POR FOL OT

2022-2023

2022-2023

Date of birth: 10th November, 2000

Email: sodenkhangsarpa@gmail.com

Instagram ID: angie_sodenz

Phone no.: 8999380773 7557819684

Address: Tsugshing house, Arithang

Gangtok, Sikkim

Language: English, Nepali, Hindi

EDUCATION

COMPETITION

2020 1st-2nd year

• Housing project Tranquility housing

• NASA Landscape trophee

2021 2nd-3rd year

• Womens Pavilion: Volume Zero TOP 50

• Poetry competition TOP 50

• Essay Competition

2022 3rd-4th year

• Natural Habitat: Volume Zero

• Maharashtra Pavilion

INTEREST

• Sketching

• Photography

• Guitar / Music

• Reading

DOCUMENTATION

• Colours of Sikkim

• Traffic of Mumbai Naka

• Traffic solutions Ashok Stambh

RESEARCH PAPER

2019

Higher secondary: Tashi Namgyal Academy

ICSE

2019-2024

Under-graduate degree: Bachelor of Architecture

NDMVP SPCOA, Nashik, Maharashtra

2023 4th year

• Traffic and tourism competition Nashik

• Development of a Hill Station: in the organic place of Sikkim (Selected for conference)

EXPERIENCE & ACHIEVEMENT

• ISHRAE Nashik Chapter member

• NPTEL UX-UI course complete

• NPTEL Contemporary architecture course complete SKILLS

ANGELA SODEN KHANGSARPA

“Purpose is the reason you journey. Passion is the fire that lights the way”

Drafting softwares

Modeling softwares Rendering softwares

Autocad Revit Sketchup

Post production softwares Microsoft office power point excel words

Indesign

Geographic information system softwares

GIS

Illustrator Photoshop

Illustrator Photoshop

01

WATER CIRCULATION DIAGRAM 0.00

1

Hotel Rasa Location: Karjat Page 3 -13

+12 M ± 0.00

0 0 0 0

+9 M

Detail D for infinity pool Detail E 400 MM in height E

-2M

+12 M -5 M

2

Trimbak Housing Location: Trimbakeshwar Page: 14-23

STAMP ANGELA SODEN KHANGSARPA ABCS +9 M

SURFLOW NOZZLE DETAIL

Competition & Documentation Page: 24-30

SECTION A-A SECTION B-B SIGN

Learner's Pool (25m*13m) 02

3 5 4 Miscellaneous Page: 37-40

Sump Overflow Channel Fresh water inlet Surflow channel and nozzel Towards drain/disposal Meter A

DETAIL D LIGHTING DRAINAGE LADDER SURFLOW NOZZEL TILE TILE ADHESIVE/MORTAR RAFT WATERPROOFING EXTERNAL WATERPROOFING WATER PROOFING GROUT WATER PROOFING SHAHABAD TILE TILE` WATER DRAINAGE PIPE 1:10 WATER PROOFING DETAIL WATER GROUT PROOFING GRATING TILE GRATING WATER PROOFING DETAIL WATER GROUT PROOFING HANDRAIL AND OVERFLOW DRAIN +10 M +1 M +5 M +7.5 M +3 M

Drafting & QGIS Page: 31-36 YEAR SEM ROLL.NO. DATE 4rd VII 18/8/2022 NDMVP S COA NASHIK

10

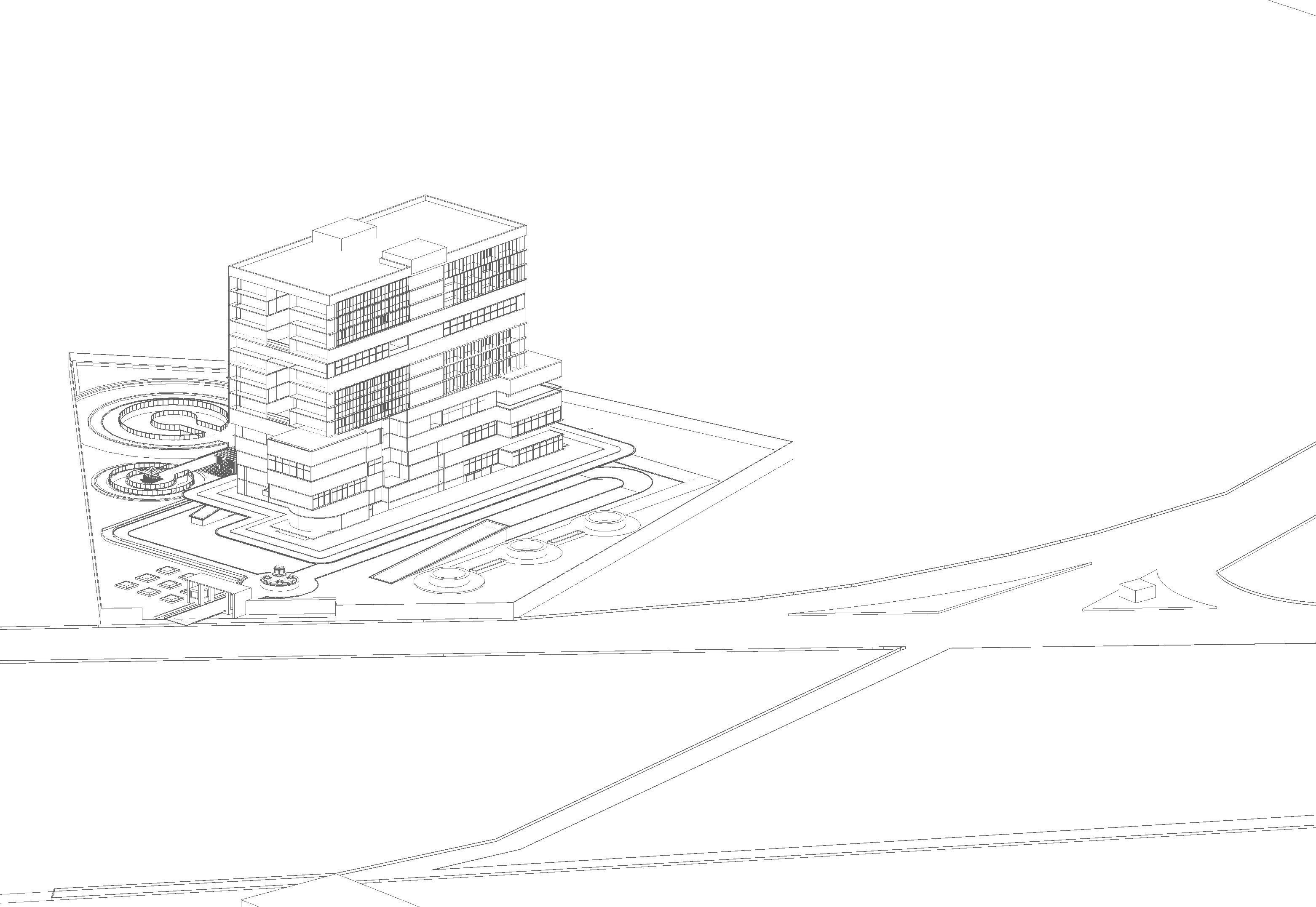

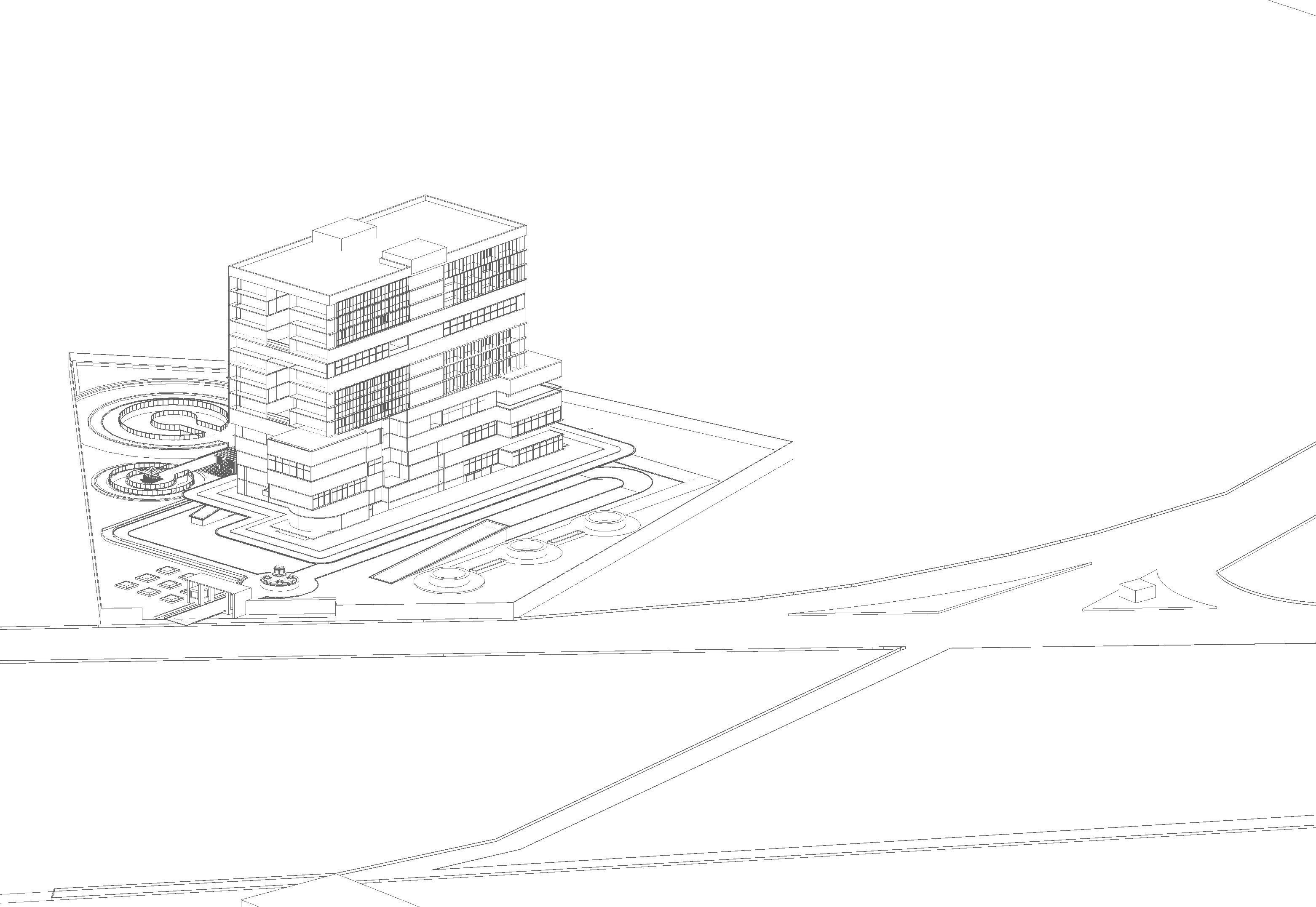

HOTEL RASA

5th semester | 3rd year | Design

Typology : Hospitality

Area : 2 hectares

Location : Karjat, Maharashtra

Known for its breathtaking vistas, Karjat is a little hill station located at a distance of 62.7 Km in the south western direction form Mumbai, also popularly known as the “City Of Dreams”

True to its name, Mumbai is the power house of the Indian cinema and holds utmost power over the industry. The fascination for films spreads through out the state of Maharashtra. Hence, keeping the spirit of the love for film industry and their actors alive, the project “Hotel Rasa” has been proposed.

Photoshop ,Autocad ,Sketch up 03 Hotel Rasa I 5th semester I 3rd year

Autocad,

up,

04 Hotel Rasa I 5th semester I 3rd year

Revit, Sketch

Twinmotion, Photoshop

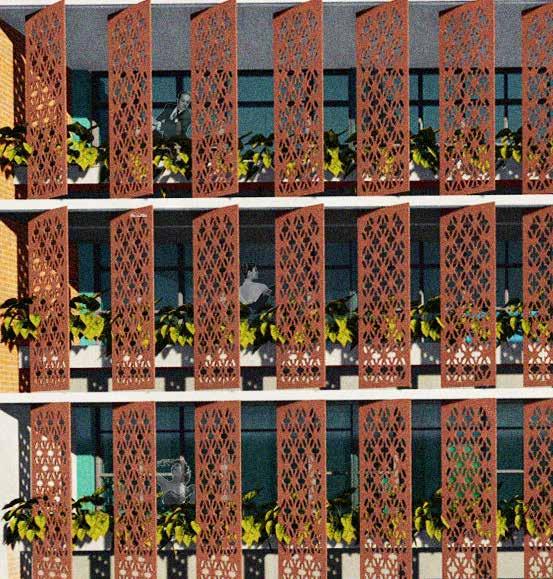

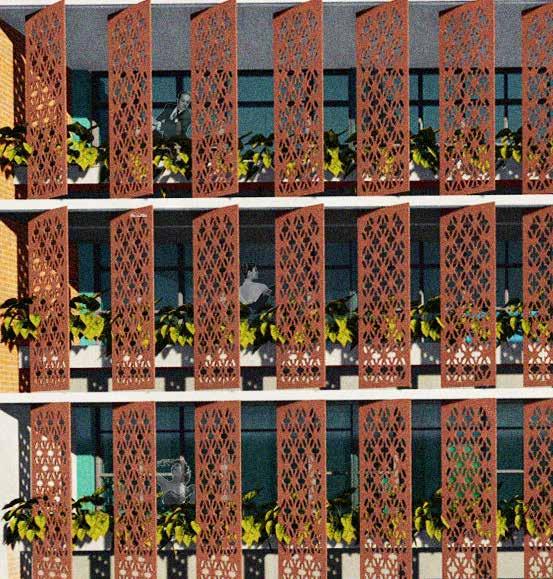

SOUL OF THE DESIGN

The design evolved from the strategies of a climate responsive building. Imitating the brutalist surroundings of the Sahyadri Hills and the vegetation exposed concrete and brick facade have been used. Strategies such as the use of louvers and the idea of the use of geothermal energy has been used. .

Design Evolution

The activity spaces have mostly been restriced to the bottom half of the structure consisting of 5 floors of heights 4m individually.

The rooms have been equally distributed between the rooms for people and the rooms for VIP such as actors, directors and so on. This design strategy has been implemented taking into consideration the need for private spaces for the actors and set crew who may visit the site for any filming activity.

05

Illustrator, Sketchup

Hotel Rasa I 5th semester I 3rd year

MASTER PLAN

24Mwideroad

Strategies

Aluminium Jaali

Screening against dust I Cooling the air I Shading against the sunlight

Linear blocks placed parallely to each other to permit the wind to unobstructedly flow through

The longer side of the building has been oriented towards the North - South direction to allow more of the diffused light to penetrate into the structure while minimizing the harsh East-west sunrays which causes glare

