The Ill

THIS ISSUE STEEL FIGHTS BACK SELF SERVICE AND THE DISABLED CATHODIC PROTECTION LEAK DETECTION AND LOCATION FUTUR E O F ENFORC EMENT VOLUM E 30 No, 3

Journal of the Association for Petroleum and Explosives Administration

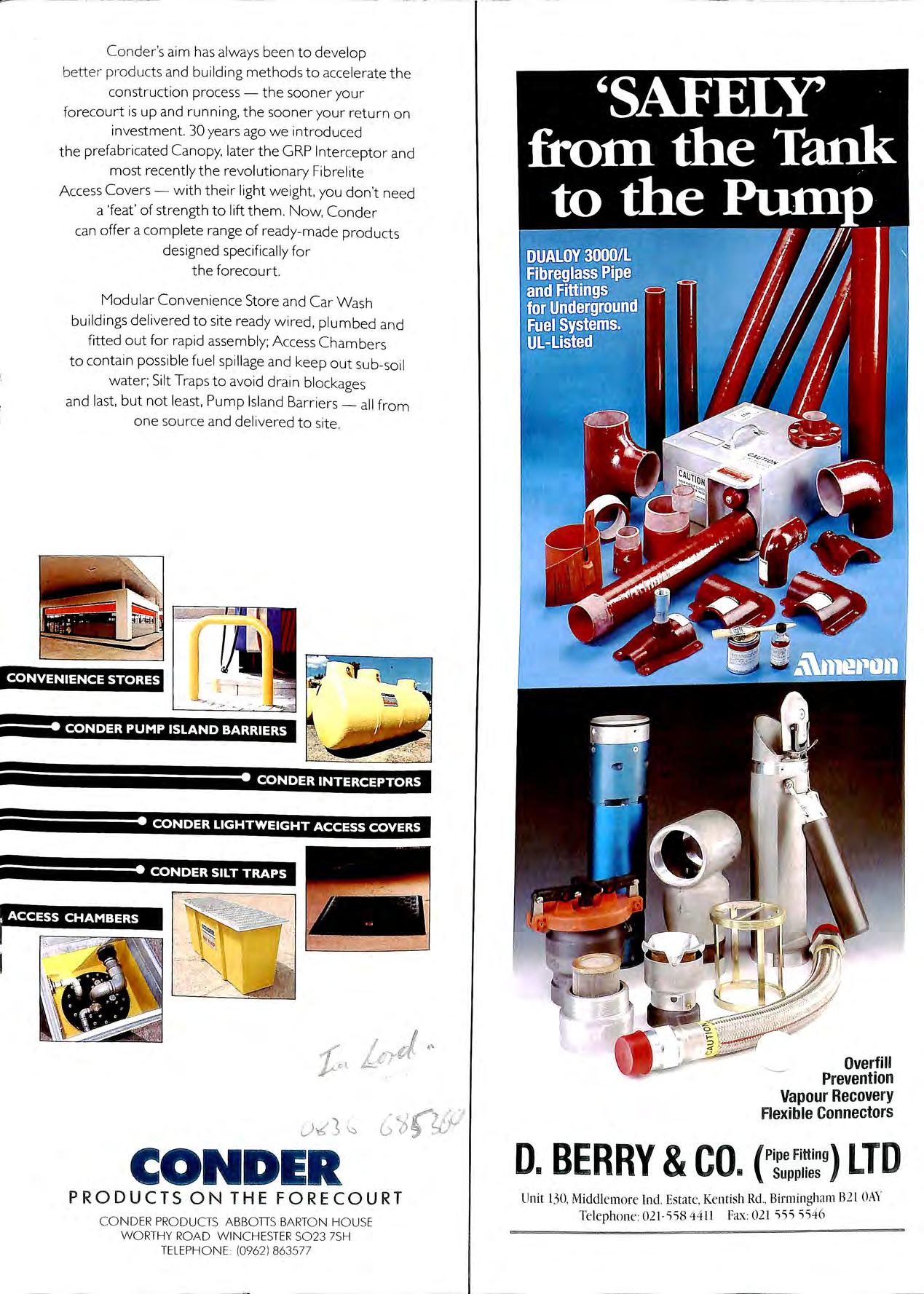

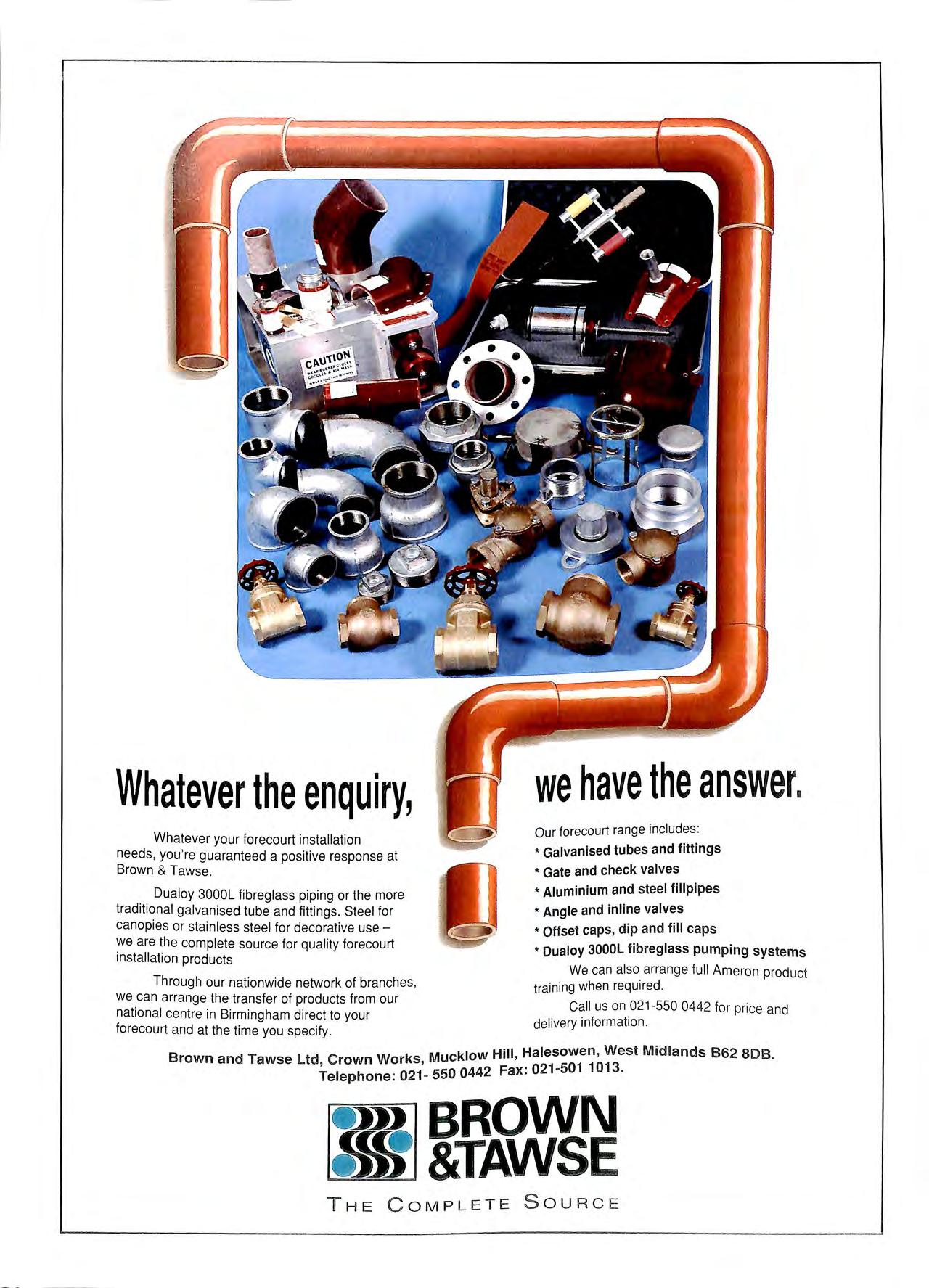

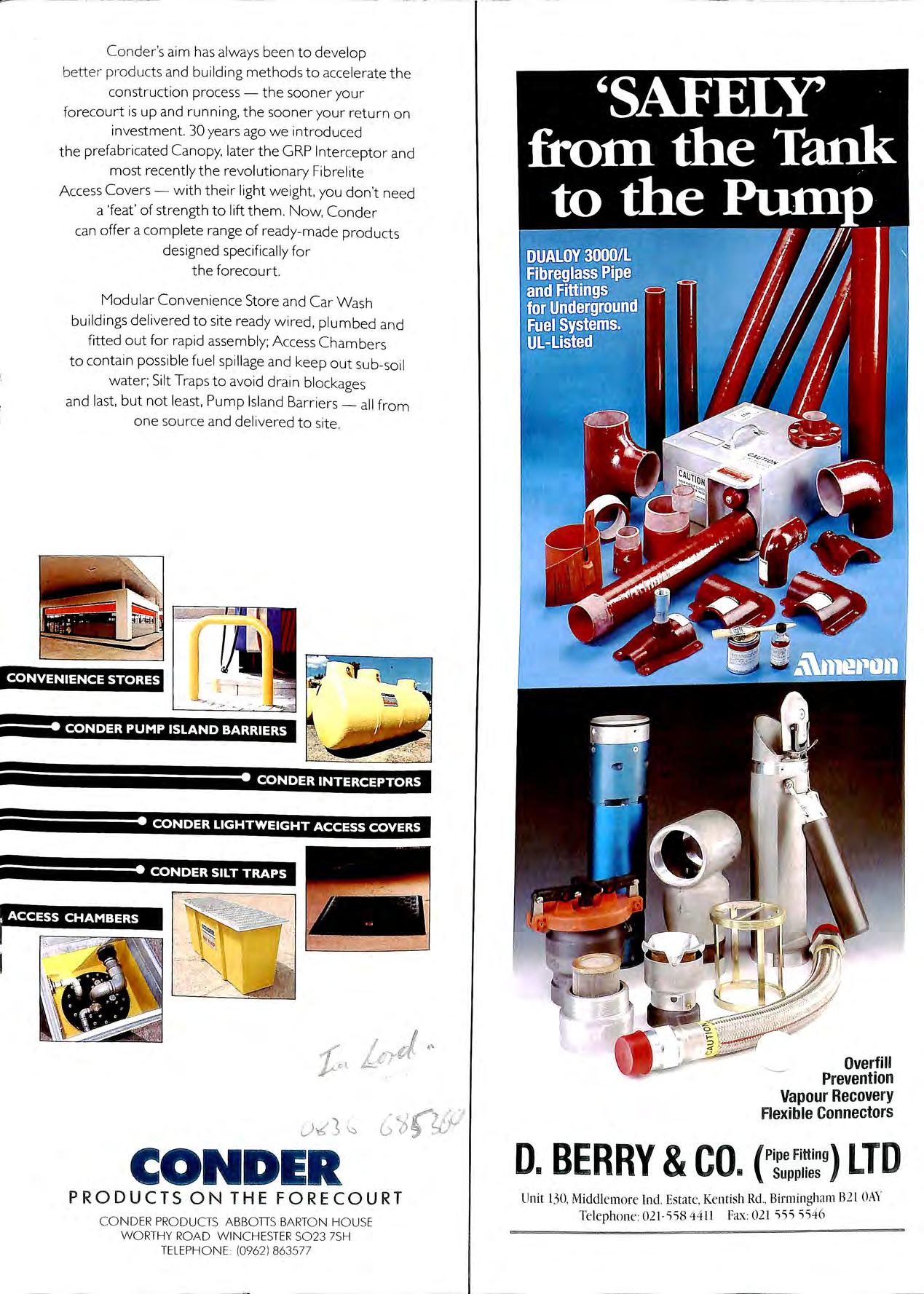

Ameron 's Dualoy"' 3000/L fiberglass piping is li s ted \Vith Underwriters' Laborator ie s for u se in und e rgro und fue l-handlin g sys te m s It h as a lso been tested a nd acce pte d by th e London Fire and Ci vil De fe nce Authorit y.

Thi s m ea n s yo u h ave the ass ura nce th a t our product has b ee n teste d und e r th e mo s t st rin ge nt co ndition s 21 ncl is rate d for press ures and te mperatures far in excess of 1·eg ul ar p e trol s tat ion req uire m e n ts.

Yuu c a n in s tall a Du a loy sys te m in et h()ut on e h a lf th e tim e re quire d to ru t in s te e l. ln fact, you ca n taper th e encl u f our pip e in less tim e th a n it ta ke<. ju s t to put a stee l pipe iP•a pi r e ' i'> e.

But h e re's the best part: yo u ' ll p roba bl y find the install e d cos t of a Du a loy sys tem to be les s th a n for s tee l-as it requires no sulphate resisting co ncrete surround.

Ameron h as a Dua loy system for eve ry und e rground fu e l-h a ndlin g nee d: wh e ther it' s conventiona l s in g le wa ll piping or a co mpl e te seco nd a r y co ntainm e nt sys te m .

For more information, write

Ameron Fiberglass Pipe Division, lA Christchurch Road, Ashford Kent, TN23 lXB or call us on 0233 613884

It's approved by petroleum licensing authorities and installs twice as fast as steel.

al oy 30 00/ L c ontai nme nt system s are also UL liste d fo r alco ho l based fuels as well as petrol

