June/July 2024

FEATURED IN THIS ISSUE:

June/July 2024

FEATURED IN THIS ISSUE:

What we do in the Shadows –Food Techies off the leash

NZFSSRC: Out now – Best Practice Guide To Managing Cronobacter

Anuga Tec – advances in packaging materials. Report from AIP

JUNE/JULY 2024 | VOLUME 24, NO.3 ISSN 2744-7308 (ONLINE) ISSN 1175-4621 (PRINT)

Readiness and Response:

Press Ltd

Rupi Court, Mt Wellington

1072, New Zealand

64 21 901 884 www.foodnz.co.nz

Food NZ is distributed online to all members of the New Zealand Institute of Food Science and Technology. An online edition is shared internationally. Visit www.foodnz.co.nz to subscribe.

Copyright © 2024 Peppermint Press

No part of this publication may be reproduced or copied in any form by any means (graphic, electronic, or mechanical, including photocopying, recording, taping information retrieval systems, or otherwise) without the written permission of Peppermint Press. The views expressed in this journal are those of the writers and do not necessarily represent the view of the Publisher, the Scientific Review Board or NZIFST

Director and Editor

Anne Scott, Peppermint Press Limited anne@foodnz.co.nz

Director and Writer

Dave Pooch, Peppermint Press Limited davep@me.com

Advertising

Anne Scott, anne@foodnz.co.nz 021 901 884

Design and Layout

Johanna Paynter, Pix Design

Regular Contributors

Esraa El Shall, John D Brooks, Laurence Eyres, Vincent Arbuckle, Dave Pooch, John Lawson , Nerida Kelton

Notice to Contributors

When submitting editorial for Food New Zealand please observe the following, Editorial to be submitted as plain text files, NO FORMATTING please. Images should be sent as high resolution .jpg or .tiff files. Do not embed images in word documents, send separate files. Any images smaller than 500 kb may not be printed as the clarity of the print may be compromised.

Advertisers

Material specification sheet and rate card on website, www.foodnz.co.nz

Executive Manager, Wendy Bayliss

PO Box 44322

Pt Chevalier

Auckland 1022

New Zealand

Networking – connecting with your peers

Regular information about your industry

Recognition through awards, scholarships, travel grants www.nzifst.org.nz/join/

Best Practice Guide to Managing Cronobacter: symbolising the best in human nature

Anuga FoodTec 2024

Nerida Kelton FAIP, Vice President Sustainability & Save Food, WPO Executive Director, AIP

“A Future for New Zealand Food” the 2019 Earle Lecture

We are all part of networks, some broader than others. Through our networks we connect for work, business and pleasure.

Phone: 022 549 8483, Email: wendy@nzifst.org.nz Website: www.nzifst.org.nz Next editorial and advertising deadline: July 20th, 2024 Features for August/September 2024

NZIFST Conference Review: Awards, events, J C Andrews Award address

Ultra-processing – an ill-considered term that is gaining increasing traction

A number of senior, highly qualified and experienced members of our Institute are increasingly concerned by the proliferation of the term ultra-processed to mean, puzzlingly, for food technologists, unhealthy foods. This situation reminds us that, apart from those of us who understand food processing from the inside, so to speak, there are many who operate in the food space who have never drilled down into the original paper that coined that term. Nor do they understand the myriad disciplines, not to mention unit operations, that are applied to prepare foods for market. Foods that are safe, palatable and, in most cases, wholesome. This classification does not accurately categorise food products by the level of the processing. It appears to consider only the number of different ingredients contained in the food. Therefore, the NOVA classification, which has coined the term ultra-processed", can lead to a negative perception by many consumers, because it neglects well-established science concepts from the food science domain.

Nutritionists have latched onto the term as a catch-all that they can use to criticise the food industry, adding further to the misinformation about foods that creates anxiety and, in some cases, severely unhealthy diets, as consumers try to follow all the recommendations they regularly see in mainstream media. This is a serious concern, primarily because of the wholesale use of an ill-defined term that adds to confusion for consumers.

In the April/May 2024 issue of Food New Zealand, Allan Main FNZIFST, wrote an in-depth article on this issue. References below are to the original papers by Monteiro C. A, from the University of Sao Paulo, Brazil, and a later paper from the same university’s Food Technology department pointing out the errors in the original NOVA Classification. The food industry is frequently criticised for producing unhealthy foods and causing (HAH!) obesity, heart disease, diabetes, you name it. As trained food scientists and food technologists I suggest it is up to us to fully inform ourselves of the original thinking that generated this term and be ready to debate it, any and every time we see or hear it being used. You can access Allan’s article HERE on ISSUU in that edition.

References:

1. Monteiro, C. A. (2009). Nutrition and health. The issue is not food, nor nutrients, so much as processing. Public Health Nutrition, 12(5), 729–731. https://doi.org/10.1017/S1368980009005291

2.Monteiro, C. A., Cannon, G., Levy, R. B., Moubarac, J.-C., Louzada, M. L. C., Rauber, F., et al. (2019). Ultra-processed foods: What they are and how to identify them. Public Health Nutrition, 22(5), 936–941. https://doi.org/10.1017/ S1368980018003762

3. Petus, R.R., do Amaral-Sobral, P.J. et al (2021):”The NOVA classification system: A critical perspective in food science”. Trends in Food Sci & Technol 116 (Oct 2021) p603-608

Newsbites is Food New Zealand's round-up of news about NZIFST members, associated companies and items that catch our interest.

NZ Excellence recognised at international awards

The Pure Food Co takes out international food innovation award

The Pure Food Co has won the Innovation of the Year category at the Asia Pacific Eldercare Innovation Awards in Singapore, recognising the best food and nutrition system on the market developed to improve the health of older people.

The Pure Food Co, which was founded in 2013 to nourish the world’s seniors, was recognised for the development of a nutritional system to improve the health of aged care residents and hospital patients in Australia, New Zealand and now France.

Delivering clinically-proven outcomes and backed by research, the Pure Food Co system can create efficiencies for aged care and health service providers, reduce food wastage and improve residents’ health and satisfaction. It also removes the costs, processes and risks associated with producing texture modified foods in-house.

Co-Founder and Co-Director Sam Bridgewater, who started the company after his step-father became ill and couldn’t find meals he wanted to eat, said the award recognised the years spent developing simple food programmes which people could enjoy while also improving their health.

“Older people need as much protein as elite athletes. However, most are getting 60% less than they need, resulting in lower muscle mass, more falls, hospitalisations and ill health. If we can turn that around, we can improve our quality of life as we age,” Mr Bridgewater said.

“Our texture modified foods include 41% more protein than comparable meals and 60% more energy.

The Pure Food Co’s Australian Director, Chris Deed, said food standards were closely monitored in aged care, as it was essential that residents were provided with the most nutritional food available to enable them to have a higher quality of life.

“We know that many aged care providers prepare their own modifiedtexture foods, but we think it’s important to ensure they’re fortified with protein and plant-based nutrients, and safe for residents that require a texture modified diet,” Mr Deed said.

Mr Bridgewater said The Pure Food Co had been working closely with chefs to develop 4,500 meal options, and the company works to continuously improve its offerings.

The 12th Asia Pacific Eldercare Awards, presented at the Ageing Asia 2024 World Ageing Festival from May 6-10, highlights organisations that redefine the ageing experience through innovative business practices, operational strategies, and service models.

Just in case you missed it

The Kiwi cheese industry’s night of nights, the NZ Champions of Cheese Awards Gala Dinner in Hamilton on Thursday 2 May 2024 was a celebration of excellence in New Zealand cheese craftsmanship.

Twenty-six trophy winners were announced following an extensive evaluation in early March assessing more than 250 locally produced cheeses, with the finest 187 already honoured with gold, silver and bronze medals.

A pdf listing all award winners in 2024 is HERE

Chief Judge, Jason Tarrant (right) at the Awards Judging in March

Andy Williams reports that New Zealand will host the International Dairy Federation Convention in 2026 at the New Zealand International Convention Centre. A programme template is being prepared and the search for sponsors and partners is underway. The website www. idfwds2026.com has been registered and information will be loaded early June.

Hill Labs is marking its 40th anniversary, a milestone that underscores the enduring influence of its founders, Dr. Roger and Anne Hill. As New Zealand's largest privately owned analytical laboratory, Hill Labs provides state-of-the-art services across the agricultural, environmental, and food sectors. Dr. Jonno Hill, the current Managing Director, who joined the family business after completing his PhD, credits the company's success to the foundational values and culture established by his parents. Since taking over the reins in 2018, he has focused on maintaining these family values, which he believes are integral to the company's strategic focus and competitive edge. The company prides itself on a steadfast commitment to enhancing customer value and continuous self-improvement. This commitment is evident in its dedication to innovation, as in its microbiology and molecular biology sectors, where a customer-centric approach and technical excellence has forged trusted partnerships with multiple, long-standing food industry customers. Hill Labs has been at the forefront of developing rapid PCR testing services since 2014, providing next-day results that support swift and effective responses to pathogen outbreaks in the food industry.

Significant achievements include the development of a Listeria PCR test that identified previously unrecognised species in New Zealand, and its response during the Covid-19 pandemic, where it was among the few commercial laboratories offering PCR testing for SARSCOV-2.

