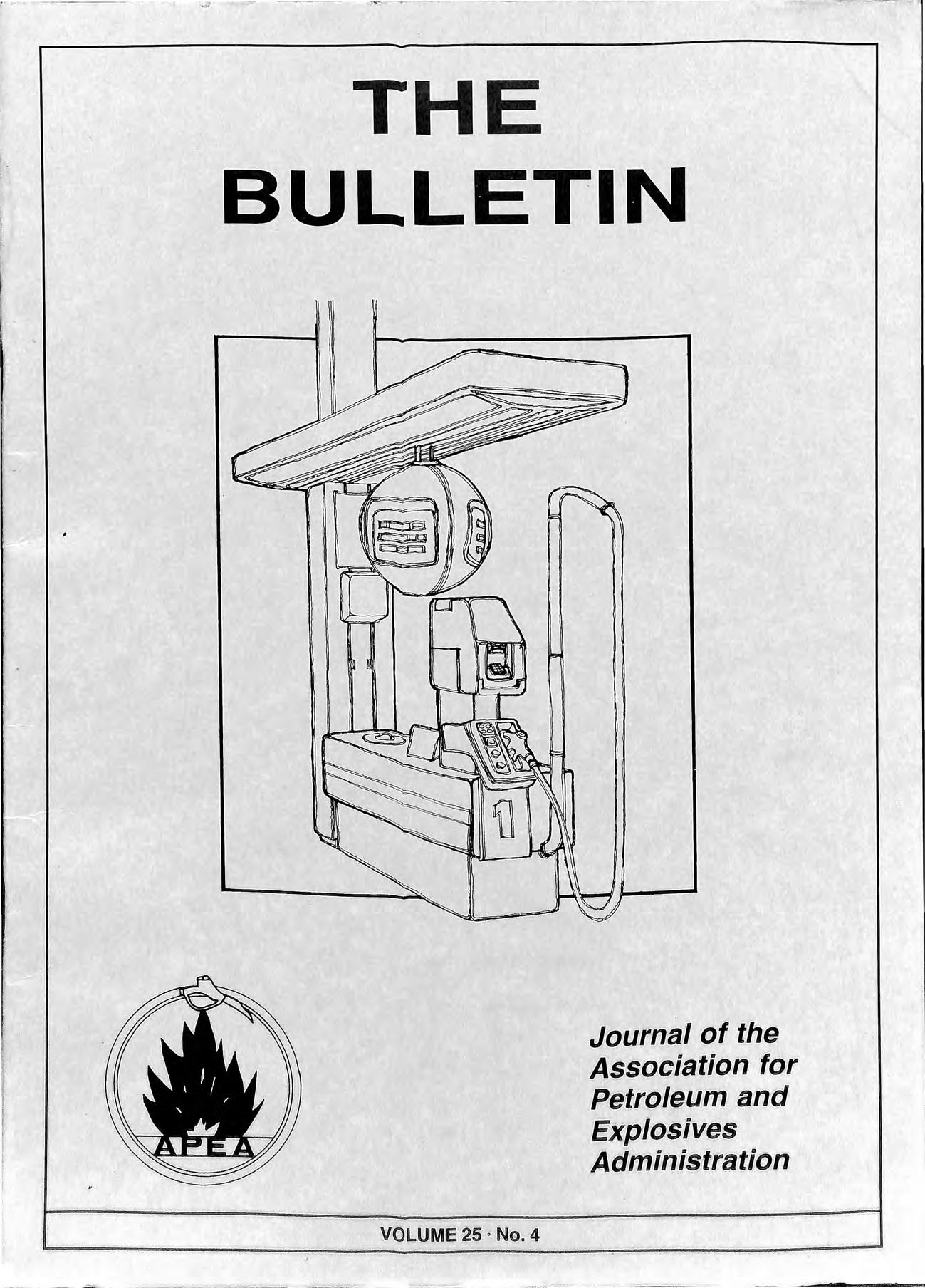

Jo ·urnal

.J

VOLUME 25 No. 4

THE BULLETIN

of the Association fo " , Petroleum an,d Explosives Administration

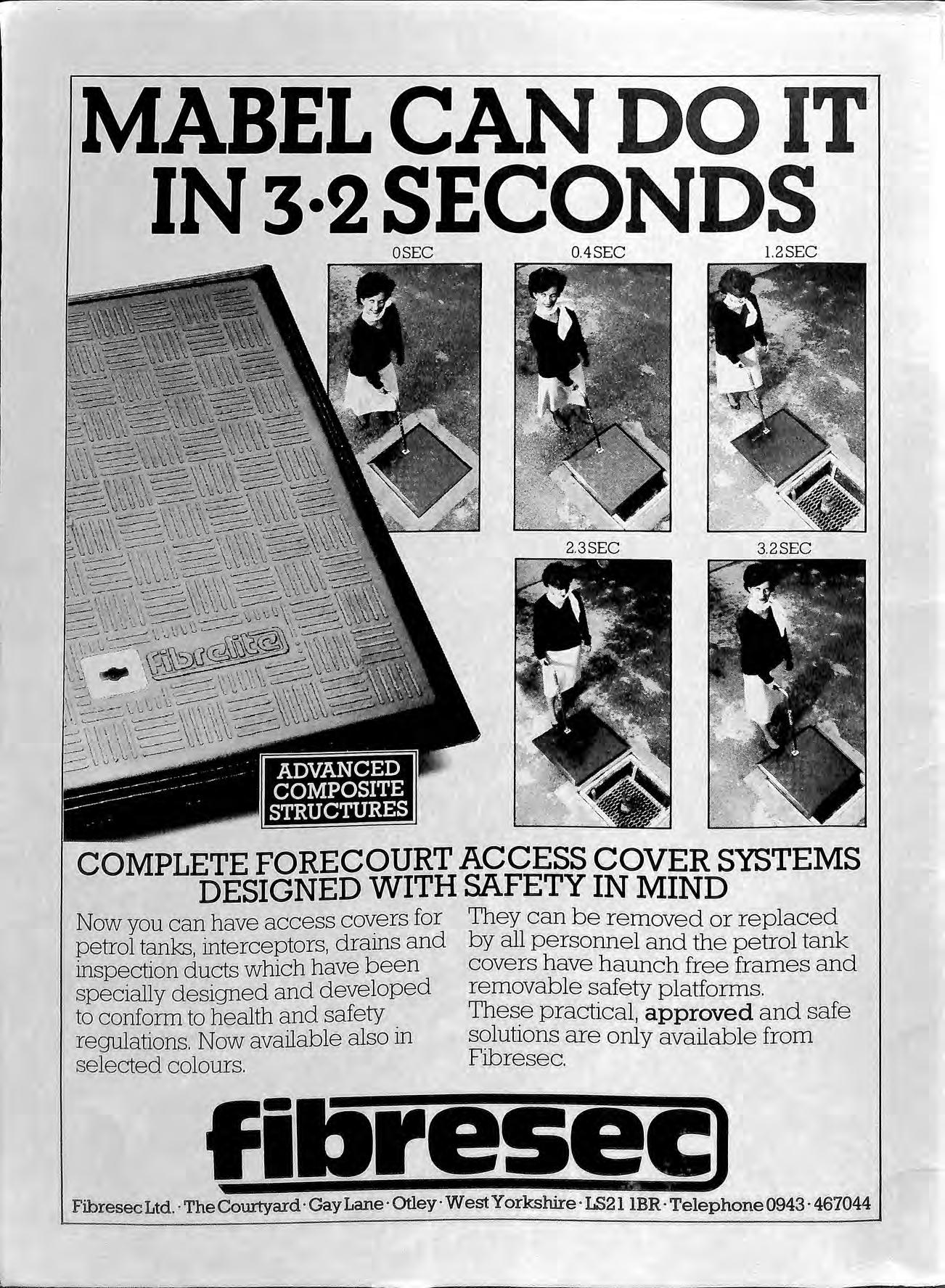

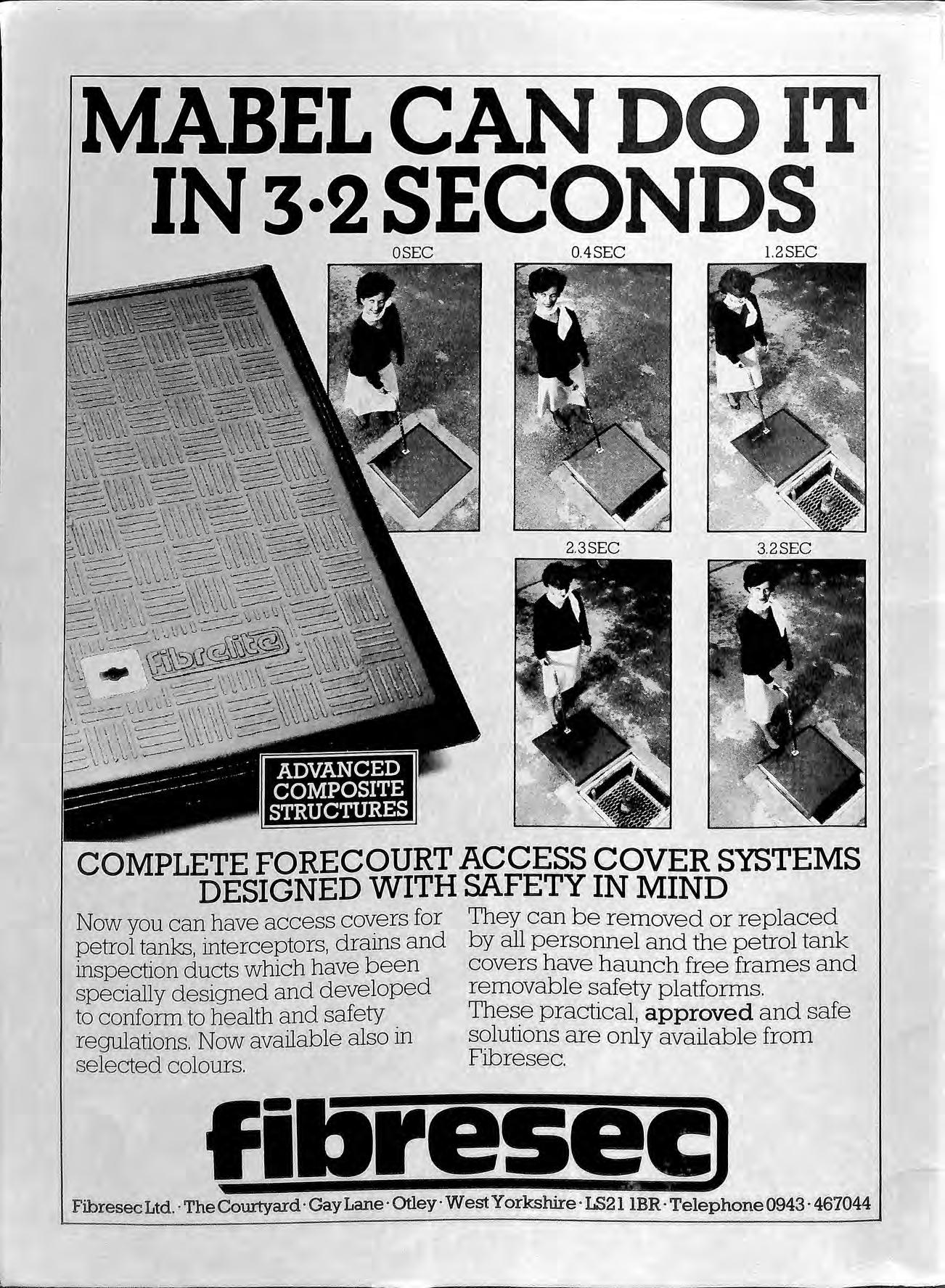

MABEL CAN DO IT IN 3·2 SECON DS OSEC 0.4 SEC 1.2 SEC 2 3SEC COMPLETE FORECOURT ACCESS COVER SYSTEMS DESIGNED WITH SAFETY IN MIND

for

They can be removed or replaced by all personnel and the petrol tank covers have

free frames and removable safety platforms. practical, app

and

solutIons are only available fr om Fibresec. Fi:bresee Ltd Tme Cou,tty;ard' Gay taRe ' Otl ey ' W est! Yorkshire ' LS211BR TeiephoFl,e 09 43·467044

Now you can have access covers

petrol tanks, inte r ceptors, drains and inspection duc ts wh]ch have been spec ially de slgne d and d ®ve lop ed to conform to health and s afety regulations, Now availab llie a1!so in sele cte d c olours.

haunch

roved

safe

O IL POLLUTION CONTROL Rapid Response Units on call 24 hours a day for Land or Water Borne incidents. ---r, 24 HOUR EMERGENCY TEL: 01-8051856 DEWCO 'PROTECTING THE ENVIRONIfIIENT' FOR DETAILS OF THIS AND OTHER OIL RELATED SERVICES: Contact : Sal es and Ma r ke ti ng D epartm ent, DE WCO SERVICES LI M ITED, HERTFORD ROAD, ENFIELD WASH, M IDDLESEX, TELEPHONE : 01 -804 1095

MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 01 800 4651 Specialists in Petrol Filling Stations D. S. Leggett (Electrical) Limited ELECTRICAL CONTRACTORS NICEIC APPROVED 181 VICTORIA ROAD, NEW BARNET, HERTS. Telephone: 01-441 3958 SPECIALISTS IN PETROL STATIONS

