THE BULLETIN

Journal of the Association for Petroleum and Explosives Administration

I .VOLUME 111 No. 2

LIMITED

Office

DRIVE,

DUAL FUEL PETROL- PROPANE MOTOR VEHICLE CONVERSIONS, TANKS & FITTINGS TO B.S. SPECIFICATIONS OR TO CUSTOMERS REQUIREMENTS.

Registered

10, STATION ROAD WITTON BIRMINGHAM 6. Telephone: 021·328 0034 Works STATION

THORNHILL ROAD, STREETLY, SUTTON COLDFIELD, WEST MIDLANDS B74 3EN. Telephone: 021·3536288 (3 Lines)

Published by the Association for Petroleum and Explosives Administration

Contents

Opinions expressed in Journal are not necessarily the views of the Association

Talking Point

Notes & News

Correspondence Book Review

Major Installations

Use of Hi-Ex Foam in Demolition of Tanks Taking the Plunge London News Proceedings

33 34 36 38 39 50 64 66 67 Cautionary Tale 68

Humberside Annual Report 69 Branch Reports 70 Orbituary 72

Honorary Secretary

Mr. E. Brown

Cambridgeshire County Council

Talking Point Recrui tment Campaign

The Association is having a recruitment drive for new members of the Association. An application form is enclosed with each copy of The Bulletin. It is hoped that each member will get at least one new member or associate to join. A colleage at your office or perhaps an Oil company engineer, contractor or anyone connected in the Petroleum or Explo$ives field. Forms to be returned to the Secretary Eric Brown who will also be pleased to send you more forms on request.

Honorary Editor

Mr. J.A.J. Thompson,

The VOLUME 18 Bulletin Number 2 December

33

MI CABLE TERMINATIONS

·BSI has now published BS. 6081 Termination for mineral insulated cables. This is a metric revision of the earlier specification (BS 4081 Part 1) which, with the decline in the use of imperial units, is being withdrawn.

The new standard contains construction and test requirements for seals and glands suitable'for the copper and aluminium sheathed mineral insulated cables specified inBS 6207 'Parts 1 and 2, and incorporates special requirements'where such equipment is to operate in potentially explosive atmospheres'. Dimensions are specified only where necessary to ensure interchange ability of complete terminations. The specificati'on also includes sever'al performance test's tha't· are intended to allow for development of new designs while maintaining a satisfactory standard in service.

There is at present no equivalent international standard.

Code of practice for sprinkler systems

BSI's code of practice for fire fighting installations, CP 402, has been revised, extended in scope and republished as BS 5306 Code of practice for fire extinguishing installations and equipment on premises. Part 1, dealing wi th hydrant systems has already appeared, and the latest to be published is Part 2 Sprinkler systems.

Sprinkler systems are designed to provide automatic means of detecting and extinguishing or controlling a fire by water in its early stages by an installation of overhead pipes on to which sprinkler heads are fitted at intervals.

Each heap, is, in effect. a heat operated valve designed to open at a predetermined temperature and to discharge water under pressure from the installation. Water emerging is directed into a specific pattern by a deflector incorporated in the head, and the flow of water from the installation also causes an alarm to sound.

The pipework incorporating the sprinkler heads may be arranged in a number of different sprinkler installations according to the requirements of the building being protected. Each installation is separately controlled and may be designed according to different systems.

Provided the equipment is designed, installed and maintained according to good practice a sprinkler installation ensures that a well directed and ample amount of water is automatically applied to the fire whilst it is still comparatively small. As only the sprinkler head or heads in the immediate vicinity of the fire open, water damage during the extinguishing of the fire is reduced to the minimum whilst the remainder of the building remains fully protected. Moreover, the installation operates automatically, it is not impaired by smoke or fumes, and it is not hindered by blockage of access routes.

Part 2 supersedes CP 402: 201 and embodies a number of changes. The opportunity has been taken to coordinate the information in it with the Fire Ofjicers' Committee's Rules for automatic sprinkler installations (29th Edition) and reference to the relevant sections of those rules are included. Terminology and definitions have been aligned with the internationally agreed terms in BS 442. New sections have been added dealing with action to be taken following a fire and when an installation is to be rendered inoperative. A new appendix deals with pipe supports. Visi t to Bacton

24 members of the Eastern Branch of the AsSOCiation went on tour of the .North Sea Gas Terminal at Bacton on July 3rd this year.

In the morning Shell UK Oil were the hosts and Mike Fletcher their safety Officer gave an admirable talk which was both interesting and informative The British Gas Council took over in the afternoon with a tour of their plant and control room.

All members enjoyed a very good day out and a special thanks Shell for the sumptuous lunch.

Notes and News

34

REGULATIONS

Explosives exemptions

The Commission have approved the subm1ssion of proposals for Explosives Act 1875 (Exemptions) Regulations to the Secretary of State. These regulations are intended to permit some degree of flexbility in implementing the requirements of the Explosives Act 1875 which, as it stands, makes no provision for exemptions.

Any exemption considered under these proposed regulations would be carefully scrutinised. It is proposed that exemptions would only be granted if the Executive was satisfied that in the circumstances of the particular case (having regard to any special conditions attached to the exemption and any requirements imposed by relevant legislation) the granting of an exemption will not prejudice either the health and safety of persons affected, or the security of any explosives involved.

If these draft regulations are signed by the Secretary of State, administrative measures will be designed to ensure adequate consultation, regarding individual exemptions, with local authorities and with management and workers' representatives.

Freight containers for explosives

The Commission have endorsed the referral to the Advisory Committee on Dangerous Substances of proposals for new regulations and a code" of practice to permit the more general use of freight containers for the conveyance of explosives by road, rail and/ or sea transport. The Advisory Committee has been asked to agree to a Working Party being set up to formulate the conditions under which explosives might safely be conveyed in freight containers.

Mine regulations

The Commission have agreed that the proposed t' 1979 Rufford Mine (No. 1 Shaft) Regula 10ns should be formally submitted to the Secretaries of State for Employment and Energy.

" " agreed that In November 1977 the Comm1sS 10n 1 gulations of HSE should produce genera re dividual mining topics to reduce the need f?r mines. sets of local regulations for part1cu

Premises: motor vehicle repair

The Commission have submitted to the Secretary of State a proposed amendment of the Health and Safety (Enforcing Authority) Regulations 1977 in respect of motor vehicle repairs establishmen ts.

The Enforcing Authority Regulations, which allocated enforcement responsibility to local authorities for premises where the main activity was scheduled in the Regulations, did not make clear the Commission's intention that motor vehicle repair establishment should be inspected by the Health and Safety Executive. The short regulation proposed is to make the necessary amendment.

POETIC LICENCE?

Out of the back of a garage at Barton, it is known as the 603 There came the sounds of music, and singing all of a glee With shutters up and one big heave, a car rolled in with ease d And muscles still taut and jack in han , he thrust it under her eaves d " " I" fted her up, an W1th one b1g heave he 1 "d " d tw1ste . she stood there all b1tter an "d go He turned around to the shutter d1 , when he heard a thunderous roar 1 1 for the With eyes agog he ran like he , flames were all over the floor The jack had slipped and she did drop, to the floor with a right old bang " ht A spark did ignite the petrol alr1g , the conditions were perfect you see He did not know this cheerful fellow, that the tank had a hole in i ts " 1n So think for a while before steep1ng style to the music and singing in glee t For kind of fate can lay you in sta e, and the funeral will be yours indeed And the funeral will be yours

IT CAN NEVER HAPPEN TO ME" ANON

PROPOSED

35

The Publication of these two letters which will be of interest to members appeared in Monthly Review and are reproduced here by permission of the Editor.

Mr. R.W. Kay Health and Safety Executive Hazardous Substances Division

Mr. R.W. Kay Health and Safety Executive Hazardous Substances Division

CAR PARKS

The South Eastern Licensing Co-ordinating Group comprises representatives of Local Authorities and other organisations concerned with the administration of the Petroleum Acts in the South East.

A recent survey amongst the local authority members into their attitude towards licensing the keeping of petroleum spirit in the fuel tanks of vehicles in car parks reveals a wide variety of approaches to the subject; no two authorities apply the same standards. Some authorities do not believe that they have the powers to license car parks at all, some accept that they have the powers but licence only specific parks such as basement or multi-storey car parks whilst others license all except the purely open air car parks. One authority, as a result of the 1974 Local Government Reorganisation licenses car parks in one pre-1974 district but not in two others. It seems highly probable that this pattern of anomolies is repeated throughout the country. In fact, it was a complaint by a national car park management firm about differing standards on the provision of fire-fighting equipment that prompted the survey.

The Group believes that it is now time to consider the possibility of a common approach among its members to the subject of car park licensing. Before we can begin to consider such a possibility, however, there are a few points upon which your advice and guidance is requested.