Continuing its innovation trajectory, Hill Labs recently introduced a 3-in-1 swab testing service that enhances environmental monitoring by detecting multiple pathogens with a single swab, thereby reducing time, effort, and environmental impact. This new service promises significant benefits, especially for the dairy industry, with more advancements anticipated in the future.

Celebrating 30 years in New Zealand this year, Langdon has over 170 years' experience sourcing the finest ingredients from across the world. Established in 1852 by Henry Joseph Langdon, a young merchant from London, Langdon sold everything from alcohol, books, buttons, and pants. Over time, Langdon shifted focus to trading in ingredients, from dehydrated vegetables, herbs, spices and botanicals, cementing its expertise in food and health ingredients. Today the fifth-generation family-owned business is run by CEO Chris Langdon, with offices across New Zealand, Australia, the United Kingdom, Singapore, and Thailand.

The local team based in Auckland represent the family values of Langdon’s rich 172-year heritage. Knowledgeable and nimble, the team are responsive and personable with a focus on creating partnerships with customers. With their headquarters in Auckland, Langdon service New Zealand with a hands-on approach, with the team on the ground valuing face-to-face opportunities with customers across the nation.

Supplying to major food and beverage manufacturers across the world, including food service and wholesale customers in New Zealand, Langdon is recognised for their strong portfolio of ingredients. Their pantry extends across many categories including herbs, spices, dehydrated vegetables, botanicals, functional ingredients, IQF, flavours exclusively from The Product Makers, and much more. Their experienced global sourcing teams have established a strong supplier network, with many partnerships lasting decades. This allows Langdon to stock a wide range of ingredients, and if they don’t currently stock a product, they can source it. As the exclusive distributor for several leading brands and ingredients across the world, Langdon has access to a unique pantry that allows them to be a one stop shop.

Langdon know the level of quality and service that customers need to create consistently great products. Traceability and sustainability have never been more important than they are today, and Langdon’s long standing supplier relationships enable transparent supply chains

competencies.

Solutions focussed, Langdon's skilled team of Product Development Technologists can assist with product innovation and reformulations as well as application assistance. With years of technical expertise and a genuine passion for food, the team knows how to use their pantry of ingredients as building blocks to flavour, and in synergy, to help elevate customers’ products or to create the next innovation.

At the forefront of what’s happening around the globe, Langdon’s procurement, marketing, product development and sales teams work collaboratively to deliver the latest trends and ingredients to customers with a proactive approach. With global insights, they’re able to help brands innovate and keep on top of what’s happening in the market.

This month the team are excited to welcome Senior Innovation Manager, Leslie Lim, who will be visiting a range of customers showcasing the exclusive flavour offering through The Product Makers. A unique tasting experience, these product development presentations not only deliver on flavour but provide insights into global trends and application assistance.

Trusted for over 170 years in Australia and celebrating 30 years in New Zealand this year, Langdon has a legacy within the food and beverage industry. The team are excited to mark the 30th milestone with a roadshow event being held later in the year, to celebrate the partnerships and successes that have been forged with their customers over this time, and welcoming new customers to explore a world of taste with Langdon.

The team are also excited to relocate to a new central business-park, based minutes from Auckland’s CBD, with a dedicated product development kitchen and resource, collaborating with the Langdon team has never been easier.

To find out more about Langdon, please reach out to their friendly team at infonz@hjlangdon.com or call +64 9 270 2040.

Professor Siew Young Quek FNZIFST

A time-honoured tradition is the inaugural lecture where a new Professor can profess anything they wish.

Dr Siew Young Quek was appointed Professor of Food Science at the University of Auckland’s Faculty of Science in 2020, but COVID-19 caused a four-year delay in her inaugural lecture. She finally gave her lecture on 14 March 2024, and to a full lecture theatre.

Siew chose to time-travel, starting with her childhood in Kedah, Malaysia. She opined that “perhaps freely playing in nature as a child helps to boost complex thinking later in life”. She passed her BSc (Hons) at the National University of Malaysia and PhD at the School of Chemical Engineering at the University of Birmingham in the UK. She lectured in the Department of Food Science at the Universti Putra Malaysia in 2000, then joined the University of Auckland as a Lecturer in Food Science in 2004. She was a member of the NZIFST Auckland branch Committee in 2006, is now an NZIFST Fellow and has contributed to the membership committee and the annual NZIFST conference in organising committee, oral presentations, and students’ posters.

Student numbers have grown since she came to Auckland in 2004. The student enrolments increased from 10 back then up to 47 in 2020 for Food Product Development and 66 for Sensory Science, the two courses she established after joining the University.

Becoming the Food Science Programme Director in October 2015, she has welcomed new staff members, including Drs Peter Swedlund, Kang Huang, Davide Mercadante and Danae Larsen. Her commitment to food science education and vision for establishing the programme as one of the leading forces in New Zealand and internationally have yielded significant outcomes. The programme has attracted students, particularly postgraduates from overseas. International sources have ranked it among the top in the food science and technology subject area in Australasia, including the Shanghai Ranking and US News & World Report Global Subject Rankings in the last few years.

Siew’s passion for food science education and research has evolved and strengthened over the years. Combining her knowledge and experience in biochemistry, engineering, and food science, she has cultivated a profound research interest in food properties, functionalities, their interplay with processing aspects, and the creation of food products for health benefits and consumer enjoyment. Her research contributions extend globally as reflected in her recognition as one of the top 2% researchers worldwide (according to the recent Stanford ranking) and have received more than 10,000 citations.

International links have been developed with the Yamaguchi University in Japan in her early career and, more recently, with the Selenium-area of ethnic minority Tujia & Miao autonomous prefecture of Enshi in China in Selenium-rich functional foods. She contributed to her research profession by serving as the Co-Editorin-Chief for Future Food, an international scientific journal dedicated to food sustainability launched by Elsevier, a reputed Scientific publisher, in May 2020. The journal achieved an excellent impact factor of 5.7 after three years.

Currently, Prof. Quek holds the position of Principal Investigator at

Professor Siew Young Quek pictured in her Professor's regalia

the Riddet CORE, the New Zealand Centre of Research Excellence in Food Research. She is also the founding director of the Future Food Research Centre at the Faculty of Science, University of Auckland.

Siew paid tribute to her many postgraduate research students (43 PhD and 169 sub-doctoral students) by showcasing some of their research work and acknowledging all who have supported her in her academic journey.

Her final words? “If you want to go fast, go alone. If you want to go far, go with a team”.

Dave Pooch FNZIFSTAre you a pessimist or an optimist?

In our last article we discussed the changes that are occurring in the New Zealand Food industry and what this could mean for our careers going forward.

We introduced the need to be proactive around developing our Career Capital, the Social, Human and Psychological components that will enable us to achieve and maintain a competitive edge in the workforce.

This month we were presented with the news that Fonterra is looking to sell its Brands business which was a shock to many, however seems logical in terms of Fonterra’s strategy.

Optimists would say, this is nothing new, the industry is always changing and there will be new opportunities that arise if the sale goes ahead. Pessimists might think differently, seeing another iconic New Zealand food business likely to be owned by an international company leading to possible rationalisation.

Regardless of which side you sit there is rapidly growing recognition that we are operating in more turbulent or dynamic times.

Sustaining your career in 2024 and beyond is not about complacency but about constantly nurturing your skills, connections and mindset. It’s about being ready for what happens next in the world of work.

Peter Drucker made an important statement a few years back.

At its core, Career Capital is the portfolio of resources professionals build over the course of their careers. This portfolio encompasses three primary components: Social, Human and Psychological. Human Capital is specifically the skills, knowledge, and expertise that increase your value in the job market. There are two strategies for building Human capital.

In the rapidly changing job market, continuous learning is not just beneficial; it's essential. We must remain adaptable, investing in both hard skills – technical abilities specific to our field – and soft skills such as communication, leadership, and problem-solving. This involves seeking out professional development opportunities, further education, and certifications relevant to your career aspirations.

Gaining diverse experiences

Varied experiences, including different roles, industries, and even cultures, enrich your professional toolkit. They not only broaden your skillset but also enhance your ability to think critically and adapt to new situations. Volunteering, internships, and project-based roles are excellent ways to gain diverse experiences.

In the turbulent or dynamic food industry the important concept of being proactive in the development of your Career Capital is that it covers 3 distinct areas of development. The Social (covered in article 1) and psychological aspects (to be covered in article 3) have risen in importance alongside the Human Capital aspect that we are more familiar with.

None should be ignored. By focusing on building Human, Social, and Psychological Capital, you will better navigate the complexities of the job market with confidence and agility, ensuring greater long-term success and fulfilment.

John Lawson is founder of Lawson Williams Consulting Group. He initially studied Biotechnology at Massey and is a professional member of NZIFST. He now enjoys leading a team of recruitment consultants, helping people like you develop satisfying careers.

You’re not the boss of me

John Brooks' view of the food world through the lens of a microbiologist.

Leaving aside the execrable corruption of English syntax by an American TV series, the title might be appropriate for this edition of Sliding On.

