LETIN

Journal of the Association for Petroleum and Explosives Administration

Here at last is an underground petrol storage tank with major advantages. Not only has it a capacity of 5,000 gallons, but also other factors which make it ideal for such users as Petrol Service Stations

The breakthrough has been achieved by Hunting Industrial Plastics, using a specially developed Polyester Resin, reinforced with glass fibre.

The tanks have proved themselves on strength. and dynamic tests Among their assets they include: 1. ease of installation; 2. the use of expensive brick or concrete IS obViated; 3. tanks constructed in this way are non-corrosive. 1,OOO's off installed in the U.S.A.

We could go on, but better still contact us without obligation. In this way, we can deal with your specific questions.

Hunting Industrial Plastics Limited, Wymeswold Aerodrome, 1 Burton on the Wolds, Loughborough, Leics. Tel: Wymeswold 880471

Reports are reaching us from many areas where the new petroleum authorities are being asked to exercise considerable tolerance in respect to what could loosely be called sub-standard petrol installations.

The biggest headache concerns those premises where tanks and pumps are not only sited well within the 14 ft. limit from a building or the highway, but in some cases are inside buildings, underneath a public footpath or alongside a dwelling house.

Licensees of such premises faced with a refusal to re-licence, often make the point that their premises originally received planning permission and have subsequently been licensed for years without any accident having taken place.

Such premises are an unacceptable risk to public safety and however sympathetic the local authority may be, to perpetuate these circumstances a local authority is failing in its duty to the public.

In refusing to re-licence, licensees must be informed of the reason for the refusal and also their right of appeal under the Act.

C. W. BRUDENELL, Deputy ControHer of Trading Standards Surrey C.C., has been ,appointed County Consumer Protection Officer, Humberside C C.

It is with regret we report the dearth of R. OROWT.HER, Gloucestershire C.C. Prior to local government reorganisation Mr. Crowther was the Chief Inspector of Weights and Measures, City of Gloucester, and was Chairman of the Wessex and South Wales Branch otf the Association in 1969.

E. W. H. HOWE, Deputy County Consumer P.rotection Officer, Bedfordshire C.C.

New legislation Itightening up the sale of fireworks and aimed at making back-garden bonfire parties s afer, is likely to be introduced by the Government early next year. The package will prohably contain la han on sales more than three weeks before Bonfire Night, a rise liD the age of cliildren >allowed to buy them from 13 to 16, >and heavier fines for shopkeepers who break these rules.

But the new safety rules fall far short of Ithe complete ban on 'retail sales of fireworks which has been demanded by the National CampaIgn for Firework Reform for the past six year,s.

Three youths came up behind 14-year old 'David Osborn in a street near his 'home <in Cherbourg Crescent, Chatham, Kent.

One hurled petrol at him from a five-gallon can, while another bent down and flkked a match at his legs.

David ran soreaming along the road as flames shot up his body.

As !l:he youths 'bolted, a f·riend of Dav,id's doused the flames wilth his overcoat.

David was taken to Medway Accident Cent-re, but allowed home after treatment to 'his tegs.

The thick overcoat 'saved him from more serious injuries.

A kind of "Frankenstein 'bacteria" which may one day be devouring o il slicks round Ithe world has been developed at the GeIJ1e raI Elemric laboratories at Schenectady, New

York. The company is now hoping to get permission from the U.S. Government to spray the next oil slick in U.S. with the bacteria in powder form.

It has been known for some time that Ithere are strains of the common bacteria 'calIed psuedomonas some of which live on petroleum and others which won't look at anything but stodgy tar. Now a super breed of bacteria capable of eating all types of oil bas been created by Dr. Anada Chakrabarty at the University of nHnois.

After the Queen started ;the oil flowing from BP's Forties Field to its refinery 'at Grangemouth, a system of traffic lights" for shipping came into operation in the River F01.'lth.

Super tankers of up to 250,000 tons _ 'Some a quarter of a mile long will take on the excess crude oil not required by the Grangemouth refineFy ata new tanker terminal off Hound Point, east of 'the Forth rail bridge.

These ships will be eight -times larger than the biggest: that have ever used the narrow naVigation channel from Beamer Rock in the Forth and 'the new systemaftrafflc lights is being introduced on the grounds of safety.

Two Lissgarage employees, Who tackled flames 12ft. high a petrol pump had been rtornoff its mounting were today praised by their managing diirector and Petersfield firemen.

The incident, at the White Rose Garage, at Hill BroW, Liss, is believed to have been caused by a customer driv.ing away from the self serv-ice pump without removing !/:he petrol pump nozzle from hi'S car's fuel tank.

The pump was dragged several feet, bre'aking electriC cables and rupturing the fuel pipe inside the pump.

Within seconds names were licking towards the canopy, but Mr. Robin Perry and serv-ice manager Mr. John Gardener, who lives on the premises were quickly on the scene. Using dry powder extingui'Shers on the forecourt and then turning off the fuel supply, they aVerted what have been a very serious fire, said 'a 'PeterS-field fireman later.

By the tIme the firemen arrived, the hase of the pump W!lS only smouldering.

dkector Mr. WilHam Baker said he was pleased his sbaff had been prompt and efficient.

The oustomer who caused the damage, estimated at several hundred pounds has not been traced The garage is open as normal today.

Paper presented by Mr. D. J. Comley, Sales Manager of L.P.G. Division, Esso Petroleum Company Limited, at the Annual General Meeting of the Scottish Branch of the Association, held at Dumbarton, on Tuesday, 11th March, 1975.

At the present time, approximately 1,600,000 tons of liquefied petroleum gas (better known in its abbreviated form of L.P:G.) is manufactured, refined and sold in the United Kingdom. This represents something between 1 % and 2 % of the total crude oil processed.

Due to the advent 'Of NOI'th Sea Oil, and l1:he fact that ·it is a much lighter oil than' the average MiddleEas't oil, it is possible that this figure may increase by 300% or 400% by 1980.

Liquefied Petroleum Gas is a term which covers two commerciall available gases namely Butane (C4 H 10) and Propane (C3 H s)' and normally L.P.G. is manufactured in pr?portions of 3 parts Butane to 1 part Propane, although thIS may vary from refinery to refinery being dependent upon ·the basic design of the mainstream of the refinery.

From a utilis'ation point of view the major advantage of over most other fuels is ,its very low sulphur content, bemg almost ·sulphur free (130-170 ppm).

.Because :of the amounts available, and the costs compared WIth other Butane ·is used extensively as a prime fuel. in such industries as heavy clay; ceramics and heavy i'orgmgs, whilst Propane is normally used for small, simple plants or for specialised applications such as heat treatment.

In gaseous form, both Propane and Butane have high calOrIfic values being approximately 2! and 3 times greater of natural gas, and also have the distinction of bemg vmtually ,free of sulphur.

W?en d:signing an ins'tallation to store and utHise L P G conslderatlOn h t b . . . . f ......as 0 e gIven to two further characteristics o '•.ue vapours.

(1) The of L.P.? vapours are considerably heavier than aIr, ·Butane bemg approximately twice the weight and Propane being I! times the weight of ah'. '

(2) Depending upon :the ambi?nt temperature both Butane ·and p.ropane can have hIgh vapour pressures, which the way the gases are utiliSed, and also the design of the vessels 'in which the L.P.G. is stored. For example :-

32°F :or O°C 60°F or 15.6°C 100°F or 38°C

Maximum Pressure Commercial Commercial Propane Butane p.s.i.g. p.s.i.g. 60 75 0 20 110 125 34 44 190 225 66 73

A further characteristic which is all-important when considering L.P.G. is that both gases, when compressed at ambient temperature, can be compreSsed into liquid fonn at quite low pressures, and this characteristic facilttates easy ,transportation in bulk from the refinery either by road or rail to the customer's premises where it is stored in the liquid phase in a pressurised vessel until required.

As stated previously, when a customer rece-ives L.P.G. he receives it and stores it in the liquid phase.

In this condition both Propane and Butane have specific gravities lower than that of water being 0.51 and 0.57 respectively

One of the main advantages of L.P.G. is that a small amount of the liquid will produce a large amount of vapour having a high calorific value. One gallon of liquid Butane will give 240 gallons of Butane vapour, and similarly one gallon of Propane will give 270 gallons of Propane vapour. The calorific values of these vapours are 3,200 and 2,500 Btu's per cubic fO'ot respeot,ively.

The vapours are ·released due 11:0 the boiling of ,the liquid L.P.G., Butane boils at 30o,F, whereas Propane boils at 40°F.

As will be seen 'by the above boiling points, Butane liquid is comparatively safe, hut considerable care must be taken when handling Propane, and protective clothing, including gloves and face visor, must ,be worn to prevent 'cold' bums should accidental spillage occur.

Although Propane and Butane are available in the United Kingdom both ·in the form of bottles and in bulk, it ,is proposed only ·tocover the latter, together with the necessary storage and handling.

The storage vessel1n a customer's premises is designed !to give between one and .two weeks suppJy, depending upon :-

(a) His maximum hourly requirement compared with his average flow requirement.

(b) 'Distance between the customer and his source of supply.

