THE BULLETIN

Journal of the Association for Petroleum and Explosives Administration

INDEPENDENT FUEL"

Opinions expressed in this Journal are not necessarily the views of the Association

Opinions expressed in this Journal are not necessarily the views of the Association

The use of L.P.G. as a fuel for motor vehicles has been steadily growing for a number of years. Many public authorities and fleet users have already converted vehicles and have provided refuelling installations.

In addition to these installations there is an increase in applications to provide storage and LPG dispensers on petrol filling stations. In these cases the HSE in a guidance note to Local Authorities have stated that such cases will be referred to the licensing authority where the premises are licensed under the Petroleum (Consolidation) Act 1928. The installation can be dealt with under additional petroleum licence conditions.

The question of LPG dispensers on petrol pump islands and the use of self service has also been considered and approved by some authorities who have imposed strict additional safety conditions in these cases.

In addition these premises are the subject of regular inspection and checking, which the HSE nei ther has the manpower or will to match, but is a necessity where public safety is involved.

Honorary Secretary

Mr. E. Brown County Council,

I am sorry to report that our chairmanJ im Cook ofS urrey has not been too well in recent months and is to go into hospital for an operation. He assures me he will be back in full swing shortly and we wish him a speedy recovery.

Jim has asked me to convey apologies to South Eastern Branch Members for a lean year of meetings, due to his illness.

The Association has ordered a quantity of ties which will be available to members from MidJune onwards.

The tie is made of Terylene Crimplene Rep and has on the black material a woven motif of red flames and initials APEA in white, inside a white pump hose outline.

There are a limited number of these ties available at £3.50 each and members wishing to order their tie may do so by sending their remittance to The Editor who will despatch the ties on a first come first served basis. Cheques to be made payable to the APEA.

On the evening of 11th February at a North London Filling Station an Esso Tanker was delivering petrol into the storage tanks. The site was closed for retail sales, but a customer called in to check his tyres on the air line. On completion of this task he returned to his automatic car and after getting in, the car surged forward hitting the tanker delivery hose and draw off pipes. The vehicle was wedged under the tanker with its engine raCing. The Tanker Driver closed off the draw off pipe valve but a split in the pipe upstream of the valve was causing petrol to come out. He then, using the remote positioned air operated foot valve swi tch, closed all foot val ves stopping further loss of petrol. After this he turned off the cars ignition and stopped what was a dangerous situation from becoming a disastrous one.

The Fire Brigade were called and the vehicle was removed without incident. The tanker although damaged was later allowed back to its Purfleet Terminal. The spillage of some 50 gallons of petrol went via the drainage system to the petroleum interceptor where it was later recovered.

The AG M of the association will be held at The Vernon Room Queensway Hall Vernon Place Dunstable Beds on Thursday 29 April 1982.

The venue is the same as the 1981 seminar, and it will also be possible to provide a sit down lunch. Details of this will be made available and a speaker has been booked for the afternoon session.

It is hoped that with a more central position the AGM will be attended by as many members as possible.

The Treasurer has asked me to remind those members who have not paid their subscriptions for 1982 that these are noW overdue.

A company offering a specialist service in fibreglass linings to industry has been brought to our attention. The company CEE-JAY manufacture special tanks, baffles, guards and covers when non-ferrous materials are preferred. They also line insitu petrol, diesel, and chemical tanks using a GRP/Polyester process. Another service which is unique is the G RP lining of existing petrol tank manholes to prevent the ingress of water, and the repair of petroleum interceptors using a GRP lining. The company have over 20 years experience in the GRP field; for more information contact Mr. Wardell of CEE-JAY Tenby Wetherfield Stansted Essex Tel 0279 815065 or 814465.

Readers who follow the BBC TV programme Tomorrows World will have seen that the programme last month looked into the realms offorecourt development. It featured the G RP tank manhole by Fibresec who have been featured in an article in The Bulletin and was also seen at the seminar last year. The programme showed the manhole being installed on a forecourt, and the test of it being filled with water before being concreted to check for leaks.

Following the successful seminar last year the Council of the Association has arranged for another on 21 October 1982 at The Queensway Hall Dunstable Speakers and subjects are being arranged with an open. i.n the afternoon. It is also intended that a small exhibitIOn Will run during the day.

On 17 November 1981 Hull Magistrates Court found Kenning Motor Group Ltd of Gladstone Bui.ldings, Cla.y Cross, Derbyshire guil ty of six offences comml tted at their Hull premises.

The case resulted from an observation made of an unsupervised delivery from a tanker on 2 1982 and subsequent investigations carried out on 7 Apnl 1982.

The company pleaded guilty to all the following contraventions of the Petroleum Licence Conditions and/ or Regulations:-

(i) failure to keep filling and dipping pipes of underground storage tanks securely locked.

(ii) failure to display notice required by the licence conditions prior to the cover plate of the storage tank being removed.

(iii) failure to clearly mark an underground petroleum spirit storage tank with a number.

(iv) failure to keep manhole openings free of water.

(v) notice to employees not signed by all employees.

(vi) failure to secure that a competent person was in charge of the storage tank for the purpose of the delivery.

Fines totalling .£4fl() were imposed and costs of £.sO were awarded.

Classification of dangerous substances for conveyance in road tankers and tank containers.

Practical guidance on methods of meeting the classification requirements of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 was published in an Approved Code of Practice by the Health and Safety Commission on 11 December 1981. The Approved Code came into operation on 1January 1982 at the same time as the major part of the new regulations.

The Approved Code has been prepared on the basis of joint discussion between the Health and Safety Executive and representatives of the CBI, TUC, local authorities, government departments and independent experts. It has been appproved by the HSC under Section 16(1} of the Health and Safety at Work Act with the consent of the Secretary of State for Transport.

The main aim of the Code is to lay down criteria to be followed by operators of road tankers or tank containers for determining whether a substance not on the Approved List possesses any of the characteristic properties set out in tabular form in a schedule to the regulations and is therefore a dangerous substance.

The Approved List, published by the HSE in August last year, details substances so far identified as those likely to be conveyed in road tankers and tank containers, together with substance identification numbers, emergency action codes and hazard warning signs which have been approved by the HSC.

The new Approved Code of Practice not only explains how substances in the Approved List have been classified their characteristic properties, but gives practical gUIdance on how substances, solutions, mixtures or preparations not appearing in the Approved List should be classified to comply with the regulations. The detailed cri teria for classification are based on the recommendation of the UN Committee of Experts on the Transport Dangerous Goods.

As a result of being able to claSSify a dan gerous substance, an operator will also be able to determine h' h hazard warning sign he should use for the purp w IC f oses 0 labelling hiS road tanker or tank container and so p 'd ., . ' rOVI e mformatlOn to the emergency services in the event f accident. 0 an

Comprehensive proposals covering the classif t' dl b 11' fd Ica IOn, Packmg an a e mgo angerous substances are tl' d ou me m a consultative document published by the Health d S e C an alety ommlSSlOn.

The proposals, drawn up following consultation with the CBI, TUC, local authorities and other relevant organisations, include draft regulations and Approved Codes of Practice to be made under the Health and Safety at Work Act.

They are deSigned to protect users of dangerous substances, those engaged in their transport by road and members of the public and emergency services who may be exposed to the substances follOWing a road accident, spillage, fire or other similar incident.

The Association welcomes the following new members. Mr. M. Denham, Associate Fuel Pumps Ltd., Mr. D. O'Connor, Member Mr. N. Nicholls Member Mr. J. Batham, Cameron Mechancial Services Ltd., Associate ' Mr. B.M. Thompson, Member Trading Standards Dept., Cookson & Zinn Limited Associate ' Mr. F J. Warren, Associate Amoco (UK) Ltd., Mr R. Marson, Associate Mr. R.A. Hughes, Member Mr. P.E. Dunk, Associate Chief Fire Officer, Member Dyfed County Fire Brigade, Mr. W. Holdsworth, Associate Webbing Products u.K. Ltd., AssociatesThese objectives would be achieved, says the document, by ensuring that the dangerous substances are supplied and conveyed in containers which are of sound construction and which carry an appropriate warning label. The labels would in most cases incl ude, for example, pictorial symbols indicating the general hazards such as 'explosive', 'highly flammable', 'toxic' or 'corrosive', together with other important health and safety information.