There is currently a minor stand-off between the Ministry of Primary Industries and a company selling unpasteurised fruit juice. It’s a little difficult to find the processor and the products they sell, but they appear to be located in a food market in Wanaka. Their website says that they have juice stocks in both the North and South Islands and offer juicing services to private and commercial growers. They process rejected fruit from growers.

The company website includes a video of the juicing machine being operated outdoors. The operator is wearing neither protective clothing nor gloves. The fruit is manually loaded from bins into a hopper and the machine cuts the fruit into two and squeezes the juice out. Obviously, the juice will contact the outside of the skin during pressing. The juice runs into a screen and then into a 20L plastic collecting drum.

The juice is not pasteurised and is sold door-to-door, at markets and online, frozen, defrosted or partially frozen. The business owner claimed that the juice is frozen “to freeze out the bad bacteria” while pasteurising the juice would wipe out “the good bacteria”. Photographs on the company website show what appear to be glass bottles with flip-off stoppers containing various juices, but there are no labels on the bottles. The company website claims “We only use Spray-free/Organic fruit”. However, comments from members of the public in various newspaper articles suggest that at least some of the fruit is picked up from private residences where fruit is offered free to the locals. There is thus no guarantee that sprays have not been used or that the fruit is in good condition and doesn’t suffer from damage, mould or faecal contamination by birds.

Failing to register

New Zealand Food Safety (MPI) issued a Chief Executive Privileged Statement under Section 289 of the Food Act 2014, warning consumers about Our Fruit Box raw fruit juices. On the face of it, it appears the issue is that the processor refuses to register under the Food Act 2014. Using the NZ Food Safety tool and entering the available information for this processor, It appears that the company needs to register a National Programme 3 under the Food Act 2014. However, this is not just about not paying a registration fee. The registration process requires that the processor have an appropriate food safety programme.

According to an article by Caroline Williams published by Stuff on

16th April 2024, the business owner claims that she does not have to register her business, as “God is her boss, not MPI” and that she will continue to sell the juice unless someone is made ill by it and can prove it. Whether you accept this kind of argument or not, there are real concerns about this behaviour.

The risks

New Zealand Food Safety Technical Paper No: 2023/14 describes a scientific research project undertaken to provide data needed to assess microbiological risks associated with frozen produce used uncooked in blended food preparations.

Many pathogens can contaminate fruits via soil, faeces and water, but some may also be transferred by handlers at all stages of growing, harvest and processing. The pathogens include Salmonella, Shiga toxin-producing Escherichia coli, various species of Listeria and Yersinia, viruses, such as norovirus, hepatitis A and parasites including Cryptosporidium and Toxoplasma gondii. Unpasteurised fruit juices are frequently associated with foodborne outbreaks of food poisoning and have been reported world-wide. Freezing is known to decrease the numbers of bacteria by only about 2 log cycles and thus is not an effective means of pathogen elimination. Perhaps the pathogens of most concern are Salmonella and Escherichia coli O157:H7 which may cause haemolytic uraemic syndrome. Dewanti-Hariyadi (2014) has published an extensive table of Foodborne outbreaks due to juices (1).

According to the NZFS Technical Paper, “There were three New Zealand outbreaks reported from 2008 to 2015 where fresh produce was the most likely vehicle for infection based on epidemiological information. These were outbreaks of salmonellosis linked to watermelon, norovirus infection linked to fresh fruit salad, and yersiniosis, of which the geographic distribution of cases suggested a nationally distributed product such as carrots and/or lettuces”. It is possible to produce safe fruit juices, but control must be placed all along the production line – processing only mature and sound fruit produced with good agricultural practices, and proper hygiene of the juicing equipment. Properly pasteurised juices are regarded as safe. Pasteurisation may be achieved by heating or high-pressure processing.

Interestingly, I raised this issue with a group of friends. They said they would drink the juice, even though the processor didn’t have a food safety plan, as they thought the risk was minimal! (1). Dewanti-Hariyadi, R. Foodreview International 2014 VOL. I/ NO. 1

World Food Safety Day is on 7 June 2024. The World Health Organization continues its efforts to mainstream food safety in the public agenda and reduce the burden of foodborne diseases globally.

This year’s theme is “Food Safety: be prepared for the unexpected”.

The theme highlights that food safety is a collective responsibility, however even when everyone is producing and using food suitably, events or unexpected situations can compromise food safety. Preparing for the unexpected underlines the importance of being ready to respond to food safety incidents and other types of emergencies, no matter how mild or severe the event.

In New Zealand, food safety incidents are situations that require us all to respond to manage the impact of a potential, perceived, confirmed health or economic risk associated with the consumption of food here, or in an export market.

Food safety incidents can occur in isolation such as during a foodborne illness outbreak, a recall, or issues with imported products. Incidents can also be caused or exacerbated by other issues including power outages or natural hazards.

To manage risks, businesses can take steps to prevent, detect, respond to, and recover from food safety incidents. A proactive approach to food safety incident preparedness will help businesses act quickly when issues arise and protect consumers.

Plan, Prepare, Act

When the unexpected happens, preparedness is key. Having a plan for when an incident occurs and practicing it ahead of time will support a successful outcome. If a good plan is up to date, well-practiced and communicated, it will support you to take immediate action when issues arise.

Sharing of information saves lives

Understand who you might need to collaborate with before an issue arises, so you can get the support you need in a response. Consider mapping out key stakeholders and making sure their contact details are up to date. Fast and accurate information sharing among all relevant stakeholders helps identify the nature and origin of food safety incidents. Open channels of information can support the swift implementation of management or mitigation measures (e.g., a recall or safety messaging).

Maintaining confidence in the food supply

Providing accurate, open, and timely information to your stakeholders, including agencies such as NZFS, the media and the

public, helps prevents further illness and maintains trust in products and the food safety system.

Act decisively

Be ready to implement your response plans, including procedures for a product recall. Traceability systems are an effective tool to track food through the food chain, so it’s easier to identify products for recall.

Everyone is a risk manager

Empower staff to act if they spot an issue and communicate plans with them to ensure everybody knows their role when issues occur.

Expect the unexpected

As yourself:

• Is your business ready for when incidents occur?

• Do you know what you would do if there was a severe weather event or an earthquake?

• How might an incident or severe event impact your operations? There are actions you can take to make sure your business is ready and prepared for incidents and emergencies. Tools and resources are available on the MPI website to assist you with preparing for a food safety incident or emergency response.

The importance of preparing for food safety incidents cannot be overstated. I know how committed businesses across New Zealand are to providing safe and suitable food. As we approach World Food Safety Day, let us use this occasion to ensure measures are in place to safeguard public health, here and abroad. Get creative and take the opportunity to update and practice plans, involve all areas of your business, and celebrate the good work that happens across the food sector to prepare for incidents and emergencies. Food safety is everyone's business.

Contact NZFS in an incident on 0800 00 83 33 or Food.Compliance@ mpi.govt.nz

How to conduct a simulated recall link

Sign up for food recall alert emails here

Familiarise yourself with our emergency information for food businesses here

National Emergency Management Agencies' Get Your Work Ready page link

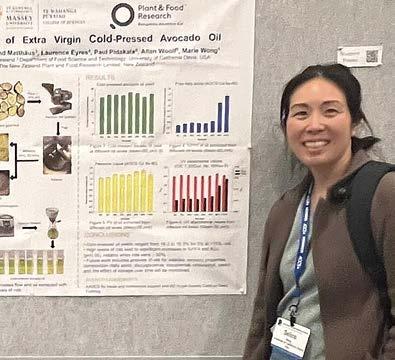

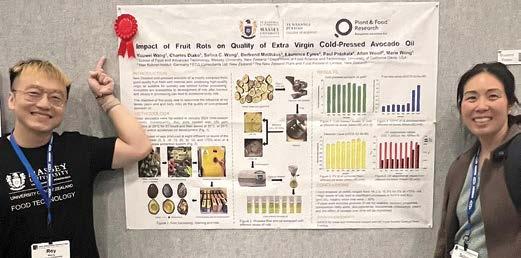

A Massey student just won an award for in the poster competition at AOCS in Montreal. Matt Miller and his AAAOCS colleagues facilitated the travel and registration for Youwei (Roy) Wang to attend this annual event, this year held in Canada. The photo shows him exhibiting the winning poster with his US supervisor for his research grant, Professor Selina Wang. The other two supervisors on the avocado project are Professor Marie Wong (Massey) his PhD supervisor and Dr. Allan Wolff (Plant & Food Research). Selina and UC Davis are offering the online course on avocados from growing to RBD oil production.

USP has submitted a standard for RBD avocado oil and it was published by the FCC and was effective on June 1, 2022. The current published Monograph is for refined avocado oil. Monographs are updated in June and December each year.

Highlights of the Montreal event were:

• Two short courses brought together a global audience to discuss lipid oxidation in foods and edible oil refining.

• Ninety industry partners filled the Expo Hall to share their products and latest innovations.

• AOCS recognized 40+ award winners for their dedication and accomplishments. Congratulations to everyone.

Researchers have developed a high-oleic acid microalgae strain suitable for nutrition, culinary, and personal care applications. They also engineered a strain capable of producing OPO (1,3-dioleoyl-2-

palmitoyl-glycerol), a structured triacylglycerol present in human milk, which can be incorporated into nutrition products for infants and toddlers.