Du

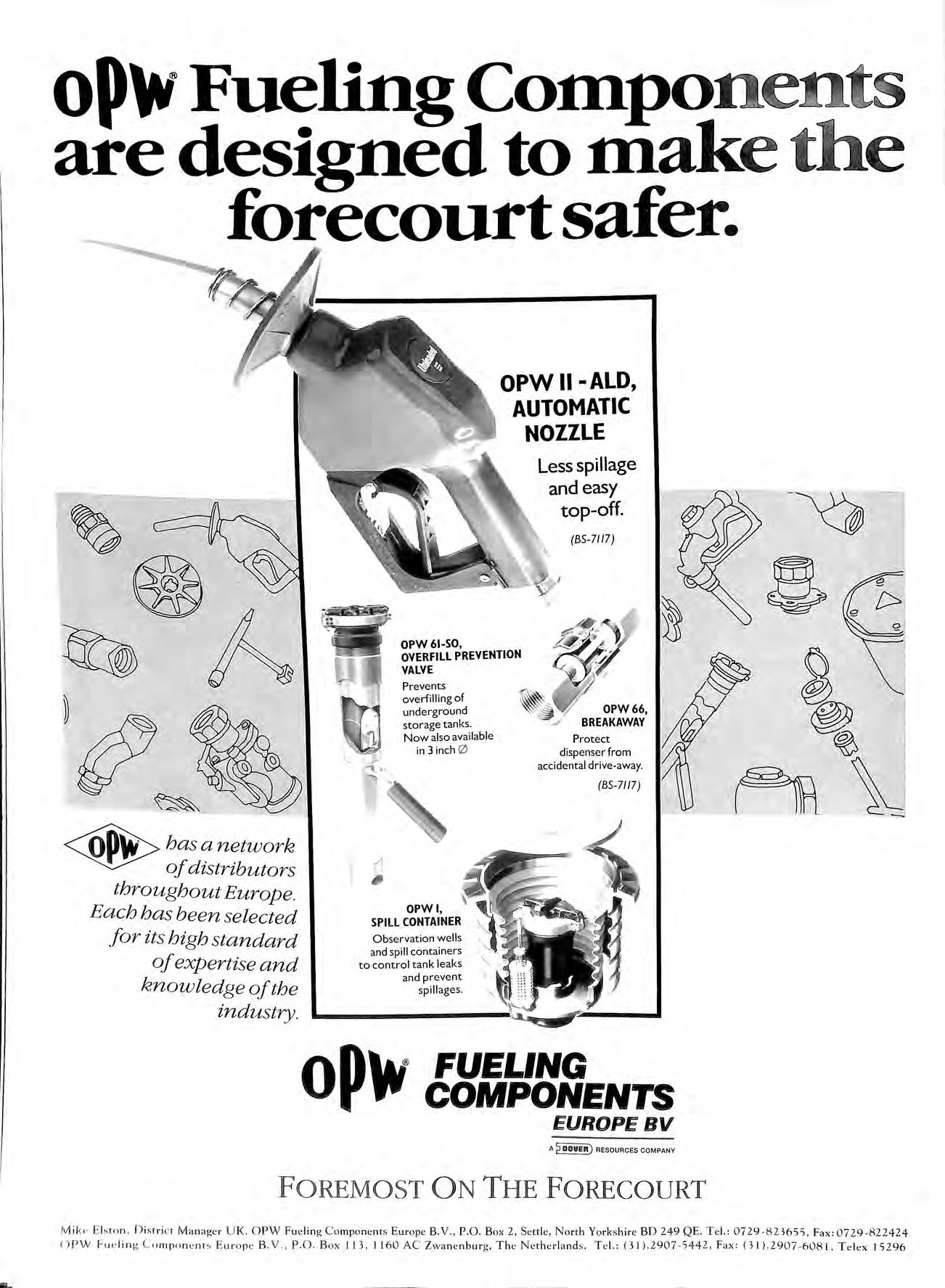

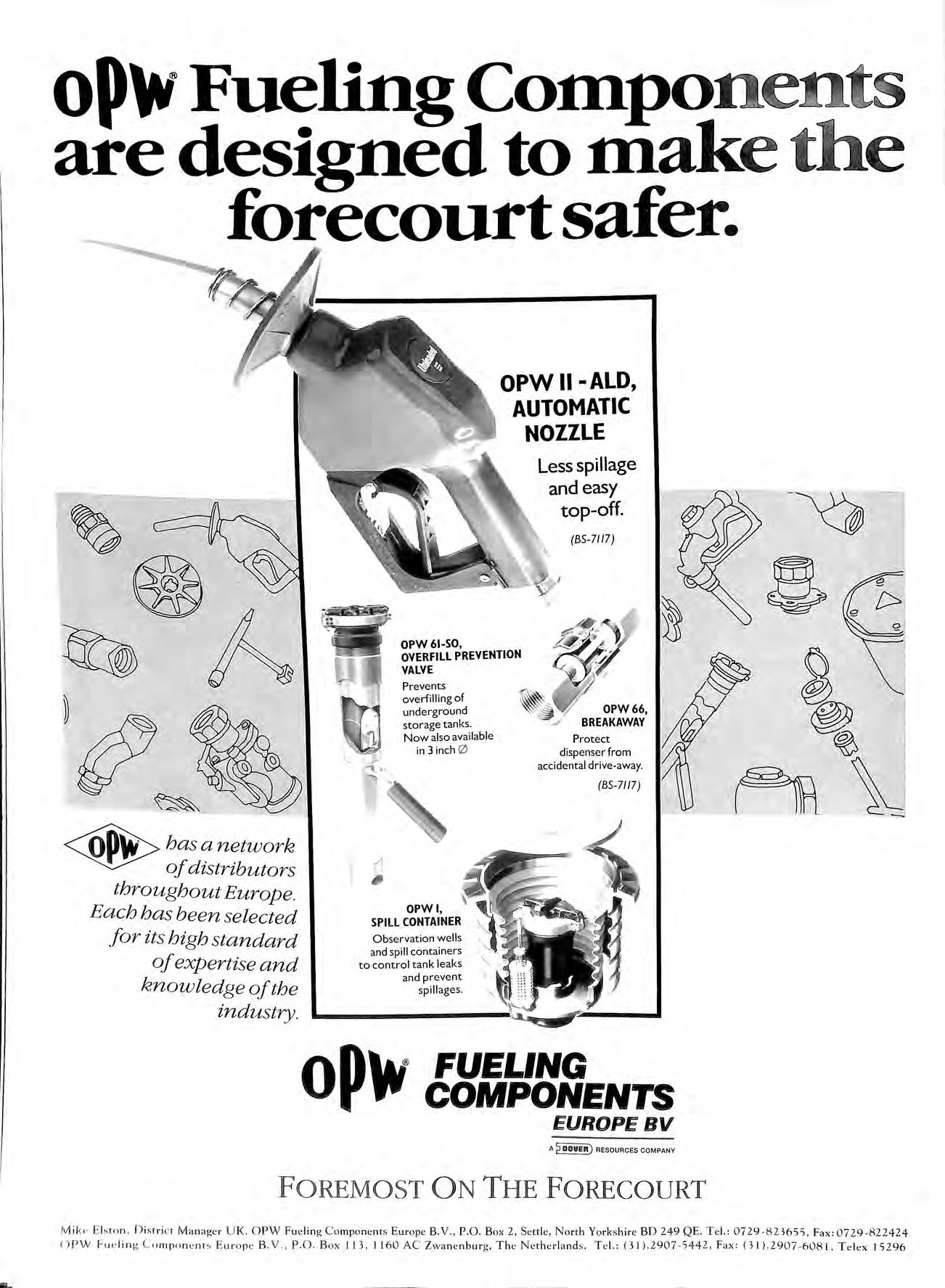

OPW have installed more overfill prevention valves world-wide, than all other competitors _combined The OPW 61-SO is designed to be a simple, low-cost solution to positive shut-off of product fill for underground storage tanks

Industry standard

Ready fitted top-tube and deflector guarantees integrity and strength of mounting

Top flange with 0-ring, easy to install.

Less restrictions than competitive valves.

Distributor network second to none.

Available in 4" and now also in 3"0

Overfill prevention valves should only be installed by installers competent to HSG-41.

p 0 OVERFILL PREVENTION VALVE WITH TOP-TUBE THE VA L VE RESTS AGAINST TH E I NSIDE OF THE DROP TUBE ALLOWING FULL FLOW. W H EN LIQUID LE VEL RISES TO A PR EDETER M I NED LEVEL, THE VAL VE A U TOMAT IC ALL y CLOSES. u e! TOP-FLANGE EASY TO INSTALL! TOP-TUBE FACTORY FITTED! FLOW-DEFLECTOR FACTORY FITTED!

•

•

•

•

•

•

•

FUEi.iNG COMPONENTS EUROPEBV A 2OOUER ) RESOUR CE S CO MPAN Y FOREMOST ON THE FOH.E COU RT Mik e Elston, D istrict Manager UK. OPW F u e ling Components Europe B.V., P.O. Box 2, Settle , North Yorks h ire BO 2 49 QE Te l. : 0729 821655, Fax:0 72 9 -822 4 24 OPW F u cling Co mp one nt s Europ e B. V., P. O. Box 113 , l 160 AC Zwa n enburg, T h e Net h e rl ands T d.: ( 11 ).2 90 7- 544 2, Fax: (1 1). 29 0 7 6081 , Te lex l S2 96

FEATURES:

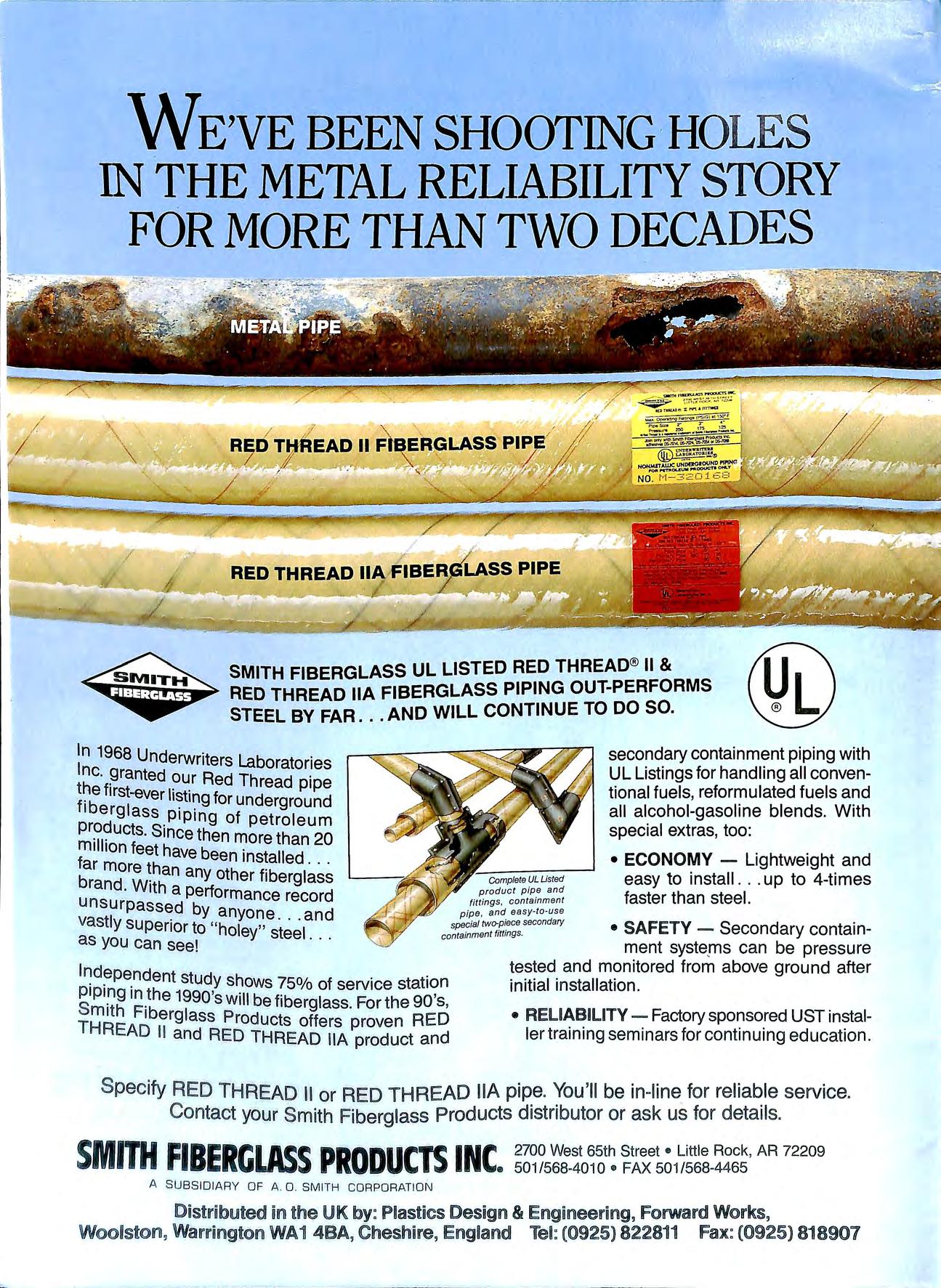

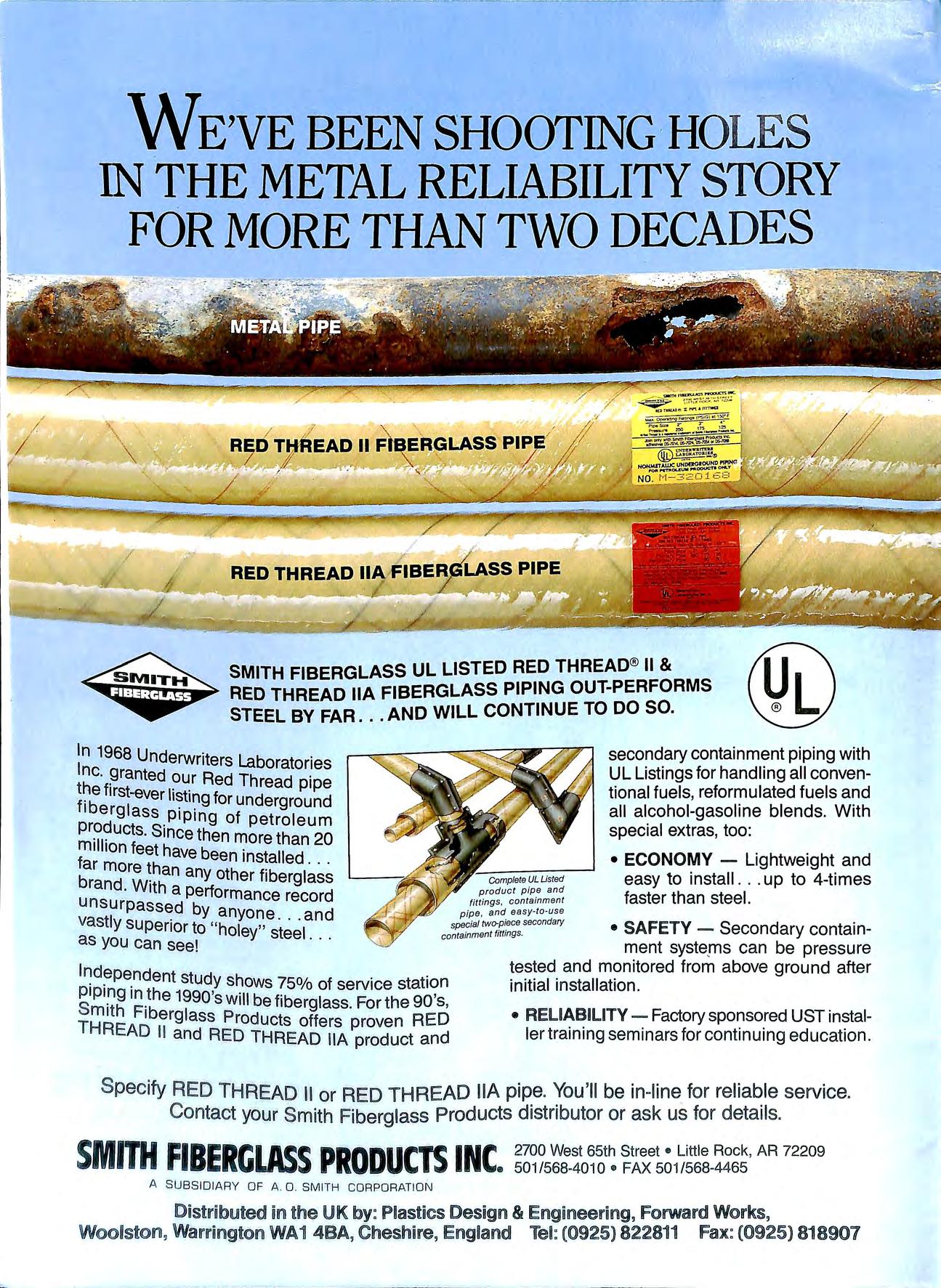

WE'VE BEEN SHOOTING ·HOLES IN THE METAL RELIABILITY STORY FOR MORE THAN TWO DECADES In 1968 U d · 1 n erwnters Laboratories nc. wanted our Red Thread pipe first-ever listing for underground 'r erglass _piping of petroleum P Since then more than 20 fm1lhon feet have been installed ar mor th · · · b e an any other fiberglass rand With u n · ' a Performance record surpassed by anyone and vastly superior to "holey" as you can see! Complete UL Usted product pipe and fittings containment pipe, and ea s y to-use spec ial two-piece s econdary containment fitt ings. secondary

•

study shows 75% of service station 1990's will be fiberglass For the 90's , THRE ib e rg las s Products offe rs prove n RED AD II and RED THR EAD ll A prod uct and •

• RELIA

training

continuing education Spec ify RE D THREAD 11 or RED THREAD llA pipe You ' ll be in-l ine for reliab le service Co ntact your S mith Fiberglass Products distributor or ask us for details SMITH FIBERGLASS PRODUCTS INC 2700 West 65th Street • Little Rock, AR 72209 ' , • 501/568 4010 •FAX 501/568 446 5 A S UB S IDI A RY OF A 0 SM ITH CO RPOR ATIO N Distributed i n the UK by: Plastics Des ign & Eng i neeri ng , Forward Works, Wo olsto n, Warringtorn WA 1 4BA, Cheshire , England Tel: (0925) 82281 1 Fax: (0925 ) 818907

containment piping with UL Listings for handling all conventional fuels, reformulated fuels and all alcohol-gasoline blends. With special extras, too:

ECONOMY - Lightweight and easy to install up to 4-times faster than steel.

SAFETY Secondary containment syste ms can be pressure tested and monitored from above ground after initial installation.

BILI TY - Factory sponsored UST installer

seminars for

JAMES LUKE & ASSOCIATES Safety & Training Consultants to the Petroleum Retail Industry Consultants on Compliance with Safety Legislation Safety Audit Inspections Training of Forecort Staff SALUKI HOUSE Postbox 41 BILLINGSHURST WEST SUSSEX, RH14 ONS Tel: 0403 88471 Fax: 0403 88425 Jobn •tgfull & 1ltb. FIRST HANGINGS BLABY ROAD ENDERBY LEICESTER LE9 SAQ Telephone (0533) 862287 Fora Comprehensive service for liquid fuel & LPG installations Consultancy des· · ' ign, 111Sta/lation, maintenance & decommissioning Gas.free certificates Site surveys LPG vessel 5 & Jo year inspections MEMBER APEA, LPGITA TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET LONDON E2 6QQ Tel: 071-739 9538 Fax: 071-729 6108 MEMBER A.P.E.A. D DC BUILDERS LTD FOR SERVICE QUALITY & RELIABILl1Y WE OFFER A COMPLETE SERVICE ON MAINTENANCE AND IMPROVEMENT WORKS TO THE PETROLEUM RETAIL MARKET D DC BUILDERS LTD 7 ST CLAIR CLOSE CLAYHALL ILFORD ESSEX IG5 OPA Teh 081°550 5216 081°550 6095

The Storage Tank Specialists Established since 1857 "'ENVIROTANK" • Single and double skin petrol and diesel tanks • Above ground double skinned and bunded tanks • Galvanised tanks • Rectangular tanks • Cylindrical tanks • Site erected tanks JOSEP H A S H STORAGE TANKS Storage tanks for all purposes Tel: 021 622 4661 P.0.BOX 16 , CHARLES HE N RY ST. , B IRMINGHAM 8 12 OS P Tel e x: 3379 78 GALTA N , Fax No : 02 1 62 2 1402 0

A. J. Bayliss (Stourport) Ltd Petroleum Engineers Petrol, Fuel Oil and Electrical Installations 3 MOORHALL DRIVE, STOURPORT-ON-SEVERN DY13 BSG TELEPHONE: 0299 824541-2-3 FAX: 0299 827638 SPECIALISING IN ALL ASPECTS OF FORECOURT PETROLEUM INSTALLATIONS AND SERVICING WELDEM LIMITED CONSTRUCTIONAL ENGINEERS CHESHIRE STREET, MOSSLEY, ASHTON-U-LYNE, LANCASHIRE, OL5 9NG MANUFACTURERS OF QUALITY STEEL STORAGE TANKS FOR THE PETROLEUM AND CHEMICAL INDUSTRIES UNDERGROUND SINGLE AND DOUBLE SKINNED ABOVE GROUND . OPEN OR SECURITY SELF BUNDED DIPSTICKS · GAUGES . LEAK DETECTION· OVERFILL PREVENTION FULL RANGE 500 GALLONS TO 40000 GALLONS PRICE LISTS AVAILABLE. SPECIALS ON REQUEST GENERAL FABRICATIONS· VESSELS · STEELWORK LARGE PIPEWORK TEL: 0457 833211 FAX: 045 7 833185

