AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING D ecember 2022/J anuary 2023 THE OFFICIAL JOURNAL OF THE NEW ZEALAND INSTITUTE OF FOOD SCIENCE AND TECHNOLOGY INC. FEATURED IN THIS ISSUE: NZFSSRC – Futures Forum highlights: The fuzzy crystal ball Mitigating Food Fraud Consulting and analytical services

NZ’S

DECEMBER 2022/JANUARY 2023 | VOLUME 22, NO.6 ISSN 2744-7308 (ONLINE) ISSN 1175-4621 (PRINT)

Notice to Contributors

Advertisers

Food New Zealand 2 NZ’S AUTHORITY ON FOOD TECHNOLOGY, RESEARCH AND MANUFACTURING Contents 10 4 EDITORIAL Wendy Bayliss, NZIFST Executive Manager 5 NEWSBITES News, views and information from around and about 9 NZ FOOD SAFETY Health Star Rating gets an update Vincent Arbuckle, Deputy Director General, NZ Food Safety 10 IUFoST REPORT IUFoST World Congress Finally Complete! Richard Archer, Phil Bremer and Anne Scott 14 OILS & FATS Oils and Fats News Laurence Eyres FNZIFST 17 SLIDING ON Germ Warfare – the battle against food spoilage Professor John D Brooks, FNZIFST 18 OVERVIEW Consultant and Analytical Services 22 PACKAGING Qualified Packaging Technologists wanted Nerida Kelton MAIP Contacts Peppermint Press Ltd 5 Rupi Court, Mt Wellington Auckland 1072, New Zealand Phone 64 21 901 884 www.foodnz.co.nz Food NZ is distributed online to all members of the New Zealand Institute of Food Science and Technology. An online edition is shared internationally. Visit www.foodnz.co.nz to subscribe. Director and Editor Anne Scott, Peppermint Press Limited anne@foodnz.co.nz Director and Writer Dave Pooch, Peppermint Press Limited davep@me.com Advertising Anne Scott, anne@foodnz.co.nz 021 901 884 Design and Layout Johanna Paynter, Pix Design, Regular Contributors Phil Bremer, John D Brooks, Laurence Eyres, Ben Sutherland, Dave Pooch, John Lawson

by Peppermint Press Limited

Published

When submitting editorial for Food New Zealand please observe the following, Editorial to be submitted as plain text files, NO FORMATTING please. Images should be sent as high resolution .jpg or .tiff files. Do not embed images in word documents, send separate files. Any images smaller than 500 kb may not be printed as the clarity of the print may be compromised.

Material specification sheet and rate card on website, www.foodnz.co.nz

copied

recording,

Copyright © 2022 Peppermint Press No part of this publication may be reproduced or

in any form by any means (graphic, electronic, or mechanical, including photocopying,

taping information retrieval systems, or otherwise) without the written permission of Peppermint Press. The views expressed in this journal are those of the writers and do not necessarily represent the view of the Publisher, the Scientific Review Board or NZIFST.

5 28

December 2022/January 2023 3 Executive Manager, Wendy Bayliss PO Box 44322 Pt Chevalier Auckland 1022 New Zealand Phone: 022 549 8483, Email: wendy@nzifst.org.nz Website: www.nzifst.org.nz Next editorial and advertising deadline: January 20th, 2023 Features for February/March 2023 Laboratory equipment, consumables, instrumentation. JOIN NZIFST NOW for Professional Development Networking – connecting with your peers Regular information about your industry Recognition through awards, scholarships, travel grants www.nzifst.org.nz/join/ On the cover Cover image: Laboratories have changed with the development of powerful sampling and testing equipment that removes much of the manual work of the past. 24 NOSTALGIA Whatever happened to…Dr John Sumner? 26 TRAINING Dairy processing training success 28 NZFSSRC FUTURES Predicting the food safety future – an approximate science 31 FOOD SAFETY Prevention of Food Adulteration and Fraud – Part 2 Tamara Coory and Steve Flint, Massey University 36 STUDENT STUDY Design and analysis of novel 3D printed foods with re-purposed animal and plant proteins. Hannah Lee, Jessica Hampton, Isobel Pope, Sahiti Peddisetti, Damir Torrico, Lovedeep Kaur, Jaspreet Singh, James Morton 39 NZIFST CAREERS End of an era: Jenny Dee FNZIFST Retires Anne Scott 40 NZIFST CAREERS Mentoring senior food technology students Jenny Dee FNZIFST 41 NZIFST NEWS INCLUDING NZIFST Conference New Members Branch News 46

The great, slimy treasure hunt: high-value opportunities for a New Zealand seaweed market Kizzie Amoore, Massey University, Albany Campus 26 39 36 14 31

FTS STUDENT ESSAY

NZIFST is pleased to welcome Wendy Bayliss to the role of Executive Manager.

Wendy, in her own words:

I have been around the food industry my whole life, growing up on a dairy farm in South Taranaki.

I went to Massey University in Palmerston North to study Food Technology and then trained to be a chef down in Christchurch at what is now ARA Institute of Canterbury.

I was fortunate to be selected for the Fonterra Graduate Training Programme which led to working for Fonterra for 10 years in research and NPD roles in New Zealand and Australia.

I took some time off working to have children and was then given the chance to work with the NZIFST as the Conference Speaker Coordinator, which has been an amazing opportunity to reconnect with the New Zealand food industry.

I have also been lucky enough to work with a whole bunch of new and inspiring foodies as a food technology consultant.

I am very excited to now be working as the Executive Manager for the NZIFST. The NZIFST has an important role to play within the New Zealand food industry.

NZIFST’s new Executive Manager, Wendy Bayliss, who took over her role in August

It is a community that has the opportunity to embrace all parts of the food industry, from manufacturing and quality to packaging and NPD, from sales and marketing to research and development. We can connect people and ideas to help grow the New Zealand food industry though efficiencies, and innovation and help to feed New Zealand and the world.

I love that we have members from academia, industry, and government, as this helps to create linkages all along the food chain to help us create a vibrant and exciting community.

I see my role as helping to connecting the dots within the food community, so get in touch if I can be of assistance (wendy@ nzifst.org.nz).

Additionally, I encourage all members to be actively engaged with your local branch and bring along work mates and other people from the food community to see what the NZIFST has to offer. Our local committee members work very hard to bring fun and interesting events to your local area, and it is always nice to do this work knowing there will be a good turnout.

I look forward to seeing many of you at our annual conference in Dunedin in July 2023.

Wendy Bayliss, Executive Manager, NZIFST

4 EDITORIAL Editorial

Newsbites

Food New Zealand’s round up of news about NZIFST members, associated companies and other items of interest.

Send in your feedback on the Geographical Indication regime

The Ministry of Business, Innovation and Employment (MBIE) is asking for feedback on changes to New Zealand’s registered geographical indications regime. This follows the recently negotiated Free Trade Agreement (FTA) between New Zealand and the European Union. Changes to our legislation are needed for New Zealand to meet its FTA obligations.

Geographical indications (GIs) are intellectual property rights similar to trademarks. They help producers give consumers information on characteristics of a product that are connected to its geographical origin. Examples include “Marlborough” (for wine produced in that region of New Zealand) “Scotch Whisky”, and "Champagne".

Under the FTA, New Zealand will register around 2,000 EU GIs for food, wine, spirits, and other beverages for domestic protection. New Zealand is also required to put in place mechanisms to protect these GIs from misuse. The changes need to be in place when the agreement comes into force, which could be in 2024, subject to required processes being completed by both New Zealand and the EU.

MBIE is asking for feedback on what changes should be made and how they should be implemented. The feedback received will inform the development of any amendments to the Geographical Indications (Wine and Spirits) Registration Act 2006.

More information on this consultation and how interested parties can provide feedback is available here. This consultation is open from 23 November 2022 until 28 February 2023.

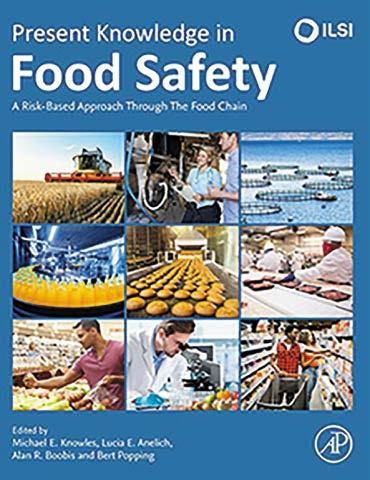

Kiwis contribute to ILSI Food Safety Book

ILSI and Academic Press have just published Present Knowledge in Food Safety and there are three New Zealand authors among the more than 100 (of 72 chapters).

One is Nigel French ("Wholegenome sequencing for Food Safety’') and the other two are Katherine Rich and Gary Bowering (“Communicating about risk in relation to food with the public and countering media alarmism”).

This new textbook presents a holistic approach to scientific advances and applications in risk assessment at key stages in the food supply chain. Conceptually modelled after ILSI’s highly successful Present Knowledge in Nutrition, this book is the first to provide coverage of new and emerging science in the risk assessment paradigm as applied to chemical, physical and microbiological safety issues at each contiguous stage of the food chain – from farm to consumption.

