Journal of the Association for Petroleum and Explosives Administration

The •

VOLUME 29 No.3

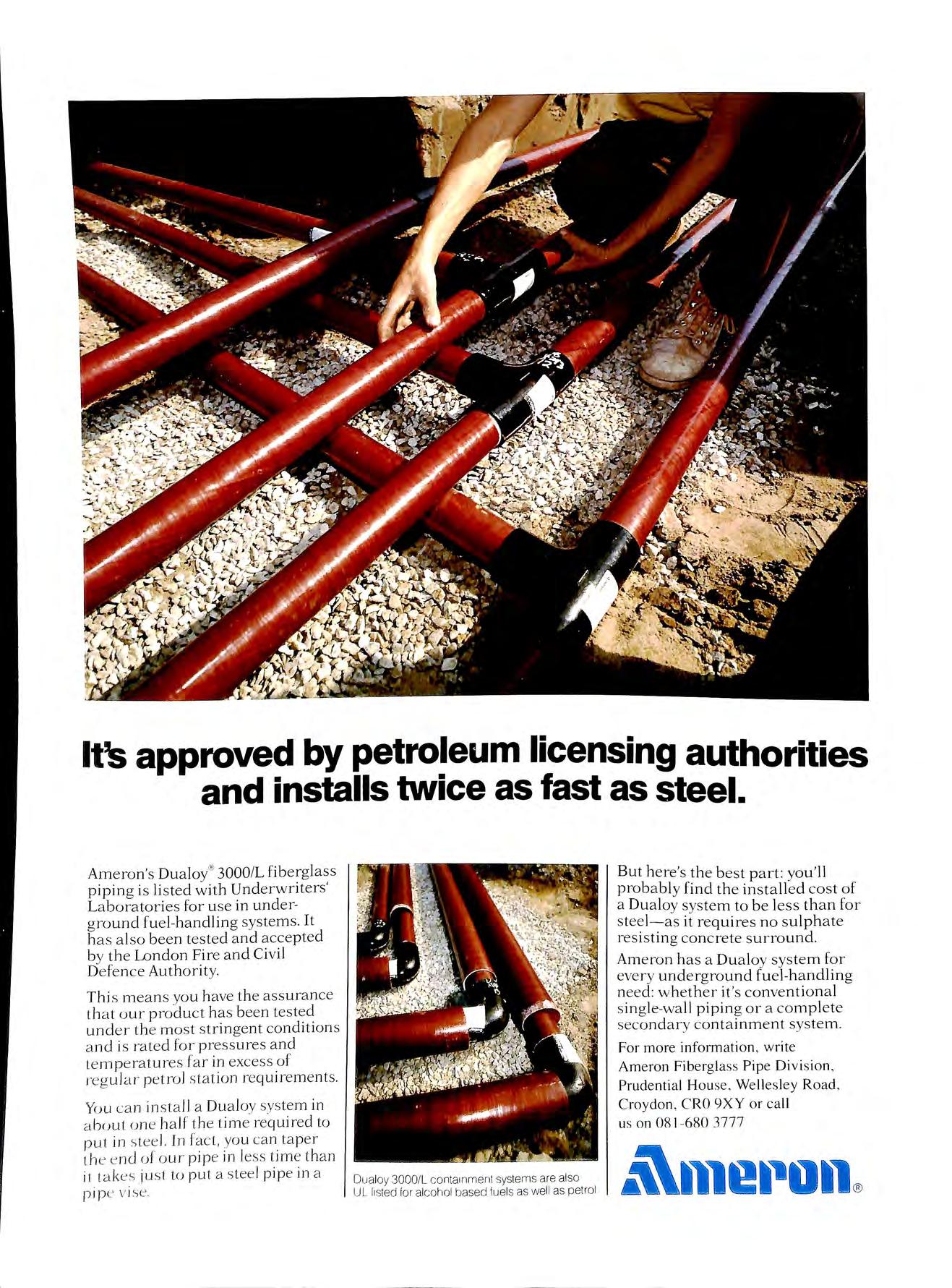

Arn ero n' s Dua lo/ ' 3000/L fiberglass pipin g is li s ted w ith Unde r wr ite r s' La b ora to ri es for u se in und e rgro und fu e l-hand lin g syste m s It h as a lso b ee n tes te d a nd accepte d by th e Lond o n F ire an d Civil De fe n ce Authorit y.

Th is m ea n s yo u h ave th e a ss u ra n ce th a t o ur p ro duc t h a s bee n te s te d un d e r th e m os t s trin ge nt co ndi t io n s a n d is rate d for p ress ures a nd Le mp e rat u res fa r in excess o f reg ul a r p e t ro l s ta ti o n req ui re m e nt s

Yo u ca n in s ta ll a Du a loy sys te m in a bo ut o n e h a lf th e tim e req ui re d to put in s Lee l. In fa c t , you ca n ta pe r th e e nd of o ur p i pe in less tim e th an it ta kes j u s t to pu t a s tee l pi p e in a p ip e v ise.

But h e re's th e best part : you 'll prob a bl y f ind the inst a ll e d cos t of a Du a loy sys tem to be less th a n fo r s tee l-as it re q ui res n o su lph a t e re s is tin g c oncrete surround Am ero n h as a Dua loy sys te m for every und e r g round fu e l-h a nd lin g need : w h e th e r it's conve nti o n a l s in g le wa ll pipin g or a co mp le te seco nd ary c ontainme nt s ys te m Fo r m o re inform a ti on , w rite Arn ero n Fibe rg la ss Pipe Di v is io n , Prude nti a l Ho use , We ll es le y Road , C ro yd o n , C RO 9XY or ca ll us o n 08 1 68 0 3777

It's approved by petroleum licensing authorities and installs twice as fast as steel.

Dualoy 3000/L containment systems are al so UL listed for alcohol based fuels as well as petrol

C p INSTALLATIONS LTD. (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all work associated with Forecourt Pipework Ameron approved for Fibre Glass Installations 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS6 7XN Tel: 0268 781184 / 781859 (24 hrs ans) Fax: 0268 776697 PHONE: 071-739 9538 FAX: 071-729 6108 TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET, LONDON E2 6QQ MEMBER A .P.E.A.

1:JiW. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial Above and Below Ground Supply - Test - Exchange - Service - lnstal Product Transfer De-Watering Removal Purchase Tank Demolition Removal Safety Filling Large Stocks of New and Secondhand Petrol and Diesel Pumps, Tanks and Accessories DAVB ROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINITY WORKS, BOURNE END LANE, HEMEL HEMPSTEAD WJ FINCH LTD (INSTALLATIONS and CONTRACTORS) Regd. Office: STONE CROSS GARAGE PENKRIDGE, STAFFORD ST19 SAS 0442 872296 Tel: 0785 715777 Fax: 0785 714123 OFFERING A TOTAL SERVICE COVERING ALL ASPECTS OF FORECOURT REQUIREMENTS, RANGING FROM CONSTRUCTION & INSTALLATION OF COMPLETE NEW BUILD OR REDEVELOPMENT, WITH FULL DESIGN & BUILD OPTION, TO GENERAL PIPEWORK & PUMP-TANK INSTALLATION & TESTING, IN ADDITION TO OUR GENERAL SITE MAINTENANCE WORKSa ESTABLISHED 1964

TAMES LUKE ASSOCIATES Safety & Training Consultants to the Petroleum Retail Industry <• . shlWiee < SALUK/ HOUSE 4 BURNT COMMON CLOSE RIPLEY, SURREY GU23 6HH Tel: 0483 222946 Fax: 0483 211328 jobn Btgfull & <!Co. Jltb. FIRST HANGINGS BLABY ROAD ENDERBY LEICESTER LE9 SAQ Telephone (0533) 862287 Fora Comprehensive service for liquid fuel & LPG installations Consu/Jancy, design, installation, maintenance & decommissioning Gasafree certificates Site surveys LPG vessel 5 & 10 year inspections MEMBER APEA, LPGITA DESIGN FUELLED B EXPERIENC Personal atte nti o n in design & developm ent for the petrol e um retail industry • Principal with over 25 years expenence • Project Manage ment specialists • Pro g ressive & innovative outlook •Consultants for statutory & planning re quire ments •C ompre h e nsive o r tailored se rvice to s uit PLANACOURT Planacourt Limited PO. Box 27 Billeti cay Essex CMll 2ES 0277 630868

The Storage Tank Specialists Established since 1857 "'ENVIROTANK" • Single and double skin petrol and diesel tanks • Above ground double skinned and bunded tanks • Galvanised tanks • Rectangular tanks • Cylindrical tanks • Site erected tanks JOSEPH ASH STORAGE TANKS Storage tanks for all purposes Tel: 021 622 4661 P.O.BOX 16, CHARLES HENRY ST., BIRMINGHAM 812 OSP Telex: 337978 GALTAN, Fax No: 021 622 1402 0

C·S·STANSFIELD MECHANICAL SPECIALISTS IN FORECOURT PETROLEUM INSTALLATIONS SERVICES Unit 10 Boundary Road Industrial Estate Sturmer, Haverhill Suffolk, CB9 7YH Tel: 0440 712505 Fax: 0440 712506 BELHAN CONSTRUCTION CO LTD Building Contractors (Est 1970) Comprehensive Development and Maintenance Services By Petrol Station Specialists 60 Connaught Gardens Shoeburyness Essex SS3 9LR Tel: 0702 295197

MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 071 800 4651 Specialists in Petrol Filling Stations D. & S. Leggett (Electrical) Limited ELECTRICAL CONTRACTORS NICEIC APPROVED 181 VICTORIA ROAD, NEW BARNET, HEATS. Telephone: 081 441 3958 Fax: 081 449 3470 SPECIALISTS IN PETROL STATIONS

EDWARDS (Tank Cleaning) Ltd THE COMPLETE FUEL TANK SPECIALIST PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED Cold cutting specialists Garage demolition Difficult location heating tanks removed Fuel tank inspection Non-destructive testing Written reports Slurry filling Gas free certification Fuel uplifting, using specialist pumping equipment All work to strict petroleum and HSE legislation *EXPERT ADVICE GIVEN FREE= APEA MEMBER * EDWARDS (Tank Cleaning) LTD 128e130 CHURCH STREET, CROYDON, SURREY, CRO lRF 0816869775 m 0816801890

Just one Teleflex flexible connector replaces these five elbows to configure an adequate 90° swing joint. ONE FLEXIBLE CONNECTOR MAKES ALL THE RIGHT MOVES. FOR SAFETY FOR EASY INSTALLATION FOR COST EFFECTIVENESS Underground storage are _only as safe as their weakest link. And piping hnked with swing joints means you're in for trouble down the line. Make the move to Teleflex flexible connectors. ...... ffi ®Telaflo PEI ••fluid systems--=-One Firestone Drive, Swffiela, CT 06078 Telephone (?03) 668-1285 FAX (203) 668-2353 Call or write for the name of the TELEFLt;X distribut0r in y0ur area

... DEWCO OIL SERVICES LTD POLLUTION CON NATIONAL 24 HOUR SERVICE IN RECTIFICATION OF SPILLAGES INVOLVING OIL PRODUCTS EMERGENCY 24 HOUR: 081-805 1856 GENERAL ENQUIRIES: 081-804 1095 INSTALLATION, COMMISSIONING & SERVICE OF SPECIALISED LEAK/SPILL PREVENTION EQUIPMENT ASSOCIATED WITH PETROLEUM PRODUCTS ENQUIRIES PLEASE CONTACT: DEWCO SALES & MARKETING DEPT. DEWCO OIL SERVICES LTD DEWCO HOUSE, 587 HERTFORD ROAD, ENFIELD WASH EN3 5UL Tel: 081-804 1095 · 081-804 7677

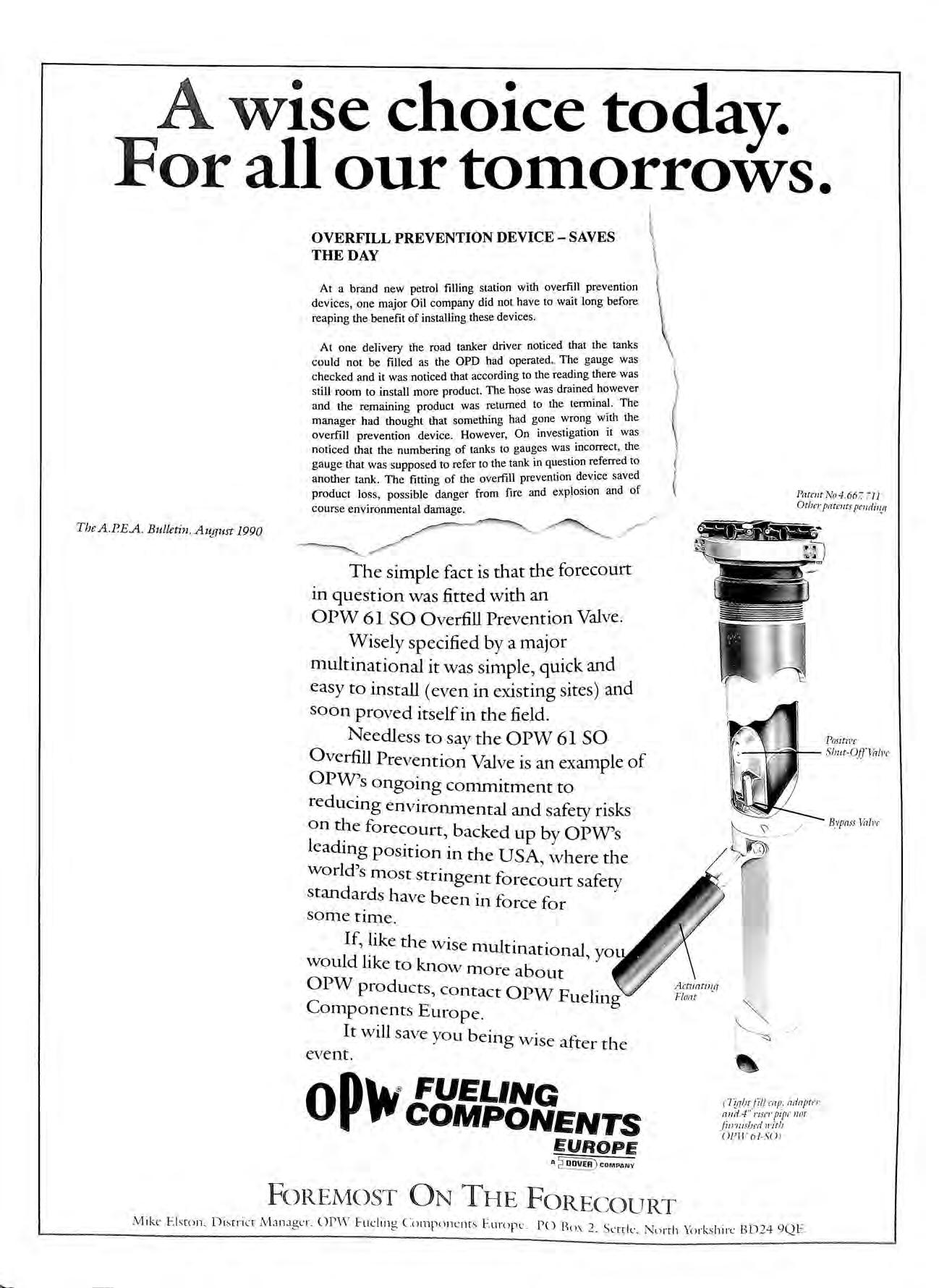

No doubt you've experienced the fact that most nozzles leak after the customer has reached his required fuel level, which results in a messy car and forecourt and a very unhappy customer (especially if he is filling up with diesel.)

