E T I

Journal of the Association for Petroleum and Explosives Administration

THE

VOLUME 1 7 NO 4

B U L

L

N

Registered Office 10, STATION ROAD WITTON BIRMI NGHAM 6. Telephone : 021· 328 0034

Works STATION DRIVE, THORNHILL ROAD, STREETLV, SUTTON COLDFIELD, WEST MIDLANDS B74 3EN. Telephone: 021·3536288 (3 Lines)

DUAL FUEL PETROL- PROPANE MOTOR VEHICLE CONVERSIONS, TANKS & FITTINGS TO B.S. SPECIFICATIONS OR TO CUSTOMERS REQUIREMENTS.

Notes & News

Dipstick Testing

NewS from the H.S.E. Legal Proceedings

The Bulletin

Published by the Association for Petroleum and Explosives Administration

Opinions expressed in this Journal are not necessarily the views of the Association

Talking Point

Song

Branch Reports

Accident Report!

A Safer Way to Carry Hazardous Eggs at 60 mph. 101 107 110

New publications from the B.S.I. Index

As a youngster, in a local cadet force, I was taught that a good soldier should follow his officer through the gates of Hades, if required to do so. When I followed Bob Holdaway into the Editor's chair of 'The Bulletin', I initially thought that I had done just that. The difficulties of producing a professional journal singlehanded, even a quarterly one, seemed at first immense and awesome. Slowly, order prevailed, and production continued, if somewhat shakily at first. Ever helpful in assisting me to find my sea legs (or printers' ink legs, in this case) were Bob, John Frid, Eric Brown, and last

but by no means least, Len and Eddie at our Cambridge printers.

It is a matter of personal regret that, now that production of our journal is running more smoothly than at any time during my turn at the helm, and with so much exciting change promised in the wind of petroleum and explosives legislation, I must regretfully step down, to devote myself more fully to my career. However, I am certain that in Jamie Thompson, our Association has elected as my successor on Honorary Editor of great ability and capacity , and an officer with a great knowledge and keen interest for all things flammable. He also buys hiS round the bar an ability which he will f1nd , f ffice' of great Lse during his term 0 0

As a mere member I will, of course continue to read' ' The Bulletin' with great interest . May I take this opportunity to thank to our journal past and present most Since r ely, hoping that the y will suppo r t Jamie as well as the y ha v e suppo r ted me , and wish ou r Associat i on well for t he f u t. ure Ho n orary Editor : J S Crewe ,

Volume 17 Number 4. April

1979

Contents Talking Point

85 86 89 93 99 Swan

Honorary Secretary: Mr J Frid

113 115

85

New Products

I have recently received information of a product which has been widely used on the continent for a number of years, and is now available in Britain for the first time. The product, "GALUTEC Leak Detection Spray" , will be of interest both to Petroleum Off i cers , and to companies involved in the pressure testing of storage tanks It comes in aerosol cans of 410g nett, and it is said that one can will last for appro x imately 1 , 000 applications. It is sprayed on the area of suspected leakage , and in the event of a leak being present, foam of a very good stability appears to indicate the source.

The active ingredient of GALUTEC is o f a pure aqueous solution; is water soluble; contains no solvents or alcoh6ls of any kind , leav es no depos1ts, and will maintain its full operational efficiency over extended storage periods. I t s p r opellant gas is carbon dioxide GALUTEC is said to be non-inflammable, non-cor r osive , non-tixic, biodegradable, and totally safe to user and equipment .

F u r t h e r information on this new product b e ob t a i ned from : GOTEC Trading Ltd ., ma y • 1 3 , Wa rn e r Road , Ho r nsey. London , N8 7HB , t el e pho n e 01 348 1 1 60

Action on Hazardous Road Spills

The Department of Transport has revised its advice to highway authorities on the assistance available and action to be taken should they need to clear up a hazardous sUbstance spilt from a road vehicle.

A new version of the Department's circular draws attention to the current legal requirements relating to the labelling and marking of vehicles and containers Carrying hazardous substances by road, describing the component parts of the panel required by the Hazardous Substances (Labelling of Road Tankers) Regulations 1978.

These, in conjunction with the Hazchem scheme, provide information for the benefit of the emergency services.

Technical information on the characteristics of dangerous substances is obtainable through the Chemical Industries Association's 'Chemsafe' scheme for assistance in freight emergencies. The circular also lists companies able to provide assistance in the transfer of a dangerous substance from a damaged road tanker or able to dispose of hazardous spillages. The arrangements for dealing with a radioactive Spillage are also briefly described.

(from "Motor Transport")

BS 5607 Ex plosives in the Const

r u c tio n Indust r y

If y o u make a mist ak e wh en wor ki n g with e xplo si v es y o u d on' t alwa y s get a sec o nd cha nc e . BS 56 0 7 i s a n e w Briti s h, Standard on th e s af e us e o f e xplo si ve s in the con s truction industry.

It examine s th e practical implication s of wo r king with this invaluabl e , y e t potentially lethal, commodity.

Notes and News

86

This new standard stresses the need for constant vigilance at all levels to prevent bad working habits. Comprehensive recommendations are given for the safe storage, handling, transportation and use of blasting explosives and accessories for tunnelling, shaft sinking, underwater blasting, land clearance and excavation.

An appendix has been included on demolition because this represents one of the main applications for e x plosives in the construction industry .

BS 5607 can be obtained from BSI Sales Department, 101 Pentonville Road, London Nl 9ND, price £5.60

Whisky & Gin Tankers Labelled as Hazardous

Whisky, gin, fire extinguishers, carbon paper and printing ink ar e among items listed as hazards in proposals made recently by the Health and Safety Commission for tightenin g c ontrol over movement of dangerous goods by road .

The commission wants th e regulations to cover t hings 'carried for private or l e isure purposes," which could apply to holidaymakers carrying bottled gas in caravans.

But there would be a cut-off level so that Carrying normal amounts would be e x empted

The consultative document seeks "a framework of controls" wh1ch would considerably e t d . . 1 O x en eX1st1ng ru es ne of the most important suggest10ns is for a wide ext enS10n of requ1rements for labelling of h · ve 1cles to tell emergency services h t o w 0 tackle a lo ad 1n case of a n a d CC 1 ent.

Ne w r oad tanke r lab 11 · e 1ng r e gula t ions we r e due to come i nto fo rc e on Ma rc h 2 8 but th e c ornm1ssi o n sa y s t h ' ese do not far e n o ugh and f a il t o cov g o e r man y th i n g s .

The co mm i ssi on s eek s two s tan da rd s Regulation s wou l d apply to b u lk t . ran s port general l y, b ut n ot t o wha t it terms " high s treet de l i v e ry situation s ."

Thus , labelli n g wo uld b e nec essa ry in the case o f r oad or rai l t a nk e rs mo v ing Scotc h whisk y fro m t he hi g h lands Bu t

a lorry loaded with large quantities of whisky in bottles and cases for shops would not be brought under the regulations.

Proposals are made about the kind of fire-fighting, first-aid and protective equipment to be carried on different types of vehicles: the loading, unloadUg and parking of vehicles: training of drivers and the types of container to be used.

("Proposals for Dangerous Substances Conveyance by Road Regulations," Health and Safety Commission, HMS 0 £2.)

From "The Daily Telegraph" March 6th 1979.

SCIENTISTS ' DISCOVER' THE CAUSE OF £6m CHEMICAL BLAST

An explosion which injured 13 people and caused £6 million of damage has led Government Scientists to a discovery which has been known to inorganic chemists for some time, that pure sodium chlorate can e x pl o de b y itself.

Mo re than 17 , 000 drums of sodium c hlorat e , a chemical used in the manufacture o f many products, from matches to weedkillers, exploded on January 4, 1977 , in a warehouse owned by James Kelman Transport and Storage, at Renfrew, Scotland.

This company " could not have for seen the disastrous e x plosive potential of the material in the light of e x isting know l e dge , " said a report published recently by the Health and Safety Executive

No legal action would be taken against them.

But inorganic c hemists said that the e x plosi v e potential of pu r e sodium chlora t e had long been "i n the light of e x isting k no wled g e ."

When h ea ted i t de c omposes in to o xyg e n and s o d iu m c h l o r id e ( ta bl e s a lt ). The c hemi ca l r eaction bet we e n the two s u bs tance s can pr odu ce a vio l e n t exp l o s ion

The fi r e which caused the e x pl o sion was s t a r ted b y th r ee bo y s bu rni n g c a r dbo ar d c a rt o n s ou t sid e the warehous e. No a ct i on h ad b ee n t a ken a g ainst t hem.

87

The £ire spread to the building and minutes later a series of explosions ripped the warehouse apart, wrecked a nearby whisky store, and flung debris up to five miles away. Because it was a Bank Holiday, few people were working in the area, and no one was seriously hurt.

The supposed secret of the sodium chlorate was found by Health and Safety Executive scientists during a series of tests at their centre at Buxton, Derbyshire. The truth dawned on them, helped by the discovery that there have been six explosions of pure sodium chlorate or potassium chlorate since 1899.

Mr Phil Nones, an inspector at the Explosives Inspectorate of the Health and Safety Commission in London told a Press conference in Glasgow that the had a blast equivalent to a VI wartime bomb or between 500lb and 1,8001b of T.N.T.

He said it had been necessary to inform the United Nations, the international shipping industry organisation (I .M.C.O.), the airlines authority (I.A.T.A.) and the international authority responsible for the carriage of dangerous goods by road (A.D.R.), which covers the transit of materials in container trucks between European centres and Britain.

Some of the revised regulations are still in draft form, ready to be presented to Parliament to become law. Mr Nones said sodium chlorate would have to take a different position in the league of dangerous materials but it was wrong to describe the chemical as an explosive.

"When you are talking about sodium chlorate causing an explosion you are talking about very substantial quantities being exposed to a very intense fire," he said. A very substantial quantity was anything over one ton.

He said that in future the Health and Safety Executive would want to know exactly how sodium chlorate was being stored but at the moment there was no statutory obligation for anyone possessing sodium chlorate to give this information.

The Health and Safety"Executive recommended that: Sodium chlorate should now be re-classified by national and international authorities; Large-scale storage of the chemical should be regarded as a potential major hazard;

Bulk storage should be kept away from where-it could be exposed to intense heat. Experiments were urged with sodium chlorate and similar materials under intense conditions which develop in fires.

"The Fire and Explosion at Braehead Container Depot, Renfrew" Health and Safety Executive. HMSO £1.75.

(From "The Daily Telegraph", March 14th

REDUCTION IN THE PERMITTED LEAD CONTENT OF PETROL

William Rodgers, Secretary of State for Transport, recently laid before Parliament Regulations* concerning lead in petrol.

The new Regulations amend the Motor Fuel (Lead Content of Petrol) Regulations 1976 which prescribe the maximum permissible lead content of petrol (in grammes per litre) and require petrol pumps in retail garages to be marked with star markings which are specified in the British Standard for petrol for motor vehicles. The star markings indicate the octane rating of petrol (which is influenced by the lead level) and, by reference to the British Standard, the maximum lead content. The amendments prOvide that._ I" the maximum level of lead in petrol will be reduced from 0.45 to 0.40 grammes per litre from 1 January 1981, 2. the test method for load Will b that in BS 5657: 1978 ISO 383 .e 1977 in place of BS 2878: and , 3. the Regulations refer to the revised version of the Brit. "f" t" 1sh Standard spec1 1ca 10n for p etrol for motor vehicles (BS 4040).

The lower lead level will be in accordance with EEC CounCil Direct" 78/611/EEC, and its imposition fulfil the Government's commitment d "" not to allow total lea em1SS10ns in th" d t " 1.s country to exceed, ue 0 1ncrease " h d . 1.n traffic, the level reac e 1n 1971.

*The Motor Fuel (Lead Content of PetrOl) (Amendment) Regulations 1979 SI 1979/1 HMSO lOp"

88 s

IP STICK TESTING

By J.R. Kelsall, Warwickshire County Council

The Department of Prices and Consumer Protection recently issued a further draft of the Regulations relating to measuring equipment for liquid fuel carried by road tankers. The two types of equipment to be prescribed by the proposed regulations are dipstick and meter measuring systems.

The proposed Regulations lay down concisely the form and construction of dipstick measuring systems. The interpretation of the requirements should not pose any great problems. The purpose of this article is to deal with the various methods of test F Or) I '-[1, 1vC'

Reproduced from "The Monthly Review", journal of the Institute of Trading Standards Administration.

available to local authorities. Warwickshire County Council T,rading Standards Department have for several years, been testing dipsticks used on liquid fuel tankers and also tankers used for transporting wines, spirits and fertilisers. The types of tankers tested have varied from large single tanks on vehicles to tanks divided into as many as seven compartments. From this experience a considerable amount of expertise has been developed.

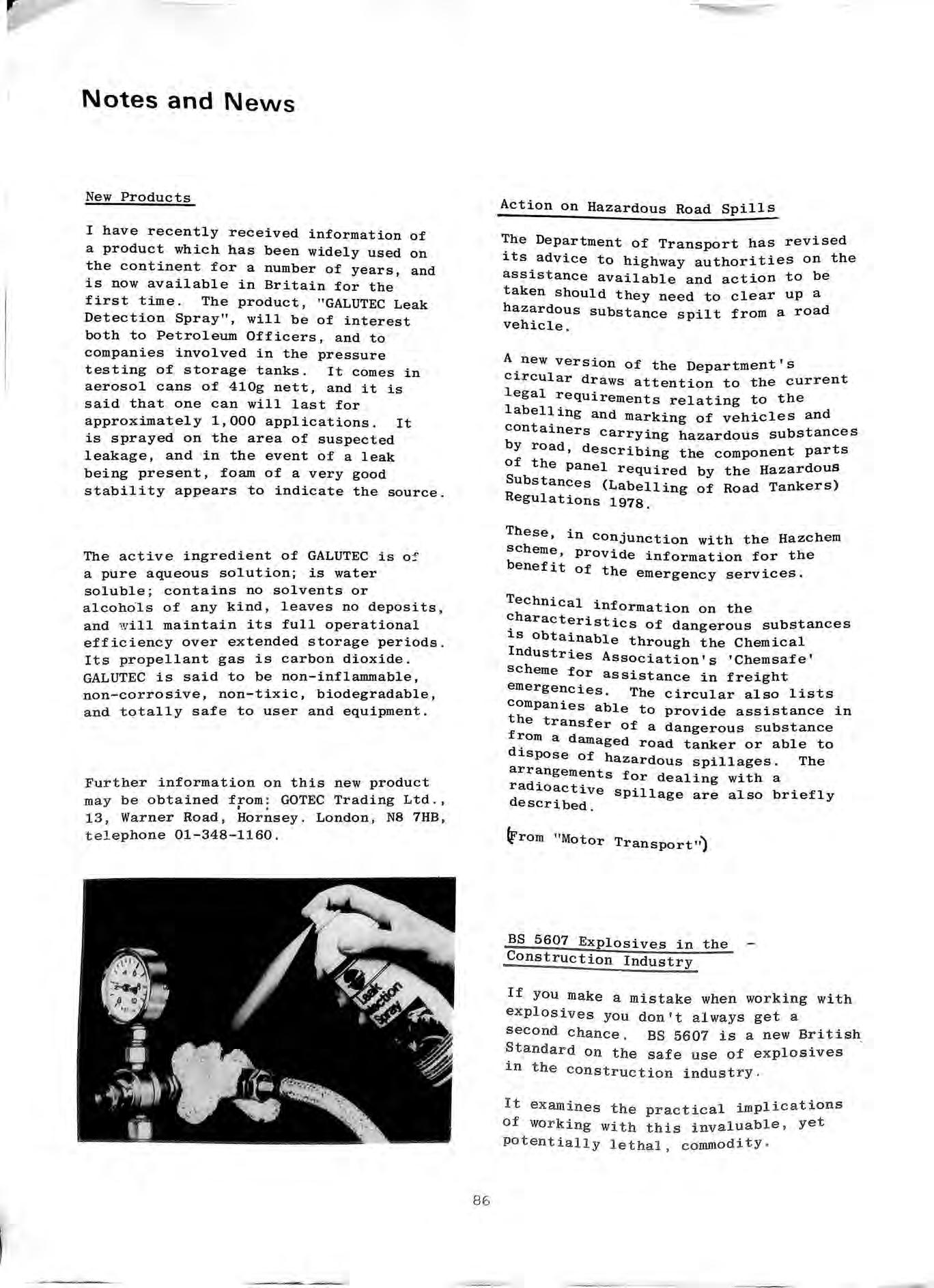

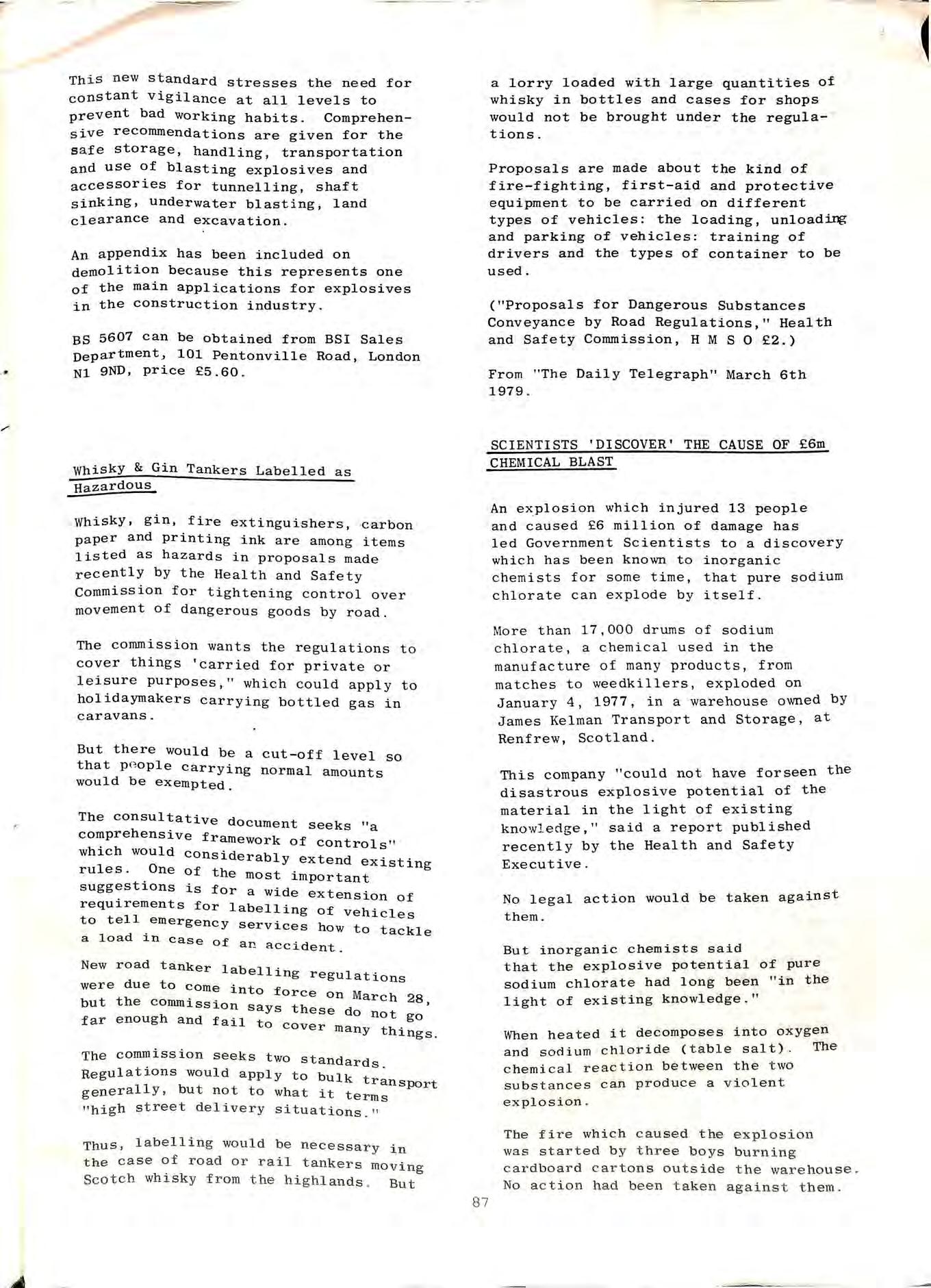

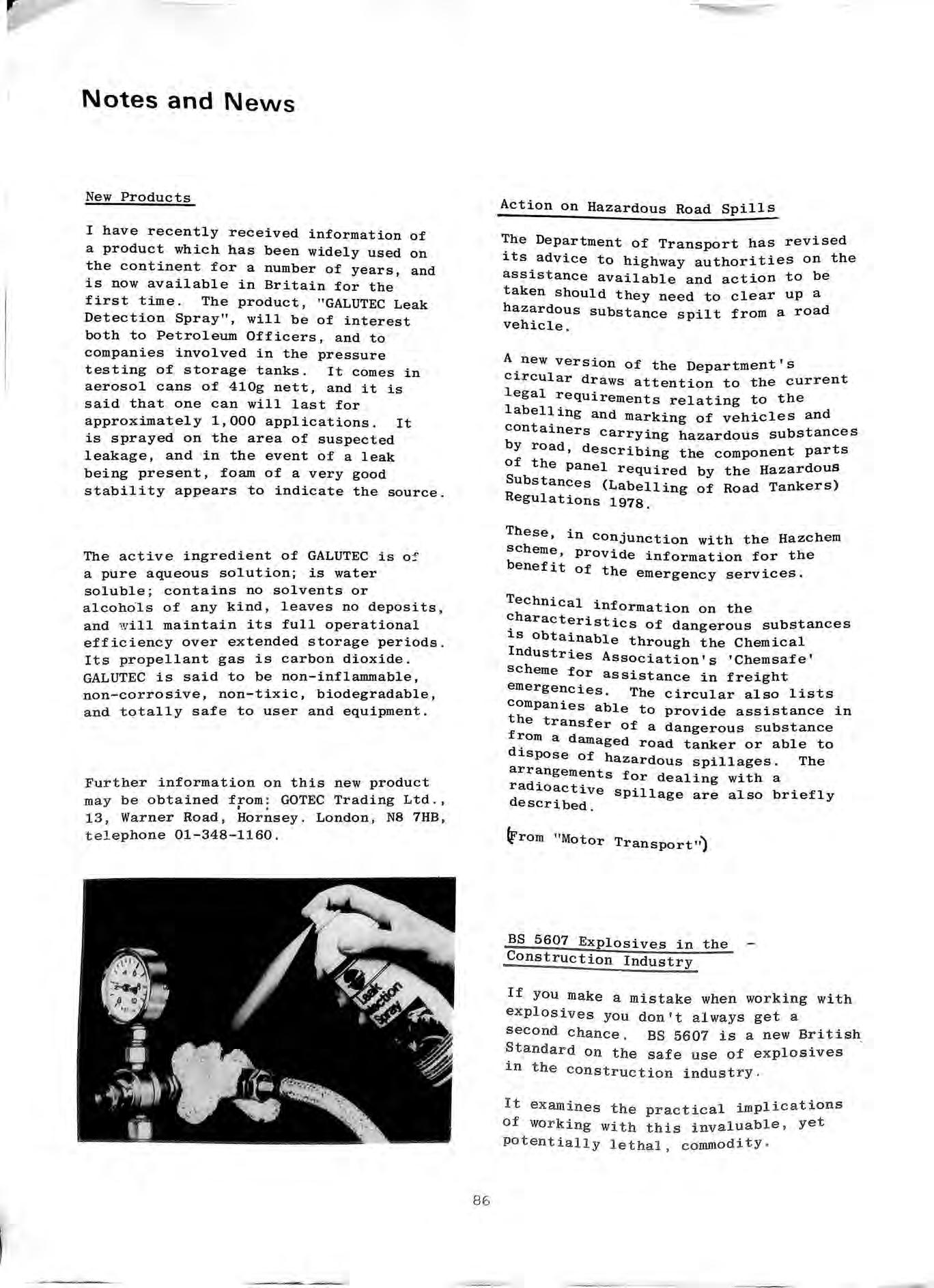

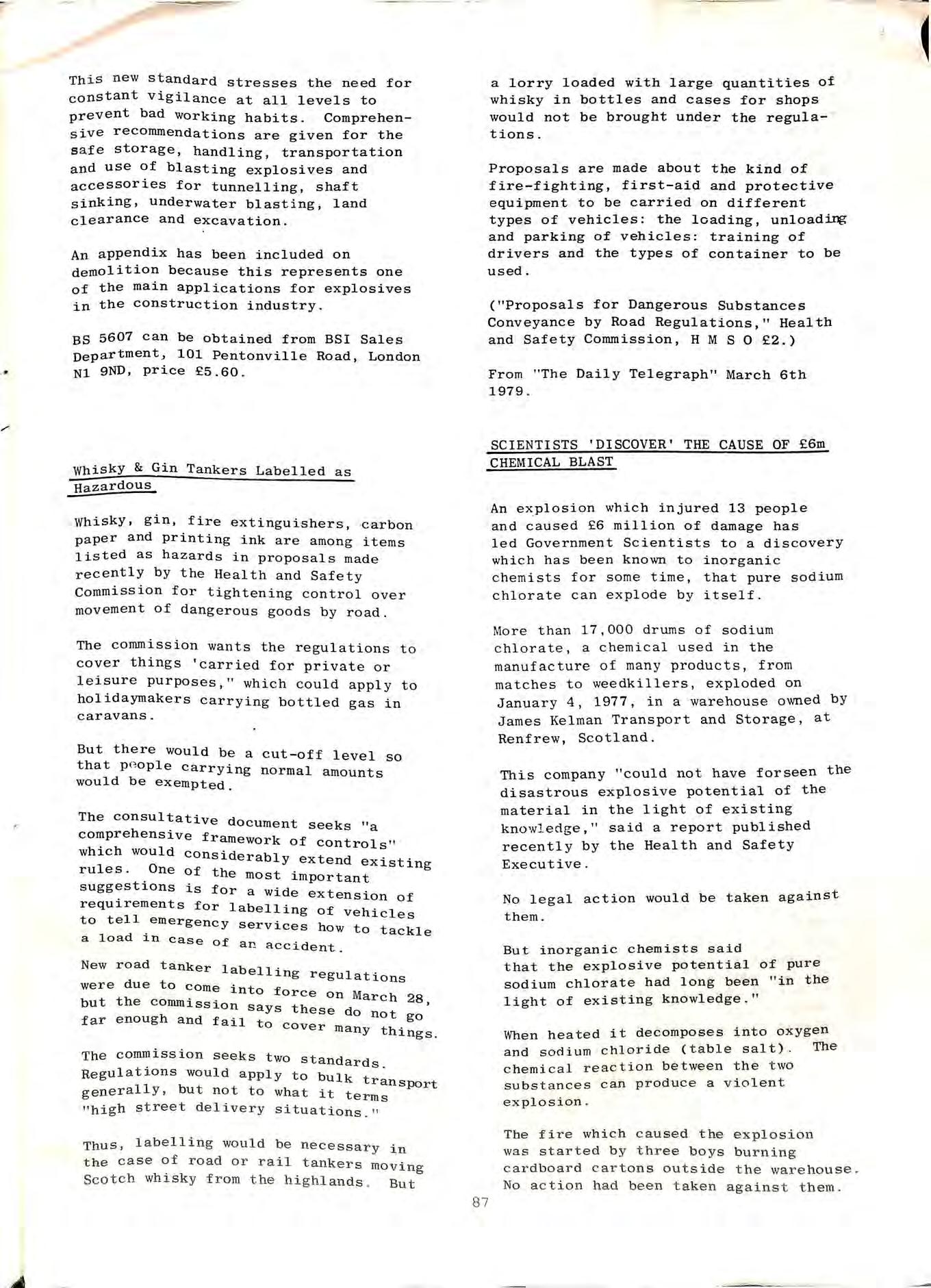

The method of test is to deliver into the tank a measured amount of liquid equivalent to the quantity shown for ]) i 1' :; 1 i t' J, t t 1I r.l 01'<, ]';)1 i 11 !; ----40. II " Il d 1( '

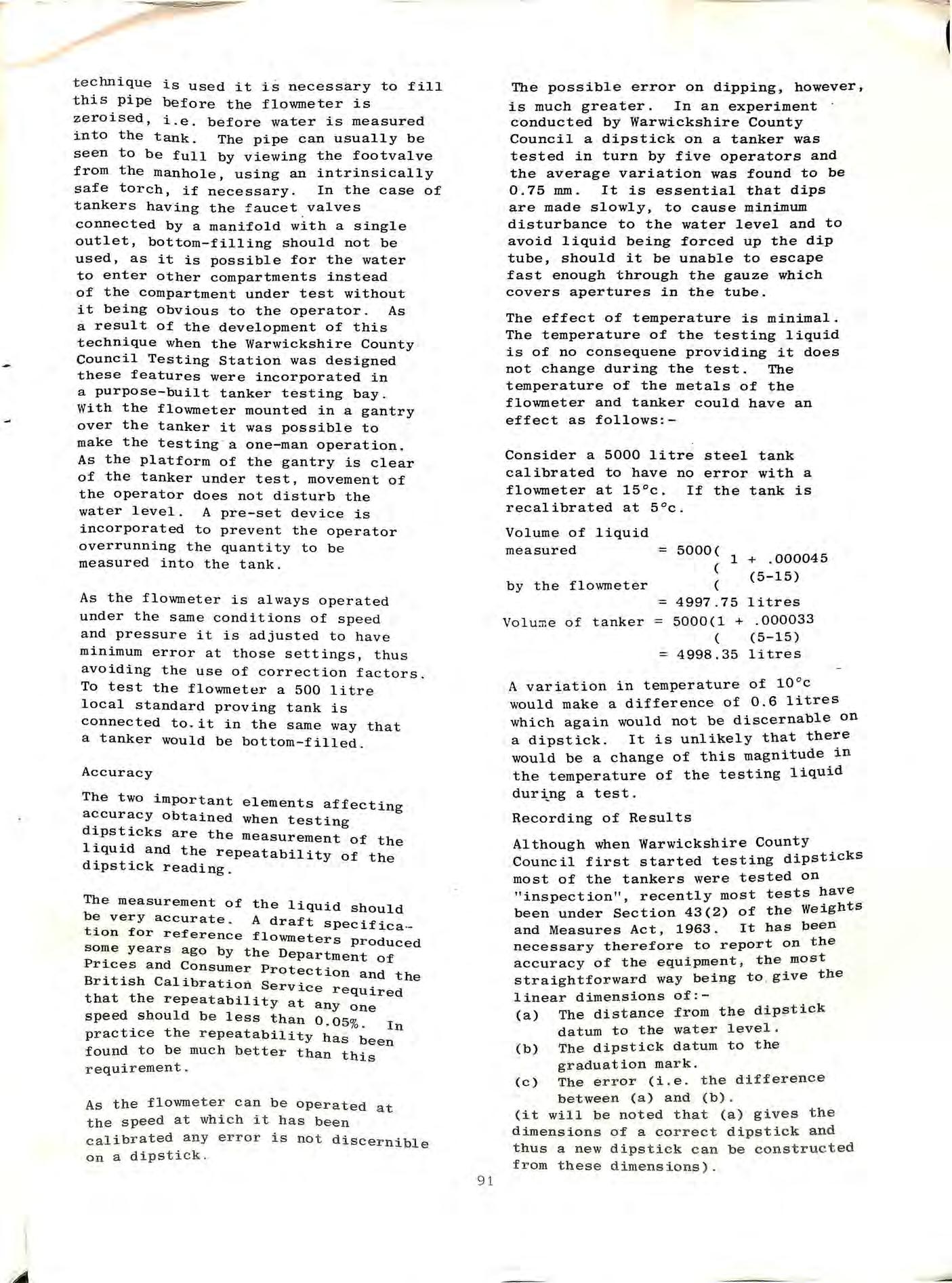

}--- Gauze Bulkhead -tr-- Dip tube Fo o t. valve Fi gure 1. 8 9

each mark on the dipstick under test and then to use the dipstick in the normal manner to compare the liquid level shown on the dipstick with the engraved mark.

