Founded in 2011, Anaya Steel is a leading supplier of value-engineered steel products and headquartered in Washington D.C. With over 31 years of experience, Anaya Steel supplies engineered steel solutions that promote technical expertise, safety, efficiency, and productivity.

For more than 30 years, the Anaya Steel team has served the global steel industry with world class products and customer service. Anaya Steel's team brings this vast experience to service its clientele with the highest quality in precision manufacturing, industry expertise, and supply chain execution.

Anaya Steel's products include, but are not limited to custom steel profiles and sections, oxygen injection lance pipes, thermic lance pipes, and other steel technologies. Anaya Steel's notable lancing solutions are manufactured by Daiwa Lance International (DLI) in Vietnam. DLI is the subsidiary of Daiwa Steel tube from Japan. Anaya Steel (US) handles the sales and marketing in North, Central and South America. We support our clients who range from automobile manufacturers to major steel plants, foundries, aluminum smelters in these regions.

The Anaya Steel team's expert understanding of steel industry allows for its team to leads with its sales, marketing, and supply execution.

DASPL is located in Kolkata, India. Our firm is a joint venture of Daiwa Steel Tubes Industries Co. Ltd.(Japan) and Anaya Steel, LLC (USA) with the manufacturing plant namely Daiwa Lance International (DLI) in Ho Chi Min City, Vietnam

DLI leads the world with an advanced lancing solution with Japanese technology accepted by major steel plants globally. Daiwa is the global leader in calorized lance pipes and thermal lance pipe.

Daiwa Anaya Steel strives to provide expert consultations, customer service, and supply chain expertise to its clients

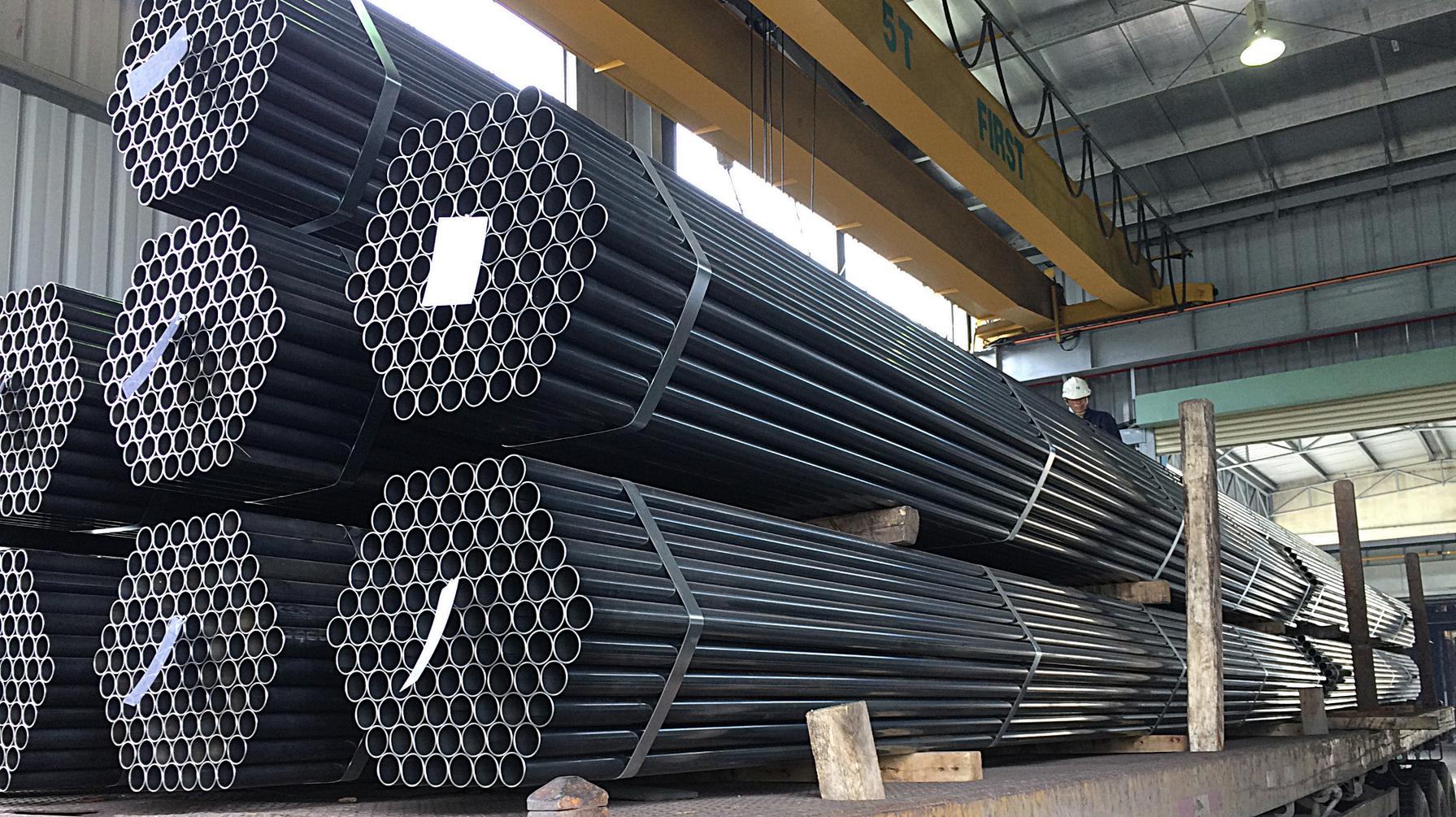

Daiwa Steel is located in Tochigi, Japan and the manufacturing plant (DLI) is in Vietnam. DLI produces high end, anticorrosion, light and effective ERW pipes having exclusive tie ups with Nippon Steel Corporation, Japan for their raw materials, coils, etc. It is a global leader in Calorized Oxygen Lance pipes and Thermic Lance Pipes. DLI’s products are used worldwide in 87 countries and over 140 major steel plants and foundries. DLI is ISO 9001 and ISO 14001 certified. Daiwa is one of the strongest pipe manufacturing companies in Japan with more than 80 years of experience and have the state-ofthe-art manufacturing facilities in Vietnam with high valueadded lancing solution.