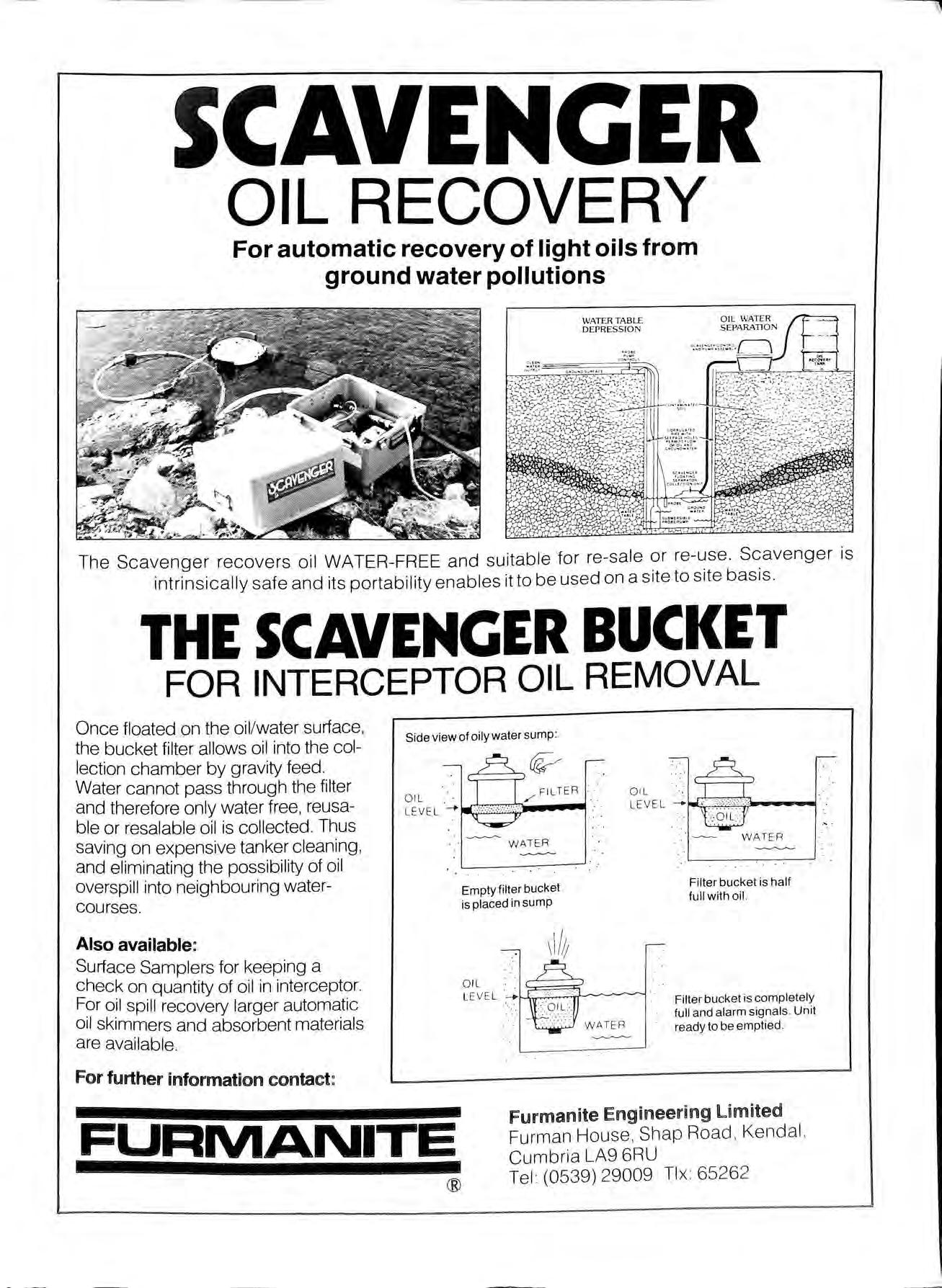

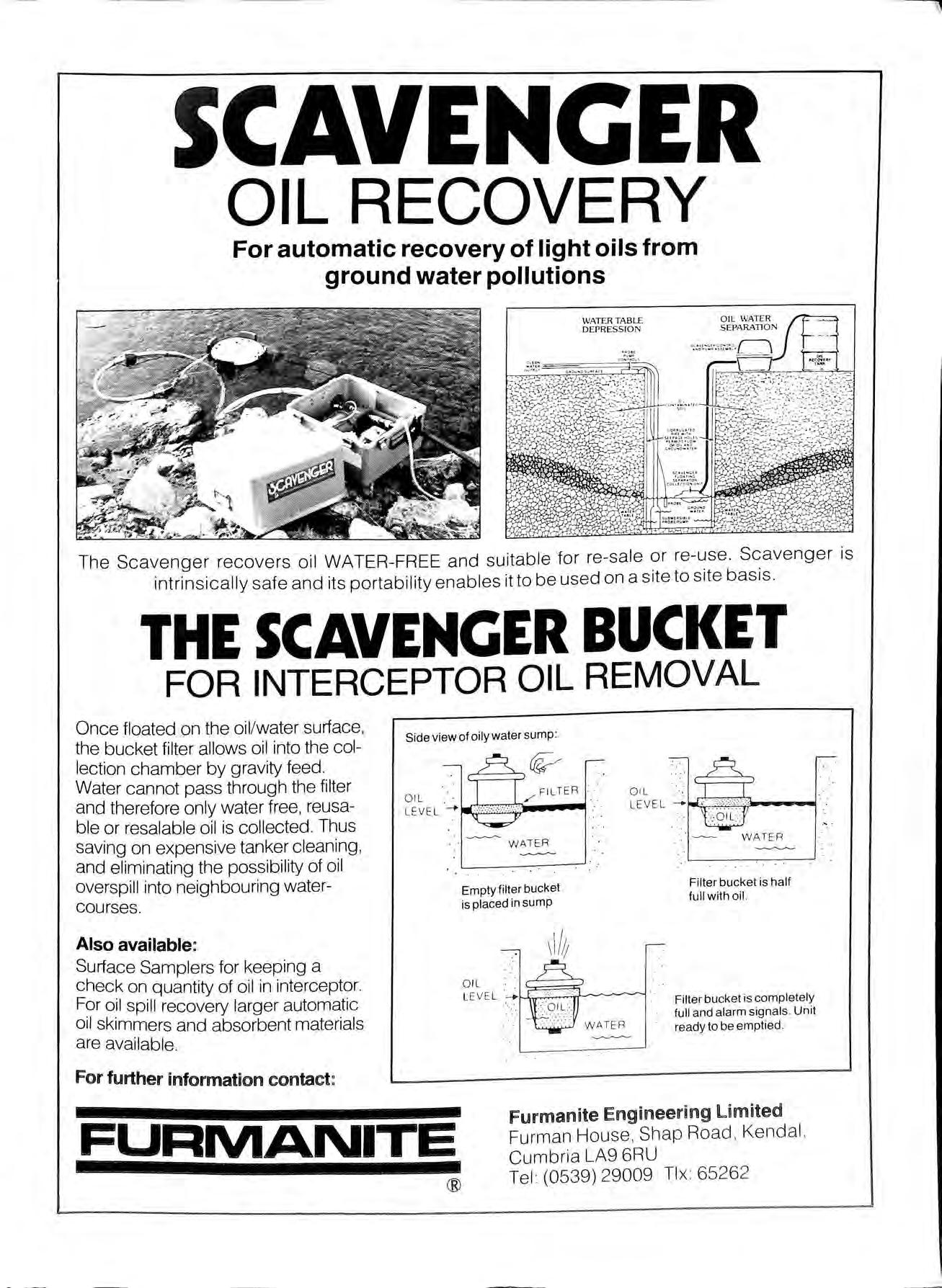

Once floated on the oil/water surface, the bucket filter allows oil into the collection chamber by gravity feed. Water cannot pass through the filter and therefore only water free, reusable or resalable oil is collected. Thus saving on expensive tanker cleaning, and eliminating the possibility of oil overspill into neighbouring watercourses.

Also available:

Surface Samplers for keeping a check on quantity of oil in interceptor . For oil spill recovery larger automatic oil skimmers and absorbent materials are available.

OIL RECOVERY For automatic recovery of light oils from ground water pollutions WATER TABLE DEPRESSION The Scavenger recovers oil WATER-FREE and suitable for re-sale or re-use. Scavenger is intrinsically safe and its portability enables it to be used on a site to site basis .

SCAVENGER BUCKET FOR INTERCEPTOR OIL REMOVAL

ENGER

THE

Side view of oily water sump:

FURMANITE ® WAT E R Empty filter bucket is placed in sump WA T ER OIL L EVEL W ATE R Filter bucket is half full with oil. Filter bucket is completely full and alarm signals. Unit ready to be emptied Furmanit e En g in eer ing li m ited Fu r man House , Shap Road , K e nd a l , Cumbria LA9 6RU Tel : (0539) 29009 Tl x 65 2 6 2

For further info rmati o n co nta ct:

W. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial - Above and Below Ground Supply Test Exchange Service Instal Product Transfer De-Watering Removal Purchase Tank Demolition Removal Safety Filling Large Stocks of New and Second hand Petrol and Diesel Pumps, Tanks and Accessories DAYBROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINITY WORKS, BOURNE END LANE, HEMEL HEMPSTEAD 0442772296 Telephone 021-236 0347 w. J. FINCH (Installations) Ltd. Steaming out and de-gassing petrol tanks; issuing gas free certificates Complete petrol and fuel oil bulk storage tank installations Petrol and fuel oil tank cleaning service Pressure testing tanks and pipe work Heaton House, Camden St., Birmingham Bl 3BZ ...

Talking Point

At the seminar in October the HSE speaker criticised petroleum licensing authorities for lack of action against licensees who contravene the conveyance regulations when receiving delivieries of petroleum spirit.

He stated that a large majority of deliveries were received without strict adherance to the Regulations and better policing was necessary. It was pointed out from the floor of the seminar that many more prosecutions had been taken recently by licensing authorities and with the lack of action by the HSE was it not a case of the pot calling the kettle

The HSE draft code for filling stations has been published for public comment and Oil. Companies in particular should study and respond to thIS document, as all the future development and trends will have to be encompassed within its structure.

It is not enough for just the engineers to comment, marketing personnel should also a close at the document. It is a fact that to obtam corporate Images world wide, major oil companies are developing schemes which may receive the blessing in the country of origin (usually the USA) but to this country will not meet the proposals m thIS new code.

The Bulletin ISSN 0263 4597 VOLUME, 25 Number 4 DECEMBER 1987 £3.00 (Free to Members)

Contents TALKING POINT NOTES & NEWS NEW MEMBERS PRESSURISED PUMPING SYSTEMS LETTERS DRIVER CONTROLLED DELIVERIES PROSECUTIONS ROAD TANKER INCIDENT PETROL PUMP DESIGN

Published by the Association for Petroleum and Explosives Administration Opinions expressed in this Journal are not necessarily the views of the Association

HUMBERSIDE BRANCH

R.

G. Kitching

Humberside

County Council,

F.

Mr.

51 52 52 55 55 57 58 62 63 :'1

EASTERN BRANCH

C. Rason Honorary Secretary:

B. D. Taylor,

SOUTHERN BRANCH M.Cox

Normond Instruments Ltd., MIDLAND BRANCH Derek Hopkins Warwickshire County Council,

Honorary Editor: Mr. J. A. J. Thompson,

TV CHEGGERS ESCAPES PETROL.

Television presenter Keith Chegwin had a burning problem his trousers caught fire.

He was driving to meet his wife Maggi Philbin at Newbury, Berkshire.