The consultative document says the proposals have been drawn up in such a way as to implement a number of EC Directives on the classification, packaging and labelling of dangerous substances and preparations covering, for example, solvents, paints and pesticides, while also providing for a complete rationalisation of existing, often piecemeal, legislation.

At present there is no commonly agreed definition of danger nor a sufficiently consistent form oflabelling. Only a small percentage of dangerous substances is subject to statutory controls, but international controls may apply and there are a variety of voluntary schemes promoted by trade associations and individual manufacturers. This situation is confusing and the emergency services in particular do not have the assurance that all dangerous substances should be suitably labelled.

Although the number of reported incidents is small in relation to the overall volume of dangerous substances supplied or conveyed by road, their consequences are socially and economically significant. The fragmentary information that is available indicate that inadequately labelled or badly packaged dangerous substances continue to be supplied and conveyed and continue to cause problems.

The proposals outlined in the document do not cover the bulk load transport (road tankers and large tank containers) of dangerous substances, as these are already covered by separate legislation, but rather the small containers such as bottles, drums, carboys, etc., which individually or collect-

Held on the 2nd April 1981 at the Red Hart, Blyth, Nottinghamshire

Welcome A warm welcome was extended by the Chairman Mr. R. Smith who expressed his delight 1;I.t the large gathering of 45 members and visitors. A special welcome was extended to Mr. S. W orsfold the National Chairman and also to Mr.]. A. Flintham and his colleagues from Total Oil. Welcomes were also extended to Mr. A. Darby of the W est Yorkshire Fire Service, Mr. J. M. MacMillan of Petrofina, Mr. C. Breneton of the Lincolnshire Fire Brigade, Mr. C. Sweeting and F. Bradley of Humberside Trading Standards Dept. Minutes

The minutes of the meeting held on the 13th November 1980 were read and accepted as a true record.

Proposed by T. Cowling

Seconded by R.D.F. Charlesworth

ively can present a risk in the event of an incident when there is inadequate information available.

The proposals do not cover retail sales of dangerous substances; these will be subject to separate measures.

Proposals for Classification, Packaging and Labelling of Dangerous Substances Regulations is obtainable from HMSO (price £8.00 plus postage, ISBN 0 11 883617 X).

In response to new legislation under the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981, the Petroleum Industry Training Board will now issue a Certificate of Attendance to all trainees who successfully complete fireground training and related courses.

Note: Full details of the training available for those engaged in the handling and conveyancing of flammable liquids of any sort can be obtained from the PITB Information Unit.

Aylesbury (0296) 27331

(Conveyance by Road) Reg. 1971

Following an incident on 13 August at Bramford in Suffolk The Marconi Co Ltd were fined £1500 for two infringements of the above regulations.

£750 for failing to ensure that no corrosive was spilt, .and £750 for failing to exhibit a corrosive notice on the vehicle.

At the same court the driver was also fined £50 on the first charge and £150 on the second charge.

The case was taken by the Suffolk County Council Trading Standards Department.

No matters arising.

Apologies were received from 6 members.

The treasurer reported that the bank balance stood in credit at £IO.30p

Owing to the poor financial state of the branch it was proposed by R.D.T. Charlesworth and seconded by E. Furniss that the subs be increased to the sum of £1.00/ annum.

This was readily agreed and endorsed by the meeting.

A letter from Mr. J. Wheatly formerlv of Nottinghamshire County Council infOlming the branch that he was accepting early retirment and therefore tendering his resignation was read.

The chainnan requested the Nottinghamshire colleagues present to infonn Mr. Wheatly of the branches good wishes on his retirement.

A further letter was read which infonned the branch of details regarding the impending visit to the Health and Safety Executive Laboratories at Buxton Election

The following officers were unanimously re-elected:Mr. R.J. Smith, Humberside County Council Mr. R. G. Kitching, Humberside County Council Mr. E. W. Dean retired

In the respective posts of Chainnan, Secretary and Treasurer.

Mr. S. W orsfold stated as a founder member of the association he was always interested in reading about branch activities, and had noted the activities of the Yorkshire and Humberside Branch. During his year of office he had visited all the branches and was convinced he had saved the best till last.

He further stated that the interesting feature of petroleum was all the anomalies that arose and the attempts to prevent these anomalies by the production of codes of practice and the meeting of interested partys to discuss these different aspects. In this way the branch was carrying out the prinCiples over which the association was fonned and in further persuance of this a seminar last year was held by the association on conveyance and a further one on forecourt equipment was to be held this year. Mr. W orsfold urged all members to attend this seminar and expressed his thanks for the invitation and the opportunity to speak.

Slides with taped commentary compiled by Total Oil Great Britain Ltd were shown by Mr. J. A. Flintham the Company's Safety Co-ordinator and were found to be of great interest. The interest was reflected in the barrage of commentary and questions put to Mr. Flintham.

The Chainnan expressed the meetings gratitude, in his vote of thanks to Mr. Flintham, for a very interesting session.

It was proposed the next meeting be held at Scunthorpe on a date to be arranged by the Secretary and Mr. G. Tankers be approached regarding a talk and film presentation in the morning and the afternoon session to take the fonn of a visit to the British Oxygen Co. Ltd premises at Althorpe.

This was agreed by the meeting.

The business meeting tenninated at 12.40pm, the afternoon session took the fonn of a talk / demonstration by Mr. BJ MacCarthy of He yes of Wigan on electical equipment.

A vote of thanks was extended to Mr. MacCarthy by Mr. R.DJ Charlesworth.

Meeting closed at 3.20 pm

The Chainnan, Mr. S. W orsfold, opened the meeting and welcomed 32 members and associates to Birmingham.

1. There was three verbal and four written apologies.

2. The minutes of the A.G.M. held on 26 April 1980 were duly accepted by the meeting.

3. Matters arising:- There was an explanation of Item 10 regarding the increase of membership fees. The Treasurer related to the meeting the new rates.

4. The Chainnan, Mr. S. W orsfold, presented his report on his year in office. He was pleased that the Branches continued to thrive which he had been able to experience first hand. It was also good to see the Council meeting on several occassions, the main business being the seminar. He thanked everyone for their loyal support during his year in office and was satisifed that it had been a year of growth within the Association.

5. The Secretary, Mr. E. Brown, submitted his report.on the last year. He said that new applications were bemg received regularly, but one or two existing members had fallen by the wayside. The Council had met times with the minutes being published in the Bulletm. He mentioned the proposed draft Regulations which will increase fees for licences by 50%. At this point. he made a plea to the meeting for every member to give serious thought as to how the Association be improved and to let him know of their conclUSIOns. Finally, he thanked his fellow officers for their help and support during the year and also the membership for voting him into office in the first place.

6. The Treasurer, Mr. R. Jones, submitted his report for 1980. The membership stood at 295 paid up members. Finances are good but only because of the seminar and the sale of the codes of practice. He concluded by thanking his predecessor for his assistance and likewise other persons for their co-operation and efforts during the past year.

7. The Editor, Mr. J. Thompson, presented his report in which he said he had managed to produce the Bulletins, but not without some difficulty. It was becoming more and more difficult to obtain suitable material and pleaded with members to help out in this matter. The annual recruitment drive through the Bulletin was again successful and the sale of codes of practice were also encouraging. He concluded by thanking all for their help and support during the last year.

At this point in the meeting, Mr. J. Frid proposed and Mr. B. Lowe seconded that it be recorded in the minutes of the Association our appreciation and thanks to Mrs..J. Thompson who has acted as Editor's Assistant.

Mr. N. Fox on behalf of the members thanked Mr. J. Thompson for the production of the Bulletin and the interesting articles which appeared therein.

Both these motions were carried unanimously.

8. Election of Officers: The following persons were duly elected.

Mr. J. Cook, Surrey c.c. Chairman.

Mr. R.J. Smith, Humberside c.c. Vice-Chairman. Mr. E. Brown, Cambridgeshire C.C. Secretary.

Mr. R.Jones, Suffolk C.C. Treasurer. Mr.]. Thompson, G.L.c. Editor. Mr. K. Ryder, Suffolk Auditor.

It was agreed not to elect a Liason Officer or Legal Adivsor.

9. Election of Council: Serving officers of the Association together with Mr. B. Thompson, G.L.C., and Mr. B. Lowe, Bedfordshire C.C., were duly elected.

