It's approved by petroleum licensing authorities and installs twice as fast as steel.

Ameron's Dualo/ 3000/L fiberglass pipin g is li sted wit h Underwriters' L a boratories for u se in undergro und fuel-handling systems. It h as a lso been tested and accepted by th e Lo nd o n Fi r e a nd Civ il De fe nce Authorit y.

Thi s m ea n s yo u have th e a ss ura n ce that uur produ ct ha s b ee n tested und e r the most stringent c ondition s and is ra te d for press ures a nd te mperatures far in excess of re g ul a r p etro l s t a tion re quire ment s.

You ca n in s tall a Oualoy yste m in abo ut one half th e time re quired to put in s tee l. In fac t , yo u ca n taper th e.: e nd of o ur pip e in less tim e than it to put a s tee l pip e in a pip e v ise.

But h ere's the best par t: yo u ' ll probably find the inst a ll e d cos t of a Du a loy syste m to be le ss th a n for s tee l-as it requires no s ulph a te resisting co n cre te surround.

Arn ero n h as a Oualoy sys t em fo r eve r y und ergro und fuel-handling n ee d: w h et her it' s conventional s in g le-wa ll piping or a comp lete seco ndar y con t a inm en t system.

For more in for mation , \Nr i te Ameron Fiberglass Pip e Di v i s ion, P.O. Box 6, 4190 CA G e ld erma l e n, Th e Ne th e rlands or ca l l u s a t 03455 7 334 1.

Introducing from the new 61-SO Overfill Prevention Valve

Features:

!he 61-SO overfill prevention valve 1s designed to be a simple, low cost solution to positive shut-off of product fill for underground storage tanks. The shut-off valve is an integral part of the 4• drop tube used for submerged filling. No extensive or expensive excavation is The OPW 61-SO can easily be into most existing locations. No special manholes are required. Installing the OPW 61-SO is as simple as changing drop tubes.

The OPW 61-SO is a two-stage shut-off valve. When liquid level rises to approximately 95% of tank capacity, the valve mechanism is released and the closes automatically with the flow. his reduces the flow rate to approximately 5 gpm through a bypass The operator may then stop the filling proce d. ss, 1sconnect and drain the delivery hose. As long as the liquid level 95% of tank capacity the valve will close aut · omat1cally each time delivery is attempted.

If the storage tank 1s overfilled to an unsafe condit.· b ion and the liquid rises to a 1 °ut 983 of tank capacity the bypass va ve closes N · into th · 0 additional liquid will flow e tank Until the level drops below a reset point.

* Slmple, easy and quick Installation no excavation or special manholes required.

* Economical - costs a fraction of expensive, complicated and difficult to install valves.

* Completely automatic operation no pre-checks to perform, no resets, no overrides to be broken or abused.

* Works at all flow rates operates directly from liquid level.

* Will accept a dipstick for gauging.

* Retrofits directly for existing tanks and 4" riser pipes.

* Automatic hose drain - for operator convenience.

* LFCDA approved.

Materials:

Valve body: cast aluminium

Float: nitrile rubber, closed cell foam

Valve: aluminium

Seals: viton

Upper & Lower Drop Tube: aluminium

Talking Point

Many members of the Association will be concerned to hear recently of a number of deaths being reported of fitter"s involved in alterations. and testing of equipment at petrol filling stations. A report on the conclusion of the first court case is within this issue of the Bulletin. and it is understood that other cases are likely to be taken.

The amount of work generated by the Industry switch to unleaded petrol is almost certainly to have increased the number of alterations carried out at filling stations over the past 12 months. and may have been a contributory factor.

The Oil Industry in general are becoming concerned and many are asking contractors to show their Health and Safety procedures to them have them agreed before work commences on sites. It has been clear that the larger companies have set procedures. but the smaller companies and "one man operations" may not have set written safe systems of work.

SEMINAR PROGRAMME

INTERNATIONAL PETROLEUM SEMINAR OCTOBER

2ND 1990 QUEENSWAY HALL DUNSTABLE BEDFORDSHIRE." SAFETY AND ENVIRONMENT AT PETROL FILLING STATIONS"

08:45 hrs Exhibition opens Registration of delegates

09: 15 hrs Coffee

I 0:00 hrs Conference opened by Eric Forth MP Parliamentary Under Secretary of State. Department of Employment

Morning Session chaired by J Thompson LFCDA

I 0: 15 hrs Vapour Balancing -stage 2 (petrol pump to storage tank)

USA experience John Rumble vice president Emco Wheaton USA European experience Dr Harold Falckenberg Elaflex W Germany

11: 15 hrs Industry solution to pressure pipe concerns

Introduced by Graham Pooley Mobil Oil UK

Rick Smith, Dennis McEachern Petroleum Monitoring Ltd Concord North Carolina USA

12: 15 hrs LUNCH AND EXHIBITION

14: 15 hrs Afternoon session chaired by B Taylor Hon Secretary

Polyethylene pipework and petrol stations Scandinavian experience Jan Ageheim Limit BY Sweden

14:45 hrs Petrotite Tank Testing George Lomax. Heath Consultants, Texas, USA

15: 15 hrs Continuous Monitoring for leaks at UK petrol stations

Mr Phillip Whitehead

Dr Rohen Bridges Normond Environmental Services Ltd UK

15:45 Open forum

16:10 Close

For hooking contact Mrs E. Taylor 0582 882170

CONOCO'S ENVIRONMENTAL INITIATIVE

CONOCO\ prc-.idcnt and Chief Executive Mr Nicandros at a llL'W' conference on April i(Jth launched an environmental 1n111ative on behalf of the company.

.\ nu1nher of important initiative' were launched among which \\a' 011e tl1<1f thL· i' lo adopt a worldv.·idc policy. that on all 1wv. petrol filling station' and renovated 'iitcs will he rc4uircd h\ rhat pol1L \ 10 have double containn1L·nt 'Y'tcms on all tanks ;111d p1pl'iillL''- 111 addition at the lill1ng ,ta1irn1-, the company 1s · '1111m111nl 10 rcdun· vapour L'n11',io11' which is undcr'>tood will 111'.<•1,,. \ap11t11 halanung ·,wg,· I B.

OVERFILL PREVENTION DEVICE SAVES THE DAY

At a brand new petrol filling station with overfill prevention devices, one major Oil company did not have to wait long before reaping the benefit of installing these devices.

At one delivery the road tanker driver noticed that the tanks could not be filled as the OPD had operated. The gauge was checked and it was noticed that according to the reading there was still room to install more product. The hose was drained however and the remaining product was returned to the terminal. The manager had thought that something had gone wrong with the overfill prevention device. However, On investigation it was noticed that the numbering of tanks to gauges was incorrect, the gauge that was supposed to refer to the tank in question referred to another tank. The fitting of the overfill prevention device saved product loss. possible danger from fire and explosion and of course environmental damage.

UNAUTHORISED TANK REPAIR

During construction work on one filling station in London a contractor damaged a petrol storage tank with a pneumatic drill. Anxious not to have this cause him or his company problems he decided to carry out unauthorised repairs using ISOPON with concrete placed over this. A diligent petroleum inspector spotted the new work and upon investigation discovered the "repair". As a result the tank was replaced and the employee dismissed.