NATIONWIDE TANK CLEANING Petrol, oil and solvent tanks cleaned to associated petroleum industry standards. TEL: (0489) 783462 INDUSTRIAL CLEANING Factory clearances, decontamination ?f buildings and removal of laboratory chemicals. NATIONWIDE FORECOURT DRAINAGE AND INTERCEPTOR SERVICE The regular removal of silt and debris from drain-lines, gullies, interceptors and catch-pits, helps to keep your garage safe from fire and forecourt flood. TEL: (0386) 47190 TEL: (0452) 507432 BULK WASTE SERVICES Wide range of containers for dry industrial waste. Static compactors installed and serviced. TRADE EFFLUENT AND SPECIAL WASTE TREATMENT AND DISPOSAL 24 HOUR EMERGENCY HOTLINE SCHEME ALSO: SKIPS IN DU STR IAL C L EAN ING GUL LY CLEANING WATER JETTING CESSPIT EMPTYING CLEAN SING SERVICE GROUP LTD Head Office: Grang e Road, Botley, Southampton, Hant s . S03 2GD TEL: BOTLE V (0489 ) 7 822 3 2/ 6 FAX : 0489 789821

MANGAN BROS. LTD . Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 071 800 4651 Specialists in Petrol Filling Stations

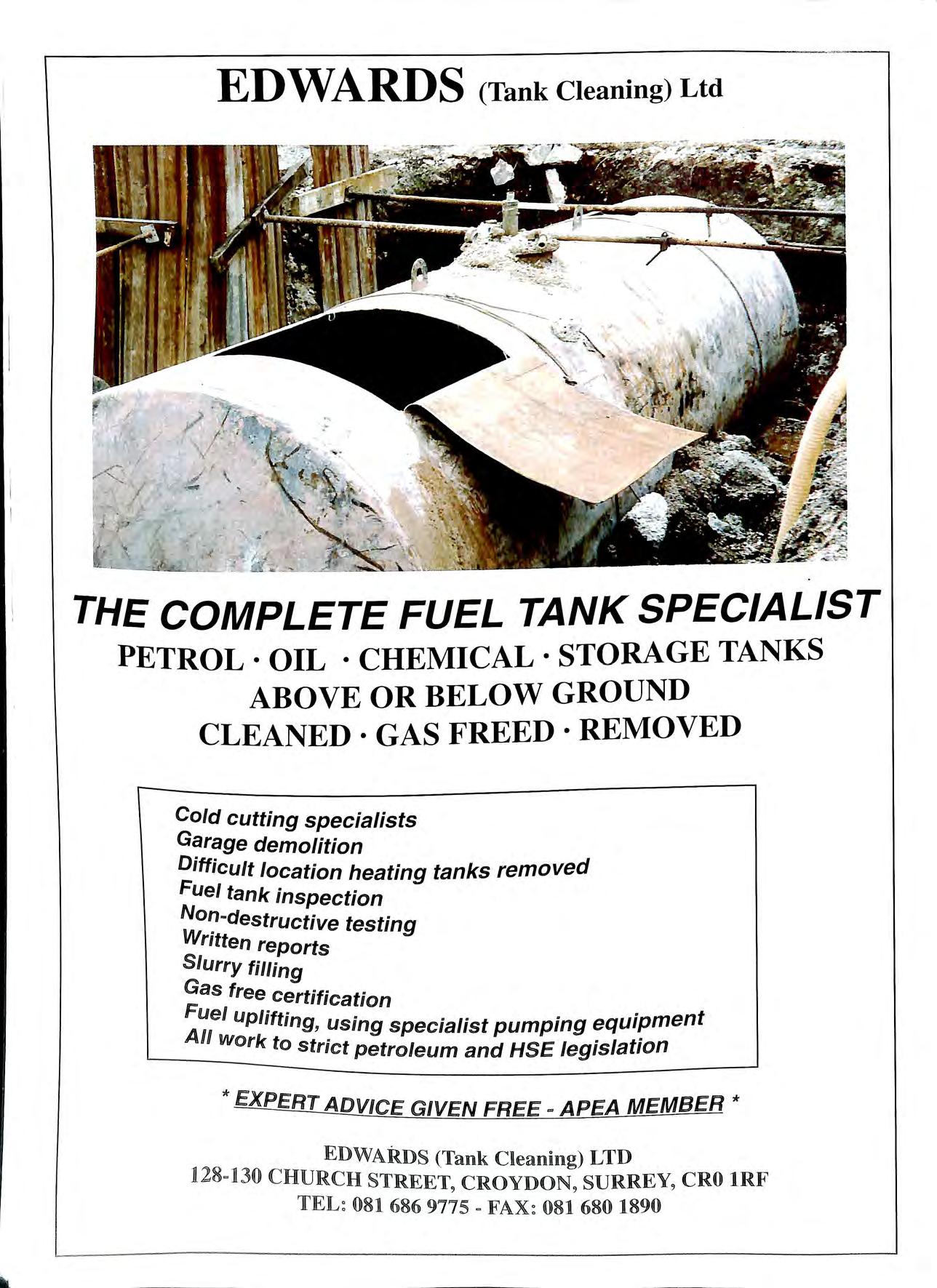

EDWARDS (Tank Cleaning) Ltd THE COMPLETE FUEL TANK SPECIALIST PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED Cold cutting specialists Garage demolition D"tf 1 icult location heating tanks removed Fuel tank inspection testing Wntten reports Slurry filling GFas free certification ue l upfft " . A ll 1 i ng, using specialist pumping equipment w o rk to stri c t petroleum and HSE legislation *EXP E RT A D VI CE GIVEN FREE= APEA MEMBER * EDWARDS (Tank Cleaning) LTD CHURCH STREET, CROYDO N , SURREY, CRO lRF 081 686 977 5 - 081 680 1890

u ILL POINT ADAPTORS u HEAR VALVES I!) 1sPENSING NOZZLES I}) REAK AWAY COUPLINGS PETROLEUM SERVICE STATION EQUIPMENT SPECIALIST l!jAPOUR BALANCING 8 VE RF ILL PREVENTION 8 BSERVATION WELLS 0 OTAL CONTAINM ENT ml 0 7 0 8 863931 m0708 868226

Talking Point

The Bulletin this volume has some interesting about some of the issues that the industry has to face m the months ahead.

The issue of GRP versus Steel is one that will to dominate the debate as manufacturers place ments of their product before the Oil Industry and try to mfluence the thinking as they plan installations, paper on cathodic protection tnes to address the problems we experience steel, another the leak detection and location when thmgs go wrong

What is however certain is that most of the Industry has moved forward in leaps and bounds over the past few years _ from and industry that had not looked forward on underground installations since the 1930' s.

Another paper mentions the problems this has to petroleum licensing authorities and the uncertainty this brings to contractors and also the need for updating of the codes of practice and the need for tho_se m the forefront of the changes to make sure that experience and knowledge is passed on.

The Bulletin

the Association for Petroleum and Explosives Administration VOLUME,30 Number3 AUGUST 1992 A company Limited by Guarantee registered in England No. 2261660 Reg. Office: Stoughton House, Harborough Road, Oadby, Leicester LE2 4LP £5.00 (Free to Members) ISSN 0263 4597 Contents TALKING POINT 47 NOTES &NEWS 48 DOUBLE SKIN TANK 51 MODERN FORECOURTS AND THE DISABLED 55 TANK & PIPE CORROSION 59 LEAK DETECTION & LOCATION 61 THE FUTURE OF ENFORCEMENT 63 NEW MEMBERS 65 LETTERS TO EDITOR 67 MEMBERSHIP SEC. EASTERN BRANCH B. J. Thompson R. G. Green ADVERTISING SEC. HUMBERSIDE BRANCH R. G. Green J. Horsburgh

Mr D. Bucknall Opinions expressed in this Journal are not

the

of the Association

Published by

Honorary Secretary:

necessarily

views

MIDLAND BRANCH NORTH WESTERN BRANCH L. Lloyd CMS Ltd.

NORTHERN BRANCH Susan Brians

Honorary Editor: Mr. J. A. J. Thompson, 47

H. Reid Pump Services (Manchester) Ltd SOUTHERN BRANCH J. Luke

and news

SEMINAR AND EXHIBITION DUNSTABLE S/6TH OCTOBER.

The seminar and exhibition will be held at Queensway Hall on 5/6th October this year with a wide variety of subjects chosen.

Exhibitor information can be obtained from Chris Knight, telephone 0992 451494. Details of the seminar can be obtained from the Hon Secretary, but members will all receive information and a chance to book early shortly.

Subjects to be covered include:-

European Double Skin Tank Standards

Mr Marez Cerec France

European Emmisions Directive

Mr B Smithers BP Brussels

Environmental Engineering at Petrol Stations

Peter Alan Mobil UK Oil

Third Party Verification of Precision Tank Testina

• b EqmpmentDr Wilcox USA

Swedish experience with Stage 2 installations Jim Healy USA

Dynamic Overfill Prevention Systems at the Filling StationBob Scully USA

Soil Surveys on Petrol Stations speaker to be announced

ELECTRICAL TRAINING COURSES

The Association is to run an electrical training course for members of the Association and the date has now been fixed for 16/17 November 1992.

A review of the provisions for electrical installations at petrol filling stations incorporating the requirements of HS(G)4 l and BS 7117 and other significant changes in the for the Electricity at Work Regulations 1989 will be made in the two day course which will be held at Haygarth House Retford in Nottinghamshire.

The residential course will be costed at £ 180 for members of the Association and £210 for non members and will include accommodation. breakfast on the 17th. with both days and an evening meal on I6th. Course notes w!ll he provided and also copies of HS(G)41 and HS(R)25. The ohjecbves of the course is to provide a better of electrics at the filling station, and is designed for, petroleum enforcement officers, Oil company engineers. and contractors staff.

Full details will be circulated to all members shortly but should you wish to book early or need more information please contact the secretary for this training course Mrs E Taylor telephone 0582 882170.

SMOKEY AND THE STAR BONFIRE

A Police Officer passing a filling station noticed smoke from a bonfire close to the vent pipes. Knowing that this was a dangerous practice he alerted the Fire Brigade and instructed the filling station to douse the fire with water.

Subsequent investigations by West Sussex Trading Standards Officers revealed that the manager had allowed an employee to bum boxes and similar waste near the vents. (The fire was within l .3m of the vents).

On the 25th March this year Texaco Ltd, TIA Star Jeremys Comer, pleaded guilty at Heath Magistrates Court to failing to take all practicable steps to secure that no naked fire or flame was dangerously near any place where Petroleum-Spirit was kept, handled or exposed, and were fined £500 with £80 costs.

The employee revealed that he had lit similar fires 5 or 6 times before and that he had been told by the manager that it was alright. (He had received no formal The manaaer has since left and the employee, who did not know the of the vent pipes, (and went quite ashen when told), has now received formal training.

HYTEK DOUBLES UP ON QUALITY

Hytek is pleased to announce that they have been awarded not one but TWO quality approvals to BS 5750.

A I dina distiibutor of fuel handling equipment, the s a ea b f "R . d h been awarded the status o eg1stere company as Stockist" and the manufacturing div1s10n, which produces a range of fuel dispensing equipment has won the coveted "Reaistered Company" approval. b

Both these approvals, granted by National Quality Assurance, also cover the international quality assurance standard ISO 9000 which is becoming increasingly important with the company's overseas contacts.

The company supplies a wide range of equipment for use in the construction of retail petrol filling stations and also to dispense fuel to commercial vehicles including those operated by local authorities. British Gas, British Telecom and many other nationwide transport operators.

These awards mark the culmination of over 2 years work _by everyone within the company to make it's products and services more responsive to the specific needs of it's customers.

For further information please contact:Kevin Arnold or Ian Taylor on telephone 0279 815600 or fax 0279 812978.

notes

48

APEA SEMINAR 1993

The Association is planning a seminar in Europe in the early part of 1993 to coincide with the opening of the Benelux branch of the Association. Speakers from key European companies will be invited to speak and it is hoped that a large number of members will be able to take advantage of the package that the European coordinator Bri a n Taylor is putting together following talks with large ferry operators. Further information will be published as detail s are firmed up but should any company wish to di sc us s matters with Mr Taylor he can be contacted on 0480 457344.

PRECISION TESTING COMPANY GETS APPROVALS

PM installations have started a tank testing services having obtained the full approvals necessary in the UK. The two trucks have been equipped in the UK. The probes and equipment to be u sed in the ha zard zones are fully approved and certified by BASEEFA and the equipment itself ha s been third party tested in the USA and the UK by independent te st houses who have verified that the te st m ee ts the leak requirement s of the US and UK. Routine te sting has already commenced in so me parts of the country and this method that can be u sed with product in the tank s is proving a popular choice. -

Easy Installation with OPW 61 SO Overfill Prevention Valve Series

The OPW overfill preve ntion valve series is des ig ned to be a s imple , lo w cost so lution to s hut-off valve .1s an integral part of the 4" drop tube used for submerged filling. The OPW 61-SO allows easy installation without break m g concrete, and no special manhole s are required.

An enhancement th at makes in stallation even eas ie r is a defl ector that is factor y-in stall ed in the upper tub e. Factory in s tallation of th e defl ec tor he lps in s ure prope r place me nt _ of the defl ec tor , and re li eves contractors from th e task ot. ri ve tting. Other in s ta ll a ti o n e nhancement s in c lud e a n upp e i tube attached to th e OPW 61-SO valve before s hippin g and a flan ae d inlet tub e includ ed with the produ c ts. Th ese 0 · I 61 SO mode l e nhancements also apply to a specia designed for a 3-inch ri se r pip e

S TEEL TANK EMPTIES

A 17 yea r o ld steel tank recent ! I , o1 pe trol as it e mpti ed fo ll Y. ost app 1ox 7000 li tres ow in g a failure is the ta nk s he ll. Th e in s tallation had rece ntl y b h I . ee n te sted before va po ur a a nc 111 g had bee n in s tall ed a nd had . . . . . . ope1ated satisfactorily /()J -, om e mon th s. Th e fa ilure oc c urr ed . ft I I d e1 a oac was d e li ve re d lrom a road tank e r whi c h was not fitt ed w ith ' a 1)(lt1r ha la nc 111 g. and it was tho ug ht that the press ure bui ld l· ; 111 c d th e tank w hi c h was late r d isc o ve red to be bad ly l ( HTI 1dn l II) b u

.th no pre -c hecks to Operation is co mpl ete ly automatic w i cl ·cl be broke n o r a bu se · Pe rfo rm. no rese ts. no ove 111 es to cl I .th w upp e 1 a n The OPW 61-SO is furni s hed co mp e te w i ne h cl ·e and in s tru c ti o ns foi lower drop tub es, mo untm g ai wa 1 · quick j ob s ite tim e.

The OPW 61-SO is s uitabl e for re mote fill applic a ti ons. w he re th e fill po int is not direc tl y over th e UST. Th e OPW 6 1-SO e nab les st ick in g of th e tank.

Fo r more in for mat ion o n the OPW 61-SO ove rfi 11 preve nti o n va lve se ri es. co nt act OPW Fue llin g co mpon e nt s E urope BV , Zwa ne nbur g. Net he rl a nd s. phon e: ( 3 1) 2907 5442: o r appro ve d d istributor s

EUROPEAN

49

OB ITUARY

CW (Jack) Brudenell

Hi s ma ny friends and form e r co ll eagues will be sad to le a rn of the death on 26 April 1992 of Jack Brudenell wh o retired as Chief Officer of Trading Standards for Humb e rside in December I 988.

Jack trained and qu alifi ed in th e service of Lond o n Count y Council, trans fen-ing to Middlese x County Council as a Di strict Inspector in I 952. Whil st there he obtained the Diplom a in Municiple A dmini strati o n and de veloped a n inte res t in the organisation of trainin g which he carried o n as a spare tim e activity .

In 1961 this interest led him to o btain a post as the fir s t region al Education and T ra ining Officer, assisting some 104 local authorities to train all type s of staff.

Wh e n the Consumer C oun cil was cre a ted in 1964. Jac k w as th e onl y local authority offi ce r a ppointed to th e ir staff. He was mvolved in the di sc uss io ns on the formulation o f th e De scri ption s A_c t. H e c rea ted the national qu alit y ass uranc e and 111format1 ve la be llin g scheme known as T E L and was a member of 40 Briti sh and 1O Intern at101_rnl Standards Committees d ealing with method s o f measuring performanc e of hou se hold goods.

In 1971 he joined Suffe y County Council as D eputy Chief Officer and in 1975 he moved to Humb erside as Chief Officer. Thi s was at a time just after reorgani sation of local government. He immediatel y began the tas k of blending the 5 sep arate authorities with their wide varie ty of differing e xperien ce a nd outlook. He became ju stly proud of his first class tea m of officers who achi eved a hi gh le ve l of performa nce and became nationally recogni sed in all spheres of trading stand ards work.

Jack Brudenell was a memb er of the A ss ociation for s ome 20 years startin g with hi s time with Suffey county Council. Followin g hi s mo ve to Humberside in I 975 he became one of th e earli es t members of the York shire and Humberside Branch th at he was a very sta unch supp orter of the Association was de monstrated by hi s reg ular a ttendance at Annu al General Meetings which in th e early days were poorly supported It was also shown by the number of Humb e rside staff attending both A ssoc iation and Branch meetin gs He supported widening th e me mb ership base of the Associ ation to include industry as well as local a uthoritie s.

