Innovators in Cleaning NOVA News 31. edition. September 2023 31th edition! Novadan´s international e-newsletter to partners!

In this edition of NovaNews, we have an article about energy prices and inflation - a theme we have chosen to comments on in several previous NovaNews, as well.

Furthermore, read about our acidic foam cleaning range or news from our membrane dept.

We also have an article about our great distributor: Prokalia with whom we enjoy a good cooperation.

How can we assist you?

At Novadan, we are proud of our many committed distributors that strive to increase awareness and sales of Novadan’s products and every day, you all do a great effort to benefit your business.

As part of “the deal” between every distributor and Novadan are - beside from products - also advice, training, joint visits etc. All of these parts supports the aim to feel well equipped to deliver a good solution to the client.

Beside from the above, Novadan also offers marketing support - free of charge for hours spend. We are here to assist you so reach out to us!

How can we assist you? Well, we cover the full range of services, from content creation to marketing materials: Flyers, product lists, product images, videos,

If you have any ”stories/experiences with Novadan products” from your country that could be of interest to our other partners/ distributors, please share it with us by emailing details (and images) to hoy@novadan.dk

Or if you are anxious to know more about some topics, which you would like us to write about - again please contact hoy@novadan.dk

NOVA NEWS:

Annette Høy Marketing Manager

by

Distributor support Contact your consultant or Annette Høy to hear more hoy@novadan.dk banners, roll ups, exhibition support etc. Our aim is to create marketing materials in the most appealing way in order to increase awareness of your company and Novadan products, increase sales and customer loyalty retention. So if you are planning to make a campaign of one of our products - lets make a suggestion with your logo on. Or maybe you are planning to go to an exhibition..?

ACIDIC FOAM CLEANING – WHAT TO CHOOSE…?

In this article I have chosen to take you through a broad selection of our products – with the acidic ”T” products in focus.

Years back, the best selling product was Foam Surklar. A product containing Phosphoric Acid in the interval 30 – 60 %. Due to the large amount of Phosporic acid, the product is effective against thick calcium deposits. Furthermore, Foam Surklar effectively dissolves protein. Foam Surklar forms a dense and stable foam layer by usage of foaming equipment. Caution must be shown when used on acidic sensitive surfaces with Acidic foam cleaning agents.

Foam Surklar must be considered Novadan’s best acid foam product and maybe the best product in the industry. However, price-wise it is only advantageous if used as a ”stand alone” product without prior alkaline cleaning.

SO, HOW IS THE “T” PRODUCTS COMPARED TO FOAM SURKLAR?

Foam 19 T

Foam 19 T can – just like Foam Surklar – be used without previous alkaline cleaning, and the product is very suitable for cleaning fat, protein, blood and calcium in the correct solution. Foam 19 T gives a strong stable foam if applied with foam equipment. The foam ensures an optimal wetting and thereby high cleaning quality and clean surfaces. The product is not suited for aluminium and other light metals. Contact your Novadan consultant if any doubts.

The acid mixture contains - among other substances - Phosphoric Acid 15 – 30 % and nitric acid 1 – 5 %.

The properties of this formula is fantastic and it is only rarely that Foam Surklar performs better than Foam 19 T.

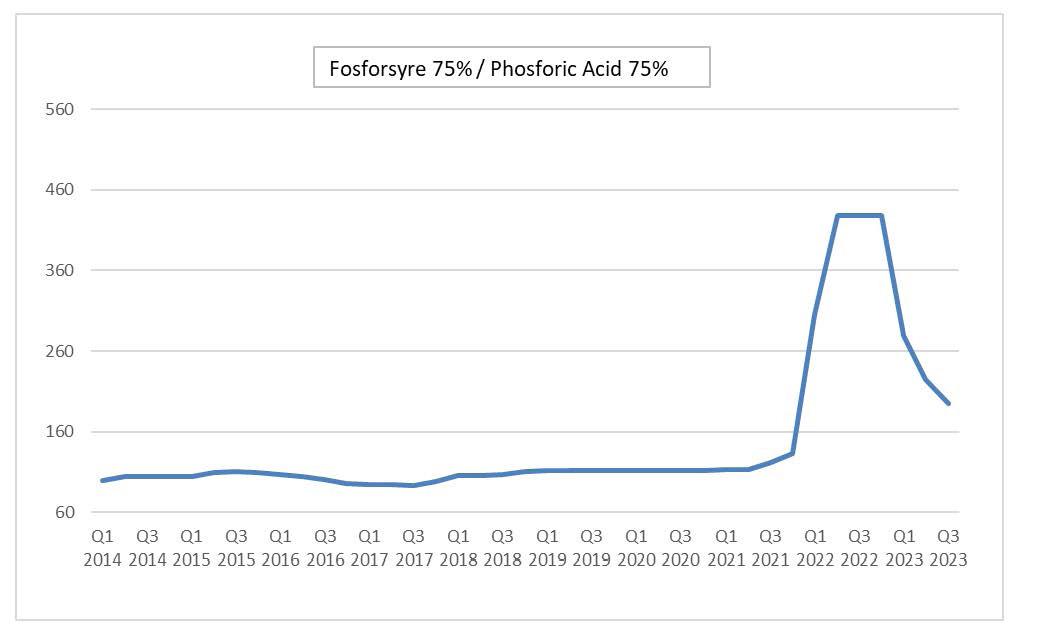

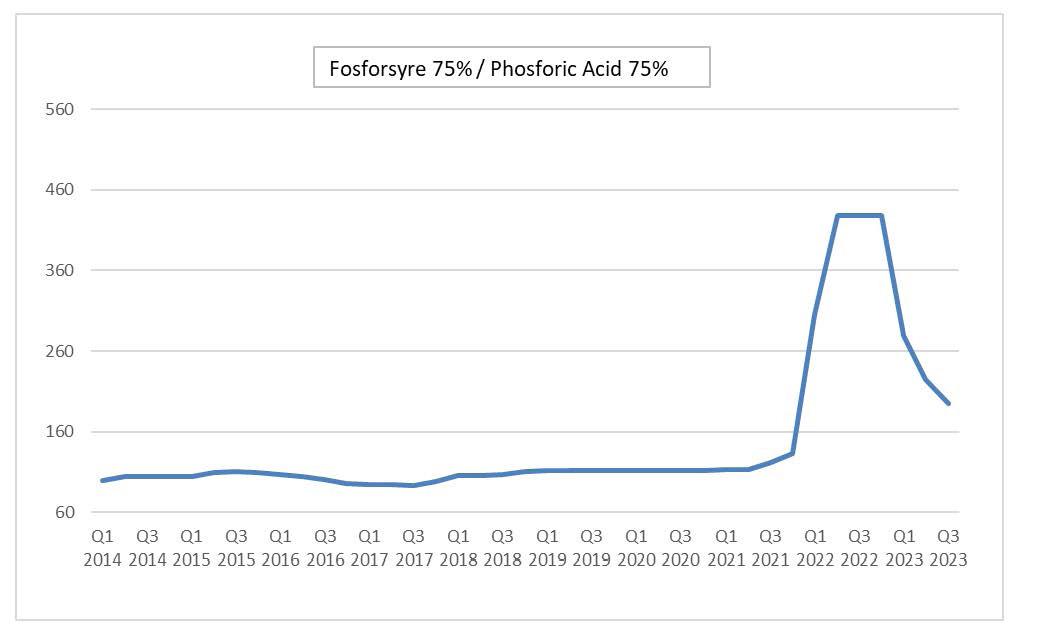

Nevertheless, the product has been affected by the failing deliveries of Phosphoric acid and has –consequently – not been in stock for a period of time. This challenge has now been solved even though it has become a bit more expensive.

