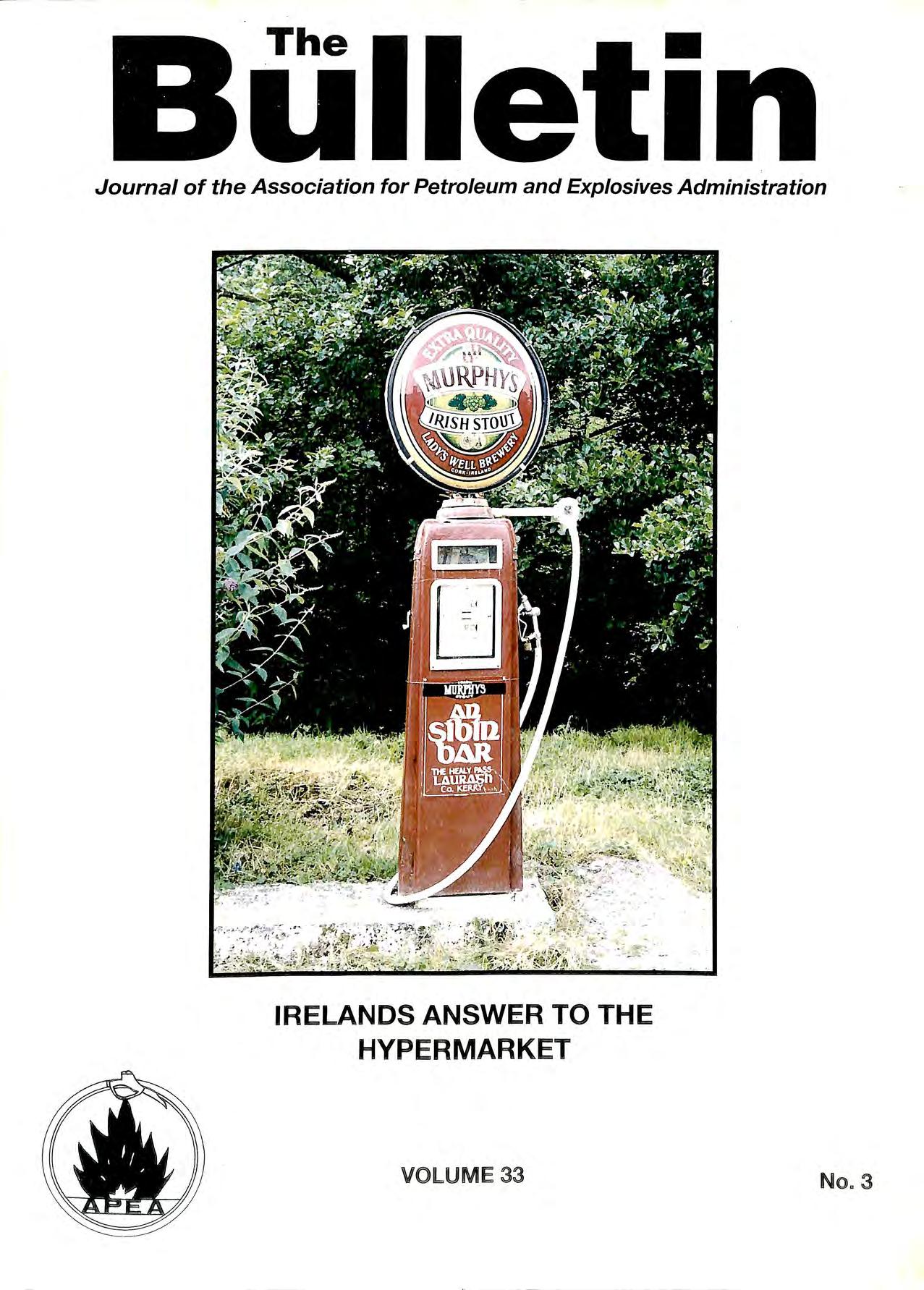

IR E LANDS ANSWER TO THE HYPERMARK ET

The •

Journal of the Association for Petroleum and Explosives Administration

VOLUME 33 No " 3

FIPS95 11

• SAFETY INTERLOCKS • TRANSPARENT MONITORING e UNAUTHORISED DELIVERY DETECTION • REMOTE DIAGNOSTICS - -CONTINUOUS TANKGAUGING , SCULLY 'INTELLICHECK' CONTROLLER e RETAINED PRODUCT INDICATION • VAPOUR RECOVERY INTERLOCK I ;i [1) ijy[o]:! M (o] di:teJ (131 !ij t'I I MODEM I ORDER POINT • AUTOMATIC LOW LEVEL REORDER TANK LEVEL Th e Scully Retail Site Vehicle Controlled Overfill Prevention System (RSVP) employs Scu ll y's unique Dynam ic Self-Check®concept to automatica lly and continuous ly test the system A puls in g s igna l simulates wet conditions on the sensors to continuous ly and automatica ll y test their abil ity to respond in case of an overfi ll. -Ul/y UK imited 9 New Street , Daventry, Northants NN1 1 4BT En gland Tel : +44 (0) 1327 704333 Fax : +44 (0) 1327 300465

OPW 11-ALD, AUTOMATIC NOZZLE

Less spillage and easy top-off.

(BS-7117)

OPW61-SO, OVERFILL PREVENTION VALVE

Prevents overfilling of underground storage tanks. Now also available in 3 inch 0

a network of distributors E throughout Europe. ach has been sele.cted for its high standard 0 f expertise and knowledge ofthe industry.

Allows detection of leakage in tank excavations.

OPW66, BREAKAWAY Protect dispenser from accidental drive-away. (BS-7117)

l({P

FUELING COMPONENTS EUROPEBV RE SOURCE S COMPANY JF(JREMOST ON TliE FORECOURT M ik e E /., rn n , / )i., rri c f M a n ag a U K. O PW F uclin g C o mp o n ent s Euro pe B. V , T e l.: 07298 2- 365 5, Fax : 072982-24 24 I ) f' \,\ h ie ling ( <> lllp <> n c-nf , E urop e B. V , P .O B ox 1 1), 11 6 0 A C Zwa n e n bu r g, T h e Ne t h e rland s T e l.: ( 3 1) 2907 -5 4 4 2, Fa x: (3 1).290 7 6 0 8 1, Tel ex 15 2 96

JAMES LUKE AND ASSOCIATES Safety & Training Consultants to the Petroleum Retail Industry :m1:11mt11111il:> SALUKI HOUSE Postbox 41 BILLINGSHURST WEST SUSSEX RH14 ovo Tel: 01403 871471 Fax: 01403 871425 }obn gfgfull & <!Co. 1Ltb. Comprelumsive service for liquid fuel & LPG installations Consultancy, design, installation, maintenance decommissioning & gas-free certificates ' Pressure Systems Regulations Surveys FIRST HANGINGS BLABYROAD ENDERBY LEICESTER LE9 SAQ Tel 0533 862287 Fax 0533 751232 MEMBER APEA, LPGA, CORGI REGISTERED TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET LONDON E2 6QQ Tel: 071-739 9538 Fax: 071-729 6108 MEMBER A.P.E.A. D DC BUILDERS LTD FOR SERVICE QUALITY & RELIABILITY WE OFFER A COMPLETE SERVICE ON MAINTENANCE AND IMPROVEMENT WORKS TO THE PETROLEUM RETAIL MARKET D DC BUILDERS LTD 7 ST CLAIR CLOSE CLAYHALL ILFORD ESSEX IG5 OPA Teh 081=550 5216 081 =550 6095

PETROL FILLING STATIONS:

ENGINEERING CONTRACTORS TO THE OIL COMPANIES FOR 24 YEARS C.R. RICHARDSON (CONTRACTORS) LTD DESIGN & BUILD Anerley Court , Half Moon Lane, Tel: 01732 838608 Hildenborough , KentTN11 9HU Fax: 01732 838064 TANKSAFE LIMITED 4 th F lo or , Bell Co urt H o use, 1 1 Blo mfi e ld S r. Lo n don, EC2M 7 AY Tel : 07 1 628 5695 or 07 1 628 485 1, Mo bil e: 0850 842828, Fax : 07 1 374 04 0 8 UK Applica to r of wa te r bas ed, va ria ble de n si ty, hard fo a m s for injection an d all void filling req u irements. Hydroca rb o n a bso rb in g fi ll e r fo r ra nks a nd pipe li n es. •!• Lig h r we ig h r and h ig h loa d bear in g •!• En viron rne n rall y sound 11 !• Fast clea n ap pli cat io n RG22 for p e rmanenr rank aba n donmenr RGS Fo r sa fe r tan k e xcava t ion or sh o rt re rm neurra li satron RC )O t h e modern backJl ll marer ia l fo r n ew rank ins ra ll arions. •!• High s up e rin1pnsed load capab ili ry •!• High in s u larion fa c ror for low product shrinkage •!• High rigid ity a nd co h es ion •!• Re tain s hydro ca rbon s f o r /itrt her infomzation and a quota ti on , call Charles Hudleston TRAININ G IN-COMPANY SHORT t our reqwremerzts Flexible arrangements to ."!ee Y at compettllve rates P I Filing Stations • Electrical requirements for ctro ' (New HSE code HS(G) 4Rll)NG RFGULATIONS • I6th EDITION IEE WI ' 9 • Electricity at Work Installations

Inspection

Electn

•

and Testing of

DGELAND DA FIEIE. MIOA f'rescnta: TERRY HE h' hi Original author of the ig Y · IEE 15th Edition 2-day short course Phone: 0737 553328

e

OF G ELECTRICAL INSPECTION &. TESTIN to HS(G) 41 & LACOTS requirem ents EMERGENCY LIGHTING: e COMPLETION CERTIFICATES based on model in BS 5266 : Part 1: 1988 TES e PERIODIC INSPECTION AND TEST CERTIFICA based on model in BS 5266 : Part 1: 1988 FIRE ALARM SYSTEMS: !CATES e INSTALLATION & COMMISSIONING CERTIF based on model in BS 5839: Part 1: 1988 £9.87 [ £8.40] +VAT per pad e CERTIFICATES OF TESTING based on mod el in BS 5839: Part 1: 1988 TESTING £16.95 e PRACTICAL GUIDE TO ELECTRICAL INSTALLATI?: h payable to: 0 d r wit c eque G Prices include p&p r e SURREY CRS 3L UNEEDA PUBLICATIONS, 5 HIGHWOLD, CHIPSTEAD,GROUNDWATER DOD TECHNOLOGY On-Site Worldwide, . ' d" t1on Groundwater and Soil Reme 13 Audits Soil Vap our Su rvey s Site lnve st.iga t io ns . . n Comp re hens ive Site Re mediatio 12 European Offices Epsom 0372 745995 061 877 7973 =

CERTIFICATES

A. J. Bayliss (Stourport) Ltd Petroleum Engineers Petrol, Fuel Oil and Electrical Installations C.,n.m cau:No FM 27512 11/12 HODFAR ROAD, SANDY LANE INDUSTRIAL ESTATE STOURPORT-ON-SEVERN DY13 9QB TELEPHONE: 01299 824541-2-3 FAX: 01299 827638 ' SPECIALISING IN ALL ASPECTS OF FORECOURT PETROLEUM INSTALLATIONS AND SERVICING FULLY ACCREDITED TO BS EN ISO 9002: 1994 C.2 s · . ... . £ _ 7 (§' BS 5750 Part 1/ISO 90001 Approved Q:- l111M ;13#11 M! :t"M :1;1•-11:1 •t•IIJ :J! I3"i i5 We do not compromise on quality where -Z.. environmental issues are concerned Internal pipework and overflow prevention valves can be supplied, fitted and tested at our works t o ensure the integrity of the sy ste m . Station Road Works Hadleigh, S uffolk , I P 7 5P N t el : 0 14 73 82306 1

Emco Wheaton Gold

That will do nicely.

Road, Westwood Industrial Estate, Margate , Kent, erg 4JR \I ' Telephone: 01843 221555 Fax: 01843 295444

' ' / NASH Nash & Partne rs ha b . R ve ee n wo rkin g 111 partnership wit h the e tail Pe trol e um i1 d d . 1 u s ti y for a lm os t thirty yea rs, planning and eve lop m g re tail i II · I nsta atio ns from a s tra ig ht forward pump c 1an ge to Euro ' 1 p e s a rges t fdlm g sta ti o n. Every s te p of th e way, fr o m feas ibility s tudi es and s ur vey in a pro1ect m a na e m e i · 0 d g 1t and commjss io ning, we tak e care of every e tail. Wh e th e r a 11 · · I ' 1a10 1 o il co mpan y or a n indi v idual dealer, o ur c ie nts a re ass ur d f I di e o ti e Nas h co mmitm e nt to quali ty and a ie 1e nce to Bssro ::> 'backe d by up-to-th e- minute te chn o logy, inn ova ti o n a nd ex per ti se. Frnm a gree nfi e l j · p . s ite to a fu ll y o p e ratio n a l in s ta ll ation, Na s h & a 1tne rs d e li ve r CP t" ea 1ve ye t hi g hl y p rac tica l s o lu t io ns. + TOW N f, L ANNE I<S PRO JEC' T MANAG ER S * l'l(O l,ERTY CONSUL Tf\NTS '\.\'-o lf&PA fff N FR S ITDAS · · · "" tat1011 A pproach+ So uthgate+ Ch ichester+

Valve?

The Emco Wheaton A1100 OPS is fast becoming the market leader Overfill Prevention Valve VERSATILE. Can be installed in any position within a full 360 degree rotation, without any risk of fouling suction pipes etc simply the best valve all round! DURABLE. Floats are internal and protected by a metal shroud which prevents damage during installation or inspection. FAIL-SAFE. In the event of the valve not resetting, it will close during the next fill, preventing a dangerous and costly overfill other valves can fail in the open position. VAP 0 UR TIGHT. fmco Wheaton have not had to introduce a bottom seal recently, because the A 1100 valve has always been fitted with one. DIPSTICK FRIENDLY• Dipstick can be used whether tank is full or empty. FAST SERVICE. The A1100 is assembled and tested in the UK. Therefore we are able to respond quickly to demands from our two UK stockists . For further information on the Emco Wheaton range of products for Service Stations , please contact Roh Laird at our Margate Office. ® Emco Wheaton Retail Europe Enterprise

GCS NationallrspectiooCourc:ilfcr Elactric:al Installation Contracting D EiC AP P ROV'ED CONTRACTO R G c s a rage onsultancy ervices Ltd Cert No FM 23290 UNIT 10 MERTHYR TYDFIL INDUSTRIAL PARK PENTREBACH MERTHYR TYDFIL MID GLAMORGAN CF48 4DR TELEPHONE {0443) 692008 FAX {0443) 692159 FUEL PUMPS AND TANKS FUEL MONITORING AND METERING EQUIPMENT PROJECT MANAGERS/ENGINEERS We are delighted to inform you that the British Standards Institution has approved our Quality Management System and awarded us BS5750 Part 2 Creditation. ·-·-·-·-·-· We shall continue to assess and inspect our Quality System to ensure that we meet the rigorous demands of our industry 1973 2 1 YEARS OF SERVICE TO THE PETROLEUM INDUSTRY 1994 HAS I I

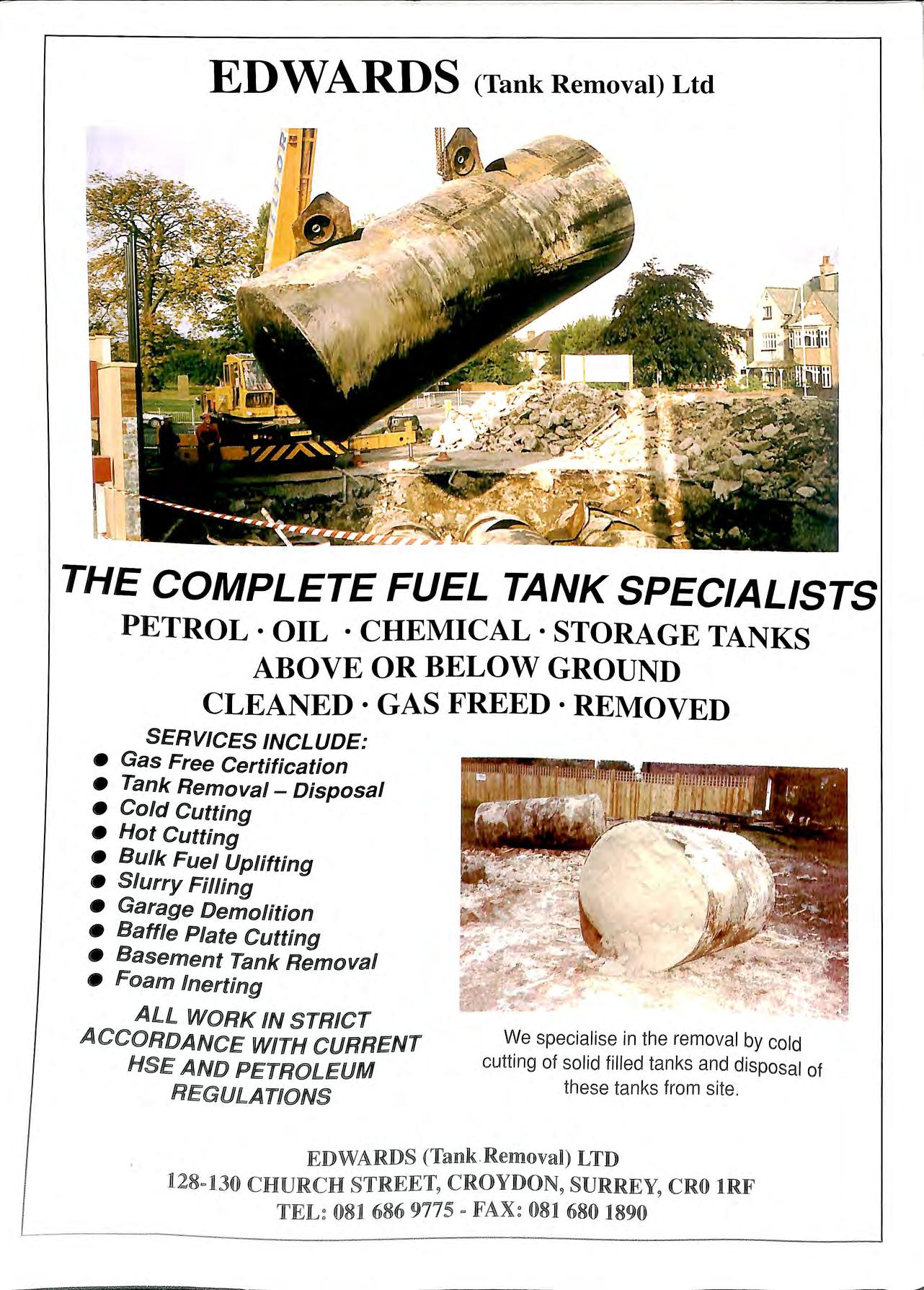

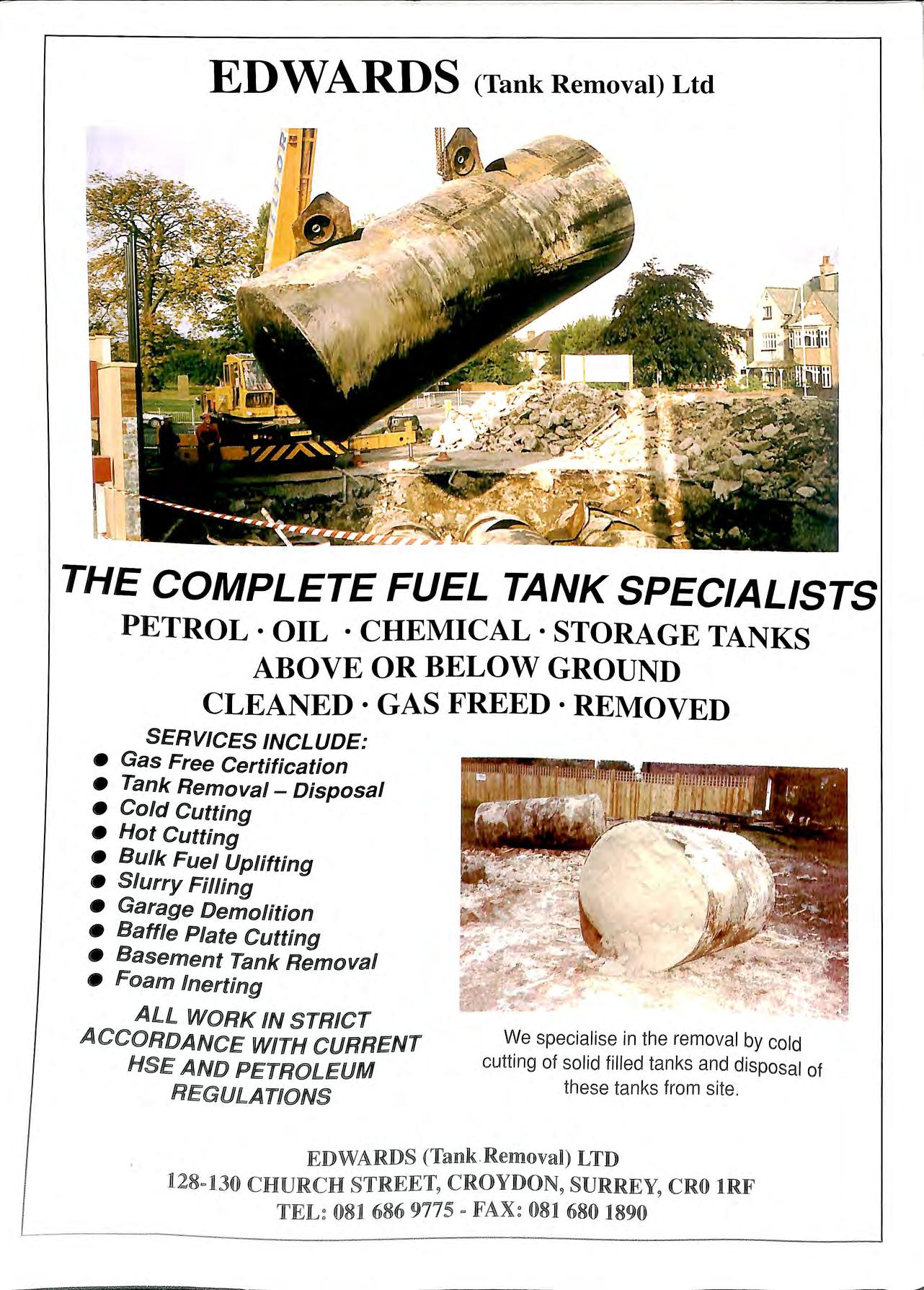

ED WARDS (Tank Removal) Ltd THE COMPLETE FUEL TANK SPECIALISTS PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED SERVICES INCLUDE: • Gas Free Certification • Tank Removal - Disposal • Cold Cutting • Hot Cutting • Bulk Fuel Uplifting • Slurry Filling • Garage Demolition • Battle Plate Cutting • Basement Tank Removal • Foam lnerting ALL WORK IN STRICT ACCORDANCE WITH CURRENT HSE AND PETROLEUM REGULATIONS We spec iali se in the rem oval by cold cutt ing of so li d filled tanks and d isposa l of these tanks fr om s it e . EDWARDS (TarukRemovaH) LTD 1t28=1t30 CHURCH §TREET9 CROYDON9 §URREY9 CRO lRF 081 686 9775 = 081 680 1890