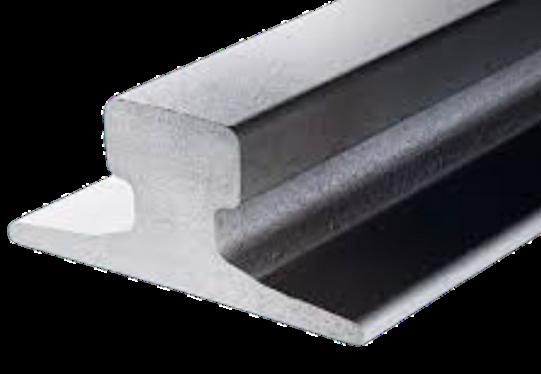

Special steel manufacturers and global suppliers of custom designed steel sections/ profiles, P.R. Rolling Mills Pvt. Ltd., has decades of experience in hot rolling steel profile as per stringent customer specifications. Located outside of Jaipur, India, PR Rolling Mills believes in displaying efficiency, excellency and innovativeness through its products and services. Their team of highly trained and skilled employees aim to surpass customer expectations.

With over 50 profiles in our portfolio, our profile development department works in tandem with production head, roll pass designers, rolling mill engineers and quality assurance teams that produces 134,000 tonnes annually.

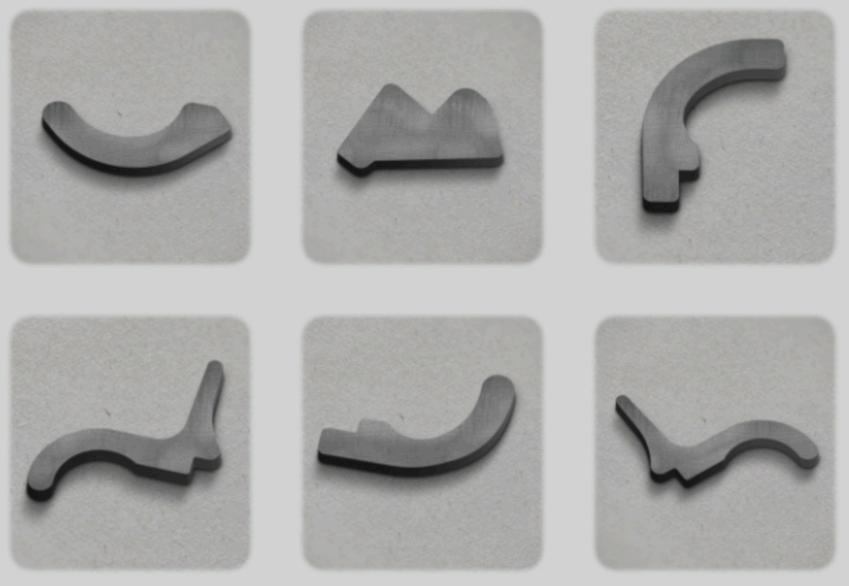

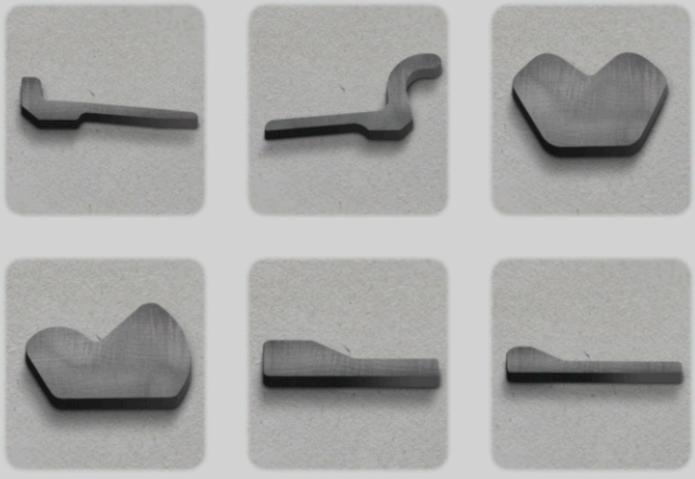

OSP is experienced in producing hot rolled special sections especially for automobile industry. The final products can be in bars, rounded or cut-to-size. Wheel sections (lock ring, side ring etc.), Door hinge profiles, Earthmoving machinery profiles are some products. OSP Steel is located in Aydın, Turkey with 110 employees and 12,000 tons of capacity under 36,000 sqm total area with 22,000 sqm closed facility. One hot rolling mill with several machinery for cold operations, tooling facility and R&D facilities are working for best quality profiles.

OSP Steel and Anaya Steel are committed to providing our clients with technical solutions with on-time delivery and bestin-class pricing.

For 34 years, we has worked with manufacturers in the United States, Japan, India, China, Vietnam, Malaysia, Spain, Mexico, and more. We understand the inner workings of tariffs, overseas logistics, intra-country logistics, and everything in-between. It’s one thing to build a world class product, but another to safely transport and clear products. We are the experts at just that in our various product lines.

We are the trusted supplier for the world’s top steel plants, mining operations, and distributors. We bring our technical expertise, engineering, and quality control to the profile industry. In our respective industries, we are known to supply the highest quality products that stand the test of the time and client’s application rigors.

We are a multi-generational family business that has been business for 30+ years. We have every intention to service our clients for hundreds of years and play the long game with our trusted clients. We service your challenges, needs, and desires as if they were our own. With offices in the US, Mexico, and India - we are here to serve you.

Our supply chain expertise and integrity allow us to work with clients in developing profiles with special cross sections and low quantities. We are able to meet the dimensional, engineering, and supply chain of our clients and deliver high quality and durable profiles.