The OPW llA nozzle is different

As soon as yo u pick it up you'll notice the new lightweight but robust design enabling easy one hand operation.

You'll appreciate the unique automatic shut off valve which virmaliy eliminates leaks on the forecourt, and, yo u' ll quickly d etect a special control

mechanism which ensures an accurate 'top off' with a gentle shut off

All reasons why, when you specify OPW, you benefit from the years of experience that have made us No . 1 in the Industry.

Op.hi FUELING P COMPONENTS EUROPE A DOVER ) COMPANY FOREMOST ON THE FORECOURT

Europe PO Box 2. Settle North Yorkshire BD24 9QE

Mike Elsron , Disrricr Manager, OPW Fueling Componems

Within the USA the tank replacement programme is being enforced by many States to combat the problems caused by leaking tanks. This in tum is having an effect on the small operator. These operators are now proposing that their new tanks should be above ground where they will not cause the environmental hazard they would below ground, and in a few cases this has been agreed.

This is one area where it could be claimed that Cyprus have beaten the USA on the front cover a petrol station which has an above ground tank, suitably labelled, with vent, tap and measuring equipment and you can see if it leaks!

Bulletin

by the Association for Petroleum and Explosives Administration VOLUME, 29 Number 3 August 1991 £5.00 (Free to Members) Contents TALKING POINT NOTES&NEWS

40 41

Talking Point SAFE WORKING IN TANK MANHOLES 44

The

Published

A company Limited by Guarantee registered in England No. 2261660 Reg. Office: Stoughton House, Harborough Road, Oadby, Leicester LE2 4LP ISSN 0263 4597

Opinions expressed in this Journal are not necessarily the views of the Association

LETTERS TO EDITOR 47 SAFETY AND ENVIRONMENTAL ASPECTS OF G.R.P. PIPE 50

SEALING BLOCK PAVING PUMP VISIBILITY APPEAL NEW MEMBERS HUMBERSIDE BRANCH J. Horsburgh EASTERN BRANCH R. G. Green Honorary Secretary: Mr. D. Bucknall, 52 53 54 SOUTHERN BRANCH M.Cox Normand Instruments Ltd., MEMBERSHIP SECRETARY B. J. Thompson MIDLAND BRANCH Mr. L. Lloyd CMS Ltd. ADVERTISING SECRETARY J. Luke 4() Honorary Editor: Mr. J. A. J. Thompson,

notes and news

SEMINAR

The APEA INTERNATIONAL PETROLEUM seminar will be held on 24 September 1991 and the programme has now been completed and will be titled:-

PETROL FILLING STATIONS ENVIRONMENTAL CONCEPTS -THE WAY FORWARD

The Exhibition will be open during the 24 September and also from 2pm till 6pm on the Monday 23 September which will enable those travelling longer distances to view the products and have longer to discuss matters with exhibitors. Members are advised to contact the secretary to book places, £30 for members and £60 for non members, exhibitors may contact the advertising secretary for details about exhibition space. Delegates in order of receipt and in order to avoid bemg d1sappomted please book your place early.

08.30 Exhibition opens, registration of delegates.

09.00 Coffee 09.50 Chairmans welcome

10.00 Conference opened by Special Guest

10.15 Morning session Chaired by J Thompson LFCDA

The USA experience

A Regulators view Jim Pim, Suffolk County NY

A Consultants view Joyce Rizzo, Lexicon Env

The European Experience

An Oil Company View Caas Zaalberg, BP Europe

A Manufacturers View Tony Bartles, Cambrian Plastics

12.15 Lunch and exhibition

14.15 Afternoon Session chaired B. Taylor, Chairnrnn

SOME PRODUCT SOLUTIONS

Flexible secondary contained pipe Marc Guindon. Enviroflex

Precision Tank and Line Testing Rob Fee. Tanknology

GRP pipe solutions Richard Graham, Ameron. Leak Detection and Location Rick Smith, Red Jacket

l5.45 Open Forum

17 .OO Exhibition and conference closes

PIPE JOINTING PR<?BLEMS CONCERN

The pipe c.ompound used · ly for steel pipes has once agam raised concern. In extensive · London area recently the p1pew?rk at a large the 1 nt had to be completely dismantled as the redeve opme d I d not set properly and ended up white and compoun 1a ft" h d · d I d . F rtunately the petroleum o 1cer a notice t 1e pow e1y. o I t' h ·ff . d refused to accept t 1e JOmts: urt er d1 erence ctn . · · · ·eve·t!ed the whole site was affected and 111vest1gation 1 ' . similar batches made up elsewhere also did not set p1operly. The suppliers of the compound are not able to satisfactory answer but installers should che.ck with then suppliers on how to mix the compound. A similar 3 years ago resulted in at least four recently stations leaking and having to be dug up with Imes bemg replaced.

STEEL TANKS

Authorities in the Midlands have reported the recent failure of some new double skin steel tanks, the problem it would appear have all been holes in the plate all the problems have been picked up in the testing process of the tanks.

GRPTANKS

Cambrian Plastics have announced the introduction of a new GRP petrol tank from their factory in Bridgend Glamorgan. The company who have for 24 years manufactured tanks for the chemical industry make their tanks on a helical winding process which they claim is stronger than other methods in use in the UK. The company also offer double skin GRP tanks and they use no filler in the construction of their tank.

Klargester who have been manufacturing single skin tanks have also just announced the launch of a double skin GRP tank. Both companies tanks have passed the prototype tests required by the HSE.

PETROL FILLING STATION GUIDE TO EMPLOYEES

The HSE has published a free leaflet for persons working at petrol filling stations covering a number of essential items:-

1) The dangers of petrol 2) Information the employer must supply 3) The Training the employer must supply

4) Personal Safety

5) How to dispense petrol safely

6) The duties of the person at the pump controller.

Copies of the leaflet may be obtained from trade associations, licensing authorities or the HSE Public enquiry points in London 071-221-0870 or Sheffield 0742 752539

GARAGE CODE

The Code of Practice for Ground Floor, Multi Storey and Underground Garages has been published by the Association for Petroleum and Explosives Administration.

The Code provides much needed guidance for architects designers and engineers, into the additional requireme lt. : b . 1 . I s needed to o tam a petro eum licence under the Petrol "d · ) A 1928 eum (Consoli at1on et .

The code provides guidance in a number of i111 ·t L bb p01 ant areas:- _o y separation. ventilation. drainage. means of escape etc. In add1t1on 1t lays down th 1 d ·d. f 1 . l .1 e s ctn ai s or mec rnmca vent! at1on for combined syste t' 1 . · · ms or petro vapour and smoke extraction.

The code also provides some lIIlI·t·011111 1 d 1 y m stan arcs across the country for petroleum lice11s111g tl · · . · au 1ont1es.

The Code of Practice tor Ground F\l)Or M It. S 1 . u 1 torey anc Underground Car Parks 1s available from

Hon Secretary APEA

Mr D Bucknall

Humberside Trading Standards

King Edward Street

Grimsby

South Humberside. DN3 \ 3Lll

Tel. 0472 341344 Fax. 0472 240529

Price: £5 for members. £I 0 non members

-II

THIRD-PARTY TESTING CERTIFIES VEEDERROOT UNDERGROUND STORAGE TANK MONITORING SYSTEMS; RESULTS

EXCEED U.S. E.P.A. REQUIREMENTS

Veeder-Root Underground Storage Tank Monitoring Systems have been certified by third-party testing to meet Federal performance standards established by the U.S. Environmental Protection Agency for Volumetric Tank Tightness Methods (capable of 0.1 gallon per hour leak detection) and for Automatic Tank Gauging Systems (capable 0.2 gallon per hour leak detection).

Third-party testing, only recently required for UST monitoring systems, confirms UST leak detection capabilities and prevents manufacturers from making unsubstantiated performance claims. Proof of third-party certification is required by law to be furnished to the system owner/user and kept at the system location for inspection by regulatory officials.

The test results showed Veeder-Root TLS-250, TLS-250i and TLS-350 Systems, when connected to Veeder-Root's new Series 8473 Magnetostrictive Probe or new Series 8472 Capacitance Probe, to be capable of detecting leaks as small as 0.1 gallons per hour with a probability of detection [P(D)] of 99% and a probability of false alarm [P(FA)] of I%.

These results exceed the Federal performance standards of 0.1 gallons per hour with a P(D) of 95% and a P(FA) of 5% set for Volumetric Tank Tightness Testing Methods.

Federal performance standards for Automatic Tank Gau cres are 0.2 gallon per hour leak detection capability with a PCD) of 95% and a P(FA) of 5%. The test results showed TLS-250 TLS-250i and TLS-350 Systems using the standard 7842 Capacitance Probe, new Series 8472 Capacitance Probe new Series 8372 Magnetostrictive Probe to be capable of P.(Fgallon per hour leak detection with a P(D) of 99% and a A) of 1%.

All testing was conducted by a nationally-recognized research instit t .d t . . u e, cons1 ered to be a leader in third-party estmg m the United States.

For copies of th t I . . 250 T e est resu ts or more mformat1on on TLS' LS250i and TLS-350 UST Monitorincr Systems contact Al o · ' Fax 038 an Chandler, Veeder-Root Ltd. Tel. 0382 833033. . 2 832382.

PR20FIT, A LOSS AND A FINE

n 6th June 199! S

Garages Ltd le at Magistrates' Court P.D.H. Petroleum (C. P guilty to two charges under the County C · Act 1928 brought by West Sussex b ouncll Trading St d d reaches of th an ar s Department concerning The incident e conditions of their petroleum spirit licence. at the corn occurred between October and November 1990 pany's L · West Sussex Th ancmg Manor F11lmg Station, Lancing, failed forthw:th e company were charged first, that they any leakage 1 1to send to the Licensing Authority notice of spirit and or oss or suspected leakage or loss of petroleum the p;·emiseseco1n_d1' that they failed to produce and maintain at · s c a1 Y records f th petroleu · or e percentage loss or gain of m spmt m respect f h 1· corn · o eac 1censed storage tank. The Pctny were maint· . . d not c·irr · ammg a1ly dip and meter readings but condit'. ymgf oui the reconciliations as re4uired by their f 1 Ions 0 licence. The company was fined £600 on each o tie charge d . . s an were also ordered to pay £80 towards p1 osecut1on costs. a total of£ 1,280.

The offence came t th L. . . , . 1 ( o e 1censmg Authority s notice on 1 Jth Novemher l 9l'() ·fi · . .,. upon not1 1cat1on from an architect that a suction lme was 1 h . 1. d h . . _. · o e 1ep ace ecause 11 was leaking. f .x<1m1nat1on of the "'records" revealed thal a loss was apparent on 8th November, and officers calculated a loss of I I! 7'1'/r for the previous week on the tank concerned.

rlw line in 4uestion remained in use until 25th No\ 1:n1her'

APEA PRESENTS SESSION AT ITSA CONFERENCE

The integrity of petroleum storage and distribution systems is critical to the safety of the public and the environment. Improvements in tank and pipeline construction and materials, together with a new approach to stock monitoring offered by new technology, can provide significant new safeguards. However, only close cooperation between the petroleum industry and enforcement agencies will ensure that the benefits available are actually realised.

The Institute of Trade Standards Administration (ITSA) working together with the Association of Petroleum and Explosives Administration (APEA) hosted a special seminar to discuss the safety and environmental implications of the technical breakthroughs.