NEW from and ENVIROFLEX: fuel delivery. Total secondary containment for suction or pressJ.ire systems, or Monoflex for direct suction systems. Easy to install and maintain , with all fuels and additives currently on the market. UL listed. PETROLmLIN E: For ofifset-fill , vent and vapour recovery. Robust and easy to use this le ak-free petrol and additive resistant ' system is based on Durapipe's patented electrofusion joi flt in g methocl. by Duragipe SUPPLIED BY THE OFFICIAL DISTRIBUTORS- for further information on either, or both , of these products call FORECOURT EQUIPMENT SPECIALISTS PURFLEET COMMERC IALS LIMITED 520 London Road West Thurrock Essex RM16 1BE. Tel: (0708) 863931 Fax: (0708) 868226

It you were losing 4,000 chocolate bars a year

•••

This is what 0.1 % fuel loss represe nts to a typical forecourt operator. Most sites are losing many more times this amount eac h year!

PetroVend' s SiteSentinel forecourt monitoring system guards against wetstock loss , leaks, theft , short deliveries to mention just a few!

It tells you through acc urate printouts and eas y to underst an d graphical ana lys is, not only how mu ch fuel yo u are los ing on a day by day basis but indi cates w here in the sys tem the loss is.

It is a modular syste m th at ca n be tailored to yo ur pres ent nee ds and expa nd ed later.

SiteSen

SiteSentinel

Wetstock Manager

is already proving a wi nn er in Ameri

use it is easy to understand and

for itself

real

... you'd post a guard! In one package SiteSentinel offers you: T Automatic Inventory T Auto-Calibration Petrol/end T Auto-Reconciliation PetrnVemrl (!E[]rnpie) • A pproved Tank TesUrng Every Day 76 Leeds Road, Newton Bar, y l eak Detection Wakefie ld, WF1 20F TEL: (0924) 291919 FAX : (0924) 376511 T Treind Package

tinel

ca beca

use, an d pays

in

sav in gs

POWERED BY EXPERIENCE E SPECIALIST ELECTRICAL ENGINEERS & CONTRACTORS TO THE PETROLEUM INDUSTRY • Close-circuit TV • Fire Alarms & Emergency Lighting • P lanne d Maintenance • Insp e ction & Test ing • Forecourt Earthing Sy st ems "/ hl'Elcl"M"cal Co11frdcl ors 1\ sso:it1 fio11 HEG ISTEHED MHTI3E ll .D MEMBER O F A.P.E.A Na tiona l Inspectio n Counci l fo r El ec trical !nsta lla ti on Contracting • •lll:Elll: AWROllEDCONTRACTOR HEAD OFF ICE : PR OJECT HOU SE ·THEDRIV E. WOR THING · WEST SUSSEX · BN11 SLL TEL: 0903 700321

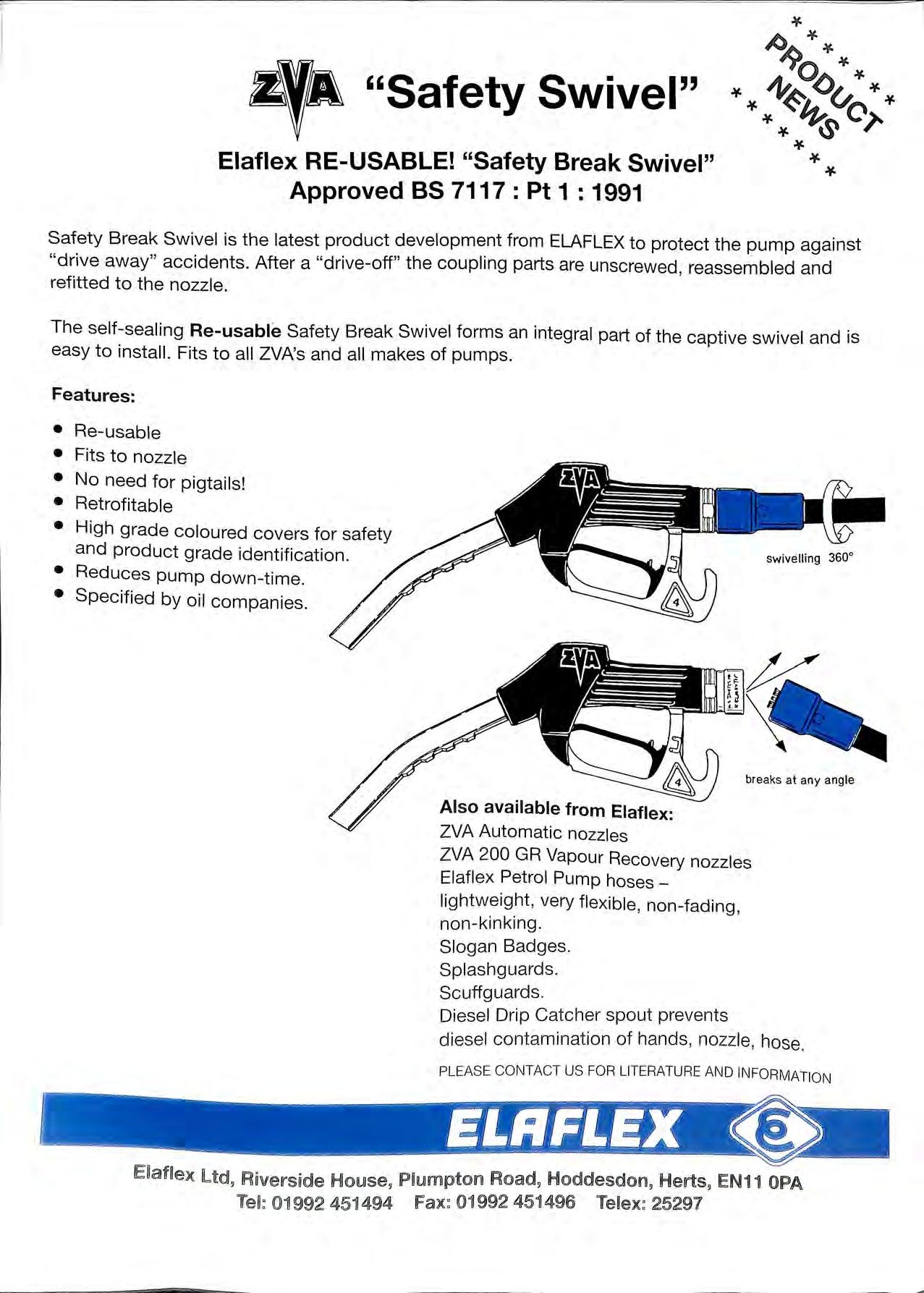

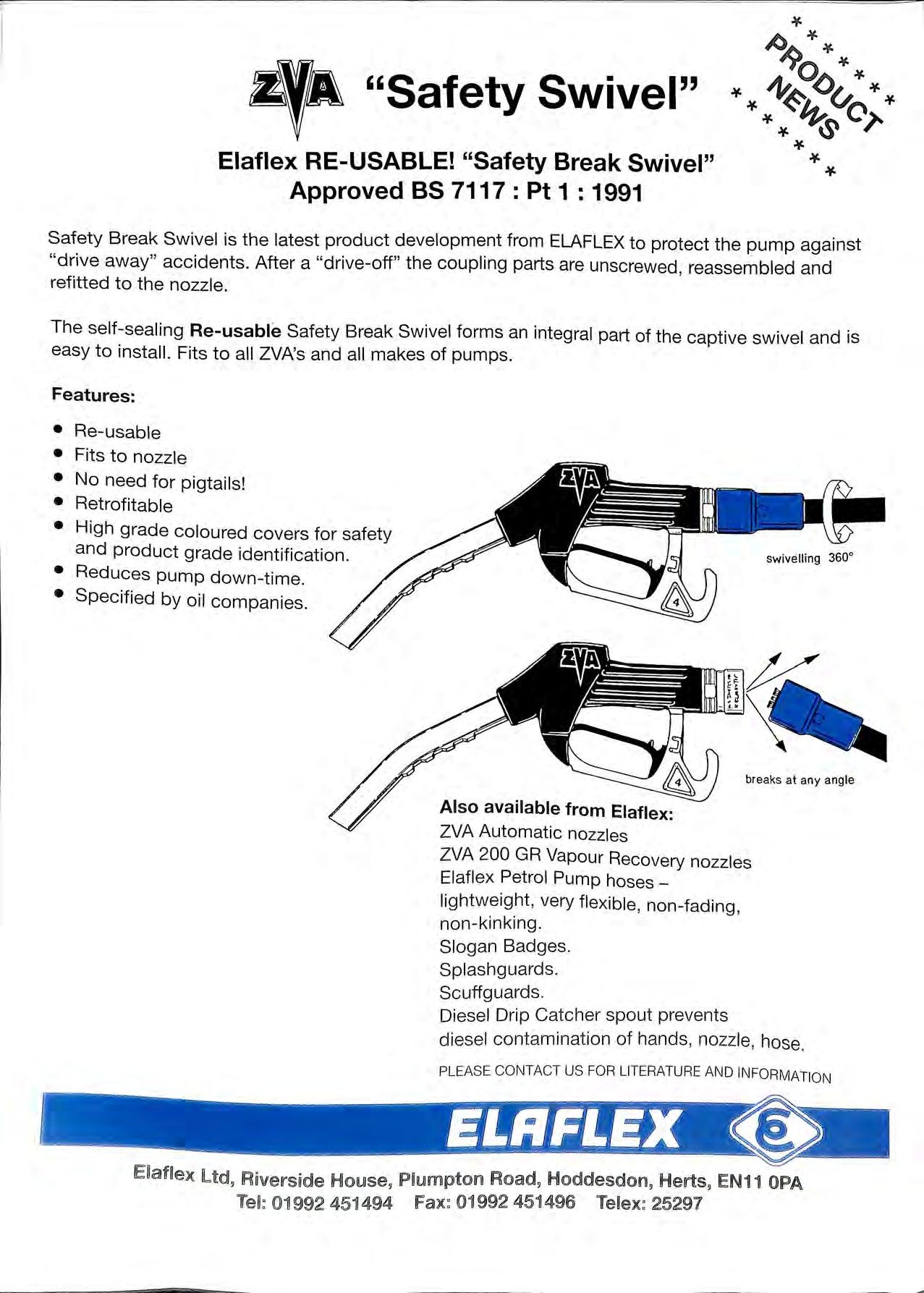

zl(/A "Safety Swivel" Elaflex RE-USABLE! "Safety Break Swivel" Approved BS 7117 : Pt 1 : 1991 Safety Break Swivel is the latest product development from ELAFLEX to protect the pump against "drive away" accidents. After a "drive-off" the coupling parts are unscrewed, reassembled and refitted to the nozzle. The self-sealing Re-usable Safety Break Swivel forms an integral part of the captive swivel and is easy to install. Fits to all ZVA's and all makes of pumps. Features: • Re-usable • Fits to nozzle • No need for pigtails! • Retrofitable • High grade coloured covers for safety and product grade identification. • Reduces pump down-time. • Specified by oil companies. breaks at any angle A lso available from Elaflex: ZVA Automatic nozzles ZVA 200 GR Vapour Recovery nozzles Elaflex Petrol Pump hoseslightweight, very flexible, non-fading, non-kinking Slogan Badges. Splashguards . Scuffguards . Diesel Drip Cat cher spout prevents d iesel contamination of hands , nozzle , hose PLE A SE C ONTACT U S FOR LITER A TURE A ND INFORMATION UdJ 9 IFUveirskJJe HotUJse 9 Road? Hoddesdon 9 Herts 9 EN1 1 OPA 992 451494 Fai x: 01992 496 25297

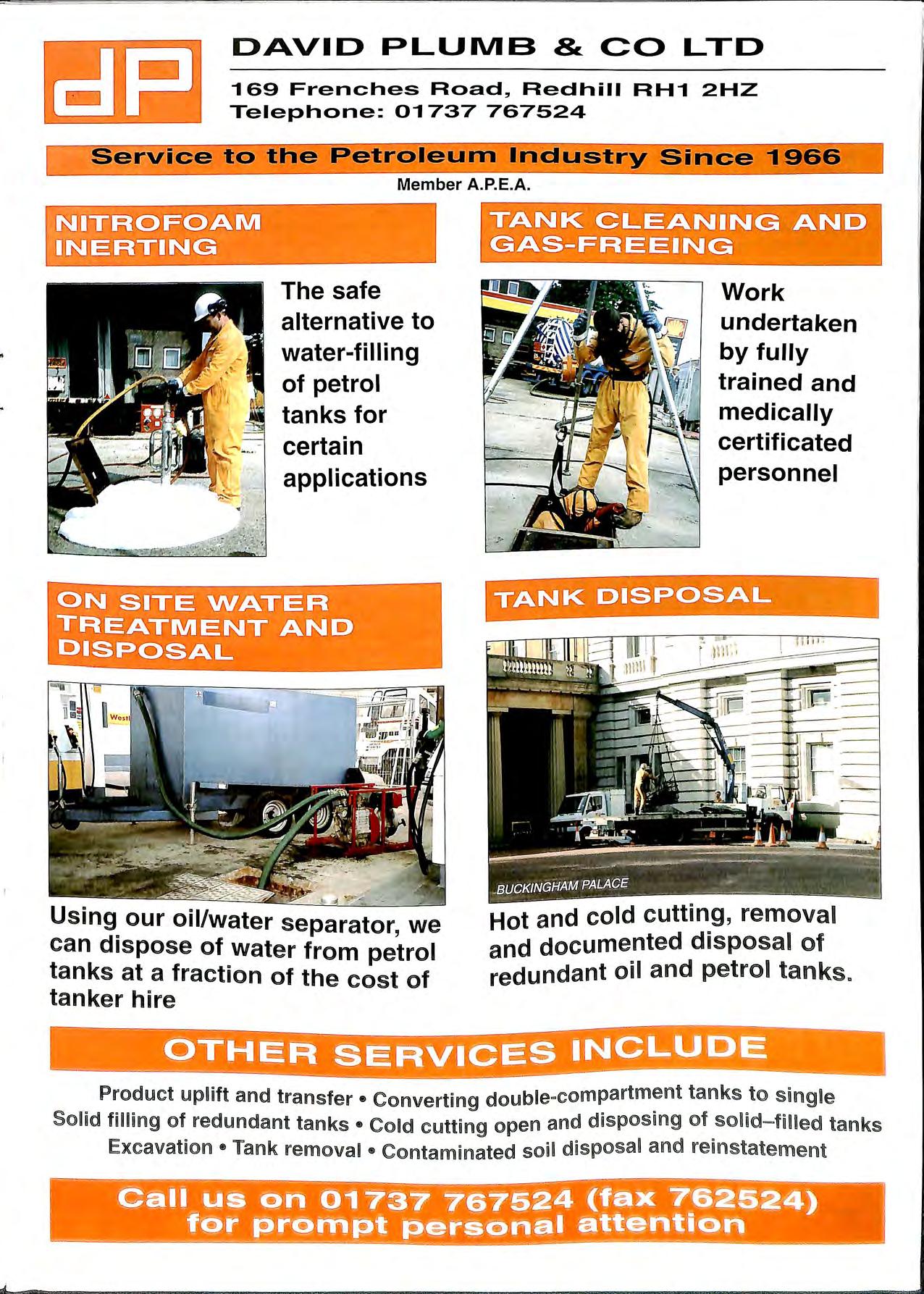

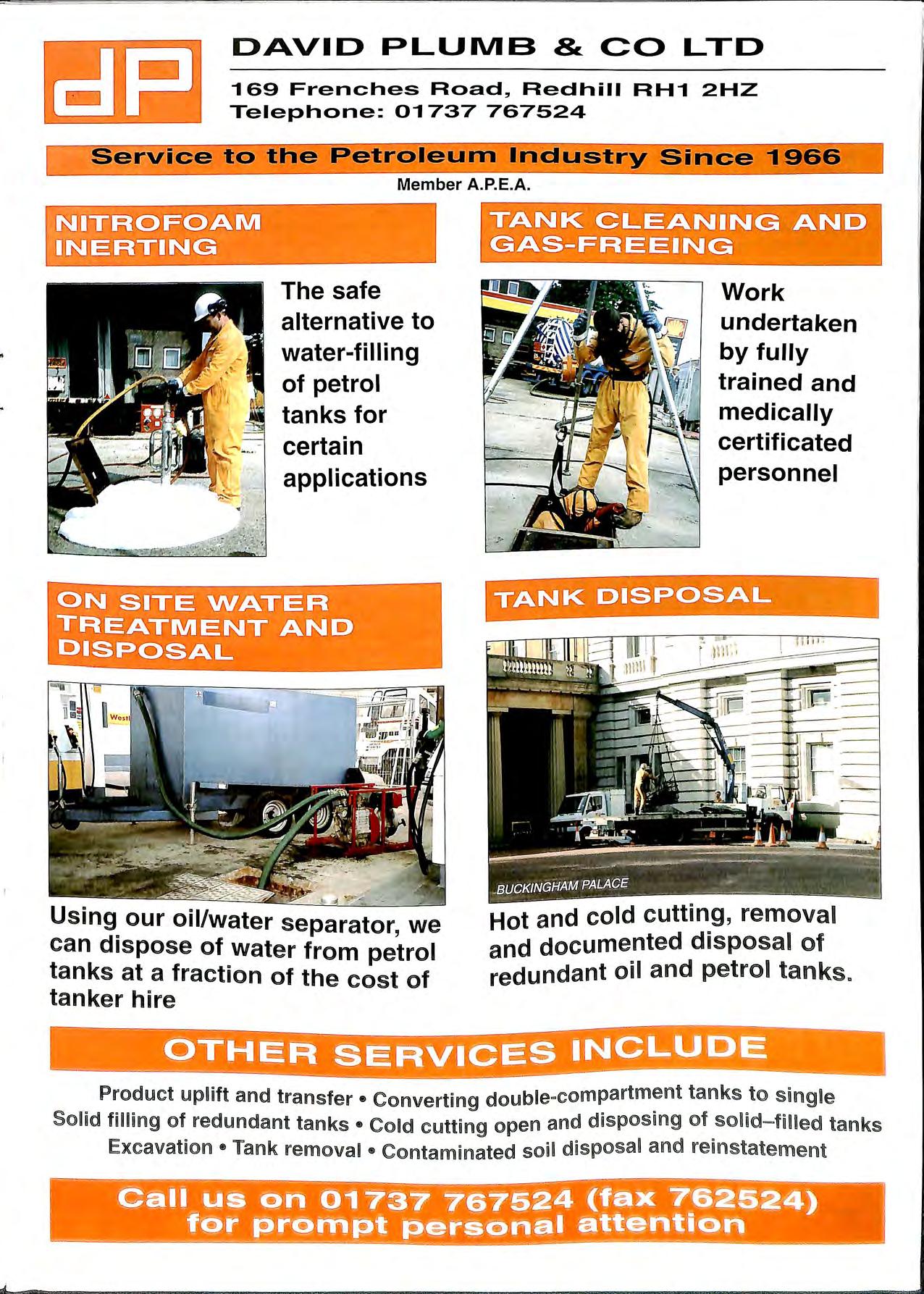

DAVID PLUMB & CO LTD 169 Frenches Road, Redhill RH1 2HZ Telephone: 01737 767524 Service to the Petroleum Industry Since 19&& Member A .P.E.A. The safe alternative to water-filling of petrol tanks for certain applications Us ing our o il / w at e r se par ator w e ca n di s p ose o f w at e r from pe'tro l t a nks at a fr ac ti o n of th e c o s t o f t a nker hire Work undertaken by fully trained and medically certificated personnel Hot a nd co ld c uttin g, removal a nd d oc um en t ed d i sposal of r edu ndan t oil and pe t rol tanks . Product uplift and transfer • Converting tanks to s i ngle So li d fii !i n g of redundant tanks • Cold cutting open and dispos i ng of so iji d-t med tanks Excavation •Tank removal • Contam i nated so u ! and reinstatement

Opinions expressed in this Journal are not necessarily the views of the Association

Talking Point

The HSE risk assessment document on petrol filling stations is to be published following the launch at the APEA conference. At the time of going to press it is expected to be available in January 1996 following a restricted pilot in a few areas. In order for this new approach to work all sides of Industry will need understanding and tolerance, and none more than the enforcing authorities. A time period to settle in, lessons to be learnt, training to be given and sufficient time for realistic assessments to be carried out. I have already read that one organisation who have predicted that sites will close en masse. This should not be the case.

