CROSS LAMINATE D TIMBER

OF THE PACIFIC NORTHWEST

CONTENTS

GOAL, SCOPE & FUNCTIONAL UNIT page 5

MATERIAL MAP page 7

PRODUCTION PROCESS page 9

LIFE, USE, & IMPACT page 11

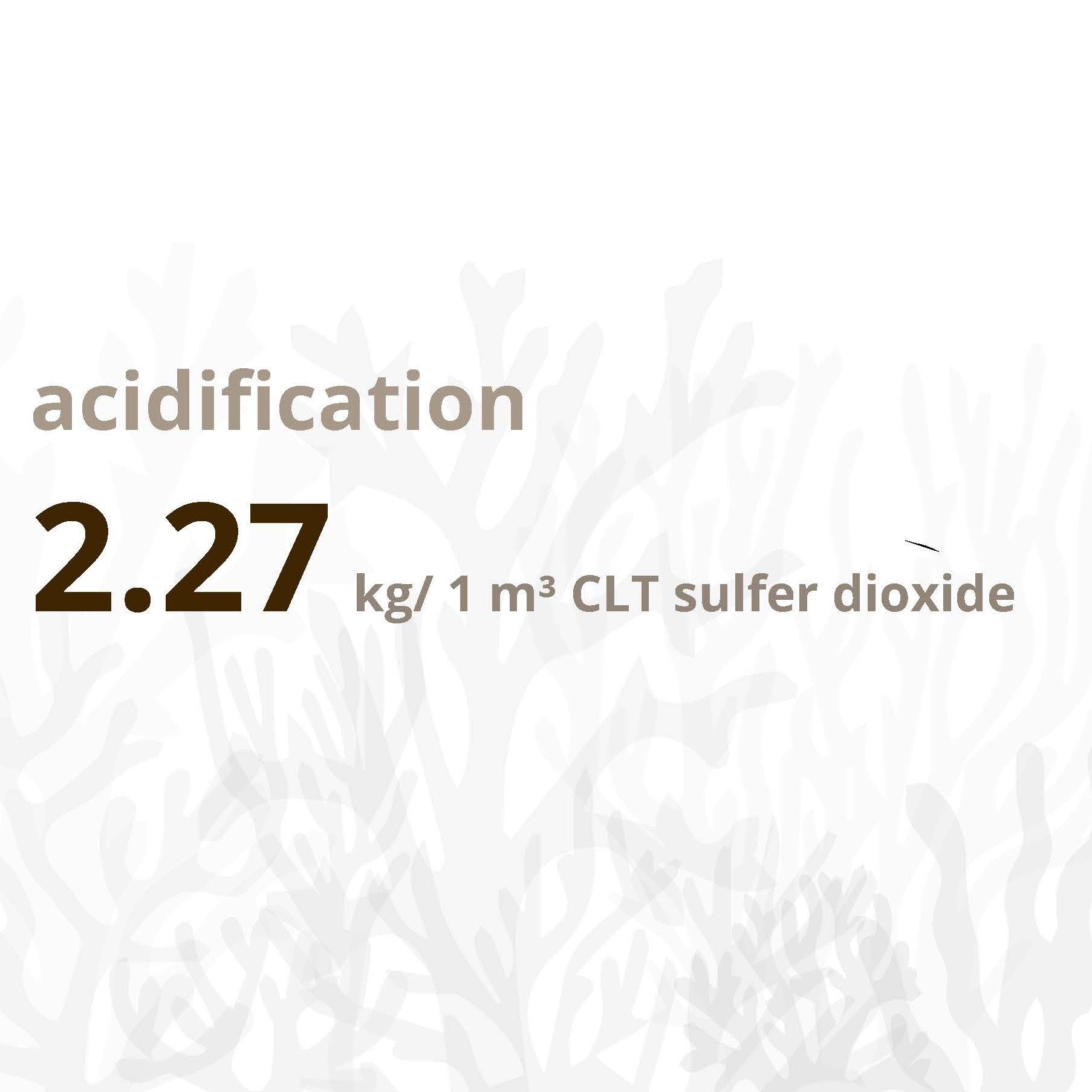

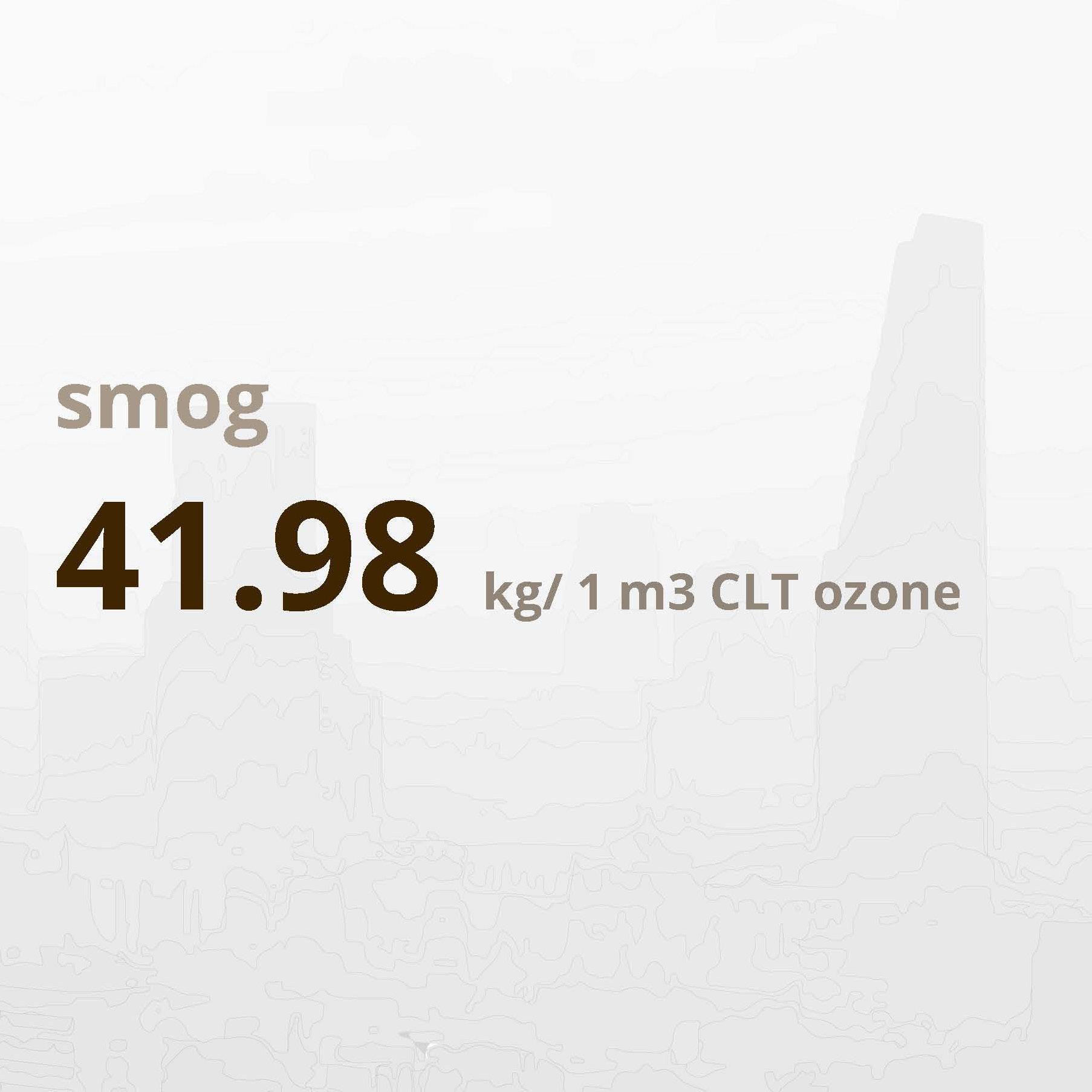

ENVIRONMENTAL IMPACT page 15

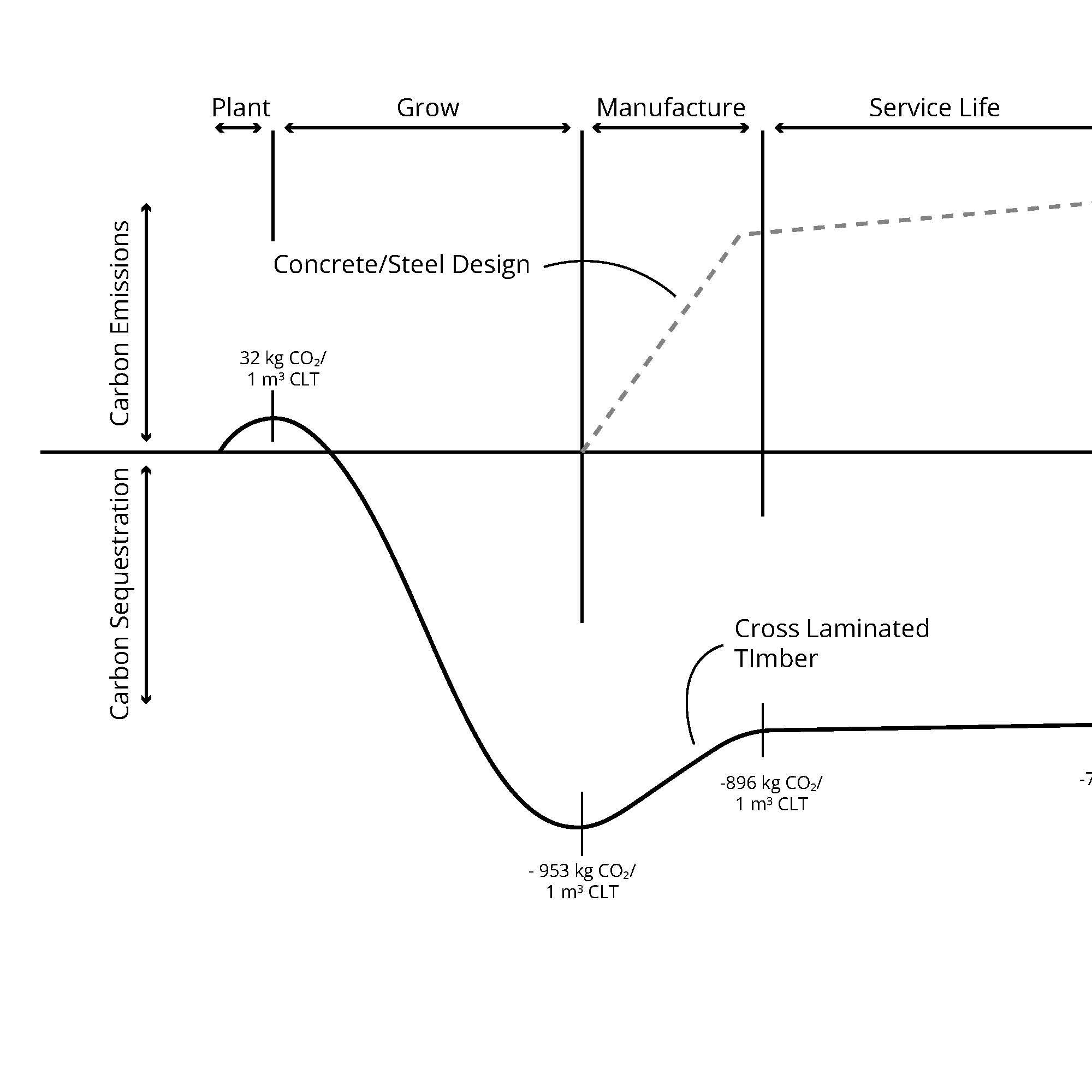

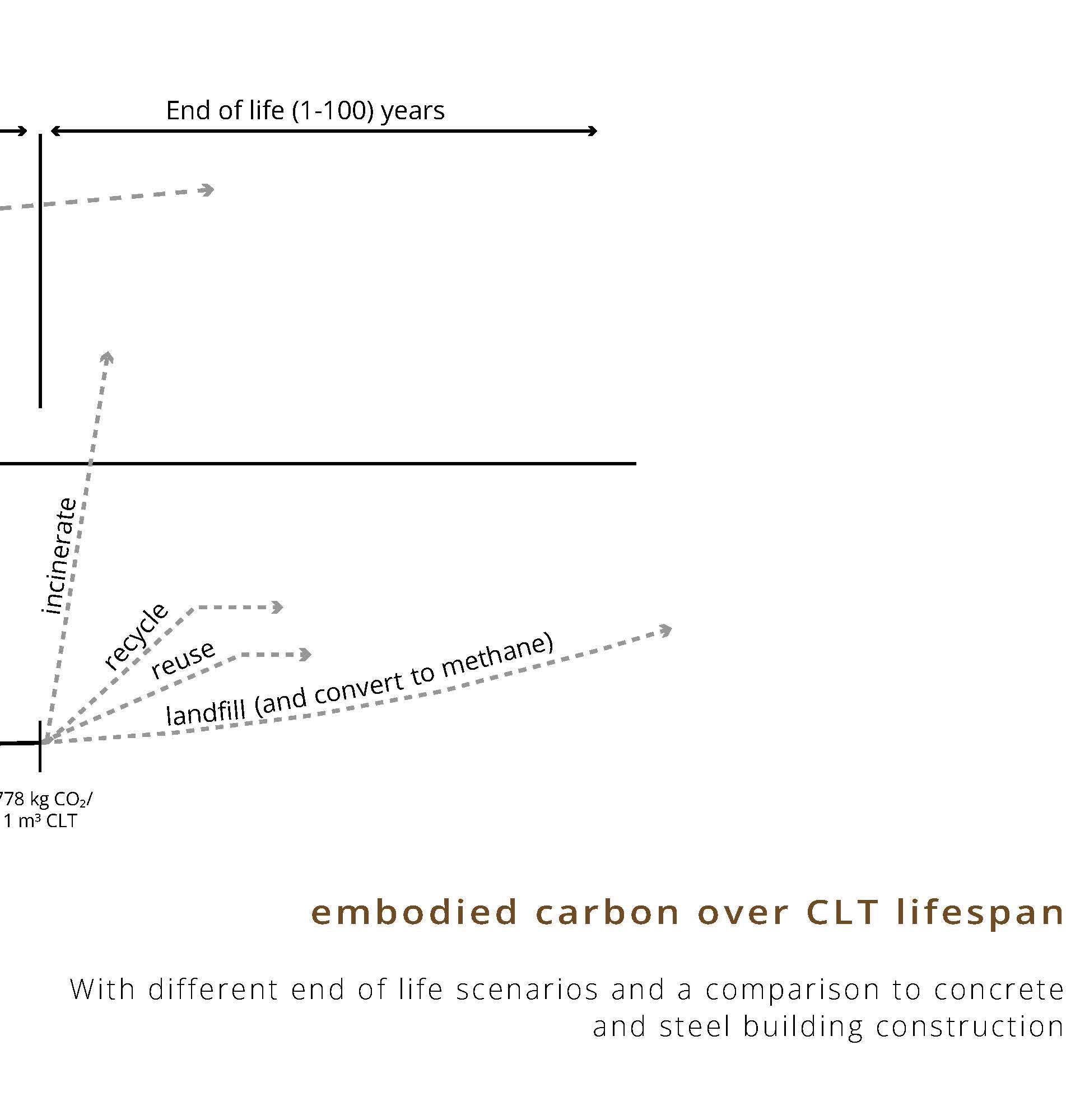

EMBODIED CARBON page 17

POST LIFE page 19

LIMITATIONS page 22

CITATIONS page 23

object of assessment

A sustainable timber based product composed of layers of wood and pressed into panels; used in construction for structural purpose. Valued for its durability and environmental, and health benefits. For our definition we are using 1 meter cubed of CLT.