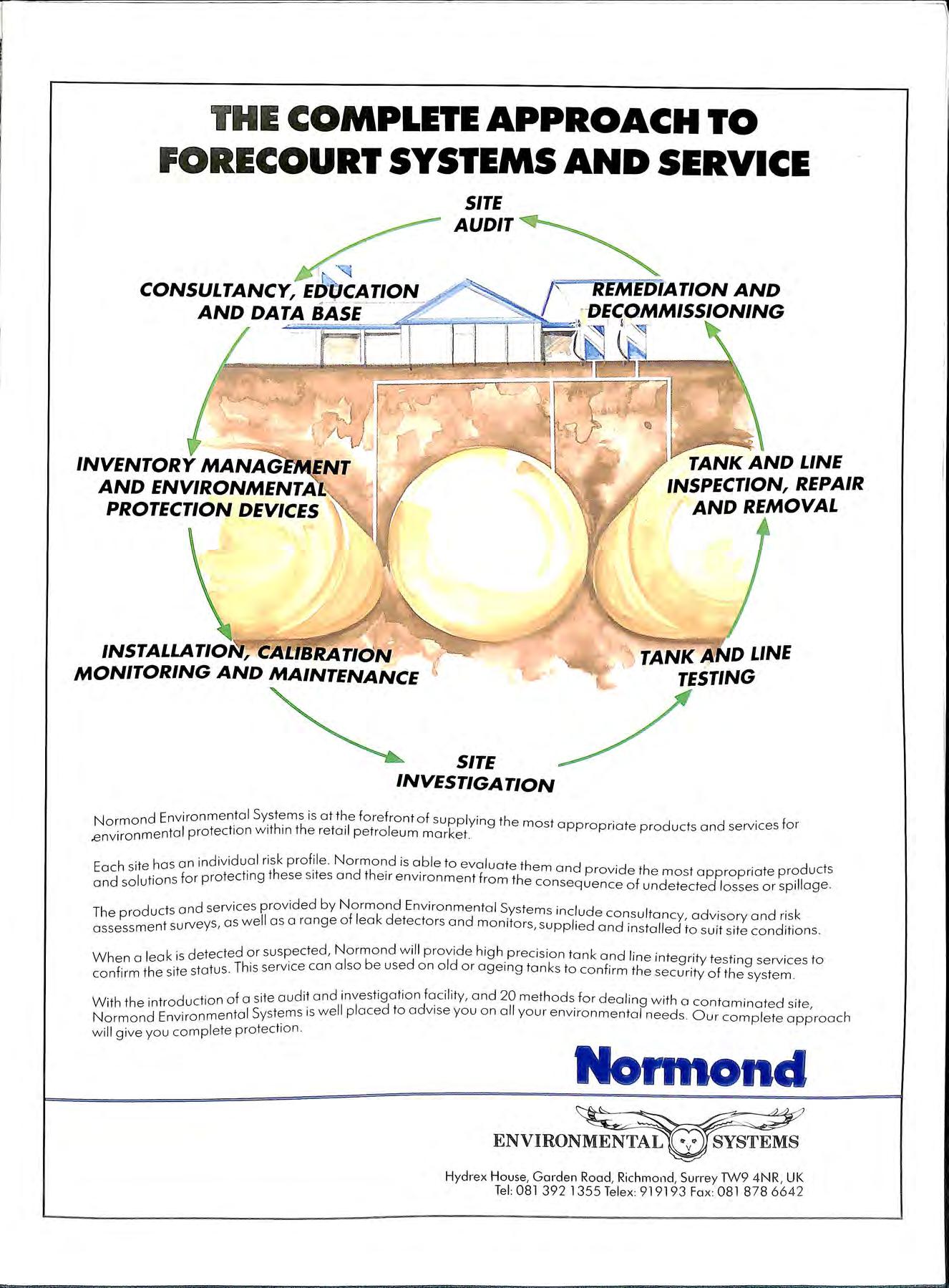

The seminar took place on Thursday 4th July, during ITSA's Annual Conference in Rotterdam. Speakers are Barry Goldsmith, BP's European Engineering Manager, Joop van Gent of Ameron BY, Geldermalsen and Dr Robert Bridges, Director of Normond Environmental Services, UK.

The session was under the Chairmanship of Brian Taylor, Chairman of APEA, and was attended by some 50 members of the APEA who attended for the day, together with many other members of industry and ITSA.

PETROLEUM OFFENCES FINES INCREASE

The maximum fine for health and safety offences in the magistrate's court is to be increased from £2000 to £5000. The government has also agreed to introduce to give magistrates the power to fine up to £20,000 for senous breaches of the Health and Safety at Work Act (1974). However, this cannot be implemented until the proposals are scheduled into the parliamentary legislative programme.

The new fines were announced by the Health and Safety Commission at the launch of their plan of work for I/92. At present, the average fine is £877 the HSC would like to see a substantial increase in this amount.

The HSC's Director General John Rimmington, explained that this would bring health and safety penalties into line with environmental protection legislation: 'It seems utterly wrong . h . t c·rn be worth that offences agamst t e natural env1ronmen ' more than offences against human life. We were getting. to tt!1e .f . h'gher penalties or situation where the law was spec1 ymg 1 Id I , H , !so said he wou the death of bluebells than for peop e. e a · . . I t d i·n senous cases. ltke to see md1v1dua managers sen ence

NORTH YORKSHIRE'S TSOs TO PRESS GOVERNMENT FOR TIGHTER FIREWORK

CONTROLS

ress for

Consumer officials in North Yorkshtre are to P 11 the Government tighter controls on fireworks. They WI urge t· tl ·ee f f ·ks rom 11 to reduce the pennitted sale period o 1rew01 · d ·ilso to restrict weeks before Guy Fawkes Night to two, an ' · banger sales to selection boxes. North Yorkshire County Council will enlist the support of the area's MPs in an attempt to get restrictions to cut the number of injuries._ Id

The Council's Public Protection Committee wc1s to N ber recently that more accidents occurred before 5th ovem than on the day itself, and bangers accounted for 20o/c of all injuries. Last year, 805 people were hurt nationally, .but Yorkshire health region recorded the second-highest figure Ill the Country for eye injuries and third-highest overall. at 17.4% of the total.

County Trading Standards Officer Gordon Gresty said 223 registered outlets in North Yorkshire had been contacted. He said there was clear support for tighter controls. and particularly control over bangers. Few outlets limiting the sale of fireworks to a few days before Bonfire Night. but the majority were in favour of the two-week restriction.

42

SOMERSET PETROL INCIDENT

Roaring fireballs and huge explosions rocked the sleepy Somerset village of Bradford-on-Tone at 0415 on 16 May, severing telephone lines at the level crossing and damaging power cables overhead.

The Gulf Oil train was only four minutes travelling time out of the county town of Taunton.

Residents awoke abruptly to find the nearby rail line between Exeter and Taunton engulfed in huge flames. Seven of 22 45-ton wagons of a freight train carrying diesel, petrol and kerosene had derailed and burst into flames. Two had exploded with severe force. The immediate vicinity was evacuated.

Vehicular access to the site was made especially difficult. Narrow country roads and bridges with weight restrictions of 3 tonnes (fire appliances weigh 16 tonnes) meant all needed police escort.

Tons of fuel had flooded the railway line and had worked its way into gullies, gushing up and spreading out further down the roadway. At one point, it flared up directly in front of a fire appliance fighting the fire but when the driver tried to reverse the vehicle it also flared up behind, so another appliance had to come to his rescue to put that fire out.

A police car which had been left beside the road with blue flashing lights to warn vehicles while the officers rushed to warn residents became surrounded by roaring flames. The battery was flat, but the police officer managed to push it clear and thus save it from being engulfed

At one point the fuel built up next to a farn1, burst into a huge fireball scorching the fann buildings and endangering livestock. The smoke was so thick and black, several white and cream coloured calves turned out murky brown. The fann animals were saved because of quick action by the farmer and local residents.

The fuel and flames had also worked its way into British Rail signalling and communications cable ducting , buried below the stone ballast. British Transport policemen investigating the derailment heard a rumbling noise coming toward them. Flames suddenly flashed up through the ballast, the superintendent standing beside the track said, "It nearly went up my trouser leg!" The ducting problem persisted for several hours after the main fire was extinguished.

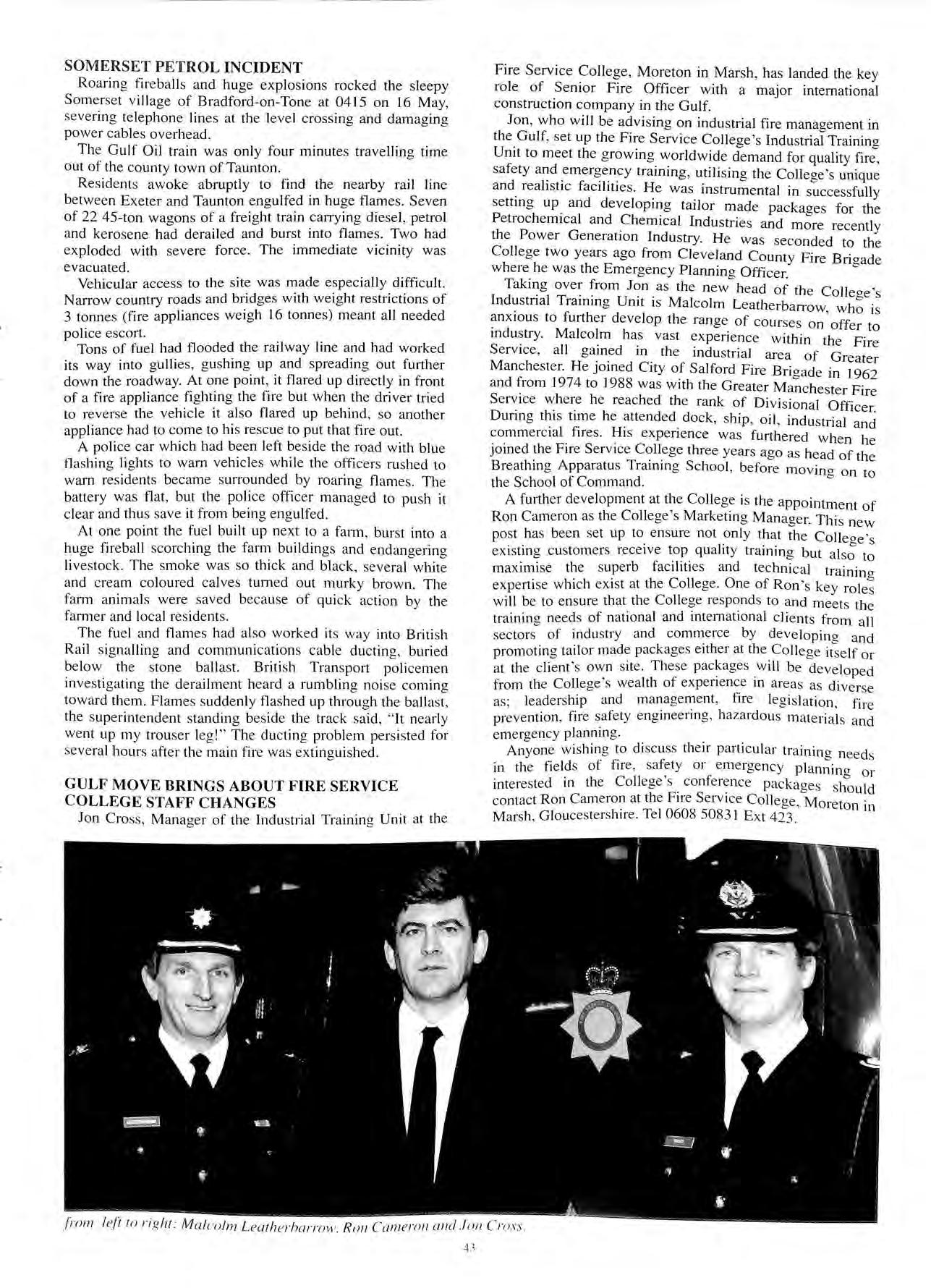

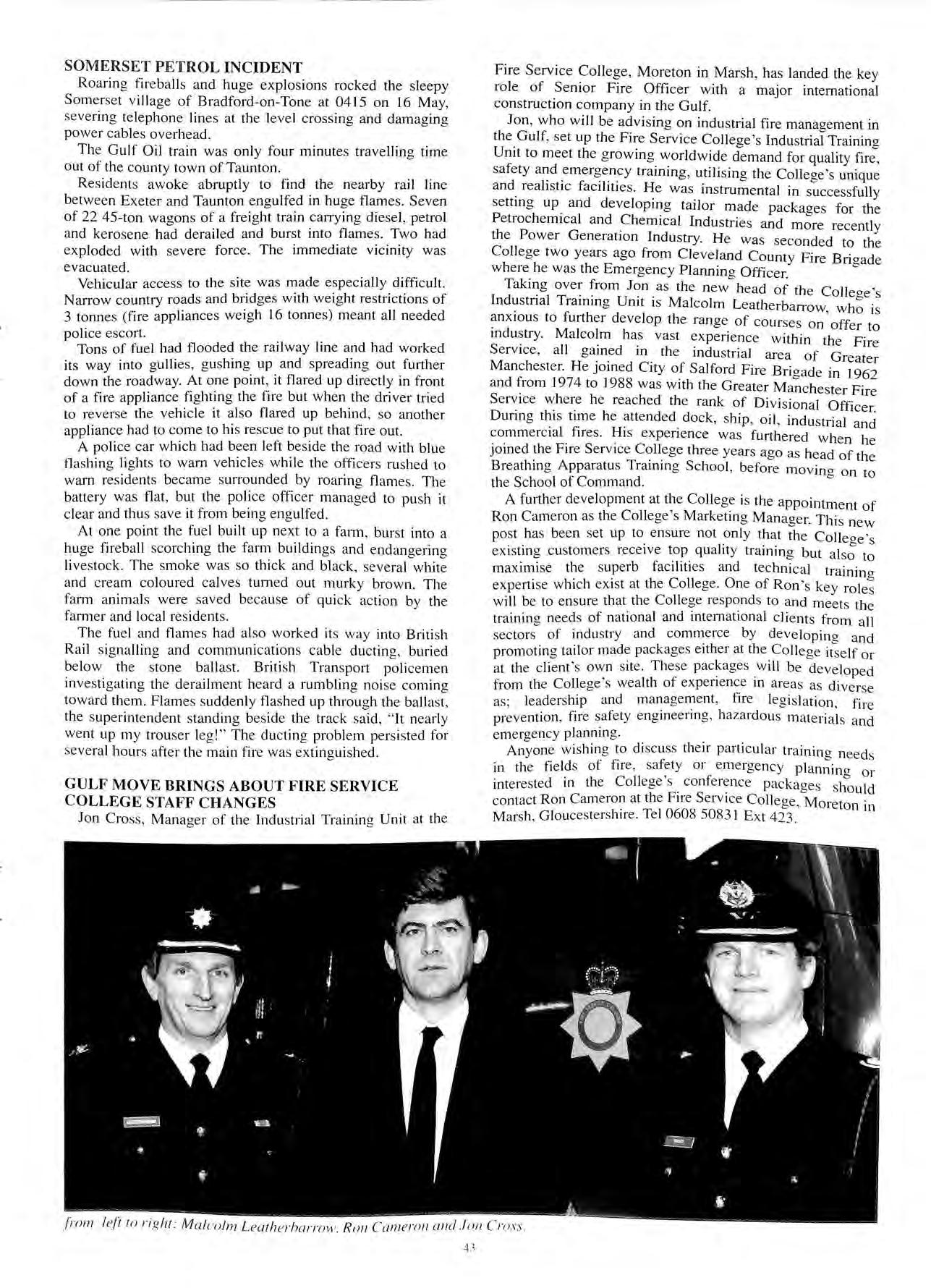

GULF MOVE BRINGS ABOUT FIRE SERVICE COLLEGE STAFF CHANGES

Jon Cross, Manager of the Industrial Training Unit at the

Fire Service College, Moreton in Marsh, has landed the key role of Senior Fire Officer with a major international construction company in the Gulf