06

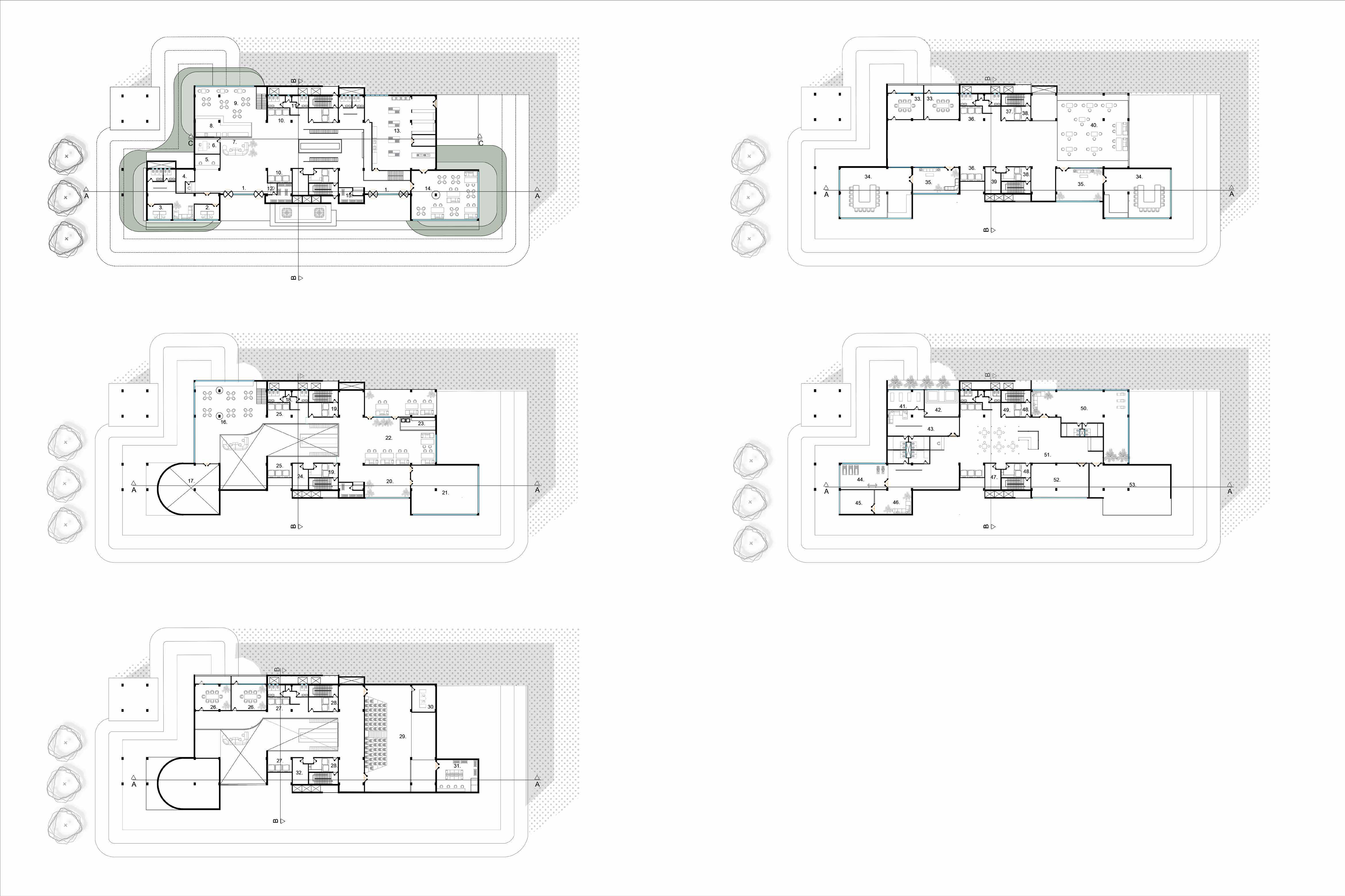

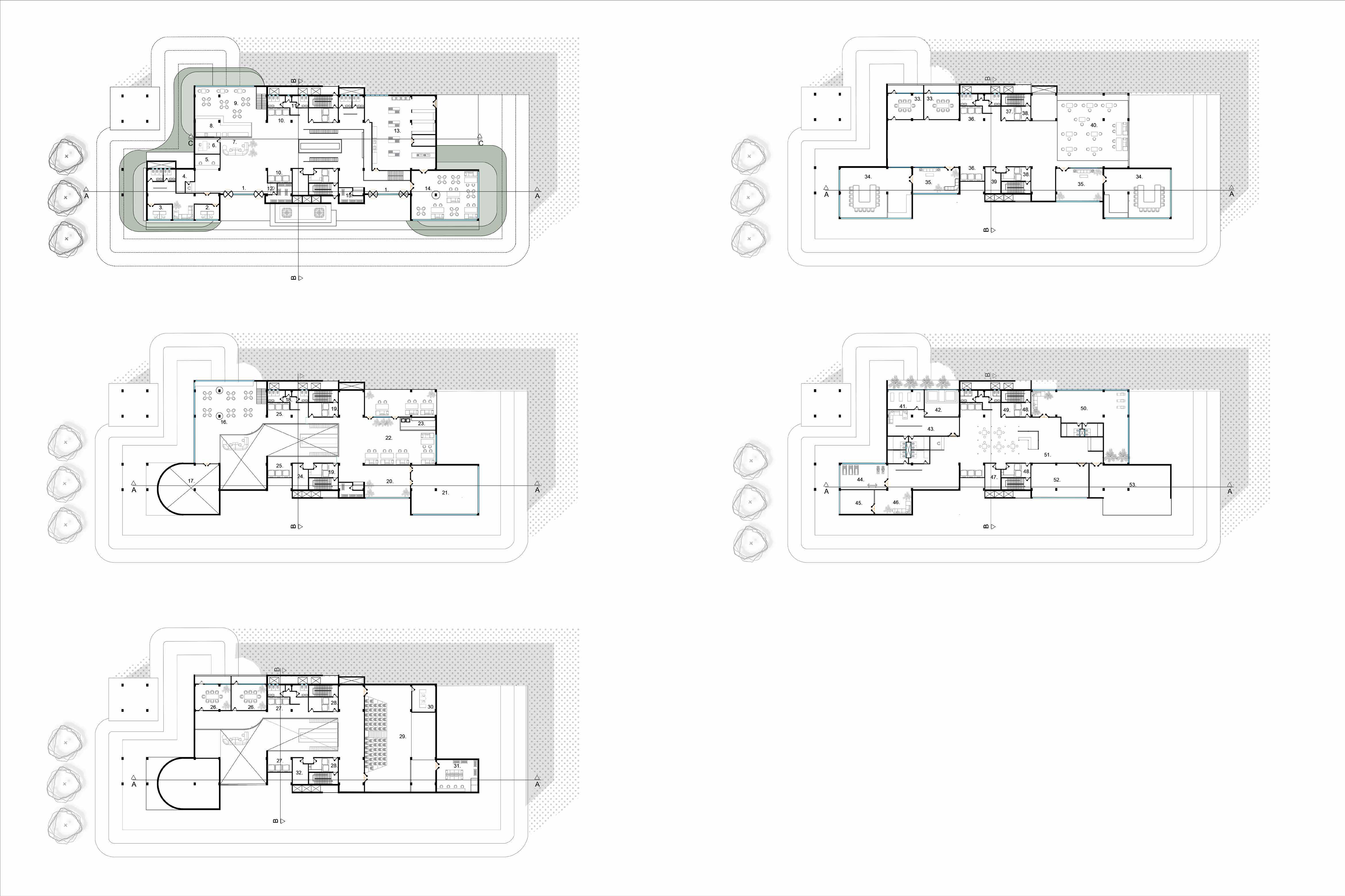

Autocad, Sketchup, Photoshop, Illustrator

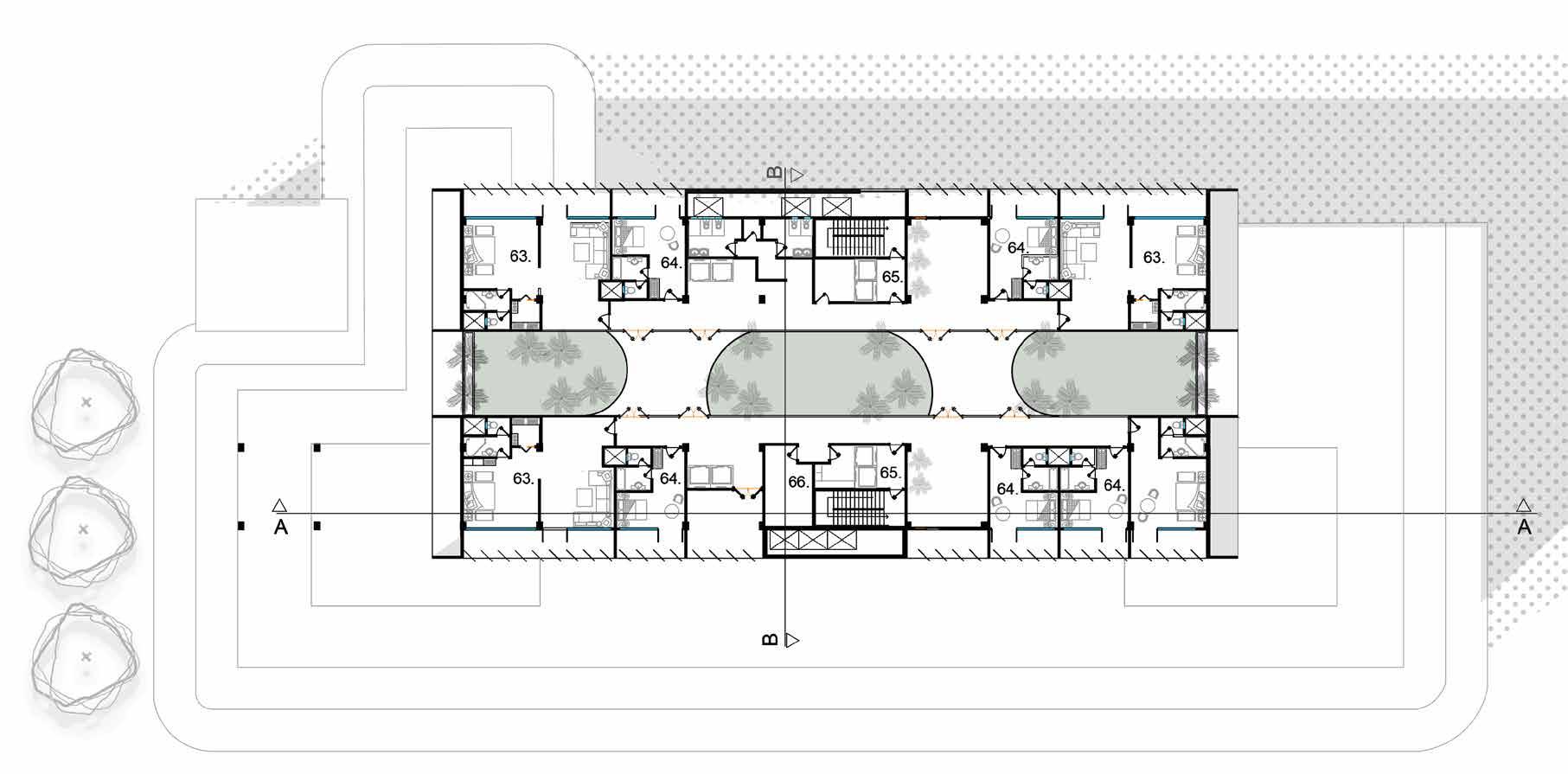

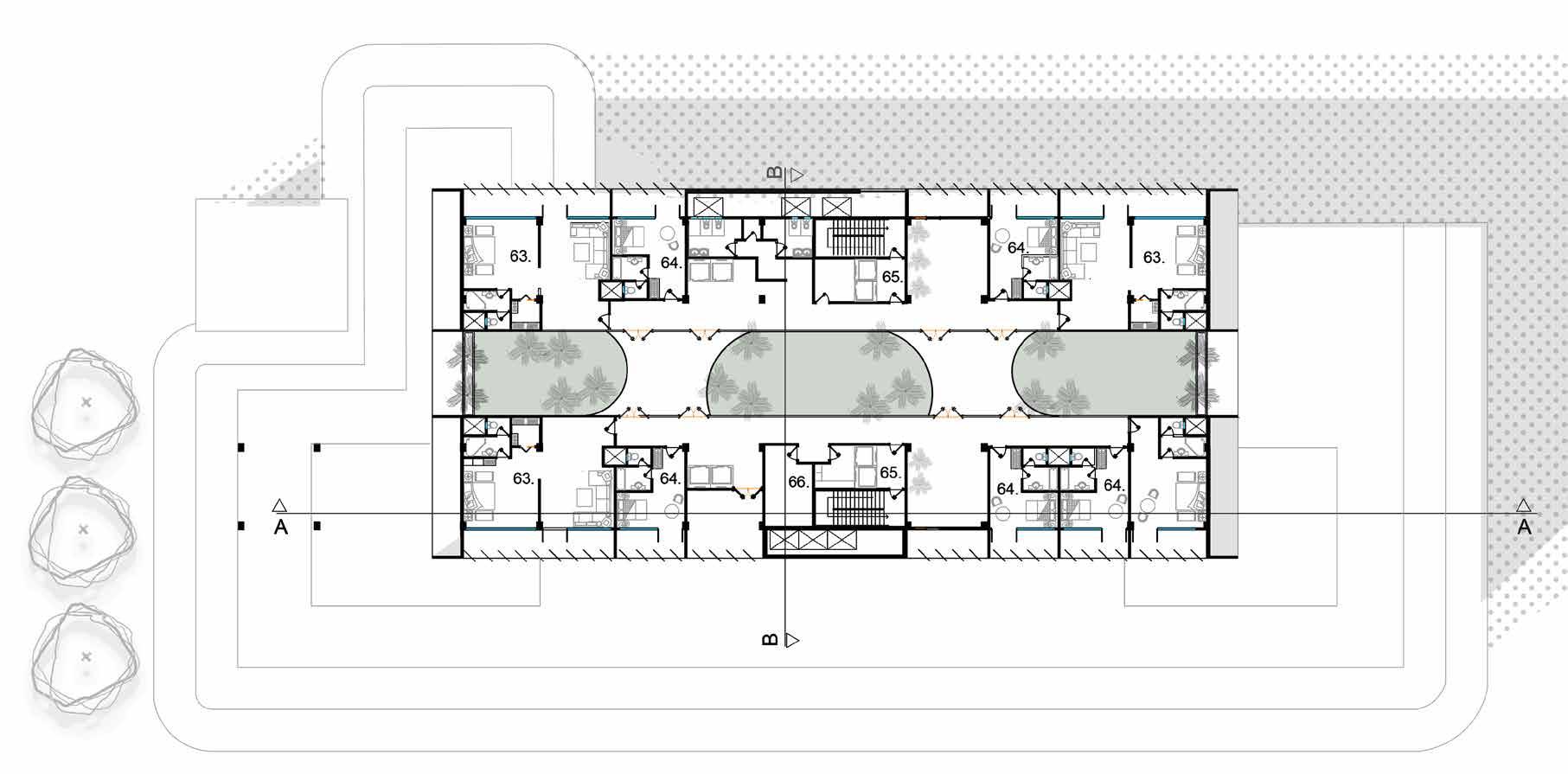

Hotel Rasa I 5th semester I 3rd year 5 10 15 0

FLOOR PLANS

Ground Floor

1. Entrance lobby2.Security office3.BMS system office 4. Luggage room 5.Tourism office 6.Front desk manager 7.Reception 8.Cafe 9.Cafe seating 10.Elevator 11.Services (Washroom/store) 12.Coat room 13.Wet and dry kitchen 14.Cafeteria/Dining 15.Coat room

Second Floor

26.Meeting room 27.Elevator 28.Laundry chute 32.Service room 29.Theatre 30.Office 31.Backstage changing room

First Floor

16. Cafeteria 17. Screening roon 25.Elevator 18.Services (Washroom/store) 19. Laundry chute 20.Waiting lounge 21. Hall 22. Restaurant 24.Service room

Third Floor

33.Meeting room 36.Elevator 38.Laundry chute 39.Service room 34.Conferece room 35.waiting lounge 40.Cafeteria

Autocad, Photoshop

5 10 15 0

5th

07

Hotel Rasa I

semester I 3rd year

Autocad, Photoshop 08 5 10 15 0 Fourth floor Rooms Rooms Rooms 54. King bedrooms, 55. Junior Suites, 56.Smoke control room 59. King bedrooms 58. Executive suites 56.Smoke control room 64.King bedrooms 63.Presidential suites 65.Smoke control room Hotel Rasa I 5th semester I 3rd year

