THE BULLETIN

Journal 01 the Association for Petroleum and

Journal 01 the Association for Petroleum and

During the past 2 d·f

belt h years a I ferent type of drive on f:>recourt petrol dispensers. ame IS Tab-Link, and its unique construction enables t IS t to last a minimum of six times conventional V-belts It s easier to service, as one reel enables the service engineer to up any length of belt to SUit all pump assemblies thereby greatly , reducing the stock carried.

When it comes to the manufacture of pump equipment a design is poSSible uSing Tab-Link, as the tensioning and sliding adjustment systems used with conventional drive belts aren't needed Tab-Link is in successful use in petrol dispensers throughout Britain, including ; serviced by Pump Maintenance Limited, and .bullt by Avery-Hardo/l Ltd., Tokheim Ltd. and Ferrantl Ltd.

Detailed

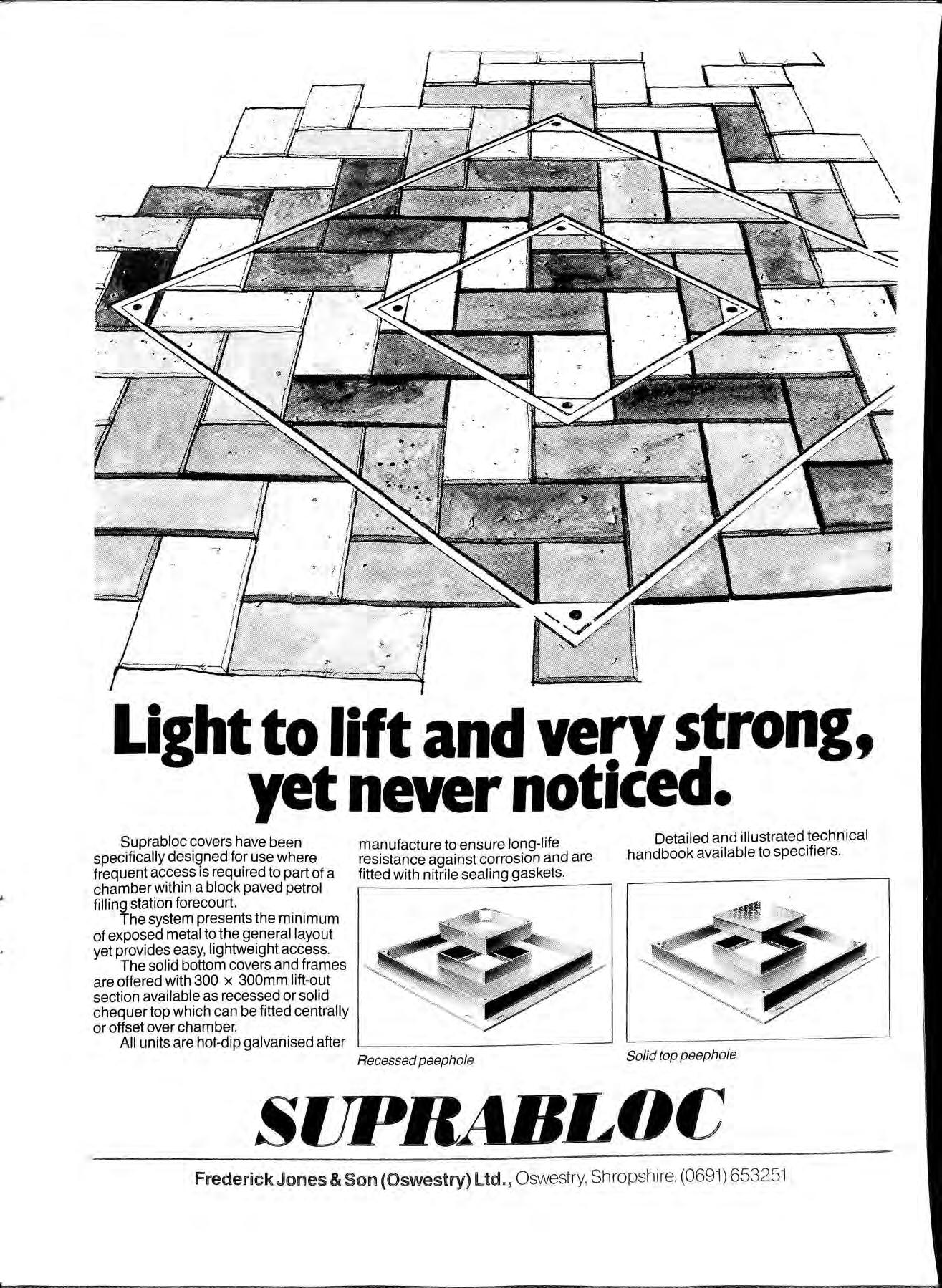

Suprabloc covers have been specifically designed for use where frequent access is required to part of a chamber within a block paved petrol filling stat ion forecourt

The system presents the minimum of exposed metal to the general layout yet provides easy, lightweight access .

The solid bottom covers and frames are offered with 300 x 300mm lift-out section available as recessed or solid chequer top which can be fitted centrally or offset over chamber

All units are hot-dip galvanised after

manufacture

(Free to Members)

Published by the Association for Petroleum and Explosives Administration

Opinions expressed in this Journal are not necessarily the views of the Association

TALKING POINT

LETTER FROM THE EDITOR NOTES & NEWS NEW MEMBERS & DIRECTORY AMMENDMENTS NEW REGULATIONS FOR PACKAGED GOODS DANISH LP GAS CODE EXEMPTION CERTIFICATES SAFETY WITH COMPUTERS NEW PRODUCT DEVELOPMENT

Mr. E. Brown, Cambridgeshire County Council,

Just what is the future for Autogas? Last year the manufacturers of car conversion kits were being downright pessimistic. But now we have a new report which predicts a much more buoyant market. Will we all be driving on LPG in 1990 or not?

Whatever the future, however, it is plain that the legislators approach it as badly prepared as they ever were. Is there going to be some definitive guidance for autogas on filling stations in the foreseeable future? Or will those whose responsibility it is to enforce safety standards be left, as usual, to muddle through as best they can?