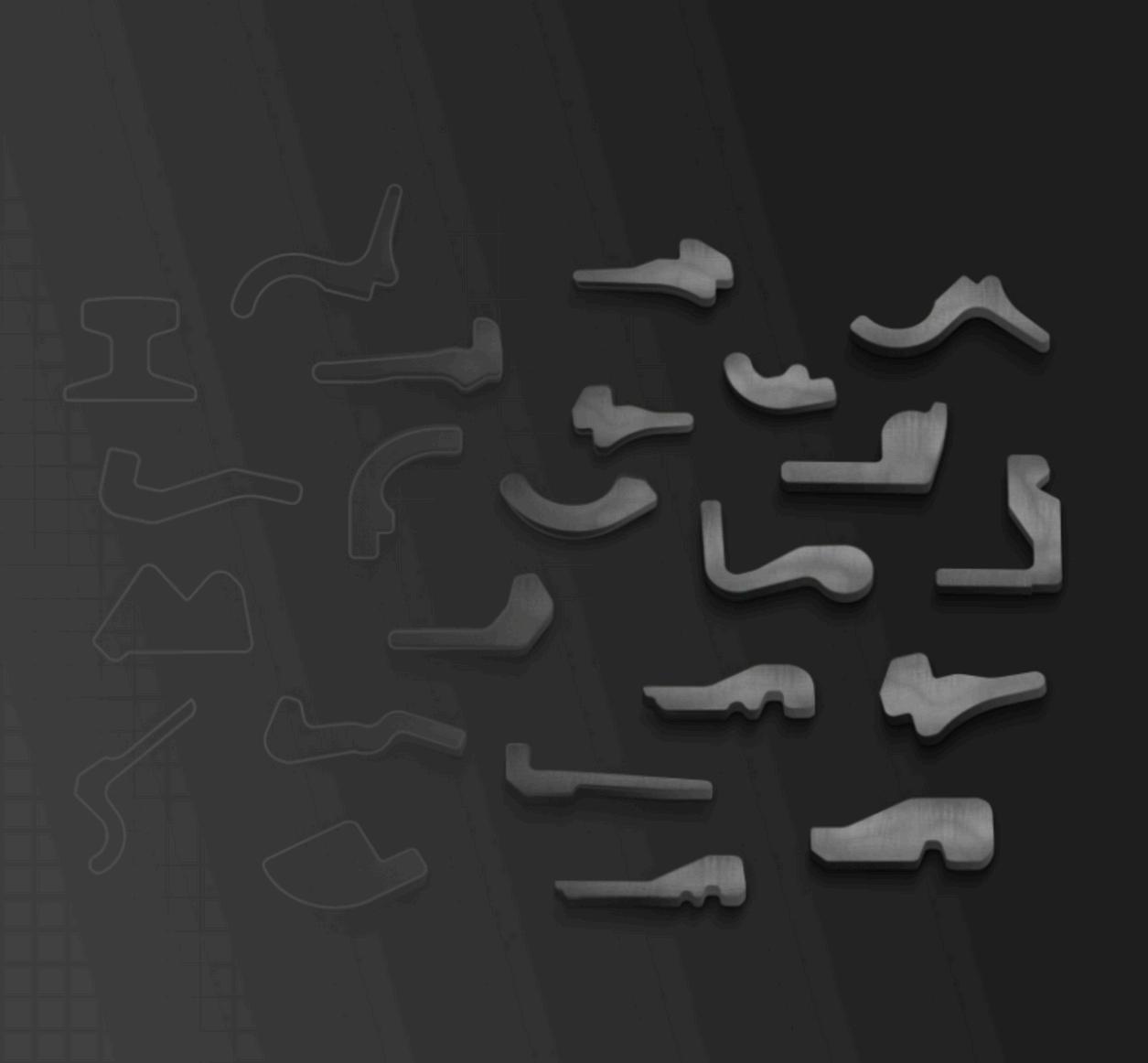

In the following pages, you will view a variety of profiles our teams have developed for the automotive, construction, mining, defense, earth-moving, and similar industries.

In general, our Indian partners at PR Rolling Mills can produce sections with a maximum unit weight of 75kg/mt, a width of 320mm, a maximum length of 12 meters or a diameter of 35-degrees. These figures are subject to the complexity of the profile.

In general, our Turkish partners at OSP Steel can produce sections with a maximum unit weight of 20kg/mt, a width of 140mm, a maximum length of 12 meters or a diameter of 35-degrees.

All mechanical and dimensional controls are made and the profiles are delivered to our clients as flat-length profiles. Curved rings or sliced

Our Indian partners at PR Rolling Mills have decades of experience in manufacturing value-engineered products that exude precision. Their product industries include:

Heavy Commercial & Light Commercial Vehicle Wheel Rims

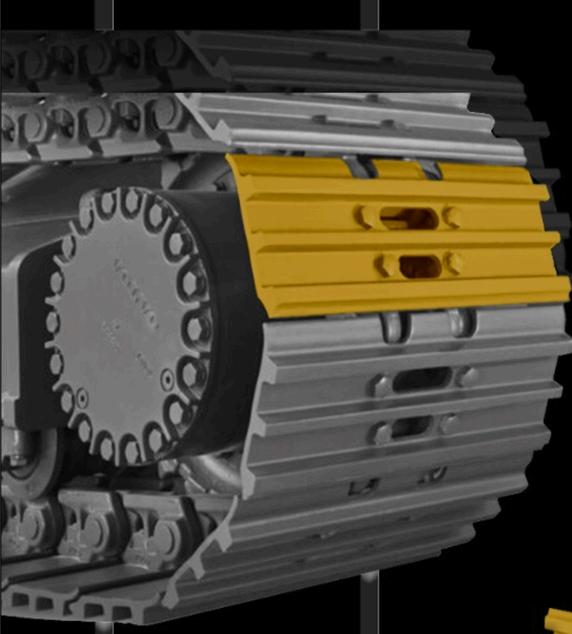

Off-Read & Earthmoving Vehicle Wheel Rims

Special Application Wheel Rims

Construction Machinery & Off-Road Vehicle Profiles:

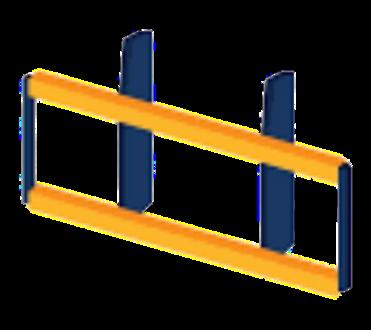

Cross Rail (Custom JCB Spec)

Toe Plate & Cutting Edge (200x20) (Custom

Specification)

Track Show – PC 200, CAT 320

Special Steel Flats for Specific Applications

Automotive Door Hinges

Construction Industry

Bridge Profiles

Scaffolding Profiles

Tower Clamp Profiles

Rim Profiles (PRM)

Earth Moving Equipment Track Profiles (PRM)

Lightweight Beams (PRM)

Our Turkish partners at OSP Steel have decades of experience in manufacturing value-engineered products that exude value and precision. Their product industries include:

Forklift Industry

Specialized Automotive Door Hinges

Construction Machinery Wheels

Profiles Ready for Cold Forming

All mechanical and dimensional controls are made and the profiles are delivered to the customer as flat-length profiles, curved rings or sliced pieces in accordance with the industry’s demands.