Foam 17 T

Foam 17 T with a Phosphoric acid content of 5 – 10 % gives a stable foam when applied by foam equipment. Foam 17 T dissolves effectively calcium – and protein deposits. The product does not contain nitrate.

The product is not suited for aluminium and other light metals.

Still, a fantastic product for removal of calcium and protein deposits. The product cannot easily handle fats and a prior alkaline cleaning is therefore recommended.

Foam 15 T

Foam 15 T is a product that was developed during the delivery crisis and the purpose was to develop a product that was not based on Phosphoric Acid. The product ensures – as our other products – a strong, stable foam when applied by foam equipment. The foam ensures an optimal wetting and thereby high cleaning quality that leaves the surfaces clean. Can be used on aluminum with caution.

It contains a quite different acid composition which looks like this: Sulfuric Acid 5 – 15 % and Methane sulfonic Acid 5 – 10%. The product requires prior alkaline cleaning.

Foam 10 T

In a world of change we have to think of different formulas than before – and from these thoughts arose the idea for Foam 10 T.

A product with an acid composition Sulfuric Acid 5 – 10 % and Nitric acid 1 - 5 % as well as an extremely effective foam package with adhesive capacity. A product that easily removes light calcium and protein deposits.

A slightly older product that should be mentioned even though is does not have the same ”foam package” as the T products is Foam 13.

by Jens Ole Jensen Market Manager Food

The product also gives a strong foam with good adhesive power which effectively dissolves calcium- and protein deposits. Foam 13 is especially suited for use on all surfaces, including aluminium, brass and copper in the recommended dosage and temperature.

In fact, it was our first Phosphate-free acid foam product with a unique composition Formic Acid 5 – 15 % and Methanesulfonic Acid 1 – 5 %.

SO, WHICH PRODUCT TO CHOOSE?

What I will encourage you to do, is to look at the situation and be objective about the nature of the task.

Analyze where the deposits come from, the hardness of the water, the nature of the equipment, materials to be cleaned and requirements and conditions about work environment and water environment.

It is my hope that you – with this writing - got a bit more understanding of our acidic foam program.

There is no reason to use the acidic strong de-greasing products for the easy tasks and conversely, it is too expensive to use the product that only can descale on surfaces that require more.

Best regards,

Jens Ole Jensen

News from the membrane department

I was asked to inform about the news from the membrane department. In the last year and a half there has been more and more focus on certain chemicals and additives. The main drivers are environmental legislation and product safety. Due to this a couple of products has changed its composition, Ro Dan Acid and Ro Dan 98 and a new product, Ro Dan 276, was added to the portfolio.

Today the standard range of membrane detergents from Novadan are without EDTA, LAS and phosphoric acid.

Ro Dan 98 as buffer for the enzyme step. Ro Dan 300E is still the enzyme product and Ro Dan 264 the standard alkaline. If an

alkaline without phosphonate is needed, Ro Dan 276 would be an option. Ro Dan Acid has been changed a bit, phosphoric acid has been removed and is replaced with acetic acid.

A couple of customers have been asking about the enzyme inactivation. How do we make sure no active enzyme stay inside the filtration plants after cleaning?

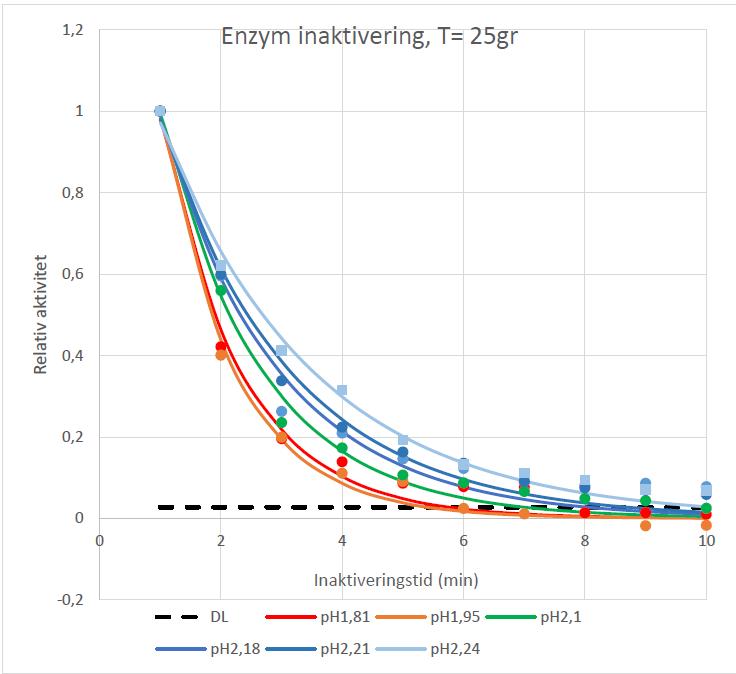

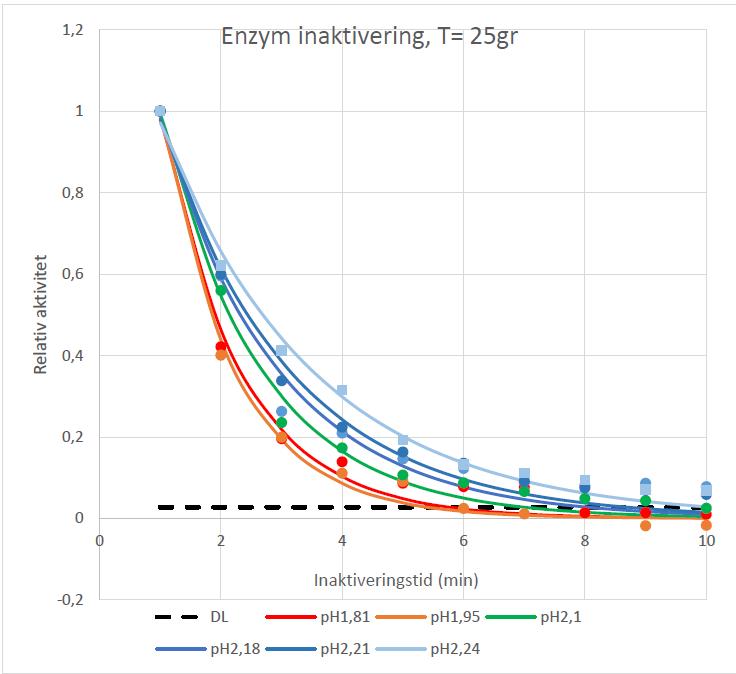

The Novadan lab team did a lot of tests to prove the inactivation of the enzyme in Ro Dan 300E. The first picture shows the correlation between pH and time.

by Ronni Rasmussen Application Specialist Membranes & CIP

Picture 1.