As your new and relativel y untried honorary edi tor, I take up my pen in trepidation, in the hopes of following in the tradition of Holdaway, Thacker, Crewe and Thompson. In common with these illustrious names, I will put in my plea for copy all the news that is fit to print.

I believe that one of the aims of an Association such as ours, and an important function of it, is to prevent its members from constantly having to reinvent the wheel from repeating mistakes made previously by colleagues. !nformation flow is very much an "in" phrase, but it is The Bulletin can be amajorpathforit within the Therefore anything and everything from a problem to a titillating tit-bit should have its place m this journal.

To fulfil this function, we need to know about prosecutions both successful AND unsuccessful warnings given, special conditions imposed, appeals which were fought off OR succeeded, any other problems encountered. For experience tells us that history has an unfortunate habit of repeating itself what you found tsterday, a colleague in another part of the country will md tomorrow. And forewarned IS forearmed.

We need to know about incidents major and trivial for even the most trivial has the seeds of a major disaster in it. 'IV e need to know about equipment that was found wanting md eSlgn, construction or maintenance. We need to know about equ' h .' bl lpment t at answered a partIcular pro em, if it is unusual or was used in an ingenious way. h e need to know where procedures were lacking and, on t e other hand, where operational systems were effectively employed.

b do not think you need time and great literary skill; notes on the back of an envelope will suffice. I will sambze any reports, removing names and identifications to protect the innocent and with due regard to the libel and sub-judice laws.

Tllechnical papers, especially from our industry members, WI always bid d h . th . . e we come New developments an t ose m · e pIpelIne are of constant interest and importance. Also Important '. th I · 11 IS e story behind the licensing of unusua msta ations h k " owever much of a one-off they were, for we never now what . hAd wh h mlg tturn up inourpatch tomorrow. n h y SI ould we. have to start from scratch when a colleague as a ready d h ' B 11 '. one t e ground work for us? That is what the u etm IS all about.

If such inform' f d b a IOn IS forthcoming I promIse to 0 my very est to pr d .., 1 b · 0 uce not only an mterestmgJourna, ut ,ils() an authontatl've S()U f' f t' rce 0 In orma Ion.

Gerry EdneyA report by Frost & Sullivan Ltd entitled "LPG Storage and Distribution Equipment Markets in Europe" forcasts an increasing use of LPG in cars through into the 1990's. It cites the Benelux countries in particular, where a 22% growth in the consumption in LPG's in the auto industry is predicted from 1983 to 1990.

Cornhill Insurance Group of Guildford have introduced a service designed to help those who transport dangerous substances covered by Regulation 7 of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations. This service. provides advice on drawing up a wri tten s-cheme and the certification of individual tanks under the terms of this Regulation. It is being co-ordinated by the Special Service Division of Cornhills Engineering Department and carried out by Cornhill's pressure plant engineers strategically located across the UK.

The Morecambe-based fire equipment manufacturers, Angus Fire Armour Ltd., has published a pocket-sized "Symbol Seeker" manual, which provides quick reference to a wide variety of hazard marking systems.

The manual, developed in association with the Lancashire Fire Brigade, is printed in full colour on film coated card. It is intended to give a convenient on-the-spot guide to all the UK and continental hazard marking systems.

A survey carried out by a major oil company reveals that with the widely fluctuating prices in a petrol price-war, most motorists would, in fact, prefer a stable price structure. The problems of searching out and remembering the cutprice filling stations cause many drivers to feel vaguely cheated.

What motorists liked were well-designed and maintained sites, clean and efficient equipment and courteous and helpful staff. What was not liked were awkward accesses and having to queue for a pump.

The survey confirmed the increasing purchase of petrol by money rather than by quantity. This was not only due to simplicity of payment but also the Great British public's total bafflement by metrication litres are incomprehensible to the majority of motorists.

The US National Transportation Safety Board has carried out investigations of 1S accidents involving vehicles transporting hazardous materials in bulk over the past 10 years in America. These accidents involved overturns, jacknifings etc caused at least in part by driver error or defiCiency. A total of fi I deaths and 283 major injuries resulted from these accidents, mostly as a result of the release of the hazardous materials involved.

Arising from this study, the NTSB believes that if employee driver licence records and operational experience were reviewed more carefully, the number of such accidents could be reduced. They call for individual states to implement a scheme of licensing drivers specifically to transport hazardous materials.

The Board suggests that as minimum to qualify for a special licence, drivers should undergo road testing and examination to demonstrate knowledge and skill in:

The rules of the road pertaining to hazardous material transport.

The operation and handling characteristics of hazardous materials vehicles

Emergency response procedures.

Loading and unloading procedures.

The Warwickshire Trading Standards Department report an incident that occurred last December. A customer was using a self-service pump at a small filling station, when the nozzle detached iteself from the hose. The pump continued to work, discharging petrol all over the customer and his car. The console operator rushed to his aid but neglected to operate the emergency switch to stop the pump. petrol continued to discharge until stopped the hmltmg device at 20 gallons. The spillage was retamed by the drainage interceptor system and subsequently taken away.

Apart from the soaking the customer received, no injuries or mainly due to the effective working of the hmltmg deVIce. Had this failed to operate a more incident could have occurred. The OffIcer instituted '" h enqUInes mto t e poor maintenance of the nozzle and the inadequate action taken by the attendant. He was satisfied that all those concerned had learnt a salutory lesson, and has not instituted proceedings.

The Executive have brought out a Guidance Note on the safe access to road tankers. Intended for all those concerned with tankers, it gives detailed advice on the standards of deSIgn and construction of ladders, walkways and other of access with a view to reducing the inherent risks. GUIdance Note GS 26 is available price SOp from the usual outlets.

also published a Guide to the 1983 ClassificatIOn and Labelling of Explosives Regulations (price £3.25 from the usual outlets) to assist those who have under these Regulations. One area where thiS GUide IS of part' I hi" h ICU ar e p IS 10 the changeover from t e old system to the UN t ... 11' sys em of claSSIficatIOn and labe mg.