PETROL POLLUTED SOIL DUMPED ON SUSSEX FARM

100 tonnes of petrol polluted soil removed from a petrol filling station in Sussex was reported to have been dumped on farmland in an area of outstanding beauty. East Sussex County Council has stated that it intends to prosecute the sub contractor responsible. The garage at Hailsham near Easthourne was demolished and redeveloped earlier this year. It involved the removal of large volumes of sub soil contaminated with petrol leakage from underground tanks and pipes which had been leaking for a number of years. The Council were alerted by "Friends of the Earth'". and having taken samples confirmed that the test revealed high contamination. The major Oil Company concerned had contracted a local licensed waste disposer to remove the soil and pointed out that the sub contractor had removed the bulk to a licensed tip.

JAPANESE PETROL STATIONS

Petrol. oil and pumped-up tyres were the most you could hope for from a petrol station at one time. Nowadays many arc minisupermarkets offering one-stop-shopping for more than simply motoring accessories: milk and bread. !lowers. toys. newspapers··· But in Japan a trip to refuel could soon become 'iomething of a day out for the family. rather than a llceting visit. Nev. legislation there has meant more freedom for petroleum nil companiL'S developing their sites: the largest Japanese oil company. ldcmihu Kosan. is already building a 11-storcy petrol 'itation with llll-sitc wimming pool. fitness centre and art gallcrie'. The change came when the oil industry wanted to diversify and rcali,cd that mmkrn ,afcty standards and equipment no longer merited tile 'tringL·nt fire rcgulat1011'> imposed more than 30 years ago.

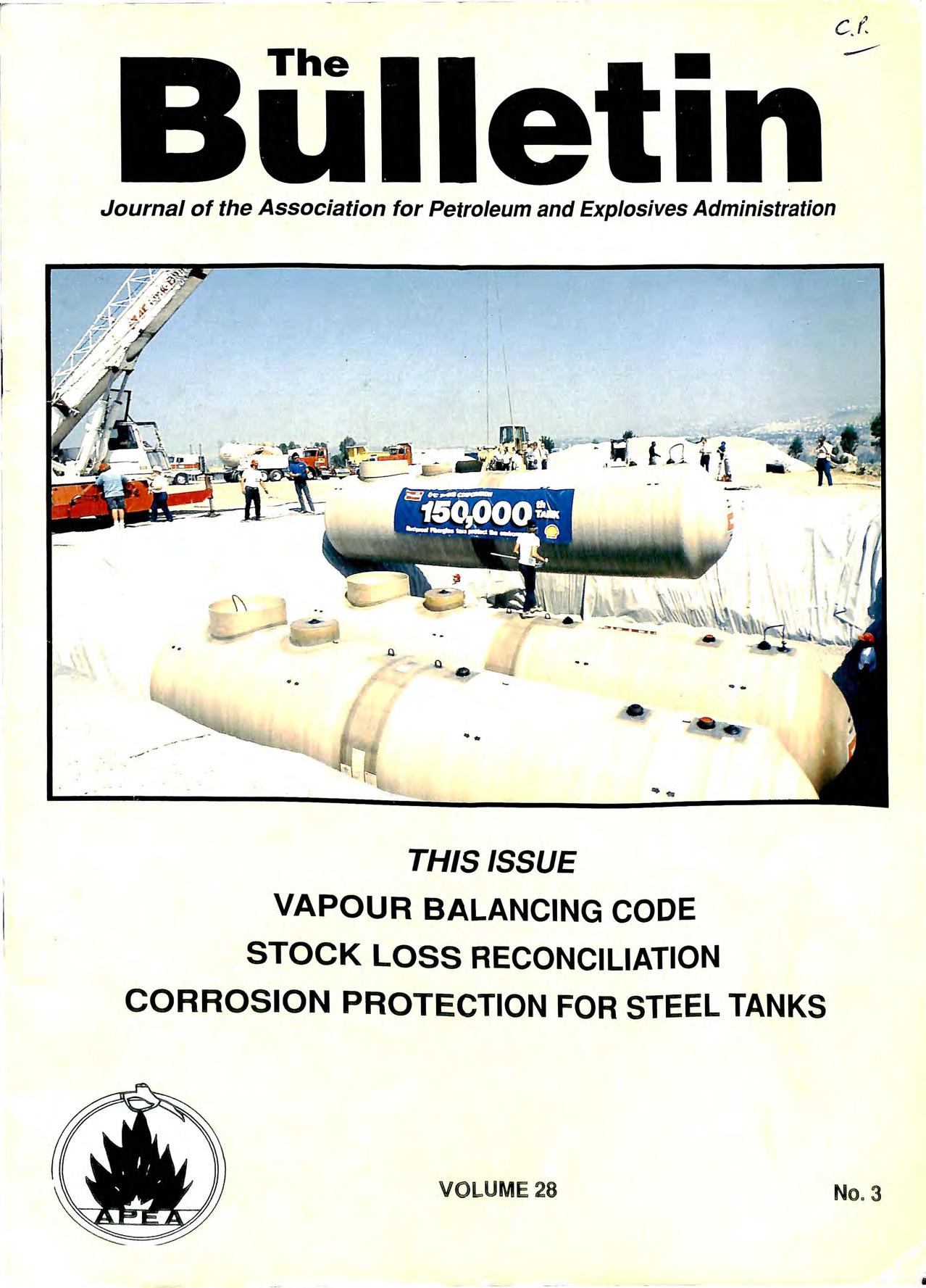

G.R.P. Storage Tanks

Many of our readers and members (hopefully all) will have been aware over the last 3 years of the introduction of GRP Underground Fuel Storage Tanks into the United Kingdom. The name mainly associated with this product has been Ferranti Resin Limited, manufacturing tanks of the Owens-Corning Fibreglas (R) type at their factory in Peterlee, County Durham.

Doubtless you will have read in the press about the financial problems of Ferranti International with their American acquisition as a result of which they decided to sell off non-core activities to raise finance to support main-stream electrical and telecommunication businesses. One of the valuable assets sold was Ferranti Resin Limited. This company has now changed its name to "Fibre Reinforced Products Limited" and is owned by Melton Medes. F.R. Products Ltd will benefit from the change in ownership and will continue to trade with renewed vigour as:-

FIBRE REINFORCED PRODUCTS LIMITED

To use the system drivers need to spend £25 on a special tank filler-cap.

When a car pulls up at a Tankman-equipped petrol station, a sensor fitted in the filler-cap "talks" to the robot pump and directs the driver to stop to that the vehicle is properly aligned for fuelling.

The driver then inserts a credit card. which activates the system. A mechanical hand unlocks and removes the filler-cap. inserts the petrol nozzle and charges the tank with fuel.

The robot hand replaces and locks the filler-cap and the driver"s credit card is automatically debited for the petrol delivered. The motorist can then drive off with a full tank of fuel. never once having left the comfort of the driving seat.

Mr Linsten said: "We can offer drivers the same level of service they expect of a garage staffed by human attendants.

Letter to Editor

Dear Sir,

Fibre Reinforced Products Ltd. are pleased to announce that the management structure remains unchanged and the company's commitment, in particular to fuel storage tanks. will remain as comprehensive as ever to its customers, licensing authorities and installers.

