OFFICERS

STANLEY USERY, President, Athens *

RYAN TURNER, Vice President, Guntersville *

STEVE SMITH, Treasurer, Hanceville *

CHARLIE PEACOCK, Secretary, Tuscaloosa*

CASEY JONES, Immediate Past President, Hoover*

DIRECTORS

Johnny Adcock, Woodland

Lou Ayers, Jasper

Marc de Beer, Huntsville

Randall Ennis, Tanner

Shane Guy, Guntersville

Tim Holmes, Decatur

Harold Hunt, Gadsden

Clint Lauderdale, Hanceville*

David Lesnansky, Cullman

Frank Loftis, Cullman

Neil Martin, Dothan

David Massey, Enterprise

Richard McElrath, Albertville

Kevin Parnell, Boaz

Mitchell Pate, Mobile

Keith Rhodarmer, Collinsville

Cliff Rule, Guntersville

Kenneth Sanders, Brundidge Jason Shell, Boaz

Jason Spann, Hanceville

Michael Starling, Shorterville*

Doug Thiessen, Montgomery

Rod Thomas, Montgomery

David Thompson, Anniston

Larry Upchurch, Lineville

Josh Whitley, Snead

Brad Williams, Jack Jamie Young, Russellville

*Executive Committee Members

ADVISORS

Vernon Abney, Auburn

Dr. Jeremiah Davis, Auburn University Dr. Bill Dozier, Auburn University

Jerad Dyess, Montgomery

Dr. Tony Frazier, Montgomery

APEA STAFF

I am honored to serve as the 2022-23 APEA president. This organization is essential for the poultry industry and its growers. Our goal is to give us a voice on the state and national level.

I look forward to seeing and meeting many of you throughout the year as I attend our annual events and grower meetings.

One of my major emphasis for the year ahead is on working to encourage a younger generation to explore careers in the poultry industry, whether it be as a grower, a service technician or a processing plant employee.

Another priority of mine is to encourage growers-producers to become more active within our organization and help influence how the association supports the industry.

With the rise of Avian Influenza, biosecurity is a major challenge as we face the future. Finding ways to continue to increase effective biosecurity should be at the forefront of our industry.

As an association, we face many challenges, with the silent beast being urban growth in many areas within the state. This is a hurdle for agriculture overall, as cities continue to grow and expand.

I am excited to work with the association and APEA staff in the year ahead. Together, we can change the future of the poultry and egg industry.

Alabama Poultry Magazine (USPS 23800; ISSN 2767519X) is published bimonthly by the Alabama Poultry and Egg Association at 465 Bainbridge St., Montgomery, Ala. 36104. Phone (334) 265-2732 | FAX (334) 265-0008. Periodicals postage paid at Montgomery, Alabama.

POSTMASTER: Send address changes to Alabama Poultry Magazine, P.O. Box 240, Montgomery, AL 36101

Editorial matter from sources outside APEA is sometimes presented for the information and interest of our members. Such material may or may not coincide with official APEA policy. Publication does not necessarily imply endorsement by APEA.