Under the guidance of four leading international experts, the book covers exposure-led risk assessment and management of changes in foodcompositioncausedbychangesintentionallymadeoradventitious at all key stages of food production. As the first book to do this in a single volume, this is a first-line resource for professionals, as well as graduate and post-graduate students in associated fields.

Horizon Europe

New Zealand in formal negotiations to join the EU’s €95.5 billion research and innovation programme.

Along with Canada, New Zealand was the first highly industrialised countrytostartexploratorytalkswiththeEUonbecominganassociated country in Horizon Europe. In the previous research programme, Horizon 2020, New Zealand participated as a ‘third country’ a status that does not offer the full benefits of association.

The Commission concluded informal talks with both New Zealand and Canada and in early September, EU member states gave approval for the Commission to continue negotiations with both countries.

New Zealand and the EU signed a cooperation agreement covering science and technology back in 2009. That has provided a general framework for cooperation and acted as a forum for regular discussions about research priorities and areas of common interest ever since.

EU research commissioner Mariya Gabriel said the EU “is glad about the perspective” of New Zealand joining the programme. “Together, we will address common global challenges from climate change to environmental degradation, from food security to health crises,” she said.

New Zealand’s Minister for Research, Science And Innovation, Ayesha Verrall, said the two parties will be able to work more closely on joint research objectives in zero carbon technologies, reducing emissions from agriculture and developing emerging technologies. “Becoming an associated country of Horizon Europe would reflect our deep relationship and shared values, especially at a time of disruption and uncertainty,” Verrall said.

From Science Business

December 2022/January 2023 5 Newsbites

Recyclable high barrier pack for dry pet food

Mondi, a global leader in packaging and paper, has developed a recyclable high-barrier packaging solution for Norwegian pet food manufacturer Felleskjøpet, that keeps packaging material in circulation and avoids waste.

Mondi’s FlexiBag Recyclable, a pre-made mono-material polyethylene (PE) bag, will replace the previous unrecyclable multi-layer solution, delivering packaging that is designed for recycling, according to

Kiwi Greentech start-up, CiRCLR, takes global stage at COP27

Northland parents of four, Sara Smeath and Chris Saunders, presented their business, CiRCLR, on stage at the United Nations Climate Conference COP27 in Egypt as part of a global cohort of top technologies addressing climate change.

CiRCLR is a New Zealand start-up whose technology separates waste from wasted opportunities, by matchmaking businesses to create circular economies. Every exchange provides sustainable transparency for businesses, their consumers and lenders. Cofounder Chris says, “We see CiRCLR as a no-brainer for businesses, that enables extracting more value from their resources while reducing waste sent to landfill. We’re helping break silos across industries with more diverse supply-chains, smaller carbon footprints and access to green finance with sustainable actions they

CEFLEX D4ACE guidelines, and is recyclable in existing Norwegian plastic recycling streams.

The material provides excellent product protection and preserves the premium pet food, thanks to its high barrier material. A slider enables easy opening and closing for the bigger bags to ensure longlasting freshness, while a handle allows for convenient transportation.

FlexiBag Recyclable has excellent print qualities that guarantee good visibility on-shelf and can communicate all product and recycling information clearly.

can prove. At COP27, Sara and Chris focused on promoting CiRCLR as the way to connect the dots for businesses, by simplifying circular economies and unlocking a $600 billion dollar "wasted" opportunity in the food and agriculture sector.

CiRCLR is 7 months old but in that short time was part of the Climate Response Accelerator at Creative HQ and is now participating in the Orion Energy Accelerator where their platform investigates connecting waste to energy. CiRCLR is also part the Ministry of Awesome Founders catalyst. Sara comes from many years in the fashion industry where she helped build circular economies and sustainable innovations for global supply chains. Chris has over ten years’ experience in product design and software development for start-ups and Fortune 500s globally. Their technology meets this year’s COP27 goals by addressing connectivity, decarbonisation and climate finance while creating a solution to transform world food systems.

6 Newsbites

FastBack 4.0 from Heat and Control

FastBack® 4.0 is the latest revolution of ground-breaking, horizontal motion conveying technology from world-leading equipment solution manufacturer, Heat and Control.

Since their introduction in 1995, FastBack conveyors have brought unmatched benefits to the food processing markets – near zero breakage and product damage, no loss of coatings or seasonings, greatly reduced sanitation and associated down time, quiet, smooth, and trouble-free operation proven with thousands of units for years of operation.

Because of these benefits, FastBack is recognised as the number one brand in horizontal motion conveying, with the highest resale value and the largest market share.

With more than 25 years and three generations of FastBack, Heat and Control takes advanced knowledge of horizontal motion conveying to the next level. FastBack 4.0 is the culmination of more than 10 years development and multiple international patents.

“Investing in continued innovation is at the heart of what we do at Heat and Control. Ensuring high performance that provides results is a priority when we undertake design development such as FastBack 4.0,” said Tony Caridis, Heat and Control, Inc. President.

FastBack 4.0 retains all the benefits that FastBack units are famous for, and includes:

• Instant reversing capability

• Trouble free – no preventive maintenance, no lubrication

• No flexures, no linear bearings, no bushings

• The longest design life

• High pressure washdown capability

• Fewer moving parts (by 70%)

• Easy maintenance – only two wrench sizes needed for all operations – 13mm and 17 mm

• Small footprint for both ease of installation and ease of sanitation.

FastBack 4.0 is a circular to linear drive horizontal motion conveyor, a new solution in horizontal motion conveying. A key design feature is a rotational (circular) drive motion that produces a horizontal (linear) motion. The circular to linear drive efficiency converts rotational motion into pure horizontal motion while also supporting the vertical weight of the pan. This is an innovation in design that has achieved multiple international patents and capacity that is found in no other design.

To help make FastBack 4.0 a reality, Heat and Control teamed up with the world leading industrial bearing manufacturer SKF (AB SKF). The development partnership resulted in a precise and customised application that meets the goal of transforming the horizontal motion conveyor category. SKF is also able to meet growth targets across the globe with their large industrial network, a scope that supports the Heat and Control vision.

When it comes to operational design goals of the FastBack 4.0, special attention was given to making it easier to own, removing the pain points that production line managers and operators face on a regular basis when it comes to maintenance, cleaning, and performance. “Feedback we receive from plant managers and operators is often about needing to reduce downtime which aligned with our goal of designing the perfect system, one that becomes the best student and not a troublemaker, offering the highest level of operability with the lowest level of effort,” said Blake Svejkovsky, Heat and Control, Inc General Manager - Product Handling Systems. www.heatandcontrol.com

Newsbites

Sanford opens new Bioactives Centre

The hidden properties of many New Zealand marine species will be explored and unlocked at a new marine extracts plant just opened in Blenheim, Marlborough. The $20 million plus Bioactives innovation centre is the brainchild of New Zealand’s largest seafood company, Sanford, and it will make the most of the beneficial properties of several of Aotearoa’s under-appreciated marine products.

Sanford’s GM of Innovation, Andrew Stanley says the plant will do two key things.

“Firstly, Sanford Bioactives will work with marine products which we already know have beneficial properties such as Greenshell Mussel powder which has proven anti-inflammatory and joint health benefits. We already make it, we already sell it, it is very popular. Our new Bioactives centre introduces new tech and equipment which gives us a chance to double and eventually quadruple our output.

“Secondly, there are the new areas of marine extracts and science we are going to explore. The potential is huge, given that Sanford is a fishing and aquaculture company that works with more than 100 different marine species. We already know quite a bit about some of their hidden properties and we will be working to discover more. This science is being done with great partners like Cawthron, Plant & Food and Massey University. Our Blenheim plant will be a home for much of that work.”

Sanford CEO Peter Reidie says some of the products Sanford will be making in Blenheim can sound like science fiction the first time you hear about them.

“Hoki skin collagen is one of those. Sanford has been producing this at a relatively small scale. We extract the collagen from the hoki skins and then one of our partners turns it into a nanofibre. That fibre is then woven into beauty masks which melt on contact with damp skin, delivering the collagen deep into the dermis. These sell out in South Korea, showing that there is huge potential to grow and to make the most of a product, in this case a fish skin, which many people would previously have seen as waste.

“This all fits with Sanford’s strategy to improve the value utilisation of the entire fish and eliminate waste. We see this approach as key to sustainability and getting more value out of New Zealand’s precious seafood.

“Blenheim is currently world famous as a centre for beautiful New

Sanford has been extracting the collagen from dried hoki skins for conversion into a nanofibre used in beauty products

Zealand wines. We believe it can and should become famous as a home for marine products and extracts that can take the world by storm.”

The Sanford Bioactives Centres is creating new jobs for scientists and technicians in Marlborough. It will eventually employ up to 48 people.

Mr Reidie says “what we know already is very exciting – more jobs, better value for our seafood – but what we don’t know yet is equally exciting. What are the products of the future that will come out of this plant? They could be anything from new beauty products to compounds with medical benefits. There is so much potential from seafood such as our Greenshell mussels, which are unique to New Zealand, and we can’t wait to see what our Bioactives team will do in the future.”

About Sanford:

Sanford is New Zealand’s oldest listed company and our largest seafood company. They farm salmon and mussels and hold just under 20% of New Zealand commercial fishing quotas.