FollOWing a convict' f . A 1875 h 0 an airline under the ExplOSIve .ct. "t e. ExplOSIves Inspectorate has reminded of their legal responsibilities under thIS Act. ompltance with the law when explosives are in conveyance depends, in part, on a consigment being di.sp.atched "fo.rthwith" and not being kept illegally. AIrlInes and sh1ppers are reminded that explosives should not be brought to an airport any sooner than is necessary to complete the legal formalities and imports should be moved out as soon as practicable.

Certificate of Exemption No 3 to the Petroleum (Consolidation) Acts (Conveyance by Road Regulations Exemption) Regulations 1980 has been issued. This allows petroleum spirit (other than for use as motor fuel) and petroleum mixtures to be conveyed in metal containers of up to a maximum capacity of 1 cubic metre or 1 tonne of product (whichever be the greater) subject to certain testing requirements.

The Executive have opened three Public Enquiry Points to help individuals and organisations quickly gain access to heal th and safety at work information and advice. Based on the HSE's Library & Information Service, their addresses are:

The enquiry points will be open between lOam and 4 pm each weekday. No charge will be made for information and advice, except for special services like photocopying etc.

The HSE have told the LPGas Industry Technical Association that their Code of Practice No 2 "Safe Handling and Transport of LPG in Bulk by Road': is inadequate. The LPGITA's bulk road group is studying the situation and wIll be making comments and recommendations soon. . f h P t I Pump Manufacturing

Followmgpressure rom tee ro Association the HSE has agreed to drop the provision of limiting devices on petrol pumps. a I mainl to new pumps, only if a firemans SWI c IS pp Y Y . '11 not apply to unattended self provided. The waIver Wl .,) 't (See 'Warwickshire InCIdent above servIce SI es.

. d B 't' h Standard BS 1710 "Identification of A reVIse n IS , P . I' nd Services" has been published. It improves on Ipemesa ., ffl'd' its redecesso r in giving instant identIfIcatIOn. 0 Ul S by providing clarification of workmg and b) introducing colour labels.

Th methods of identification are included baSIC ree d 'f" I identification by colour only; basic i e?tI IcatIOn co and code indication and basic identificatIOn colour used m . t' 'th the user's own particular colour scheme. conJunc IOn WI

All pipelines in land transport should this t d d which is available from BSI, Lmford \IV ood, san ar , .' , ,) Milton Keynes, Bucks MK14 hLE; pnce ,£l1.2(

The International Conference on the Metering of Petroleum and its Products will be held in London on 7th and 8th March 198!). The organisers are calling for abstracts of papers offered to be sent to them by 1st August.

Further details on the conference can be had from Miss 1 Man;ot, Oyez Scientific & Technical Senices Ltd Bath House (:-lrd Floor), !)(i Holborn \" iaduct, Lundun ECl A 2EX: telephone: 0 I 2:·Hj 4080.

Gilbarco Limited operate a fleet of trailer mounted volumetric proving vessels used in the calibration of white petroleum products at bulk oil installations, and the appearance of these Regulations posed the question: would the Regulations apply to a mobile trailer-prover in a "nominally empty" state travelling on the public road?

Following consultation with H. & S. E., a typical prover was presented for examination and some drainage experiments were conducted using petroleum product in order to establish a drain which ensured that product remaining withing the epoxy lined prover tank was of such volume as not to cause hazard to health and safety.

Gilbarco then applied for a Certificate of Exemption as allowed by Regulation 22 and this in due course was granted subject to conditions.

This is believed to be the first Certificate covering this form of vehicle.

Vice Chairman and Page 7 M.D. Duchesne,

The Treasurer would remind members that this will be the last copy of the "Bulletin" whicy they will receive if their current subSCriptions remain unpaid. The Association is dependent on the payment of subscription for the greater part of its income, and the sending of reminders is costly. If, therefore, your subscription is in arrears, it is hoped you will help by paying it as quickly as possible and so continue receiving your "Bulletin".

Your Seminar Sub-Committee announce that there will be a TRADE EXHIBITION AT THE SEMINAR AT DUNSTABLE on Tuesday, October 16th. Persons wishing to exhibit their services or products may book space by Mr B. Taylor telephone 0582 414175. generally are reminded to put this date into t elf Diaries.

Page 1 Miss A. Andrews Resigned.

Page 4 J.G. Burgess, Mid Bucks Engineering Ltd., G J. Burgess, Mid Bucks Engineering Ltd., Page 7 D. Durham