Jon, who will be advising on industrial fire management in the Gulf, set up the Fire Service College's Industrial Training Unit to meet the growing worldwide demand for quality fire, safety and emergency training, utilising the College's unique and realistic facilities. He was instrumental in successfully setting up and developing tailor made packages for the Petrochemical and Chemical Industries and more recently the Power Generation Industry. He was seconded to the College two years ago from Cleveland County Fire Biio-ade where he was the Emergency Planning Officer. 0

Taking over from Jon as the new head of the Colleo-e 's Industrial Training Unit is Malcolm Leatherbarrow wh 0 0 · . f , IS to u1ther develop the range of courses on offer to mdustry. Malcolm has vast experience within the Fire Service, all gained in the industrial area of Greate Manchester. He joined City of Salford Fire Brigade in 196; and from 1974 to 1988 was with the Greater Manchester Fire Service where he reached the rank of Divisional Officer During this time he attended dock, ship, oil , industrial and commercial fires. His experience was furthered when he joined the Fire Service College three years ago as head of the Breathing Apparatus Training School, before moving on to the School of Command

A fmther development at the College is the appointment of Ron Cameron as the College's Marketing Manager. This new post has been set up to ensure not only that the Colleo-e 's existing customers receive top quality training but als; to maximise the superb facilities and technical traininoexpertise which exist at the College. One of Ron 's key will be to ensure that the College respond s to and meets the training needs of national and international clients from all sectors of industry and commerce by developing and promoting tailor made packages either at the_College itself or at the client's own site. These _will be developed from the College's wealth of experience 111 areas as diverse as ; leadership and management, fire legislation , fire prevention, fire safety engineering, hazardous materials and emero-ency planning.

wishing to discuss their particular training needs in the fields of fire , safety or emergency planning or interested in the College's conference packages should contact Ron Cameron at the Fire Service College, Moreton in Marsh , Gloucestershire. Tel 0608 5083 I Ext 423.

Mal c olm L e arherharmw. Ron C am e ron and ./011 Cmss . 4"l

WORKING ON PETROL FILLING STATION FORECOURTS

Prepared by Mr. C. M. Broughton, Health & Safety Manager, Ferranti International pie, on behalf of the Association of Forecourt Systems Contractors.

Summary

Assessments required under the Control of Substances Hazardous to Health Regulations were underway when a fatality to an Installation Engineer brought the forecourt service operations into sharper focus. An in-depth in-house review, together with HSE input, was carried out and from the findings of the review it was decided that significant changes were necessary to our working practices and procedures.

New working practices were developed and at this stage our major competitors were contacted. The results of their research was incorporated into our study and the resultant system and justification, the subject of the paper presented at the AGM on l 6th April 1991, is outlined below.

Review

overview review of the operations were carried out and it was decided to investigate exposure to:

I) Vapour generated by service work, breaking of leaks and forecourt spillage, refuelling vehicles, measure checks and also from venting nitrogen from a tank after a pressure check.

2) Carbon Monoxide generated by vehicles, particularly s.Iow running conditions, and bei?g slightly heavier n air has a tendency to settle m manholes and chambers.

3) Oxygen Deficiency occurring because of 'natural' e.g. microbiological effects and rusting, due to use op Oitrogen from a pressure test or from high levels of etroleum vapour.

In the main 1 . . on petrol fillteop e .workmg on or associated with workmg degree of h ng station forecourts were not aware of the azards asso . d . h b monoxide · ciate wit petroleum vapour, car on The onJ or oxygen deficiency. 't L y safety crit . f 1 s ower Ex ena or petroleum vapour seemed to be app · plosive (flam b·1· ) · · Th' · rox1rnate\y 1 So/, ma 1 Ity L1m1t (L.E.L.) 1s 1s usually a sa"e · 0 in air (equivalent to 15 OOO ppm) and 1 Workm l' . ' set. This is too h'igh fg 1m1t of 20% L.E.L. (3,000 ppm) is m th or ah · e region of 300 yg1ene standard which should be exposure with a 750 for .an 8 hour all day, every day Most people seem dp lO mmute, short term exposure. 20% ox e aware th· t · Ygen howeve h a air contams approximately clear S r w at was f 1 · · · ome people th · a sa e ower limit was not he fatal even thou hought .that a l % drop in oxygen would typ1c· II g expired · a Y contains on\ 17 air used to revive people workmg limit for oxy y % oxygen. The HSE set a safe safet 'd · gen at 18°/i a d h' · · Y s1 e smce people 0 n t is 1s set well on the ·1t I(JO' can st1 II breath . lb ' 1r oxygen. a en with difficulty

.. People knew the least about C' fiom fatalities with car exh· . f arbon monoxide mamly h aust umes It most t at carbon monoxide was de · · was assumed by carbon monoxide is odourle · C· tebctable whereas in fact ( · ss. ar on monox·d h )ccupat1onal Exposure Standard th 8 h I e as an · e our ·11l day e Jay standard of .'i() ppm. However t ' . : very ' o put this mto pc:rspect1ve excursion above this to a level of 400 ppm for a 2 hour period would only lead to headaches and discomfort.

As a result of all the above it was decided that it was necessary to continuously monitor for petroleum vapour, carbon monoxide and oxygen and that monitors with audible and visible alarms would be necessary.

The range of monitoring equipment available is very wide and not all equipment is suitable. Measurement of petroleum vapour at the levels required is very difficult unless very sophisticated equipment is used.

I do not intend to cover the topic in any depth however the following points are worthy of note:

1) Employees are more likely to use one instrument rather than several. An obvious point but one often missed.

2) The lead in petrol will contaminate the sensor in many monitors. This point is not always made clear by suppliers.

3) The composition of petroleum is variable and the vapour composition will differ from the liquid. This point needs to be considered when calibrating the equipment. We are currently calibrating our instrument against Pentane.

4) The carbon monoxide sensor will respond to petroleum vapour. This point although generally to the Technical Service Departments was not commumcated to us at the time of purchase although the end usage made clear. Some sensors are more susceptible to this cross sensitivity than others.

5) The exposure to petroleum vapour is to duration high peaks (further infonnation is given 10 '1 later section) which can cause unnecessary alann conditions. A monitor is available which is capable 0: carrying out a Short Term Exposure measured over a 10 minute period which ehmmates t 15 problem.

Operations of Field Engineers

. e to Throughout the tests no significant levels 0 '. exposur the d 1 many mstances carbon monoxide were detecte · n 50 n was · et ·1t PP1 , ' carbon monoxide alarm on the morntor, s ' b d e to the h' rned to e u tripped. However m all cases t is see . h t the alarm presence of petroleum vapour. Even ass the levels was not due to the presence of petroleum pduration to be were neither high enough or of long enoug of concern.

. h 1 ncentration of At no time during the tnals was a let a dco levels were h t' ally hazar ous · oxygen measured althoug poten 1 d ·surisation detected directly in discharge one of a tank under nitrogen. More s1g111f1cdntly d . h I . ket had allowe Particular tank test a leakmg man o e gas h 1 chamber over a the nitrogen to bleed mto the man ° e . . . in period of 24 hours. Whilst the lower explosive hmi_t was. in excess of 100% L.E.L. (i.e. above J.5% petroleum vayow air) the oxygen content was still only reduced to 19.2 Yt•. Despite the above results because of the lack of with high levels of carbon monoxide and low. levels 0 oxygen it is recommended that continuous mo111tormg be carried out.

44

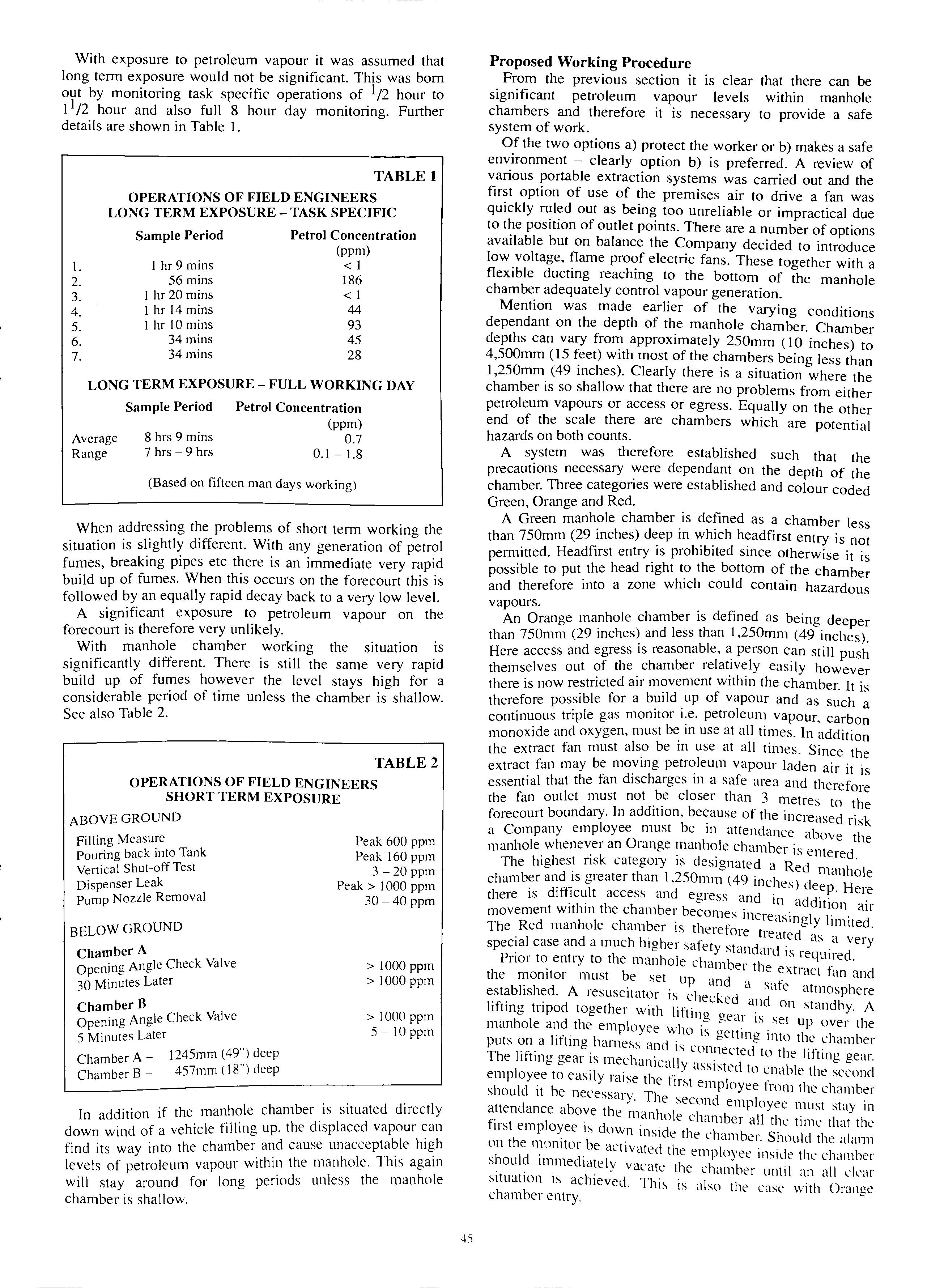

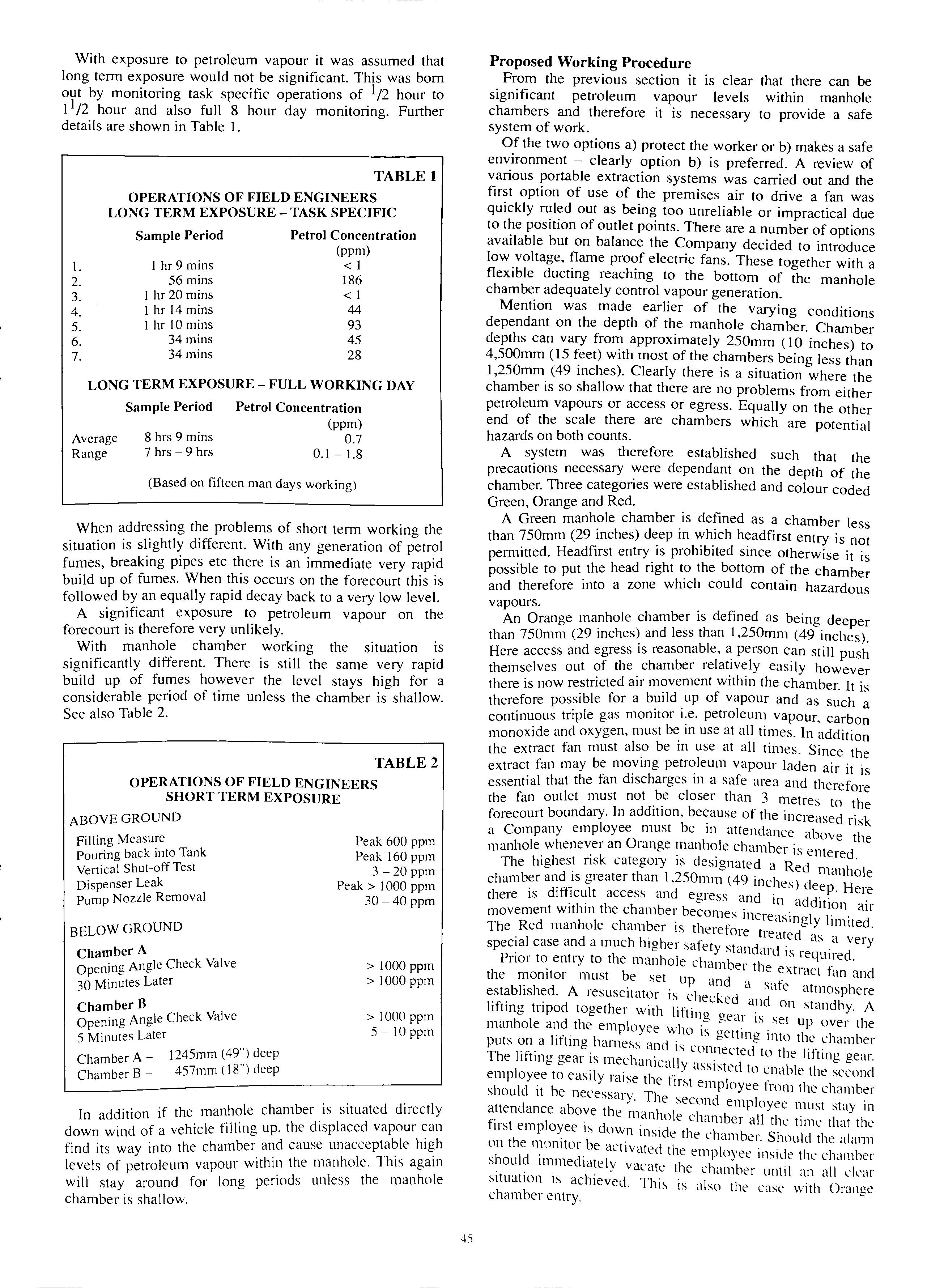

With exposure to petroleum vapour it was assumed that long term exposure would not be significant. This was born out by monitoring task specific operations of 1/2 hour to 11/2 hour and also full 8 hour day monitoring. Further details are shown in Table 1.