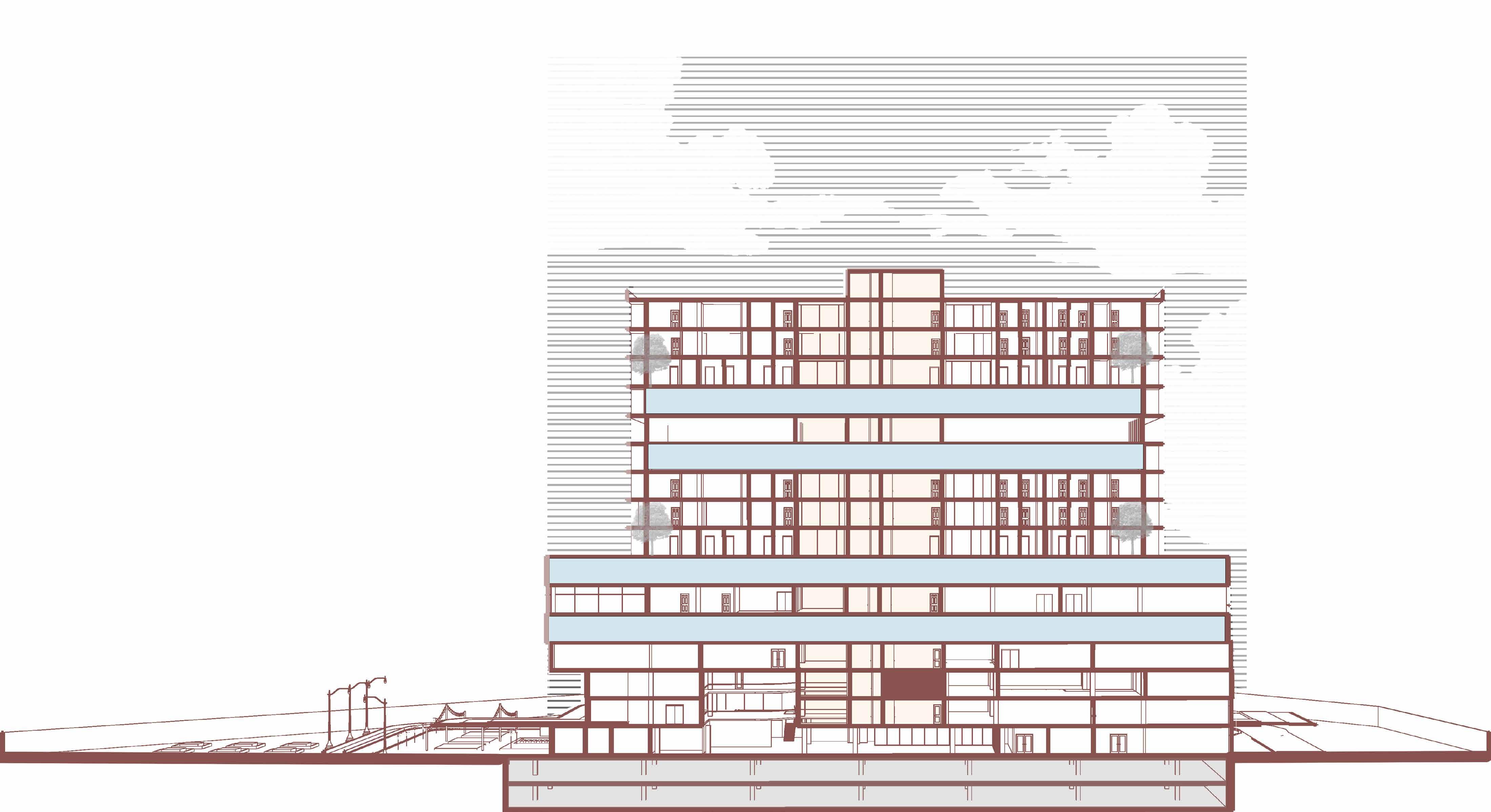

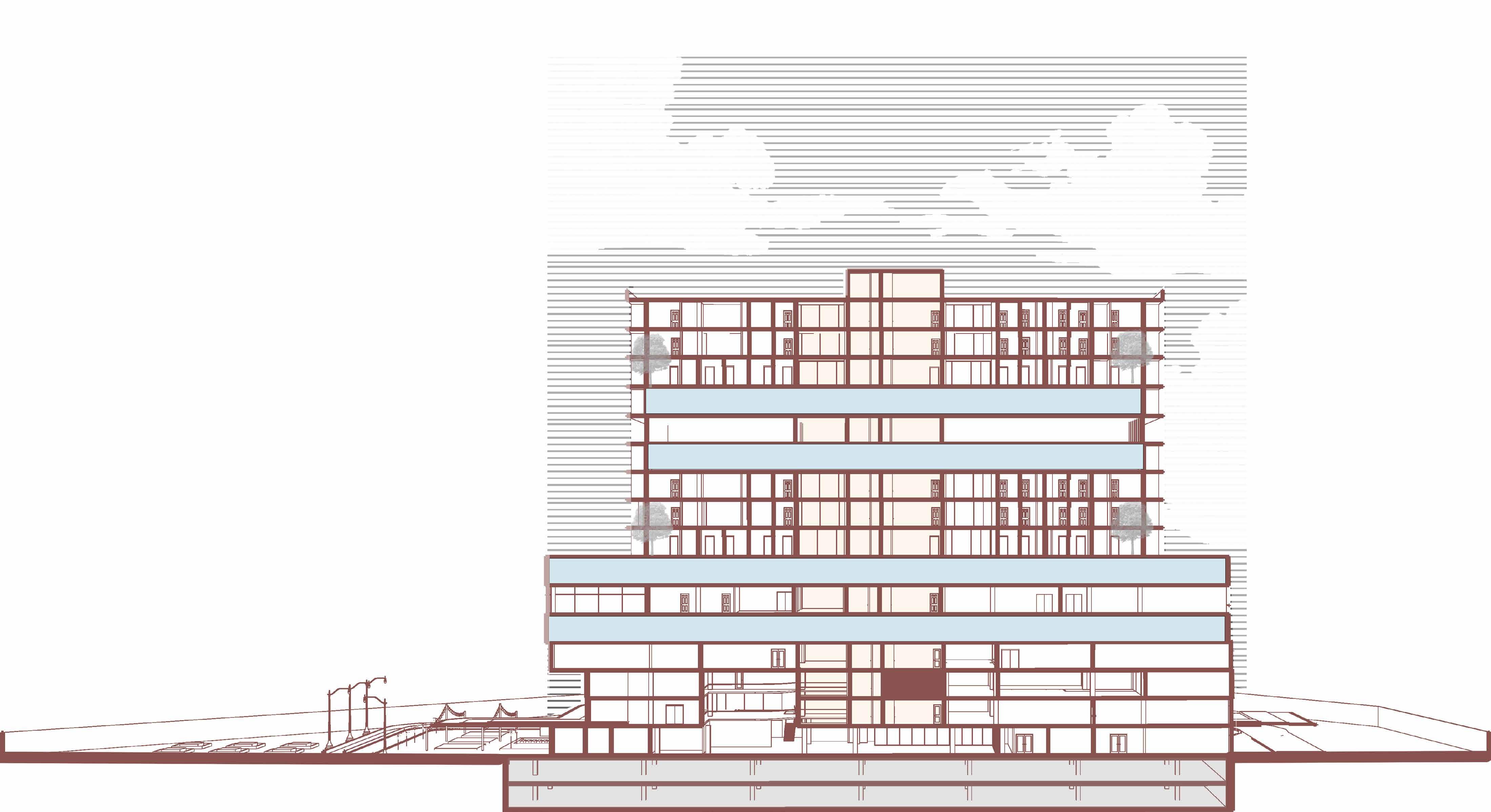

09 Hotel Rasa I 5th semester I 3rd year +8.75 m +4.6 m +12.95 m +17.05 m +19.9 m +23.75 m +26.3m +30.45 m +34.6 m +38.75 m +41.6 m +45.75 m +48.3 m +52.45m +56.6 m +60.75 m

Revit, Sketchup, Photosop,Illustrator

Twin size room

SECTION A-A 1 2 3 0

Entrance lobby Balcony

10 +8.75 m +4.6 m +12.95 m +17.05 m +19.9 m +23.75 m +26.3m +30.45 m +34.6 m +38.75 m +41.6 m +45.75 m +48.3 m +52.45m +56.6 m +60.75m

Hotel Rasa I 5th semester I 3rd year

1 2 3 0

Revit, Sketchup, Photoshop,Illustrator

SECTION B-B

Seatingarea Space usedforexhibition et c

ewing Gallery 11 Hotel Rasa I 5th semester I 3rd year Place for Concerts I Exhibition I Set design entertainment centre I Green space for leizure purpose Sketchup, photoshop, twinmotion

Vi

louvers allow for cooling of air & diffusion of sunlight

12

Autocad, Sketchup, V-ray, Photoshop

Hotel Rasa I 5th semester I 3rd year

13

Sketch up, revit, Twinmotion

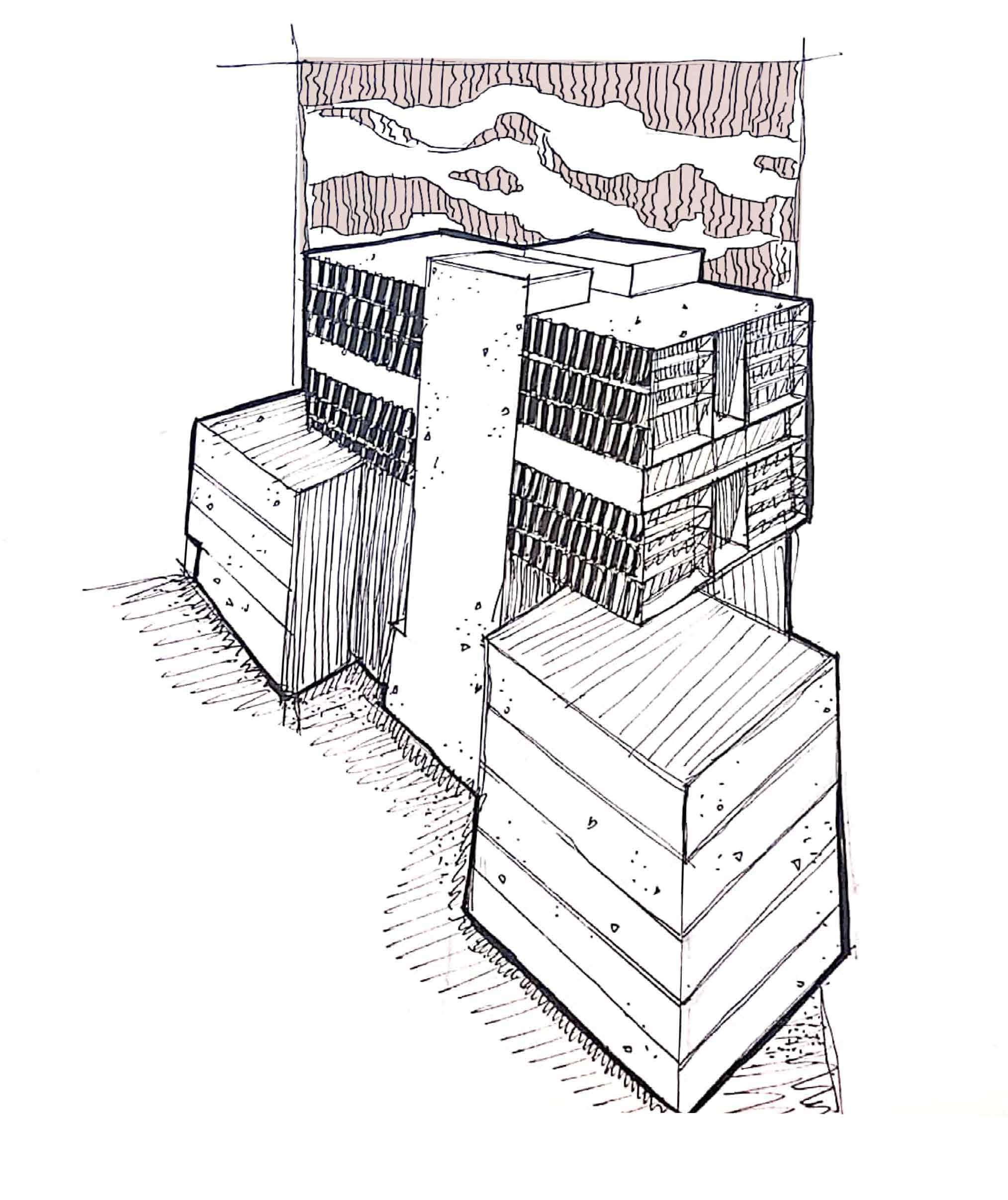

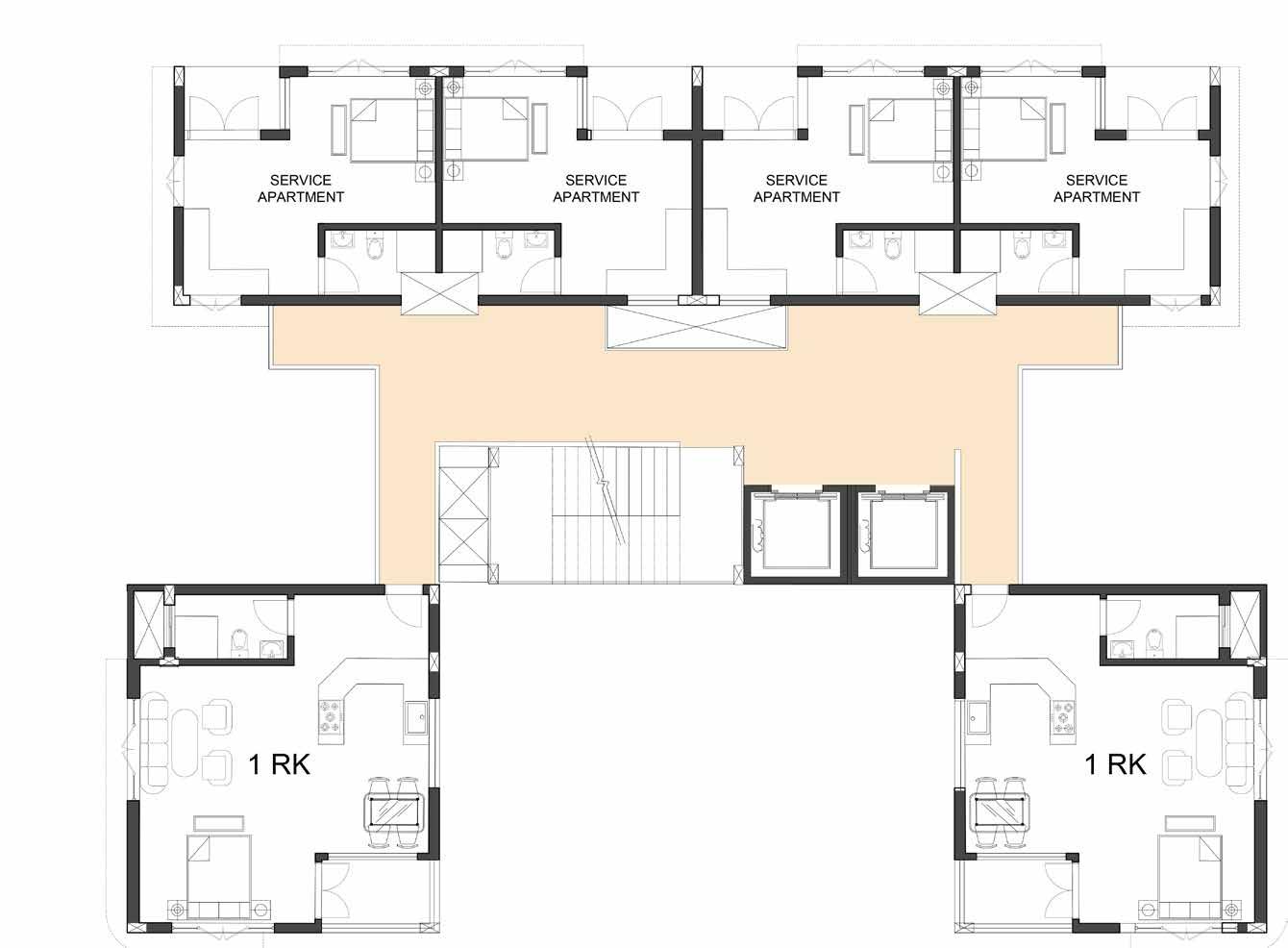

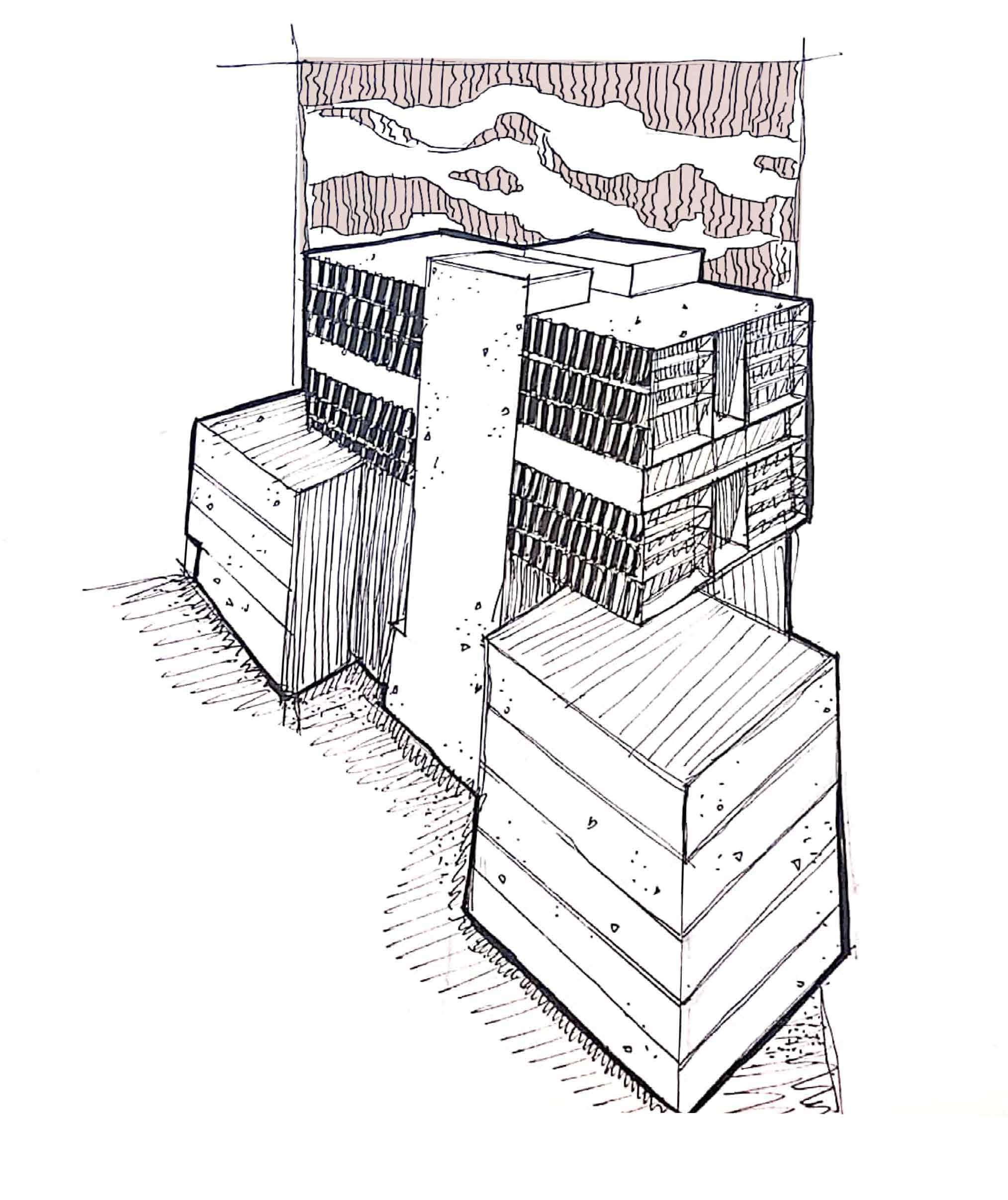

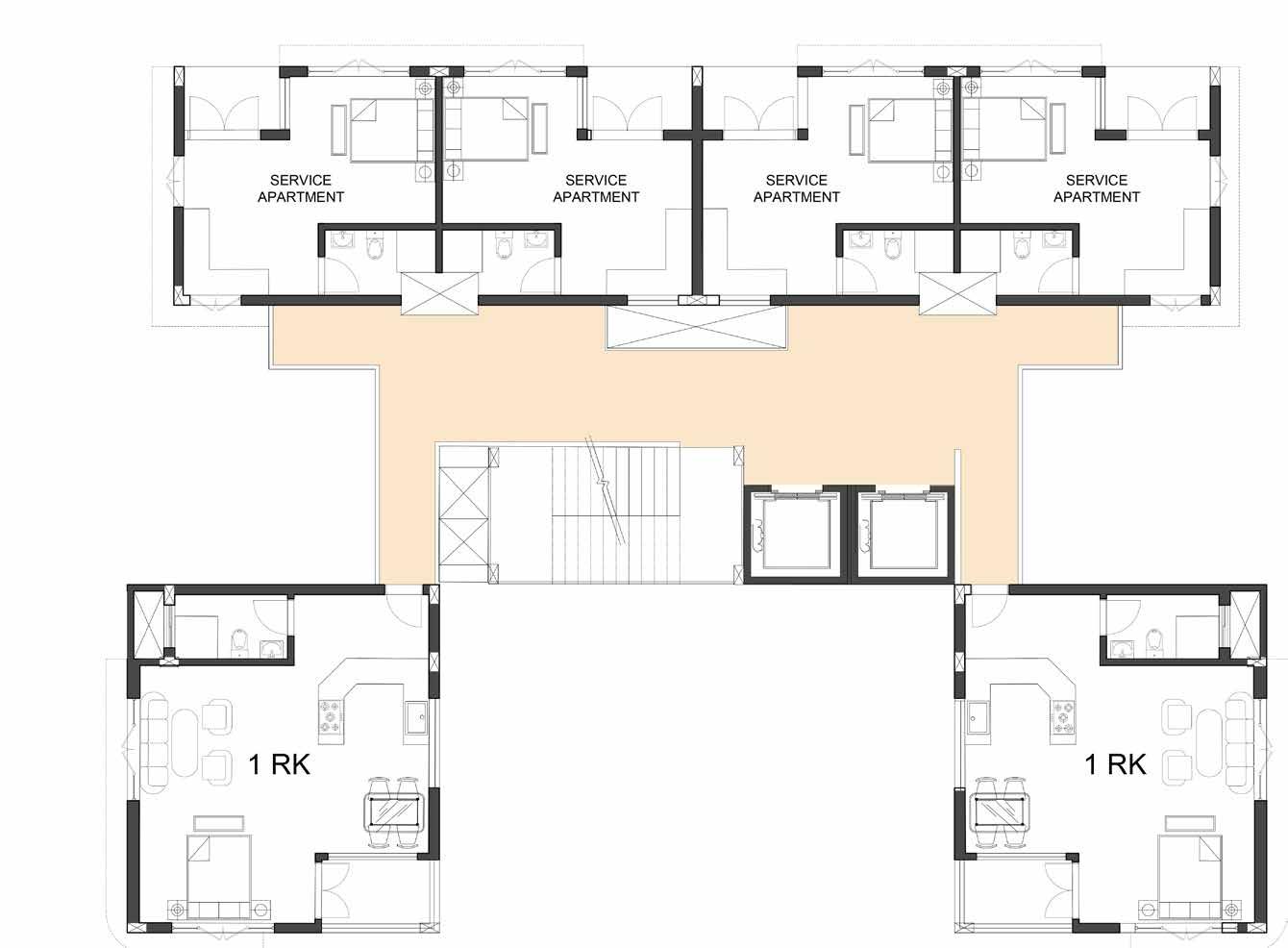

TRIMBAK HOUSING

2 Trimbak Housing

7th semester | 4th year | Design

Typology : Housing

Area : 2 hectares

Location : Trimbakeshwar,Maharash-

Known to be one of the most religious and sacred places in India, Trimbakeshwar is also the origin of the river Godavari which flows through Nashik. Housing the tri ling, it attracts flocks of tourists every year giving a rise to the economy of the place, but does Trimbakeshwar town have enough facilities to house the mass of tourists and pilgrims? and are the residents of Trimbak satisfied by their current living conditions?