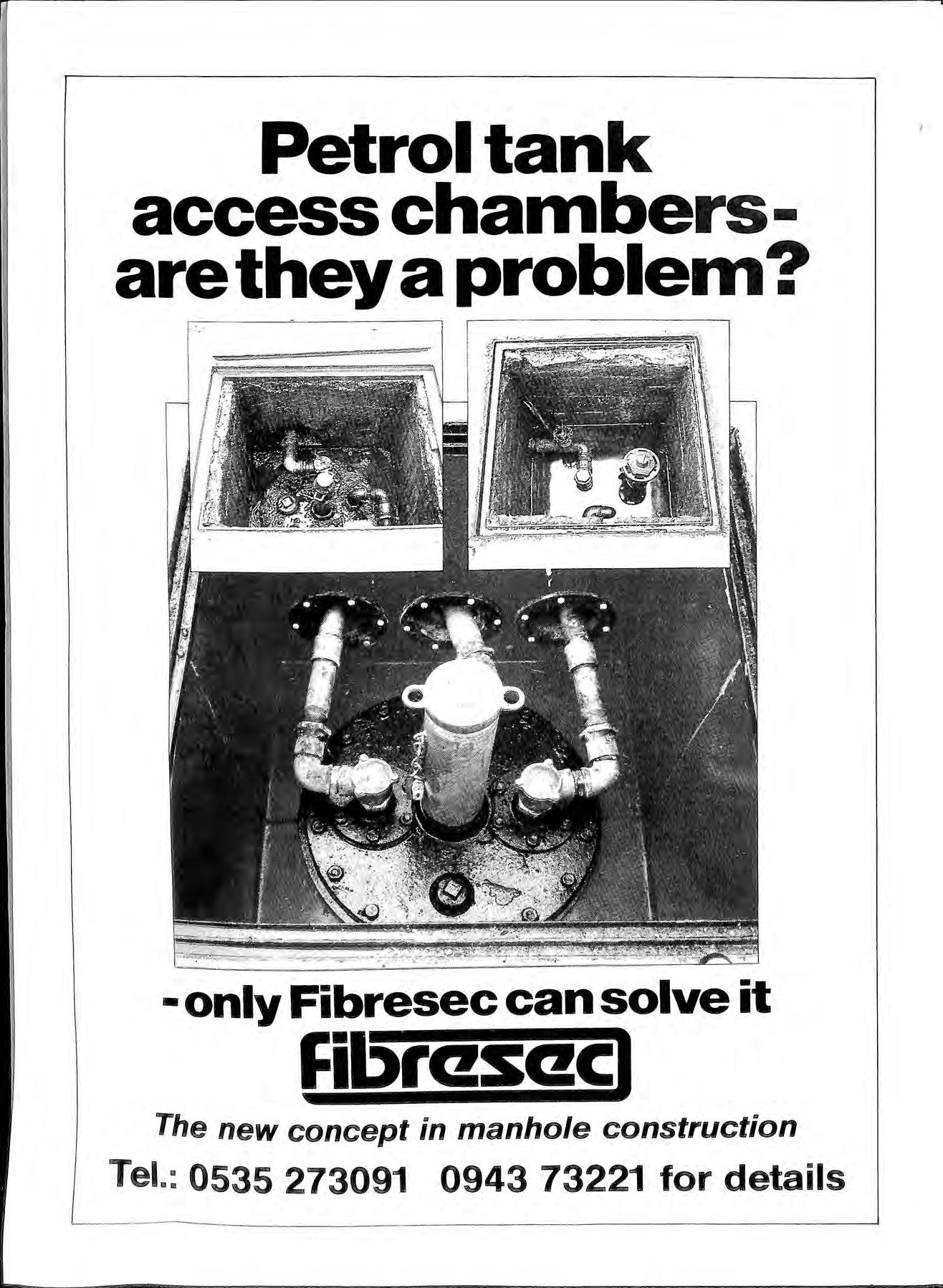

Page 8 Fibersec Marketing Ltd.,

F.A.O: Mr. Pardoe

Fibersec Marketing Ltd.,

Page 24 T.S. Welsford,

The Association welcomes the following new members CJ. Cooper PProposals for regulations and approved codes of practice on the conveyance by road of dangerous substances in packages etc have been published by the Health & Safety Executive. These new regulations will revoke, inter alia, those Regulations of the Petroleum Spirit (Conveyance by Road) Regulations 1957 and the other Orders and Regulations made under the 1928 'Act which were not previously revoked by the tanker Regulations. The Consultative Document is a complex package, containing as it does not only the draft regulations, but also draft codes of practice on operational provision and the classification of dangerous substances as well as a draft "approved list" of dangerous substances.

In the main, these proposals are not revolutionary, extending the principles of the requirements of the tanker Regulations to vehicles carrying small tank containers, drums, carboys, sacks, cartons etc and to hopper and tipper vehicles.

In inviting comments on the Consultative Document, however, the HSE recognise two areas which could give rise to controversy, and would welcome views in particular on these. One is the minimum container size. The draft regulations propose controls on dangerous substances only (with certain exceptions) when they are conveyed in receptacles having an individual capacity of 200 litres or more. But the HSE recognise that existing legislation controls some dangerous substances conveyed by road in far smaller quantities and in attempting to maintain these controls have come up with some very complicated regulations with a host of schedules. So they have produced a parallel proposal which is a less complex alternative, controlling substances down to much lower levels perhaps 5 litres and have offered this for comment. Furthermore, the Consultative Document pleads for any other suggestions of how to overcome this particular problem.

The other area for concern is labelling of the vehicle. This causes similar problems. The basic proposal calls for labelling of a vehicle when it is conveying SOOkg or more. The label for a vehicle conveying between 500 and would be two simple orange diamonds with an exclamation mark and the words "Dangerous Goods". Above :i,OOOkg, the vehicle, if conveying a single substance or two or more substances with the same hazard, should show three hazard warning panels (as worn by the tankers). Here again the HSE recognises that there will be problems with part-loads, partial delivery and back-loading, milk-run delivery journeys etc and would welcome any comments anybody would care to make on this question.

A label incorporating black symbol, lettering and border on a fluorescent orange background has been proposed as the basic labelling requirement for consignments of 500kg or more of regulated packaged dangerous goods.

It is proposed that formal responsibility for enforcement of these regulations on the road should rest with the HSE. It appears that discussions are taking place with the Department of Transport so that the Departments Traffic Examiners can add "limited" roadside checks on documentation of vehicles conveying dangerous substances to their present random checks on compliance with road traffic legislation. It is envisaged that reports on apparent breaches of the regulations would be sent to the HSE for following-up. The HSE say that they recognise that this proposal carries implications for the enforcement responsibility of the tanker Regulations.

The proposals are very complicated and convoluted, and will give a severe twitch in the eye to anyone who studies them. The HSE claim that they will introduce a more comprehensive and flexible system of control than that provided by existing regulations under the 1928 Act. Your correspondent does not doubt the improvement in flexibility, but wonders about the how comprehensive they will be. He searched in vain for some comparability between the various definitions of minimum quantity and Regulation 23 of the Petroleum Spirit (Conveyance by Road) Regulations he could not establish the position of LPG conveyed in cylinders, which is an important subject and should be clarified and he felt that the whole subject of labelling was a mess. As to the enforcement your Chairman has already expressed himself forcefully on the willingness of HSE to follow-up reports on contraventions of the tanker Regulations. And it would now appear that everybody EXCEPT the Petroleum Officer is to get a say in enforcement of the regulations.

Comments on the Consultative Document were supposed to have been received by HSD A4 not later than July 16th. However, this should not inhibit anyone with strong opinions from expressing them as soon as possible.

The "Proposals for the Dangerous Substances (Conveyance by Road in Packages etc) Regulations 198- is available from the HSE, Publications Sale Point, Room 4.14, St Hugh's House, Stanley Precinct, Bootle, Merseyside L20 3QY. Price £7.00.

enough from the storage tank and dispenser etc. to allow the pump to be disconnected in the event of fire.