Indeed all the sites that are operating at the moment in the UK, do so with a license and the blessing of the petroleum licensing authority, there will be little change other than to concentrate the mind of us all on the real risks at the site and not the perceived problems.

VOLUME33 Number3 AUGUST 1995 £8.00 (Free to Members) Contents TALKING POINT NOTES&NEws PROSECUTIONS NEW MEMBERS IRISH BRANCH E. Riney Texaco Ltd ADVERTISING SEC R. G. Green · Honorary Secretary· Mr. D. BucknalJ The Bulletin Published by the Association for Petroleum and Explosives Administration A company Limited by Guarantee registered in England No. 2261660 ISSN 0263 4597 EASTERN BRANCH Mrs B. Jacketts Cookson & Zinn Ltd 39 40 22 34 HUMBERSIDE BRANCH P. C. Lusmore

MIDLAND

L. Lloyd Veeder Root NORTHERN BRANCH M. Silman NORTH WESTERN BRANCH H. Reid Pump Services (Manchester) Ltd SOUTHERN BRANCH J. Luke Honorary Editor: Membership Secretary: Mr. J. A. J. Thompson, Mr. B. J. Thompson _________________

BRANCH

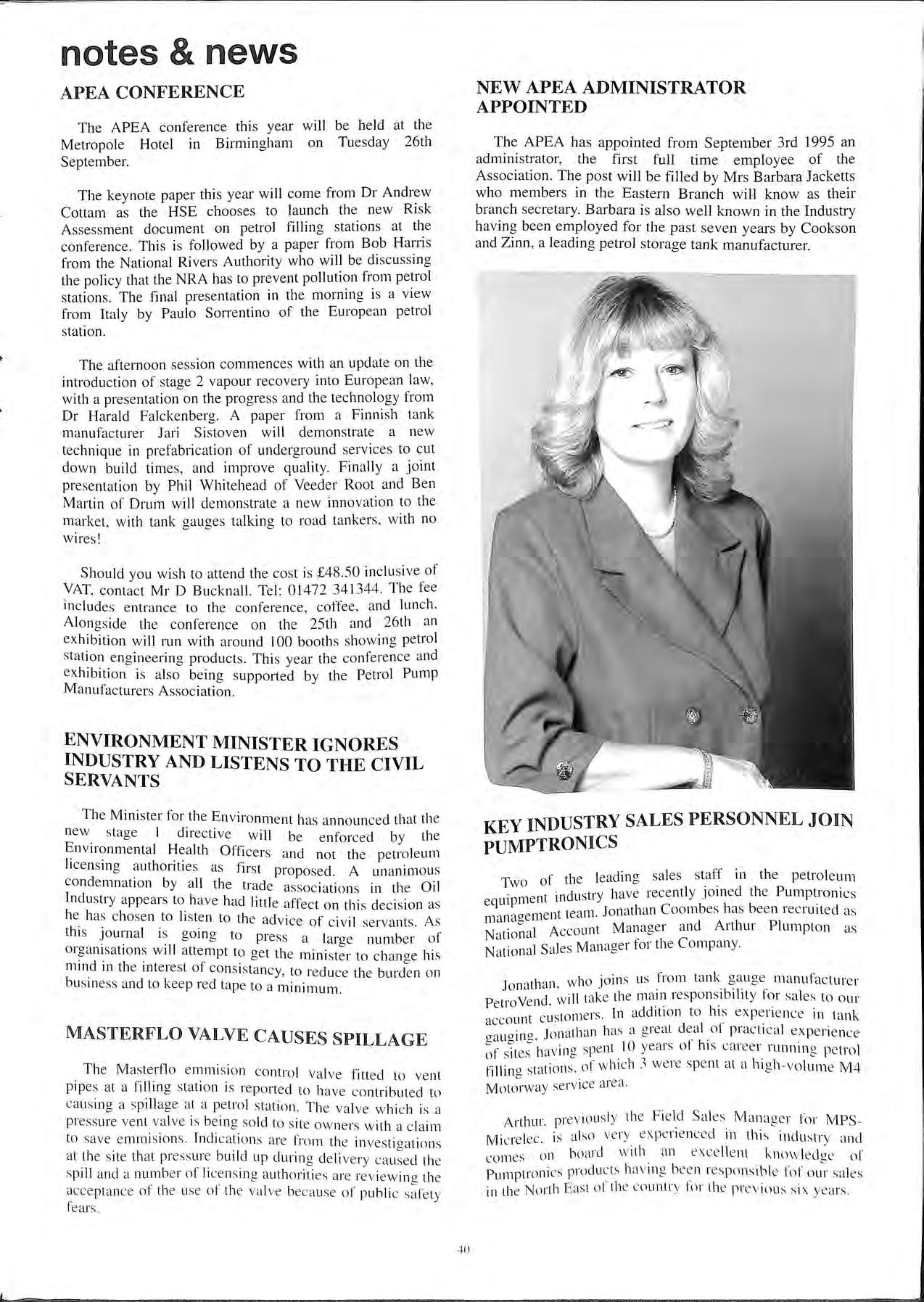

APEA CONFERENCE

The APEA conference this year will be held at the Metropole Hotel 111 Birmingham on Tuesday 26th September.

The keynote paper this year will come from Dr Andrew Cottam as the HSE chooses to launch the new Risk Assessment document on petrol filling stations at the conference This is followed by a paper from Bob Harris from the National Rivers Authority who will be discussing the policy that the NRA has to prevent pollution from petrol stations The final presentation in the morning is a view from Ita ly by Paulo Sorrentino of the European petrol station.

The afternoon session commences with an update on the introduction of stage 2 vapour recovery into European law, with a presentation on the progress and the technology from Dr Harald Falckenberg. A paper from a Finnish tank manufacturer Jari Sistoven will demonstrate a new technique in prefabrication of underground services to cut down build times , and improve quality. Finally a joint presentation by Phil Whitehead of Veeder Root and Ben Martin of Drum will demonstrate a new innovation to the market , with tank gauges talking to road tankers, with no wires!

Should you wish to attend the cost is £48.50 inclusive of VAT, contact Mr D Bucknall. Tel: 01472 341344. The fee include s entrance to the conference, coffee , and lunch Along s ide the conference on the 25th and 26th an exhibition will run with around 100 booths showing petrol station engineering products. This year the conference and exhibition is also being supported by the Petrol Pump Manufacturers Association.

ENVIRONMENT MINISTER IGNORES INDUSTRY AND

LISTENS TO THE CIVIL

NEW APEA

APPOINTED

ADMINISTRATOR

The APEA has appointed from September 3rd 1995 an administrator, the first full time employee of the Association. The post will be filled by Mrs Barbara Jacketts who members in the Eastern Branch will know as their branch secretary. Barbara is also well known in the Industry having been employed for the past seven years by Cookson and Zinn, a leading petrol storage tank manufacturer.

SERVANTS

The Mini ster for the Environment has announced that the new stage I directive will be enforced by the Environmental Health Officers and not the petroleum ltcensing authorities as first proposed. A unanimous condemnation by all the trade associations in the Oil Industry appears to h ave had little affect on this deci s ion as he. ha s chosen to listen to the advice of civil servants. A s thi s JOUrnal is ooino to · f a a p1 ess a large number o orgamsat1ons will attempt to get the minister to change his rn1I1d In the 111terest of con s1stancy, to reduce the burden o n bu s ine ss and to keep red tape to a minimum.

MASTERFLO VALVE CAUSES SPILLAGE

The Ma sterflo e mmi s io n control va lve fitt ed to ve nt pipe s at a filling s ta tion is re ported to hav e contributed to ca us ing a spillage at a petrol sta tion. Th e va lve w hich is a press ure ve nt va lve is being so ld to s ite ow ners w ith a claim to save. e mmi s io ns Indi ca ti o ns a re from th e inv es tigation s a t th e s ite that press ur e build up during d e li ve ry ca used th e spill a nd a numb e r of li ce ns in g authoriti es are rev ie wing th e acce pta nce of the use of th e va lve beca use of public s; fe ty fe ar s.

KEYINDUSTRYSALESPERSONNELJOIN PUMPTRONICS

Two of the leading sales st_aff in the petroleum equipment indu stry have rec e ntly JOrn e d the rn a naoement team Jonath a n Coombe s has bee n 1ecrn1ted as Account Manage r and Arthur Plumpton a s N ational Sal es Manager tor th e Company.

Jonathan , who join s us from ta nk_ gauge manufacturer P t Vend will tak e th e marn res pon s1b1hty tor sales to our e 10 , 1 account c ustom e rs In ad d1t1on to 11_:' ex p e ri e nce in tank oauoing. Jo nathan has a grea t deal_ ol" practical experience sites hav in g spe nt 10 yea rs o1 hi s caree r runnin g p e trol fillin g stat ion s. of w hi c h 3 we re sp e nt at a hi g h -v olume M 4 Motorway se r vice a rea

Arthur. prev io us ly th e F ie ld Sales Manag e r for MPS Mi c re le c. is also ve ry expe ri e nc e d in this industr y and co mes o n boa rd w ith an ex ce ll e nt kno w le dge or Pumptronics product s hav in g res ponsibl e fol sa les in th e North Eas t ot th e c ountr y tor the pre v iou s s ix ye ar s

notes & news

40

Sofitam Pump Services have been appointed a Master Distributor for Dayco Europe, one of the world's leading industrial hose producers.

The company will act as major suppliers of Dayco's high quality forecourt and commercial fuel dispenser hose assemblies.

In particular Sofitam will target the product, which is approved to all European standards including BS3395, to the aftermarket and plan to implement an aggressive pricing policy to make the hoses "extremely attractive both in terms of quality and price".

Meanwhile, work is already underway on the manufacture of a special type of hose for what Sofitam Pump Services' describe as part of a major nationwide installation.

Dayco Europe, is part Mark IV Industries, the multibillion dollar American conglomerate. Its automotive division manufactures transmission and fluid handling systems and fuel line assembly.

"We see the refuelling sector as a key vertical market and are delighted to appoint Sofitam Pump Services as a Master Distributor. We regard Sofitam as part of a highly and established group of companies with mfluence throughout Europe," said Dayco General Sales Manager Ian Geddes.

"FORECOURT CONTRACTORS SAFETY ASSOCIATION GOES FROM STRENGTH TO STRENGTH"

The has continued to grow over the last few years, and m answer to many enquiries from all sides of the Petroleum Industry, Chris Munton the current Association prepared the following report to bring interested parties 'up to speed' with their activities. He states:

".We have been in existence now for some four years, havmg been established with the aid of an EC Grant, and we recently been included in the Technical CoOrdmatmg Body set up to produce a replacement to HS(GJ41. We have also been invited to assist the joint IP/APEA Sub Committee producing a Contractors Safety Manual. We are pro-active in the field of safety on the forecou11, and PTF Petroleum Trainincr has been appointed to undertake our 1995 Certificate of Competence training workshops. The FCSA is indebted to CONOCO who have agreed to support and sponsor the Association drive towards a meaningful self regulation of safety standards w1thm the. industry by providing conference and meetmg lac1ht1es at their Warwick Headquarters. I am delighted that our acceptance by the Industry at the highest level an opportunity for the Association to play an act iH:' role in formulating safety policy and representing the < 0111ractors pomt of view·. It also provides our n1t·mher-.;h1p with a ··voice in the Industry and an ability lo ,.,.11 ahre;1-.;1 !lf lhe late<.;t developments in Contractor safety

requirements as they are approved by the Regulatory Bodies and The Petroleum Companies.

With the many changes in Safety legislation currently being discussed and the mandatory nature of the guidance procedures under consideration, the more that we, the Contractors, can contribute towards a meaningful self regulation of safety standards, the better. As a requirement of membership, our Members have to provide delegates to undertake an independently audited Competency Assessment in order to achieve FCSA Safety Coach status. Following in-house training with the assistance of their Safety Coach, their full staff then undertake a similar training programme in order to be awarded an FCSA 'Safety Passport' to signify their status as Competent Persons. Over 30 Companies have applied for Membership including such organisations as Global/MSI, Conder Products, Parkersell, The Turton Group, Station Maintenance, Forecourt Services, Taskforce, Serco, Cleansing Service and many others. We have approved 35 Safety Coaches at our regular Safety Workshops which are conducted by an ex Petroleum Officer.

For further information and/or membership application forms, please contact: The Secretary, FCSA, PO Box 6120, LONDON, SWl5 lXF.

NEW LEXICON FOR PETROLEUM

The Petroleum Equipment Institute has released a new publication entitled Petroleum Equipment Lexicon Terms Used in Petroleum Marketing Operations. The was authored by Howard Upton, executive vice president of PEI from its inception in l 951 to 1987. Howard collaborated with a panel of industry experts and Robert N. Renkes, current executive vice president of PEI, to produce the definitive dictionary of terms used in n:iarketing operations. The book, two years in the :Viii serve as a reference source for people mvolved any area of the industry, including regulatory personnel m federal, state, and local UST agencies.

'J_'he entries include a one-or two-line definition of a In most cases, a further explanation or clarification is given. For people new to the industry, the Petroleum Equipment Lexicon will provide valuable insights into vocabulary and abbreviations that will be essential in their work. For industry veterans, the book is intended to serve as a reference manual. Names, addresses and phone numbers of scores of industry organisations and publishers of periodicals are included.

The Petroleum Lexicon does not provide definitive engineering or techmcal. data. It provides general explanations for words. equipment. and concepts commonly used in the petroleum marketing equipment industry. The Petroleum Equipment Lexicon, ISBN 09642638-2-3. is available through PEI. P.O. Box 2380, Tulsa. OK 7410 I. Fax 918 49 J 9895. The cost for members is $20; $30 for non-members. All orders must be prepaid.

EDITORS NOTE: The Lexicon is an excellent book which I have already found useful and made reference to on numerous occassions. I will be reviewing this in full in the next edition

PUMP SERVICES

AS DAYCO MASTER DISTRIBUTOR

SOFITAM

APPOINTED

Sainsbury's PLC were fined£ 18,000 on 28 June 1995 by Chichester Magistrates after pleading guilty to charges resulting from two separate incidents at their petrol filling station in Chichester, West Sussex.

In the first incident a pump was authorised while the engine of the vehicle was running and the operator failed to stop the dispensing operation even when he knew that the car engine was running. To compound the problem the site supervisor spoke to the customer and allowed him to continue dispensing which eventually spilt over the exhaust of the car. An ex Police Chief Inspector provided an excellent detailed statement which was backed up by video evidence from the camera system on site.

The second incident, two weeks later, occurred when a fire broke out in the engine compartment of a car arriving on site. Neither of the two site attendants implemented any emergency procedure and continued to dispense petrol. Due to the prompt action of other customers, who used the fire extinguisher on site, the fire was out by the time the Fire Brigade arrived. At no time during the incident was the site closed or cleared. Subsequent interviews of the attendants revealed that they had had inadequate training.

TEXACO SITE PROSECUTED

These two cases arose out of a spillage of some 50 litres of petroleum spirit during delivery to this petroleum filling station.

P.M.A. Service Stations Ltd, was prosecuted by the LF.C.D.A. n?t keeping records of training of staff and Mr bemg the "competent employee" under the fegulat1ons_ of 1992, responsible for seeing in the delivery, or n?t. measured ullage in the storage tank before perm1ttmg dehvery.

Both pleaded guilty before Justices at Richmond Magistrates' Court on 12 July 1995. The Court were told of potential dangers, the filling station being a busy mam road and bounded by residential flats. The company was fined £500 and order to pay £400 and the employee who is now unemployed fined £80 with costs of £50.

WINCANTON DRIVER FINED

The above case was disposed of at Highbury Corner Magistrates Court on 9 June 1995.

The prosecution of Mr Stephen Ri"ddell 1 • · arose rom two contraventions ot the Road Traffic (CmTiaoe of D· . . S b . c <111ge1 ous u stances 111 Road Tankers and Tank c t · l R I · l 9 J on ame1s egu at1ons I J_ Station on 9 January 1_995. The detendotnt omitted hefore delivery of petrol rnmmenced. to make a record 111 the prescrihed form of the numhers of the tanks and to which delivery of the petrol would he made. Secondly. he failed to ensure that the delivery hose was connected to tl1L' appropriate tank on site:

the result being that 4 star petroleum spirit was delivered into a Diesel oil tank.

Interviewed under PACE, the driver admitted his responsibility; but said he was driving an unfamiliar tanker on the relevant night, and that the tags identifying the petrol "were partially hidden once the crash bar was raised."

At the hearing on June 9 the defendant pleaded guilty to both offences. The Magistrates made particular enquiry about the hazard resulting from the contraventions. The Petroleum Inspector, Mr. Humm, informed the Bench that no. dange_r woul_d arise from the mixed diesel and petrol bemg delivered mto a customer's tank. The risk arose from need to clear the diesel tank of 4 star petrol by removing its top, to get access to the contaminated material, which created some risk of ignition. It was accepted that because the work would be cmTied out be qualified contractors, this danger would not be great.

In mitigation, Mr. Riddell said that he could have made the required record subsequent to the delivery of petrol without detection. His honesty in not doing this was a matter the court should take into consideration when passing sentence. He repeated the point made in his interview that he was unfamiliar with the tanker driven on January 9, and that the tags identifying the petrol being carried were obscured by the raised crash bar. He also gave evidence of heavy financial outgoings on his house and family.

The Bench said that despite the matters in mitigation (which were accepted) the offences needed to be dealt with by means of a financial penalty, rather than a Conditional Discharge. Fines of £ 100 on each of the two summonses were imposed; and the defendant was ordered to pay £300 costs to the LF.C.D.A.

WORKSHOP FINED £500

A vehicle workshop in Kentish Town was fined £500 and ordered to pay £ 1,000 in by magistrates for a o_ffence discovered after an employee was burnt while weldmg.

On 21 July the court heard that the employee _for Filmflow Ltd of Regis Ro.ad, NW5. a d Spl 1yino vehicles, which used cellulose thmners -a M · < c ·xture of petroleum subject to hcensmg. He was weldmg nu d ?" 1· oinponent for a van when he 1g111te a --' 1tre contamer a c of thinners. The container was kept open tor_ ease ol access d Was sited only 2-3 metres from the weldmg plant. As a an . . r· result. the employee's clothes caught ire and he sutlered burns to his arms and head and was rushed to Moul Vernon Hospital hy air ambulance.

The London Fire & Civil Defence Authnrity told the court that it was the enforcing authority for the Petroleum (Consolidation) Act was 1.wosecuting the defendant company for unlawlully keepmg a petroleum mi'i.ture without a licence.

The company. which pleaded guilty. said in m1tw.ation that they were not aware of the law and were a small farnil) company.

HYPERMARKET HAMMERED!