The main problem with the test is to measure into the tank the correct amount of liquid. Most manufacturers of dipsticks use proving tanks of the delivery type shown in SWM 267 using water. The difficulty with this method is that the quantity which can be delivered is limited to the size of the proving tank although the incremental quantities usually vary on the same dipstick. Thus a number of proving tanks of different sizes would be required to cover the different increments encountered. In addition proving tanks are liable to operator error in that the water supply may be stopped before the tank is full or the outlet valve closed before the tank is empty. Once this type of error has been introduced it is present for the rest of the test.

Warwickshire County Council has always advocated the use of flowmeters for the measurement of the testing liquid for the following reasons:-

1. The flowmeter can be used to measure any required quantity of liquid.

2. If the meter is used cumulatively any error in reading at one point is corrected on the next measurement.

3. The flowmeter is easily transportable and can be used to conduct tests in any situation where testing liquid is available.

Initially tests were made at local petroleum depots by connecting a reference flowmeter to the loading arms used for loading tanker vehicles. A hose was connected to the loading arm and then to the meter which remained in the trailer in which it was transported. A hose was then taken from the outlet of the meter into the top of the tank to be tested, the hose being fitted with a valve to prevent it draining when the control valve on the meter was closed. The meter was controlled by an operator on the ground and a second man on the tanker made in the normal manner when the liquid level had settled. The meter readings for the quantities required, has to be calculated for the speed, pressure and type of testing liquid, usually kerosene.

As time went on it was apparent that this method of test was becoming unpopular to the management of depots as a loading gantry could be occupied for a day, restricting the loading of other tanker vehicles. From a safety point of view, the speed at which the liquid was being ejected from the pipe into the tank was above that recommended to avoid a static build-up even though the vehicle and piplines were electrically bonded to earth. To reduce the speed would have required a pipe of such a diameter that it would have been difficult to handle. To overcome these problems the testing medium was changed to water which was readily available from fire hydrants in quiet corners of depots.

The question raised in using water was whether the mark made on the dipstick was at the same level as the mark made by an equal quantity of a hydrocarbon liquid. To verify this an experiment was conducted using and kerosene set at exactly the same levels by means of probes. It was found that a dip made into the water with a dipstick smeared with water finding paste coincided with a dip made into kerosene with a clean, dry dipstick. Without water finding paste however the dip was inch below this mark due to the different menisci and surface tensions of the liquids.

One problem which arose when using loading arms at fuel depots was that of clearing the pipe lines of the testing medium when the test was complete.

Lines were usually emptied into suitable receptacles but there was inevitably, considerable spillage. With water the lines could be emptied into storm drains, the slightly contaminated water eventually though a petrol interceptor at the site.

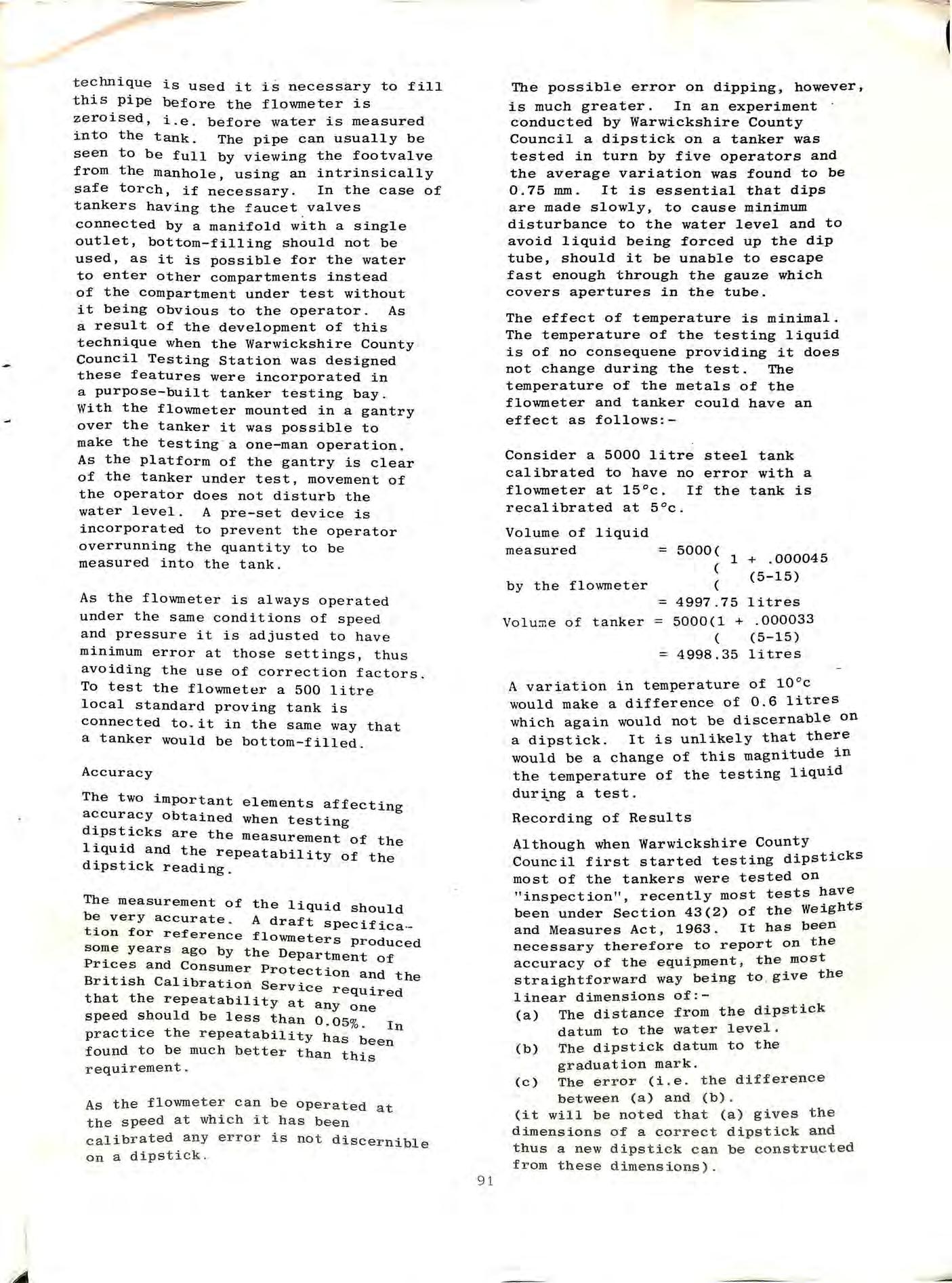

The next development was to fill the tanks with water from the bottom, i.e. through what is normally the outlet pipe. This had the advantage that it avoided the manhandling of hoses on to the top of the tanker and also that after the first few litres the water level rose steadily, thus saving a considerable amount of time waiting for the surface to settle before taking a dipstick reading. Figure 1 shows a diagrammatic arrangement of a typical tanker. In the majority of tankers the capacity of the pipe between the faucet valve and the foot valve is not included in the capacity of the tank compartment. This means that when the "bottom filling"

90

technique is used it is necessary to fill this pipe before the flowmeter is zeroised, i.e. before water is measured into the tank. The pipe can usually be seen to be full by viewing the footvalve from the manhole, using an intrinsically safe torch, if necessary. In the case of tankers having the faucet valves connected by a manifold with a single outlet, bottom-filling should not be used, as it is possible for the water to enter other compartments instead of the compartment under test without it being obvious to the operator. As a result of the development of this technique when the Warwickshire County Council Testing Station was designed these features were incorporated in a purpose-built tanker testing bay. With the flowmeter mounted in a gantry over the tanker it was possible to make the testing a one-man operation. As the platform of the gantry is clear of the tanker under test, movement of the operator does not disturb the water level. A pre-set device is incorporated to prevent the operator overrunning the quantity to be measured into the tank.

As the flowmeter is always operated under the same conditions of speed and pressure it is adjusted to have minimum error at those settings, thus avoiding the use of correction factors. To test the flowmeter a 500 litre local standard proving tank is connected to.it in the same way that a tanker would be bottom-filled

Accuracy

The two important elements affecting accuracy obtained when testing are the measurement of the and the repeatability of the dlPStlCk reading

The measurement of the liquid should be very accurate. A draft '. t · f speclflca 10n or reference flo t wme ers p r oduced some years ago b y the D t epa r ment of P r lces and Consume r P r ot t · ' ec 10n and t he Br l t lsh Callbr a t io n Ser v ' lce reqUl r ed that t he r epea t ability at an Y one speed sho u ld be less than 0 0 5 t %. In prac tlce h e r e p eat a bil i ty h as b ee n foun d to be muc h be t t e r t h a n th is require me nt .

As the flowmeter can be operated at the speed at which it has been calibrated any error is not discernible on a dipstick

The possible error on dipping, however, is much greater. In an experiment conducted by Warwickshire County Council a dipstick on a tanker was tested in turn by five operators and the average variation was found to be 0 75 mm. It is essential that dips are made slowly, to cause minimum disturbance to the water level and to avoid liquid being forced up the dip tube, should it be unable to escape fast enough through the gauze which covers apertures in the tube

The effect of temperature is minimal. The temperature of the testing liquid is of no consequene providing it does not change during the test. The temperature of the metals of the flowmeter and tanker could have an effect as follows:-

Consider a 5000 litre steel tank calibrated to have no error with a flowmeter at 15°c. If the tank is recalibrated at 5°c.

Volume of liquid measured by the flowmeter

5000( ( (

1 + .000045 (5-15) = 4997.75 litres of tanker = 5000(1 + .000033 ( (5-15) = 4998.35 litres

A variation in temperature of 10 ° c would make a difference of 0 . 6 litres which again would not be discernable on a dipstick. It is unlikely that there would be a change of this magnitude in the temperature of the testing liquid a test

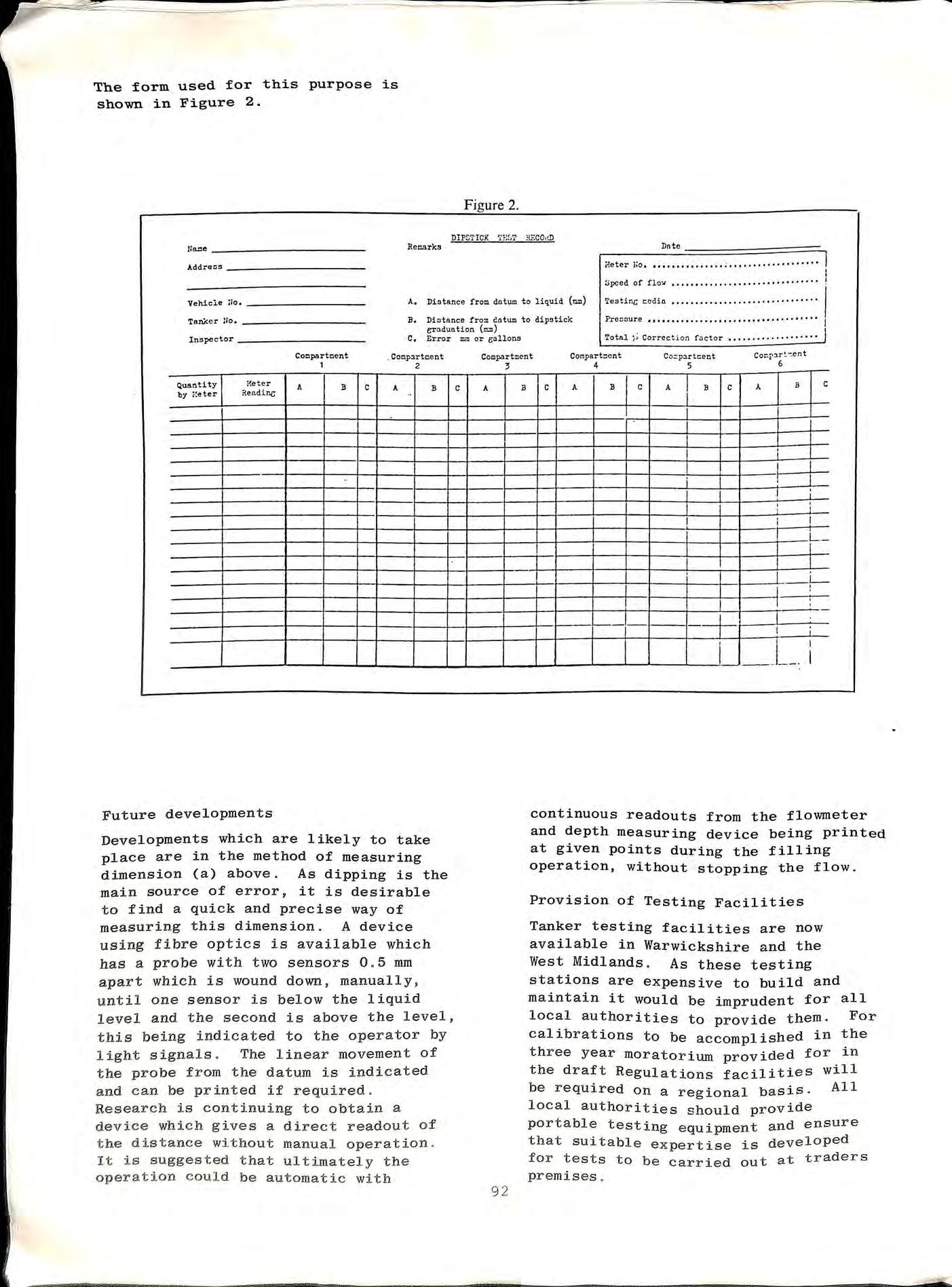

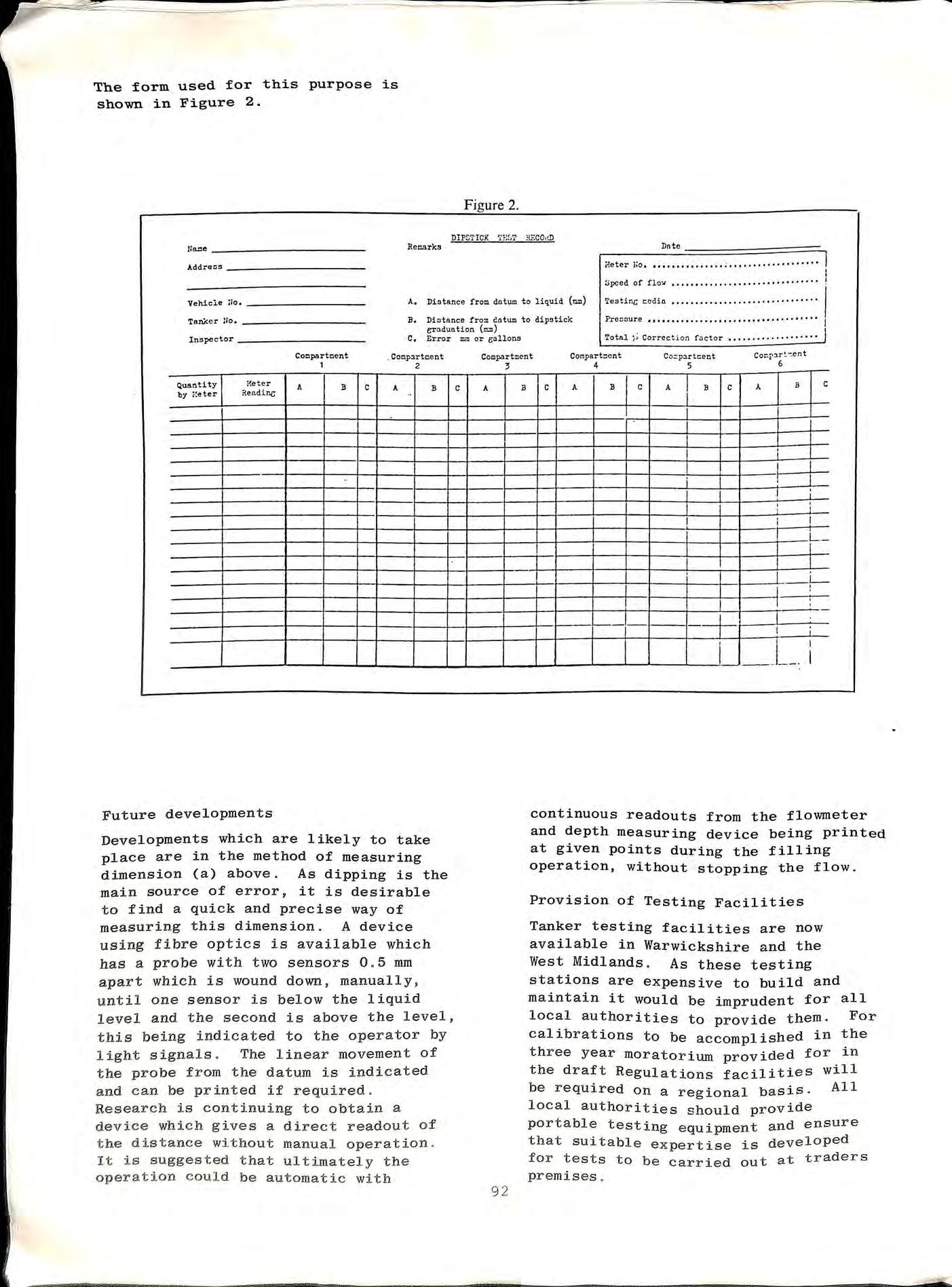

Recording of Results

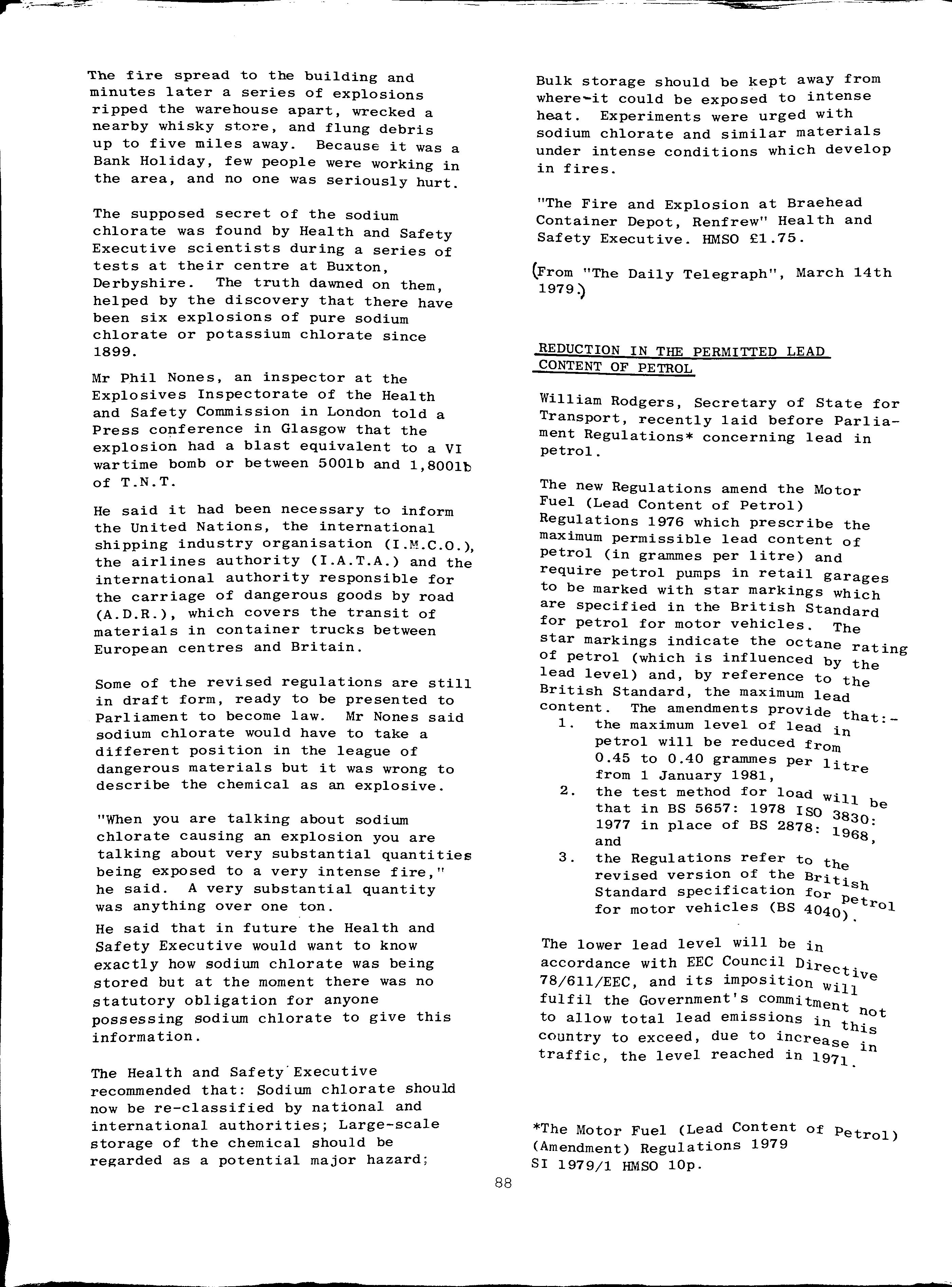

Although when Warwickshire County Council fi r st started testing dipstickS most of the tankers were tested on "inspection" , r ecently most tests have been under Section 43(2) of the Weights and Measu r es Act, 1963 It has been necessar y there f o r e to r eport on the accu r ac y of the equipment , the mo s t st r aigh t fo r wa r d wa y be i ng to giv e t h e linea r d i me n sio n s of :-

(a) The dis t a n ce fr om the d ips tic k d a tum t o t he wate r lev e l. (b) The d i ps tic k dat um to t he g raduati o n mark.

(c) The e rr o r (i. e the differ e nce between (a ) and (b). (it will be noted that (a) gives the d i mensions of a correct dipstick and thus a new dipstick can be constructed from these dimensions)

91

F u ture d evelopments

De v elopme n ts which are likely to take plac e a r e in the met h od of measuring dime n s ion ( a) a b o v e . As dipping is the ma in sou rc e of e rr o r , it is desirable to find a qu ick and p r e c ise way of me a s urin g t h is d i men s i on . A device using f ibre optics i s a v a il a bl e wh i c h has a probe with t wo s en s or s 0.5 mm a part which is wound d o wn, manu al ly , until one sensor is b e low the liquid level and the second i s above th e l e v el , this being indicated to the operator by light signals. The linear movement of the probe from the datum is indicated and c an be printed if required Research is continuing to obtain a devi c e wh i ch gives a direct readout of t he dis t ance without manual operation . It i s suggested that ultimately the ope ra ti on c o ul d be automa t ic with 92

continuous readouts from the flowmeter and depth measuring device being printed at given points during the filling operation, without stopping the flow.

Provision of Testing Facilities

Tanker testing facilities are now available in Warwickshire and the West Midlands. As these testing stations are expens i ve to build and ma i ntain it would be imprudent for all local autho rities to pro vide them For c a l i br a tio ns to b e acc omp l ish e d i n the thre e y ea r moratorium p r o v i d ed f or i n th e dr aft Regula t i on s facilities wil l b e r e quired o n a r eg ion a l ba sis. Al l loc al aut h oriti es should pr o v i d e portabl e t es ting equi p ment an d e n s ure that s uitable experti s e i s d e v e lop e d for te s t s to be carried out at traders premises

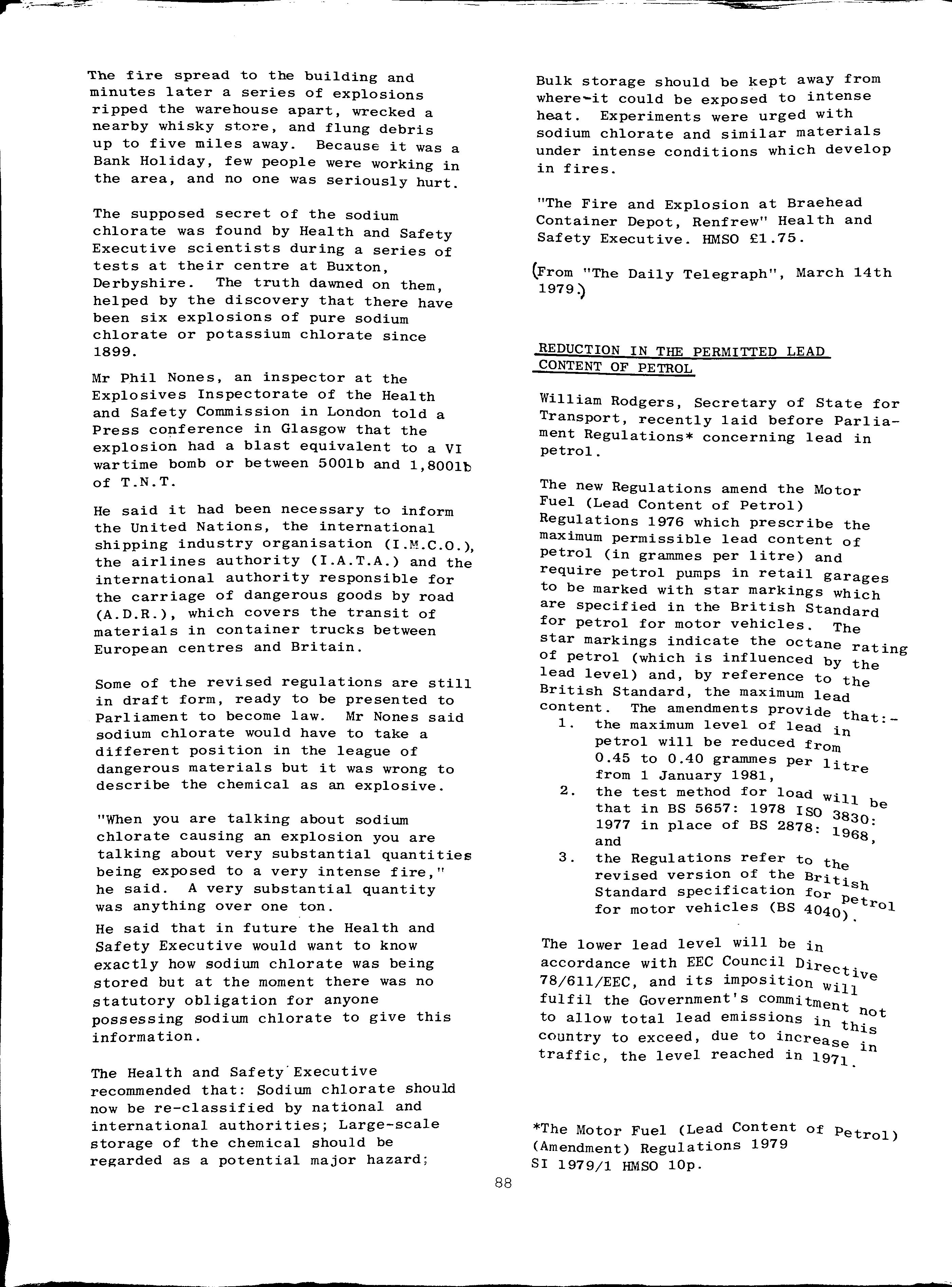

The form used

this

lI=e ___________ Addre.s Figure 2. Remarks Da te Vehicle ilo. A. Distance from da t um to liqui d (1:l!Il) i1eter 1;0 •••••••••••••••• ; •••••••••••• • •••••• ! of fla..., • ••••••• • •• • ••••••• • •••• • •••••• ! Te stinG •••••••••••• / ••••••••••••• I TaMe r !loo _________ B. Di:Jtance from da tum to dipstick ffT 3 dua tion (m:n) Total j ; Corre ct io n factor ••• • ••• •••••••••••• j Inspector C. Error mm or g allo ns Quantity by !·:ete r 11et e r Rend i nc Cocpartr::lent 1 A B coopartme nt 2 A B C Compartment 3 A B Compart:::l c n t 4 A B c Co:: p,:utce n t 5 A B C i I I I 6 A B i 1 1 ; I I c t-

for

purpose is shown in Figure 2.