As a contribution to the protracted discussions on the problems of LPGas on filling stations, we publish a translation of the relevant abstracts from the Danish Government's Code of Practice for LPGas. This has been in operation since 1971, and is generall y considered as being a very practicable document. Recommendations for approval of systems in respect of LPG filling stations 1. SCOPE

$7, .para. 2, the govt. notice states that LPG filling statIOns shall be established in accordance with systems approved by the Government Fire Department and that operation of stations shall be as prescribed in instructions approved by the Government Fire Department.

All pipe connections on the tank shall be fitted with shut-off valve and excess-flow or non-return valve cf. however, 3.1.3. The excess-flow or :valve shall be mounted nearest, either right next to or mside the tank.

The foundation of the tank shall be such as to prevent dangerous stress arising in the pipe system.

The. following exceptions are made to the reqUIrements of 3.1.1 :

a) boss for filling valves, if the valve functions as a combined excess-flow and non-return valve or as a double non-return valve;

b) boss. for gauging device of the blow-off type, the internal diameter of the bleed hole IS not larger than l.4mm.;

c) boss for safety relief valve, and

cl) ?OSS with internal diameter maximum 1.4 mm., , mtended for manometer.

fhe tank sh 11 re I· a m all other ways conform to the gu ahon:> of th M·· insp t· e 100stry of Works (factory ec IOn auth ·t· ) . co t Oflles 10 respect of pressure n alOers and due notification shall be made.

fhe pump I· h sh II b w llC shall be designed for this purpose, a e fitted ·th f· d . . electric WI Ixe pipe connectIOns. The motor shall meet the requirements of heavycurrent regul· t" f . . a Ions or less explosive rooms. A certificate f DE , . . ram MKO shall accompany the applicatIOn for approval.

Electrical inst'll . a ahons on the dispensing unit shall meet the requir f h . ements 0 eavy-current regulatIOns for hlghl y-explosive rooms. A certificate from Df"M KO shall accompany the application for approval.

l"he Ill,rmal start Switch on the dispensing unit shall be proVided With an emergency switch placed far

3.2.4 The filling hose coupling (filling pistol) and the fuel tank's filling valve shall be so formed as to avoid use of more than one coupling piece.

3,2.5 Pipe connections between tank, pumps and dispenser shall be made so as to avoid stress in the pipes, for instance, by use of expanding bends.

3.2.6 Pipe sections that can be sealed off at both ends containing liquid shall be provided with safety relief valves.

4.1 Operating instructions shall, over and above detailed instructions in use of the filling station, include the following:

a) Filling of motor vehicle fuel tanks must only be carried out by personnel employed at the filling station.

b) Filling of fuel tanks other th'}n those for which the installation concerned is designed, and which are permanently mounted in motor vehicles and supplied with gauging device for maximum filling is prohibited.

c) The vehicle engine shall be stopped before the cap on the filling boss is removed.

d) Before filling is commenced, inspection of the filling boss shall take place. Should wear or damage of the boss or its packing be determined, filling must not be carried out until the damage has been repaired. Should it be established during the filling operation that the connection is not absolutely tight, filling shall cease immediately and the gasket be replaced.

FUEL TANKS MUST NEVER BE FILLED MORE THAN H5% OF THE VOLUME.

e) After completed filling, the filling boss is recapped and the gauging device used to ensure that the tank contents do not exceed the maximum permitted.

f) The filling station and surroundings shall be kept clean and tidy. Easily ignitable vegetation shaH be removed.

g) Tank lorries engaged in supplying the filling station's storage tank shall always park on the area reserved for the purpose.

4.2 Operating instructions shall always indicate the position of the emergency switch, cf. 3.2.:-3.

5.0 $ 7, para. 1, of the govt. notice states that filling stations may only be established with the permission of the local fire authorities.

5.1.1 Only filling of fuel tanks mounted in motor vehicles and fitted with safety valve and gauging device to safeguard against filling over the maximum permitted)imit may take place at filling stations.

5.1.2

The various sections of the filling station shall be constructed of materials of the correct strength for use with propane.

5.3.1 Warning signs reading "NO SMOKING or NAKED LIGHT" and "FUEL TANKS MUST NOT BE FILLED ABOVE 85% OF VOLUME" shall be mounted on or near dispensers.

5.3.2 At least 1 hand extinguisher shall be positioned near dispensers.

5.4

5.4.1 Operating instructions in permanent form and approved by the Government Fire Department shall always be available near dispensers (emergency switch location).

5.1.3

5.1.4

5.1.5

Ducts and shafts for electric cables, compressed air pipes, etc. shall be sealed gas-tight against buildings and between the various sections of the filling station.

Storage tanks on the filling station shall be in compliance with the regulations in section 4.

Gas dispensers etc. shall be situated outdoors as prescribed in 5.2 of the regulations. Pumps (or compressors) shall be mounted in permanent positions.

5.2.1 Dispensers shall be at least:

(i) 8m. away from openings (including doors and windows) in outer walls which limit premises where open fire is used.

(ii) Srn. from inflammable storage in the open and inflammable buildings, cf. however, 5.2.2 and, iii) 2m. from openings in outer walls (including doors and windows) or buildings other than those mentioned under I) and II).

5.2.2 The provisions of 5.2.1. II), do not apply to the following:

a) filling valves, dispensers and blow-off pipes belonging to tanks containing inflammable liquids and, b) single-storied bUildings with hard roof and outer walls corresponding to Danish Standard BDstructural section 60 wi th surfaces which conform, as regards fire safety, at least to Class 1 facing.

5.2.3 Dispensers not mounted on raised platforms shall be protected either by a minimum 0.5m. high guard rail or minimum 0.7m. high collision posts (mechanical at least equal to cement-fillied 100mm. dIam. steel piping), securely fixed in place.

5.2.4 installations on dispensers etc., and at a dIstance of up to 4m. away, shall comply with heavycurrent regulations for less explosive rooms.

5.2.5 Emergency stop switches connected to dispensers be placed sufficientl y far from storage tanks and etc. to ensure that the pump can be stopped case of fIre during operation. Emergency stop SWItches shall be placed outside in easily accessible and clearly marked spots.

5.2.6 Dispensers shall be provided with safety equipment conforming to 5.3 of the regulations and the precautionary measures mentioned in 5.4 shall be duly observed.

