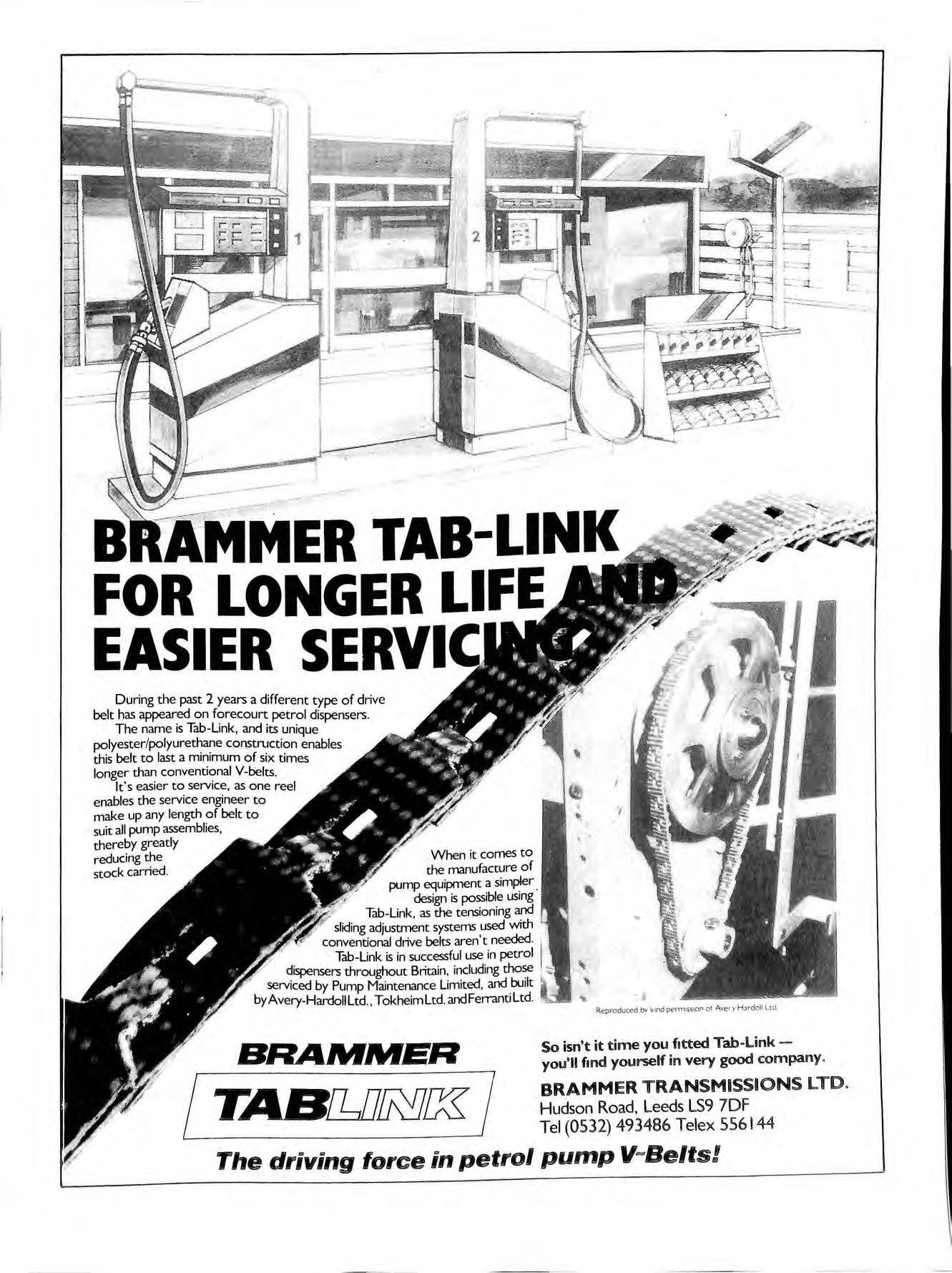

During the past 2 years a different type of drive belt has appear.ed on f?recourt petrol dispensers

The name IS Tab-Link, and its unique polyester/polyurethane cOilStn.Jction enables this belt to last a minimum of six times longer than conventional V-belts

It' s easier to service, as one reel enables the service engineer to make up any length of belt to suit all pump assemblies, thereby greatly reducing the stock carried

When it comes to the manufacture of pump equipment a simpler design is possible using · Tab Link, as the tensioning and sliding adjustment systems used with conventional drive belts aren't needed : Tab-Link is in successful use in petrol dispensers throughout Britain, including those ! serviCed by Pump Maintenance Limited, and built by Avery-Hardoll Ltd , Tokheim Ltd. and Ferranti Ltd.

(Petroleum & Civil Division)

Members of the Association for Petroleum & Explosives Administration

Units 29 & 30, Rabans Close Industrial Estate, Aylesbury, Bucks., HP19 3RS

Telephone: Aylesbury (0296) 22039 & 34481

£2.50 (Free to Members)

Published by the Association for Petroleum and Explosives Administration

Opinions expressed in this Journal are not necessarily the views of the Association

TALKING POINT

NOTES & NEWS

CONVEYANCE & DELIVERY OF PETROLEUM SPIRIT

DRIVER CONTROLLED DELIVERIES SELF-SERVICE TRENDS ON PETROL FILLING STATIONS

LONDON NEWS

GRP REPAIR TO PETROL TANK

12 13 16 17 20 21 23

At the AGM of the Association I was voted in as Chairman for 1984/5 and it is with mixed feelings that I relinquish the post of editor to Gerry Edney. I took the job on five years ago having had my arm twisted and after some hard work found the post rewarding. I felt that changes in typeface, printers, design and colour of covers and a more professional approach to advertisements were improvements to the journal over the past five years.

The aim of the Bulletin to discuss, inform on topical issues is more difficult for the editor to be objective over.

I would like to thank all readers, contributors and advertisers for their support and hope that Gerry Edney gets that same support. He will need informati,on, of interest, prosecutions, interesting or unusual problems encountered and information on new and eXlstmg services.

Mr, E. Brown, Cambridgeshire County Council,

Mr. J. A. J. Thompson,

The AGM of the Association was held at Dunstable on April 18th and the following Officers were elected

Chairman J. A J. Thompson, G.L.c.