Sanfords debuted on the New Zealand Stock Exchange in 1924.The company is focused on sustainability and on maximising the value of the resources gathered from New Zealand’s oceans. Sanford sites can be found in 15 locations around New Zealand and in Melbourne, Australia, with 1,400 staff and sharefishers who are committed to innovation. Sanford’s scientists are on a mission to find new ways to make the most of the life-enhancing properties of seafood, from antiinflammatory supplements to skin-nurturing collagen.

For more, please visit: www.sanford.co.nz

8 Newsbites

Health Star Rating gets an update

What you need to know

Presented by Vincent Arbuckle, Deputy Director General, NZ Food Safety

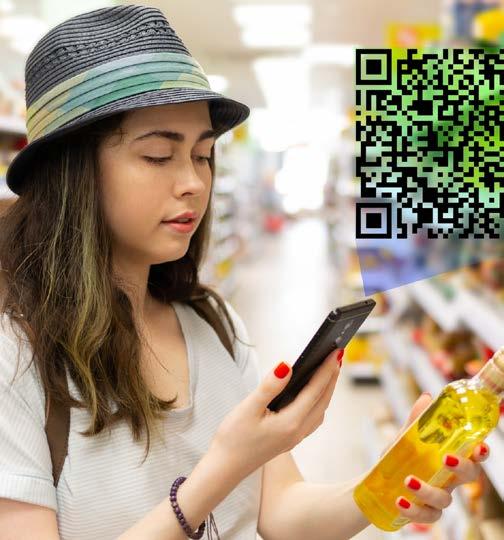

When we announced the latest Health Star Rating (HSR) milestone in November, there was much accompanying media coverage. I was interviewed on radio and TV, and both print and online articles carried the news that most food labels had been updated to reflect an upgrade to the system.

Consumer interest

This strong media interest is a good gauge of consumer interest. People lead busy lives, and it can be difficult to make healthy choices at the supermarket, so consumers appreciate the at-a-glance nutritional information the stars provide.

Consumer research from 2018 shows that three-quarters of shoppers recognise HSR. The same research showed that shoppers’ use of the system had increased from one in ten in 2015 to three in ten in 2018. These numbers are the most recent we have, but fresh research could be on the cards under a new monitoring framework that’s being developed, and we expect these figures have gone up.

Consumers also appreciate that concerns about discrepancies in ratings – again highlighted in the media in recent years - have been heard. That ratings are now tougher on sugar and salt is good news and increases the level of trust they can have in the system.

The worth of the system was reinforced by Nestlé’s November announcement about making the nutritional value of its global portfolio transparent in its yearly reporting – and that their evaluation benchmark would be HSR. “HSR will provide a single basis of comparison for our broad, global offering of food and beverages across 186 countries, except for our specialised nutrition products,” Nestlé said.

Supporting reformulation for health

Reformulation is another example of how the system helps deliver health benefits to consumers. Research published this year in the online journal BMJ Nutrition, Prevention & Health shows that consumer purchases of starred products have lower salt and higher fibre content compared with these same products prior to the introduction of the HSR system. The research concludes: “The positive effect on nutrient purchasing of HSR-labelled foods likely arises from reformulation of products to achieve a better HSR label.”

Shoppers clearly care about nutritional information and what they’re buying, so it’s great to see more food businesses working to give their consumers the information they want. If you haven’t adopted HSR yet, it’s worth considering.

What you need to know

• Started in 2014, the trans-Tasman HSR system is a front-ofpackage labelling system that allows consumers to compare the nutritional values of similar foods by using a scale of 0.5 to 5 stars.

• A scheduled independent review in 2019 found that although the system was performing well, there were improvements to be made to better reflect dietary guidelines.

• The updated system was implemented in 2020, with all label changes needing to be made by 14 November 2022. For products with a shelf-life of 12 months or longer, a stock-intrade provision was made for a further 12 months.

What’s changed?

• The algorithm underpinning the HSR calculator more strongly penalises total sugars and sodium.

• The system remains voluntar y – and there is no government charge to use it – but if uptake by manufacturers does not meet a 70% target by 2025, government will consider making it mandatory. The interim uptake targets for intended products are:

• 50% by 14 November 2023

• 60% by 14 November 2024

Which foods should carry ratings?

The foods intended to carry HSR labelling are those that:

• are permitted to use the system, and

• are required by the Australia New Zealand Food Standards Code to have a nutrition information panel, and

• can vary in nutritional composition.

Which ones shouldn’t?

You can't use HSR labelling on alcohol or beverages resembling alcohol, kava, or some special purpose foods such as:

• formulated supplementary foods for young children,

• foods for special medical purposes, or

• infant formula.

Uptake monitoring

• Uptake in NZ was last officially monitored in early 2018 to inform the five-year review of the system. At that time, there were 2997 eligible products displaying a HSR in the NZ Nutritrack database, representing 20.9% of eligible products in the database that year. Food groups with the greatest uptake were packaged fruit and vegetables, cereals and cereal products, and non-alcoholic beverages.

• Current informal reports from industry estimate that around 6000 products in supermarkets have health stars on their labels.

• Uptake monitoring will next be done in November 2023.

How to calculate a rating

It's easy to use HSR on your product. You don’t need to register – just calculate your product’s rating and prepare the label. Links to a handy calculator and label artwork can be found on the Ministry for Primary Industries website.

Still have questions?

New Zealand Food Safety administers HSR in NZ. If you have questions, contact our labelling gurus phillippa.hawthorne@mpi.govt.nz or rebecca.doonan@mpi.govt.nz.

December 2022/January 2023 9 Food Safety

IUFoST World Congress finally signed-off!

Where it began

You will remember 2020 – we were all dressed up and ready for the IUFoST World Congress in Auckland. The Food Science and Technology world was beating an aerial path to our South Pacific door. Then Covid19 struck and we had to cancel. We were left with no punters and a potential debt of ~$300k to our sponsors. We had spent their money but given them no conference!

IUFoST is the International Union of Food Science and Technology. Many national IFSTs of the world are members. NZIFST has been an adhering body since the 1960s. The World Congress is held every second year and is the chance for one nation to strut its stuff and show of its food science and technology capabilities.

We had been waiting since the 1960’s to host a congress and finally won the right for the 2020 Congress at the Dublin Congress in 2016. A small group from the organising committee attended the 2018 Congress in Mumbai and received, at its closure, the symbols of authority – a bell on which are engraved the host nations’ names, and the IUFoST flag – as hosts of the 20th World Congress in Auckland in 2020.

Phsssphttttt.

Fortunately, we had built a strong relationship with Singapore Institute of Food Science and Technology (SIFST) who were to host the 21st World Congress in 2022. We had included SIFST in our conference organising committee since 2020 (as Singapore did with Italy who have it in 2024). When we had to cancel, SIFST kindly granted us the first half day of their Congress to strut our stuff before handing over the flag and bell. Furthermore, they kindly gave us free registrations and access to booths for our major sponsors. Fortunately for us many of our sponsors had agreed to trade reimbursement for the option of free access to the 2022 Congress in the heart of South East Asia.