5.4.2 Proprietors of filling stations shall ensure that operating attendants are thoroughly familiar with: a) the properties of LPG with due regard to the danger of fire and explosion. b) use of the filling station's hand extinguishers, and c) the operating instructions which apply to the filling station.

4.0 SI 7, para 1, of the govt. notice states that: i) installations must not be used before they have been tested by the supplier or by a person authorized by and on behalf of the supplier, and that, ii) similar testing shall be carried out in case of change of supplier.

SI 7, para. 2, of the govt. notice states that: i) directions for use, drawn up by the supplier, shall accompany any new installation and shall always be kept near the installation, and that, ii) the directions for use shall be in accordance with the technical regulations, cf. 4.6.

S25 f the govt. notice states that installations with capacities of over 200 kgs. and up 2.5,000 k ay only be established with the permISSIOn of t;;'l:al fire authorities and shall be: either in accordance with the technical regulations. or installed in conformity with conditions laid b the fire authorities which are, as regards fIre p;otection, no less rigid than the rules in the technical regulations.

$29, para. 6 and 7, of the govt. notice states that: .) tank installations situated on forced routes or I outside built-up areas, may be supplied from 2axelled tank lorries with a volume of up to 12,000 litres and that ii) other tank installations may be supplied from tank lorries with a volume of up to 8,000 litres.

$31 of the govt. notice states that: i) LPG shall be handled with due caution with particular regard to danger of fire explosion that may eXIst m the event of leakmg gas and that

ii) LPG consumers are responsible for ensuring that the installations in use are in good order, that the directions for use are followed, that any pt:'rson concemed with operation of the unit receivt:'s appropriate guidance and that tht:' tt:'sting mentioned in S 17, para 1, has been carried out.

4.1.1 General

a) Tanks shall be erected out in the open and must not be covered by either roof or similar.

b) Tanks positioned in such way that they are open to the risk of collision, shall be protected either by a guard rail, minimum 0.5m. high, securely fixed in place, or by minimum 0.7m high collision posts (at least equal in strength to concrete-filled 100mm. diarn. steel piping), securely fixed in place maximum 1.5m. apart.

c) Tanks erected on sites to which unauthorized persons have free access, shall be enclosed by a non-flammable fence, minimum 1.8m high, with a gate which shall be locked when the tank is not under surveillance.

d) Should the installation include several tanks, these shall be at least 1m. apart.

e) Electrical installations up to 4m. above ground level in the immediate vicinity of tanks and at a distance of up to 4m. away, shall conform to heavy-current regulations in respect of less explosive rooms.

f) Tank valves shall be at least 3m. away from cable and drain shafts.

g) Blow-off openings for safety valves shall be so positioned as to prevent the danger of blown-off gas being ignited or in any other way causing damage should the valve be activated.

h) Warning signs reading "GAS STORAGE, NO ADMITTANCE" and "NO SMOKING or NAKED LIGHT" shall be displayed next to tanks or be painted on the tanks themselves.

i) Filling of tanks by tank lorries shall take place in compliance with the requirements of 4.3.

4.1.2 Installations with storage capacities up to kgs. in tanks above ground (container volume max. 2,400 litres)

a) Tanks shall be at least: 15m. away from other inflammable storage in the open and inflammable buildings, and :im. from non-inflammable buildings, lines of adjoining property and public thoroughfares.

b) Tanks erected without proper foundations, shall be provided with a support of non-combustible material. The support shall be so formed as to raise the tank minimum 10 cm. and maximum 30 cm. from ·the base.

c) The rules laid down in 4.1.1 shall be observed.

c) The rules laid down in 4.1.1 shall be observed.

4.1.4 Installations with storage capacities over 5,000 kgs. and up to 25,000 kgs. in tanks above ground (container volume max. 55,000 litres).

a) Tanks shall be at least: 50m. away from other inflammable storage in the open and inflammable buildings, 15m. from non-flammable buildings and lines of adjoining property, and 8m from public thoroughfares.

b) Tanks shall have proper foundations (down to frost-free depth).

c) Tanks shall be equipped with at least 1 frostproof water tap wi th %" hosing suspended in an easily accessible spot. The hose shall be equipped with a spray nozzle and be long enough for use both on the parking lot used by tank lorries cf. 4.3, and the entire tank area. At least 1 hand extinguisher shall also be available.

d) The rules laid down in 4.1.1 shall be observed.

4.2

4.2.1 Tanks shall be at least 3m. away from all buildings and from lines of adjOining property and public thoroughfares.

4.2.2 Where an installation includes several tanks these shall be at least 1m. apart. '

4.2.3 Tanks be covered in such way as to afford protectIOn from ground loadings due to vehicular traffic etc. The covering shall, however always be minimum 50 cm. in depth. '

4.2.4 Tank valves shall be at least 3m. away from cable and shafts. Val:es shall be properly protected agamst.damage, mcl udmg that which maybe caused by vehICular traffic. Precautions shall be taken to ensure that no unauthorized persons can gain admittance to valves etc. •

4.2.5 Warning signs reading "GAS STORAGE IN UNDERGROUND TANK", "NO ADMITTANCE" and "NO SMOKING or NAKED LIG HT" shall be displayed near valves etc.

4.2.6

4.2.7

4.3

4.3.1

Blow-off openings for safety valves shall be so pOSitioned as to prevent the danger of bl.own-off gas being ignited or in any other way causmg damage should be valve be activated.

Filling of tanks by tank lorries shall take place in I · ·th the requirements of 4.3. comp lance WI

4.1.:-3

Installations with storage capacities of over 1,000 kgs. and up to 5,000 kgs in tanks above ground (container volume max. 11,000 litres).

a) Tanks shall be at least: ISm. away from other inflammable storage in the open and inflammable buildings. Hm. from non-inflammable buildings and lines of adjoining property, and :im. from public thoroughfares.

b) Tanks shall have proper foundations (down to frost-free depth),

, 11 t· n sites (one or more tanks) shall All tank msta a 10 h h , k· area with free approac were tank mclude a par Illg f'll· . T I . h II k during the I mg operatIOn. he ornes s a par 'h k ki hall be at least as bIg as t e tan lorry par ng space sib th· tallation and shal e on an area out m servmg e IllS the open to which the public has no access.

