Work is at long last nearing completion on issues that will have a radical effect on the way petrol filling stations are built and operated. The working party is in the process of discussing the reams of comments which Local Authorities and Industry made on the draft document, and it is hoped that on completion of this work that the HSE will be able to publish the document.

Some concern has been expressed by Industry that there is no forum for dispute other than by appeal on requirements laid down by licensing authorities, or for that matter on unsatisfactory designs of filling stations by Oil Companies which licensing authorities may object to.

The Association would support such a scheme where disputes could be put to an arbitration panel for a hopeful solution which will satisfy both parties, but at the same time not remove the fonnal appeal procedure in the more serious disputes.

The British Standard on Petrol Pumps BS7 I I 7 was issued in February 1989, and talks on implementation ?ates have now been infonnally agreed between parties and the. HSE will give guidance on this aspect 111 due course. The · s the difficulties that manufacturers face 111 the recogmse ·t· n per"iod and would recommend that petroleum officers trans1 10 1 t When faced with these problems next year. are to eran

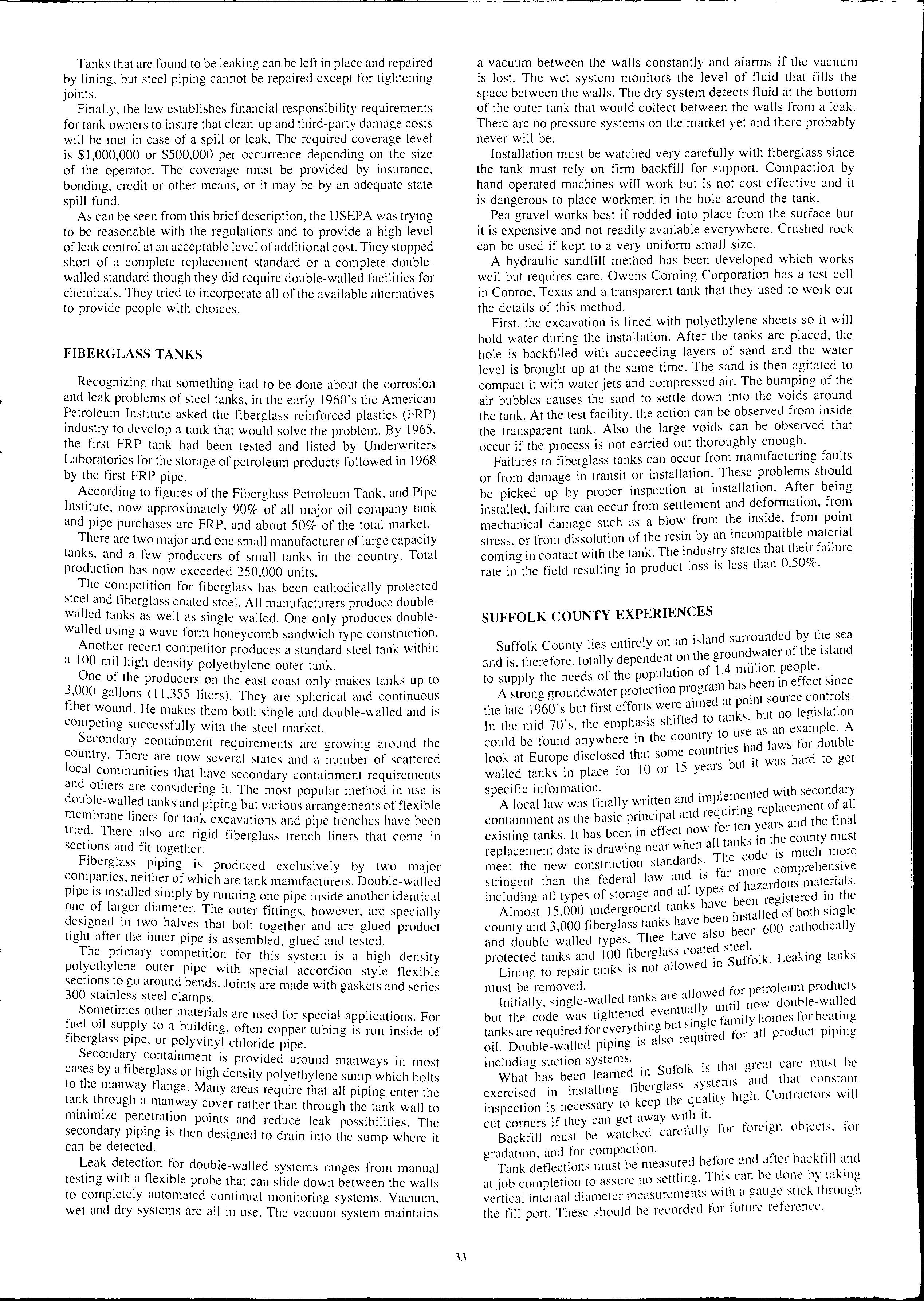

Size of Leak Gallons Gallons Gallons Gallons Per Hour Per Day Per Month Per Year

One/two drops per .05 1.2 36 438 second

Intermittent stream 0.9 21.6 648 7776

1/16 inch stream 3 72 2160 25920

1/8 inch stream 10.2 244.8 7344 88128

3/16 inch stream 14 336.9 10107 121284

1/4 inch stream 38.8 931.2 27936 335232

As this table indicates, there is no such thing as a small leak. Over a period of months or years, the cost of even the smallest product leak can be very expensive, both in terms of lost petrol damage to the surrounding ground and fire hazard.

SEMINAR OCTOBER 3RD 1989 "SAFETY AND ENVIRONMENT AT PETROL FILLING STATIONS." QUEENSWAY HALL, DUNSTABLE, BEDFORDSHIRE. PROVISIONAL PROGRAMME AT TIME OF GOING TO PRESS.

9:00 am Registration of delegates Exhibition opens

9:45 am Coffee

10: 15 am Conference opened by Special Guest

10:30 am Morning Session Hon Editor Chaired by J Thompson

Safety and Environmental Problems at petrol filling stations

Rory Hennessy London Fire Brigade

Secondary Containment -A way forward Dennis O'Brien MPC Containment Systems, Chicago, USA.

Vapour Balancing at the Filling Station. Barry Goldsmith and David Ivall BP Oil Herne! Hempstead

12: I 5 pm Lunch and Exhibition

2: I 5 pm Afternoon session Chaired by B Taylor Hon Secretary

Leak Detection on 24 Hour operated sites. Alan Chandler Veeder Root Ltd Dundee.

Hydrocarbon sensing. Heinrich Koppitsch Raychem Corporation Munich W. Gennany.

Double Skin Steel Storage Tanks John Boudry Cookson & Zinn, Hadleigh, Suffolk.

Remedial Action on leakage. Paul Turner Groundwater Technology Group of Companies, Epsom. (Australia, Canada, USA, and UK)

3 :45 pm Open Forum

4:30 pm Close Seminar and Exhibition. Details available from CONFERENCE SECRETARY MRS E. F. TAYLOR ,

The address shown for Humberside Trading Standards Department on page 12 of the Bulletin Vol. 27 No. I. The current address is:

9th Floor, Kingston House Tower, Bond Street, Hull, North Humberside. HUI 3EN.

Filling stations will be banned from becoming minisuperrnarkets if one local council has its way.

A proposal to restrict garages and filling stations to selling only fuel and items such as snacks, tobacco, sweets and soft drinks is included in the draft copy of the Huntingdonshire District Council local plan.

The reason behind the move is so that existing shops are not driven out of business by filling stations.

The plan, published today, says: 'There has been a trend in recent years for garages and filling stations to sell an increasingly wide range of consumer items, many of which are unrelated to transport services.

'The district council will restrict retail sales at garages and filling stations to the range of goods associated and ancillary to the business.