Unfortunately, there has been a scarcity of housing facilities and proper sanitation for the tourists and the residents feel the need to move to a better place where the services are up to the mark and where they would not face troubles of roof leakages during the monsoons, hence a housing project for the residents of Trimbak as well as a rental for the tourists and the pilgrims was the need of the hour.

15

Trimbak housing I 7th semester I 4th year

0

Photoshop,Autocad,Sketch up

16

Trimbak housing I 7th semester I 4th year

Autocad, Sketchup, Lumion, Photoshop

use of podiums at two different level to segregate activities

1 RK & Service Apartment

SOUL OF THE DESIGN

The design was formulated as a responce to the terrain of the site, with a difference of 7m from the lowest to the highest contour.

The podium acts as a separation between the rental apartment and the residential apartment as well as the amenities area with the housing area.

Residential Apartments

2 wheelers parking

17

Autocad, Sketchup, Illustrator

Trimbak housing I 7th semester I 4th year

MASTER PLAN

Following the street scape of the Trimbak town, a linear apporoach to the planning has been made. The slope of the site allows for play of spaces at various heights.

The activities have been distributed between different levels, ensuring the privacy of the residential area while maintaining the connections of various activity areas.

This has been possible by the placement of the 2 podiums, placed one a top the other.

18

5 10 15 0 Trimbak housing I 7th semester I 4th year

Autocad, Sketchup, Photoshop, Illustrator

19

SECTION D-D SECTION A-A

Trimbak housing I 7th semester I 4th year

Autocad, photoshop

SECTION C-C

SECTION B-B

20 Autocad, photoshop Trimbak housing I 7th semester I 4th year

3 6 9 0

1 RK & SERVICE APARTMENTS MASSING CONNECTIVITY 1 BHK & 2BHK APARTMENTS Trimbak housing I 7th semester I 4th year 21

Autocad, Sketchup, Illustrator, photoshop

ISOMETRY EXPLODED VIEW

Trimbak housing I 7th semester I 4th year

Autocad, Sketchup, V-ray, Photoshop

LIVING ROOM

DINING & KITCHEN 2 BEDS AND WASHROOM

Trimbak housing I 7th semester I 4th year 22

Trimbak housing I 7th semester I 4th year

Autocad, Sketchup, twinmotion Photoshop

23

Window section through wooden chajja

COMPETITION & DOCUMENTATION

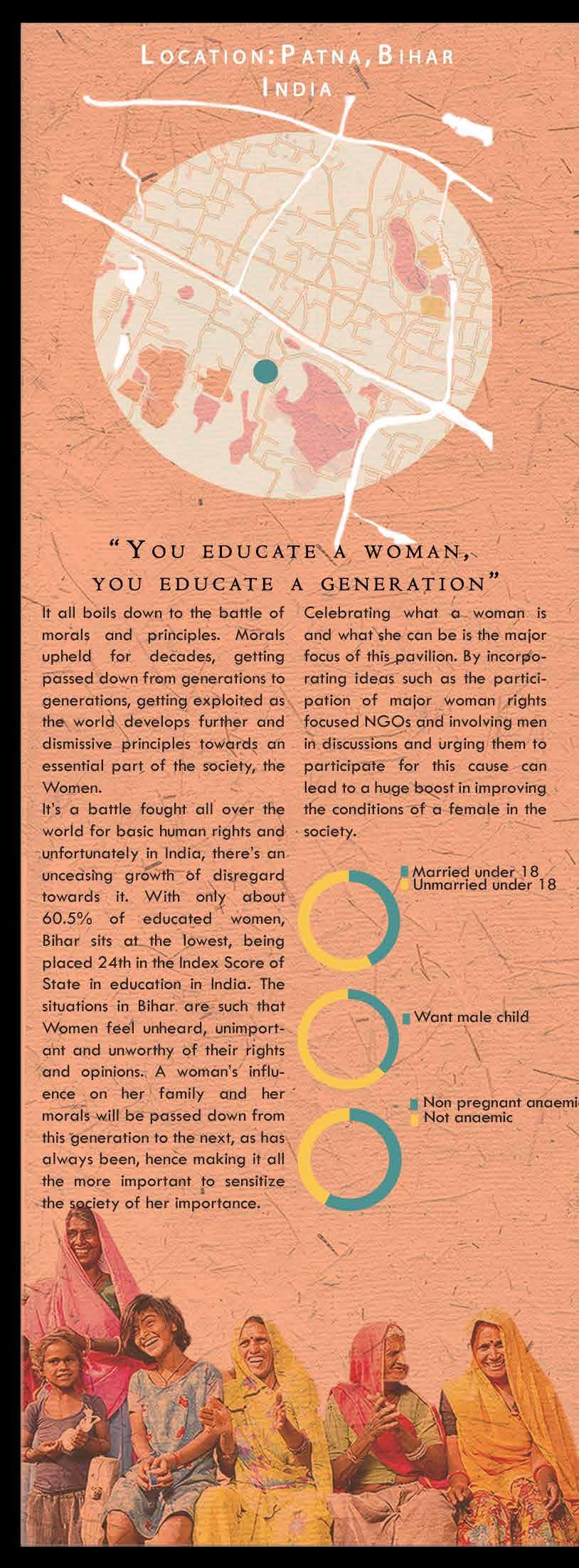

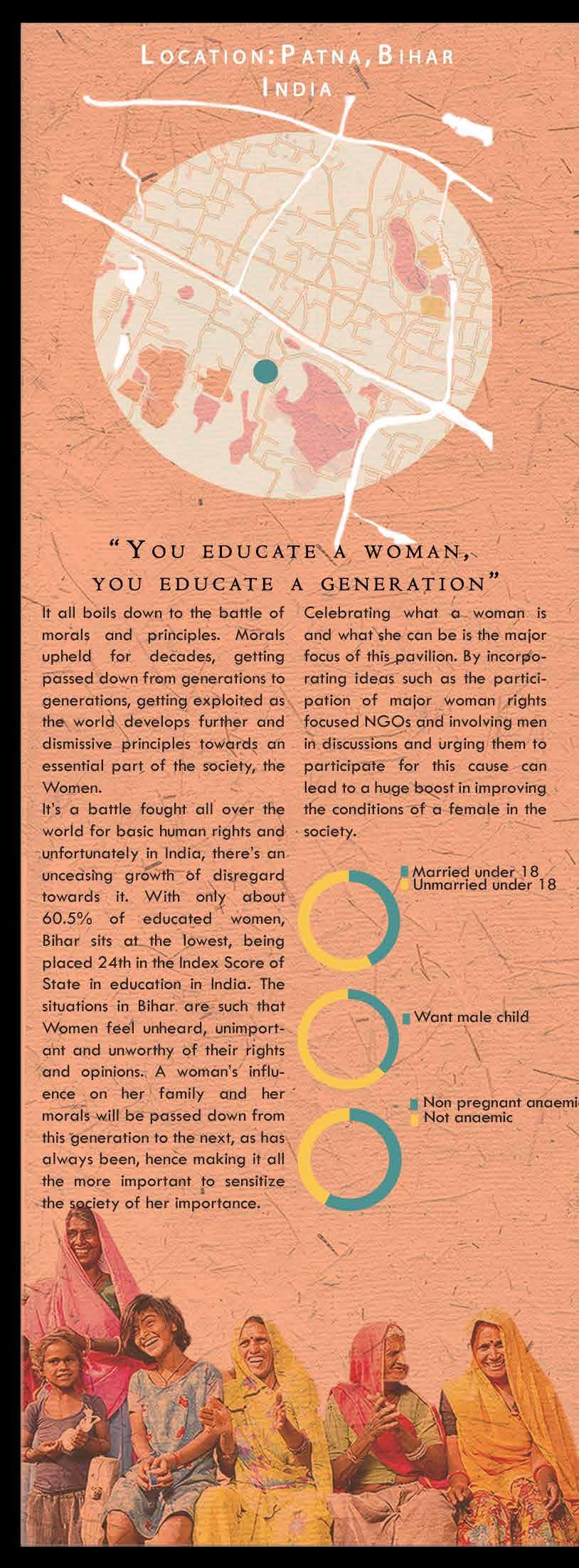

WOMENS PAVILION

PROMOTERS: VOLUMEZERO

Top 50 Selected

BRIEF

To locate a place where women are in most need of help and education.

To create a pavilion for them to openly interact and learn about various fields of knowledge.

Womens pavilion I Competition I

25

Autocad, Sketchup, Lumion, Photoshop

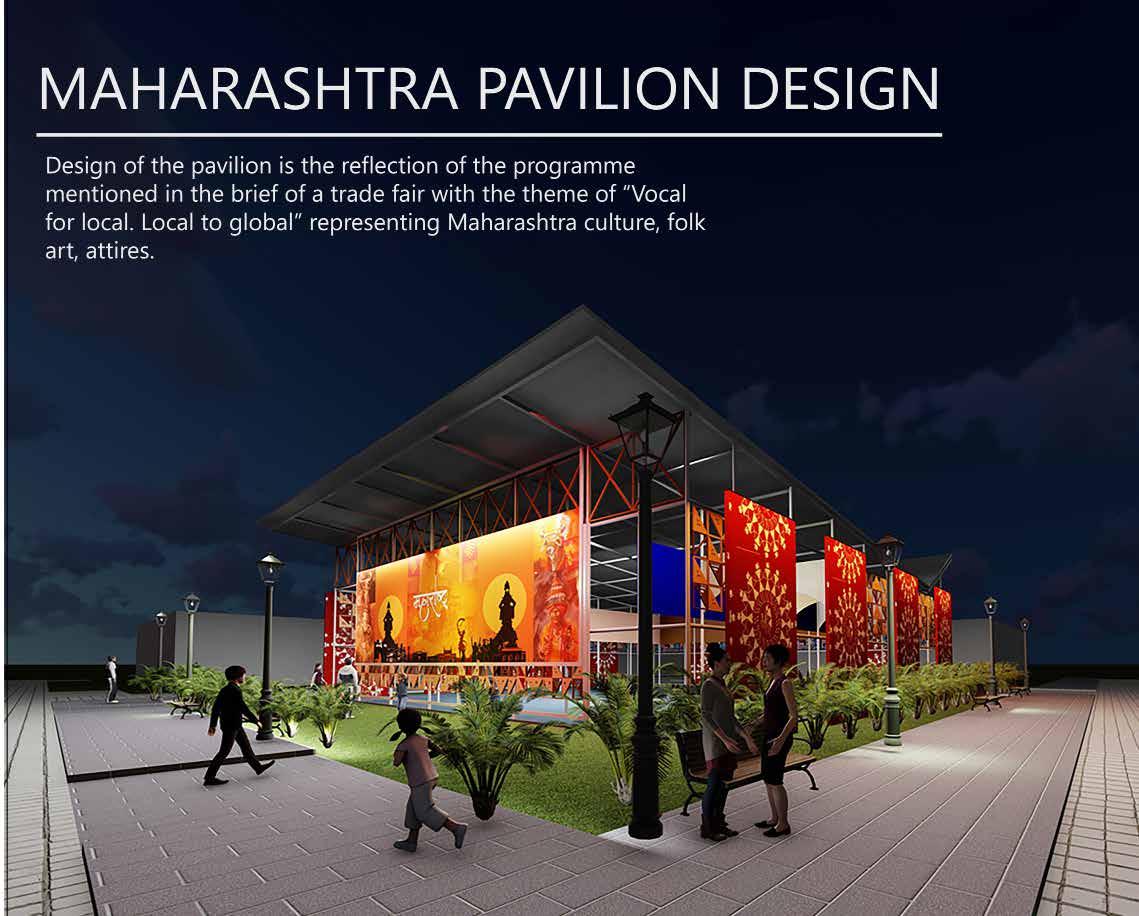

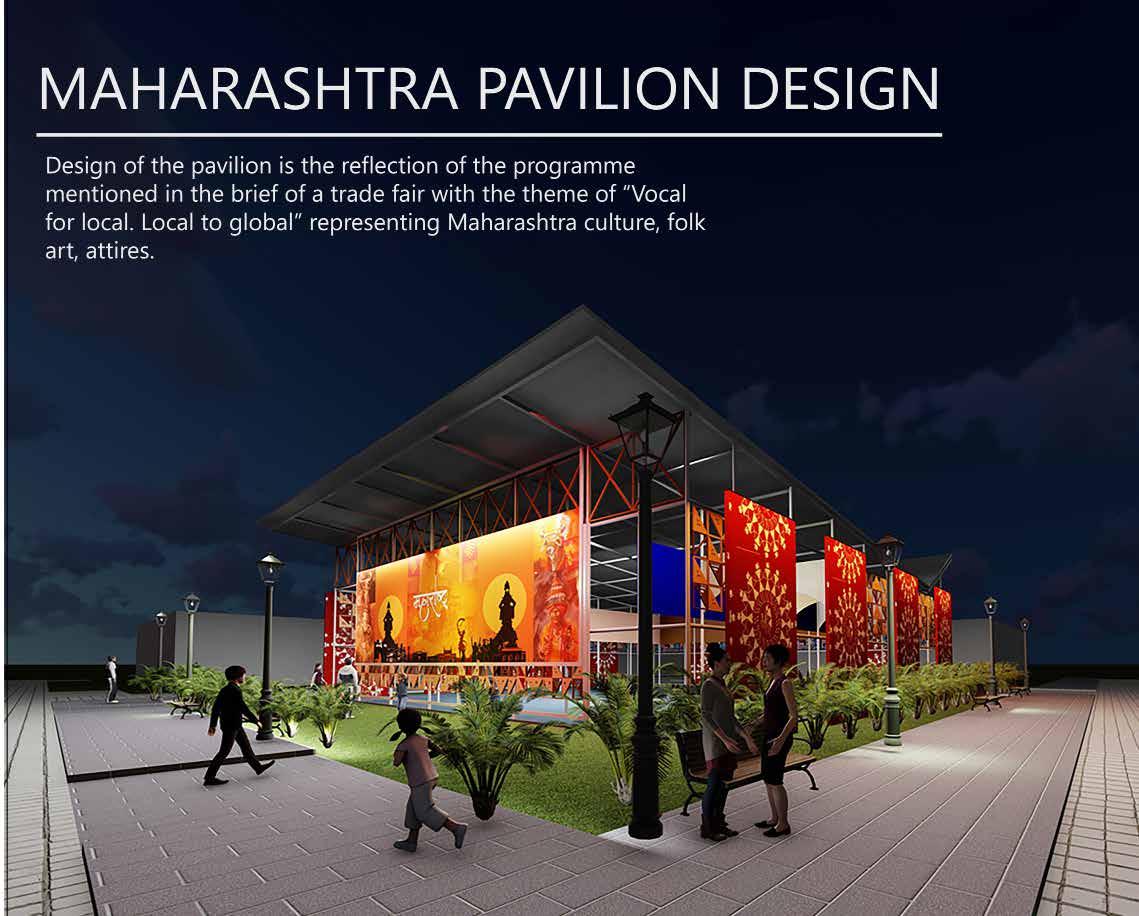

MAHARASHTRA PAVILION

PROMOTERS: ITPO BRIEF

To create a pavilion best representing the culture and diversity of Maharashtra to be constructed in Pragati Maidan, Delhi, abiding by the moto “Vocal for local, local to Global”