Chegwin said: 'I called in to get some petrol and spilt some on my trousers. I thought they had dried out, but they started smoking then I realised they were on fire.

'All I can think is that a loose wire dangling under the dashboard set light to the fuel. They were getting pretty hot so I stopped at the side of the road and leapt out to beat out the flames.'

He presented an eye-catching spectacle when he arrived at the station minus trousers.

'I had to take them off because they were badly burnt.' he said.

STORAGE OF SOLVENTS

Many industrial chemicals I solvents come under the Petroleum Acts. Throughout the country, different licensing arrangements are enforced. In some areas, the records, kept may refer to 'Petroleum Spirit' or 'Petroleum Mixture' as being stored on a premises rather than the specific chemicaVsolvent. It would be advantageous to identify the product specifically on licences, licence applications and renewals for the following reasons:

i) Enforcement Officers need to be aware of any health hazards associated with the product.

ii) An industrial installation is likely to change the product as processes change.

iii) The safety of an installation may be affected by change of use (e.g. tolerance of seals to different chemicals)

iv)Considering the implications of a change of use, and the scope for non-reporting, positive confirmation on licence documentation would seem a simple solution.

The above comments arose following experiences on a small industrial unit where the change of solvent led to the of all of the pump seals, and our subsequent enquIrIes.

Comments from around the country as to how the problems are tackled or as to whether the above are considered a problem would be welcome.

PROFILE OF BASEEFA

BASEEFA is the national certifying authority for electrical equipment for use in flammable atmospheres other than gassy mines. It is also the approved body for this purpose in the EEC Flammable Atmospheres Framework Directive No 761l17/EEC of 18.12.75.

It was set up by MINTECH in 1967 following requests by industry for the service and became part of the Research and Laboratory Services Division (RLSD) of HSE in 1975.

The functions of BASEEFA are:

To assess. test and certify electrical apparatus to national. international and BASEEFA standards;

2 To offer design consultancy for electrical apparatus;

3 To carry out testing for apparatus to special requirements to assist in the development of a product prior to the certification stage;

4 To assist in the development of standards for this area;

5 To assist in securing acceptance of BASEEFA certification hy foreign authorities.

The organisation consists basically of three sections responsible to the Director of BASEEFA and his Deputy. The sections are:

(a) Flameproof section: which deals with all enclosure protection concepts such as flameproof Ex d, pressurised Ex p, oil-fired Ex 0, powder-filled Ex q and battery operated vehicles.

(b) Intrinsically Safe and Light Current section which is responsible for all intrinsically safe Ex i equipment, light current Ex N equipment, gas detectors and electrostatic spray guns.

(c) The Reliability Concepts section: which is responsible for increased safety Ex e equipment, heavy current Ex N equipment, petrol pumps and heating tapes.

All sections deal with special Ex s equipment and dust protected equipment, as appropriate.

The technical sections have administrative back-up from a support unit (EECSU) which also services the HSE (M) Mining Certification Service. For special technical problems which arise in certification, BASEEFA have back up from the other sections in RLSD.

An Electrical Equipment Certification Management Board (EECMB) oversees the work of the Electrical Equipment Certification Service (EECS) including BASEEFA and HSE(M) supported by technical advice from Advisory Councils (BACo and CEEMAC). The EECS is self financing as far as its certification, testing, conulstancy and surveillance activities are concerned.

Details and conditions of the service are given in the Electrical Equipment Certification Guide and helpful information and costs are given in this Newsletter which is published twice yearly. As well as its own Standards, BASEEFA publishes a List of Certified Equipment and Technical Rules.