'Exceptions to the policy may be made where small communities have no shopping facilities.

Providing pump manufacturers and licensing authorities with a common specification, the recently published BS 71 17 Metering pumps and dispensers to be installed at filling stations and used to dispense liquid fuel Part 1 Construction covers pumps and dispensers for dispensing liquid fuels into the tanks of motor vehicles, boats and light aircraft, and into portable containers.

This first part of BS 7117, which gives particular attention to electrical, hydraulic equipment and electrical apparatus msta e wit m, or mounted . d" on, the housings of metenng ord 1dspensers, will ensure that pumps meet the requ1s1te stan ar of construction d f I 1 an safety irrespective o ocat10n or supp 1er.

Two further parts of the standard, giving guidance 0 n installation and maintenance respectively, are in preparation, while the Health and Executive is to publish a Guidance Note on construction and operation of petrol filling stations referring to Parts 1 and 2. [BS 711 7 subscribers' price £15.30] '

A £ l ·3 million "super-safe" prototype road tanker has just had its first showing in Britain.

TOPAS -Tanker with Optimum Passive and Active Safety is equipped with a host of safety features, including a rear-view video camera to help the driver reverse. The vehicle is the result of an eight-year research programme in Gem1any headed by MercedesBenz.

Key safety features on TOPAS are:

• Anti-lock breaks (ABS);

• Acceleration skid control system (ASR);

• Giant rear signal display panel;

• "Low-line" tank design; and

• All-round safety skirts.

On TOPAS , the tank itself sits much lowerth::m on a conventional tanker. This lowers the centre of gravity by almost one foot and increases the vehicle's stability round corners. Furthennore , the side ski11s prevent cyclists or other road users from getting under the vehicle if there is an accident. The skirts also help to suppress spray thrown up in heavy rain.

The tanker itself, unlike most conventional tankers, can be filled and unloaded from the bottom. That means there is no need for the driver to clamber on the top of the vehicle.

Finally, on the rear of the tanker is a large s ignal board on which illuminated direction signals can be called up by the driver to give following drivers a more than adequate warning of hi s intention to turn left or right.

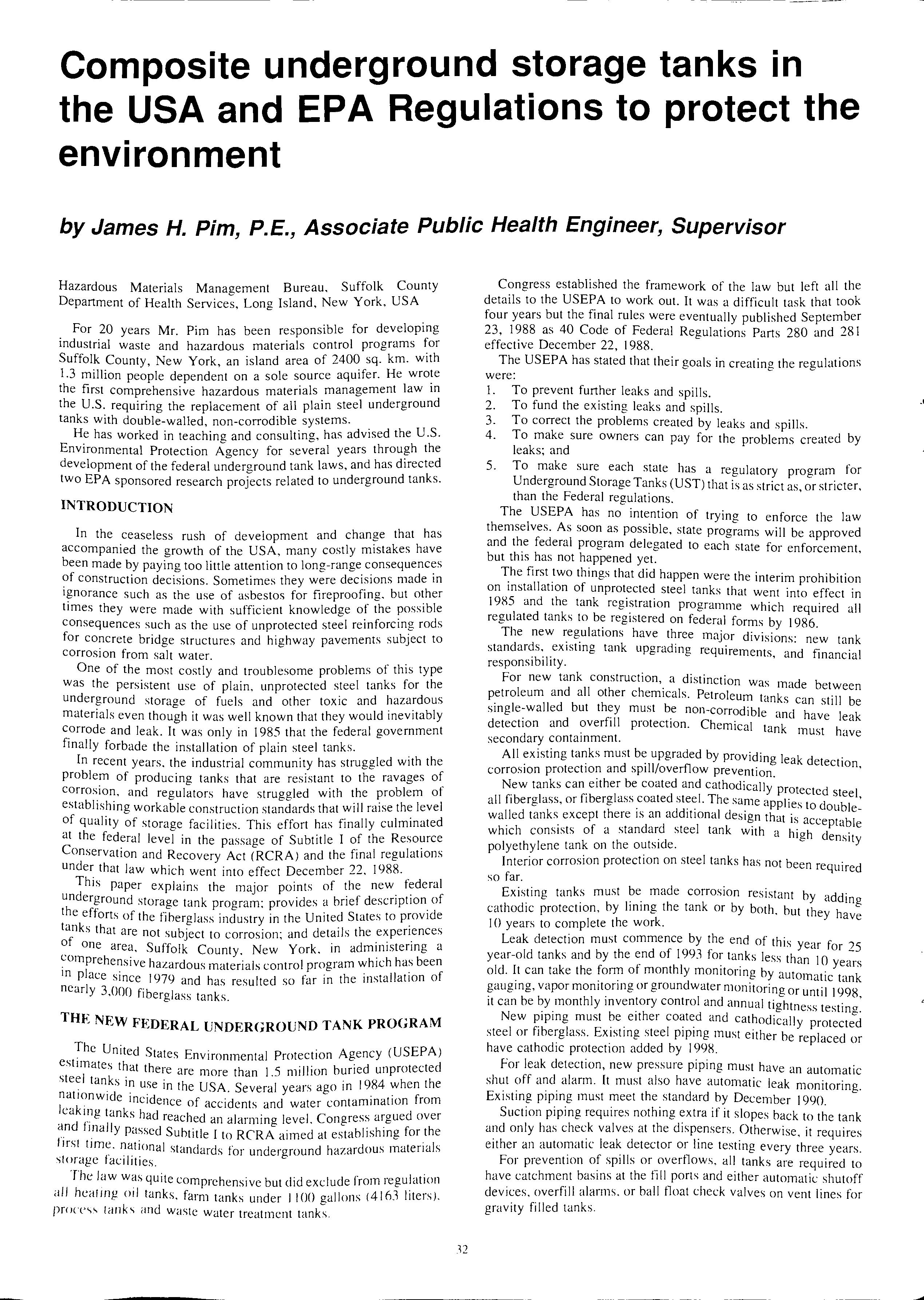

Shell Netherlands BY have in stalled it s first GRP tanks in Holland. In a statement they announce that the recently produced Dutch standard on GRP tanks and pipes have made this installation possible. They had also observed a Shell GRP installation in the UK.

Shell stated that the use of ribs in the tank provid ed high stiffness and strength, although GRP required a high e r investment this was offset by a longe r life expectancy (50 years) with re-use eve n a po ss ibility. Th ey also s tated that USA , Canada, Norway and Sweden have had satisfactory long term experience with non corroding GRP tank installations.

A filling station that kept petrol without a licence has been fined £ 1,500 by Leeds magistrates.

Kuwait Petroleum (Great Britain) Ltd admitted keeping petrol without a licence at Bramley Filling Station , 275 Broad Lane , Leeds. The company was ordered to pay £249.89 costs.

Mr Roger Butterfield , prosecuting for West Yorkshire Fire Service , said that in February this year the o w ner of a nearby house had complained to the fire service about a strong smell of petrol in the house.

Station Officer Roger Marris had visited Bramley Filling Station and found the petrol tank s unlocked. He discovered that ther_e had been a spilling of between one and two gallons dunng delivery, and that this spillage had not been reported to the fire service. The petrol had found its way through underground drams mto the house. The resulting smell meant that the occupants could not use the lounge for three days.

A delivery s lip at th e filling station had been completed incorrectly.

WI ·1 I ki"na h·is records Station Officer Marris found that 11 e c 1ec ,,, ' I 11acl !lot renewed its licence for keepmg petrol , which t 1e company ' d · d Decemb er 31 I 988 A renewal notice and a remmcler ha expire on · · had been sent but had not been acted upon.