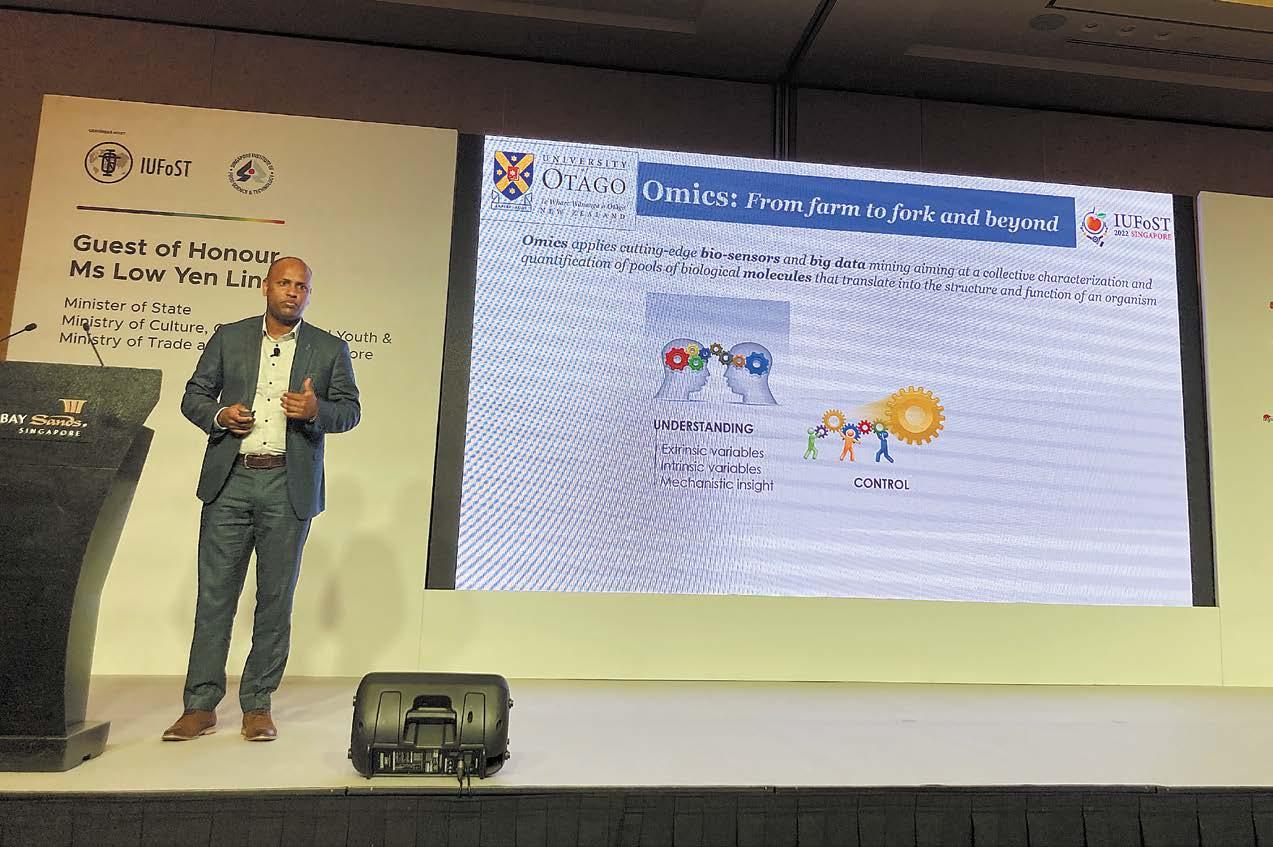

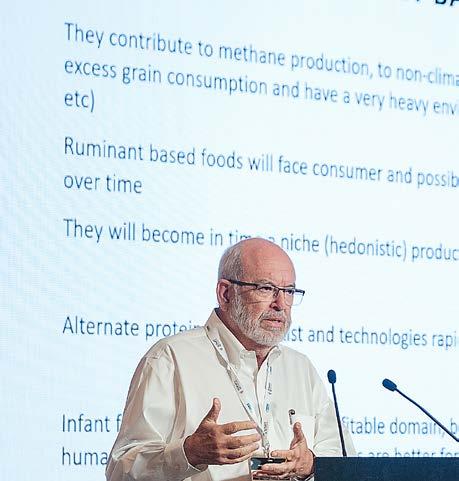

So planning for 2022 was actually quite a big deal. And it has just happened: 30 October to 3 November in Singapore. In the end we presented:

• Two major 30 minute plenary talks in the first morning

• Two shorter form 15 minute plenary talks later in the morning

• Two 90 minute sessions on New Zealand research in the parallel session part of the Congress

All our speakers did us proud and the word “New Zealand” was audible frequently. Our four plenary speakers were:

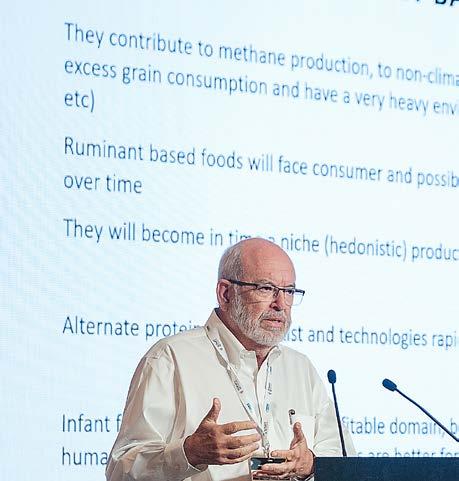

• Jeremy Hill from Fonterra and the Riddet Institute spoke broadly about the Delta Model. He showed that the world has enough protein already for its 2050 population needs, albeit poorly distributed. Plant protein is important and will expand but, overall, no more protein, or even essential amino acid, is needed.

• Sir Peter Gluckman followed with a pretty tough appraisal of the challenges to food and nutritional science posed by the food system now. More efficient routes to produce protein than raising ruminants are inevitable.

• Dr Jim Bier of Tatua talked about modern specialised dairy protein nutritional ingredients, especially tailored hydrolysates.

• Nikos Patiniotakis, Global Brand Manager for Zespri, who is based in Singapore, presented on building a brand around Kiwifruit, especially through approaches tuned to the different cultures of Asia.

Collectively our speakers gave a high-powered look at New Zealand’s quite sophisticated food industry – accentuating its positive progression.

Phil Bremer and Richard Archer attended the General Assembly of IUFoST. The Royal Society of NZ supports our attendance at General

10 IUFoST

Richard Archer, Phil Bremer and Anne Scott

Jeremy Hill, Fonterra, right and Peter Gluckman, were Keynote Speakers in Singapore, and used the opportunity to give a high-powered look at New Zealand’s sophisticated food industry

Assemblies – it is all part of the international science system which sets and maintains standards.

An important role of IUFoST is to honour well-performed food scientists, technologists and engineers. Several Kiwis were honoured or inducted during the 2022 Congress:

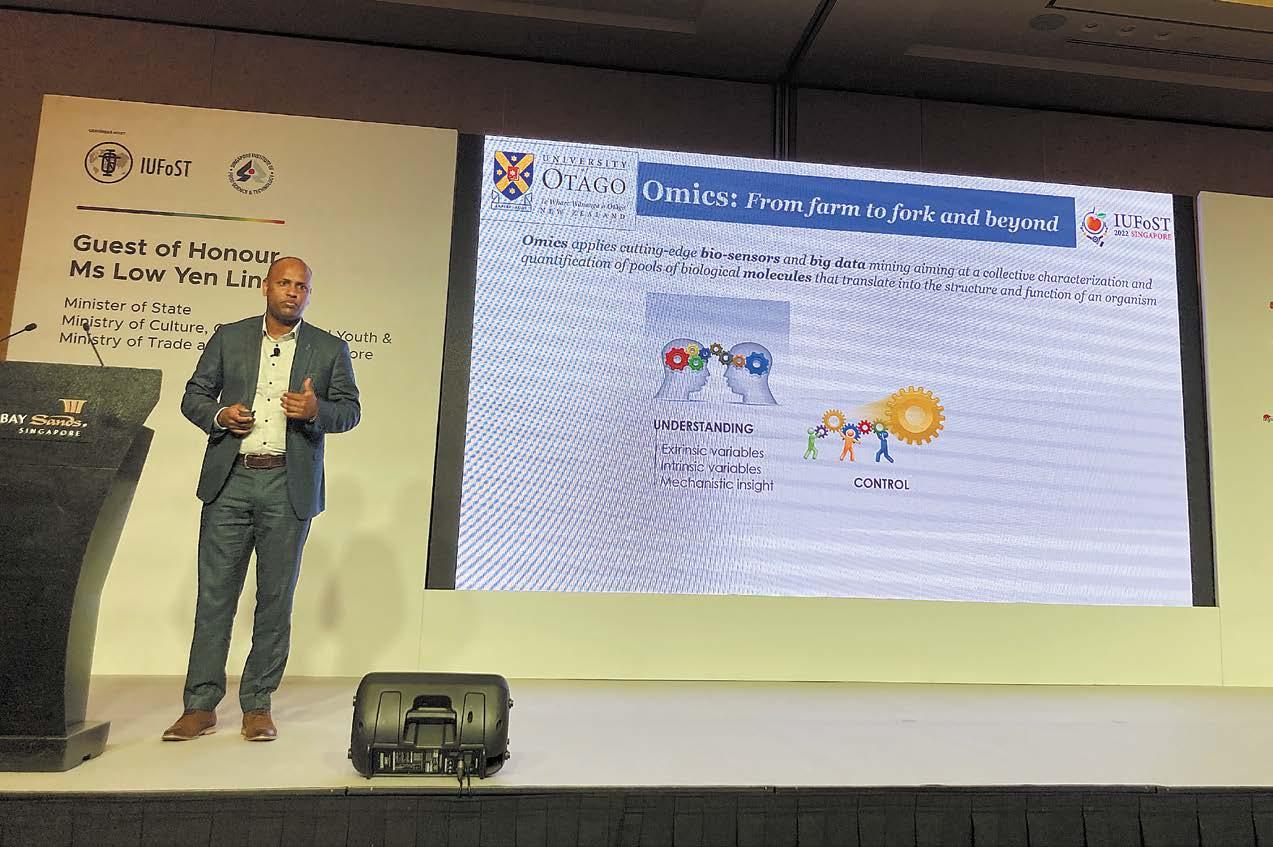

• Dominic Agyei won the Young Researcher Award 2021

• Biniam Kebebe won a Young Scientist Award for 2022

• Richard Archer and Indrawati Oey were elected IAFoST Fellows in 2020

• Anne Perera was elected IAFoST Fellow in 2022 That’s it! Eight years!!. One year of preparing a bid, three planning a conference and all the detail of our Auckland Congress (including watching our preferred venue burn), then two more years of disorganising our Auckland Congress and mounting a fraction of one remotely in Singapore – all now done. (See below.)

NZIFST in Singapore

Many people contributed to organising this, including Singapore-

based alumni and staff from Massey and Fonterra. Yi-Chern Lee, an established NZIFST member now working for Fonterra in Singapore did not stint. Dr Mathew Zhou (now lecturing with Massey at SIT) was on the scientific committee. Dr Oni Yuliarti, now lecturing at SP was a huge part of the main organising committee. Anne Perera and Don Otter helped organise our parallel sessions. Collectively they carried a lot of the local weight and looked out for the New Zealand chapter, most ably.

We, NZIFST, have ended up with only a small loss out of these eight years thanks to the generosity and flexibility of our sponsors, skill of our conference organisers and efforts of our members.