A funeral se rvice was held at Hull on Frida y 1 M ay and was attended by man y fri e nd s a nd former co ll eagues fr om all parts of the country . Dee pe st sympath y is e xtend ed to hi s wife Dorothy , daughters Jill , Kim and Sall y, and g randchildren Alasta ir a nd Clair.

GOING DUTCH

A pa rt y of o . 30 tt d d vei me mbe rs including ma ny w ives a e n e a Semina H 8 h T <1 111 o ll a nd a rra n oed by th e Eas te rn ra nc he party "' s uccess full y made th e 111 ght-t11n e cross in g fr o m H h ar w ic to Th e Hoo k with o ut a ny maj or mi sha ps.

The se min a r was li e ld · 1 111 t 1e ce ntre of Ho ll a nd at Ge ld e rm a lse n by co urtesy of A nii ei·o11 Tl · as 1e se mm ar w , we ll orga ni sed in c ludin g three excell e nt pre pa red p rese nt ati o ns. Me mb e rs fo un d the pa pe r prese nted by Pe te r Va n de r Gaag of E. P.S. Ma rke tin g o n var io us leak detec ti o n sys te ms mo st inte res tin g. M r C ha rl es de Boer o f Po le m

prese nt ed a pape r o n the ma nu fac ture of G.R P. Storage Ta nk s. He shared hi s va lu abl e ex perie nces in th e di ffe re nt me th ods of in sta llin g th ese ta n ks in E uro pe. Fin all y , Soop va n Ge nt of A mero n gave a prese nt a ti o n o n G .R.P . pipewo rk sys te ms a nd th e be nefit s th ese sys te ms have bro ught world -w id e.

The re was tim e in the late af te rn oo n to re lax fro m th e bu sy sc hedul e . With the ladi es in mind a nd exc ur s io n was made to Th e Fl o ri ade F lowe r Fes ti va l w hi c h is he ld eve ry te n year s The arr a nge me nt for th e ni g ht fe rri es a nd se min ar we re exce ll e nt a nd gave me mb e rs from indus try a nd loca l a uth o riti es the o ppo rtu nity to d isc uss in fo rm a ll y ma ny Pe tro le um ma tte rs.

so

DOUBLE SKIN STEEL TANKS

By John Jenkinson Managing Director, WEFCO Group Ltd.

To try and accurately quantify the rel ative qualitie s of Double Skinned Steel and GRP Tank s would be a folly. lt would be s hockingly e moti ve and s ubjective (with a hint of bias) and unlikely to achieve an accurate technical co nclu s ion. There are droves of papers a nd statistics available both in Europe and the United States offering pract ical experience and advice.

The photograph s hown above wa s taken from a j o urn a l in the U nit e d Sta tes w ith the cap ti o n:

'Stmc turol Failure Im proper fn stal!otirm" 'Does it rea ll y rnal!er'

T he point be in g mad e was that failure s in GRP tanks c ou ld res ult in catastrop hi c loss with a ll stored contents be in g lo s t aft e r st ru ct ur a l fai I ure. Stat istic s ava i\abl e from th e U S. re port GRP tank failure rat es to be ten tim es worse than co rro s ion protec te d stee l tank s and attr ibuted t hese I to:

Press ure

Fa ult y manul'a c turin g.

Ground se ttlement. Manway riser pressure

Mechanical damage Internal and External. Failures caused by se nsiti ve and difficult installation procedure s

An independent survey carried out by a national trade publication in the United States s ugge s ted there was a move away from GRP and that Steel protected tanks command a 68% market sha re at all C-store/petrol locations, whilst. GRP only hold a 22 % share. The balanc e was made up o1 co mpo s ite tank s and others.

Suffice it to say that in the United Kingdom durin g the la s t two years. with one exce ption , a ll the major oil co mp a ni es, mo st of the s upermark e t c hain s and a hi g h proportion of independent fuel di s tributors ha ve made a wise and well conce ived d ec is ion o pting for Steel Double Sk inn ed Tank s (DSST) w ith a so phisti cate d ex te rnal co ating and e lectro ni c leak d e tec tion

5 1

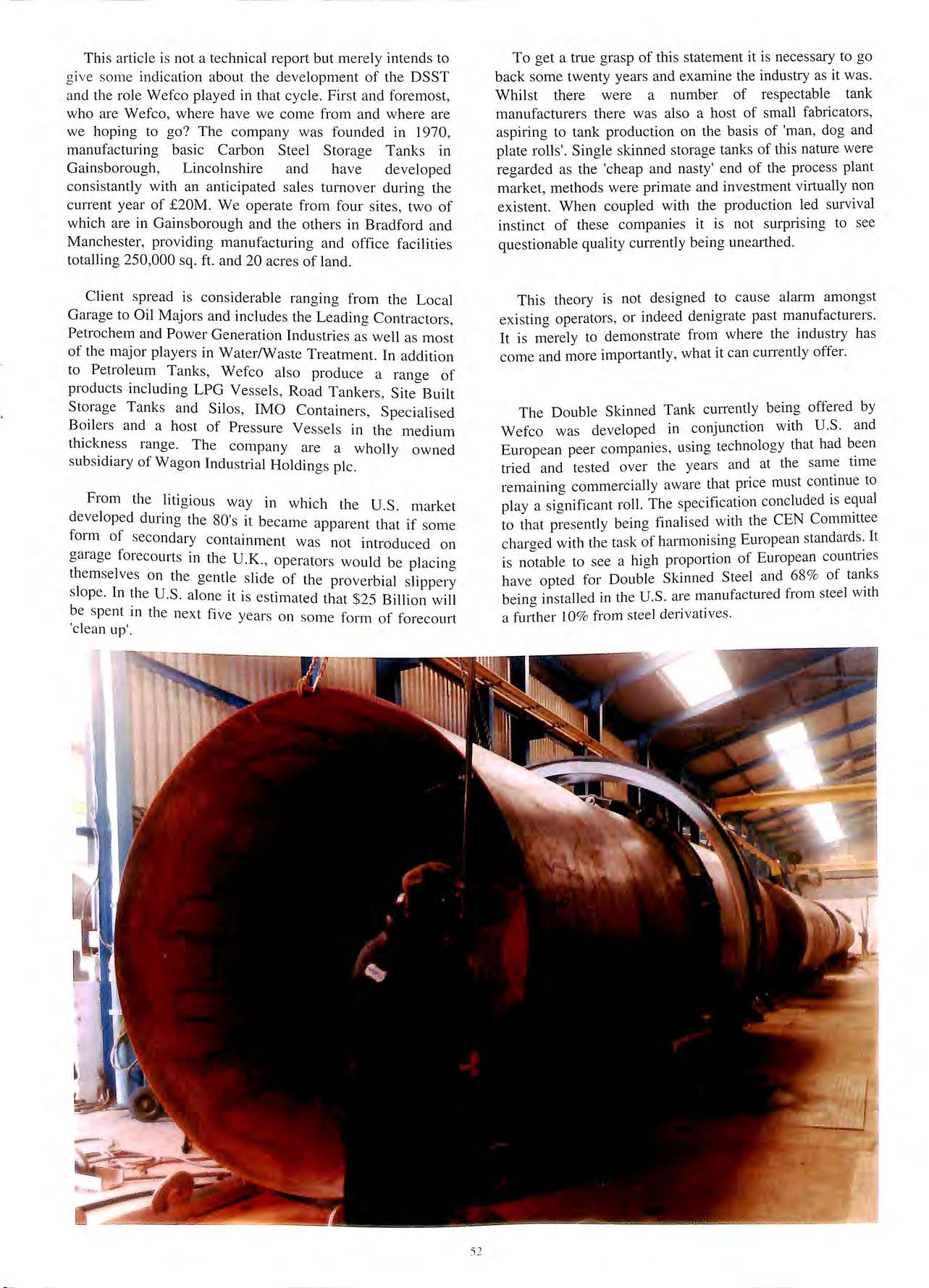

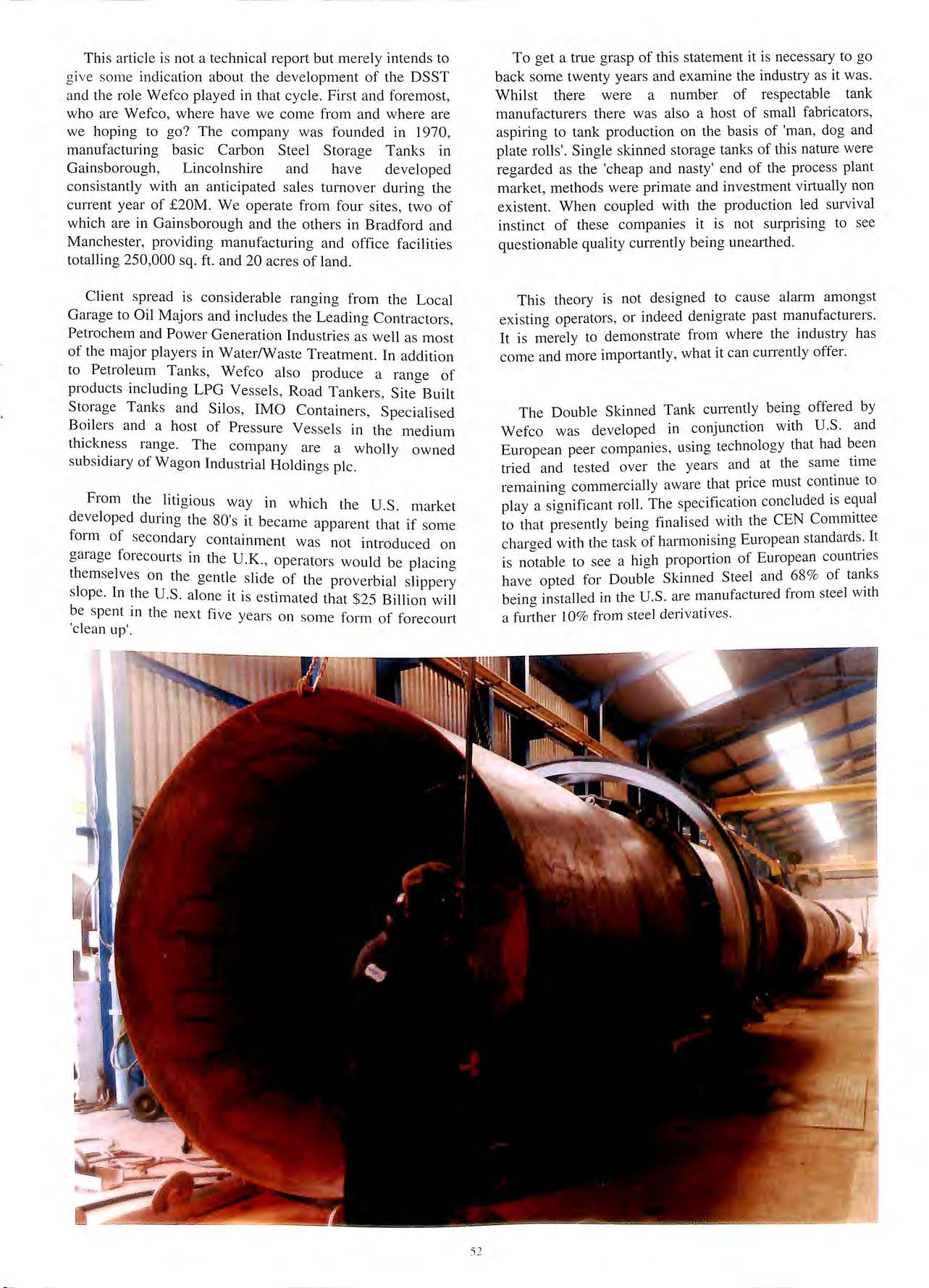

This article is not a technical report but merely intends to g ive some indication about the development of the DSST and the role Wefco played in that cycle. First and foremost, who are Wefco, where have we come from and where are we hoping to go? The company was founded in 1970, manufacturing basic Carbon Steel Storage Tanks in Gainsborough, Lincolnshire and have developed consistantly with an anticipated sales turnover during the current year of £20M. We operate from four sites, two of which are in Gainsborough and the others in Bradford and Manchester, providing manufacturing and office facilities totalling 250,000 sq. ft. and 20 acres of land.

Client spread is considerable ranging from the Local Garage to Oil Majors and includes the Leading Contractors, Petrochem and Power Generation Industries as well as most of the major players in Water/Waste Treatment. In addition to Petroleum Tanks, Wefco also produce a ranoe of products including LPG Vessels, Road Tankers, Site 0 Built Storage Tanks and Silos, IMO Containers, Specialised B01lers and a host of Pressure Vessels in the medium range. The company are a wholly owned subs1d1ary of Wagon Industrial Holdings pie

From the litigious way in which the U.S. market developed during the 80's it became apparent that if some form of secondary containment was not introduced on garage forecourts in the U.K., operators would be placing themselves on the gentle slide of the proverbial slippery slope In the U.S. alone it is estimated that $25 Billion will be spent in the next five years on some form of forecourt 'clean up'

To get a true grasp of this statement it is necessary to go back some twenty years and examine the industry as it was. Whilst there were a number of respectable tank manufacturers there was also a host of small fabricators , aspiring to tank production on the basis of 'man , dog and plate rolls'. Single skinned storage tanks of this nature were regarded as the 'cheap and nasty' end of the process plant market, methods were primate and investment virtually non existent. When coupled with the production led survival instinct of these companies it is not surprising to see questionable quality currently being uneaithed.

This theory is not designed to cause alarm amongst existing operators , or indeed denigrate past manufacturers. It is merely to demonstrate from where the industry has come and more importantly, what it can currently offer.

The Double Skinned Tank currently being offered by Wefco was developed in conjunction with U.S. and European peer companies , using technology that had b.een tried and tested over the years and at the same time remainino commercially aware that price must continue to play a si;nificant roll. The specification concluded is to that presently being finalised with the CEN Committee charged with the task of harmonising European standards: It is notable to see a high proportion of European countries have opted for Double Skinned Steel and 68 % of tan.ks beino installed in the U.S. ai·e manufactured from steel with b a further 10% from steel denvat1ves.

52

the specification had been brouaht in line with the remamder of E . o Pl.od urope, 1t was nec essary to consider the uction f T the 1 aci ity and Q.A. In May 1991, Wefco became on Y compa petrol n y m the U.K. co ntinuou s ly producing eum tanks to · l!Isp900 l. receive accreditation to BS 5750 Part

Whi lst a Deu A existed s· ma utomated Production Facility had mce 1980 · · sub stantial f" ' not wishing to rest on our laure ls, a 1ve ftaure s . o ur expand d f 0 um was rnvested rn 199 l to bnng e ac 11Jt · 1· plants and be able Y m me w ith the best. of the Eu 1:o_p ean demand Th to cope w ith the ant1c1pated add1t1onal e new produ t 1· perform s c ton me shown on adjacent page s ext reme ly well d . productivity 0 l an g ives a quality and indu s try. 0 iarantee un surpa ssed by anything in the

Th e Endopren p durabl e o lyure thane coatin a is extremely e , s cratch re s ist 1· o o f 500 . ant , a pp ted to a minimum thickne ss microns and s , ·k d es 1)at h T ' Pell te sted to 25000 vo lts prior to ' < c · he rubb · d e J· ei covere d s upport cradles used during Ive ry tooethe r .tl ' . ' t, 1 ° WI 1 on s ite repair k its se nt with every an < re duce s th · k · d , , e 11 s of las trn g tran sport and rn stallat1on c1mc1 ae Our 'c t 1 ° · us Omer c a re ' se rvic e fo ll ow s each delivery w n 1 a telepho h . ne c e c k li s t to establi sh all as pects of th e wo 1k we nt accordin g to p lan.

Ca thodi c protect1.011 . f. I d b us rn g sa c n 1cia a no e s a re e rno o ff e re d a t a b 0 c o s t are ly 5 % of se llin g pri c e whi c h a re both ve r y e asy to m o nito r a nd ca n g ua rantee the life of th e ta nk s to we ll 0 2 5 . ve 1 ye ars Th e Propy le ne Gly c o l mi x ture use cl in th e 1nte 1·s t1·t· J · · 1a s pace as a medium to detect ev en th e s m a ll es t o f le a l<s 1s b. cl cl b i · II · , · 10 eg ra a e , e nv1ronm e nta y fr1 e ncl ly ve 1· · . Y easy to m o n 1to r a nd e x tre mel y c o st e ffec t! ve. Pro g rcss 1 , cJ J · ·, ve eve o pm e nt of o ur produc t has proclu cecl a d c.., ig n f"o r t he int e rs titi a l s pac e c a pa bl e of be in g ove r p rc..,.., un secl to the ex te nt of a t le as t o ne third in ex cess of I Ill' ll 6 ha r c ur re nt! y he in g s ug ges te d by CEN.

. I I doubt that Steel Double Skinned There 1s abso ute Y no o T k with Endoprene Polyurethane coatrngs a nd Stoiaoe an s t effective and Catho dic protection are by far the most cos k L t 1 bi the m ar et. ongev 1 y structura ll y reliable tank avai a e on I not subject to the of life is more than adequate a nd stee _ is .· d "th construction a nd in s tallation difficulties expe11ence w1

GRP

. . ompany within o ur

With the assistance of a s1ste1 c Ch be ·s w ith a f GRP Access am I c gro up , Wefco now of er with sea ls designed variety of sh apes and f1x111gs, complete . ·k ( ht after p1pewo1 to make the chamber totally watei ig f. ·t t of o ur 01 ecou1 installation. The contrnued developmen ,. , · bi to of1er a o ne product range has the Objective of being a e . f 11 stop' shoppin g concept. Exciting new product s w ill 0 ow in the month s ahead

Weldem Ltd. of Mossley, East Manche s ter o nce regarded as the 'Gentlemen' of the tank market were recently acquired by Wefco , making the combi ne d sum of our two companies a formidab le team in the indu stry.