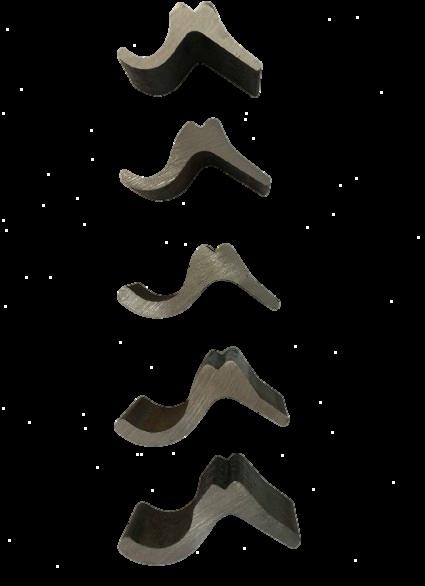

Daiwa CA Lance lasts 3 to 10 times longer than mild steel lances and is used not only for the melting and refining of steel by blowing oxygen gas, but is also used for the injection of carbon, lime, and/or other additives. Daiwa CA Lance has been used since 1955 around the world including Japan, USA, and Europe. Current Daiwa CA Lance is advanced and really customer oriented product with cost saving

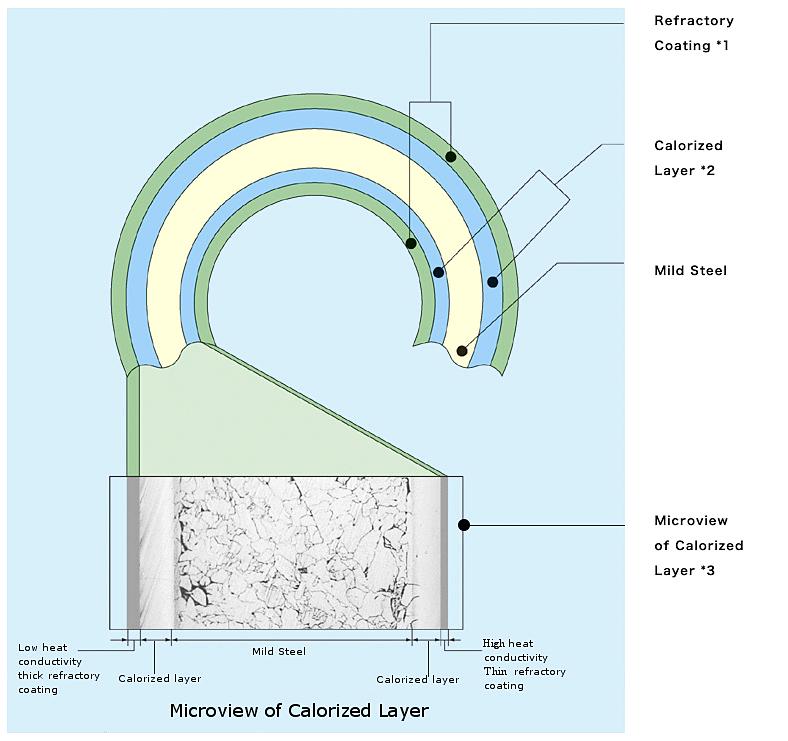

The CA Lance Pipe is an ERW Lance Pipe with a calorized layer. This layer is accomplished through the process of diffusion and refractory coating. Both the calorized and refractory coated layers produce a strong heat resistance and anti-oxidization protection that achieves minimum consumption of the lance pipe.

This pipe can withstand a high temperature of 2050 – reducing the consumption and saving up to 40-45% of the annual purchase. The CA Lance Pipe lasts 4 to 16 times longer than mild steel lances and is not only used for the smelting and refining of steel by blowing oxygen gas but is also used for the injection of carbon, lime, and/or other additives.

The calorized layer and the refractory coating layer together generate the strong heat resistance and antioxidation to achieve minimum consumption of lance pipe to cut down your cost.

Strict quality control is done at each production process over the raw materials to the finished products. Rest assured, our clients Receive the best of the best of products – in addition to world class service.

Our partners use the most advanced technologies in our manufacturing process. This allows for manufactured products with competitive prices and best quality

1.

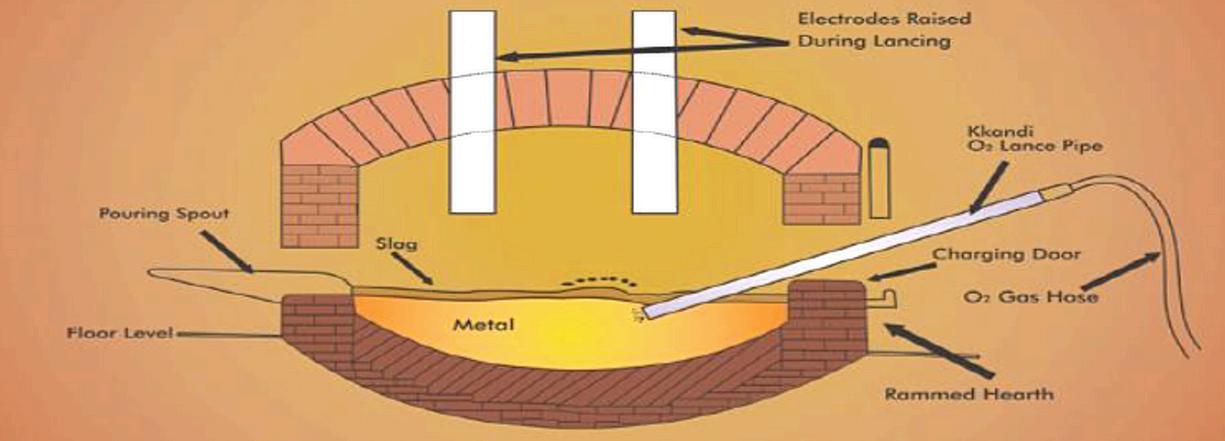

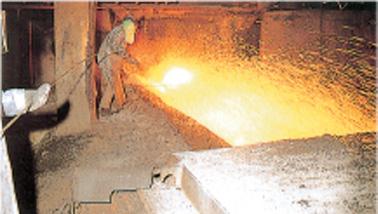

Cutting steel scrap, melting and refining steel at electric arc furnance.

2.

Injection of carbon, lime powder and/or other additives for adjusting grades of carbon steel or special steel.

3.

Removing slag inside oxygen converter.

4.

Other uses which require strong resistance against heat, oxidation, sulfuration, vanadium attack, etc.

1.

Oxygen is used in the manufacturing of metals like steel, copper and zinc. Chlorine is used in the manufacture of Aluminum. These gases react with the undesirable impurities and form their respective oxide or chlorides. These oxides or chlorides then float to the surface of the molten metal and are removed.