The first and most vi tal question is liDo Local Authorities have powers under the

Petroleum (Consolidation) Act, 1928 to license the keeping of petroleum spirit in the fuel tankS of vehicles in car parks?" No. 6 of the Petroleum Spirit (Motor Vehicles etc.,) Regulations, 1929, by implication, suggests that the answer to 'this question is "Yes", but do you have an opinion based on more positive evidence?

Assuming you believe that car parks can be licensed under the 1928 Act, have you any recommendations on the standards, both structural and which should be imposed? Are there any records which show that car parks provide particular, abnormal fire risks?

Apart from the more long term aspect of providing a basis upon which to work to produce a common policy, your advice will be most welcome to that local authority which has to decide whether to license car parks in all areas or to discontinue licensing in the one area currently controlled by licence.

Finally, have you any proposals in hand to give national guidance on the licensing of car parks?

Yours Sincerely, Keith Blackbourn Secretary

SELCOG

Mr. K. Blackbourn Secretary South Eastern Licensing Co-ordinating Group

Dear Mr Blackbourn, CAR PARKS

1. I refer to your letter of 15th May about the problems connected with the licensing of car parks the provisions of the Petroleum (Consolidation) Act, 1928 which have been drawn to the attention of SELCOG.

2. The basic question of local authority powers to license the keeping of petroleum spirit in the tanks of vehicles in car parks has never been determined by a Court of Law. Whilst we hold views based on a legal opinion I regret that they cannot be considered as authoritative; nor, I'm afraid, are they likely to lead to uniform standards of fire fighting equipment.

CORRESPONDENCE

Dear Mr Kay,

36

3. It is on the interpretation o£ the Petroleum Spirit (Motor Vehicles etc). Regulations, 1929 that the opinion is based and it relies on a distinction between the ordinary meaning o£ the words "kept" 2.Ild "used" as applied in 1929. Brie£ly, 1-"0 advice we have received is, (a) Petroleum spirit in a £uel tank o£ a vehicle mayor may not be kept there, within the meaning o£ the Regulations, depending on the circumstances.

(b) 1£ it is what one would call ordinary "use" then that is not "kept". (c) Purpose is the determining £actor and in practice this will in the main be deduced £rom length o£ time and use or lack o£ it.

1£ this opinion is £ollowed, then a car park in normal use does not require to be licensed.

4. As you may know, the Home O££ice issued in 1957 a Model Code o£ Principles o£ Construction and Licensing Conditions £or garage buildings. When the Health and Sa£ety Executive took over responsibilities £or the 1928 Act, a revision o£ the Code was well under way but it has not been completed, partly because o£ the legal situation. Strong reservations have also been expressed by the Department o£ the Environment who are anxious to control structural reqUirements under the more £lexible standards o£ Building Regulations a principle with which we agree. Where car parks are to be licensed, operational requirements will need to be related to individual circumstances.

5. We do not have it in mind to provide national guidance on these questions although we shall have regard to the di££iculties you mention in the course o£ the review o£ legislation relating to highly £lammable liquids which is now being undertaken on the instructions o£ the Health and Sa£ety Commission.

6. DOE have proposed that eg multi-storey car parks, should £all within a sub-division o£ Purpose Group VIII o£ the Building Regulations which cater £or low risk and low fire load oCCupancies. We have no evidence to suggest that this is not appropriate, but we would say that the definition o£ a car park should t· 1 d ·ld· no lnc u e bUl lngs containing petrol d. . . . lspenslng facll1tles or other Similar t t s ruc ures.

Sincerely R.W. Kay

Dear Sir

As you know, there have been Regulations of Conveyance by Road of Petroleum Spirit £or many years. Those current for the. time being are the 1957 regulations.

They contain one paragraph (among others!) which states that the general design of any Tank Wagon over 1,500 gallon capacity must be approved by a Government Inspector Schedule 1, para. 6 (1) (b).

This sounds £ine but since the HSE took over, the 'approved design' in many instances do not comply with the Regulations!

This makes the task o£ the Local Authority Petroleum Inspector who has to en£orce these regulations slightly more di££icult.

So in order to assist him, the HSE issued 'Advice for Local Authority O££icers concerned with the Conveyance by Road o£ Hazardous Substances.'

Most o£ this so called Guidance was incorrect, wrong in Law, mistaken in elementary chemistry and showed lack o£ understanding o£ the principles of electrical sa£ety.

In the Guide, the HSE admitted that they approved vehicle design which contravened the Regulations.

wrote a le tter criticising this At the time I "Guide". The HSE objected to "its tone and contents,' but failed to reply although invited to do so.

ealised that some However the HSE probably r k ' I pectors new Local Authority Petroleum ns d.d and hence more about the work than they 1 th the LA's have been excluded from e the new Tanker Labelling enforcement of dra£t regula- Regulations and from the new tions for conveyance.

It is becoming apparent, that experience in the practical application of sa£ety tions is a positive disadvantage! regula-

No doubt the HSE who will enforce Regulations when road will also be they are right.

consider that the police the new the vehicle is on the less critical. May be

C.L. DAVIDS, F.I. Fire E., A.M.F.P.A., M.A.P.E.A.

37

Yours

Dear Sir,

At a recent meeting of the Yorkshire and Humberside Branch of the Association, discussions took place on the pressure testing of existing underground petroleum storage tanks by outside contractors.

It was stated that a number of local authorities had adopted the practice of issuing to licencses, whose existing petroleum storage tanks were due for testing for soundness, blank certificates to be completed by petroleum engineers/ fitters, stipulating the details of the site, the pressure at the beginning and the end of the test and as to whether or not the tank was sound. The certificate to be signed by the engineer and returned by the licensee to the local authority.

In these days of financial cuts and staff reductions one can see the reasons for this practice being adopted. However is this not passing the responsibility of a most important and fundamental requirement to persons who may be proficient in their particular field but no not have the long term safety commitment to the licensee or the local authority, and who look to the local authority to accept their responsibilities.

I appreci ate that this work may be likened to that carried out by electrical contractors when issuing electrical certificates, but surely ensuring the soundness of a tank is one of the basic fundamental requirements prior to the issue of a license and the expertise for which is already available in local authorities.

Adoption of this system raises a couple of questions:-

1. Who accepts the responsibility when a tank which had received "a clean bill of health" from a contractor shortly afterwards becomes the subject of a major incident?

2. Will this lead to certificates being issued by contractors for work carried out on new installations and at what point is the line drawn?

I appreciate we are going through difficult times, but we can ill afford to sacrifice high safety standards, expertise and a

commitment to duty, therefore through the Bulletin I would appreciate any comments on this practice from interested parties.

Yours faithfully R.G. Kitching

BOOK REVIEW by Bookworm

Continuing a consideration of past publications which may have been missed on the fi rs t time aroun d.

ELECTRICAL SAFETY ENGINEERING

Although only three of the thirteen chapters could be said to be directly applicable to the petroleum officer, it is a book which I must recommend.

The author W. Fordham Cooper was until 1963, H.M. Electrical Inspector of Factories and as such he draws from a wealth of personal experience in his subject.

Chapters 10, 11 and 12 are the most pertinant from our viewpoint, dealing with fire and explosion hazards, electrical equipment for danger areas and particular fire hazards respectively. But the rest of the book should not be disregarded. Cooper deals variously with control of staff, accident reporting and mechanical causes of electrical failure in addition to a great amount of detail on design and control of equipment and circuits. A chapter dealing with statistical studies of safety factors and accidents is also included and is very comprehensive. Although it must certainly be described as an eminently, scholarly text book, it is most readable and benefits greatly from the frequent examples which are given to illustrate the pOints.

The book was published in 1978 by Butterworth and Co. (Publishers) Limited of 88, Kingsway, London, WC2 and costs £15 net.

CHEMISTRY OF HAZARDOUS MATERIALS

In this book, published in 1977 by Prentice Hall, the author Eugene Meyer sets out to prepare the fire fighter with details of the hazards associated with a wide range of materials. His stated intention is to do

so at a level which is neither too elementary nor too specialised. I think he succeeds in this aim.

The book is exceedingly well laid out with photographs and graphics giving form and substance to the chemical reactions described. Numerous self assessment questions are included to enable you to gauge your understanding of the concepts presented.