Maharashtra pavilion I Competition I

Autocad, Sketchup, Lumion, Photoshop

Maharashtra pavilion I Competition I

Autocad, Sketchup, Lumion, Photoshop

26

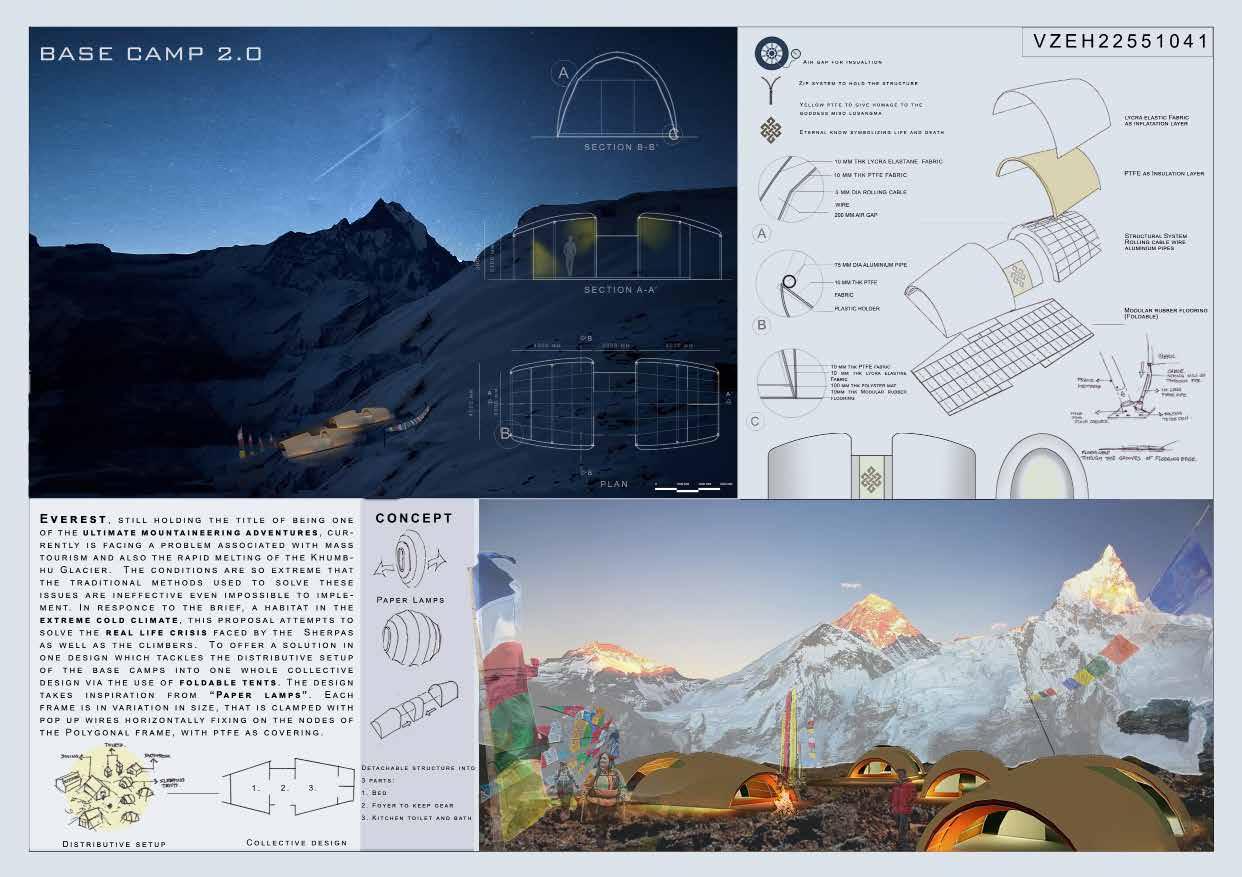

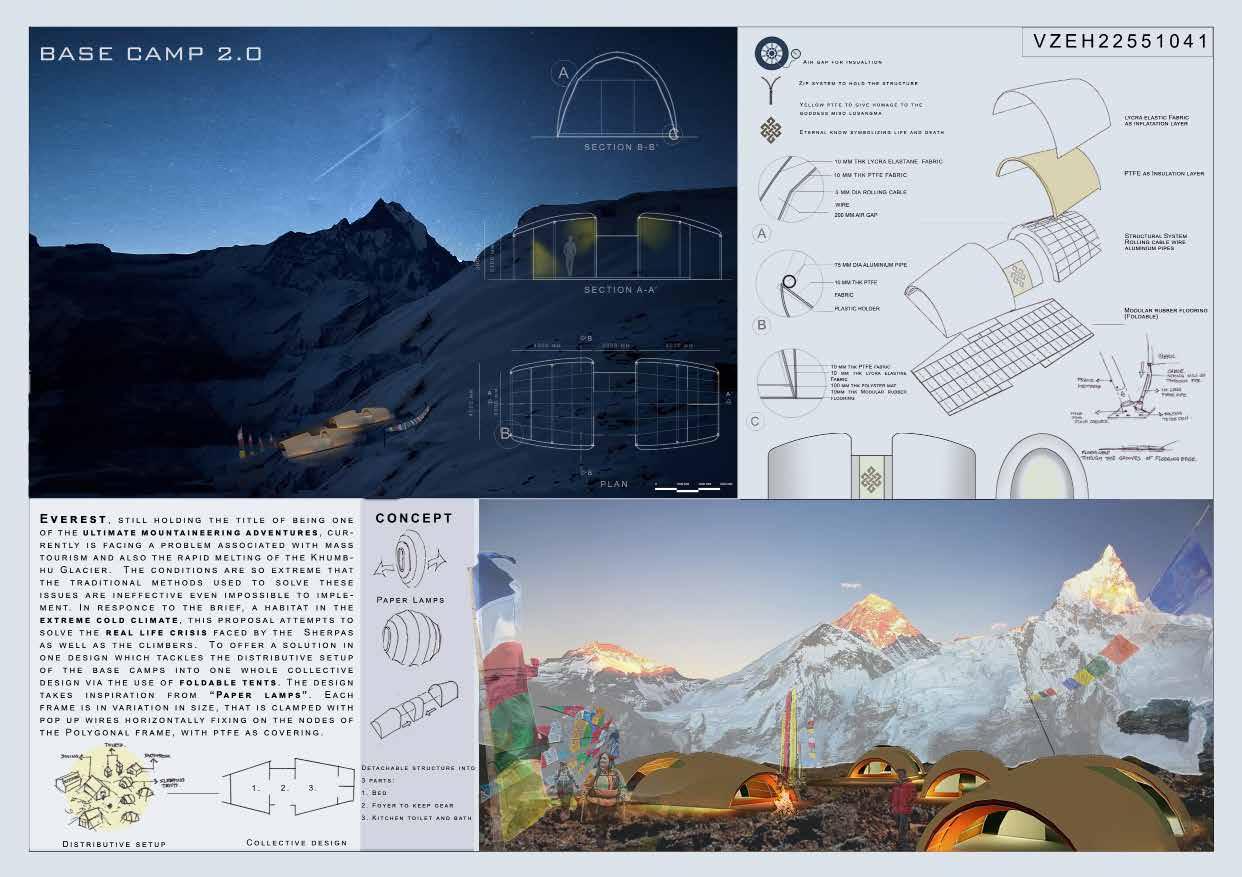

EXTREME HABITAT

PROMOTERS: VOLUMEZERO BRIEF

To locate a place where the climate and the environment creates a challenge for people to live in.

To create a structure respectively catering to all the challenges in the particular site chosen .

Extreme Habitat I Competition I

27

Autocad, Sketchup, Lumion, Photoshop

PROMOTERS: ACEDGE

BRIEF

To understand the basic colour theory of the traditional structure of the place we recide in.

Colours of Sikkim I Documentation I 28

DOCUMENTATION Photoshop

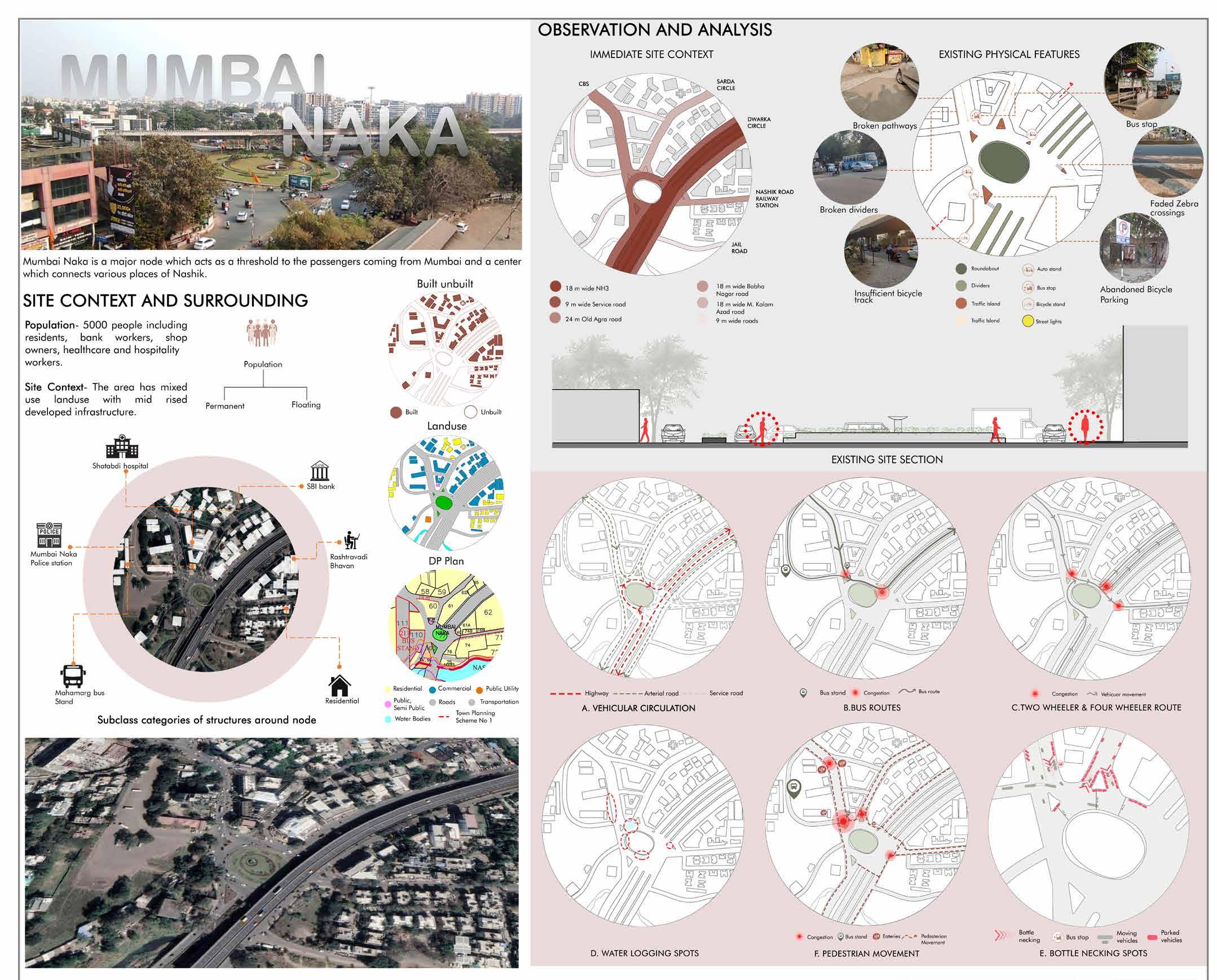

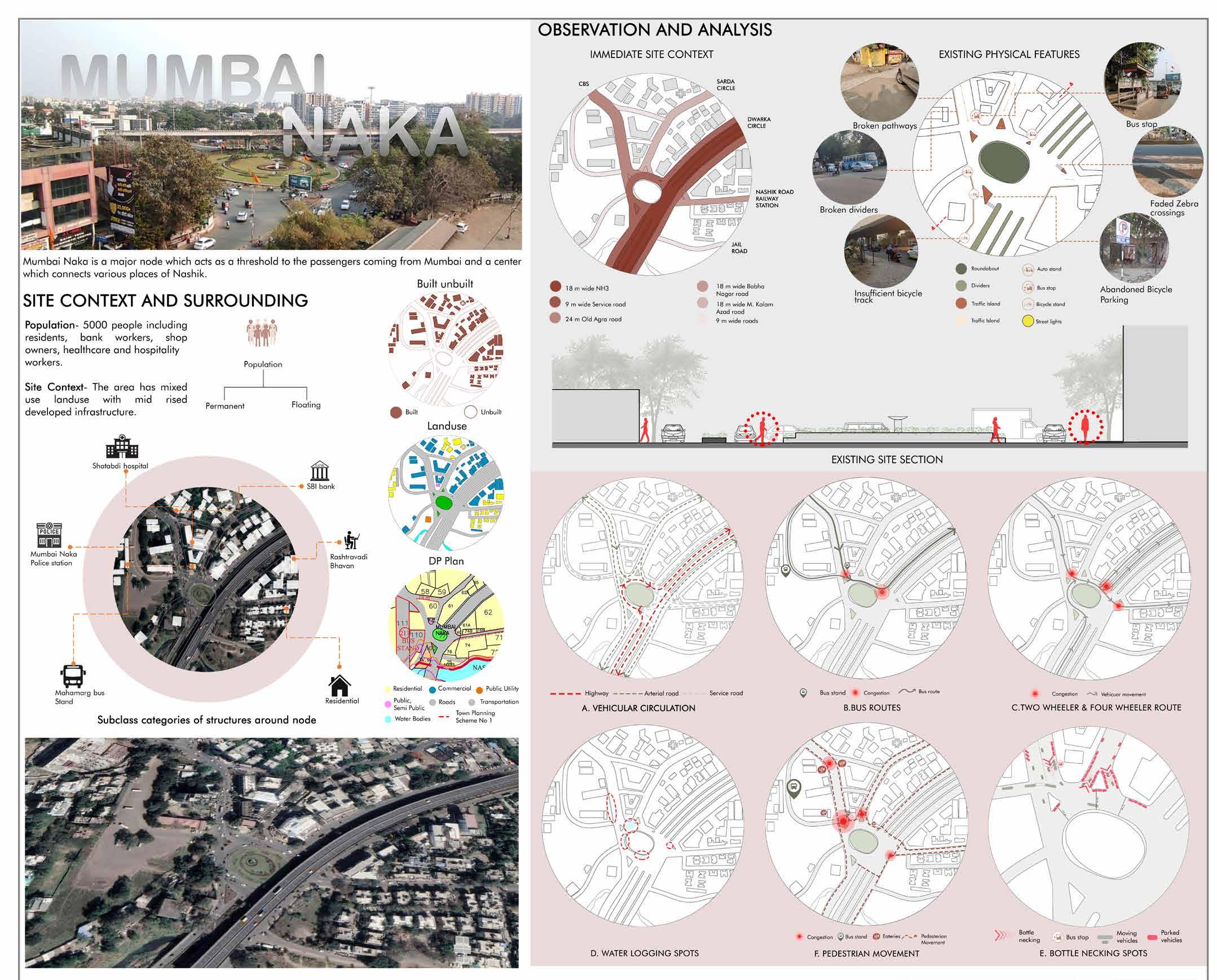

PROMOTERS: NASHIK TRAFFIC DEPARTMENT

BRIEF Location: Mumabi Naka

Group 1

Consolation prize

To locate a node within the city of Nashik which evidently causes traffic and congestion which may lead to accidents