Vice Chairman Mr. M. Duchesne, Heron Service Stations Ltd.

Secretary Mr. E. Brown, Cambridgeshire County Council.

Treasurer Mr R J . . ones, Suffolk County Council.

Editor Mr G A Ed . . . ney

Auditor Mr. M. Phillips

The following members were elected to Council

Dr. G. T. Jeacocke, O.B.E.

Mr. K. Lees, Lees Petroleum Ltd.

Mr. I. Nairne, Gilbarco Ltd.

Mr. B. J. Thompson, G.L.c.

There followed an interesting discussion on driver controlled deliveries with Mr. Smith of the GLC and Dr giving views on the proposals. The afternoon seSSIOn was cut short due to a visit to the Queensway Hall by Princess Anne.

The Association is holding its annual seminar on Petroleum on 1 October 1984 at Dunstable. It is hoped that members WIll note the date in their diaries, details of the programme which is being finalised will be published in due Course.

A young. forecourt attendant recently suffered superficial burns to hIS head and back when flames t t d t f h 1 ' s ar e 0 appear out 0 t e petro tank filler pipe of the c th t h f 11 ' ar a e was re- ue mg.

Despite numerous enquiries th h e cause as not been definitely established

The vehicle involved, however a 1()U'J Peu t "()" • Od go.).) estate car, has a plastic petrol tank.

Copies of the Association's membershl' p II b ro can now e supplied for the sum of £5.00

The roll includes the names and addresses of the Assoeiation's Officers, Honorary, Retired and Ordinary Members.

All orders should be sent to the Hon. Treasurer, Rod Jones at Trading Standards Department, 4b St. Mary's Square, Bury St. Edmunds, Suffolk. IP33 2AJ. Cheques and Postal Orders should be crossed and made payable to A.P.E.A.

A publicised "day of action" by Local Authority staff uncovered one aspect of the problems petroleum officers encounter during their work.

A contractor engaged by a major Oil company to redevelop a large petrol filling station and install a number of new tanks in an urban area was told not to concrete the tanks that day as officers would not be available to inspect the work.

The contractor ignored this advice and concreted. Some days afterwards it was discovered that the concrete was of poor standard as pieces fell away from the tank, revealing all sorts of rubbish around the tanks. The licensing authority and Oil company cooperated in having around 3 cu metres of wire, bricks, paper and rubbish removed from around the tanks. It was also discovered that the concrete was of poor quality, with insufficient cement which had been placed dry to avoid compaction. The consequences of this remaining in this area, which would have certainly caused the tanks to leak in a short period horrified all those involved. It is most fortunate that the incident was discovered and highlights the need for close control in what is an important area of public safety. It is also perhaps a lesson to those awarding contracts that the cheapest tender may not always work out that way in the long run.

Regulations to metricate health and legislation applying to explosives were laid before ParlIament by Mr. John Selwyn Gummer, Minister of State for Employment.

The regulations amend the Explos.ives Act 1 and subsidiary legislation, and will come IOtO operatIOn on 8 May 19H4.

The regulations, which stem from an E.C Dire.ctive, replace the imperial measurements WIth SUItable equivalents while preserving existing safety standards. In certain cases the metricated values have been set so as to take full account of current practice (as regularised by current certificates of exemption granted by HM Chief Inspector of ExplOSives) rather than simply to metricate existing legislation.

Premises and plant which are already in existence or under construction and which comply with the old measurements do not need to be modified.

The regulations were prepared in consultation wi th appropriate g-overnment departments, trades unions, local authorities and other appropriate bodies.

Fibresec Marketing Co. Ltd. have produced a new heavy duty manhole cover which will stand up to all the rigours wear and the axle loading of the heaviest tanker; it is remarkable in that it is a fraction of the weight of the present manholes on the market. The cover which is constructed of GRP can be moved with one hand from a standing position with the minimum of stress to the user. The cover and frame are also designed to repel water. Tests are being carried out to its suitability by major oil companies who see the handling advantage for forecourt staff, the manhole has been accepted for use in the London area and it is hoped that a fuller report will be in a future issue of the Bulletin.

Minutes of the Yorkshire and Humberside Branch of the Association for Petroleum and Explosives Administration held on the 22nd Sept. 1983 at the Red Hart, Blyth, Nottinghamshire.

The Chairman Mr. R.J. Smith extended a warm welcome to the 28 members and visitors present. With a special w.elcome .bein? extended to Mr. Bill Wright of the Lincolnshire Fire Service and Mr. Jerry Pollard of the Greater Manchester County Council.

The minutes of the meeting held on the 29th March 1983 were read and accepted as a true record.

Proposed by M. Ray

Seconded by C. J. Plaxton

Apologies were received from 10 members.

The Treasurer reported that the balance in the Current Account at The Treasurer expressed concern With regard Its members subscriptions and urged members to pay their dues.

A short talk was then given by representatives of Calor Gas re?arding. the installation of c.P.S. storage and dispensmg eqUipment.

This proved to be an interesting and topical subject. A vote of thanks was given by the Chairman to Mr. Doyle, Mr. Baker and Mr. Glenney for their efforts.

The question of proposed lI1creases in Petroleum Licence fees and the question of rendering tanks temporarily safe were discussed.

The morning meeting concluded at l2.S0 p.m. The afternoon session was devoted to a talk by Mr. Bill Hocknell of Conoro on the Refining of Petroleum. A vote of thanks was given by Mr. R.J. Smith and the meeting terminated at :i.40 p.m.

On the 9th March 1984 the Midlands Brartch held its Spring Meeting at Haygarth House, Nr Retford a guests of Pump Maintenance Ltd. Haygarth House houses the training school for employers of Pump Maintenartce artd the electronic workshops. Bill Massie, the Chairman of the Branch, welcomed members and guests from all over the Midlands.

The subsequent tour of the school served to demonstrate the ever increasing complexity of modem metering and dispensing equipment. Of particular interest were the repair workshops for the electronic parts of dispensers. The need for adequate back up to field engineers was obvious.

The thanks of the Branch are extended to Geoff Hemingway, the principal, and all his staff for their hospitality and enthusiasm.