alabamapoultry.org

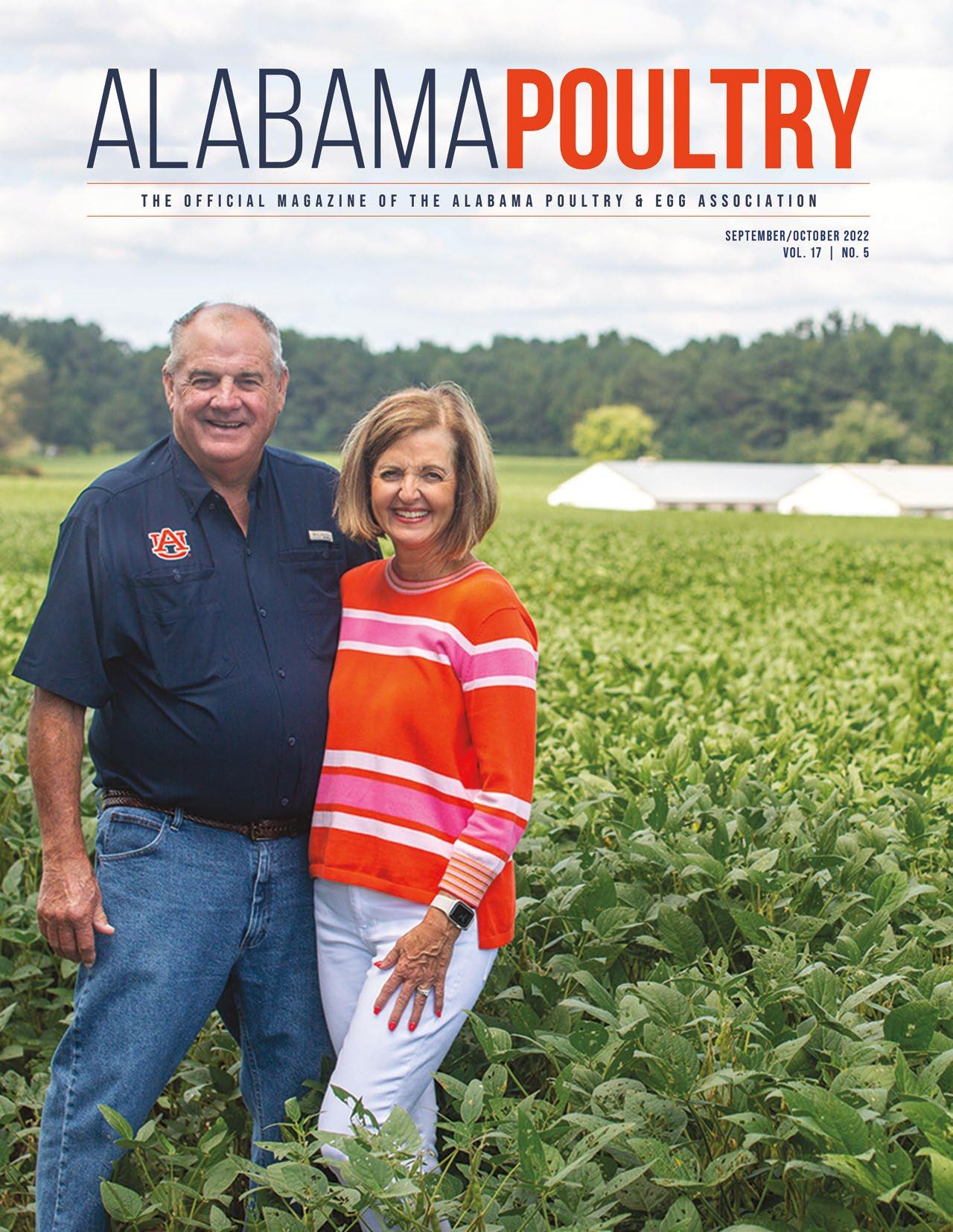

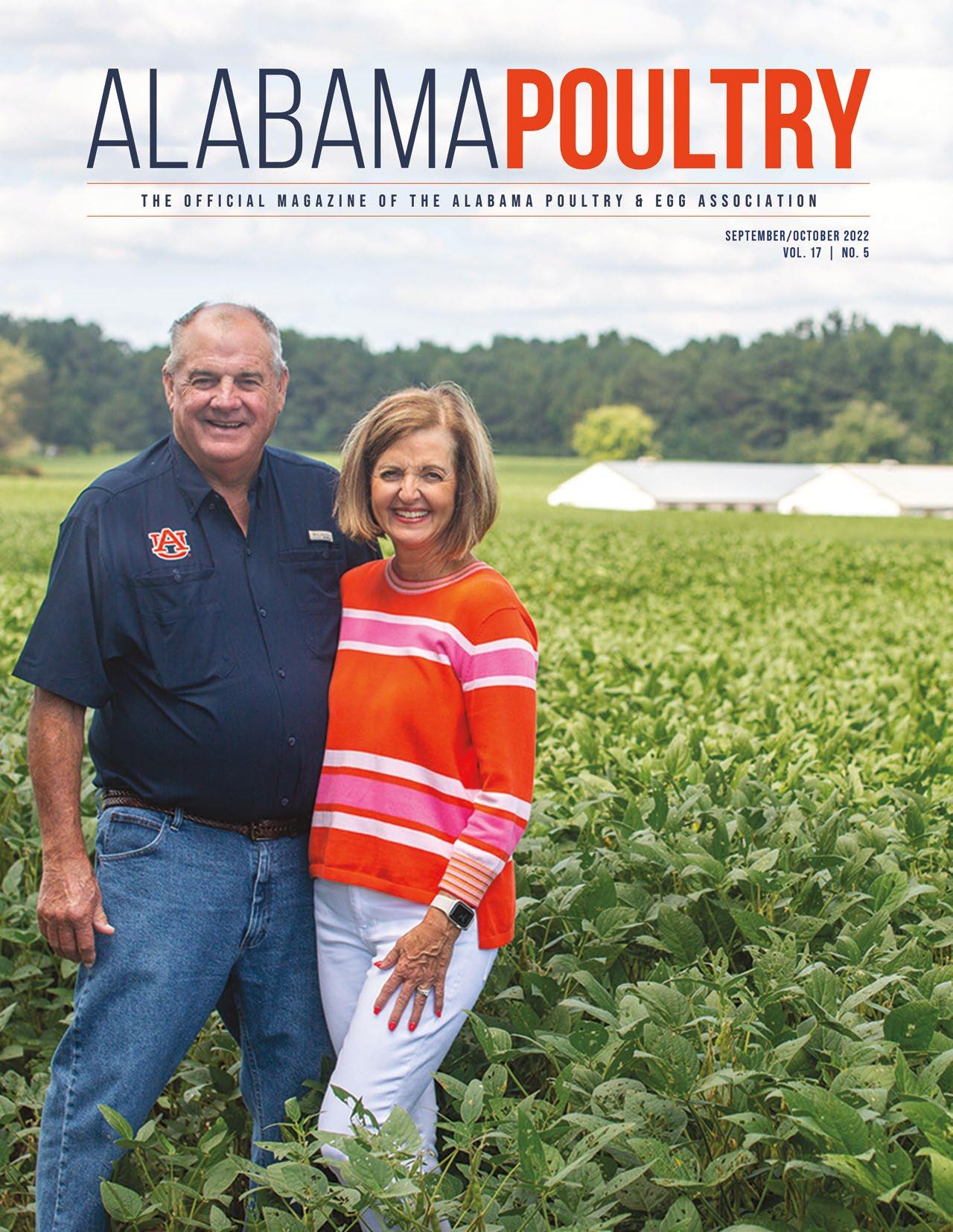

On The Cover

Stanley Usery serves at 2022-23 president of Alabama Poultry and Egg Association. He and wife, Jenny, are excited to enact change within the Association.

september - october 2022 | ALABAMA POULTRY 3

In This Issue 4 Usery Leads the Flock 6 Construction of a Dead-Poultry Composter 11 APEA Hosts Annual Meetings 18 Practices Impact On-farm Health 24 Made From (semi) Scratch 28 Practical Applications

Chief Executive Officer Johnny Adams Associate Director Ray Hilburn Communications Director/Editor Morgan Flowers Administrative Director Jennifer Shell

Stanley Usery

U se R y L ea DS TH e F LOCK

ALABAMA POULTRY | september - october 2022 4

At the risk of repeating a hackneyed, totally unimaginative cliché, Stanley Usery says his primary objective as APEA president is to promote the poultry industry to Alabamians and make them aware of its economic impact throughout the state and how poultry and eggs go from farms to the grocery store.

“As an industry, we need to sell our story,” the Limestone County poultry farmer says. “And if we don’t sell our story, somebody else will. And they’ll be selling it the wrong way.

Usery has been an advocate for Alabama agriculture since the mid1970s, when he started as a full-time farmer with his dad on a thriving rowcrop operation.

In 1991, Looking to diversify, Usery ventured into the poultry business, building three broiler houses and adding a fourth several years later. He expanded his operation in ’99 when he bought five, 40- x 400-foot houses from an existing farm.

Today, he and his eldest son, Stan Jr., produce more than 5.5 million pounds of meat annually in those nine houses and use the abundant supply of poultry litter to fertilize their close to 1,000 no-till acres of cotton, soybeans, wheat and corn.

“Basically, Stan manages the row crops, and I take care of the poultry,” says Usery, a contract grower for Tyson Foods-Shelbyville.

Stan Jr. partnered with his dad on the Elkmont farm in 2005 after graduating Auburn with a B.S. in agronomy and a master’s in plant pathology. In mom Jenny’s words, “he was born a farmer.”

Usery says farming is a family affair for him. He credits his success to his family who continually steps up when they are needed.

The same can be said of Stanley, who, too, was born to farm—but his father had other thoughts.

“Daddy told me I couldn’t stay in agriculture,” Stanley says. “He wanted me to go to college, to find something else to do for a living.”

After trying college for a while, Usery decided to head back to the farm.