In the refinery, the UP.G. ·is ofiten stored under refrigerated conditions, thus reducing the vapour pressure to such a low point as to anow the storage vessels to be designed to withstand 'a maximum pressure in the region of 1.5 p.s.i.g. Such -storage vessels can contain as much as 8,000 tons 'Of L.P.G.

L.P.G. spheres are also found in 'refineries, and in the premises of customers who use extremely large amounts of L.P.G. These vessels are usually designed to contain between 750 rons 'and 2,000 .tons 'Of L.P.G., and although costly to install allow the storage of large amounts of L.P.G. in the minimum number -of storage vessels, and 'also the minimum area 'Of land.

Normally, however, the customer's storage vessel is a horizontal vessel, 'Or vessels, each vessel having incorporated in its design two cradles, ·these cradles being mounted on concrete plinths, so that 'the tank is approximately 2ft.3ft. dear of the ground.

The capacity '()If the \Storage vessel is invariably expressed in tons, and the length and diameter of the vessel will depend upon its capaoity. In the case of Ess'O Petroleum Company Limited, customer's installations are designed to accept a minimu mquantity of one full road tanker of L.P.G. which is normally between 13.5 ,tons and 17 tons, and therefore -the smallest tank encountered is usually of 20 tons capacity, having approximate dimensions 'of length 75ft., diameter 8ft., whereas a 100 ton vessel will be 75ft. in length and 12ft. in diameter.

The are designed to B.S.S. 1515 for working pressures up to 100 p.s.i.g. for Butane and 210 p.s.i.g. for Propane.

The location of :the storage vessel in the customer's premises is governed by two Codes of Practice.

The first Code of Practice is issued by the L.P.G.I.T.A. (Liquefied Petroleum Gas Industry Technical Association) which is an Association of producers and distributors of L.P.G.

The second Code of Practice ·is based on the L.P.G.I.T.A. code and 'is the Home Office Code of Practice. This is the C'Ode used by .the Factory Inspectorate, and is therefore the ''One normaBy referred to when des,igning an installation. Generally the codes recommend that vessels up to the capadty of 55 tons are situated at least 50fit. from buildings, roads and -boundary fences, and that vessels over 55 tons capacity should be at least 7Mt. from similar points.

The tank or tanks -should stand ,in a compound which is a concreted area, extending approximately 10ft. from each side of the lbank, and the area should be surrounded by a 15 'inch high wall, 'and surmounted hya chain link fence 6ft. 6ins. high. Access to the comp'Ound should be by gates in the compound fencing, Itwo sets of gates being placed at 'Opposite ends 'of the -c'Omp·'Ound. The gates should not be of the self locking type, and should be secured only when persons are not working -in the compound.

In cases where land is restricted, the overall safety distances may be reduced by the erection of radiation walls, or the tank may be installed underground. In the latter case, the 'tank 'is situated in a concrete lined pit and back-filled with sand with a top cover of at least 2£t. and, in such an installatIon, the clearance distances are reduced as foll'Ows:

For vessels up to 55 t'Ons capacity 10ft. from boundary fence, road or building.

F'Or vessels over 55 ,tons capaoity 151it. from boundary fence, road or building.

In all cases, prior to 'installation, -the proposed tank positions are discussed with the appr'Opriate Factory Inspector and F,ire Officer to ensure complete agreement.

To comply with the Codes of Practice, -all vessels must be fitted with safety relief valves set 'at 'a predetermined pressure; pressure gauge; c'Ontents indicator and themoAlso, aB vapour and Hquid 'Offtake lines are fitted with excess flow valves so that, If 'any line is fractured, such line will be shut off and is'Olated instantly.

In addition to the 'above there is a liquid fiU line and a vapour return line. On discharging, the tanker is connected to both these lines so that the pressures 'in the tanker and the storage vessel can be balanced, :thus ensuring minimum time. This is particularly important as ,it is possible for bursts :t'O occur in the flexi'ble line connecting the vehicle and the storage, and therefore the reduction in delivery time wi1l inevitably mean a reduction in the number of times that this dangerous conditi'On may arise. Depending upon local conditions and bye-laws, above ground installations may also require wate'r spray sets to be attached to the vessel. Cel'tainly this is recommended on all :tanks over 60 ton capacity. These water sprays are deSigned to cool the storage vessel should a fire 'Occur in premises When these water sprays are filtted they are mevltably deSigned t'O ensure ill water coverage oaf 0.2 gallons per minute -per square foot of surface area 'QIf the vessel.

Often it is not possible t'O conneot the spray sets directly ont'O the local water supply, either due t'O lack of available quantity or pressure of water in the main and therefore "dry" sets, and incorporate a remote c'OnnectlOn pomt, for the use of the Fire Brigade in the event of a conflagration. '

When is J?ut a cust'Omer's storage vessel, the IS filled lIqUid L.P.G. until the tank is approxunately 90% L.P.G. is naturally a gas, some of the L.P,G. lIqUId wIll vap'Orise until the equiHbrium vapour pressure has 'been set up in 'the vessel.

. If. is then removed from the tank, further lIqUid !S the heat of vaporisation being taken !rom the lIqUid m the tank. In tum, the liquid will absorb neat from the atmosphere 'through the wetted section of .wa,lls This system is called 'Natural Vaporand IS used ID small Pr'Opane inSltaUations. Propane IS. partIculady useful -in this respect, due ro the considerable difference .betw.een 'the ambient temperature n'Ormally enID thiS c'Ountry,and the boiling point of Propane, thtsbemg very low at -40o'F.

The flow of gas that can be obtained from such an installation depends upon the following conditions:

(a) The amount of liquid L.P.G. in the tank, and therefore the wetted surface of the tank.

Cb) The ambient temperature.

For eXlample, if we take a 30 ton Propane tank which is 40ft. long and 9ft. diameter, and the tank is about 50% full of liquid, and an ambient temperature or 25°F (say a wintery night of 6° of 'frost), then we would expect an available gas offtake of 90 therms per hour, at a pressure uf 5 p.s.i.g. or 65 therms per hour at a pressure of 15 p.s.i.g.

Such a system is used extensively in such applications as poultry farms, bitumen heaters, etc.

Although this type of plant is simple to install and operate, its 'application is somewhat limited due to the following reasons:-

(1) It cannot be used for Butane, because Butane has a boiling point of 30°F and therefore under the conditions stated, no vaporisation would take place.

(2) Ofiten the gas offtake required is greater ;than that which can be obtained by natural vaporisation.

(3) Commercial gases do contain propOItions of other gases in them. Under natural vaporisation conditions, preferential vaporisation ttakes place, i.e. Propane before Butane, and therefore one does not obtain a consistent quality of gas at all times.

In order to overcome the limitations imposed !by the simple type of L.P.G. plant described above, and in particular to utilise Butane, which is somewhat cheaper than Propane, most plants are designed to utilise liquid L.P.G. from the storage vessels, rather than the gases from the vapour space at Ithe top of the tank.

Normally the liquid Propane, or Butane, is fed by gravity or by a small pump to a heat exchanger called a 'vaporiser'. fhe vaporiser can be of any size and is designed to cope with the maximum gas demand of the process or factory and can be of two ba'sic types:-

This type is normally installed adjacent to the storage vessel, 'and is heated by a 'safe' heating medium (that is, no ,ignition source is present). Such heating mediums are electricity, steam and hot water, the latter being 'the most common, the 'sOurce of hot water being sman L.P.G. fired boilers situated remote from the storage 'area. The rate of vaporisation is controlled by I1quid level controllers s'itua'ted in the vaporiser.

Where the installation of 'indireot fired' vaporisers in t?e storage would require long runs of gas lme from the vaporIser to ,the point of usage, such as would be encountered in a brickworks 'direct fired' vaporisers may be used. '

These vaporisers use the 'L.P.G. itself as the heating medium. Small amounts 'Of L.P.G. are tapped off, 'at the

inlet to the vaporiser, allowed to vaporise and ·then passed to gas burners ,inside the vaporiser, which in 'turn heat the L.P.G.liquid flowing into the vaporiser.

This is particularly important, 'as 'already mentioned, in brickworks. For example, if you consider transmitting L.P.G. vapours over a i mile you may require a 4 iinch or 6 inch main, whereas in the liquid form, with a direct fired vaporiser, adjacent to the kiln or dryer, the supply line may be only 1 inch in diameter.

The one main disadvantage of direct fired vaporisers, is that under ,the Codes of P,ractice, they are treated in similar ways as L.P.G. storage vessels in 1:hat they must 'be positioned with minimum clearance distances from L.P.G. storage vessels, building and boundary fences.

At the present .time ,there are three ways of utilising Butane :md Propane gas.

(I) Burning the gas in ,its neat form.

(2) Mixing the L.P.G. with air and using the air/gas system.

(3) Burning Butane in its liquid form.

(I) Neat L.P.G.

It is possible to distribute Butane and Propane in the same way as towns gas, but -if this is done consideration .should be given to the dewpoint, or the temperature at WhICh the reliquefication of the gases occurs.

Propane can, and often is, distributed throughout 'a works at a pressure of up to 40 p.s.i.g. without any problems. At this pressure the dewpoint is 'approximately 20°F, so there is virtually no likelihood of liquid Propane being condensed into 'the lines, because seldom is the 'ambient temperature so low.