10. After discussion the following motion was unanimousl y agreed. "That if in the opinion of the Council of the Association it became necessary to increase membership subscriptions in 1981 an increase of upto £1 on all subscription shall be implemented from January 1982"

11 Any other business.

a. The Hon. Secretary proposed that Mr. Cliff Peacock be elected an Honorary Member in appreciation of his long and loyal service to the Association. This was seconded by Mr. Minns and carried unanimously.

In this article C.L. Davids by means of an interesting mathematical exercise proves what to many must be an unlikely truth

When testing any vessel, be it tank or pipe line, by air or gas pressure, the observable pressure drop will depend on the full scale reading of the gauge. This should in turn depend on the applied pressure.

Assume that the observable pressure drop, which can be called the sensitivity of the test, is nP. Where n is some fraction andPis the applied pressure. For example, with n = 1/50 and P = 10, the observable pressure drop would be 15 lb. If Pis 100 then the lowest drop which could be observed would be 2 lbs.

The air or gas lost during a pressure test over a time t hours is proportional to the area of the hole times the velocity of the escaping gas. This velocity is in turn proportional to the square root of the pressure.

Therefore, we can say:

Where K is some constant A is the area of the leak, t is time, and P is the

The pressure drop due to this loss of air or gas is proportional to:

Air Lost/Capacity.

b. The Hon. Treasurer drew members attention to the problemt of unfranked mail. If anyone had to pay excess postage would they contact him for a refund.

c. Mr. Fox raised the question of Branch Rules and the voting rights of Associate Members. After much discussion the Council was asked to look at the Constitution and Rules with the view to ammendment.

d. A short discussion took place on the involvement of the Association on the storage of L.P.G.

e. It was suggested from the floor that in order to involve the Health & Safety Executive in Association matters they should be encouraged to attend Branch meetings.

12. Mr. Cook, Chairman, closed the meeting and in so doing thanked Mr. W orsfold for his work and support of the Association during the past year.

The afternoon session was taken up by Mr. Fowles Smith, D.M.S., M.I.Corr.T.,M.Inst.M., who spoke on the problems of corrosion and how it can be prevented. This was found to be an interesting talk and was well received by the meeting.

A vote of thanks to Mr. Fowles Smith was given by Mr.]. Cook and endorsed by the meeting.

Therefore Pressure Drop equals: J5At yP Capacity

If this can just be detected it equals nP. Therefore: nP = KAtyP Capacity KAt or fl = Capacity xyP

This confirms facts which are very well known, i.e. that the sensitivity of the test or the likelihood of a given leak being detected depends on :

1. Size of the leak, i.e., A; the larger it is the more likely it will be detected.

2. Time of test, i.e., t; the longer the test, the better the chance of detecting a leak.

3. Inversely as capacity; larger tanks are less likely to show up a given leak.

But it is not so well known that it is inversely proportional to the square root of the pressure_ The higher the pressure the less likely one is to detect a small leak. The pressure applied must be at least one and a half times the working pressure, but any further increase in pressure does not increase the sensitivity as long as this increase means that a gauge with a larger full scale deflection must be used

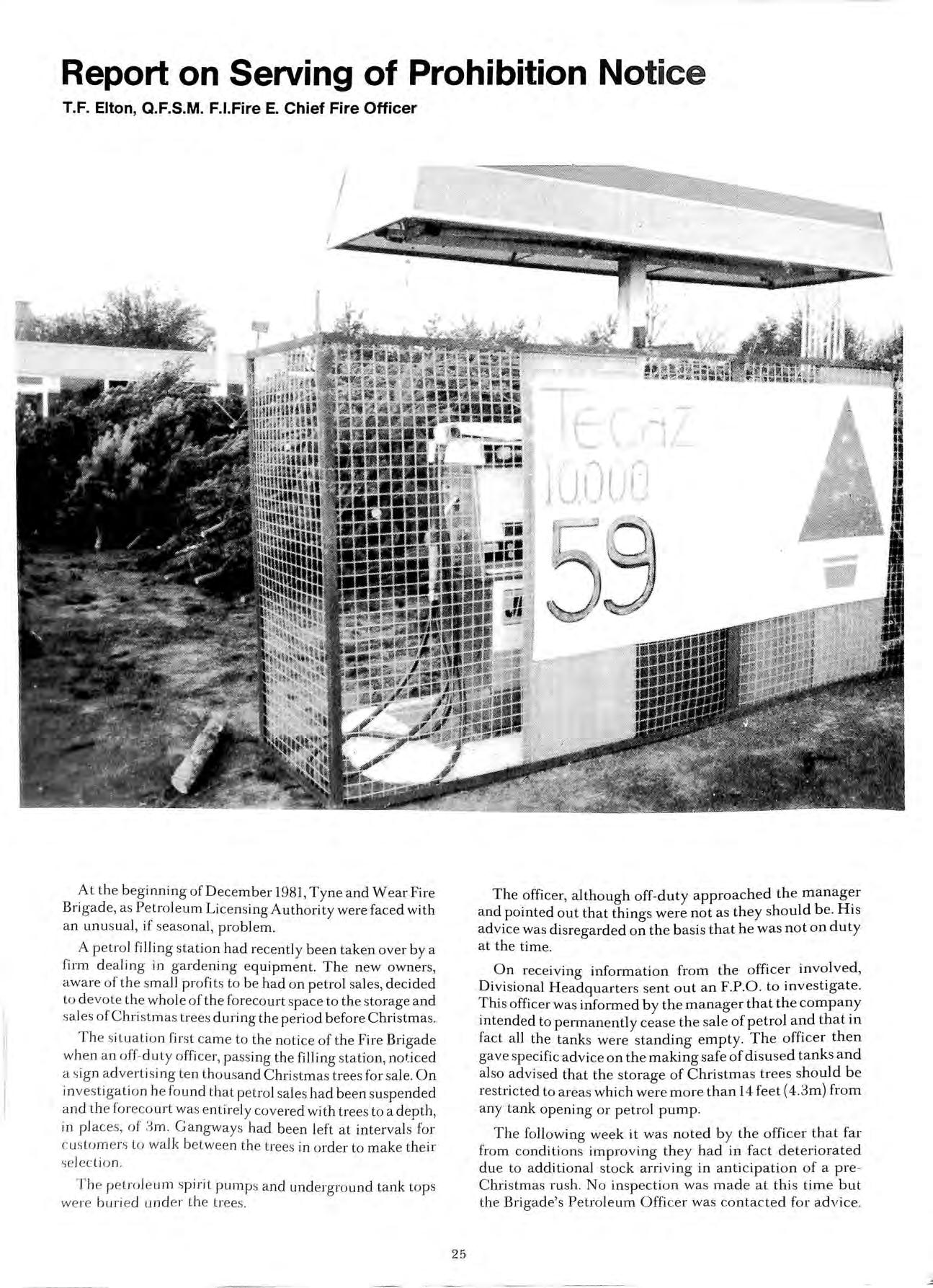

A t the beginning o f December 1981, Tyne and W ear Fire Brigade, as Petro leum Li cens ing Authority were fac ed with a n unu s ua l, if seasonal, problem

A petro l filling stat io n h ad recently been taken over b y a firm d ealing in gardening equipm ent. The new ow ners, awa re of the sm a ll p ro fi ts to be had on petrol sales, decid ed to d evote the w ho le of the forecourt sp ace to the storage a nd sa les of Christmas trees during the peri od before Christmas.

The situ a ti o n first ca me to the noti ce of the Fire Brigade wh en a n o ff duty office r, pass ing th e fillin g sta tion, nohced a sign adverti s in g te n th ou sand C hri stmas tree s fo r sale On inv est igat io n h e found that pe trol sale s had been suspended a nd th e fo reco urt was entirely cov ered with trees to adepth, in p lace s, o f 3 m. Gangways had been left at interval s for c ustome rs to wa lk be tw ee n the trees in o rd er to make their se lec tion.

T h e p e tro le um spiri t pump s and und e rground tank top s we re bu ri ed und e r t h e trees.

