimized Plan~

This is a snapshot of JALEC’s actual operation. MRO X1, X2 and X3 means that those tasks are outsourced to certain MROs but we have to consider what if there was some risk in outsourcing to this country’s operation, hence the red box around those tasks. If some problem, such as a resurgent health problem, was to occur in the area, we might need to suspend outsourcing to those MROs; so, we need to have alternative plans. We can do this with Fleet Planner by quickly changing the parameters (figure 5.2).

Although this is just a simulation, it shows what can be done in a short time with Fleet Planner by changing the parameters. We can make a Plan B for if we had to suspend outsourcing to these MROs in which case, we’d have to change other plans for heavy maintenance. IFS Fleet Planner will make those other plans: also, we can introduce other parameters to easily make a Plan C or Plan D. That gives us the option to choose an appropriate plan depending on the situation. It is possible to confirm various data and the feasibility of a plan with outputs from multiple simulations which also helps to establish strategies and manage costs. This enables us to maintain a stable and efficient operation while avoiding risks which is one huge advantage to be gained from using Fleet Planner.

Yield management

Yield Management

Case Study of JALEC

Yield is calculated as the planned time from the last maintenance event divided by the maximum required interval (figure 6.1).

Yield = Planned time from last done(Act) / Required Interval(Max) increase the yield from, say, 95 percent to 96 percent, i.e., by one point, that makes it possible to release 33,000 man-hours for work that needs to be done in the year because maintenance cover is extended. That means that the aircraft can be utilized 66 more days in the year. So, if you increase this yield by more points, as shown in figure 6.2, you can utilize aircraft in the fleet more through the year and reduce the total amount of work that needs to be done. This is a very big advantage of using IFS Fleet Planner to manage the yield of the maintenance work. Of course, it depends on how to use Fleet Planner as we need to manage and adjust the plan based on this KPI, but if you use Fleet Planner as we do, it will generate more opportunities to gain man-hours and increase the utilization of the aircraft.

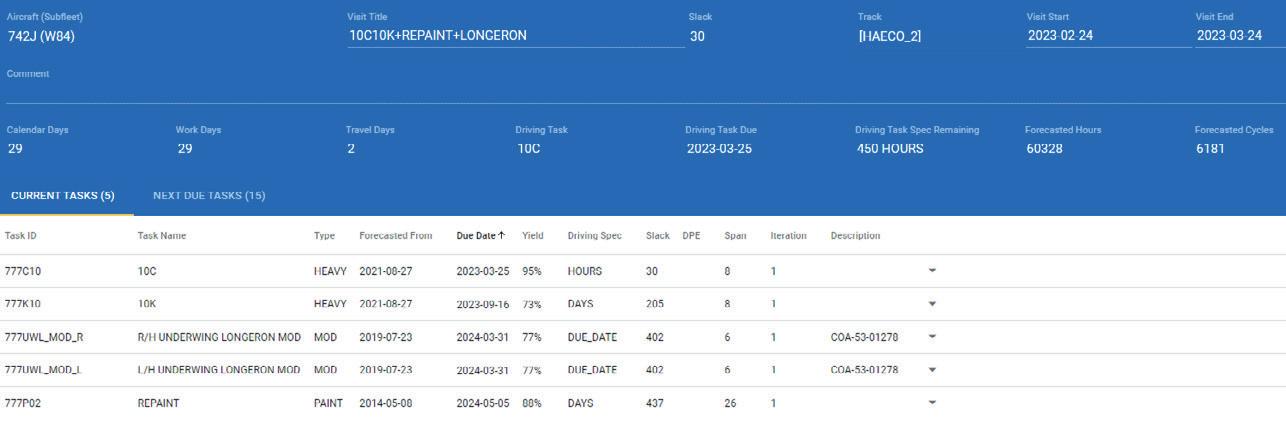

Innovative planning

IFS Fleet Planner can build a work package with multiple heavy maintenance tasks. Figure 5.1 shows an aircraft, 742J, with the visit title reflecting the package of maintenance work to be undertaken by HAECO in China. Fleet Planner can show that this 10C package is yielding 95 percent while the 10K package is yielding 73 percent. So, JALEC monitors and controls this yield as a KPI (Key Performance Indicator) in our operation.