“I went and bought me a tractor and two plows,” he says, “and when I got home with them, daddy said, “‘Well, I guess you’re serious then.’”

Yes, he was serious. And he’s just as serious in his president’s role and in his main mission of telling the story of poultry in Alabama.

“We have to educate the public about the industry. Most people don’t know the economic impact the poultry industry has on Alabama. We should be proud the poultry industry brings in over $15 billion to Alabama.”

Usery knows this is nothing new; it’s also been the priority of many of his predecessors. But it’s increasingly essential as the public, lawmakers included, continue to pass off the industry as something that just is.

On top of all the day to day challenges the poultry industry faces, public perception has quickly risen to the forefront of daily challenges.

Poultry has been good to Usery and his family.

“I love our chickens and watching them and our crops grow,” Stanley says. “It’s been a good living. And of everything I grow, the biggest is raising a family.”

Stan and Jenny just celebrated their 46th anniversary. Their family now includes Stan Jr., wife Kari and daughters Jessa and Kate; Clay, wife Kari and children Caroline and Sully.

While Stan Jr. works on the farm, Clay works for Redstone Arsenal and helps when he has time. Usery jokes Clay is the company pilot.

Usery currently serves on the Limestone County Farmers Federation Board, the Limestone County Co-op board and is a member of the Auburnbased National Poultry Technology Center’s advisory committee.

september - october 2022 | ALABAMA POULTRY 5

Usery sons Clayton, left, and Stan Jr., right, are always looking for new ways to help improve the family farm.

CONSTRUCTION OF A DEAD-POULTRY COMPOSTER

BY: KEN MACKLIN, JOSEPH B. HESS, JAMES O. DONALD AND JOHN P. BLAKE

Learn about the different disposal methods for dead birds, especially poultry composting. Included is guidance on building a poultry composter.

Disposing of dead birds is an ongoing problem for poultry producers. More than twenty million broilers are processed weekly in Alabama; however, there are more than 300,000 mortalities on Alabama farms each week. Disposal of these mortalities is a serious problem for the producer. If this problem is not solved, it may limit the future expansion of the state’s poultry industry. One method of disposal is a deadpoultry composter.

Disposal Methods

Open-bottom burial pits used to be the most common method of disposing of dead poultry and currently should be considered only if there is a catastrophic event on the farm. Open-bottom burial pits can affect water quality when they are in certain soil types. Residue can also remain in these pits after years of use. Because of these two reasons, other methods of disposal for poultry carcasses are used.

Incineration is one of the biologically safest methods of disposal. However, it tends to be slow and expensive. Incineration can also generate nuisance complaints, even when highly efficient incinerators are used. Particulate air pollution is generated by incinerators as well.

Rendering is one of the best means for the conversion of dead poultry into a valued, biologically safe protein by-product meal. However, producers using this method run the risk of transmitting disease. Disease organisms can be picked up on the truck and spread from farm to farm. However, having a good biosecurity plan in place will reduce this risk.

Because of costs, stricter regulations, and the chance of disease transmission, poultry producers are interested in finding other disposal methods. Composting is one such alternative.

The Composting Formula

Poultry composting has been approved in Alabama by the state veterinarian’s office, state and local health departments, and the Alabama Department of Environmental Management

(ADEM). Alabama broiler producers have shown great interest in the composting technique.

Preliminary studies of poultry composting were carried out by Dennis Murphy at the University of Maryland’s Poultry Research and Education Facility. The composting process involves mixing prescribed amounts of dead birds, poultry litter, a carbon source such as straw, and water.

Caked or used poultry litter (usually pine shavings, sawdust, peanut hulls, or rice hulls) and manure is the primary compost medium. These materials supply ammonia nitrogen for the growth of bacteria. Because a mixture of poultry carcasses has a large supply of nitrogen (N), straw is used to supply additional carbon (C) to adjust the C:N ratio.

The mixture should be composed of 1 part poultry carcasses, 2 parts poultry litter, 0.1 part straw, and 0.25 part water, based on weight, not volume. Such a mixture will have a C:N ratio of about 23:1 and moisture content of about 55 percent. Acceptable C:N ratios are between 15:1 and 35:1. Acceptable moisture contents are between 40 and 50 percent.

Other options for the disposal of dead birds are limited, and composting is a desirable environmental and economic alternative. However, composters must be properly designed and constructed if they are to be effective.

Building the Composter

One of the first points to consider in building a composter is size. Two types of composting bins are required: a primary or first-stage composting bin and a secondary or second-stage composting bin (figure 1).

Other points to consider in building a composter are location, type of structure and materials.

ALABAMA POULTRY | september - october 2022 6

FLOORPLAN OF A COMPOSTER

Figure 1. Floorplan of a composter showing primary and secondary bins (not to scale).

Figure 2. Front and side elevations of composter, showing eave heights (not to scale).

Figure 3. Floorplan of composter combined with dry-stack storage facility (not to scale).

september - october 2022 | ALABAMA POULTRY 7

Capacity

20,000 210 1 210 40,000 420 2 420 60,000 630 3 630 80,000 840 4 840 100,000 1,050 5 1,050 120,000 1,260 6 1,260

Storage space for raw litter and finished compost must be available or built into the composter. Composters can vary considerably and still function properly. However, all good composters share certain features.

Size. The capacity of the first-stage composter bins is calculated by a formula based on farm capacity, bird size at the end of the production cycle (market weight), and the mortality rate.

Cubic feet of first-stage composter = Farm capacity per cycle x Bird market weight x 0.0025

A minimum of 1 cubic foot of secondary composter bin is required for each cubic foot of first-stage composter capacity.

For most farms, the above formula will call for a large composter, which is needed for year-round operation (table 1). Ideally, the composter should be sized so that the average day’s mortality will make a single layer in the primary bin.

Location and Access. Properly managed composters have minimal odor. Still, the unit should not be placed near neighbors or the farm residence. The site should be well drained and should provide access to spreader trucks. An allweather road and work area are desirable.

Foundation. An impervious, weight-bearing foundation (concrete) is critical for all-weather operation. A concrete foundation keeps out rodents, dogs, etc., and prevents contamination of the surrounding area. The concrete foundation should be a minimum of 6 inches thick.

Building Materials. Specify pressure-treated lumber or other rot-resistant materials because they withstand the biological activity of composting.

Roof. Some materials may be composted in the open, but poultry composting does not work well uncovered. A roof ensures year-round operation. It also controls rainwater and percolation, which can be serious problems (figure 2).

Gutters may be needed to divert water away from composting bins. High eave heights, which allow easy movement of equipment, may expose compost and raw materials to blowing rain. This has been a problem on several large units in Alabama. Gutters and partial sidewalls or curtains have helped to minimize this problem.