The licence had eventually been renewed in Ma y , said Mr Butterfield.

p 1 's 11rnnaaer of company-managed sites, Mr Kuwait etro eum ' "' , b h If cl .ttecl the offence on th e companay s e a Owen Pomtmg , a mi

d Id not be taken on th e alleged

NOTE· Procee rngs cou 1 1· f . 1 ·eofthelicenseetorenewt1e1cence. contraventions due tot e ai ui

Hazardous Materials Management Bureau. Suffolk County Department of Health Services, Long Island, New York, USA

For 20 years Mr. Pim has been responsible for developing industrial waste and hazardous materials control programs for Suffolk County, New York, an island area of 2400 sq. km. with 1.3 million people dependent on a sole source aquifer. He wrote the first comprehensive hazardous materials management law in the U.S. requiring the replacement of all plain steel underground tanks with double-walled, non-corrodible systems.

He has worked in teaching and consulting, has advised the U.S. Environmental Protection Agency for several years through the development of the federal underground tank laws, and has directed two EPA sponsored research projects related to underground tanks.

In the ceaseless rush of deveiopment and change that has accompanied the growth of the USA, many costly mistakes have been made by paying too little attention to long-range consequences ?f construction decisions. Sometimes they were decisions made in such as the use of asbestos for fireproofing, but other times they were made with sufficient knowledge of the possible consequences such as the use of unprotected steel reinforcing rods for concrete bridge structures and highway pavements subject to corrosion from salt water.

One of the most costly and troublesome problems of this type was the persistent use of plain, unprotected steel tanks for the underground storage of fuels and other toxic and hazardous materials even though it was well known that they would inevitably c.orrode and leak. It was only in 1985 that the federal government finally forbade the installation of plain steel tanks.

In recent years. the industrial community has struggled with the problem of producing tanks that are resistant to the ravages of corrosion, and regulators have struggled with the problem of establishing workable construction standards that will raise the level of quality of storage facilities. This effort has finally culminated at the federal level in the passage of Subtitle I of the Resource Conservation and Recovery Act (RCRA) and the final regulations under that law which went into effect December 22, 1988.

This paper explains the major points of the new federal underground storage tank program: provides a brief description of the efforts of the fiberglass industry in the United States to provide tanks that are not subject to corrosion; and details the experiences of one area, Suffolk County. New York. in administering a comprehensive hazardous materials control program which has been Ill place since 1979 and has resulted so far in the installation of nearly 3.000 fiberglass tanks.

The United States Environmental Protection Agency (USEPA) :stimates there are more than 1.5 million buried unprotected steel tanks Ill · · 1984 h h · use Ill the USA. Several years ago m w en t e 11 1 ationwide lllcidence of accidents and water contamination from cakmg tanks h· d , d and finally p.assaedrSeacb·h.ed an alarmmg level, ahrgue,. ovther · · u tllle I to RCRA aimed at esta 1s mg 1or e first national standards for underground hazardous materials 'torage facilities.

The law was quite comprehensive but did exclude from regulation all heating ml tanks, farm tanks under 1100 gallons (4163 liters). lanks and waste water treatment tanks.

Congress established the framework of the law but left all the details to the USEPA to work out. It was a difficult task that took four years but the final rules were eventually published September 23, 1988 as 40 Code of Federal Regulations Parts 280 and 281 effective December 22, 1988.

The USEPA has stated that their goals in creating the regulations were:

I. To prevent further leaks and spills.

2. To fund the existing leaks and spills.

3. To correct the problems created by leaks and spills.

4. To make sure owners can pay for the problems created by leaks; and

5. To make sure each state has a regulatory program for Underground Storage Tanks (UST) that is as strict as, or stricter, than the Federal regulations.

The USEPA has no intention of trying to enforce the law themselves. As soon as possible, state programs will be approved and federal program delegated to each state for enforcement, but this has not happened yet.

first .two things that did happen were the interim prohibition on mstallat1on of unprotected steel tanks that went into effect in 1985 and the tank programme which required all regulated tanks to b: registered on federal forms by 1986.

The new have major divisions: new tank standards. ex1stmg tank upgradlllg requirement d f" · I ·b·1· s, an manc1a respons1 1 1ty.

For new tank construction, a distinction wa . d b s ma e etween petroleum and all other chemicals. Petroleum ta k . 11 n s can st1 be smgle-walled but they must be non-corrodible d h· detection and overfill protection. Chemical ta akn ave leak . n must have secondary contamment.

All existing tanks must be upgraded by providing I k d . corrosion protection and spill/overflow prevention. ea etection, New tanks can either be coated and cathodically pr t d o ecte steel all f1bderglakss, or f1berghlass The same applies 10 walle tan s except t ere 1s an a 1t10nal design that is a b . .. . . . . d d . · ccepta le which consists of a stan ar steel tank wnh a high d . polyethylene tank on the outside. ensny

Interior corrosion protection on steel tanks has not been required so far.

Existing tanks must be made corrosion resistant by add" cathodic protection, by lining the tank or by both, but they I0 years to complete the work.

Leak detection must commence by the end of this year for ? 5 year-old tanks and by the end of 1993 for tanks less than 1o e;s old. It can take the form of monthly monitoring by auto t. y. k. ma 1c tdn vapor momt?nng or groundwater monitoring or until 1998 , 11 can be by monthly mventory control and annual tightne. t ·t· N . h ss es lllg. ew p1pmg must be e1t er coated and cathodically p t 1 d I f.h 1 E . . I . . ro ec e stee or 1 erg ass. x1stmg stee p1pmg must either he re laced or have cathodic protection added by 1998. p

For leak detection, new pressure piping must have an automatic ?ff alarm. It must also have automatic leak monitoring. Ex1stmg p1plllg must meet the standard by December 1990.

Suction piping requires nothing extra if it slopes back to the tank a?d only has chec.k valves at the Otherwise, it requires ellher an auto':'1at1c detector or Ime testing every three years.

For prevention of spills or overflows, all tanks are required to have catchment basins at the fill ports and either automatic shutoff devices. overfill alarms. or ball float check valves on vent lines for gravity fi lied tanks.

Tanks that are found to be leaking can be left in place and repaired by lining, but steel piping cannot be repaired except for tightening joints.

Finally, the law establishes financial responsibility requirements for tank owners to insure that clean-up and third-party damage costs will be met in case of a spill or leak. The required coverage level is $1,000,000 or $500,000 per occurrence depending on the size of the operator. The coverage must be provided by insurance. bonding, credit or other means, or it may be by an adequate state spill fund.

As can be seen from this brief description, the USEPA was trying to be reasonable with the regulations and to provide a high level of leak control at an acceptable level of additional cost. They stopped short of a complete replacement standard or a complete doublewalled standard though they did require double-walled facilities for chemicals. They tried to incorporate all of the available alternatives to provide people with choices.

Recognizing that something had to be done about the corrosion and leak problems of steel tanks, in the early l 960's the American '.etroleum Institute asked the fiberglass reinforced plastics (FRP) mdustry to develop a tank that would solve the problem. By 1965, the first FRP tank had been tested and listed by Underwriters Laboratories for the storage of petroleum products followed in 1968 by the first FRP pipe.

to figures of the Fi berg lass Petroleum Tank, and Pipe now approximately 90% of all major oil company tank and pipe purchases are FRP, and about 50% of the total market.

There are two major and one small manufacturer of large capacity tanks, and a few producers of small tanks in the country. Total production has now exceeded 250,000 units.

The competition for fiberglass has been cathodically protected steel and fiberglass coated steel. All manufacturers produce doublewalled tanks as well as single walled. One only produces doublewalled using a wave form honeycomb sandwich type construction.

Another recent competitor produces a standard steel tank within a mil high density polyethylene outer tank.

ne of the producers on the east coast only makes tanks up to 3.'000 gallons ( 11,355 liters). They are spherical and continuous fiber wound. He makes them both single and double-walled and is competing successfully with the steel market.