IThe officer, although off-duty approached the manager and pointed out that things were not as they should be. HIS advice was di sregarded on the basis that he was not on duty at the time

On receiving information from the officer involved, Divi sional Headquarters sent out an F P O to investigate. Thi s officer was informed by the manager that the company intended to permanently cease the sale of petrol and that in fact all the tanks we re standing empty. The officer then gave specific advice on the making safe of disu sed tanks and also advised that the storage o f Christmas trees should b e restricted to areas which were more than 14 fe et (4.3m) from any tank opening or petrol pump.

The following week it was noted by the office r that far from co ndition s improving they had in fa c t dete riorated du e to a dditional stoc k arriving in anticipation of a pre C hrist mas ru sh. No inspection was made at this time but th e Brigade's Petroleum Officer was contacted for adv ice.

In order to fully understand the considerations and deliberations that subsequently led to action being taken, it is important to understand the legal aspects involved.

First, the Petroleum (Consolidation) Act 1928 requires that petroleum spirit, when kept in certain quantities must be licenced by a specified authority, in this case the County Council. The same Act also allows the licensing Authority to attach such conditions to a petroleum licence that it sees fit.

In the case of a licence issued by Tyne and Wear two conditions were applicable in this case:

a) Condi tion 10, forbidding the storage of other flammable materials with petroleum spirit, except with the consent of the Chief Fire Officer, and

b) Condition 15, requiring the licensee and every person to take all reasonable steps to prevent aCCIdents from fire or explosion.

It was clear that in this case both these conditions were not being met.

Second, the Public Health Act 1961, in a specific disused petroleum spirit tanks, lays a responsIbilIty on the occupier to make these safe from fire and In Tyne and Wear the Fire Brigade is the enforcmg ty for this section of the Act, and generall y allows a penod of twenty eight days for such tanks to be made safe.

Third, the coming into force of the Petroleum (Consolidation) Act 1928 (Enforcement) Regulations 1979 had effect of adding to the arsenal of petroleum enforcmg autho 't' f flexibility. n les, weapons 0 greater power and

The Prohibition and Improvement Notices Improvement Notices can only be issued in CIrcumstances whe e I b I' . r an nspector e leves that a legal conhas taken place. A Prohibition Notice may only if an Inspector is of the opinion that there is or WI e . k f . ' , a ns 0 senous personal injury.

These notices a . T d W re, In yne an ear generally regarded as an alt . , b emahve to prosecution. They ideally fill the gap etween the very strong letter and legal action.

However, no notice is ever issued unless a) there is evidence to justify it a subsequent appeal or m a magistrates court and b} , can be shown to have been a properly issued notice I.e. no procedural errors}.

Improvement N t' 11 . h h 0 Ices genera y cover CIrcumstances were t ere is no risk f I' . 0 persona mJury even though a legal contraventIOn has taken place. An example of this could be a petrol station wh' h h 11 d . IC as a owe Its petroleum mterceptor become blocked, (Condition 12 attached to petroleum lIcences requires interceptors to be kept clear and free from obstructions).

Th f e recIpIent 0 an Improvement Notice may appeal in to an Tribunal within twenty one days of recelvmg the notIce. The entering into an appeal has the effect of suspending the notice until the appeal has been heard and a ruling made.

From this it can be seen that at least twenty one days should be allowed for any work, to allow an appeal to be lodged.

A prohibition notice is much strZmger meat and can only be issued if the Inspector is of the opinion that there is a risk of serious personal injury, should certain conditions be allowed to occur or continue. The notice may be 'Immediate' if the risk is imminent or 'Deferred' if it is not.

It is important to note that a Prohibition Notice may be served even though no legal contravention has taken place. For example a 'deferred' notice could be served to prevent some proposed activity which the Inspector considers would be hazardous.

Rights of appeal in the case of a Prohibition Notice are slightly different in that although the period of time allowed for appeal is the same (twenty one days), the entering into an appeal does not have the effect of suspending the notice. In other words an Inspector can stop a dangerous activity immediately, even though an Industrial Tribunal may subsequently modify his requirements following an appeal.

It will be seen from this that a Prohibition Notice is an extremely powerful weapon which should only be used as a last resort.

In order that these notices are held in high regard by the fire officers and also by any Petroleum Licensee unfortunate enough to receive them. Tyne and Wear Metropolitan Fire Brigade have adopted the following procedure.

Notices must be approved by the Deputy Divisional Commander responsible for Fire Prevention and also the County Solicitors Department before they are served.

This reduces to a minimum the chances of a notice failing due to a procedural defect and totally eliminates the chance of a notice being served inappropriately.

To summarise then, in the case of the Christmas trees the following courses of action were considered.

1. To prosecute for fail ure to comply wi th the cond.i tions f1 a petroleum licence. This was rejected, because It wou not remove the immediate risk and a court could have taken the view that as the defendent was not storing petroleum the conditions of licence did not apply.

2. Require that the tanks be rendered perm.anently safe. This too was rejected because in this case, at the end of the twenty eight days whIch be allowed for the work, the licensee could qUIte lega!ly return to the sale of petrol. In other words WIth Christmas over and the tree sold he would have not onl y had his cake but have eaten every crumb too!

3. As a legal infringement was taking place of conditions of licence) an Improvement NotIce could have been served. However, as at least twenty one days must be allowed for work, this too was rejected.

4. It was finally decided that in the circumstances the only appropriate action to take was to serve a Prohibition Notice forbidding the storage of Christmas trees within the licensed area. This was taken as being anywhere within 14 feet (4.3m) of any pump or tank opening.

The notice was drafted by Headquarters Fire Prevention staff, approved by the County Solicitors Department and served on the Occupier the same day.