• Microalgae converts simple sugars into lipids on an industrial scale quickly and efficiently using fermentation.

• By understanding the biology of microalgae, we can design the oil and how it is produced using classical strain improvements, genetic engineering, or a combination.

Note that Dr Julian Davies of DSIR pioneered this work 30 years ago and Colin Ratledge of the UK has maintained his groundbreaking work on microbial oil.

Developing lipids in oleaginous microorganisms has benefits beyond environmental sustainability. Researchers can alter the lipid composition of an oil on a much faster timescale than when it is agriculturally produced. Fatty acids can be fine-tuned on a glycerol backbone to produce the exact triacylglycerol composition for a specified application at industrial scale. The progress of biotechnology over the past decade has now made its way into the marketplace, resulting in consumer awareness of the advantage of microbial oils.

Reference: Microbial production of omega-3 fatty acids: an overview N Kannan, AS Rao, A Nair - Journal of Applied Microbiology, 2021 - academic.oup.com

Omega-5 also known as punicic acid, is a long chain polyunsaturated fatty acid found in certain seed oils like pomegranates. It is also recognized as “Trichosanic acid” with molecular formula C18H30O2, with molar mass 278.43 g/mol with melting point of 4445ºC. Punicic acid is an isomer of conjugated α-linolenic acid and a ω-5 polyunsaturated fatty acid which have structural resemblance with conjugated α-linolenic and linoleic acid, for instance the number of double bonds and atomic arrangement. Due to health benefits associated with these fatty acids, scientists are showing great interest in exploring functional and nutraceutical properties of punicic acid against various metabolic ailments. Omega-5 fatty acids are less well known than their Omega-3 cousins and may have similar health benefits, but are far less thoroughly researched, and even the safety of Omega-5 supplements has not been well investigated. The only foods that contain the long chain polyunsaturated fatty acid known as punicic acid are salmon, coconut oil and pomegranates, and pomegranate oil is the basis of most supplements.

The International Union of Pure and Applied Chemistry (IUPAC) designated its name as 9Z, 11E, 13Z-octadeca-9, 11, 13-trienoic acid.

As we enter an age of personalised nutrition, consumers will have access to more resources that help them identify which products work and which products do not. For those that make the effort to see a healthcare practitioner on a regular basis, cardiovascular health is consistently examined, and when medication is necessary, blood tests and other tools verify whether the medication is having an effect. At home tests, such as the Omega-3 Index Test from Omega Quant, may offer similar verification. The Omega-3 Index is the measure of Omega-3 EPA and DHA levels in red blood cells, and its inventors have published ample research demonstrating how one’s Omega-3 Index may influence the trajectory of one’s long-term health. More than that, it provides a tool for consumers to measure and track the progress of an intervention, specifically Omega-3 supplementation, and determine whether the amount of Omega-3 fatty acids in their system in increasing.

The optimal range of the Omega-3 Index is between 8 and 12%, so the test also allows consumers to set goals and measure progress. This could help improve compliance. “Seeing improvements in their numbers is what motivates [consumers].”

Unfortunately, official guidance on how much omega-3 EPA and DHA to consume does not really exist. ALA is the only essential fatty acid that has a set “adequate intake level” while no levels are set for EPA and DHA

That is not to say that everyone needs over 800 mg of EPA and DHA. The range of doses on the market does not necessarily have to be a negative. If a person consistently eats seafood or other sources of Omega-3s for example, they may not need such high doses. Offering a range of doses may help retain customers if they start low and decide to increase their intake or vice versa.

Other Bioactives to take along with omega-3 include: Phospholipids (lecithin), lutein, vitamin E, astaxanthin and Coenzyme Q10.

References

1. Bernhard, B.; Heydari, B.; Adbullah, S.; Francis, S.A.; Lumish, H.; Wang, W.; Jerosch-Herold, M.; Harris, W.S.; Kwong, R.Y. Effect of six month’s treatment with omega-3 acid ethyl esters on longterm outcomes after acute myocardial infarction: The OMEGAREMODEL randomized clinical trial. International Journal of Cardiology. 2024, 399. DOI: 10.1016/j.ijcard.2023.131698

2. Omega-3 Fatty Acids. National Institutes of Health Office of Dietary Supplements. February 15, 2023. https://ods.od.nih.gov/ factsheets/Omega3FattyAcids-HealthProfessional/ (accessed 202403-22).

3. Harris, B. Omega-3 Cochrane meta-analysis is highly flawed, researcher writes. Nutritional Outlook. August 30, 2018. https:// www.nutritionaloutlook.com/view/omega-3-cochrane-metaanalysis-highly-flawed-researcher-writes (accessed 2024-03-22).

The link between the human microbiome and disease is a rapidly growing field of research. There is increasing evidence for interaction between the gastrointestinal tract (GI) and the central nervous system (CNS). The gut-brain axis can thus be defined as a two-way communication system that functions through pathways such as neural pathways (enteric and sympathetic nervous systems, etc.) and humoral (including cytokine signalling and microbial signalling). The

gut microbiome is a richly diverse community of bacteria that initially colonise the gut following birth and maintain a stable composition throughout life.

The term Hybrid Wiped-Film Distillation refers to a combination of the low thermal stress processing of Wiped-Film Distillation with the separation capabilities of a Packed Fractionating Column.

The Wiped-Film acts as a once-through, low thermal stress, low hold-up, partial reboiler for the distillation. The appropriate size and surface area of the Wiped Film Evaporator is determined by scale-up calculations based on distillation Pilot Plant trials.

• Constant, controlled feed rate

• Steady vacuum level

• Steady evaporator temperature

The bottom of the Packed Fractionating Column is connected to the vapour arm of the Wiped-Film Evaporator, and is filled with column packing of a variety of commercially available distillation column packing types.

The diameter of the column is chosen based on the feed rate to the system, and the height of the packed column is chosen according to the number of theoretical plates needed for the desired separation. The diameter and column height are critical design parameters. Sufficient theoretical plates, as determined by the depth of the packing in the column, must be used for a successful separation, but a large excess of column height will cause too much pressure drop, thereby raising the pressure in the reboiler, and thus require a higher reboiler temperature for the desired boil-up for the column. The higher required temperature can cause thermal degradation of the material being processed. A professionally designed column balances the number of theoretical plates needed for the separation against the resulting pressure drop to enable the desired separation.

The column diameter needs to be appropriately designed to manage the desired boil-up. A column that is too small in diameter will flood at the desired distillation rate. A column that is too large in diameter will not allow sufficient contact between the vapor and liquid in the column and will give a very inefficient separation.

The condensed liquid from the overhead condenser is split into two streams by a three-way valve, using a timer to control the ratio of distillate take-off vs. reflux returned to the column. The proper reflux rate must be determined to allow the required energy exchange between vapor and liquid and cause the enrichment of the light key component(s) at the top of the column.

A few examples of applications successfully developed on a Hybrid Wiped-Film Distillation System are:

• Omega-3 concentration and separation

• Edible Oils

• Flavour component purification

• Fragrance component purification

• Nutritional Supplement purification

• Fatty Acid fractionating

• Fatty Acid Ester fractionating

• Terpenoid separation from natural oils

• Many other temperature sensitive separations.

Food Techies are an active lot and many of us have interests and enterprises on the side that will fascinate the rest of us. Often skills and attitudes acquired in Food Technology get applied to a hobby – often the hobby builds new skills. This column records the odd interests, quirks and side hustles of Food Techies when we are not watching. We pull back the curtain and take a peek….