2. Traditionally an ordinary Pipe has been used. The material of construction is Low Carbon Steel (Mild Steel),

To transfer these gases to the molten metal, a pipe is needed. This pipe is the Lancing Pipe and the process of injecting gases into molten metal is known as Lancing.

4.

Electrically Resistance Welded (ERW ) in the shape of a pipe. Since the molten metal is Steel or Copper or Zinc, and the pipe is of Mild Steel, the pipe melts into the Molten Metal, at the end which is dipped into it. Besides because of the high temperature of the Molten Metal, the pipe also gets oxidized and melts faster into the Molten Metal. Hence the pipe gets consumed and has to be replaced.

3. The rate of replacement decides the cost of production. Therefore, in order to contain the cost, it is imperative to reduce the rate of replacement of these pipes.

Our Daiwa CA Lance also has a thin refractory on the interior surface that shields the steel from direct contact with oxygen stream. On the exterior surface, it has a thick refractory coating that effectively protects the steel from heat attack.

Daiwa Lance has a homogeneous calorized layer both inside and out.

During the calorization process, aluminum diffuses into mild steel when heated up to 1,000°C and forms heat resistant aluminum-iron alloy (calorized layer) over the surface of mild steel.

When calorized lance is exposed to a high temperature in our manufacturing process, the calorized layer forms a heat resistant aluminum oxide (almina) film over the surface. This surface protects the mild steel against severe oxidation.

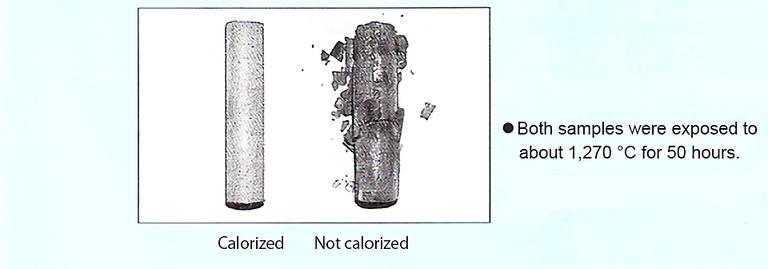

When burnt, the MS (black iron) pipe oxidizes severely. In contrast, our calorized pipe maintains structural integrity when exposed to high heat. Please see above for visual explanation of chemical process. When our lance pipe is exposed to heat, the aluminum diffuses in the surface by the action of oxygen. This then oxides to alumina and produces the following chemical reaction: 4AI + 3O2 = Al2O3 + 7608 Calories.

Advantages of Calorized Lance Pipe – Compared to MS Lance Pipe

A Plain Mild Steel (MS) Lance will begin to combust at 1,425 degrees C. In contrast, our calorized lance will start to combust at 2,050 degrees C.

This combustion difference leads to a reduction in the rates of replacement. Depending on the application and circumstances, our Calorized Lance Pipe will last 4-6 times longer than a Plain Mild Steel Lance.

Whilst the cutting speed and heat input is equivalent to that of the Plain Mild Steel Lance Pipes. ·The cost of the Calorized Lance Pipe is not 4 - 6 times the cost of the Plain Mild Steel Lance Pipe. Hence there is a net savings in the cost of pipes used

As infrequent replacement is required, the down time is reduced directly by 4-5 times. This brings a minimum savings of 10 mins. Per heat and at 17/18 heats a day it translates into 180 mins. i.e. 3 hrs./day. This is equal to 900 hrs./year.

Our Calorized Lance Pipe is virtually guaranteed to increase efficiency, increase safety, and decrease costs in our clients' facilities. Below is an in-depth breakdown of average savings.

Savings in Electricity Cost equivalent to 900 hrs./year.

Savings in Labor Cost 900 hrs./year.

Higher yield equivalent to 900 hrs./year.

Lower Inventory Cost.

Lesser space for storage of Lancing Pipes. There are also energy savings of heat in your production process and oxygen saving in the shorter lancing operation time.

The SC Lance Pipe is another lancing technology produced in Japan by Daiwa. Our SC Lance is structured as a exceptionality quality pipe as per the Japanese standards. Our SC Lance Pipes are used in Electric Arc Furnaces (EAF) to remove carbon content from molten metal and in blast furnaces, BOF’s, and non- ferrous smelting furnaces.

The SC Lance Pipe is primarily used to supply oxygen at high temperature to the tap hole of the furnace to start the flow of molten metal. The Lance also generates high temperatures of over 3,000C to melt solidified steel and slag. This pipe is manufactured through ERW process using superior quality coils from Nippon Steel, Japan.

Our SC Pipe (MS pipe)'s raw materials include coils that are imported from Nippon Steel in Japan. Each pipe undergoes our rigorous quality control procedure and manufacturing best practices Rest assured, our MS pipes are reliable, perform safely, and are trusted by world class steel plants.

Removal of slag on the wall of ingot case. Used for tap hole opening, ladle cleaning. Injecting various kinds of gases in molten metals. Removal of pig iron at the iron notch of blast furnace.

The Ceramic Lance Pipe is a Mild Steel (MS) Pipe with the layer of ceramic coating. This pipe does not contain a calorized layer such as the CA Lance Pipe, but it does include a ceramic layering. For this reason, its lifespan is less than the CA Lance Pipe, but more than our traditional MS Lance Pipe.

Opening nozzles in Tundish and ladles.

Injecting Carbon and other powders in Electric Arc Furnace and ladle.

Opening the iron notch of blast furnace.

Injecting Argon into ladles.

Injecting Argon and Oxygen into A.O.D furnaces.

Injecting Flux for degassing in Aluminum smelting furnace.

Cutting scrap, Raising Bath Temperature and decarburizing.

Our Thermic Lance Pipe is another lancing technology that is manufactured in Japan. The principle behind this lance is to harness the oxidation heat of high temperature. This high temperature is achieved by the pressurized oxygen to inside ignited steel tube.

The steel tube is with a proprietary combination of wires and/or an inner pipe. This combination generates a powerful combustion. The combustion ultimately generates a flame of 3000C – without any noise or vibration to break the materials quickly. This torch effect is then used for cutting and boring large iron casting, stainless steel, brass, nonferrous metals, concrete ceramic, and natural stones.

Our Thermic Lance Type T includes a pipe with a combination of wires and an inner pipe. This particular combination produces a straight flame at high speed to splash out materials to make hole or break up it quickly. The materials suitable for Type-T are carbon steel, iron, slag, copper, aluminum, and brass.