I refer to the circular HSGB31l 2811 978 dated 3 August 1978 issued to all county councils in England and Wales, Re ional and Island Authorities in Scotlan.d Harbour by the Hazardous Substances DIVISiOn 'B' of the Health & Safety Executive, 'Leak Testmg 0 Petroleum Spirit Storage Tanks'.

"It IS

In ara ra h 3 of that circular I quote p g p . f a new tank tu the recommended that leak testmg 0 I d I· Ily or d ·ther ly rau Ica excavation should be e.1 fthese methods may be II A combmatiOn 0 Pneumatic a y ...... . b I . the man way k "th ter to Just e ow used by filling the tan Wl .wa d as a resul t of meetings I·d" Th ethods lIste were I etc. em. ·atl·ons the Institute . hi· . a thontyass OCI , it is said, Wit Icensmg u h carr out the tests. of Petroleum and contractors w 0 Y etroleum storage matters and have

I am not a expert m p. leumofficerforarelatively only been alocal authontypetloI I t at our APEA red to many lave me short tIme ed certain instruction concerning meetings. rece.lv II and testing and have obeyed underground tank 1l1sta atiOn d 1 h h d ·th some modifications introduce over t le t e met 0 ,WI years, laid down by my Authonty.

I had never heard of the of the which Mr. Caines highlighted in Ius paper 111 the last Bulletin causing complaints to his company .later whe.n di stick'readings were apparently inaccurate a IS w:ter filled as recommended. At previous meet1l1gs It has been alleged such a method tends to cause the tank togo oval. Were any tank manufacturers in on the diSCUSSIOns with the H.S.E.?

In the same circular it recommends the pressure applied not to exceed 7 p.s.i. this if I remember correctlv after the 10 p.s.i. test had been deemed to be highh dangerous especially as some authorities tested tanks abovt' ground before installation to this pressure.

On a visit to a manufacturer of petroleum tanks. I \\as in a party whose guide had been in the business Iw said il I

remember correctly, some 40 years. He had begun by making the things and had risen to managerial level. He stated quite categorically there was only one way to test a tank and that was pneumatically pressurising it and soaping all the welds. Ifhe is correct this, of course, can only be don on a site above ground. Having myself found leaks on welds and knowing others who have done so also, on brand new tanks in the past using this method I tend to agree with him.

At another APEA Branch meeting I attended, a gentleman formerly of the Cement & Concrete Association alleged that the recommended mix of sulphate resisting concrete was useless being far too weak to be effective and, if I remember correctly, said it would be far better if the tank was slightly rusty (as most reinforcing rods and mats are) to allow the concrete made with more cement used in the mix to bond to same, instead of being coated with bitumen.

In view of all these varying assertions put forward by experts in their respective fields it amazes me there has not been a strict method laid down on testing and installation which must be followed nationally instead of just recommendations. If they are right then should not one be formulated quickly? Otherwise I imagine this dangerous substance will still be stored in oval, flat bottomed, leaking rusting containers, which cannot be accurately dipped, as may surely must be now! Tested by some of course in highly dangerous circumstances ..... .

Glad you get to Branch meetings as well as read the Bulletin, it seems to have sparked off some interest. It is the aim of the Association to acheive uniformity; I would suggest you applyJor the first copy ofthe APEA code ofpractice on petrol filling stations, it will answer most of the questions you pose, but we have not quite accepted rusty tanks yet!

On January 1st 1982 the above regulations came into force and replaced the petroleum Spirit (Conveyance by Road) Regulations 1957.

With the change in these regulations, the enforcement of the regulations moved from the petroleum licensing authority to the Police while on the publicway, to the factory inspector or environmental health officer while on premises.

This has meant that from 1 January 1982 that the job of enforcing the regulations while delivering pertoleum spirit to public filling stations has moved to bodies that neither have the expertise, manpower nor the inclination to set up some procedure to deal with problems that arise.

The only exception being the unloading of petroleum spirit Regulation 20(1) which gives limited powers to the Licensing authOrity.

To take as example the London area in the 5 years prior to the change in legislation the follOWing inspections were made on Road Tankers conveying petroleum spirit.

Senior Petroleum Officers made annual inspections on Road Tankers based in London, including detailed checks of their internal fittings.

All Petroleum Officers carried out "casual" inspections when in the course of their duties they encountered vehicles carrymg petroleum spiri t. Casual inspections were Iimi ted to the examination of external fi ttings and labelling requirements but they did provide an important check on the observation of operational requirements.

]977 110 at 15 premises 20% of tankers had faul ts

1978 133 at 18 premises 20.0% of tankers had faults

1979 142 at 17 premises 55.6% of tankers had faults

1980 88 at 12 premises 53% of tankers had faults

1981 48 at 5 premises 50% of tankers had faults

Number Percentage faults Cautions Prosecutions

1977 373 11.2% 16 3

1978346 7.8% 10 2

1979240 12.5% 9 2

1980245 8.5% 15 2

1981 206 5.3% 6 4

During 1982/3 the Metropolitan Police/HSE have made no such inspections or checks and are showing a marked reluctance to do so. Complaints about road tankers are finding their way to the factory inspectorate who with limited resources on manpower find they are often unable to follow up such complaints, an if they do at the expense of some other visit.

In addition spillages of petrol, contraventions of the regulations by tanker drivers have gone unreported at petrol filling stations, caused by the reluctance of the HSEI EHO to get involved. It has been found that many are unaware of their responsibility and suffer generally from a lack of expertise.

A recent case of the same driver being responsible for two large spillages of petroleum spirit on forecourts and being cautioned, prosecuted or even talked to by the HSE IS an illustration.

Another case of a tanker driver smoking while his tanker was being off loaded and causing a spillage of spirit is another case where the Licensing Authonty as acted on the delivery contravention but the HSE would not act on the other infringement.

. . change in the

Major Oil compames are pressmg or a . Regulations as they wish to use round the clock deh vJr7to improve efficiency and are putting the case controlled deliveries. This will exacerbate the Sltua lOn unless effective control is exercised.

b tances and for the

The Regulations cover dangerous su sdi' d 1 . k well they are e 1 vere major part these regu atlOns wor, h' h the to manufacturing plants and factories over w lC factory inspector has control.