Traffic Solutions I Competition & Documentation I

29

Autocad, sketchup, photoshop

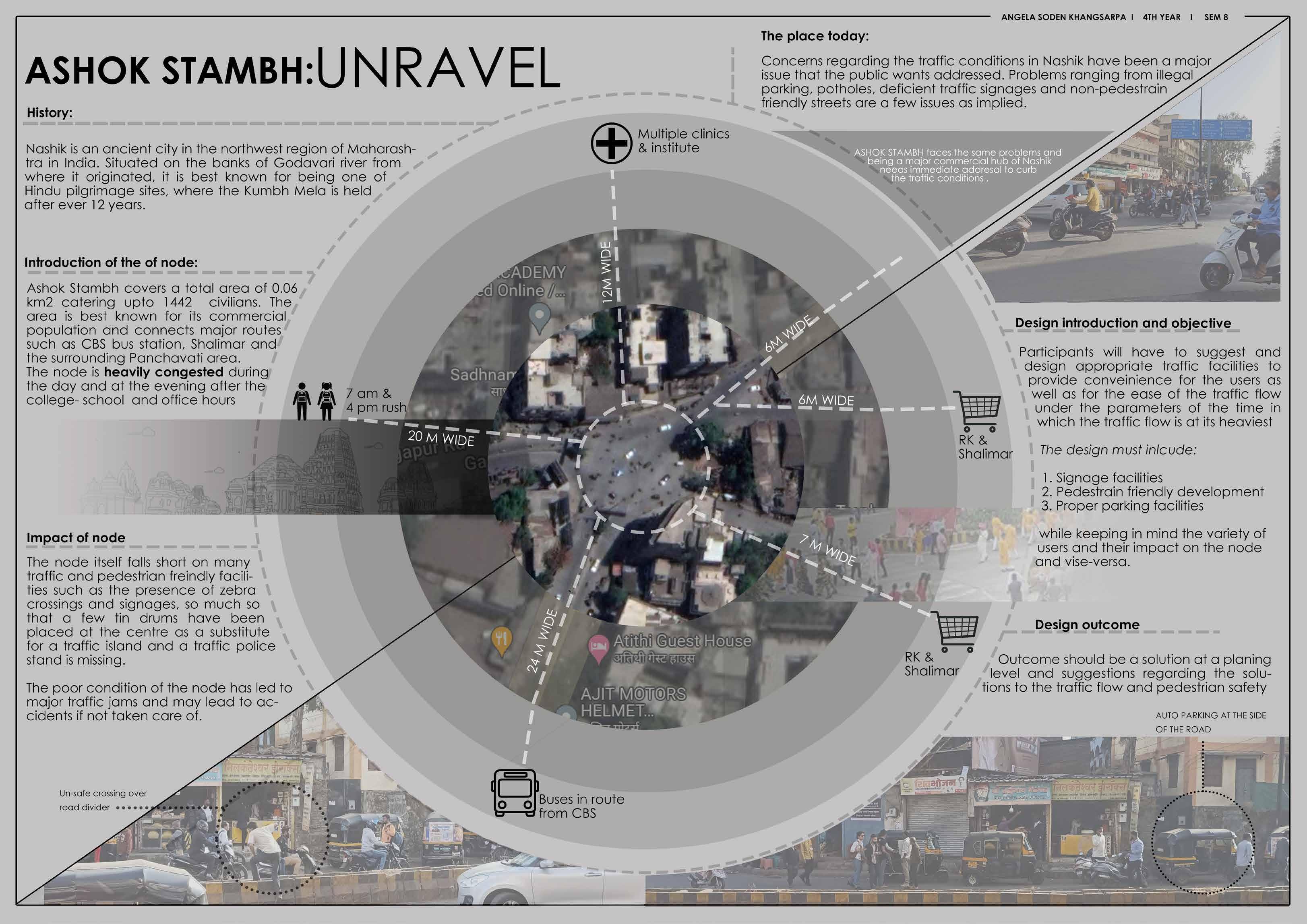

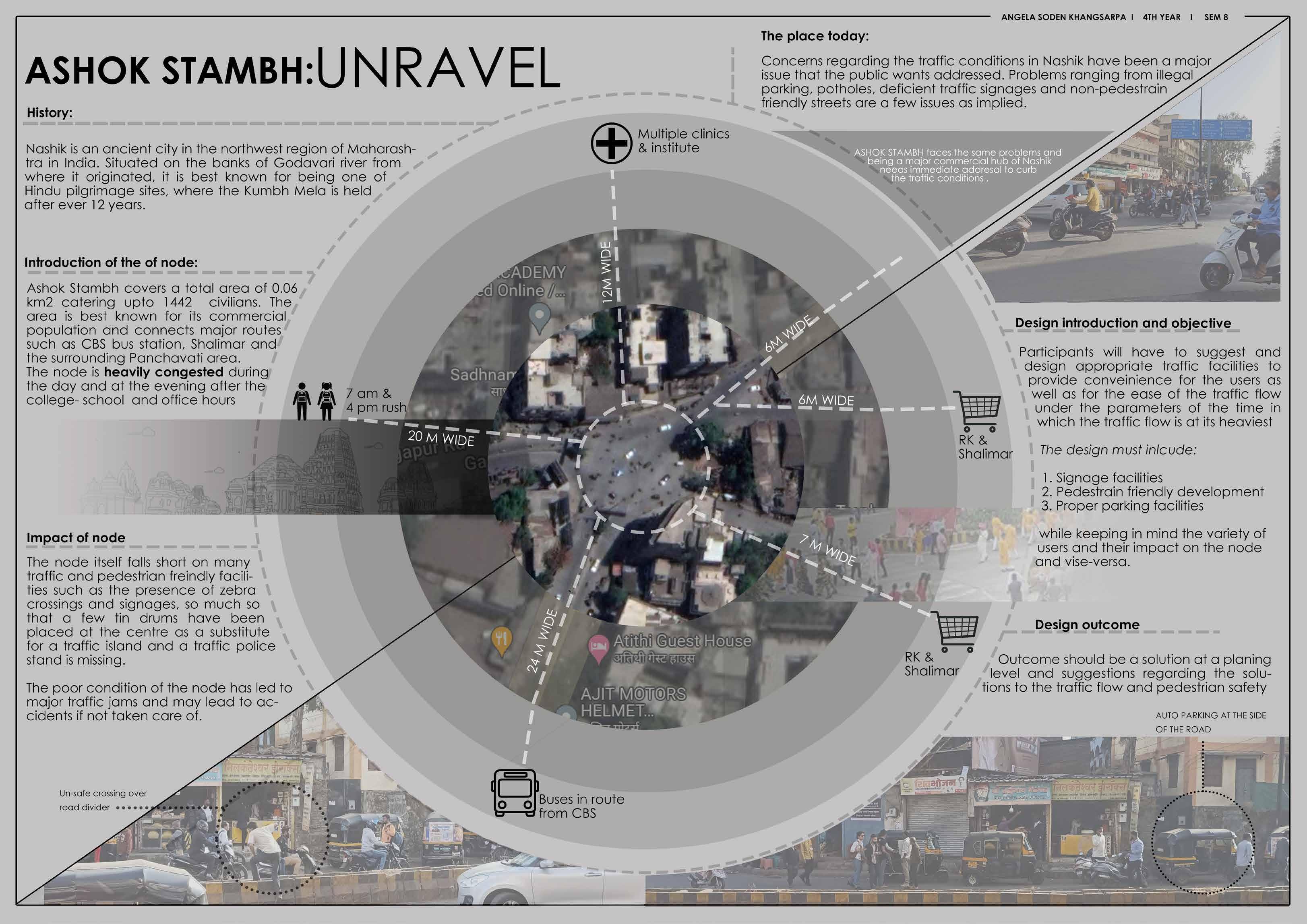

DOCUMENTATION BRIEF

To locate a site in the city of Nashik with evident road cogestion and traffic problem, to document and formulate a design brief

Location: Ashok Stambh .

Traffic Solutions I Competition & Documentation I Autocad, sketchup, photoshop 30

SURFLOW NOZZEL

WATER DRAINAGE PIPE

Detail E 400 MM in height

TILE ADHESIVE/MORTAR

RAFT

WATERPROOFING

EXTERNAL WATERPROOFING

SKIMMER DETAIL

SURFLOW INLET NOZZLE

DRAINAGE GRATING

JUNCTION BOX

LADDER

DRAINAGE

WORKING DRAWING

WATER PROOFING

SURFLOW NOZZLE DETAIL

WATER PROOFING GROUT

LIGHTING

SHAHABAD TILE

DETAIL D

HANDRAIL AND OVERFLOW DRAIN

DIAGRAM D

TILE

1:10 WATER WATER

Working Drawings I 3rd year I

CENTER LINE PLAN

EXHIBITION CENTER

NOTES

ARE IN METRIC UNITS AND ONLY WRITTEN DIMENSIONS SHOULD BE FOLLOWED EVERYWHERE.

2. LOAD BEARING STRUCTURE IS FOR GROUND+1 FLOOR.

3. DISCREPANCY IF ANY SHOULD BE BROUGHT TO THE NOTICE OF AN ARCHITECT PRIOR TO EXECUTION.

4. EXCAVATION AND MASONRY WORK SHOULD NOT BE EXECUTED PRIOR TO THE CHECKING OF AN ARCHITECT.

5. LOCATION AND SITTING OF THE BUILDING SHOULD BE CHECKED BY AN ARCHITECT.

6. THE LENGTH AND WIDTH OF COLUMN AS PER GIVEN IN TABLE SHOULD BE STRICTLY FOLLOWED.

7. BEARING CAPACITY OF SOIL= /SQ.FT

8. CONCRETE MIX SHOULD BE M-20

9. REINFORCEMENT SHOULD BE SHOWN TO CONSULTING ENGINEER. 10 PROPER STRUTTING SHOULD BE DONE TO THE ADJOINING BUILDING.

SPECIFICATION

1. ALL WALLS ARE OF 230MM THICK BURN BRICK MASONARY.

2. EXTERNAL DOUBLE COAT SAND FACED PLASTER.

3. INTERNAL SINGLE COAT GYPSUM PLASTER.

4. FLOORING AS PER GIVEN DETAIL.

Ground floor plan

First floor plan

SECTION A-A

REVISIONS

SECTION A-A

SCALE 1:50

SECTION B-B

DRAWING-II

745

SECTION Planter Mesh Planter Mesh Planter Mesh Planter Mesh D3 3375 900 900 Screed and tile 50mm Water proofing membrane Brickbat Coba Water proofing membrane Brickbat Coba Screed Screed Plaster Channel Clamp Mesh 230 600 3166 3140 740 Marble tile 600 600 W2 1118 A B F C D C D F A B A B A B 6 7 13 15 17 18 19 20 22 23 24 25 33 34 35 36 37 38 39 14 16 26 27 +600 mm +3375 mm +7350 mm +8245 mm +10645 mm +11845 mm +2750 mm +5650 mm 600 666 1024 1073 3166 551 1900 1900 1900 1900 809 300 300 1088 4365 3090 1915 W2 +2750 mm +5650 mm 100MM pcc bed 50MM Sand 150MM Murum 300MM DRP Drip mould 745 2460

Planter Mesh Planter Mesh Planter Mesh Planter Mesh SCALE 1:50 EXHIBITION CENTER 1. ALL DIMENSION ARE IN METRIC UNITS AND ONLY DIMENSIONS SHOULD BE FOLLOWED EVERYWHERE. 2. LOAD BEARING STRUCTURE IS FOR GROUND+1 FLOOR. 3. DISCREPANCY IF ANY SHOULD BE BROUGHT TO THE ARCHITECT PRIOR TO EXECUTION. 4. EXCAVATION AND MASONRY WORK SHOULD NOT EXECUTED PRIOR TO THE CHECKING OF AN ARCHITECT. 5. LOCATION AND SITTING OF THE BUILDING SHOULD CHECKED BY AN ARCHITECT. 6. THE LENGTH AND WIDTH OF COLUMN AS PER GIVEN SHOULD BE STRICTLY FOLLOWED. 7. BEARING CAPACITY OF SOIL= /SQ.FT 8. CONCRETE MIX SHOULD BE M-20 9. REINFORCEMENT SHOULD BE SHOWN TO CONSULTING ENGINEER. 10 PROPER STRUTTING SHOULD BE DONE TO THE BUILDING. SPECIFICATION WORKING DRAWING-II REVISIONS 1. ALL WALLS ARE OF 230MM THICK BURN BRICK 2. EXTERNAL DOUBLE COAT SAND FACED PLASTER. 3. INTERNAL SINGLE COAT GYPSUM PLASTER. 4. FLOORING AS PER GIVEN DETAIL. STAMP NOTES REVISION DATE DISCRIPTION SUBJECT TITLE : FOR : MR. KEY PLAN SIGN SECTIONS NORTH NAME ANGELA SODEN ↓ Ground floor plan First floor plan D3 Marble tile 600 600 D3 3375 900 900 +600 mm +3375 mm floor level +7350 mm +8245 mm parapet level 900 900 Porcelain tile 600 600 2826 Screed and tile 50mm 1487 900 Water proofing membrane Brickbat Coba Water proofing membrane Brickbat Coba Screed Screed Plaster Water proofing membrane Brickbat Coba Base coat Screed Plaster C Channel Clamp Mesh 230 600 3166 3140 740 Marble tile 600 600 W2 1118 A B F C D C D F A B C D C D A B A B 13 15 17 18 19 20 22 23 24 25 33 34 35 36 37 38 39 14 16 26 27 +600 mm +3375 mm +7350 mm +8245 mm +10645 mm +11845 mm +2750 mm +5650 mm 600 666 1024 1073 3166 551 1900 1900 1900 1900 +2750mm lintel level` +5650 mm lintel level 397 809 300 300 1088 1073 1024 437 4365 3090 1915 1090 W2 W2 W2 +2750 mm +5650 mm 100MM pcc bed 50MM Sand 150MM Murum 300MM DRP Drip mould Drip mould ↓ DOWN PANTRY OFFICE SPACE ↓ WC WC UP OFFICE SPACE WAITING AREA 387 2378 2551 2088 3809 4175 750 ↓ UP A A B B Total area: 125 m2 Total area: 125 m2 3800mm x 4700mm 1693 1240858 950 3440 mm x 3163mm 3808mm x 4007mm

Planter Mesh 5235 SHEET NO.

1. ALL DIMENSION

WORKING

STAMP

REVISION DATE DISCRIPTION NAME SUBJECT TITLE : FOR : MR. KEY PLAN SIGN Ground floor and First floor plan NORTH ↓ ↓ ↓ Ground floor plan First floor plan A A B B W2 D3 +600 MM +650 MM +625 MM Start face (0,0) End face +10460 End face +15359.94 A B C D E F A B C D E F 1 2 3 4 5 1 2 3 5 C1 450X230 C2 450X230 C3 450X230 C4 450X230 C5 450X230 C6 450X230 C7 450X230 C8 230X450 C9 230X450 C10 450X230 C11 450X230 C12 230X450 C13 230X450 C14 450X230 C15 450X230 C16 230X450 C17 230X450 C18 230X450 C1 450X230 C2 450X230 C3 450X230 C4 450X230 C5 450X230 C6 450X230 C7 450X230 C8 230X450 C9 230X450 C10 450X230 C11 450X230 C12 230X450 C13 230X450 C14 450X230 C15 450X230 C16 230X450 C17 230X450 C18 230X450 1500 Start face (0,0) End face +10460 End face +15359.94 A B C D E A B C D E F 1 2 3 4 5 1 2 3 4 5 2458 +3375 MM ↓ UP W1 W1 W1 D1 D3 D2 D2 D3 V1 1 2 7 8 10 11 12 19 18 17 16 15 14 13 21 22 23 24 25 26 27 28 29 30 31 32 39 38 37 36 35 34 33 2509 490 1450 158 1500 Tread 300 mm Riser 175mm 371 3617 1244 149 F +4000 MM +1400 MM +2750 MM +4750 MM +5650 MM 3440 6370 150 1485 2030 1661 W2 W1 W1 W1 W4 D1

Tread 300 mm Riser 175mm 1232 490 1426 V1 V1 W1 W2 W3 1200 X 2000 MM V1 V1 V1 W3 1350 X 1200 MM +625 MM 2001 2390 6370 4 V1 500 X 600 MM 1800 X 2100 MM D1 D2 D3 700 X 2100 MM 900 X 2100 MM WINDOW VENTILATOR DOOR 1800 2000 MM 600 MM 550 MM 600 MM 550 MM 900 MM 1024 MM 1500 MM 1000 MM 2100 MM 2100 MM 2100 MM Lintel level Sill level DIM Lintel level Sill level DIM Lintel level Sill level DIM W2 W2 W2 W4 W4 W4 W4 W4 W4 1800 1200 MM 1466 1323 1158 3220 2989 3440 2750 3440 3440 D2 D2 D2 116 1000 1500 1000 1500 1000 1500 1000 1500 1000 1500 1869 1706 855 775 3609 3708 3807 600 MM 550 MM 3 Autocad