Secondary containment requirements are growing around the country. There are now several states and a number of scattered local co · · h mmu111t1es t at have secondary containment requirements and others are 'd · · · cons1 ermg 1t. The most popular method in use is double-walled tanks and piping but various arrangements of flexible m.embrane liners for tank excavations and pipe trenches have been There also are rigid fiberglass trench liners that come in sections and fit together.

Fiber?lass _Piping is produced exclusively by two major neither of which are tank manufacturers. Double-walled pipe is installed.simply by running one pipe inside another identical of lar_ger diameter. The outer fittings, however, are specially .es1gned 111 t"'.'o halves that bolt together and are glued product llght after. the mner pipe is assembled, glued and tested.

The primary for this system is a high density outer pipe wnh special accordion style flexible to go around bends. Joints are made with gaskets and series 300 stamless steel clamps.

Son:etimes other materials are used for special applications For 011 sup?ly to a building, often copper tubing is run inside of f1berglass pipe. or polyvinyl chloride pipe.

Secondary containm t · 'd en is prov1 ed around manways 111 most casehs by a flberglass or high density polyethylene sump _;hich to t e manway flange M . . . . k h · any areas 1equ1re that all p1pmg enter the . t .rough a cover rather than through the tank wall to mmimize points and reduce leak possibilities. The secondary pipmg is then designed to drain into the sump where it can be detected.

.for double-walled systems ranges from manual test111g with a flexible probe that can slide down between the walls to completely automated continual monitoring systems. Vacuum. wet and dry systems are all in use. The vacuum system maintains

a vacuum between the walls constantly and alarms if the vacuum is lost. The wet system monitors the level of fluid that fills the space between the walls. The dry system detects fluid at the bottom of the outer tank that would collect between the walls from a leak. There are no pressure systems on the market yet and there probably never will be.

Installation must be watched very carefully with fiberglass since the tank must rely on firm backfill for support. Compaction by hand operated machines will work but is not cost effective and it is dangerous to place workmen in the hole around the tank.

Pea gravel works best if rodded into place from the surface but it is expensive and not readily available everywhere. Crushed rock can be used if kept to a very uniform small size.

A hydraulic sandfill method has been developed which works well but requires care. Owens Coming Corporation has a test cell in Conroe, Texas and a transparent tank that they used to work out the details of this method.

First, the excavation is lined with polyethylene sheets so it will hold water during the installation. After the tanks are placed, the hole is backfilled with succeeding layers of sand and the water level is brought up at the same time. The sand is then to compact it with water jets and compressed air. The bump111g of the air bubbles causes the sand to settle down into the voids around the tank. At the test facility, the action can be observed from inside the transparent tank. Also the large voids can be observed that occur if the process is not carried out thoroughly

Failures to fiberglass tanks can occur from manufacturing faults or from damage in transit or installation These problems be picked up by proper inspection at 111stallat1on. be111g installed, failure can occur from settlement and mechanical damage such as a blow from ms1de: from stress. or from dissolution of the resin by an mcompauble coming in contact with the tank. The indust.ry states that their failure rate in the field resulting in product loss 1s less than 0.50%.

Suffolk County lies entirely on an island surrounded and is therefore, totally dependent on the o t le is an ' 1 · f 1 4 milhon peop e. to supply the needs of the auon ° ·has been in effect since

A strong groundwater protecuon pr?gram ' . t source controls. the late i 960's but first anned at ;t no Jeoislation In the mid 70's, the emphasis slufted to tan s, l A . h ntry to use as an exa could be found anywhere 111 t e cou . h d Jaws for double d I d th t some countnes a look at Europe 1sc ose a · but it was hard to get walled tanks in place for 10 or 15 years specific information.

ited with secondary

A local law was finally wntten and repi'lcement of all containment as the basic principal and reqfu'.rtll1g ears, and the final · ff ·t now 01 en Y · ' existing tanks. It has 111 e cc 11 k. in the county must replacement date is draw1.ng near a is much more meet the new construction .. f nore comprehensive stringent than the federal law and 15 hazardous materials. including all types of storage and all 0been registered in the Almost 15,000 underground tanks bave · 1·t·illed of both single f.b 1 tanks have een II s ' county and 3,000 1 erg ass · been 600 cathodically and double walled types. Thee have also 1 00 fb lass co·1ted stee protected tanks and 1 .1 eig' · 'd Suffolk. Leaking tanks · · k · 1s not ·11lowe 111 Lmmg to repair tan s ' must be removed.

11 d for petroleum products II d tanks ·ire a owe Initially. single-wa e ' · ' 11 until now douhle-walled but the code was tightened. family homes for heating tanks are required ut.sll1'ired for all product piping oil. Double-walled pipmg is also iequ including suction systems. . S ,. lk ·s that great care must be Wh h b Ie·1111ed 111 uio 1· ' at as een f'b 1 ss s)'stems and that constant . d . i·nstalhno I erg ,1 exercise m · e , h ality high. Contractors will inspection is necessary to keep t e. qu. , 'f tl ey can get away with it. cut comers 1 1 t' 11 f )r foreign objects. tor Backfill must he watched care u y l grad·Hion and for compaction. must he measured and after hackhll and · b 1 t'o 1 to ·issti1·e 110 settling This can be done by takm!! at JO comp e 1 1 ' · · · · • • • • vertical internal diameter measurements with '1 g,1ugt the fill port. These should be recorded for furnre reference.

Several tests are nece ssary throughout th e co nst ruction to in sure a sou nd system Th ese in clude an a ir and soap te st of th e tank initially, hi gh pressure test of primary piping, air tes t of tank afte r backfill, pip e s lope mea s ureme nt s, se cond a ry pipe pre ss ure tes t, and detection and alarm sys tem tests.

The failure s of fiberglass tanks th a t ha ve occ urre d in Suffolk County are of se veral ty pes. So m e ha ve been factory faults suc h as pin hol es at fittings or rib s. Most have been detected during in stallation but a few have caused minor leak s Several tank s have been dam aged by rough ha ndlin g or blows from e xcava tin g eq uipm ent. One tank was damaged intern a ll y by a ga uge stick and another o ne had a hole pun c hed throu g h th e bottom b y a pi pe dropped inside T he two m aj or causes of catas trop hi c failure have

bee n se ttl e m e nt resu ltin g in ove r de fl ec ti on, and overpressur izatio n caused by pumped delivery of fuel ra th e r than gravity delivery. Th ese two problem s have occurred at a total of fiv e s ites. The failure ra te in Suffolk seems to be comfortably below th e indu s try estimated national average of 0.50%.

Pipe failures have been ve ry limit ed. A few fac to ry fau lt s have appea red a nd occasionally the use of incorrec t ce m e nt o r in adequ a te curing time in cold wea th er has ca use d joints to fail.

In su mmary , the Suffolk County experiences with fib e rg lass tanks and pipes has be e n very positive. Only a few fa ilures have occ urred so far. Ma nways have been pro v id ed in a ll tanks to make access co nven ie nt for th e future if in spec tion o r re pair prove s necessary.

Members of the Ea ste rn Branch had a mo st enjoyab le and interesting morning at Shell Gas T e rminal , Bacton , Norfo lk The morning began wi th a video o n L.P.G. sh owi ng th e safe ty precautions to be take n when storino and hand iin o th e product.

The members were then taken o n° a ouided of the terminal and saw where the gas is piped from the North Sea into the te rmin a l. In the terminal the m e mb ers saw the di ffere nt staoes where th e 0 vanous impunt1e s in the gas are removed . Afte r th e gas pressure and temperature a re regu lated and a pungent smell is added , th e gas is pumped into the Nat iona l Grid.