38

SOME ASPECTS OF THE LICENSING OF MAJOR INSTALLATIONS & DISTRIBUTING DEPOTS

T Kane, Assistant Head, & Safety, Strathclyde Regional Council

In considering an application for a licence to store petroleum spirit, the petroleum officer must approach it from three angles, 1. Safety of the proposed location, taking into account adjoining property. 2. Safety of the personnel to be employed on the site. 3. Protection of third parties from environmental pollution, as well as their safety. No matter what the size or type of the installation, a can and drum store; a filling station; a distribution depot; or a major installation, each must be conSidered with these points foremost in the officer's mind. Each case must be considered on its merits so that it becomes obvious that no set of Regulations cJUld cover the wide variety of installations which are proposed. This is not to say, however, that no guidance is available or that guidance should not be available, and so the need for a Code of Practice becomes self-evident. 1968 saw a revised edition of a previous Model Code of Principles of Construction and LicenSing Conditions issued by the Home Office, in two parts, referring to storage in cans and drums stores and filling stations in Part I and to distributing depots and major installations in Part 11. My main concern in this paper is with Part 11 of this Model Code and is an attempt to highlight some of the main problems in the licenSing of distributing depots and major installations which the petroleum officer will meet. Accepting the indication in the Code that distributing depots may store up to 5,000 tons,and that storage facilities for quantities in excess of this amount should be regarded as major installations, two sets of principles of construction are provided and one set of licensing conditions which, it is suggested, will be suitable for either type of installation. The principles of construction are broadly similar and indeed identical in certain sections, and it is probably within these varying sections where the problems will arise even though these sections do tend to be more specific in their requirements. The areaS where variation in the principles are indicated are confined to that of fire-fighting and the disp "t" and types of tanks to be installed. Much d;ff" lt "" h the y and trouble can be avoided lf the appllcants approac petroleum offi t th formulation of their ideas, cer a the very earliest stage in e and certainly before th At a preliminary discussion the e submission of plans. applicant can be advised what the local authority will be looking "for in the construction and why it will be looking for this. A bold statement of requirements can be met with some reSistance but if it is accompanied by the , reasoning behind the requirement it becomes readily acceptable in most cases. Economic and other factors can be highlighted by the applicant and taken into conSideration with regard to safety by the officer, since these are facts of

39

life. The fact that a road tank-wagon driver will insist upon recognition b,y the employer that he can be asked to handle only one twenty foot length of hose when making a delivery and that if he is called upon to handle more than one such length at an'installation, then he must have a mate to assist him, can be a oonsiderable factor in deciding where tanks are to be sited in an installation.

Having tuned into each other's wavelength, a joint visit'to the proposed site will be the next step, to be joined by the Fire Prevention officer and possibly Planning and Building Control officers. The suitability or otherwise of the location becomes more readily identified in this way and the safety of the installation taking into account the surrounding property can be decided upon. At this stage Fire Prevention will be concerned with establishing that there will be adequate water supplies and suitable access facilities to the site. The petroleum officer will be looking for a location which will provide the installation with adequate facilities to receive the product and to despatch it; as well as to store it in an area which will not present a hazard to the populace; nor in such a manner that pollution will affect third parties. It is not really desirable that a distributing depot should be sited in inner cities or congested residential areas from the point of view of public safety, but to site it in a remote rural spot is probably not ideal either when one takes into account possible oppOSition from conservationists and perhaps additional economic problems which would result. On the other hand perhaps mounding of the storage tanks might enable one to approve such a situation within a city area which could be safe.

Depending upon the access facilities required at the proposed installation, the possible choices for siting may be very limited. Giant ocean tankers need adequate harbour or jetty facilities to deliver the crude oil or refined product to a terminal. The terminal need to despatch its products by pipeline only in which case one may be able to isolate the site with the minimum of inconvenience. However if rail and/or road facilities are required for the despatch immediately there arises the problem whether these facilities will be available ln a isolated part.

Having agreed on a suitable Site, consideration must next be given to the layout having regard to the means of escape for the employees and occupiers of adjoining property in the event of fire. This again calls for the advice of the Fire Prevention officer with regard to a) the disposition of fire fighting equipment and materials for the initial stages of the fire-fighting operation until the local fire brigade appears on the scene b) ensuring that the roads within the depots are adequate to allow access for fire-fighting purposes

40

0) the best use of natural supplies of water from rivers and oanals rivers do dry up in summer d) determining whether or not a semi or fully automatic foam system will be necessary e) systems to be employed for cooling tanks f) coupling and fire-fighting equipment to be used The Model Code was framed bearing in mind.public safety, and is concerned with the prevention of fire and the means of preventing fire from spreading. Thus the recommendation that in the case of floating roof tanks, the nearest point on the fire wall should not be further than 100 ft from the tank shell, was made to ensure that cooling water could be applied to the tank shell from the fire wall. If the floating roof of a large tank were to sink during a fire, then there is no option but to allow the fire in the tank to continue because the demand for water, foam compound etc would be so great. What would require to be done initially would be to cool the tank to contain the product and to provide water curtains to protect the adjacent tanks. An incident has been recorded where a fire started in a tank farm involving four large tanks of crude oil. The tanks were fitted with a semi-automatic foam system and water WaS wasted in producing foam which was applied inside the tank shell whereas the fire situation was in the bund area. Situations like that can produce a good argument against automatic fixed systems. With the advent of the floating roof tank which means there is no vapour space above the liquid provided there is immediate dissipation of static charges by earthing of the roof of the tank to the shell, this type of tank is a safer proposition. Before this practice of bonding the roof to the shell there were incidents of fires at the seals, but these could be extinguished without difficulty, us.ing portable appliances. With improved bonding and the virtual elimination of seal fires, there is not the same justification for fixed fire-fighting installations on floating roof tanks. However another factor which affects the fire-fighting requirements is that of manpower. Since the site may be relatively remote from the local authority's fire station, it is imperative that the oil company's employees must be able to contain the incident until the fire brigade appears on the scene. To do this there must be the necessary facilities on the site and the necessary manpower to operate it. Modern installations of greater storage capacities tend to go in for greater d th anpower automation which in turn invariably re uces e m' reqUired. The minimum number to operate the site on any one shift may not be known or adVised to the licensing authority at the initial discussions and can be lost Sight of in the subsequent development. It shJuld be established early on what manpower will be available at all stages as the installation comes into use, and the level should be such that it can operate the appropriate equipment at all these stages in a competent manner. Some of this equipment will be fixed, Bome mobile, Bome semi or fully automatic and all the fire h0se coup-

41

lings should be interchangeable with those of the fire brigade as well as with those in any other large depot or installation within the area. When agreed upon it will be necessary to ensure through a stipulated drill that fire-fighting teams have frequent practices and that the equipment is tested at regular intervals. Records of personnel who take part in the exercises and the details of the exeroises should be retained for production. This kind of stricture oan be inoluded in the conditions of licence. The co-operation of the Firemaster should be sought so that the local fire brigade could also take part in similar exeroises and become familiar with the layout of the installation. To sum up on the fire fighting aspect, it is the aim in the event of a major spillage involving fire to prevent the fire from reaching adjoining tanks. Permanent water jets can cool the tanks and provide protection from fire at an adjacent tank by means of a curtain of water. Removal of the crude oil or refined spirit from the affected tank and the enclosed area should follow and finally effor.ts to extinguish the fire itself, using foam, should be made. The sitting and. spacing tanks can often be an area of difficulty. Pumphouses, filling points, tank openings, can filling rooms etc should be sited not less than 50 feet from the boundary fence or wall and a reduction in this distance might be acceptable but should never be less than 20 feet. With the present day tendency to vandalism, good reason must be given to justify the reduction of this distance. Such spots should be as far from the boundary as is reasonable. In the distributing depot storage tanks will be of the horizontal cylindrical type or small vertical tanks. No distances for the spacing of vertical tanks up to 30 feet in diameter and not exceeding 45 feet in height in distribution depots are indicated, and the points which govern the deciSions on this aspect are constructional and maintenance purposes. When tanks exceed these dimensions then the spacing distances indicated in the section prescribing for major installations apply, as they would if a distributing depot were to instal new tankage which would increase the total of petroleum spirit stored there to above 5,000 tons. The layout of tanks should be decided upon on the basis pf accessibility for fire-fighting and the avoidance of SPillage. from one tank flowing towards another tank. In major installations the problem which is more likely to arise will be "Is the 50 ft distance between the tank and the boundary enough?" The surroundings of the installation may call for an increase in such a distance. Groups of small tanks of diameter not exceeding 30 ft can be regarded as one tank if not more than 8,000 water tons is stored in the group. Minimum distances are then specified in the Code for groups of small tanks, fixed roof tanks and floating roof tanks. The distances in the case of floating roof tanks are less because of their better safety record when compared with fixed roof tanks. Where a floating roof tank and a fixed roof tank are adjacent, the distance between the two is calculated upon the basis of the recommendation between fixed roof tanks. Modern steels are such and welding techniques have developed so that very large tanks present no great problems in oonstructton and in ocean terminals storage