32

Working Drawings I 3rd year I

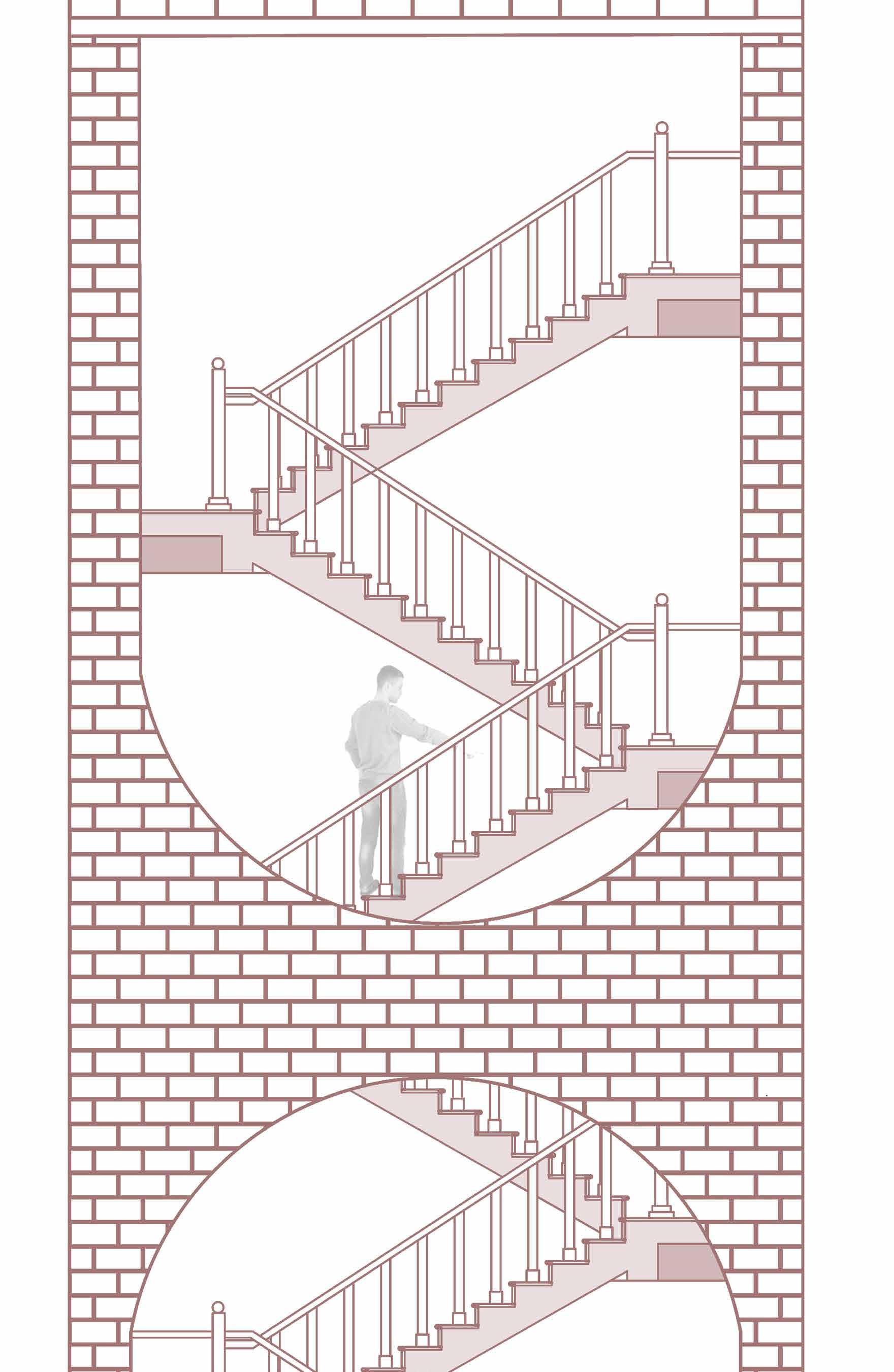

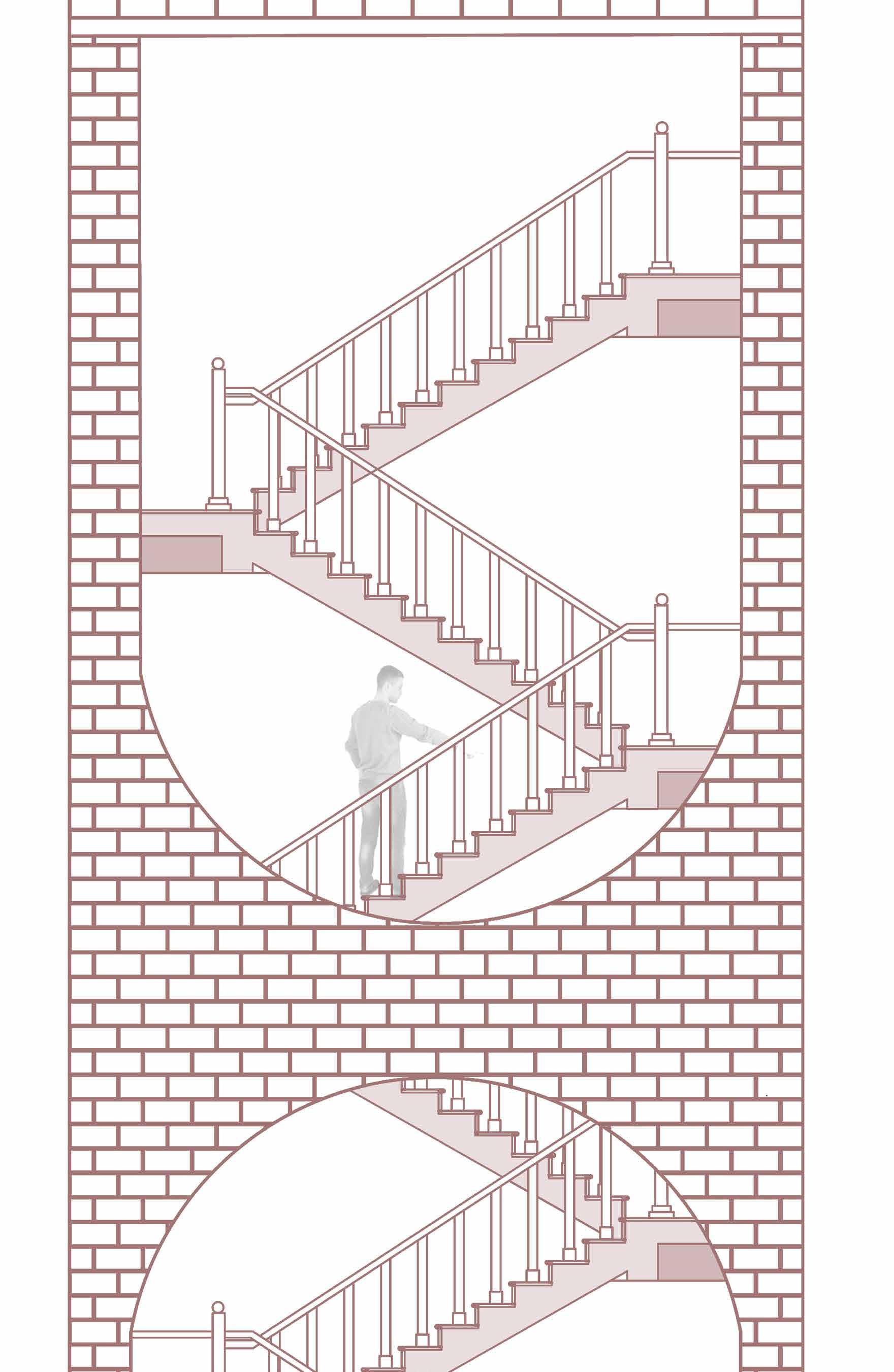

Staircase from ground to first floor

Staircase from first floor to terrace

Over head water tank

GROUND BEAM 230X600MM 12MM REVISION DATE DISCRIPTION NAME Staircase Detail 1 2 3 4 5 6 7 8 9 10 11 12 19 18 17 16 15 14 13 20 21 22 23 24 25 26 27 28 29 30 31 38 37 36 35 34 33 32 +2750 mm +5650mm +1400 mm +4750 mm UP C6 450X230 C7 450X230 C10 450X230 C11 450X230 1 2 3 4 5 6 7 13 15 17 18 19 20 21 22 23 24 32 34 35 36 37 38 14 16 25 26 2 3 3 2 E F E F 2 3 3 2 E F E F C6 450X230 C7 450X230 C10 450X230 C11 450X230 13 15 17 18 19 14 16 F Tread 300 mm Riser 175mm Tread 300 mm Riser 175mm F Marble tile 25 mm thk Screed 25 mm thk +2796 mm Overhead water tank +600 mm +3375 mm +7350 mm +10645 mm +11845 mm +2750 mm +5650 mm +2750mm +5650mm Connection of rail to balusters and rail to Newel Post tongue and mortise joint Newel post 100 x 100 Rail 100 x 50 Baluster 75 x 50 Tread 300 mm Riser 175mm Tread 300 mm Riser 175mm Anti skid groove Nosing with groove for LED panel lights Overhead water tank Water proofing membrane Screed 3 bituminous coats Screed Brick bat Coba Can't Block Manhole F F 300 300 4365 3090

33 Waist slab Screed 15mm Tile 15mm 100MM pcc bed 50MM Sand 150MM Murum 300MM DRP

33 2460 Porcelain tile 600 x 600 1487 GROUND BEAM 230X600MM 12MM Ø 900 D3 +600 +8245 Thin set adhesive Ceramic tile 400 400 mm 3191 5 5 F F F F Soil 1200 1024 800 +3375 mm floor level +2750mm lintel level` +5650 mm lintel level Waste water pipe Soil pipe 100 mm dia Drip mould

Working Drawings I 4th year I

.BASEMENT PARKING

EXTRINSIC WATERPROOFING LAYER

BASEMENT PLAN & SECTION (B-1 & B-2)

BASEMENT PLAN & SECTION (B-1 & B-2)

(SCALE 1:200)

Distribution bars 8mm Main bars 12mm Half brick thick protective walling Construction joint R.C basement slab 50mm cement/sand (1:3) protective screed 3 coat horizontal mastic asphalt 30mm thick 100 mm thick mass concrete base Standard triangle tile- bottom view 65mm screed Grating Normal backfill Brush wood or similar to filter Rubble fill French drain Pump Sump To drainage facility outside Concrete wall 3mm Waterproof asphalt Shahabad tile 25mm Trimix layer 75mm Triangular tile for drainage Plum concrete Drainage for Basement -2 level Drainage for Basement -1 level 100 dia H.C pipe SLOPE SLOPE SLOPE -3500 LVL -7000 LVL Trimix concrete Triangular tiles Shahabad tile Distribution 30mm Half brick thick SECTION B-B 1:80 slope ENTRANCE AHU ROOM DOWN FROM OUTSIDE UP FROM BS-2 DOWN FROM BS-1 DOWN FROM BS-1 1. PUMP ROOM 1. PUMP ROOM A A A B-1 B-2 B B B B ENTRANCE EXIT A STAMP ANGELA SODEN KHANGSARPA ABCS YEAR SEM ROLL.NO. DATE NDMVP S COA NASHIK

SIGN Earth Fill 118 100 METER ROOM

-3500 lvl -7150 lvl +2300 lvl -3500 lvl -7150 lvl +3500 lvl 0.0 lvl 0.0 lvl 3500.44 3500.00 1:10 slope ratio RAFT Foundation SECTION A-A LEGEND Column size: 450-700mm Distance between 2 columns: 10 m and 7.5m 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 4 M R O A D 2 M R O A D 2 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 2 way road 2 M R O A D 3 M R O A D 3 M R O A D 2 M R O A D 4 wheelers 2 wheelers AREA 2600 M2 2 M R O A D 3 M R O A D 3 M R O A D 2 M R O A D 4rd VII 32 18/8/2022 SECTION B-B ENTRANCE AHU ROOM DOWN FROM OUTSIDE UP FROM BS-2 DOWN FROM BS-1 DOWN FROM BS-1 PUMP ROOM PUMP ROOM A A A B-1 B-2 B B B B ENTRANCE EXIT A STAMP ANGELA SODEN KHANGSARPA ABCS YEAR SEM ROLL.NO. DATE NDMVP S COA NASHIK

SIGN Earth Fill 118 100 METER ROOM (SCALE 1:200) -3500 lvl -7150 lvl +2300 lvl -3500 lvl -7150 lvl +3500 lvl 0.0 lvl 0.0 lvl 3500.44 3500.00 1:10 slope ratio RAFT Foundation SECTION A-A LEGEND Column size: 450-700mm Distance between 2 columns: 10 m and 7.5m 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 4 M R O A D 2 M R O A D 2 M R O A D 6 M R O A D M R O A D M R O A D M R O A D 6 M R O A D 2 way road 2 M R O A D 3 M R O A D 3 M R O A D 2 M R O A D 4 wheelers 2 wheelers AREA 2600 M2 2 M R O A D 3 M R O A D 3 M R O A D 2 M R O A D 4rd VII 32 18/8/2022 SECTION B-B 1:80 slope ENTRANCE AHU ROOM DOWN FROM OUTSIDE DOWN FROM BS-1 DOWN FROM BS-1 1. PUMP ROOM 1. PUMP ROOM A A A B-1 B-2 B B ENTRANCE Earth Fill 118 100 METER ROOM -3500 lvl -7150 lvl +2300 lvl -3500 lvl -7150 lvl +3500 lvl 0.0 lvl 0.0 lvl 3500.44 3500.00 1:10 slope ratio RAFT Foundation SECTION A-A LEGEND Column size: 450-700mm Distance between 2 columns: 10 m and 7.5m 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 4 M R O A D 2 M R O A D 2 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 2 way road 2 M R O A D 3 M R O A D 4 wheelers 2 wheelers AREA 2600 M2 2 M R O A D 3 M R O A D SECTION B-B 1:80 slope ENTRANCE DOWN FROM OUTSIDE DOWN FROM BS-1 DOWN FROM BS-1 1. PUMP ROOM A A A B-1 B-2 B B ENTRANCE ANGELA Earth Fill 118 100 METER ROOM -3500 lvl -7150 lvl +2300 lvl -3500 lvl -7150 lvl +3500 lvl 0.0 lvl 0.0 lvl 3500.44 3500.00 1:10 slope ratio RAFT Foundation SECTION A-A

450-700mm Distance between 2 columns: 10 m and 6 M R O A D 6 M R O A D 6 M R O A D 4 M R O A D 2 M R O A D 2 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 6 M R O A D 2 way road 2 M R O A D 3 M R O A D 4 wheelers 2 wheelers AREA 2600 M2 2 M R O A D 3 M R O A D Distribution bars 8mm Main bars 12mm Half brick thick protective walling Construction joint R.C basement slab 50mm cement/sand (1:3) protective screed 3 coat horizontal mastic asphalt 30mm thick 100 mm thick mass concrete base Standard triangle tile- bottom view 65mm screed Grating Normal backfill Brush wood or similar to filter Rubble fill French drain Pump Sump To drainage facility outside Distribution bars 8mm Main bars 12mm Half brick thick protective walling Construction joint Normal backfill Brush wood or similar to filter Rubble fill French drain outside Concrete wall 3mm Waterproof asphalt Shahabad tile 25mm Trimix layer 75mm Triangular tile for drainage Plum concrete Drainage for Basement -2 level Drainage for Basement -1 level 100 dia H.C pipe SLOPE SLOPE SLOPE -3500 LVL -7000 LVL Trimix concrete Triangular tiles Shahabad tile Distribution bars 8mm Main bars 12mm 30mm cement/sand grout Half brick thick protective walling Construction joint R.C basement slab 50mm cement/sand (1:3) protective screed 3 coat horizontal mastic asphalt 30mm thick 100 mm thick mass concrete base Standard triangle tile- bottom view 65mm screed

LEGEND Column size:

34

Pump Pump

Out (Clean) Chlorination/ Disinfection Meter

Filters A

water A-A

Overflow Channel Fresh water inlet

CIRCULATION

35

Pump Pump Fresh water

SWIMMING POOL

OLYMPIC POOL (GROUND

Detail 6 m DEEP

generated from the displacement of swimmers bodies.A pool with a balance tank maintains a constant depth regardless of how many people are in the pool.

± 0.00 +9 M +12 M Detail D

Balancing tank

POOL

SECTION B-B

FLOOR)

Screen to remove floating dirt, leaf

SAND FILTER:

Once the swimmers exit the pool the extra water that the balance tank has been holding returns to the pool and the balance tank returns to

SAND FILTER:

Water is pumped into a canister containing sand of a certain size (between 45 and 55 millimeters). The water flows through the sand and comes out the other side. As the water flows, the sand itself traps debris found in the water.

Towards drain/disposal

Water is pumped into a canister containing sand of a certain size (between 45 and 55 millimeters). The water flows through the sand and comes out the other side. As the water flows, the sand itself traps debris found in the water. The more the filter is used, the denser the sand becomes and the more effective and efficient the filter is.

The process of backwashing dislodges trapped debris and contaminants, flushing them out through your value’s waste line or a hose that is connected to the pool pump. When the filter media is clean, the pressure gauge is lower and water can easily flow in and out of the system.

The more the filter is used, the denser the sand becomes and the more effective and efficient the filter is.

Towards drain/disposal

SECTION B-B

CARTRIDGE FILTER:

Cartridge filter systems work by pushing water into a tank. The skimmer collects the larger debris and the secondary basket collects the smaller particles. Finally, the water flows through polyester filters, which catches any remaining dirt..

C C SECTION C-C E

LEIZURE POOL (INFINITY POOL)

CARTRIDGE FILTER:

LIGHTING RAFT EXTERNAL WATERPROOFING WATER PROOFING GROUT WATER PROOFING TILE` HANDRAIL AND STAMP ANGELA SODEN KHANGSARPA ABCS YEAR SEM 4rd VII NDMVP S COA NASHIK ± 0.00 +9 M +12 M -5 M -2M

Detail E 400 MM in height

TILE WATER PROOFING DETAIL WATER GROUT PROOFING GRATING TILE GRATING WATER PROOFING DETAIL WATER GROUT PROOFING WEIR SKIMMER DETAIL SURFLOW INLET NOZZLE

POOL (INFINITY POOL) C C SECTION C-C E Back entrance Soling GRATING

Detail D

Backwashing is a pool term used to describe a filter cleaning method which reverses the flow of water through your filter system. While most pool filters help to remove organic material by pushing water through a porous medium (typically sand) and returning the clean water to the pool, over time larger particles build up in the filter. This can reduce the efficacy of your filter due to an increase in pressure and even lead to damage.

The process of backwashing dislodges trapped debris and contaminants, flushing them out through your value’s waste line or a hose that is connected to the pool pump. When the filter media is clean, the pressure gauge is lower and water can easily flow in and out of the system.

D DETAIL D LIGHTING JUNCTION BOX DRAINAGE LADDER SURFLOW NOZZEL TILE TILE ADHESIVE/MORTAR RAFT WATERPROOFING EXTERNAL WATERPROOFING WATER PROOFING GROUT WATER PROOFING DRAINAGE GRATING SHAHABAD TILE WATER DRAINAGE PIPE

Balance Tanks are primary used for the storage of excess water generated from the displacement of swimmers bodies.A pool with a balance tank maintains a constant depth regardless of how many people are in the pool.

Once the swimmers exit the pool the extra water that the balance tank has been holding returns to the pool and the balance tank returns to

Backwashing is a pool term used to describe a filter cleaning method which reverses the flow of water through your filter system. While most pool filters help to remove organic material by pushing water through a porous medium (typically sand) and returning the clean water to the pool, over time larger particles build up in the filter. This can reduce the efficacy of your filter due to an increase in pressure and even lead to damage.

The process of backwashing dislodges trapped debris and contaminants, flushing them out through your value’s waste line or a hose that is connected to the pool pump. When the filter media is clean, the pressure gauge is lower and water can easily flow in and out of the system.

E 400 MM in height E

HANDRAIL AND

SURFLOW

Entrance Entrance WATER PROOFING GROUT WATER PROOFING

SURFLOW NOZZEL TILE TILE ADHESIVE/MORTAR RAFT

WATERPROOFING EXTERNAL WATERPROOFING

LADDER

WATER CIRCULATION DIAGRAM LIGHTING

6 m DEEP Machine room Machine room Balancing tank (22ft * 22ft) (6.7m*6.7m) Air blower Back entrance Hot tub Sump Overflow Channel Fresh water inlet Surflow channel and nozzel Towards drain/disposal Screen to remove floating dirt, leaf Balancing tank To drain Pump Pump Fresh water Out (Clean) Chlorination/ Disinfection Meter Filters A SECTION A-A WATER CIRCULATION DIAGRAM D DETAIL D LIGHTING JUNCTION DRAINAGE LADDER SURFLOW NOZZEL TILE TILE ADHESIVE/MORTAR RAFT WATERPROOFING EXTERNAL WATERPROOFING WATER PROOFING GROUT WATER PROOFING DRAINAGE SHAHABAD TILE Back entrance WATER DRAINAGE PIPE GRATING TILE GRATING WATER PROOFING DETAIL WATER GROUT PROOFING SKIMMER DETAIL SURFLOW INLET HANDRAIL AND OVERFLOW DRAIN +10 M +1 M +5 M +7.5 M +3 M

SECTION C-C WATER DRAINAGE PIPE 1:10 TILE WATER PROOFING DETAIL WATER GROUT PROOFING GRATING TILE GRATING WATER PROOFING DETAIL WATER GROUT PROOFING WEIR SKIMMER DETAIL SURFLOW INLET NOZZLE

DRAINAGE GRATING SHAHABAD TILE

Balancing tank 22ft) (6.7m*6.7m) blower Sump Overflow Channel Fresh water inlet Surflow channel and nozzel Towards drain/disposal Screen to remove floating dirt, leaf Balancing tank To drain Pump Pump Fresh water Out (Clean) Chlorination/ Disinfection Meter Filters A WATER CIRCULATION DIAGRAM Entrance LEIZURE POOL (INFINITY POOL) C C SECTION C-C E Soling WATER DRAINAGE PIPE TILE WATER PROOFING DETAIL WATER GROUT PROOFING GRATING TILE GRATING WATER PROOFING DETAIL WATER GROUT PROOFING WEIR SKIMMER DETAIL

Balance Tanks are primary used for the storage of excess water generated from the displacement of swimmers bodies.A pool with a balance tank maintains a constant depth regardless of how many people are in the pool. Once the swimmers exit the pool the extra water that the balance tank has been holding returns to the pool and the balance tank returns to D Detail D for infinity pool

E SURFLOW NOZZLE DETAIL

Detail E 400 MM in height

Sump

Screen to remove floating dirt, leaf

DIAGRAM D DETAIL D LIGHTING JUNCTION BOX DRAINAGE LADDER SURFLOW NOZZEL TILE TILE ADHESIVE/MORTAR RAFT WATERPROOFING EXTERNAL WATERPROOFING WATER PROOFING GROUT WATER PROOFING DRAINAGE GRATING SHAHABAD TILE WATER DRAINAGE PIPE 1:10 TILE WATER PROOFING DETAIL WATER GROUT PROOFING GRATING TILE GRATING WATER PROOFING DETAIL WATER GROUT PROOFING WEIR SKIMMER DETAIL SURFLOW INLET NOZZLE HANDRAIL AND OVERFLOW DRAIN

Balancing tank

Fresh

Detail D for infinity pool Detail E 400 MM in height SURFLOW NOZZLE DETAIL Machine room Balancing tank (22ft * 22ft) (6.7m*6.7m) Air blower entrance Learner's Pool (25m*13m) Sump Overflow Channel Fresh water inlet Surflow channel and nozzel Towards drain/disposal Screen to remove floating dirt, leaf Balancing tank To drain Pump Pump Fresh water Out (Clean) Chlorination/ Disinfection Meter Filters A

D LIGHTING JUNCTION BOX DRAINAGE LADDER SURFLOW NOZZEL TILE TILE ADHESIVE/MORTAR RAFT WATERPROOFING EXTERNAL WATERPROOFING WATER PROOFING GROUT WATER PROOFING DRAINAGE GRATING SHAHABAD TILE

flushing them out through your value’s waste line or a hose that is connected to the pool pump. When the filter media is clean, the pressure gauge is lower and water can easily flow in and out of the system.