We had around two dozen Kiwis as delegates at the 21st Congress plus another two dozen Massey Singapore alumni and students assisting with its organisation. People from Otago, Massey, Auckland, Lincoln and several New Zealand companies presented or attended. It was great to catch up with many Massey and Otago alumni who were presenting or attending. Cuddon Ltd had a booth at the Congress. That is not bad. In 2024 the Congress will be in Rimini in Italy. I wonder who we will have there...?

Richard Archer and Phil Bremer

anything from 1000 to 3000 delegates, and only 3 years to prepare –preparations moved quickly. NZIFST was fortunate that Rosemary Hancock is also a professional conference organiser so with her guiding hand the Institute and Congress committees got to work. An event this large needed a professional management team so Avenues Event Management was appointed in that role. Budgets, plans, committees, venues, catering – the work rolled on. Sponsors were locked in, scientific content was planned, abstracts were called for, registrations started rolling in and by 2019 all was on track but then…

The IUFoST Congress that wasn’t

In 2015 NZIFST was invited to make a bid to hold the 2020 IUFoST World Congress in New Zealand. Anne Scott was NZIFST President at that time and presided over the Exec and Board meetings that investigated the proposal and agreed to make a bid for the Congress. A face-to-face presentation was required to be made at the 2016 Congress in Dublin.

The Board was generously supported by Tourism New Zealand as development work progressed. Part of the role of TNZ is to support international events such as conferences and expositions for the benefit of tourism operators, such as hospitality and venue providers, so they have a full year of bookings, especially in the winter or low season. TNZ allocated us a budget and a design house which helped create our logo and a slick bid document and PPT presentation for IUFoST. The first draft of the bid document was 86 pages, but the balance was more touristy than Congress. After several iterations an acceptable design was achieved – in 52 pages. At the same time a PowerPoint presentation was created that included a wonderful TNZ video of New Zealand scenery.

A Congress Committee was collected – actually 2 committees, a Scientific Programme Committee, chaired by Gordon Robertson, and a Congress Organising Committee, chaired by Andrew Cleland.

Gordon Robertson and Rosemary Hancock were charged to carry our bid to IUFoST Congress in Dublin and, gratifyingly, we were awarded the 2020 Congress baton, on our first try!

Once the reality had sunk in – we now needed an event for

Venue change

Our chosen venue, the new International Convention Centre, had been having construction problems, and they kept moving their opening date more and more into the future. Finally, we changed venues to the Aotea Centre which necessitated many hours of rejigging the spaces for presentations, exhibits and social events –not to mention renegotiating with exhibitors who now had a less perfect space. We were vindicated for making the change when the still incomplete ICC construction site suffered a major fire in October 2019.

Pandemic

April 2020 saw all of New Zealand and much of the world reeling from the appearance of the Coronavirus. By that time, Richard Archer was NZIFST President and bore the brunt of the many discussions and meetings that culminated in the devastating realisation that 2020 Vision had to be cancelled.

The great unwind

But that was far from the end of the story. NZIFST had invested a 5-figure sum in getting this far. Sponsors and exhibitors had committed even more money. Many hours were spent negotiating so that our Institute maintained its reserves while exhibitors and sponsors received benefits from their investments. Arrangements were made with Singapore Institute of Food Science and Technology to complete the IUFoST Congress ceremonial handover in Singapore this year.

Anne Scott

December 2022/January 2023 11 IUFoST

The story of NZIFST’s activities at IUFoST Congress in Singapore started in 2015.

NZIFST members at IUFoST Congress in Singapore

Congratulations to our members whose achievements were recognised in Singapore.

Above, NZIFST President, Phil Bremer, right, at the formal, very belated, handover of the IUFoST Congress flag and bell to Richard Khaw SIFST President and co-chair of the Congress Organizing Committee at this year’s opening session

IUFoST

12 Food New Zealand

Dominic Agyei from Otago University won the Young Researcher Award 2021, right

Dr Anne Perera was elected a Fellow of IAFoST in 2020 and was presented with her award in Singapore by Dr. Ogugua Aworh, President of the IAFoST Council

As always the great and the good fill the front row, Guest of Honour, Ms Low Yen Ling is seated 5th from the right in a pink jacket, and our NZIFST President, Phil Bremer, is on the right, cradling the IUFoST Bell and Flag before the handover

December 2022/January 2023 13 IUFoST

Richard Archer, (above) was elected a Fellow of IAFoST in 2020 and received his certificate in Singapore. He also introduced the session of New Zealand Special Invited Speakers and Young Scientist Award Presentations

Biniam Kebebe from Otago University won a Young Scientist Award for 2022. He is pictured here making his presentation.

Dr Indrawati Oey from Otago University was elected a Fellow of IAFoST for 2022 and was presented with her award in Singapore by Dr. Ogugua Aworh, President of the IAFoST Council

Oils and Fats News

Laurence Eyres FNZIFST

AGM of the Oils and Fats Group

The AGM and Annual gathering was held on 14th of November at the Grand Harbour Chinese Restaurant. Our Chairman maintained his AGM duration policy of “keeping it short” and a lovely evening was enjoyed by a convivial group of 21. Thanks to Sally Xiong for arranging our delicious dinner and the Chair for his selection of excellent wines. The committee remains unchanged.

Pain and inflammation

Most of my colleagues and friends in my senior age group suffer from some form aches and pains and this is universal. So, what should we take for these aches? The most active pharmaceutical that I have found is diclofenac (Voltaren). However, like all pharmaceuticals, drugs have side effects and consequences. Non-steroidal anti-inflammatory drugs (NSAIDs) are used to reduce mild-to-moderate pain and inflammation (swelling).

These include

• Aspirin Ibuprofen (Nurofen, Advil, Motrin). Ibuprofen can treat a range of conditions including post-surgical pain and pain from inflammator y diseases, such as ankylosing spondylitis.

• Naproxen (Aleve, Anaprox DS, Naprosyn)

• Celecoxib (Celebrex)

They work by blocking and reducing enzymes and hormones that cause pain and swelling in your body.

NSAIDs can be used for short-term pain such as when you have an injury or a flare-up of symptoms but they are not suitable if you have stomach problems because they may cause stomach bleeding. They may also not be suitable if you have asthma, heart, liver, or kidney problems.

While anti-inflammatory drugs such as ibuprofen or naproxen can be effective for acute pain, long-term use can cause harmful side effects, including kidney and gastrointestinal damage. Some natural supplements can be highly effective for certain conditions, and some have fewer side effects. However, not all supplements are effective or safe for everyone. Although pharmacological pain therapy offers several alternatives, pain management remains often unsatisfactory.

What about natural remedies?

Natural medicinal approaches, commonly referred to as complementary medicine or dietary supplements, continue to grow in popularity. Americans spend more than $30 billion each year on complementary

health products and practices. Unfortunately, a great proportion of supplements have no beneficial effect in this area and its always useful to check out the background scientific evidence for supplements. Natural health remedies with background scientific data for efficacy include high purity fish oil, astaxanthin, PEA and resveratrol.

Pain pathways

Cells in injured and inflamed tissues produce several proalgesic lipidderived mediators, which excite nociceptive neurons by activating selective G-protein-coupled receptors or ligand-gated ion channels. Recent work has shown that these proalgesic factors are counteracted by a distinct group of lipid molecules that lower nociceptor excitability and attenuate nociception in peripheral tissues. Analgesic lipid mediators include endogenous agonists of cannabinoid receptors endocannabinoids, CBD oil), lipid-amide agonists of peroxisome proliferator-activated receptor-α PEA, and products of oxidative metabolism of polyunsaturated fatty acids via cytochrome P450 and other enzyme pathways. Evidence indicates that these lipid messengers are produced and act at distinct stages of inflammation in the response to tissue injury and may be part of a peripheral gating mechanism that regulates the access of nociceptive information to the spinal cord and the brain. Growing knowledge about this peripheral control system may be used to discover safer medicines for pain.

PEA is technically referred to as a “pro-resolving lipid signalling molecule.” What this means is that through impacting central control mechanisms within our cells, PEA has an ability to resolve inflammation and cellular stress. This extremely beneficial effect has been demonstrated in over 600 scientific investigations. The potential clinical applications of PEA are quite broad, but research and popular use have focused on its use as an anti-inflammatory and pain-relieving agent in conditions like low back pain, sciatica, osteoarthritis, etc. Preclinical and human studies have also investigated its effects on depression, boosting mental function and memory, autism, multiple sclerosis, obesity, and metabolic syndrome. While it shares many features comparable to cannabidiol (CBD), the advantage of PEA is that it has better science to support its use. Having said that, the use of medicinal cannabis is growing, Use of cannabinoid compounds

14 Oils & Fats

There are many drugs prescribed for pain relief but like all pharmaceuticals, many have side effects and unintended consequences

News and views

the

of

from

world

lipids

as therapeutic agents dates back at least 4000 years, with medical references documenting the first medicinal use in 2737 BC in China. It seems like a small percentage of THC attenuates the action of the CBD. I wanted to grow some plants in the back garden for research purposes, but the Financial and Compliance director said no!