Our Thermic Lance Type W includes a pipe that is fully packed of wires. This combination produces a wider flame at higher temperature compared to Type-T. The purpose of this is to dissolve solid materials that have high melting points such as stainless steel, nickel, concrete, refractory materials, nature stone, etc.

Alternative Applications

Include:

1. Fusing and cutting steel pipes and large scrap objects.

Removing deposit metal from converter or electric furnace.

2. Cutting and clearing solidified spillages of metals. 3. Cutting and drilling fire brick refractory

When a tool is worn out, mining operations generally need to replace the parts. This is when the Thermic Lance Pipe is used. A thermic lance pipe can help fuse the holding pin to remove the worn parts.

The Thermic Lance Pipes is also used to cut the removed parts made by special tool grade steel that is difficult to cut by acetylene torch or other method.

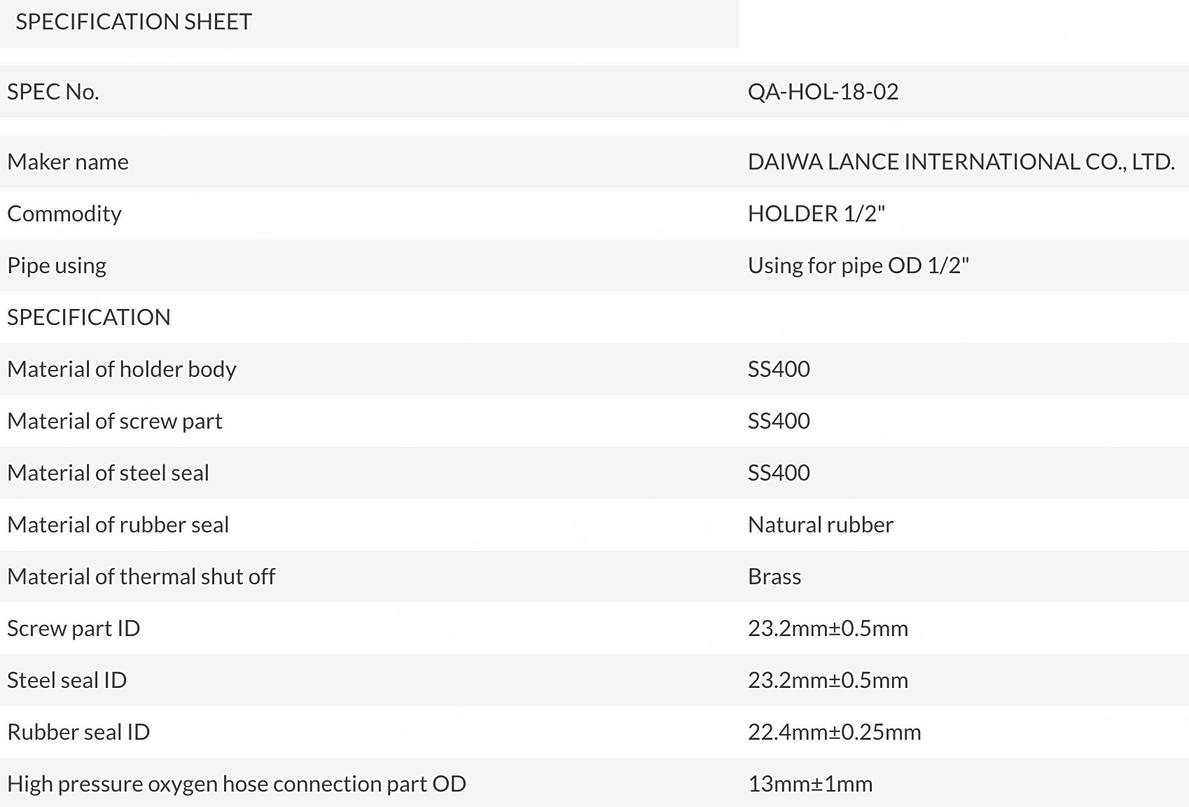

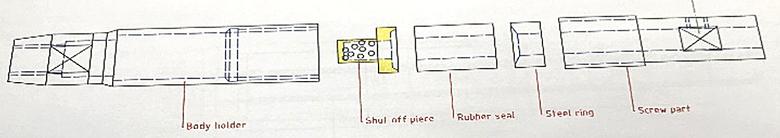

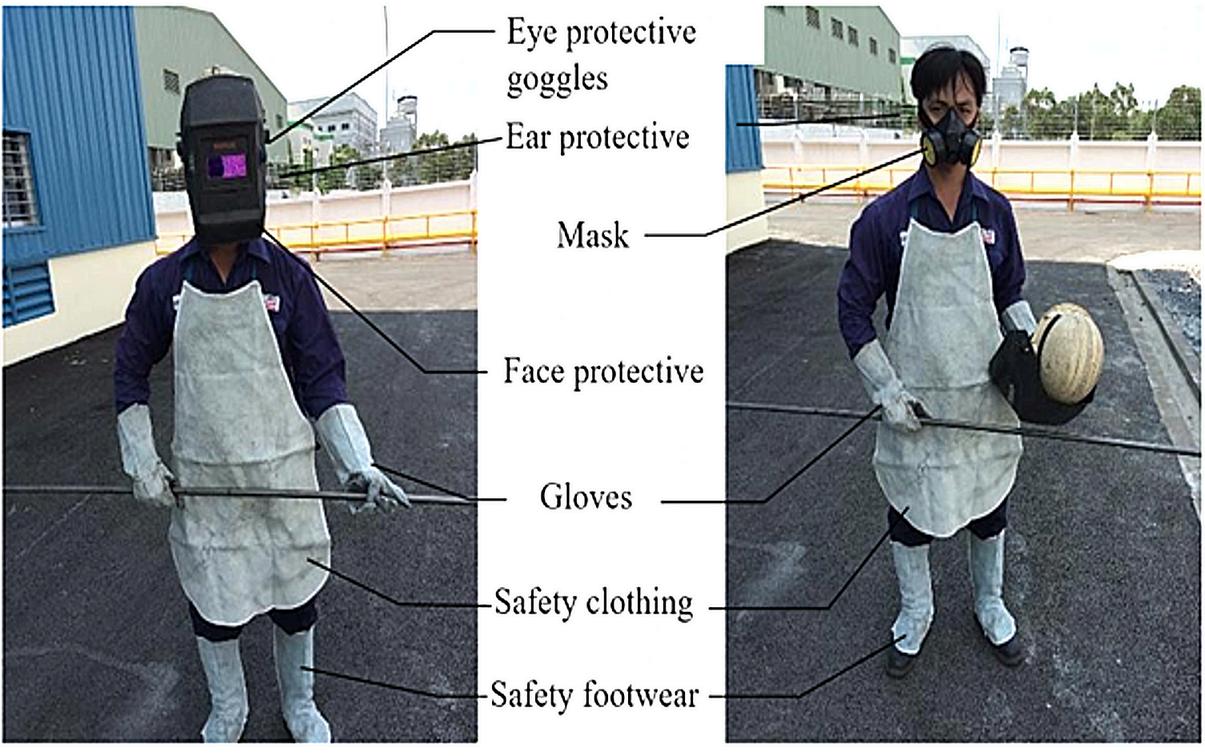

Our Lance Holder is a tool that is used to hold the Lance Pipes to pass oxygen through the same pipes and produces high temperatures for safely cutting iron castings, stainless steels, brass, ceramic.