The tests showed that the lower the pH the faster the enzyme inactivates. When pH is below 2 the enzyme deactivates in 5-6 minutes.

by Ronni Rasmussen Application Specialist Membranes & CIP

Picture 1.

The tests showed that the lower the pH the faster the enzyme inactivates. When pH is below 2 the enzyme deactivates in 5-6 minutes.

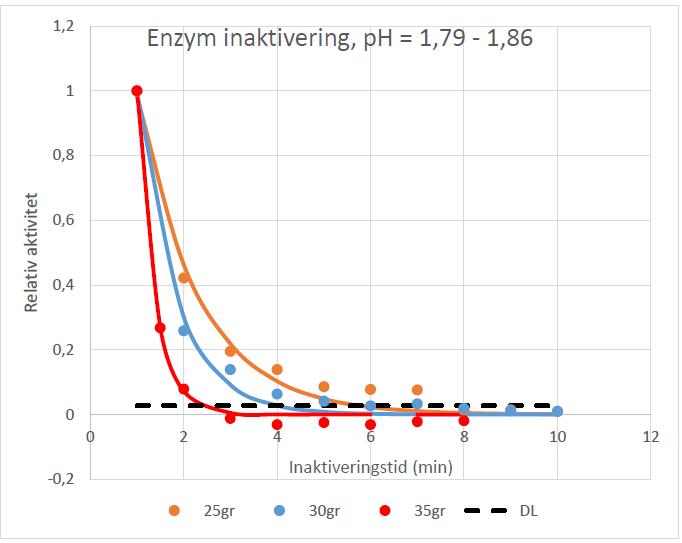

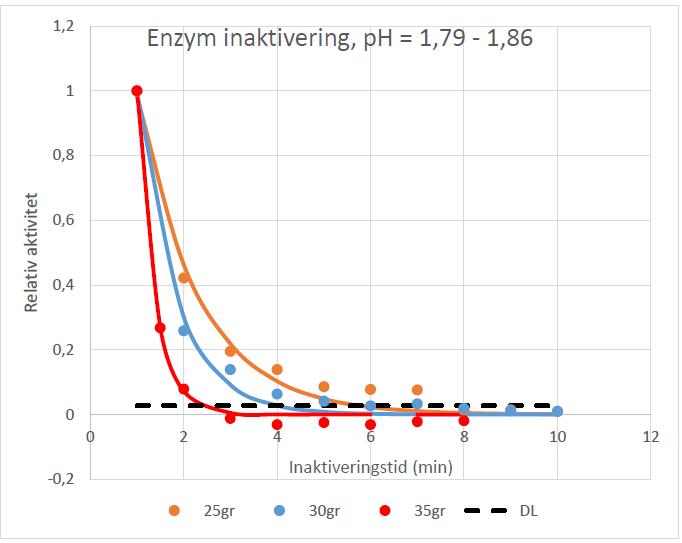

Second picture shows the correlation between temperature and time.

This test shows that the temperature has an impact on the inactivation of the enzyme. The higher the temperature the faster the inactivation.

On top of these test a risk assessment has been made.

Novadan always recommend doing the enzyme step as early as possible in the CIP. Then you have more flushes to dilute. The acid step must be after the enzyme step. pH 2, at least 35 C and a circulation time of more than 15 minutes is recommended.

We in Novadan are still trying to find a reliable test method to do at site right after the CIP. This would then be a part of the Novadan CIP audit.

PROJECT IN COLLABORATION WITH UNIVERSITY STUDENT

During the spring of 23 a student from Aalborg University Esbjerg was doing a project in collaboration with Novadan. The project was his final exam for the education as Chemical Engineering and Biotechnology

The demand for milk alternatives has bloomed and one of the alternatives is oat-based drinks. The development of new products increases. Novadan get some enquiries from the OEM’s about CIP of membranes after production of oat based products. Membrane filtration instead of a decanter to remove the oat slurry after milling, cooking, saccharification and pasteurization.

The project was about this topic. Production of oat slurry, run it through a UF Plate and Frame membrane and afterwards try and clean it. Using different blends of enzymes from Novozymes, collecting data and determine the best possible way of cleaning.

The amount of sediment was massive, and the membrane fouled severely making the cleaning very difficult. One step CIP to be able to compare the different steps. Cellulase, Amylase, Protease and Lipase in different blend were tested. Both low pH and high pH enzymes were tested. But a clean water flux of less than 20 is far off what we are used to in the dairy business.

To be able to succeed the task, different membranes and/or pretreatment should be chosen.

Novadan is going to build on the experience and develop detergent for CIP of Oat based drinks.

2.

Picture

by Annette Høy Marketing Manager

International Food Contest

Every second year, Novadan has a stand at the HI-exhibition in Herning, Denmark - we are in the hall of the International Food Contest - the hall were the dairy industri present their innovative dairy products. and visitors have the change to taste all the delicious cheese, yoghurt, milk etc..

This time, we focus on membrane cleaning, Nova Insight and optimization of the CIP plant.

We are looking forward to having the chance to talk to people / customers from the industry and maybe build our network and get new leads.

A fantastic cooperation with Prokalia

At Novadan we are lucky to have a lot of great customers – in Denmark as well as abroad. In this edition of NovaNews, we will introduce you to one of our export customers within the Agriculture segment: Prokalia from Sweden which is an example of a very successful and loyal, long lasting cooperation.

Novadan and Prokalia started the cooperation back in 1994. At that time it started as part of the company Kemikalia which was part of the Dairy Association in Sweden. In 2005, a restructuring took place where the Novadan part was peaceable separated from the rest. Bo Johansson had been involved from the beginning in 1994 and together with two external investors, he started Prokalia which he ran from Helsingborg. Right from the beginning, the strategy was to put together a range of quality products for milking systems, disinfection and udder hygiene.

First Kemikalia and later on Prokalia were cooperating regarding these product with more or less sales people allocated in Sweden.

In connection with the retirement of Bo Johansson, the founders decided to sell, and from Novadan’s point of view, it was very successful that Prokalia was sold to Kemikalia in 2005. “Prokalia came home again”, so to speak. In the meantime, Kemikalia had been established in previous dairy buildings in Skurup in the South of Sweden.

In Skurup it was – and still is - Anders Olsson as CEO and part-owner of the company that continues and builds the Prokalia- and Novadan part of the business in close cooperation with small and middlesized distributors in Sweden. Especially this year, Prokalia is facing a very promising development. As a curiosity, Anders Olsson was already as a young man working at Kemikalia in 1994 where the first Novadan products were launched and in 2008, he became a boss and part-owner of the company.