goal

Our project aims to promote CLT as a viable alternative to traditional concrete and steel construction in the US. The intended outcome is to encourage its use and provide valuable information to potential users.

scope

The scope covers tree regeneration and forest management, CLT manufacturing, and its use until it reaches its final stage as biomass fuel. Assuming a 60-year lifespan in well-maintained buildings with proper moisture management, there’s potential for CLT to extend beyond 100 years. Post-use, it can be downcycled into furniture, wood particle products, or serve as a secondary structural system before being converted to biomass fuel.

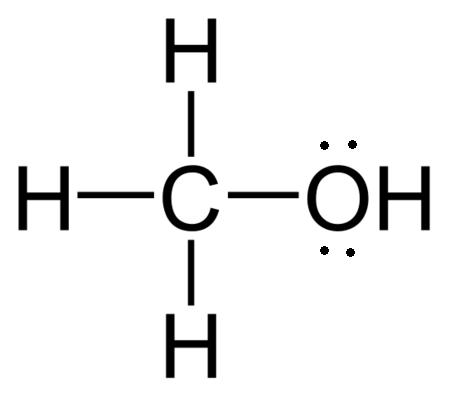

Douglas Fir trees are grown and harvested in the region west of the Cascade Mountains in Oregon and Washington

Resin is manufactured at Akzo Nobel Wood Coatings in Salem, Oregon

The harvested trees are transported to Freres Mill, located in Mill City, Oregon

The resin and lumber are transported to DRJ Wood Innovations in Riddle, Oregon to be manufactured into Cross Laminated Timber

seedling operations

fertilization & thinning tree growth (50 years for mature hight)

logging & felling transportation freres

end joining panel lay up & vaccuum press planing transportation to

production process

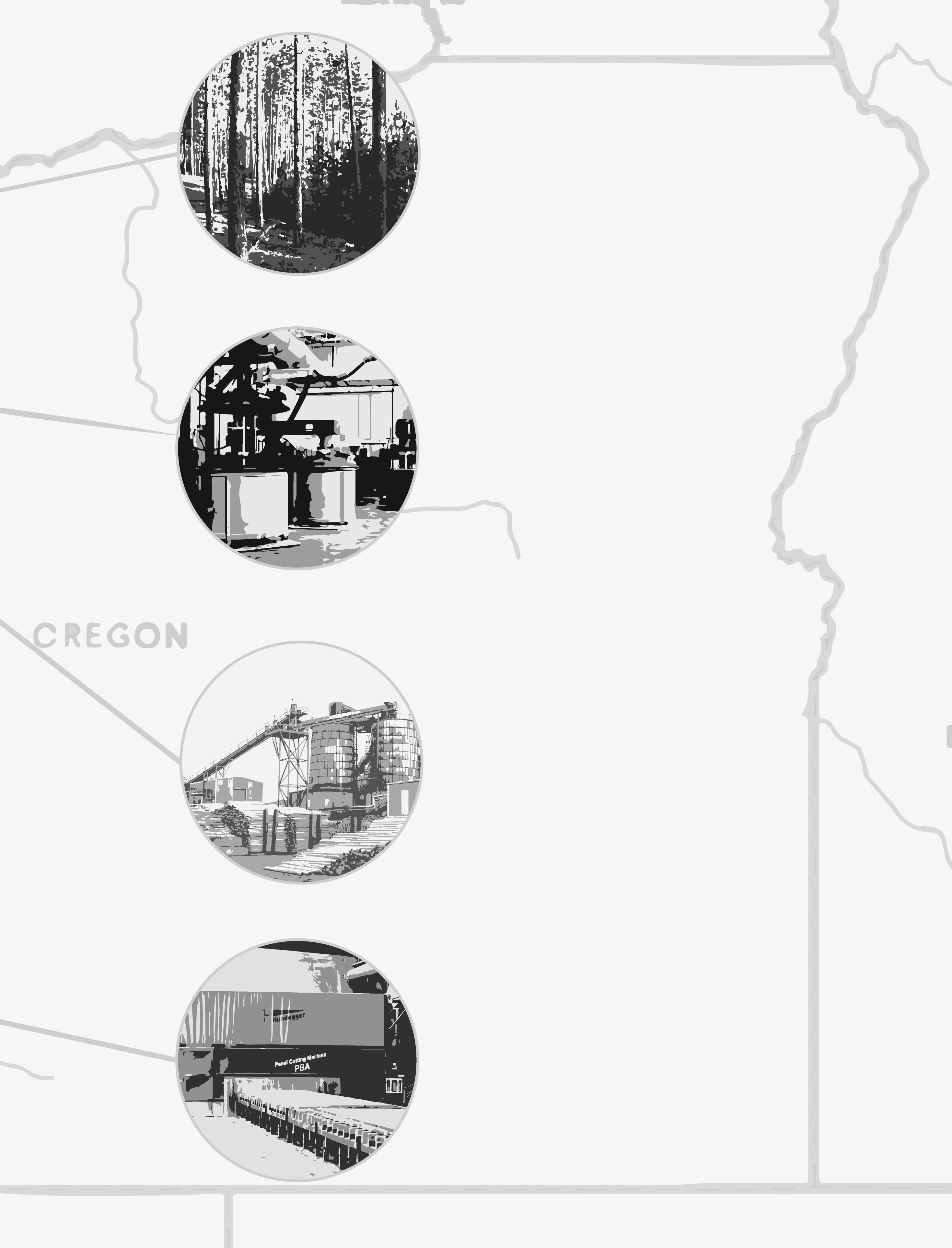

Cross Laminated Timber construction starts with tree growth in the forests, planks, dried, and vacuum pressed with resin to create the final product.

in the forest and ends when the CLT is disassembled from the building

transportation to freres mill

transportation to drj wood innovations site

trees are cut into planks

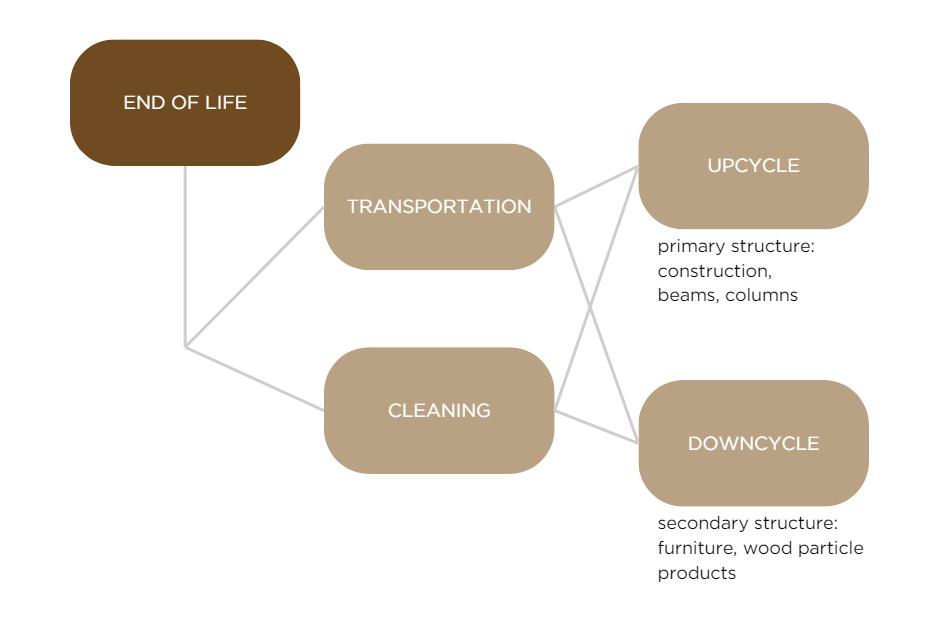

end of life

planks are kiln dried

forests, and ends with the trees being cut into product. Our scope starts with the regeneration of trees building and burned for energy.

1) Douglas Fir

Private Forest Landowners, Freres Mill

2) Energy: Gas, Diesel, electricity

2) Lubricants

2) Fertilizers

2) Water

Freres Mill

1) Rough Dried Lumber

Azkonobel

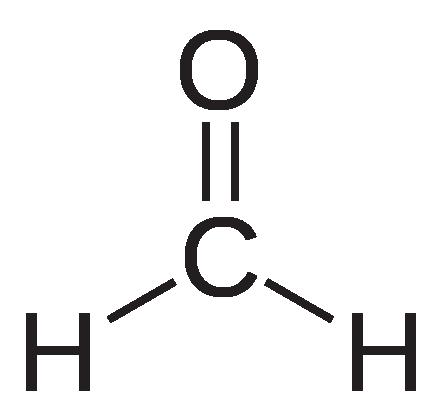

1) Melamine

Formeldahide Resin

1) Melamine

2) Electricity

2) Energy (Gas, Diesel, Wood Fuel, Natural Gas)

DRJ Wood Innovations

0) Cross Laminated Timber Assembly Use

1) Formeldahide 1)douglas fir energy: gas, diesel, electricity

lubricants

water

fertilizer

forests capture atmosphere

end of life biomass, sawdust from manufacturing is burned to create energy

timber products are resused or recyled to create new product

CLT used in structures, is sequestered

capture carbon from atmosphere

carbon is stored in the timber for life

structures, carbon sequestered

CLT assembled

end of life- why reuse?

Without proper decisions in materials and decomposable resins, many mass timber panels cannot be recycled at their end-of-life due to resins, composite systems, etc. This results in the panels going to landfills.

Reusing the panels helps to extend the mass timber’s life and decrease its carbon impact.

challenges to reuse

- damage inflicted during life of panels (wear and tear)

hidden defects and damage not visible to the eye (requires testing for structural use)

- reprocessing the panels to cut connections and defects

- panels can loose structural integrity during improper storage

- transportation , panels require transportation from its original use to production plant for cutting and then transported to new site

- new design based on panel size and capabilities

limitations

Our argument and conclusions are based on existing data and research, without firsthand project experience. This may affect how well we can predict what happens to the product in its use and post-life. Additionally, the potential for reuse is contingent upon proper product maintenance, adding another layer of uncertainty to our assessments.

Bushi, L.; Meil, J.; Finlayson, G. 2022. A cradle-to-gate life cycle assessment of North American wood product resin systems. Ottawa, Ontario, Canada: Athena Sustainable Materials Institute. http://www. athenasmi.org/wp-content/uploads/2022/03/Wood_Resins_LCA_Report_Final_Athena_With_CRS_Feb_2022. pdf

Cradle to gate life cycle assessment of softwood lumber ... (n.d.). https://corrim.org/wp-content/ uploads/2018/06/SE-Lumber-LCA-may-2013-final.pdf

DrJ Wood Innovations. (n.d.). About. Retrieved February 23, 2024, from https://www.drjwoodinnovations. com/about/

Durability of Cross Laminated Timber (CLT). Engenuiti. (n.d.). https://engenuiti.com/our-thinking/ durability-of-cross-laminated-timber-clt

Freres Lumber Co. (n.d.). Freres Lumber Co. Retrieved February 23, 2024, from https://frereswood.com/

Cradle to gate life cycle assessment of softwood lumber ... (n.d.). https://corrim.org/wp-content/ uploads/2018/06/SE-Lumber-LCA-may-2013-final.pdf

Mass timber p, Dodoo, A.,et al. (2022, May 1). Circular economy in mass timber construction: State-ofthe-art, gaps and pressing research needs. Journal of Building Engineering. https://www.sciencedirect. com/science/article/abs/pii/S2352710222005757

Wilson, James B. “Life-cycle inventory of formaldehyde-based resins used in wood composites in terms of resources, emissions, energy and carbon.” Wood and Fiber Science (2010): 125-143.