NORTH EAST LONDON FURNITURE COMPANY FINED

The owners of a North East London office furniture manufacturers have been fined £2,250 for three contraventions of their petroleum licence discovered after a major fire at their premises.

Following a serious blaze involving chemicals and needing eight fire engines at Wallis Furniture, Fowler Road, Hainault last June, Petroleum Officers from the London Fire and Civil Defence Authority inspected the premises and discovered the contraventions. They were an obsolete 'notice to employees' instruction, no written statement of operating and emergency procedures as required by the licence and a failure to give relevant instructions to contractors working in a hazardous spraying area.

The company pleaded guilty to all the charges at Redbridge Magistrates Court on 9 February. Awarding costs of £590 to the Authority, the Magistrates took into account the Company's previously clean record and evidence that all the issues that resulted in the contraventions had been resolved.

FIFE REGIONAL COUNCIL PROSECUTES LICENSEES

I. changing to a guilty plea, on advice of his Q.C., a licensee was fined £250 for each of the following contraventions of his conditions of licence at Kirkcaldy Sheriff Court in June J995.

(i) allow an operating attendant under the age of eighteen years to be in sole charge of a licensed premise;

(ii) did fail to have the fill pipes of tanks securely locked at all times otherwise than for immediate use.

.A Prohibition Notice was issued closing the site until a s.uitably competent person arrived to take control of the licensed premises.

2 · After a guilty plea, a licensee was fined a total of £750 for following contraventions at Dunfermline Sheriff Court 111 July 1995:

<i) failing to keep written records showing that theoretical training and practical

<iiJ mstructions had been given to employees; failing to comply with the requirements of Schedule 4 , of the Road Traffic <Road Tankers and Tank Regulations relating to the delivery of fuel hy way 1· 1. 1. o a 1censee controlled de 1very.

In the latter case. d 1· d I Jy , · d e 1very at 111ght was ma e w len on one person wa . h JI , · s on t e self service site. A delivery was a owed to proce 'd · 1 · d e W1t 1 no competent person 111 atten ance a conse"uence w· . h h . . I '1_ <ts t at t e wrong tuel was de!Jverec to an 11iaprropnate t· k TI " ' . 1. . c1n · le suhsequent emptying and trans1e1 o uel 1n reme r· I · · I . . ( 1" Work resulted in a spillage requmng t le <1llu1d<1nce of th, , ,d t e111e1gency servKes who 1n turn contc1cte 1ht· fkpan111e 111 1· ·r· · h · 0 rad111° Standards. the latter emg ,, lor tl, 1·., i:-. le It t nsmg of petroleum sites.

HAMMERHEAD® AND SOLO PUMPS CLEAN UP AFTER MAJOR

POLLUTION

INCIDENT IN DEVON

NRA Marcus Hodges Environment and Geotechnical quick to respond to avert pollution threat to Exeter's water supply.

In an incident in April where approximately 7,000 litres of heating oil leaked into the ground adjacent to the River Loman near Tiverton, Devon, the NRA assisted by Marcus Hodges Environment and Geotechnical Instruments were quick to avert a major pollution problem.

Vandals are alleged to be responsible for the opening of valves on a 15,000 litre oil tank and associated bunding at an Engineering Works in Tiverton, releasing approximately 7,OOO litres of heating oil into the ground adjacent the tank, which quickly found its way into the River Loman.

The NRA responded quickly with pollution prevention measures, although a considerable quantity of oil had already drained into the River Loman by the time they were alerted.

The loman flows into the Exe just below Tiverton. The public water supply for Exeter is abstracted from the River Exe approximately 15 miles downstream from Tiverton. The intake for the abstraction was closed as a precaution following the oil spill.

Specialist Consulting Hydrogeologists and Environmental Engineers Marcu Hodges Environment of Exeter were called in by the NRA to investigate the groundwater contamination and to control the flow of oil to the River.

The site setting, proximity of services and depth to groundwater restricted the use of interceptor trenches. Four boreholes were therefore rapidly drilled adjacent to the spill area. Specialist environmental equipment manufacturer and contractor Geotechnical Instruments of Leaminoton Spa was called in to install pump recovery systems. "'

Instruments installed 4" diameter positive air displacement pumps (Hammerhead® and Solo) in the two boreholes closest to the spill area to draw down the water table and induce the flow of oil into the boreholes. They also installed a 2" diameter Hammerhead top fill positive air displacement pump to recover the product.

"The recovery is proceeding extremely well", said Geoff Bown of Marcus Hodges Environment. "GI was quick off the mark to supply highly specialised equipment which has been very effective in recovering oil from the ground and controlling the seepage of oil into the river."

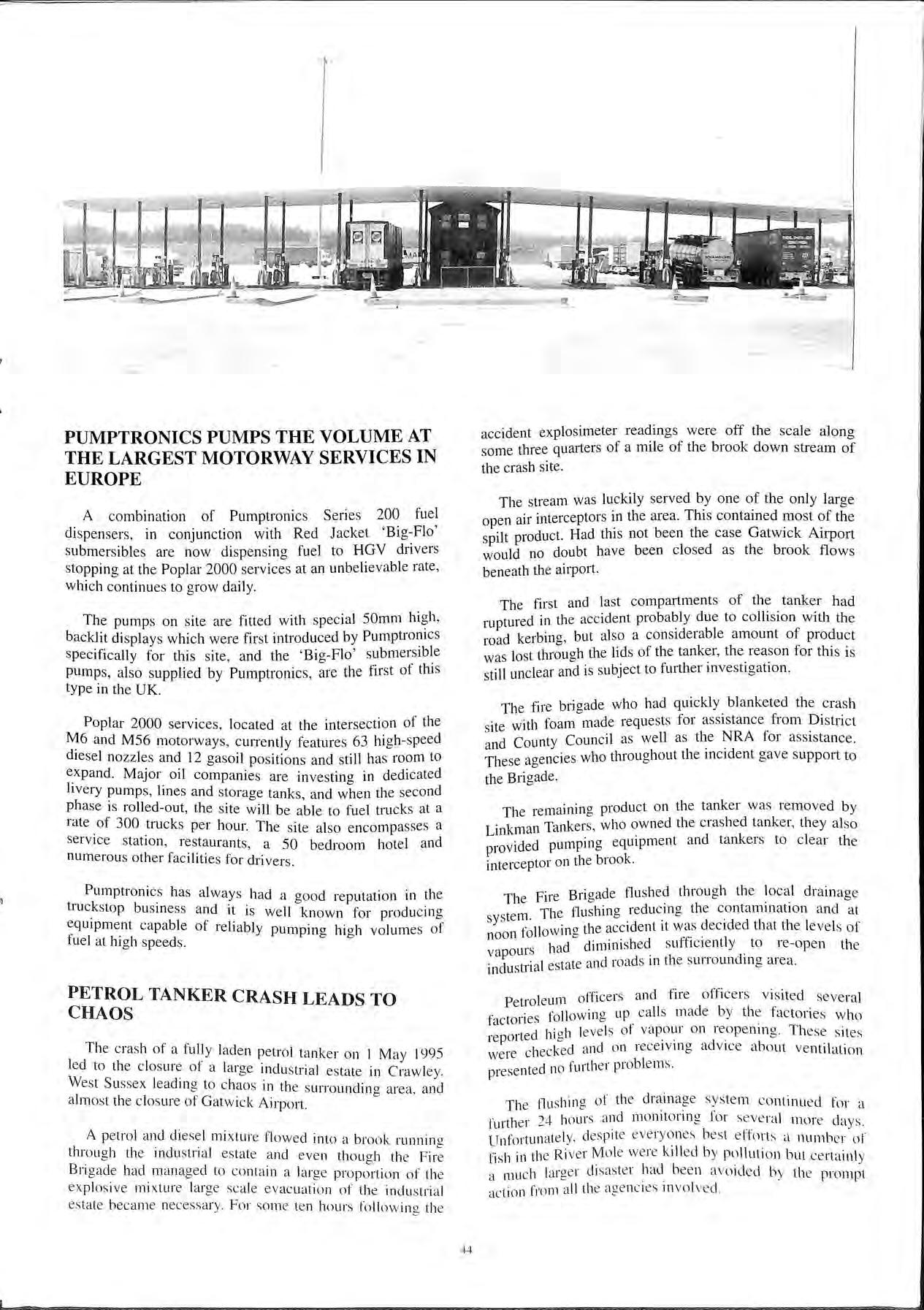

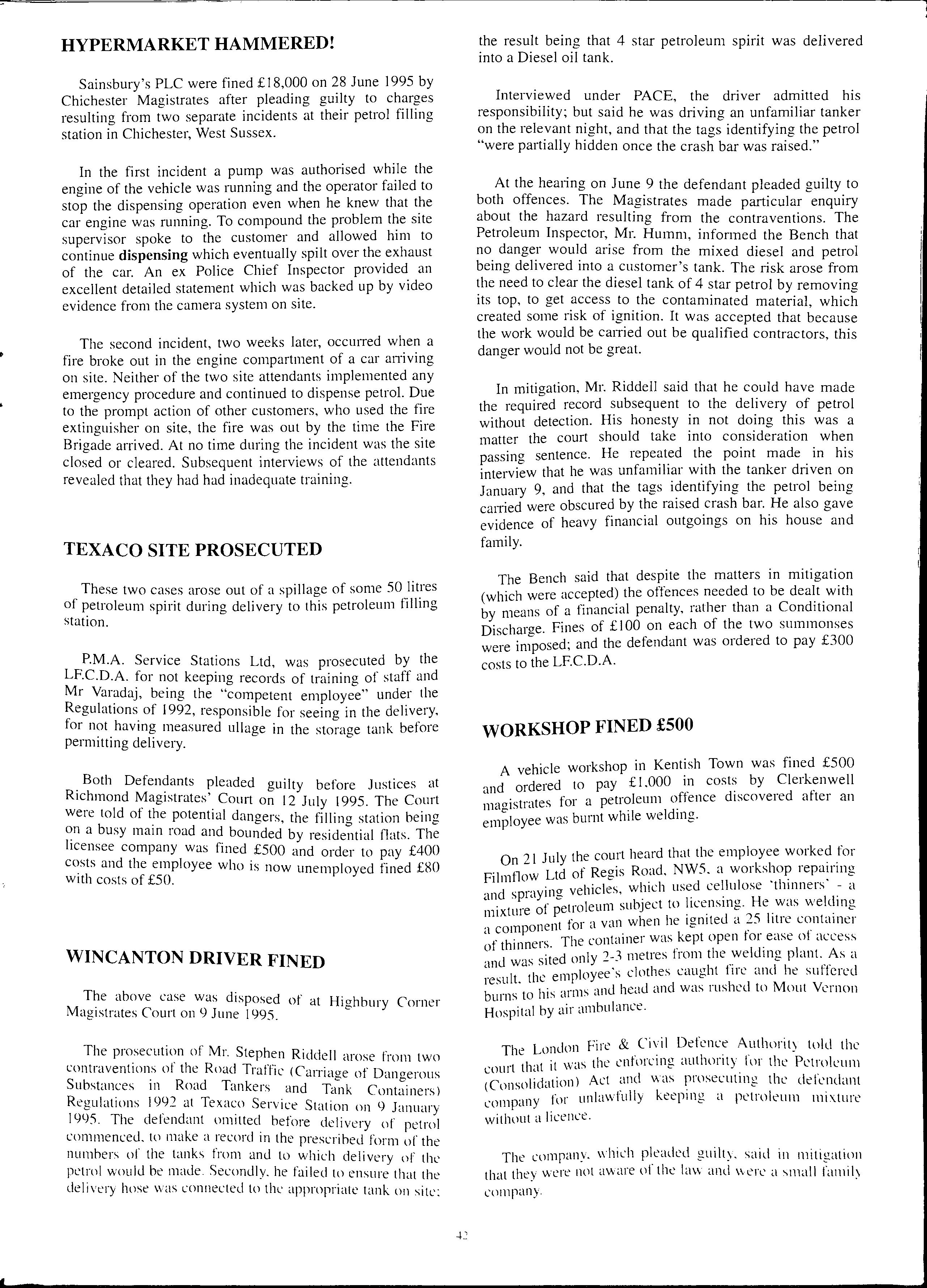

PUMPTRONICS PUMPS THE VOLUME AT THE

LARGEST MOTORWAY SERVICES IN EUROPE

A combination of Pumptronics Series 200 fuel dispensers, in conjunction with Red Jacket 'Big-Flo' submersibles are now dispensing fuel to HGV drivers stopping at the Poplar 2000 services at an unbelievable rate, which continues to grow daily.

The pumps on site are fitted with special 50mm high, backlit displays which were first introduced by Pumptronics specifically for this site and the 'Bia-Flo' submersible ' b pumps, also supplied by Pumptronics, are the first of this type in the UK.

Poplar 2000 services, located at the intersection of the and M56 motorways, currently features 63 high-speed diesel nozzles and 12 gasoil positions and still has room to e.xpand. Major oil companies are investing in dedicated livery pumps, lines and storage tanks, and when the second phase is rolled-out, the site will be able to fuel trucks at a rate .of 300 trucks per hour. The site also encompasses a service station, restaurants, a 50 bedroom hotel and numerous other facilities for drivers

p h umptI 0111cs as always had a aood reputation in the truckstop b s· d · · 0 u mess an It 1s well known for producing equipment capable of reliably pumpina high volumes of fuel at high speeds. 0

PETROL TANKER CRASH LEADS TO CHAOS

The crash of a ful!y laden petrol tanker on 1 May 1995 to the closure ot a large industrial estate in Crawley. est Sus se x lead111g to chaos 111 the s urroundina area and almost the closure of Gatwick Airport. 0

A petrol and di ese l mixture flowed into a brook runnin a through the indu s tri a l es tat e and even thouah th e Brigade had mana ged to contain a large of th e ex plo s ive mi xt ure large scale ev acuation of the indu st rial estate becam e ne cess ar y. For some ten hours followina th e "'

accident explosimeter readings were off the scale along some three quarters of a mile of the brook down stream of the crash site.

The stream was luckily served by one of the only large open air interceptors in the area. This contained most of the spilt product. Had this not been the case Gatwick Airport would no doubt have been closed as the brook flows beneath the airport.

The first and last compartments of the tanker had ruptured in the accident due to collision with the road kerbing, but also a considerable amount of product was lost through the lids of the tanker, the reason for this is still unclear and is subject to further investigation.

The fire brigade who had quickly blanketed the crash site with foam made requests for assistance from District and County Council as well as NRA for assistance. These agencies who throughout the 111c1dent gave support to the Brigade.

The remaining product on the tanker was removed by Linkman Tankers, who owned the crashed tanker, they also provided pumping equipment and tankers to clear the interceptor on the brook .

The Fire Brigade flushed through the local drainage t TI The f!ushina reducing the contamination and at sys e1 . 0 followina the accident 1t wa s decided that the levels of 0000 c ff I l ·s had diminished su 1C1ent y to re-open the vapou ' d. industrial estate and roads m the srn 1oun 111g a1 e<1.

Petroleum officers and fire officers visited several factories following up calls made by the factories who ·ted hiah leve ls of vapour on reop e nmg. These sites 1epo1 c d were checked and on rece1vmg a vice about ventilation presented no furth e r problem s

Th e flu shin g of th e drainage sys tem continued for a further 24 hour s and monitoring for seve ral more cla ys . Unfortunately, despite eve ryo nes best effo rt s a numb e r of fi sh in th e Ri ve r Mole were killed b y pollution but certainly a mu ch large r di saste r had bee n avoided b y the prompt action fr o m all the age nci es m vo lved.

44

"Fortunately the. National Ex'JJC ie were no serious injuries when a buildino afl e' coach crashed into the filling station "' : r swerv missing the f'J tng acmss the forecourt and narrowly llinps and · had to take canopy stanchion. The coac h dnver spontaneou · , · · f h co l1ded with .s evasive actton when a lo ca us a car push. veh i c le. · mg it mto the path of his on-commg

With the front f' office, the /'Jc .' 0 !h e coach embedded in.lo the manager'.> t.s 1engery l I . . rear e 1neroo 1" • · anc G nver had to evacuate vta the <'.)L ,( y exu.

Although the !he unwanfed peirofeum in stallation was unaffected by . . t111ru1·1on tl /" If. I 1· few duv 1· umi/ · ' _ 1 e 7 mg stat ion had to c ose or o uirr i(:'(i oui UC1urul repairs to the building hod been 1es1ed. one. the e lectrical installation checked and

/he < nn se quen<e I / 10111 h/ ,· 11 1 Wo u d ho ve been far more senous , ug1c , Of I I I I 171 1 nonna/l v bus' \' l t'Nls· 111 e had a 1 111 r Je e n refue//i ' · · · ng m the /7U171/'J narrow/ \ ' missed bv !he ( I( It /1

4:'i

photo courtesy West Yorkshire Fire Service.

WHO IS TESTING THE TESTERS?

By Roger Marris West Yorkshire Fire and Civil Defence Authority

Tank testing and in particular precision testing has been the subject of much debate in recent times. In fact there appears to have been a pre-occupation within the industry of slagging-off (a quaint Yorkshire colloquialism) each others systems mines better than yours yours can't do what mine can etc etc.

The purpose of this brief article is not to discuss the merits or otherwise of the various systems available, which after all have received their individual certificates of conformity. It is to raise the standards of workmanship and compliance with the stipulated test procedures applicable to the particular piece of equipment.

I am minded to draw attention to the sometimes doubtful quality of workmanship following the circumstances that surrounded a recent tank test in the West Yorkshire area.

The tank in question is a five year old dual compartment vessel installed in the traditional 150mm concrete surround. As readers will immediately realise a tank of this age should not need testing unless a leak is suspected. Unfortunately for the oil company, a misreading of the PLAs reminder letter for pipework testing resulted in an order being placed to test the tanks.

Herein starts a chain of events that almost lead the oil company representative to despair.

• !he.tank is precision tested with the testing contractor issumg a failed certificate for compartment ·A'.

• ;he company representative gives an order to a ank. hnmg contractor to inspect the tank and caiTy out repairs as As it happens the tank lining contractor is also a precision tester in his own right.

• After removina 'd . I o res1 ua product, clearnng and the compa1tment, a visual and ultrasonic exammat1on failed t 'd 'f o 1 ent1 y any perforation or areas contractor reported that "the tank had little detenorat10n from new".

• The contractor th d' . en 1sconnected and plugged off all tank openmgs except lh d 1 · e vent an ell the tank m a to for ground water ingress. In the mformat1on was received from the orioinal testmg contractor stating the approximate size of the hole and a latitude of location.

• A week later a further i11iernal visual examination of the lank took place. This inspection also failed to detect any perforation or water ingress. The tank was again left in drr condition pending further instructions.

• Following discussions with the PLA, it was agreed that the. compartments could be filled with product subject.ed to a further precision test. Only this time by a different system, the original tester refusing to re-test.

The second precision testing contractor passed compartment 'A' but failed compartment 'B' !

• By now this was bordering on the incredulous and the oil company representative, with the consent of the Petroleum Officer, asked the tank lining contractor to prove the two compartments with his own precision technique.

This contractor's system found leaks on the pipework joints connected to both compartments. Following repairs, the compartments were re-tested and passed as tight.

The oil company and PLA accepted the results of the fourth test and the compa1tments were recommissioned and returned to service.

In my introduction I refer to standards of workmanship, my concerns being raised by the above events and anecdotal evidence from POs, competitive tank testers, oil company engineers etc. Of course the US.EPA standard allows for a false alarm for a false alarm rate of 5%, but two false alarms by two different systems on opposing compartments of the same tank is beyond and I can only conclude that poor workmanship or failure to adhere to procedures was the cause of the alleged leaks rather than a malfunction of the systems.

At the end of the day a simple, albeit unnecessary, £600 tank test cumulated a final bill of £5.500.

Re-testing a tank by the same system that failed the tank ·. a policy that at least one PLA has adopted_ and others are IS possibly contemplating. The reasons supportmg th.1s are understandable and should prevent the devious site operator from selecting a re-test by a less accurate system.

However. such a policy may disadvantage the conscientious operator where the ongmal tester stands by the results of his test and refuses to return: as in the case l have highlighted.

If anecdotal evidence is anything to go by. the instances of erroneous tests appears ll: increased following the demise of the crude non-prec1s10n methods.

May 1 suggest that all interested parties within the industry pay the same attention to the qualitv nf workmanship. compliance with method statemcnh ai;d the continued accuracy of the equipment as thev did to the introduction of the\ arious indiYidual precision. systems.

l J

PROTECTING OUR ENVIRONMENT

By Carl Denby

Just consider for a moment the routine things we do in our life , day after day, and the effect they have on the natural e · · · h' di nvuonment'. taking a shower or bath , was 111g s he s, laundry, dnv111g the car, mowing the lawn , maybe dnnkrng a pint of beer at the end of a long ha rd day. All the thrng s we do and take for granted have an environment pnce. tag , admittedly for most of us our actions taken mdi v idually the damage done is minimal , but multiply thi s by the population of the United Kinadom then the entire World and th · 0 · 1 · e environmental impact is devastatmg, p ac111g o ld mo ther nature under a con stant stra in. Add to this ever 1n creas1no ind t·· I · h 0 us 11 a pollution lev els and you ave an e nvironmental catast roph e loo ming.