Figure 6.2 shows actual data from JALEC’s operations.

Actual Yield will always vary because of the operational circumstances. JALEC monitors and manages Yield as a KPI, to optimize the cost.

In JALECʼs case, Fluctuations of Yield affect MH and Aircraft Utilization.

This is very easy to understand. IFS Fleet Planner is a Cloud-based system so that it can be used anytime, anywhere in the world. It’s easy to share information between team members. My team at JALEC have built a Pit-Board in the office to share various data including the Fleet Planner and other operational data such as weather analyses.

Using Fleet Planner provides the opportunity to improve the yield.

The actual yield will always vary because of operational circumstances, which was especially the case during the COVID-19 period. So, at JALEC, we monitor and manage yield as a KPI in order to optimize the cost in all cases. In the case of JALEC, fluctuations of the yield (center column of figure 6.1) mean that, if we can

Any time that they get together in front of the Pit-Board, the team can share ideas and maybe get together in a Scrum. This is in line with a Japanese expression that two heads are better than one so five heads must be incredible! The Pit-Board brings innovation to your plan.

Workload mitigation

Another one that’s easy to understand. Before we introduced IFS Fleet Planner, we made the heavy maintenance plan using Excel spreadsheets. That was time-consuming as a manual process with significant risks for human error. Any coloring to identify different tasks had to also be done manually and, if someone wanted to share information, they’d have to send an email with an attached file. It added to workloads and was a headache.

After introducing Fleet Planner, one person is able to complete the same volume of work for the 200 aircraft, where previously it would have needed two. Not only that, but also the business quality is improving, is more flexible and is taking less time. We can get information quickly and, if anyone is working from home, it’s easy to share with colleagues in real-time. It means that everybody is healthier and is happy.

In Conclusion

The introduction of IFS Fleet Planner has empowered our people to be more innovative and the robust plans produced by our innovative planners give us confidence to manage the operation. Having a stable operation contributes to our passengers’ experience, improves how we work with customers and empowers us to continue to evolve. In other words, IFS Fleet Planner provides us with a route to realize that 0-0-100 target.

At the time of writing, IFS is developing additional parameters which JALEC has requested to further improve the capability available within our existing solution. We are increasingly realizing the potential that fleet planning engineers can gain from IFS Fleet Planner.

Atsushi Kita

Atsushi Kita has worked in JAL/JALEC for twenty years, now mainly for maintenance planning and corporate strategies. He has supported customers as Director of Sales and Marketing of JALEC. Also, he has represented JALEC at ‘ATEC’, an association which is comprised of Japanese aviation companies, to develop and improve Japanese regulations working with the Japanese authority.

JAL ENGINEERING CO. (JALEC)

JALEC is an MRO business 100 percent owned by Japan Airlines with 4,000 engineers and mechanics working across three main bases. The business has certifications in 17 countries and regions and is responsible for managing 200 aircraft for four operators in the JAL group, as their airline maintenance department. Also, JALEC provides MRO services for fifty customers include, line maintenance, base maintenance, engine shop, component shop and training.

Ifs

IFS is a provider of software solutions for global aerospace & defense (A&D), whose solutions support a complete spectrum of maintenance management capabilities from heavy MRO to line maintenance. IFS’s innovative enterprise solutions empower A&D organizations to quickly adapt and manage change whilst delivering bottom-line value, increasing efficiencies and cost savings, and safeguarding compliance. IFS customers include BAE Systems, Lockheed Martin, General Dynamics, SAAB, GE Aviation, Pratt & Whitney, HAL, Emirates, LATAM, Qantas, China Airlines, Air France-KLM, and Southwest Airlines.