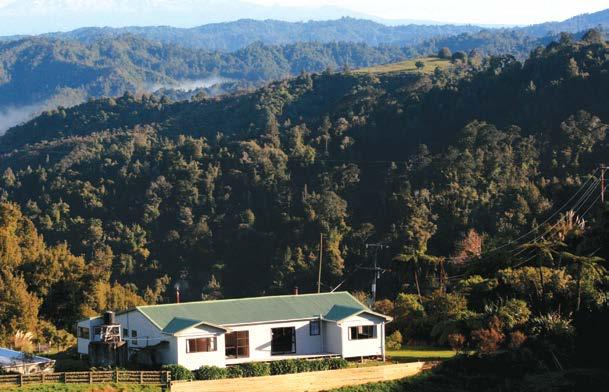

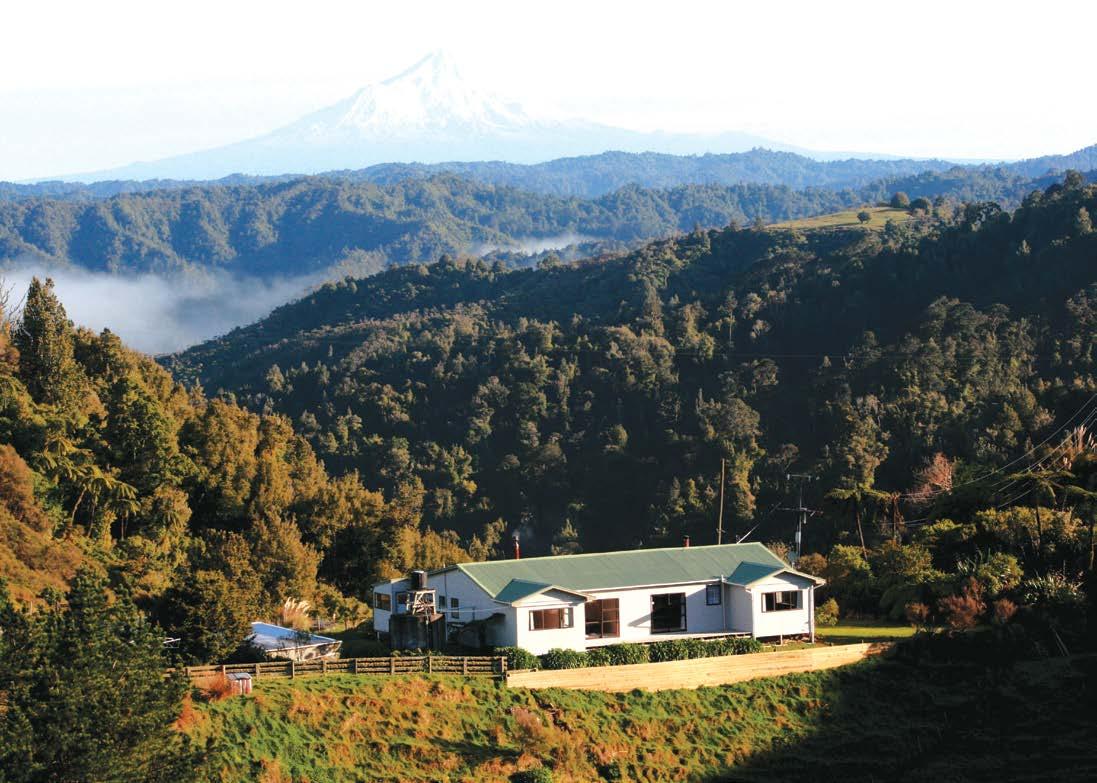

carbon farmers

In 2011, Richard and Deb Archer plus Dennis and Irene Thomas plus long-term friends, Paul and Diane Stephenson went farming. We bought a 104 Ha sheep and beef farm about 22 km inland of Waverley in South Taranaki. Its four-bedroom house gets views of both Taranaki maunga and the Tasman sea – plus a wee breeze. We sit on a watershed at the headwaters of the Kohi stream, a tributary of the Whenuakura. This is tiger country and DOC is our biggest neighbour.

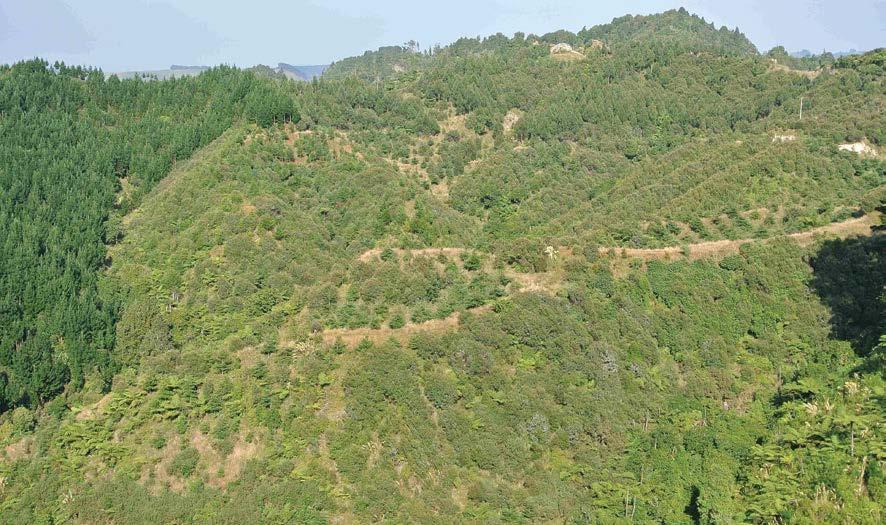

Our plan was to make Manuka honey to give us early revenue and grow timber for revenue for the next generation. At the same time we planned to sequester our lifetimes’ carbon emissions. So we planted about 50,000 manuka seedlings and about 45,000 exotic trees – with the help of an Afforestation Grant Scheme grant for the exotics and a Regional Council grant to retire an erosion-prone paddock into bush. The grant money helped with fencing and planting.

While we are not rich yet, the honey money and Grant income has paid for much of the forest development. We used professionals for all the planting (84 Ha), all the pine pruning (22 Ha) and for pruning around 1000 selected Cupressus lusitanica trees. Meanwhile Paul prunes the other 1500 cypresses and the 2500 Eucalyptus fastigata and Richard prunes the 4500 redwoods. And not one of us pays any gym fees. Dennis does all the house and structure maintenance and the accounts. Paul looks after forestry planning and ETS carbon

credits. And Richard does pest control (goats, deer, possums, rats, stoats, pigs, hedgehogs, rabbits and feral cats) with guns and traps plus controlling gorse with scrub bar and spray. Farming, we learnt, is all about killing stuff.

We also help look after kiwi living next door on the DOC block – we are part of a group of neighbouring landowners running trap lines organised by the Mt Hiwi Kiwi Trust. We have heard Kiwi and seen footprints in mud but not yet seen any ourselves – maybe because they only wander after wine time.

Twelve years in, our plantings are maturing. All the pines silviculture is finished. The rest of the exotics are pruned to around 5 m of the planned 6.5m. The manuka is in full production (2 to 3 tonnes of honey annually) most around UMF15. We have recovered from a tornado, two cyclones and about 50 slips (totalling ~15,000 m³ of rock and soil). We’ve also planted a thousand larger natives, mostly

How the view changes as the trees take hold and thrive

podocarps within 250 m of the house, and graze about 2 Ha of grass round the house. We know most of the land well but none of us has yet walked the southern boundary – as none of us can abseil!

Forestry typically incurs heavy costs for a decade then lower maintenance costs. That suits shareholders who can use annual losses on their personal books and the look-through company structure is designed for that purpose. We arranged our investment so that honey revenue covered most of the silviculture costs across those first ten years. Now that we are merely maintaining and make profits, we have restructured to a normal private company.

Our AGS grant meant we could not receive carbon credits off the relevant area for the first decade. The recent financial year is our first of picking up carbon credits in our own right and we are learning the art of selling in a fickle market while retaining sufficient credits to cover potential liabilities. We also face some deferred maintenance including a big bill to rebuild a road to one of the hive sites. Maintaining 3 or 4 km of track on a temperate rain-forest property can be expensive.

the odd possum…and then there are the

feral cats

Just when things were coming right we had a collective rush of blood: In June 2022 we bought another 80 Ha sheep and beef farm a bit North of Hunterville. Different district and region, similar contour, different soil, similarly poorly suited to grass and ruminants. This time we are in our 70’s and not 60’s. We picked a property with no house or woolshed to look after and only 7 km off SH1 and only one hour from Palmerston North. We don’t want more pruning – so no exotic forest.

Last winter we planted the Eastern half in manuka as before. This winter we are doing the Western half. We’ve built a small shed for tools and smoko. Again, we have some some Regional Council grant assistance toward planting costs. In total, we are planting nearly 90,000 manuka at 3m centres and interplanting perhaps 2,000 podocarps on a regular grid for timber next century. We will progressively put flaxes on track margins and gullies. This time we have invested in goat-proofing the boundary fence and using professional hunters to clean up before planting. We plan for the podocarps to seed the property in random fashion so our great, great

grandchildren have both a native forest plus native timber from the original grid of grandfather trees.

Carbon credits and honey and some wild meat should provide some modest payback in our lifetimes. We are hoping for a more favourable position under the emissions trading scheme for native forests at some point. And we are hoping for an easier and more robust system of permitting felling of native trees planted for timber a century earlier.

Why did we spend so much on some tired old land? We all fancied turning some country too soft for sheep and beef back to trees and birds. And we were interested in investment. Each of the six of us has a different balance of incentives. Some want work, some play, some adventure, some riches, some to build something great, some to dream something even greater. Dennis wanted a genuinely green retirement income; Paul wanted to nurture a forest, not just invest in pines and Richard wanted to drive diggers and shoot stuff. Our food tech, engineering and teaching backgrounds have made us pretty practical and pragmatic but with dreams intact. We can now see the capital asset building and can feel the profits starting to flow. We can now prune and fell trees, shoot and trap animals, count carbon credits and dollar notes, argue and agree. We can smell the fresh air, hear the birds and drink in the views.

If any other Food Techies fancy doing similar re-wilding things in their shadows drop us a line. We can tell you heaps about what not to do and even show you around. None of this is for the fainthearted. You won’t make fortunes. Guns, ladders and saws all have their dangers. Carbon accounting challenges even a fastidious food engineer. The weather is against you, and if the land is affordable then access is precarious. But you can spend your shadow time in paradise!

The Chinese government is encouraging its people to consume more cows’ milk. ‘A cup of milk a day makes Chinese people strong’, was the well-known slogan of a leading Chinese dairy company. Official dietary guidelines have raised the recommended intake of liquid milk equivalent per day from 300g to between 300g and 500g (roughly equivalent to half a litre).

The impressive increase in height of the Japanese population after they started consuming dairy milk has not gone unnoticed. The Japanese instituted a national school lunch programme, including milk, following WWII.