Kemikalia has a production of ingredients for the Dairy Industry and has been to several restructuring processes. The name Kemikalia has now been recplaced by SACCO SYSTEM NORDIC. Sacco System is an Italian company and is, today, shareholder. The purpose of the brand PROKALIA is still to sell Novadan products (among others).

by Hans Erik Nielsen Market Manager - Agro

by Hans Erik Nielsen Market Manager - Agro

It will always require two parties for a great cooperation where you “give and take”. Novadan prefers the long term cooperation of which we – fortunately – count numerous examples. In this edition we praise – as an example – Prokalia for almost 30 years of a loyal, honest and uncomplicated cooperation.

From Novadan we thank you and hope to continue our story in many years.

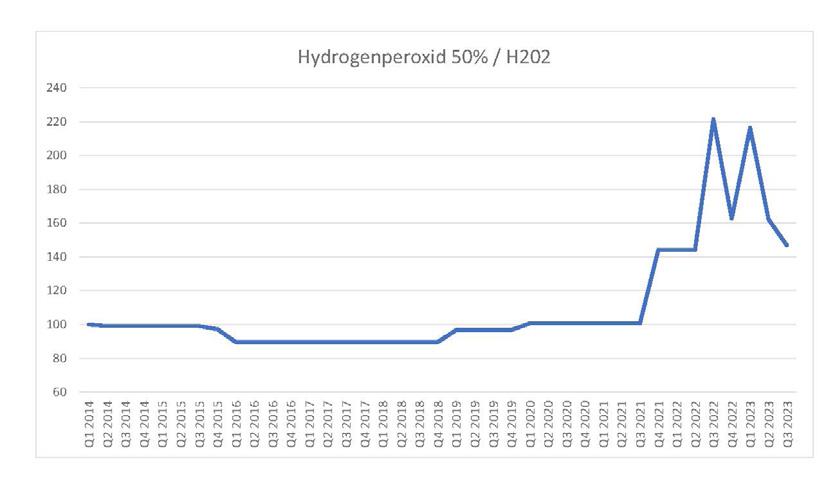

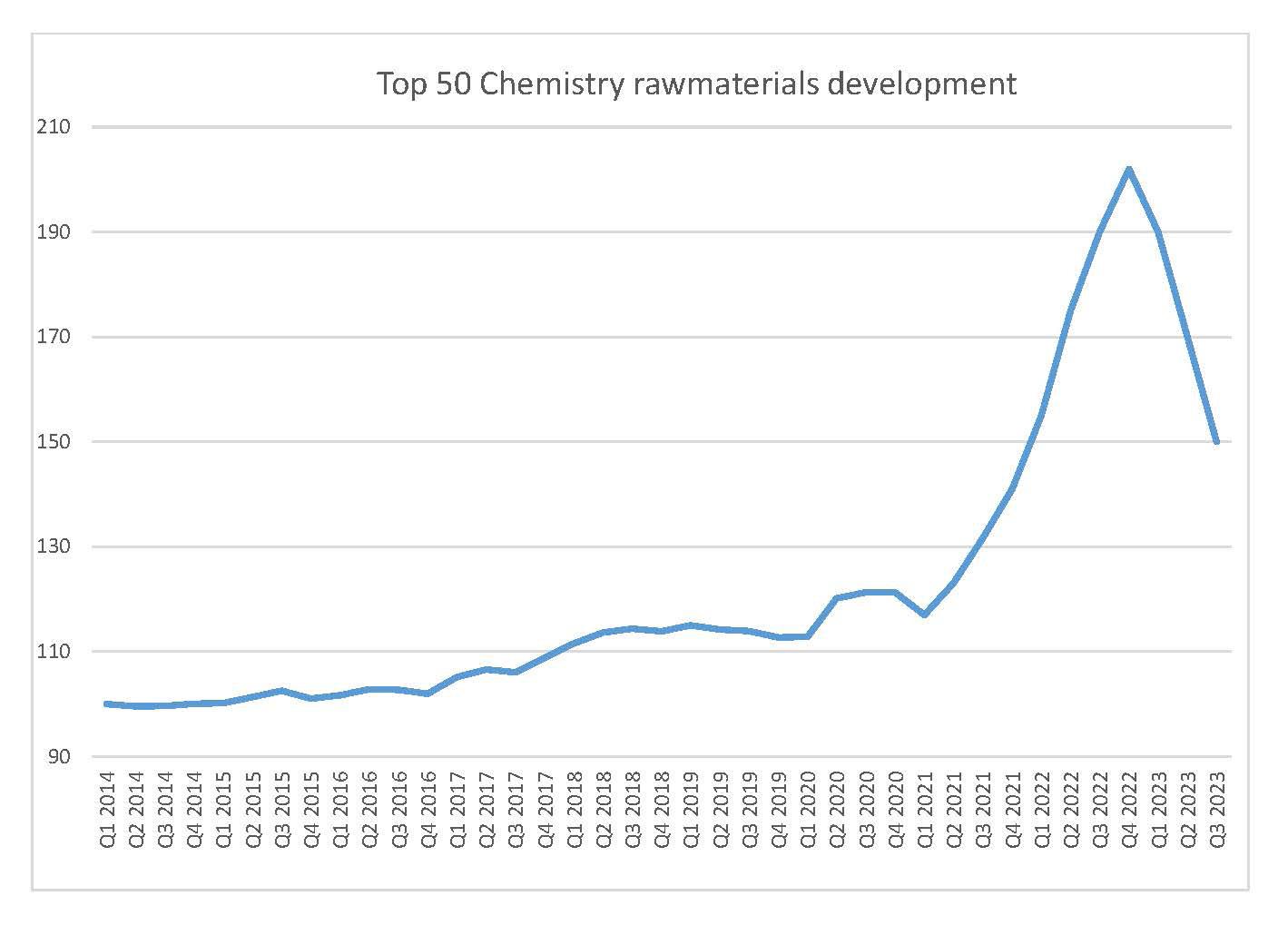

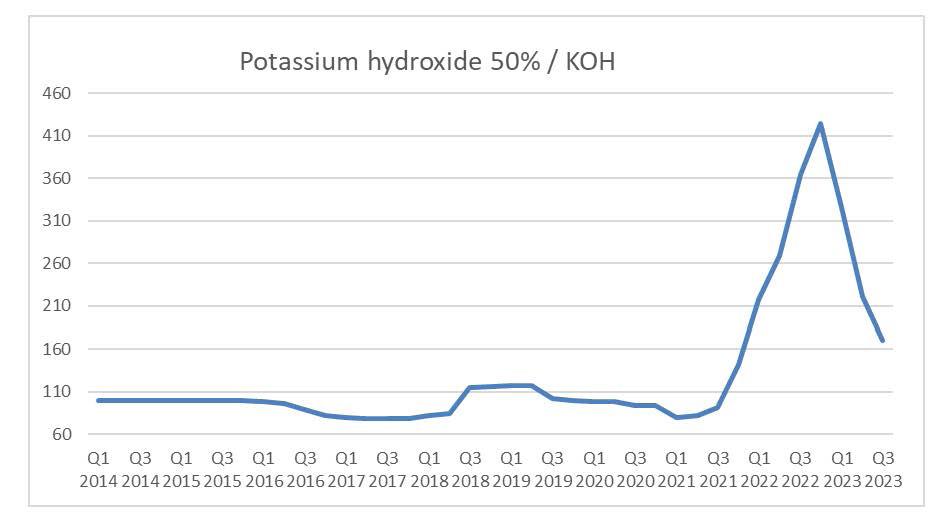