NEWS FRO M THE HEALTH AND SAFETY EXECUTIVE

CONSULTATION

Conveyance of dangerous substances

The proposals for regulations concerning the conveyance of dangerous substances by road have been referred to a special Working Party with instructions to make such proposals in relation to the transport of packaged (as opposed to bulk) dangerous goods as will permit the Commission to publish, as soon as possible, a consultative document covering all dangerous goods.

COMMISSION

Change of membership

Following the retirement of Mr. E.M. Jukes, The Secretary of State for Employment has appointed Mr. G.W. Bone MA, CEng, FI MechE, as Commission member, Mr. Bone is Chairman of Ransomes, Sims and Jefferies Limited and Chairman designate of the Engineering Employers Federation Health and Safety Committee.

Plan of work: April 1978 to March 1983

The Secretary of State has approved the Commission's forward plan of work within the following programmes.

Programme 1

Projects relating to particular hazards, eg dust, toxic sUbst '. ances , nOIse and VIbration, machinery and nuclear hazards.

Programme 2

Projects relating to a part.lcular Indust ry, eg construction . ' mInes and quarrIes, but excluding Work appropriate to programme 1.

Programm e 3

Control of air pollution, inclUding specific emission problems in va r ious industries .

Programme 4

General matters not relating to other programmes, eg sex discrimination, civil liability, etc.

Programme 5

Research, including medical research, not related to other programmes eg design and development of specialised breathing apparatus, alcoholism in industry.

Pro g ramm e 6

Implementation of the HSW Act, including general issues of policy and organisation, planning and participation by industry, information and advisory services and ongoing work of general interest.

Programm e 7

Enforcement and inspection, advice to industry, assistance to policy branches etc.

The programmes 0 wor are full in the Commission's forthcoming Report 1977-78 due to be published and available as soon as possible.

f k to appear in

CROWN BODIES

Question in the House

The following Parliamentary Question and Answer is quoted from Hansard, House of Commons, 24 Octobe r 1978, Part 11 :

Mr. Greville Janner asked the Secretary of State for Employment whether he will seek to introduce ns legi s l a tion to extend the provls 10 of th e He al tl1 and Safety at Work , ete. Ac t 1974 to th e Crown and thereby removing Crown immunity in respect of t he service of prohibition and improvement notices and prosecution under that Act and othe r indust ria l safe ty leg is lat ion

93

Mr. Golding: The Health and Safety at Work, etc. Act 1974 is binding on the Crown and the Government are committed to taking whatever action is necessary to secure compliance by all Crown bodies.

The Health and Safety Commission takes the view that amending legislation should be introduced to remove the Crown's immunity from enforcement and prosecution. The Commission has provided Ministers with a paper setting out its views and detailing some problems experienced by the Commission in dealing with Crown bodies. My right hon. Friend and other Minsters concerned are now considering that paper and the issues it raises.

Meanwhile, the Commission has introduced a special form of notice which the Health and Safety Executive's inspectors will serve on Crown bodies in circumstances where a statutory improvement or prohibition notice would have been served on an employer in the private sector. This means that the action taken by the executive in relation to Crown establishments is similar to that taken elsewhere.

FILMS

A catalogue of films is obtainable by post on to.Health.and Safety Executive, Spec1al ProJects Section, Baynards House, 1, Chepstow Place, London, W2 4TF.

New Films

Recent films include What do the diamonds say? a 12-minute film about road tanker marking and also Health at work, a 27-minute film introducing the Employment Medical Advisory Service, and One step away, 15 minutes on the hazards of working on roofs and how to guard against them. These two films should be generally available by early January 1979. Two further films, John Davies, Factory Inspector, 25 minutes about the day-to-day work of a factory inspector, and A guide to guards, a 20-minute technical f1lm, should be generally available by early February.

Films are available for hire or purchase from Central Film Library, Government Building, Bromyard Avenue, London, W3 (tel 01-743 5555); Welsh Office Film Library, Oxford House, 3rd Floor, Hills Street, Cardiff (tel 02 22-44171); or Scottish Central Film Library, 16-17 Woodside Terrace, Charing Cross, Glasgow (tel 041 3329988).

REGULATIONS

Road tanker labelling

The Hazardous Substances (Labelling of Road Tankers) Regulations 1978 (SI 1978 No 1702) were laid before Parliament by the end of 'November. Laid 2fl November 1 n78, they come into effect on 28 March 1979. These regulations make mandatory and extend to multi-loads the Voluntary Tanker Marking SchemeA detailed guidance booklet on the scope and practical application of the regulations will be published in the forthcoming year.

Acetylene importation

Following consultation, new safety regulations covering the importation of compressed acetylene were laid before Parliament on 30 November and came into effect on 6 December. The Compressed Acetylene (Importation) Regulations 1978 (SI 1978 No 1723) provide for importation under licence issued by the Health and Safety Executive in the same way as explosive materials. Granting of the licence, which at present costs £14.00, is conditional on a number of safety reqUirements, detailed in the regulations. When applying for a licence, prospective importers will have to provide the executive's Explosives Inspectorate with certain information to ensure these requirements have been met. Application forms for the licences can be obtained from HM Explosives Inspectorate, Health and Safety Executive Thames HOuse North Millbank, London, SWl ,

94

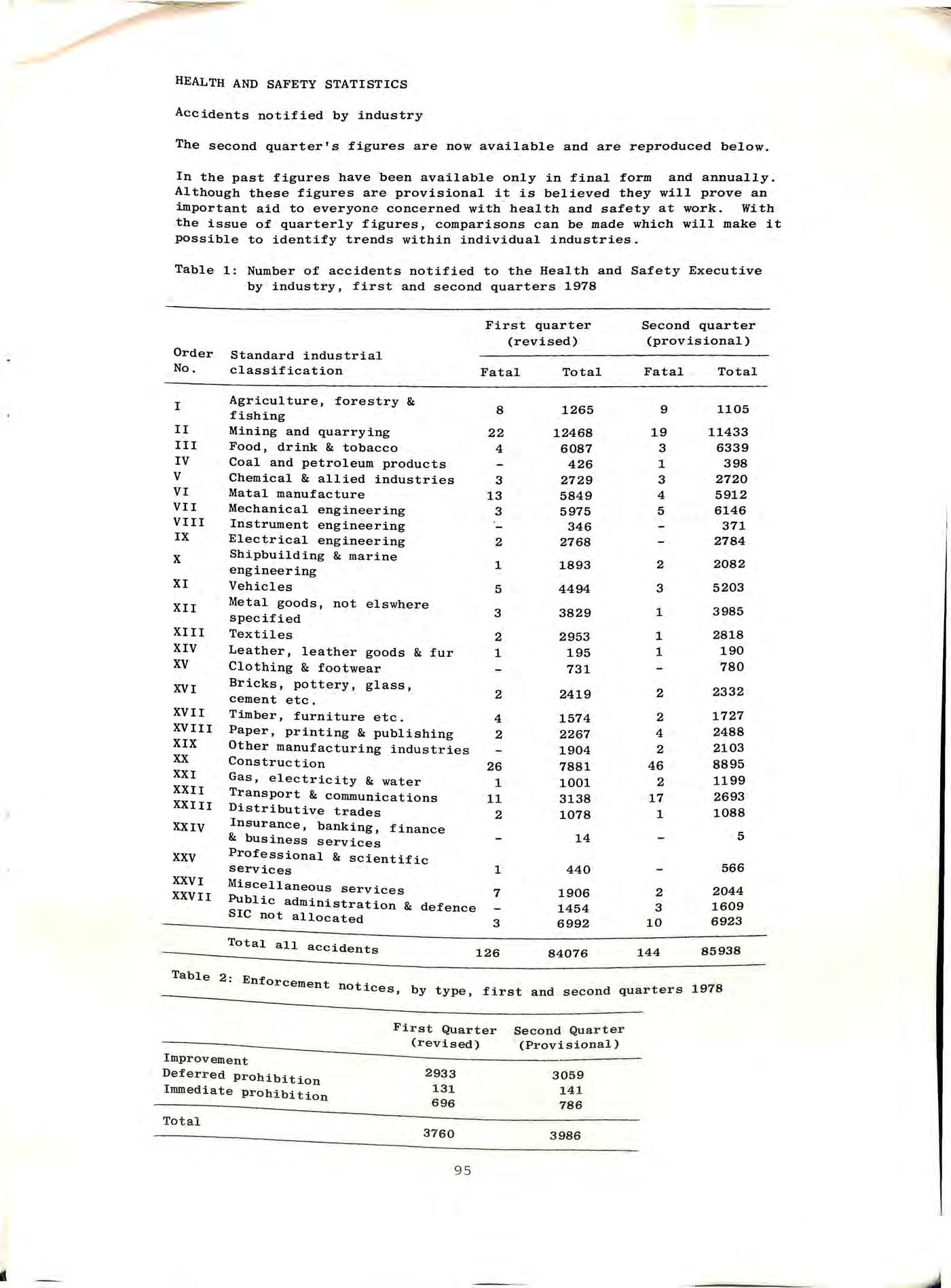

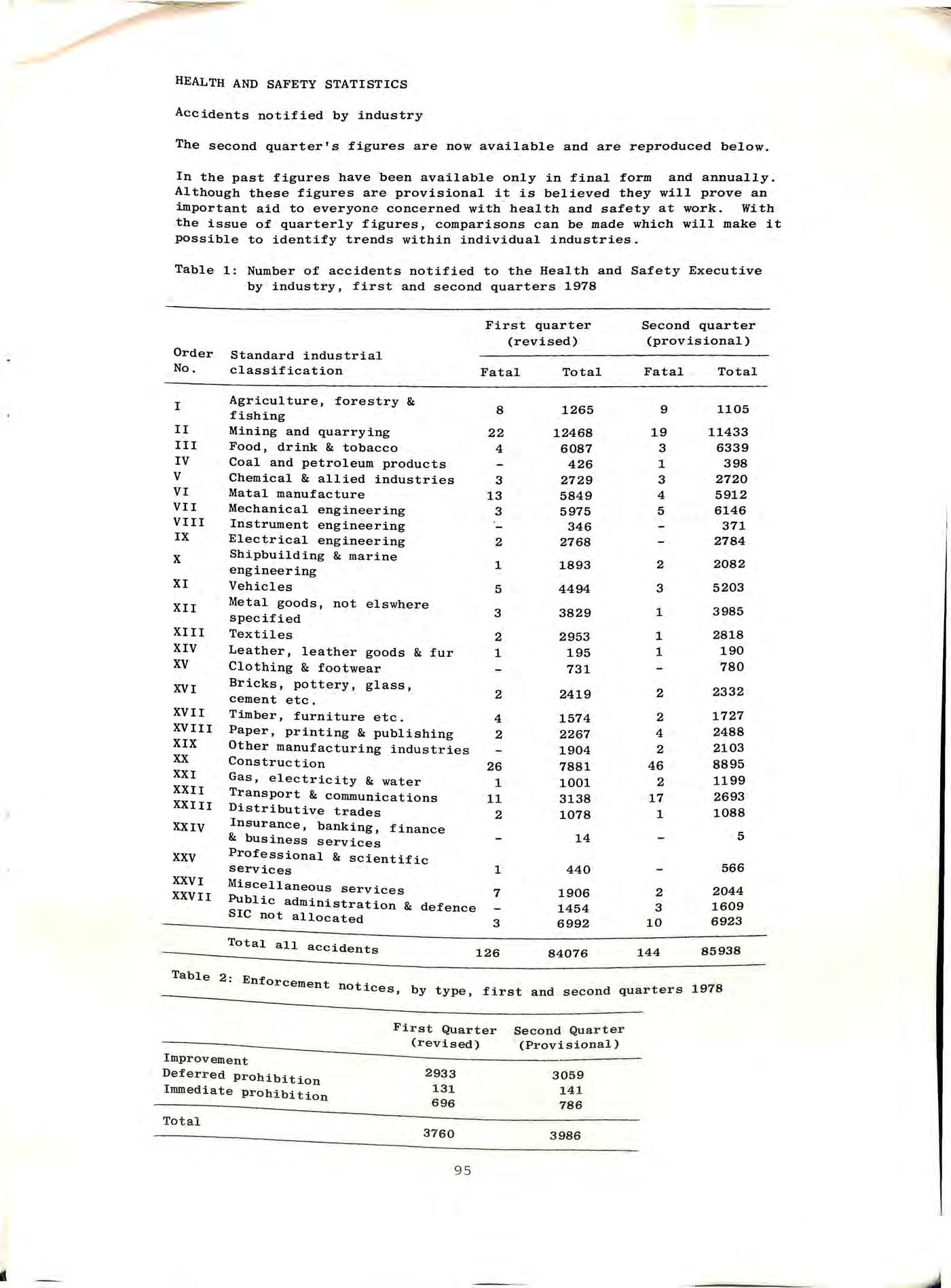

HEALTH AND SAFETY STATISTICS

ACCidents

notified by industry

The second quarter's figures are now available and are reproduced below.

In the past figures have been available only in final form and annually. Although these figures are provisional it is believed they will prove an important aid to everyone concerned with health and safety at work. With the issue of quarterly figures, comparisons can be made which will make it Possible to identify trends wi thin individual industries

Table

Standard industrial classification

Agriculture, forestry & fishing Mining and quarrying Food, drink & tobacco

Coal and petroleum products Chemical & allied industries Matal manufacture Mechanical engineering Instrument engineering Electrical engineering Shipbuilding & marine engineering Vehicles Metal goods , not elswhere specified Textiles

Leather, leather goods & fur Clothing & footwear Bricks, pottery, glass, cement etc Timber, furniture etc. Paper, printing & publishing Other manufacturing industries Construction Gas, electricity & water Tr ansport & communications Distributive trades Insurance, banking, finance & business services

Professional & scientific serVices

Miscellaneous se r vices Public administration & defence SIC not allocated

Total all accidents

Tabl e 2 : Enfo

First quarter (revised) Fatal 8 22 4 3 13 3 2 1 5 3 2 1 2 4 2 26 1 11 2 1 7 3 126

Total 1265 12468 6087 426 2729 5849 5975 346 2768 1893 4494 3829 2953 195 731 2419 1574 2267 1904 7881 1001 3138 1078 14 440 1906 145 4 6992 84076

Second quarter (provisional)

Total 1105 11433 6339 398 2720 5912 6146 371 2784 2082 5203 3985 2818 190 780 2332 1727 2488 2103 8895 1199 2693 1088 5 566 2044 1609 6923 85938

1: Number of accidents notified to the Health and Safety Executive by industry, first and second quarters 1978 Order No. I II III IV V VI VII VIII IX X XI XII XIII XIV XV XVI XVII XVIII XIX XX XXI XXII XXIII XXIV XXV XXVI XXVII

r

t

I

rov eme nt

Fatal 9 19 3 1 3 4 5 2 3 1 1 1 2 2 4 2 46 2 17 1 2 3 10 144 e rr

ceme n

noti c es , b y t y pe , first a n d s e co n d q u a r t ers 1 9 7 8

mp

De f

ed prohibi ti on I mmed ia te prohib i tion Total F ir s t Quart e r ( re vised) 2 93 3 131 6 9 6 3760 95 Se c o n d Qua r te r (P r o vi s i o na l) 3 0 59 141 786 3 986

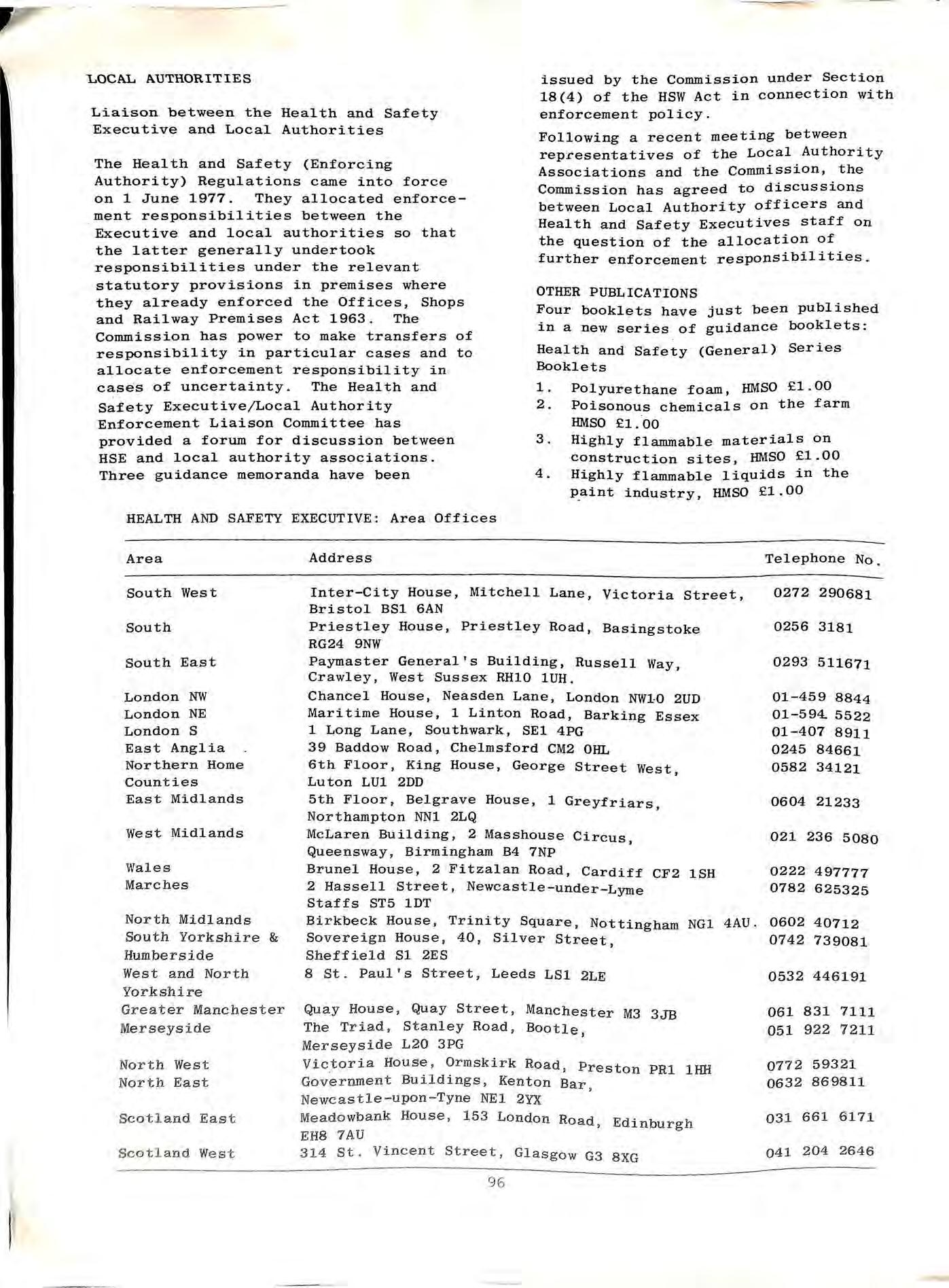

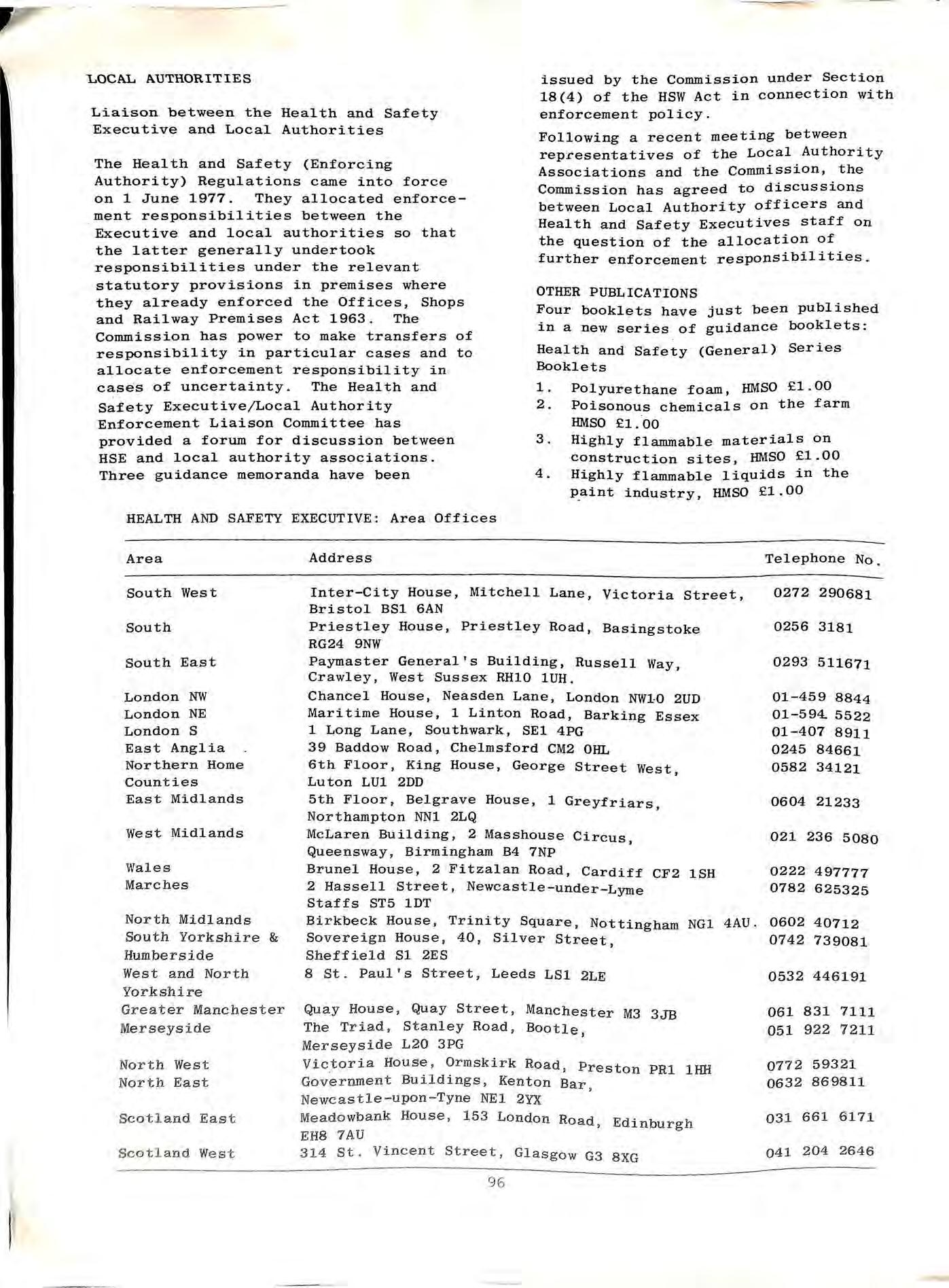

LOCAL AUTHORITIES

Liaison between the Health and Safety Executive and Loc al Authorities

The Health and Safety (Enforcing Authority) Regulations came into force on 1 June 1977. They allocated enforcement responsibilities between the Executive and local authorities so that the latter generally undertook responsibilities under the relevant statutory provisions in premises where they already enforced the Offices, Shops and Railway Premises Act 1963. The Commission has power to make transfers of responsibility in particular cases and to allocate enforcement responsibility in cases of uncertainty. The Health and Safety Executive/Local Authority Enforcement Liaison Committee has provided a forum for discussion between HSE and local authority associations. Three guidance memoranda have been

HEALTH AND SAFETY EXECUTIVE: Area Offices

Area

South West South

Sou t h East London NW London NE London S East Anglia No rt he r n Home Counties East Midlands

Wes t Mi dl an ds Wa le s Ma rch es

North Mi d l a n ds South Yorkshire & Hu mberside West and North Yorkshi r e Greater Manchester Me r seys i de

Nor t h Wes t No r t h East

Sc o tl an d Eas t

Scotland We s t

issued by the Commission under Section 18(4) of the HSW Act in connection with enforcement policy.

Following a recent meeting between representatives of the Local Authority Associations and the Commission, the Commission has agreed to discussions between Local Authority officers and Health and Safety Executives staff on the question of the allocation of further enforcement responsibilities.

OTHER PUBLICATIONS

Four booklets have just been published in a new series of guidance booklets: Health and Safety (General) Series Booklets

1. Polyurethane foam, HMSO £1.00

2. Poisonous chemicals on the farm HMSO £1.00

3. Highly flammable materials on construction sites, HMSO £1.00

4. Highly flammable liquids in the industry, HMSO £1.00

Address

Inter-City House, Mitchell Lane, Victoria Street, Bristol BSI 6AN

Priestley House, Priestley Road, Basingstoke RG24 9NW

Paymaster General's Building, Russell Way, Crawley , West Sussex RHlO lUH.

Chancel House, Neasden Lane, London 2UD Maritime House, 1 Linton Road, Barking Essex 1 Long Lane, Southwark, SE1 4PG 39 Baddow Road, Chelmsford CM2 OHL

6th Floor , King House , George Street West, Luton LU1 2DD

5th Floor , Belgrav e House , 1 Greyfriars, No r thampton NN1 2LQ

McLaren Building , 2 Masshouse Circus, Queens wa y, Birmingham B4 7NP

Br uneI House , 2 Fitzalan Road, Cardiff CF2 ISH 2 Hassell St r eet , Newcastle u n de r-Lyme Staffs ST5 1DT

Telephone No. 0272 290681 0256 3181 0293 511671 01-459 8844 01-594. 5522 01-407 8911 0245 84661 0582 34121 0604 21233 021 236 5080 0222 497777 0782 625325

Birk be ck Ho u se , Tr inity Square , Nottingham NG1 4AU. 0602 40 7 12 So verei g n Ho u se , 4 0 , Silver St r eet , 0 7 42 7 39081 Sheff i e ld SI 2 ES

8 St Paul's S tr ee t, Leeds LS 1 2LE

Quay Hou se , Qu a y S tr ee t, Ma nc heste r M3 3JB

The Triad, Stanley Ro ad, Bo ot le , Merseyside L20 3PG

Vi c toria House, Ormskirk Ro a d, Pre s ton PR1 1HH Governme n t BUildings, Kenton Bar, Newcastle upon Tyne NE1 2YX

Meadowbank House , 153 London Road, Edin burgh EH8 7A U 314 St Vinc e n t St r eet , Glasgow G3 8XG 96

053 2 4 46191 061 8 3 1 7 111 051 92 2 72 11 0 772 59 32 1 0632 869811 031 661 617 1 041 204 2646