TABLEl

OPERATIONS OF FIELD ENGINEERS LONG TERM EXPOSURE TASK SPECIFIC

Sample Period

I. 2. 3. 4. 5. 6. 7.

I hr 9 mins 56 mins

I hr 20 mins

I hr 14 mins I hr 10 mins 34 mins 34 mins

Petrol Concentration (ppm) <I 186 < I 44 93 45 28

LONG TERM EXPOSURE FULL WORKING DAY

Average Range

Sample Period

8 hrs 9 mins 7 hrs -9 hrs

Petrol Concentration (ppm) 0.7 0.1 1.8

(Based on fifteen man days working)

When addressing the problems of short term working the situation is slightly different. With any generation of petrol fumes, breaking pipes etc there is an immediate very rapid build up of fumes. When this occurs on the forecourt this is followed by an equally rapid decay back to a very low level.

A significant exposure to petroleum vapour on the forecourt is therefore very unlikely.

With manhole chamber working the situation is significantly different. There is still the same very rapid build up of fumes however the level stays high for a considerable period of time unless the chamber is shallow. See also Table 2.

TABLE2

OPERATIONS OF FIELD ENGINEERS SHORT TERM EXPOSURE

ABOVE GROUND

Filling Measure

Pouring back into Tank

Vertical Shut-off Test Dispenser Leak Pump Nozzle Removal

BELOW GROUND

Chamber A

Opening Angle Check Valve

3o Minutes Later

Chamber B

Opening Angle Check Valve

5 Minutes Later

Chamber A _ l 245mm (49") deep

Chamber B - 457mrn ( 18") deep

Peak 600 ppm

Peak 160 ppm 3 -20 ppm

Peak> 1000 ppm 30-40 ppm

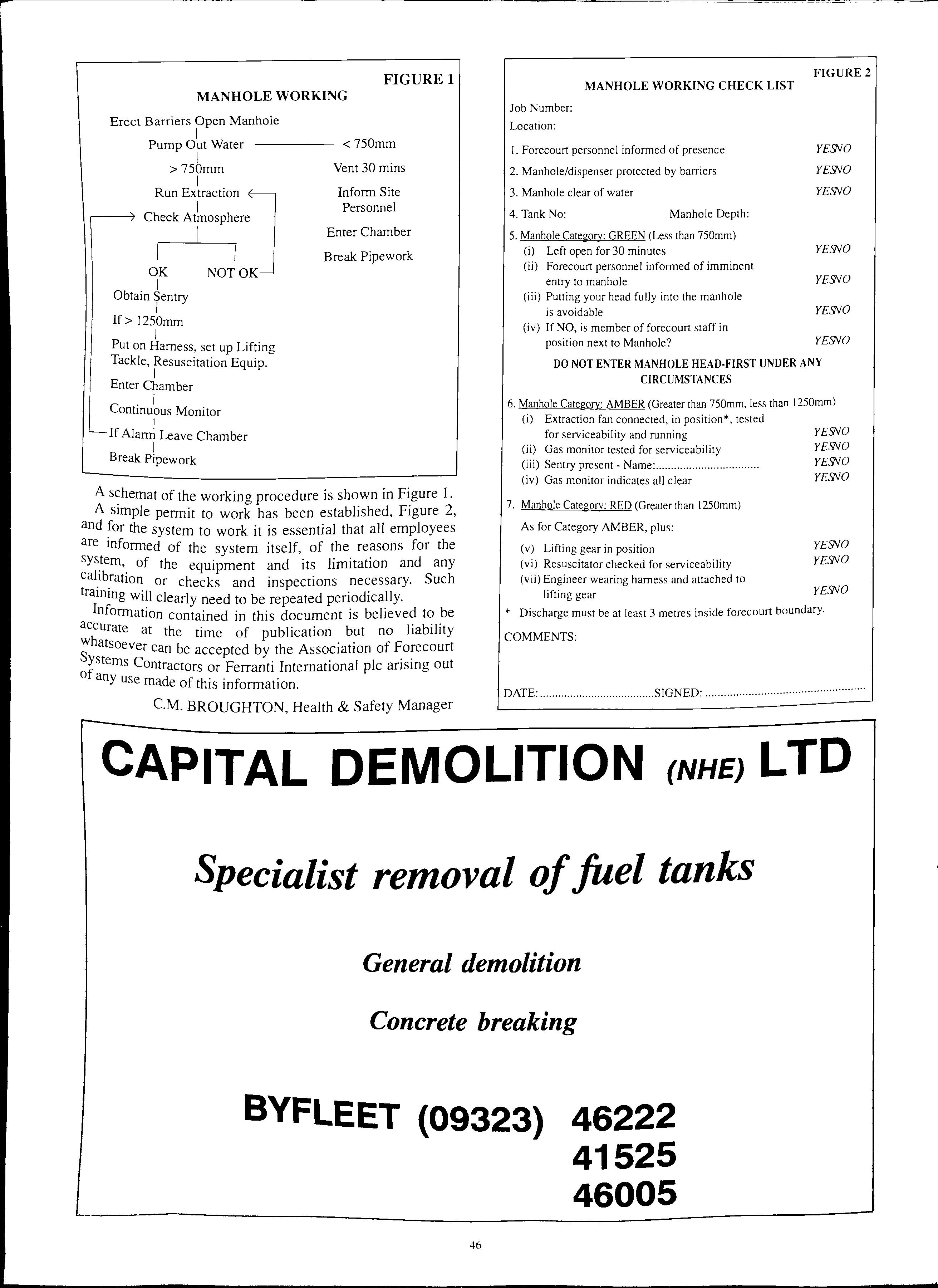

Proposed Working Procedure

From the previous section it is clear that there can be significant petroleum vapour levels within manhole chambers and therefore it is necessary to provide a safe system of work.

Of the two options a) protect the worker orb) makes a safe environment clearly option b) is preferred. A review of various portable extraction systems was carried out and the first option of use of the premises air to drive a fan was quickly ruled out as being too unreliable or impractical due to position of outlet points. There are a number of options available but on balance the Company decided to introduce low voltage, flame proof electric fans. These together with a flexible ducting reaching to the bottom of the manhole chamber adequately control vapour generation.

Mention was made earlier of the varying conditions dependant on the depth of the manhole chamber. Chamber depths can vary from approximately 250mm (10 inches) to 4,500mm ( 15 feet) with most of the chambers being less than 1,250mm (49 inches). Clearly there is a situation where the chamber is so shallow that there are no problems from either petroleum vapours or access or egress. Equally on the other end of the scale there are chambers which are potential hazards on both counts.

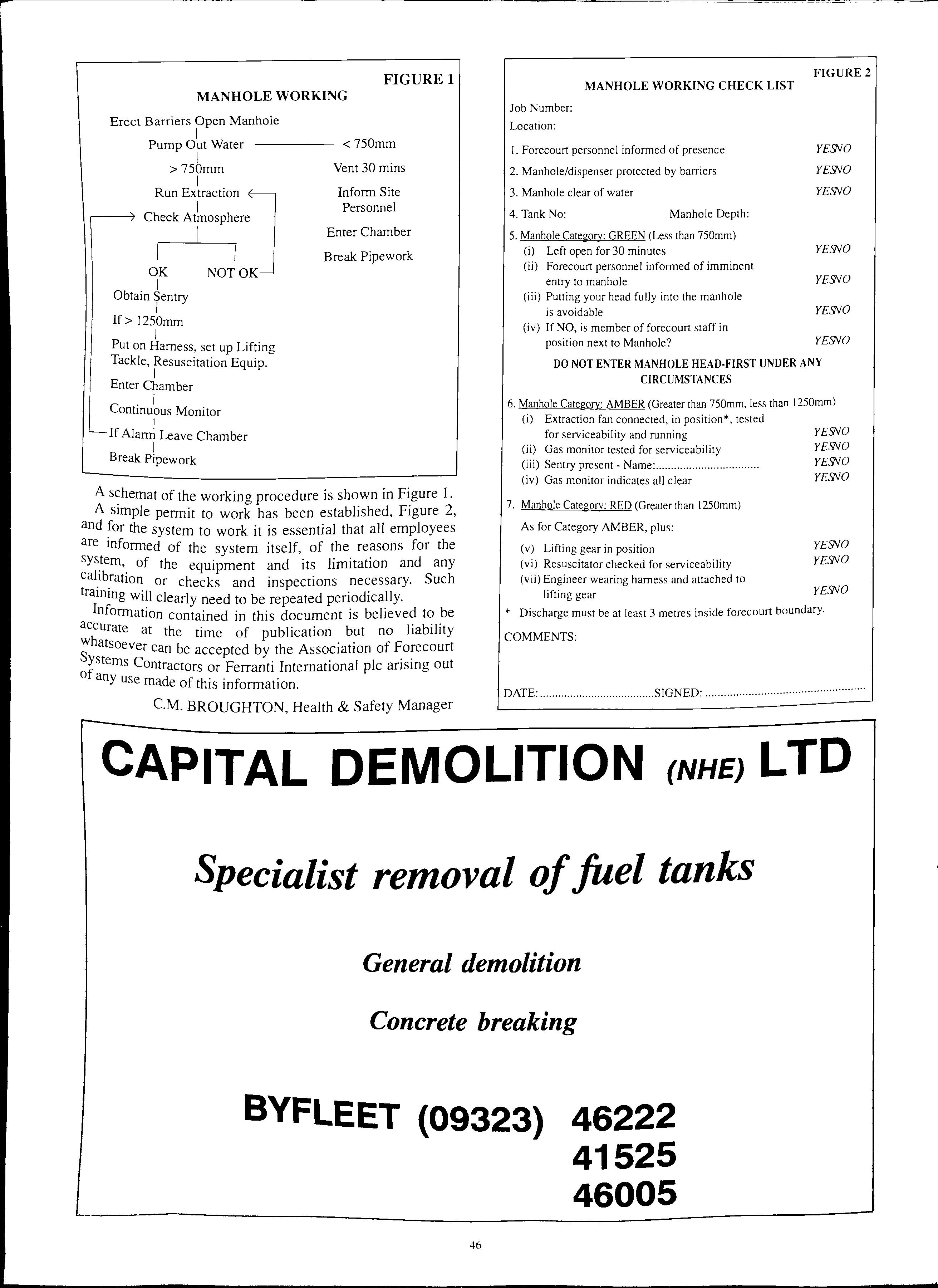

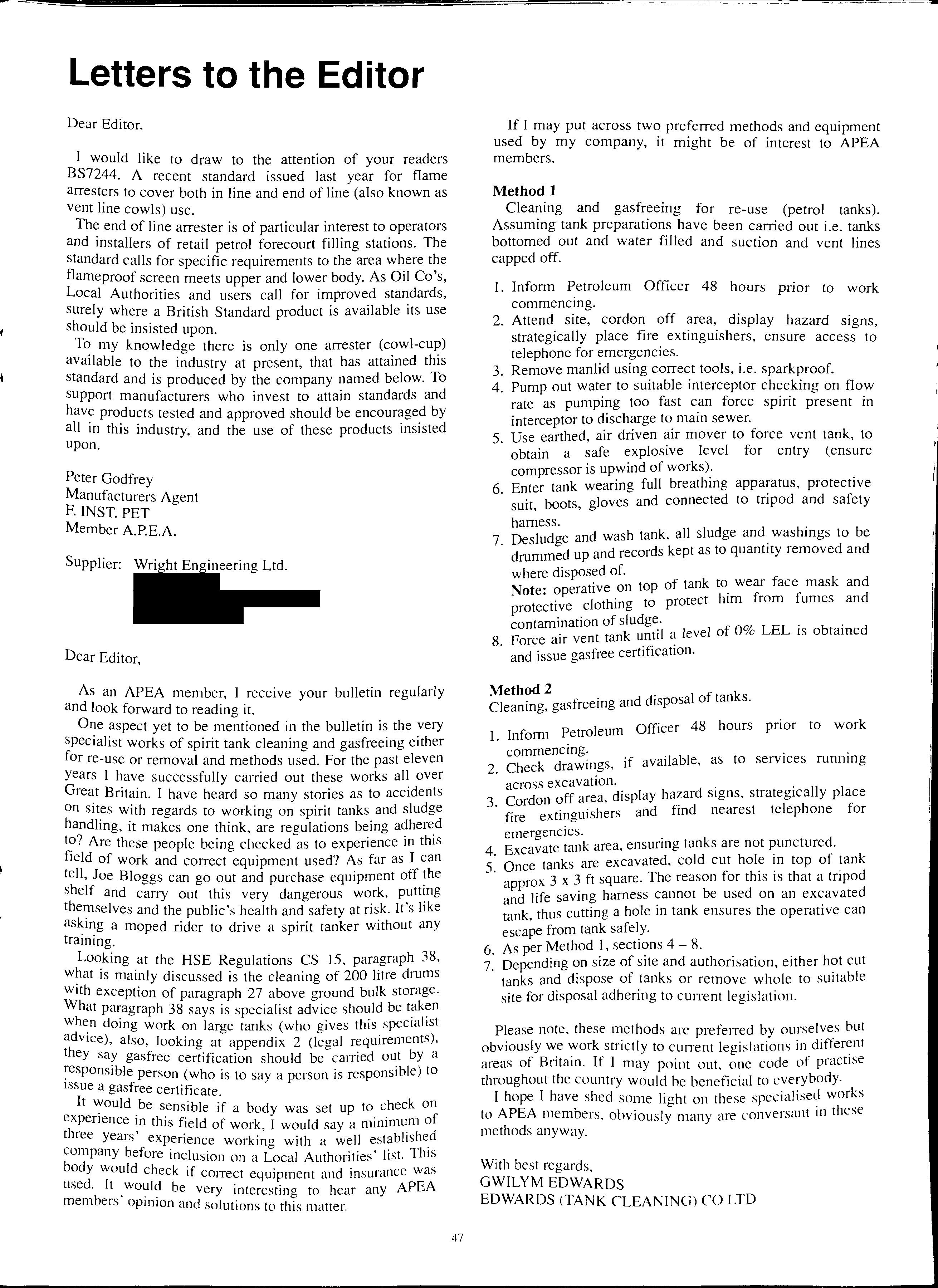

A system was therefore established such that the precautions necessary were dependant on the depth of the chamber. Three categories were established and colour coded Green, Orange and Red.