Raw Ingredient Storage. In some parts of the country, more and more producers are building separate manure storage barns to facilitate the handling of manure after it leaves the poultry house. In Alabama, however, most composters are being built with the capacity to hold enough manure for the composting cycle. This capacity is essential because of the wet weather in the state and the difficulty of acquiring and transporting litter during the winter and spring months.

Finished Compost Storage. Secondary compost bins provide a place for the temporary storage of compost. The producer must use the compost or move it to long-term storage as secondary capacity is filled. An all-weather manure storage barn meets this need. Finished compost can also be stored outside on a well-drained spot, if it is properly covered with plastic to prevent saturation from rain.

Utilities. An all-weather water line is necessary for adding moisture to the compost mixture and for cleanup and washdown of equipment, concrete, and operators. At least one 20-ampere, general-purpose GFCI duplex receptacle should be installed at each composter for operating small tools. Incandescent lights should be placed at several locations for night or predawn operation.

Cost. The design for a typical free-standing farm composter is shown in figures 1 and 2. Total costs will depend on the size of the composter, which is based on the size of the flock, and the cost of labor to construct the unit.

Though more expensive, combining a composter with a dry-stack storage facility offers an ideal system for composting and temporary storage (figure 3). Large amounts of manure and compost can be stored and kept dry in these structures for land application according to seasonal crop requirements.

Note: The drawings in this publication are for planning purposes only. They are not working plans. Have a local builder or engineer check the structural integrity of any building you wish to construct.

ALABAMA POULTRY | september - october 2022 8 9/26/22, 3:12 PM Table 1. Number of First-Stage Composter Bins Required Based on Flock Size (Based on 4.2-Pound Bird) Page 1 of 1 about:blank

Required Cubic Feet For Primary Bins Number of Bins (5'x5'x8') Required Cubic Feet For Secondary Bins

TABLE 1

ALABAMA POULTRY | september - october 2022 10 Clean Recirculating/Cool Cell Pads Now to Keep Birds Cool this Summer SaniDate® 5.0 helps control: • Algae and mold • Bacteria growth • Mineral buildup Maintaining clean pads will: • Increase air flow and wind speeds • Reduce the need for replacement pads • Keep birds cooler Decreased Air = Decreased Efficiency SaniDate® 5.0 is a peroxyacetic acid-based chemistry that is EPA-registered, OMRI-Listed, works on contact and then breaks down into non-toxic compounds. After Before 1-888-273-3088 | BioSafeSystems.com Mix SaniDate® 5.0 with our BioFoamer® Foaming Agent and apply using foaming equipment* of your choice for thorough coverage and extended contact time. *Must be compatible with acid-based chemistries. Stubborn Dirty Pads?

Above: 2022-2023 executive officers were elected at the annual meeting July 17-19. From left are Johnny Adams, Chief Executive Office; Steve Smith, treasurer; Casey Jones, immediate past president; Stan Usery, president; Ryan Turner, vice president; Charlie Peacock, secretary; and Clint Lauderdale, executive committee member. Not pictured, Michael Starling, executive committee member.

APEA HOSTS ANNUAL MEETINGS

Morethan 400 industry professionals, farmers and families gathered in Sandestin, Florida, July 17-19 for Alabama Poultry and Egg Association’s annual and summer board meetings.

To kick things off, folks flocked to the annual “Welcome to the Beach” reception for board members and sponsors, but it was on to business at the board meeting the next morning. Board members heard industry updates and discussed plans for the upcoming year.

Members also elected the 2022-23 board and executive officers during the meeting and rounded out the second day of events with the awards banquet and auction, which both were a success.

The final event of this year’s meetings was a round of golf at Baytowne Golf Club.

Thank you to our sponsors and to all those who helped make this a successful meeting.

september - october 2022 | ALABAMA POULTRY 11

AWARDS

ALABAMA POULTRY | september - october 2022 12

Presidential Award: Dr. Jessica Starkey, middle

Top Salesman to Breeder Growers: Barry Smith – Tyson Foods, Snead

Top Team Ticket Sales: Koch Foods, Gasden

Top Salesman of $200 tickets: Roger Witt –Koch Foods , Gadsden

Top Salesman to New Ticket Purchasers: Lonnie Wiggins – Koch Foods, Gadsden

Pictured: Greg Smith of Koch Foods

Met Team Quota: Koch Foods , Ashland

Top Salesman to Broiler Growers: Judy Dutton -Tyson Foods, Snead

Top Rookie Award: David Monroe -Koch Foods, Gadsden

Presidential rooster presented to Casey Jones, right.

Distinguished Service Award: Jeff Sims, middle

Not Pictured: Top Team based on Quota: Peco Foods

september - october 2022 | ALABAMA POULTRY 13

Closest to the Hole (left to right): Travis Bentley, Phillip Cowart, Jordan Scott, Todd Grisham.

Second Place Team: John SPort, Chris Gary, Keith Jones and Paul Bryars.

Closest to the Hole (left to right): Randy Wilson, Jeff Hixon, Keith Jones and Todd Grisham.

ALABAMA POULTRY | september - october 2022 14 A l abama A g Credi t • A l abama Farm Credi t A l abama Pow er • A rm & Hammer • A vi agen Inc. BarnTool s • Boehri nger Ingel hei m • Ceva ChemStati on • Chore-Ti me Equi pment Cobb-Vantress Inc. • Compl ete A gri Servi ces Cumberl and • D & F Equi pment Sal es Inc. Di amond V • El anco A ni mal Heal th Fi rst South Farm Credi t • FITCO • Haw ki ns Inc. Huvepharma • Internati onal Paper • Jones Hami l ton Co. Jamesw ay Chi ck Master Incubator • Kunafi n Li ve Oak Bank • Marel • Meyn A meri ca Moti on Industri es • Ri ver Val l ey Ingredi ents Sunbel t Rental s • Vi nci t Group Westrock • Z oeti s 2 0 2 2 S U M M E R B O A R D A N D A N N U A L M E E T I N G Sponsors

ROSS-USA11/2019 ROSS 308/ROSS 308 AP • Leading FCR • Impressive Daily Gain • Strong Livability ROSS 708 • Highest Yield • Excellent Breeder Performance • Exceptional Livability A diverse male portfolio to meet any market requirement. Visit www.aviagen.com/Ross to learn how Ross® will deliver for you. ROSS DELIVERS

GOVERNOR IVEY CONTINUES ADVANCING BROADBAND ACCESS ACROSS STATE

MONTGOMERY – Governor Kay Ivey has awarded more than $26 million in state funds to provide broadband services in numerous locations throughout Alabama.