An article recently published in The Bulletin sugges ted it_ may take s ome time to break down traditionali s t view s of s teel as the med ium for petroleum storage and that o ne co uld not imagine a ny other material but GRP for interceptors. When c on s iderin g the fac ts of the matter and that o nl y one Major ha s opted for GRP Petrol Tank s the former is ce rtainl y correct

Of the latte r, it wou ld seem there has ne ver been a credib le Stee l a lte rnativ e a vai lab le , a s ituation no w be ing re ve rsed by th e intro du c tion from Wefco of a Sin g le and Doub le Wa ll Oi l/ Wate r Se parator , lined inte rnall y a nd ex te rnall y and fitted w ith C o a le sc ing Filte rs . Pe rh a ps th e Int e rce ptor traditi o nali s ts mi g ht a lso like to think ag ain ')')

53

MODERN GARAGE FORECOURTS:

OR FOR THOSE WE SERVE, OR HAVE TO SERVE THEMSELVES.

BY BRIAN BLAKE.

The advancement of modem technology with new 'shiny' self service pumps, the installation of self service Garage shops, where you can buy anything from Newspapers to Flowers to a 3 course pre-packed Microwave Meal. The modern Garage Forecourt has perhaps in the main, been by the average motorist. tight and increased margins have no doubt played their part also in the denuse of the old style Garage.,

However, I would submit that not all sections of Society have welcomed all aspects of this new 'breed' of Garage. Gone are the days, when you could rely on a friendly attendant to serve you with the 'odd' oallon and with the sale they oave G S 0 o you reen h1eld stamps! as well! all for 25p a oallon ( t I h "' , no , asten to add 25/30p a gallon was not that '.11any years ago). I mourn, the passino of 'the old style attended' oara "' . d "' ge service , particularly as a severely disable motonst wh , lf ' ere se service pumps' have presented further problems to If I myse and many thousand of fellow disabled co leagues.

Improved t h I d ec no ogy, and Soc1et1es greater awareness an under t d. 11 s an mg of the disabled persons needs, have a owed a · s1gmf1cant increase in mobility for the mcapacnat d 's If . e person, therefore the mcreased prov1s1on of e -service' G eh · arages nationally , has sev erely restricted the o1ce of Garaoe d f ·1· c"' s an ac1 1t1es to the disabled driver.

Motorway s h d bi ave allowed greater mobility for the isa ed and h with d. ' b muc ha s been done to assist the di sabled, f d isa led toilet s and wheelchair ramp s etc., but a un amental pr bi f 0 em exists when the driver requires petrol , o course if th d · ' ). bi ' . e nver ha s an able bodied passe nger no 10 em exists but · tl , many driver s travel mdependently as 1s 1e 1r choice. '

In th e main the · · 111capac1tated dnv e r tend s to use his local Ga rao e. where th 0 · e ca1 1s rec o g111 sed , and tne s also to c onform to 'off I · h pea< o ur s, to rn1111m1 se pressure on Garage pe 1so nn e l howeve i· th.

1 ' is severe y re s tnct s the 111d1v1dual , tro m a c ho ice of · se 1vices and Garage s, not encountered by th e ab le bodi e d mo tori st.

Rece nt G uid e lin es for th e di sa bl ed driver , whe n re LJuirin g se r v ice o r ass is tance ha s been oive n by a b pa n 1c u Ja r Gove rnm e nt s pon so re d mo torin g C hari ty, they q 1gges 1 amo n gs t o th e r thin gs . t hat 'a ny di sa bled driv er re quirin g a ss is ta nce firs t. dri ve to cas hp o int and indi ca te 1hro u g h th e w ind ow to th e atte nd a nt , o r alte rnativ e ly as k a le Ilo w d r i ve r lo po int n ut yo ur p rese nce o n th e fo reco urt' 1

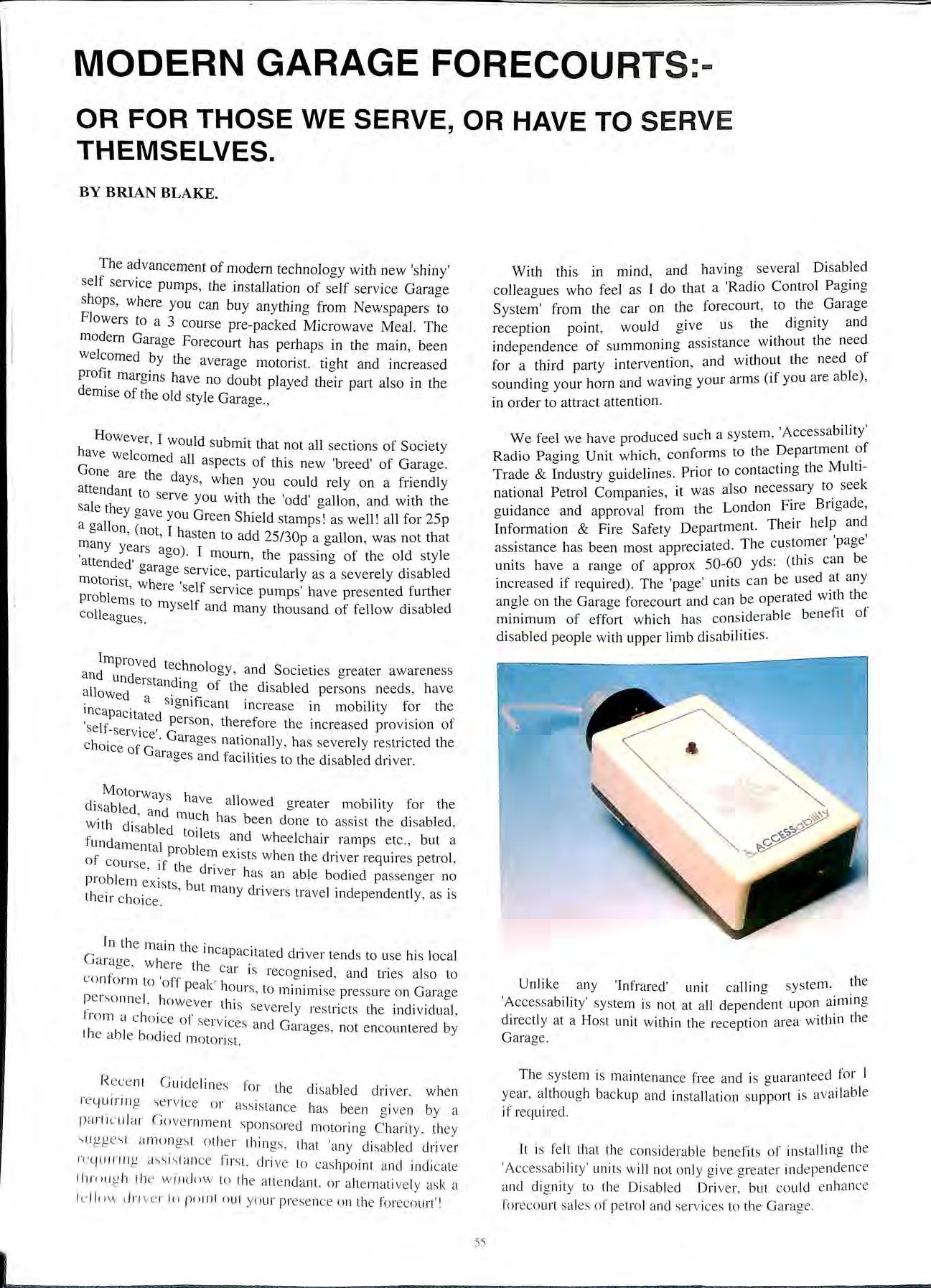

With this in mind, and having several Disabled col!eaoues who feel as I do that a 'Radio Control Pagmg from the car on the forecourt, to the Garage Id l!S the di anity and reception po111t, wou give o · si·stance without the need independence of summomng as for a third party intervention, and without the need of cl · ur arms (if you are able), sounding your horn an wavmg yo in order to attract attention.

h tern 'Accessability' We feel we have produced sue a sys , Radio Paaina Unit which, conforms to the 0 0 t ctina the Mu t1- Trade & Industry amdehnes. Pnor to con a "' "' I necessary to seek national Petrol Compames, 1t was a so h L don Fire Bn °ade, guidance and approval from t e on ° D ·t e11t Their help and Information & Fire Safety epa1 m · , , · cl The customer paae assistance has been most appreciate 0 So 6 0 ds· (this can be units have a range of approx Y · cl .f d) Th ' ' 11.ts can be used at any mcrease 1 require . e page u1 b erated with the angle on the Garage forecourt and can e op . h h ·c1ei·able benefit of m1111mum of effort wh1c as cons1 disabled people with upper limb disabilities.

Unlike any 'lnfrarecl' unit calling system , the 'Acce ssability ' system is not at all dependent upon aimmg directly at a Host unit within the reception area within the Garage.

The sys tem is maintenanc e free and is guaranteed for I year, although backup and in stallation s upport is available if required.

It is felt that the co nsid erab le benefits of in s talling th e 'Accessa bilit y' unit s will not o nl y give greater ind epe nd e nce and dignity to th e Di sabled Driv e r, but co uld e nh a nce fo reco urt sa les o f petrol and se rvices to th e Ga rage.

-

55

TECHNICAL INFORMATION & PRICES

Range : SO+ yards

Frequency: 458 8000 MHz

R adio Band: Ch. 12

Power Supply: 13 amp outlet socket

Page Unit Battery Supply : PP3 (1 supplied initially)

Dimensions: Host Unit Pager: 9 25" x 4.25" x 2. 25" Weight: 9oz

Customer Page Unit: 4 0" x 2.0" x 1.0" Weight: 2oz

The Host Unit can be free standing , window or wall mounted.

Prices: Host Unit Pager: £130.00

Customer Page Units: £ 15.00

For further information please contact: Brian Blake, telephone 0 252 331123.

·

cn

We do not compromise on quality where environmental issues are concerned . Internal pipework and overflow prevention valves can be supplied, fitted and tested at our works to ensure the integrity of the system. COOKSON AND ZINN LIMITED 111+ S tati o n Ro a d W or k s H a d lei g h, Su ff o lk, IP7 5PN fax : 04 73 8241 64 I i i f . te l: 0 4 73 82306 1

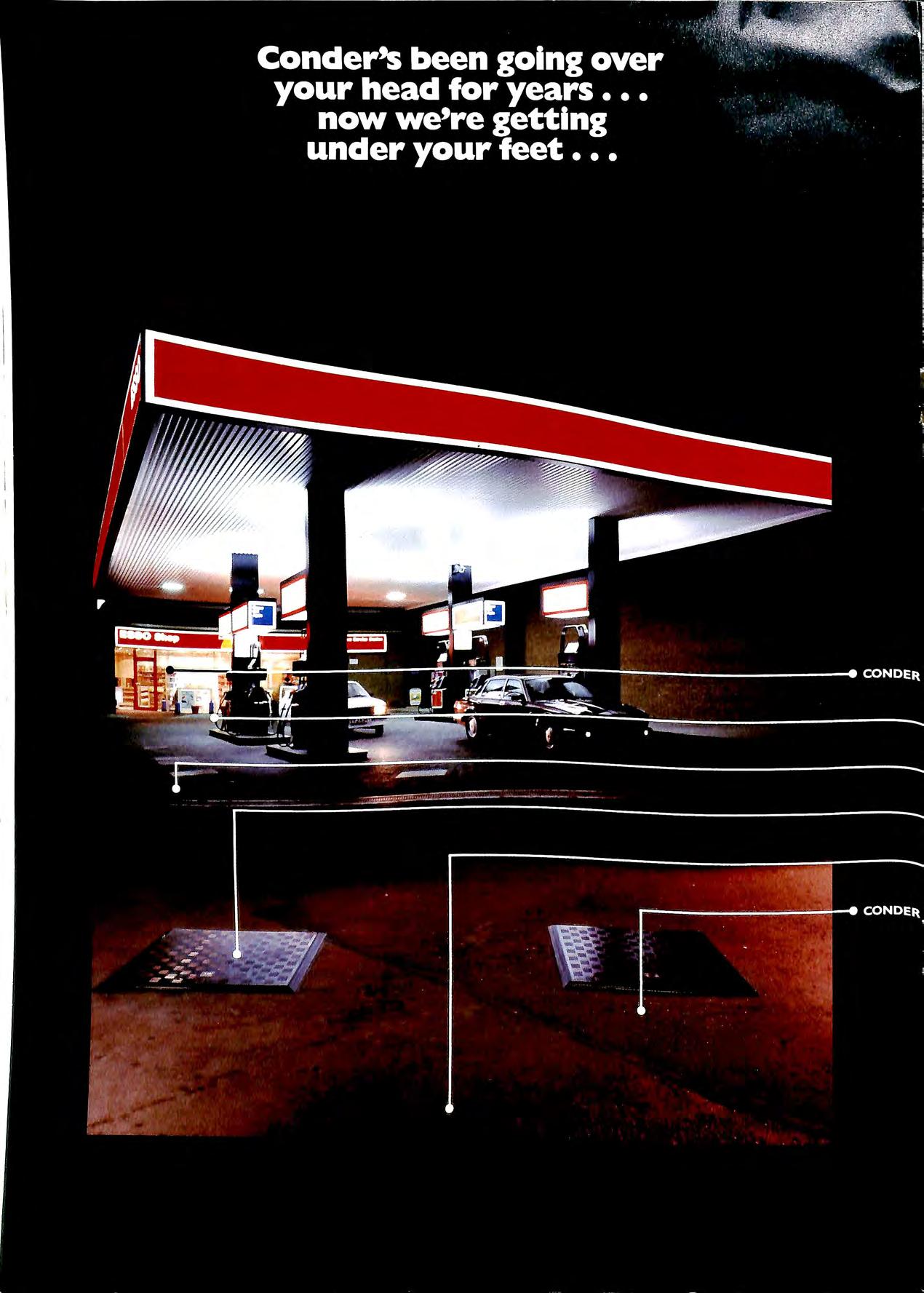

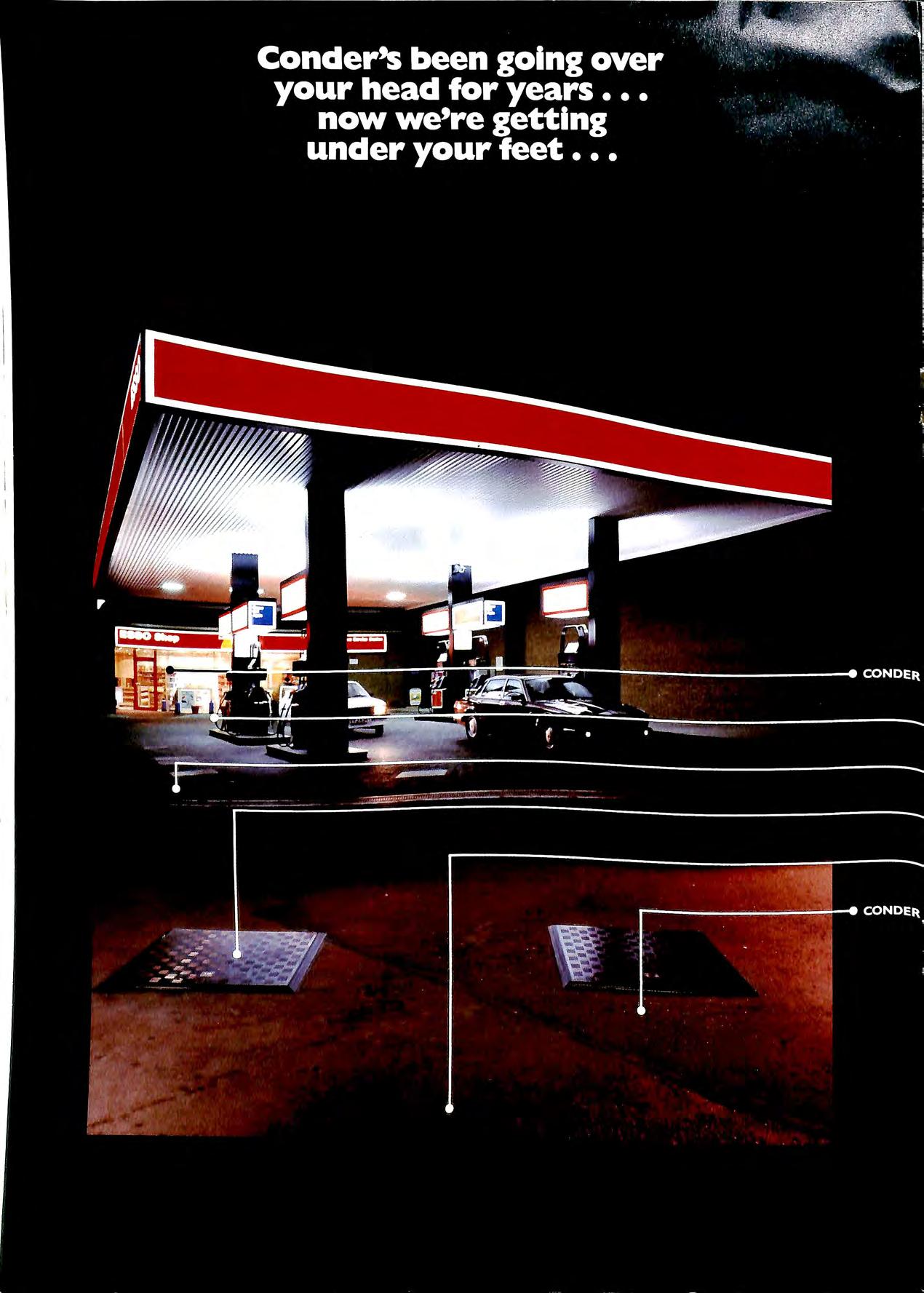

Conder's aim has always been to develop better pmducts and building methods to acce lerate the construction process the sooner your forecourt is up and running, the soo ner your return on investment. 30 years ago we introduced the prefabricated Canopy, later th e GRP Interceptor and most recently the revo lution ary Fibrelite Access Covers with their light weight, you don't need a 'feat' of strength to lift them. Now, Conder can offer a comp lete range of ready made products designed specifically for the forecourt.