A ll is not doom and g loom , there are ten s of thousand s of peo pl e all ove r the World who are actively in vo lved in e n viro nm e nt a l protec tion in o ne way or a noth er, some g? od , some not so good , but there are also ten s of thou sand s 0 1 peo pl e o ut there w ho don the e nvironmental cap for purely comme rc ia l rea so ns, marketing so called e n v ironm e ntal protec t io n equipm e nt making a maz in g ly ex tra vaga nt pe rfo rman ce c la im s a nd not g iv in g a stuff w he th e r ii act uall y do es the j o b, thi s kind of market in g wha t / wo uld co ns id e r a crime again st soc iet y. is beco ming 'e riou s ly co mmonpl ac e thr o ugho ut indu stry in parti c ular ll U I' ow n pe tro le um re ta il and ass oc iat ed indu str ies . T hi s ki nd o l p racti ce has an ad ve rs e effect in man y ways. o n

what the rest of us are striving to achieve, it lulls the rnstomer into a sense of false security, he feels he has clone thmgs nght , his pumps are well maintained, hi s forecourt IS clean and tidy, hi s tank s and pipe work are tested and ·f· cJ certi ied. He has the ultimate vapour recovery system an so on , he goes about hi s life feeling everything in the World IS rosy only to find all is not what he was told or sold, of course he phones the company concerned and more often than not receives the followino comment "it's not my b b ' pro lem pal, it was OK when we in stalled it" or "can_t understand it mate, it seems you have a problem " or "well it d1dn 't leak when we tested it". The fact that the forecourt operator is now sitting on a major problem whether it be_ above average vapour emission s or sub- so il I ground watei contaminabon from tanks and pipe line s that have probably been leakmg for month s, maybe years, he now faces an extremely large bill or even bankruptcy.

The main point I am mak.ino is we all have a respo nsibility to at least try to get it 0 right , we all re ly upon one anoth e r to ea rn an hon est livin g in the profess ion we c hoose , ri ght from th e top of the tree in the oil company hi g he rarc hy to the e ng in ee r, the pipe fitter , th e forec?urt re tail e r, th e li ce nsin g authoriti es, eve n though mos t o f us hav e neve r met or eve r lik ely to , like it or not we a re a tea m a nd s hould show a tea m spiri t in ca rryin g out o ur dut y to protec t o ur indu stry and the e nviro nm e nt.

,-. I I

47

Fig 2.

Product

Head Pressure= 0.5 P.S.I.

Fig 1.

Product level 95%

Head Pressure = 2.5 P.S.I. Hole Detectable

level -----------+---+-;-i-----1 1-----1 Same Hole V No Leak!

V

• •

Leak!

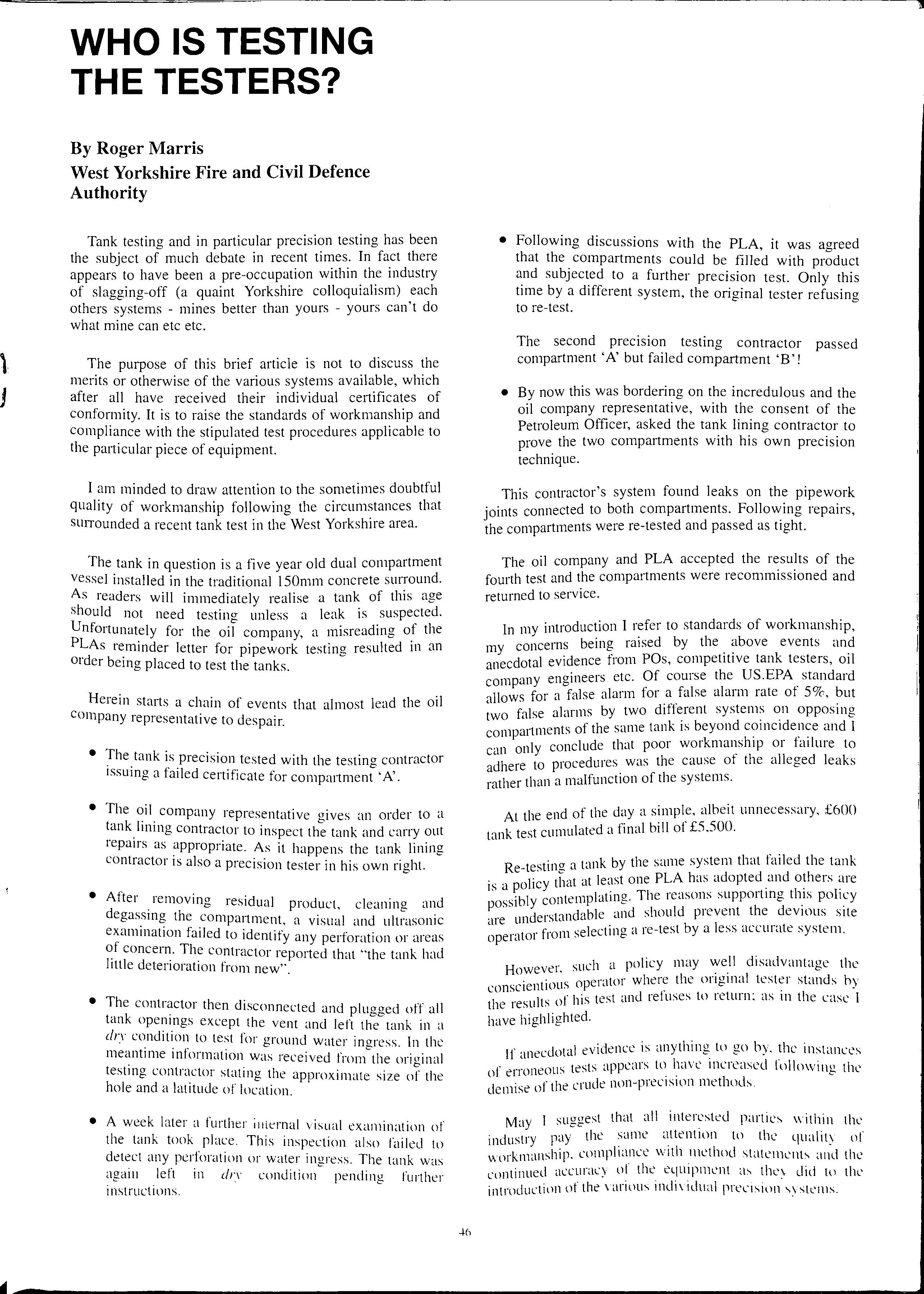

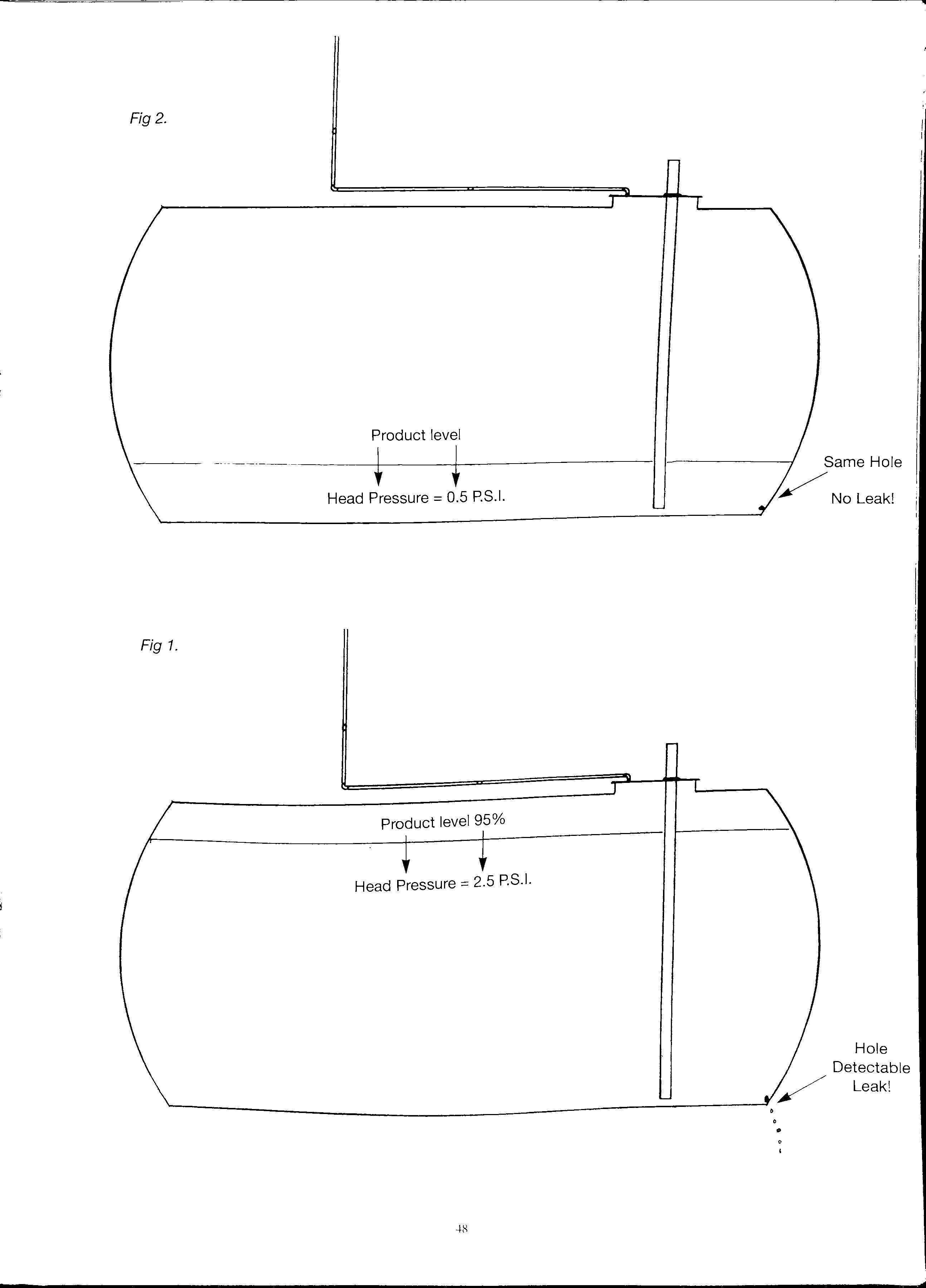

A typical example of a purely commercial decision giving a high degree of risk to getting the job done wrong has been taken by certain tank testing companies ie to test storage tanks with low product levels and enormous ullage space , the theory being our probe will detect any change in level of the product and then our ullage tester will do the rest of the tank shell. The truth is the system was never designed to be operated in this way, there is a very high risk that any hole located at the base of a tank being tested will not be detected purely and simply because of the lack of head pressure being created by the low volume of fuel the end "here's your certificate Mr Retailer, tank is tight along comes a tanker, fills up the tank and hey presto increased head pressure leakina tank unhappy retailer and yet again the environment out Hence the reasonina behind the us EPA d · · bh · tank ·11 1 b · · • • ec1s1on t at a wi on Y be certified to the product level at the time of therefore if the tank is only 50% full at time of es mg is should only be certified to that capacity. So to do

the job right the tank should be tested to at least the nominated safe working capacity (applicable to volumetric testing only) with the exception of cases when suspected leaking tanks are being tested when the only options are to test with whatever product level you have, however if the low tank contents is unacceptable the contents should be uplifted and the tank filled with water, to carry out the test.

Contrary to certain comments made in the past I have had in the region of twenty years experience in environment protection engineering on major land reclamation projects creatina seventy acre lakes from old open cast quarries, b minimising the environment impact of deep m1mng/ quarrying operations, bridge construction and many more. I don't profess to get it right all the time but I do my b_est_ and that s all I request of others to work together to get it nght, because the other option is not the kind of legacy I want to leave my children.

By D. 0. Horton Sou th York h" F" 8 nre nre & Rescue Services

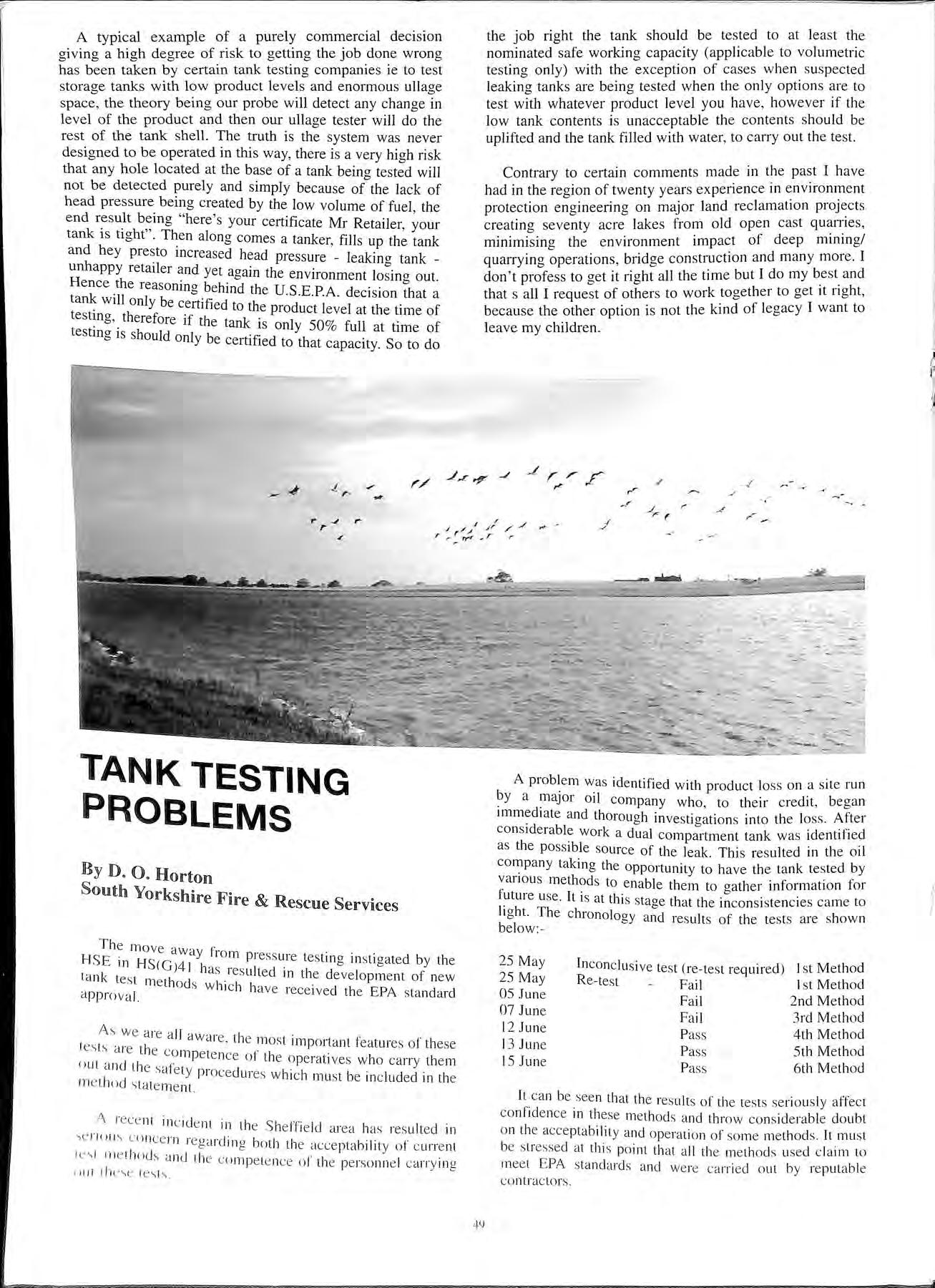

A probl_em w_as identified with product lo ss on a s ite run by a ?1aJor 011 company who, to their credit, began immediate and thorough investigations into the lo ss After considerable work a dual compartment tank was identified as the pos sible so urce of the leak. This resulted in the oil company tabng the opportunity to have the tank tested by meth?d s to .enable them to gather information for e use. It I S at thi s stage that the inconsistencies came to ight. The c hronology and result s of the te sts are shown below:

Jun e

Jun e

Inconclu sive te st (re- te st required) I st Method Re-test Fail l st Method Fai I 2nd Method Fail 3rd Met hod Pass 4th Method Pass Sth Method Pass 6th Method

m e t lo s tate me nt.

A re c e nt in c icle 11t th S h 11 I . 111 e e 1e d are a ha s res ulted 111 c o nce rn reoa 1d 1 · l b th h ·1 · <= 1 g o t e acce pta br rty of c urre nt k ' \ l m e thod s ·111 ·' th · · c u e co mp e te nce o f th e pe rso nn e l carry1ng • >lll l hl:' \l:' tes ts.

It. c an be. see n that the res ult s of th e tests seriou s ly affect co nfid e nce 111 these method s and throw con sid e rab le doubt o n th e acceptab ilit y and ope rat io n of some methods. It mu st be stresse d at thi s po int that all th e me thod s used claim to mee t EPA standard s and we re ca rri ed o ut by reputable co ntra c to rs.

I ....,,- ' · r

TANK TESTING PROBLEMS ,..

I'/

f·

p1e ss ure test

es ulted m the development of new approval. 0 s w hi c h ha ve re ce ived the EPA standard As we a re a ll ·iwa · I · t . . . . < ' e . t l e mo st important fea tures o l the se es ts a re th e co mp t , . . e e nce o t the operatives who ca rr y th e m o ut c1 nd th e s·ife t d . I d · < Y p1 oce u res wh ich mu st be in c lud ed in th e

The mov e away

HSE in HS(G 41 h

mg mst 1gated by the tank tes t cl as .'

4lJ

/ / , ., ..< ,.r. /*"> / , ,..,_, r J ( ,r

07

12

13

25 May 25 May OS June

Jun e

June

1S

REPORT ON ACCURACY OF AIR WATER TEST

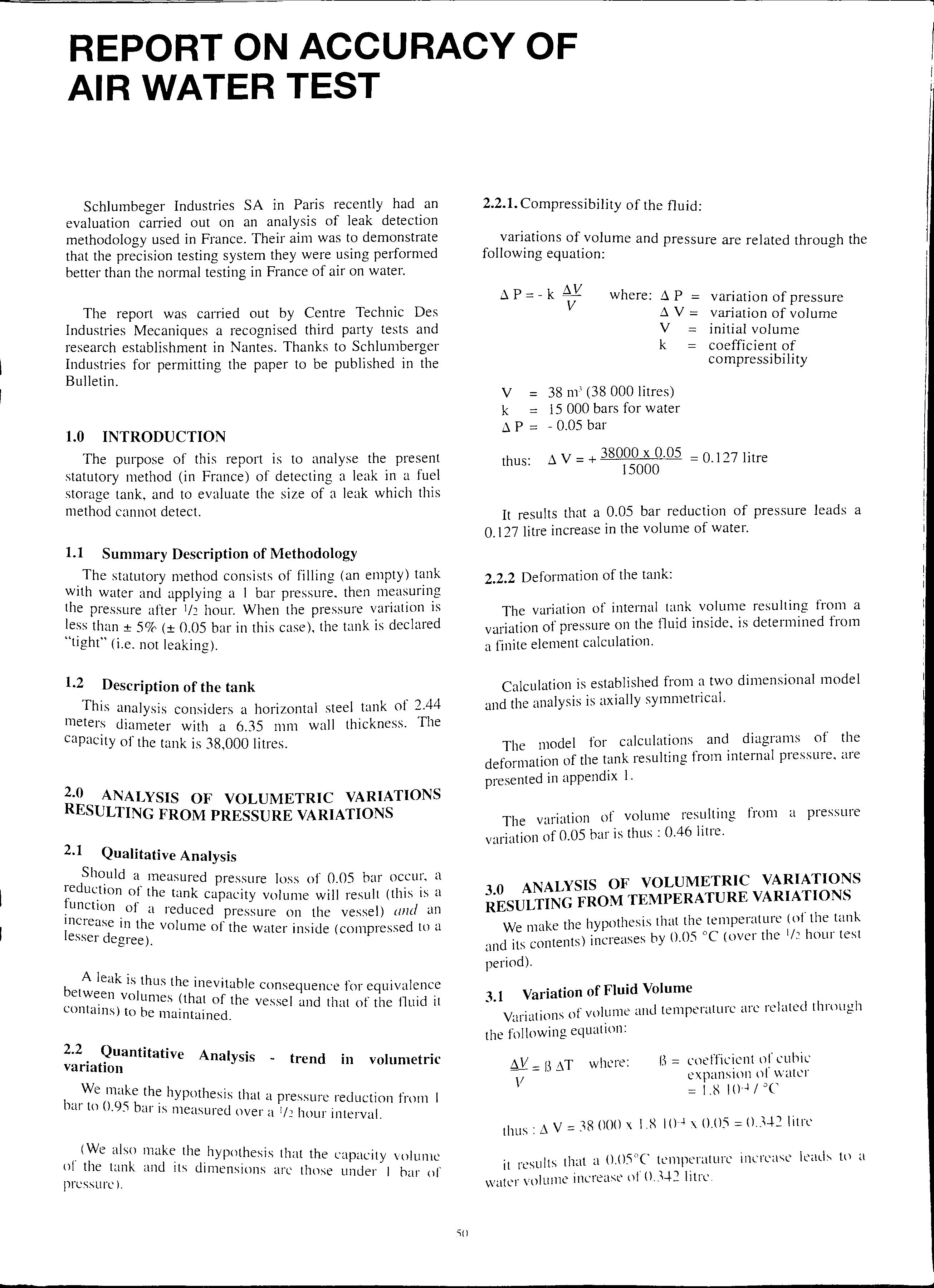

Schlumbeger Industries SA in Paris recently had an evaluation carried out on an analysis of leak detection methodology used in France. Their aim was to demonstrate that the precision testing system they were using performed better than the normal testing in France of air on water.