A Green manhole chamber is defined as a chamber less than 750mm (29 inches) deep in which headfirst entry is not permitted. Headfirst entry is prohibited since otherwise it is possible to put the head right to the bottom of the chamber and therefore into a zone which could contain hazardous vapours.

An Orange manhole chamber is defined as being deeper than 750mm (29 inches) and less than I ,250mm (49 inches). Here access and egress is reasonable, a person can still push themselves out of the chamber relatively easily however there is now restricted air movement within the chamber. It is therefore possible for a build up of vapour and as such a continuous triple gas monitor i.e. petroleum vapour, carbon monoxide and oxygen, must be in use at all times. In addition the extract fan must also be in use at all times. Since the extract fan may be moving petroleum vapour laden air it is essential that the fan discharges in a safe area and therefore the fan outlet must not _b_e closer than 3 metres to the forecoui1 boundary. In add111on, because of the increased risk a Company employee must be 111 attendance above the manhole whenever an Orange manhole chamber is ent . d . . k . . e1e

> 1000 ppm > !OOO ppm

> 1000 ppm 5 - !O ppm

In addition if the manhole chamber is situated directly down wind of a vehicle filling up. the displaced vapour can find its way into the chamber and cause unacceptable levels of petroleum vapour within the manhole. This agam will stay around for long periods unless the manhole chamber is shallow.

The highest ns category 1s designated 1 Red 1 · . ' man 1ole chamber and 1s greater than l ,250mm (49 inches) d H . d"ff. I d eep. e1e there 1s 1 1cu t access an eoress and in dd. · h. h h "' d 1t1on air movement wit 111 t e c amber becomes incre·i.· 1 1 h I I . 'smg Y 1m1ted The Red man o e c rnmber 1s therefore tp· l dL. · . I d h . ea e as a very specta case an a muc higher safetv sl'lnd i · · h J • < ail is 1equ1red Pno1 to entry to t e manhole chamber the e . .. . · the monitor must be set u ·u d . xtiact tan and bi" ·I d A . . . . p ' 1 a sate atmosphere esta 1s 1e . 1esuscitator 1s checked . d lifting tripod together witl1 l1.ft1.110 dn on standby. A "' <>ear 1s set manhole and the employee who is t . · · up over the puts on a lifting hames 1 · "'e tmg mto the chamber Th l"f. L. s <lnl is connected to the lifting ue·ir e 11 tmg gear mechanically assisted to enable the loiyee bto eas1 y raise the first employee from the chamber s ou l It e necessar,.. Tt1, , , i d J · e seconl employee must st·1v 111 atten ance above the . I 1 , . · · ' J f 1 man 10 e llMmber all the t11ne that the irst emp oyee is down inside the chamber. Should the alann on the 1ncm1tor be activ· t I h . . a el t e employee ms1de the chamber should 1mmed1atelv val"lte th 1 b , ' e c 1am er unt II an all clear situation Is achieved. This is also the case with Orange chamber entry. L

A of the working procedure is shown in Figure I. A simple permit to work has been established, Figure 2, and the system to work it is essential that all employees are Informed of the system itself, of the reasons for the sys_tem, of the equipment and its limitation and any cal_ib_ration or checks and inspections necessary. Such will clearly need to be repeated periodically. nformation contained in this document is believed to be at the time of publication but no liability ; atsoever can be accepted by the Association of Forecourt rtems Contractors or Ferranti International pie arising out 0 any use made of this information.

C.M. BROUGHTON, Health & Safety Manager

C.M. BROUGHTON, Health & Safety Manager

MANHOLE WORKING CHECK

Job Number: Location: I. Forecourt personnel informed of presence 2. Manhole/dispenser protected by barriers 3. Manhole clear of water 4. Tank No: Manhole Depth:

5. Manhole Category: GREEN (Less than 750mm) (i) Left open for 30 minutes (ii) Forecourt personnel informed of imminent entry to manhole (iii) Putting your head fully into the manhole is avoidable (iv) If NO, is memberof forecourt staff in position next to Manhole?

YE!NO

YE!NO

YE!NO

YE!NO YE!NO

YE!NO

YE!NO

DO NOT ENTER MANHOLE HEAD-FIRST UNDER ANY CIRCUMSTANCES

6. Manhole Category: AMBER (Greater than 750mm. less than l 250mm) (i) Extraction fan connected, in position*, tested for serviceability and running (ii) Gas monitor tested for serviceability (iii) Sentry present Name: (iv) Gas monitor indicates all clear

7. Manhole Category: RED (Greater than l250mm)

As for Category AMBER, plus: (v) Lifting gear in position (vi) Resuscitator checked for serviceability (vii) Engineer wearing harness and attached to lifting gear

YE!NO YE!NO YE9VO YE9VO YE9VO YE9VO YE9VO

* Discharge must be at least 3 metres inside forecourt boundary.

COMMENTS:

DATE:

SIGNED:

FIGURE 1

I Pump Out

I >750mm I Run

J

I

I

I

I

C I

I If

I

MANHOLE WORKING Erect Barriers Open Manhole

Water

Extraction

, +•ph;re OK NOT OK

Obtain Sentry

If> 1250mm

Put on Harness, set up Lifting Tackle, Resuscitation Equip

. Enter Chamber

ontmuous Monitor

Alarm Leave Chamber

Break Pipework

<750mm Vent 30 mins Inform Site Personnel Enter Chamber Break Pipework

LIST

FIGURE 2

CAPITAL DEMOLITION (NHE) LTD Specialist removal of fael tanks General demolition Concrete breaking BYFLEET (09323) 46 46222 41525 46005

Letters to the Editor

Dear Editor,

I would like to draw to the attention of your readers BS7244. A recent standard issued last year for flame arresters to cover both in line and end of line (also known as vent line cowls) use.

The end of line arrester is of particular interest to operators and installers of retail petrol forecourt filling stations. The standard calls for specific requirements to the area where the flameproof screen meets upper and lower body. As Oil Co's, Local Authorities and users call for improved standards, surely where a British Standard product is available its use should be insisted upon.

To my knowledge there is only one arrester (cowl-cup) available to the industry at present, that has attained this standard and is produced by the company named below. To support manufacturers who invest to attain standards and have products tested and approved should be encouraged by all in this industry, and the use of these products insisted upon.

Peter Godfrey Manufacturers Agent F. INST. PET Member A.P.E.A.

Supplier: Wright Engineering Ltd.

Dear Editor,

As an APEA member, I receive your bulletin regularly and look forward to reading it.

One aspect yet to be mentioned in the bulletin is the very specialist works of spirit tank cleaning and gasfreeing either for re-use or removal and methods used. For the past eleven years I have successfully carried out these works all over Great Britain. I have heard so many stories as to accidents on sites with regards to working on spirit tanks and sludge handling, it makes one think, are regulations being t?? Are these people being checked as to experience in this field of work and correct equipment used? As far as I can tell, Joe Bloggs can go out and purchase equipment off shelf and carry out this very dangerous work, putting themselves and the public's health and safety at risk. It's like asking a moped rider to drive a spirit tanker without any training.

Looking at the HSE Regulations CS 15, paragraph 38, what is mainly discussed is the cleaning of 200 litre drums with exception of paragraph 27 above ground bulk storage. What paragraph 38 says is specialist advice should be when doing work on large tanks (who gives this specialist advice), also, looking at appendix 2 (legal requirements}, they say gasfree certification should be carried out by a person (who is to say a person is responsible) to issue a gasfree certificate.

It be sensible if a body was set up to check on experience in this field of work, I would say a of three years' experience workino with a well established company before inclusion on a Local Authorities' list. This body would check if correct equipment and insurance was used. It be very interesting to hear any APEA members op1111on and solutions to this matter.

If I may put across two preferred methods and equipment used by my company, it might be of interest to APEA members.

Method 1

Cleaning and gasfreeing for re-use (petrol tanks). Assuming tank preparations have been carried out i.e. tanks bottomed out and water filled and suction and vent lines capped off.

1. Inform Petroleum Officer 48 hours prior to work commencing.

2. Attend site, cordon off area, display hazard signs, strategically place fire extinguishers, ensure access to telephone for emergencies.

3. Remove manlid using correct tools, i.e. sparkproof.

4. Pump out water to suitable interceptor checking on flow rate as pumping too fast can force spirit present in interceptor to discharge to main sewer.

5. Use earthed, air driven air mover to force vent tank, to obtain a safe explosive level for entry (ensure compressor is upwind of works):

6. Enter tank wearing full breathmgd prdotec!1ve suit, boots, gloves and connecte to tr1po an sa1ety harness.

· b Desludge and wash tank, all sludge and. washmgs to e

7· drummed up and records kept as to quantity removed and where disposed of. N t·ve on top of tank to wear face mask and ote: opera 1 . f d . 1 thing to protect him ram fumes an protective c o contamination of sludge.

. t tank until a level of 0% LEL 1s obtained

8. Force air ven and issue gasfree certification.

Method 2 1 f

tanks

Cleaning, gasfreeing and d1sposa o .

I. Inform Petroleum Officer 48 hours prior to work commencing.

·

2 Check drawings, if available, as to services running across excavation.

. . Cordon off area, display hazard signs, strategically place

3· fire extinguishers and find nearest telephone for emergencies. Excavate tank area, ensuring tanks are not

4

· 0 tanks are excavated, cold cut hole m top of tank

5. nee " h' . h . d approx 3 x 3 ft square. The reason ior t 1s 1s t at a tnpo d life saving harness cannot be used on an excavated an . k h . tank, thus cutting a hole in tan ensures t e operative can escape from tank safel.y.

6 As per Method !, 4 - 8.

7 Depending on size of site and authonsat10n, either h?t cbult tanks and dispose of tanks or remove whole to smta e site for disposal adhering to cuITent legislation.

Please note. these methods are preferred by ourselves but obviously we work strictly to cuITent legislations in areas of Britain. If I may point out, one code of practise throughout the country would be beneficial to everybody.

I hope I have shed some light on these to APEA members, obviously many are conversant 111 these methods anyway.

With best regards, GWILYM EDWARDS EDWARDS <TANK CLEANING) CO LTD

47

Conder's aim has always been to develop better products and building methods to accelerate the construction process the soo ner your forecourt is up and running, the sooner your return on investment. 30 years ago we introduced the prefabricated Canopy, later the GRP Interceptor and most recently the revolutionary Fi brel ite Access Covers with their light weight, you don't need a 'feat' of strength to lift them. Now, Conder can offer a complete range of ready-made products designed specifically for the forecourt.

Modular Convenience Store and Car Wash buildings delivered to site ready wired, plumbed and fitted out for rapid assembly; Access Chambers to contain possible fuel spillage and keep out sub soil water; Silt Traps to avoid drain blockages and last, but not least, Pump Island Barriers all from one source and delivered to site.

CONDER PRODUCTS ON THE FORECOURT CONDER PRODUCTS A BBOTIS BARTO N HO USE WORTHY ROAD W INCHESTE R S023 7SH TELEPHO NE (0962) 863577 Overfill Prevention Vapour Recovery Flexible Connectors Unit t:m Midcllemore Ind Estate. Kentish Rei Birmingham B21 OAY Telephone 02 1·558 44 11 Fax 021 fri "> 546

ENVIRONMENT AND SAFETY ASPECTS OF FIBERGLASS PIPING SYSTEMS FOR BURIED FUEL LINES IN EUROPE

By J. Van Gent Sales Manager Ameron Europe Fiberglass Pipe Division

Sometimes when we are faced with unpleasant facts we try to ignore them and this has been the case with tanks and ?ipes and ongoing leakage of petroleum products. Provided It was not embarrassingly obvious, small leaks continued to and product losses ensure these things cannot remain hidden away. The majority of leaks were known to be caused by material corrosion and in particular in the underground steel pipelines. Leaks here count for approx. 50%-?0%. As such the compelling factor in selecting matenals for underground tank and pipe installations for Petrol Filling Stations has to be whether they are suitable for long term service.

A few years ago if the question was asked, the answer woul_d have been steel or some other metal pipe material, provid.ed with a coating for insulation to protect it from corrosion. Today we are faced with serious environmental pressures and a greater realisation of the risks of ground water contamination by hydrocarbons. This answer does not meet the s · evere reqmrements anymore and as a result we focus on other materials and systems that have leak and corrosion resistant properties. The answer is as as usual in such considerations. If we mainly have to eat problem of materials corrosion, the choice of a that cannot corrode is the simple answer! b and pipelines of non-metallic nature-plastic-would e t answer? The answer is yes provided such plastic matenal is c· bi . , . b h m d" apa e to withstand corrosion and attack y t e he 1.um to be carried and has sufficient mechanical and P ys1cal property.