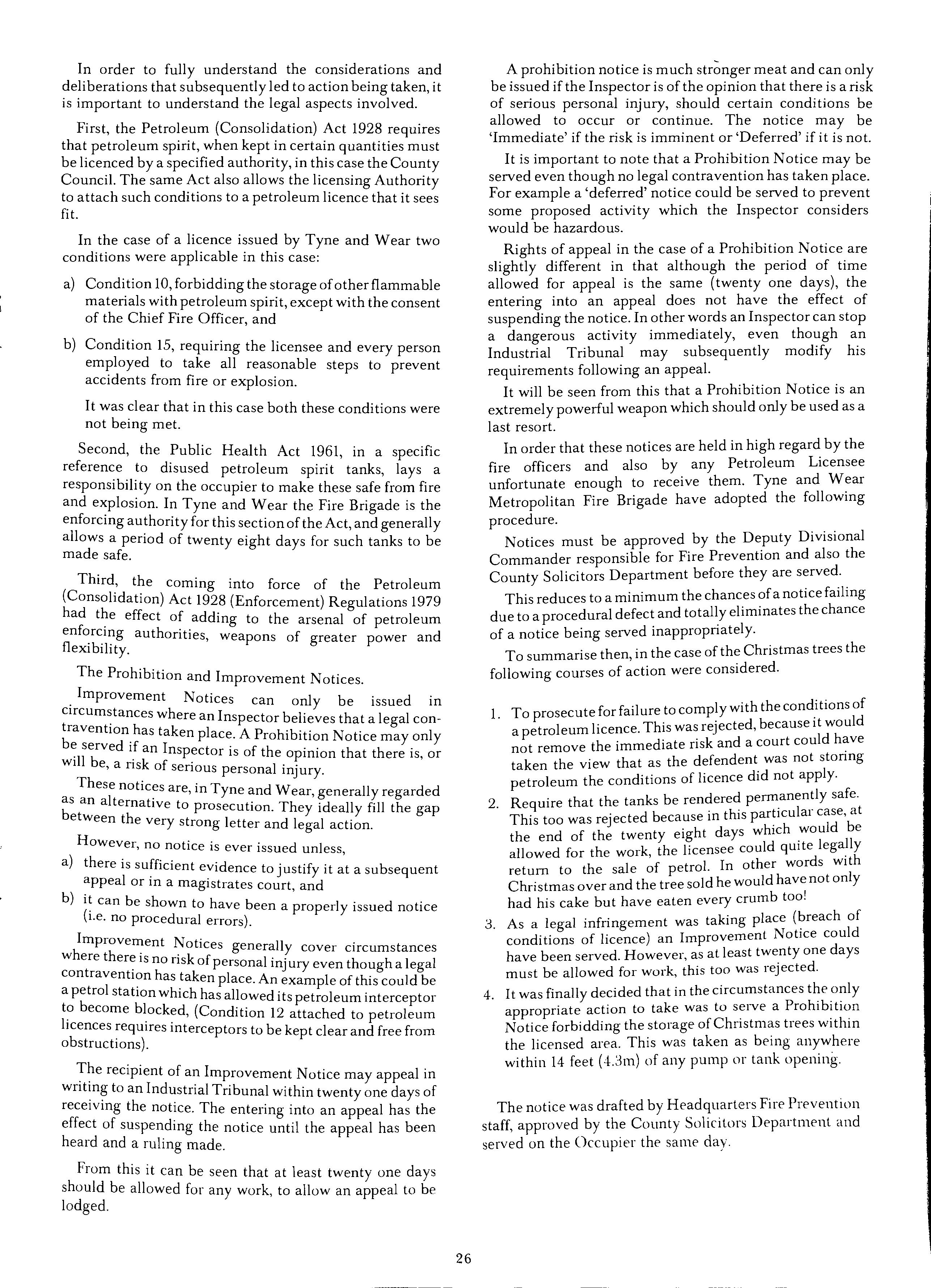

It was delivered by two Inspectors and it was considered that their evidence would be sufficient in the event of an appeal. However, a Brigade photographer took a series of photographs of the circumstances in order to add weight to their opinion if this was required.

In the event the Occupier took immediate action to remove the trees from the prescribed areas and much to the surprise of all concerned, he had the tanks filled with concrete five days later.

The whole exercise was considered to have been a complete success. Not only because a potentially hazardous situation was quickly brought under control, but because the close co-operation that exists between the Fire Brigade and the County Legal Department enabled swift and positive action to be taken at short notice.

An explosion in a South Glamorgan garage occurred shortly after a delivery of petrol. It is thought that an unusual accumulation of vapours, caused by humid weather, was ignited by a spark from an air compressor.

The explosion caused seve re blast and fire damage to 60 per ce nt of the building and 80 per cent of the contents, and a lso cause d slight damage to house s some 60 metres away.

A contributory fa ctor to the incident was the siting of ve nt pip e out lets from a tIiple compartment underground petroleum storage tank.

The building was co nstructed in 19.59 and consisted of masonr y wall s, concrete fl oo rs and roof of light steel truss ing cove re d by ce ment asbe stos sheet s It comprised a work sh o p s di splay area s tores and office at ground level wit h addit ional s torage at lower ground floor. The frontage o n th e A4 0 .58 c ons is ted of a canop y cove re d forecourt and pub l jc fjllin g s tation .

The bUilding was extended in 1976 to provide a further workshop at ground level and store and lower ground floor. The extension was of similar construction to the original bUilding.

The petroleum installation comprised one triple compartment and one double compartment underground storage tank. It was served by four pumps (three petrol and one diesel).

The vent pipes serving the triple compartment tank were each 4.35 m high. They were positioned for most of their height in a duct formed between the old and new outlets of the vent pipes extended above eaves level on the front of the original premises by about 600 mm but were below the eaves of the new extension due to the higher roof construction. The vent pipes of the double compartment tank extended some 1.5 m above the eaves of the old building on the sout h of the front elevation.

At about 0830 on the day of the explosion, 15,400 litres of petroleum spirit were delivered. A statement made by the occupier (who was in the office at the time of the explosion) described how the smell of petroleum vapours which was normally strong when a delivery took place, was much more pronounced on this particular day. Because of this he closed the door of the office to prevent further entry of the vapours. Weather conditions were warm, dry and sultry with no wind.

The occupier stated that the explosion occurred simultaneously with the initial operation of an electric air compressor situated at the foot of the staircase leading to lower ground floor.

There seems little doubt, that a larger than normal accumulation of petroleum vapours were present on this occasion. This can be attributed to the particularly humid conditions present at the time and the location of the vent pipes outlets.

by P.R. Taylor B.Sc.(Eng) Managing Director Chiltern Glass Fibres Ltd.

by P.R. Taylor B.Sc.(Eng) Managing Director Chiltern Glass Fibres Ltd.

Many glassfibre diprods are now in use, particularly on garage forecourts. The following article relates to the control of electrostatic electricity during dipping procedures.

Chiltern Glass Fibres Ltd. produced the first fibreglass diprods in 1975 and received approval from the Health & Safety Executive in that year.

Subsequently discussions concerning the control of static electricity during dipping procedures led to a two year period of study jointly financed by Chiltern Glass Fibres Ltd. and a major oil company. The Electrostatics department of the University of Southampton was contracted to undertake the work and they subsequently produced two reports which were approved by the Institute of Petroleum.

The objective was to define the desirable electrical characteristics of a "safe" diprod. One already had the conflicting usage of conducting non-ferrous (brass) diprods and insulating wooden diprods. Nor were the use of these diprods particularly confined to storage tanks and road tankers respectively.

The following questions were considered in the University of Southampton report:-

Why are conducting brass diprods used in storage tanks?

Why are insulating wooden diprods used in road tankers?

Where is the static electricity generated, how does it diSSipate, and what is the effect of differing diprod materials?

As the vent pipe outlets were almost directly above the office, the natural down flow of petroleum vapour which would occur during delivery would cause the vapour to find its way beneath the canopy and enter the building via the open office door.

It is considered that a considerable quantity of vapour, sufficient to form an explosive mixture, entered the office before the door was closed and accumulated at lower ground floor level via the staircase.

The si ting of the vent pipe outlets was adversely affected by the higher roof level of the extended building. This factor, together with the prevailing weather conditions, prevented the proper dispersal of petroleum vapours during delivery.

This defect was rectified three days after the incident by re-locating the vent pipes so that the outlets now extend 600 mm above the eaves of the new building and at least 1.5 m from all openings.