However, Butane is a different matter. If Butane is distributed at 10 p.s.i.g. and at a temperature in excess of 55°F, then again ;there is no problem. If at this pressure the temperature of the gases falls below 55°F, the Butane liquid can be deposited in the system. To prevent the occurrence of Ithis problem there are two solutions.

(a) All lines carrying neat Butane vapour are traced and lagged, the tracing usually being achieved with electric tape hea'ting. Many brickworks operate on neat Butane at pressures up to 15 p.s.i.g. and having taken this precaution 'have no problems.

The dewpoint is reduced by mix;ing Butane with air, prior to transmission in the pipelines.

The amount of air that is introduced to the Butane ,to form an 'air/gas mixeure 'Is dependent upon:-

(a) The lowes!t ambient temperature likely itObe encountered.

(b) The pressure at which the mixture is to be distributed.

(c) Whether ,the air/gas mixture is to be used to replace gas or not.

For example, if Butane gas is mixed with three times its own volume of air, then at a pressure of lOp.s.i.g. the dewpoint ,is reduced from 55°F to -17°F, and the mixture can be transmitted safely at that pressure. This solution toO the dewpoint problemi:s particularly important when a customer is considering conversion ,to Butane 'from either toOwns gas or natural gas.

By mixing Butane and air -in cextain proportions it ;is pos'sible to produce a mixture, which is equivalent. to that of the fuel it is replacing. Neat Butane has a calorific value of 3,200 Btu/,cubic !foot, and a specific gravity 'of 2.0.

Towns gas has a caloOrific value of 500 Btu/cubic foot, and a speclfi.c g'ravity of 0.47.

There is a formula 'caned ,the Wobbe Index which ,is as foll'Ows:-

If two gases have the same Wo]}be Index, then they will be 'interchangeable, that is, use the same transmission lines, with 'the same pressure drops, and use the same burners, with the same heat 'OUtpUit at the same pressure conditions. It so happens that ;the 75/25 'air/gas mixture used as the example earlier has a Wobbe Number of 730, which is the same as the Wobbe Number for towns gas, and can therefore be used to replace it. Similarly a mixture oOf approximately 50/50 air/gas mixture will replace natural gas.

It is proposed not to dwell too long oOn this point, because the type of mixer will depend very muCh upon the 'applicatIon.

Basically there are two types ofmixers:-

(1) Mechanical Mixer.

(2) Venturi Mixer.

In the mechanical mixer, normally the L.P.G. and air both at atmospheric .pressure are induced the unit 'by electric blowers or compressors, mixed and then blown into the distribution mains. Normally the pressure available in the works from such a plant Is up to 30" w.g.

The Venturi mixer uses ,the Kinetic energy in the L.P.G., the 'L.P.G. entraining the air from the atmosphere. The advantage of this system is that there are no moving parts, but has the disadvantage oOf hay.ing a poor turn down ratio. To meet small load demands, such as pilot 'burners during weekends, etc., when the main gas using plant is shut doOwn, a gas holder has to be installed on the outlet of the mixer, thus allowing the mixer to run intermittently.

Recently work has been carried out on developing systems allowing Butane to be handled and fired ,in its liquid state. These systems must be used in outside locations such as quarries, because it is necessary to run the, burner equipment at very high pressures toO maintain the liquid state. Apart from this compJoication the main advantages are the use of small bore pipelines and the eHmination ,of vaporisers, traCing and lagging 'of lines.

Safe Handling of L.P.G.

L:P.G. is as safe as any 'Other fuel when handled properly, and 1,t is highly imp'Ortant that staff who come into c'Ontact with L.P.G. should be trained so that they 'are fully aware of the potential hazards and the recommended precautions.

To this end, Esso Petr'Oleum Company Limited run several L.P.G. Safety and Fire ,Fighting Courses for L.P.G. customers each year, at their Fawley Refinery at S'Outhampton.

At these courses, the customer has the opportunity of actually fighting L.P.G. fires, and is therefore in the .position of knowing how to control such an oOutbreak oOn his own plant.

H'Owever, the main objective ,is ,to ensure that fires do not 'Occur. Fire Fighting is reaIIy the last Hne of defence. It is probably a fact that over 98% oOf all fires which 'Occur are .fires that could be avoided. They fall into three main groups:-

(i) Pe'Ople fa'iling to recognise that a fire hazard .exists.

(ii) Pe'Ople failing to carry out the correct safety procedure.

(iii) Gross carelessness.

The most impOI1tant 'aspects of 'Fire Prevention are:(a) GOOD HOUSEKEEPING

L.P.G. Tank storage area Keep clean, free from weeds, .rubbish, timber, old discarded pieces of equipment, suc:h 'as pipes, valves, etc.

Equipment L.P.G. pumps kept clean and:the electric motors lubricated 'as required, flanges kept tight and free tirom leaks, electrical wiring kep'tin good order. Fire equipment Dry powder extinguishers should be hung on brackets well clear oOf 'the ground, in weatherproof Iboxes. They should be hung in a conspicu'Ous p'osition, painted ,red with 'the words 'DRY POWDER FIRE EXTINGUISHER' painted on the 'Outside od' the hox. The extinguishers 'sh'Ould be checked regularly, kept ,in a clean condition, and ifree if'rom obstruction. Hydrants and fire hoses if located on 'site must he regularly maintained.

From this aspect, Fire Prevention does not have to be restrictive. A high standard 'Of maintenance wi1l:(a) ·ov:ralI. e.fficiency of the plant _ this wlll assIst >ID mamtaIDlDg Production Schedules.

(b) Attention :t'O ,leaking fl:anges, glands, etc., will pre.vent acx:umulations of dangerous gas concentratlons, whIch are always a potential fire hazard.

It is the responsibiItty 'at management to ensure that employees work safely and also that they are fully aware of the precautions which have 'been recommended:-

Clean area and dean work.

Be on lookout at aB times for L.P.G. liquid or vapour leaks.

Never overfill an L.P.G. vessel beyond 92% liquid level.

No smoking {)r naked lights within 50 feet of L.P.G. storage, 75 :feet for storage over 60 tons capacity.

Check water spray equipment is working (1f fitted) once 'a month, remove and clean any blocked water spray jets and replace. Check fire alarm warning system.

Carry out frequent fire drills with own staff and twice yearly with ,the local fire brigade.

Ensure if any work is being carried out in the maintenance of L.P.G. equipment, that all the safety rules are observed.

Ensure that all members of staff and contractors working on site know how to use fire protection equipment.

Never store Propane in a Butane storage vessel.

Fire and possihle explosion is the greatest possible hazard on an L.P.G. installation. It seems logical to suppose that concepts like the fire triangle, auto-ignition and explosive ranges .:>f L:P.G. vapours and flashpoints, should be understood by everyone. Fire Prevention where L.P.G. is used stems from an understanding of these concepts as much as from the exercise of care and common sense and from the practice of good housekeeping.

The Fire Triangle gives the essentials for combustion.

This gives the most simple and direct explanation of the chemistry of fire. When these three occur in the right proportions simultane'Ously, 'there is fire or explosion. If one is taken away, fire or -explosion no longer exists.

FUEL Leaka'ge or spillage of L.P.G. liquid or vapour are the greatest potential danger.

OXYGEN In the form of the air supply (21 % of the atmosphere) around provides the second leg of the triangle. HEAT Temperature the means of ·ignition can :take the form of arcs, sparks, a naked flame, static electricity, the elements (both Hghtning and sun) and ,in cases of autoignition, the existence of a suffiCiently hot surface, or a.rea, the area within a heated chamber, a hot pipe, etc.

The greatest possible emphasis must be placed on fire

Since little can be done ab'out removing oxygen from the alr around us and since the mixture of air with L.P.G. vapours presents the greatest potential menace all emphasis obviously be placed on fuel supply 'and means :Jf 19l11'tlOn. Much can be done to prevent their presence under conditions which would create a fire hazard. If a fire should result involving L.P.G., under no circumstances must the fire be extinguished untO the source of the fuel leakage has been eliminated. by closing the nearest isolating valves each side of the leak.

It is essential to recognise the kind of conditions in which, given source of ignition, L.P.G. vapours catch fire explode. There is a minimum proportion of vapour aIr below which ignition does not occur and a maxlffium concentration above which it does not occur. These are known as the lower and upper explosive limits. Mixtu:es of L.P.G. vapour to air between these Iimits ar: and are referred to "as being within the range , e.g.

L.P.G. Propane Butane

Lower explosive limit 2.2 % vapour rto air l.9% vapour to air

Upper explosive limit 9.5 % vapour to aIr 8.5% vapour to air

It ,is extremely important to remember that heat alone can be a source for ,the ignition of L.P.G. vapours. If, for instance, Butane vapour leaks into the and dilutes to its explosive range, and if it comes mto contact with a hot material a'bove 806°F (430°C) e.g. hot brickwork ut this heat. then spontaneous (auto) ignition will occur.

H a vapour to air mixture exists within their respective ranges:-

Butane ,approximate ignition point will be about 806°F (430°C).