All information and publications with the exception of the BASEEFA List can be obtained from the ECSU, Health and Safety Executive, Harpur Hill, Buxton, Derbyshire, SK17 8JN Tel 0298 6211 Telex 668113 RLSD G. Fax 0298 79514. The BASEEFA List can be obtained from HSE Sales Point, Room 414, St Hugh's House, Stanley Precinct, Bootle, Tel 051-951 4224.

notes &

news

)2

The Association welcomes the following new members W. A. Wright Peter WorraII John A. Ward John Ward & Associates

New Members

Ltd

D. E. J. Ashby

Total Oil (Great Britain) Ltd

L. M. Lombardo Hollydene

Edward A. Cairns Tokheim Limited

Roger Davidge

Gordon Christopher Kinnear

L. G. Treliving

R. M. Rumbold

M. D. Mulvana

Total Oil (Great Brit a in) Ltd

Thomas F Mitchell clo John Ward & Associates Ltd

A. M. Bearman

Total Oil (Great Britain) Ltd

Jeffrey Attwood

Total Oil (Great Britain) Ltd

D. E. J. Ashby

Total Oil (Great Britain) Ltd

L. M. Lombardo Hollydene

Edward A. Cairns Tokheim Limited

Roger Davidge

Gordon Christopher Kinnear

L. G. Treliving

R. M. Rumbold

M. D. Mulvana

Total Oil (Great Brit a in) Ltd

Thomas F Mitchell clo John Ward & Associates Ltd

A. M. Bearman

Total Oil (Great Britain) Ltd

Jeffrey Attwood

Total Oil (Great Britain) Ltd

53

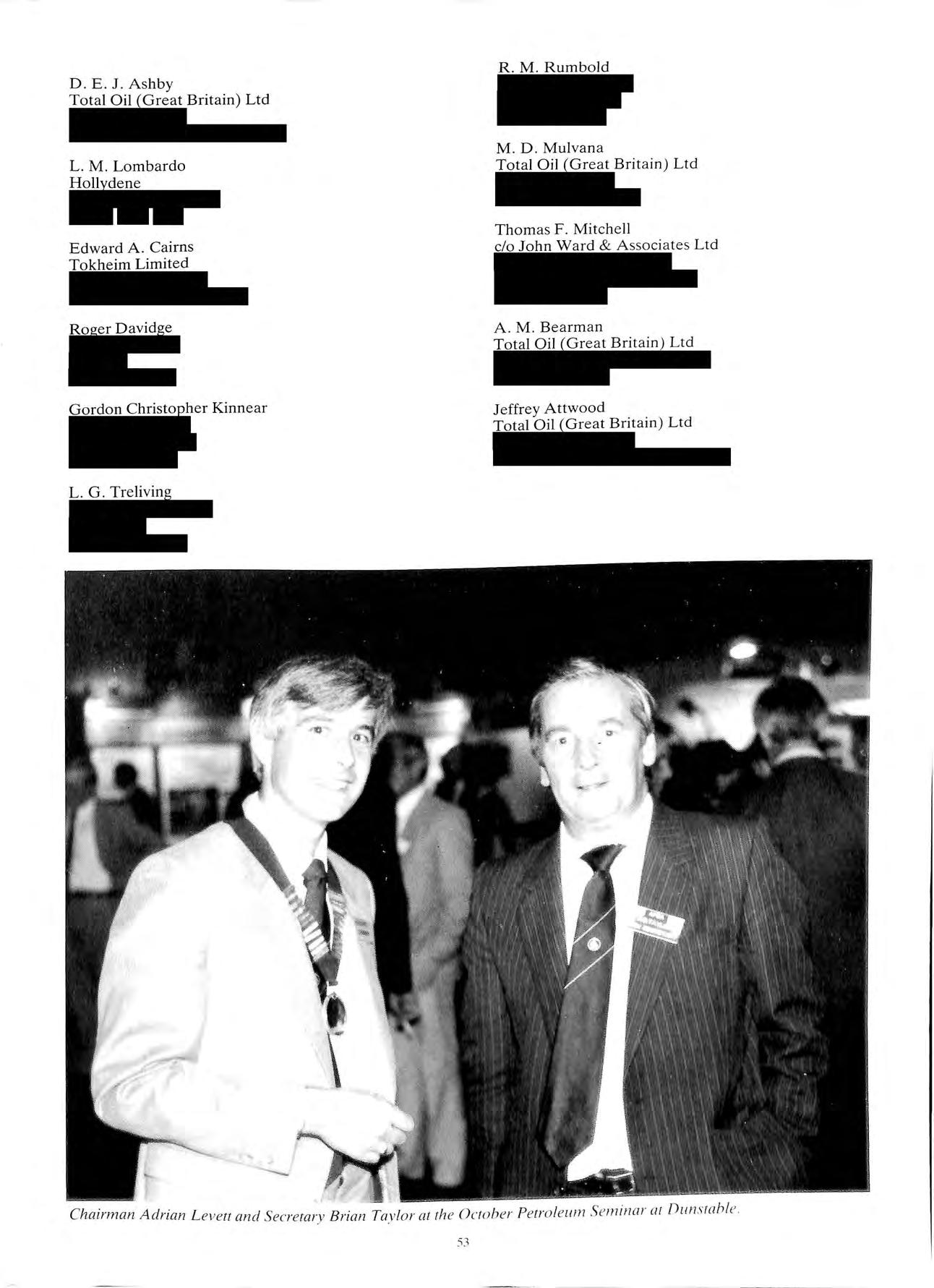

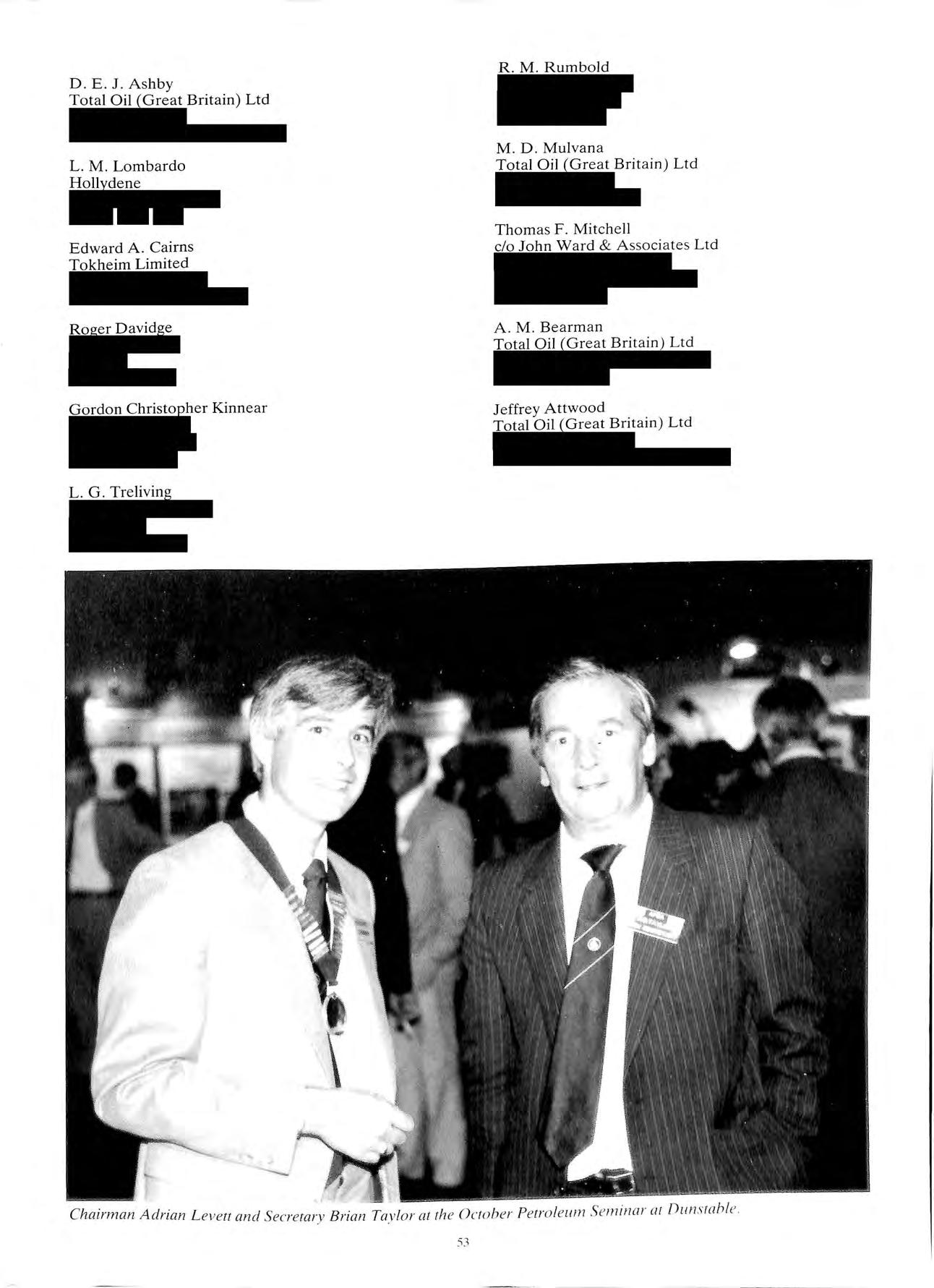

C hairman Adrian L evell and S ec re rarv Brian Tav/or a£ th e OClOber P e tr o le um S e minar (It Dunsf([hl e