These are manufactured using only the best class metals that resist erosion and corrosion. It helps in fixing the lance pipes properly to avoid any uncontrolled rotation. The ends are generally both smooth and threaded and it comes in accordance with the various specifications of the outside diameter of the pipes. The Lance holders also helps in any kind of oxygen leakages with the help of specialist seals or clamps proving safety to the work task performer.

Please contact your Daiwa Anaya Steel contact for detailed specification sheets

Oxygen Hose Connect with Lance Holder

Holder Spare Parts (Above)

Clamping Machine (Left)

Steel

Couplings

Steel

Oxygen Hose Connect with Lance Holder

Holder Spare Parts (Above)

Clamping Machine (Left)

Steel

Couplings

Steel

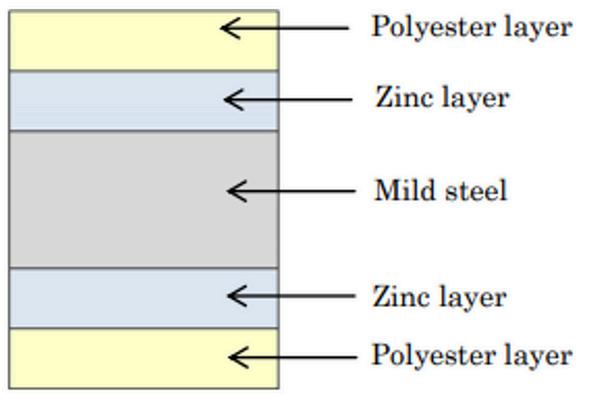

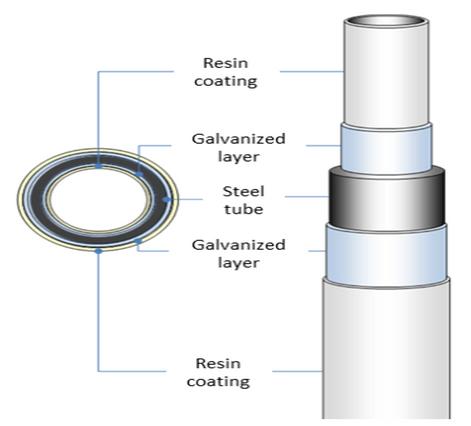

Our color coated pipe is a galvanized steel pipe with polyester powder coating over the surface. This product has longer time durability due to dual protection of metal plated and resin coating on both the sides of the pipe.

The resin coating (on both sides) provides superior rust protections – especially in high moisture environments. Our colored pipe is generally produced in white, but is available in custom colors. The color coating protects the steel from the sun's heat and provides protection from deterioration for vinyl sheet. Both the ends of the pipe are swaged for connection.

Layers of Coating on Pipe

Structure

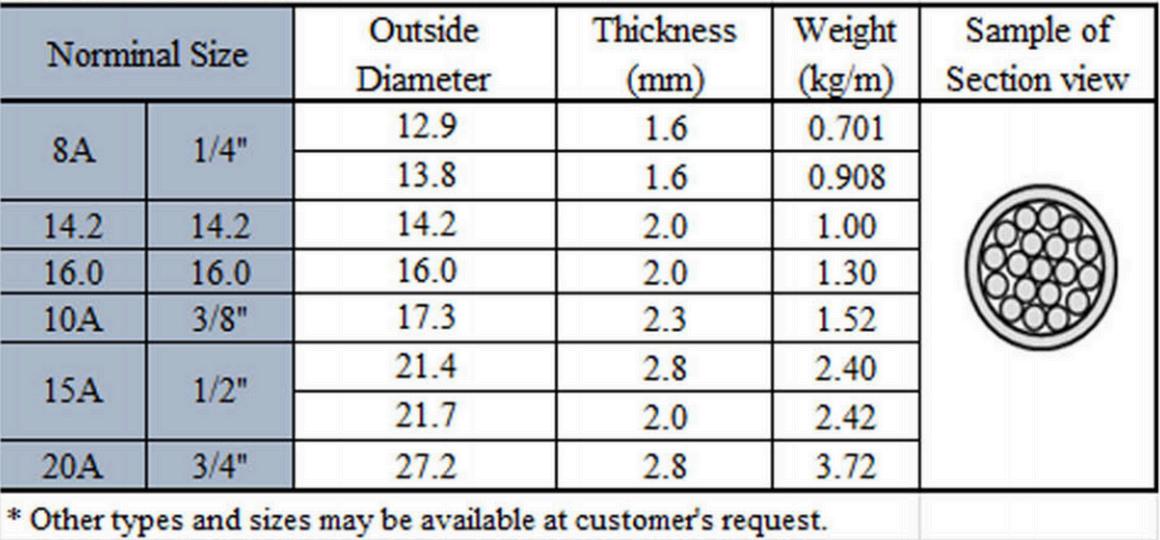

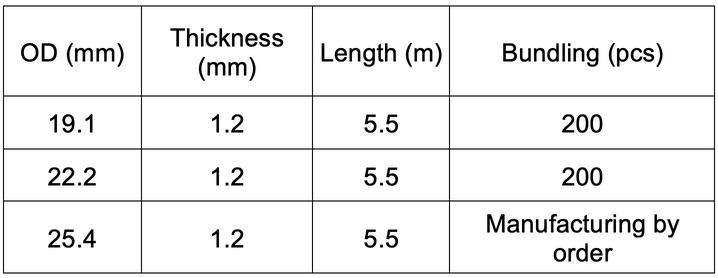

Technical Specifications:

USED IN THE GREENHOUSES BY WINDING THE SHAFT OF VINYL SHEET. OTHER APPLICATIONS INCLUDE PROVIDING HEAVY DUTY PROTECTION AGAINST CORROSION.