42

tanks of diameter 250 ft and 12 ft high have been installed, which are capable of storing crude oils. The Code indicates that for tanks exceeding 60 ft in height consideration should be given to the distances listed, being inoreased in a reasonable ratio proportionate to the height of the tank. Bunding provides the next major p:.r.'oblem area and the Model Code contributes to this b.Y not using the word at all, but calling for a fire wall. This fire wall is then detailed with reference to spillages due to overflow or a major leak being directed to safe areas; to ensure retention of the net capacity of the largest tank in a group; to withstand the pressure to which it would be subjected if the exposed area were filled with water. In relation to fire-fighting it is designed to provide protection for personnel at agreed locations to be of a height measured from outside ground sufficient to protect personnel who are and to be at such a distance that cooling water can be played from the wall onto the tank shell. Again cognisance of the type of tank is made when the capacity of a group of tanks in one main enclosure is limited to 60,000 water tons if of the fixed roof type and 120,000 if of the floating roof This latter figure be increased in some circumstances with large floating roof tanks but the number of such tanks should not exceed three. The exposed area of an intermediate enclosure or a main eclosure should not exceed 100,000 sq ft. Finally the Code indicates that·the enclosure should have proviSion for adequate drainage for the removal of water and such water and water from any area where there may be contamination from hydrocarbons must pass through a petroleum interceptor before enterlng any public drain or water course. The Home Office Circular 182/1968 indicated that at the time of the issue of the Model Code, that a bund would not act as a petrol retaining basin in the event of a major Spillage "since petroleum spirit will inevitably seep through the bund floor even if provided with a concrete base". However Circular 30/ 1974 issued at the time of local government reorganisation in England and Wales implies that a bund if constructed of liquid-proof membrane, or with walls reaching down to (or below) the water table, is capable of retaining liquid spillages. In these days the prevention of seepage becomes more than ever important since the safety of the populace at large can soon become a fruitful area for the media and the least hint that an installation would not be capable of preventing seepage would soon raise alarm in the local population, conservation societies etc. The attitude of the oil companies is a little difficult to understand in this area. They appear to want to try any means other than provide the minimum when it comes to bunding. It seems to me that the provision of a concrete base of reasonable thiCkness, even though it may not be completely capable of retaining the spillage will in fact retain it for a sufficiently long d' t per10 of time so as to at least. This ought to be the leas minimise seepage that is requir d l"d f membranes e. I am not aware of the quality of the 1qu1 =proo to the c.ircular may be referring, but if they are capable of doing the job effect1vely then the applicant should be persuaded by all means to use them.

43

This may mean a long fight and one carried on through the upper echelons of the oil company concerned, but with the weight of public opinion against them in the event of the having to be resolved in public be it the local council or an appeal to the Health and Safety Executive the scales should be weighed in favour of the licensing authority, and an appeal become unnecessary. Where the"water table is such that a wall can reach down to or below it, then this seems a perfectly reasonable method of protection, but one with which I am not familiar.

Tanks should be constructed to the appropriate British Standard, which in the case of the horizontal, cylindrical type is BS 2594: 197- and in the case of the vertioal type of tank, is BS 2654: 1973. Since in the latter case the tank will be constructed on site and the appropriate Standard is a very technical and complicated document for the average petroleum officer to follow, one has to rely upon the applicants to employ contractors and engineers who are men of integrit,y and can be relied upon to do an honest job. This highlights the main weakness of licensing in the hands of the local authorities. To be a complete petroleum officer, he would have to have adequate knowledge and expertise among other things of building constructionj tank construction; electrical installation; drainage requirements. No authority to my knowledge has such a person on its staff and none trains .its officers in all these areas. Basically petroleum officers pick up a certain amount of knowledge as_they carry out the job and they can pick the brains of the architects, builders, engineers, fitters, and BM Inspectors at the Health and Safety Executive with whom they come in contact. This being so if in doubt in any sphere one can try to enlist the appropriate experts within one's local authority departments such as architect and related services; building control etc with varying degrees of success in my own case, I must admit. Having touched on the constructional problems which may arise, attention must now be turned to the operational side and in this sphere there is no doubt that the majority of hazards will arise. Where an installation is fed by ocean going tankers normally the harbour authority should have bye-laws governing the places and at which and the manner in which ships should moor for loading and unloading petroleum spirit and detailing the precautions to be observed with such ships. I believe that at one time there was a Home Office Working Party drafting a Code of Practice for loading and unlOading petroleum spirit in harbours but I do not think that anything was finalised. It is an areas which the Health and Safety Executive are investigating at present, but once again the officer has to fall back on his own experience and commonsense in advocating the measures which he deems necessary to prevent spillage. There is also an International Oil Tanker and Terminal Safety Guide published. Check-list systems for shore and ship personnel are commonly used by the major oil companies and by itemizing particular points tend to avoid nverlooking an important item. Thus there oan be automatic checking for naked lights; galley requirements;

44

the eleotrioal and radio requirements; closure of doors, ports etc which need to be olo8ed; oondition of hoses and their proper rigging; proper positioning of valve8; tanks properly venting; fire fighting equipment ready for use; emergency towing wires in position. The provision of movable booms confines escaping oil but tidal conditions not be favourable for their use. However containment is preferable to dispersal into unknown areas where there are no restrictions on ignition. During loading and unloading operations there should be responsible persons on duty aboard ship and ashore; at control valves at both locations; adequate crew to contend with emergencies; telephone or radio communication between the berth and pumphouse must be in good working order; all signals should be clearly understood at the change over of shift. There should be emergency procedures to stop the flow of oil in the event of the failure of a manifold or a hose. Transport b,y rail is governed by British Rail conditions. British Rail provide the locomotives and the oil companies the rail-tank-cars and the loading and unloading facilities including fire prevention requirements. Locomotives should stop a safe distance from the nearest loading point diesel driven and fitted with flameproof electrical equipment and a flame/spark arrester on the exhaust. A responsible person should be in control of the rail tank: cars entering the siding. Points should be locked in the "off" POSition to prevent other trains entering the siding and warning signals POSitioned at either end of the train _ flameproof or intrinSically safe red lights at night. After removal of the locomotive the rail tank cars should be prevented from accidental movement. Overfilling of road tank wagons is the most likely hazard in a distributing depot, more so than overfilling storage tanks. Filling is done through preset metres in open-sided sheds at higher level gantries, so that vapour build up should not be a hazard. However failure to set the meter correctly, or to empty the compartment completely at its previous discharge could cause an overspill. Top loading tanks and loading racks can be fitted with high level cut outs, and safet,y can be improved by making it impossible to begin delivery until the loading arm is correctly positioned in the tank. To reduce the possibility of electrostatic discharge initial slow filling of the tank until the bottom of the fill arm is covered, is restricted to 3 ft/second and thereafter increased. It would appear that bottom loading is a safer method. Vapour emission would be nullified; Splashing minimized. and because high level cut-outs are essential to th" ' bl involved 1S system, overfill should not occur. The cost and trou e in convert" " " "11 t "11 be some Lng eX1sting top-loading systems may mean that 1t W1 s 1 time before bottom loading is common in this country, but agitation to persuade the oil compan" " N d bt automation 1es of 1tS desirability should do no harm. 0 ou will help to " " t 1mprove the safety of the present top 10ad1ng sys em. Fail safe devices and high level alarms strangely enough seem to present a problem in some major installations. I say "strangely enough" since one would

45

imagine that the major oil companies would be only too anxious to prevent overfill and almost certain loss of product in no small quantites, when one considers the pumping rates at product is loaded into storage tanks. A loss from a water fed terminal of 40,000 gallons of refined product waS reported. Investigation showed that the product had been unloading from an ocean going tanker for some hours and the routine checks of the levels in the tank were being recorded. However it failed to register with the checker that there waS a variation in the quantity unloaded for specific periods of time. Later investigation ·showed that the supply line to the tank had been obstructed by a piece of pigging sphere and pressure had been built up. When the pressure dislodged the blockage, the surge of product in the tank set up a wave action in the tank and caused the gauge to fail. Excess product built up in the tank rupturing the roof seam and causing over-spill. Total spillage was contained in the bunded area and there was no evidence of leakage. Since Customs and Excise granted an exemption certificate for this quantity one must accept the figure. There was no high level alarm system fitted in this installation and the method of checking was to carry out a visual check of the above ground tank at set times during unloading from the ship, recording the time and the quantity registered. In the event of anything having to be reported to the control room, the checker had to run to the nearest telephone point and obtain contact in that manner. This method of checking certainly allowed many loopholes. What would happen in the event of the checker collapsing or suffering a heart attack? How long would pass before the control room was aware of this and how much could overspill in that space of time? Even though the checker had discovered something waS amiSS, the time required to reach the telephone would mean the escape of a considerable quantity of product. Two way radio would be a more rapid means of oommunication. In 1973 there was published a draft of "Advice on Means of Preventing Major Spillages of Petroleum Spirit" by the Home Office. There it was advocated that at new water-fed installations each storage tank should be fitted with a high level alarm and also at existing water-fed installations all underground storage tanks, including those fed by an above-ground service tank, should be fitted with high level alarms. When it comes to aboveground storage in existing installations the indication was that alarms need not be fitted if they were surrounded with bunds capable of preventing any spillage of product from entering any watercourse and that a condition of licence would be included to call for constant monitoring during filling operations. I take the view that the high level alarm and automatic cut off should be called for in all water fed installations as being the safest method of preventing overspillo I regret to say that in the terminal referred to above, my predecessor prior to reorganisation did not manage to persuade the operator that such a system would be infinitely to their existing one, and the only improvement he obtained was in the proviSion of radio facilities to replace the telephones 0