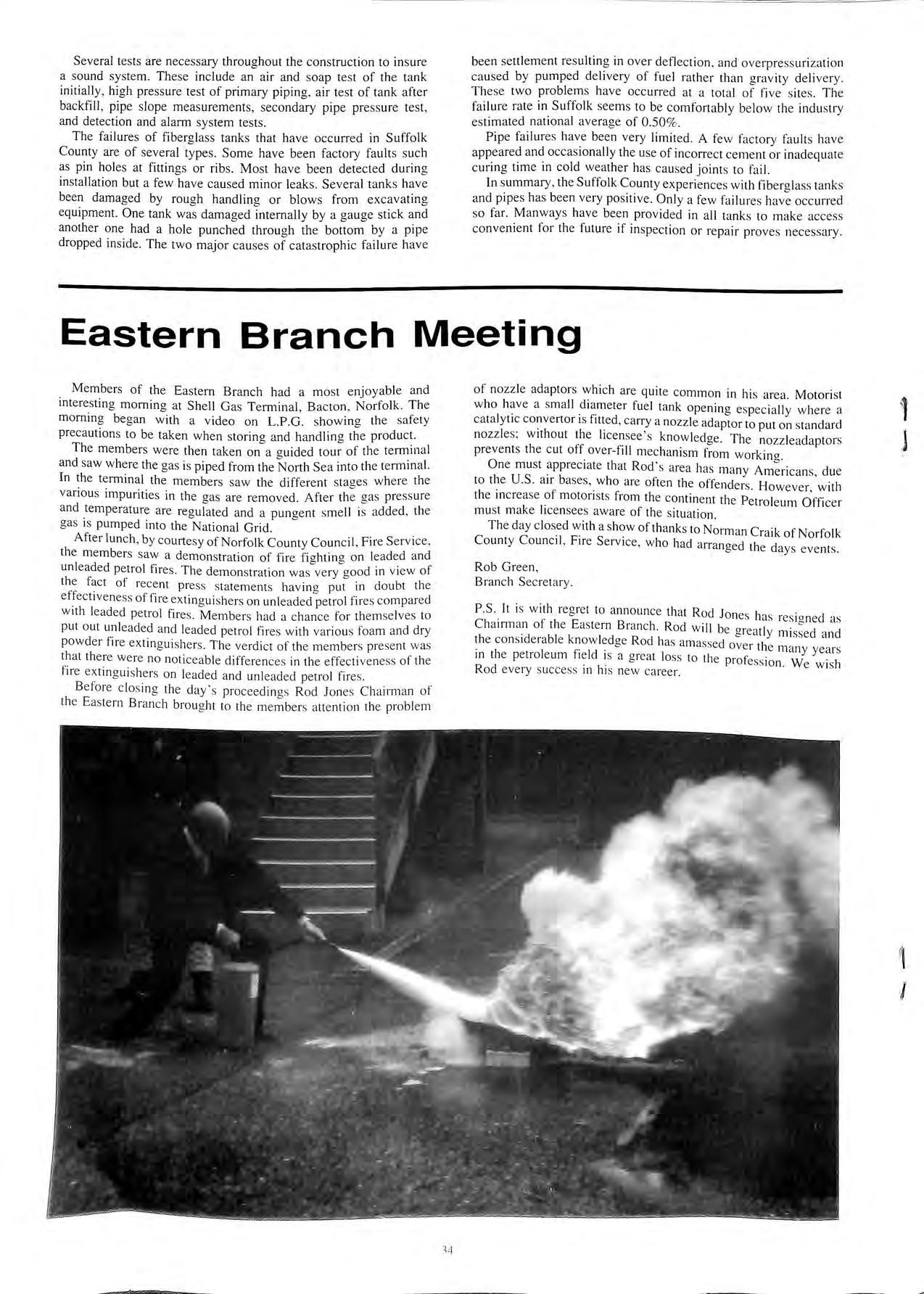

After lun ch, by courtesy of Norfo lk County Counci l, Fire Se rvice, the members saw a demon stration of fire fighting on le aded and unleaded petro l fires. Th e de mon s tration was ve ry goo d in view of th e fact of rece nt pre ss s tate m e nt s ha v in g put in doubt th e effec ti ve ness of fire ext in g ui s he rs on unl eaded pe trol fire s compared w ith lead ed petro l fires Membe rs had a c hance for them se lves to put out unl eaded a nd leaded petrol fire s with va riou s foam a nd dry powder fire extingu ishe rs. T he ve rdic t of the m e mbers pre se nt was that th e re were no no ti ceab le d iffe re nc es in the effec tivene ss of th e fire extingu is he rs on leaded a nd unl eaded petro l fires.

Before c los in g the day' s proceed in gs Rod Jones C hairma n of th e Easte rn Branc h brou g ht to the me mb e rs a tten tion th e prob lem

of nozz le adaptors w hi c h are quite common in hi s area. Motorist w ho have a small _d ia_mete r fuel tank ope nin g es pec ia ll y w he re a cata lyll c co nve nor is fitt ed , ca rry a nozzle ada ptor to put on sta ndard no zz les; wit hout th e knowledge. Th e nozz leadap tors preve nt s the cut off over-f1ll m ec ha ni s m from work in o

One must apprec iate th at Rod 's a rea has many du e to the U.S. a ir bases, who a re often th e offe nd e i·s Ho e · ·th w ve1, w 1 th e 111crease of motori sts from th e co ntin ent th e Petroleum Officer mu s t m ake lic e nsees awa re of th e s ituation.

The day c lo s_ed w ith a show of th a nks to Norman Cra ik of Norfolk County Counc il , Fire Service w ho had ·1rranoed tt1 d ' ' o e ays eve nt s Rob Gree n , Branch Sec retary.

P.S. It is wi th reg re t to a nn o un ce th a t Rod Jo ne s I · I ms res 1g nec as Chairma n of th e E as tern Branch. Rod w ill be o1·e· tl · d d "' d y m1 sse a n th e cons idera ble knowledge Rod ha s amassed ove tl · r 1e many yea rs 111 the pet1o leum fie ld 1s a g reat loss to the profe · W · ss 1on. e w is h Rod every success 111 hi s ne w career.