The report was carried out by Centre Technic Des Industries Mecaniques a recognised third pmty tests and research establishment in Nantes. Thanks to Schlumberger Industries for permitting the paper to be published in the Bulletin.

1.0 INTRODUCTION

The purpose of this rep011 is to analyse the present statutory method (in France) of detecting a leak in a fuel storage tank, and to evaluate the size of a leak which this method cannot detect.

1.1 Summary Description of Methodology

The statutory method consists of filling (an empty) tank with water and applying a I bar pressure, then measuring the pressure after 'h hour. When the pressure variation is less than± 5% (± 0.05 bar in this case), the tank is declared "tight" (i.e. not leaking).

1.2 Description of the tank

This analysis considers a horizontal steel tank of 2.44 meters diameter with a 6.35 mm wall thickness. The capacity of the tank is 38,000 litres.

2·0 ANALYSIS OF VOLUMETRIC VARIATIONS RESULTING FROM PRESSURE VARIATIONS

2·1 Qualitative Analysis

Should a measured pressure loss of 0.05 bar occur, a reduc_tion of the tank capacity volume will result (this is a '.unction of a reduced pressure on the vessel) and an mcrease in the volume of the water inside (compressed to a lesser degree).

A leak is thu th · · b b · s e mev1ta le consequence for equivalence volumes (that of the vessel and that of the fluid it contams) to be maintained.

2.2 9uantitative Analysis trend in variation volumetric

We make the hypothes1·s that · 1 · · b· · · a pressure rec uct10n from <11 to 0.95 bar is measured over a 'h hour interval.

(We also the _hypothesis that the capacity volume ol the tank and its dimensions are those under f bar of pressure J.

2.2.1. Compressibility of the fluid:

variations of volume and pressure are related throuoh the following equation: 0

LiP=-k LiV v where: Li P = Li v = v = k V 38 m-1 (38 OOO litres) k 15 OOO bars for water Li P = - 0.05 bar

variation of pressure variation of volume initial volume coefficient of compressibility

thus: Li V = + 38000 x 0.05 =0.127 litre 15000

It results that a 0.05 bar reduction of pressure leads a 0.127 litre increase in the volume of water.

2.2.2 Deformation of the tank:

The variation of internal tank volume resulting from a variation of pressure on the fluid inside, is determined from a finite element calculation.

Calculation is established from a two dimensional model and the analysis is axially symmetrical.

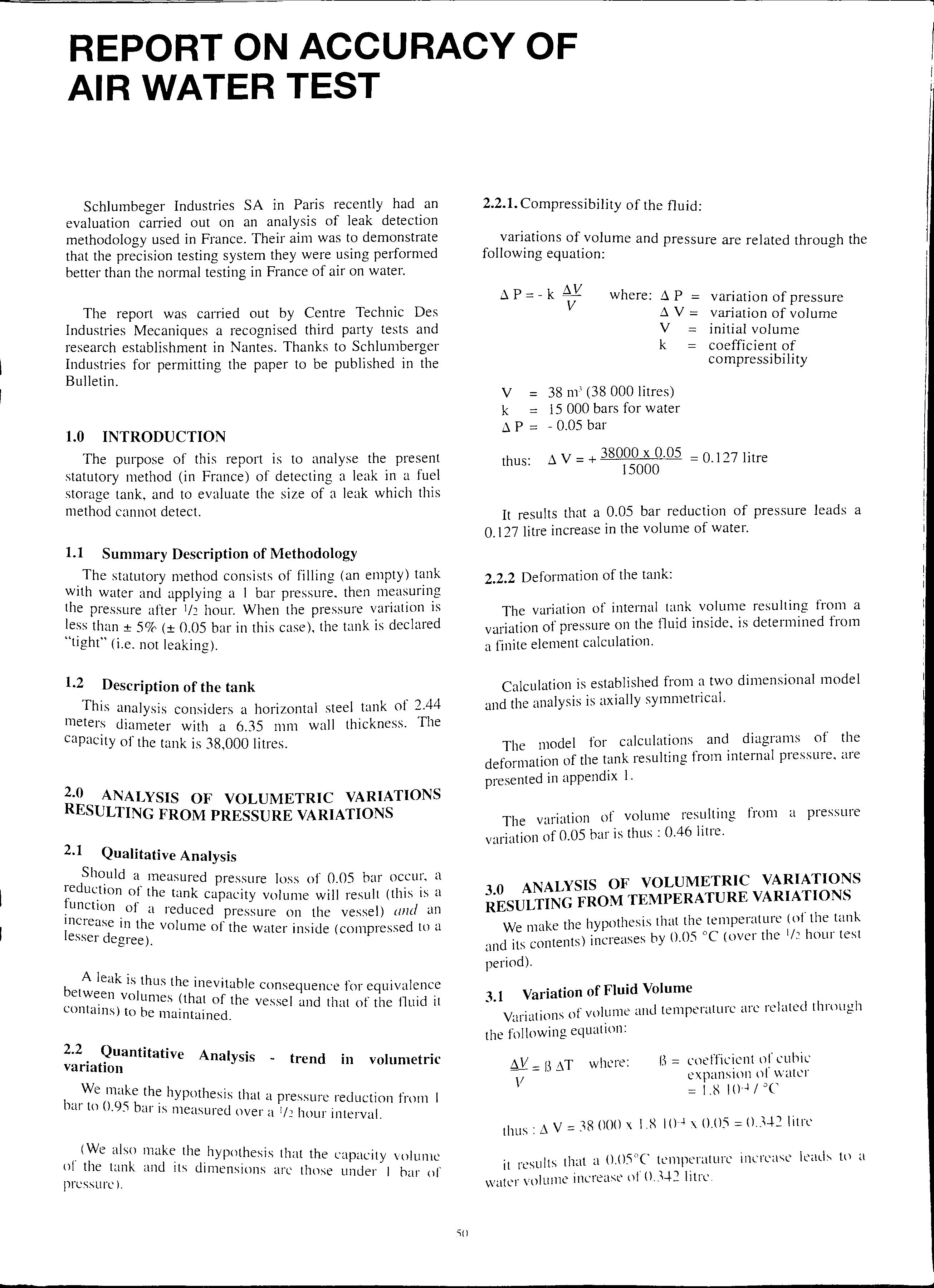

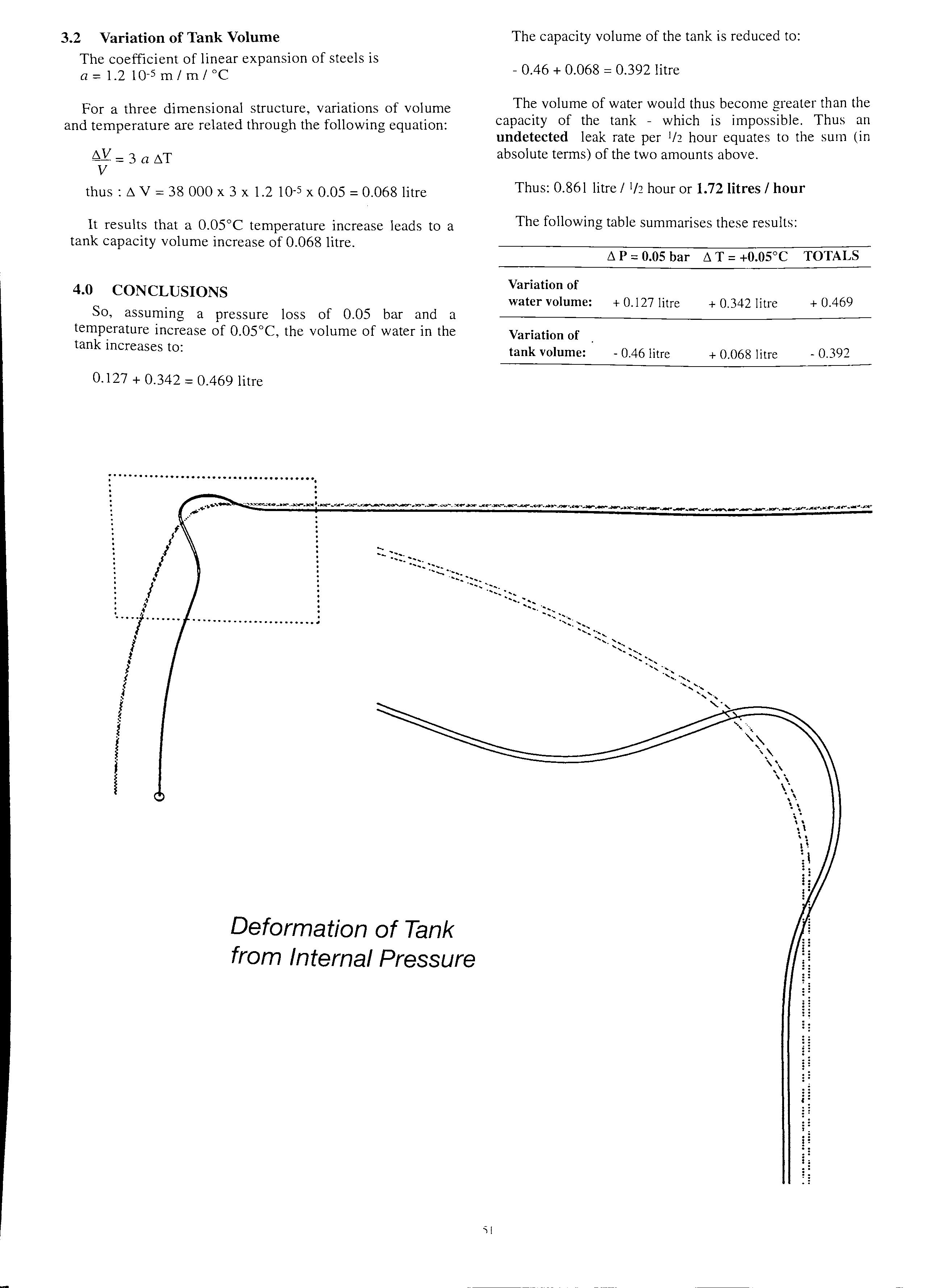

The model for calculations and diagrams of the deformation of the tank resulting from internal pressure. are presented in appendix I .

i 1 Jt'110 f1·0111 <'I 1Jressttre

The variation o · vo ume resu 1 o t vaiiation of 0.05 bar is thus : 0.46 litre.

3 o ANALYSIS OF VOLUMETRIC VARIATIONS RESULTING FROM TEMPERATURE VARIATIONS

We make the hypothesis that the temperature (of the tank d · t nts) incre·1ses by 0 OS °C (over the 112 hour test an its con e · '· · · period).

J.l Variation of Fluid Volume

V · · )f. Vt)lume and temperature are related through anauons l the following equation:

= f3 where: \I B = coefficient or cubic expansion of water = 1.8 10--1 I °C

y = 38 OOO x 1.8 I0--1 x 0.05 = O.J42 litre

it results that a 0.05°C temperature increase kads to a water volume increase of lLH2 litre.

'ill

3.2 Variation of Tank Volume

The coefficient of linear expansion of steels is a= 1.2 10-5 m Im I °C

For a three dimensional structure, variations of volume and temperature are related through the following equation:

6.V=3a6.T v

thus : 6. V = 38 OOO x 3 x 1.2 10-5 x 0.05 = 0.068 litre

It results that a 0.05°C temperature increase leads to a tank capacity volume increase of 0.068 litre.

4.0 CONCLUSIONS

So, assuming a pressure loss of 0.05 bar and a temperature increase of 0.05°C, the volume of water in the tank increases to:

0.127 + 0.342 = 0.469 litre

Deformation of Tank from Internal Pressure

The capacity volume of the tank is reduced to:

0.46 + 0.068 = 0.392 litre

The volume of water would thus become greater than the capacity of the tank which is impossible. Thus an undetected leak rate per 112 hour equates to the sum (in absolute terms) of the two amounts above.

Thus: 0.861 litre I If2 hour or 1.72 litres I hour

The following table summarises these results: tJ. P = o.os bar tJ. T = +o.os 0 c TOTALS

Variation of water volume: + 0.127 litre + 0.342 litre + 0.469

Variation of tank volume: 0.46 litre + 0.068 litre 0.392

l / / •I ··/··· ·· I I I f ! { .... ······............... .

.-,.:.;.o ,.:Clf"'_..,.,. _.._..,.._._,.tl,. __.., .,.....z..,...-.-_,._....., -·,,....,.,...- A.r•,ig A,,...-"'.-'

'ii

FIRST AID TREATMENT FOR OIL SPILLAGE

By Patrick Horsham*

By Patrick Horsham*

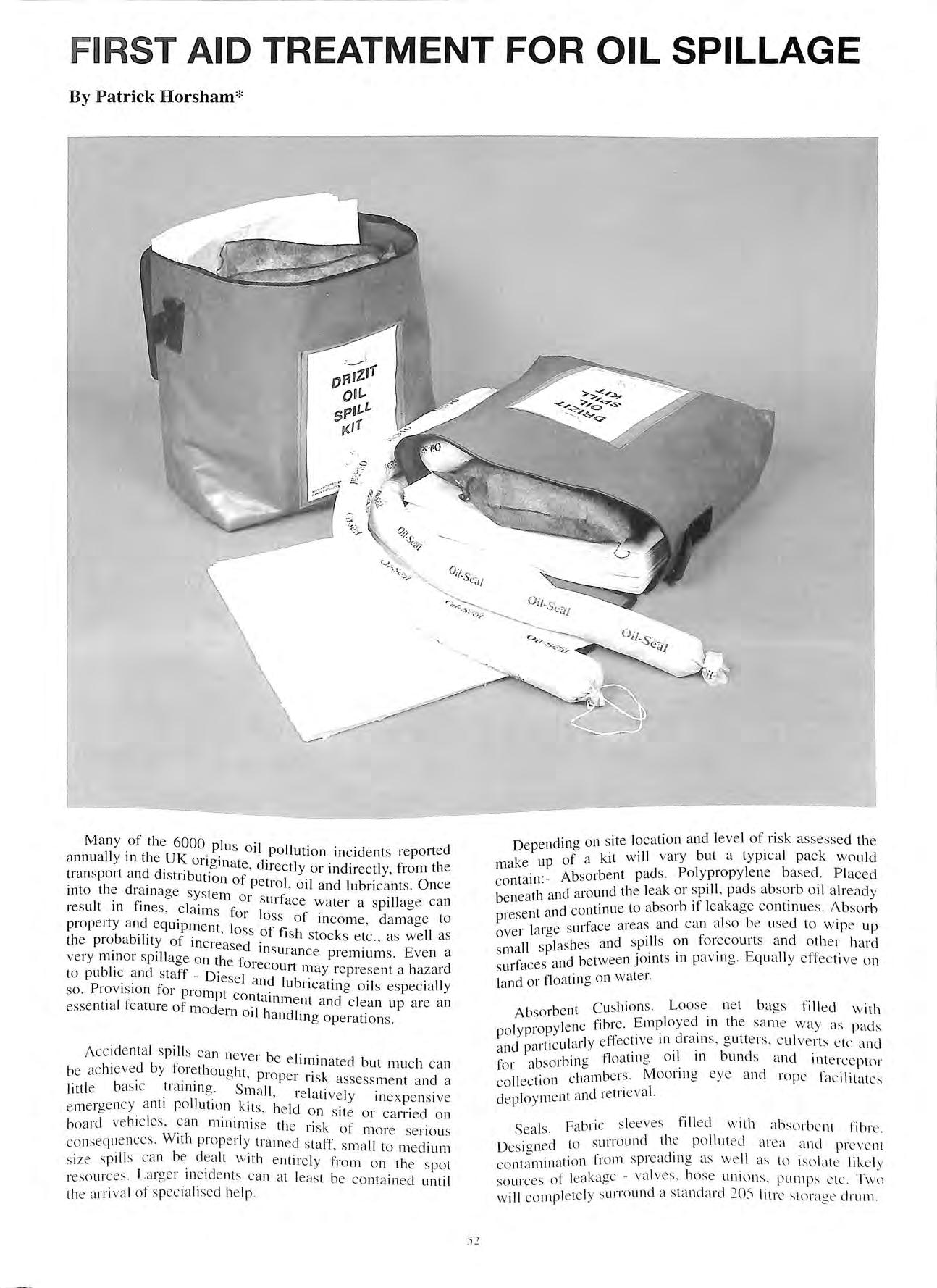

Many of the 6000 plu s oil annually in the UK .· _pollut1on mc1dents 1epo1ted oiigmate direct! · · d.· I f· tl tran s iJoit and di s t .· b . ' Y 01 m 11 ect y, 1om le 11 ut1on of petrol ·1 .· 0 into the drainacre ' 01 and lub11cant s. nee "' sys tem or surfa ·11 re s ult in fin es 1 · <ce water a s pt a ge can ' c aims for lo f Property a nd equipil 1 ss o m co me , damage to lent , oss of f h the probability of · . is s to ck s e tc. , as well as mc1eased in s L . very mmor s pillage on the f . p1em1um s Even a to public and staff _ 0 01 eco ui t may re prese nt a hazard iesel and lub .· t. ·1 II so. Pro v is ion for pro 11ca mg 01 s es p ecia y mpt co ntarnm e nt ., d I esse ntia l feature of mod <dl c ea n up are a n · e m oll handling operations.

Accidental spill s ca n neve . b r . be ac hie ve d b y forethoucrht I . e e rn1mat ed b ut mu c h ca n · · 0 ' pi o pe i n sk assessment a nd a littl e ba s ic t1 amm g. Small i·el t. I , a 1ve y m ex pen s1ve e m e rge ncy a nti pollution kits he ld 011 ·t · ' s 1 e 01 earned o n board ve hi c les. ca n mm1mi s e th e ri·s k f · o m ore se ri o u s co nseq ue nce s W ith properly tra in ed staff. s m a ll to m ed ium s ize sp ill s ca n be. de a lt w ith e ntire ly from on th e spot re so ur ces La rge r 111 c 1d e nts c a n at least be c onta in ed until th e a rri va l of s pec ia li sed he lp.

D e pendin g on s ite location and leve l of. ri sk assessed the make up of a kit will vary but a typical p ack would tain Ab so rb e nt pads. Polypropyl e ne b ase d. Placed con' · ·11 cl b b ·1 b th and around th e leak or sp 1 , pa s a so r 01 a lready e nea ·t· I k . t alld Co ntinue to abso rb 1 ea age co ntmu es. Absorb prese n ' lai·cre suiface areas and ca n a lso b e u sed to w ipe up ove1 < "' II spla shes and s pill s o n fo reco urt s and other h a rd sma · · · · E 11 f · f S ., 11d betwee n JOmts Ill p av m g qua y e fec t1 ve on s ur ace " la nd o r fl oa tin g o n wa te r.

Absorbent C us hi o ns L oo s e _ net bags filled w ith po lyprop y le ne fibre. m the way as pads d ·t i· c ul ar l)' effect ive Ill cl1a1n s, g utte 1s , c ul ve rt s e tc ' Ille\ a n pai ' · ' for abso rbin g floatmg o ". m buncl s a nd int e rc e ptor co ll ect io n c ha mb e rs. Mooring ey e a nd rope facilitat es deploym e nt a nd re tr ie va l.