46

High level alarms were recommended in the Home Office document for underground tanks at rail fed installations, new and existing, and for above-ground tanks at new and existing installations where the tanks are not clearly visible from the siding. Where latter condition does.not exist the document indicated that if high level alarms were not fitted then a fire wall surrounding the tank and constant monitoring during filling operations and the maiDtenance of suitable records should be called for by the local authority. At such an installation where cyclohexane was stored in two above ground tanks, the rail Siding was sufficiently remote from the tanks that a fire wall was provided and monitoring carried out at set intervals. On one night during the filling operation, the appropriate drill had not·been carried out to enaure that the appropriate valves were in their correct position and consequently one tank overfilled and spillage occured into the bunded area. The appropriate drill was carried out so that the effects of the spillage were minimal and no one was injured. However the time taken by the checker to reach the nearest telephone when he discovered the overspill contributed to the loss of product. The firm have now agreed to the installation of high level alarms and automatic cut off devices. No doubt the major hazard at Flixborough shortly before this occurence helped them to make this decision! Other recommendations in this document related to road fed installations which did not involve high level alarms but called for the equivalent procedure of Regulation 16 of the Petroleum Spirit (Conveyance by Road) Regulations 1957 if the storage tank did not exceed 22,000 gallons and proper supervision during operations if the tanks exceeded this capacity; semi-buried mounded tanks or automatic loading bays required further advice from BM Inspector of ExplOSives; and so far as the document referred to refineries it would be a matter for negotiation between the licensee and the local authority how far its recommendations should be implemented. Why this document never progressed beyong the drafting stage again I do not know, but it seemB to me that if the local authority is not to insist upon its recommendations then the licensee must do his homework and justify why it is not necessary for him to comply with such recommendations and still have a satisfactory system which would prevent major SPillages. Finally the document specifically referred to the isolation of storage tanks; non-return valves; automatic cut off devices; level alarms; and fail safe types used in all installations. Where devices are not of the latter type, monthly testing of the device should be called for, to enSUre that·t· . 1 is 1n good operat1ng order. The remainder of the Model Code is normally non-controversial and there are accepted practices which meet the requirements called for. Pumps should be Sited in the open air and pumphouses ventilated at high and low levels, resort to mechanical ventilation being called for if installed below ground level. For filling sheds and can and drum stores, ventilation must be efficient and the means of escape for those employed in them should be looked at closely, in

47

particular the positioning of the fire exits. Prevention of outflow of petroleum spirit can be effected from these stores by means of a 6 inch sill across the door. The minimum exposure of petroleum spirit is the most effective prevention to the build up of explosive limits and must be aimed at at all times. The Institute of Petroleum "Electrical Safety Code 1965" is the yardstick to be used in determining what electrical apparatus is to be installed and in what manner. Earthing, bonding, telecommunications and are also covered b,y this Code. Annual inspection by a competent person of the electrical equipment must be carried out before the renewal of the licence. I should like to see regular inspection at set intervals of all storage tanks incorporated in the conditions of licence. This condition is imposed in filling stations licenced by my local authority with rega.rd to underground storage tanks at intervals of 20, 25 and 30 years and thereafter at every second year. The test in those Oases is a pressure test. Even though the above ground tank can be visually inspected with ease, nevertheless being subject to wind and weather, this must have some effect upon the construction and after the passage of time regular checks would appear to be desirable. This is an area, however, which I have not examined in depth and no such condition has yet been imposed in our licences. The of the Model Code devoted to Conditions of Licence is an adequate base upon which to build. Those conditions which are relative to particular installations eg details of fire fighting equipment; drills to be followed for fire fighting; monitoring of loading or unloading operations etc can be applied specifically. Because of publio awareness of the hazards which are associated with such installations, it behoves the petroleum inspector to approach each new proposed installation very warily, and to call upon the assistance of all local authority departments involved in such projects, together with that offered by the Health and Safety Executive, to assess all the possible difficulties and problems which may arise. Having thus identified them, and discussed with the applicants the most effective ways to avoid them arising, then the installation will in all probability be a safe one from the word "go". This is not the end of the matter, though. It is that once an installation has been completed and goes into operation, the petroleum inspector must be a regular visitor and become ver,y well acquainted with the management, so that the ongoing exercise is a familiar one to both licensee and licensing officer. Licensing by remote control is not, to my mind, effective control. Licensing of such installations as the Flixboroughs, Grangemouths and Sullon Voes of this world cannot be administered from London or Edinburgh. A man on the spot is needed at all times o I welcome the recent move by the Health and Safety Executive to appoint regional liaison officers throughout the country. The licensing authorities will now have readily available consultative procedure nearer at hand to keep

48

their officers abreast with the developing techniques and thoughts on the problems involved in the licensing of distributing depots and major installations whioh will result in safer installations both for life and property. Problems will arise in licensing and be overcome and other problems will no doubt take their place, but BO long aB the petroleum officer involves himself and is prepared to listen to all facets of the problem, then he is the greater part of the way to ensuring that the installation is a safe one. That is the aim of the exerci se.

251i=t

'BUr-JD WALL

f.+t'T2..At2..D Por NT

*

ZONE... [A-QEA49

This paper is produced by kind permission of the Building Research Establishment with acknowledgement to the Journal of Hazardous Materials who first published the paper.

PROTECTION OF LARGE FLAMMABLE STORAGE TANKS DURING REPAIR BY MEANS OF NITROGEN-FILLED HIGH EXPANSION FOAM*

A.A. BRIGGS Fire Research Station,

Summary

Storage tanks contaminated by flammable residues require protection during repair or demolition. Nitrogen-filled high expansion fire-fighting foam-has been proposed for this protection. In this series of tests a 500 tonne aviation fuel storage tank was filled with appropriate foam to observe foam behaviour with particular reference to oxygen contamination in aged foam. For comparison, gas inerting with nitrogen was included in the test series. In one test a hot cutting procedure was monitored for void formation and oxygen contamination of the foam.

Oxygen contamination was low in foam up to three hours old. Voids and oxygen introduced by hot cutting were rapidly purged. The use of foam enabled the tank to be rendered inert using less nitrogen than with the gas alone and had the additional advantage that the inerting agent was visible.

Introduction

Tanks which have been used for storage of flammable liquids may present a major fire and explosion hazard when their repair or demolition is required. The hazard may be continuous as with volatile liquids or it may arise during operations, notably by the decomposition of solid residues and subsequent ignition of the vapours by a hot cutting torch. The problem arises in fuel storage facilities, chemical plant and industries where flammable solvents are used. Although they may attract less coverage by the media than the explosions at Dudgeon's Wharf (1969) and Sheffield Gas Works (1973), reports are made all too frequently of explosions which cause loss of life and/or considerable damage. Thus the need remains for a method which is both safe and convenient for wide-spread use.

A number of methods are available for safe working when repairing or demolishing tanks but all have limitations. The safe methods are: avoidance of hot working, removal of flammable materials or of air within the tank; in practice more than one method may be required to be used. If air is not to be removed from the tank, then either all traces of flammable material must be disposed of, to permit hot working, or the freely available flammable

50

material must be removed prior to cold working. Cold working has practical disadvantages in that it may slower than hot working, skilled manpower for it may be less readily avaii..:ole, and certain types of repair activity cannot be undertaken. Removal of flammable material can also be time consuming, particularly where tenacious residues are present and where special constructions may have to be put inside the tank to clean the less accessible surfaces, e.g. the underside of the roof. Obtaining protection by removal of air, that is by introduction of an inert gas or steam, avoids some of the labour-intensive requirements, but operational difficulties may be encountered particularly on large tanks. Ensuring that the whole of the atmosphere within the tank is safely inerted, both at the beginning of the operation and during its progress, when openings in the tank may be formed, ca? become difficult and would require expertise in gas sampling and analysIs. Water can be used to displace vapour/air mixture from a tank but. there substantial limitations to its effectiveness. Petroleum products, wIth aSSOCIated sludge and other water-immiscible materials are difficult, if not impossible, to displace by a water purge. There remains a need for an method which requires simple criteria to describe safe conditions and WhICh will cope effectively with the hazards arising "from hot cutting

A relatively new and promising approach uses high-expansion fire-fIghtmg foam with an inert gas as an inerting medium. The advantages of the method are:

(1) positive displacement of flammable vapours from within the tank;

(2) visual indication of the inerting medium;

(3) possible suitability for hot cutting, subject to rapid displacement of foam destroyed by the heat;

(4) avoidance of need to dispose of large volumes of contaminated water.