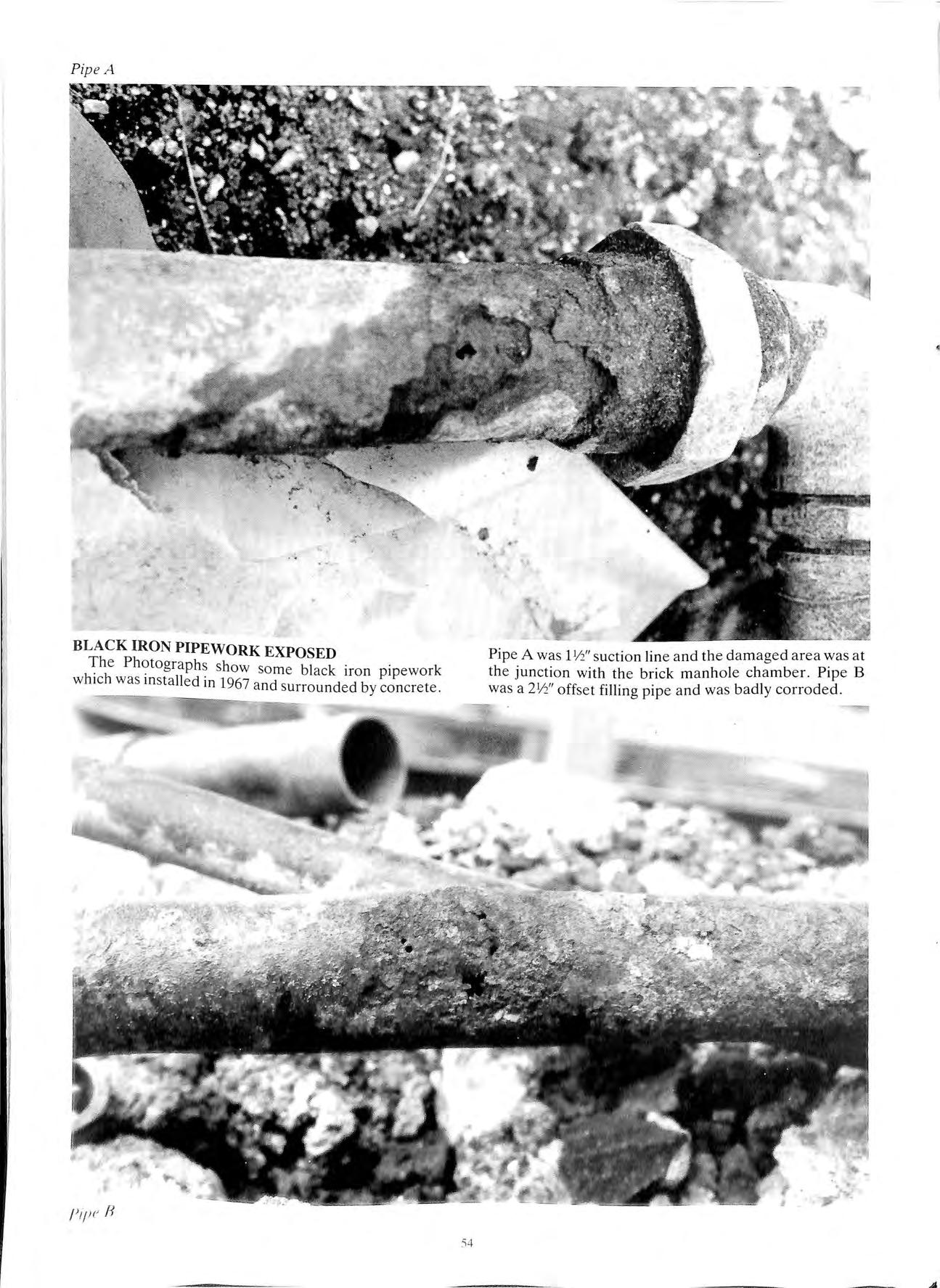

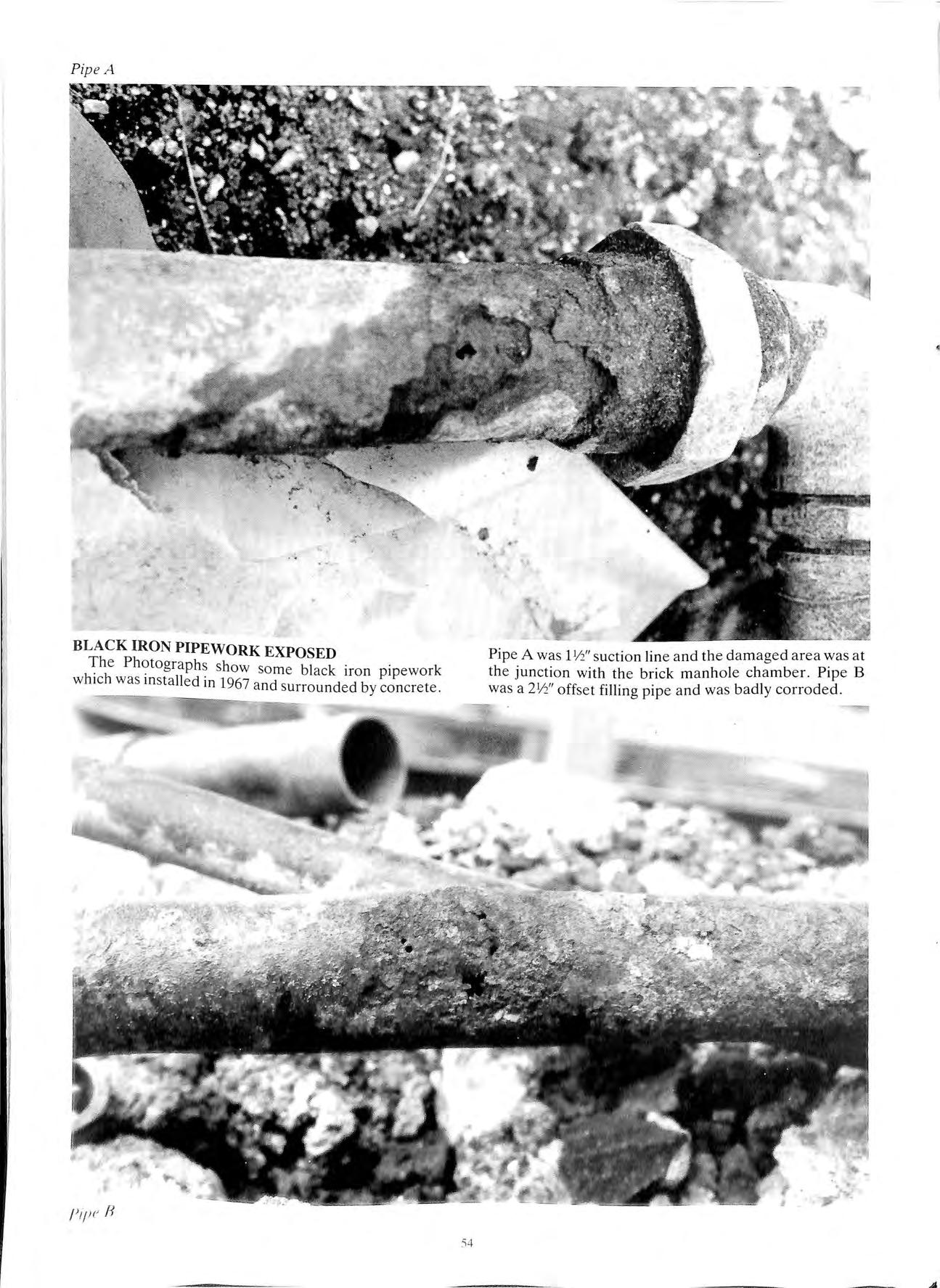

BLACK IRON PIPEWORK EXPOSED

Photographs show Some black iron pipework whIch was Installed in 1967 and surrounded by concrete .

Pipe A was 1If2" suction line and the damaged area at the junction with the brick manhole chamber. PIpe B was a 2If2" offset filling pipe and was badly corroded ' ''''''''l''"1