Used frying fats for biodiesel

Years ago, used cooking oil (UCO) was considered hazardous waste. By law, restaurants had to dispose of it safely, so they paid companies to take it away until the industry realised that plant- or animal-based oils could be converted into biodiesel (mainly in the USA) – a green energy source.

Today, restaurants sell their used oil. They get only a small fraction of what they paid for it, but for restaurants struggling to make even a meagre profit, trading a monthly expense for a mini-revenue stream makes sense.

Used cooking oil also can be used to manufacture animal food, compost, health and beauty products and various household cleaning and maintenance solutions.

Biodiesel is the primary use for used cooking oil, as it reduces dependence on environmentally toxic fossil fuels.

“Feedstock”, or source material, for biodiesel includes soybeans; canola, corn, and other plant oils; rendered animal fats; winter oilseed cover crops; used cooking oil; and other biomasses,

Investigating recovery from Covid

Even though most individuals with COVID-19- experience substantial recovery, there is considerable population of individuals with persistent symptoms such as breathlessness (plus olfactory dysfunction) and fatigue, who seemingly have limited therapeutic options. To assess the efficacy of treatment with high doses of omega-3 fatty acid (O3FA) supplementation, researchers conducted a randomised, placebocontrolled, double-blinded clinical trial among patients with laboratoryconfirmed or clinically suspected COVID-19 infection and self-reported, improvement between March 2020 and October 2021.

Patients were prospectively recruited for the current clinical trial if they exhibited evidence of quantitative post Covid problems, which was defined as a Brief Smell Identification Test (BSIT) score of 9 or less. The study included an experimental group and a control group. Participants in the experimental arm received O3FA 2g supplementation, which included eicosapentaenoic acid 1366 mg and docosahexaenoic acid 504 mg, whereas those in the control arm received an identical placebo. Each of the treatments was to be taken daily for 6 weeks. The primary study outcome was small improvements in well-being.

Reference: Omega-3 fatty acid supplementation for the treatment of COVID-19-related olfactory dysfunction. Abstract presented at: AAOHNSF 2022 Annual Meeting and OTO Experience; September 10-14, 2022; Philadelphia, PA. Otolaryngol Head Neck Surg. 2022;167(1 suppl):P147.

Omega-3 Cognition

A new study published in J. Nutrition suggests that positive associations between omega-3 polyunsaturated fatty acids and better cognitive function may vary according to other dietary factors and sex. There is growing interest in examining the protective role of omega-3 polyunsaturated fatty acids in cognitive health among older adults. Yet, studies comparing lower versus greater dietary intakes of omega-3 polyunsaturated fatty acids on neurocognitive outcomes remains somewhat inconclusive. It is speculated that the effect of omega-3 polyunsaturated fatty acids on cognitive function could be masked or confounded by the presence of other fatty acids in the diet including omega-6 polyunsaturated fatty acids, monounsaturated and saturated fatty acids. Untangling the interrelation between fatty acids that share similar biological pathways could improve our understanding of the specific effect of omega-3 polyunsaturated fatty acids on cognitive functions. Research also suggests that brain metabolic activity in aging males and females may not be the same (“Drat!”). As a result, sex-related differences in cognitive function are also important considerations. Considering the evidence for sex-based differences in omega-3 fatty acid concentrations, it is surprising that few studies have examined the moderating role of sex in the association between omega-3 fatty acids and cognitive function.

December 2022/January 2023 15 Oils & Fats

Biodiesel is the primary end-point for used cooking oil

Note I always ask my wife for help when it comes to remembering names and events.

In some studies, higher omega-3 polyunsaturated fatty acid concentrations were associated with better non-verbal memory and processing speed in models not including other fatty acids. The magnitude of these associations varied when other fatty acids were entered in the model. Associations with verbal episodic memory were limited to higher concentrations of eicosapentaenoic acid, an omega-3 polyunsaturated fatty acid that is particularly important to brain structure and function, whereas there was no association between omega-3 polyunsaturated fatty acids and executive function. Higher omega-3 polyunsaturated fatty acids were associated with better verbal and nonverbal episodic memory in females and with better executive functioning and processing speed in males.

The results of this cross-sectional study showed that higher concentrations of omega-3 polyunsaturated fatty acids were associated with better nonverbal episodic memory, processing speed, and, in some cases, verbal episodic memory. Reference: Fatty Acids and Cognitive Domains in Community-Dwelling Older Adults from the NuAge Study: Exploring the Associations with Other Fatty Acids and Sex, The Journal of Nutrition, Volume 152, Issue 9, September 2022, Pages 2117–2124, https://doi.org/10.1093/jn/nxac110

Avocado oil standards (Codex)

Professor Selina Wang of UC Davis has been leading a group of science researchers working to produce a standard for Avocado oil. No standard exists at present. Fraudulent activities abound in this area and it's similar to the situation with Olive oil. Countries that produce high quality olive oil, such as California, Australia and New Zealand, lamented for many years over the IOC trading standard for olive oil which was “loose as a goose”. These 3 countries now have their own standards which are much tighter than the IOC. I suspect the same may be true for the proposed Codex standard. One distinct marker of adulteration in avocado oil is the lowering of the level of Cis octadec11-enoic acid (cis vaccenic acid, an isomer of oleic acid). A topic to be pursued by the UC Davis group.

Unfortunately, the workings of such scientists are usually unappreciated by industry who confuse science and standard setting with compliance and food law. Expecting scientists to enforce draft and non-existent food laws is both naïve and shows a lack of understanding of key issues.

References:

i Green, H. S.; Wang, S. C. Food Control 2023, 143, 109277 “Evaluation of proposed Codex standard for Avocado oil.

ii.Green, H. S.; Wang, S. C. Food Chemistry Advances 2022, 1, 100107

“Cis-vaccenic acid: New marker to detect seed oil adulteration in avocado oil”

iii.Green, H. S.; Wang, S. C. Applied Food Research 2022, 2(2), 100190 “Extra virgin grade avocado oil can be achieved using whole fruits or only mesocarp.

Use for Avocado seeds (or pips)

For the first time, ground avocado seeds are being used in beauty products, replacing the now banned and environmentally harmful plastic micro-beads previously used. After three years of research, development and product testing, Westfalia Fruit’s business in the UK is supplying the ground avocado seeds to the premium beauty brand Dr. Craft for use as a part of a range of cosmetics.

The extraction process is very complex, but with perseverance a perfect particle size and process was discovered to work within a cosmetic body scrub as the replacement for microbeads.

Currently, avocado waste components, including skins and stones, are used in low value anaerobic digestors. Their sustainable inclusion in beauty and cosmetic products opens a new, higher value alternative in-line with a history of identifying, implementing, and pioneering, innovative and industry leading methods to reduce inputs, waste and reinforces a commitment to protecting the health of the environment.

New food/nutrition books from Tim Spector

Tim Spector, an epidemiologist, and co-founder of the ZOE nutrition study, wants to change the way people think about food. His 2015 book The Diet Myth popularised the idea that each of us has a unique and constantly changing gut microbiome that is crucial to our health. Spoon-Fed, in 2020, exposed diet misinformation. Food for Life, at over 500 pages, overlaps with these but offers more information than ever before. It aims to think about food for “our individual health, the health of our society and the health of our planet.” It’s complex, hard to digest and obviously good for us, like an enormous portion of fibrous vegetables, well balanced with olive oil and spices. Would make a good Xmas present for the foodies in your life.

Saturated fat and linoleic acid – a new look

Tim Spector attempts to destroy the “myths” around saturated fat and omega-6 fatty acids. I plan to look again at this area and report back. Food nutrition is never simple and there are always a host of conflicting factors. There is no such thing as one theory to rule them all. (Apology to Tolkien)

[If you like to listen to your health advice, Tim Spector has a podcast: Zoe Science and Nutrition. Ed]

16

Oils & Fats

Professor Selina Wang of UC Davis has been leading a group of science researchers working to produce a standard for Avocado oil – none is in existence to date

Sliding on

Germ Warfare – the battle against food spoilage

Professor John D Brooks, FNZIFST

John Brooks' view of the food world through the lens of a microbiologist.

It’s not all PCRs and gene sequencers

I’m sure that many people yearn for the glamorous life of the food microbiologist leading the war against microorganisms – yeah, right! Perhaps those people visualise the microbiologist surrounded by modern laboratory equipment, such as PCR machines and gene sequencers, but the sad fact is that what is portrayed in films and television just isn’t reality. It might be the case in forensic work or pathogen testing, but in the food industry, much of the work involves monotonous sampling and plate counting.

The reason for this is that there is a constant battle between food manufacturers and the microorganisms that can cause spoilage or food poisoning. Food safety is assessed in relation to counts of specific bacteria, yeasts and moulds. The International Commission on Specifications for Foods was formed in 1962 and wrote Microbiology of Foods Volume 2: Food Commodities in 1980. This was updated in 1996 (1). Our Microbiological Reference Criteria for Food were published by the Ministry of Health and Version 2 appeared in 1995. The Reference Criteria are expressed in the ICMSF format as a guide to indicate when food can be considered unacceptable or unsafe.

The result is that many food microbiologists and technicians spend a large part of their working day conducting plate counts on foods, with the result that very large numbers of plates must be poured and diluents prepared.