The nine grants totaling $26.6 million were awarded to broadband providers across the state. Once work is completed, the expanded broadband service will provide the capability to serve nearly 15,000 additional households, businesses and public facilities, including schools and police and fire services in areas without access to broadband service. Broadband providers supply the access to broadband service, but households and businesses must still pay for connecting to the service.

The expansion will also provide additional links to make it more feasible to supply future broadband service within those areas.

“Alabama continues to make strides in providing reliable high-speed internet services for families and businesses throughout Alabama,” said Governor Ivey. “I extend my thanks to legislators who realize the importance and the huge impact that access to broadband services mean for Alabama. I also thank the service providers for their willingness to be a part of this mission to change the lives of Alabamians.”

The Alabama Department of Economic and Community Affairs administers the Broadband Accessibility Fund grants from state funds allocated by the Legislature. The grants are issued through ADECA’s Alabama Digital Expansion Division, which was created by legislation signed by Governor Ivey in 2021 focusing on broadband expansion in Alabama.

“Having access to high-speed internet service can change the world for families in rural areas particularly when it comes to education, health care or running a business” said ADECA Director Kenneth Boswell. “I am honored to have the trust that Governor Ivey and the Alabama Legislature have placed in ADECA to administer this program that is making a difference for people throughout the state.”

GRANTS AWARDED

BLOUNT/ETOWAH COUNTIES

Comcast Cable Communications – $1.32 million to provide access to 956 households, businesses and public institutions in the towns and communities of Allgood, Altoona, Walnut Grove, Pana, Ellison Crossroads and Redbud.

CHEROKEE COUNTY

Comcast Cable Communications – $4.74 million to provide broadband access to 2,778 households, businesses and public buildings in the towns of Leesburg, Sand Rock and the community of Anderson.

COLBERT COUNTY

Comcast Cable Communications – $1.2 million to provide broadband access to 1,567 households, businesses and public establishments near the town of Leighton and the communities of Ford City and Hatton and an area near the town of Littleville.

DEKALB COUNTY

Farmers Telecommunications Corp. – $3.4 million to provide broadband access to 826 households, businesses and public service institutions in or near the towns, cities and communities of Mentone, Valley Head, Fort Payne, Cloudmont, Cloudland, Union Hill, Moon Lake, Ponderosa, Bankhead, Little River East Fork, Little River West Fork, Oakdale, Sylvania Gap and DeSoto State Park.

JACKSON COUNTY

Farmers Telecommunications Corp. – $4.37 million to provide broadband access to 1,818 households, businesses and public buildings to include all or parts of the towns and communities of Dutton, Section, Langston, Powell, Macedonia, Davistown, Pleasant View, Hodge and Hancock Crossing.

LAUDERDALE COUNTY

Spectrum Southeast – $2.31 million to provide broadband access near the town of Waterloo. The project will make high-speed internet available to 2,267 households, businesses and public institutions.

MOBILE COUNTY

Comcast Cable Communications – $686,298 to provide broadband access to 438 households, businesses and public institutions in the communities of Alabama Port and Mon Louis.

ST. CLAIR COUNTY

Comcast Cable Communications – $3.63 million to provide broadband access to 2,104 households, businesses and public institutions in an area adjacent to the town of Ragland.

WALKER COUNTY

Spectrum Southeast – $4.95 million to provide broadband access for 2,097 households, businesses and public institutions in the areas of the towns of Oakman and Nauvoo. ADECA administers a wide range of programs that support law enforcement, victim programs, economic development, water resource management, energy conservation and recreation.

ALABAMA POULTRY | september - october 2022 16

september - october 2022 | ALABAMA POULTRY 17 Drinking Water Treatment Highly effective disinfectant and pH modifier www.hawkinsinc.com • Agrihawk@hawkinsinc.com Scan this QR code to watch our video testimonials It’s a safe, dependable way to disinfect agricultural drinking water.

PRACTICES IMPACT ON-FARM HEALTH

BY: KEN MACKLIN

In broiler production, there are four categories of disease-causing agents that can persist on farms: viral, bacterial, fungal and parasitic. Some of these categories have only a few significant species or strains, such as with fungi and parasites, but viruses and bacteria have several. Viruses and some parasites can only reproduce in their target host, whereas most bacterial and fungal species may reproduce in the host as well as in the environment.

The parasites of importance in commercial poultry, mainly coccidia, must leave the host to complete their life cycle in the litter. Once complete, parasites may reinfect other chickens. Almost all viruses and some bacteria are contagious and may move directly from bird to bird. This is not true of fungal and parasitic infections. Typically, fungal infections are associated with young chicks, while the other three disease agents may infect chickens at any age.

In most cases, the presence of these infectious agents on the farm does not result in clinical disease, but rather low-grade infections in the birds that are draining on body maintenance requirements in terms of taking nutrients, or energy, away from growth and decreasing feed efficiency.

In other words, most broilers expend some of the nutritional energy they get from feed to control the impact of low-grade infections. These nutritional energy expenditures can be in the form of mounting an immune response, maintaining their body temperature, poor absorption of feed and general responses to stress.

Years of experience with commercial broiler production allows us to predict the presence of significant diseasecausing agents, and the industry has developed integrated health programs that target each of the above-mentioned categories. For example, feed additives have been developed to prevent and/or

control certain bacterial and parasitic infections, whereas vaccines are often administered for immunizing flocks against common viruses and coccidiosis. The hatchery makes every effort to reduce or limit fungal and bacterial infections in the newly hatched chicks by having in place a rigorous sanitation program.

It remains a common misconception, however, that the various health programs — sanitation products, feed additives, vaccines, etc. — provided at the hatchery, in the feed or administered to the chick are all that is needed to guarantee flock health. In fact, meeting the health needs of the broiler at the farm is at least as important, perhaps more so than the integrated health programs in limiting infectious.

It must be remembered that proper management on the farm complements the integrated health programs and provides a foundation for the flock that will maximize the effectiveness of the

ALABAMA POULTRY | september - october 2022 18

vaccines, feed additives and hatchery sanitation. Marginal management in terms of improper house temperatures, poor air quality, excessive litter moisture and general stress will increase disease susceptibility in most flocks. This will cause a shift in the energy in the feed from being used for growth to body maintenance.