With delivery of petroleum spirit to petol filling stati??s it is different the factory inspector or EH? wil! hardly the main authority being the petroleum hcensmg authonty who are concerned with safety. It should be remem?ered that a petrol filling station unlike a factory the pubhc has constant access and the need for extra care was always recognised by the Petroleum Spirit (Conveyance by Road) Regulations 1957.

The case therefore for Petroleum Licensing Authorities being responsible for enforcement of the while on Petrol Filling stations and other premlses licensed to keep petroleum for refuelling, is overwhelming.

It is time the HSE changed the legislation to protect the PUBLIC from the dangers that lack of enforcement and inspection is exposing them to at the moment.

The UK Petroleum Industry Association has produced a draft code of practice for the guidance of persons involved in driver controlled delivery of Petroleum Spirit. It has worked with the HSE in this and it is hoped that agreement will be be reached to issue a certificate of expemption to allow driver controlled deliveries, as these are not permitted under existing legislation. Discussion on the code up to present has been within the petroleum industry and the HSE (although earlier codes had been drawn up in the 1970's) The Association produces the draft for information of its members, and will be pleased to receive informed comment on the proposals which it will pass on to the appropriate bodies.

1.1 This code has been prepared by the United Kingdom Petroleum Industry Association for the guidance of persons concerned with driver controlled deliveries (DCD's) to premises licenced for the storage of petroleum spirit.

1.2 Its aim is to set a safe standard of good practice for driver controlled deliveries in line with the requirements contained in The Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 Certificate of Exemption No.? of 1983 See Section 2.0.

1.3 The code represents a standard of good practice and takes the form of recommendations. It does not attempt to define every detail of a safe procedure.

The following are the conditions specified within the Certificate of Exemption.

2.1 The licensee of the premises at which it is intended to unload petroleum spirit in accordance with this certificate of exemption, shall, at least one month before the commencement of such unloadings, inform the authority empowered to grant petroleum spirit licences under the Petroleum (Consolidation) Act 19213 ("the licensing authOrity") of such intention.

2.2 Once so nominated in accordance with 2.1 above unloading shall not take place in accordance with Schedule 4 to the Regulations unless:-

(a) at least one week's notice has been given to the licensing authority of the intention to cease unloading in accordance with the certificate of exemption; or

(b) where,. due any failure of the eqUipment, compliance WIth the conditions in this certificate is not possible, and both the operator of the road tanker and the licensee have agreed to revert temporarily to unloading in accordance with Schedule 4 to the Regulations.

All instances of the reversion referred to in (b) shall be notified to the licensing authority by the licensee within one week of their happening.

2.3 The operation of unloading shall be in accordance with the UKPIA code of practice: 'Driver Controlled Deliveries (DCD's) to premises licenced for the storage of petroleum spirit.

2.4 Each storage tank shall(a) be marked at the fill pipe to show the tank number, product grade and maximum capacity; (b) have the fillcap locked with a captive padlock, the key of which shall have a profile different from that used on other such storage tank number corresponding to that on the fill pipe; be fitted with a suitable device other than the dipstick which shall provide a visible means of establishing the ullage and which shall be available to the driver in charge of the unloading throughout the unloading operation.

2.5 Adequate and safe illumination of not less than 10 lux (I lumen per square foot), together with means accessible to the person in charge of the unloading for SWitching it on and off, shall be maintained inthe area in which the road tanker stands during unloading and in the area in which the storage tank filling pipe and any device for ascertaining the contents of the storage tank are situated.

2.6 A telephone in the Delivery Control Box shall be available to the driver in charge of the unloading.

2.7 A fire extinguisher, other than any carried on the road tanker, haVing a minimum test fire rating of 144B (BS5423) shall be available to the driver in charge of the unloading.

2.8 A site plan of the petroleum filling station indicating the position of the delivery point, product, grade, capacity and number of each storage tank shall be available in a readily accessible position to the driver in charge of the unloading.

2.9 The operator of the road tanker shall ensure that the driver thereof is given written details of any special conditions in respect of the unloading of petroleum spirit which are attached to the licence of the premises. Such conditions shall be observed throughout the unloading by the driver in charge of the unloading.

2.10 The licensee of the premises shall, prior to the delivery of petroleum spirit, ensure that the ullage each storage tank is measured and that two copIes of a certificate are completed as required by paragraph 7 of Schedule 4 to the Regulations. He shall also ensure that one copy of the certificate is made available to the driver in charge of the unloading.

2.11 The driver in charge of the unloading shall not commence the unloading of petroleum spirit into any storage tank until he has in his possession a copy o.f certificate referred to in 2.1 () above and has verIfIed that the quantity to be delivered be safely received by the storage tank speCified on the certificate by checking visually the tank measuring device (referred to in 2.4(c) above).

2.12 During the whole time that unloading into any storage tank takes place, the driver in charge of the unloading shall, so far as is reasonably practicable, ensure that no petroleum spirit overflows from the storage tank or at the filling point, and shall keep constant watch on the storage tank, the carrying tank and the connecting hose(s) through which the unloading is taking place.

2.13 Before departing from the premises the driver in charge of the unloading shall ensure that all fill pipes to the storage tanks into which deliveries have been made are securely closed and padlocked, and shall ensure that all manhole covers are securely replaced.

Driver controlled deliveries in accordance with Certificate of Exemption No.? will be made only to those premises nominated by the licensee with the agreement of the supplying company and only after the licensing authority concerned has been notified and has given its approval in writing. Notification should be made by the licensee using the form shown in Appendix 1.

Tank fill pipes should be clearly marked with the tank number, product grade and maximum capacity of the tank. Marking should be securely fixed and clearly visible to the driver making the delivery.

4.2

tank measuring device should provide a vIsIble means of establishing the ullage and this should be available to the driver in charge of the delivery.

Where a device such as a remote readout is used it .display .the tank number, be continuously mdIcatmg and m the event of fail ure of the device should indicate the tank is full. '

4.3

Ea.ch storage .tank fill pipe should be capable of bemg locked m the closed position with a device which cannot itself be detached from the fill-pipe. The keys of such locking devices should have different profiles to the locks on any other storage tanks and should be clearly marked with the tank A set of these keys should be retained by the hcensee of the premises.

4.4

Lighting to at least the minimum standard outlined in 2.5 above should be maintained over the whole of the delivery area at the premises.