The company has now manufactured and supplied some 300 tanks for forecourt use, with a steadily increasing demand over the last year. Problems have been few. and minimal. and the ability to supply on-time at short notice has been acknowledged by customers. several of whom are now committed long-tenn users.

The initial range of single compartment tanks has also now been expanded to include multi-compartment tanks following successful completion of prototype tests agreed with the London Fire & Civil Defence Authority and the H.S.E. A number of the compartmented tanks have been installed by a major oil company and a hypermarket chain as well as several independent dealers.

For further information please contact Malcolm Griffiths or David Martin at Fibre Reinforced Products Ltd.

Robot Pumps for the UK?

Petroleum Officers may have to look into proposals for the ultimate in technology Robot Petrol Pumps that fill up the car automatically.

The system has been tried out in Sweden for the past nine months and motorists there arc so pleased with it that a national service station chain is about to introduce it at 500 garages.

The robot Tankman pumps could he on British forecourts in two or three years.

··Both we and the consumer' are delighted \\ ith the invention said Henrik Linsten. of Stockholm's Tran, Robotics. We will launch it on the llK market a-. soon a-. possible

I was delighted to see published in the May issue of The Bulletin the 's Code of Practice for Stage 1b Vapour Balancing at Petrol Filling Stations. I noted however, that is was an uncorrected draft which was printed. This is singularly unfortunate, given as it does a poor impression of the Association as well as misleading infonnation.

It I may be permitted, I will point out what I believe should be the corrections:-

Para I. I the final sentence should read "In addition. petroleum officers and fire officers "

Para 1.2 the word "recovery" should be omitted from line 3

Para 2 the numbering system is not really consistent with other paragraphs

Para 2.1 ( 1) and (2) are alternatives and to be correct this should be written·-. To prevent this occurring. vents should be either:

( 1) manifolded at a level greater than .l5m above the road tanker stand ground level or. if below ground or helo\,. 3.5m (2) fitted with an approved de,·iec to prevent tl\'ertlo\\ and product mixing··.

Para 2.2 the number 2 at the end ,)r thi' paragraph slwuld be replaced hy the word ··it""

Para 6 (3 l should read ··Before C\)nnecting the hose from the under!!rouml swragc tank to thl' road tankcr till' · of the dl'll\l'r\ slllHild l'llSUI\' ... person Ill l , ,,..

Al I I t th, ·ode the '\t)tc at thl' end of the tc\t i, t ioug i not part o ' L · innimplcte.

The first illustration is captil)Jll'd it ,h,iuld lw ·· manifold at lo\\ level not ··high IC\l'l a,; slllm n. ·\lsn. in thi' illustration. the note (2l should b,· be amc11lkd tt1 hl' ,·,11isi-.1c11t with para 2.1 ( 2 l "hich L·alls for ··an appn" "''' il'l' tu prn cnt ovcrflm, and product mi\ing'·. not an t1\l'I"11ll prC\l'lllllln d,,, IL'l' in each tan"

Finally, the sign s at the vapour connection point on both illustrations are labelled as " warning signs " Thi s could be confused with the warning label referred to in 2.1 (6) whereas they are, in fact , the " connect vapour line before off-loading" sign referred to in para 6 (3) This should be made clear in the illustrations. Referring to them as " vapour connection signs " or " vapour connection warning signs " should achieve this.

As an advocate of stage I b for petrol stations (and a contributor to thi s code) I am particularly anxious that this initiative by the Association should be seen as professional and authoritative so as to encourage a uniform interpretations throughout the UK. I hope that y ou will be able to incorporate these corrections in the Code and republish it in the next issue of The Bulletin with a suitable note.

Yours faithfully , H K M Lugg

Editorial Note

The errors were made at the printing s tage and are corrected in the reprint with this issue.

As Editor I wish to thank Mike Lugg and others who helped the APEA produce this code , from the comments already received many members have already found it useful although it had a few mi s take s

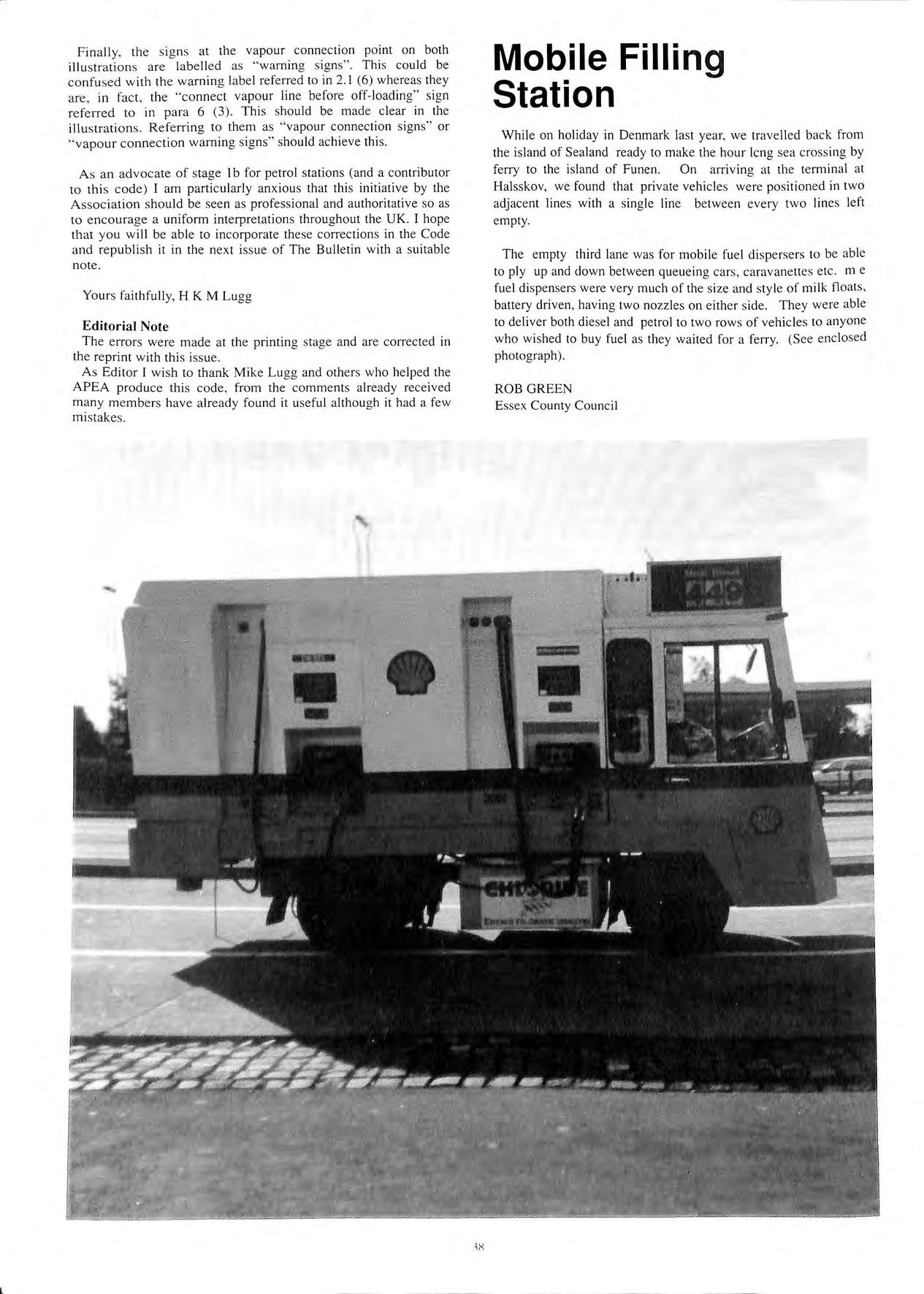

Mobile Filling Station

While on holiday in Denmark last year, we travelled back from the island of Sealand ready to make the hour Ieng sea crossing by ferry to the island of Funen. On arriving at the tern1inal at Halsskov, we found that private vehicles were positioned in two adjacent lines with a single line between every tw o lines left empty.