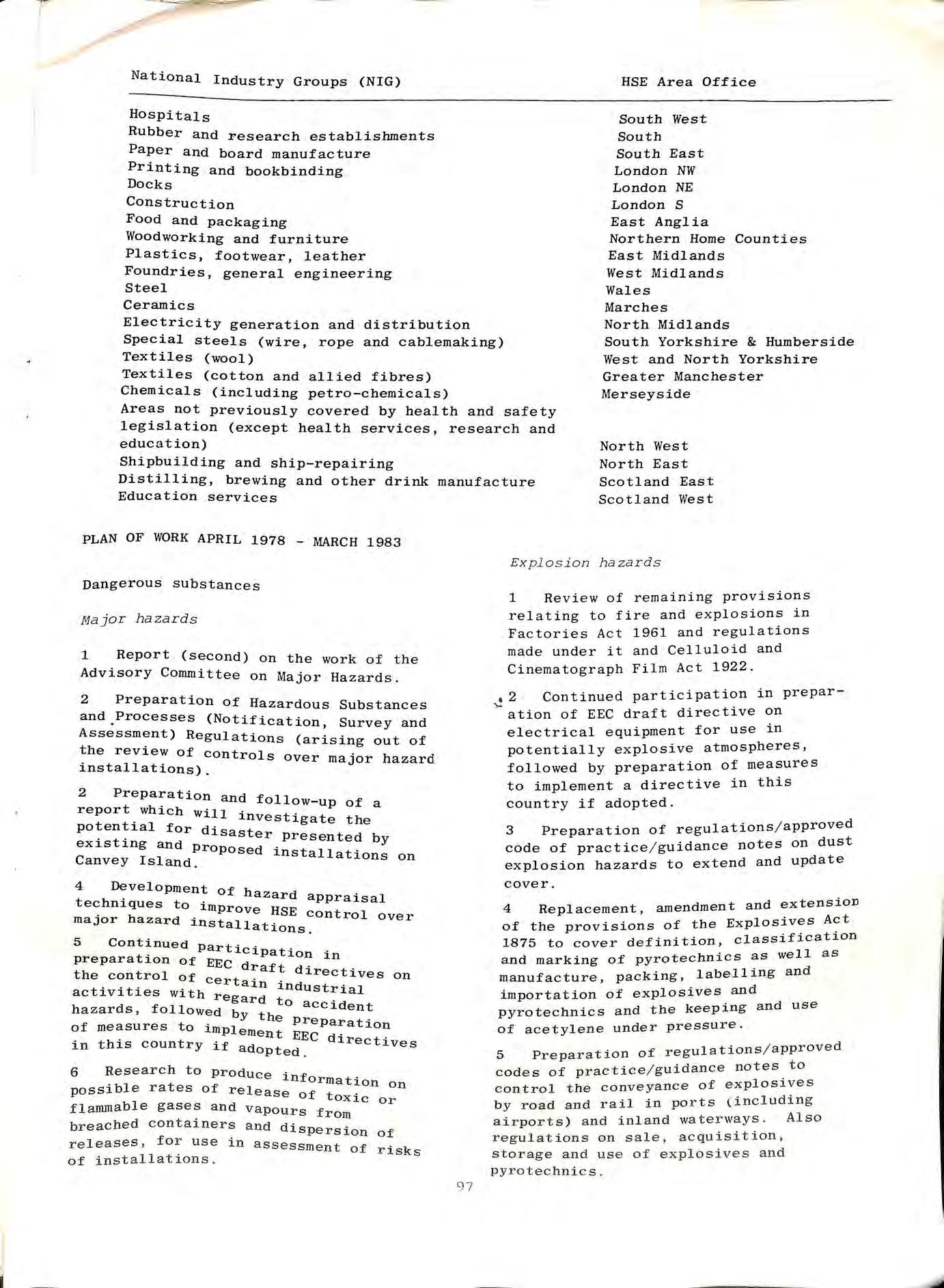

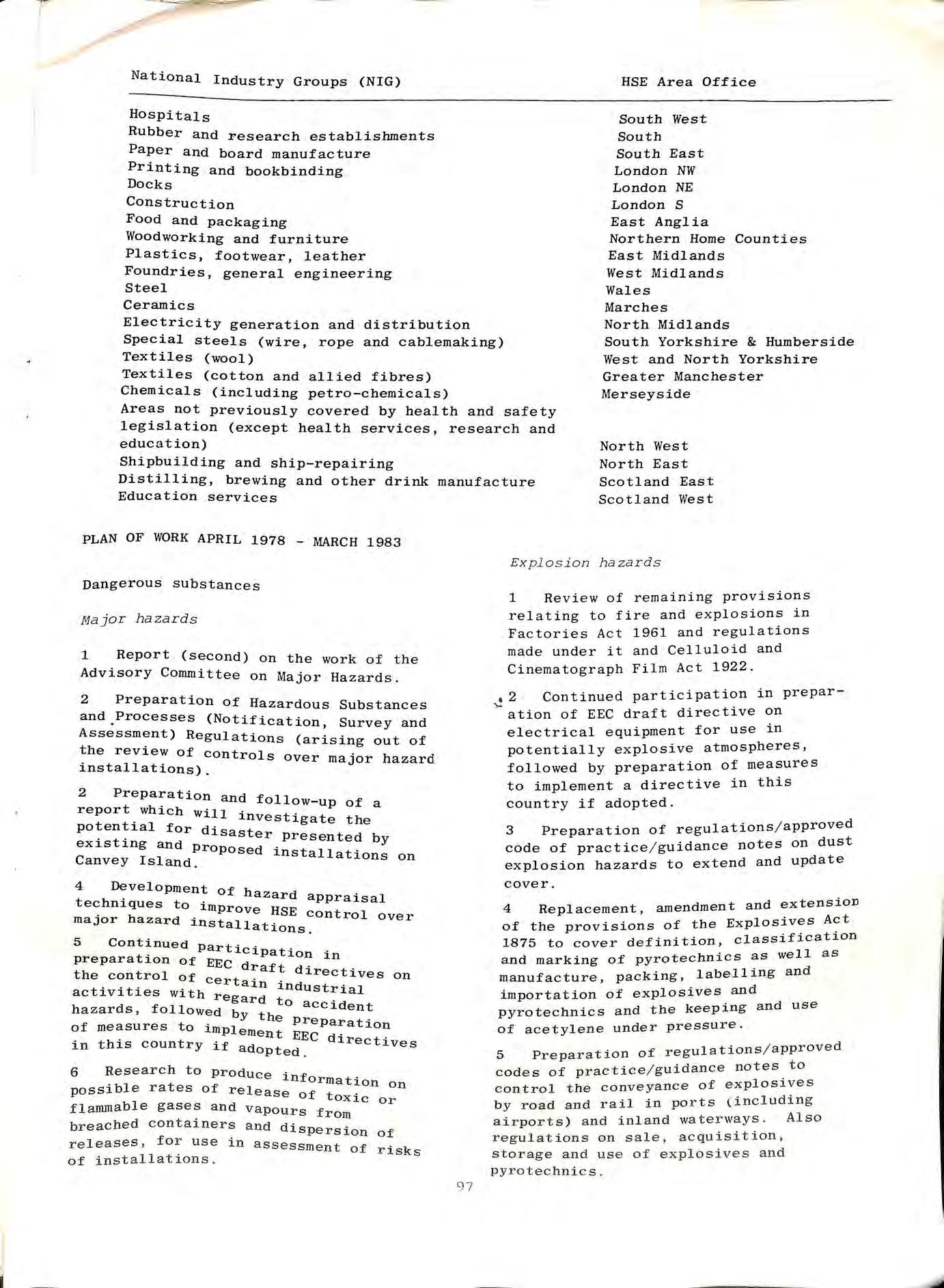

National Industry Groups (NIG)

Hospitals

Rubber and research establishments

Paper and board manufacture

Printing and bookbinding Docks

Construction Food and packaging Woodworking and furniture Plastics, footwear, leather Foundries, general engineering Steel Ceramics

Electricity generation and distribution Special steels (wire, rope and cablemaking) Textiles (wool)

Textiles (cotton and allied fibres) Chemicals (including petro-chemicals)

Areas not previously covered by health and safety legislation (except health services, research and education)

Shipbuilding and ship-repairing Distilling, brewing and other drink manufacture Education services

PLAN OF WORK APRIL 1978 MARCH 1983

sUbstances

Major ha za rds

1 Report (second) on the work of the Advisory Committee on Major Hazards.

2 Preparation of Hazardous Substances and.Processes (Notification, Survey and Assessment) Regulations (arising out of the review of co t 1 installations). n ro s over maJor hazard

2 Preparation and foIl ow-up of a report which will l' n t· ves 19ate the potentlal for disast er presented by C exlstlngI land proposed installations anvey sand.

HSE Area Office

South West South South East London NW London NE London S East Anglia Northern Home Counties East Midlands West Midlands Wales Marches

North Midlands South Yorkshire & Humberside West and North Yorkshire Greater Manchester Merseyside

North West North East Scotland East Scotland West

Ex pl o s i on h azards

1 Review of remaining provisions relating to fire and explosions in Factories Act 1961 and regulations made under it and Celluloid and Cinematograph Film Act 1922

• 2 Continued participation in preparation of EEC draft directive on electrical equipment for use in potentially explosive atmospheres, followed by preparation of measures to implement a directive in this country if adopted.

3 Preparation of regulations / app r oved code of practice / guidance notes on dust explosion hazards to e x tend and update cover.

4 Development of h techniques to azard appraisal

on lmprove HSE co t 1 major hazard n ro over lns t all a tions.

5 Continued part . . lClpation preparation of EEC d ln the cont r ol of r aft directives on ce r tain ind t activities with us r l a l r ega r d to haz ar ds , fo l low e d b y th accldent o f measu r es to im p lem et p r epa r atio n e n EE C d' . in this c o unt ry if a d l r e c tlves opted .

6 Rese arch to p rod u ce inf or mat po ss ible rates of re l ease of t on OX 1 C or f l a mm ab le gas e s and vapour s f , rom br e ached container s and dispe rSlon of release s , fo r u s e in a ss e s sment of risks of installati o ns

4 Replacement , amendment and extension of the provisions of the Explosives 1875 to cove r definition , c lassif i c a t l 0n and marking of p yr ote c hnics as well a s manufa c tu r e , packin g, labellin g an d impo r tatio n of e xp losiv e s an d . and use p y rote c hniCS an d the keep l n g o f ace ty le ne und er p r es s u re.

5 P re p aration of regulations / approved c od e s of practic e / guidance notes to c on trol t h e conveyance of explos i ves b y roa d and rail i n po r ts (including airp o rts) and inland wate r ways Also r egu l ations on sale , a c quisition , sto r age and use of e x p l osi v es a n d py r ote c hni c s

97

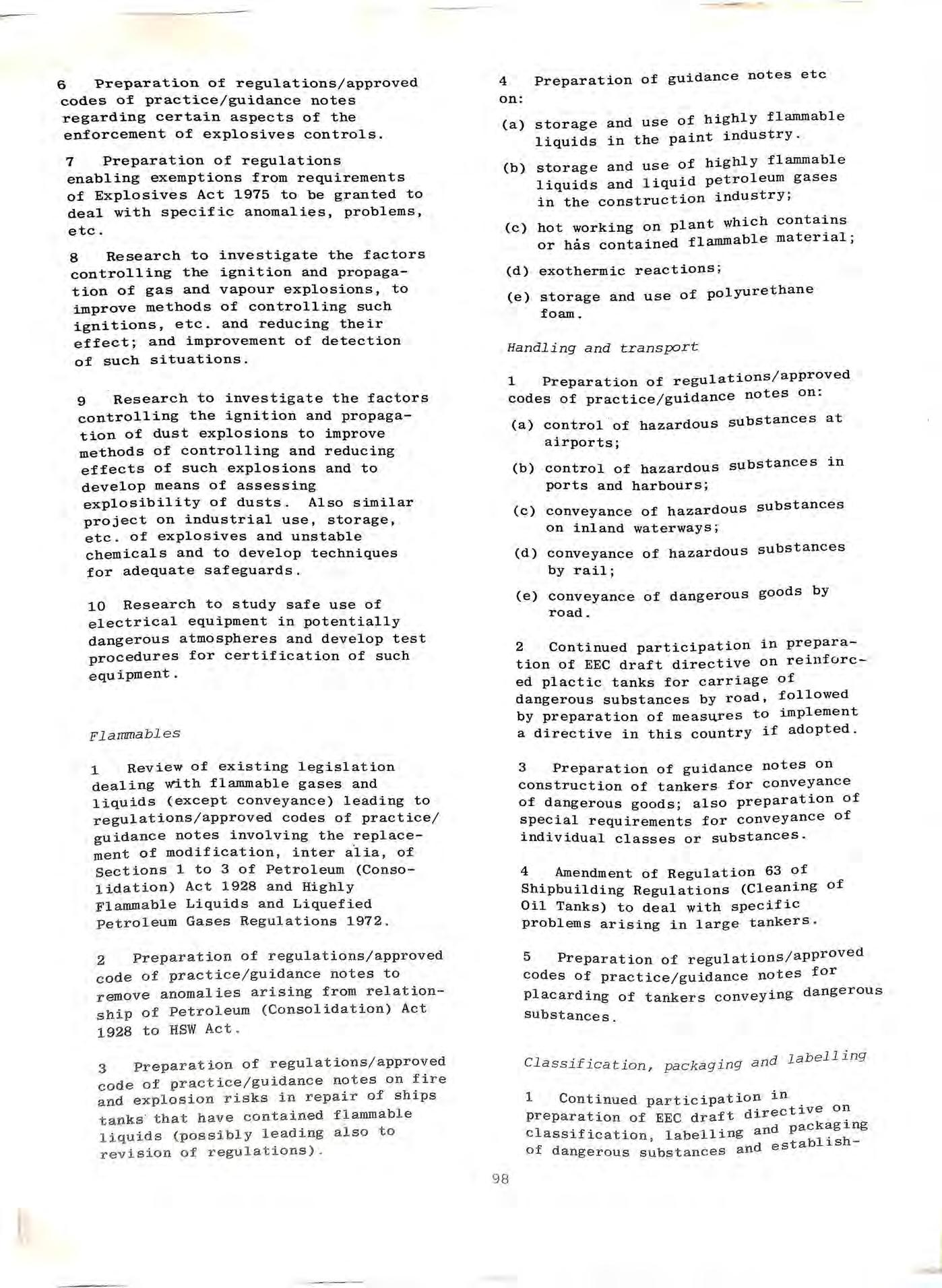

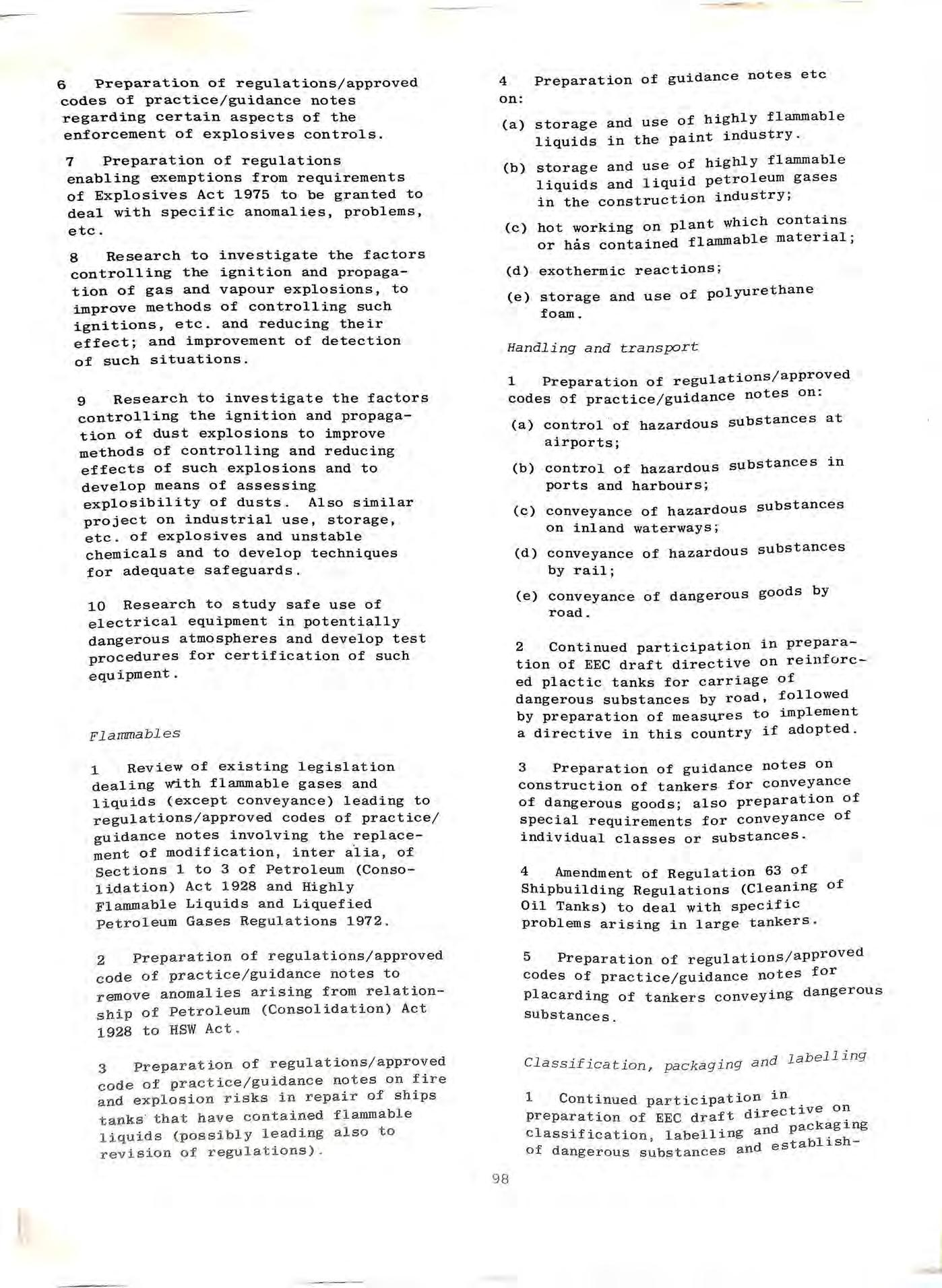

Preparation OI regulations/approved codes OI practice/guidance notes regarding certain aspects OI the enforcement of explosives controls.

7 Preparation of regulations enabling exemptions from requirements of Explosives Act 1975 to be granted to deal with specific anomalies, problems, etc.

8 Research to investigate the factors controlling the ignition and propagation of gas and vapour explosions, to improve methods of controlling such ignitions, etc. and reducing their effect; and improvement of detection OI such situations.

9 Research to investigate the factors controlling the ignition and propagation of dust explosions to improve methods of controlling and reducing effects of such explosions and to develop means of assessing explosibility of dusts Also similar project on industrial use, storage, etc of explosives and unstable chemicals and to develop techniques for adequate safeguards.

10 Research to study safe use of electrical equipment in potentially dange r ous atmospheres and develop test procedures for certification of such equ i pment

F l a mmables

1 Revi ew of ex i sting legislation d eal i ng flammable gases and l iqui ds ( e x cept c onv e y ance) leading to r egu lati o n s / approved codes of prac t i ce / gu i d anc e n o t es invol vin g the replaceme n t of modification , inte r aiia , of s e ction s 1 t o 3 o f Pet r oleum (Co n so lidati o n) Act 1 9 28 a n d Hig h l y Flamm able Li qui ds an d Liquefied Petrol e um Ga s es Regu lation s 1972.

2 Pr e paration of regulat io n s/ ap p r o v ed code of practic e /guidance note s to remove anomalies arising fr om r e lati o n ship of Petroleum (Consolid a tion) Act 1928 to HSW Act .

3 Preparation of regulations/approved code of practice/guidance notes on fire and explosion risks in repair of ship s tanks' that have contained flammable liquid s (possibly leading also to revision of regulation s)

4 Preparation of guidance notes etc on:

(a) storage and use of highly flammable liquids in the paint industry.

(b) storage and use of highly flammable liquids and liquid petroleum gases in the construction industry;

(c) hot working on plant which contains flamm able material; or has contained (d) exothermic reactions; (e) storage and use of polyurethane foam.

Handling and transport

1 Preparation of regulations/approved codes of practice/guidance notes on:

(a) control of hazardous substances at airports;

subs tances in (b) control of hazardous ports and harbours; (c) conveyance of hazardous substances on inland waterways; (d) conveyance of hazardous substances by rail; (e) conveyance of dangerous goods by road.

2 Continued participation in preparation of EEC draft directive on reinforced plactic tanks for carriage of dangerous substances by road, followed by preparation of to implement a directive in this country if adopted

3 Preparation of guidance notes on construction of tankers for conveyance of dangerous goods; also preparation of special requirements for conveyance of individual classes or substances.

4 Amendment of Regulation 63 of Shipbuilding Regulations (Cleaning Oil Tanks) to deal with specific problems arising in la r ge tankers

of

5 Preparation o f r egulations / app r oved codes of p r actice / guidance n o tes fo r plac a r di n g of tanke r s conve yi ng da n ge r ous s ub s t a nce s .

Classification, packaging and labelling

1 Continu e d participat i on in preparation of EEC draft direct1ve nd paCkag1ng cla s sification, labelling a l' h of dangerous substances and e s tab 1S

6

98

ment of a notification scheme for protection of man and the environment. Followed by preparation of measures to implement a directive in this country i f adopted.

2 Preparation of regulations/approved code of practice/guidance notes on marking of buildings to inform fire services of hazards from dangerous substances.

3 Preparation of measures to implement an EEC directive on the classifipackaging and labelling of paints, varnishes, glues, etc.

preparation of EEC draft directive on the classification, packaging and labelling of solvents, followed by preparation of measures to implement a directive in this country if adopted.

5 Preparation of regulations/approved code of practice/guidance notes for establishment of testing stations for UN packaging performance tests.

(The above items are from the HSC Newsletter , Published Bi-monthly by The Health and Safety Commission) .........................................................................................................

4 Continued participation in the

LEGAL PROCEEDINGS

KENT

Carrying Matches

At Tonbridge Magistrates Count on 10th January 1979 Mr. R. Jameson of Hove, Sussex, the driver of a petroleum-spirit tank wagon pleaded guilty to a contravention of Regulation 4 of the 1957 Regulations.

The Magistrates remarked tha t carrying matches was a serious offence and one which carried a ma x imum penalty of £1,000. In the event a fine of £100 with £25 costs was imposed.

Petrol Spillage

Proceedings we ' . . re 1nst1tuted aga1nst the dr1ver of apt e rol tanker and the manager of a f·ll· 1 1ng station following a sp11lage during th P etrol d 1· e course of a e 1Very

The driver had connected ment of his tank one compa r tt er to an u d ank but a secOnd h n e r ground at t he tanker although secu r ed the ground in th was me r el y laid on e dJ. r ect . unde r g r ou n d tank W 10n of a sec o n d fau cet was he n the outlet a p p r o x · l itre s of pet r ol 100 manhol e c hambe r and J. nt o the t ank forecourt . a cro s s t h e

A charge under Regulation 16(6) Conveyance Regulations w 1 of the a s aid against the manager who had signed the Petroleum Certificate , Mr . L . Dawson

of Wrotham Sevenoaks, Kent alleging that he failed to secure that no petroleum-spirit escaped at the filling pOint He pleaded not guilt y and the case was dismissed.

The driver Mr. Reginald Jones of Hornchurch, Essex pleaded guilty to failing to observe all precautions necessary for preventing (Regulation 2) He was fined £15

Unauthorised Alterations

At West MaIling Magistrates Court on the 7th November 197 8, Winsor Garage (West MaIling) Ltd ., were found guilt y in their absence of a number of offences under Petroleum and Weights and Measures legislation. The Pe t roleum ma t t ers related to :-

(a)

(b)

(c)

Conditions Sheet not displa y ed (Se ct ion 2 ( 4 ) 192 8 Act ) Ele ctr i c a l Ce rti fi cat e p rovi de d (Sec t io n 1(3) 19 28 Ac t ) Sale s k i os k install ed with ou t c onse nt ( Section 1(3) 1928 Act)

f £5 0 00 £1 00 00 and £150. 0 0 F1ne s 0 , . ly were impo s ed. The use of re spect1ve t 1 Pumps which had not been two pe ro d f it for use for trade by an pa ss e as f weights an d measures J.nsp e ctor 0 brought penalties of £40 00 each Costs of £40 00 we re imposed

99

Lighter Carried

The driver, Mr. M.G. Lewis of Basildon., Essex, of a petrol tank wagon was fined £25.00 with £5.00 costs by the Dartford Justices on 15th November 1978 after pleading guilty to an offence under Regulation 4 of the 1957 Regulations.

The Court heard that despite having a complete set of the Regulations in the cab of the vehicle and there being a notice on the trailer prohibiting the carrying of matches or lighters, a cigarette lighter was being carried in the cab.

Matches Carried

A tanker driver, Mr. Peter Bradick of Hove, Sussex was fined £250.00 with £10.00 costs after pleading guilty to a charge of carrying matches whilst attending a petroleum tank wagon.

The case was heard before the West MaIling Magistrates on 21st November 1978.

Contraventions of Licence

For keeping petroleum mixtures in contravention of his licence conditions, Mr. J. Matthews of Chartham Service Station, Chartham, Kent was fined £75.00 with £25.00 costs by the Canterbury Magistrates on 15th December 1978.

The licence permitted the keeping of petroleum-spirit in underground tanks only, and despite warnings having been given, paints were kept in three locations at the site. Separate Informations were laid in respect of each unauthorised location. A guilty plea was made in each case.

WEST SUSSEX APPEAL TO CROWN COURT CONVEYANCE

An appeal was heard in Chichester Crown Court on 24 November 1978 by Her Honour Judge P.A. Coles, Q.C. The Appellant was Tank Truck Transport Ltd. and the Prosecutor, West Sussex County Council.

The Appellant was prosecuted before the Worthing Magistrates for the following offences against the Petroleum Spirit (Conveyance by Road) Regulations 1957.

1. Using an articulated vehicle. for the conveyance of petroleum-spirit the load unit 0/ which was not

constructed in accordance with a design approved by an Inspector of Health and Safety (Reg.1 1 and Part 11 1st Schedule).

2. Six separate offences of failing to keep locked the caps of the six filling openings of a tank wagon used for the conveyance of petroleum-spirit (Regulation 12).

The Justices found all the offences proved. The Defendant Company appealed against the decision in (2) on the grounds that (a) the driver and not the Company should have been prosecuted and (b) if unsuccessful on (a) there was only one offence and not six.

Counsel for the Company submitted that the regulations varied in their application and some could only be applied to the person operating the vehicle, some to the person owning the vehicle, and some to the driver. He suggested that in Regulation 12(2) the closing and locking of the lids was the drivers responsibility and that carrying the key was both the driver and the employers responsibility. When the vehicle had left the terminal the employer had no control over the state of the lids.

Dismissing this part of the appeal, Her Honour decided that there was nothing in this Regulation referring specifically to a driver, it was the Company's responsibility to comply with the requirements, and she proceeded to hear a submission that there was only one offence. Counsel for the appellants referred to Part 11 of the First Schedule to the regulations, paragraph 8(2) as amended, which states "a carrying tank of more than one thousand one hundred gallons capacity shall be divided into self contained compartments no one of which shall be more than one thousand one hundred gallons capacity, and referring to Regulation 12, suggested that as it dealt with "the carrying tank" of a tank wagon or tank trailer, there could only be one such offence in respect of apt· ar vehicle regardless of how many compartments were.

In allowing the second part of the JUdge Coles quashed five of the summonses leaving one to stand as convicted by the Worthing Justices.

(From

100

The Monthly

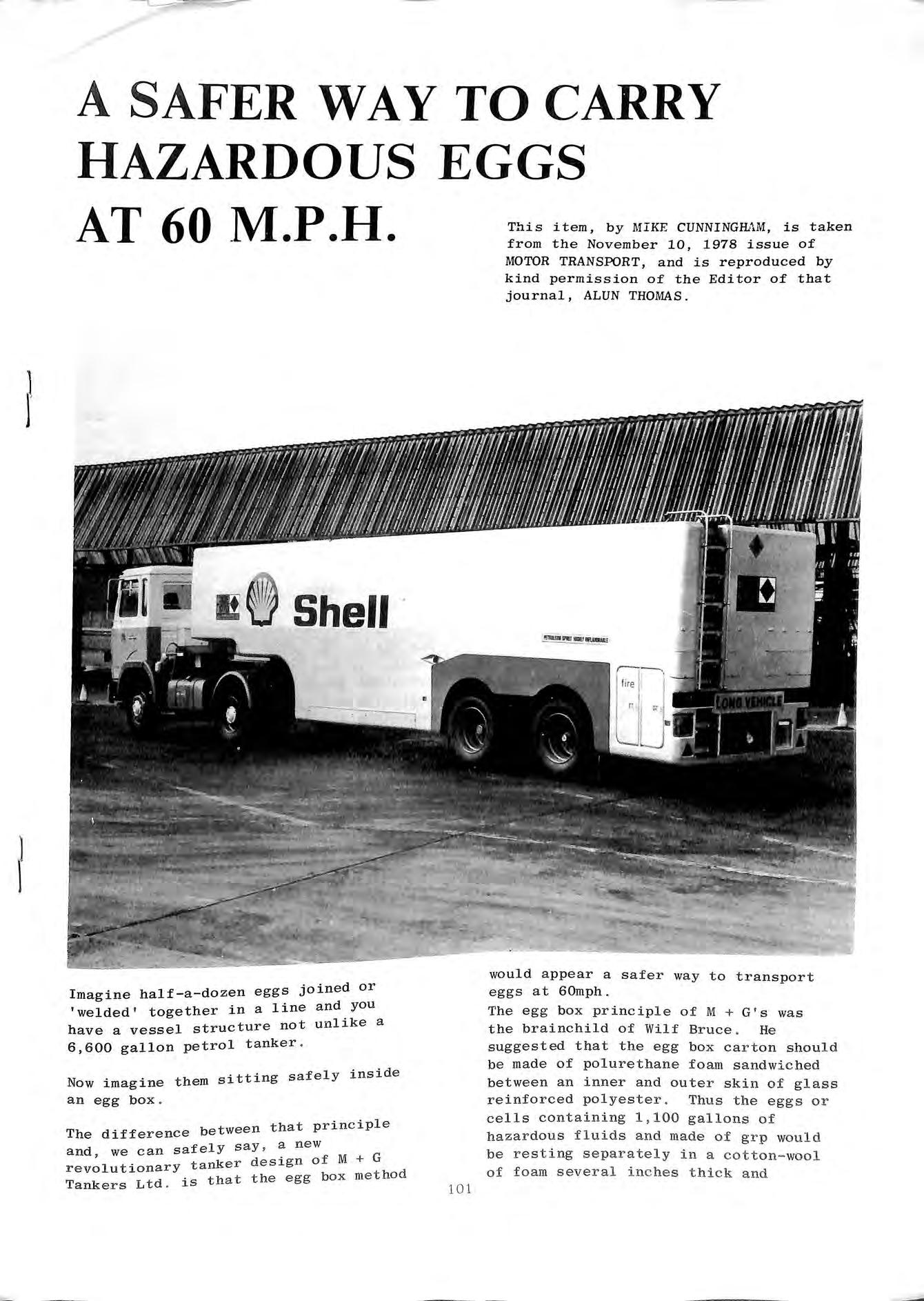

A SAFER WAY TO CARRY HAZARDOUS EGGS AT 60 M.P.H.