Market Update

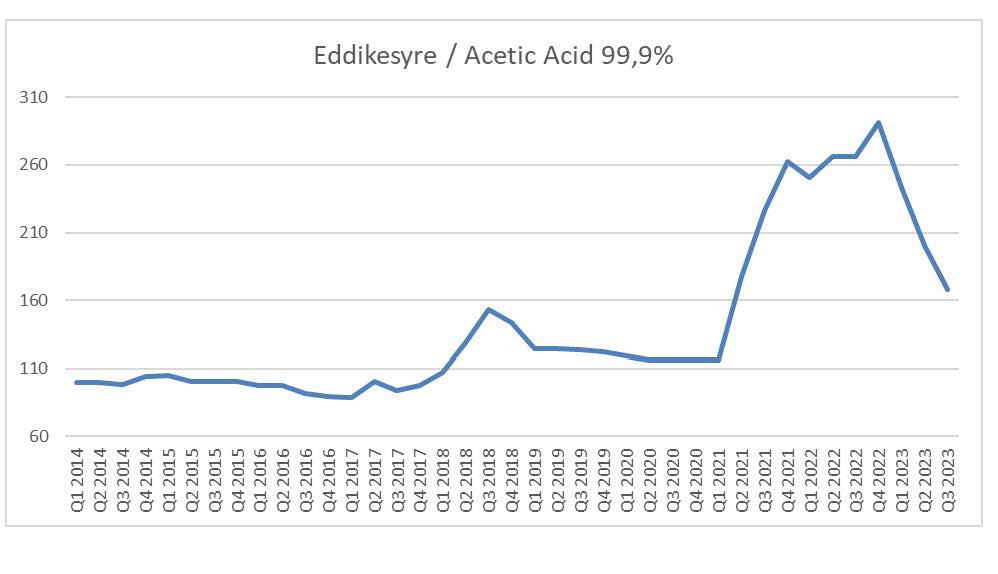

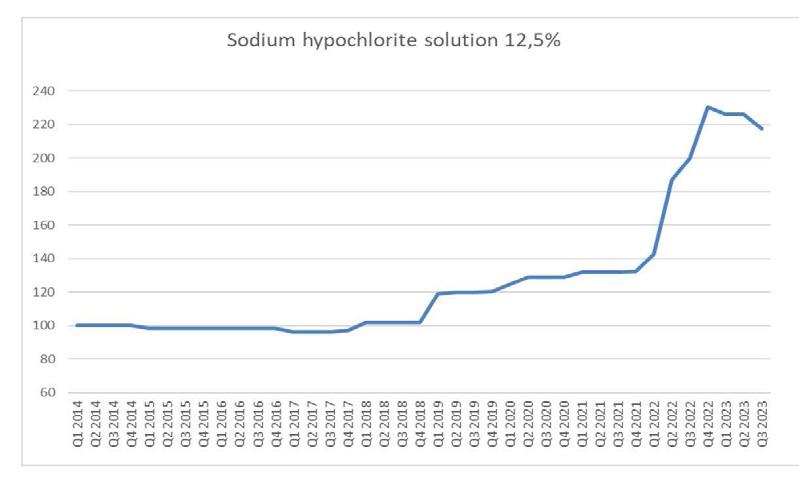

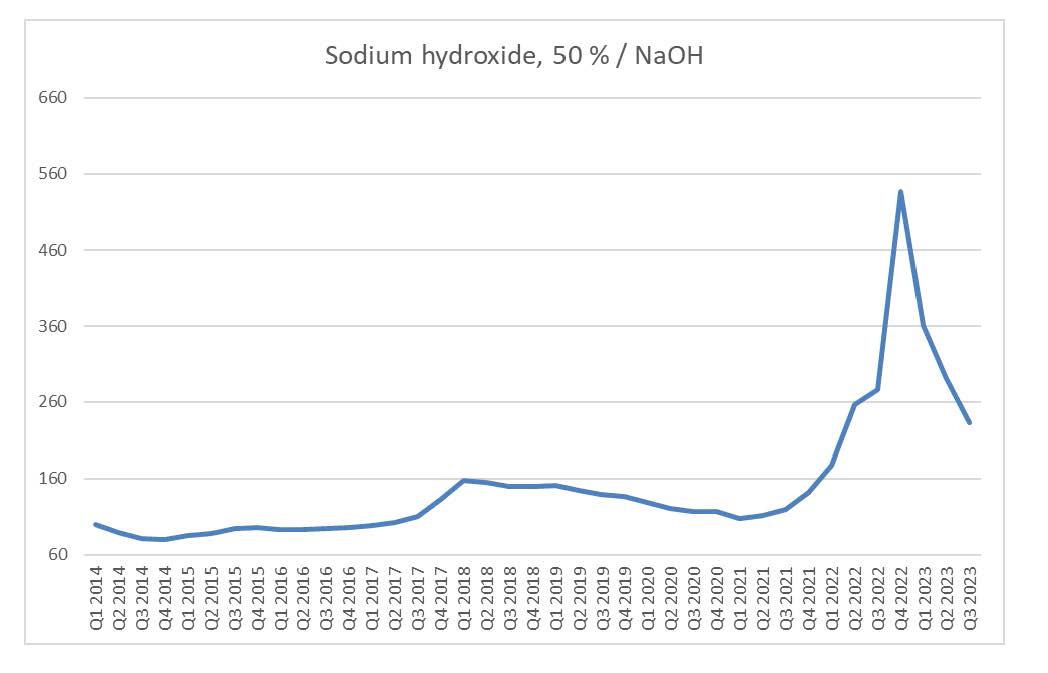

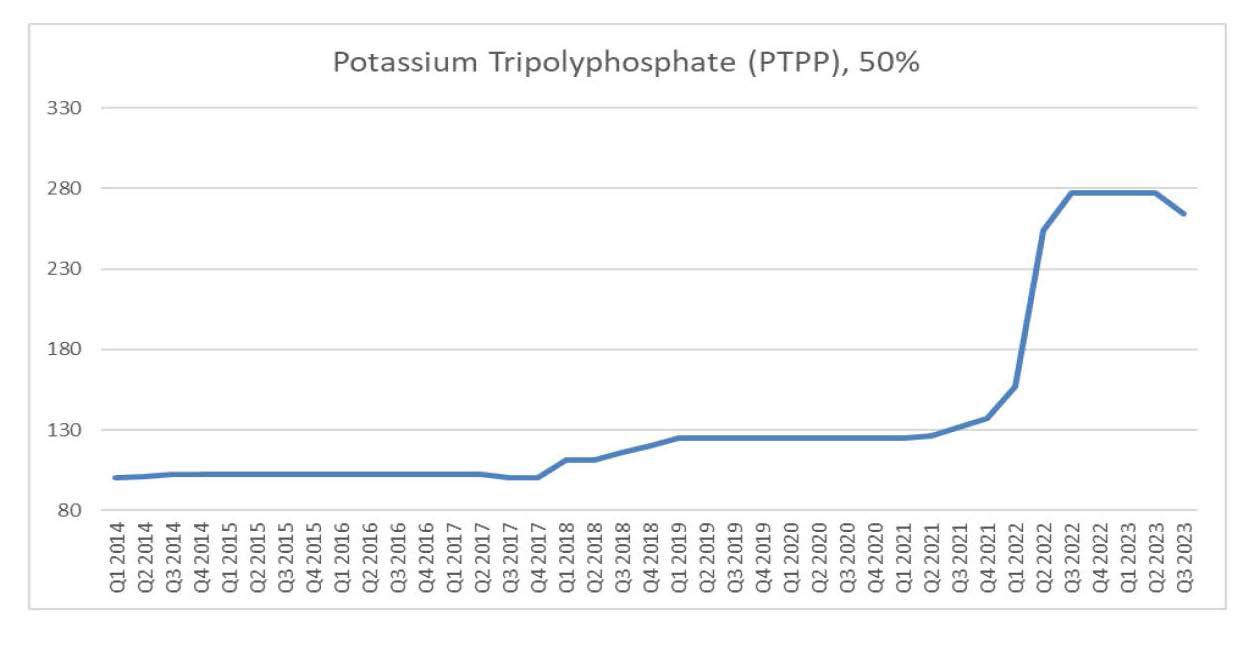

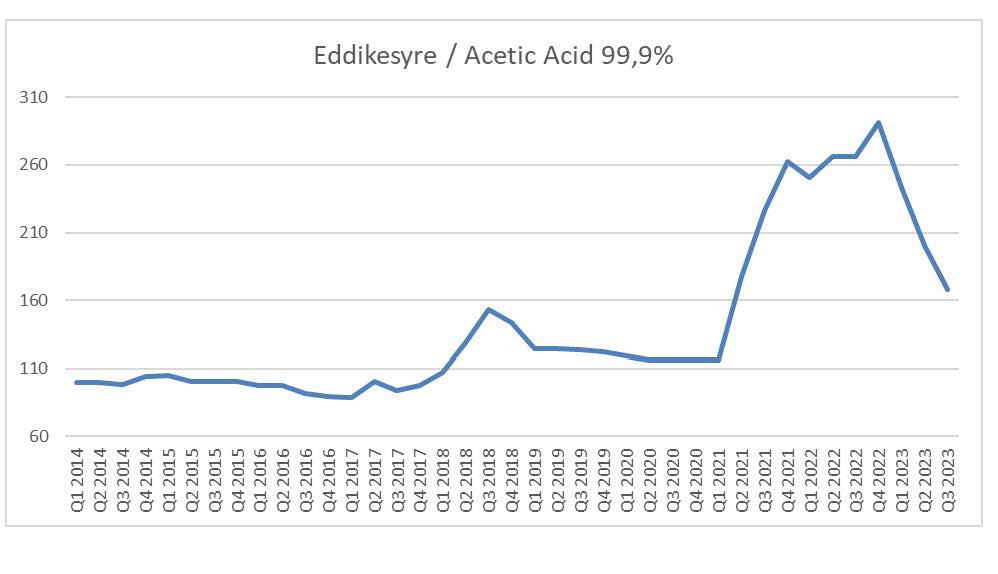

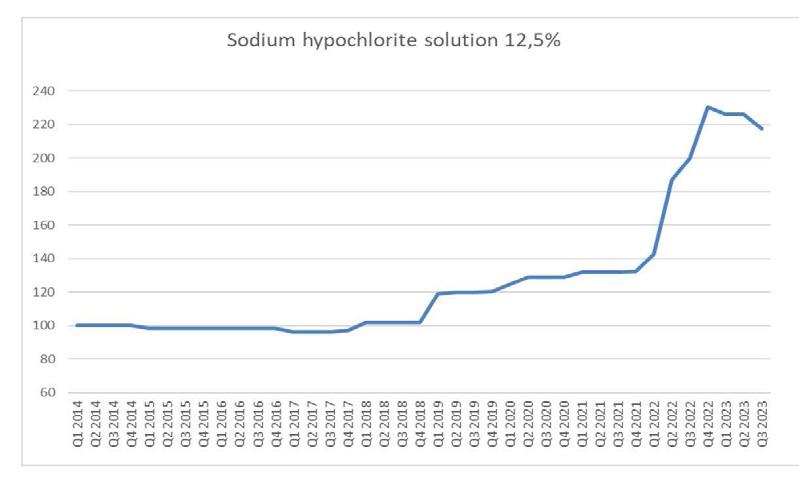

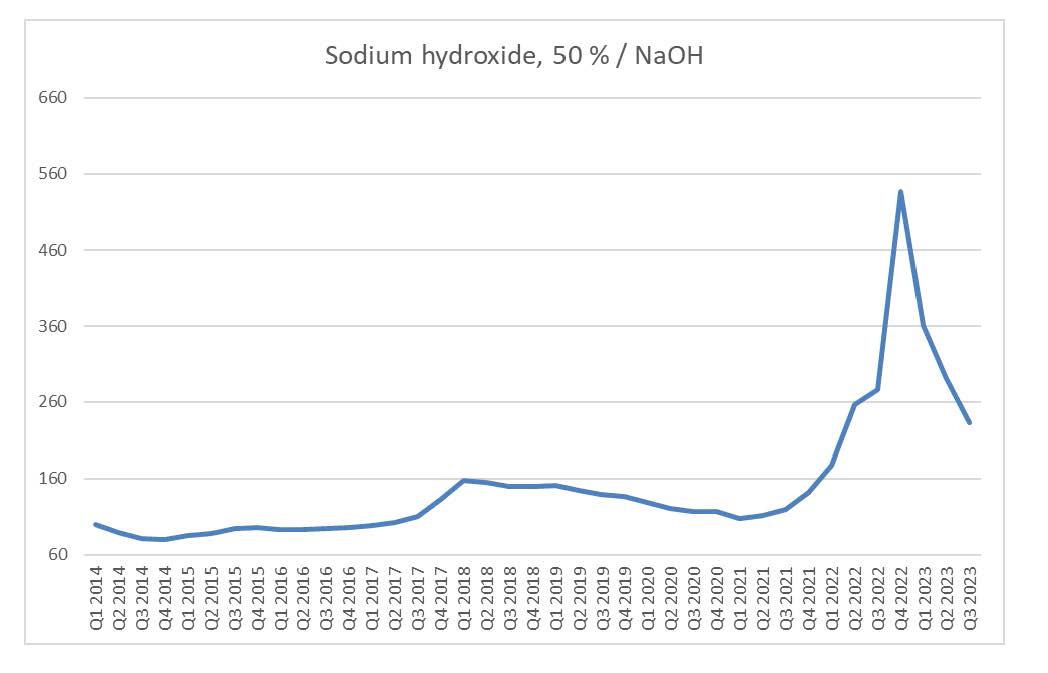

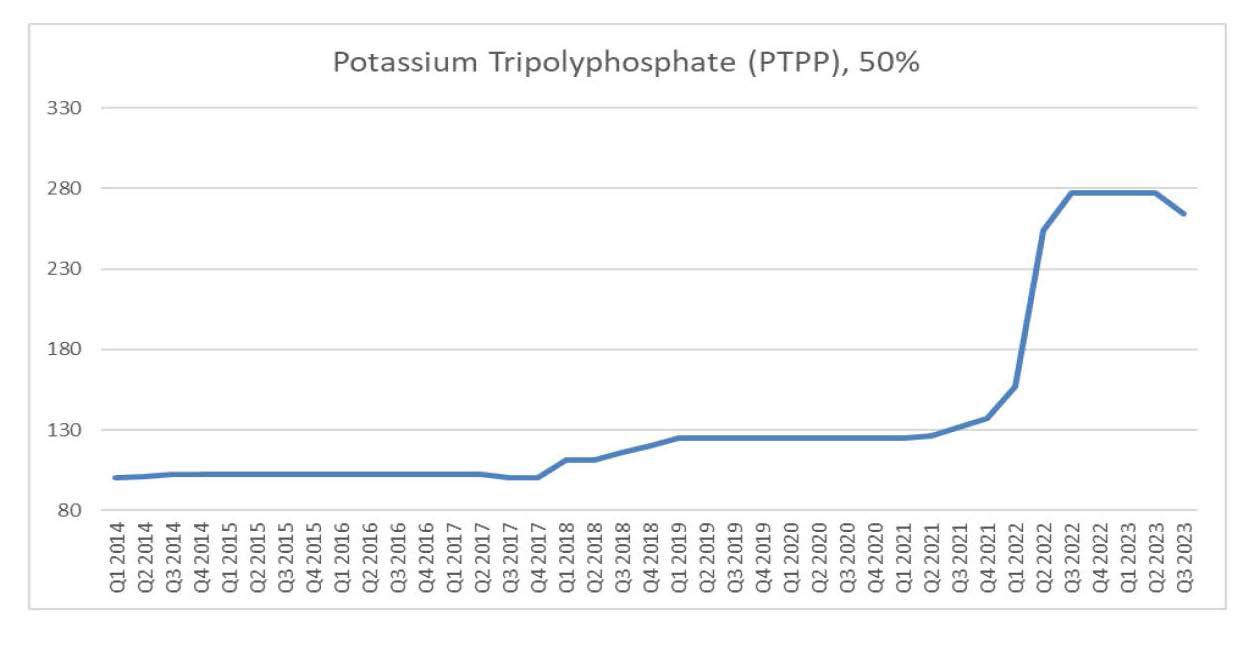

An update of the raw material situation and expectations for Q4, 2023.

Already now, the summer is behind us and we are approaching autumn and the last quarter of the year.

During the past two quarters, it is our feeling that the markets have stabilized regarding delivery performance on raw materials. In generel we experience more or less normal delivery times from our suppliers which - of course - is positive and a sign that the markets are normalizing.

The inflation has been fallling in Europe in 2023, however it is still higher than previous years (>3%6%).