The difference in broiler performance among houses or farms within a complex comes down to percentages of feed nutrient energy going from growth to body maintenance requirements because of disease or some other stress. It is important to know that in most instances, the energy generated from consumed feed goes to body maintenance and feather development first, and whatever is left over is used for growth. Therefore, meeting the needs of the flock with optimal management limits nutritive requirements for maintenance and maximizes flock performance.

The following are some examples of the impact of management in limiting the number and viability of infectious agents and their relationship to body maintenance, immunity, disease prevention and general flock health.

Upon arrival at the farm, the chick must eat and drink immediately. Why? Because rapid feed and water consumption provides the critical nutrients necessary for development of tissues and organ systems — intestinal, immune and respiratory, to name a few — that provides for maximum performance and health, both immediately and long-term for the chick.

In most cases, the chick will have been vaccinated with various vaccines that replicate in tissues and produce some degree of infection for later flock immunity against resident field diseasecausing agents on the farm. For this reason, as well as providing a good start to the chick, it is critical that the brooding environment provides optimal conditions for the chick in terms of air quality, housing environment and litter moisture.

Now, with all of this said, it is necessary for the chick to have exposure

to some of the infectious agents found at the farm to encourage the development of a strong immune system. However, it must be emphasized that exposure must be limited, and stress, such as poor air quality, incorrect temperature and wet litter, must be avoided at any time

As the flock ages, body maintenance requirements increase dramatically, and efficiency in the conversion of feed nutrient energy to growth decreases as the bird gets bigger. It is crucial that the changing needs of the broiler be met continuously to minimize body maintenance from day of placement until marketed.

Low litter moisture and plenty of fresh air limits the number and viability of bacteria, viruses and most parasites. In contrast, excessive litter moisture and poor air quality and quantity provide an ideal environment in which most infectious agents will thrive. Fresh air dilutes the number of viruses and bacteria numbers. This greatly reduces the potential for respiratory diseases, such as infectious bronchitis and E. coli–caused airsacculitis.

Viruses that suppress the immune system, such as Marek’s, REO and infectious bursal disease, are also diluted with fresh air from proper ventilation. It is important to realize, though, that proper ventilation must never sacrifice the correct temperatures necessary for flock optimal performance.

Management factors at all levels impact the chick's life and are interrelated. Good farm management of the facility, equipment, temperature, litter moisture and air quality will keep to a minimum the requirements for body maintenance and have an enormous positive impact on poultry health.

Management and health programs are inseparable and must be considered in combination with all facets of live production during the grow-out. In general, proper implementation of the management practices mentioned above in this article will positively impact broiler health and growth while limiting the numbers and viability of all four categories of infectious agents.

september - october 2022 | ALABAMA POULTRY 19

20 Years of Proof Better Settlements from Better Litter 800-448-4723 | Info@ImpactPoultryProducts.com ImpactPoultryProducts.com

20

MS AL LA

september - october 2022 | ALABAMA POULTRY 21 256-475-0490 PSTEAM@POULTRYSOUTH.COM LEARN MORE ABOUT OUR PROCESS AT WWW.POULTRYSOUTH.COM 80 FARMS SOLD IN THE LAST TWO YEARS! Largest poultry farm brokerage team in the nation More closings than anyone More boots on the ground Nationally awarded multiple times More experience Most proven When you need a Pro, Experience Counts. Find Local Products Visit our searchable database today to find locally-grown products across Alabama.

production has a relatively small environmental footprint. It takes 1.82 pounds of feed to produce 1 pound of chicken. Fifty years ago, that required 2.4 pounds of feed.

poultry

LEARN MORE ABOUT DOWN TO EARTH: AGRICULTURE SUSTAINS ALABAMA AT DOWNTOEARTHAL.COM

AlabamaPoultry and Egg Association welcomes Pike County native Morgan Flowers as communications and membership director.

In her new role, Flowers will work with integrators, producers and allied members to serve and promote the poultry industry within Alabama. She will also coordinate the bimonthly magazine, maintain website updates and manage the association’s social media page. In addition, Flowers will be responsible for developing and maintaining membership programs.

Upcoming Events

Nov. 1 - Southeast Alabama Grower Meeting

Ariton, AL

Ariton Baptist Church | 6:30 p.m.

Nov. 29 - South Alabama Clay Shoot

Ravenwood - Newville, AL

Dec. 6 - Wiregrass Grower Meeting

Ion, AL

Ion Baptist Church | 6:30 p.m.

Dec. 15 - Central Alabama Grower Meeting

Luverne, AL

Tom Harbin Ag Center | 6:30 p.m.

Visit alabamapoultry.org for more upcoming events

FLOWERS JOINS APEA AS COMMUNICATIONS, MEMBERSHIP DIRECTOR

“I’m honored and excited to join APEA staff,” Flowers said. “God has blessed me to work with Alabama’s largest agriculture industry, and I’m looking forward to building relationships with industry partners throughout the coming years.”

The 2018 Auburn University College of Agriculture graduate brings significant experience and knowledge to the table, having previously worked with Alabama Farmers Cooperative as publication editor and with Tennessee Farmers Cooperative as graphic and media designer.

APEA CEO Johnny Adams said Flowers’ background and know-how will strengthen the position and advance the association.

“We are glad to have Morgan join our staff and continue to promote the poultry industry,” said Adams. “She has an understanding of the agriculture industry and a strong grasp of communications that will enhance our communications and marketing efforts.”

Flowers and her husband, Shawn, currently live in Brundidge on her family’s cattle farm and actively involved with Springfield Baptist Church.

september - october 2022 | ALABAMA POULTRY 23

The boys of fall and all of Alabama are getting ready for some football, so that means families will be looking for some easy chicken dinner recipes to serve.

Whether you’re coming home from work on a busy weeknight or planning a tailgating party for the weekend, this Slow Cooker Chicken Spinach Lasagna will be ready for dinner when you are. It’s so easy, you don’t even have to cook the lasagna noodles before layering them in the slow cooker.

If you need a hearty, last-minute soup, Shortcut White Bean Chicken Chili that starts with canned Great Northern beans is the answer to your dinner dilemma. It’s also one of my favorite ways to use leftover or rotisserie chicken.

SHORTCUT WHITE BEAN CHICKEN CHILI

Prep time: 10 minutes, Cook: 15 minutes, Yield: 8 servings

• 1 small onion, chopped (1 cup)

• 3 cloves garlic, minced, or 1/2 teaspoon garlic powder

• 1 tablespoon olive oil or vegetable oil

• 1 (32-ounce) carton chicken broth

• 3 (15.5-ounce) cans Great Northern beans, drained

• 1 (4.5-ounce) can chopped green chiles

• 1 1/2 teaspoons ground cumin

• 3/4 teaspoon dried oregano

• 1/2 teaspoon salt

• 1/4 teaspoon ground pepper

• 3 to 4 cups chopped cooked chicken

• 4 ounces shredded Monterey Jack cheese

Kathleen Phillips is a Southern shortcut recipe developer and cookbook author who uses her talents to make life easier in the kitchen. Find more of her recipes at GritsandGouda.com.