IShe" -

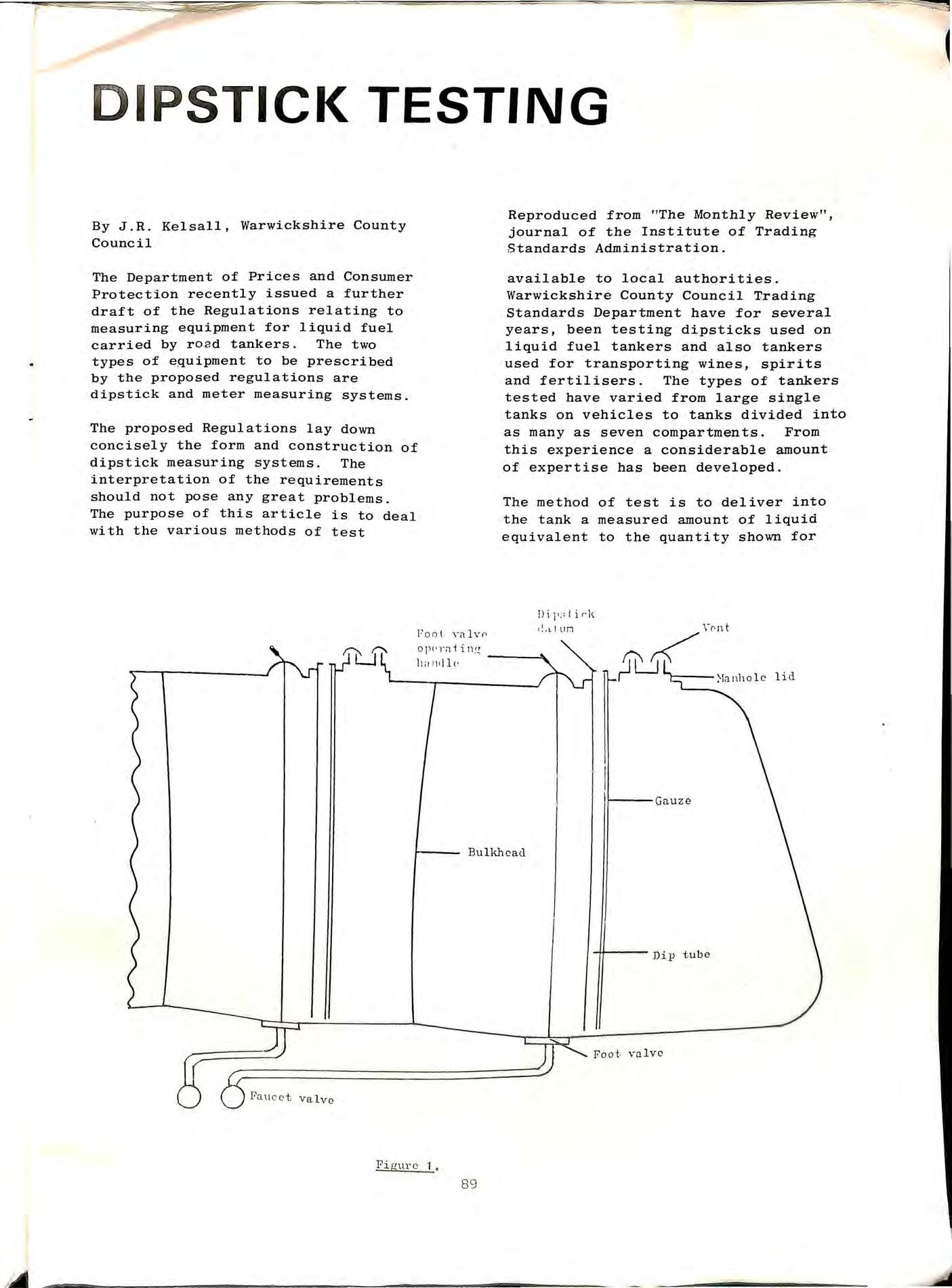

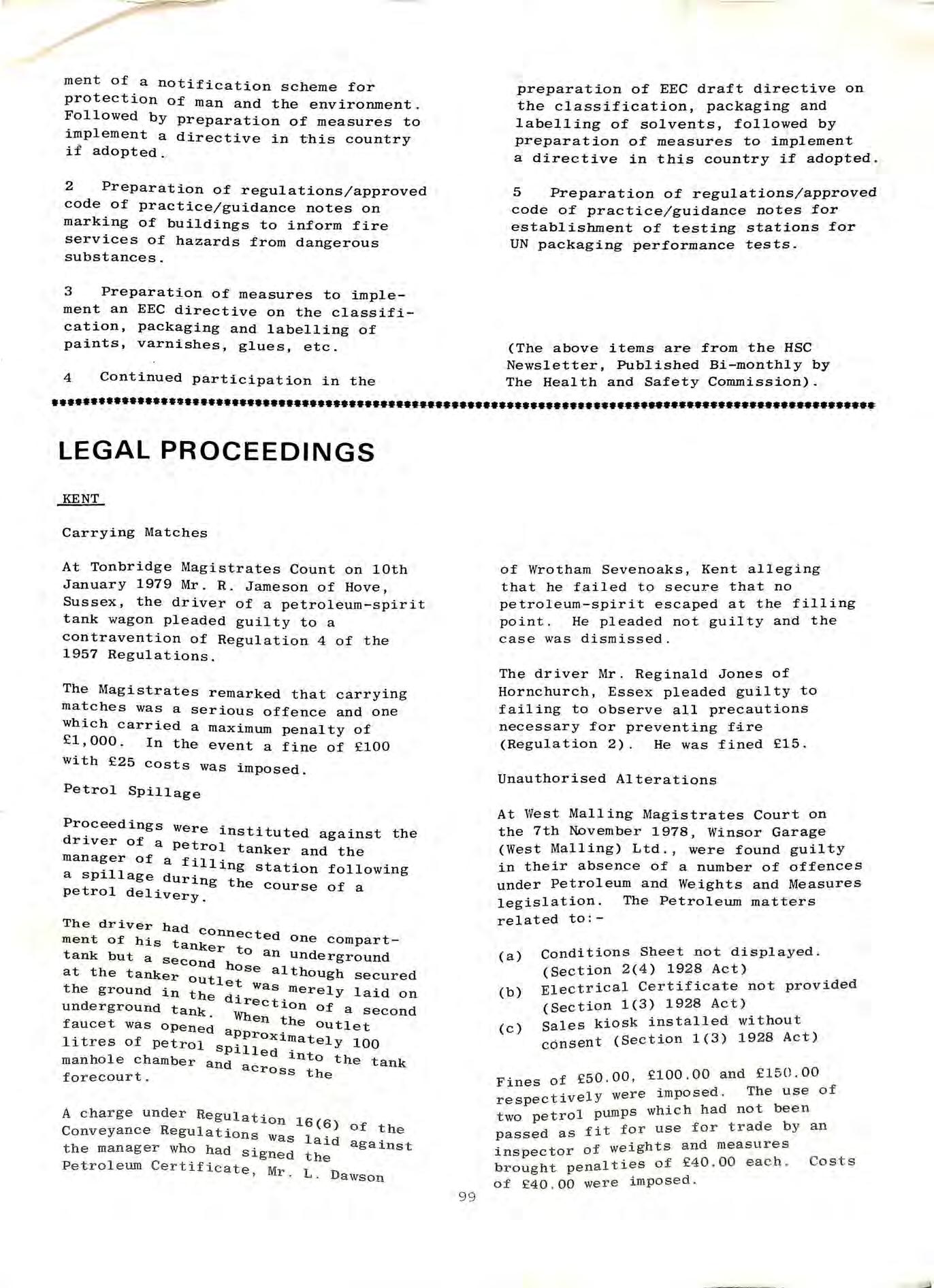

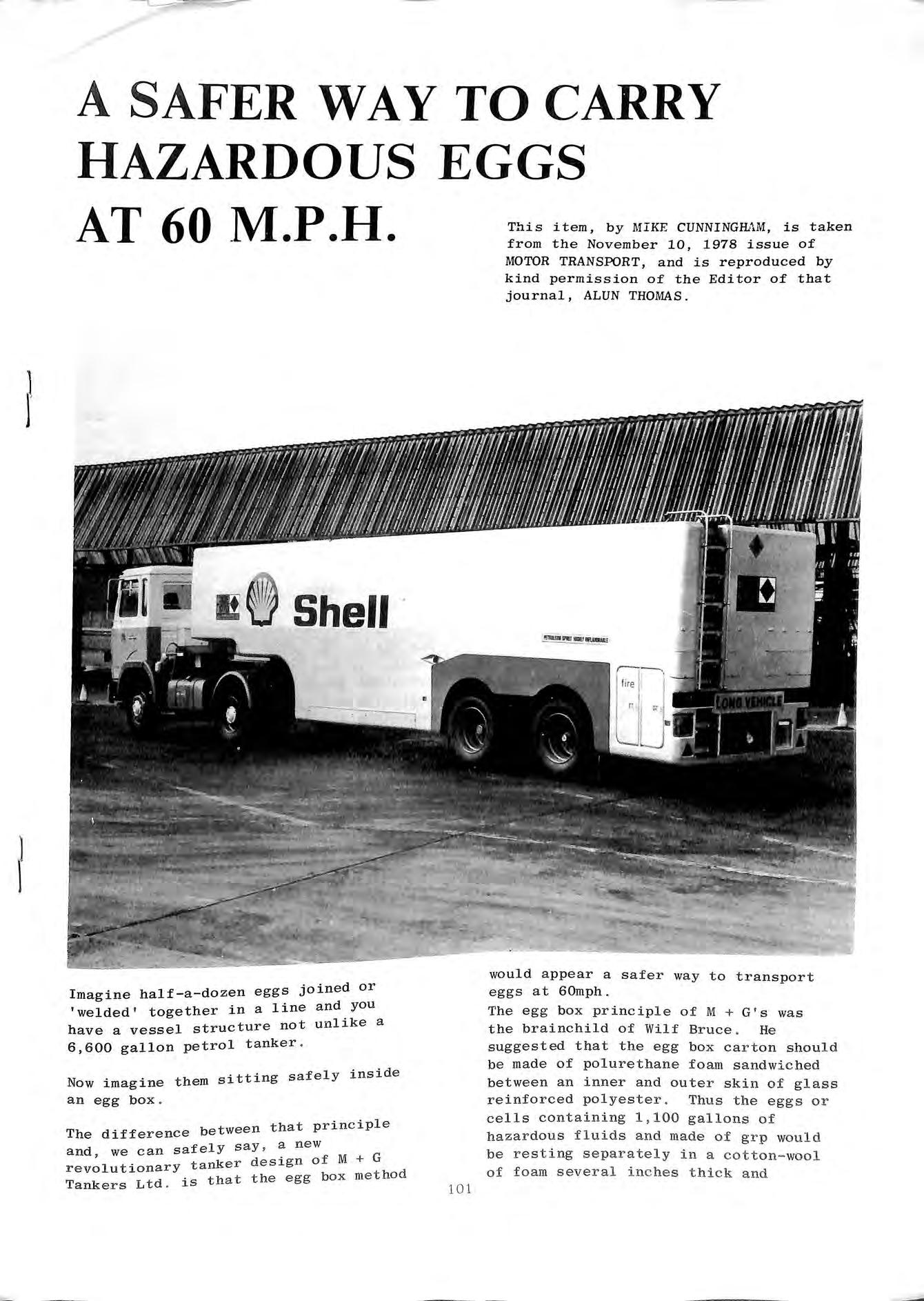

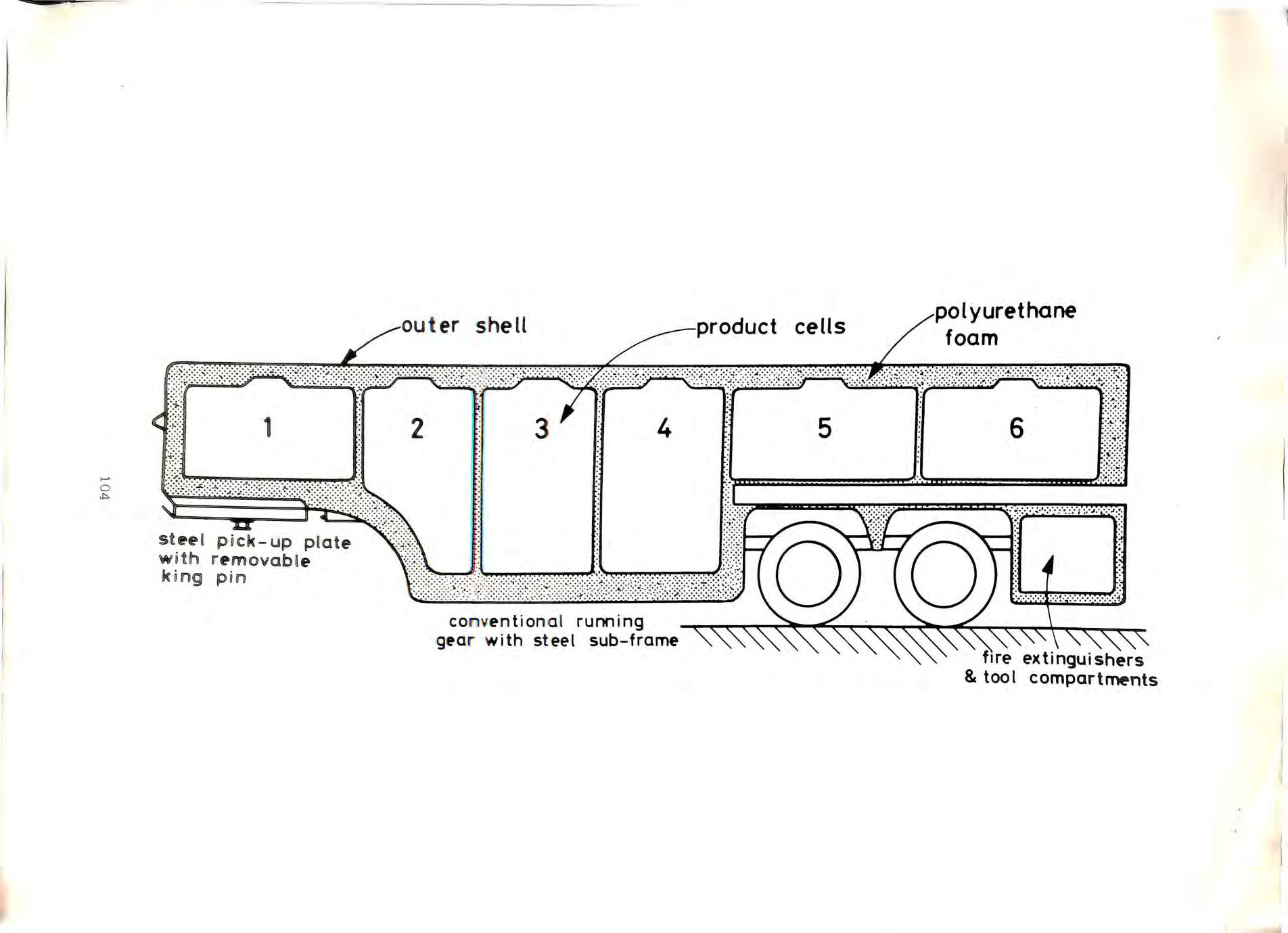

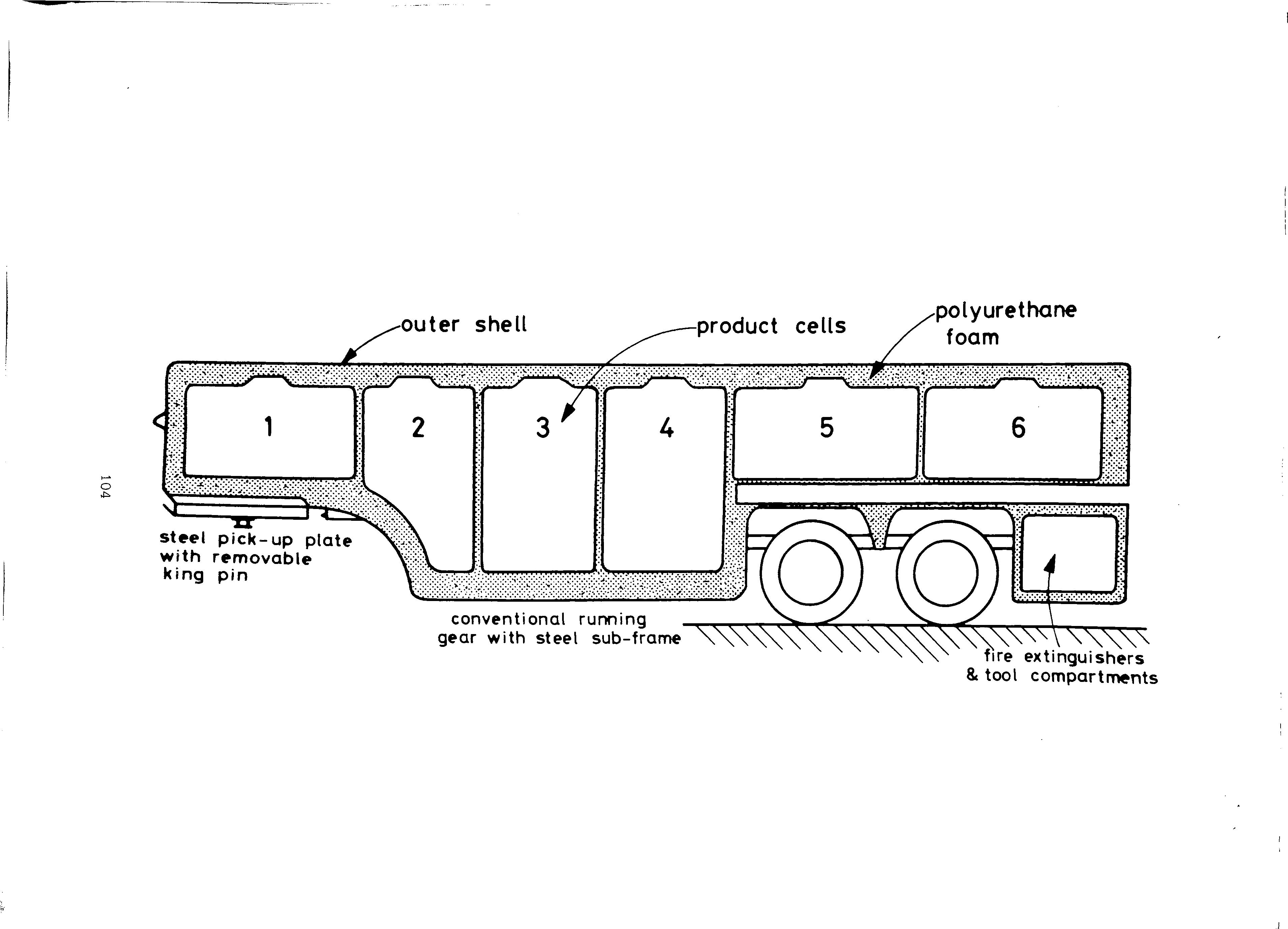

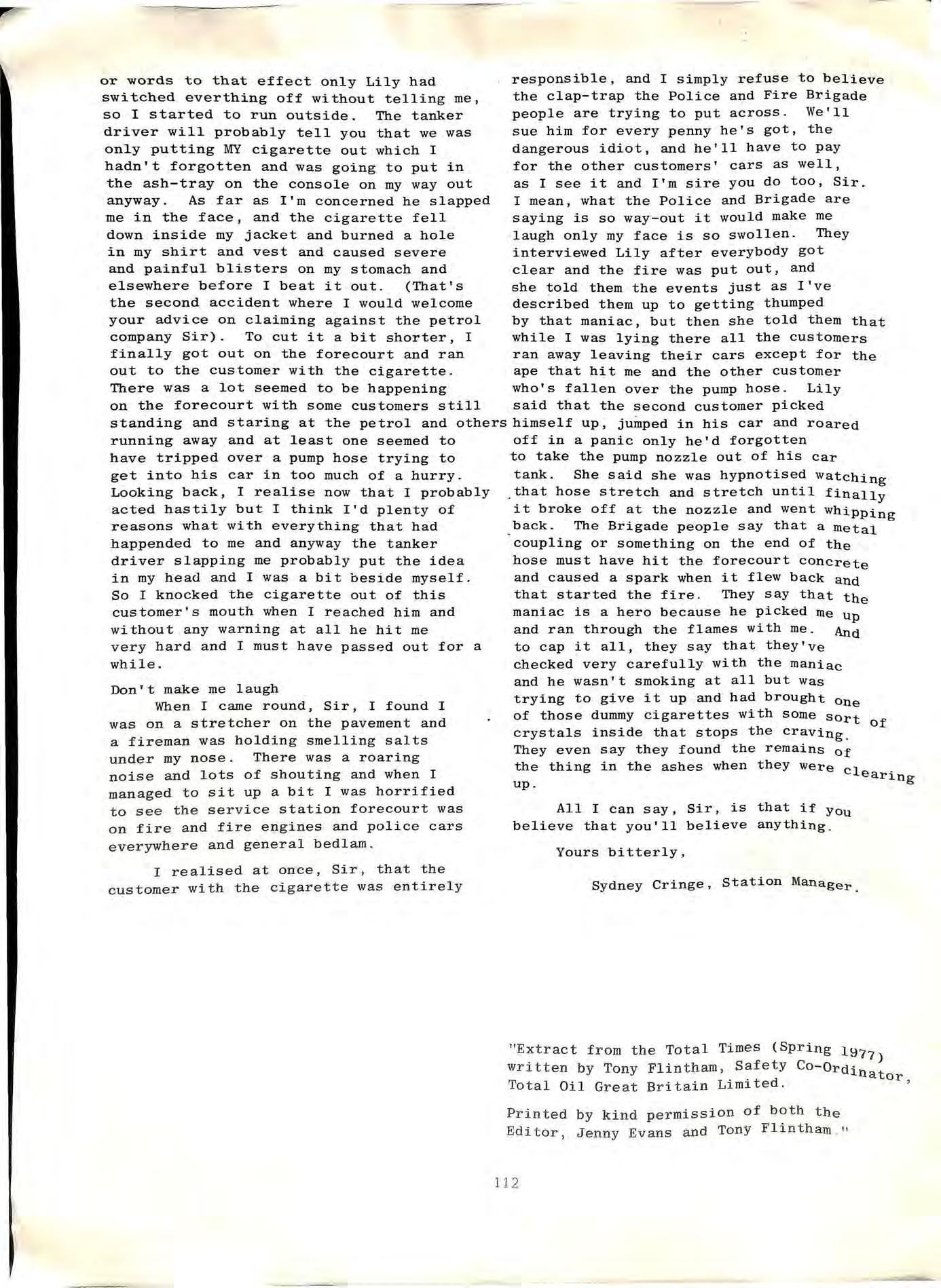

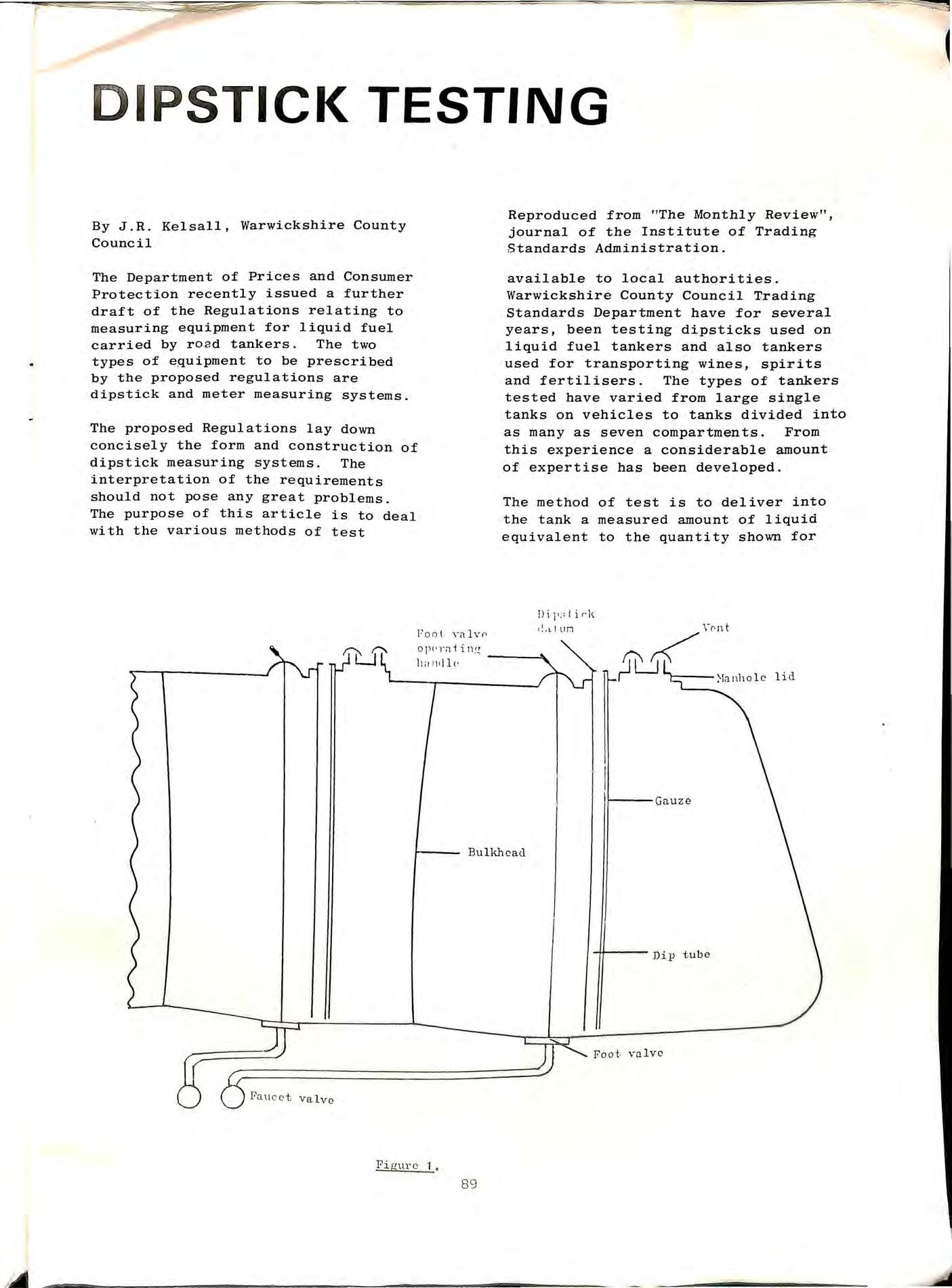

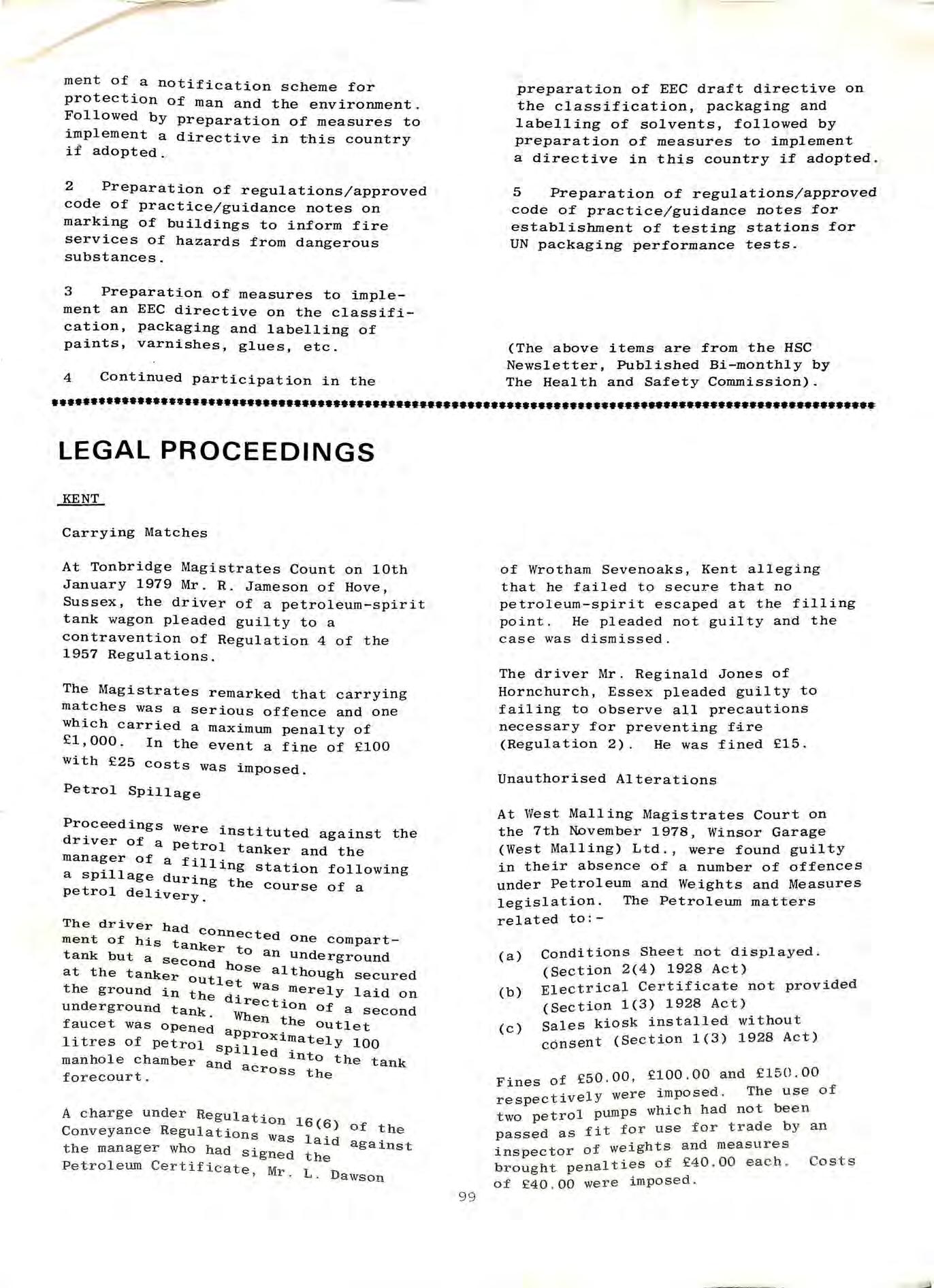

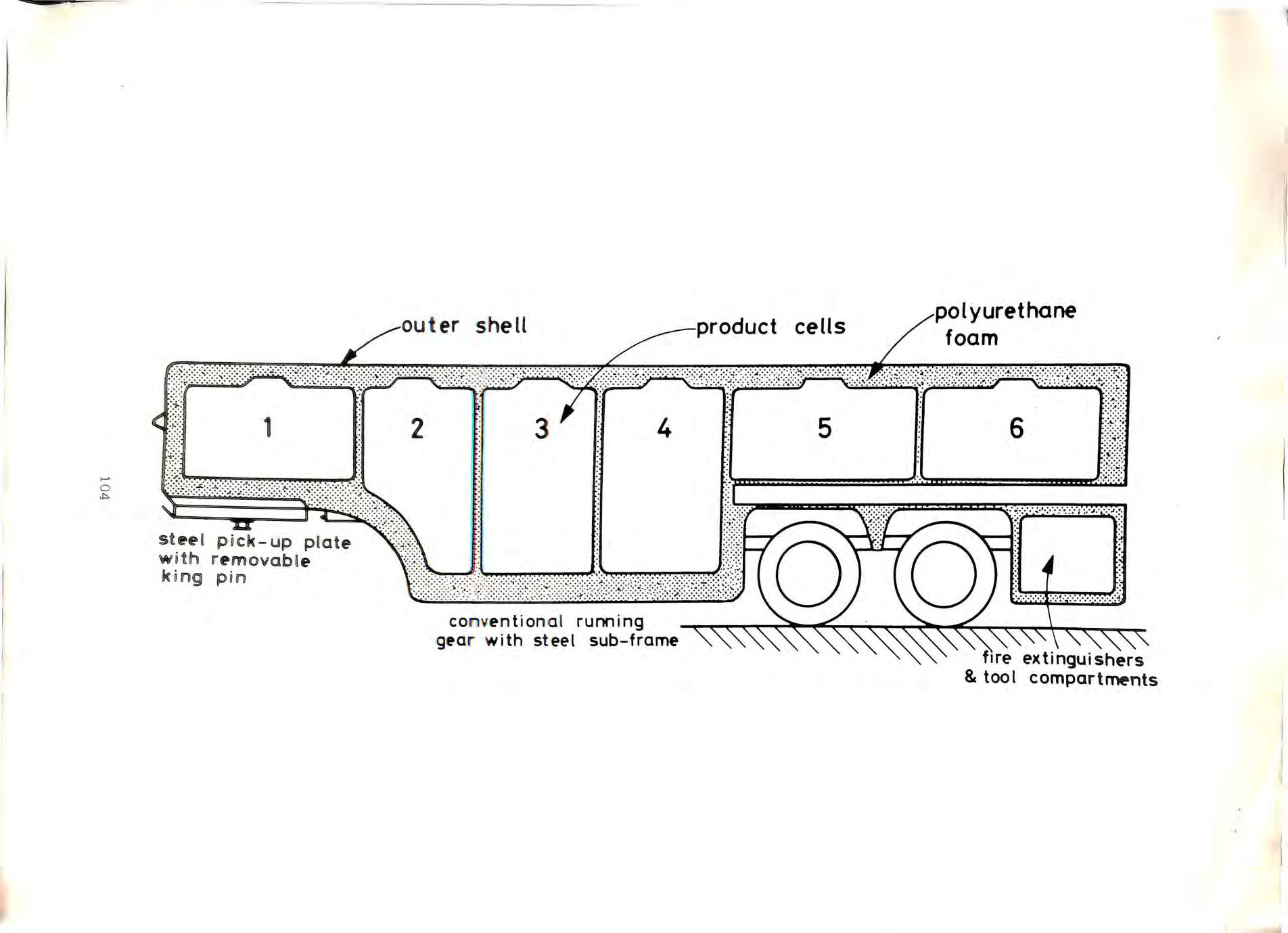

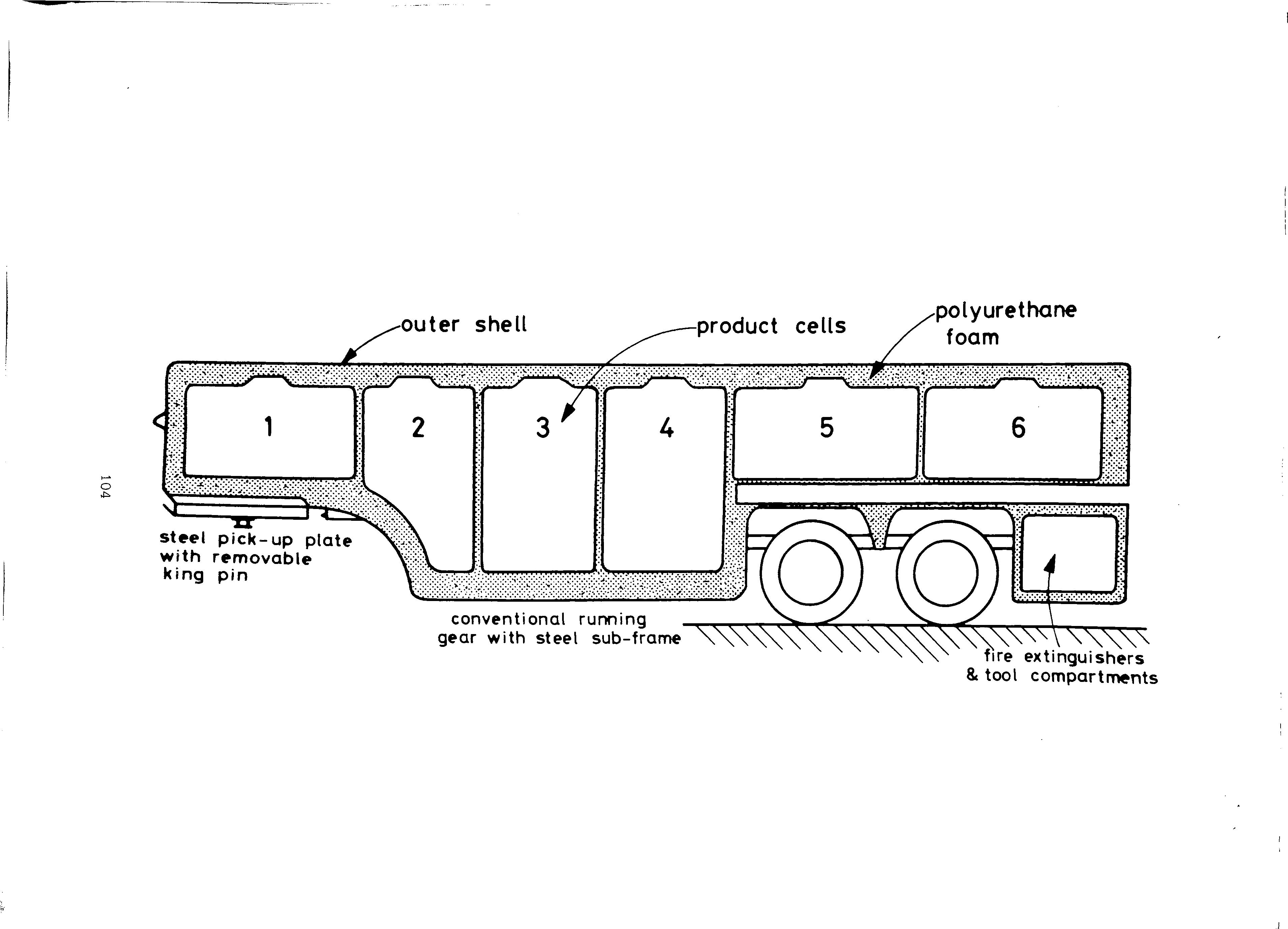

Imagine half-a-dozen eggs joined or 'welded' together in a line and you t not unlike a have a vessel struc ure 6,600 gallon petrol tanker.

them sitting safely inside Now imagine an egg box.

bet ween that principle The difference and we can safely say, a new , ok r design of M + G revolutionary ta e method Tankers Ltd is that the egg box

would appear a safer way to transport eggs at 60mph.

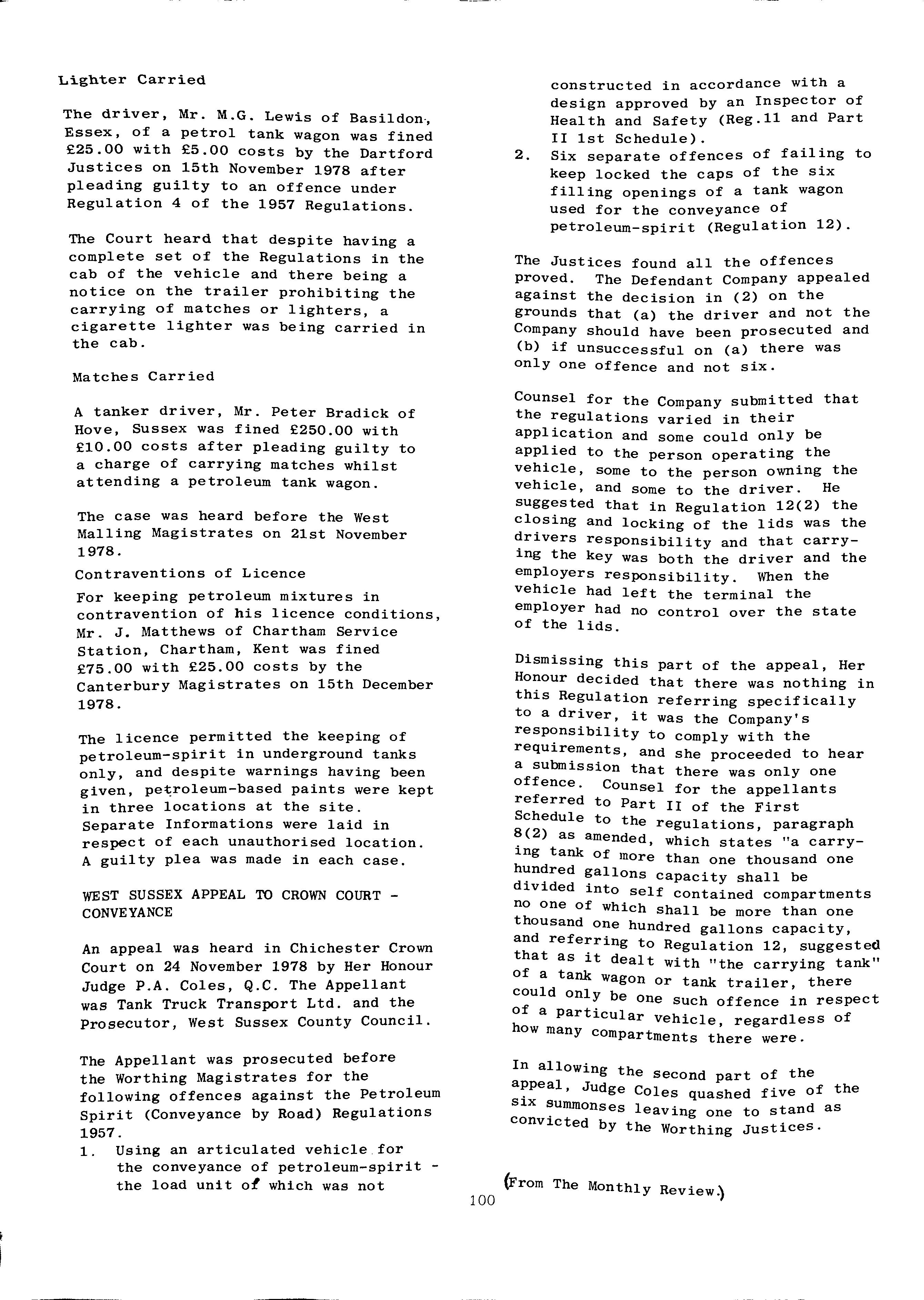

The egg box principle of M + G's was the brainchild of Wilf Bruce. He suggested that the egg box carton should be made of polurethane foam sandwiched between an inner and outer skin of glass reinforced polyester. Thus the eggs or cells containing 1,100 gallons of hazardous fluids and ma de of grp would be resting separately in a cotton- woo l of foam seve ral inc hes thick and

i

101

This item, by MIKE CUNNINGHAM, is taken from the November 10, 1978 issue of MOTOR TRANSPORT, and is reproduced by kind permission of the Editor of that journal, ALUN THOMAS.

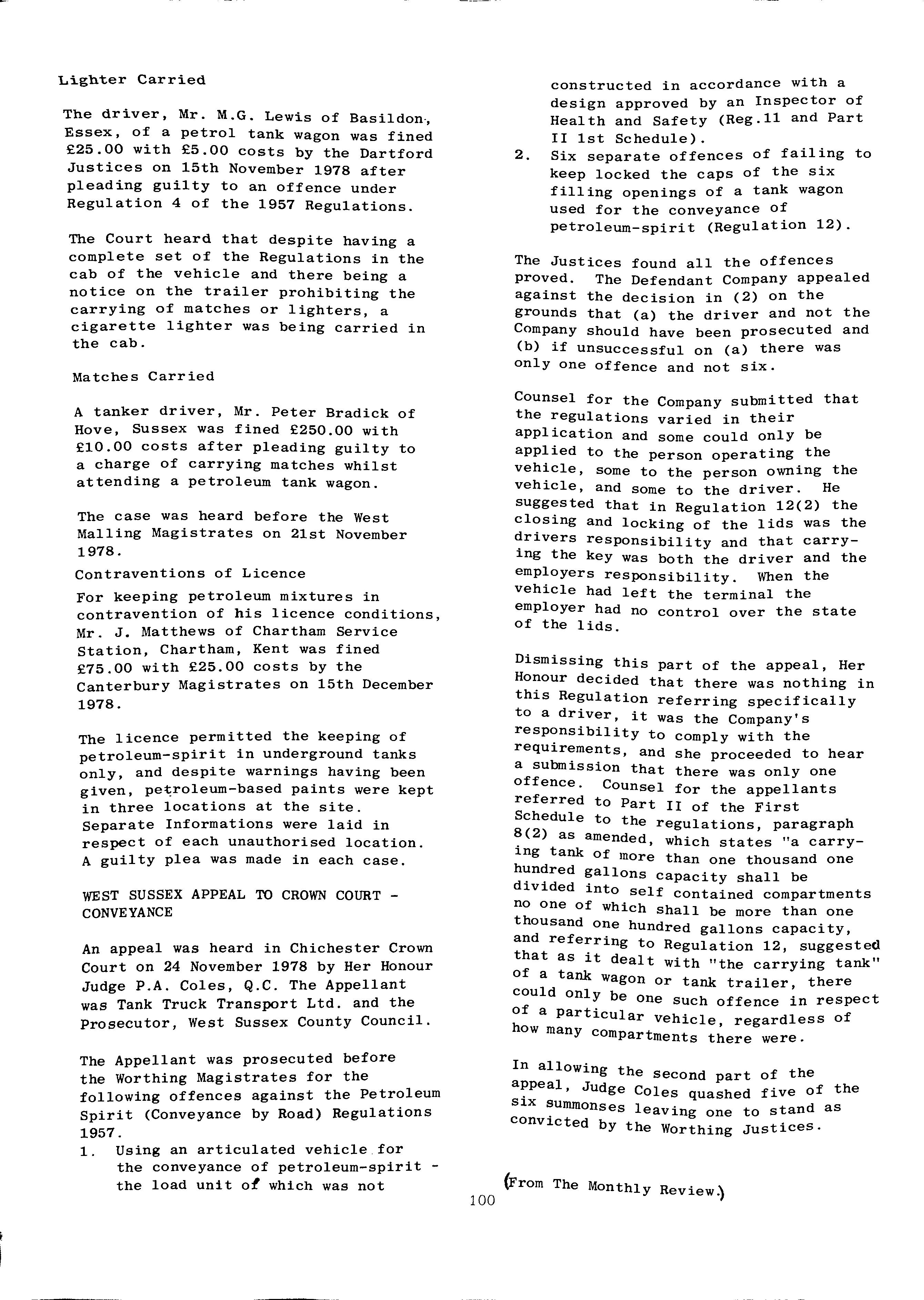

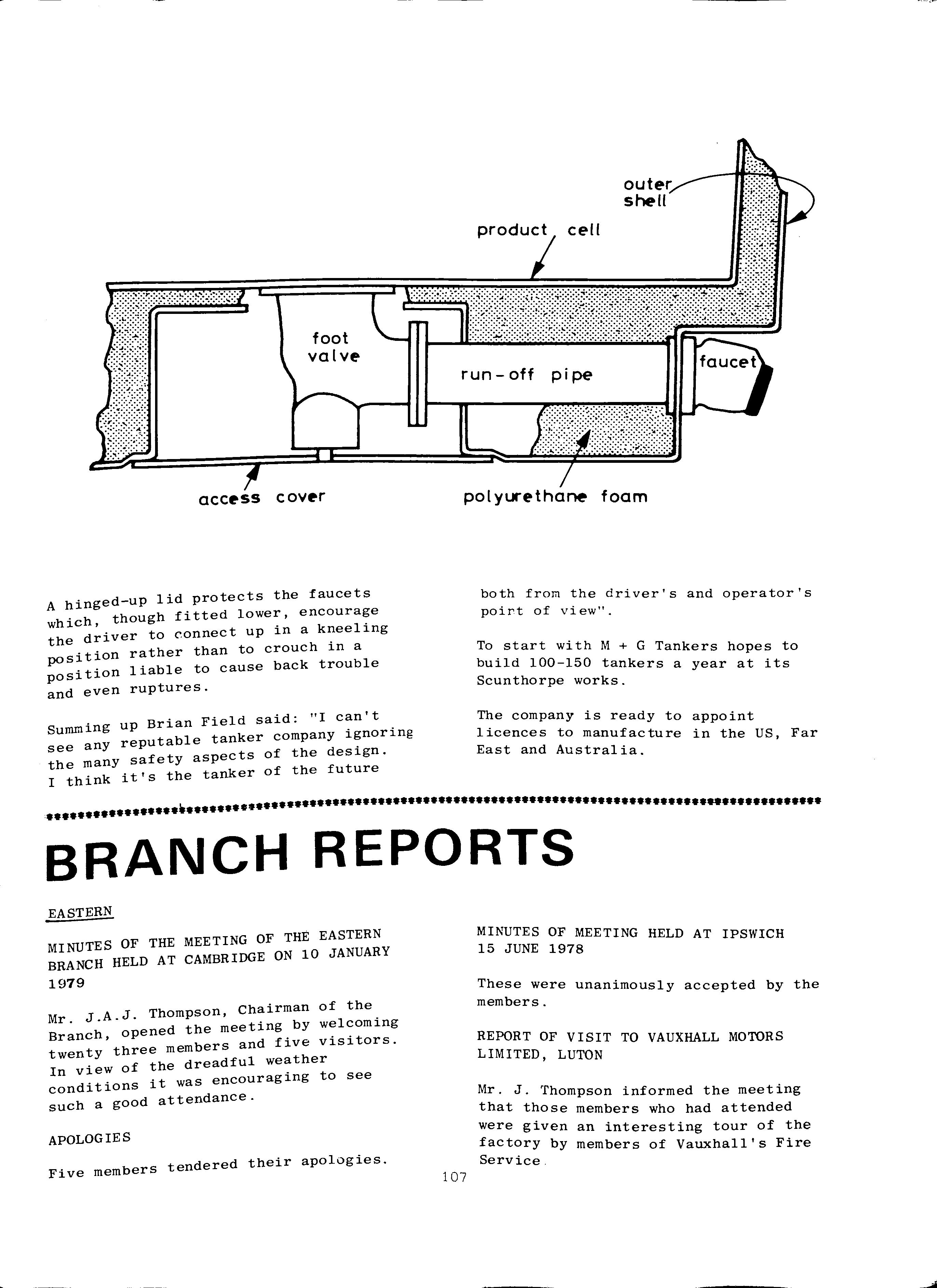

product cell

pol yuret hone foam

p r otected by a second armour coating of grp outside

That ma r vellous idea was taken up by Interdom Holdings jointly with J & J Dyson , which formed M + G Tankers (under the b anne r of M + G Trailers of Lye) two yea r s ago when it recruited the "best tan k e r b r ains in the business". This was afte r the idea had captured the i n t e r est and co-operation of Shell Oil UK .

Vi s i to r s to the Motor Show at Birmingham wil l h a v e see n a smooth l i ne low-slung 6,6 00 gall o n (3 0 , 000 l i t r es) plastics t a nker tr a il e r whi c h h as a host of othe r safety a nd ope r a ti o n a l f ea tur es de v e l op ed around this ori g inal c o nc e pt of Wilf Bruce's. What's more it i s in She ll UK Oil livery a nd und e rgoing f ull fl e et trials

Tankers have been built before in plastiCS but never ma de double-skinned with the vessel at least a s a fe 50mm away and free from any bridge that could penetrate the inner skin under impact