So ironically, while some western consumers are switching to alternative plant milks, the Chinese are going in the other direction. In fact, it was the Chinese who first developed plant-based milk 2000 years ago, from soya beans, the only plant to contain all the essential amino acids (protein constituents) the body cannot make for itself. However, soya beans lack other nutrients and growth factors in cows’ milk.

Although dairy milk consumption in China has risen dramatically from virtually zero at the end of WWII, their per capita consumption is only a third of the global average, and a tenth that of the world’s top milk consumer, Finland. Local dairy production has also vastly increased, from 1.2 million tonnes in 1980 to 42.0 million tonnes in 2023, but there is a shortfall of about 30% between what they produce and what they consume. China is still the largest importer of dairy products. An historical lack of cold chain distribution and home refrigeration facilities means that milk is mostly sold in shelf-stable formats, such as UHT milk, ambient yoghurt and milk powders. Uneven economic growth has resulted in uneven market expansion across different regions and hence milk consumption patterns vary across the country.

Given the government’s support for milk, an ageing population interested in maintaining bone and general health, coupled with the preference for imported milks (There is still a lack of trust in local product following the 2008 melamine scandal, when six infants died and thousands were hospitalised.) our government and dairy industry want to know much more about where, when, why and how milk is consumed, in the massive Chinese market. Homogenous it is not.

As part of a government-funded research programme, NZ Milks Mean More, Professor Joanne Hort (Fonterra-Riddet Chair of Consumer and Sensory Science at Massey University) designed

Dr Ao Chen, who joined the FEAST laboratory team in 2021 and assumed responsibility for the research project into Chinese Dairy milk consumption

and commissioned research into Chinese milk consumption habits. Joanne is an expert in testing how and why consumers respond to food and drink in different ways and how this affects purchasing decisions.

In 2017 Joanne imported her well-developed methodology from Nottingham, England, when she moved to New Zealand. Her fiveyear-old Food Experience and Sensory Testing (FEAST) laboratory at Massey University in Palmerston North contains an array of hightech equipment to discern the nuances of local consumer likes and dislikes – how taste is affected by smell, colour, texture, sound, salt and sugar content, acidity, packaging, product preconceptions, nutrition claims, attitudes to food provenance and sustainability, surroundings, social context, temperature, and affordability. Taste preferences are individual, but there are distinct cultural and genetic differences which can be generalised. These studies are not just interesting but are vital to the success of new product launches, especially in foreign markets, to enable them to compete in crowded retail settings.

Joanne’s 2022 survey of 1000 Chinese consumers who regularly consume milk, compared the consumption characteristics of adults aged between 45 and 75 in the mega-cities of Beijing, Shanghai, and Guangzhou, with two smaller provincial cities: Chengdu (southwest) and Shenyang (northeast). This choice of comparison proved important. The focus was on older adults, a fast- growing population in China. The idea of a product designed for consumption by older adults is a very well-developed concept in China. Foods designed for older adults in the Chinese market are now dominated by milks. Dr Ao Chen, who joined the FEAST laboratory team in 2021 and assumed responsibility for the research project, grew up in

Chengdu, and came to New Zealand in 2013 to study pastoral dairy farming systems. Ao was surprised at the differences between milk consumption habits in New Zealand and China. His knowledge of Chinese dietary customs and regional variations has been particularly useful in interpreting the results of the research qualitatively.

He reports the key research findings as follows. “Most dairy milk in China is consumed by city-dwellers. It requires a changed mindset, and new ideas and exotic foods and drinks tend to be adopted first in the big cities, where people are more open-minded and affluent. Nearly half of the consumers consume UHT milks because of its popularity in the market. UHT is distinctly preferred by consumers in Chengdu and Shenyang (73% and 78% respectively), whereas powdered milk is favoured in Guangzhou. Fresh pasteurised milk in China is not very common but in recent years, its popularity has been increasing, especially in Beijing and Shanghai."

“Seventy five percent of participants drink their milk straight, as part of breakfast, at home. In the big cities they often pair it with more exotic western style breads and cereals and sometimes make other beverages with the milk. In the smaller cities they tend to consume milk with more traditional breakfast foods such as steamed buns. In cold, northeast Shenyang, they often skip breakfast during the

short daylight hours of winter and drink their milk before bedtime or flexibly during the day. Except for preparing doughs, milk is seldom used as an ingredient in cooking.”

“Generally, butter and cheese consumption is negligible, though yoghurt is becoming popular. The Chinese are not yet addicted to lattes and flat whites and are not in the habit of adding milk to tea. However, milk is added to bubble tea which is increasingly popular with the younger generation. The Chinese don’t particularly relish the taste of milk on its own, so about one in ten will add sugar or honey. It is the nutrition and health benefits of milk driving consumption,” says Ao.

Ao is often asked why the Chinese are taking to cows’ milk with such enthusiasm when many are reputedly lactose intolerant (lacking the genetic mutation which enables digestion of lactose past infancy). He says that even though Asians generally suffer from lactose malabsorption, in fact most Chinese can drink milk without ill-effect, provided they don’t drink too much at once. The beneficial bacteria in their colon would process the by-products of lactose. Therefore, it is not regarded as any impediment to increased consumption.

Link to paper: https://www.journalofdairyscience.org/article/ S0022-0302(24)00045-6/fulltext

This article has been written exclusively for FoodNZ by the NZ Food Safety Science & Research Centre.

Philip Wescombe, Oceania’s R&D Manager, Chaired the Centre’s Industry Advisory Group during the term of the Cronobacter project

Associate Professor Simon Swift (University of Auckland) who was heavily involved in the informationgathering

The definitive guide to managing Cronobacter, just launched, may not make the best-seller list, but it represents the best in human nature and many years of New Zealand’s experience in producing safe, top quality infant formula. It has the potential to save lives that have only just begun.

Contributing New Zealand dairy companies suppressed any competitive angst to pool their knowledge about managing Cronobacter for the greater good. NZ Food Safety Science & Research Centre (Centre) Chief Scientist, Distinguished Professor Phil Bremer, believes it’s a world first. The guide will soon be available from the NZFSSRC website* for anyone to learn from, here or overseas.

The project was initiated and co-funded by a number of producers of infant formula/ingredients for infant formula, with strong support from Oceania Dairy limited, and the Universities of Otago and Auckland. Philip Wescombe, Oceania’s R&D Manager, was chair of the Centre’s Industry Advisory Group when the project was conceived

and stayed with the project to completion. Our forward-thinking participating companies opened the doors to Phil Bremer (University of Otago) and Associate Professor Simon Swift (University of Auckland), giving them the freedom to inspect facilities and observe their processing and testing regimes, interrogate their testing records, sit down with their people and understand exactly what they do, discover any tips and tricks they had to offer, and learn what the greatest challenges were and how they managed to resolve them.

One of the food safety managers involved explained that unforeseen breaches of their strict exclusion protocols could occur, such as a maintenance worker bringing in contaminated clothing or tools, undetected ruptures in air and water seals, and roof leaks. Regular sampling of the factory environment is designed to identify these events, followed by challenging forensic backtracking to locate the possible breach.

The researchers also met with regulatory authorities and, importantly, successive drafts of the guide have been extensively reviewed by industry members, regulators and other academics to produce the most up-to-date guide to best practice. Fonterra’s experts in this domain had an oversight advisory role and painstakingly reviewed the comprehensive guide. No stone was left unturned.

The exhaustive research was stop-start over a couple of years due to COVID-19 lockdowns delaying many in-person visits. But they persevered and everyone is proud of the result.

Cronobacter sakazakii is highly dangerous to babies under two months, who have undeveloped immune systems. It can cause sepsis and fatal meningitis. (The bacteria are named after Cronos, a Titan in Greek mythology who swallowed his infants when they were born, in fear of being replaced by them.) The bacteria can survive in dry environments like infant formula, and multiply in the comfortable temperature range of formula if it is not stored and consumed as recommended. It takes very low numbers of the bacteria to cause infection.

In the US, as recently as 2022, two of four babies who became very sick with Cronobacter sakazakii, died. This was a further spur to the project, though none was needed. In the US case, all the babies

had been fed formula from the same factory in Michigan, although reportedly no genetic link could be found between the samples from the facility and isolates from the powder and water used to feed the babies.

Phil says New Zealand regulatory authorities and dairy companies have strict controls to prevent contamination, robust sampling regimes to test for Cronobacter sakazakii, and clear guidelines on what to do if contamination is found. Industry knows only too well that if it is found in infant formula, it has the potential to cause enormous disruption – product recalls, factory closures and exclusion from international markets, which could extend beyond the facility concerned and cast a long shadow over the whole industry’s reputation. In the US case above, the recalls resulted in a critical nationwide shortage of infant formula for a time.

While we have robust testing strategies and great regulatory oversight,

Research and Development Manager, Yili Innovation Centre Oceania, Dr Philip Wescombe:

“Yili has developed dairy industry and research partnerships at its innovation centres around the world, including membership of the New Zealand Food Safety Science & Research Centre.

“We are particularly excited that Oceania Dairy Limited (a subsidiary of Yili) was an industry member involved in driving the development of best management practices for Cronobacter sakazakii for the benefit of the whole dairy industry.