The process has been used commercially [1] but the trials described in this paper were made in order to examine certain aspects in more detail. The investigation concentrated on the following:

(a) to investigate whether a large tank could be satisfactorily filled with high-expansion foam without forming large voids within the volume or on the underside of the roof· , .

(b) to establish that foam stability was sufficient to enable the tank to be fIlled even when conditions of limited access for foam were simulated i.e. the foam becomes aged;

(c) to examine the extent to which air (oxygen) could penetrate the top surface of the foam in the tank and thereby dilute the nitrogen which originally formed the bUbbles. Conversely the extent to which nitrogen from the foam would dilute the air could also be examined· ,

(d) to study the effect of hot cutting of the steel tank on adjacent foam and associated void formation· ,

(e) to compare the effectiveness of foam inerting with the introduction of nitrogen gas alone. "

A commercial, as distinct from laboratory, scale was chosen and, indeed,

51

the 500 tonne tank made available, by courtesy of the Property Service Agency, appears to be the largest storage tank test for which reports are available.

In addition to the aspects studied in the present work, other factors of practical importance and should be considered in relation to the widespread adoption of the technique. In particular, the rate at which flammable vapour can diffuse through the foam must be taken into account, and the behaviour of solid deposits of relatively low temperature may also be important. The present work was aimed at answering those questions which were particularly applicable to the large volume tank which became available for the experiments.

For technical and economic reasons the usual choice of inert gas is nitrogen, although carbon dioxide, inert gas from burners, and even argon may be used as conditions require.

The synthetic foaming agents used for high-expansion fire-fighting foam, normally filled with air, are applicable to the inerting process. The requirements for foam for inerting are:

(1) good fluidity for reaching corners, purging pipework, etc., although in special circumstances a "stiff" foam may be required;

(2) low drainage rate, since drained foam is likely to be (a) less fluid since smaller "lubricating" bubbles tend to disappear because of gas diffusion into the larger ones, and (b) more susceptible to contamination by diffusion of flammable vapours both because of time factor and the thinning of the bubble walls;

(3) reasonably dry, to minimise losses while hot cutting;

(4) commercially realistic.

Conventionally, foams are specified by expansion ratio and drainage rate. For the present exercise expansion ratio has some effect on ease of hot cutting while drainage rate may reflect problems of increasing stiffness and vulnerability to contamination. However a quantitative description of fluidity was desirable. A foam generator suspended above a clean flat surface will normally produce a conical heap of foam. In this exercise the base angle of this cone (the repose angle) was estimated but two problems were encoun tered:

(a) a foam with low repose angle in bulk may present a relatively steep angle as its leading face moves across a surface;

(b) the surface of foam is usually uneven and, with small quantities, it may be difficult to decide on a mean value.

Test programme

The final choice was influenced by tank availability and size, costs, staff available etc. as well as the technological aspects. The series thus became:

(1) purging with nitrogen to provide a basis for comparison for reaching inert conditions;

52

(2) filling with foam from the top of the tank with a target fill time of two hours;

(3) filling with foam from near the base of the tank with a target fill time of two hours;

(4) filling with foam from the top with a target fill time of nominally five hours.

The generation of foam is largely based on empirical procedures and, on the scale of these tests, requires considerable support facilities. Contractors were therefore employed for foam generation.

Description of tank

The tank was of steel plate, 14 .6 m (48 ft) diameter with cylindrical walls 3.7 m (12 ft) high and a conical roof 4.6 m (15 ft) above the base at its peak: its capacity was thus around 670 m 3 (23500 fe). For foam access a number of 0.61 m (2 ft) diameter manheads were available. For a base fill a manhead near ground level was chosen; for a top fill one in the roof but close to the wall. A 15 cm (6 in) manhead near the peak of the roof served as the-principal vent. Fig. 1 shows the tank and the general site layout.

53

Fig. 1. General view of tank

As a basis for design for monitoring the tank during a foam filling exercise, it was assumed that a void not exceeding one per cent of tank volume could be tolerated. This figure is the highest desirable since under the worst conditions an explosible void of this size might lead to tank disruption, if it was ignited. However, the exercise was essentially aimed at producing information relevant to industrial conditions rather than guaranteeing comprehensive safety of an actual hazard. The one per cent criterion corresponds in this tank to the equivalent of a 1.8 m (6 ft) cube and would have required at least 150 sampling points for full coverage.

The basis criterion for safety is the absence of an explosible atmosphere. However gas analysis on the scale implied above would be demanding on equipment and time. As discussed below three banks each of nine sample lines were constructed. Two banks were used to give full analytical coverage to the sector of the tank most prone to contamination i.e. furthest from the foam input. The remaining bank was distributed round the walls of the· tank approximately at the remaining points of the compass. These gas analysis lines were supplemented by foam detectors which, in conjunction with gas analysis, can be used to infer safe conditions. On the assumption that a source of ignition would arise only external to the tank, e.g. sparks from a cutting torch, foam detection points were confined to positions close to the walls and roof with an inner ring to allow for spark penetration.

Experimental Foam properties

It was impracticable to foam reliably on the exposed test site. Preliminary tests at the FIre Research StatIOn had shown that the larger of the generators used (designated "12 inch") produced foam with expansion ratios from 115 to 300 and half drainage times- from 4.2 to 25.0 min. These figures do not t? each other and there was no simple relationship between properties. Operational conditions at the site were not IdentIcal but If dIfferences are discounted then, based on the laboratory tests, the expansion ratio was probably in range 120-180 and the half-drainage time was of the order of 20 min. For a fill from the base the of foam may have affected the properties.

Again, although conditions were different, the small (designated "4 inch") generator used for most of the last test produced foam of similar expansion ratio and drainage rate.

Gas analysis

For oxygen determination three paramagnetic oxygen meters with recorder outlets were used. As the tank was to be filled in two hours (or more) a determination at each sample location at 10 min intervals was adequate. A sample rate of one per minute per oxygen meter was allowed. Three

54

banks were made each containing nine sample lines of 6-mm bore mild steel with a tenth line to fresh air for frequent calibration checks. A diaphragm pump was used to transfer samples. The appropriate line was chosen by opening a solenoid valve operated by a "master" cam timer on a 10-min cycle. As the air to foam interface was the principal interest, provision was made to move the sample points vertically as the fill progressed. Each bank was arranged as a 3 X 3 matrix horizontally and vertically. One bank of nine lines was allocated to three points around the circumference while the other two banks were used to sample one "sector" more intensively (Fig. 2).

To remove foam from the gas sample foam breakers were used. The sample was sucked through two compartments in cascade, each of which contained 15 cm3 of de foaming liquid, before passage along the sampling line to the meter. Bank 3 1 and 2 GS4 GS6 --__ G S 5 GS3 , 'GS2 '-....GSl a)

Fig. 2. Arrangement of gas sampling lines.

Plan view of sampling pOints 0-9m b) Side view of typical gas sampling l-8m array

55

Since the sampling required physical removal of foam, channelling through a thin layer of stiff foam to the atmosphere could lead to spuriously high oxygen readings. With possible exceptions in the last, there is no evidence of channelling during these tests.

Foam detectors

Two types were used: one depending on the electrical conductivity of foam and the other on its optical absorption.

Conductivity plates. These comprised a pair of 10 cm square copper plates, parallel and separated by 10 cm to form a conductivity cell; the outward facing surfaces were painted to provide electrical insulation. The electrical cables also acted as the means of suspension. In operation, 12 V dc was applied across the selected pair of plates and the current measured. (dc was found preferable to ac as problems due to polarisation were less than those of capacitance). The plates could give rise to spurious readings if mounted close to metal walls or fittings. They provided a comparative indication of foam condition but quantitative interpretation would only have been possible if: (a) the foam liquid was of constant known composition; (b) the relationship between. conductance and drainage (which may not be linear) was known. These conditions did not apply in these tests.

As a check on foam continuity between successive pairs of plates the input potential was also applied across one plate each of successive pairs. Because of their simplicity, a large number of conductivity plates were used to give coverage approximately equal to the detection of a void of regular shape of one per cent of the tank volume.

Optical detectors. To supplement the conductivity plates, photoresistive cells were used in conjunction with a light source (Fig. 3). The cells formed two arms of a Wheatstone bridge completed by two sections of a small trimmer resistor external to the tank. With no foam present the bridge was balanced. When foam penetrated the open light path the bridge became unbalanced to give a of one to two volts. No quantitative interpretation of results has been attempted but foam movement caused variation of the output potential. The optical detectors could be mounted close to walls, roof trusses, etc., and were used to supplement conductivity plates in the shoulder and roof of the tank. One set of five was suspended across the tank to give a general picture of foam movements.