_ approximate igni'cion point will be about 871 OF (466°C).

Auto-ignition is, of course, the principle 'On which the diesel engine operates.

Butane and Propane will ignite if a spark is applied. to it art a temperature below freexing point. It is ess:ntIal distinguish very clearly what is meant by fiashpomt. It 'IS the Iowest temperature at which L.P.G. off sufficient vapour to form a mixture which wil11gnIte m the presence of an arc, spark, or naked light, or other source of direct ignition.

L.P.G. vapours are heavier than air and lighter and follow ground contours and will travel consIderabl distances depending on ambient temperature, wind strength and direction.

Safe dilution point is generally accepted as 50 feet, from source of emissi'On. In assess·ing ,this safety margm, ambient temperature, wind and prevailing conditions MUS.T be considered. Any heavy emission of vapour could, m favourable downwind conditions, dilute at greater distances than this, to a vapour to air ra;tio within the explosive ran¥e. If such a vapour flashes, the flame will increase in intenSIty as it f.ollows rthe V'8pour ,trail back towards the s'Ource of the leak. Explosions can arise from various heat sources, e.g. welding or burning operations, use of poI1l:able grinders or chipping hammers, non-flameproof electrical equipment, or any material liable to produce sparks, or give rise to spontaneous combustion.

When L.P.G. liquids are pumped, either from the delivery vehicle or from the static storage to a vaporiser, static electricity is generated. Therefore the vehicle must be connected to an earth bond, to discharge staltic. The resistanece to earth should not exceed 106 ohms. L.P.G. 'static tanks must be fitted with an earthing copper strip and spike. All flanges in liquid lines should be copper bonded together.

Thermal expansion in pipelines containing L.P.G. liquid, which have been closed by shutting off valves at each end of the pipeline could present a serious problem. This is overcome by ·fitting 'between each pair of valves a small pressure relief valve, which w?-H vent to atmosphere at a lower pressure than the maxImum s·ad'e pressure of the pipeline.

Percentage increase Approximately ,in volume per 100°F (38°C) Propane Butane Temperature rise 'is:- 17% 10%

It therefore can be seen tthat if there is no vapour space and the liquid is heated say by sunlight, to cause an increase in volume, the pressure will increase by about 2000 p.s.i. (0.7 kg/cm2) for every 10°F (-12°C) rise in temperature.

L.P.G. is being handled every day and has been for years in perfect safety. This ,is because tthose using. L.P.G. know what the hazards are, know whalt precautIons to take, and take them.

IT IS ONLY PEOPLE WHO TAKE CHANCES THAT ENDANGER THEMSELVES AND OmERS.

Unfortunately it is not possible to produce a fire extinguisher which can be used with complete success on aH varying types of fires. (Some ·claim :All Purpose'. for some dry chemicals). Wvth L.P.G. fires (whIch are as Class 'C' fires), we should use a dry powder 'extmgUIsher in the first 'instance, and should consider our extinguisher as our piece of 'First Aid Equipment'. Many fires start at first in a small way, and have very successfully been put out with dry powder extinguishers before ,they could grow to'a large L.P.G. fire, and get out of control.

Dealing with incidents involving L.P.G. is a serious responsibHlty. For this reason it is essential that no time should be lost in summoning the assistance of the Fire Brigade. In very extreme oircumstances ,it may be deemed necessary to risk igniting a L.P.G. gas leak in order to prevent the build-up of a large area od' L.P.G. vapours which may be ;n the flammable range and which could ignite from a nearby source of ignition with possible disas'trous effects. The decision to ignite such a gas leak must be made by both the senior management on site and a senior officer from the Fire Brigade. It is doubtful whether any fi·re officer would assume responsibility for 'starting such a potentially serious fire with the results of the ignition so unpredictable.

Where L.P.G. is stored it ,is most important that all personnel working should he familiar with the dry p'owder

fire extinguishers distributed about the L.P.G. storage tank area, ·and adjacent to other L.P.G. ancillary equipment. They should also understand the principles underlying their design, maintenance and use.

Hand fire extinguishers are designed for small fires, and therefore must be used close to the fire, and should not be used in trying to do the job for which more powerful fire extinguishing equipment would be required. In using fire extinguishers do not be caught by .tackling a fire alone without back-up support.

Always send somebody to raise the alarm; if alone, call this assistance first, unless you can immediately put out the fire with the equipment provided. This advice is not Ito discourage the use of fire extinguishers, 'but to emphasise that a person using them should know what the extinguisher is designed for, and what can be expected of it. Fu111:hermore, a lot may depend on the skill with which the extinguisher is used.

May be of two types:-

(1) The dry powder is expelled by pressure released into the body of the extinguisher rfrom a C02 cartridge. t2) The dry powder is expelled by pressure maintained in the body of the extinguisher by air or nitrogen.

The method O'f putting each eX'tinguisher into use should be studied 'and fully practised by all personnel, who should familiarise themselves with the particular extinguisher which they will be expected to use and maintain, and should study the requirements rfor:(a) Regular inspection and maintenance. (b) Operation under fire conditIons. (c) Servicing and recharge ·after use.

Dry powder extinguishers are produced in varying s·izes from generally 2 Ibs. (0.9 kg) to 150 lbs. (68 kg). It is recommended that dry powder extinguishers for L.P.G. installations should be not smaller than 20/25 lbs. (9/11.3 kg). This size can be easily handled by one man, and is large enough to fight a reasonably sized L.P.G. fire. They act principally as a smothering agent. The base od' Ithis dry powder ;s normally sodium bicarbonate which is mixed with some inert material, such as chalk, dry clay, whiting, etc.

Other 'types of powders produced in recent years are 'Purple K' which has a Potassium bicarbonate base and 'MONEX' this is produced by reacting Urea with two Potassium based salts.

It must be understood that the continual existence od' flame depends on a 'Chain reaction from one burning molecule to :rhe other and the effect of us'ing dry p'owdler in its very fine form is to 'interrupt this chain reaction by the application to the atmosphere of myriads of fine pal!ticles of powder, which prevent 'any further supply of oxygen from combining with the combustible material or substance.

Note Always remember that When a fire has been extinguished by dry powder, y.apours may perculate through the powder and may re-ignite from hot metal, smoldering

lagging, etc In dealing with a fire where constant re-ignition is experienced, 'or where difficulty is experienced in extinguishing the fire, it may be necessary to cool surrounding metal, lagging, etc., to below the products auto-ignition temperaturE by means of water, fog or spray.

Non-kink hoses, 1" (25 mm) in diameter and 150ft. (45 mm) in length are installed on specially construoted hose reels. They should be sited at strategic points adjacent to L.P.G. plant. The hose terminates in a dual purpose nozzle which directs the water in the form of a fine spray or jet.

Note When using on a L.P.G. fire, or to cool hot metal it must only be applied in the form 'Of a fine spray.

Water is clean, usually comparatively plentiful,and 'has the highest specific heat of any known 'Substance, which gives it remarkable cooling properties. Water is used to keep cO'ol or protect buildings, structures and L.P.G. tanks, which are either adjacent to or involved in a fire. L.P.G. fires present problems to the firefighter, in many cases they cannot readily be eX'tinguished, and even if this is achieved, the possibility of explosive re-ignition of the vapours usually exists. It will therefore usually be necessary to aHow a liquid spill or vapour leak to continue burning, whilst cooHng with water, flame exposed equipment. As a close approach to a fire in an L.P.G. storage 'Compound may be difficult, and possible collapse of unprotected L.P.G. storage vessel's .md pipelines likely, water spray protection to this equipment is essential, ,to prevent what may initially be quite a minor spill f.rom growing into a ma}or conflagration.

Lt is necess'ary to 'Supply sufficient water to protect the L.P.G. vessel from radiant heat from !the -fire, either by hoses and mobile equipment, fixed monitors or fixed water spray systems, which may be automatic. The heat input to the liquid portion of :the L.P.G. vessel, must not produce more vapour than the pressure relief valves can relieve, or the pressure wi,thin the vessel would rise to a dangerous level, and the vessel would rupture.

L.P.G. vessels may f.ail at the ordinary working pressure If the steel above the liquid contents is weakened by exposur.e to It is evident from past experience, that :very lIttle tIme may be available (may be as little as mmutes) for manual fire-fighting equipment to be brought mto play, and that some form of manually or automatically ?,perated w.ater spray system is required if vessel failure IS to be .lv-oIded when serious leaks Occur.

L.P.G. vessels properly protected with a full and adequate water spray system, wiH reduce the heat input rate to the contents from in ex'cess of 20,000 Btu/sq.ft. (21.101 kJ) for an unprotected vessel ,to s'omething 'Of 'the order 'Of 6 000 Btu/sq.ft. (6,330 kJ) for a water spray ted ' 'n1.. h 11 f th pro]ec vessel. J.ue S e o. e pressure vessel must no.t the f eed 570°F (299°C) 'or it will rupture, but if appHed before :the st:el temperature rises to high, steel temperature Will slowly fullaImost immediatel t 212°F the point of waiter. Rivulets Of must be aVOIded, WhICh may pennit the steel skin temp-

era'ture between them to rise rapidly to the failure temperature of the s:teel. The water must be sprayed over the entire surface of the L.P.G. vessel, necessitating the careful positioning of -the water sprays, taking into account the angle of the spray, and ,the curvature of the vessel. With fires involving vertical L.P.G. vessels, a heat input rate of about 28,000 Btu/sq.ft. (29,542 kJ) would be experienced, but with full water spray protection the heat input rate would be reduced to about 4,700 Btu/sqft. (4,959 kJ).