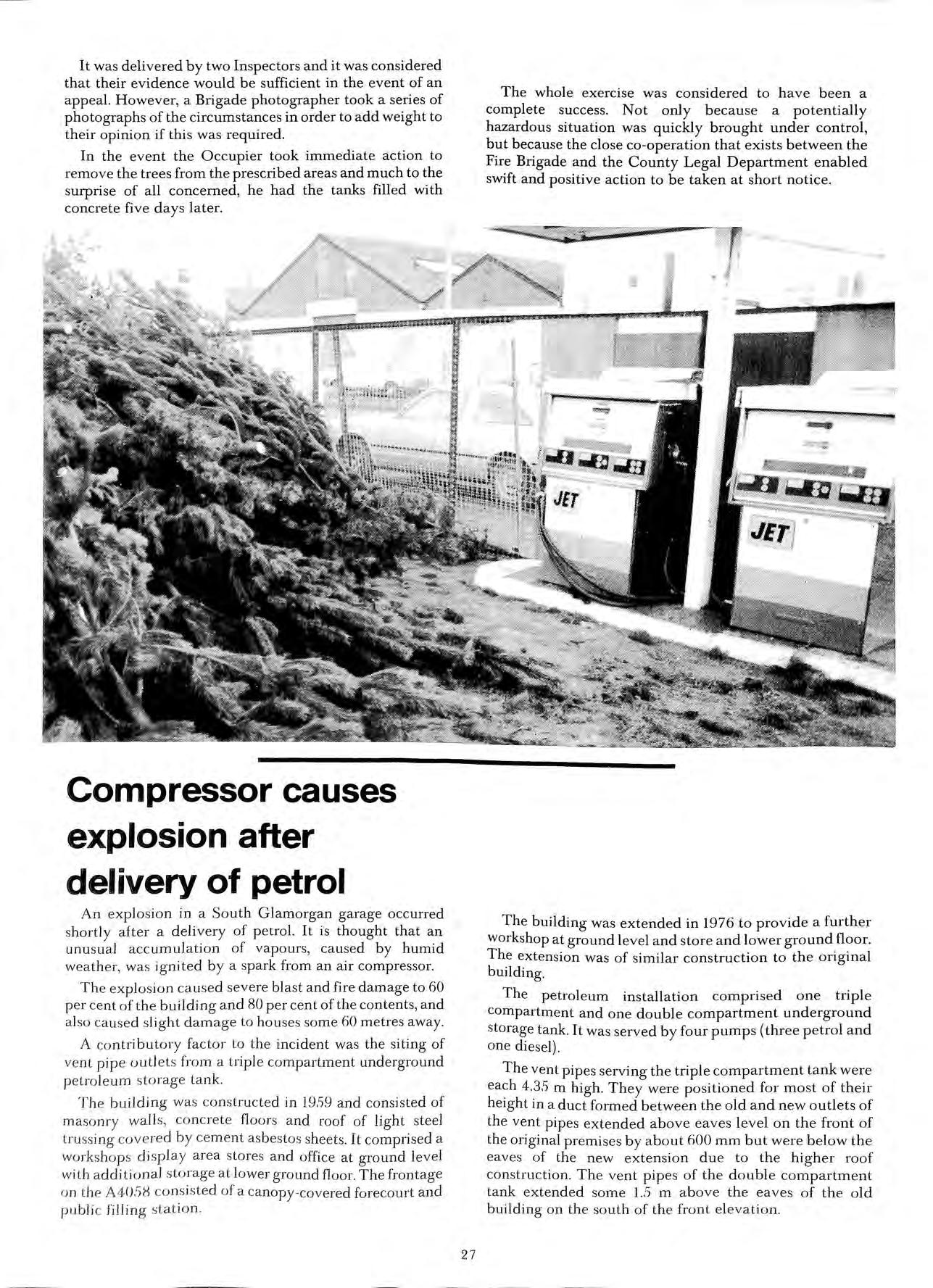

Fig. 1. Discharge at mouth of dip tube.

Fig. 2 Discharge in tank at fuel suiface.

The greatest risk was seen as dipping a conducting rod mto a charged fuel surface. Figs. 1 and 2 indicate possible paths of discharge under such conditions and highlight the risk involved.

The Southampton University conclusion was that the variability of all conditions was considerable and no clear answers to current practice could be given. Therefore a compromise would be to construct a "semi-conductor" diprod which could not be charged by rubbing and would not dis sipate any static charge s in a dangerous manner.

Such a material should ideally have a reSistivity of 10Hnm , and Chiltern Glass Fibres Ltd. found they could con sistently produce a material with this resistivity, by modlfymg the resm system of the glass reinforced plastic.

The Institute of Petroleum comment on the So uthampton University report was that modified glass remforced plastic dlprods we re as safe as, if not safer than exi sting rods. '

It is inte res ting to note that, to the be st of the industry' s knowl edge, no aCCident s hav e e ve r been recorded which have been attributed to wooden diprods , whereas there is so m e d o ubt o ver metallic diprods under s ecified Circ umstances p

Wooden diprods al so manufactured by Ch'lt GI l " b L I ern ass ' J res td. were subjected to te stl'ng and . f t I J In ac ' , very c ose ly m e t the Ideal res istivity recommendations of the So uth a mpton U niversity re port. Th e black colour on the ha rdw oo d rods is fo rm ed by a 4 t h' I " ·-s age c emlca Imp reg n a tIOn pro cess, whi ch effec tiv ely form s a semi co nd uct ive laye r.

The chemical treatment process was developed at leas t 50 years ago, and it is not thought that obtaining a semiconducting layer was paramount in the development of the process!

However, it may well explain the excellent safety record of rods treated this way. It should be noted that cheaper wooden diprods on the market are not chemically treated in this manner.

Before discussing more sophisticated gauging systems, many thousands of diprods are in use, mainly using nonferrous materials. Investigations show that at least 60% of brass diprods cause incorrect readings due to distortion and many may be so badly bent as to be unusable.

Glassfibre will remain straight in use and will not break in service. The material is extremely light (see Fig. 3) and can be coloured to facilitate easy reading.

Recent improvements in shape and rigidity of the 'T' profile substantically increase the materials' resistance to mechanical abuse. The materials will withstand 8 tons axle loading (as shown in Fig. 4).

Many tank gauging systems are sold on the basis of greater accuracy than diprod systems In practice, the diprod is as accurate as the calibration system used to make it. Dial gauges may only have a scale length of 3ft or less to register the contents of a 9ft tank whereas a diprod has a depth ration of unity.

It may not be generally recognised that road tankers are individually calibrated by Weights & Measures inspectors using sophisticated fibre optic equipment before being used for trade The cost per compartment is approximately £45 Storage tanks are not calibrated and diprods are prepared to nominal dimensions.

The manufacturers are allowed a 4% volumetric tolerance between actual and nominal dimensions. Today there is absolutely no reason why diprods (or gauges) should not be prepared indiVidually. The only cost incurred is collecting a limited amount of data relating to tank dimensions.

Fig. 3. GRP is easy and light to us e.

This approach is far more reliable than expecting tank producers to manufacture to tighter tolerances. The money spen.t garage forecourt operators at present in having speCialist calibrations undertaken when stock losses are or electronic gauges installed, would be qUickly repaid.

It is recognised that once an underground tank has had hydrocarbons introduced, it is necessary to obtain "gas free" certification before the tank can be entered and dimension taken for calibration purposes.

One alternative is to pump out any residual fuel into a suitable recepticle, and then to drop via "proving vessels" repeated known quantities of product into the tank and take successive dip readings.

Both the above alternatives are extremely time consuming, and in the latter case, required a road tanker to be in constant attendance. A resultant cost in excess of £1000 is not uncommon for a typical garage forecourt.

Chiltern Glass Fibres Ltd. have successfully developed a different approach, taking full advantage of current computing power.

In graphical analysis, it is well known that a curve can be drawn through any three points. Although the curve representing the relationship between weight and contents on a storage tank can be very complex, by obtaining approximately 10-12 weight/vol ume points, a curve can be "fitted" representing a specific set of tank data.

The method does not require the operator to know the initial tank contents, neither is it necessary to empty the tank. Best results are obtained by filling the tank from below 1/4 full to over 3/4full.

The integrity of the method is self-expressing, the computer analysis reports on how closely a produced calibration agrees with the data obtamed on site. Reference to Fig. 5 shows a R.M.S. deviation of 2 gallons. On the calibration in question, this represents an agreement to within 1.0mm of height.

It is fel t that far more use ofthis technique will be made in the future.

GALLONS

MM VOL DIFF 300 321 1600 527 0900 708 1 1200 877 2 1500 1040 01800 1202 32100 1369 42400 1548 02700 1749 4 3000 2010 0-

RMS VOLUME DIFF: Diameter 2134 Length 3894 Dish 84 Slope 33359

Rod Length (mm) 3658 Total Volume 13917 litres (3061 gallons)

Fig. 5. Sample printout of calibration analysis.

One of the many problems facing local authority petroleum officers, oil company engineers and contractors when installing tanks is the method to use to prevent the tank floating or moving while concrete is being placed in the excavation. Many of us have experienced a tank moving or floating out of the excavation causing problems for a lL

Some Authorities require hydraulic testing which means that with the tank full of water, movement is less likely; but not unknown. The majority of Authorities require an air pressure test and this is where problems occur. The current method of using wire ropes or hawsers and some form of eye cast into the base varies in reliability. The wire ropes are placed over the tank surface and are fastened and tightened by a variety of methods mostly "Heath Robinson" and usually suspect; and at what cos t to the protective surface of the tank ?

A method recently marketed has brought what is felt to be a more professional way of securing tanks, which I hope will be given a trial by the industry.