Recording system and tank layout

Groups of 5 or 10 were adopted for all systems. Continuous recording of all sample points was not practicable and not necessary. The core of the system was a single pen chart recorder set to a 0-10 m V range since this corresponded to full-scale deflection on oxygen meters. The input was controlled by banks of relays. Each recording cycle was triggered by a cam on the master timer.

56

Components supported by 10 gauge copper wire framework with all junctions bedded in polyester resin (not shown)

Fig. 3. Optical detector.

(1) Oxygen analysis: the output from each meter was fed successively to the pen recorder for a second or so towards the end of the minute sampling period. The position of the corresponding valve opening was noted manually but since only one note of this for each test was needed, the system was virtually automatic.

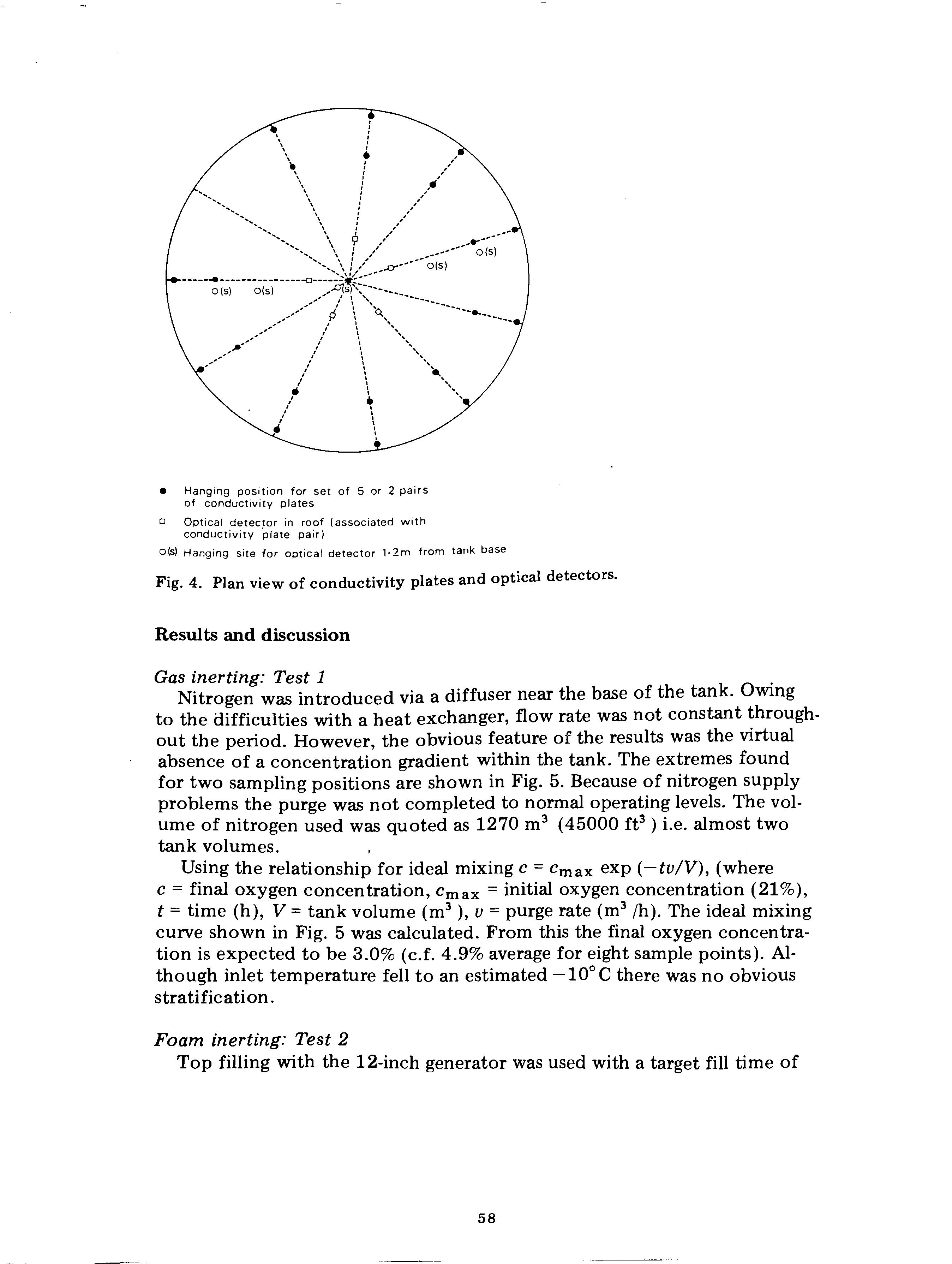

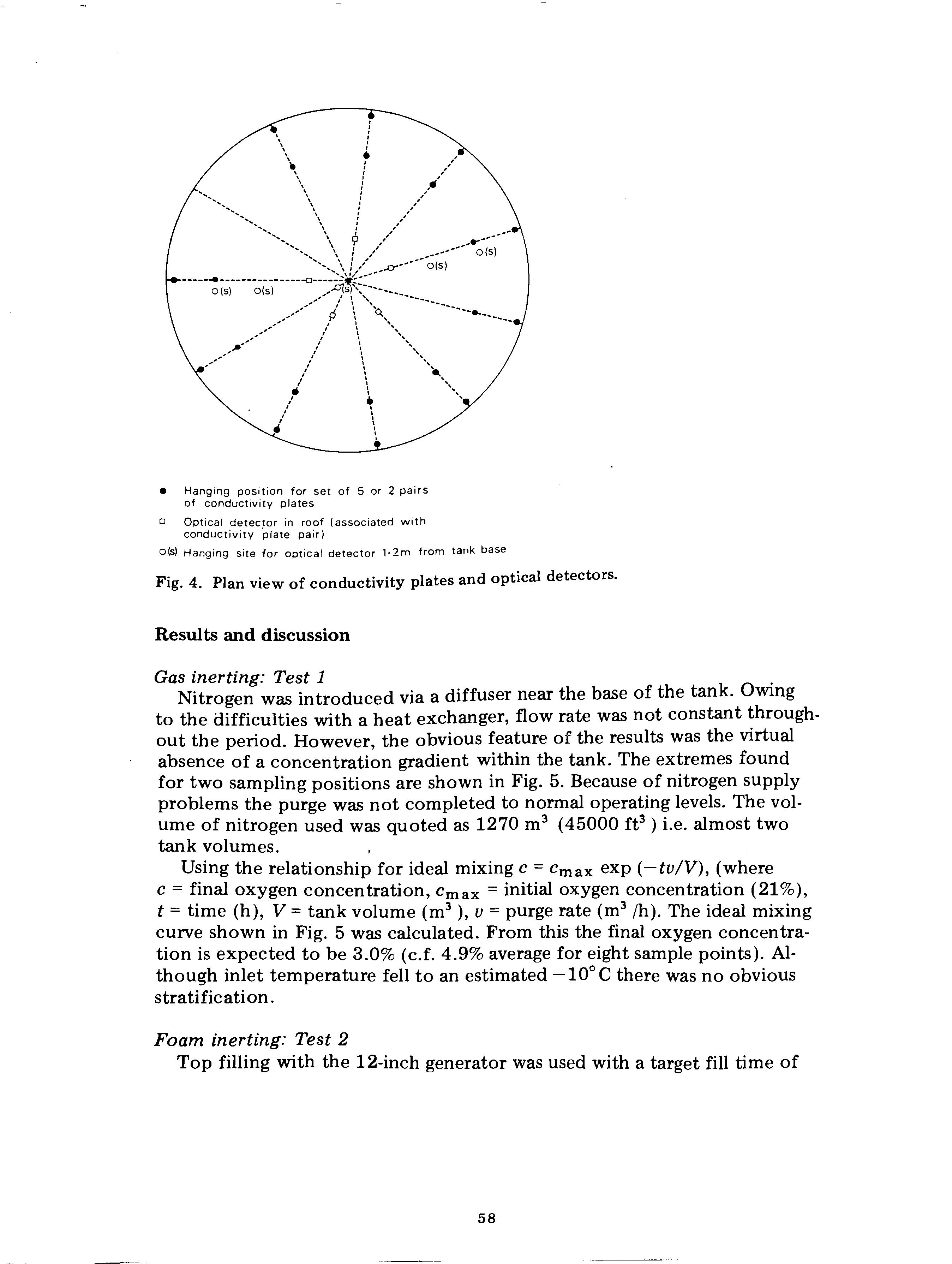

(2) Conductivity plates: these were arranged in groups of five: the 3.7 m tank height allowed a 0.9-m vertical separation between each pair. With ten sets of five distributed round the outer (wall) ring, the horizontal spacing averaged 4.6 m. A second ring of ten was arranged 1.8 m from the wall. Near the peak of the roof two sets paired to give a ring of five close to the roof and a second ring 0.9 m vertically below. The full layout is shown in Fig. 4. Distribution of points was uneven because the tank was found to be reinforced by eleven roof trusses. These provided convenient supports for equipment but re-design to modules of eleven was impracticable.