When protecting a horizontal L.P.G. vessel, it is necessary to provide water sprays both above -and below the horizontal centre-line, to cover with water spray the entire surface area of the vessel, as direct cooling 'Of hot spots by water drop bombardment is required. Water cannot be relied upon to run down over hot zones if these are below the horizontal centre-line of the ves'sel, as the heat input to the liquid stored in the vessel in the lower portion may be very high if only upper spray bars are fitted. Whatever type of waJter spray protection is provided, i.e., fixed or mobile system, the pumps, pipework or hoses should be able to discharge water at a pressure and rate sufficient to maintain an adequate film 'Of water over the entire surface of the vessel and supports under fire conditions, i.e. a minimum of 0.2 gallons per sq. ft. ()If the surface area of the tank/minute (9.8 litres/minute).

In some circumstances when frequent deliveries are made into storage consideration should be given to the prov,ision of mobile or fixed water spray systems, giving suitable and effective protection !for road ,tankers and rail tank cars offloading areas, in addition to the static L.P.G. storage. All water spray systems should be dry systems, to protect against freezing, and should be fitted with drain cocks, to empty the system a,fte'r use.

When using fire hoses with a wide angle spray, it will only have a short range, but affords -the maximum protection for the fire-fighter. A dense spray of waiter may be used as a barrier between the flame and fire-fighter to protect them against radiant heat, thus pe'rmitting closer approach for such important step's as closing a Vlalve to shut off the flow 'Of L.P.G. feeding -the fire.

Solid jet!> of water must never be sprayed onto a liquid L.P.G. leak, as ,the water will make the 'L.P.G. boil very very rapidly, and -increase the size of ,the vapour cloud and will very much intensify the size of the fire.

When L.P.G. liquid or vapours escap'e from storage vessels or pipeHnes all available means should 'be used for Hmiting their spread and preventing 'ignition. This may possibly be carried out by using a water spray or water sprays, between the leak and s'ources Cif ignition. The extent -of the contaminated area should first be defined and the area identified by suitable warn-ing signs, cordoned off and patrolled.

If a leak oocurs ,in a liquid line or vapour line, the L.P.G. pumps md vaporisers should be shut down, and the leak isolated by closing valves on the upstream and downstream side 'Of rhe leak. Traffic control should be established and vehicles excluded from the area the Fire Brigade should be called. Firemen attempting to disperse Ithe vapour cloud should never enter the vapour area, 'and must have protecting water fog availa'bleat all times. All furnaces, sources of ignition and hot work must be shut down.

After dispersal of the vapour cloud and before any repair opera't;ions 'or production recommenced, tests should be made in all Iow lying areas, using a portable gas detector, to establish if any hidden vapours still remain.

If a leak occurs in an area adjacent to adjoining properties owned by outside intere'sts, prompt measures must be taken to notify those concerned of the potential hazard that exists and :tD eliminate any source of ignition.

Successful fire extinguishment results from the systematic applicatiDn of planned procedures. Those born of panic often add to the seriousness of the emergency.

Butane and Propane fires should only be extinguished by cutting .)ff ;the fuel source. As the valves are situated under the vehicle and are most likely rio 'be involved in the fire, this can be difficult. Each vehicle carries two dry powder extinguishers, and provided swift action ,is taken at the time of the fire, it may be pDssible tD exrtinguish the fire with dry pDwder and then dose the valves. If the fire is too severe, then water spray fog should be used to enable the Fire Brigade '1;0 get in close t'O the valves. M the same time, other branches should be applying copious amounts of water to the vehicle tank to keep the pressure in the tank under control.

If the principles of good operating practice outlined are observed, the probability 'Of leakage, fires and explosions will be minimised. However, accidents do occur, and it is impDrtant to know the basic fundamentals of handling L.P.G. in emergencies.

It is not widely appreciated that cylindrical L.P.G. storage vessels can fail in a fire at a 'Circumferential seam. If this happens the ,sudden release of pressure energy !through the open end will send the vessel off 'like a rocket. This is a most important thing to remember when planning the IDcatiDn of 'the L.P.G. tanks, and when fighting fires in tank compDunds.

When an L.P.G. leak occurs, ,it may be discovered by (a) ice forming around the leak (b) a visible vapour cloud (c) liquid can be seen either dropping 'Or in a puddle (d) the leak has ,ignited.

1. Approach the fire or leak from downwind.

2. Keep all pel's'Onnel 'Out of the vapour cloud area.

3. Eliminate all sources of ignition in the vicinity at 'Once.

4. Police the area, keep all persDnnel at least 200 feet, or further if possible, away tfrom the area, except those necessary to cope with the situation.

5. N'Otify the Fire Brigade, Police 'and adjacent property 'Owners.

1. If escaping L.P.G. is not on fire, isolate the leak by closing adjacent valves either side of the leak.

2. Water spray is most effective in helping to disperse L.P.G. vapour clouds. :If available, -it should be used as soon as possible, directing the spray streams aCT{)SS the path of the vapour and dispersing the vapour intD a safe location. Those handHng ,the hoses should avoid entering the vapour cloud and should keep l'Ow behind ilie spray, so that they will 'be somewhat protected from radiant heat should the vapour cloud be ignited unexpectedly.

3. In some instances of leakage from a road tank vehicle without a fire, it may be desirable to remove the vehicle to some remote area, such as a blocked 'Off road or 'Open field, where it can continue to leak away fr{)m a source 'Of ignition. However, if this is to be done, the tank should be removed in a vertial position. Never drag the vehicle in a manner which might damage valves or pipework 'Or create sparks.

1. Do not extinguish unless leakage can be stopped, except under certain extreme conditions.

2. Lf the escaping gas is on fire, immediately apply large quantities of water as quickly as possible to all surfaces exposed to hea:t, with approach to ilie tank being made from the sides. Concentrate on piping and metal surfaces of ihe vessel and/or adjoining vessels, equipment exposed to flame 'or intense heat.

3. Should a delivery of L.P.G. be taking place when the fire 'occurs, if the vehicle is nDt involved, ask the driver tD remove the vehicle.

4. If the only valve which can be used to stop the flow 'Of 'is involved in fire, consider the possibility of effectmg shut-off by protecting firemen with water fog full proteotive clothing whilst they are dosmg the valve. P.roceed slowly to aVDid any flashbacks or trapping firemen in the flames.

5. Controlled burning 'Of escaping L.P.G. (which cannot be sh,ut off by a valve) is a cDmmonly accepted practice of fire-fightmg. The application of sufficient water to keep the shell 'Of the vessel and piping cool allow the fire to consume the L.P.G. in the tank WIthout danger of causing failure.

6. fire extinguishers are very effeotive fDr extmgUlshmg small L.P.G. fires and also for a man',s clothing ignited' in a fire. ExtmgUlshmg a?ent be directed along the vapour stream from 'Immediately above the pDint of discharge.

7. When sufficient water is not available tD keep the tank cool, some warning '0: increased pressure may be noted by the pressure valves Hfting, the increased volume 'Cif fire 'Or nOIse level. This should serve as a signal Ito consider the withdrawal of all men tD a safe area. every case the pressure relief valves, should hft and become ignited, must not under any Circumstances be exltinguished, until the tank pressure falls, when the relief valve will close and it will extinguish itself. '

The term 'auto-refrigeration' refers to the phenomenon which occurs when the pressure is rele'ased on a vessel containing liquid L.P.G. In other words, the liquid is being withdrawn from the tank faster than the tanks normal boiloff rate. The latent heat is taken from the liquid L.P.G. as a result of some -of it changing its state ·to vapour, the residual liquid 'becoming even colder. This state is more evident with Propane than Butane due to its much lower boiling point. After a short period of time a thick ice deposit starts tD form 'On the outside of the tank, which will tend tD insulate the tank from the sun's rays, and will slow dDwn the rate of natural vaporisatiDn even more, and still more ice will build up. To overcome auto-ref.rigeration, the amount of L.P.G. being withdrawn from Ithetank must be greatly decreased, and after a while the ice will start to melt.

Staff must receive adequate 'instruction and refresher training in the correct 'Operating procedures for storing and handling L.rp.G. They must be thoroughly familiar with all the P'Otential hazards. Familiarity tends t'O breed contempt and it is the job of management t'O aVDid any danger Of complacency in their approach '1'0 the hazards of handling L.P.G Only well trained personnel carrying out the right 'Operating pr'Ocedures and using properly designed equipment can handle L.P.G. safely.

TABLE 1.

Propane

;) Calorific value (gross) a) Btu/cu ft. of vapour b) Btu/lb. c) Therms/Imperial gallon 'Of liquid d) Therms/long ton

2) Cal'Orificvalue (net) a) Btu/cu fit. vap'Our b) Btu/lb.