SECTION A-A WATER CIRCULATION DIAGRAM

LEIZURE POOL (INFINITY POOL)

Backwashing is a pool term used to describe a filter cleaning method which reverses the flow of water through your filter system. While most pool filters help to remove organic material by pushing water through a porous medium (typically sand) and returning the clean water to the pool, over time larger particles build up in the filter. This can reduce the efficacy of your filter due to an increase in pressure and even lead to damage.

Detail E 400 MM in height SURFLOW NOZZLE DETAIL Learner's Pool (25m*13m) Admins office UP Machine room Machine room Balancing tank (22ft * 22ft) (6.7m*6.7m) Air blower Back entrance Learner's Pool (25m*13m) Janitorail Hot tub Sump Overflow Channel Fresh water inlet Surflow channel and nozzel Towards drain/disposal Screen to remove floating dirt, leaf Balancing tank To drain Pump Pump Fresh water Out (Clean) Chlorination/ Disinfection Meter Filters Waiting area Reception A Entrance

Detail D for infinity pool

LEIZURE

Cartridge filter systems work by pushing water into a tank. The skimmer collects the larger debris and the secondary basket collects the smaller particles. Finally, the water flows through polyester filters, which catches any remaining dirt..

Detail D for infinity pool

± 0.00 +9 M +12 M ± 0.00 +9 M +12 M -2M Detail D for infinity pool

NOZZLE DETAIL

(25m*25m

The process of backwashing dislodges trapped debris and flushing them out through your value’s waste line or a hose to the pool pump. When the filter media is clean, the pressure and water can easily flow in and out of the system.

Detail

Learner's Pool (25m*13m)

Sump Overflow Channel Fresh water inlet

Surflow channel and nozzel

SECTION A-A

OVERFLOW DRAIN ± 0.00 +9 M +12 M ± 0.00 +9 M +12 M -5 M -2M

WATER CIRCULATION DIAGRAM

1:10

D for infinity pool

Detail

E SURFLOW NOZZLE DETAIL Admins office CHANGING AND SHOWERING ROOM Woman's Pool (25m*13m) +10 UP JURY PANEL + Machine room Machine room Balancing tank (22ft 22ft) (6.7m*6.7m) Air blower Back entrance JURY PANEL Storage/Janitorial Washroom/ Learner's Pool (25m*13m) DIVING POOL (25m*25m depth=5m) OLYMPIC POOL (50m*25m depth=5m) Athlete seating Cafeteria Janitorail Hot tub Sump Overflow Channel Fresh water inlet Surflow channel and nozzel Towards drain/disposal Screen to remove floating dirt, leaf Balancing tank To drain Pump Pump Fresh water Out (Clean) Chlorination/ Disinfection Meter Filters Waiting area Reception Reception Waiting area Waiting area Pantry A A B B A A B B

SECTION A-A SECTION B-B D DETAIL D

JUNCTION BOX DRAINAGE

Back entrance Soling +1 +5 M +7.5 M +3 M WATER DRAINAGE PIPE 1:10 TILE WATER PROOFING DETAIL WATER GROUT PROOFING GRATING TILE GRATING WATER PROOFING DETAIL WATER GROUT PROOFING WEIR SKIMMER DETAIL SURFLOW INLET NOZZLE HANDRAIL AND OVERFLOW DRAIN +10 M +1 M +5 M +7.5 +3 M CARTRIDGE FILTER: Cartridge filter systems work by pushing water into a tank. The skimmer collects the larger debris and the secondary basket collects the smaller particles. Finally, the water flows through polyester filters, which catches any remaining dirt.. SAND FILTER: Water is pumped into a canister containing sand of a certain size (between 45 and 55 millimeters). The water flows through the sand and comes out the other side. As the water flows, the sand itself traps debris found in the water. The more the filter is used, the denser the sand becomes and

OLYMPIC

(1ST FLOOR)

the more effective and efficient the filter is.

Backwashing is a pool term used to describe a filter cleaning method which reverses the flow of water through your filter system. While most pool filters help to remove organic material by pushing water through a porous medium (typically sand) and returning the clean water to the pool, over time larger particles build up in the filter. This can reduce the efficacy of your filter due to an increase in pressure and even lead to damage. The process of backwashing dislodges trapped debris and contaminants, flushing them out through your value’s waste line or a hose that is connected to the pool pump. When the filter media is clean, the pressure gauge is lower and water can easily flow in and out of the system.

STAMP ANGELA SODEN KHANGSARPA ABCS SIGN ± 0.00 +9 M +12 M ± 0.00 +9 M +12 M -5 M -2M Detail D Detail D for infinity pool 6 m DEEP Detail E 400 MM in height E SURFLOW NOZZLE DETAIL Learner's Pool (25m*13m) DIVING POOL (25m*25m depth=5m) OLYMPIC POOL (50m*25m depth=5m) VIEWING GALLERY VIEWING GALLERY Working Drawings I 4th year I

Balance Tanks are primary used for the storage of excess water generated from the displacement of swimmers bodies.A pool with a balance tank maintains a constant depth regardless of how many people are in the pool. Once the swimmers exit the pool the extra water that the balance tank has been holding returns to the pool and the balance tank returns to

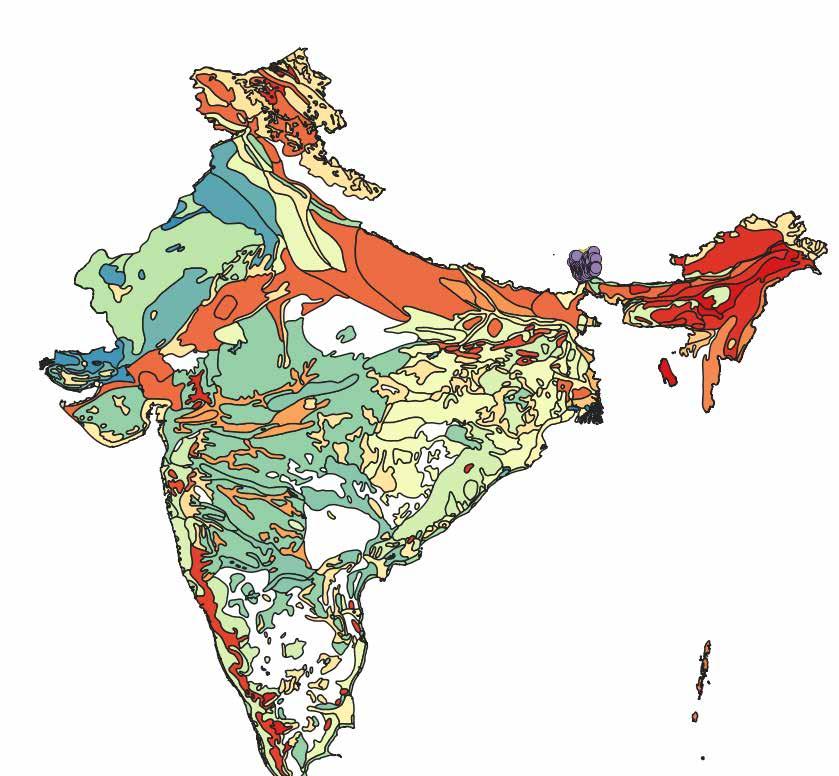

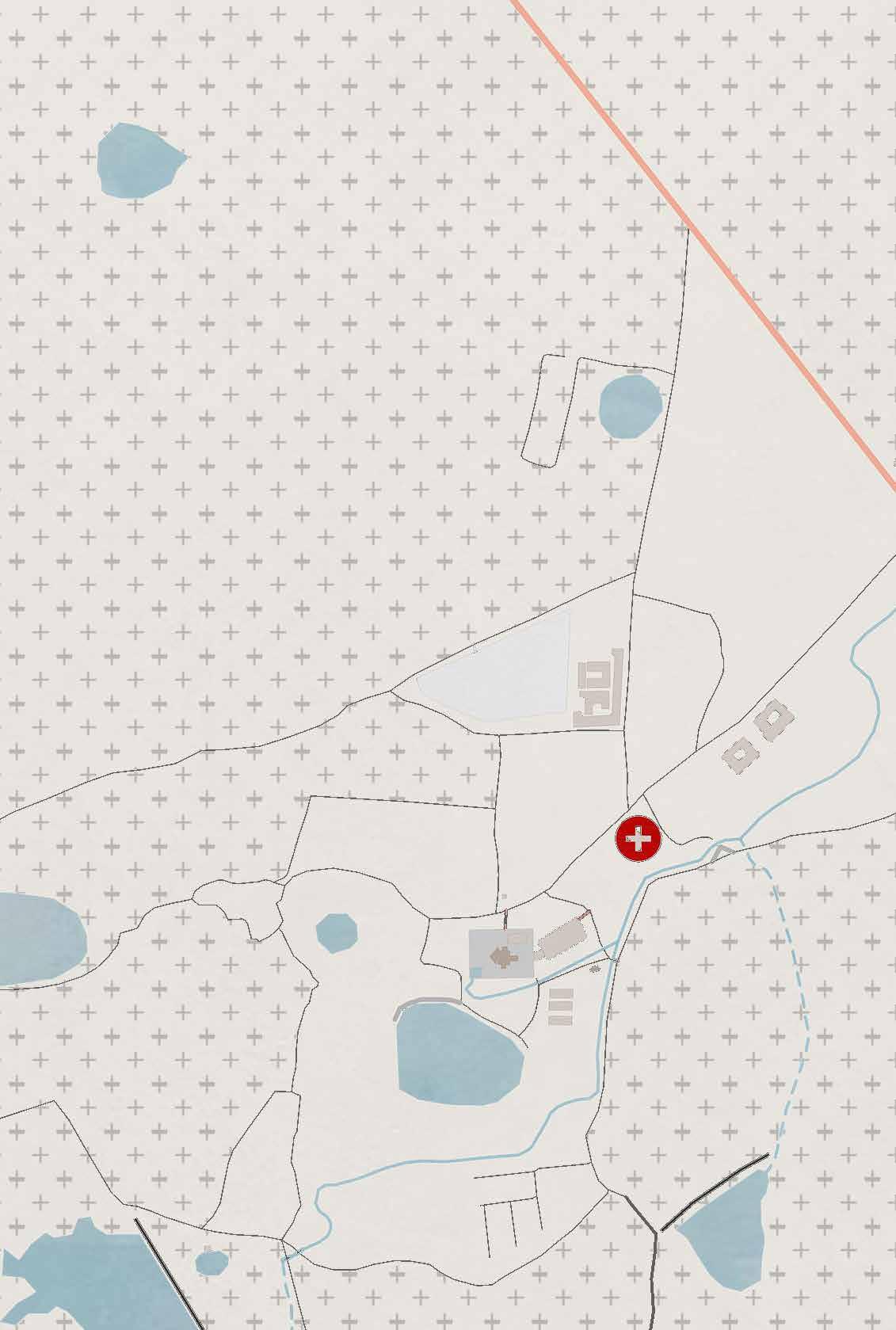

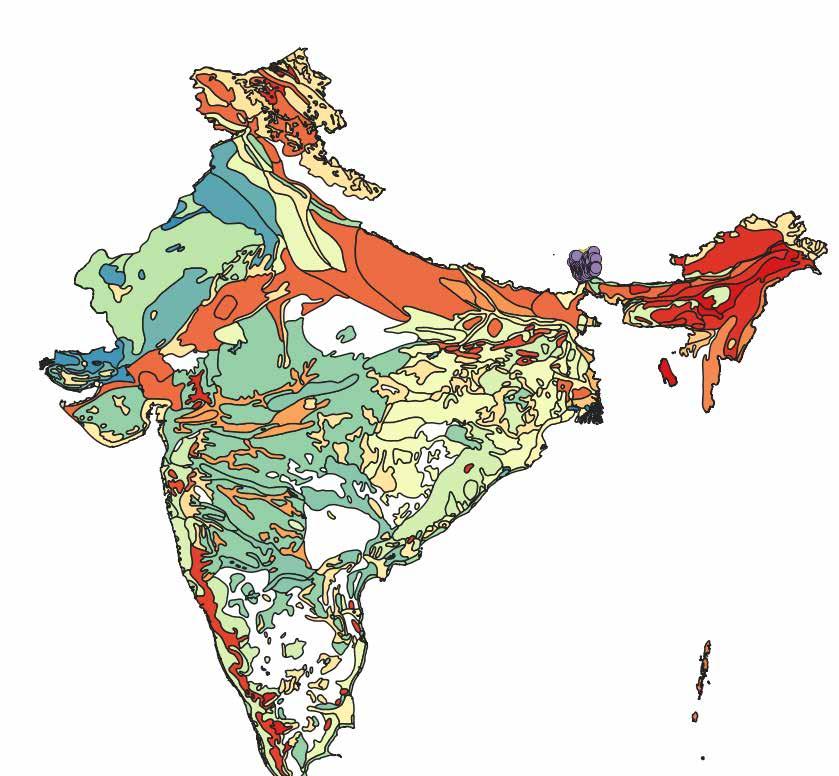

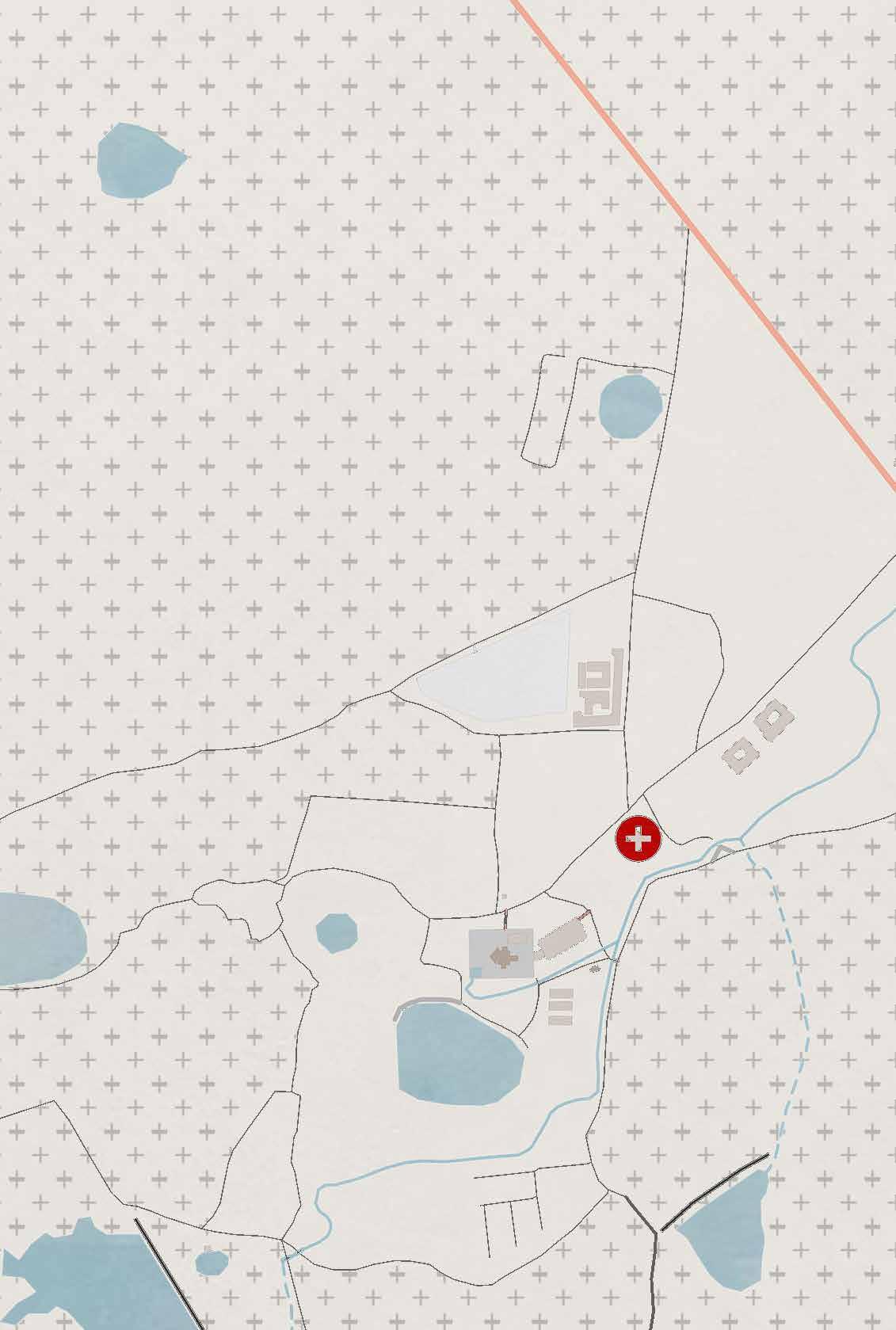

GIS

Keypoint s

1.Digitization and data input

2. Area and length calculation

3. Soil typology analysis

4.Topography analysis

5. Organization of data from excel to QGIS attribute table (Helpful in survey)

• Labeling houses as kaccha, paccka houses along with the typology of roads

• Digitization of water bodies, roads and river.

• Marking location and symbolization of villages

• Soil analysis

• Contour formation and natural drainage patterns.

QGIS QGIS I 4th year I

36

SKILLS

Model making

1.Unilever Campus model 2nd year project

2. Tensile Structure elective 3rd year

3. Muhadi housing community-2nd year project

4.Housing project Karjat 4th year

Models I Mixed Year I

37 1

Fileboard, Foam board, Paper mache , Foam

Models I Mixed Year I

38 2 3 4

Elastic cloth, foam board, foam board

SKILLS

Sketches and drawings

.1. Oil paint

2.Water colour

3. Colour pencils

4. Micron

5. Alcohol markers

39

Drawings

Photography

Photography 40

Emphasis

Positive & negative Story Detail

OOO Thank you for your time Angela Soden Khangsarpa sodenkhangsarpa@gmail.com +91 8999380773

2022-2023

2022-2023

Illustrator Photoshop

Illustrator Photoshop

Maharashtra pavilion I Competition I

Autocad, Sketchup, Lumion, Photoshop

Maharashtra pavilion I Competition I

Autocad, Sketchup, Lumion, Photoshop