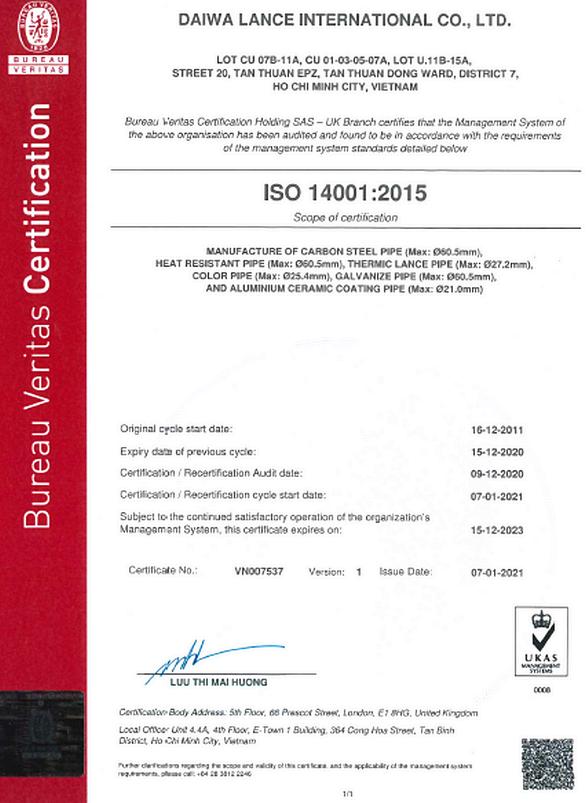

Daiwa Lance International has always been keen on following the international standards towards manufacturing and hence the factory received the 1st ISO certificate in 2001 following the ISO 14001 certificate in 2011.

Lately, DLI has renewed their certification of ISO 9001: 2015 and ISO 14001: 2015 approved by Bureau Veritas on 8th of Jan 2021.

DLI has always been active on execution of customer survey's annually to ensure they receive superior product quality while lessening the impact on the environment, and manufacture products in compliance with environmental laws, regulations and policies. The aforesaid requirements are fully met in both the products of Daiwa’s CA Lance and Thermic Lance.

Full Container Load Packaging

Less Than a Container Load Packaging

Chemical Analysis

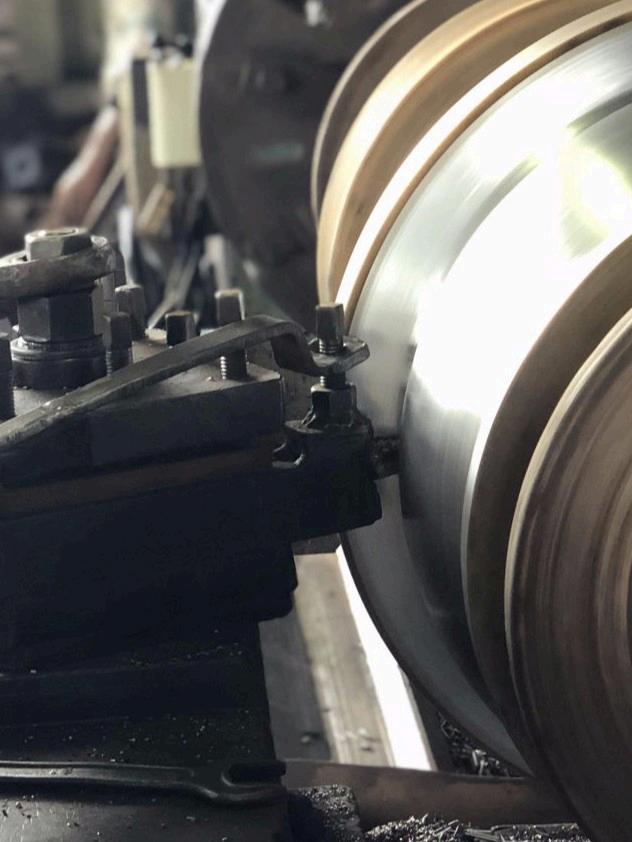

High Frequency Welding

At Daiwa Anaya Steel (DASPL), our team is committed to our customer's success. Although we provide products, our extreme focus is to provide solutions that allow our customers to succeed in the long run. This means providing products that are exceptionally safe, drive efficiency, and allow our customers to run more profitable operations. Rest assured, our team is committed to our client's goals.

You will see our attention to detail in everything that we do at Daiwa Anaya Steel. That includes each of our products that are manufacturing with the best raw materials and quality control standards. The excellence continues with our approach to customer service. Our team is an advocate for you and your business's operations. We guarantee world class products and customer service.

Daiwa Anaya Steel's team has been immersed into the steel industry for over 30 years. In addition, we fully intend on being around 100 years later. For this reason, we think longterm in everything we do. This includes our choice in materials and our approach to building relationships with our clients, We always work hard to deliver long-term value.

ANAYA STEEL – UNITED STATES OFFICE

Address: 10625 Jones Street, Suite 101A, Fairfax, Virginia 22124 USA

Email: sales@anayasteel.com

Tel: (703) 596-1056

Fax: (888) 285-2572

Web: www.anayasteel.com

ANAYA STEEL – MEXICO OFFICE

Address: Blvd. Adolfo Lopez Mateos #1702 Stadium Piso 4, 37500 León, GT Mexico

Email: sales@anayasteel.com

Web: www.anayasteel.com

DAIWA ANAYA STEEL PRIVATE LIMITED

Address: 1, AJC Bose Road, 4th Floor, Kolkata, India, 70020

Email: sales@daiwanayasteel.com

Tel: (91) 33-22816670

Fax: (91) 33-40033823

Web: www.daiwaanayasteel.com

DAIWA STEEL TUBES INDUSTRIES (JAPAN)

Address: 4530-1 Washijuku, Sakura-city, Tochigi 329-1411 Japan

Web: www.daiwast.co.jp/en

DAIWA LANCE INTERNATIONAL

Address: Road 20, Tan Thuan Export Processing Zone, Tan Thuan Dong Ward, District 7, Ho Chi Minh City, S.R.Vietnam.

Email: info@daiwalance.com.vn

Web: www.daiwalance.com.vn

Note: This is the manufacturing factory

Daiwa Anaya Steel services the following areas: India Middle East CIS North Africa Central Africa