Modular Convenience Store and Car Wash buildings delivered to site ready wired, plumbed and fitted out for rapid assembly; Access Chambers to contain possible fuel spi ll age and keep out sub-soil water; Silt Trap s to avoid drain blockages and last, but not least , Pump Island Barriers all from one so urce and deli ve red to si te.

CONVENIENCE STORES CONDER PUMP ISLAND BARRIERS CONDER INTERCEPTORS CONDER LIGHTWEIGHT ACCESS COVERS CONDER SILT TRAPS 07J (?ff' CONDER PRODUCTS ON THE FORECOURT CO NDER PRODUCTS A BBO TIS BARTON HOUSE WORTHY ROAD W INC HESTER S023 7S H TELEPHONE (0962) 863577 Overfill Prevention Vapour Recovery Fl exible Connectors Unit 130, Middlemore Ind Estate, Kentish Rd Birmi ngham B2l OAY Telephone: 021· 558 44 11 fax : 021 5'Vi 5546

CORROSION

SOME LEGAL ASPECTS

By H M Hatley, F I Corr Pipeline Maintenance Ltd

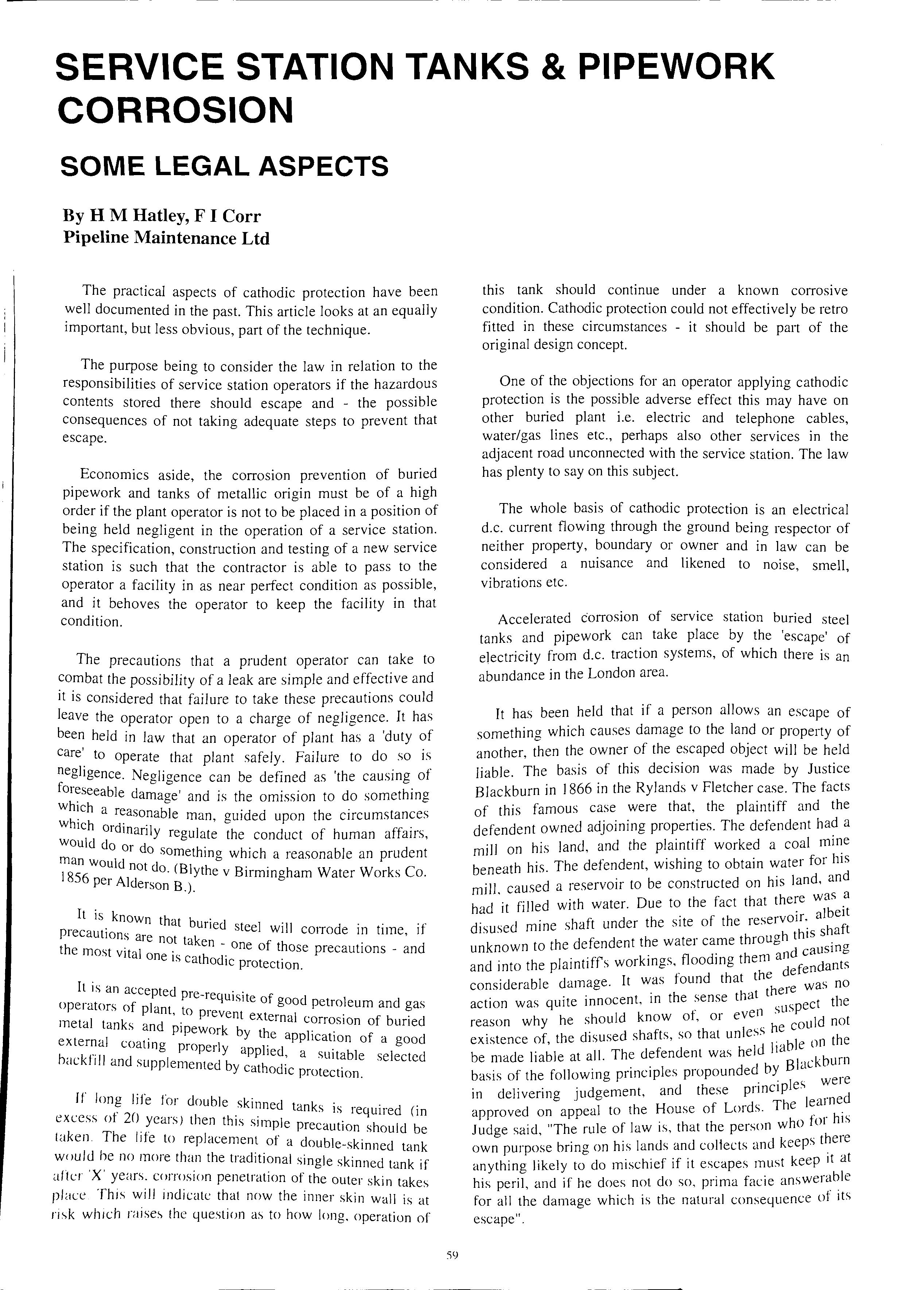

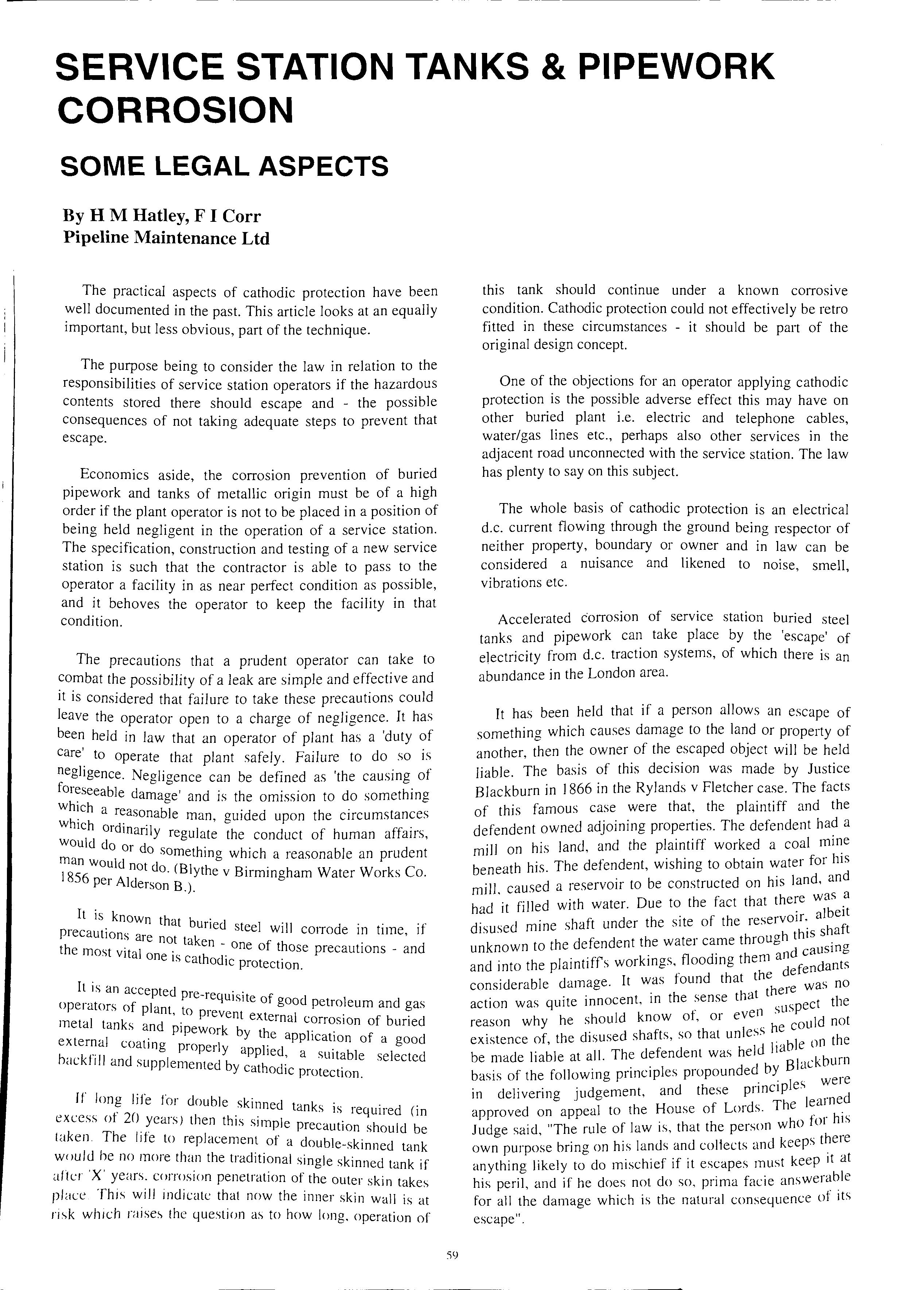

The practical aspects of cathodic protection have been well documented in the past. This article looks at an equally important, but less obvious, part of the technique.

The purpose being to consider the law in relation to the responsibilities of service station operators if the hazardous contents stored there should escape and the possible consequences of not taking adequate steps to prevent that escape.

Economics aside, the corrosion prevention of buried pipework and tanks of metallic origin must be of a high order if the plant operator is not to be placed in a position of being held negligent in the operation of a service station. The specification, construction and testing of a new service station is such that the contractor is able to pass to the operator a facility in as near perfect condition as possible, and it behoves the operator to keep the facility in that condition.

The precautions that a prudent operator can take to combat the possibility of a leak are simple and effective and it is considered that failure to take these precautions could leave the operator open to a charge of negligence. It has been held in law that an operator of plant has a 'duty of care'. to operate that plant safely. Failure to do so is negligence. Negligence can be defined as 'the causing of damage' and is the omission to do something a reasonable man, guided upon the circumstances W IC Ord' 'J w Id man Y regulate the conduct of human affairs, ou do or do h' . man w Id somet mg which a reasonable an prudent ou not do (BJ th B' 1856 pe Aid · Y e v Irmmgham Water Works Co. r erson B.).

It is known that b . . precautions are uned steel will corrode in time, if not taken on f h . the most vital on . . e o t ose precautions and e is cathodic protection.

It is an accepted pre-re uisit operators of plant t q · e of good petroleum and gas ' o prevent exter , I . metal tanks and · na corrosion of buried external pp1peworlk by the applicatio_n of a good roper y applied , . bi hackfill and supplemented b , : a su1ta e selected Ycathodic protection.

If long life for double skinned tank. " , f s is required (m excess o 20 years) then this simple · · · precaution should be taken. The life to replacement of a d bi k' ou e-s mned tank no more tha_n the traditional single skinned tank if alter X years. corrosion penetration of the outer skin takes place. This will indicate that now the inner skin wall is at risk which raises the question as to how long. operation of

this tank should continue under a known corrosive condition. Cathodic protection could not effectively be retro fitted in these circumstances it should be part of the original design concept.

One of the objections for an operator applying cathodic protection is the possible adverse effect this may have on other buried plant i.e. electric and telephone cables, water/gas lines etc., perhaps also other services in the adjacent road unconnected with the service station. The law has plenty to say on this subject.

The whole basis of cathodic protection is an electrical d.c. current flowing through the ground being respector of neither property, boundary or owner and in law can be considered a nuisance and likened to noise, smell, vibrations etc.

Accelerated corrosion of service station buried steel tanks and pipework can take place by the 'escape' of electricity from d.c. traction systems, of which there is an abundance in the London area.

It has been held that if a person allows an escape of something which causes damage to the land or property of another, then the owner of the escaped object will be held liable. The basis of this decision was made by Justice Blackburn in 1866 in the Rylands v Fletcher case. The facts of this famous case were that, the plaintiff and the defendent owned adjoining properties. The defendent had a mill on his land, and the plaintiff worked a coal beneath his. The defendent, wishing to obtain water for !us mill, caused a reservoir to be constructed on his land, and had it filled with water. Due to the fact that there was _a ir albeit disused mine shaft under the site of the reservo : h ft h h thIS S a unknown to the defendent the water came t roug . g and caus1n and into the plamt1ff s workmgs, floodmg them & dants f d h the de1en considerable damage. It was oun t at was no th that the1 e action was qmte mnocent, m e sense ect the k f ven susp reason why he should now 0 , 01 e Jd not . h . I ·s he cou existence of, the disused shafts, so t at un es. . ble on the be made liable at all. The defendent was held ha kb d b Blac urn basis of the following pnnc1ples propounde Y . 'pies we1e in delivering judgement, and these pnnci · d approved on appeal to the House of Lords. The Judge said, "The rule of law is, that the person who for his own purpose bring on his lands and collects and keeps anything likely to do mischief if it escapes must keep It at his peril, and if he does not do so, prima facie answerable for all the damage which is the natural consequence of its escape".

SERVICE STATION

PIPEWORK

TANKS &

59

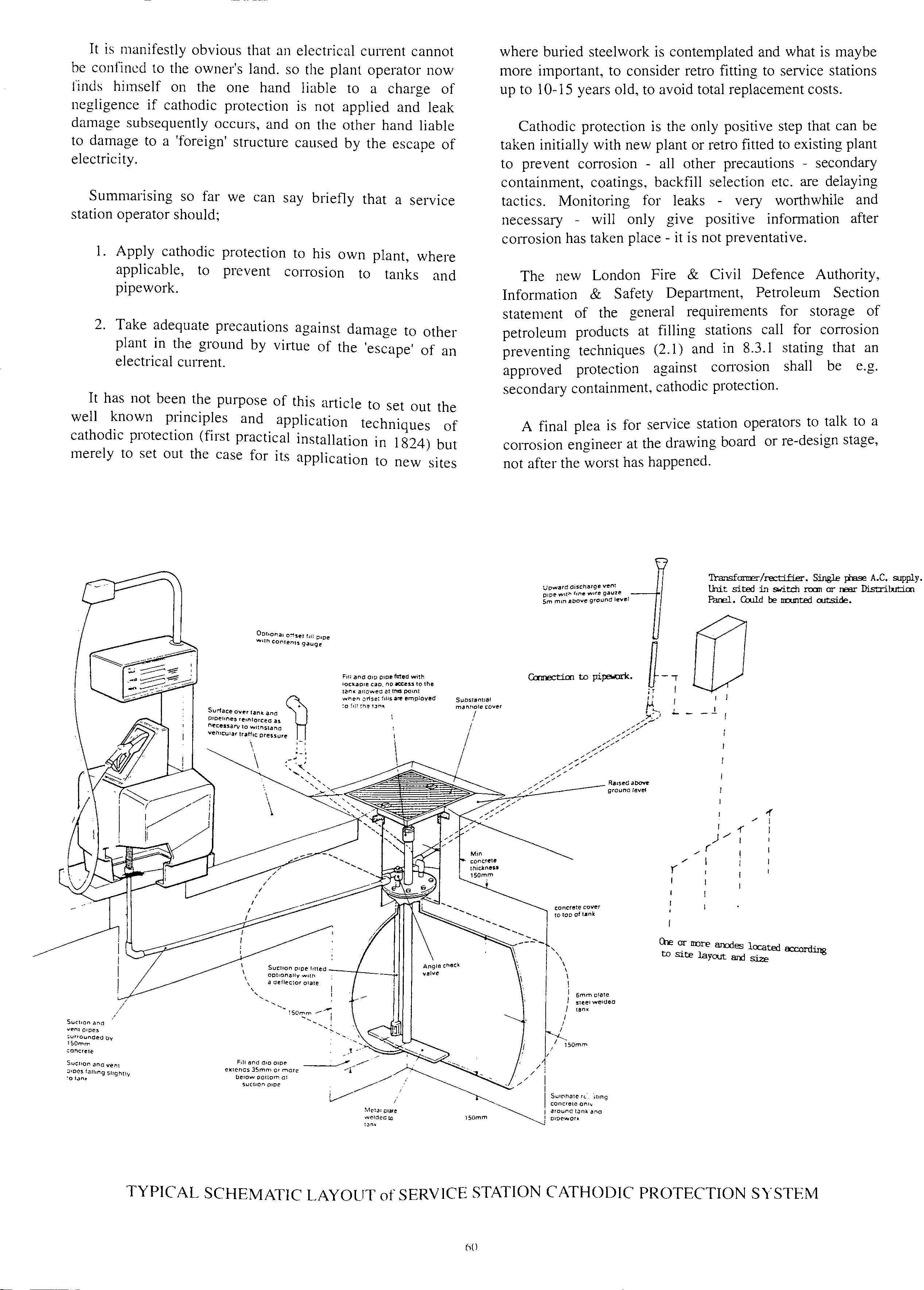

It is manifestly obvious that an electrical cun-ent cannot be confined to the owner's land. so the plant operator now rinds himself on the one hand liable to a charge of negligence if cathodic protection is not applied and leak damage subsequently occurs, and on the other hand liable to damage to a 'foreign' structure caused by the escape of electricity.