Th e Hea lt h and Safety Execu t ive was n a tur a ll y c oy abo u t i ssuing any app r oval

for the design before doing its own tests. It had to ensure that even a prototype would be leak-proof in a collision before it would allow petroleum spirit to be carried.

Influenced

Memories of the tanker disaster in the village of Westoning in 1976 in Which a aluminium petrol tanker exploded and n fire to the Bedfordshire village had Set strongly influenced the HSE's earlier finding that current tanker deSign regulations were of limited value .

The HSE insisted that the new dOUble _ ski n plastiCS tank p r oposal WOuld ha v e to compl y with Eu r opean ADR regulatl" ons a n d d esign codes before a pet r OleUm l i ce nc e c ould be g r a n ted

Shel l UK Oi l wen t a s t e p fu r the r t h a n ADR by apply i n g its own s tandar ds i n th l i g ht o f mu ch r es earch done b y She l l e Re s earch at Thornton, Che s hire. Indee d its re s ear c h faciliti es a nd knOWledge prOVided invalu a ble in f ormation about how the plastiCS tank s hould b e formed and stres s ed .

outer shell

102

A miniature tank vessel was built to the new design proposal. It then was £illed with 5cwt o£ water and tossed over a quarry edge.

The tank never burst even though the £all of 88ft was the estimated equivalent of a 32 ton tanker in a head-on collision. This test was performed eight times before HSE officials were satisfied.

In a fire situation, the HSE found that a single-skin grp tanker filled with naptha would withstand the envelopment of flames for 16 minutes whereas steel and aluminium tanker flame tests had to be abandoned after four minutes.

The reasons are many steel will warp and split under thermal stressing aluminium will melt at low temperatures. PlasticS however, do not burn readily and resist heat transfer.

Double-skinning greatly increases the resistance to heat transfer. The outer skin used on the M + G tank is fire resistant to BS 476/7 1971 section 2, clasS 2. The unsaturated polyester foam is also fire retardent it's almost impossible to burn. Extra foam thickness is added around the road wheel arches to

prevent heat transfer from fires caused by tyres overheating.

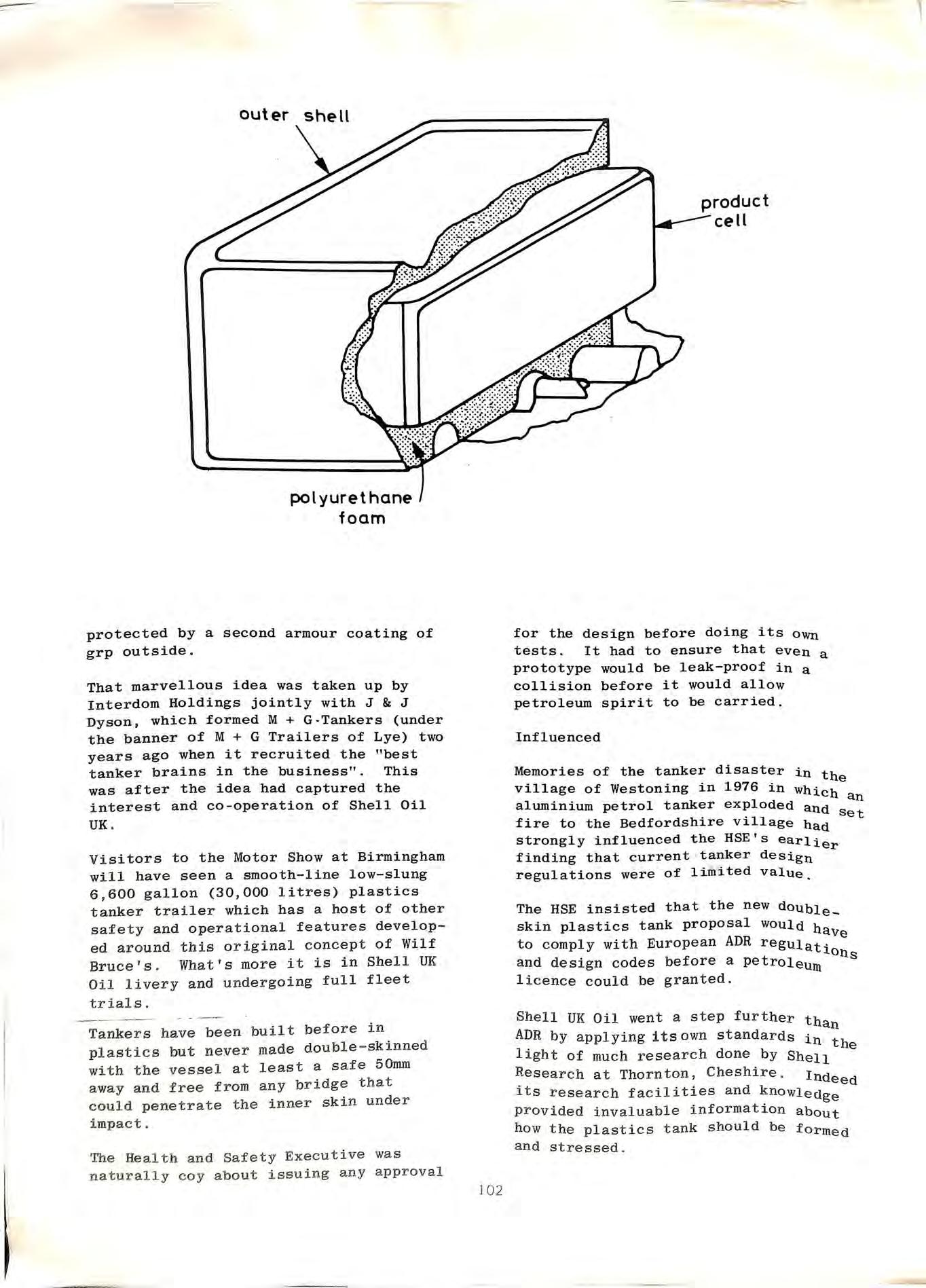

The benefit of manufacturing in plastics and foam is to allow practically any desired shape to materialise. The tank can be "sculptured" to provide extra strength without any great sacrifice of the all-important unladen weight.