:;4

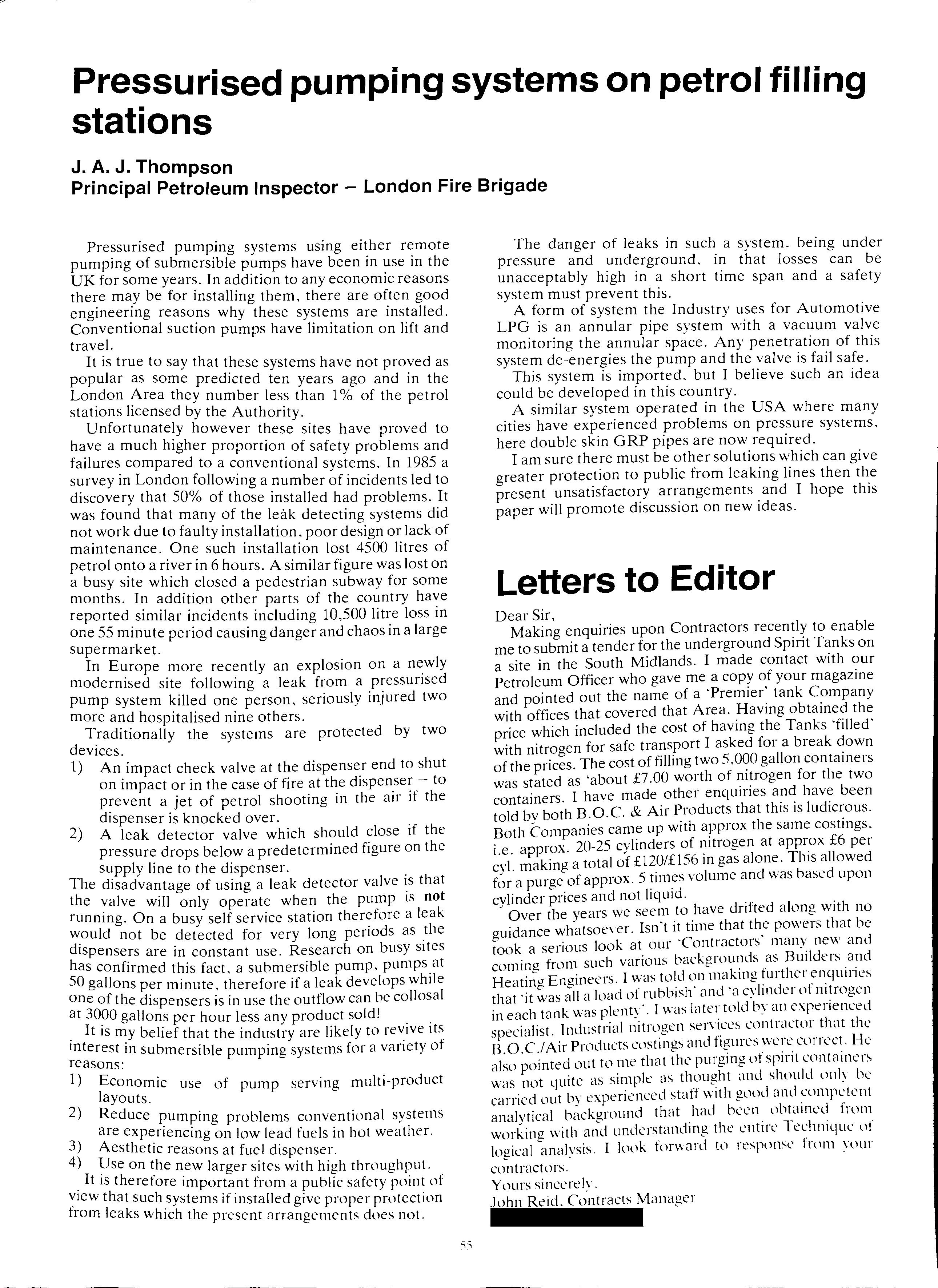

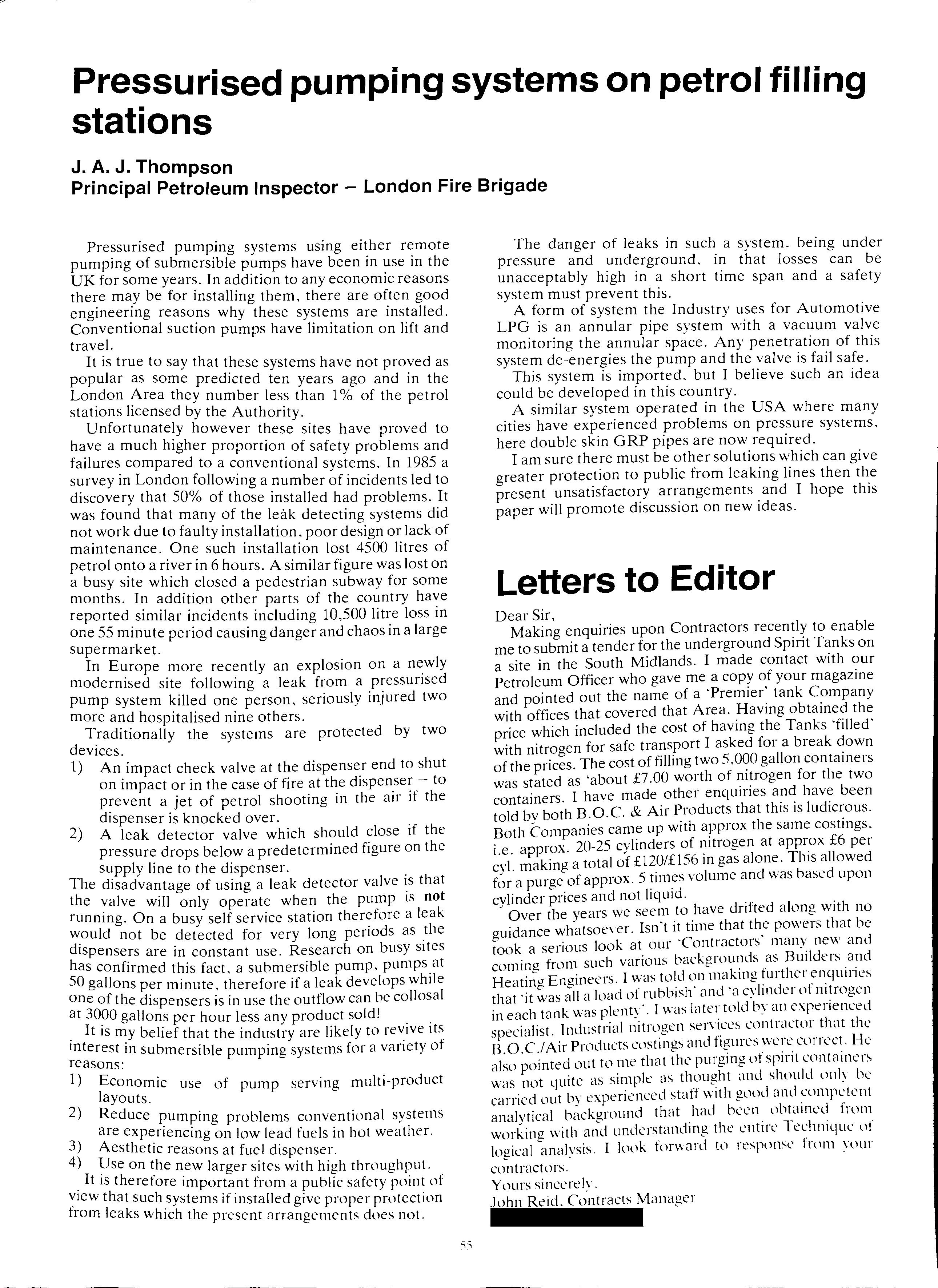

Pressurised pumping systems on petrol filling stations

J. A. J. Thompson Principal Petroleum Inspector - London Fire Brigade

Pressurised pumping systems using either remote pumping of submersible pumps have been in use in the UK for some years. In addition to any economic reasons there may be for installing them, there are often good engineering reasons why these systems are installed. Conventional suction pumps have limitation on lift and travel.

It is true to say that these systems have not proved as popular as some predicted ten years ago and in the they number less than 1% of the petrol stations hcensed by the Authority.

Unfortunately however these sites have proved to have a much higher proportion of safety problems and failures compared to a conventional systems. In 1985 a survey in London following a number of incidents led to discovery that 50% of those installed had problems. It was found that many of the leak detecting systems did not work due to faulty installation, poor design or lack of maintenance. One such installation lost 4500 litres of petrol onto a river in 6 hours. A similar figure was lost on a busy site which closed a pedestrian subway for some months. In addition other parts of the country have reported similar incidents including 10,500 litre loss in one 55 minute period causing danger and chaos in a large supermarket.

In Europe more recently an explosion on a newly modernised site following a leak from a pressurised pump system killed one person, seriously injured two more and hospitalised nine others.

Traditionally the systems are protected by two devices.

1) An impact check valve at the dispenser end to shut on impact or in the case of fire at the dispenser to prevent a jet of petrol shooting in the air if the dispenser is knocked over.

2) A leak detector valve which should close if the pressure drops below a predetermined figure on the supply line to the dispenser. The disadvantage of using a leak detector valve is that the valve will only operate when the pump is not running. On a busy self service station therefore a leak would not be detected for very long periods as the dispensers are in constant use. Research on busy sites has confirmed this fact, a submersible pump, pumps.at 50 gallons per minute, therefore if a leak develops while one of the dispensers is in use the outflow can be coIIosal at 30?0 gallons per hour less any product sold!

. It IS my belief that the industry are likely to revive ItS Interest in submersible pumping systems for a variety of reasons:

1) Economic use of pump serving multi-product layouts.

2) Reduce pumping problems conventional systems are experiencing on low lead fuels in hot weather.

3) Aesthetic reasons at fuel dispenser.

4) on the new larger sites with high throughput.

It IS therefore important from a public safety point of view that such systems if instaIIed give proper protection from leaks which the present arrangements does not,

The danger of leaks in such a system. being under pressure and underground. in that losses can be unacceptably high in a short time span and a safety system must prevent this.

A form of system the Industry uses for Automotive LPG is an annular pipe system with a vacuum valve monitoring the annular space. Any penetration of this system de-energies the pump and the valve is fail safe.

This system is imported. but I believe such an idea could be developed in this country.

A similar system operated in the USA where many cities have experienced problems on pressure systems. here double skin GRP pipes are now required.

I am sure there must be other solutions which can give greater protection to public from leaking lines then the present unsatisfactory arrangements and I hope this paper will promote discussion on new ideas.

Letters to Editor

Dear Sir, Making enquiries upon Contractors recently to enable me to submit a tender for the underground Spirit Tanks on a site in the South Midlands. I made contact with our Petroleum Officer who gave me a copy of your magazine and pointed out the name of a 'Premier: tank C?mpany with offices that covered that Area. HaVing obtained the price which included the cost of having the Tanks 'filled' with nitrogen for safe tra?sport I asked for a break of the prices. The cost offIlhng two 5,000 gallon containers was stated as 'about £7.00 worth of nitrogen for the two containers. I have made other enquiIies and have been told bv both B.O.C. & Air Products that this is ludicrous. Both Companies came up with approx the same costings. i.e. approx. 20-25 of at appr,ox £6 per cyl. making a total of £1201£156 In gas alone. ThiS allowed for a purge of approx. 5 volume and was based upon cylinder plices and not hqUld, Over the years we seem to have drifted along with no guidance whatsoever. Isn't it time that th,e powers that be took a selious look at our 'Contractors many new and coming from such various backgrounds as Builders and Engineers. I was told on making that 'it was aII a load of rubbish' and 'a cyhnder of in each tank was plenty', I was later told by an expenenced specialist. Industrial serv!,ces contractor that the B. 0, C.I Air Products cost1l1gs and figures were correct, He also pointed out to me that the purging of spirit was not quite as simple as and should only be carried out by experienced staft With good and analytical background that ,had bcen, from working with and understand1l1g the entire 1 ech11lque ot logical analysis, I look forward to response from your contractors, Yours sincerdv.

John Reid. Co'ntracts Manager

Dear Editor,

In reply to the letter recently enclosed in an issue of the Bulletin from our National President, I feel that I wish to reply in the following way.