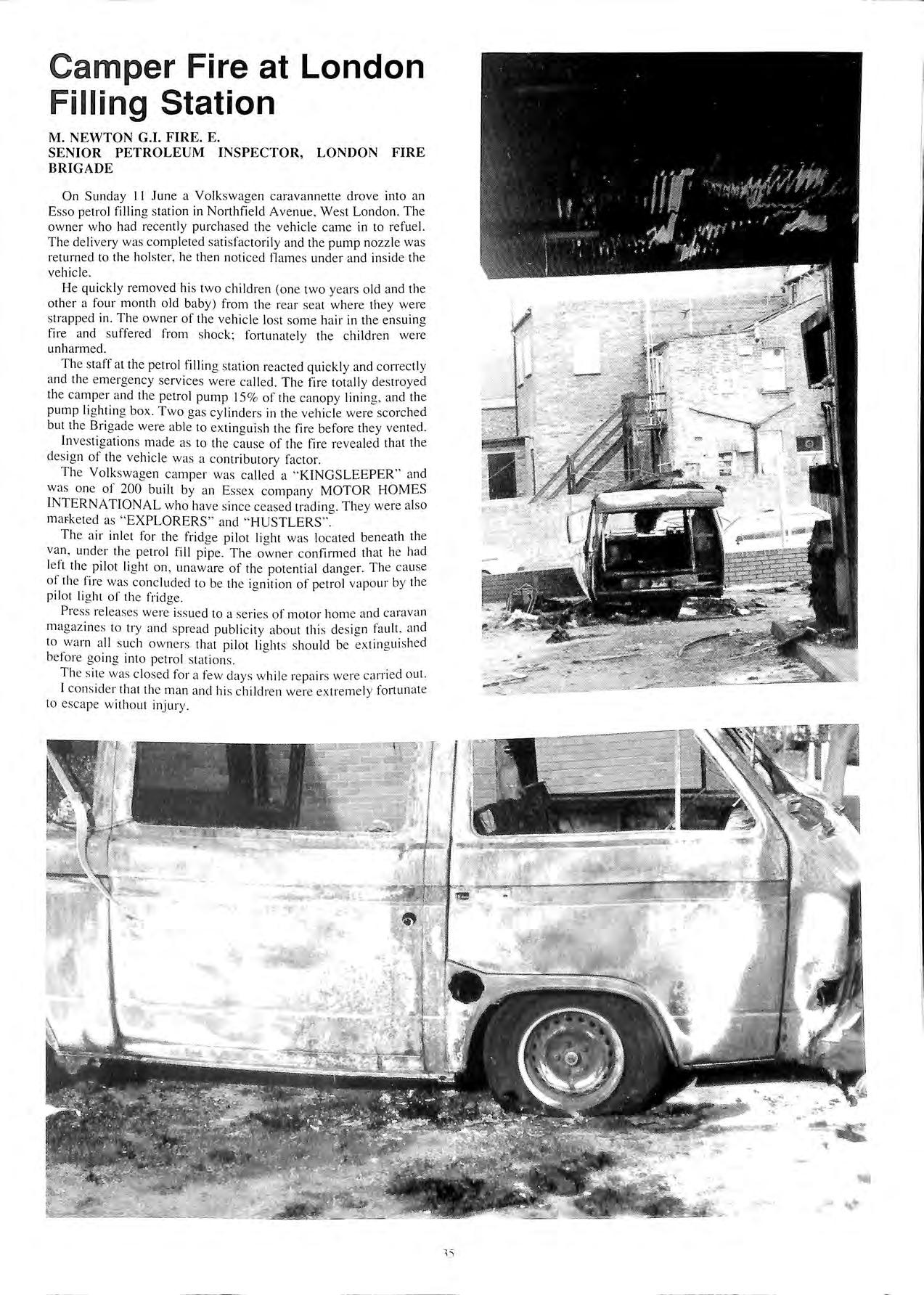

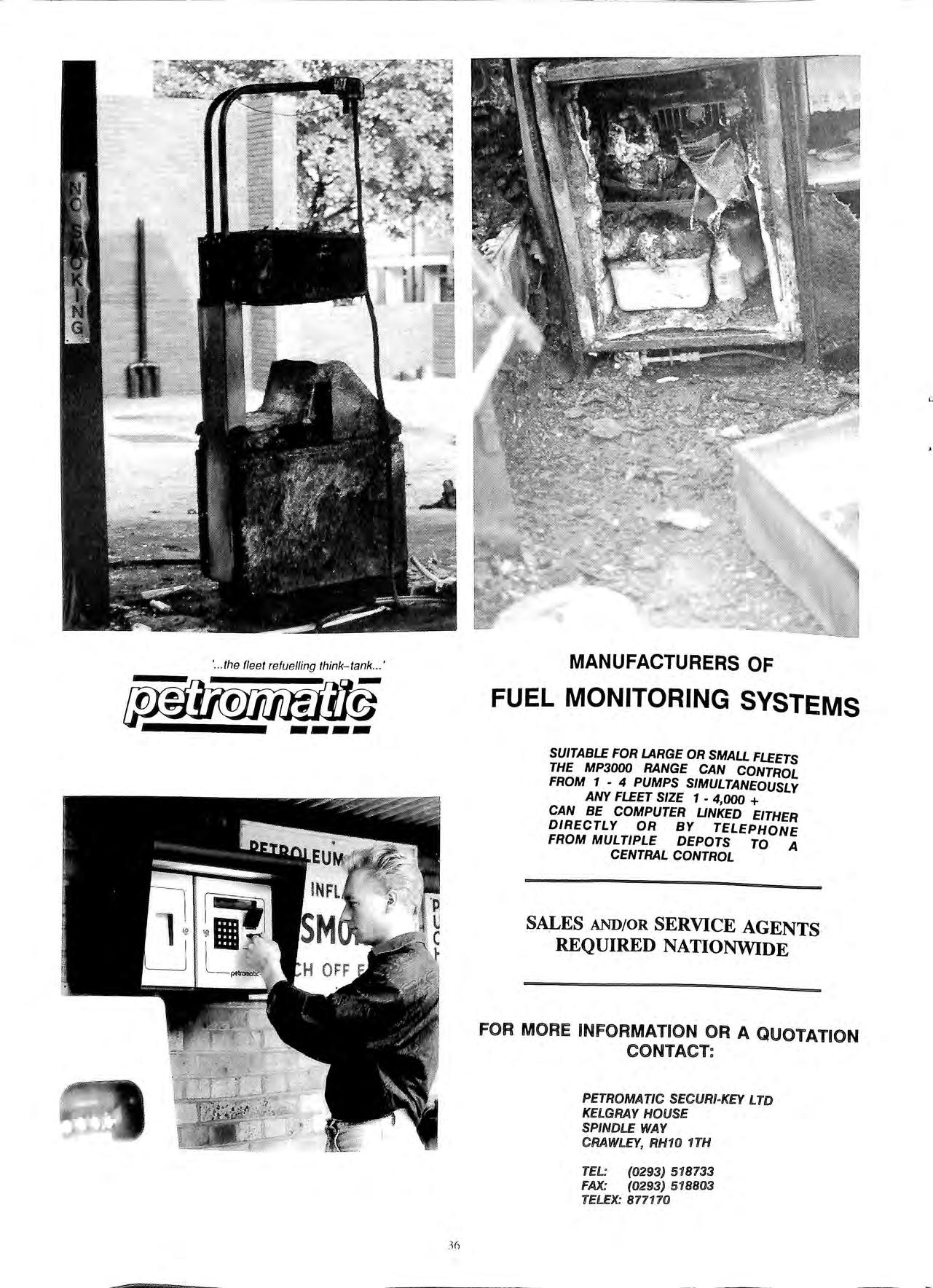

On Sunday 11 June a Volk swage n cara va nnett e drove into an Esso pe trol filling s tation in Northfi e ld Avenue , W es t London. The owner who had rec e ntly purchase d the ve hi c le came in to refuel. Th e deliv e ry was co mpleted sati sfac to ril y a nd th e pump noz z le was re turn ed to th e hol ster, he then noti ced flam es un der a nd in s ide th e vehicle

He quickly removed hi s two children (one two years old and th e other a four mo nth old b ab y) from the rea r sea t where th ey we re strapp ed in Th e owner of the vehicle lost so me ha ir in the ensuing fire and s uffere d from shock ; fortunately th e children were unh arm ed.

The staff at th e petrol filling station reac te d quickly and correctly and th e em e rge ncy services were called. Th e fir e totally destroy ed th e camper and the petrol pump 15 % of the ca nopy lining , and th e pump li g htin g box. T w o gas cylinders in th e ve hicle we re sco rch ed but th e Brigade were able to ex tin g ui s h th e fir e before they vented.

Inv es ti ga ti o ns m ade as to the ca use of th e fire revea led th at the de s ig n of th e ve hicle was a contributory fac to r.

The Volk swage n camper wa s ca ll ed a '' KINGSLEEPER " and was one of 200 built b y an Es se x co mp a ny MOTOR HOM ES INTE RN ATIO NA L who ha ve s in ce ceased tradin g. The y were also m aFke ted as "EXPLORERS" and " H US TLERS ".

The a ir inlet for the frid ge pilot li g ht was loc ated beneath th e van. under th e petrol fill pip e The owner co nfirmed that he had left th e pilot li g ht on, unaware of the potential clanger. The cause of th e fire was concluded to be th e ig niti on of petrol vapour by th e pilot li g ht of the fridge.