Summarising so far we can say briefly that a service station operator should;

1. Apply cathodic protection to his own plant, where applicable, to prevent corrosion to tanks and pipework.

2. Take adequate precautions against damage to other plant in the ground by virtue of the 'escape' of an electrical CUJTent.

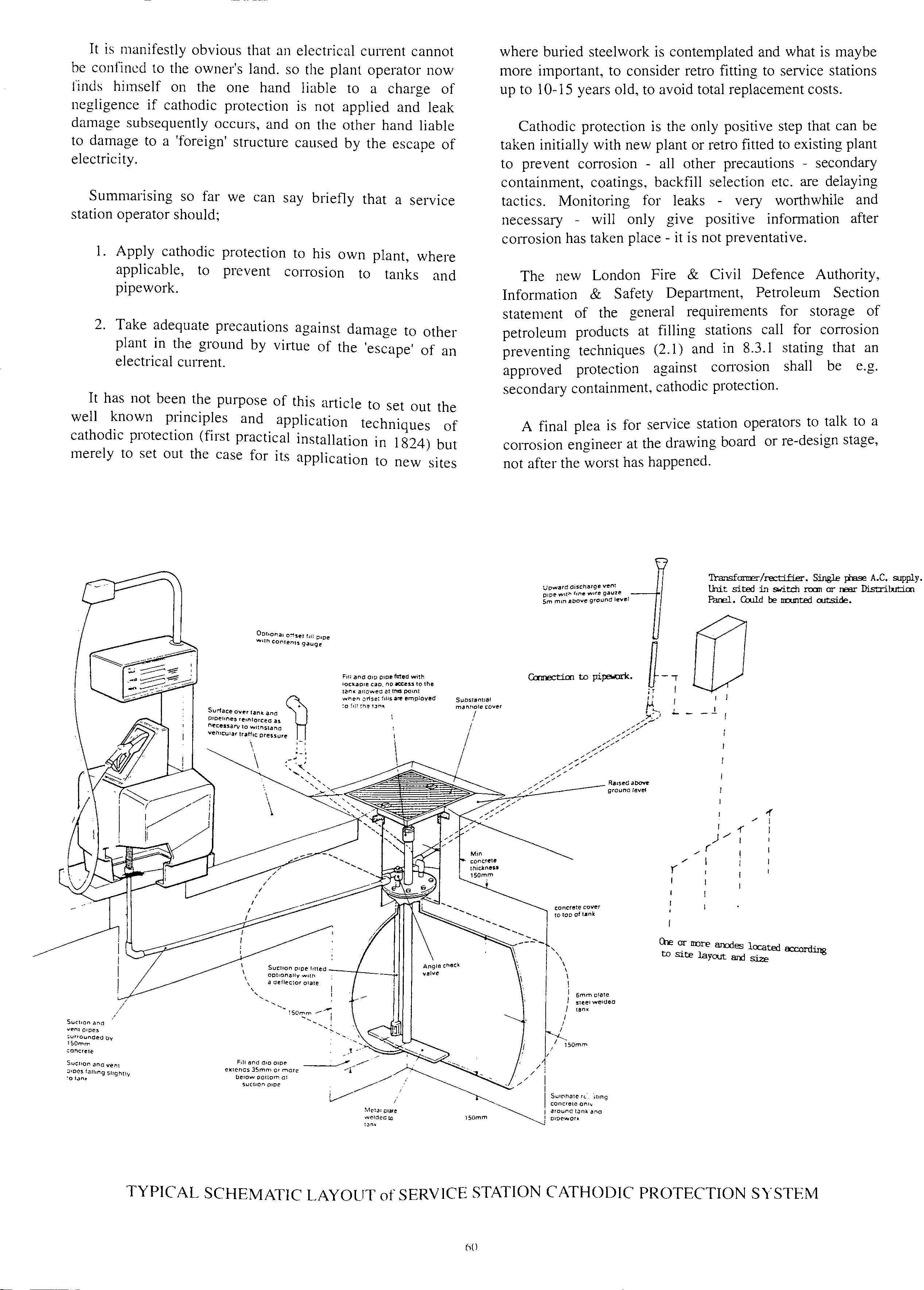

It has not been the purpose of this article to set out the well and . application techniques of cathodic protection (first practical installation in 1824) but merely to set out the case for its application to new sites Oo11ona1 o!1se1 tm 0 08 wi1r, con1en1s gauge

where buried steelwork is contemplated and what is maybe more important, to consider retro fitting to service stations up to 10-15 years old, to avoid total replacement costs.

Cathodic protection is the only positive step that can be taken initially with new plant or retro fitted to existing plant to prevent con-osion all other precautions secondary containment, coatings, backfill selection etc. are delaying tactics. Monitoring for leaks very worthwhile and necessary will only give positive information after con-osion has taken place it is not preventative.

The new London Fire & Civil Defence Authority, Information & Safety Department, Petroleum Section statement of the general requirements for storage of petroleum products at filling stations call for con-osion preventing techniques (2.1) and in 8:3. l stating that an approved protection against con-os1on shall be e.g. secondary containment, cathodic protection.

A final plea is for service station operators to_ talk to a con-osion engineer at the drawing board or re-design stage, not after the worst has happened.

'fumsfarn>,,/rectifi.er. Single iiese A.C. supply. l.hi.t site:! in sw.i.tch roan ar DEBI" Distrilxrt:im Fanel. O:iuld be munte:l rut.side.

Surfaceove-r1an11.ane1 P•ce11nes re1ntorcee1 as necessary 10 wnhs1ana vehicular 1ratf1c pressure Fill and 01p 01oe flrled with 1oc1r.ao1e cao. no xces.s 10 the 1an11 a11owea a1 lfllS point wnen ortset Mis are employed :o !1U fh!!t.Jnk Subs111nua1 mannale caver Suchan ana """' o•oes :>urrounaea bv 10:.0mm ;:o,,crere Suction and veni :llOCS f<Uhng shghUy l.lnr \ ,-, \. ;_; Suc11on 01oe fined---+-001ronallv with \ a aellec1or plate j ,_ l Foll and dip D•Oe ex1cnos J5mm or more be1ow oouom ot suc11on 01oc ' ' Mct.:i101.111e WCldCdto I 150mm Aa1sl!d above grauna levef ccnc:rete cover ta top of tank ' ' \ \ I I I I 6mmplatl? I s1ee1W1!tded / tank I I I !SOmm Su1Dh8!C n·_ concrete on1v ;uouna 13nll and 01pcwou: r I -( )""'I "' ( I I I I ., .- I I Qie ar nore anodes lac:ated according to site layout and size TYPICAL SCHEMATIC LAYOUT of SERVICE STATION CATHODIC PROTECTION SYSTEM ()(l

LEAK DETECTION AND LOCATION

By Richard Smith Director of Sales for Environmental Petroleum Marketing Services The Sales and Marketing Organisation for the Red Jacket Petroleum System in Europe

I stood at this Podium last year and described Red Jackets Electronic Leak Detection System; How it works, and why we believe it is the system for Proactive Leak for forecourt applications throughout the world. With a installed base approaching 60 systems, and 8 miles of cable installed in the ground, reaching from the Western portion of the U.K. to Hungary and we thought this would be a good time to review what we have learned, both about the system, and what Red Jacket sees as the future for the forecourt as we approach the 2lst Century.

What gives Red Jacket the right to express their views on the future of the forecourt? For one thino- I badgered the hell out f h · ::::" 0 t e program chairman to let me address the

But more importantly, Red Jacket has a substantial portion of the worldwide submersible pump market, and has been supplying those pumps for better than 35 years.

We have learned pressure distribution systems for the forecourt is not just a passing fad, but a reality. Oil companies want the option of remote tank farms, with larger storage tanks, and with direct fills. They like the idea of larger sites with more nozzles, but fewer sites overall. Pressure Systems provide these options. However, Oil companies have come to the realization they must protect the environment, not because they have suddenly gotten religion., but because it makes good economic sense. The battle is no being waged between competing technologys who has the best, most cost effective, environmental protections system.

We feel the Electronic Leak Detection System, with its Cable Monitoring and Leak Location Capability, and its control of the Submersible pump is a viable alternative to the available Product Containment Systems. I refuse to stand h · ere and launch a tirade ao-ainst the competing technologies, but I will list Red Jackets view of the Pros and Cons of our Detection System and what we believe to be the Pros and Cons of the other Systems. You must understand h th ·11 b · • w e er we sell electronics or not, we WI e mvolved in the pumps, subject to our friends at BASEEFA, so c!ur discussion is based on our corporate beliefs in the environmental protection field.

We believe our system is the most accurate, fastest reacting Hydrocarbon Detection System available in the world. We have seen at a site in this country, where our Reel Jacket, EPA approved, Pressure Decay Precision Leak Test rO.O"i GAL/HRJ System passed a Line Pressure Test. hut our Cahle System picked up a leak. This is not to berate our Pressure Transducer Technology. it exceeds the EPA (iuiclelines. It is meant to illustrate the accuracy of our Cahle Based System One word concerning the 0.05

GAL/HR EPA Guidelines. There's nothing magical about the number. When the guidelines were established, no-ones equipment could detect leaks any smaller. Everyone would like 0.01 GAL/HR leak rate and I believe the cable is approaching this rate. One more word about the EPA and why Red Jacket does not currently market the Cable Based System in the U.S. when the EPA will allow a Line Pressure Test once a year and call it Leak Detection, in conjunction with a Pressure Piping System, there is not a commercial incentive for the Oil companies to use the product. However, come to PEI and you will see it introduced.

In Europe, Regulators require Leak Detection while the pump runs hence the advent of the Cable. Installed properly, we believe we can detect leaks of singular ounces within singular minutes. We talked about the Pros last year, but to the shock of my superiors, Jets talk about the Cons. We must get back to detecting leaks where we are supposed to detect leaks, in underground piping-not above ground piping or dispensers. The system cannot differentiate between actual leaks and spills or drips. The system will go into alarm when Liquid Product reaches the Cable (end of discussion). The new HSE Directorate covering dispenser containment trays will help solve the Dispenser Leak problem. We have Systems installed in this country in conjunction with these trays and they have performed flawlessly. The normal dispenser weeps are deflected into the trays and onto the forecourt, where they are spotted and repaired.

Concerning background contamination on retrofitted sites, unless Liquid Product is induced into the ground, the cable will not go in to alarm. A case in point is an abandoned suction line with product remaining in the line. When the water table rises, it flushes the product through a variety of pipes, we believe GRP Pipe, if installed properly is an excellent product distribution Its inert. It wilj not decompose. But regardless of the delivery system, if it leaks the cable will find it. But lets not shoot th Messenger. Our Major 'Con' is we are perceived to be 'toe accurate'. In the overall operation of a station, should accept small amounts of product in the ground? If its around the Dispenser, thats up to the Regulators and Oil companies here to decide.

With installation. of Dispenser Trays, the product Will not come m contact with the Cable. so we do not h·i\'e ' opinion on Dispenser Leaks. On spllb around the Submersible Pumps. especially the mamtenance of th . h . ·11 nse pumps. proper service tee mgues w1 elim111ate those s .11 h . ·11 ,. . p1 s if those tee mgues w1 e 1m111ate those spills _ it' th · ose techmques are followed. Red Jacket 1-. committed to Work with our Pump D1stnhutors to ensure those Pu1np Se1-,.· ,· ·Jt:1110 Techniques are implemented and followed. '='

ii

111

On the subject of spills around underground product lines, we definitely have an opinion. Any incident should be reported, as accurately, as quickly and as reliably as possible. Our challenge is to better adapt Laboratory Technology to field conditions. Bottom line the System is worthless unless it meets the criteria set forth by the industry. Beep when there is a leak, keep quiet when there isn't, and function reliability for the life of the station. Plus, be there when it breaks. Red Jacket will be there long after they put me out of pasture.

On our competition, let me add our views on their Pros and Cons. Red Jacket does not believe accurate overall site Leak Detection, in a real time basis (that is, no site down time), can be accomplished form inside the tank. Even our own EPA approved Pipeline Pressure Decay System requires approx 2 hours of Pump Down time to perfom1 a Precision Leak Test. They are great for Inventory Control, and can help in spotting a leak, but we believe it cannot pass as Site Leak Detection. Notice I did not address Leak Detection of the tank.

The interesting trend in the industry is the advent of Flexible Single Wall Pipe with and overlappino shell beino d , e , e use as Secondary Contamment'. Our own distributor sells one. First let me address all secondary containment. Studies show: I believe the experience in this country bears it out; It .1s tough to accurately achieve a Post Installation Single Wall Pipe Test. It is nearly impossible to achieve an accurate Leak Test on the interstitial space, approaching the 60.-80 PSI thresholds expected of the inner pipe. When usmg submersible pumps, normal operating pressures of 30 PSI are common. If you take Hydraulic Hammer mto you can have instaneous line pressures exceedmg line pressures. In a catastrophic leak. if an ln.ner Wall tested at 60 PSI will not hold the product. will an Interst1cal Space tested at 3-5 PSI hold it? How much product will fill the Interstical Space before it reaches Alarm Device? From a servicing standpoint, technicians 111 the U.S. have been injured or killed from enterino a man chan:iber filled with enriched Hydrocarbon "'Vapor. (Basically caused by the Inner Pipe leaking, but not enough to. reach the Alarm Device) plus, where is the leak? The third con has always been the cost This is where the flexible pipe with containment has held promise. However. the same pressure test constraints for their Interstical Space hold as well. From what we understand from our experiences in the USA, some of these Inner Pipes aspirate. that is'. they weep Hydrocarbon Vapor. so Vapor monitonng in the Interstical Space is not an option. It is also our understanding some of the Flexible Systems expand under pressure. In the U.S. Red Jacket has mstalled software to differentiate between this expansion and a leak. in their Pressure Decay System. currently being sold in the U.S. but in a secondary containment environment. we are not sure of its operating characteristics. Due to the blending of additives in current gasolines to boost Octanes. we have seen Pump Impellers and Internal Casings deteriorate. in both suction and our own Pressure Pumps. Will there he chemical reactions with the additives and the Piping Systems'? We understand the installation of Teflon Liners has helped with this Concern. The industry basically knows from experience the life expectancy from Coated Steel Piping. and if installed

properly the basic non deterioration of GRP pipe, but the long term durability of the new Flexible Piping Systems to our understanding has not been determined. By the way, another plug for cable, if it leaks we find it, plus we'll tell you where it is. We are not in a position to comment on the cost of either rigid of flexible secondary containment systems.

If this sound like a bunch of rambling thoughts, it is. However, we believe it accurately reflects the state of the industry as a whole. You folks, the APEA members, plus the oil company engineering staffs, are the ones under the gun. You have people like me. hounding every day, trying to convince you our particular 1s best. You riohtfully question if the technology is sound, but more is that particular or product manufacturer, going to be around m 5 years when the installation goes to hell in a hand basket? As a regula.tor, you might say, thats the oil company's problem not mme. But every regulator I have ever talked to takes a sensible, pragmatic approach to the reahse the problem of environmental protection is thetr problem now and will be their problem 5 years from now as well. We had a very interesting conversation with the from Colchester, about all the changes taking place m the industry. As a specific system proponent, we tend be very single minded about the advantages .of our system. He, however, raised several very mterestmg pomts concerning the overall balance between oil company requests and petroleum officers requirements. He the regulatory concerns in human terms, concerns s hke me tend to overlook. His bottom line was. h 1 e do my J·ob better I'm for. Balanced with the Oii e ps m h · company's desire for a reasonable on t eir . t t There"ore we see a partnership between mves men . '' , reoulator, oil company and supplier as the only "' · I the computer industry, everyone dealt with alternative. n IBM. Why? Not because they were the most mnovat1ve. or h ·t· b t because their technology was sound and the c eapes , u Id b Ol1111ed on to be there to solve the problems they cou e c h I ate not sailino on a boat 111 the greek islands they e p Cl e , e th Y dl.d a Ieaveraged buyout of their company. because e took the money and ran.

Red Jackets view of the future of the industry is quite simple. The Pressure Distribution Lines will be leak rotected. Notice I did not say detected or contained. p ·11 . H Specific sit requirements w1 require spec1hc systems: ere ·s where we talk about the tanks. The tanks will be L protected by in that will.tell in a 'real time basis' (no down t1111e). it that tank 1s leakmg or not. We believe they will replace mandated tank replacement programs. because these systems will tell you that l 2 years 6 hours 15 minutes after installation this tank is sound and J 2 years 6 hours and 15 minutes after installation this tank is leaking. Come to PEI and you will sec one. Althl)Ligh everyone in !he e1wironmcntal protection busi11l'ss is engaged in rather sharp rnmpetilion. it is the oil industry and their regulators that will win. specifically because nf this competition.

Thank you. I hope it has serwd tn further the debate and your thinking.

THE FUTURE OF PETROLEUM ENFORCEMENT

A F Le vett C o uncil M e mber Jul y 1992

Adrian Levett h fi as 0 1 many yea rs be en a m emb e r of the Cou nczl As a fi . . Cl . · 011ne 1 iazrman and Fello w oif the Asso · ; LA Ctatw n i e has repre sente d th e A PEA on th e COTS! ITSAICACF OAJA PEA Work ing Group. H e is emp loyed by Wa · k h · T 1w 1c s tre radmg Standards D ep a rtme nt.