We have had instances within recent months of line failures but by examinations of sites or actual investigations we ?O not consider that any of them are due to failure of jointmg compounds as such. One instance that I can quote, related to a problem occurring in premises adjacent to the where petrol vapours were entering this particular The suction lines of petrol vapours were entering this particular building. The suction lines of the adjacent site were tested for soundness and one failure was found. Close examination of the forecourt surface under which the lines were passing, showed a fracture. This occasion is not unusual in certain areas of Nottingham, being a mining and it was quite obvious to ourselves that the line faIi.ure had been caused by slight movement in the ground, which we assumed would have affected a joint, probably an elbow that was around this point of the forecourt. A more rec t' . en mCIdent that has occurred was revealed by excavaplace adjacent to existing manhole chambers ere It was found that the encasement of lines was not complete as the pipe was entering the manhole. In other although the contractor would have been advised by t e Petroleum Officer at the time (this being some fifteen years. ago) the contractor had not followed the instruction

It was assumed when revisiting the site finding a lorecdo urt area completed that the instruction had been folowe.

a have recently carried out their own test on ly.prepared piece of pipe in which joints were made th ng. compounds and actual methods of jointing, 'de pipe Itself then terminated in an upstand which we conSI ered would b . . mall £ . e exertmg an mternal pressure to that norm The joints that were made were PTFE Y m Llthage, Petrotite, Lac-o-tite and just was I Without any jointing compound, the pipework hard e b0; two days so that the Lithage would in actual fact afteren e ?re the petrol was introduced into the test rig and in a a of four weeks all joints were still found to be sound.condition. On the 6th July 1987, in that headin f ,pe National Information Service, under the ments rh °t h etroleum News', there is reference to comWhere th ave been made by the Institute of Petroleum that com IS so called problem would appear to exist. I feel in a very ment. offered by the Institute sums up the situation been manor. ! that a great deal of alarm has of facts that cI the media m by publishing details had knowled them. consulting people who in general particular field. I feel that the media that has be e approached to try and correct the alarm

I trust am.ongst filling station operators. trust that y may be of interest to you and I firmly of thOU W.I . excuse me expressing my mind but I am non existanec opmlOn that the supposed problem is in fact a . e one.

YOurs Sincerely, C. Horsburgh Senior En£ ' Nottin h Officer g amshlre County Council.

Dear Editor.

J have recentl h. the Health & S. r ad with Mike Sewell of petroleum s .'.a ety Executive concerning the unloading of PInt at marina's.

As YOU are awa R . I h1Jlicrous SI. re egulatlon 20 and Schedule 4 of the r".. ." u )stances (Conv' b R . d . . d T • kn<, iJlld f<tnk COl .' eyance. y oa m Roa lan, I' ltamers) Regulations 1981 provide for wllu/;lI IIlg I le unl I" '. , ,... Ode I11g of petroleum spmt at any

petroleum filling station and other licensed premises, under 100,000 litres, where the petroleum spirit is intended for use as fuel for motor vehicles.

A petroleum filling station is defined in Regulation 2 as having the same meaning as in Section 23 of the Petroleum (Consolidation) Act 1928.

The Act defines petroleum filling stations as any premises used or intended to be used for fuelling motor vehicles.

Motor vehicles are again defined in Section 23 of the Act as all mechanically propelled vehicles intended or adapted for use on the roads.

It appears to me, therefore, that where a delivery is made to a marina, etc., when the petroleum spirit is intended for fuelling motor boats the requirements of Schedule 4 of the Regulations do not apply.

My thoughts were clarified by the fact that the 1929 Regulation for the keeping and use of petroleum spirit in motor boats, motor vehicles etc., were amended to include an internal combustion engine by the Petroleum Spirit (Plastic Containers) Regulation 1982. This would seem to confirm that a motor vehicle is not a motor boat.

It has been put to me that the requirements of Schedule 4 should, therefore, be put within the licence conditions attached to a petroleum spirit licence issued to places where the fuel is intended for motor boats.

I do not think this is possible as the 1928 Act, in Section 2(3),. only allows the Local Authority to attach conditions relatmg to mode of storage, nature and situation of premises which, and return of goods with which, petroleum spirit IS to be stored, facilities for testing petroleum spirit and genfor the safe keeping of petroleum spirit. .

This does not allow for the conditions to relate to the delivery of petroleum spirit.

The Health & Safety Executive agree that delivery at marinas have been overlooked and I would be obliged if any reader has an answer to this under current legislation.

Kind regards.

L. B. Wilson Principal Technical Officer Cambridgeshire County Council

Dear Editor, would like to comment on the prosecution article BulVolume 25 N02, the prosecution taken followmg an mspectors visit to a forecourt in Peterborough on 11 July 1986.

The last sentence of the last paragraph mentions a point where the Law needs amending but does the Law need amending? '

Surely the whole essence of the safety aspects of the delivery procedure and intended by the Legislators is that both the person. in charge of the underground tank, the perSO? the vehicle, are together at the pOSitIOn spmt IS bemg delivered. In the event of an emergency It IS pe.rson in. charge of or attending the vehicle responsibilIty to Immediately shut off the tankers delivery fawcet and that he cannot do from the kiosk. Even more important therefore that the driver is at the tanker.

Paragraph 10 of the Regulations means the person attendmg the vehicle shall keep a constant watch at the tanker from which petroleum spirit is being delivered. If in this case the person in charge of the underground tank had been. able to see the tank connection from the kiosk, would It be that this arrangement would also satisfy the RegulatIOn. In my opinion it would not. One cannot keep a constant watch either 'on' or 'thereon' a tank or tanker unless one is at the 'on' position ie at that point.

If there was any doubt why not take the prosecution and let the Court decide.

J. Johnson West Yorkshire Fire Service

'in

Driver-Controlled Deliveries of Petroleum Spirit

M.G. Sewell, BSc DIC CEng MIChemE, Health and Safety Executive, London

It is now 3 years s· I .' d I b II . h mce last wrote on this subject an aSlca y WIS to u d' d . th t · p ate you with what has happene m e mean Ime.

WHA DRIVER-CONTROLLED DELIVERIES?

I thmk It would n t ., . d f t of what th 0 come amiss Just to remm you Irs, Th" ehconcept of driver-controlled deliveries means. IS IS were th d I' d th t tie e Ivery of petroleum-spmt IS er e 0 a. of the tanker driver, and the licensee C?f the flllmg station tak ff t' t This has certam advant es no e ec Ive par deliver at ni ht whages for .01.1 companies in that they can it is not sol!ly fllhng is shut dowfl:' station goes ov n ed such tImes. Once a ftlhng deliveries will to deliveries, all time of day. one by this method irrespective of the

Although the concept f d . .' 0 nver-controlled delivenes IS new m respect of th d I' ., h b . fee Ivery of petroleum-spmt. It as een m use or ab' . d t . l' num er of years m the petroleum m us ry m re atIOn to th d . '1 Th th t . e ehvery of kerosene and gas Ol. us e anker dnvers are used to the basic concept of deliveries, but there are special precautIons which they and th th I' Ived ' e 0 er peop e mvo , must follow m respect of such d I' . f t leum 't e Ivenes 0 pe ro spm.

CONSULTATION ON REVISION OF SCHEDULE 4

As you all know th d I' ..' e e Ivery of petroleum-spmt to ftlhng statIOns IS currently controlled by Schedule 4 to the Dangerous Substances (Conveyance by Road in Road Tank Con.tainers) Regulations 1981 (the "Road Reg.ulatIOns"). Following representations by, and with, the UK Petroleum Industry ASSOCiation ("PIA") we went out to informal consultation in March 1985 on a draft revision of Schedule 4. revision included the concept of drivercontrolled delIveries as an alternative to the existing procedure.

There were a number of critical comments on certain aspects of draft revision, but no organisation was agamst the principle of driver-controlled delIvenes. As a result, the HSE decided that the next step should be a series of trials at specified filling stations to see how the would operate in practice In order to al.low this to happen, Certificates of ExemptIOn would be Issued in respect of the individual sites, with the eventual aim of a full revision of Schedule 4 if all went well.

It so that the Road Tanker Regulations are bemg revised with the aim of making the reVised in late 1989 or early 1990. If Schedule 4 IS to be revised this is when it would take eff Th ' ect. ere are, therefore, up to 2 years for experience to be galOed via the trials.

PIA CODE OF PRACTICE

.well as laying down the legal requiren;e.nts in, of Exemption, or later in the reVISIOn of C edule 4, it was agreed that the PIA would prepare a ode Practice to cover the operational details not to the legal documents. This was issued for with the draft revision of Schedule 4, and Th' by the Institute of Petroleum in May 1987. b IS b?de IS. to some extent. provisional and is likely to e Ject. to amendment as experience is gained. A final f v.erslllon wI.1I be published at the time that Schedule 4 is lOa y reVIsed.

TRIAL SITES

We. with the PIA that there should be about 1012 sItes around Great Britain with, as far as an even spread of licensing authorities between FIre and Standards Departments. As about ?-6 compames are currently interested in this It n;eans that each company will operate 2-3 SItes, all sites being company-owned.

We deCIded that one site would be dealt with first before further sites were considered. This site was chosen as an Esso site in South Shields with tankers out of the Esso terminal in Tynemouth. I now Wish to diSCUSS the procedures adopted at this site as the later sites have all followed the same procedure.

Firstly, local discussions took place between Esso and the licensing authority we became involved. A site meeting of all the concerned then took place where ?raft CertIficate of Exemption (based on the revlslOp. of Sched.ule 4) was discussed and any speCial conditIons peculIar to the site were agreed. We then went out to local consultation on the draft Certificate with the following people the licensee, the oil company, the shop stewards at the tanker terminal, the local TGWU official and the Chief Environmental Health Officer of the local District Council. Following consultation, the Certificate of Exemption was finally issued in December 1986 and operations began in February 1987.

One of the conditions of the Certificate of Exemption is that a review meeting shall be held, at intervals no greater than 4 months, between the licensing authority, the licensee and the oil company's terminal. At the South Shields site there have now been two such review meetings and I attended the second of these. There have been about 150 driver-controlled deliveries to this site without any operational problems occurring. There have been a few minor teething problems with some of the equipment, but not such as would affect the gauging of the tank ullage. I think it would not be inappropriate to quote the senior shop steward of the Esso tanker drivers at the Tynemouth terminal, who stated at this second meeting "It was an excellent operation bringing major benefits especially in the field of safety".