S e a ls Fabric s lee ves fill e d w ith absor b e nt fib re D es ig ne d to s urr ou nd the po lluted ar e a a n d p re ven t co ntami nat io n from s pread m g a s we ll a s to is o lat e lik e ly so ur ces of le akag e -va lves h os e unio ns pu m p s e tc Tw u w ill comp le te ly s urro un d a s ta ndard 205 l itre s to ra ge drum

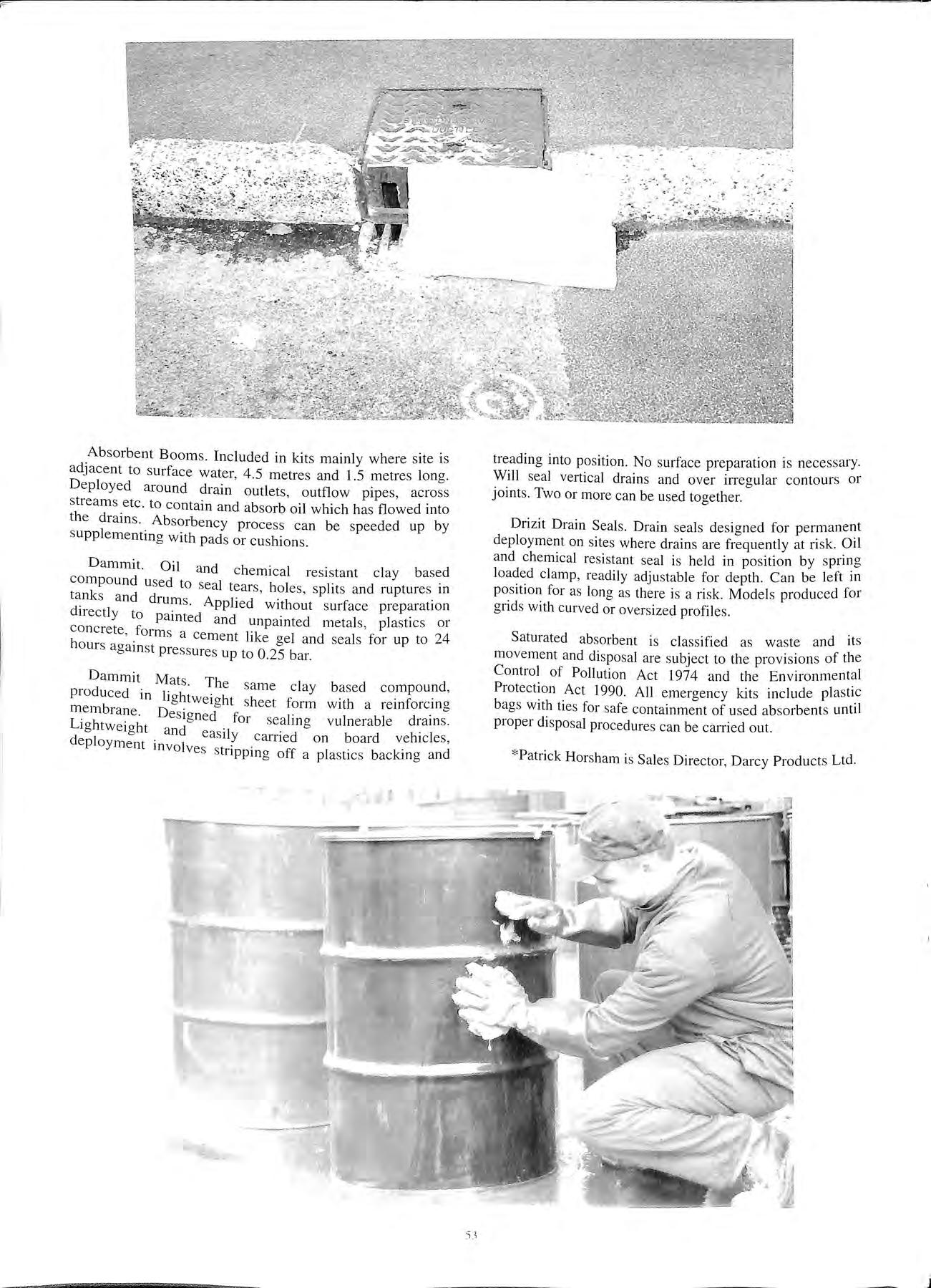

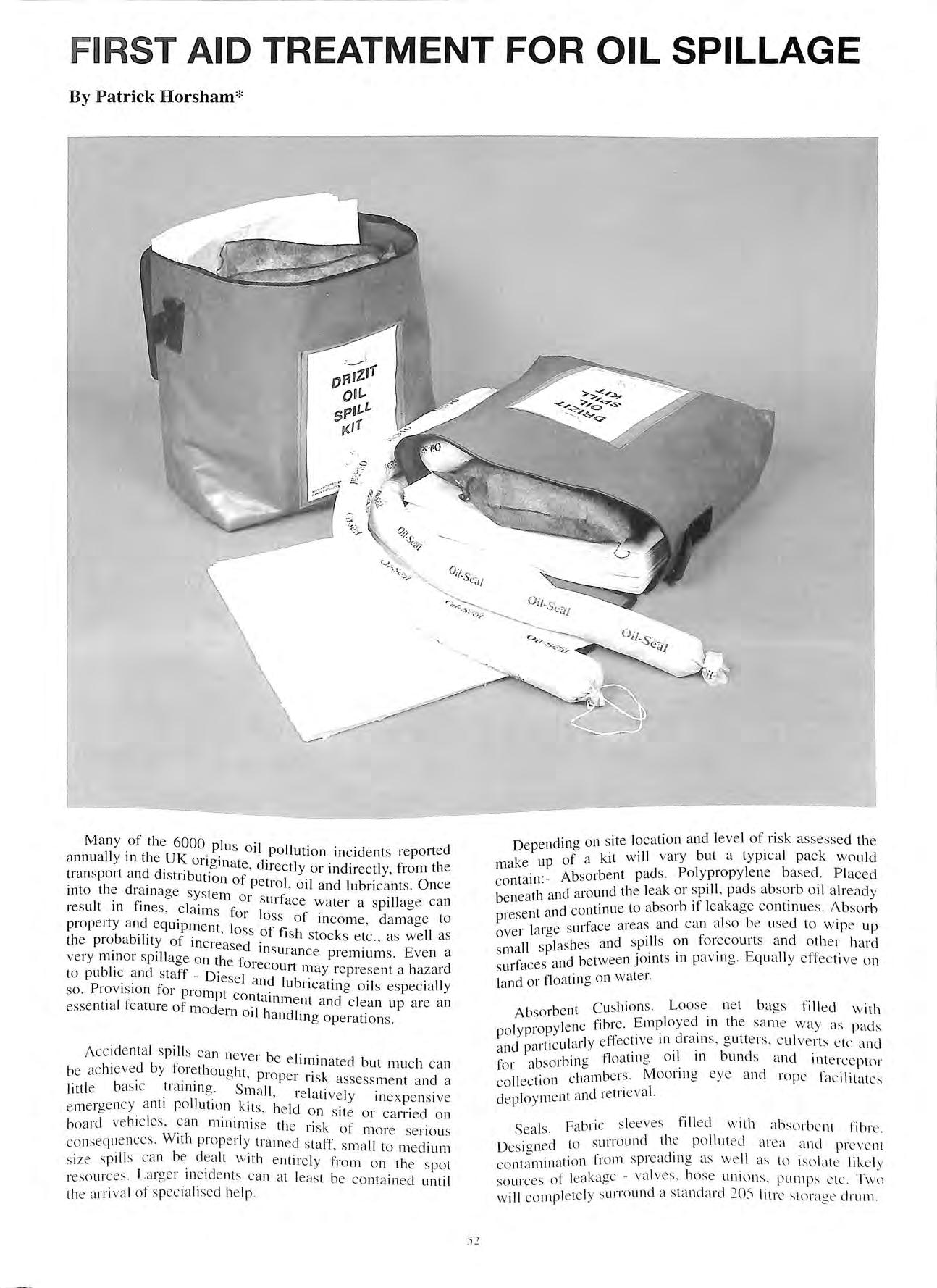

Absorbent Booms. Included in kits mainly where site is adjacent to surface water, 4 5 metres and 1.5 metres long. Deployed around drain outlets, outflow pipes, across streams etc. to contain and absorb oil which has flowed into the drains. Absorbency process can be speeded up by supplementing with pads or cushions.

Dammit. Oil and chemical resistant clay based compound used to seal tears, holes , splits and ruptures in tanks and drums. Applied without surface preparation directly to painted and unpainted metals, plastics or concrete, forms a cement like ere] and seals for up to 24 hours against pressures up to 0.2S bar.

Dammit Mats. The same clay based compound, produced in lightweicrht sheet form with a reinforcing membrane Designedb for sealing vulnerable drains. Lightweight and easily canied on board vehicles, deployment involve s stripping off a plastics backing and

treading into position. No surface preparation is necessary. Will seal vertical drains and over irregular contours or joints. Two or more can be used together.

Drizit Drain Seals. Drain seals designed for permanent deployment on sites where drains are frequently at risk. Oil and chemical resistant seal is held in position by spring loaded clamp, readily adjustable for depth. Can be left in position for as long as there is a risk. Models produced for grids with curved or oversized profiles.

Saturated absorbent is classified as waste and its movement and disposal are subject to the provisions of the Control of Pollution Act 1974 and the Environmental Protection Act 1990 All emergency kits include plastic bags with ties for safe containment of used absorbents until proper disposal procedures can be carried out.

*Patrick Horsham is Sales Director, Darcy Products Ltd.

New Members The Association welcomes the following New Members

Lane Eurotest Environmental Technology Ltd

Moffatt

J Leadbetter M Tarrant Meggitt Petroleum Systems (UK) S J Neil Forticrete Ltd RE Brancher Environ Europe Ltd J Singleton WT Sylvester M H Clarke Industrial Flow Control Ltd D Duff S H Howell KL Merrison R C Whittaker J Brodin F Wennstrom UK Ltd S G East R Shenton Fuel Energy Services Ltd S J Bennett Thomas Sands & Ptns TA King W Hooguliet Lasaulec Engineering J Munday M J McCarthy N Jennings Jennings Construction Design R J Parr S Foley GT Webb A J Bishop R Smith Marley Pumps W S Moriarty Saber Equipment Corp. PC Horsham T Landin EIA & Partners J W Warnar Plasticon Heerenveen BY Mrs A Boyall G Bernard Fowler J P Duffy

EM

J

M

E KRose B Allerton WCFFuels E Peterson Veeder Root Environmental Systems Ltd V Clarke Clarman Architects JG Boyes Phoenix Maintenance Ltd F Benedetti PVolk A Lang N Payne W Singleton 2 R H Good al I MD Sloan 1\i l1n1olhy D Honeyman CJ P Kehoe Mobil Oil Co Ltd P Siewart NM Hugh Schlumberger Electronic Transactions RPS PA Cusack H Rafstedt A B Sydmontage NPayne R Turner Air Box Services GM Miller Highland Regional Council A Cowan L R Lewis J B Scoll D K Castledine NP Friel N P & M T Friel & Co Ltd D McKenna Victaulic Systems J V DeRado James Bennett R J McGlynn SM Nathwani Klargester Environmental Engineering Ltd. C 0 Neill A & G Electrical Engineers P Raposo Repsol Petroleum Co Ltd DEivin D E Pump & Tank Services SC Cleary Pump Services Ltd D H Attnn

D V Arthur BP Oil Ltd DJ Bergin Pump Services Ltd N O ' Sullivan Pump Services Ltd P Donlon Pump Services Ltd N O'Kelly Pump Services Ltd PR Howard T Robson Robson Walker Electricentre P N Davies T J Williams Shelford Petroleum Oil Transport Ltd R J Quarmby J Suesse Pipetech (Forecourt Installations) Ltd W JS Howard A Kerrison Technical & Mechanical Services (Brighton) Ltd B Fitzpatrick I Farmer I Henderson MR Sharland RR Turner Quality services for today's f orecoitrt HIGH QUALITY RE-IMAGING OF PUMPS, CANOPIES, SHOPS POLE SIGN ERECTION & MODIFICATION PLANNED IMAGE MAINTENANCE PROGRAMMES PUMPS &EQUIPMENT - HAULAGE, STORAGE &DISTRIBUTION Valley Road, Cinderford, Gloucester Gl 14 2NY Telephone: 0594 826364 Fax: 0594 822807

quality computer generated engraved Signs & Brac ke t s for Underground Pipework Systems for Grade, Vapour Recovery, Vent, Tank, Pump & Overfill Prevention . Made to order in our modern workshops. D Berry & Co. (Pip e Fitting Supplies) Ltd. , Unit 130 Middlemor e Ind. Estate, Kentish Road, Birmingham B21 OAY Telephone: 0121 -5 58 4411 Fax: 0121 555 5546

High

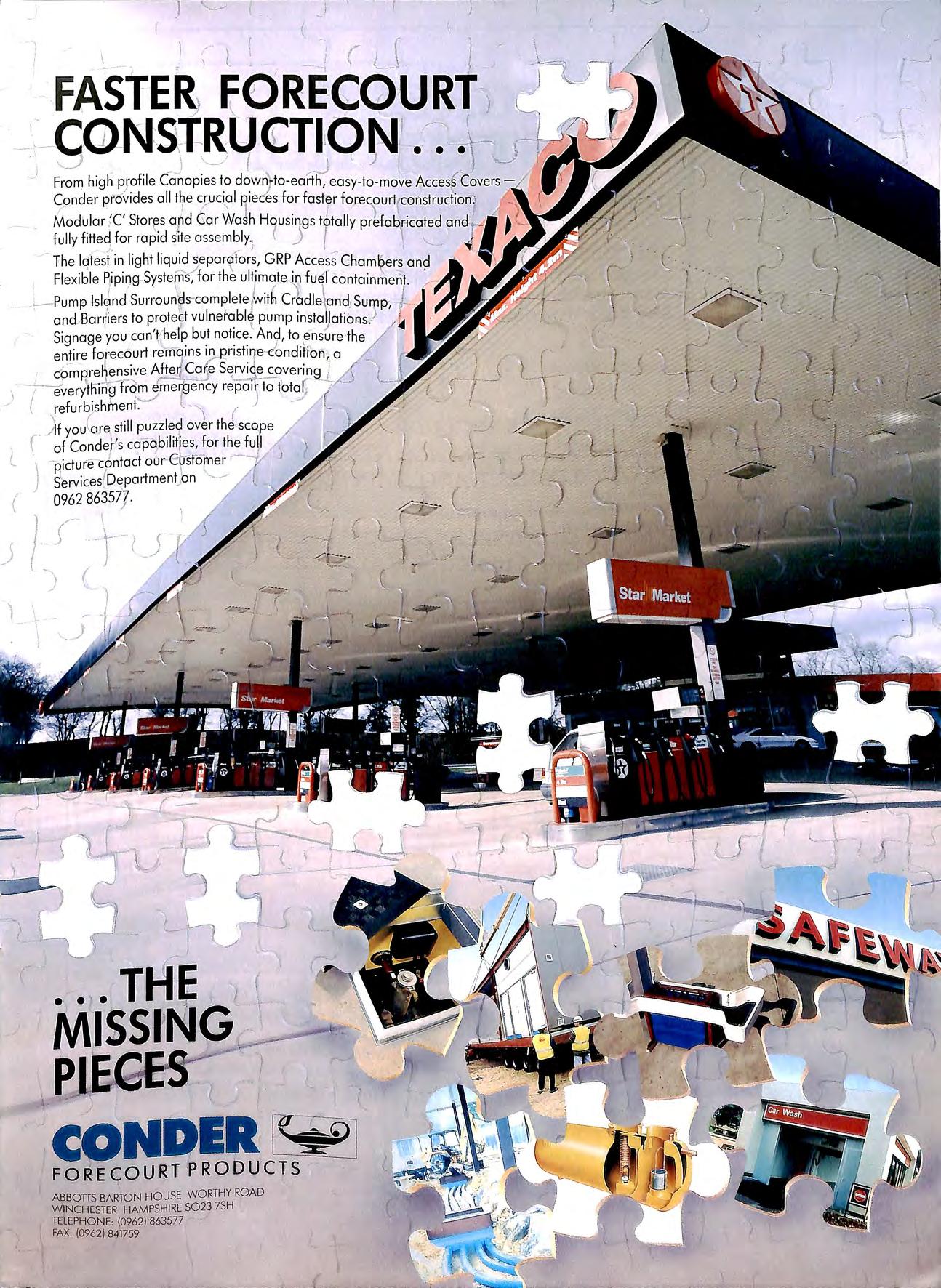

J '·-.-" ( . _ , ,i c l , _ ( c.X l L . CJ \ l I \ \,____/ I d '.\ ,-.._,) /'.: Frail) high Canopies t_o easy-to-move Access Covers / \ 9 2nder provid es all t ?e CJ.UC1 ? I P. 1eces for fastrr r fo_i:ecourt(construct1on Modolm !C' Sto'( ' ofd Wa l h Ho"';"9 ' t6tally pc1fab Hrnted efld .t ) I_ full y for rapid s'1te a ssembl y.1 ( J { ., _ The leftest _ li g ht GRP Acces s and · \ L v • Fl ex ibl e Pi 1p111g Syste rn s, for the ultimate in fu el containm ent. _ 1--Pump lsl d nd c l d le a nd, Sump·- I .. / , , r I ) b . , ' t to vu 11pump insta) atio r.i s) Signage you can bu_t to .e nsure the e ntire fo recourt remains in pn st1 e e:ond1 ti en , a I r s . I cb m w e ·ensi ve coverin g : \. LL { re furbi shment. · ( · r L yo J a.Je still pu zz lec;J o ve r the scop e ) ( ( of Condeh ca pa bil iti es , for the full } I ( E r' .l \ P. ictu re t o ntact our 1sto r er .--, · ) J ) ..____. ,... / , \ 0962 86357]- ( _J l· __ _)(/ \ - .-r·--- ( _5 ) ( ) 'I I{ ) 1 -CONDER [l PRODUCTS A BBOTIS BARTO N HO USE WO RTH Y ROAD W IN CHESTER HAMPSHIRE 5023 75H TEl EPHO NE, (0962) 863577 FAX : (0962) 841759 _J j 1 I