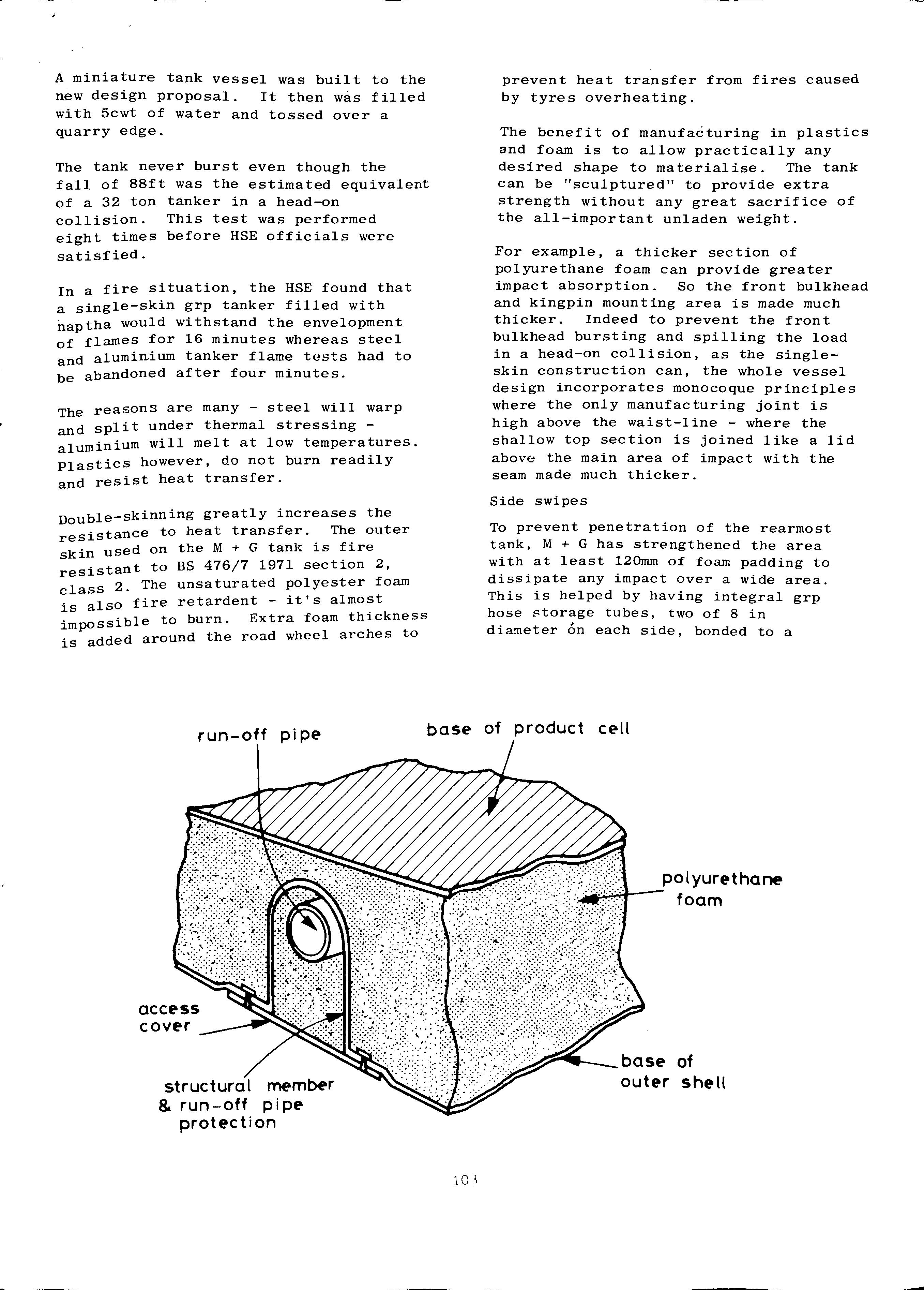

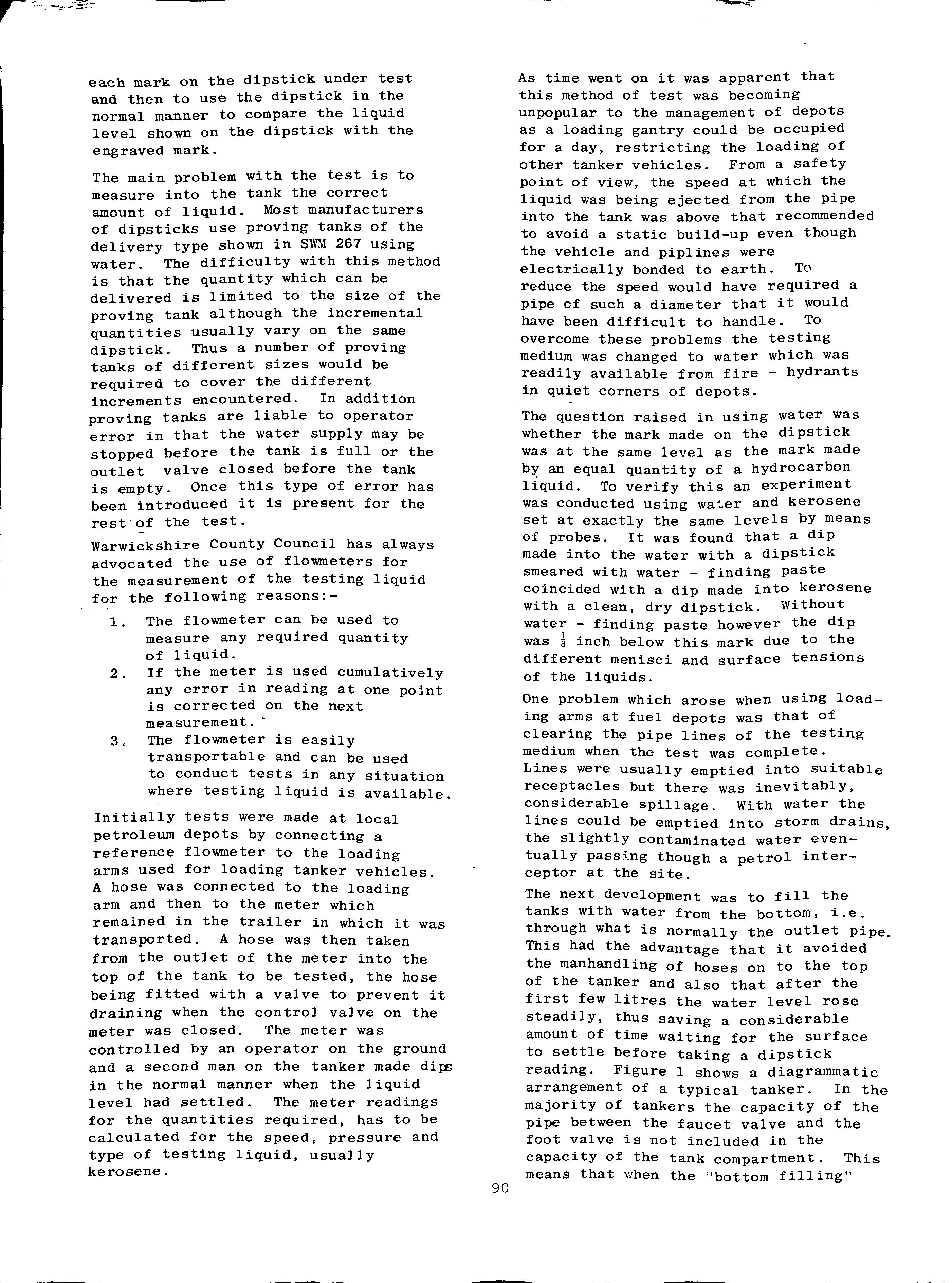

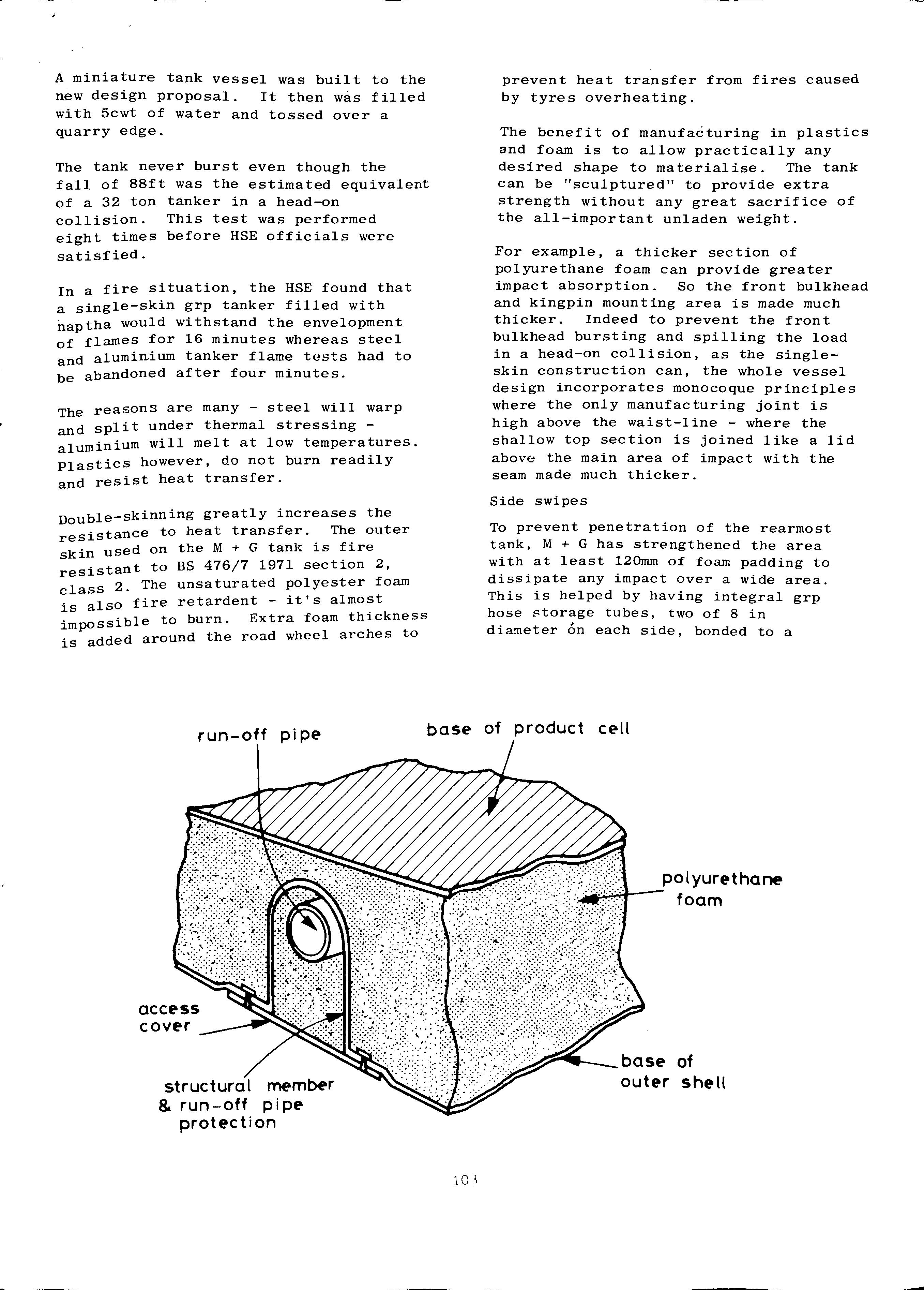

For example, a thicker section o£ polyurethane £oam can provide greater impact absorption. So the front bulkhead and kingpin mounting area is made much thicker. Indeed to prevent the front bulkhead bursting and spilling the load in a head-on collision, as the singleskin construction can, the whole vessel design incorporates monocoque principles where the only manufacturing joint is high above the waist-line where the shallow top section is joined like a lid above the main area o£ impact with the seam made much thicker.

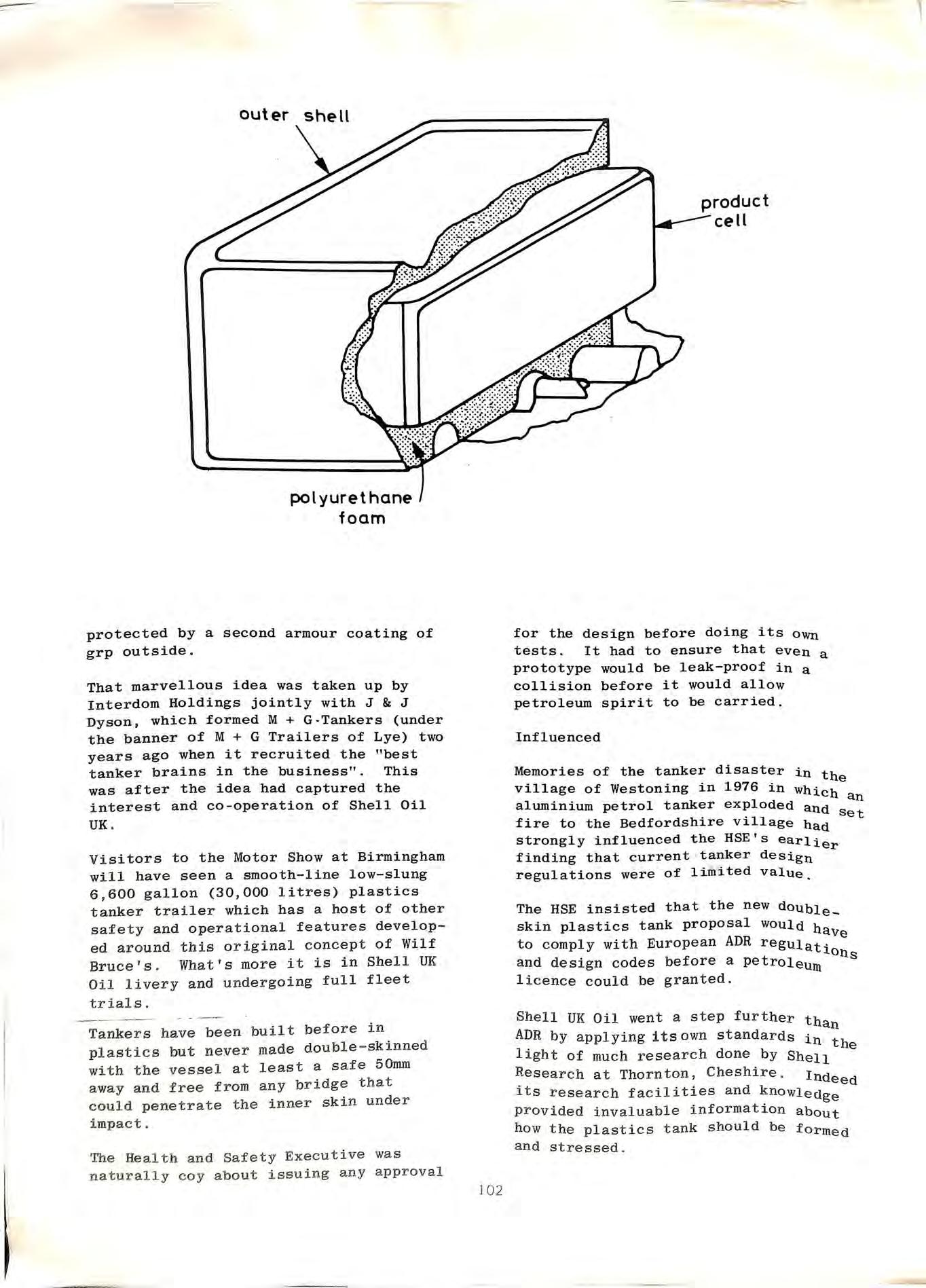

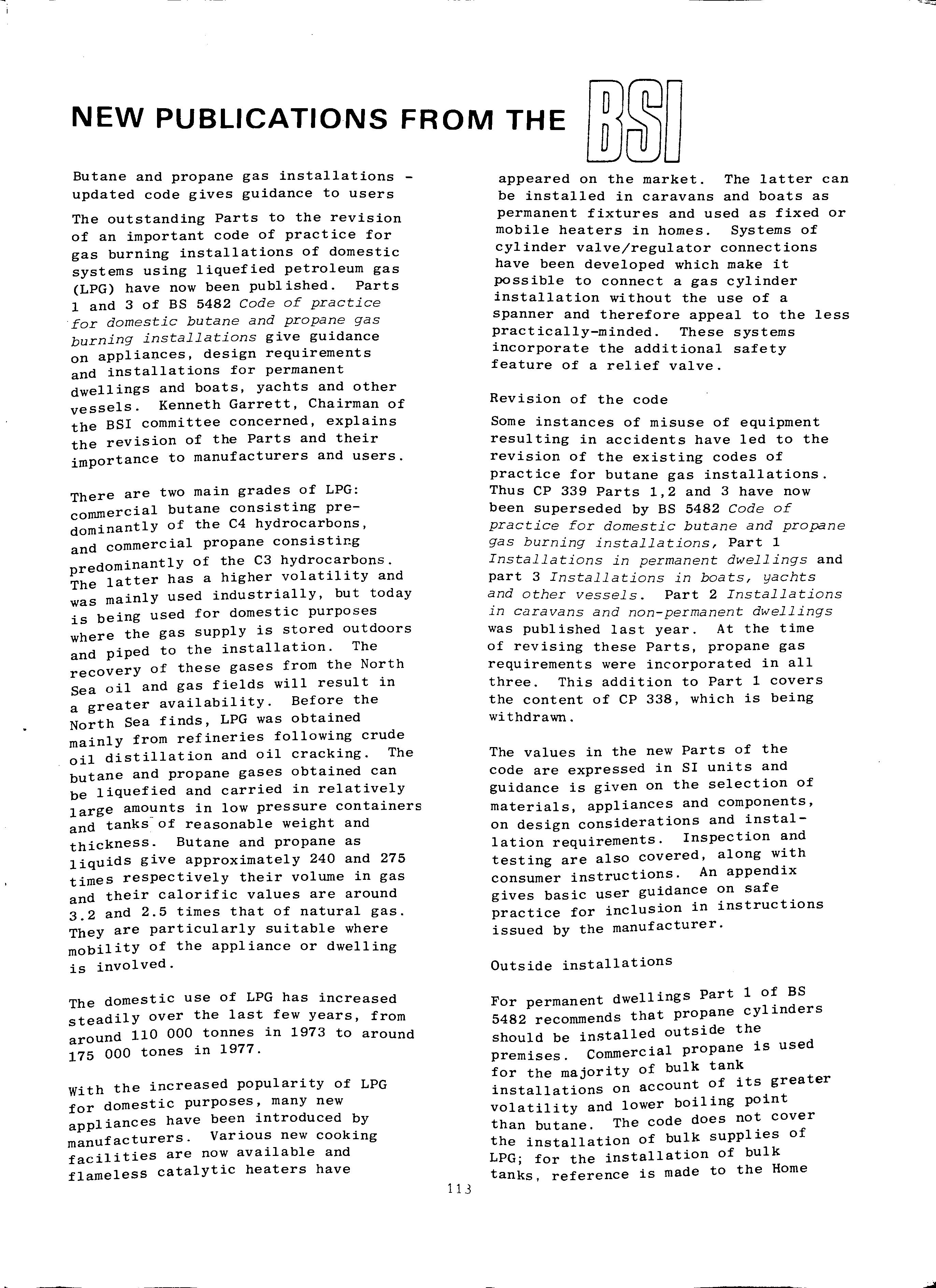

Side swipes

To prevent penetration of the rearmost tank, M + G has strengthened the area with at least 120mm of foam padding to dissipate any impact over a wide area. This is helped by having integral grp hose tubes, two of 8 in diameter on each side, bonded to a

.'

run-off pi pe base of product cell cover structural member & run-off pipe protection 1 polyurethane foam

o .!» 1 st p e[ pock-up p l at e with r p movabl e king pin U ou t er s hell product cells 2 3' U 4 U 5 ']I :Ii : .• ·$ < ;•• co n ventional running gea r with st eel sub-frame U pol yurethane foam 6 fire extinguishers & tool

rear crash-bar beneath. Any impact is transmitted and absorbed by the tubes along the sides of the rear two tanks and forward of the trailer suspension.

The crash under-run bar is attached to the trailer bogie. With polyurethane packed between double-skinned panels the risk of penetration in a side-swipe is considerably less.

In a Birmingham underpass a petrol tanker split open after a side-swipe collision, spilling 300 gallons on to the road in a busy crowded area. Such a situation is far less likely with this new tanker design. The construction techniques allow designer greater freedom to make the tanker overall more compact the shapes of the individual tanks don't really matter as they can be made completely accurate in the moulding process and thus repeatable.

So M + G and Shell have ended with a tanker trailer which is shorter (34ft) and sits more squat on the road. Though higher overall, (10ft 6in) the centre of load gravity is lowered by 330mm (13in) in relation to normal steel or aluminium tanker construction.

With so many safety problems overcome to the satisfaction of HSE, there remained the most difficult of all Static electricity before a petroleum spirit licence could be granted.

Static can be quit e se v ere i n s ide a plastics tanker during loading. The build up in voltage made by the fuel swi s hi ng o v e r th e surface interior is qu i te dramatic t ile r e p \ l{: j n g surfa ce to-air space is crammed with volts till like a f l as h of lightning they track in a spark build-up sometimes a foot lo ng .

The second form of lesser static build up comes from air-friction over the outer plastic skin caused by wind or when travelling. This is overcome by finishing the tank with an antistatiC gel coat.

To overcome the problem inside the tanks, a special gel coat is also used and a system of continual earthing by ring-main type dispersal from all metal fittings to loading and discharging points is incorporated.

The way in which this is done remains very much a guarded secret, while patents are filed

The effect is to make the plastics tank virtually as good at discharging static build-up as a steel tanker. With the patentable system the "relaxation" OI static will allow loading at the rate of between 300 to 450 gallons a minute.

"Following successIul tests at Thornton a petroleum spirit licence has been granted for the new tanker design," said development engineer Eric Sheperd, quoting the number 1678/S/86.

Much of the revoluntionary thinking that has gone into producing M + G Tankers Ltd's plastics tanker is built around making road tanker handling of petroleum spirit much safer. It is virtually crash-proof, fire-proof and leak-proof claim its makers, and shortly the first ever tanker roll-over accident test will be staged to prove physically mounting theoretical evidence. This has never been attempted with any tanker design.

Introducing just safety only improvements to road transport without considering the economic advantages would be suicide for M + G Tankers.

There are 12,000 to 15,000 tankers carrying liquids many of which are hazardous. A good many are ten times more hazardous than the 6,000 petroleum spirit wagons operating in Britain which have a very good safety record.

So far, with Shell UK Oil guidance M + G tankers have concentrated on' petroleum spirit tanker operation

The double skinned plastics tanker competes very favo urab ly with aluminium construction which is now chosen, because of its weight saving, in 60 per ce n t o f t a nk e r pur c h a se s At £ 2 0 , 000 the plastiCS i s c on s i d ra bl y more expensive than mild-steel at between £ 12,000 £14, 000 and al ulT\inium b e twe n £17,500 to £19,500.

However, at six tons unl aden weight, the plastiCS tanker is li ghter than steel and slightly heavier than aluminium. It competes very favourabl with insulated tankers because in y original form the ready-made thermal conductivity, or K-factor, of the tanker is so good that heat loss is considered nil.

Such loads as bla ck oil which is pumped at more than 70 deg C can be left standing overnight and re main pumpable next morning. Wine will remain ther mally st a ble and milk will not curdle No r is the tank tainted

1 0S

...... o 01::> 1 st.el

outer shell 2 4 conventional

product cells 5 . pot yurethane foam 6 fire extinguishers & tool

pick- up plate with removable king pin

running gear with steel sub-frame

rear crash-bar beneath. Any impact is transmitted and absorbed by the tubes along the sides of the rear two tanks and forward of the trailer suspension.

The crash under-run bar is attached to the trailer bogie. With polyurethane packed between double-skinned panels the risk of penetration in a side-swipe is considerably less.

In a Birmingham underpass a petrol tanker split open after a side-swipe collision, spilling 300 gallons on to the road in a busy crowded area. Such a situation is far less likely with this new tanker design. The construction techniques allow designer greater freedom to make the tanker overall more compact the shapes of the individual tanks don't really matter as they can be made completely accurate in the moulding process and thus repeatable.

So M + G and Shell have ended with a tanker trailer which is shorter (34ft) and sits more squat on the road. Though higher overall, (10ft 6in) the centre of load gravity is lowered by 330mm (13in) in relation to normal steel or aluminium tanker construction.

With so many safety problems overcome to the satisfaction of HSE, there remained the most difficult of all Static electricity before a petroleum spirit licence could be granted.

Static can be quite severe inside a plastics tanker during loading. The build up in voltage made by the fuel swishing over the surface interior is quite dramatic the reducing surfaceto-air space is crammed with volts till like a flash of lightning they track in a spark build-up sometimes a foot long.

The second form of lesser static build up comes from air-friction over the outer plastic skin caused by wind or when travelling. This is overcome by finishing the tank with an antistatic gel coat.

To overcome the problem inside the tanks, a special gel coat is also used and a system of continual earthing by ring-main type dispersal from all metal fittings to loading and discharging points is incorporated.

The way in which this iA Gone remains very much a guarded secret, while patents are filed.

The effect is to make the plastics tank virtually as good at discharging static build-up as a steel tanker. With the patentable system the "relaxation" of static will allow loading at the rate of between 300 to 450 gallons a minute.

"Following successful tests at Thornton a petroleum spirit licence has been granted for the new tanker design," said development engineer Eric Sheperd, quoting the number 1678/S/86.

Much of the revoluntionary thinking that has gone into producing M + G Tankers Ltd's plastics tanker is built around making road tanker handling of petroleum spirit much safer. It is virtually crash-proof, fire-proof and leak-proof claim its makers, and shortly the first ever tanker roll-over accident test will be staged to prove physically mounting theoretical evidence. This has never been attempted with any tanker design.

Introducing just safety only improvements to road transport without considering the economic advantages would be suicide for M + G Tankers.

There are 12,000 to 15,000 tankers carrying liquids many of which are hazardous. A good many are ten times more hazardous than the 6,000 petroleum spirit wagons operating in Britain which have a very good safety record.

So far, with Shell UK Oil guidance, M + G tankers have concentrated on petroleum spirit tanker operation. The double-skinned plastics tanker competes very favourably with aluminium construction which is now chosen, because of its weight saving, in 60 per cent of tanker purchases. At £20,000 the plastics is considerably more expensive than mild-steel at between £12,000-£14,000 and aluminium between £17,500 to £19,500.

However, at six tons unladen weight, the plastics tanker is lighter than steel and slightly heavier than aluminium. It competes very favourably with insulated tankers because in original form the ready-made thermal conductivity, or K-factor, of the tanker is so good that heat loss is considered nil.

Such loads as black oil which is pumped at more than 70 deg C can be left standing overnight and remain pumpable next morning. Wine will remain thermally stable and milk will not curdle. Nor is the tank tainted.

105

So the design lends itself to the widest possible use. Stainless steel tank-lining can be used, too.

The economic life of the double-skinned plastics tanker is thought to be longer than the 12 years usually sought by oil companies . What do you do with a tough 34ft long bo x after that is another guess

Main tenance costs should be consider-ably less because the makers rule out the possibility of leaks and accident damage can be repaired in 12 hours.

Usually three repaints are needed in a life-time on metal tankers and that can run to 12 weeks downtime plus the high cost of painting.

"We hope in the near fu ture to have the tanker delivered ·without need of paint ing and with the customer's colour and l ogo impregnated in the grp," said Mr Brian Field , M + G's managing director

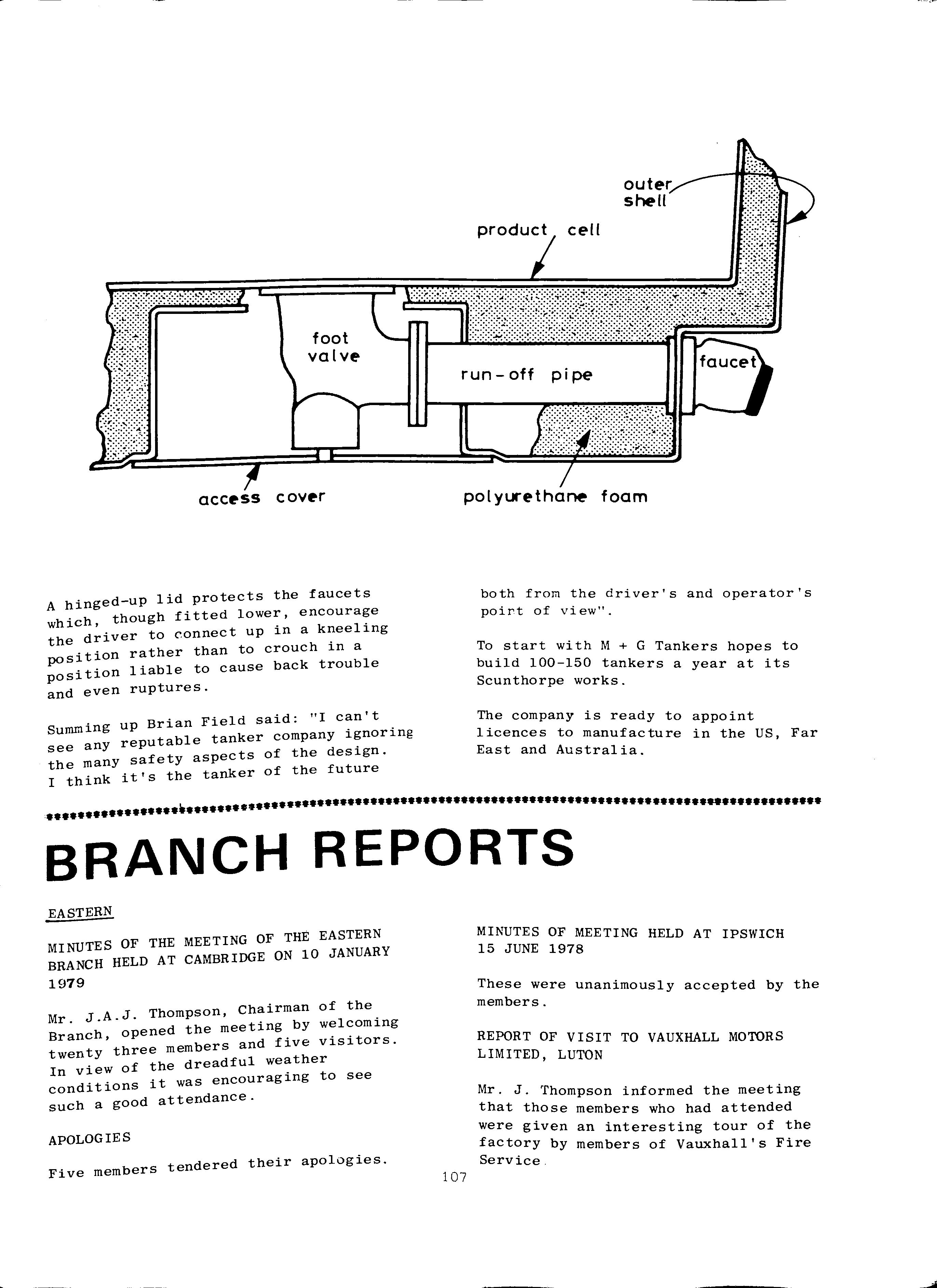

Ma int enan c e of the foot valves is made easy by havin g re move able sections round th em There are no stee l pipes as such because six hose tubes runnin g from the foot valve to the faucet are bonded in a deta chabl e double skinned section

A suction pipe line leading to the rear-mounted Drum Pluto 4 pump is bonded integrally to form a spine beneath the row of tanks.

Remote control

Foot-valves are operated by Emco pneumatic equipment with push button control placed near the top manholes and by remote control at the rear. It is impossible to drive away accidently while the tanker is loading or discharging till all valves and doors are closed. A pneumatic interlock system incorporated with the valve and brake system prevents this happening.

There are acres of flat space for the driver operator to walk along when opening manlids and dipping tanks. This reduces the risk of operators losing their balance and falling nearly 11ft. The su rfac e between the overt the manlids turn protection g1ven 0 i s coated with aluminium oxide gr1t bonded durin g construction.