“The seriousness of Cronobacter sakazakii detection and prevention cannot be understated. Even when Cronobacter sakazakii is identified and prevented from reaching consumers, the identification event can have serious and ongoing implications for supply chains, which we witnessed during a recent infant formula recall in the United States in 2022.

“Research suggests that shortages of baby formula nationally in the US resulting from the voluntary recall of products and the shutdown of the manufacturing facility, led to increases in the national out-of-stock rate of infant formula from 18% to 70% over the summer of 2022.

“The consequences of the contamination event were compounded

Phil says some companies have more experience than others in managing Cronobacter sakazakii. In order to bring all New Zealand infant formula producers up to the same high standard, industry leaders kindly agreed to share their expertise and knowledge. Nervousness about any suggestion that contamination of product with this pathogen is a possibility, is understandable. Markets are increasingly jittery and there is zero tolerance of Cronobacter in infant milk powder. New Zealand has an excellent record and will do everything in its power to keep it that way.

*The official title of the guide is The Management of Cronobacter in Powdered Infant Formula (PIF) Manufacturing and/or Dairy Processing Plants in New Zealand. It will be uploaded to www.nzfssrc.org.nz

by the fact that the manufacturer was the major supplier of infant formula for the US Government’s Special Supplemental Nutrition Program for families with low incomes and nutritionally vulnerable infants.

“We are therefore honoured to be part of the development of this code of practice and sincerely hope that industry partnerships such as those developed here in New Zealand with food safety researchers can also be developed around the world.’’

General Manager Quality and Compliance, Oceania Dairy Limited, Hila Mory, added

“When it comes to a bacterium like Cronobacter, it is not necessarily enough just to maintain high hygiene standards. We must continually improve on best practice by researching and sharing knowledge.

“As a bacterium, Cronobacter sakazakii can evolve and become tolerant of cleaning agents, which means we need to continually innovate to maintain our food safety practices to the highest possible standards. The code of practice draws upon a robust foundation of scientific inquiry, extensive research, and invaluable practical insights. Its primary aim is to support manufacturers to produce safe powdered infant formula.”

Aluminium free aseptic cartons, seaweed films, top wrap labelling and paper based trays lead the charge

Nerida

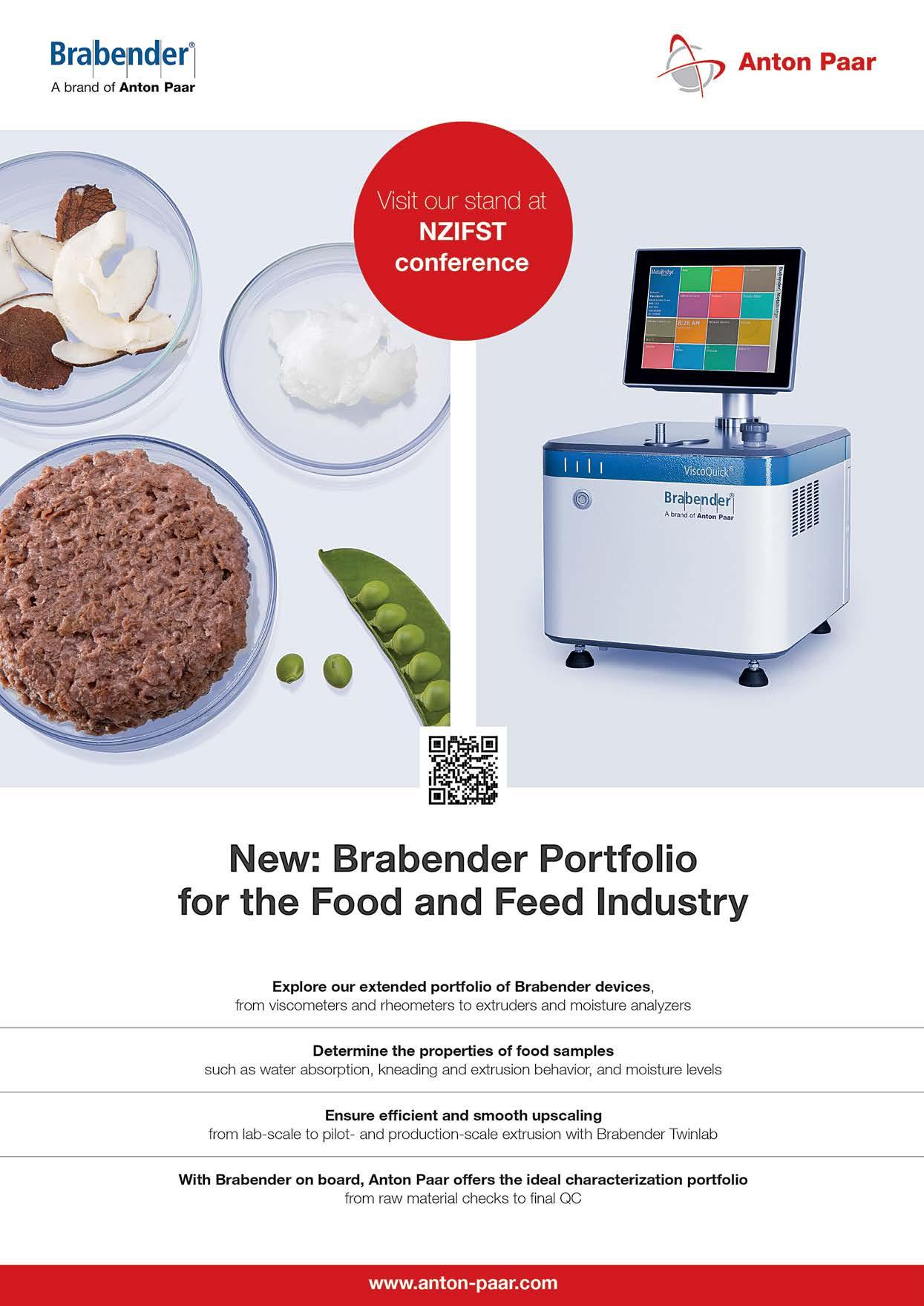

Joining 39,999 other people from 133 countries I recently ticked off my first participation at Anuga FoodTec which was held in Cologne, Germany.

As Anuga FoodTec is the leading international trade exhibition for the food and beverage industries, the World Packaging Organisation (WPO) decided to exhibit for the first time and also participate in three speaking sessions during the four-day show.

I had the opportunity to visit some of the exhibition stands, talk to a number of exhibitors and see what packaging is new, innovative and intuitive. I was particularly looking for packaging that is recycle ready, offers improvements to packaging to provide lower environmental impacts, new advancements in paperisation and renewable materials and what is happening in Save Food Packaging design.

Some of the packs that I wanted to share were the SIG Alu Free cartons, Sea6 Energy seaweed films, Micvac ready meal packs, Multivac Top Wrap and Top Close labelling and Paperboard and G. Mondini Slimfresh.

SIG Alu Free cartons are an aseptic carton with no aluminium layer. The carton is FSC certified paperboard, is fully recyclable and produced with 100% renewable energy. The SIG Alu free carton has a carbon footprint up to 27% lower than standard SIG packaging material, thanks to a unique composite with no aluminium layer. It is specifically designed for liquid dairy products such as plain white UHT milk, cream, and other oxygen-sensitive products. The carton is made from up to 82% renewable paperboard, with ultra-thin polymer layers to contain and protect products over long periods without the need for refrigeration.

SIG also recently added the option to link to 100% forest-based

renewable materials via a mass-balance system. The SIG Alu free carton is another step towards removing aluminium from aseptic cartons but still maintain shelf life and barrier for products.

www.sig.biz

Micvac is an innovative food processing and packaging solution company which has designed a unique in-pack cooking and pasteurisation method that provides healthy ready meals.

The original idea was borne out of trying to preserve one of the most delicate foods there is – mussels. The inventor (and founding father), Dr Joel Haamer, conducted extensive research into marine food cultivation and preservation throughout his career. He found that the best way to preserve mussels was to get rid of all the oxygen and use a fast thermal treatment. 23 years later Micvac is a thriving business.

Micvac vs food loss and waste

The team at Micvac understand the environmental impacts of food loss and waste and they wanted to ensure that the system not only extends the shelf life of ready meals but also improves production methods to minimise food loss.

The Micvac solution sees the food cooked and pasteurised in the packaging; portion by portion. The food is usually packed raw, with very few pre-cooking steps. This means that there is far less risk of excess food loss in the production process, as there is no need to prepare large batches.

Micvac multifunctional valve

The Micvac valve is at the core of the packaging design and is constructed in layers with a special adhesive in between. As the temperature rises, the air pressure opens the valve to release the

Canadian Company Henshall Foods has adopted the MicVac solution for limited shelf-life microwavable meal packs that incorporate a unique pressure valve system that screams when the food is adequately reheated

steam, and with it the air/oxygen molecules in the package. When cooling begins the valve closes and the package is airtight again. The remaining steam condenses, thereby creating a vacuum in the package.

This is a natural vacuum, allowing the meal a prolonged shelf life. The valve is able to repeat this over and over again. When the end consumer heats up the meal in the microwave oven at home, the valve once again does its duty and opens up to release steam – and with it a whistling signal.