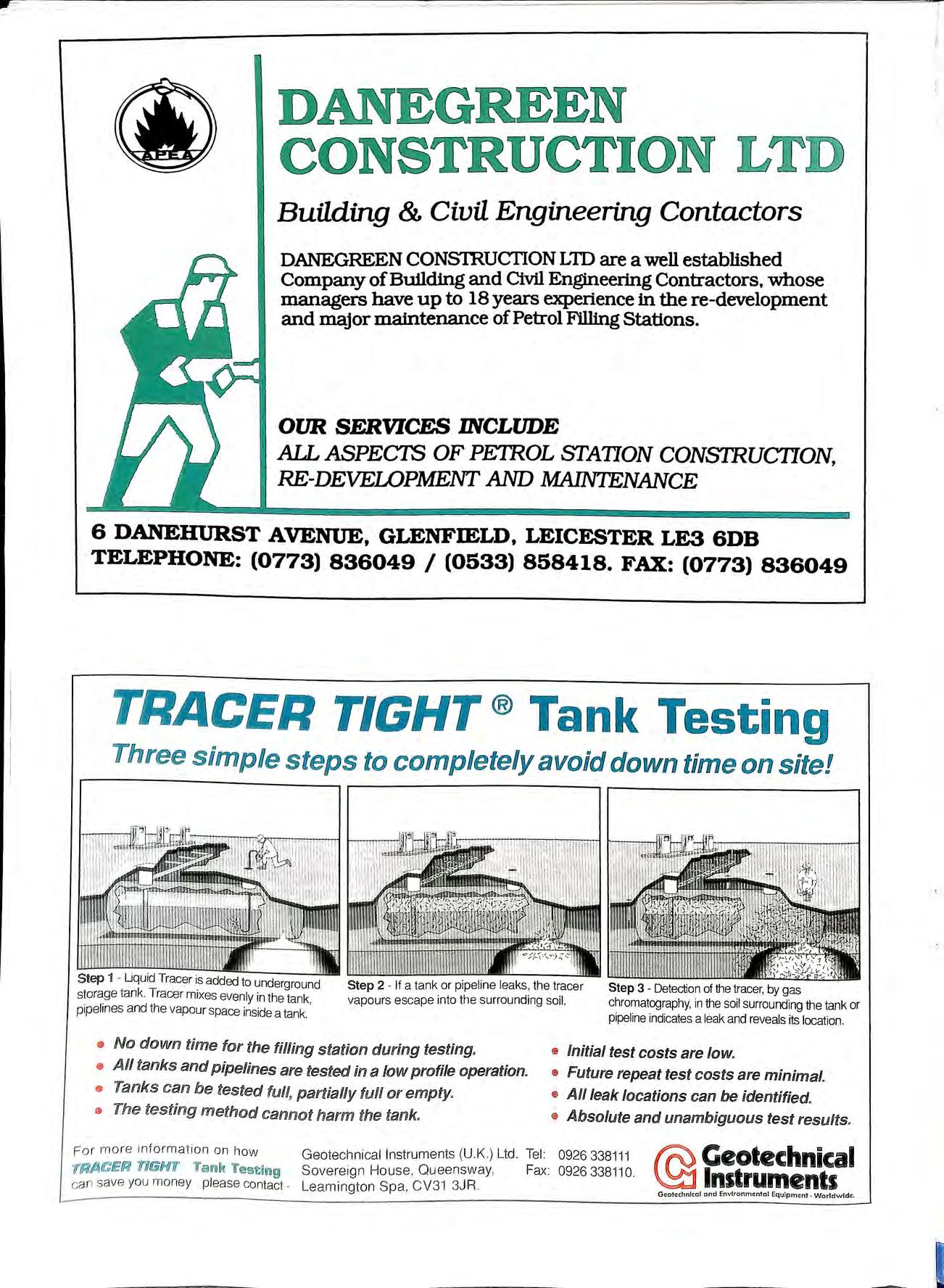

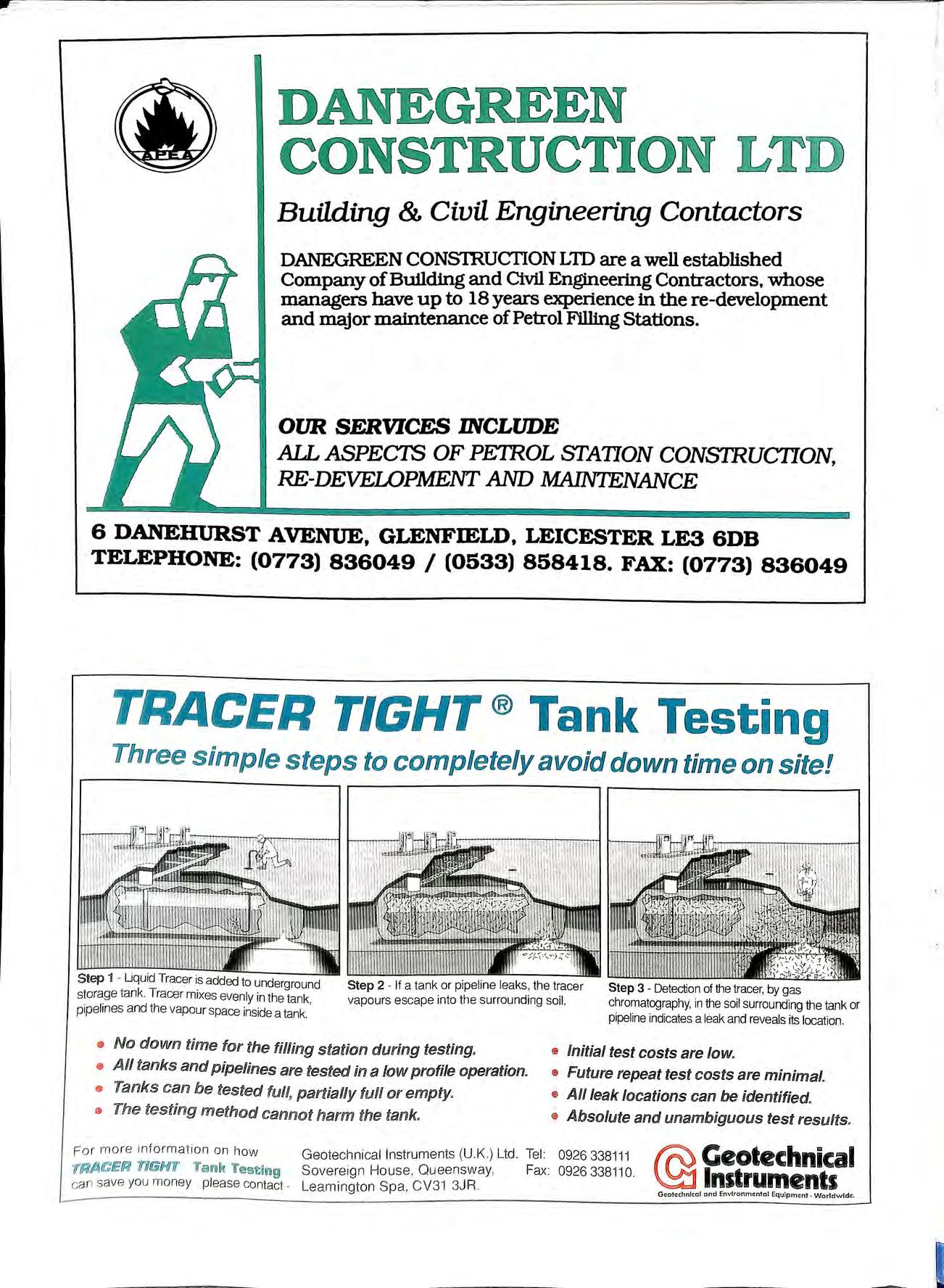

DANEGREEN CONSTRUCTIO Building & Civil Engineering Contactors DANEGREEN CONS1RUCTION LTD are a well established Company of Building and Civil Engineering Contractors, whose managers have up to 18 years experience in the re-development and major maintenance of Petrol Filling Stations. OUR SERVICES INCLUDE ALL ASPECTS OF PETROL STATION CONSTRUCTION, RE-DEVEWPMENT AND MAINTENANCE 6 DANEHURST AVENUE, GLENFIELD, LEICESTER LE3 6DB TELEPHONE: (0773) 836049 / (0533) 858418. FAX: (0773) 836049 TRACER TIGHT® Tank Testing Three simple steps to completely avoid down time on site! Step 1 Uquid Tracer is added to underground storage ta nk. Tracer mixes evenly in the tank , pipe li nes and the vapou r space inside a tank Step 2 If a tank or pipeline leaks, the tracer Step 3 Detection of the tracer, by gas vapo urs escape into the surrou nding soil. ch rom atography, in the soil surro unding the tank or pipeline indicates a leak and reveals its location • No down time for the filling station during testing. • All tanks and pipelines are tested in a low profile operation. • Tanks can be tested full, partially full or empty. e The testing method cannot harm the tank. e Initial test costs are low. • Future repeat test costs are minimal. • All leak locations can be identified. • Absolute and unambiguous test results. For more information on how Geotechnical Instruments (U.K.) Ltd. Tel: 0926 338111 rN Ceotechnical Instruments rRACEffl T!UGI!« iairok 1'esti111g Sovereign House , Queensway , Fax: 0926 338110. can s ave you mo ney please contact Leamington Spa , CV31 3JR Gcotcchnko1 and Envlronmcntal Equipme nt Worldwide

Acro n BUILDING CONTRACTORS LTD 1OOs High Street, Hampton, Middlesex TW12 2ST Contractors to Leading Oil Companies for 30 years. All aspects of Forecourt Work from Door Locks to Tank Installations. 24 Hour Call Out •Telephone: 081-979 7516 •Facsimile: 081-941 0036 A MEMBER OF THE A.P.E.A. Forecourt Refuelling Specialists • Approved contractor to many of the major oil companies • Approved installer of the latest Ameron and U.P.P. pipework • Building work undertaken with Independent Pump Services Operative e Tank, pump and pipe':"ork • Electrical testing and installation e Sales and installation of all forecourt associated equipment including new and refurbished fuel dispensers Bndependent Pump Services Ud Adur BoaltJard. Old Shoreham Road Sho reham-hl}-S ea, West Sussex BN4 3 5TA T el (027 3) 4'i483 J Fax i02T3J 464863 ION INE 0 ..... I UI co .......,, l> >< rz m CD N .... w ... A. = w Barnes Construction Experienced and Quality Assured Contractors in the construction, refurbishment and maintenance of service stations. 6 Bermuda Road Ransomes Europark Ipswich • Suffolk IP3 9RU Telephone: 0473 272222 Fax: 0473 272955 OPW61-SO , OVERFILL PREVENTION VALVE Pr·events overfilling of underground srnr·age tanks. Now also ava ilable rn 3 inch 0 Prntect dispenser· from acc id ental drive away. (BS-7117) OPW II ALO, AUTOMATIC NOZZLE Less sp ill age. Easy top off (BS-7117) PUMP SERVICES ( MANCHESTER) Ud western Park, Kansas Avenue , Salf o rd , Ma n c hester M 5 2GL Tel e phone 061 873 7428, FAX 061 848 7 193

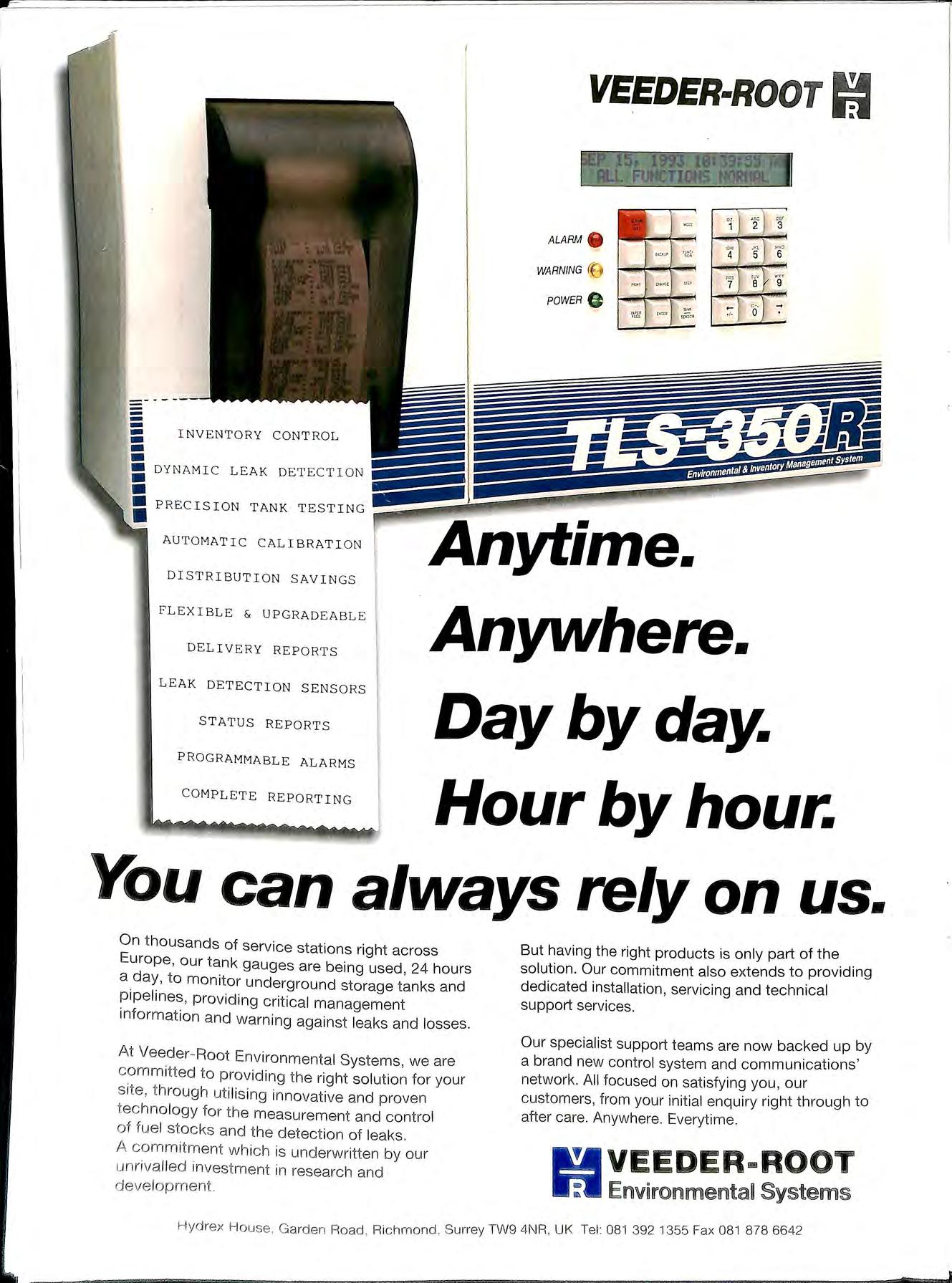

--------------·VEEDER-ROOT Ef 0, .<llC 3 1 2 ALARM 8 ,_ "" ,,_ 6 4 5 WARNING "'' ay 9' 7 POWER e ·· O• I':t/rt /.. 0 DISTRIBUTION SAVINGS FLEXIBLE & UPGRADEABLE Anywhere. DELIVERY REPORTS LEAK DETECTION SENSORS Day by day. S TATU S REPORTS PROGRAMMABLE ALARMS COMPLETE REPORT I NG Hour by hour. You can always rely on us.

service

storage

critical management information

warn

leaks and losses

On thousands of

stations right across Europe, our tank gauges are being used , 24 hours a _day, to monitor underground

tanks and pipelines, providing

and

ing against

At Veeder Root Environmental Systems, we are comm itted to provid ing the right solut ion for your site , th rough utilising innovat ive and proven technology for the measurement and control o f fue l stocks and the detection of leaks

A c ommitment Wh ich is underwritten by our unrivalled investment in research and d eve lopment.

b VEEDER - ROOT 1:1 Environmental Systems H ydmx Hou se, Ga,den Road Richmond , Su,,ey TW9 4NR , UK M 081 392 1355 Fax 081 878 6642

But having the right products is only part of the solution. Our commitment also extends to providing dedicated installation, servicing and technical support services. Our specialist support teams are now backed up by a brand new control system and communications ' network. All focused on satisfying you , our customers , from your initial enquiry right through to after care. Anywhere. Everytime

Securipipe & L i1 Victaulic sys{ems The complete non-corrosive steel pipe iointing system for your forecourt + Quality installations at competitive costs + Boasts the inherent strength of steel + Lasting protection against corrosion + High integrity iointing + Technical support Putting your forecourt at the forefront of technology For furth e r information Tel : Victaulic Systems (01462) 422622 Briti s h Ste el CRSI (01 536 ) 4021 2 1 British Steel Victaulic Syst ems

LEAK DETECTION SYSTE M S FOR DOUBLE SKIN TANKS.

LEAK DETECTION SYSTEMS FOR DOUBLE CONTAINMENT PIPES AND DISPENSER SUMPS.

TYPE 2000 INTELLIGENT TANK CONTENTS GAUGING SYSTEM.

INTERCEPTOR

• EURCGAUGE EURO-INDEX

*Systems accepted

.....•.................•................•..•••.......

Techno ogy fo environmental protection EUROGAUGE COMPANY LIMITED IMBERHORNE LANE , EAST GRINSTEAD, WEST SUSSEX RH19 1RF D.M. PETROLEUM SERVICES ProP> ri etor :- D . B . MAJOR Specialists in Forecourt Pipework Installations Ameron Approved Installer U. P . P Approved Installer 10'5 WDbury Road LetchworthHerts SGS 4JQ Telephone: 0462 480824 Fascimile: 8462 480824 Mobile: 0836 280239

LEVEL ALARMS. *85 5750 Part 1 quality assurance. *All systems meet relevant safety standards (EEx ia l/C for Zone O & EEx ib l/C for Zones 1 or 2).

by LFCDA

TALK TO THE EXPERTS on: 0342-323641 Fax: 0342-315513 Northern Sales: Tel & Fax: 0706-370695

F ORECOURT C ONTRACTORS S AFETY A SSOCIATION "Promoting safety training and self regulation for Contractors working within a Petroleum Retailing Environment" 'Safety Coach' says "Why don ' t you join those leading forecourt contractors who are now FCSA approved with individual Certificates of Compe t ence and their own Safety Coach" For Inform atio n and Ap plic ation F or m s co nta ct : The Secretary9FCSA, PO Box 6 120 9 LONDON SW15 lXF Phone/Fax: 0181-780 1711

C>PW LINK FUEUNG COMPONENTS EUROPE e v A DOVER R ESOURCES CO MPA NY HAMPSON LINK HAMPSON are official UK distributors for OPW Fueling Components and EBW International, both of whom are recognized worldwide as leading suppliers to the petroleum forecourt industry. Therefore, Link Hampson are ideally placed to supply; vapour-tight overfill prevention devices , Stage I B vapour recovery equipment, sp ill containers, monitoring wells, breakaway couplings and a wide range of automatic and manual nozzles Premium Products - Superior Service Link Hampson A Division of UTC (UK) Umited UTAC House, Bone Lane, Newbury, Be rkshire, RGl4 SUH Telephone: O1635 524200 Fax: 01635 550331 lw LEDBURY WELDING & ENGINEERING LTD. lw NETHERWOOD ROAD, ROTHERWAS INDUSTRIAL ESTATE, (T E l : 01432 275566) HEREFORD HR 2 GJU (FAX : 01432 358493) A COMPLETE RANGE OF ABOVE & BELOW GROUND STORAGE VESSELS OUAUTY UNIDERGROUNO TANKS DOUBLE AND SI NGLE SKI N QUALITY UNDERGROUND TANKS SPEC IA LIST COAT IN G LEAK DETECTION - OVERFILL PREVE NTIO N DEVIC ES MANWAY ACCESS FRA M ES M ULTIPLE CO M PA RT MEN TS ABOVE GRO lLJJ N [l) 9 FlUlllY BLINDED TOTALLY ENCLOSED ,, 60 0 GAllON TO 20/000

Biotal's treatments for contaminated soil and

can remove the hazard without undue interruption to business. Site investigations, fully-costed remedial proposals , specialist treatments and sound advice on all aspects of petroleum contamination.

For a free confidential consultation and/or site visit please call Peter Vernon on our helpline.

McCARTHY BAINBRIDGE PARTNERSHIP Chartered Surveyors:Project Managers 30 Years' experience in the design, planning, construction and cost control of service stations, showrooms and workshops throughout the country From the installation of a single tank to a comprehensive development contact: 3 Park Court, Pyrford Road, West Byfleet, Surrey KT14 650 Tel: 01932 352 727 Fax: 01932 351 545 CP INSTALLATIONS LTD. (Established 1968) • Specialists in Petroleum Pipework lnslallalions • New and existing Tanks and Lines rested • Modifications lo existing Installations • And all work associated Wilh Forecourt Pipework • Approved for UPP Pipework Installations and Envirollex • Approved for Ameron and Smiths Fibreglass installations 39 Brook Road, Weir Industrial Estate Rayleigh, Essex SS6 7XN Te l : 01268 7811 B4n81859 (24hrs ans) Fax : 01268 776697

your retail

Are

?

Soil and groundwater contaminated with petroleum products at

site

you concerned about your site

groundwater

"' Biotal Limited, 5 Chiltern Close, Cardiff, CF4 5DL, UK.

Fai

01222 766945 "' 8 OVERFILL PREVENTION INSTALLATION THE COMPANY Bortec Limited are the in novato r s in this new co nc ept in th e remova l of existing SOmm an d I OOmm aluminium internal fillp1pes. to install EMCO Wheaton or OPW over fill prevention va lves t o LI VE TANKS /t Makes Sound Sense To Use The Barte e Method YES The method is SAFE (we have proved it to H S E and LONDO N LICE N SIN G AUTHORITY ) YES In most cilSeS your t anks and site stay fully operational while we are working YES We can operate when yollr STATION IS CLOSED (our units are compl e te ly independent or outside services) YES Th is is th e mosc COST EFFE CTIVE method to install overfill prot ec t ion Th e safe. fast and eco nomical solution ta fillpip e extraction B"'TEC Overfill Prev enti on Installation Hudson H ill Hedingham Road Wethersfie ld Esse>< CM7 4EH Te l: (0371 )850921 Fa><: (0371) 850719

Tel: 01222 766716

:

ITH

Introducing SMITH FLEX™

Flexible Dual-Wall System with Stainless Steel.

Check out the new standard in flexible underground piping the UL Listed SMITHFLEX dualwall system. SMITHFLEX piping is designed to handle all

• The first flexible piping to pass the UL 842 fire test and the UL 536 vibration test.

Continuous Containment.

• 3" diameter corrugated containment pipe is constructed of specially formulated polyethylene.

• Superior deformation resistance from burial loads.

Easy Installation.

The Perfect Flexible Primary.

• i m permeab l e

• Corrosion resistant.

• 2" inside diameter high volume flow in a flexible pipe.

• Made entirely of 316-L low carbon corrugated stainless steel.

• Maintains 100% strength retention over time.

• Completely contained and secure d within the outer jacket so it is INSTALLED AS A SINGLE UNI T.

Smith Fiberglass Products has systems no special tools or served petroleum marketers since equipment are needed to install. 1968 with a variety of fiberglass

• Unlike some flexible piping

• joining system makes it easy to field-fabricate in all kinds of

piping systems including the first UL Listed nonmetallic underground petroleum system. Call us today for more information.

• We have your complete piping package available, all corrosionresistant from tank to dispenser: Flexible dual-wall piping and fiberglass pipe, sumps and vapor lines .

0753 840000

0753 831113

Al 777

Pen d ing H X PIP

Patent

Your Single Source Supplier.

FIBREGLASS PRODUCTS DIVISION Castl e Hill House Windsor SL4 1 PD. United Kingdom Tel: