AFTEX 2 2016 - Cover_Layout 1 29/09/2016 10:36 Page 1

ISSUE TWO 2016 DEUXIÈME EDITION 2016

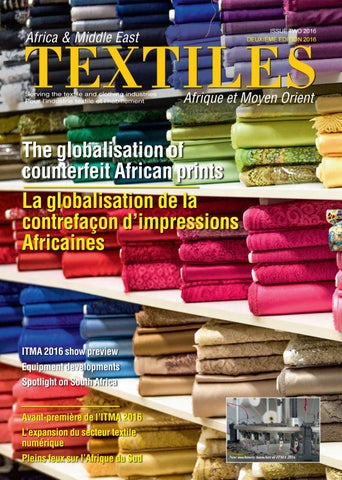

The globalisation of counterfeit African prints La globalisation de la contrefaçon d’impressions Africaines

ITMA 2016 show preview Equipment developments Spotlight on South Africa

Avant-première de l’ITMA 2016 L’expansion du secteur textile numérique Pleins feux sur l’Afrique du Sud

New machinery launches at ITMA 2016