This is supported by increased costs in the market (energy contracts agreed in 2022 at higher prices, increased fixed operating and labor costs and higher manufacturing costs in general). It is our expectations

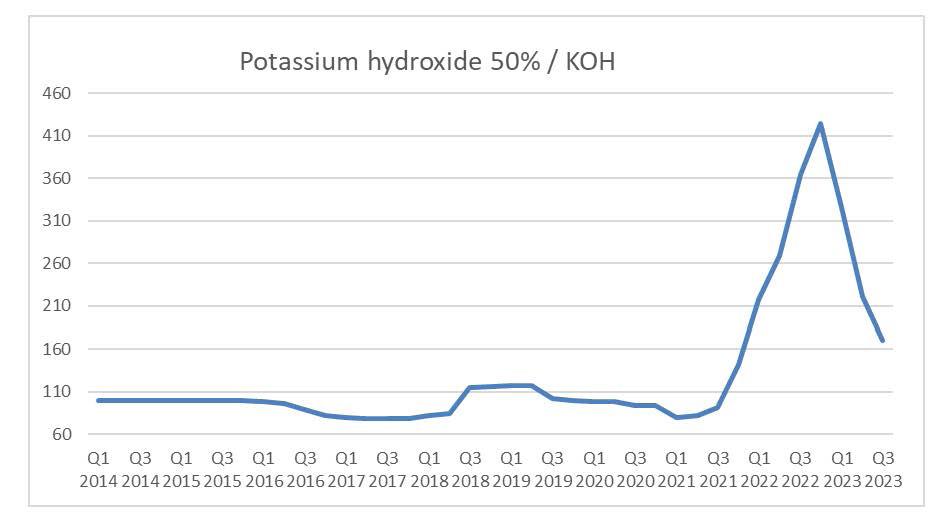

that raw material prices will stabilize the last quarter of the year. The unknown factor is still if we will se increased energy prices in Q4 (2023) and Q1 (2024) due to the winter. Alkaline raw materials have continued to fall during the summer. The current level is however still above previous times’ raw material prices and we will start to see a stabilized price level during the end of Q3. In generel, most raw material prices show a downward trend and is no longer subject to energy surcharges from manufacturers.

Taught by experience it is very difficult to predict the future and what to expect. At Novadan we follow the raw material markets and their development closely in order to react on the market conditions while also ensure the necessary raw materials needed for our products and customers.

How does it look right now - and for Q4, 2023?

• We see signs that the hydrochloric acid deliveries are stabilizing in the market.

• Phosporic acid is back in the market - however at a slightly higher price than before.

• Complex binders (MGDA): Complex binders– both MGDA and EDTA are still challenged on deliveries and price. This is expected to continue in Q4.

• In generel, higher inflation rates than normal (incl. wage increases) in all countries that put pressure on the supply chain.

• The deliveries are more or less normalized - compared to 2022.

• The energy challenge in Europe is more secure than it was 12 months ago. However, we can expect to see increasing energy prices in Q4 due to the coming winter.