Webbing Products U.K Ltd, offer this improved system of securing tanks against flotation during installation, using technical knowledge developed for the manufacture of webbings for fabric li fting slings and speCialist lo ad lashing applications

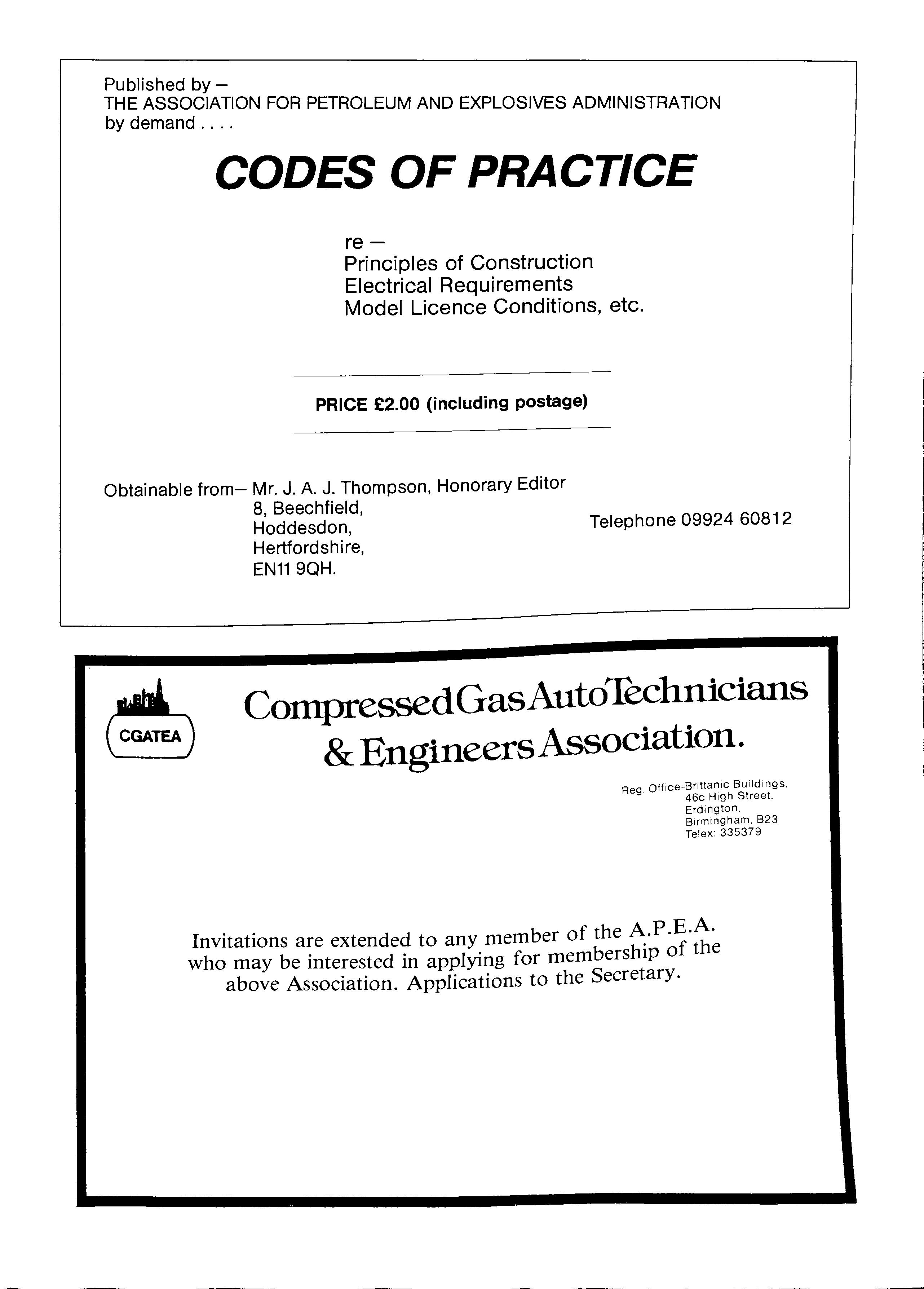

The kit is in two parts:

a) The Anchor Strap. This is 100mm wide High Tenaci ty Webbing, approximately equal in length to the circumference of the tank. Two protective corners are fitted equi distant from the centre of the anchor straps; the distance between them being equal to the diameter of the tank. Each end of the anchor strap has an eye, formed by sewing with High Tenacity thread using a 'British Standards' stitch pattern as approved for lifting slings.

b) The Tension Strap. This is a 50mm wide High TenaCity webbing approximately 3 metres long with a ratchet tension er attached to one end by sewing with High TenaCity thread, using a 'British Standards' stitch pattern as approved for load las hing applications. The ratchet tensioner is an approved cargo lashing tensioner and has two sets of locking pawls. One is operate d by a spring loaded locking plate which can be released by finger pressure The second is ope rated by pumping the ratchet handle, and is released by a cam action when the handle is opened to 180°.

The assemblies have been subjected to rigorous testing and a destruction test certificate by The Sheffield Testing Works Ltd., which indicated a breaking strength of 16 tons per assembly can be supp lied

The flotation force i.e. the upward thrust of a steel vessel in water, is equal to the weight of water displaced le ss the weight of the vessel. For example a 12,000 galls tank (single compartment) in water would exert an upward thrust of 5l.6 tons. The flotation force in cement is variable, depending on site conditions, and calculations are based on loadings required to secure a tank in water. On thi s basis one TANKLASH assembly per 2,500 galls (11,000 litres) is advised. Therefore for a 12,000 galls (54,000 litres) capacity tank 5 lashings are recommended in order to allow an adequate Safety Factor.

The company here Ifeel erron the side of caution, but it is no doubt proper to accept this advice.

High TenaCity Yarn 9S Kgs /mm 1

The moisture absolption of IS .04 %,. the bsolTltion of Wood IS 20 X,. This IS slgmftcant mOlstUle a r ' h k are lashed using' steel ropes whIch are tenslOned w en tan s d oden wedges between the wIre ropes and the by nVIl1g wo .'

k Th edg'es retall1 mOIsture whIch can lead to tan. e w . I I 'f h .. oxidization of the metal, parttcu ar f y I t e protectlvde . h b damaged. LikeWIse I wIre ropes are use co atIl1g as een d . d b b I th the tank surface an tens lOne y ott e Il1 contact WI . b d . did' . s then the protective coatlI1g can e amage ea ll1g SClew f rust Neither of these conditions arise to the formatIOn 0 with T ANKLASH.

lOOmm wide High TenaCity Webbing

Iti to n s 50mmm wide High Tenacity Webbing 8 tons. Ratchet Tensioner in straight pull 5 tons.

The 500mm Tension Strap is threaded to fonn a lo op thereby increasi ng the strength rating x 2 = Hi tons.

The Ratchet Tensioner is in one side of the Tensi o n Strap loop which forms one half of the assembly, thereby increasing th e strength rating x 4 = 20 tons.

(For comparison purpo ses 16mm stee l wi re rope, :3 core 36 strand has a break strength of LS tons.)

Chemical Properties.

In the environment of this application the las hings a re chemically stable and the protecti ve coat ing on the lash ing is an Ac ryli c Resin.

. I' ro ce dure itself IS qUIte SImple. The The ll1stal atIOn p f h . I 'd acrosS the b ase 0 t e excavation h . straps are al d anc Ol b e is poured The base is poure over before the as laced on the base and the straps are the straps. The tan Then the tension strap is passed placed over the tan d' b ck to the ratch et forming a loop. through each eye, an datig'htened and the tank is secure. The ratchet IS tenslo ne , ' d ntag'es in USll1g thI s sys tem, some There are many a va c I elves POll1t o ut. which the company t 1ems .'

The W e bbing which is soft and fl eXIble IS made of high . t .' Is which is st ronger than stee l. tenacI ty ma e Ila ."

It eliminates the us e of anchor POll1t s b e l11g cas t 111 the slab, wire ropes, b ot tl e screw s or clamp s

I t will not damage the prote c ti ve coa ting of the tank.

It saves on labo ur costs and is qui cker and eas ier t o u se.

The costs compa re favo ur ab ly w ith wire ropes a nd assoc iated fittings , at aruund±: Wea c h strap comp lete, with d espatc h b e in g g uaranteed within two wurking da ys

Alto get h er a n impress ive id ea w hi ch de se rve s a trial.

Inform at ion on the produ c t can b e ubtained frum Webbing Produ cts lIK Lld Spa St ree t. Padiharn , Nr Burnle y Lancashire BBI '2 (Wi'2 7 1'2:\ 1

the resulting smell in the nearby town caused widespread complaint. A school 4 miles away from the jetty was evacuated because the teachers suspected a gas leak. These incidents highlight a need for extreme care in handling this very smelly material.

The throughput of crude and process oils at petroleum refineries for 1980, in England and Wales, was 77 400 000 tonnes which represents a marked decrease from the levels of about 88 000 000 tonnes returned for 1978 and for 1979. An average total daily rate of 238 tonnes of sulphur recovery resulted from the 10 refineries, out of 16, engaged in this practice. This is a welcome increase on the return for 1979. The average rate of emission of from combustion processes, etc at all the refmenes thIS year dropped to 671 tonnes/day compared with 740 tonnes/ day for 1979. This appears to be related essentially to the reduction in throughput.