Ready Meals made with the Micvac method have a shelf life of approximately 40-60 days which in turn ensures that stores can keep food waste to a minimum. The packs are designed with portion control, extension of shelf life and consumer convenience in mind. A Micvac-made portion, with its unique extension of shelf-life design features, lasts a considerable time in the fridge. A portion-cooked ready meal is less likely to be wasted through the Micvac solution.

Micvac and packaging

The package used at Micvac is in many ways superior to other meal

solutions. A Micvac portion has a minimum of plastic per kilogramme of food, thanks to the vacuum and cooking process. The Micvac tray is designed to use just the right amount of packaging for the contents, which means no unnecessary airspace is transported. Furthermore, the trays are recyclable, and the plastic gets used in the production of new products.

In light of Save Food Packaging design and technologies for minimising food loss and waste, Micvac really stood out to me as unique, and I look forward to seeing this business extend elsewhere in the world.

www.micvac.com

Visiting the Multivac stand at Anuga FoodTec actually took two trips as there was so much to discover in the way of advancements in sustainable packaging solutions, fibre-based trays and some very impressive top wrap and top close labelling.

If your fruit and vegetables don't have to be packed in a modified

Top Close labelling technology from Multivac seals trays from above and labels them in a single pass

atmosphere or a vacuum, then your trays can be sealed with labels and marked directly.

Top wrap labelling seals the trays with a label from above and over two sides so that the content of the tray is secure from falling out or being easily removed from the tray. The packs are automatically labelled on the line, providing tangible cost savings compared to time-consuming, manual packaging solutions.

There are a wide range of label materials available to match the recyclability regulations for each country and a combination of cardboard trays and paper labels optimise recyclability of the pack. The cut-outs are designed for air circulation.

In the case of Top Close labelling, a label adheres only to the edge of the tray. Top Close labelling seals trays from above and labels them in a single pass. The carrier material is retained in the centre of the label so that your product does not come into contact with the adhesive.

I saw paper-based meat trays across multiple stands and I was interested to see if there had been any advancements in functionality and sustainable packaging design features. The Multivac PaperBoard formable paper stood out to me for its thoughtful and intuitive design.

The PaperBoard series has been designed to eliminate single use plastics, reduce the use of plastics and improve recyclability of the packs.

PaperBoard material can be run on packaging systems in the form of rolls, pre-cuts, or trays. Paper fibre and cardboard composites with different grammages and functional layers are available. The use of functional layers makes it possible to produce paper-based packs that meet the barrier property requirements of the respective product. What I personally like about the PaperBoard series is that the design is a step ahead of many other available solutions in the market for separability of the components for recycling. So many consumers

get frustrated by some of the packs on the market as they can’t easily separate the film from the paper. This in turn means that the separable components end up in the wrong disposal bin and the pack that has been promoted as reducing single use plastic and being "more sustainable" is not actually meeting sustainable design standards.

The PaperBoard design however does separate easily as I tested multiple packs. The design features are intuitive and ensure that the paper and the film can, in fact, be easily and quickly separated by a consumer.

www.multivac.com

I was lucky enough to have shared a stage with Ludwig Schmidtchen from Sea6 Energy at a Science Slam presentation and I walked away thinking a lot more about seaweed and whether this is a viable alternate for some packaging films. It is certainly an area that we need to better understand.

Seaweeds, characterised by their efficient utilisation of solar energy and minimal resource requirements, offer a promising solution to address the pressing challenges of resource scarcity and environmental degradation.

The utilisation of seaweed biomass extends beyond traditional boundaries, encompassing the production of bio stimulants for agriculture and horticulture, food and feed ingredients, and the development of innovative biomaterials tailored for the packaging industry.

Headquartered in Bangalore, Sea6 Energy believes that there is a critical need to design innovation strategies to meet the escalating demand for raw materials, particularly within the packaging industry. Sea6 Energy is actively engaged in research and development efforts to formulate seaweed-derived biomaterials such as coatings and extrusion compounds for flexible films and rigids. These biomaterials offer several advantages, including biodegradability, renewability, and reduced environmental impact, positioning them as sustainable alternatives to traditional packaging materials.

Sea6 Energy have become a pioneer of innovative technologies for sustainable, large-scale and mechanised farming of sea-plants and the conversion of this sea-plant biomass to novel products for use in agriculture, aquaculture, food ingredients, renewable chemicals, bioplastics as well as Biofuel.

Sea6 Energy are developing seaweed-based, compostable films that can be used for packaging of FMCG goods and fast foods. These films, when discarded into the environment, will compost in a few months and are available in Food and Non-food grades. The commercialisation of first materials is targeted within the next 12 months.

I look forward to watching Sea6 Energy developments in the future. https://www.sea6energy.com/solutions/bio-plastics/

The last stand that I wanted to talk about was G.Mondini and the first thing that stopped me was the display of the SlimFresh for Salmon. The skin pack solution offering thinness of pack was the first thing that caught my eye. Compared to other solutions for Salmon packaging that I have seen recently, this one really stands out.

SlimFresh

SlimFresh is composed of a flat cardboard support as its base laminated with a thin layer of plastic film and sealed with a top skin web as a second invisible skin around the product. The resulting vacuum skin pack offers the possibility of extending food shelf-life, ensuring freshness and bringing logistic benefits.

Recycling and sustainability are the drivers of this new pack and removing the plastic film liner from the paper is simple, ensuring efficient recycling of the paper/fibre support.

The SlimFresh skin pack solution is made up of a cardboard base combined with vacuum skin packaging. The pack offers a uniquely

SlimFresh technology from G. Mondini is composed of a flat cardboard support as its base laminated with a thin layer of plastic film and sealed with a top skin web as a second invisible skin around the product

shaped window and the laser cutting of paper allows each brand to be able to create several window shapes depending on the product shape and size. It has the ability to pack irregular shapes for better merchandising and offers all the benefits of skin packing to ensure optimal package performance.

https://www.gmondini.com/

If you are planning to attend the next edition of Anuga FoodTec on the 23rd to 26th of February 2027 I would recommend that you allow at least two days to walk around the show. I also look forward to returning to Anuga FoodTec in 2027 to see even more advances in sustainable packaging and recycle ready packs. Imagine what we will see in three years!

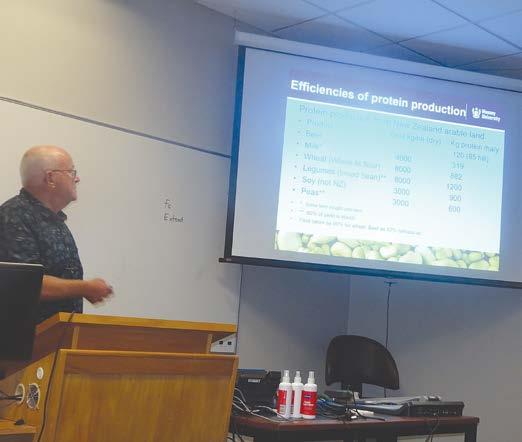

Dr Marshall’s view is just as timely and valid in 2024 as it was in 2019

The Earle lecture is a biennial award presented to a distinguished recipient who has made notable contributions to the impact of engineering and technology in New Zealand. It is hosted jointly by the Manawatu Branches of the Royal Society of New Zealand and the Institute of Professional Engineers and honours the contributions of Dick and Mary Earle, well-known to NZIFST, recognising their immense contribution to biotechnology and food technology regionally, nationally and globally.

Early in October, 2019 Dr Kevin Marshall, a long-standing Wellington member of NZIFST and the JC Andrews Awardee in 2006, delivered the 2019 Earle Lecture in Palmerston North on the subject “A Future for New Zealand Food”. In his opening comments, Kevin confessed to having known the Earles for his entire career with his professional and personal paths intertwining with Dick and Mary’s since the 1960’s. Indeed Kevin admitted that his first ever job application as a fresh BE graduate was to Dick and Mary at the Meat Industry Research Institute of New Zealand ... he was declined! A short while later when Kevin enrolled at Massey University for his post-graduate degree it was under the supervision of Prof Dick Earle.

Kevin has since experienced a long and distinguished career spanning an extensive cross-section of our key food export industries including dairy, fruit, meat and seafood. Kevin’s assessment of the prognosis for our food future derives from the insights enabled by that that deep knowledge of the New Zealand food industry, leading him to an alternative scenario from zealots who proclaim that our food future is vegan, and all animal farming in New Zealand must stop. Unlike those who proclaim doom unless we frame an animal-free future for Kiwi food, Kevin anticipates our core platform of animal-based food exports will be retained but reframed to a more sustainable model, supplemented by alternative uses of land in a few areas where overintensification of animal farming cannot be sustained even with better control practices.

In preface to his lecture, Kevin professed his belief (informed by his personal GP) that there are “no bad foods but there are certainly bad diets” implying that public and individual health responds to managing long-run consumption rather than maligning single foods. Later reflection identified that this philosophical tenet likely embodies a broader Marshall doctrine that oversimplification of issues by distilling them to isolated factoids commends ineffective solutions to problems and causes irrational choices to be made. That position seemed to be reflected in the underpinning logic of Kevin’s analysis of the prognosis for animal-sourced foods in our future that followed.