As you probably know plastics are separated in 2 major groups. '

= (PE. PVC etc.)

rmosets

(POLYESTERS, VINYLESTERS, EPOXIES)

Without go· · · 1 difi .mg mto too specific details, an essentia erence which· · " · · · · h therm 1 . is important 1or our selection cntena 1s t at the op astics have lower mechanical strength than rmosets ar t 1 and b ' e 0 a arge extent permeable to hydrocarbons tern ecome weak, finally melting after increased perature Mech · 1 · · 1 · are f h · amca properties of certain thermop ast1cs Thurt er droppmg rapidly under sub-zero conditions. e.rmoplastics are therefore not the ideal non-metallic matenals for PE our purpose. Nevertheless the thermoplastic is used and a . , I 1· appl . . pproved m some countries for fue me 1cat1on H · A t : ere m The Netherlands 1t 1s not allowed.

f uh?mh atically we come to the group of thermoset plastics O W IC the h t ·t· bi 0 cured epoxy type has proved to be the most su1 a e choice ..,., b · h · I · 1 0 o tam sufficient strength and mec amca properties, glassfibers are used in combination with the epoxy. The answer has been found!!

underground storage tanks (UST's), the combination ot hberglass a d I · b h . · · n po yester/vmylester appears to e t e solution.

manufactures glassfiber reinforced epoxy pipe fittmgs for use as underground products and vapor l1m 'i. It marketed under the productname DUALOY 1,1 JI II J/J,. The concept of connections between pipe & fittings

is not a threaded joint as commonly used for galvanized and black steel lines, but a less time consuming adhesive joint. The design of the Dualoy 3000/L joint, a so called taper male x taper female guarantees an easy and reliable connection method.

Dualoy 3000/L pipe is easy to work with. It can be cut to length using an ordinary hacksaw. The cut end of the pipe is then tapered with a portable tapering machine. Both cutting and the tapering of male ends can be accomplished without even getting out of the trench and is a matter of seconds.

A two component epoxy adhesive kit is mixed and applied on the male & female ends. The both parts are then brought together by inserting the male tapered end into the female or bell end. Curing of the adhesive takes place under temperatures > 18 degrees Centigrade and curing time depends on actual temperature. For this reason, usually a silicone rubber heating blanket is wrapped around the joint. This blanket, which has a thermostatic control, reaches a temperature of approx. 130 degrees Centigrade. At this temperature the connection is completely cured within approx. 20 minutes.

As indicated before, threaded joints (BSP or NPT) in steel have often proved to be the weak point as respects reliability. In DUALOY 3000/L adhesive bonded joints are very seldom causing a problem.

Some engineers of oil companies, having in mind the experience with steel joints prefer the use of hoses, metallic or non-metallic, with the idea that only 2 joints will be needed per line. One at the beginning and one at the end. To their opinion, this limits the risks a leaking joints because steel joints are the weakest point. This is logical from an experience based on steel. It has however no reference to fiberglass pipe systems where adhesive bonded connections are not giving any concern, either short term, or long term. In considering and judging fiberglass systems, other criteria are valid.

Us_ing fiberglass piping and you noticed we do not call it plastic anymore the need for cathodic protection measures does not exist. This again is an extra above steel or other protected metals.

Corrosion resistance is secured, not only from the inside but also from the outside. For this reason a layer of epoxy resin on the outside forms an integral part of the product.

Yet more advantages are to come!

weight of fiberglass piping is only approx X of the weight of steel piping. This does not only benefit the workman, having to install the line. Also transportation and installation equipment, handling and storage aspects are positively influenced.

Maybe one of the most important benefits of DUALOY 3000/L fiberglass piping is that a complete system of pipe & fittings is available for single or primary pipelines and for dual containment or secondary pipelines. DUALOY 3000/L is available in diameters 2", 3", 4" and 6". In secondary systems a diameter pipe. next larger to the primary pipe is used as the outside pipe. Fittings consisting of 2 180 degree segment shells are available and bonded together onto the

)()

j

pipe, using again a two component epoxy adhesive kit. In this manner a pipe in pipe system becomes available, not relying on any metal part. The space between inner-and outer pipe can a.o. be used for leak detection purposes. Leak detection systems, varying from simple detection cables to sophisticated computer controlled equipment sets are available at the market.

Where connections need to be made with steel parts, a complete range of flanges and BSP/NPT threaded (reducing) adapters is available for both primary & secondary system.

Fiberglass Pipes manufactured by Ameron and others have been in use in the USA for Petrol Filling Stations and Terminals, since the late sixties. In 1989 they accounted for about 65% of pipes used underground thus it can be seen Oil Companies, Authorities and Installers had come to realise the benefits over twenty years. Since 1989 it is estimated 85% of pipes are fiberglass so compulsion also brought about a dramatic change with the introduction of the Environmental Protection Agency Regulations.

In Europe we did not exactly have to start at the beginning, over twenty years of good experience built up in the U.S. has meant some Oil Companies with sister operation are willing to use fiberglass pipe here. One Company has made it a Worldwide policy to advocate the use of fiberglass pipes and tanks and others have made a major commitment to fiberglass pipes.

It has not been easy to introduce fiberglass products because besides the Oil company, National and Local Authorities must accept and approve the product as suitable for use. Also the installers have to be trained in new assembly and working techniques. I shall come back on these issues later.

The two largest user States in Europe are the Unite? Kingdom and The Netherlands where some eight Oil Companies together with Supermarket and Hypermarket stores are regularly installing our pipes with in excess of I00 stations in service.

Does this mean we have achieved our aims? No, there is a great deal of work to be done but we hope that the audience today and the wider body of interested parties will realise the significant benefits of using fiberglass pipes for Petroleum Piping at the Service Station. .

Let us look at the problems so far experienced m establishing our products to the markets and take some of the objections to change:-

Cost:-

Yes, per metre run fiberglass is a little more than steel but it brings significant benefits, light weight, '.ully corrosion resistant ease of installation etc. The total cost should mo;e than outweigh the materials price differential. Obviously the first fiberglass installation by the Contractor does not give the best impression of speed but by or third site it is dramatically faster to complete t e pipe work and hence costs are down.

Comparability:-

It is not fa" · h

Ir to compare todays service stat10n wit yesterdays u t · d · n onunately this may be forgotten by some epartments w"tl · D · 1 1111 the Oil Company. The Marketmg 1v1s1on may f · d not ully appreciate how much more is require of th E . . operational ngmeermg to deliver an today M k . n meets the environmental needs of del . · ar edtmg requires a new station to open on time and 1ver pro uct th h breakdown. No pumps and .f. rrnally alongside a conve111ence store that 1s s1g111 1cant to co · .· .bi mpany profits; all supplied for the lowest p1 ice poss1 e.

Yesterday it was sufficient to have the basic concept of steel tanks, pipes, electrics and dispensers. Today the site may require:-

Double Skinned Tanks

Full Leak Detection & Monitoring Systems

Overfill Preventers

Vapour Recovery Systems

and more to be an Environmentally Advanced System.

All these factors have made a tremendous difference to the cost implications of the Underground Pipe and Tanks System. It used to be a rule that five per cent of the Service Station cost was enough to cover the underground items. Today it can be double!!

Approvals:-

DUALOY 3000/L has Underwriters Laboratories Approval in USA and Canada. In Europe, various approvals have meanwhile been obtained. As a selection I mention The Netherlands, France, Sweden, United Kingdom and Iceland. Other European states are close to approval including Denmark and Spain while some Mediterranean and Middle Eastern Countries are already installing fiberglass pipes and tanks with increasing frequency.

You will imagine we are happy with all these approvals but in fact we are not! From country to country different rules and standards are valid. And if they are not valid for fiberglass, they are suddenly I remember an installation of DUALOY 3000/L m Breda. Approved by KIWA in The Netherlands and installed last months later I obtained an order for a truck stop stat10n, JUSt er the border in Belgium. Distance about 20 km 's from KIWA approval was not valid a?d instal!ation ractices completely different. The installat10n has fmally faken place but this highlights the Although problem area, drinking water contammat10n, 1s the same m The Netherlands as in Belgium, rules or rather the of I and qualifying equal standards means that suitable ru eds cts like fiberglass pipes are difficult to be used. This pro u . I ·11 l·es for almost all European countnes. w1 not app I d" ")) h speculate on the reasoning but au 1ence w1 s are my opinion that this is not a thmg. . .

In this respect I would hke to mention ex1sten.ce_ of EPACT. EPACT stands for European Promot10n f Composite Tanks and Tubulars. Members are leadmg 0 nufacturers of raw materials and composite materials as mall installers. Fmther end users such as Oil Companies are as Associate Members. The objective of is to promote the use and acceptance as well as to · rove the knowledge of composite materials for imp EP'ACT t kstation applicat10n. tt orgamses semmars, works an unifom1 standards for UST's and pipelines in fiberglass has edited a For those p_eople interested, further address and details can be made available.

Training

Earlier l said that I also would look at training. In some countries installers of Underground Tanks and Pipes may be termed as specialists, that is to say the Company has built up years of experience_ in _the field and by this means are competent and Some areas require official registration of these compa111es. However, the gap between old and new techniques is significant and Ameron have adopted a system of training and certification of individual workers and their employers so that both Oil Companies and Authorities can know who is trained to handle fiberglass pipe. (A similar scheme operates in the USA organised by the members of The Fiberglass Tank and

:'ii

Pipe Institute). This is proving effective to eliminate site difficulties but we strongly believe the other of new, related equipment need to join forces. m t?e up dating and training in procedures. It is not sufficient JUSt to sell to the market if long and short term problems are to be avoided.

Installation

Some contractors have proved more able to meet the new challenge than others. Where problems have occurred with fiberglass pipe one thing is very evident they all during the construction stage where they can be monitored and corrected. A few only have occurred fairly soon after the site has entered service and these inevitably are due to some fundamental mistake in site construction techniques. If the installation procedures laid down by the manufacturer are closely followed it is hard to make mistakes. Ameron have even advanced a guidance note for other contractors on the site so that all parties are informed:

The facts

Gradually the realisation is dawning with Oil Companies Authorities that we only thought there were no problems with old and existing sites. The reality is we do, and even though catastrophic failures are few, many sites, are neve_rtheless very possibly already leaking small but contmuous levels of Hydrocarbons into the ground. The modem tank and pipe integrity testing methods show only too easily that traditional test methods at site construction stage and on subsequent reinspections often do not reveal defects.

Too often during these early days we have heard the comment "We never had a problem with steel pipes when we installed them." Fair enough for the contractor, he probably has a 1 year guarantee on his workmanship and then he is off the hook.

Even Oil Company staff have felt it is acceptable to have to dig up the forecourt after a few short years to remedy a problem. Nobody has put in a steel pipe system with up date monitoring and detection systems and we believe if this had been the case not only would fiberglass pipe have started in the European Market years ago, it would today be, as in the USA, the most widely used product for buried fuel pipe systems.

A great deal of this presentation has been about the use and application of Fiberglass Pipe Systems Dualoy 3000/L as manufactured by Ameron. Ameron can supply further specific product and installation details on request. Although Fiberglass UST's are not manufactured by Ameron, we can advise on well-established manufacturers and suppliers of these tanks.

Finally, as to the issue of this paper.

I have not met anybody the last two years that said he was not concerned about our environment.

. I not met anybody that was not convinced that protection of our drinking water resources is essential for our survival.

I have not met anybody that said that fiberglass pipe and could not be a helpful solution to the problem of leakmg mstallations.

I therefore can only conclude that no excuse or alibi is left not to immediately consider the application of non-metallic fiberglass pipe and tank systems.

BLOCK PAVING ON SERVICE STATION FORECOURTS

John A. Emery, Hamilton Green Construction International Ltd.

John A. Emery, Hamilton Green Construction International Ltd.

Block paving is now widely used in the UK and overseas for the access areas surrounding pump islands at service stations. The major benefits of this form of paving over traditional ones are its attractive appearance its ability t b ' ' 0 _e taken up and relaid when forecourt changes are and its ability to be put into use immediately after mstallation.