Autumn is also a favorite season for baking sweet treats. These bite-size Peanut Pie Tassies are perfect for fall festivals, bake sale fundraisers, and of course, football parties. Honey Bread Pudding is a frugal dessert made with egg custard–soaked French bread cubes. If you want to “gild the lily,” drizzle this New Orleans dessert with my homemade Vanilla Sauce, found on the blog at Gritsandgouda.com.

• Monterey Jack, lime wedges, cilantro and sour cream, to use for toppings

Cook the onion and garlic in the oil in an 8-quart pot over medium heat, stirring often, until onion is almost tender.

Add chicken broth to deglaze the pan. Add beans, green chiles, cumin, oregano, salt and pepper. Stir chicken into the soup mixture. Cover and bring to a boil over medium-high heat. Reduce heat to a simmer and cook 10 to 15 minutes.* Serve in bowls and top with cheese, fresh lime juice, cilantro and a dollop of sour cream, if desired.

*If you prefer a creamier texture, partially mash the beans with a potato masher right in the pot.

ALABAMA POULTRY | september - october 2022 24

Sponsored by: Find local products at SweetGrownAlabama.org

Preheat oven to 350 degrees.

HONEY BREAD PUDDING

Prep: 15 minutes

Bake time: 40 Minutes

Yield: 15 servings

• 1 (16-ounce) loaf French bread

• 3 1/2 cups whole milk

• 3 large eggs

• 2 cups sugar

• 3/4 cup raisins, optional

• 1/3 cup melted butter, divided

• 1 teaspoon vanilla extract

• 1/3 cup honey

Tear or cube bread into 1-inch pieces. Place cubes in a large bowl and pour milk over bread. Give it a gentle stir and let stand 10 minutes.

Whisk eggs in a medium-size bowl; add sugar, raisins, 3 tablespoons melted butter and vanilla, stirring well. Pour egg mixture over soaked bread as you stir gently. You want the pieces of bread to hold their shape. Pour mixture into a buttered 13- x 9-inch baking dish.

Stir together honey and remaining melted butter; drizzle over bread pudding. Bake at 350 degrees for 40 to 45 minutes, or until edges are browned and mixture is bubbly. Serve warm or chilled.

PEANUT PIE TASSIES

Prep: 15 minutes, Bake: 19 minutes

Yield: 18 servings

• 1 refrigerated, rolled up pie crust dough, or half of a (14.1-oz.) package

• 2 tablespoons salted or unsalted butter

• 1 large egg

• 1/3 cup light corn syrup

• 1 teaspoon vanilla extract

• 3/4 cup lightly salted, unsalted or salted skinless peanuts, chopped Preheat oven to 350 degrees.

Roll pie crust out on counter and let rest 15 minutes. Meanwhile, make the filling. First, melt butter in the microwave for 30 seconds. It will be almost melted, but not too hot. Cool slightly; add egg and beat with a fork or wire whisk until the egg white is frothy and butter is melted. Add the corn syrup and stir well. Stir in the chopped peanuts. Set aside.

Using a rolling pin or smooth, cylinder-shaped glass, smooth out any wrinkles in dough and roll into a 12-inch circle. With a 2 1/2-inch cookie or biscuit cutter, cut into 16 circles. Use a thin spatula or dough scraper to transfer the pastry to the mini muffin pans. Reroll dough to cut out 2 more rounds.

Using your fingertips, gently press the dough to the bottom of ungreased mini muffin pan. Don't press too hard into the pan to avoid the crust sticking. Fill each tart shell with about 1 tablespoon filling. Be sure to stir the mixture in the bowl occasionally because the peanuts rise to the top.

Bake on the center rack of the oven 19 minutes, or until the center of the filling is puffed and the crust is golden brown. Remove the pan(s) from the oven and immediately run a sharp knife around the outside edges of any tassie where the filling has bubbled over. Instead of transferring the tassies to a wire rack to cool, use the knife to gently tilt them to one side in the muffin pan to cool right in the pan.

SLOW COOKER CHICKEN SPINACH LASAGNA

Prep: 12 minutes, Cook: 4.5 hours Yield: 8 servings

• 1 (10- to 12-ounce) package frozen chopped spinach, thawed

• 2 1/2 cups shredded or coarsely chopped cooked chicken

• 2 (10.5-ounce) cans cream of chicken soup

• 1 1/2 cups whole or 2% milk

• 1 (8-ounce) carton sour cream

• 3 cups pre-shredded mozzarella cheese, divided

• 1/3 cup shredded Parmesan cheese, divided

• 1/4 cup finely chopped onion, optional

• 1/2 teaspoon garlic salt

• 9 uncooked lasagna noodles

Squeeze water from thawed frozen spinach over sink. In a large bowl, combine spinach with the chicken, cream of chicken soup, milk, sour cream, 2 cups of the mozzarella cheese, half the Parmesan cheese, onion and garlic salt. Be sure to hold out the remaining cheese to put on top.

Coat the slow cooker* insert with cooking spray. Arrange 3 of the lasagna noodles in the bottom of the slow cooker insert, breaking them in half as necessary to fit. It's okay that not every inch is covered.

Spoon one-third of the spinach mixture over the top of the first layer of lasagna noodles. Repeat layers of pasta and spinach mixture, ending with the last one-third of spinach mixture on the top. Sprinkle the remaining 1 cup of mozzarella cheese and remaining Parmesan cheese over top.

Cook on low for 4 1/2 to 5 hours, or until the edges are browned and the mixture is bubbly.

*An oblong/oval slow cooker is better than a tall round one because it creates more surface area for the long noodles.

september - october 2022 | ALABAMA POULTRY 25

COMMERCIAL POULTRY MORTALITY MANAGEMENT ECONOMICS

BY: DENNIS BROTHERS AND M. KENT STANFORD

Recent events have prompted many poultry growers to reexamine their current method of daily mortality disposal and consider new options for their farm. Mortality disposal management is a significant concern on a farm, and a detailed examination of all the requirements, costs and impacts of any method should be part of a good business decision. However, a simplified look at the estimated input costs, the first year’s total cost, combined with longer-term financial estimates, can assist growers with these decisions.