The most suitable space shall be chosen for the parking lot, with particular, regard to avoiding backwards driving and shall m any case allow the lorry to drive away without (without backing), Unavoidable backwards dnvmg from a public thoroughfare to the parking site shall be from the same side of the road as the approach to the site, in order to avoid the tank lorry having to cross the road,

4.3.2 The perimeter of the parking space shall be clearly marked and shall be at least: i) 4m. away from any kind of building, lines of adjoining property and public thoroughfares, cf. however, 4.3.3, and ii) ISm. from inflammable buildings, cf. however, 4.3.4.

The perimeter shall furthermore on three sides be at least 10 m. away from doors, windows and other openings in the outer walls of buildings with more than two stories.

4.3.3 In less dens'ely built-up areas with low buildings (detached or terraced houses and smaller industries etc.) and outside urban districts, the distance requirements mentioned in 4.3.2, i), do not apply. Permission to place the parking site next to a building applies only, however, to one of the long sides of the site. The other three sides shall be at the required distance of minimum 4m. from any kind of building.

4.3.4 The provisions of 4.3.2, ii), do not, however, include single-storied buildings with a hard roof and with outer walls corresponding to Danish Standard BDsection 60 with surfaces, as far as fire safety IS concerned, least conforming to the requirements of Class 1 facmg. The perimeter of the parking area shall also, however, be at least 4m. from such buildings.

4.3.5 The parking space shall thus be situated as to allow complete surveillance of the area during the filling operation (Le. of tank lorry, hose and tank). The hose shall be maximum 25m long.

4.3.6 Where tank installations also include inflammable liquids, the parking area for LPG tank lorries may be as for tank lorries carrying inflammable lIqUIds as long as this does not cause the requirements of 4.3.1 4.3.5 to be disregarded.

Four certificates of exemption have been issued recently by the Health and Safety Executive under the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981.

Certificate No. 2 of 1984

This exempts the conveyance of compressed hydrogen in cylinders which are attached to trailers, often referred to as "hydrogen tube trailers". It has only just become apparent that the Regulations apply to these trailers, and the exemption has been issued so that the three firms involved can take steps to comply with the Regulations, eg, fit hazard warning panels to the trailers and train their drivers. The certificate expires on 30 September, 1984.

Certificate No. 3 of 1984

A number of the major oil companies wish to adapt existing petrol tankers or build new tankers so that they can be filled from the bottom and hence recover the vapour which is normally displaced. This will be a safer system of filling with no petrol vapour being released to the atmosphere, but it does mean that different type of adapter mst be used in place of the normal outlet valve. These adaptors are fitted with clip-on caps instead of usual screwcaps and the certificate grants exemptIOn from paragraph 14( 1) of Part I of 2 to Regulations which requires that outlet pipes be fItted WIth screwcaps. Certificates Nos. 4 and 5 of 1984 (see page 4)

These have been granted respectivelr ,to Limited and Moor, Barrett and Redwood LImIted gIve 1 t · n from the Regulations for the operatIOn of tota exemp 10 d J: h "I t 'c provers" These are tanks or pIpes use lor t e vo ume n' .' d calibration of petroleum fuel metenng eqUIpment, an , although they are nominally empty when conveyed by road, they may still contain some petrol or kerosene vapour.

The safety implications offailed computer-based system, referred to as programmable electronic systems (PES's) are to be the subject of guidance which is expected to be issued by the Health and Safety (HSE) early next year.

The guidance, currently in draft form and the subject of a wide consultation exercise, will be published in three parts:

Part 1: General Requirements the general problems to be overcome, together with a framework in which they can be resolved in a systematic manner;

Part 2: Safety Integrity Assessment -a method for assessing the safety integIity including hardware and software aspects of the PES;

Part 3: Safety Integrity Assessment: Case Stud, -a working example using the methods set nut in Part 2.

A spokesman for the HSE said: "!he need !or guidance arises from the rapid evolutIOn of PES s, ,;hIch has meant that in the safety context the store of and advice is not available to the extent tradltI.onally has been the case. The aim is to provIde manufacturers, suppliers and users with a sound. basIs for decision-making on, for example, what constItutes an acceptable and reasonable level of safety."

The three documents will provide generically-based guidance enabling in-depth assessments to be irrespective of the application in which the PES IS bemg used. It is recognised there is a vast spectrum of applications of wide ranging complexity and ?azard potential and the documents will enable further to be formulated in specific areas, for example, machmery safeguarding and safety shutdown systems. The development of such guidance should allow the PES assessment process to be simplified.

Those wishing to be incl uded in the consul tation exercise or who have general enquiries about the proposed guidance, should contact:

Mr M Sayer FI5 Health and Safety ExecutiveThe accurate measurement of wet stock has always presented many difficulties. Technology is solutions however, and two new systems are representatIve of the type of answers that are available.

Contents Measuring Systems Ltd claim to have developed a system which enables filling station tank Contents to be instantly measured to a very high degree of accuracy. Called the CMS 2000, it is based on experience in use of capacitive fuel measuring systems in the aerospace and similar industries. Capacitive techniques in measuring the Contents of fuel tanks are said to eliminate the inherent problems in accuracy' encountered with dip sticks, pressure sensors and float systems and to be more economic than It is claimed that accuracy with the CMS 2000 IS great enough to enable leakages to be monitored.

F h .

urt er detaIls from: Contents MeaSUring Systems Ltd., KLG Works, Putney Vale, London SWl5 :my.

Extended service life and accurate operation unaffected bv changes in preSSure and temperature, viscosity, vapour, foam, or coating bUild-up are claimed by NatlOllal SOllics for their "Sensall" range of ultrasonic l'qlJld level detectors, which are now available in this

r"

I-rmlH'r df'tilils from: George Meller Ltd., Orion Park, \"If hlip/d 'h elllW Ealing. London W l:-l

Detection of escaping vapours is very impo:tant in tracking down leaks. In response to. the p.roblems, is developing equipment, which whIle bemg more senSItIve and accurate, is also becoming more operator-proof. Two new devices have recently come onto the market.