• The war in Ukraine is continuously expected to cause uncertainty and nervousness in the markets in generel, and supplies of raw materials can consequently be affected.

by Jens Bramsen Sales Director

Top 50 raw materials (only chemicals)

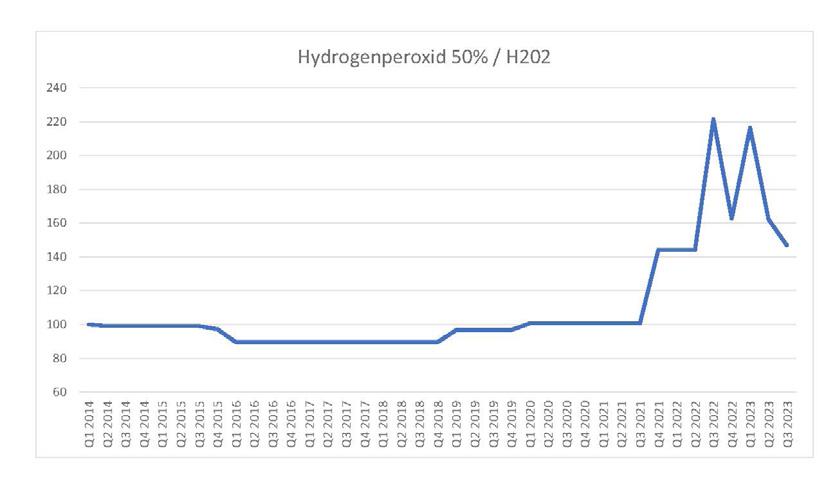

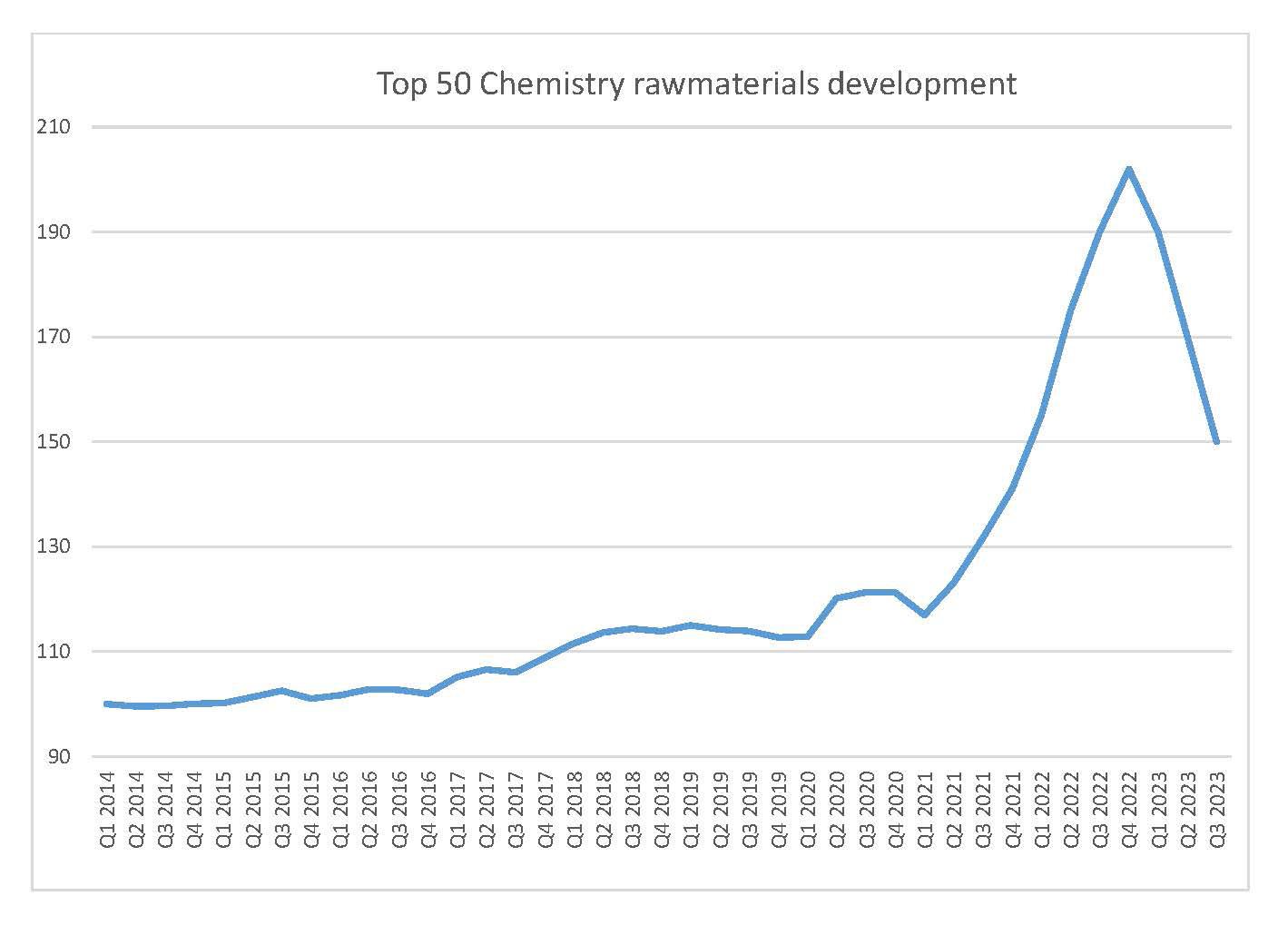

The curve to the right illustrates the development of the 50 largest raw materials in Novadan (only chemicals).

As shown, we have logged the figures since Q1 2014 and until now. The curve shows which turbulence the raw materials have been exposed to in 2022.

Are only chemical products subject to price and deliveries?

No, we face challenges in all areas. It seems as if, though, that several things have stabilized (cans, packaging, pallets etc) compared to last year. But the pressure from increased wages in Europe has - all things being equal- had a an influence on prices compared to before.

by Laila Schou Poulsen

I am 43 years old, originally from Aarhus but have been based in Kolding for the past 16 years. I have a Masters degree in chemistry and an Academy Profession degree in Leadership and Management.

I recently worked at Eurofins Environment –for 6 years as an analytical chemist and for the past 9 years as a laboratory manager with the responsibility for both production, R&D as well as quality within my department.

My spare time is spent with my three boys aged 7, 11 and 13, and on activities such as spinning, running, padel tennis, fitness, gardening, house keeping and training my 10 month old french bulldog, Baloo.

by Allan Hornshøj Sales and CIP Specialist

My name is Allan. I am 37 years old.

I live in Vemmelev with my wife and my two kids.

I have been in the dairy business since I was 15 years old.

I was trained as a dairy man back in 2011. In 2015, I started a new career and have primarily worked with hygiene control in the food industry - both on the Danish market but especially internationally.

In my spare time I spend time with my family and train young boys to play soccer.

I am looking forward to becoming part of Novadan and to join their trip.

Kvalitets- og Udviklingschef

Laila Schou Poulsen

NEW EMPLOYEES

Kvalitets- og Udviklingschef

Allan Hornshøj

Sales- and CIP Specialist

by Ronni Rasmussen Application Specialist Membranes & CIP

Picture 1.

The tests showed that the lower the pH the faster the enzyme inactivates. When pH is below 2 the enzyme deactivates in 5-6 minutes.

by Ronni Rasmussen Application Specialist Membranes & CIP

Picture 1.

The tests showed that the lower the pH the faster the enzyme inactivates. When pH is below 2 the enzyme deactivates in 5-6 minutes.

by Hans Erik Nielsen Market Manager - Agro

by Hans Erik Nielsen Market Manager - Agro