Introduction

Th ere has be en co n s ide rabl e c han ge in th e area of petro le um reg ul at io n Dri ve n by te chn o log ica l c h a nges, in creased e n vironm e nta l awar e ne s s , p rod uc t va lu e a nd de man d fo r mo re so phi stic a ted m a rk e tin g a rrangem e nt s , th e who le infras tru cture of pe trol e um di s tributi o n ha s c ha nged T o be effective the e nfo rce m e n t ac ti vit y mu s t a lso c ha nge Co mpa ni e s qu e stion w he ther e nfo rcem e nt age nc ie s have suffic ie nt t h · I · h · f ec m e al kn ow led ae ca n d ea w it is s ues o uni fo nn·t o , 1 Y and have th e m ea ns to put mto effec t th e necess ary h . c a nges 111 a reaso na bl e tim e sc a le .

b As in m any o th e r a reas of o u r work th e c h a n cre is dri ven Y E ur opea 0 h n stand ard s . S ho rt ly sta nd a rd s a ppro ve d u nd er t e Co nstru c t' p. io n 1o du cts Rea ul a t1o ns w ill mflu e nc e w ha t ca n o r ca nn ot b o add t e acc epted for pe troleum 111 st a ll at1 o n s In I io n th e He 1 h & k· a t S afety E xe c uti ve has reco n ve ne d th e W O ! m a par t h rece nt! 0 h Y o n t e g uid a nce d oc um e nt H S (G )4 1 Onl y Y t e Nati I R. dr aft 1 ' o na 1ve rs A u th o rit y ha ve pre p a re d a po ic y a u1d a d f· 11· Sta l 0 nee oc um e nt o n pe tro le um 1 m g . ' io ns

To re m a in c re di b l f tl · k 1 e e n o rcem e nt aae nc ies mu s t rad ica ll y 1e i 1n t 1e ll' a1Jp roa 1 0 c 1 to 1eg ul at1 ng the indu stry Thi s pa per p u ts fo r w a rd so m e tho ug h ts o11 th I d · e w a y a i e a

Con struction Requir ements

T ra d it io na ll y a u th o ri tie s ha ve e stab li she d c o ns tr uc t io n re q u1re rn e n ts tha t ha ve life ti me o f ma ny years T he Ho m e O IJ1c e M o d e l C o d e p u blis he d in 196 8 had a c urre nc y of a lmo " t 20 y e a rs. It is un li ke ly in th e mod e rn cl im a te tha t it w o u lc.J h a ve a c urre nc y o f o ne ye a r T he re mu st be a sy s te lll o f' rev ie w pe r hap s e ve n o n a 6 m o n thl y ba s is a t w hi c h t im e the lll Os t lllod e rn a cce pta b le tec h no log y is a d u cd l<i the a pp rn ve d c o ns tru c ti o n re qui re me nt s a nd mo st

impo rt a ntl y th ose te chniqu es no w s upe rsede d tec hniqu e s o r tho se no t set o ut in a re leva nt publi she d sta nd a rd s, poss ibl e a Eu ro p ea n sta nd ard are acce ptabl e

A s ig nifi ca nt probl e m lies in dete rminin g w ha t is ac ce pta ble. cl ea rly guid a nce is ava il able th ro ug h HS (G) 4 l bu t th e lead tim e in rev iew in g thi s is a lread y provin g to be to o lo ng. Guid a nce co ul d be obta in ed from o ne o f th e lead a uth oriti es p a rti c ul a rl y L FC DA w ho a re abl e to focu s th e ir atte n tio n on pe troleum e nforc e men t activit y throu a h a s pec ia l unit. H oweve r, ex pec tin g th e m to di sse min a t: th e res ult s o f th ei r wo rk to a ll li c en si ng auth o riti es pl ace s a n un acce ptabl e b urden o n o ne a utho rity Ex perien ce o f a uth o r it ies , eve n th ose fr om o ut s ide the U K · ' IS di ss e min a te d th ro ug h th e A PE A magaz in e 'The Bull e tin ' M ee tin g s be twee n th e IP a nd the APEA di sc L ·ISS tec h no log ica l c h a nges ; aga in d issemin a ting thi s in fo rm a ti o n pro ves to be a tro ub le so m e bu siness. Th e minutes o f s uc h m ee tin gs a re no t pu b li shed a ny w here

In s u mma r y

A n a uth o rit y mu st be p re pa red ac t qui c kl y a ltho ug h so urces of in fo r mat io n are ha rd to f in d In so me auth o ri ties th e p ro cess for see in g _th ro ug h c ha nges to co nstru ct io n require me nt s is lo ng-w mded and ma y re q uire me m b in vo lve men t. I s ug ge st in suc; h a ra p idl y c ha ng ing a re a offi ce rs s ho uld be e m po we re d to ha ndl e thi s iss ue

Licen ce Cond ition s

T hese di c tat e , u nd e r the a u tho rit y of th e li ce nce th . . b , e wa y Ill w hi c h the site mu s t e o pe ra ted a nd ma· . . <I11t a 1n e d T ra d1t 1o na ll y the s ta ndard form o f li c e nce In s l" "t 1 · • " c , e c ma n y ye a1s c1 nd o ft e n bee n s ui ted to e ve ry s ite li ce nc ed h a n aut ho rit y y

This is no longer the case. It is likely licence conditions will need annual review and probably contain one or more special conditions related to that site. In one instance it is recognised by the law; driver control deliveries are regulated under a special licence for which a special fee is payable. LACOTS have provided the secretariat for a Working Group consisting of the ITSA, APEA, and CACFOA which last year produced a set of standard licence conditions. Already these require modification yet many licence authorities have not adopted them or are adopting a variation of them.

The_ I_ack_ of unif?rmity of licence conditions adopted by auth_ont1es 1s a ma.ior source of grievance of operators. In particular the large degree of inertia in the system of review by authorities of licences is contributing to the problem.

I would be difficult for a licensing authority to explam why m the event of an accident a site was allowed to operate in a manner that did not reflect best modern practise.

A means for ensuring a continuous review of licence conditions has to be found possibly through the group convened and supported by LACOTS. If this is to be the case the group must consist of knowledgeable practitioners aware of latest service developments.

Life of Existing Sites

With rapid technological changes being introduced there is a vast range of standards between old and new sites. Sites have a reasonably long life particularly if minor improvements are permitted to be made. However, the pace of dictates that older sites will only meet a far lower standard in a relatively short time. It is important that a means of improving what might by regarded as_ sub standard sites in the light of modern changes be found.

In particular those sites with single skin steel tanks in should perhaps have a maximum life of 10 years imposed as of now. Similarly, those without interceptors 5 years, those with vent pipes attached to buildings or near 2 years. Similarly the phasing out the old style interceptor and its replacement with the new single chamber separator and coalescer and the addition of overfill protection needs to be considered on a phased basis.

This approach will mean that many small private will in fact be required to be taken out of service m the very near future.

Each authority should have a rollino proaramme to e e ensure the removal from service of sites that fall below a minimum acceptable standard.

Operators

Much attention is paid to the construction of installation and the provision of safe equipment. The single biggest weakness in the distribution of petroleum is the human being. significantly more effort should be paid by licensing authorities to the training of operators. This was envisaged

in the first publication of HS(G)41. Many authorities have failed to capitalise on the opportunities this provides to raise the overall standard of safety at installations.

Adequate training of operators takes time and in particular the availability of adequate training courses. Large operators may find this easy to achieve small operators find it next to impossible. Local authorities must address this problem.

Records and Administration

Sections 2 to 4 above require a more sophisticated record system than previously envisaged. With the life of sites limited, licence conditions probably being reissued each year and construction requirements changing on a six monthly basis the system must be both sophisticated and reactive. The uniform licence conditions agreed by the working group last year envisage a site plan being maintained for each site. In itself this adds to the problems of record keeping; the most up to date plan must be identified.

Training

To remain credible enforcement officers need regular training. Training opportunities for petroleum enforcement are extremely limited. ITSA have operated a course for many years which is highly regarded. However. I suggest events are leaving the contents of the course behind. with enforcement split between Trading Standards Departments and Fire Authorities the issue of training and unifo1mity become more complex. It is simply not sufficient to say to an enforcement officer 'from now on double skin steel tanks only please make sure the monitoring and then send them out the door to do their duty. this has already led to misunderstandings between tank manufacturers and enforcement authorities on the right way to handle and install such tanks.

Recommendations

a) Each authority should reconsider its constructions requirements 6 monthly. This would need to be supported by authorities close to technological change issuing guidance. LACOTS could take a lead role in this.

b) Licence conditions should be reviewed each year, specific licence conditions tailored to an individual are almost certainly necessary. The Workmg Group that prepared the original uniform licence conditions should meet regularly to review these.

c) Sites u_sing ol_d technology should be giwn a specific date aftl'r which thl'y must meet new requirements.

d) Authorities should enforce more rignrouslv thl' requirement that opl'rators are trained.

e) Proper arrangements need to be made to ensure enforcement officers are trained. This requires an initiative b) the APEA or ITSA.

6-1

New Members The Association welcome the following new members

Cunningham

Elmore M Elmore P O'Hallorhan Health & Safety Authority D Whelan J P Boyd J Cole M Heenan Rohe11 John Farrar Burmah Castro! OJ Ltd M .I Daisley J Precious Asda Stores PLC D Trott Densigns Petroleum Developments Ltd D Courtney EBWINC T Melvin RJ Milo Universal Valve Co Ltd DJ Brown County Tank & Pump Services Ltd p L Higgins R C Mergel J Mullauer Mullauer TankanJagan A Hobbs Electrical Testing I .td D Elvin G C Bell T Pickup Alfedi G Norris Emco Wheaton UK Ltd DI Bell S Eades A & H Construction & Devpmt Ltd GS Bailey C A Bailey & Sons P W J Haygarth AN Stokes Sandpiper F G Nuenighoff Mohil Europe Ltd A E Plenclerleith

H

N Doyle S

Letters to Editor

Dear Editor

Ref. Volume 30, Page 4 A.P.E.A. Bulletin Petroleum Alert at Garage in Leicestershire.

As the above publication is intended for the consumption of Petroleum Licensing Officers and the petroleum industry in general, I feel it would be helpful to explain how the accident occurred and under what circumstances, rather than simply announcing the incident and reporting its satisfactory conclusion.

I would be most grateful therefore if you could print a follow up to this article so that the same mistakes which gave to rise this accident, may be avoided in the future.

In the few proceeding days prior to the incident, a firm of competent tank and pipework engineers were carrying out site alterations. This included a conversation from a standard vent system to vapour balancing. (Stage I B ). On the J6th October 1992 work had commenced on the vapour recovery manifold. At the end of the working day the vapour return valve had not yet been fitted, so the end of the manifold was blanked off; unfortunately the orifice plates had been fitted to the vent risers and no signs had been placed against tank fills or on the manifold that vent pipes were now n1anifolded. In addition th: operator was unaware that to receive a delivery would be hazardous.

The tanker arrived on the l 7th October 1992 for a routine delivery. Vents on this site sit well back from the tank fill points, so without prior warning from the operator, the tanker driver could not have been expected to know of the problem he was about to encounter.

The delivery began in textbook fashion, each party being present and completing his relevant safety checks. readings were taken and dips checked, delivery connections were made and delivery commenced. Three deliveries had been connected and after approximately 20 minutes the tanker driver began to suspect a problem as he still had fuel in his tanks. (Due to the orifice plate being fitted prematurely, a substantial back pressure had been created within all tanks connected to the vapour balancing manifold.)

He therefore proceeded to check the dips un his compartments and found that he was still holding a considerable amount of fuel. The operator checked his gauging system and found them to indicate all tanks full. At this point the tanker driver aborted his delivery as he suspected an overfi 11 due to faulty gauging. Excess fuel was drawn off at the pumps and a delivery hose was disconnected and underun, it was then disconnected froll1 the tank and the tank cap was replaced loosely on the fi II pipe.

A second deli\ ery hose was disconnected froll1 the ta11ker. underun and removed from the fill pipe. at this point petrol welled up from within the tank and the driver just managed to get the cap on but only loosely due to pressure· Simultaneously petrol began spraying from the still loose fitting cap on the first tank. It was at this point that the Fire Service was called and the site was evacuated by the site

personnel. Fortunately most of the spillage was confined to the tank manhole chambers, as pressure form within the tanks subsided after a short time.

The lessons to be learned from this incident are as follows:

1. When installing or retrofitting vapour recovery manifolds, never fit the orifice plates or pressure vacuum valves until the system is complete.

2. Signs should be fitted on all tank fills and vapour balancing manifolds at the earliest possible stage, to warn that the vent system is manifolded and the vapour return connection should be made.

3. Operators should inform the tanker tenninal of the changes taking place and must explain the situation to the tanker driver on arrival.

In conclusion some of the mistakes made were the result of bad practice, others could have been avoided by a more adequate liaison between all parties concerned.

I hope the above details will prove to be of interest to you and your readers.

Yoms Faithfully Chief Fire Officer Leicester Fire & Rescue Services. Dear Editor

RE: Explosion at Filling Station

I read with interest your article on page 23 of Volume 30, The Bulletin.

The van had been stolen the previous afternoon in Halifax and by the next day was happily doubling up as a very dubious petrol tanker.

Our company was requested to degas the tank and remove it from the van. The tank certainly was a precision piece of work. clearing the back door by a few thoug'.

At the time, we were advised that there was possibly a second \·an Ill s11111lar operation but this could not be confirmed.

However, approximately one week ago we were called in to resol\'e an identical tank installation on another transit. bein<T held b\ the local Police. Luckilv tJ1., L·\ 11·,,,1 11 I t c • • · e al no suffered the same fate as his counterpart.

We again carried out the degassing of this tank and its removal from the van.

How thi_s second \an had not blown up was a mvstery as the explos1metcr reading at the drivers scat ,, as due to a leak on a weld. this had been plugged with bath sealant'

If these guys had turned their skills and im.'.cnuit\ to kgal use tlwy would prohabh he millilrnaircs. A; it is. arc hnth 'helping the pnlil'C \\-ith their enquiries'.

Y nu rs Si 11l'crt'I

M Marc1vnski

Tank-( 'lean l.imilL'd.

Aden con Draughting Services Ltd. MARBR IDGE HOU SE, HAROLDS ROAD , THE PINNACLES , HARLOW, ESSE X, CM 19 SBJ Te lep hone : 0279 422050 Fax: 0279 4 33663 Specialists in the preparation of drawings for petrol filling service station redevelopments/alterations and tank or equipment installations and obtaining all necessary statutory authority approvals (i.e. planning permission, building regulation approval , petroleum officer approval etc.) MEMBER A.P.E.A. Consu ltants to I n d us try 46 Denham Lane ,\1""' Cha/font St . Peter l l1: / Bucks SL 9 OET \> Tel: 04 94 872204 I . QUALITY BS5750 Accred itatio n P rocesses Audits -Total Qua li ty Man age ment -Tra ining 2. ENVIRONMENTAL MANAGEMENT System a nd Site Au dits Syste m Developme nt Trai ning 3. HEALTH & SAFETY Acc id e nt Invest igat ion Syste m and Site Audits C ontractor Audits Tra inin g for thos e w ho c are about QUALITY for thos e who c are about SAFETY TRAINING IN-COMPANY SHORT COURSES Rexible arrangements to meet y our requirements at competitive rates • Electrica l requirements for Petrol Filling Stations (New HSE cod e HS(G} 41) • 16th EDITION IEE WIRING REGULATIONS • Electricity at Work Regulation s 1989 • Inspe cti o n a nd Tes ting o f Electrical Insta ll a tions Present e r: TERRY HEDGELAND BA. FIEI E. MIQA O rigin a l a uthor of the highl y succe ss fu l IE E 15th Edition 2-d ay short course Phone:0737553328 e PRACTICAL GUIDE TO ELECTRICAL INSTALLATION TESTING £11. 95 e QUICK GUIDE TO THE ELECTRICITY AT WORK REGULATIONS 1989£3 95 e TEST SCHEDULE for recording eledrical installation test resull s e COMPLETION SCHEDULE for recording detail s o f installed equ ipment, with chec k list £HO e COMPLETION CERTIFICATE for compliance with IEE Wiring Regulation s l Sth or 16th Edn please slate e SURVEY SCHEDULE & TEST REPORT for [£8 00] +VAT. in service and older installations e APPLIANCE TEST RECORD for recording period ic appliance inspection and lest results per pod e CERTIFICATE OF ELECTRICAL INSPECTION & TESTING for petrol filling slations-to HS(G} 41 & LACOTS requiremenls Prices include p&p Order with cheque payable lo · UNEEDA PUBLICATIONS, 5 HIGHWOLD, CHIPSTEAD, SURREY CRS JLG SUBSURFACE POLLUTION. THE PROBLEM'S UNDERGROUND. THE SOLUTION'S UNDER HERE. Comp lete the coupon and we' ll introdu ce you to the most adva nced, effec ti v ni ues for comb ating subs urface e our uni q ue range of processes, including proven Germ a n techno logy h American Dual/Vacuum Extract ion Mil ler spec 1ahse in a nd t e d oving haza rdous p etro l, d iese l a nd so lven t polluti o n mo rn tonng an rem t d d s· ed not t · Ou r me thod s are fast cost effec tive, sa e an e ign o int erru pt Yo ur complete so lution 'phone the HELPLI N E 0924 223784 , o r return the co upon now Miller Environm enta l Lt d ., Miller Hou se, Pontefract Road Nor manton, West Yorkshire WF6 1RN Te lephone: ( 0 924 ) 8 91 51 6 Telefax: (09 24 ) 69 0 4 6 6 MILLER GROUP CIVIL ENGINEERING CONSTRUCTION DEVEWPMENTSENVIRO NMENTAL HOMESMINING -------Name __________ Title Co mp any _________________ Address _ _ 01