This is particularly so in the dairy industry, though large laboratories such as these may use automation for plating, such as spiral platers and robotic sample diluters, and image analysis for counting. This is, of course, very expensive and involves a lot of plastic that probably cannot be recycled. Against this background, it is a bit disappointing that food borne infections continue unabated in USA, UK and Europe. Ready-to-eat foods, such as leafy greens, have recently shown up with Escherichia coli contamination, while berry fruits have been associated with Hepatitis A infections.

Special Agent – microbiology

Of course, some food microbiologists do lead an interesting life. These are the Special Agents who investigate food contamination, food poisoning and food spoilage. While it might be argued that there is nothing new under the sun. Each case is different – human error, mechanical breakdown, packaging failures and poor equipment design may all figure in the systematic examination, leading to an understanding of what has gone wrong and a suggested solution. Investigation often involves looking closely at the process and interviewing operators. Access to a suitable microbiological testing laboratory is often essential in identifying the problem.

Factory design

Looking back over many years as a consultant microbiologist, I can think of lots of investigations where the explanation was a surprise:

A dried vegetable processing operation in which the product had spikes of contamination. On this occasion, I was fortunate to see the problem immediately. The vegetables passed through a steam blancher which was located under a cold air trunking. Steam condensed on the trunking, which was covered in a thick black tarry layer, and every so often, condensate would fall onto the vegetables being conveyed to the drier. A factory design fault.

Overloading

Staphylococcus aureus contamination of canned product. This was not a low acid food and therefore was not subject to a 12-D process. The immediate suggestion was that the cans were leaking during cooling, sucking in cooling water. However, it was found that the cans were dump loaded into a lidded vessel and hot water was introduced and held for the duration of the process schedule. With a temperature above 75°C for a suitable time, the Staphylococci should have been destroyed. We eventually discovered that the vessel was overloaded and some of the cans were above the water level, so did not receive the scheduled process.

Dangerously slow cooling

In a small pie shop, minced meat for pie filling was cooked on a stove in large pans of about 35 L capacity, which were then put into a chiller to cool. On occasion, the pies spoiled after the growth of Clostridial spores activated by the heating. It was found that the pans of meat took over 48 hours for the centre to cool to about 12°C. The solution was simple – put the filling into shallow trays for cooling.

Damaged food contact surface

Listeria monocytogenes was found in sliced meat. The slicer was a standard design, but was very difficult to clean properly and dried meat residue was found in the transfer mechanism. The slicer was mounted on a stainless steel table, and the whole area was meticulously cleaned. However, the table surface was heavily scratched and two feet-mounting spikes penetrated the stainless steel. Unfortunately, the stainless steel was only a couple of millimetres thick and was laid on Medium Density Fibreboard (MDF). The result was that the MDF got wet every time the table was cleaned and was colonised by L. monocytogenes. These examples show that those working in processing facilities may be essentially blind to the potential failures and a fresh set of eyes with appropriate experience may recognise the problems quickly.

Foodmicrobiologist.007@gmail.com

References

1. ICMSF. (1996) Microorganisms in Foods 6: Microbial Ecology of Food Commodities.

2.Ministry of Health (1995) Food Administration Manual S. 11: Microbiological Criteria

December 2022/January 2023 17 Sliding On

Overview: Consultants

• Technical support with food recalls,

• New product development,

• Key customer quality assurance requirements.

Our satisfaction comes from helping food businesses meet their customer and regulator y obligations in a practical way.

We have strong food industry networks, in-depth knowledge of regulatory requirements, and a sound working relationship with the Ministry for Primary Industries.

Get in touch now via our website (www.assuredfoodsafety.co.nz) to discuss your requirements.

AsureQuality

AsureQuality has your food assurance needs covered

Assured Food Safety Ltd

Providing practical food safety solutions since 2002

Whatever your business in the food industry is, you want advisers who understand your reality. You need a practical approach to managing food safety. You need people like us.

We understand that you need to manage food safety compliance and product development in a way that enhances business growth. You must comply with regulatory or key customer requirements and manage risk. You want peace of mind in these areas so you can focus on your "real" business.

If you're new to the food industry, or to supplying the major retailers, the myriad of requirements can be confusing. You may need someone to help guide you through the processes, assist in choosing service providers and getting your food labelling right. The team at Assured Food Safety will help.

Who are we?

We're a New Zealand based team of like-minded food industry professionals who are passionate about food. Managing Director Shane Hopgood’s philosophy is to provide food safety advice and food safety solutions that are robust, cost effective and technically credible.

Our broad range of services include:

• Developing and implementing Custom Food Control Plans (FCP), My Food Plans, Risk Management Programmes (RMPs), National Programmes,

• Training your staff in food safety, food labelling, allergen management, HACCP or internal auditing,

• Review and development of product labelling,

• Assisting you to meet food importer requirements,

AsureQuality is a leading provider of assurance services to New Zealand’s food and primary production sectors. With over 145 years’ experience and over 1700 dedicated people, they offer a comprehensive range of services - on the farm, in the factory and right through to the supermarket shelves and consumers.

AsureQuality’s Food Laboratories are led by a team of scientists and industry experts who support more than 500 staff at peak capacity. The team understand that speed and accuracy in food testing services can make a huge difference for a food producer, so to support this, their laboratories are open every day of the year, conducting up to 10,000 lab tests per day. AsureQuality also invests significantly in the latest innovations and continual methodology development to stay one step ahead of meeting ever-changing demands for food producers. The laboratory offers around 6,000 different test types, over 250 matrices, and is the market leader in offering new services, including the accredited FT-NIR service; delivering one day confirmations following presumptive outcomes for Listeria, Salmonella and Cronobacter; with technology that delivers market-leading low false-positive rates for rapid microbiology testing. From environmental swabs and raw materials through to finished products, AsureQuality Laboratories offer food testing services covering composition, safety, government, international and customer regulatory requirements.

Complementing the expertise in lab testing, they also offer a wide range of services across the value chain; delivering verification, audit, and inspection services which enable you to meet the most demanding market access requirements: Assurance Marks which help you provide trust and transparency for your consumers and specialist industry training services for your staff delivered by the AsureQuality Academy.

As a New Zealand Government-owned entity, AsureQuality helps deliver trust in New Zealand food, helping producers provide confidence for their consumers, while unlocking and growing the value of our $70+ billion food industry. Visit our website at asurequality.com.

18 Overview

A collection of service providers for the food industry including product development or reformulation, analytical, food safety and auditing providers.

Hill Laboratories – Blenheim

At the Blenheim site, Hill Laboratories mainly serves the wine industry with a suite of testing for every stage in wine production. They specialise in wine export analysis and have a number of other related analyses to meet all major winery testing needs.

Site Manager at Hill Laboratories Blenheim site, Vanessa Burrows, finds Megazyme kits the perfect solution for testing all export wine samples. “The kits are stable and ready to use – they go straight into the instrument with no preparation needed. They also have a decent shelf-life, so there’s no fear of running out. Our supplier, Food Tech Solutions, (FTS) runs an amazing, overnight service which ensures that we are always able to carry out testing when required.”

“We have been buying Megazyme kits from FTS for 15 years. They are the exclusive New Zealand distributor for Megazyme enzymes and wine testing kits and even with the disruption of supply chains due to the pandemic, there was never any problem with supply. We use both autoanalyser and manual kits in our wine testing.”

Hill Laboratories is New Zealand's largest privately owned analytical testing laboratory and have led the way in analytical testing for many years with an extensive range of tests, using the latest technology and methods. As a New Zealand accredited laboratory by International Accreditation New Zealand (IANZ), Hill Laboratories' commitment to quality is tantamount to their overall operating philosophy. Their primary quality standard is ISO/IEC 17025:2017 which incorporates the aspects of ISO 9000 relevant to testing laboratories.

Food Tech Solutions Ltd. was established in 1998 to help satisfy demands within the food industry for testing solutions to support companies in product, plant and site testing and accreditation. Their distribution facility is in Auckland, servicing customers on a national basis.

About Megazyme Kits

Many of the analytical methods distributed by FTS and developed by Megazyme have been validated as official standard methods, recommended by the relevant regulatory bodies and scientific associations following rigorous inter-laboratory evaluations. These stamps of approval confirm that their accurate, reliable, quantitative and easy-to-use test methods meet customers’ exact specifications.

About Megazyme

Megazyme was founded in 1988 in Sydney, Australia and has been based in Bray, Ireland since 1996. Megazyme has always focused on the development of test kits and reagents for use in analytical and research laboratories. The company is recognised as one of the world’s most dynamic and innovative life sciences businesses, winning a number of prestigious awards. The company was acquired by NEOGEN in 2021.

December 2022/January 2023 19 Overview

Vanessa Burrows, Blenheim Site Manager using Megazyme kits in wine analysis

Beverage and Food Gurus Ltd (BFG’s)

Beverage and Food Gurus Ltd (BFG’s) was launched in 2021 with the vision to provide a full technical solutions service to the beverage, food and pet food industries. Their goal is to create a one-stop shop for your technical needs with the right people, equipment and capability all in one place.

The principles of BFG’s – Sam Borgfeldt and John Evans – are food technologists with over 45 years of combined experience in the food and beverage industry, and they are supported by a team of experienced product development and food technologists from a range of category backgrounds.