106

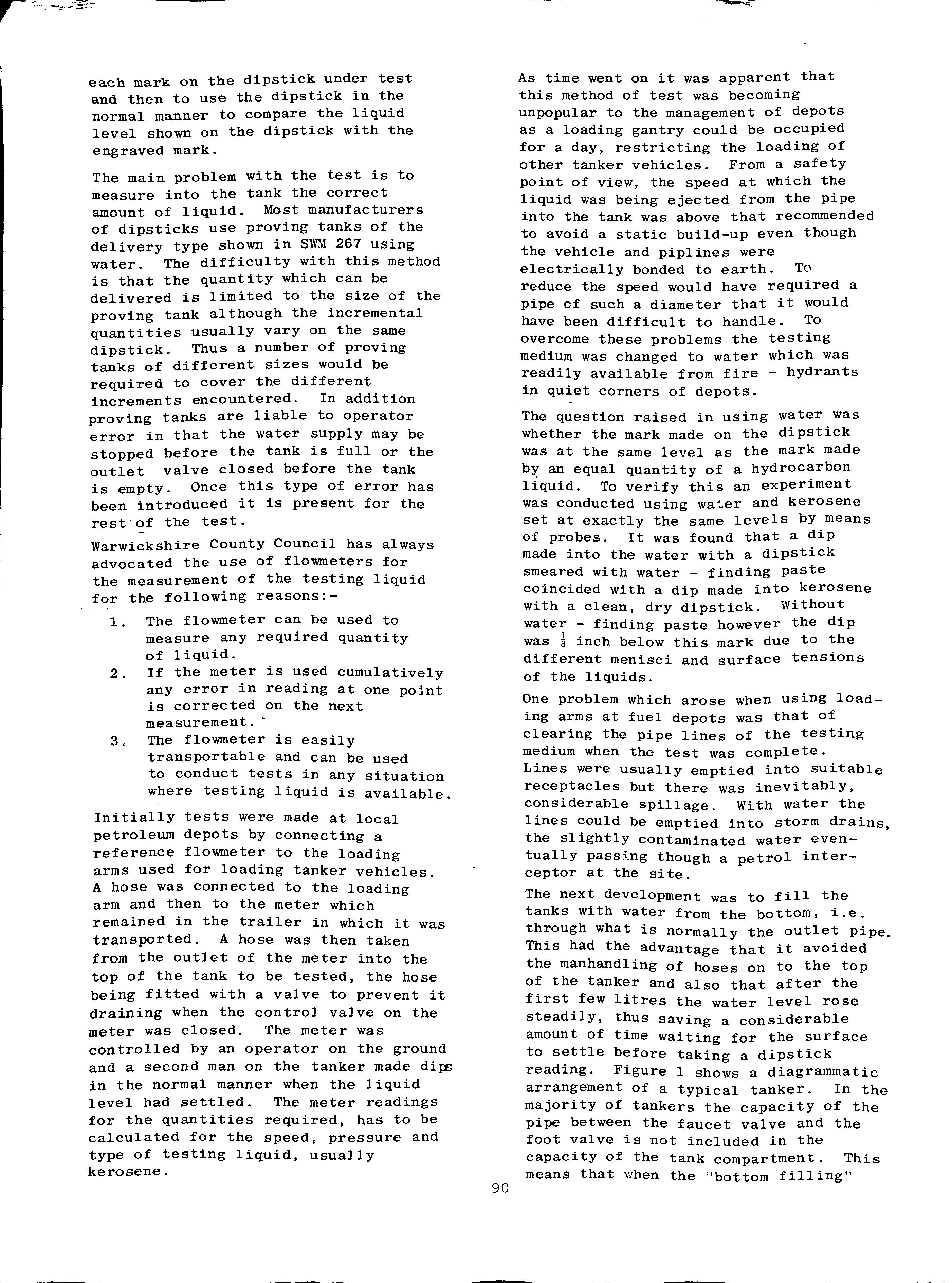

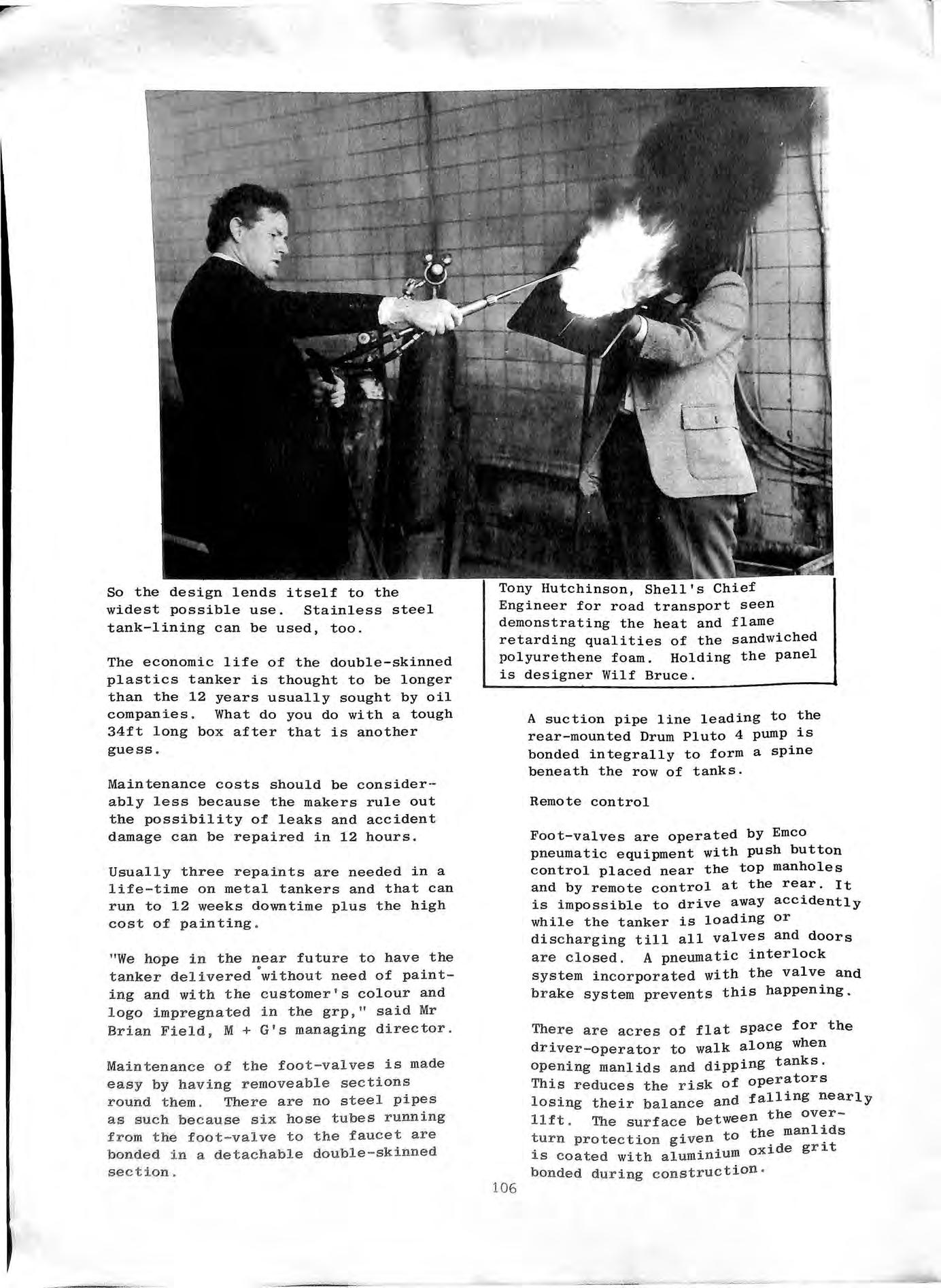

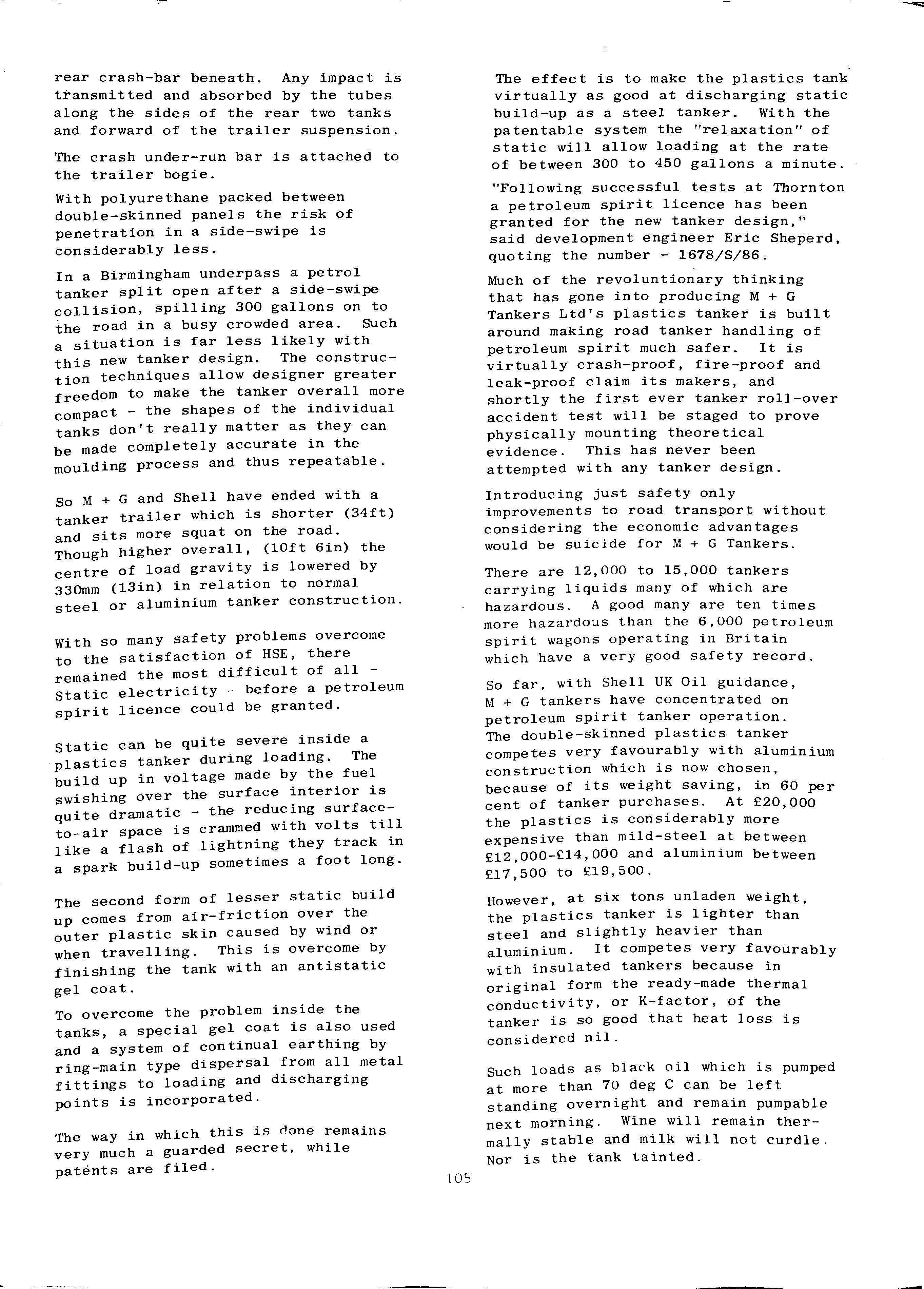

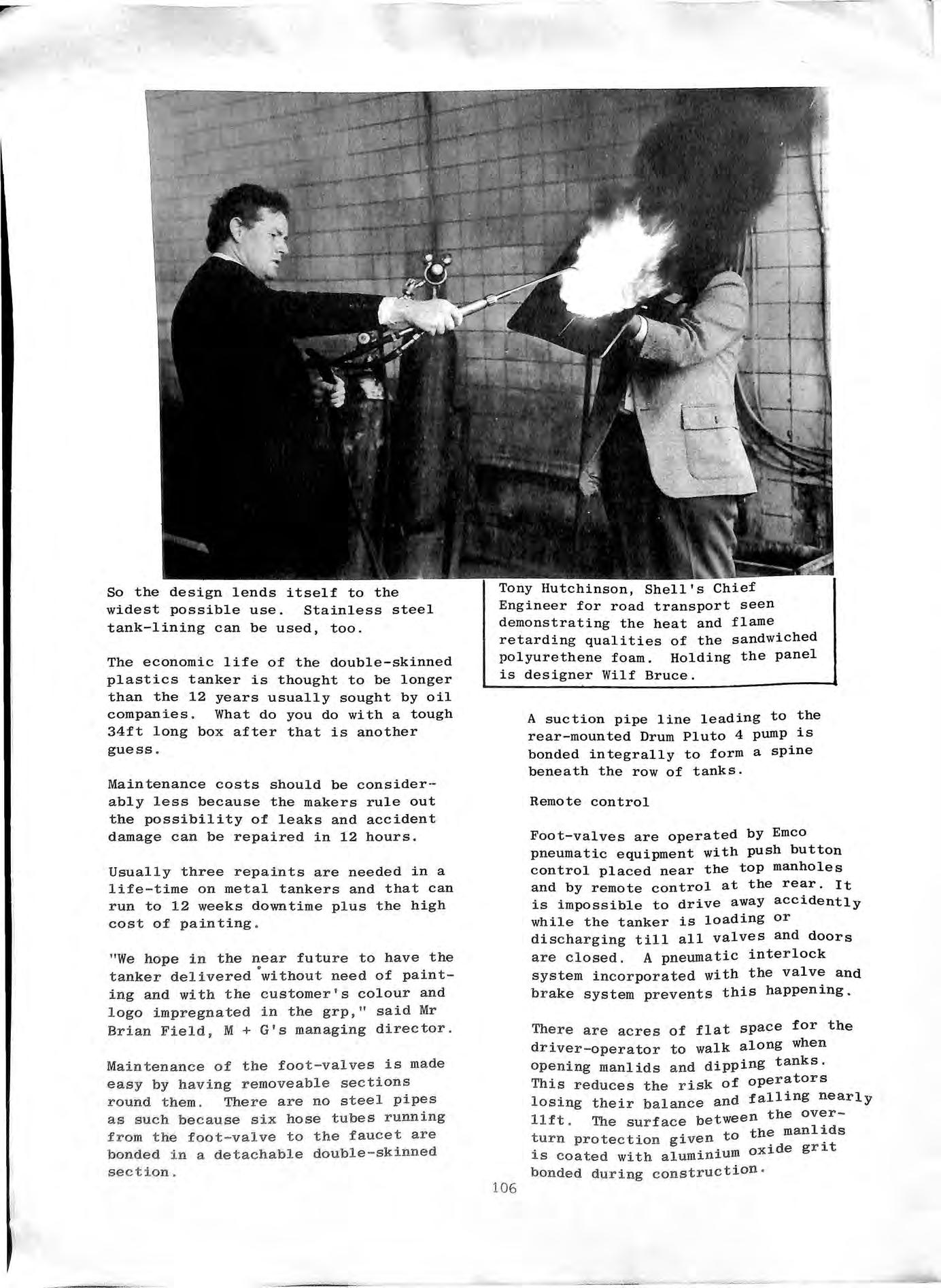

Tony Hutchinson, Shell's Chief Engineer for road transport seen demonstrating the heat and flame retarding qualities of the sandwiched polyure thene foam. Holding the panel is designer Wilf Bruce.

A hinged-UP lid protects the faucets which, though fitted lower, encourage the driver to connect up in a kneeling position rather than to crouch in a position liable to cause back trouble and even ruptures.

Summing up Brian Field said: "I can't see any reputable tanker company ignoring the many safety aspects of the design. I think it's the tanker of the future

product cell

run - off pi pe

outer shell pol yurethoneo foam both from the driver's and operator's pOil"t of view".

To start with M + G Tankers hopes to build 100-150 tankers a year at its Scunthorpe works.

The company is ready to appoint licences to manufacture in the US, Far East and Australia.

BRANCH REPORTS

EASTERN

MINUTES OF THE MEETING OF THE EASTERN BRANCH HELD AT CAMBRIDGE ON 10 JANUARY

1979

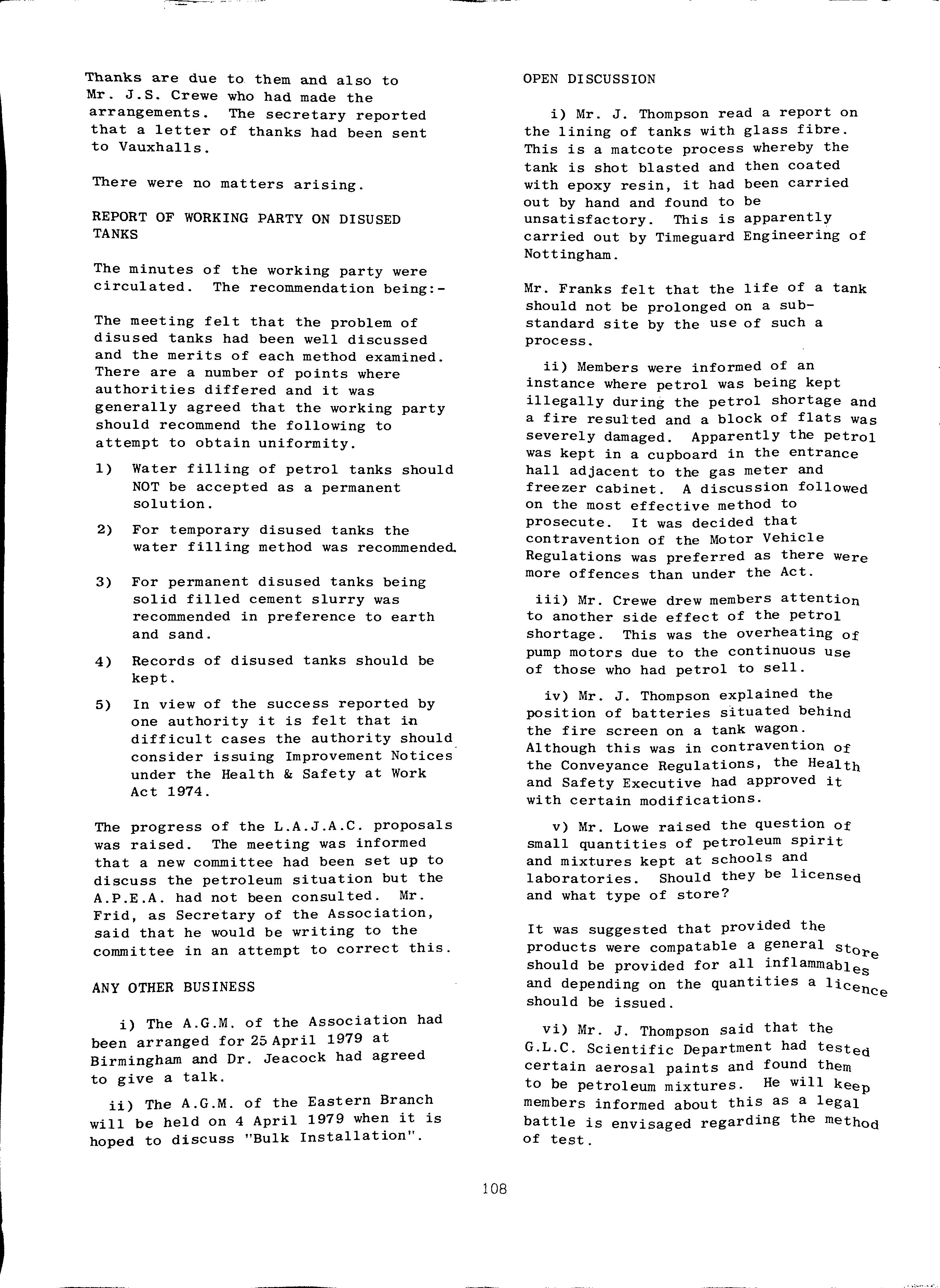

Mr. J.A.J. Thompson, Chairman of the Branch, opened the meeting by welcoming twenty three members and five visitors. In view of the dreadful weather conditions it was encouraging to see such a good attendance.

APOLOGIES

Five members tendered their apologies. 107

MINUTES OF MEETING HELD AT IPSWICH 15 JUNE 1978

These were unanimously accepted by the members.

REPORT OF VISIT TO VAUXHALL MOTORS LIMITED, LUTON

Mr. J. Thompson informed the meeting that those members who had attended were given an interesting tour of the factory by members of Vauxhall's Fire Service,

:.....................................................................................................

Thanks are due to. them and also to Mr. J.S. Crewe who had made the arrangements. The secretary reported that a letter of thanks had been sent to Vauxhalls.

There were no matters arising.

REPORT OF WORKING PARTY ON DISUSED TANKS

The minutes of the working party were circulated. The recommendation being:-

The meeting felt that the problem of disused tanks had been well discussed and the merits of each method examined. There are a number of points where authorities differed and it was generally agreed that the working party should recommend the following to attempt to obtain uniformity.

1) Water filling of petrol tanks should NOT be accepted as a permanent solution.

2) For temporary disused tanks the water filling method was recommended

3) For permanent disused tanks being solid filled cement slurry was recommended in preference to earth and sand.

4) Records of disused tanks should be kept.

5) In view of the success reported by one authority it is felt that in difficult cases the authority should consider issuing Improvement Notices under the Health & Safety at Work Act 1974.

The progress of the L.A.J.A.C. proposals was raised. The meeting was informed that a new committee had been set up to discuss the petroleum situation but the A.P.E.A. had not been consulted. Mr. Frid, as Secretary of the Association, said that he would be writing to the committee in an attempt to correct this.

ANY OTHER BUSINESS

i) The A.G.M. of the Association had been arranged for 25 April 1979 at Birmingham and Dr. Jeacock had agreed to give a talk.

ii) The A.G.M. of the Eastern Branch will be held on 4 April 1979 when it is hoped to discuss "Bulk Installation".

OPEN DISCUSSION

i) Mr. J. Thompson read a report on the lining of tanks with glass fibre. This is a matcote process whereby the tank is shot blasted and then coated with epoxy resin, it had been carried out by hand and found to be unsatisfactory. This is apparently carried out by Timeguard Engineering of Nottingham.

Mr. Franks felt that the life of a tank should not be prolonged on a substandard site by the use of such a process.

ii) Members were informed of an instance where petrol was being kept illegally during the petrol shortage and a fire resulted and a block of flats was severely damaged. Apparently the petrol was kept in a cupboard in the entrance hall adjacent to the gas meter and freezer cabinet. A discussion followed on the most effective method to prosecute. It was decided that contravention of the Motor Vehicle Regulations was preferred as there were more offences than under the Act.

iii) Mr. Crewe drew members attention to another side effect of the petrol shortage. This was the overheating Of pump motors due to the continuous use of those who had petrol to sell.

iv) Mr. J. Thompson explained the position of batteries situated behind the fire screen on a tank wagon. Although this was in contravention Of the Conveyance Regulations, the Health and Safety Executive had approved it with certain modifications.

v) Mr. Lowe raised the question of small quantities of petroleum spirit and mixtures kept at schools and laboratories. Should they be licensed and what type of store?

It was suggested that provided the products were compatable a general sto r should be provided for all inflammabl es e and depending on the quantities a licenCe should be issued.

vi) Mr. J. Thompson said that the G.L.C. SCientific Department had tested certain aerosal paints and found them to be petroleum mixtures. He will keep members informed about this as a legal battle is envisaged regarding the method of test.

108

vii) Mr. Gray asked if any progress had been made with the approval of plastic cans?

Apparently, the British Standards Institution are looking into this but nothing has been forthcoming.

The British Standards Institution are also reviewing B.S. 2954 which should be out shortly.

viii) Mr. Burgess of Mid Bucks Engineering asked what were the recommendations for making a tank safe prior to slurry filling. His company were reluctant to remove the lids until the tank was gas free. They used venturies rather than steam as static electricity tended to build up if not properly earthed.

Members discussed this matter and the L.A.J.A.C. proposal to remove spirit and use dry ice or fill with water was perhaps favoured.

ix) Mr. J. Crewe made his usual plea for material to be published in the Bulletin. He also said that he was changing employers and his new address would appear in the current edition of the Bulletin.

After lunch two films were shown by kind permission of the Shell Film Library.

The meeting closed at 3.00 p.m.

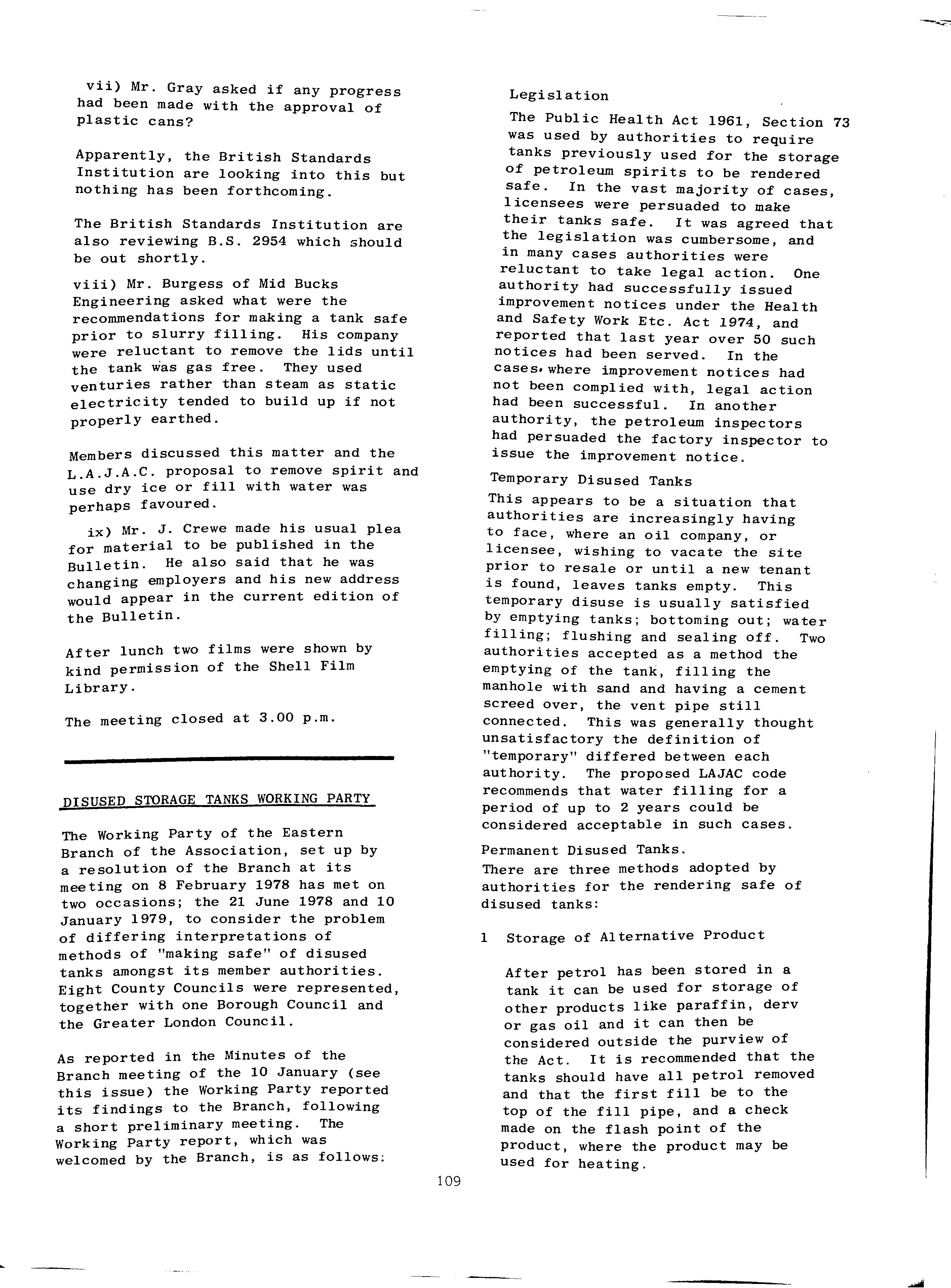

DISUSED STORAGE TANKS WORKING PARTY

The Working Party of the Eastern Branch of the Association, set up by a resolution of the Branch at its meeting on 8 February 1978 has met on two occasions; the 21 June 1978 and 10 January 1979, to consider the problem of differing interpretations of methods of "making safe" of disused tanks amongst its member authorities. Eight County Councils were represented, together with one Borough Council and the Greater London Council.

As reported in the Minutes of the Branch meeting of the 10 January (see this issue) the Working Party reported its findings to the Branch, following a short preliminary meeting. The Working Party report, which was welcomed by the Branch, is as follows:

Legislation

The Public Health Act 1961, Section 73 was used by authorities to require tanks previously used for the storage of petroleum spirits to be rendered safe. In the vast majority of cases, licensees were persuaded to make their tanks safe. It was agreed that the legislation was cumbersome, and in many cases authorities were reluctant to take legal action. One authority had successfully issued improvement notices under the Health and Safety Work Etc. Act 1974, and reported that last year over 50 such notices had been served. In the cases. where improvement notices had not been complied with, legal action had been successful. In another authority, the petroleum inspectors had persuaded the factory inspector to issue the improvement notice.

Temporary Disused Tanks

This appears to be a situation that authorities are increasingly having to face, where an oil company, or licensee, wishing to vacate the site prior to resale or until a new tenant is found, leaves tanks empty. This temporary disuse is usually satisfied by emptying tanks; bottoming out; water filling; flushing and sealing off. Two authorities accepted as a method the emptying of the tank, filling the manhole with sand and having a cement screed over, the vent pipe still connected. This was generally thought unsatisfactory the definition of "temporary" differed between each authority. The proposed LAJAC code recommends that water filling for a period of up to 2 years could be considered acceptable in such cases.

Permanent Disused Tanks.

There are three methods adopted by authorities for the rendering safe of disused tanks:

1 Storage of Alternative Product

After petrol has been stored in a tank it can be used for storage of other products like paraffin, derv or gas oil and it can then be considered outside the purview of the Act. It is recommended that the tanks should have all petrol removed and that the first fill be to the top of the fill pipe, and a check made on the flash point of the product, where the product may be used for heating.

109

3

Ideally the petrol tank should be rendered safe before removal. Authorities differed in their interpretation of this, some asking for gas certificates, others accepting water filling while excavating the tank, or filling it with an inert gas. On removal from the ground the tank should be labelled "Danger Petrol Tank". It was agreed that once out of the ground, the tank ceases to be the legal responsibility of the petroleum inspector under the Public Health Act or Petroleum Act Morruly it is felt that the authorities should consider informing the Health and Safety Executive of the destination of the tank. The enthusiasm of the Health and Safety Executive was reported to vary from area to area.

Sol id Filling

The petrol tank prior to solid filling was treated in different ways by authorities. The tank may be filled with water and flushed, thus reducing the risk of trapping petroleum vapour in voids. Steam cleaning, nitrogen purging and the use of dry ice are other methods adopted. It was agreed that it was preferable to have a tank gas free before solid filling but in pr actise providing due care is taken solid filling could take place

after one of the precautionery methods . The use of cement slurry was favourite amongst authorities although one also allowed earth or sand filling. Difficulties were reported using these methods due to voids being left i.e. in the shoulders of the tank.

Conclusions