3) Liquid Gravity a) S.G. @ 60°F., w.r.t. water = 1 b) lb. Imperial gallon c) Imperial gallons/ton

4) Vapour specific gravity -a) w.r.t Air at s.t.p. b) Rati'O of gas volume to liquid v'Olume a:t s.t.p. c) Ib.l00 cufit. d) eu ft./lb. e) cu ft./long ton

5) Boiling point at one atmosphere OF °C

6) Vapour pressure, psia temperature 32°F or O°C 60°F {)T 15.6°C 100°F or 38°C

7) Sulphur 'content (Maximum) ppm w /w Maximum %

8) Free water content

9) FlammabiHty range, ·gas/air % Lower Upper

10) Combusti'Onair required, stoichiometric air cu fit/cu ,ft. L.P.G.

11) Maximum flame Itemperature, in Air C 12) Maximum burning velocity cm/sec. ft/sec. 13) lJatent hea't 'Of vapora'tion @ 60°F. Btu/lb.

14) Specific heat of liquid Btu/lb. OF

2,500 21,500 1.10 480 2,300 19,850 0.51 5.1 440 1.5 270 11.6 8.6 19,250 -49 -45 Typical Maximum 70 75 HO 125 190 225 60 0.006% Nil 2.0 10.0 24 1980 42 lA 170 0.60

Butane 3,200 21,200 1.23 475 3,000 19,700 0.57 5.75 390 2.0 240 15.2 6.6 15,000 20 -7 Typical Maximum 20 20 34 44 66 73 50 0.005% Nil 1.8 9.0 30 1990 42 lA 160 0.57

Storage Categories

Wa:ter capacity of individual storage vessels in Htres

Up to 450

Over 450 to 2,250

Over 2,250 to 9,000 Over 9,000 to 135,000 Over 135,000 to 337,000 Over 337,000

TABLE 2.

Nominal· L:P.G. capacity (tonnes)

0--0.2 0.2-1.0 1-4 4-60 60-150 150

Siting Categories

From Building/Property line 'Or fixed point of ignition

Above ground None 3 7.5 15.0 23 30.0

Water capacity of individual storage vessels in U.K. gallons

Up to 100

Over 100 to 500 Over 500 to 2,000 Over 2,000 to 30,000 Over 30,000 to 75,000 Over 75,000

Nominal· L.P.G. capacity Tons)

0--0.2 0.2-1.0 1-4 4-60 60-150 150

Distance in

Between Vessels

Under Above Under ground ground ground 3 None 1.5 3 0.9 1.5 3 0.9 1.5 3 1.5 1.5 5 1.5 of ! sum of 1.5 5 diameter of 1.5 adjacent vessels, whichever is the greater

From Building/Propel'ty line or fixed point of ignition

Distance in feet Between Vessels Above ground Under ground Above ground Under ground

None 10 25 50 75 100

10 10 10 10 15 15

None 3 3 5 5 it. or! diameter of adjacent vess'els, whichever ,is the greater

5 5 5 5 5 5

Note 1

The maximum total water capacity of all storage vessels in a group musrt not be greater than three times tile water capacity of the largest vessel permitted in any particular sItting category. The maximum number 'Of vessels in a Group must not exceed six.

Note 2

For underground ,storage up to 500 U.K. gallons (2,250 litres) water capacity, the distance .from the valve assembly on the manhole cover and the loading/unloading point in the building/property line or any fixed source of ignition must be at least 10ft. (3m); for vessels above 500 U.K. gallons, this distance must be at leasrt 25ft. (75m).

Note 3

Actual product capacities can be calculated from the specifiC gravity of the L.P.G.beingstored.

The information giVen in this table is based on the Home Office Code 'Of Practice for the 'Storage of L.P.G. at Fixed Installations' and on the Code of Practice 'Ins'llallation of Fixed Bulk L;P.G. Storage 'at Consumers' Premises' published by the Liquefied Petroleum Gas Industry Technical Association (U.K.)

•

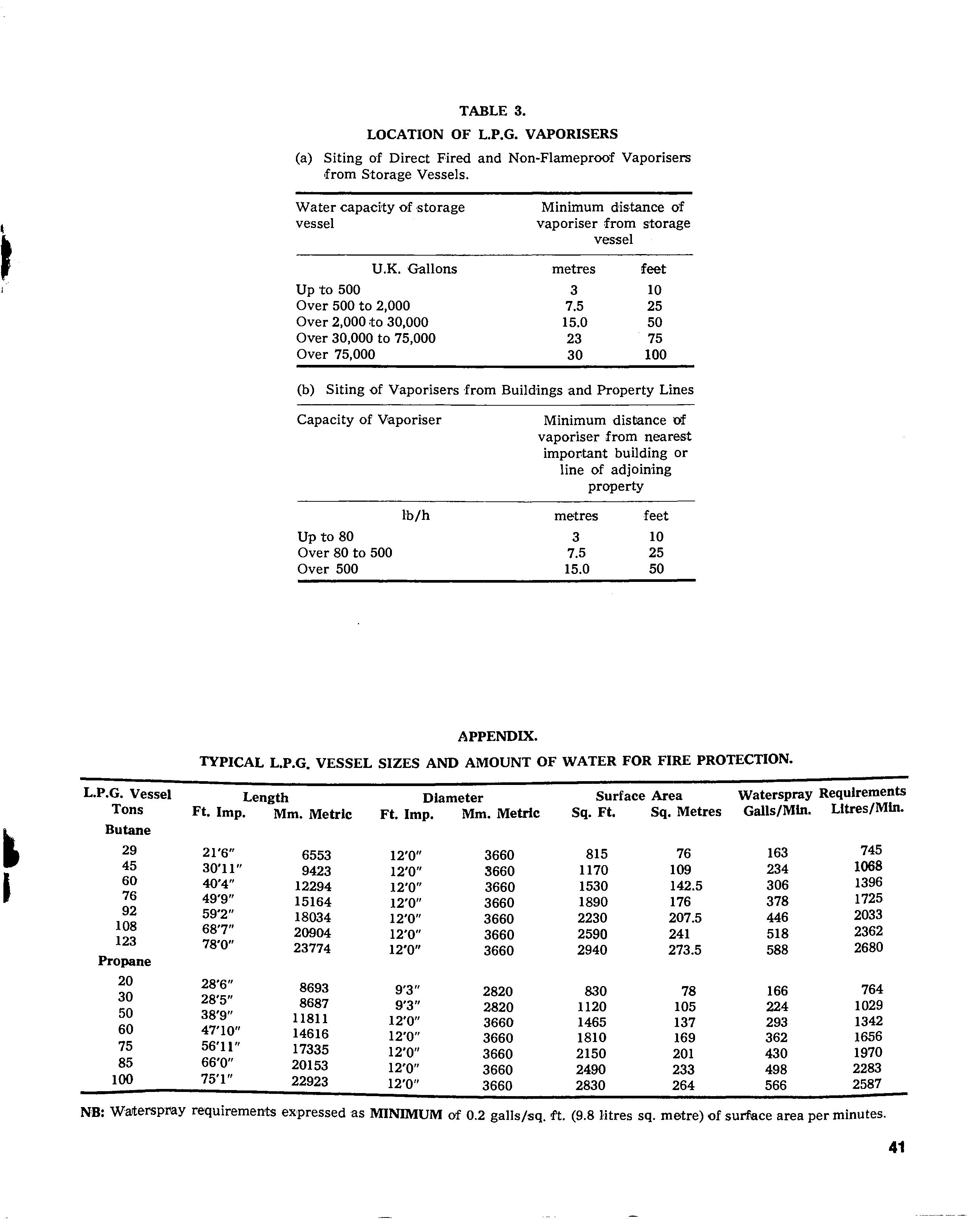

TABLE 3.

LOCATION OF L.P.G. VAPORISERS

(a) Siting of Direct Fired and Non-Flameproof Vaporisers from Storage Vessels.

Water capadty of storage vessel U.K. Gallons

Up to 500 Over 500 to 2,000 Over 2,000 ;to 30,000 Over 30,000 to 75,000 Over 75,000

Minimum distance of vaporiser from storage vessel metres feet 3 10 7.5 25 15.0 50 23 75 30 100

(b) Siting of Vaporisers from Buildings and Property Lines Capacity of Vaporiser

lb/h

Up to 80 Over 80 to 500 Over 500

APPENDIX.

feet 10 25 50

Supply Vaporiser

Supply Vaporiser

Supply

Vaporiser

112" dia.

TYPICAL OVERALL LENGTHS (Based on 12' dia.) 30 tons capacity 21' 6" 45 60 100 "

31' 0" 40' 6" 69' 0"

A preliminary. report 'On the fire and explosion at .the Gulf refinery at Philadelphia USA . th ( 50) . f F' , '" appears In'· e current No. Issue '0 Ire Int·e t' I . . rna' IOna, the quarterly journal 'On fi·re protectl'On which is published in E I' h ·F h d Ge (with Spanish ng IS ,. renc an' rman A h by Unisaf Publications Limited. not er pen'Odlcal publ' hed .b of the fire protecti IS ' y U".l1saf IS FIre, the journal . " on profeSSIOn which appears monthly and IS now 'ID ItS 68th S . will be sent f year. ample copIes of both periodicals ree on request too D 't PE U . af L' . Unisaf H'Ouse 32/36 D ep, nls Imlted, , udley Road, Tunbridge Wells, Kent.