BFG’s has a fully equipped product development laboratory in central Auckland, with their services including regulatory compliance, labelling compliance, shelf life and sensory analysis. They deliver to clients’ briefs on time and on budget while working independently with all reputable food and beverage ingredient suppliers. BFG’s also provides unparalleled expertise in technical and FMCG business advice: coaching, food, beverage and pet food technical project management, operations and strategic advice.

As well as this, BFG’s provide technical training via the popular Jumpstart series, run in conjunction with the New Zealand Food Innovation Network

They work with companies of all sizes, from start-ups to multi-nationals and work closely with their clients to deliver products and solutions in a timely and efficient manner. They are approachable and knowledgeable with experience in a wide range of categories. Get in touch with them today for a no obligation chat.

Eurofins Food and Water Testing NZ

www.eurofins.co.nz

Really local. Truly global.

Eurofins Food and Water Testing NZ offers an unmatched scope of independent analytical testing and support services to customers across the food, water, and agricultural industries. Our extensive

laboratory network is spread nationally with facilities in Auckland, Taupo, Hastings, Wellington, Christchurch and Dunedin, offering customers easy access to all our services.

Through our international network, we draw on a portfolio of over 200,000 analytical methods for characterising the safety, identity, purity, composition, authenticity, and origin of food and agricultural products. Our testing services are supported by the highest level of scientific expertise, fast turnaround times, and competitive pricing. Available testing expertise includes microbiology, food nutrition, general chemistry, pesticide residues, potable and process water, environmental, and physical and chemical contaminants.

We believe in listening to, and working closely with, our customers to understand their needs, delivering tailor-made solutions to help them achieve their goals. We offer the dairy, meat, seafood, apiculture, food processing and petfood sectors a unique range of analytical techniques to assure quality and safety standards, and provide solutions to support product development, compliance, and market access.

Our extensive IANZ accreditations in the areas of potable water, sewage and effluent, trade waste and environmental analysis, have enabled us to provide sampling and analytical testing services to councils and other organisations around New Zealand for over 25 years. We offer the full range of drinking water tests for MAV compliance/GV checking.

The Eurofins network of companies in New Zealand has evolved out of local laboratory acquisitions into what it is today – a national collaboration of scientific expertise and innovation, driven by a team with a deep commitment to contributing to a safer and healthier world. While our roots are local, our expertise is global.

Produco

Food Safety & Regulatory Compliance Specialists

Produco provides expert food safety and regulatory compliance services to dairy, food and beverage, honey, horticulture, meat, seafood and transport industries.

They're highly experienced in assessing the regulations that your products require, meeting FSSC22000, BRC, SQF, ISO9001 standards and ensuring compliance to domestic and overseas export regulatory requirements.

Their team of senior technical managers, quality assurance managers,

Overview

BFG’s consultants, Wendy Bayliss, left, Jess Chong and Sam Borgfeldt provide a full technical solutions service to the beverage, food and pet food industries

specialist advisors and food technologists are agile, capable project managers that deliver your business-critical projects, fill recruitment gaps, and backfill while staff are on other projects.

Their customers span small operations to large multi-nationals. With consultants based around the country, Produco will visit your site and then work remotely to deliver your project on time, to your requirements.

HACCP Plans | Risk Management Plans | Food Control Plans: Technical services to design new, complete plans for greenfield sites, significant changes to existing RMPs, and to improve existing systems. Training of your staff at completion to lift capability and understand changes.

Auditing: Internal audits, Supplier audits, Food Defence, Vulnerability assessments. Evaluating your facility, suppliers, and systems with guidance to remedy defects or non-conformances to create a step change in your business.

New Product Development (NPD): They take your concept and turn it into a commercialised, store-ready product. reformulation (cost savings), quality improvements (functionality), nutritional development, flavour development, ingredient substitution and ‘Clean Labels’.

Labelling Requirements | Label Translations: Compliance to domestic and export markets. Specialist product category knowledge of Infant Formula, Supplemented Foods, F&B. Chinese (Mandarin) to English translations.

Incident Management | Product Recall: Have a persistent pathogen? Plastic in your product? Highly experienced and skilled at facilitating problem solve workshops to establish root-cause of failures.

Quality Management Systems | Validation: They inspect the outputs of a system/process to ensure it consistently meets your business requirements and customer requirements.

Produco: Comply with us.

Telarc

The Benefits of Certification in the Food Industry

Food safety is a growing concern and impacts both consumers and businesses worldwide. While much of the world’s food supply is safe, high profile cases regularly underline the potential danger of foodborne threats to consumers. Food related diseases affect tens of millions of people and cause billions in healthcare-related and industry costs annually. The globalisation of the food supply and consolidation in the food retail industry have resulted in the demand for an internationally recognised standard of food safety management.

Third party certification means that an independent organisation has reviewed the processes of a company and has independently determined that the company’s systems comply with specific standards and regulatory requirements for food safety and/or quality. Certification against a leading, internationally recognised management scheme

reduces information asymmetries in supply chains, thereby generating a uniformly high and globally understood standard of food processing and production.

Regulatory requirements, including overseas market access, labelling and sound traceability are key areas where we can add our expertise and ensure your business is ready to meet your customer’s demands.

Telarc is New Zealand’s largest auditing body with a strong presence in the beverage industry and a growing market share in food safety management. We conduct audits with expert, experienced auditors who are backed with the resources of an industry-leading company. We are also able to verify your regulatory compliance with recognised verifiers in both the food and wine sectors. We are proactive in our approach; ensuring clients can implement and continually improve their system in accordance with the standard, adding value in every visit.

We can help with your HACCP and ISO 22000 certification requirements, GFSI standards (FSSC 22000, BRCGS), regulatory requirements such as Food Act and WSMP verification, and customer audits such as WSE and SQMS. We can integrate these to your quality, health and safety and environmental standards and also assist with other approvals such as GAP. Check our website at www.telarc.co.nz for further information.

Quality Auditing Specialists

Quality Auditing Specialists Ltd (QAS) offers a range of evaluation and verification services to the food and wine industries nationwide.

Maree Haddon leads a team of practical, efficient and objective evaluators and verifiers who offer consistency of interpretation of standards for Multi-Sites, Custom and Template Food Control Plans, National Programmes, Importers and WSMPs.

All evaluators/verifiers have a strong background relating to manufacturing, food service, horticulture, retail, storage and transport and are fully qualified to fulfil all your requirements.

Our team will work with your business to ensure you are meeting your Food Act or Wine Act compliance requirements while endeavouring to keep the process practical and simple.

We also offer consultancy services through the sister company, Quality Systems Specialists (QSS), that include Integrated Management Systems, Food Safety, HACCP development, training and internal audits. QSS can help you develop appropriate documented systems that will meet the requirements of the Food Act and the associated legislation.

QSS can develop and deliver training packages to suit your company’s needs. Training includes general food safety, HACCP, internal auditing, traceability or any other area where you require assistance. The training can be undertaken via virtual meeting at a central location or alternatively, if you have the facilities available, at your place of business. QSS has developed online webinars focusing on Allergens, Labelling, Managing Traceability, Verification & Corrective Actions and Recalls, Self-Reviews & Self Checks. These can be either one on one or in a team session.

December 2022/January 2023 21 Overview

Qualified Packaging Technologists wanted

Nerida Kelton MAIP

Nerida Kelton MAIP

It is fair to say that if you were to graduate high school tomorrow in Australia and New Zealand there is no direct career path to become a qualified packaging technologist.

With no undergraduate degrees in packaging technology available through universities many find their way into the industry via an engineering, industrial design or food science degree. Very few people start their working life as a packaging technologist or engineer. The challenge is that Packaging Design and Technology is in fact a science that requires the appropriate higher education and training in the discipline.

The flow-on effect is that even though packaging design is well and truly in the spotlight there is a limited supply of truly qualified packaging technologists and designers in the region. Most of these talented people are already entrenched in a business and are not looking to leave their current role anytime soon.

There is a juxtaposition happening right now in the industry and it is interesting to watch.

On one hand the recent abundance of job advertisements for skilled packaging technologists, often thinly veiled in sustainable or procurement roles, is a clear sign that the industry is in desperate search for the ever-elusive qualified packaging technologist.

On the other hand, the high volume of applications every year for the Australasian Bioplastics Association (ABA) and AIP Scholarship Programme indicates that many people are looking to upskill and to become a qualified packaging technologist. The applicants are often young and newer to the industry, with insufficient income to be able to invest in a Degree in Packaging. They see the scholarship programme

22 Packaging

ABA Awards two Scholarships for 2022

The Australasian Bioplastics Association (ABA), in partnership with the Australian Institute of Packaging (AIP), offers an annual Scholarship programme for Australia and New Zealand.

The Scholarship programme enables one eligible candidate to undertake a Diploma in Packaging Technology and a second person the opportunity to undertake a Certificate in Packaging.

The first 2022 ABA Scholarship was awarded to Lea Reynolds AAIP, Commercialisation Manager, Steggall Nutrition, to undertake a Certificate in Packaging.

Through embracing and undertaking further education, she would like to assist in educating others to make more environmentally friendly and sustainable packaging decisions, and more importantly educate her own children who can continue to educate future generations.

For Lea, being awarded this invaluable opportunity means that she can continue to learn and grow as the industry changes and be confident in the information that she has learned to tackle challenges and to make informed decisions.