The number of registrations giving rise to complaint fell only a little compared with the previous year, the total volume of complaints was considerably less. ThIS was no doubt due in part to reduced working levels, but energy conservation programmes at various sites and other positives steps by companies to effect improvements have all helped to reduce emissions.

Refineries on the north side of the Thames figured prominently in complaints last year. About ISO complaints were made to refinery staff. It is pleasing to record that less than 30 complaints were received in this area in 1980. Companies concerned have shown considerable achievement and have co-operated also in the establishment of a joint programme for ambient air monitoring.

The majori ty of complaints concerning petroleum works are related to odour. In view of the quantity and type of materials handled and the complexity of processes involved, coupled with the necessity of sites to 'breathe' to some extent at times, there is a constant need for vigilance to minimise and contain emissions. It is notable that companies are channelling effort into the reduction of hydrocarbon losses from areas such as loading and unloading operations, storage and liquid effluent handling, as well as other process operations. Improvements are being made in techniques of checking and monitoring and involving well-equipped mobile laboratories.

The sour water stripper at one major refinery suffered bluckage problems associated with inleakage of sea water at the heat exchangers on the catalytic reformer. Use of titanium tube bundles at the heat exchangers has solved the problem.

Complaints concerning two separate refineries were Cl JI1nec Led wi th the handling of ethyl mercaptan, a chemical use for the odorising of LPG. The first incident was caused by cleaning out of drums used to contain the mercaptan. Tht' second was because of a small leak in a drum stored at the refinery jet t y. It was a walm day with a light breeze and

Two emission incidents involved steam boiler plants. One concerned dark smoke due to instrument failure and the other caused acid smut discharge. The latter created considerable public complaint and arose whilst the boiler was firing 100% liquid fuel at low load during a partial refinery shutdown. Detailed investigations have led to agreements to increase soot blowing frequency, and to use sonic vibrators for soot blowing, to install new smoke meters, and to operate at higher oxygen levels when burning 100% heavy oil. Also it is intended in the longer term that new burner assemblies and control instrumentation will be fitted to improve combustion effiCiency.

Few new refining units have been commissioned at sites during this year, but in 1981 it is expected that major catalytic cracking and hydrogen fluoride (HF) alkylation units currently under construction will be commissioned in the Milford Haven, Thamesside and Humberside areas. Large sulphur recovery units are included in several of these major schemes. A number of other plans for major projects designed to help meet the demands of changing markets have been examined on requirements for air pollution control.

Modifications to process units at two older refineries are ei ther in hand or being programmed. They incl ude changes in catalytic cracking regenerator systems and catal yst types which will reduce carbon monoxide emissions.

Reduced working and intermittent shutdowns ha resulted in more frequent flaring at some ethylene pIa v t e N . h I I n s. ear one SIte t ere were severa comp amts of damage to potato crops from ethylene. Although some justificar was agreed not all cases were explicable. For example Ion ,some adverse local measurement for ethylene could not b related to any plant operational fault. The camp e concerned have now purchased special equipment to regularly for any ethylene leakage. At the same site work. proceeding to moni tor more closely the gas put to flare fr IS the various production plants. Meters will be used measure mass flows both from production and to high and low level flares.

Two bitumen plants were commissioned during the year each fitted with incinerator and tall chimney. against some other works of this type indicated that in certain cases the incinerator systems were being overloaded and steps were taken to rectify conditions.

Work has continued steadily at Britain's largest onshore oil field in Dorset. The oil obtained is light and sweet but this year there were some complaints of odour by a nearby farmer. Main processing involves removal of some hydrocarbons and these are burned at a ground level flare. Tests showed that combustion was not as efficient as expected and it resulted in some faint odour downWind. The Inspectorate were also involved in developments concerning an exploratory oil well not far from Basingstoke.

Two local authorities in the Milford Haven area have expressed their interest in implementing Part 4 of the Control of Pollution Act and have asked for an initial meeting with representatives of the four oil refineries, the power station and the Inspectorate to plan the setting up of the required consultation arrangements.

Please address any communication to the undersigned.

Honorary Secretary Eric Brown Cambridgeshire County Council Hinchingbroke Cottage Brampton Road, Huntingdon Cambs. 048057344

I wish to apply for Membership/Associate Membership of the above Association and I enclose the sum of £. being the Annual subscription.

Name: Address:

A h · C· ........................................................................................... ut ontyor ompany d h t y with the fee. The completed form should be returne to t e secre ar A . M mbership £10 per annum. SubSCriptions: Membership £9 per annum; ssoclate e . d Offcers within the meaning of Membership is open to those persons who are authonse 1 the Petroleum or Explosives Acts. I· ·ble for Person not e Igl Associate Membership is open to any body, company or transport of Membership but being otherwise concerned with the handlmg, storage substances covered by this legislation.

Technical progress within the industry promoted by Oil companies and large industrial groups during recent years has increased difficulties encountered by Local Authorities in the Administration of Petroleum and Explosives Act.

The Association was formed in 1958 and its objects are to further:-

1) The advancement of scientific, technical and legal knowledge in this field.

2) To supply and interchange information.

3) To try and promote uniformity in administration.

4) To promote the formation of branches.

5) To co-operate with other bodies having similar objects, or who are otherwise connected with Petroleum or Explosives legislation.

The Association publishes a Code of Practice covering the following.

a) Minimum Pre-licensing requirements for storage of Petroleum.

b) Licence conditions for Coin Operated Petrol/Oil dispensers.

c) Certificates on completion of electrical works at Petrol Stations.

d) Minimum requirements for "Hazard Areas" on Petrol forecourts.

e) Minimum requirements for Underground Car Parks and Garages.

f) Recommended Code of Practice for Basement, multi storey and enclosed type car parks.

g) Special conditions for Unattended Self Service at retail petrol stations.

h) Special conditions for Post Payment Self Service petrol stations.

This code is available to members and non members on application to the Association.

This is a quarterly journal published by the Association and is sent free to all members, it includes news and topics of technical and a legal nature covering all aspects of Petroleum and Explosives.

The Association consist of Fellows, Members and Associate Members and Honorary Members. It is governed by the National Council and consists of Officers of the Association and eight elected members.

, Association is still growing and gains strength and recognition in this field. The National Council branch secletarys act as clearing house for day to day enquiries. The Bulletin provides the forum for controversIal and the branch meetings are a means of exchanging information knowledge and experience. I t also proVides a plate f 'd I h onn or speakers from members of the Association, Industry, Government departments an e sew ere.

Please complete the membership form overleaf and send it with your subscription to the Honorary Secretary.

rePrinciples of Construction Electrical Requirements Model Licence Conditions, etc.

PRICE £2.00 (including postage)

Obtainable from- Mr. J. A. J. Thompson, Honorary Editor 8, Beechfield, Hoddesdon, Telephone 09924 60812 Hertfordshire, EN119QH.

Reg. Office-Brittanic Buildings. 46c High Street. Erdington, Birmingham, B23 Telex: 335379

Invitations are extended to any member of the A;.P .E.A. who may be interested in applying for membershIP of the above Association. Applications to the Secretary.

sForecourt access covers with optional centre, or offset filler covers and dipstick inspection facility.

Suprasteel covers are made to withstand the heavy traffic of a garage forecourt - and they 're made to last.

With a full range always available to suit any requirement, delivery to site is fast normally only seven working days from receipt of order and by our own transport .

Distributors :

Lemford Building Supplies Ltd., 31-33 Wetherhill Road , London N102LJ

Telephone (Alan Donnovon) 01 4440066

Northern Ireland: James P Carry & Co. Ltd ., Princess Dock, Belfast BT15 1EE

Telephone (James Fleming) 0232 745211

Northern Ireland Agent: Alister Kirk & Co, 21nver Park, Hollywood, Co Down. Telephone 023173565

Republic of Ireland Agent: Patrick O 'Donavan , Lisheen, Elton Park , Sandycover,Co Dublin. Telephone 0001 803771

For detailed and illustrated technical handbook write to : F re d e ri c k Jo n es &Son Ltd., Oswestry, Shropshire.

or telephone 0691 3251 and ask for Ad rian Davies , Haydn Williams , Alan Cook or Christian Fjelle .

SpeCialist manufacturers to the petroleum construction industry.