Pre ss re leases we re iss ued to a se rie s of m o to r home and carava n mag a z in es to try and sp read publicity about thi s design fault, a nd to wa rn a ll suc h ow ners that pil o t li g ht s sho uld be ex tin g ui shed before go in g int o petrol s tation s

Th e s ite was cl osed for a few day s w hil e re pairs we re ca rri ed o ut. I co ns id er th at the man and hi s c hildren were ex tre m e ly fo m111 ate to escape witho ut injury

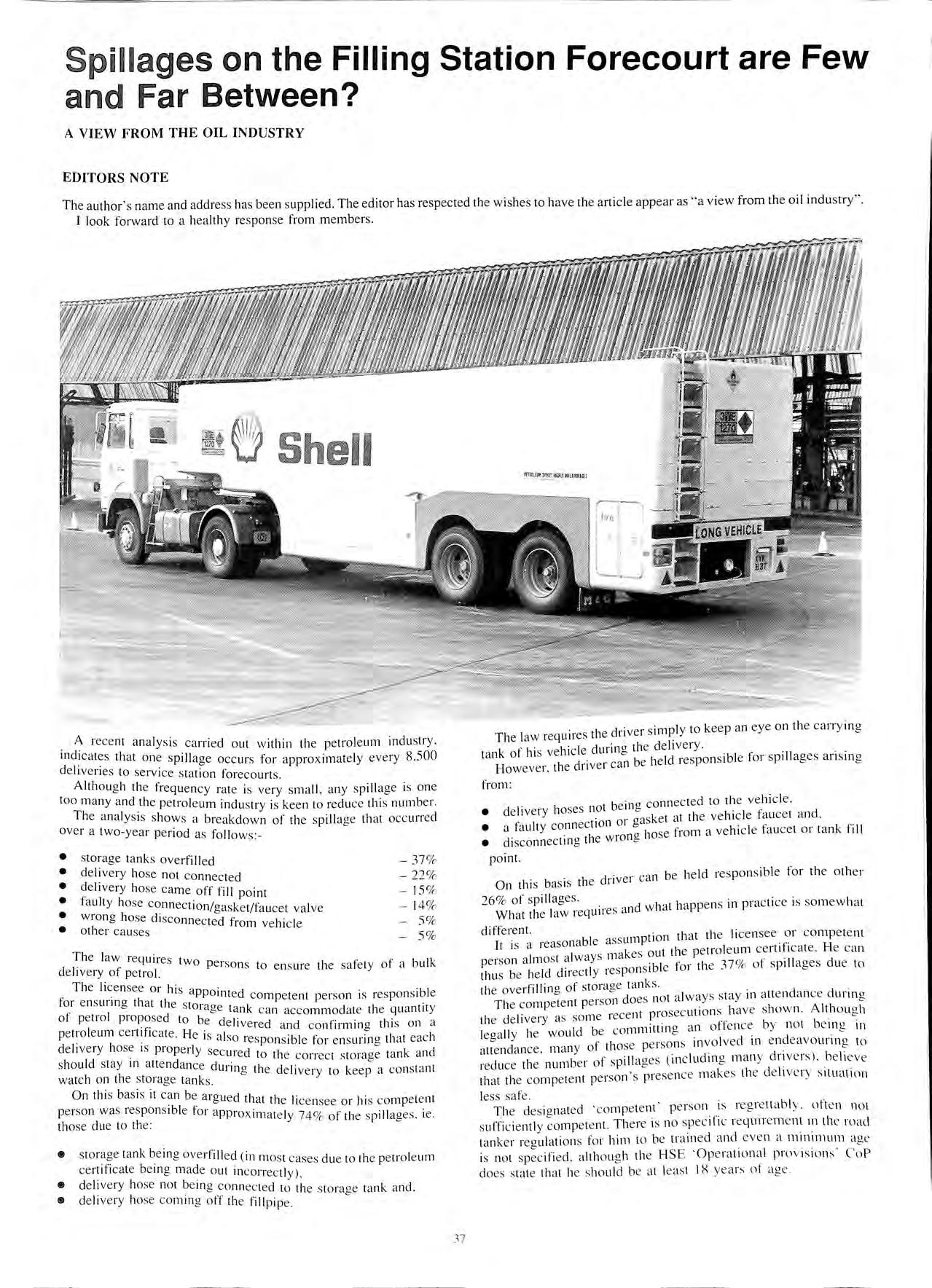

A rece nt ana lys is carri e d o ut w ithin th e pe tro leum indu stry. md_1 ca tes th a t on e s p ill age o cc urs fo r a ppro x im a te ly eve ry 8,500 de li ve ri es to se rv ice s tati o n for eco urt s

A lth o ug h th e fre qu e nc y ra te is ve ry s m a ll , a ny s pill age is o ne too m a n y a nd th e pe tro le um indu s try is kee n to re du ce thi s numb e r Th e a na lys is s hows a bre a kd ow n o f th e s pill age that occ urred ove r a two yea r pe riod a s foll ow s :

• s torage ta nk s o ve rfili ed 37 %

• de li ve ry hose not co nn ec te d 22 % • de li very hose ca me off fill po in t 15 % • fa ult y hose co nn ection /gaske t/fa uce t va lv e 14 % • wro ng hose di sc onn ec ted fr o m ve hi c le 5 % • o th e r ca uses 5 %

Th e law re quires t w . cl I . f 0 pe 1so ns to e n s ure th e sa fe ty o f a bulk e 1ve1y o pe tro l.

T he li ce nsee o r hi s a · · · I f h ' pp o int e cl co m pe te nt pe rso n 1s res po ns 1b e o r e ns unn cr t a t th e s ta r · f 1 "' age ta nk ca n acco mm o d a te th e q ua ntit y O pe tro p ro pose d to be d e live re d a nd co nfirmino thi s o n a Pe tro le um ce rt1f1 ca te He · I · I · IS a so res po ns ibl e lo r e ns urin g th a t eac 1 de li ve r)' hose 1s pro pe rl y s cl cl ec u1 e to the co rrec t s torage ta n k a n s ho uld s tay Ill a tte nd a nce durin g th e d e li ve ry to keep a co ns ta nt wa tc h o n th e storage tan ks.

O n thi s bas is it ca n be a rcr ue d tli ·lt tli e 1· I · ip e te nt "' ' 1ce nsee or 11 s co n pe rso n was res po ns ib le for app rox im a te ly 74 % o f th e s pi ll ages . ie. th ose clu e to th e:

• s tora?.e ta n k be in g over fill ed ( in mos t cases du e to th e pe tro le um ce rti fica te be mg m ade o ut in co rrec tl y). • de liv e ry hose no t be in g co nn ec ted to t he s torage ta n k a nd • de live ry hose co m ing off th e fill p ipe.

·. I d ve r s impl y to kee p an e ye on th e ca rry in g Th e la w requn es ti e 11 k f 1·. 1 ·c1e durin o th e de liv e ry. ta n , o i 1s ve ll d.- "' be he ld res p o n s ib le for s pillages a ri s in g H oweve r , the 11ve 1 ca n fr o m:

1 t be in o co nn ec ted to th e ve h _ ic le , • de li ve ry i oses no "' · f cl oaske t a t th e ve hicl e a uce t a n • a fault y conn ec tion °1 fr o m a ve hicl e fa uce t o r ta n k fill • di sco nn ec t111 g th e w i o n"' po int. d · c·rn be he ld res pon s ib le fo r th e ot he r

On th is ba s is th e n ve i ' 26 % of s pill ages , d w ha t ha p pe n s in prac ti ce is so m ew h a t Wh a t th e law requ11 es <1 n diffe re nt. · th a t th e li ce nsee o r co m pe te nt

It a re ason a bl e ass umpti o n is ' . kes o ut th e p e trol e um ce rtifi cate. H e ca n pe rso n a lm os t al w<1lys m apo ns ib le fo r th e 37 % o f s pi ll ages d ue to thu s be he ld direc t Y 1es th e ove rfillin ° o f sto ra ge tan ks. · "' 1 doe s no t a lway s s tay 1n a tt e nd a nc e cl unn g

T he co mp e te nt pe 1so 1 · rece nt pro sec uti o n s h ave s how n . A lth o u g h th e de h ve ry as so m e · I II I Id be co mmittin o a n ofte nce b y n o t b e 111 g 111 ega y i e wo u e cl · d Of tli ose pe rso ns invo lve d m e n eavo unn g to a tte n a nce, m a n y · redu ce th e num be r o f s pill ages ( in c lu d m g m a n y dri ve rs). b e li e ve th a t th e co mp e te nt pe rso n 's p rese nce m ake s th e d e li ve ry s itu a tion le ss safe.