The empty third lane was for mobile fuel dispersers to be able to ply up and down between queueing cars, caravanettes etc. rn e fuel dispensers were very much of the size and style of milk floats, battery driven , having two nozzles on either side. They were able to deliver both diesel and petrol to two rows of vehicles to anyone who wished to buy fuel as they waited for a ferry. (See enclosed photograph )

ROB GREEN Essex County Council

ROB GREEN Essex County Council

WHY MAKE BATTERIES?

Charles Frey

Highland Tank

Manufacturing

Co. Ltd. U.S.A.

Any attempt to design corrosion protection for underground storage systems requires an understanding of the natural forces that cause corrosion. This is an attempt, in untechnical language, to acquaint you with these forces.

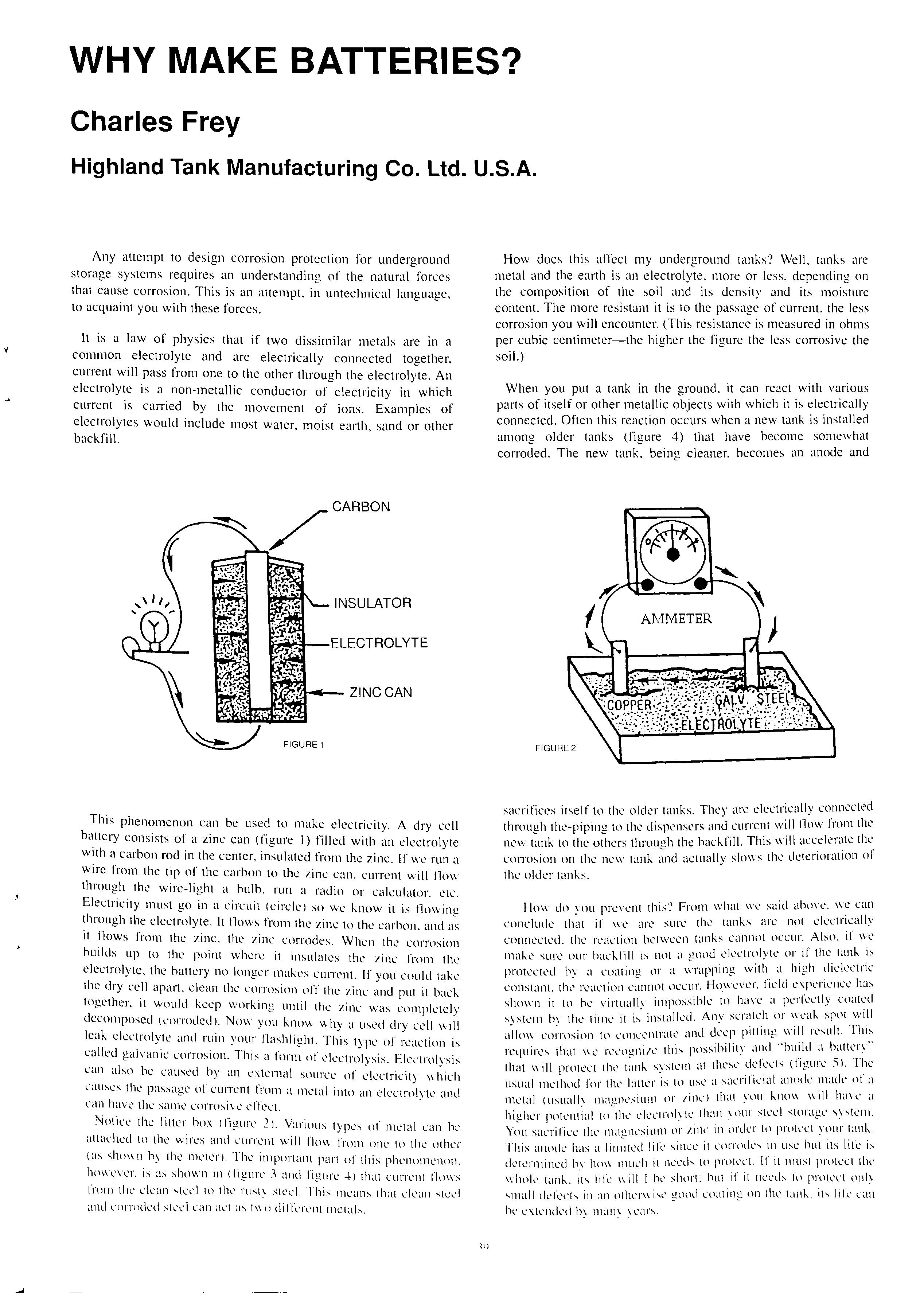

It is a law of physics that if two dissimilar metals are in a common electrolyte and are electrically connected together. current will pass from one to the other through the electrolyte. An electrolyte is a non-metallic conductor of electricity in which current is carried by the movement of ions. Examples of electrolytes would include most water, moist earth, sand or other backfill.

How does this affect my underground tanks? Well. tanks are metal and the earth is an electrolyte. more or less. depending on the composition of the soil and its density and its moisture content. The more resistant it is to the passage of current. the less corrosion you will encounter. (This resistance is measured in ohms per cubic centimeter-the higher the figure the less corrosive the soil.)

When you put a tank in the ground. it can react with various parts of itself or other metallic objects with which it is electrically connected. Often this reaction occurs when a new tank is installed among older tanks (figure 4) that have become somewhat corroded. The new tank, being cleaner. becomes an anode and

INSULATORFIGURE 1

This phenomenon can be used to make electricity. A dry cell consists of a zinc can (figure 1) filled with an electrolyte with a carbon rod in the center, insulated from the zinc. If we run a wire from the tip of the carbon to the zinc can. cu1Tent will tlow through the wire-light a bulb. run a radio or calculator. etc. Electricity must go in a circuit (circle) so we know it is tlowinl! through the electrolyte. It !lows from the zinc to the carbon. and a: it tlows from the zinc, the zinc corrodes. When the corrosion builds up to the point where it insulates the zinc from the electrolyte, the battery no longer makes current. If you could take the dry cell apart. clean the corrosion off the zinc and put it back together. it would keep working until the zinc was completely decomposed (corroded). Now you know why a used dry cell will leak electrolyte and ruin your tlashlight. This type of reaction is called galvanic corrosion. This a form of electrolysis. Eledrolvsis can also be caused hy an external source of electricity which causes the passage of current from a metal into an electn;lyte and can have the same corrosive effect.