Block Paving

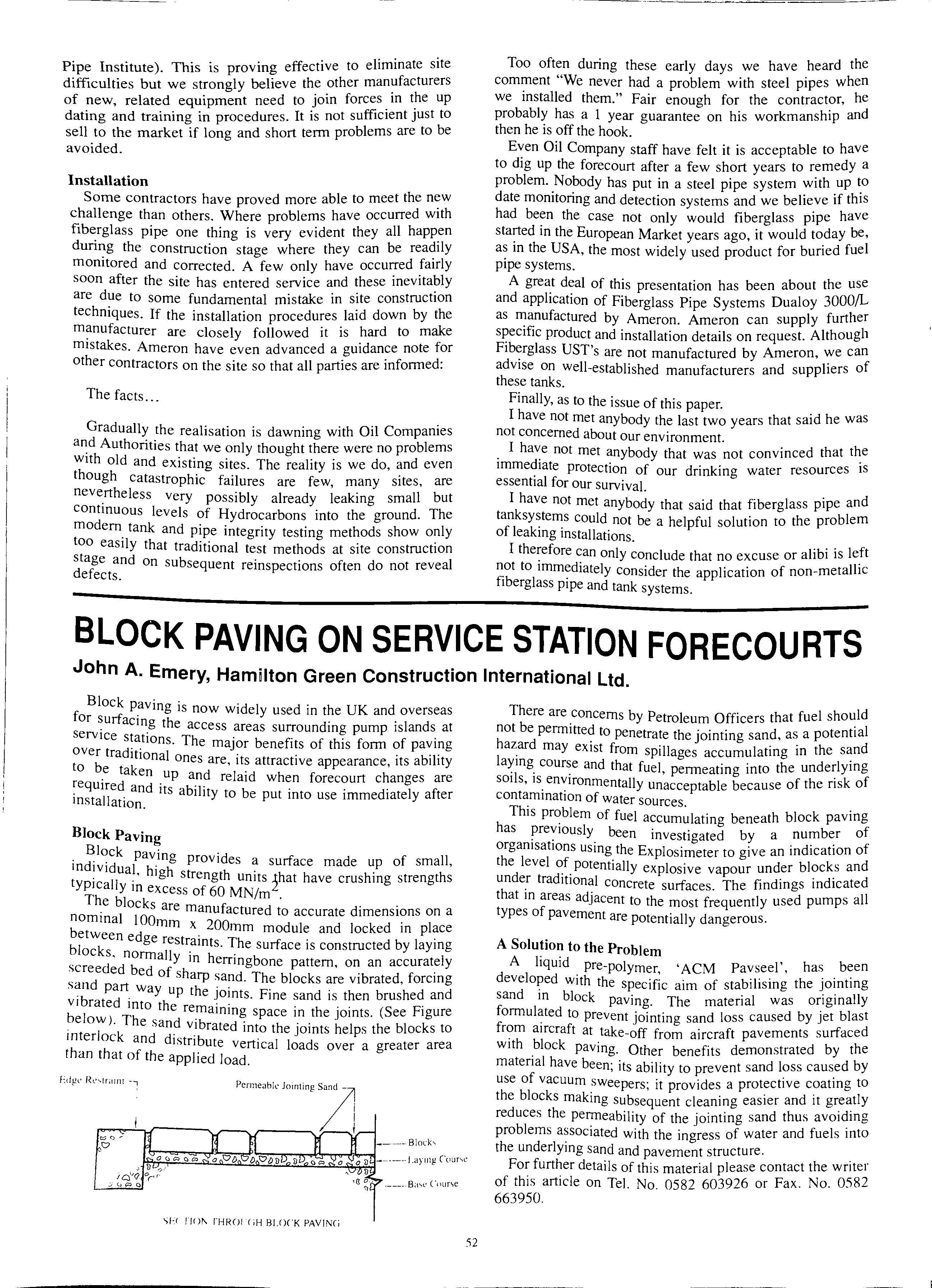

Block · . d" . pavmg provides a surface made up of small, m high strength units 1hat have crushing strengths typically in excess of 60 MN/m2. blocks are manufactured to accurate dimensions on a IOOmm x 200mm module and locked in place etween edge restraints. The surface is constructed by laying blocks. normally in herringbone pattern, on an accurately screeded bed of sharp sand. The blocks are vibrated, forcing part way up the joints. Fine sand is then brushed and vibrated into the remaining space in the joints. (See Figure below). The sand vibrated into the joints helps the blocks to interlock and distribute vertical loads over a greater area than that of the applied load.

There are concerns by Petroleum Officers that fuel should not be permitted to penetrate the jointing sand, as a potential may exist from spillages accumulating in the and that fuel, permeating into the underlying s01ls, is_ unacceptable because of the risk of contammat1on of water sources.

This of fuel accumulating beneath block paving has been investigated by a number of orgamsat1ons using the Explosimeter to give an indication of the level potentially explosive vapour under and unde_r trad1t1onal concrete surfaces. The findings indicated that m areas adjacent to the most frequently used pumps all types of pavement are potentially dangerous.

A Solution to the Problem

A liquid pre-polymer, •ACM Pavseel ', has been with the specific aim of stabilising the jointing sand m block paving. The material was originally to prevent jointing sand loss caused by jet blast from aircraft at take-off from aircraft pavements surfaced with block paving. Other benefits demonstrated by the material have been; its ability to prevent sand loss caused by use of vacuum sweepers; it provides a protective coating to the blocks making subsequent cleaning easier and it greatly reduces the permeability of the jointing sand thus avoiding problems associated with the ingress of water and fuels into the underlying sand and pavement structure.

For further details of this material please contact the wnter of this article on Tel. No. 0582 603926 or Fax. No. 0582 663950.

f:d!!t> Re rra1111 --., I ''"' r c:7 1"101\ rHROI :(<H BLOCK PAVING 52

V WEST YORKSHIRE FIRE SERVICE APPEAL WITHDRAWN DURING HEARING

J D Johnson GIFireE, West Yorkshire Fire Service's Senior Inspector of Petroleum and Explosives reports in respect of an Improvement Notice issued under the Health and Safety at Work etc Act 1974.

The Morrisons Supermarket firm Wm Morrisons Supermarkets PLC appealed against an improvement notice dated 22 November 1990 in which it was stated that Morrison, as Licensee/Occupier at a petrol filling station at Queensway, Morley, Leeds, were contravening and the reasons for such contraventions were that in the opinion of the Inspector "a hazardous situation on the forecourt was present by the controller at the forecourt control position not having a clear and unobstructed view of self service dispensers Nos 1, 6, 7 and 12 and the whole of their respective dispensing areas". West Yorkshire basing its opinion on the fact that the forecourt controller is required to ensure practical and effective control of the acts or omissions of any person on the forecourt, to be able to see what all persons (members of the public) are doing at all times whenever vehicles, of whatever description, car, high sided car, van, lorry are parked or about to park in a hazardous area associated with any pump.

The '74 Act allows suggestions, if thought necessary, to be included within such Notice as to an accepted method or methods of overcoming the stated contravention and in this instance the following was suggested.

EITHER 1 Re-design the forecourt layout to an acceptable arrangement in such a way as to provide the controller at the control point with a clear and unobstructed view of each side of the following multi-product dispensers and the whole of their respective dispensing areas.

Multi-product dispensers Nos 1/2, 5/6, 7/8 and 11/12.

OR 2 Provide a closed circuit television system, of an acceptable type with a monitor located at the control point (and forming part of the forecourt control equipment) to cover the following multi-product dispensers and their respective dispensing areas, the vision of which are obstructed from the controller at the control point.

Multi-product dispensers Nos 1, 6, 7 and 12.

Dispensers Nos I, 6, 7 and 12 are those positioned at the en.d outer sides of what is basically a six square pnncipal, end on to the controller kiosk, with the centre pair ?f pumps just off the centre of the position of the controller m the kiosk.

The history of the new filling station dated back to late l 989 • when informal discussions were held between West Fire Service and MrnTison 's Architects prior to the submiss1on of formal plans to the local Building Control

At that time it was suggested that the 0 a CC:TV systems would he an acceptable way of overcom111g forecourt vision obstruction problems and would prevent having to re-design the forecourt dispenser layout.

The matter of the forecourt layout and the need to provide operational supervision, was also brought to the attention of the Architects in correspondence following the formal submission of plans for Building approval in October and November 1989.

During 1990, as the project neared completion, and then came into operation, the licensee used the existing current petroleum licence for the old installation which was sited immediately adjacent to the new one, to operate the new forecourt.

As the forecourt dispenser layout had not been altered, from the original plans submitted, it was assumed by West Yorkshire Fire Service that a CCTV system would be installed and this was still assumed up to the time that it became evident that Morrisons would not confirm their intentions in writing.

A subsequent visit to the filling station by Officers ascertained that the original problems highlighted at planning stage were actually evident, in that when vehicles were parked for refuelling at the inner side of the outer dispensers, it was not possible, from the control position, to see at all times what persons were doing in the outer dispensing area, the inner vehicle, particularly if of the large variety, totally obstructing the controllers view.

The Improvement Notice was then issued.

The appeal stated the following grounds:

Firstly, it should be emphasised that Wm Morrison Supermarkets PLC have given West Yorkshire Fire Service the opportunity of re-considering their action in the light of this the appeal may be abandoned.

2 The requirement to install CCTV is unworkable as the very purpose for it is required (the attendant see all dispensers) IS unworkable as the attendant IS involved in other duties, such as the collection of money, serving of customers, answering of telephone etc and therefore, cannot be aware all of the time.

3 The Improvement Notice is unworkable as the attendant cannot possibly be looking at the input from every camera on the forecourt all of the time. By necessity, some frnm of switching will be required to flick pictures from each of the cameras onto one screen. Alternatively, a screen will be required for each camera which again means the attendant scanning each of the screens in order, whilst also attempting to attend to other duties.

4 No other Authority in the country has this requirement, which would suggest to use that it is unworkable.

5 The London Fire Service, which is taken as the bench mark for all such matters. has not. as far as we know. insisted upon this type of protection/surveillance.

6 The Institute of Petroleum guidelines on these matters quite clearly state that the dispenser should only be visible to the attendant except when a vehicle is parked at the dispenser.

7 The above, are the main points of argument of the Company's case. obviously indicated in outline at stage.

In the grounds of appeal, later refl1:arked on th.e Secret to the Tribunals, when replymg t.o. s suggesting that t?e Tribunal v1s1t the site to understand the nature of sight Imes, was the fact the improvement notice was based on a factual statement that the controller at the forecourt control position ?oes .not have a clear and unobstructed view of the self service and their respective dispensing areas," and that the notice of appeal did not appear to challenge this statement. The Tribunal did not visit the site.

The appeal hearing commenced at the Regional Office of the Industrial Tribunal at Leeds on 28 February 1991.

The Tribunal consisted of a Chairman and two members, West Yorkshire Fire Service (Respondent) being represented by counsel and Morrisons (Appellant) by a Solicitor.

Prior to the hearing, the legal bodies representing the appellant and respondent had agreed that, for the purposes of clarification it would be suggested to the Tribunal that the Fire Service be allowed to begin the hearing by putting the Fire Service's reasons for issuing the Improvement Notice.

The Chairman would not agree to this proposal and asked that precedent be indicated for such proposal, when it was up to the appellant to initially proceed. No such precedent could be indicated and counsel was allowed only briefly to draw the Tribunal's attention to certain numbered documents in the respondent's bundle, which were relevant ie a case outline only.

. The Chairman then referred to the improvement notice Itse.lf and brought the appellant's attention to the fact that the specified that "it was the inspector's opinion (an appointed inspector) that a hazardous situation on the forecourt was present" and inferred that they, the Tribunal, were not likely to accept other opinion. The Chairman suggested a short adjoumement for the parties to resolve the After adjoumement, the decision of the Tribunal was unanimous in that the Appeal is dismissed on withdrawal by the appellant. The following reasons being given.

S The Tribunal convened to hear this application and Mr of counsel representing the Fire Service explained t e background to the case. However, after discussions

between Mr Stordy and Mr Hall, solicitor on behalf of the appellant, the tribunal was advised that the improvement notice will be complied with and that terms have been agreed between the parties as to its implementation. On that basis, the appeal is withdrawn.

It was agreed by Morrisons to install a CCTV system. The appellant also agreed to pay all Fire Service costs m this matter. Costs amounted to £ 1,486.37.

Conclusion

The points which would have been put forward to the appeal matters set out in the grounds of appeal, pomts 1-7 above are as follows:-

a Points 2 and 3

These matters have yet to be taken up with Morris?ns and refer to certain aspects of them training thelf staff correctly. Training, specifically practical training, i:iust include provision for ensuring that forecourt control of paramount importance and that such control, as req_mred by their Conditions of Licence, has to be consistent and continuous. As such no other tasks which prevent such control are permitted.

b Points 4 and 5

This comment is not correct. Cambridgeshire have numerous installations London and Dyfed have them, other Authorities, Fire or Trading Standards Authorities, have them. West Yorkshire has 34 such installations.

c Point 6

It is suggested that the 1978 Institute of Petroleum guidance may have been acceptable prior to the. pumps/dispensers that could be operated both sides at t same time, when forecourts operated at a much slower pace and were much easier to control. With HS(G)4 l now exactly what has to be on. forecourt ie controlling what each person is dm g, emphasis being on the person not the vehicle, control has now to be done practically not, as has been the case, theoretically.

New Members The Association welcomes the following new members G. A. Bartle Cambrian Plastics Ltd oa C. J. 0. Morris F Inst Pet General Mai t ces Limited I .ew1s F Gknclay /o..,eph Ash & Son Ltd. M. D. Kurowski P.M. Services J. Collins Gilbarco Limited Peter Walkden Les Walkdcn Ltd 54

Joseph

& Son Ltd R. M. Pass Murco Petroleum Ltd J. A. Walker C. S. Madan & Co Ltd

Mr Simon R. Procter

Ash

Richard Dunn Dewco Oil Services Limited

Anne Rodda County Pumps Ltd

Peter G. Volk Repsol UK Limited

Mr Douglas John Wheatley Bartee Limited

Mr D. Gooch Abacus Cleaning Service

C. M. Christoforou Texaco Ltd Stephen F. Day Texaco Ltd

David T. Marston BSc, C.ENG, M.l.C.E. Texaco Ltd

Tim Collins Texaco Ltd

Nigel Bass W. T. Burden Ltd

Steve Kent National Fuel Manager British Telecom PLC

A. T. Hawley Plastics Design & Engineering Division

Paul Rayner Link Hampson

Ronald Melvin Turner Petroleum Training Federation

Clive Rone Nicholls Rose Blizzard and Associates

David Kenneth Sommers Powys County Council

John R. Gray Turnkey Design Partnership L1m1ted

Roy E. Hockedy F.R.l.C.S., A.S.V.A., M. Inst. Pet.

C. D. Hart Jenkins & Gosby

Peter Dusha City Health Surveyor

Philip Riley P. R. Services

John Riley Liam Mulcahy BP Oil (Ireland) Ltd P. J. Guthrie Property Services Agency BM Eastern

Maurice Tennick Eurogauge Company Limited

Stuart Dron Kuwait Petroleum GB Ltd

Richard James Taviner C. J. Taviner & Co Ltd

J. A. Jenkinson WEFCO (Gainsborough) Ltd

John Martin Bradley Groundwater Technology International

M. W. G. Butler Texaco Ltd

Christopher John Greenslade EMCO Wheaton UK Ltd

Richard Dunn Dewco Oil Services Limited

Anne Rodda County Pumps Ltd

Peter G. Volk Repsol UK Limited

Mr Douglas John Wheatley Bartee Limited

Mr D. Gooch Abacus Cleaning Service

C. M. Christoforou Texaco Ltd Stephen F. Day Texaco Ltd

David T. Marston BSc, C.ENG, M.l.C.E. Texaco Ltd

Tim Collins Texaco Ltd

Nigel Bass W. T. Burden Ltd