"Trac-a-Leak" is a new portable gas leak detector which claims to sense and locate even the smallest leak of propane and butane. Simply operated, the gives a cl:ar, audible signal which rises and falls WIth the varymg concentrations of gas detected.

Further details from: Maester (UK) Ltd., 84 Watersgreen, Macclesfield, Cheshire SKll 6LH

A continuous monitoring device, the Model 3700, simultaneous detection of oxygen deficiency, gas and hydrogen sulphide with both audible and alarms. Battery operated and fully portable, the Mo e 3700 is designed as Intrinsically Safe and is presently awaiting full certification.

Further details from: MDA Scientific (UK) Ltd., Ferndown Industrial Estate, Wimboume, Dorset BH21 7RZ

A remote level indicator for LPGas has been produced. Named "Lekton", the unit gives a readout of how much gas is left in a bulk tank and can operate at any distance from the vessel. It has been designed to work with any float level gauge, or in conjunction with potentiometer-type or solid state sending devices. The unit gives a continuous LED bar graph readout each light indicates 10% of tank capaci ty. It is available in mains or battery operated versions.

Further details from: Hilldriver Electronics, 75 Mislon Road London W14 OLH.

John Davis & Son (Derby) Ltd., has its existing range of electrical equipment for hazardous atmospheres by acquiring the design, manufacturing and marketing rights of the Mexco International Ltd.'s range of flameproof lighting equipment and other items.

The new Davis range includes luminaires, head-lights, generators, isolators, junction and fuse boxes and plugs.

Further details from: John Davis & Son (Derby) Ltd., Alfreton Road, Derby DE2 4AB.

(Petroleum & Civil Division)

Members of the Association for Petroleum & Explosives Administration

Southern Bay Premises, Alton House Estate, Gatehouse Way, Aylesbury, Bucks.

Telephone: Aylesbury (0296) 22039 & 34481

•

•

•

•

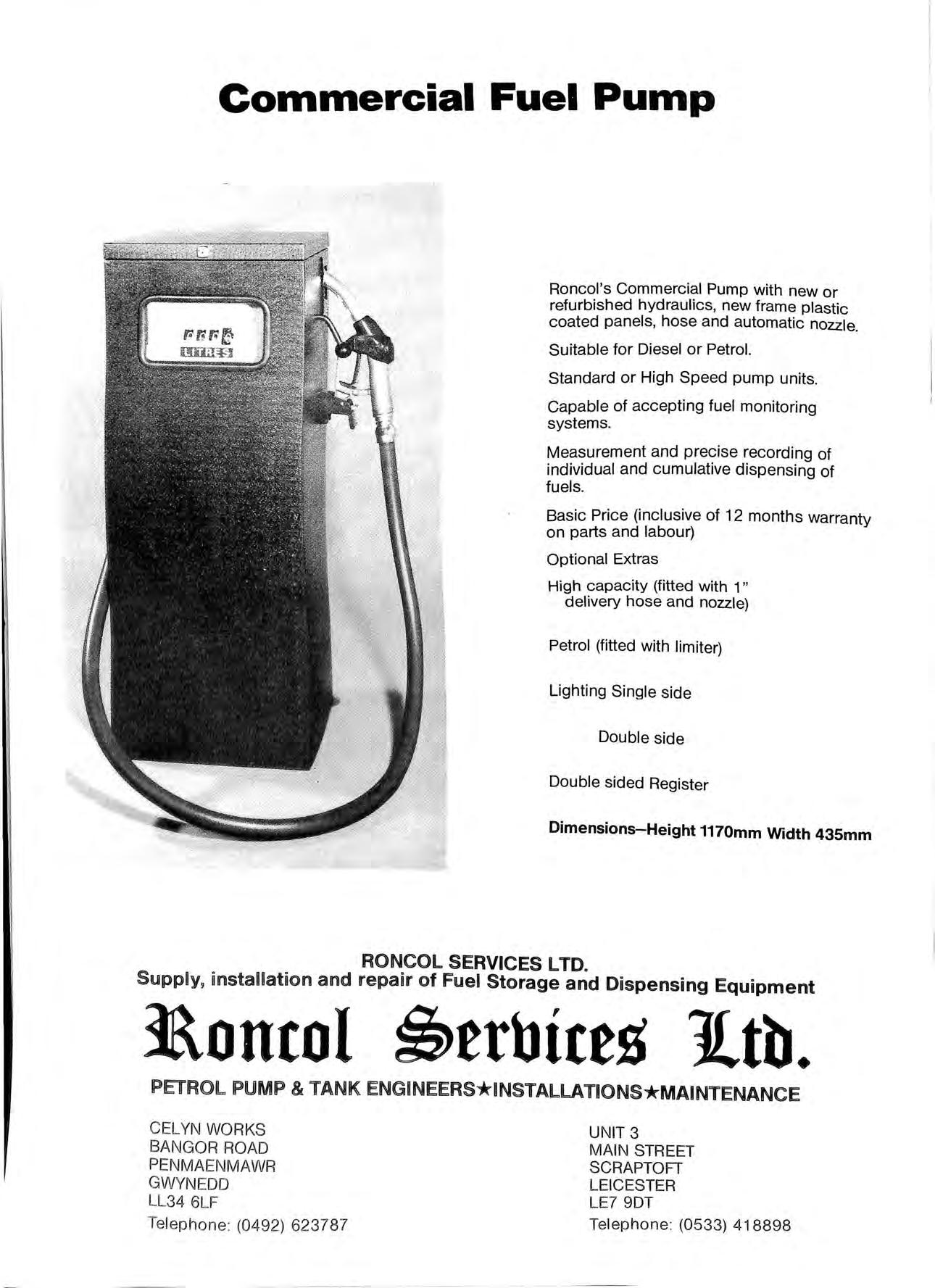

Roncol's Commercial Pump with new or refurbished hydraulics , new frame plastic coated panels, hose and automatic nozzle

Suitable for Diesel or Petrol.

Standard or High Speed pump units. Capable of accepting fuel monitoring systems

Measurement and precise recording of individual and cumulative dispensing of fuels.

Basic Price (inclusive of 12 months warranty on parts and labour)

Optional Extras

High capacity (fitted with 1" delivery hose and nozzle)

Petrol (fitted with limiter)