Methods of Disposal and Cost Considerations

The only approved poultry mortality daily disposal methods for Alabama are:

• composting — shed and in-vessel (drum)

• incineration

• mortality freezers for rendering

A potential fourth available method is mortality dehydration. It is a new method that is not currently approved but is being evaluated at this time by the Alabama Department of Agriculture & Industries. Using industry standards, manufacturer recommendations and estimates, the long-term cost for each method can be compared. However, there are also many hidden costs and less than obvious aspects, like environmental concerns and litter/ compost value, that should be considered for each. For now, let’s look at how borrowed capital, rental fees, fuel, labor and maintenance affect the estimation of long-term total cost of each of these four methods.

Our example considers a farm consisting of two 66- x 600foot broiler houses, raising 6.5-pound target weight birds with typical placement of 104,200 total birds. A 49-day flock with

ALABAMA POULTRY | september - october 2022 26

14 days of out time yields 5.8 flocks and 284 bird-days per year. A “bird-day” is a day that birds are in-house and mortality management is expected. For input costs, the example farm pays $60/ton for shavings, $3 per gallon for LP gas, $50/gal for diesel fuel for tractor use and $0.12/kWh for electricity. Many farmers do not calculate their own time as paid labor, but to create a fair comparison and to illustrate the cost if someone were hiring labor to perform these duties, labor is also calculated at $15/hour.

Overall Analysis

In our example estimation, the drum composter comes out highest in cost per bird-day. This is mainly due to the assumption a grower would use the manufacturer’s recommendation of fresh shavings at the proper rates for all the compost bulking material/carbon source. Growers considering this method should discuss other less expensive options with the composter manufacturer. The six-bin shed composter comes out the least expensive, mainly due to the low energy requirements and low maintenance costs longterm. If choosing this method, however, it must be understood that there is a much higher management requirement to get the job done correctly and avoid possible negative impacts to the farm. The other methods yield similar long-term cost estimates per bird-day.

Beyond the simple financial analysis of these methods, growers should consider other reasons behind choosing one method over another. Growers should ask themselves questions like:

• How much time do I have to manage my mortality disposal method?

• Do I have enough labor available to properly execute a method?

• Do I need additional structures built to house a method?

• Am I in an area where I need to be more concerned about neighbor relations and therefore choose a method with the least possible negative impact potential?

A grower must also consider how long they intend to grow. The right choice may be different for someone just beginning and someone looking to retire within five years.

A further evaluation of each mortality management method, as well as consideration of the value of the output produced from each method, will soon follow. But this costonly evaluation should help growers begin to make a choice of mortality management that fits their farm’s current situation best.

september - october 2022 | ALABAMA POULTRY 27

PRACTICAL APPLICATIONS

NOW IS THE TIME TO CONDUCT AN ANNUAL HEATING SYSTEM TUNE-UP

J.D. Davis, C.M. Edge, J.C. Campbell, K.G. Griggs, and C.R. Smith National Poultry Technology Center – September/October 2022

It’s that time of year to be performing a full heating system tune-up as you are cleaning up your heating system between flocks. Many growers blow off heaters each flock with a handheld or backpack blower. This gets the visual dust build up off the outside surfaces but there is likely more buildup within the heaters. If your round radiant brooders are showing yellow flames or sound a little off, you probably have more cleaning to do than blowing them off with a backpack blower.

Typical practice is to blow off the outside of the heaters each flock (left), however, if the heater is showing yellow flames, there is likely dirt build up inside the heater (right).

After cleaning the outside surfaces, follow the manufacturer manual to remove the brass burner orifice (left). Check that the orifice is clean of debris. Visually inspect the burner tube for debris caked on the walls.

It is easiest to use compressed air and an air nozzle to blow the burner tube and burner out. Apply air until you see no dust leaving the burner. This will take a minute or two per heater to perform.

Growers with tube heaters must blow or sweep off the tube reflector to improve its ability to reflect heat more efficiently to the floor. Like the round heaters, you must periodically inspect both the outside and inside of the burner box for opportunities.

ALABAMA POULTRY | september - october 2022 28

It is important to repair any air ducts that are broken (left) as these allow dirt and moisture to enter the box as well as spiders to build nests in the electronics (right).

While you have the burner box open, inspect the blower fan for debris accumulation. This fan isn’t in terrible condition, but the debris can slow the blower down affecting fan operation and efficiency. A lack of air will cause the burner to cake soot inside the burner tube, reducing both the heater longevity and efficiency.

In addition to cleaning your heaters, you should also check the heater hoses for cracks. You can use a soap solution to identify any leaking hoses and replace them with gas rated hose. It is also a good time to check your heating system gas pressure, making sure gas lines are turned on and all the heaters are running. The gas pressure must be set within the minimum and maximum supply pressure rating listed on the heater name plate.

Bottom Line: Spending a few extra minutes tuning up each heater this fall will increase your heater longevity and maximize the available heat your heaters can provide as well as the amount of heat that reaches the floor during chick placement. Cleaning will also make the heaters run more uniform across heating zones making the house floor temperatures more uniform.

september - october 2022 | ALABAMA POULTRY 29

ALABAMA POULTRY | september - october 2022 30 www.gapoultry.com

AL 855-513-9919 Holly Pond, AL 855-675-0505

AL 888-394-7458 Ozark, AL 334-443-0240 Petrey, AL 334-335-2294

Pine, AL 256-331-2817 © 2022 Hog Slat Inc. All Rights Reserved. Prices and promotions subject to change without notice. Hog Slat reserves the right to correct printing and pricing errors. Don’t risk your flock’s feed conversion because of old, inefficient pans. Upgrade them with GrowerSELECT ® Classic Flood feeders available in 10 different configurations. Extended, non-prorated 5 year warranty Target Your FLOCK’s Feed Conversion CL ASSIC FLOOD CL ASSIC FLOOD A small business loan isn’t just about the money. It’s about making the most of it. To learn more, visit us at liveoakbank.com/poultry

Chancellor,

Ider,

Spruce

It’s never a dull day on the farm. Since 1916, Alabama Ag Credit has helped farmers like you finance improvements and upgrades for everything from supplies to tractors to tools that get the job done. Whether you’re starting or expanding your agricultural operation, we offer long-term or short-term credit options. Call us today to learn about our competitive rates and how our relationship lending can help your farm thrive.

AlabamaAgCredit.com Call 800.579.5471

september - october 2022 | ALABAMA POULTRY 31

MEMBER

Showing up for work before the sun does. Some don’t get it, but we do.

AG03-45223-Chicken-ALPoultry-2019.indd 1 12/11/18 3:25 PM

Michael Starling, Member in Henry County