Unisaf are responsible for The Yell'Ow Book which IS an annual directory 'Of B 't . , . n am s fire servIces, 'both. ublic and mdustnal,c'Omplete with a "Wh·' ·Wh" P • '0 S '0 and a com'buy.ers 'guide. A list of books published 'Or suppbed by Ums8!f may be obtained by writing to the Fire Book Department (Dep't PE), at theab'Ove address.

The Ass'Ociati'On has reprinted its Code of Practice in respect of Principles of Construction, Electrical Requirements, and Model Licence Conditions, etc. This reprint has been undertakenfollowjng repeated enquiries and requests for the Associati'On's Code.

Copies of the Code of Practice are obtainable from the Hon. Secretary, Hon. Editor, or Mr. B. W. C. Thacker, at a cost 'Of 75p post free.

Armngements have been made, through the g'Ood offices 'Of Mr. T. Lister, Chief Fire Officer, West Midlands Fire Service, for the Annual General Meeting to be held at the Headquarters of the Brigade at Birmingham, late in April, 1976. Full details, 'including the titles of papers too be presented will be notified to members early in the year.

It is most important that portable fire appliances should be kept in their allotted positions and not be misused. The provision of brackets, shelves or base blocks will help to show if any appliance is missing.

Extinguishers should be recharged in accordance with the supplier's instructions immediately after they have been completely or partially discharged. One refill for each extinguisher should 'always be kept available for this purpose.

Inspection and testing should be carried out by the suppliers or firms specializing in this work, or a properly trained member of the staff. The table below is intended as a guide to ,the frequency of inspection required for each of the main types of ettinguisher.

The date of inspection should 'be ,indelibly recorded on a label securely attached to the extinguisher or painted on the hody (it should not be stamped into the body of the extinguisher). Alternatively, the date may be recorded in a special register; each extinguisher should have an identification to correspond with the item m the register.

The periodical pressure testing of extinguishers other than carbon dioxide entinguishers is no longer considered necessary. But any extinguisher showing signs of internal corrosion or damage should be taken out of service and replaced.

Water (gas pressure) should be opened up annually and the following checks made.

See that:

(1) The extinguisher is fiHed to the correct level.

(2) The nozzle, internal discharge tube and -strainer, snifter valve and vent holes in the side of the cap are no1: dogged.

(3) The plunger moves ,freely.

(4) The cap joint washer and the hose are in good condition.

(5) No corrosion is visible either internally or externally.

(6) The gas cartridge is weighed to deteotany loss and if this exceeds 10 percent of the weight of the contents the cartridge should be replaced. The sealing washer should also be checked to ensure that it lis in good condition.

Every extinguisher should be discharged at ,least once every five years.

As these extinguishers are pressurized ,they may only be opened for inspection after discharge. They should be discharged and opened up annually and the :following checks made.

See that:

(1) The extinguisher is pressured correctly hy examining the indicating device or tell-tale indicator both before and after discharge.

(2) The nozzle, internal discharge tube and strainer and vent holes in the cap are not clogged.

(3) The operating mechanism is in good order.

(4) The cap joint washer and hose are in good condition.

t5) No corrosion is visible internally or externally.

Water s'Oda/acid

Water (s'Oda/acid) extinguishers sh'Ould be 'Opened up annually and the following checks made.

See that:

(1) The extinguisher is filled t'O 'the correct level.

(2) There has been no acid leakage which can be caused by seepage past the lead stopper in the case of some turn-over models, or which may be the result of a cracked bottle. (Cracked !bottles sh'Ould he replaced). If leakage has occurred the extinguisher should be recharged.

(3) The nozzle, internal discharge tube and strainer, snIfter valve and vent holes in the side of the cap are not clogged.

(4) The plunger or hammer moves freely.

(5) The cap joint washer and the hose are in good condition

(6) No corrosion is visible either internally or externally. Each extinguisher should be discharged at least once every five years. Turn-over models (open acid bottle), however should be discharged every two years. Arliter discharge, extingu'ishers should be thoroughly washed out with clean water and any piecesaf glass or solid matter removed.

Foam (chemical) extinguishers should be opened up annually and the following checks made.

See that:

(1) The extinguisher and inner container are filled to the correct level.

•

(2) The nozzle, internal strainer and vent holes in the side of the cap are not clogged.

(3) The releasing device moves freely.

(4) All washers are in good condition.

(5) No corrosion i:; visible either internally or externally.

It is not necessary to stir the contents of this type of extinguisher and stirring may, in fact, cause damage. Every extinguisher should be discharged once every two years.

Foam mechanical

Foam (mechanical) extinguishers should be opened up annually and the following checks made.

See that:

(1) The extinguisher is filled to the correct level.

(2) The nozzle, internal discharge tube and strainer, snifter valve and holes in the side 'of the cap are not clogged.

(3) The plunger moves freely.

(4) The cap joint washer and hose are in good condition.

(5) No corrosion is visible internally or externally.

(6) The gas cartridge is weighed to detect any loss and if this exceeds 10 per cent of the -contents the cart:ridge should be replaced. The sealing washer should also be checked to ensure that it is in good condition.

ExtingUishers should be discharged at least once every two years, or once every four years in the case of extinguishers where the fDamcompound is in a sealed container. After discharge, foam extinguishers should be thoroughly washed out with clean water and any wild matter should be removed.

Dry pOWder extinguishers should be checked annually as follows:

These models cannot be opened up for inspection. They should therefore be weighed as a check against loss of powde.r, .and if a loss of weight ,is deteoted the supplier or a firm should be consulted. Some models are fitled a pressure gauge whioh gives a rapid check but the extmgUlsher shOUld, nevertheless, still be weighed, as gauges are not always accurate.

The follOWing checks should also be made.

See that:

(1) The hose is in good condition.

(2) The nozzle is not clogged and the squeeze grip nozzle control moves freely. (Do not grease or oil this control).

(3) No corrosion is visible externally.

Every extinguisher should be discharged at least once every five years.

These models should be weighed to check that they are filled with the correct quantity of powder. They should be opened up annually, and where a discharge control is fitted on the nozzle at the end of the hose, this should be operated before opening to relieve any pressure which may be present. The following checks should then be made.

See :that:

(1) The nozzle, internal discharge tube, snifter valve and vent holes in the 'Side of the cap are not clogged.

(2) The cap joint washer and the hose are ·in good condition.

No corrosion is visible externally.

(4) The plunger and the squeeze grip nozzle control move freely. (Do not grease or oil this control).

(5) The powder is free from caking.

(6) All washers and hose are in good condition.

(7) No corrosion is visible internally or externally.

(8) The gas cartridge is weighed to detect any loss and if this exceeds 10 per cent of the contents the cart:ridge should be replaced.

Every extinguisher should be discharged at least once every five years.

All dry powder extinguishers should be kept perfectly dry after being discharged and not washed out.

Carbon dioxide

Carbon dioxide extinguishers require rather different maintenance from most other types of extinguisher. At least once every twelve months, ,the extinguisher should be weighed and the body inspected for external corrosion. If a loss. of weight, indicating that leakage is occurring, or corrosion is detected the extinguisher should be hydrauhcaHy tested by the supplier or 'a specialist firm. This test should be 'repeated thereafter at intervals of five years.

If no such .Joss or corrosion is detected it is necessary for a hydraulic test to be carried out only at intervals of 10 years on the first two occasions. Subsequent tests should be carried out every five years.

In :the event ()If an extinguisher being discharged during the first 1C' years, however, the same conditions apply as when leakage or corrosion is detected.

In addition to the checks mentioned above the following should also be made.

See ,that:

(1) The horn, hose and valve assembly are in good condition.

(2) The squeeze grip horn control moves freely. (Do not confuse this with 'the actuating mechanism on the valve assembly).

The pressure used for hydraulic testing varies according to the kind of steel used ii'or the body of a carbon dioxide ertinguisher.

Vaporizing liquid extinguishers should be checked annually as follows.

These models cannot be opened up for inspection. They should therefore be weighed and if a loss of weight is detected the suppliers or a specialist finn should be consulted. Some mode1s are fitted with '3 pressure gauge which gives a rapid check, but the extinguisher should, nevertheless, still be weighed as gauges are not always accurate. The following checks should also be made.

See that:

(1) The nozzle is not clogged.

(2) No corrosion ,is visible externally.

Every extinguisher should be discharged at least once every five years.

These models should be 'Opened up and the following checks made.

See that:

(1) The extinguisher is filled to the proper level.

(2) The nozzle, in:ternal discharge tube and strainer, and vent holes in the side of the cap 'are not clogged.

(3) The plunger or other operating device is free to move.

(4) The cap joint washer and the hose are in good condition.

(5) No corrosion is visible internally or externally.

(6) The gas cartridge is weighed to detect any loss and if this exceeds 10 per cent of the weight of ,the contents the cartridge should be replaced. The sealing washer should also be checked to ensure that it is in good condition.