Notice the litter box (figure 21. Various types of metal can h'-' attal'l1ed to the wires and current will flm1 from one to the other (as shown hy the meter). The impurtant part of this phenomenon. ho11 ever. is as shown in (figure and figure 4) that current lhl\\ s from the clean 'tee·! to till' steel. This mc·ans that dean steel and corroded stel'i L"<lll aL·t a' t11<1 dillnent metab.

sacrifices itself to the older tanks. They arc electrically connected through the-piping to the dispensers and current will !low from the new tank to the others through the back rill. This will accekratc the corrosion on the new tank actually slows the deterioration of the older tanks.

How do you prevent this'? From what we said above. we can conclude that if we are sure the tanks are not electrically connected. the rc·action hetwecn tanks cannot occur. Also. if we make sure our had.fill is not a good electrolyte or if the tank is protected by a L"Oating or a wrapping with a high dielectric constant. the reaction cannot occur. However. field experience has shown it to he virtual!\· impossible to have a perfectly coated svstem h\ the 1ime it is. installed. Any scratch or \\l'ak spot will ,;llow L'o;·rosi1ll1 to co1Kentrate and lkep pining will result. This requires 1hat we ren1gni1e this possibility and "'build a hallery"' that will protect 1he tank system at these defects (figure 51. The usual method for the latter is to use a sacrificial anode madL' of a metal ( usualh mal!ncsium 11r 1i11c\ that y1H1 k111111 \\ill ha\'c a higher potential to 'the L'leL·trolytl' than ynur stel'l s111ragc system. You sacrifice the mal!nL'sium or 1.inr in 11nkr to pnllc'L't \our tank. This anode has a lim,itcd !iii: since it cornidc'' in use' hut its lik is lklermined h1 ho11 mul·h it JlL'l'lb 111 prntc'ct. If it musl protL'cl till' 11lwk· tank. i.ts life 11ill I he sllllrl: hut ii it JlL'l'<b Ill protc•1·t onh small dcfeL'h in an 111hen1 ise good L'l'ating on till' tank. it-, lik can he e'1c'lllkd by many year'>.

/CARBONFIGURE3

We have illustrated that corroded steel can be a different metal new steel. Steel affected by aerobic bacteria (needs oxygen to hve) found near soil surface can be different from that affected by anaerob_ic bacteria (lives where oxygen is not available) found deeper in the soil. Unfortunately, the latter affects the steel at the bottom of the tank causing it to have a higher potential to the electrolyte (the backfill in this case) than the aerobic bacteria and the corrosion occurs at the bottom. Similarly, if the tank sits on a concrete pad, the concrete can cause the steel next to it (the bottom of the t k · an again) to have a lower potential to the backfill than the rest of th t k e an and current flows causing corrosion at the concrete pad o · · rganic matter such as scrap wood, paper, and other forms of trash f , are o ten pushed into the hole when backfilling, this can cause 1 t 1 . h · e ec ro ys1s because of the effect these substances ave on base ste 1 If h · · · . · e · t e tank is protected f rom electrolysis with coating and a d . no es, It is also protected from bacterial and other types of corrosion.

Another cause f 1 travel th · 0 e ectrolys1s comes from stray currents, which rough the g d These roun and use your tank piping as a conductor. · currents c· b which · an e caused by electric railways and street cars use D.C current . d b . d l" · an y in uced current used by pipe me

companies to protect defects in the protection on their pipes. This induced current is fed to the ground through a carbon electrode and will find its way to any defect in the pipeline's protective covering. If it finds your piping and tank a good pathway on its travels, where it leaves your tank, it can literally eat your steel (figure 6). Dielectric fittings on your tank insure that your tank is not likely to be used as a pathway by this induced current.

What determines then the life of a steel storage system? ls the backfill an active electrolyte? How good a coating does it have? ls my system connected to other metallic structures with which it will react? ls the backfill clean and homogeneous?-no trash or organic matter?

Requirements for total protection include appropriate coating, cathodic protection and electrical isolation. These are used in the sti-Po® system.

Coating-A good coating is one that is easily applied, has a high-dielectric value, can withstand field abrasion, is not affected by burial and is resistant to the product being stored. It must be applied according to manufacturer's specifications over a properly prepared surface.

Cathodic Protection-We must ass ume coating damage will occur and take measures to protect the system at any coating damage with application of sacrificial anodes or impressed current cathodic protection. In combination with a coating, as described above, it is easily and relatively inexpensive to attach sacrificial anodes. Impressed current is more appropriate as a retrofit for uncoated systems. CAUTION: Impressed systems must be professionally designed and closely monitored.

Electrical Isolation To insure that your storage system is not affected by stray currents and that your anodes are not reacting with foreign structures, it must be electrically isolated from these extraneous metals. Dielectric unions or bushings specially made for this purpose and compatible with the product stored are available.

Remember: Your anodes will react with and protect any metal (more noble) to which they are in electrical contact. Their service life is directly related to the uncoated metal surfaces to which they are attached. Therefore, you do not want them attached to foreign structures you are not concerned with (water mains , gas mains, lift bases , well casing, etc.).

Monitoring-Mo st states require monitoring of cathodically protected systems. Impressed current systems should be monitored monthly on a regular schedule. Sacrificial anode sys tems should be monitored yearly. This is especially important if the system doe s not have a good coating. Monitoring is usually very simple, taking an average of five minutes a tank. NOTE: The Steel Tank Institute does require monitoring for warranty protection within six months and then every three years, as p e r federal law. If your sti-P3.i ® tank requires monitoring by federal law. the Steel Tank Institute 's Watchdog Program will provid e free monitoring at required intervals.

Interior corrosion can only occur in a petroleum tank if it ha s a water bottom. This corrosion may be present where the dipstick or product coming through the drop tube disturbs the bottom of the tank. A 12 " square s triker plate under the fill opening effectively prevent s thi s phenomenon. All Hi ghland s ti P .i ® tank s have this feature

These steps---coating, anodes and isolation are embodied in the sti-P3c tank, as furnished by licensees of the Steel Tank Institute with a structural limited warranty (sample on request). This is the only such wananty in the industry. The cost is modest , the system pre-engineered and idiot resistant (if not idiot proof) , and gives you the strength of steel and long term protection against corrosion.

By using a special portable cathodic protection voltmeter and a copper sulphate half cell, it is easy to check the effectiveness of your anodes.

Connect the negative tenninal of the meter to the tank and the positive lead to the half cell. Then place the half cell base on the earth over the tank. A reading of .850 volts or more negative indicates protection exists. Equipment for thi s, CPV-2 voltmeter with half cell, co sts approximately $100 from Highland and may be used to check all your tanks. Complete in s tructions will be furnished.

After serving with the United States Navy, Chuck Frey returned to college and received a bachelor 's degree in Industrial Management from Duquesne University. He came to the Highland Tank, Stoystown Plant in 1956 where he spent some time setting up production standards befo re opening the Manheim Plant in 1961.

At Manheim Chuck felt the need for a more technical approach to sales to help Highland ' s customers. He made an intens e study of environmental damage due to tank leakage. He was soo n considered an authorit y on preve nting tank corrosion , having published severa l articles in trade magazines, including Fuel Oil News. He is currently active in the National Association of Corrosion Engineers (NACE); vice c hairman of the TlOA-14 Committee on protection of undergro und s torag e sys te ms and the Te c hnical Committee of th e Stee l Tank ' In stitute for which he rece ived th e 1988 Sonn e nberg Award. He i' cons ult ed by officials in many of the north eas tern as well as th e federal EPA , and is a member of th e Joint Stee ring Committee on Corrosion Control for NACE in liai son to th e Environmental Protection Agency. He ha s a lso given many seminars to groups w ho are interes ted in what causes corrosion and ho w to prevent it.

Prosecutions

HEAVY FINES FOLLOWING EXPLOSION FATALITY

Peterborough Crown Court ordered Nobels Explosives to pay £250,000 plus £92,000 costs following the van explosion in Peterborough last year.

The case follows an incident where a van, which carried no markings to indicate it contained explosives. caught fire at the Fengate Industrial Estate in Peterborough.

When the van exploded shortly after the arrival of the brigade. one fire fighter was killed and more than 100 people injured.

The company was found guilty of neglecting to ensure. as far as reasonably practicable, the safety of its employees, and of persons not in its employment, in particular Fireman John Humphries, who died in the incident.

PROSECUTION OVER LICENSEE AND CONTRACTOR ERRORS

Save Service Station Limited have a station at Whitehall Road, Great Bridge, West Bromwich. A tank was being tested on the site on 23rd January 1989. A test rig was left unprotected when the contractors left the site to obtain more Nitrogen. A customers vehicle backed into the rig, broke the connection to the tank and petrol gushed into the air. The site was made safe by Operational Personnel, Fire Prevention Officers inspected the premises and as a result seven summonses were taken out against the Company. They were heard by the West Bromwich Magistrates Court on 23rd April 1990 with the following results:-

I. to prevent the escape of petrol

Fmed £250

2. Failing to de-activate control systems when leaving the control point

Fined £150

3. to de-activate systems and close the forecourt following the spillage Fined £150

4 · Failing to display licence conditions

Fined £100

5.

such companies. This may involve having more than one person attending the site.

Two booklets are available from the Health and Safety Executive "Working Alone in Safety" which gives guidelines for contractors (and indeed persons working in petrol stations) alone, and "Safe Systems of Work" which explains procedures to be adopted in such cases. These are all available free of charge from the HSE who can be contacted on 071 221 0870 or from your local HSE area office.

H.S.E. Statement

1. A contractor involved in petroleum pipework and maintenance was fined £ 1OOO by Magistrates for failing to take steps to ensure safety during work in a filler pipe pit.

2. The case under Section 3( 1) of the Health and Safety at Work ect Act 1974 was brought by the HSE following an accident on a petrol station forecourt in which a fitted died when he slipped head first into the filler pipe pit and drowned in the 4" of liquid in the bottom of the pit.

3. The Court heard that the deceased was checking a line and was working on the non-return valve 41 inches below ground level by leaning down into the 2 foot square pit. Although other workmen were on site it was a few minutes before the incident was noticed.

4. As a result of this incident and another fatal accident involving solo working in a forecourt pit a reminder is issued to anyone who may need to enter a manole, pit, sump or similar confined space of the risks involved. In any situation where the head and shoulders of the workman may be inside an area where movement of persons or air are restricted an assessment should be made of the riskes involved in the operation to be carried out and a safet system of work devised to avert those risks.

5. In assessing the risks and drawing up a safe system of work, the possibility of a slip of fall of bumping the head should be considered in addition to the entry of hazardous vapours or gases into the pit. Any of these factors could render the workman incapable of getting out of the pit unaided. even though the pit is open at the top.

6. Failing to notify the Authority of a Tank Test

Fined £ 1()()

Failing to keep six months delivery records

Fined £I 00

7 · The view of one petrol pump obstructed by a poster on a wmdow 111 the kiosk

Fined £50

In addition costs of£ 100 were Awarded against the Company makmg a total of£ 1OOO.

CONTRACTOR FINED AFTER FITTER DIED IN PETROL TANK MANHOLE

The Health and Safety Executive prosecuted Technical and Services <Brighton) Ltd for breaches of the Health and Safety at Work Act 1974. followinl! an incident where a fitter was found dead in a petrol tank manhol; last year.

The case came ahnut following alterations 10 a Mohil filling 'tatron 111 Mitcham in London when Sean Davies the fitter working in a petrol tank manhole unfortunately died.

The company pleaded not guilty. hut after a lengthy case at Wimbledon Magistrate' Court the case was proved against the '-" impany who were fined t: I OOO with U100 costs.

lhe Health and Safety Executive an: concerned that contractor' 'arr) Ill.[! 0111 this work should he aware of the dangers involved in '' orkin.u 1n lank manholes and Dr Penny Chown of the HSE has po11J1L'd <Jill 1h;11 ,1 '><tk ')stem of \\ork ,11011ld he drawn up hy all

6. Contractors are advised that wherever work in a pit (or other restricted space) more than 2ft deep is likely an assessment should be made and a safe sytem of work drawn up. taking into account the nature and duration of the task. It is recommended that:-

Where the method of work may invove the entry of the head and shoulders into the pit a second person should be present to assist in rescue.

Whenever possible residual liquid and/or sludge should be removed from the pit prior to entry.

The atmosphere should be tested to ensure sufficient oxygen is present prior to entry.

7. Where entry into deeper shafts or pits or into tanks may be required a much more detailed system of work should be drawn up and further instruction and training l!iven to those involved.

8. Those who are responsible for premises or for letting contracts also have a part lo play in ensuring the safety of those carrying out the work. Sufficient information should be provided at an early stage to allow a thorough assessmelll to be made. Any features of the site or the task which may re4uire special attention should he highlighted. eg the depth or size of pits: and known ground conditions which may present a ha1.ard. Monitoring the safety arrangements and performance of contractors lo ensure that safe systems of work have been provided and are being used.

9. Guidance on work in confined spaces and on safe systems of work is available in the following puhlications:-

HSE (luiclancc Note GS:'i ·Entry into confined ->paL"L''- · HSE Summary Shccl SS 'Confined Spaces·

1-ISE l.caflet INDt(I 176L ·safe systcrm of work·

STOCK LOSS RECONCILIATIONS

LICENCE CONDITIONS

Brian Thompson West Sussex County CouncilSome months ago I was enjoying a pleasant drink with your editor when carelessly, (l now realise). I mentioned that my Authority, West Sussex County Council. was to update its Licence Conditions to reflect modem safety requirements. and in particular to tighten up on the condition requiring daily reconciliation records to be kept. Your editor then turned into something resembling a high pressure salesman and persuaded me contribute this article.

Background

In the previous I 8 months or so we had experienced an increase in the number and size of losses-leaks at licensed premises resulting in saturated forecourt subsoil and penetration into drains, sewers and ducting both on and adjacent to the premises, and involving unacceptable amounts of man hours spent in rectifying the problems. We therefore decided to analyse the causes to see if preventative measures could be taken.

Without question the main contributory factor was found to be the lack of adequate reconciliation records. or even if adequate records were kept, the results were not being interpreted correctly and the necessary remedial action applied.

The other major factor was that licensees with off-set fills were not bothering to check tank manholes, and in many of our investigations this was where product was found.

Remedy The existing licence conditions applicable to leaks/ losses and the requirement to keep daily records where then examined in detail and the following new conditions where drawn up.

G.13 The licensee shall forthwith send or cause to be sent to the licensing authority notice of any accident, explosion or fire involving petroleum spirit or petroleum mixture. and of any or loss, or. suspected or loss of petroleum spirit at the hcensed premises and shall without delay take all practicable steps necessary to remedy any such leakage or suspected leakage or any condition likely to cause any such leakage. accidei;t. explosion or fire and shall thereafter carry out at his own expense such works of alteration or construction as may be re4uired by the hcensmg authority to effect such remedy as aforesaid.

G.15 Due precaution shall be taken to prevent escape of petroleum spirit from .t.he premises. or into any drain. sewer or other waterway. All oil-set. tank. lme and intercepter manholes, and pump housing shall be inspected weekly for product contamination and a record of their condition kept at the premises for three months (see G.13-.

A.II The licensee shall in respect of each licensed storage tank:-

(al at least once during each working day. unless otherwise agreed in writing. ascertain the cont_ents of each compartment of tl;e tank and take a meter readmg ot each pump connected to the compartment. ensuring that no_ petroleum spirit is placed in. or removed from the compartment 111 the_ period between ascerta111111g the contents and taking the meter read111g:

thl keep at the premises records of all such contents and metn readings and of all dt'lin·ries to the tank. pnidul'lng and on the premises rel'ords for the percentage loss or' gain in ·respect ,,f each tank/n1111partn1L·n1. WherL' a loss is. in of 0. _c; OVL'r a period of a II eL'k lhL'n the \iccns111g autlmriti ,hall he 1101ifiL·d \\ itlwul dl'la1. Wlll're ii i' aL'l'L'plcd praclil'L: for Jos' reL«lllL iliations tn he 11 ithin a l1lller figure than O.'i''i. lill'n \\ hcnl'\ l'J' that rigurL' IS L'\L'L'l'lktl (ll L'r a period ol a llL'l'J,. lhL· iiL"L'll'ing au1hon11 'hall hL' notified furtlrn ilh ('iL'L' (i. I.

(c) produce such records for the last preceding three months at all reasonable times on the request of an authorised representative of the licensing authority:

(d) carry out at his own expense such tests as may be required by the licensing authority to ascertain the soundness of any tank.

The figure of 0.5% in condition A.ll(b- was chosen because it has traditionally been the ·Alarm Point' in this Authority and many others. although it was recognised that lower reconciliation percentages are used. and achieved. by a number of oil companies. It was also recognised that many non-retail keepers. such as farmers. who do not have to use weights and measures approved dispensers would have reconciliations in excess of 0.-% whilst their installations were sound. These would be dealt with by the proviso in the first line of condition A.II that an agreement in writing could be considered for such premises.

Four Hundred and Seventy Four sets of the New Conditions were sent out in February of this year to those licensees with Petroleum-Spirit storage, Two Hundred and Seventy Two of which are retail premises. A letter was also enclosed drawing their attention to the main changes in the conditions and requesting the following acknowledgment to be returned:-

* I/we' ' being the licensee/s. or in the case of a Limited Company the Company Secretary. for Licence No. issued in respect of the premises

hereby acknowledge that I/We have received. read and understood the revised Licence Conditions dated December. 1989 in respect of the aforementioned site. -I/We confirm that I/We have instructed staff accordingly and return herewith the previous Licence Conditions.

Signed Date PTS4/l

We operate a licensing system whereby the licensee retains his and attaches the yearly renewal receipt to it. By the end of the month 47'/c had returned the acknowledgement and by the ot the second month 64%. We then began the '"Chase Up and found that the vast majority of those outstanding couldn't find thell' licences. the non-retail sector being by far the binoest culprits. ' "'"'

The reaction from the retail trade has been overwhclmingl\ good 111 that they now. (if they didn't before). have a 'Datum',t<; to. Where necessary we have visited sites and offered ad1·ice and suggested formats of compiling reconciliation records. It is als,1 to note th'.ll many oil companies no11 supply ILLOnuliat1on record lormats dcsignL'd in terms of percellla!!e loss/ga111. '

.By the end of May 11e had recci1·cd four notifications from rc1ail sllcs t'\ceeding 0.5'; but in all L'<tses the c\Cl'\SL's \IL're found to be due to L·au-;e-. othL·r than kab and 11 L're I\'L'l i fiL•d. Fnur non-retail silL''- had that time alsn bL'L'll gra111L'd ".-\n .-\g1\'L'mcn1 in 11 riling" from the requirL'l11L'I11 10 tlip and otlll'r re:·ords arc being monitored 10 -.ce i r the O.'i'i is a fair ·Datum Figurl· · n1n-,idering the di-.pcnsing L'LJUipment in usL'. '

Tlw l'\L'rci-.L· ha-. illlpl'lllL'd our rl'iatin1i..hip \\ ith till' lllaj11ril\ 1it our licensL'L'' and als1i had the adtiL'ti hL·nl'l'it that ii allraL·tt:d atte111i11n 111 lhL' fonn llf RR(· South. in addition l<' being 1111 ilL'd l<' contrihutL' Ill an artiL·k i11 an oil cnn11x1n1 ·s "m magaiine. \\ hlL'h L'nabkd till' lkparllllL'nl Ill slrL'SS that 1' partnl•r,hip hc111cL·n u-, and thL· IIL'L'nscL'. a-, 11ur .Jl11nt 1s 1,1 t'n'lll\' lhal Iill' pn1dUL'l L'nlL'l'gL'' rl'lllll the Ill•//k nnJ\.

FOR PETROLEUM AND EXPLOSIVES ADMINISTRATION STAGE 1 B

VAPOUR BALANCING AT PETROL FILLING STATIONS Code of Practice

Vent pipes to petrol storage tanks provide a means of venting tanks during nonnal operation. For most of the time they allow air to be drawn in to replace petrol as it is drawn from the tank. During a road tanker delivery a large volume of vapour is discharged from the vent pipes into the atmosphere. While safety precautions are taken to ensure that ignition sources are sited away from vent pipes, fires and accidents still occur. In addition petroleum officers, and fire officers are often called to deal with complaints from members of the public about smells and alleged fire risks from vent pipe discharge.

Developments within the Oil Industry in recent years with 'bottom loading' road tankers has provided the opportunity to control vapour emissions during filling of the road tanker at the terminal (stage 1A) and also for the control at the petrol filling station (stage 1B ).

At the time of publication of this code the major oil companies have these facilities. but it is expected that others will follow. Stage I B aims to cut discharge level by at least 95% by returning displaced vapour back into the road tanker.

Instead of normal vapour discharge the vent pipes are manifolded to a vapour return line. The line is in turn connected to the road tanker by a flexible hose.

In order to provide the tank with an inlet for air and a safeguard for over pressurisation, one or two vent pipes remain fitted with a pressure vacuum valve or a flow restrictor plate. (Both these fittings still need to retain a flame arrester).

Some of_ the major oil companies are fitting these systems as they are concerned over environmental issues and at complaints from certain sites regarding vapour concentrations during road tanker some cases licensing authorities may require vapour balancmg as the only safe alternative. The APEA has_ liaised with petroleum industry and the Health and Safety makes the following recommendations 111 the mterest of safety for the fitting of such systems.

SPECIFICATION

Manifolding Vents

As vapour balancing will usually involve the manifolding of all spirit vent pipes (diesel being excluded) it necessary to prevent the contents of the tank from overflowing into other tanks in the event of an overfill situation. To prevent this occurring. tanks should be either:-

(

1) Mani folded at a level greater than 3.Sm above the road tanker stand ground level or if helm>. ground or below t2) Fitted with an appro\·ed device to prevent overflm\ and product mixing.

On retrofitting an exi;;ting ;;ite a dn·icc to prevent product m1x111g be accepted \\ ithin the velll pipl' where the pq1e' are manifolded.

(4) On new sites or where substantial alterations are to be carried out it is recommended that the overfill prevention device should be installed in the tank fill pipe. This is to avoid pressurising the tank and dispenser.

(5) Diesel tanks are not permitted to be part of the system.

(6) Where work is to be carried out on tanks which are manifolded it is essential for safety reasons that isolation from the system is made. Therefore it is recommended that a warning label should be fitted to the tank stating:

WARNING THIS TANK IS MANIFOLDED. ISOLATE TANK VENTILATING PIPE BEFORE COMMENCING ANY WORK.

2.2 Vapour Return Line

A vapour return line to be provided and fitted with a lockable spring loaded poppet valve with a flame arrester immediately behind it.

2.2.1 This prevents direct entry into the tank venting system. The spring loaded valve will normally only open after insertion of the corresponding fitting on the vapour return hose.

2.2.2 The flame arrester will stop any external fire from entering and travelling along the vapour return line to the storage tanks.

2.2.3 The vapour connection should have different fittings and be clearly labelled to prevent connection of a delivery hose in error.

2.2.4 The lowest point of the vapour return system should be capable of being drained to allow for removal of any possible condensation.

2.2.5 The system should be installed to existing standards for vent pipes and to be pressure tested on installation.

2.2.6 It is recommended that where all tanks can be filled from a single road tanker position they should be connected to a common vapour return line.

3 PRESSURE/VACUUM VALVES

Where a pressure/\'acuum valve is fitted the maximum setting should not exceed O.Spsi (3.6kpal.

4 GAUGES

4.1

4.2 4.3

Solid state probes should be suitable for this applil·atilln without modification. Hnirostatil'/pnl'umatic gauges. (il' those pump-up dial gauges. and t?lectril· systems whil'11 operate with a small comprt•ssorl will be afkctl'd by thl' fitting of a vapour balancing system.

These systems work by displacing a column of product with air. the pressure of which corresponds to the 11eight of the displaced product. Therefnrl' chang<'s in pressure within the tank \I ill affl'ct the gauge readings.

An) pump-up dial gaugl' will not he suitahk. The manuracturer should be consulted w lwre sll'llls are used as some manufal·turers are able to prm ide a simple upgrade tu meet this new rl'quircment.

OPERATIONS

The effectiveness of the vapour balancing system depends upon the correct action by the delivery driver.

The recommended sequence of events is that the vapour recovery hose should be connected up before any liquid hoses. This is to ensure that vapours will always be handled safely.

It follows that the vapour hose must not be disconnected until all the liquid hoses have been discharged and disconnected.

The objective is at all times to prevent accidental release of vapour at ground level. Only road tankers equipped for vapour balancing should be used to deliver petrol to sites with this facility.

LICENCE CONDITIONS

The Association recognises that additional licence conditions will be needed to cover the safety aspects. It recommends the following:

(

1) The vapour balancing system shall be maintained as approved.

(2) The vapour return connection shall be clearly labelled 'CONNECT VAPOUR LINE BEFORE OFFLOADING' and locked when not in use.

(3) Before connecting the delivery hose from the underground storage tank to the road tanker, the person in charge of the storage tank shall ensure that the vapour return line is connected between the road tanker vapour connection and the vapour return point.

This code of practice is provided in the belief that adherence to the recommendations will provide safe installations.

Typical vapour balancing installation with manifold at high level.

Flow restrictor or pressure vocuum v<Jlve

Vents manifoldecJ into 3" line

Vapour Connection Warning sign

Vcipour connection

Vents from tanks

Separate diesel vent -.-

Delivery fill hose

NOTES: (1) Low level manifolding may be underground.

(2) An overfill prevention device should be fitted to each tank. (see however note 2. 1 (3)).

Tzinkers

VJpour cor111ect1or1

Typical vapour balancing installation with manifold at low level.

KIMBOLTON FIREWORKS LIMITED FIREWORK MANUFACTURERS AND IMPORTERS

By Revd R. Lancaster MAC.Chem FRSC

It has generally been assumed that the Explosives Branch of the H & SE supervised the manufacture of fireworks in the UK. Manufacture has been in accordance with the Explosives Acts and the Inspectorate looked into matters if their attention was drawn to them. However the huge increase of importation into the UK created huge problems since they had to issue the importation licenses and as such be responsible.

At first testing was carried out by the H & SE but it quickly became clear that they had neither the money nor the resources to deal with this. As a consequence we now have a British Standard for fireworks and enormous problems of a different kind.

1. The Standard was put together by people who had no real inside knowledge and feel for the commercial side.

2. The firework trade did not fight hard enough to put their case.

Two glaring examples are as follows:-

A. For Garden Fireworks a testing distance of three meters was set. No spark may go more than three meters. However in practice most small wheels will throw the odd spark up to four or five meters. This means that most wheels are now off the market or they have to be classed as display fireworks and viewed at twenty five meters!

B. Good old British touchpaper must not bum more than thirteen seconds. On a good old damp British November night it will bum as long as twenty seconds even though it only burnt (say) ten seconds on testing.

Fireworks are made over the year to be sold mainly at one period and so the actual manufacture follows a two year cycle at least. In practice this means that the new BS can take up to three years to fully implement. The manufacturers and importers begged

Government to bear this in mind and make this very clear to Trading Standards Officers in particular. Some individuals has a 'field day' with the media and in some cases it was clear that the BS was not fully understood. One result since January 1990 is that one major manufacturer has decided to cease production, but carry on the name as an importer. The other result is the largest importer in the UK has decided to cease importation of fireworks and concentrate on other goods. It is particularly worrying that in the UK we have this inbuilt capacity to destroy our own industry and open the door to importation. Beef, eggs, cheese, shell fish what are we doing?

The main burden for the manufacturer/importer is testing and batching of production. This is very expensive and although civil servants have denied it has made fireworks more expensive; they are becoming more like signals. On the same basis, the insistence of classing fireworks and high explosives in the same way, we now have to move some fireworks in special vehicles with double manning. It is calculated that for over 100 kilos of l.3G, an explosive van and two men is at least£ 1 per mile.

Perhaps the biggest problem was the decision to take the BS into the EEC as an EEC standard. It means that the present BS is frozen and cannot be changed and that now we have gone through all this trauma and 'burden and heat of the day', the whole thing will be change again. One thing is certain, the French and the Germans do no like the BS and intend to change it!

Finally a plea. We all agree that there should only be fireworks of good quality on the market and the industry is doing its best. Can we ask all individuals do be really sure of their facts before they speak and give us the time to do our best to produce a sensible result with the EEC. Above all protect British business.

Corroshield System 80 tank rehabi Iitation is not a repair or temporary solution: (it is new tanks for old) backed by our guarantees extended for as long as you require

COMMERCE HOUSE, THE MALTINGS STATION ROAD SAWBRIDGEWORTH , HERTS. CM21 9JX Telephone : 0279 723448