(3) Optical detectors: one set of five was suspended 1.2 m above the tank floor along a diameter to monitor foam movements. This was permanently attached to five channels of a 6-point rapid response recorder. A second set was mounted near the peak of the roof.

(4) Relay system: a bank of relays to regulate access to the pen recorder was provided for each detection system. The circuit arranged that as one relay switched off, its successor was switched on until the cycle was completed. The cycle was initiated by closure of the switch of one of ten cams on the master timer. This switching led to successive monitoring of the outputs the three oxygen meters, ten pairs of conductivity plates (which, lndclUSIVe of cross-linking of plates led to eighteen outputs) and five optical etectors. '

To

.,NOe

bridge output

Photo conductive cells 12V O· 1A bulb

57

• Hanging position for set of 5 or 2 pairs of conductivity plates

o Optical detector in roof (associated with conductivity 'plate pair)

o(s) Hanging site for optical detector 1·2m from tank base

Fig. 4. Plan view of conductivity plates and optical detectors.

Results and discussion

Gas inerting: Test 1

.

Nitrogen was introduced via a diffuser near the base of the tank. Owmg to the difficulties with a heat exchanger, flow rate was not constant throughout the period. However, the obvious feature of the results was the virtual absence of a concentration gradient within the tank. The extremes found for two sampling positions are shown in Fig. 5. Because of nitrogen supply problems the purge was not completed to normal operating levels. The volume of nitrogen used was quoted as 1270 m 3 (45000 ft3 ) i.e. almost two tank volumes.

Using the relationship for ideal mixing C = C max exp (-tv/V), (where C = final oxygen concentration, Cm ax = initial oxygen concentration (21%), t = time (h), V = tank volume (m 3 ), v = purge rate (m 3 /h). The ideal mixing curve shown in Fig. 5 was calculated. From this the final oxygen concentration is expected to be 3.0% (c.f. 4.9% average for eight sample points). Although inlet temperature fell to an estimated -100 C there was no obvious stratification.

Foam inerting: Test 2

Top filling with the 12-inch generator was used with a target fill time of

58

Fig. 5. Test 1: nitrogen gas inerting.

2 h. The stream of foam was continuous and spread rapidly and evenly across the tank. The repose angle of fresh foam was 10-15° from horizontal with a leading edge 0.6 m (2 ft) high of rather steeper angle (30-£0°). As the gas analysis shows, in Fig. 6, very little air diffused into the foam and there was only slight dilution of the air above the foam by nitrogen.

22

•"\ ............. ....

........... ---0

20 18 16

14 o Q; 12 c. .... • 0 ..........0 :::::;--0 10 Ql Cl

-. ::::::-:::-.... 8 o • Time-min 0--0 GS2 bottom .--. GS8 top: 3·7m from tank base after 60minutes Ideal mixing curve

I I I I \ \ I I I I I I I I I I I I I I I I I I I I \ \GS7 \ I I I I I I I I I I I I I GS5\ \ \ I I I I I I I I I I

• I • I !

22 GS5to :20 \ \GS2 top 18 -1-Lt \ I 16 C 14· Ql o 12 I 10 c Ql g: 8 )( o 6 4

20['--

20 40 60 80 Time-min GS2 top: 2·7m from base of tank GS5. GS7 top 1·8m from base of tank

59

Fig. 6. Test 2: top fill.

Foam inerting: Test 3

Base filling with the 12-inch generator was used with broadly comparable results to the first fill. (Test 2). Simulated columns with hardboard surfaces 230 mm (9 inch) square cross-section were installed and as can be seen from Fig. 7 foam flowed round them to leave an almost indiscernible "valley" in one case and a visible but shallow valley in the second.

Fig. 7. The flow of foam around a simulated column.

There was a failure of water supply for 20 min during the fill and a subsequent instability of foam supply for a time Typical gas analyses are shown in Fig. 8.

When the tank was full of foam after a total period of 145 min, an oxyacetylene torch was used to cut the tank. This was synchronized as far as possible with the gas analysis system. At the analysis point close to the cut, oxygen concentration rose to a level of 6% and may have been still rising when the analysis cycle moved on. However, the other sampling points to either side and those l.8 m from the wall showed no perceptible rise and, at the next cycle, the oxygen concentration was again close to zero at all points. As can be seen, (Fig. 9), the foam moved quite closely behind the flame to purge any void. To ensure safe conditions the foam generator was used to maintain the foam level within the tank.

60

22 ,---20 18 16 - 14' c Q) u 12 ... Q) a. 10 Q) Cl 8 >)( 0 6 4 2 0 "--""", ", GS5 top \ .. \ -------=----'0. \ ".. • • I' \ \ \ \ • \, I , " , \ \ \ \ \ \ \ \ \ \ \ \GS2 top \ \ \ \ \ \ \ \ \ \ \ \ \GS8 mid \ \ \ I " I " \ \ GS8\ \ , " . \ \ top \ \ \ \ \ \ I I L I ._-==-,__...::G:!;S:::.2:. b __ o o _It. 1 • 20 40 60 80 100 120 140 180 Time-min GS2 top: 2 4m from tank base GS5 top: 2 4m from tank base GS8 top: 2·7m from tank base GS8 mid: O·gm from tank base Fig. 8. Test 3: base fill. Fig. 9. Hot cutting showing foam purging 61

Foam inerting: Test 4

The foam provided from the 4-inch generator for this top fill test did not descend as a continuous stream. This would be undesirable in practice because (a) descending, separated clouds of foam may generate electrostatic charges; and (b) tank atmosphere may be occluded in· the mass of foam.

As the fill progressed, foam breakdown increased correspondingly. After 3 h a layer 1.2 m (4 ft) had formed across most of the tank but progress had become very slow. The repose angle of the bulk of the foam was again only a few degrees but the leading edge was high and steep (60 0 ).

The 4-inch generator was removed and the 12-inch generator in base fill position was used briefly with the intention of pushing the old foam to the main gas analysis system. The oxygen concentration for three analysis points showed 1.5% oxygen while the fourth, which was probably most susceptible to sample channelling, showed 3-4% oxygen. The results are summarized in Fig. 10. In view of the unfavourable conditions, these analyses are more clearcut than might have been expected.

Fig. 10. Test 4: slow top fill.

Foam

behaviour: general

(1) The output from the sUspended optical detectors showed a continuous ripple indicating foam movement while foam generation proceeded but with relative quiescence when foam supply ceased.

(2) The conductivity plates showed that: (a) while the wettest foam was most frequently found near the bottom, it could also be found half-way up the mass of and (b) foam near the top or, for the slow fill, near the outside edge, lose at least 95% of its electrical conductance. Despite this it stIll to offer a useful barrier to oxygen diffusion.

Foam mobIlIty round the columns has been described above.

l

1---------_4" generator--_______

E14 Q) u ;;;12 c. Q)

)(

22 20 ...-..12" generator beganj

n 1a ! ! 1.1 11 16 : :

a

o 6 4 11 1 1 1 I 1 1 1 I 1 1 I 1 1 1 1 1 1 1 1 1 I 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 \ \ GS2 I 1 1 1 1 : : bottom9 : 0_0.____ 2 : _ _L L_ 20 40 60 ao 100 120 140 160 1aO 200 220 240 Time-min

62

Future requirements

Weighing estimated costs benefits a future programme might include the following progression:

(1) more detailed examination of oxygen introduction and foam breakdown by a cutting torch;

(2) measurement of diffusion of volatile and gaseous hydrocarbons thlough foam;

(3) devel?pment of a simple method to describe foam mobility;

(4) exammation of potential void situation;

(5) correlation of variables in foam properties. (This section is a considerable programme in itself).

Conclusions

Tests with the 500-tonne tank, under practical conditions, showed It could be satisfactorily filled with high-expansion foam containing mtrogen without forming large voids which could .present a hazard if flammable vapour and air were present. Filling either at the top or the base of the tank gave satisfactory results.

(.2) Foam breakdown did not present a significant problem during a filling perIod of 2 h. The results of the third foam test suggest that longer filling times may be acceptable. However, in general, faster filling is preferable for both technical and economic reasons.

(3) Sampling of the gas within the tank showed that there was a relatively sharp change in composition when the foam arrived at the sampling point. There was some evidence of nitrogen entering the air immediately above the foam, particularly with the filling at the base of the tank, but not sufficient to give protection. Once the foam reached the sampling point, the oxygen concentration dropped to a low value.

(4) The rapid decrease in oxygen concentration at the foam surface indicated that, on a practical scale, the visible presence of the foam at a point implies a low oxygen concentration in the foam.