Every extinguisher should be discharged at least once every five years.

hand pump models including air pump transient pressure models

The following checks should be made.

See that::

(1) The nozzle is not clogged.

(2) The hose, if any, is in good condition.

(3) The pump mechanism ,is in proper working order. This can be checked by making one or two strokes with the nozzle pointing in both an upward and downward direction. The handle should then be returned to the "locked" position.

(4) No external corrosion is visible.

In addition, every extinguisher should be examined monthly to check for loss brought about by evaporation, and "topped up" where necessary. Every extinguisher should be discharged annually.

When the periodical discharge of gas container and hand pump models is being carried out the liquid can be poured into a suitably large clean earthenware or glass vessel and can be used for recharging the extinguisher, which should then be "topped up"

Note: The Home Office have recommended to fire authorIties that they should in future advise against the use of C.T.C. in fire extinguishers.

(With acknowledgement to the Fire Protection Association)

One thing which we are short of in this country :is some uniformity regarding the safety standards which should be applied to LPG. You 'are aware of the dangers which can OCcur if the product is misused, there is no danger in LPG providing it is 'handled safely. The LPGITA, for those of you who are not aware, the ,initials stand for Liquified Petroleum Gas Industry Technical Ass'Ociation, and this is an Association which was formed as far back as 1947 in this country, 'and is formed of representatives from all the major oil suppliers and also from LPG distributors 'Such as Calor Gas and BOC Air Products and more recently perhaps, people who are associated with the LPG iindustry as a whole. The pur'pose of the LPGITA is to produce codes of

practice using the expertise 'of the people involved on the various standing committees to use codes of practice to promote the safer use of the product.

There are three codes of praotice, one of them being LPGITA Code of Practice, in fact, the have eleven codes of practice, I think I am right in saying, and these cover such things as installation and maintenance of bulk storage at consumers premises, :recommendations for control of fire involving LPG, storage of full and empty LPG cylinders, maintenance ill fixed bulklJPG vessels and S'O on, l'ight down to number eleven, which 'is the recommendation for the safe handling of'LPG used as an 'internal 'Combustion engine fuel for motor vehicles. Believe it or not, I am right

in saying 'that this is probably the only code of practice which ;s available for IJPG conversions in this country today. However, construction use regulations are being updated and we believe that the new draft will be available for comment to the various associations such as ours in the very near future. What they will contain we do 'not really know. We do believe that this, even though it was only produced two years ago, 'is now relatively out of date and needs re-writing, If the construction use regulations are as slack as they are, it will be our intention to put this of practice forward to the Health and Safety CommiSSIOn for recognition as the main code of practice to be used throughout the U,K., so this really boils down to the fact that the people who are in this kind of market should of this and ideally, they should be working to It. If they are working to this we have got a uniformity of safety standards going through the industry and judging from what I have seen recently, and to a lesser extent some of the things I have heard from various people, we are all worried about the same thing that there is no People are disregarding it and, the unfortunate thing IS that there is a very inherent danger of people setting themselves up as "experts" in converting vehicles to run on LPG, so much sO,and I am choosing my words very carefully h:re, they disregard all recognised standa'rds. What I saymg is, ·that there are so many people getting involved the. LPG automotive market, too many, and too many , ack street people. There has been an Association formed m Yorkshire which I would like to see spreading throughout the country, but what I would personally like to see ,is, people who are involved in the IJPG market should be either full members or associate members of the LPGITA. You can partake in the various standing committees which I will to you, You can be involved in the wri'ting or rewr.l>tmg of the codes of practice and you can make your VOIce heard throughout the industry,

The LPGITAconsists of a number of Standing Committees the first of which I am Chairman, is the Safety Committee and our purpose is to colleot statistics of ,incidents which OCcur throughout the UK and at the end ()If 'any given year a report 'On these statistics and recommendations as to the re 'f f f own mg '0 codes of practice or the requirement ,or new codes of practice to be written. Our 'basic funotion IS -safety, We have d' , , h' a pro uotlOn and logIstIcs commIttee who andhng a draft oodeon ,transporting LPG by sea and to extend this to rail. Surprisingly enough th ou.g we have been shifting LPG for years and years' ere IS no code of practic If h' ' great depth 'On th' ,e or SIpS. I wiIl not go into any a great deal of tU::,e vanouscommittees as that would take

Our ·third working g , of LPG, The pea 1 rohup I,S, concerned with the bulk use pew 0 Sit 'On th' f I committee are experts fro I, par ICU ar standing like to s,tress at this star: the OIl, mdustry and I would contradiot me 'f th ,g, I believe, and anyone can I ey Wish th t . h' , . and within the LPGITA ' h a Wit m the Oil compames the country 'On LPG Th we , aye the grea'test expertise in , ere IS no doubt in m . d soever, and it is proved by ,th f et ' Y mm What, e a that we ar 'ted Sit 'On various British Standard C . e mVI to Committees etc If the G ommlttees, Home Office , ., "'.' overnment od of document relating to safety or to LPcir uce any kind people asked to comment and I th'nk we are the first , I we are the only

people who, when dealing with a person like Rex Walpole, who is the Chief Chemical Factory Inspector, will come to Us asking for advice, the same as we will ask him.

We have a fourth committee which is concerned with cylinder use 'Of LPG and this is through the whole gambit of cylinders from the small cartridges right through to 104 lb. cylinders. Not surprising, this is composed mainly of Calor Gas, BOC, Shell, BP and Air Products because obviously they are the people mostly concerned with this type of market.

That basically explains ,the LPGITA. We will, sometime this year, become members of the European Association and this obviously will lead to a much wider coverage of LPG regulations which are applicable in Europe at the moment and which are not applicable here; not -that they have any better ideas than we have, even though they have been in the market 'longer, so there will be a full and complete exchange on codes of practice and on information relating to safety. Going back to what I said earlier, I want to stress upon you all that the LPGITA is here in existence as a technical association, there is great emphasis placed upon it by the major oil companies, Calor, BOC, etc. The membership has increased tremendously and we are doing an excellent job, not only in our eyes but the eyes of the Government, because whether you know .jt or not, anyone who supplies even a carburreter to be used on a car has a legal responsibility to his customer to make sure that the part, the vehicle, ,the equipment or whatever it may be, as well as the cylinder 'Of gas, is going to be used safely, and we believe that our code of practice will be adopted by the Health and Safety at Work Commission and if that is the case it means that anyone who is a member of the LPGITA and even if you are not, you will be able ItO get help and assistance from us for the very difficult and detailed Act which is coming in and will have widespread responsibilities for us all.

Yorkshire Auto Gas is a company which has been carrying out gas conversions for about 4! years 'and was specifically formed to do gas conversions for motor vehicles. In that time we have gained ;considerable experience and spent a great deal of time on the continent where we have looked at gas conversions in the gas convers,ion industry in countries which have been doing this for 15 years and more. We are the sole concessionaires for Landy Hartogg, a Dutch company, and it is with theirco-operaHon thaJt we have been able to develop to the stage we have reached, We do not only conversions for petrol engines but also for the bigger diesel engines where we have conversions available and a fair amount of experience in operating diesels on mixtures, usually in the region of 60% diesel, 40% propane. In our own right we are developing some diesel engines as straight gas engines and have at'tracted the linterest of some of the engine manufacturers with whom we are co-operating.

I think it is necessary to try and give some factual informon the effffects of opera'ting the spark ignition on gas.

I Will try to be objective and not talk about particular conversion equipment, but to talk specifically about the effects on the engines regardless 'Of the make of conversion fitted.

I will first say a few W{)rds aoout fuel. For those operators or potential 'operators who are not aware ()f the fuels available, theLPG is generally either propane of butane or can be a mixture. The octane rating of propane is in the region of 110 as against 4 star petrol at 98. Butane is around 87, so if y{)u wish t{) operate on butane it has got to be on engines with Iow compression ratios because it is 10weT than the lowest grade petrol. The other problem of operating on butane, "is that at zero degrees there is no pressure, which in a road vehicle, because the tank is usually at the same level or below the level of the engine, y{)u have difficulty in starting because you 'are not getting 'the fuel in the winter when you have very cold mornings, so butane on its own, for two reasons, 'the octane rating and the pr{)blems 'of operating 'in winter, is not a suitable fuel in my opini{)n. Propane does not present these problems but even better than propane, perhaps, is to operate on a mixture. From the miles per gallon, engine point 'Of view and fuel avaHability, perhaps, it could be advantageous to operate on mixtures and one company in the UK do offer 'a mixture of 'fuel and in my humble ()pini{)n ,is a good mixture. That is a propane/butane mix but I do not know what the mix is and would suggest that a good mix is in summer 50-50, and in winter 70% propane, 30% butane. On the continent, particularly in Holland 'and Denmark 'it has been the practice to use a mixture for many years. The trouble with us·ing a mix is that it does present problems to the fuel supplier because of pressure differentials, it creates problems at the terminal in I{)ading tankers and it could create problems at the delivery point if the vessel has had a lot of propane in it immediately before the mix is put in because you have got these pressure differentials, it may also cause difficulties getting the mix into a tank that has had propane or contains propane.