4.5

Where necessary consideration shall be given to devices such as lifting barriers, chains or cones which can be used to enable the driver to manoeuvre safely into and out of the delivery area.

The driver should have access to a 'Delivery Control Box' which should contain the following:' 4.0.1 means of switching on and off the lighting over the delivery area.

5.0 6.0

4.6.2 telephone with numbers for emergency contact.

4.6.3 site plan showing each tank position together with its indentification number and maximum capacity.

4.6.4 special licence conditions applicable to the filling station.

4.6.5 alternative measuring devices (see 4.2 above).

4.6.6 manhole cover lifting keys (where manhole covers are fitted).

The licensee of the premises shall provide:

4.7.1 Afire extinguisher{s) (other than that on the delivery vehicle).

4.7.2 Sand or' earth together with tool{s) for containing any spillage. Which should be available to the dnver dunng the whole period of the delivery.

Prior to the delivery being made the licensee should:-

5.1.1 follow the procedure given in Section 2.10 of this document. The original copy should be placed in the Delivery Box f?r the t · f the driver making the dehvery. aten IOn 0 h

5 1 2 Place only the keys (see Section 4.3.1) for t . e ., tanks shown on the Petroleum Certificat.e m the Delivery Control Box for the dnver making the delivery.

5.1.3 ensure that the items listed in 4.6 a?ove in place and where applicable are m so un working order. d l' er

5.1.4 ensure that access and egress .to kell v area is free from obstructIOns 1. y. impede the safe manoeuvring or of the tanker thoughout the peno 0 delivery.

ANY

DUTIES OF THE SUPPLYING COMP

6 1 Planning Deliveries

. .' h uld be planned to ensure that the Dehvenefs sOh vehicle compartment are not contents rom eac k {. ( more) storage tan s I.e. one split between two or compartment into one storage tank).

6.2 Despatching

6 2 1 Vehicles used for making driver controlled deliveries must be fitted with bottom operated footvalves. .'

6.2.2 The driver should also be proVIded WIth i) key for delivery control box.

ii) specific information to the sIte:special licensing condItIOns, method of access/egress from delivery area an.d position of Delivery Control Box Thls infolmation can be documented usmg a 'Site Access Card'.

7.0

7.1 Before delivery the driver should:-

7.1.1. park vehicle in the designated area..

7.1.2 open Delivery Control Box and sWitch on delivery area lights (if necessary).

7.1.3 remove copy of certificate from box and check grades and quantities against delivery invoice to ensure they agree.

7.1.4 check each nominated receiving tank and compare ullage with quantity to be delivered into this tank to ensure it can be safely received.

7.1.5 at this stage should there be any discrepancies the driver should not proceed with the delivery but contact his depot supervisor for further instructions.

7.1.6 position fire extinguisher{s) near the fill point.

7.1.7 remove manhole covers (where fitted), unlock and remove fillcaps with key provided and connect delivery hose{s) to nominated fill pipes and then to correct vehicle faucets.

7.1.8 Recheck that all connections are secure and correct and then proceed with the delivery.

7.2 During delivery the driver should:-

7.2.1 the whole of the delivery remain m constant watch on the storage tank{s) fill points, hoses and vehicle to ensure as far as is practicable that no leakage of product OCcurs.

7.3.1 check the gauges to ensure that the quantities have been safely received.

7.3.2 close all valves on vehicle.

7.3.3 drain, remove and stow hoses on vehicles.

7.3.4 replace fill pipe caps and lock (if necessary) and replace manhole covers' (where fitted).

7.3.5 replace the fill pipe keys in the Delivery Control Box.

7.3.6 ensure that any equipment removed from the Delivery Coptrol Box is returned and safely stowed.

7.3.7 a. copy of the Company's delivery , m the Delivery Control Box.

7.3.8 sWitch off lighting over the delivery area (if necessary) and lock Delivery Control Box.

7.3.9 ensure that the Delivery Control Box key is returned together with a copy of the invoice to the depot.

The procedure to be followed by the dri th event of a ver m e extent of emergency will vary depending on the or hi e. emergency, whether or not the licensee Th s agent IS on the premises and other factors e following are I.. . should follow d gen:ra gUldehnes which the driver 8 ependmg on circumstances·o

.1 stop the flow of d cl' h pro uct from the vehicle by Osmg t e footval d vehicle. ves an for faucets on the

H.2 use the tel h ep one prOVided to contact the emergency services and h' d , IS epot. seek the assistance of th I' , th . e Icensee or hiS agent ifhe IS on e premises.

H.4 if any spillage OCCurs end earth or sand 'd eavour to contain it with ,avOl any SOur f' " d k ' ce 0 Igmhon an a It empt to eep bystanders aw f h'" f h '/1 ay rom t e vlclmty () t P Spl age

NOTE: The licensee must be notified of any incident which occurs on his premises in his absence immediately or as soon as is practically possible.

All persons concerned with driver controlled deliveries of Class I petroleum products should receive appropriate training on the procedures to be followed and the nature of the dangers which may arise.

In general the driver should receive training in accordance with Regulation 21 of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 and in particular the follOwing items:-

9.1 his duties as outlined in Section 7.0 of this code.

9.2 the operation and use of equipment when making a driver controlled delivery and the operation and use of the equipment concerned with a DCD.

9.3 action to be taken in the event of an emergency at a nominated site.

Appendix 1

The Dangerous Substances (Conveyance by Road in Tankers and Tank Containers) Regulations 1981 CertIficate of Exemption No.?

Name of Licensee of Premises under the Petroleum (Consolidation) Act, 1928

Address of Premises

I hereby request approval for driver controlled deliveries of Petroleum Spirit to be made under the conditions in Exemption Certificate No. ? to the premises named above.

I certify that the premises named above meets the Criteria for Nominated Sites stipulated in the Certificate of Exemption.

* *

The date on which you wish this to become effective Attach a letter from you Supplyin? to make deliveries under ExemptIOn Certificate No

No. of sites per company tail petrol filling stations in the U.K and concluded that Brand

The Institute of Petroleum has completed a survey of re-

Total Self Company- Retailing there are now 23,097 petrol filling stations. service owned Derv

The Regional breakdown indicates there are 19,746 in Esso 3,255 1,218 1,144 1,750 England and Wales and 2,061 in Scotland, 1,109 in Nor- Shell 3,008 1,497 1,192 1,256 them Ireland; 141 in the Channel Islands and 40 in the Isle BP 2,011 852 738 821 of Man. Texaco 1,740 641 946 499 Jet/Glove 1,119 277 256 325

The number of outlets fell by 1011 over last years figure National 1,055 428 327 396 but the number of self service sites in the UK rose by 532 to Mobil 955 681 584 407 now take 33.2% of the total. Bunnah Group 951 150 178 339

The following figures are reprinted from Petroleum Re- Fma 915 256 281 394 view, the monthly magazine of the U.K Institute of Total 795 405 597 290 Ultramar/Summit 588 29 341 156 Petroleum. 588 8 9 167 Sadler/Pace Anglo 588 1 142 Elf 505 356 207 189 ICI 475 97

Analysis of each company site Gulf 412 190 172 151 Others 4,140 592 670 1,436 Brand % Self % Company % retailing Grand Total 23,097 7,677 7,333 8,718 service owned derv Esso 37.4 35.1 53.8 Shell 49.8 39.6 41.8 No. of company sites as % of UK total BP 42.4 36.7 40.8 Texaco 36.8 54.4 28.7 Brand Total Self Company- Retailing Jet/Globe 24.8 22.9 29.0 service owned Derv National 40.6 31.0 37.5 14.1 15.9 15.6 20.l Mobil 71.3 61.2 42.6 Esso 19.5 16.3 14.4 Shell 13.0 Bunnah Group 15.8 18.7 35.6 1O.l 9.4 BP 8.7 ILl Fma 28.0 30.7 43.1 7.5 8.3 12.9 5.7 Total 51.5 75.4 36.6 Texaco 3.6 3.5 3.7 Jet/Glove 4.9 Ultramar/Summit 4.9 5.3 26.5 4.6 5.6 4.5 4.6 Sadler/Pace 1.4 1.5 28.4 National 8.9 8.0 4.7 4.l Anglo 0.2 24.1 Mobil 2.0 2.4 3.9 Bunnah Group 4.1 Elf 70.5 41.0 37.4 4.0 3.3 3.8 4.5 ICI 20.4 Fina 5.3 8.l 3.3 3.4 Gulf 46.1 41.7 36.7 Total 0.4 0.4 1.8 Ultramar/Summit 2.6 Others 14.3 16.2 34.7 2.5 0.1 O.l 1.9 Sadler/Pace 1.6 Anglo 2.5 2.2 Elf 2.2 4.6 2.8 ICI 2.l 1.2 2.5 2.4 1.7 Gulf 1.8 7.7 9.1 16.5 Others 17.9 100.0 100.0 100.0 Total 100.0

J No. at Total

Company- %0/ Average site year

total owned total throughput (IG) ending 7,677 66.8 7,333 31.7 :239,66:1* 1983 23,097 33.2 15,420 1982 24,108 7,145 29.6 16,963 70.4 7,563 31.4 225,868t 1981 24,760 6,712 27.1 18,048 72.9 7,796 31.S 211,914 1980 25,527 6,022 23.6 19,505 76.4 8,011 :11.4 210,492 1979 26,480 5,340 20.2 21,140 79.8 8,166 30.8 198,03:1 1978 28,295 4,966 17.6 23,329 82.4 8,63:2 30.5 182,818 1977 29,751 4,4:·m 14.9 25,312 85.1 8,823 29.7 162,80.') 1976 30,383 3,794 12.5 26,589 87.5 8,944 29.4 155,146 1975 31,426 3,448 11.0 27,978 89.0 8,458 26.9 142,800 1974 32,662 3,226 9.9 29,4:16 90.1 7,529 2:1.1 14\,00 *estimated trevised

An explosion occurred in an LEB chamber housing a junction box on the forecourt of a large filling station. No petroleum was involved and the only damage was to the disconnecting box which was abandoned and the chamber solid-filled.

An automatic car, driven by a lady, crashed straight into the wall of the sales kiosk at a self-service petrol filling station. The station was closed while emergency arrangements for structural safety were made. Two hours later, while the station was still closed. another lady driver got out of her car without applying the hand brake. The car rolled into the other side of the kiosk, causing further damage. No petroleum or equipment was involved. The filling station needed to be closed later to enable the kiosk to be rebuilt.

A Contractor who was installing underground tanks on a congested site repeatedly rejected the petroleum inspector's demands that the excavation should be shuttered. The contracts manager, who was based in Birmingham, claimed to have installed many underground tanks without shuttering and could not be persuaded of the necessity, despite warnings that the installation would not be approved and the obviously unstable nature of the excavation. As foreseen the excavation did collapse and happened to fall on the contracts manager himself, who suffered considerable injuries and was removed to hospital. The tanks were eventually installed to the satisfaction of the inspector.

On a night of very heavy rainfall a senior inspector responded to a request from the Brigade to attend a filling station where the forecourt drainage had flooded the interceptor, causing petrol from the interceptor to back up gullies etc., flooding the forecourt. The inspector advised against the use of portable pumps and in any event the road drains had also been flooded by the storm. Alocal authority 'sludge gulper' was called and the interceptor was emptied and cleaned out, in the cirmcumstances the only practical way of dealing with the situation.

A customer at a multi-storey car park reported a strong smell of petrol near the main stairs and lift shaft. The cause was found to be a leakage of petrol from the corroded fuel tank of a J' ag h I uar car pus ed on one of the open-an leve s. The Brigade wa" II d d f' d ., ca e an a ter puttmg down san as an absorbent, the area was hosed down by the Brigade into a gully connected to the interceptor. The amount of lost eLml was up to 1h' • II P .' .) ?a Dns. The petroleum inspector was nul. adVIsed of the mCIdent until 2 days later, when he cautIOned the manager on the failure to report the incident.

A North London EHO received a complaint of apparent pollution in the back garden of a private house behind a filling station. The district petroleum inspector could find nothing significantly wrong at the station except that the surface concrete around the tank manholes and the walls of the chambers were in poor condi tion, suggesting that minor delivery spillages might be to blame. Steps were taken to stop seepage and Esso engineers considered digging a sump to alleviate the pollution but the problem was still unresolved some 6 months later when the agrieved resident made a claim for damages against the oil company. The increased interest shown by the latter thereafter was commendable and figures were produced from a recent Weights and Measures check which revealed considerable under measure at the pumps and a loss of throughput in consequence. The installation was then tested and one tank found to be leaking. A number of boreholes were made on the Station, in the access road, and in the gardens at the rear and samples removed for laboratory anal ysis showed that roughly 1350 cubic metres of soil were contaminated.

A sump was dug within, but at the rear of, the petrol station property and a pump installed and connected to a 45 gallon drum. The pump, which was supplied by Esso's Abingdon Research Station, is of special interest as it :emoves only petrol or oil, leaving water behind. It all necessary safety devices, including one whIch prevents overfilling of a drum connected to it. Though sufficient spirit was recovered to require a second drum the contamination remained and Esso arranged for the removal and replacement of large quanti ties of soil and sub-soil.

As a result of complaints of petrol smells in a flat in North-west London the district inspector visited regularly over a period of 3 months but could not establish the cause until he chanced to notice the attendant at a nearby filling station mopping down the pump islands with petrol. The bucket used for the petrol was washed out and rinsed down the The inspector caused the practice to cease ImmedIately and warned the licensee of its dangers.

The continuing story of the licensee who fails to recognise the possibility of a leak of petroleum spirit when a fault develops on site was recently enacted in North-east London. Petrol smells were reported in a restaurant, an amusement arcade and several private houses in a stretch of road containing a number of filling stations. The knew his search was over when, at one site, he readIly obtained 100% LEL readings at low level in the TBA shop and an admission that a pump had been malfunctioning for some weeks and suction line tests had been arranged. The cause was a holed non-return valve and complaints ceased once this had been remedied and the drains had been flushed by the local authority. The licensee was cautioned for failure to notify the Council of a suspected leak.

(a) One of the senior petroleum inspectors found difficul ty in gaining access to premises at the rear of a filling station in Feltham where he suspected that petroleum mixtures were being kept without a licence. he eventually visited the premises, accompanied by a police constable, and found about 25 gallons of petroleum mixture on the premises. The occupier was prosecuted and fined £100 with £20 costs for the offence of keeping without a licence.

(b) The occupant of a workshop in North London was fined £50 and ordered to pay £80 costs for keeping petroleum mixture without a licence. Petroleum was stored in the open boot of a large car and spraying was carried out beneath a plastic sheet suspended form the ceiling. There was no mechanical extract or alternative means of escape and there were numerous sources of ignition. The upstairs sub-Ieasee, whose sole access was by way of a vertical iron ladder on the outside of the building, was, after delays due to nonappearance, prosecuted for a similar offence and fined £250 with £100 costs at the same court.

(c) A routine inspection of a filling station revealed a leaking pump, from petrol had formed a pool of 6 square feet on the forecourt. In addition daily dip records were not being maintained on three tank compartments which were more than ten years old and both the dry powder and the foam extinguisher on the forecourt were insufficient. The licensee was prosecuted and fined £500, £200 and £500 respectively for the three offences with a total of £113 costs.

(a) During the period 4 firms were cautioned for infringement of the Blackwall and Rotherhithe Tunnel By-Laws. The infringements related to the carriage through the tunnels of pro hi bited substances including cylinders of gases and LPG and in instance, fireworks. No infringement of the Woolwich Ferry By-Laws was reported.

(b) A police motor cyclist white fumes issuing from an open-backed lorry m Tower Hill. He stopped vehicle and. summoned the Brigade who discovered ammoma and hydrochloric acid in drums on the vehicle. Fumes were issuing from one of the hydrochlOriC acid drums. The Scientific Adviser and Petroleum Inspector were called. The Brigade made the containers safe and washed down the area around the drums. The cause of the fumes was found to be the fitting of incorrect closures to the hydrochloric acid drums. The inspector ascertained that no fire extinguisher was being carried on the vehicle. The company and driver are to be cautioned for infringements of the Corrosive Substances (Conveyance by Road) Regulations 1971.

A driver of a large tanker making a delivery at a filling station was taken to hospi tal for treatment after a spillage of petrol. The driver had released the foot valves and commenced delivery into the offset fill from No. 1 compartment. He then commenced to remove the drip caps from the remaining compartments. When he removed the cap from No. 5 compartment petrol poured out over the forecourt. The driver held the drip cap against the flow and shouted to the forecourt supervisor who dropped the foot valve. About 250 litres of petrol was lost from the 2700 litres in the compartment. The Brigade was called and flushed down the forecourt. The Petroleum Inspector arranged for the interceptor to be cleaned and advised on the reporting the incident to the HSE.

An inspector was called out in the early hours of the morning to investigate a complaint of a strong smell of petrol in a private house. On inspection ofthe road drains it was discovered that an elderly car, parked over a road gulley was leaking petrol from a defective tank into the drain. When questioned the owner of the car confirmed that he had been aware of the defective tank "for about 2 weeks" and was awaiting an opportunity to replace it. In the meatime he was keeping the car on the road and topping up the tank. He was instructed to remove the remaining petrol from the tank which was then made safe with water. The drains were then flushed and the recess on manholes vented. The petrol smell rapidly disappeared folowing this action.

Mr Noble gave a talk to members of the. West Middlesex University Hospital, Plastic Surgery Umt on the control and storage of petroleum.

Mr Worsfold gave two talks to petroleum officers of the Associated British Ports on the inspection of large petroleum installations.

Mr Chaplin gave a lecture to the National DemolitIOn T G the sace removal of petroleum tanks. rammg roup on l'

Mr Chaplin gave a talk at an industrial fire safety course organised by the London South Area Liason Group on petroleum safety.

Nr Noble gave a talk on as part of the Brigade's Interphase Specialist Fire PreventIOn Course.

Mr J. Thompson gave talks to members of Esso Petroleum Co, Ltd's Terminal.

Mr Noble escorted Mr Satiman of the Singapore Fire Service and Messrs Tan Ke Wat and Tan Ling Siah of the Port of Singapore Authority on visits to various licensed installations.

An inspector, having received news of the theft overnight of three petrol pumps from a recently vacated site, was pleased to report that the disconnected suction lines had been reasonably well sealed.

Mr Worsfold escorted Mr Sharma of the Indian Fire Service on similar visits.

Messrs Chaplin and Noble escorted members of the Brigade'S SpeCialist Fire Prevention Course on visits to various licensed installations in their areas on two occasions.

On 20th October 1975 a 2000 gallon underground Petroleum Spirit storage tank was installed at an Agricultural Machinery Distributors premises (there being two existing 1000 gallon underground petroleum spirit storage tanks installed in 1949 within 50 yard of the new installation.)

The installation was checked at each stage, and the tank was surrounded in 6 inches of 1:2:4 mix sulphate resisting concrete.

In 1982 all the tanks were linked, via gate valves, to a Gasboy commercial pump, which was controlled by a key reader security system, linked to a micro-processor fuel monitoring system.

During the Autumn of 1983 it was noticed that losses greater than under normal circumstances were being indicated, and after exhaustive tests the problem was

indentified as the 2000 gallon tank. Nitrogen pressure tests appeared to be satisfactory as did full tank ullage tests, however, as the quantity was reduced fuel losses were shown. The licencee subseqently decided to commission and engineer to inspect and, if possible, re-line the tank in question. This proved to be a valuable exercise as this authority had not been approached regarding such works before.

During December 1983 the tank was rehabilitated and when the tank interior was examined a fracture of one of the end shells was found at the bottom . It was apparent that water ha.d and left the tank interior as shown by the severe pIttmg of the area in question. (Photo 1).

After gas pressure testing the tank was put back mto servIce with an initial life of 10 years.

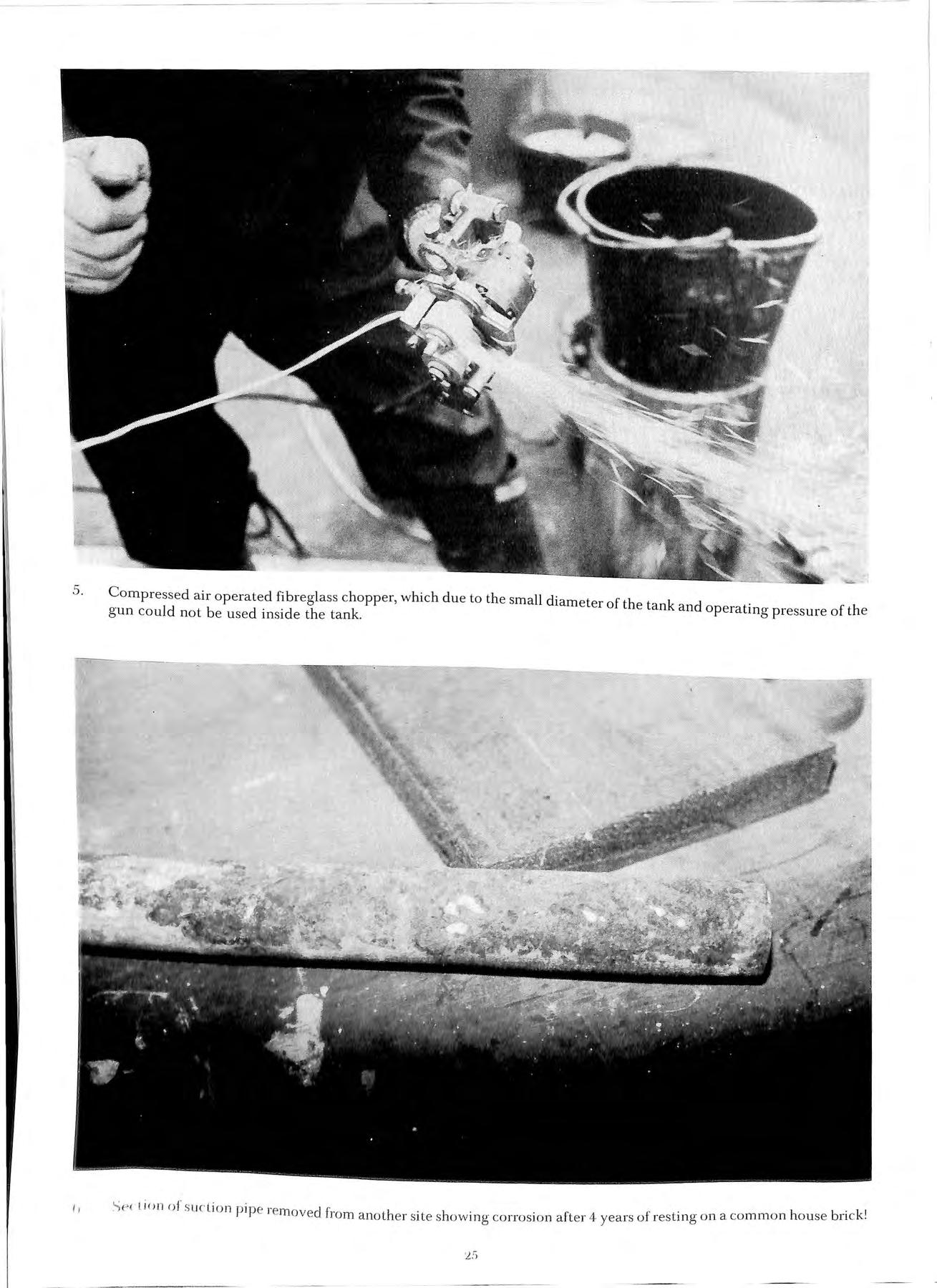

The other photographs show the work in progress.

x 5 inch diameter hi g h ve locity blower units in operat ion, and sand blasting e quipment.

Illustrated 1800 gal. unit complete with Gasboy model 390 Fuel Co ntrol K20 unit. Automatic Nozzle and 12' x '%" hose.

Throughput 8 10 G.P.M. ca librated in imp. ga/. litre measure to customers requirements.

The pump illustrated is a K5 key controlled unit

A full RANGE of fuel control units with or without tank installations.

Illu strated below 1800 gal. unit complete with Gasboy model 1820 Automatic Nozzle and 12' x %" hose.

Throughput 8 10 G P. M. cali brated in imp. gal. or litre measure to customers requirements.

•

•

•

•

/ 221,

A simple but effective mounting allows fast. secure

attachment direct to either tank-top or stand-pipe The UCC Lockable cannot be unscrewed, remaining

Roncol's

Suitable for Diesel or Petrol.

Standard