Th e des ignate d ·com pe te nt · pe rso n is reg re tt ab ly. n f\e n no t s u ff ic ie nt ly Th e re is no s pec ifi c re quire m e nt in th e rn a cl ta n ke r reg ulati o ns fo r him to be t ra in e d a nd eve n a minimum <i ge is no t a lth o ug h the H SE ·Op era ti o n a l p ro v is io n s' CuP do es s ta te th a t he s ho ul d be a t le as t I !:-\ yea r,; of ag e

Although the Health and Safety at Work etc. Act does require a degree of training to be given and much training has been carried out within the Industry, the menial nature of the work and the resulting high turnover of staff tends to negate such training.

There is, obviously, the conscientious competent person who will correctly check storage tank ullage and may satisfy himself that the delivery hose is connected to the right storage tank, but even he will never check that the hose is securely connected. He sees that as the driver's job.

On the other hand there is the driver who will be a mature person, will have undergone considerable training and will be adjudged by his employer as fully competent.

It is not difficult to imagine the frustration of such a driver where the law requires him to be effectively directed by this 'competent' person when in practice, the driver is more likely to be distracted by him.

As the industry and probably the enforcement authorities must know, in the majority of deliveries it is in fact the road tanker driver who, working from the petroleum certificate, will lift manhole covers where necessary, select the correct fillpipes and connect hoses to both storage tank and vehicle tank.

It is reasonable to assume therefore, that in practice, in the majority of deliveries, the competent person's responsibility effectively en_ds when he has made out the petroleum certificate and it is the dnver who then assumes the responsibility for the rest of the delivery.

So, how can the present arrangement be improved?

The Industry believes that the menial nature of the work will to result in a high turnover of forecourt staff, with little improvement in its competency to receive bulk deliveries of petrol.

The Industry believes in the establishment and enforcement of sound regulations.

It therefore believes that the law should be changed to make the enforcement role easier and more effective, by more clearly defining

the roles of the competent person and the driver such that when an offence is committed, the offending party is clearly identifiable.

The Industry believes that the competent person should be responsible only for completing the petroleum certificate (prior to the arrival of the road tanker). The driver should then be responsible for the actual delivery.

Thus, if a spillage occurs because a tank overfills (ie. because the petroleum certificate has been made out incorrectly), it is the responsibility of the competent person. Any other spillage would be the responsibility of the driver.

Currently the delivery situation is too grey an area.

The driver may take on the responsibilities of the 'competent' person knowing that if anything goes wrong, it will be the 'competent' person's responsibility. He may thus attempt deliveries if tanks are badly labelled, if lighting is poor or if other hazards exist.

If the driver knew that he would bear the responsibility for a safe delivery, he would act responsibly.

The above proposed delivery procedure would appear to be little different to what exists in other countries around the world. France does have regulations similar to the UK but this is the exception. Most other countries have few regulations with no apparent worse record in respect of forecourt incidents, than the UK.

In many countries it is common practice for the driver to assume the whole responsibility for the delivery, including the dipping of tanks. UK Industry does not support this approach, believing the s_hould. share of the responsibility for the but l_1m1tmg this to cert1fymg that storage space for the delivery is and that storage tanks, valves and pipes leading to them are all m good order.

There is currently an opportunity to change the Iegi"sl· t. t . h . . A . a ion o improve t e present snuauon. re the Industry and the L" · A h k d f 1cens111g ut ontles gomg to ta e a vantage o this opportunity?

NITROGEN

THE QUICK INEXPENSIVE 100% SAFE WAY OF INERTING WITH NO PROBLEMS ASSOCIATED WITH WATER SUPPLY AND TANKERING AWAY ETC. OR OTHER COSTLY TIME CONSUMING AND SOMETIMES

SUB-LICENCES are at the moment being considered to enable Companies to operate this patented process with simple automatic equipment from their own small vans. EXAMPLE: It takes only a few minutes and one cylinder of Nitrogen to totally FOAM inert a 1500 gallon compartment, and so on. The sub-licences, officially registered at the UK Patent Office, will include full training being given in these procedures and other associated ANALYTICAL and NITROGEN services that may be required on the Forecourt, during the Contractors routine day to day work. Training may be undertaken on the Contractors own sites to save staff 'down time' and is simple and non-time consuming. Demonstrations can be arranged on our own glass panelled petroleum vessel.

NITROGEN INERT FOAM is suitable for 'MOTHBALLING' during periods of shutdown or extended 100% inerting for EXTENDED CLOSURES. After Foam filUng the vessel is sealed off and remains 10?% inert with Oxygen content at ZERO, no problems of re-distribution of improperly purged gases, or corrosion etc. as with water fill methods exist.

NITROGEN INERT FOAM may be used in most situations for MANHOLE with product in situ, or if preferred the product may be lifted and quick and simple FOAM mertmg may be earned out, before the work is undertaken.

NITROGEN INERT FOAM provides quick and inexpensive inerting prior to manhole removal and slurry filling.

NITROGEN INERT FOAM is highly suitable for inerting_ prior to and the excavated be loaded and safely transported foam filled for disposal if the demolition 1s undertaken, Fo_am filled, m safety on site. Foam filled vessels are unaffected by 'Pecker' Perforation or porosity as are water filled vessels and any spirit leakage can be simply blanketed with this process.

NITR<JGEN INERT FOAM gives 100% safety during and as a PLUG,_ a_llows alterations to be carried out on pipework that has held product, 1n complete safety, m close proximity to hazardous areas.

We also undertake all other Nitrogen and Hi-tech service associated with the Petroleum and Chemical Industries.

GAS FREEING using inert foam or other nitrogen purging techniques.

LEAK TESTING by Helium trace and other modern techniques.

HOT WORK modifications and repairs to Lloyds and ASME. BOTTOMING and CLEANING, REMOVAL or SLURRY FIWNG.

'MOTHBALLING'.

FILLED RESIN or glass reinforced, spirit or solvent resistant linings, engineered to Lloyds Inspectorate Of Shipping approval.

ULTRASONIC TESTING under totally inert or Water Filled conditions, and GRIT ABRASION to S.A.3 using 'NITROaBRADE' @!)equipment, under totally inert Constant Purge situations.

Welbeck House High Street Guildford Surrey GU1 3JF

Tel: Guildford (0483) 38227

Corroshield have been lining petrol storage tanks for over a decade endorsing our quality of specification and experience in this specialist field

Corroshield System 80 tank rehabilitation is not a repair or temporary solution: (it is new tanks for old) backed by our guarantees extended for as Jong as you require In any forecourt operation

CORROSHIELD LIMITED Unit 1, Hackers Close, East Bridgford, Nottingham NG13 BPG Telephone: (0949) 21032

COMMERCE HOUSE, THE MALTINGS, STATION ROAD, SAWBRIDGEWORTH, HERTS. CM21 9JX Telephone: 0279 723448 '