With the Esso site in South Shields underway, various other oil companies then applied for Certificates of Exemption. The companies currently involved are Shell, Mobil, Texaco and BP with sites respectively in Bolton, Basildon, Coventry and Nelson/Abercynon. The Certificates of Exemption have been issued in respect of the first 3 of these but none are yet operational. It is expected that further sites in London. Leamington Spa, Edinburgh, Nottinghamshire, for example, will be submitted for consideration.

REQUlRMENTS FOR DRIVER-CONTROLLED DELIVERIES

Having dealt with the present position in relation to the trial sites, let us now look at some of the requirements which have been laid down for drivercontrolled deliveries in the Certificates of Exemption. The first and most important point to make is that the requirement for the licensee to measure the storage tank's contents, and to sign a Certificate as to quantity, has not been done away with. There one difference, however. in that the measurement is 110\\ ut

.,7

the tank ullage rather than the quantity in the tank. This makes it easier for the driver to compare his delivery note with the tank ullage reading on the Certificate to determine whether the quantity of petroleum-spirit in the road tanker can actually be delivered into the storage tank. Some of the other main requirements are listed below.

1. Once a filling station goes over to driver-controlled deliveries it riiust under this mode of operation unless

(a) at least one week's notice in writing has been given to the licensing authority that operations will revert to the procedure set out in Schedule 4: or (b) due to equipment failure, the Schedule 4 procedure has been reverted to temporarily, in which case the licensing authority must be notified within one working day of the change.

2. Each tank must be fitted with a suitable measuring device which continuously indicates the ullage in the tank and which indicates that the tank is full in any fault situation.

3. Each tank must be fitted with an audible high level alarm.

4. A telephone must be provided which is accessible to the tank driver and which enables him to make direct contact with the emergency services or the oil terminal.

5. The road tanker must be fitted with bottom-operated foot valves and there must be a means of quickly shutting-off all the foot valves in an emergency.

6. The road tanker must be loaded in such a way that the contents of a compartment will not need to be split between two storage tanks.

7. Not more than two storage tanks must be filled at the same time.

8. Each storage tank fill-point must be clearly marked to show the tank's number and the maximum quantity (and grade) of petroleum-spirit which may safely be filled into the tank.

9. Each fill-point cap must be locked with a captive padlock, the key of which shall be marked with the tank number and shall have a profile different from that for any of the other storage tanks.

10. Adequate lighting must be provided for the site and the control box, with additional emergency lighting for the box in case of a power failure.

The maIn constructional difference between a drivercontrolled delivery site and any other site is the fitting of a control containing all the necessary operational and eqUipment for the driver to use. The box is usually fItted t<? the outside wall of the sales building in a position tothe storage tank fill-points. Details concernII1g the control box are given in the PIA Code of Practice, and Mr M A Cox of Normond Instruments will no doubt be dealing with this in more detail in his paper. ' ,

OPI!=RA TIONAL REQUIREMENTS

I .would like to give a brief description of the mam operatIOnal aspects of driver-controlled deliveries.

I. a delive.ry is due, the licensee will complete a CertIfIcate SImIlar to the one currently required by Schedule 4 but with a few minor differences. He will place this in the control box together with the keys for the padlocks un the relevant fill openings.

2. When the dflver arrives on site he will unlock the control box. switch on the site lighting (when appropf1ate). remove the fire extinguisher and other safety equIpment and check that there is a dialling tone on t he telephone.

He will then check the ullage gauge against his delivc' f\ note and the Certificate left by the licensee. In ,Jdril1 1on to Vlewll1g the digital read-out of the ullage

gauge, the driver will take a print-out from the attached printer. If the figures tally and it is clear that the relevant storage tanks can take the quantities in the road tanker, the driver will continue with the operation.

4. If there is any discrepancy in the figures, or the gauge is at fault and hence indicates that the storage tanks are full, the driver will immediately telephone the terminal and inform his supervisor. In most cases the supervisor will inform the driver to abort the delivery, unless arrangements are made to contact the licensee.

5. Assuming all is well, the driver will next take the keys for the fill-cap padlocks and proceed to discharge the tanker. After discharge is complete, he will take a further print-out of the ullage gauge readings before returning all the equipment to the control box and locking the box.

6. In any emergency situation the driver will immediately abort the delivery, telephone the terminal and emergency services and carry out such other emergency action as appropriate.

I hope the above description has indicated to you that much thought and effort has gone into the development of the procedures for driver-controlled deliveries, and that they are no less safe than the existing procedures currently laid down in Schedule 4 to the Road Tanker Regulations. Indeed, because of the problems which have come to light with the existing system, certain people are of the view that this is a safer practice with less scope for things to go wrong. I leave it for you to judge.

PROSECUTIONS

WEST YORKSHIRE FIRE SERVICE ARREST WARRANTS ISSUED

John Johnson GradIFireE, Assistant Divisional Officer (Petroleum Officer) reports of a further interesting cas:, pursued by the West Yorkshire Fire Service which resulted In total fines, including costs, of £2,638.000.

The case started on Friday 30 January 1987 at 0849 when a 999 call was received at Brigade Control reportmg a spillage of petrol at a Service Station in the Leeds area. An appliance was mobilised in response.

On arrival, the Officer in Charge was approached by the tanker driver of a tanker delivering petrol into underground tanks who stated that it was not his fault and that the vent pipes were blocked!

The Officer noted a small pool of petrol around one of the forecourt petrol pumps and a petrol soaked rag was pushed into a pipe at the base of the same pump. When the was removed a jet of petrol issued from the pipe whIch was collected into containers. An estimated quantity of some 1520 litres was collected.

Further investigation at the petrol tanker delivery point found the tanker delivery hose was connecte? to underground tank Number 3, together with a of petrol in the manhole chamber to the same tank. The dnver commented that he could not couple the hose because i.t was full of petrol! (An OFFENCE in respect of petrol escapIng at the fill point).

It was apparent that tank Number 3 had been overfilled. The tanker delivery hose was full with 1600 litres of petrol in the vehicle pot and a defective air separator on the petrol pump. fed from Number 3 tank. allowing petrol to t10w onto the forecourt. The petrol in the tanker hose was drawn of through the pump which enabled the hose to be coupled.

The Divisional Petroleum Officer arrived and found that spirit was being delivered into tank Number 1 and there was no one from the Service Station keeping a watch on the tank, the attendant being in the forecourt shop. (An OFFENCE in not being in constant watch).

On production of the petrol delivery certificate it was noted that column three was not signed for tank Number 1 or Number 3 into which spirit had already been delivered. (An OFFENCE by the driver for beginning delivery before the certificate had been signed in his presence). The Officer asked the attendant for the copy of the Certificate and again, this was not signed for tank Number 1 or 3. (A further OFFENCE by the person in charge of the tanks).

When the delivery had been completed and the tanks filled approximately 1600 litres had been over ordered and had to be returned in the tanker to the terminal. Samples of petrol were taken from the manhole chamber of Number 3 tank in the prescribed manner, the remaining contents were also removed and it was estimated some 15 litres of spirit was present in the chamber.

The question of quantities of spirit to be delivered then arose. The attendant had originally instructed the driver to drop 10,000 litres into tank Number 3 and had entered that quantity on the certificate. However, the tank was full when only 8,400 litres had been delivered.

In the absence of the Licensees (three partners), the attendant was in charge of the storage tanks for the delivery and it was due to his incompetence that tank Number 3 was overfilled. (An OFFENCE The Licensee shall secure that some competent person )

During the investigations at the garage, customers were seen by the Officer to drive onto the forecourt and serve themselves with petrol at the attended service site). The attendant commented that regular customers tended to serve themselves! (An Offence permitting unauthorised persons access to petroleum spirit).

Following the petrol spillage investigation, a full inspection of the premises was carried out on 10 February 1987 when the following OFFENCES relating to the Conditions of Licence were reported and submitted to the Licensees.

a Underground tank Number 1 not securely closed and locked.

b Underground tank vent pipes not securely fixed to the building.

c Permitting a collecting space for petrol or vapour beneath pump Number 1.

d Not ensuring pump delivery hose efficiently maintained.

Summonses and Notices to Accused were served on the attendant and the three joint Licensees on 27 April 1987.

Action was to be taken against the tanker driver but the Fire Service were informed in correspondence from his employers that he was no longer in their employ, been made redundant and with regard to the incident JI1 which he was involved, he was awarded two days suspension with loss of pay, the matter with regard to the driver was, therefore, not proceeded with.

The matter came before Magistrates Court on 3 July. 1987, where all defendents indicated they intended to enter not guilty pleas on all counts. The Magistrates. therefore. dealt with the mode of trial and directed the case should be heard by the Magistrates and was adjourned to Thursday 20 August 1987.

When the case returned to Court on 20 August the Defendents failed to turn up and the Magistrates issued Warrants for the arrest of the Defendents being backed for to appear before the Court on 2 Septemb;r 1987. (The effect of Warrants being backed for bail is that the Defendents were arrested. taken to the Police Station and after a while released on bail to appear on the specified date).

At the initial hearing, the Defendents were represented by a Solicitor but at the hearing on 2 September Council had been instructed and they were represented by a Barrister. Following guilty pleas in respect of the charges and the prosecution presentation, a previous Court case in 1986 was cited where one of the Joint Licensees was successfully prosecuted by the Fire Service and was fined a total of £1,700 for similar contraventions at another of his petrol filling stations in the West Yorkshire Area.

The attendant was fined £100 on each of two charges of not signing the delivery certificate before discharging into the appropriate tanks.

In all eight charges were brought against the Licencees who were fined a total of £2,050.00. Cost of £338 plus £50 Advocacy fees were awarded to the Fire Service.

Punch Service Stations Ltd.,

Berkeley Service Station, Doncaster Road,

Scunthorpe.

On Tuesday 28th October, 1986, a Company Director was in his car showroom at Doncaster Road, Scunthorpe, when he saw some workmen working on the forecourt area of an adjacent petrol filling station. Petrol sales were still being operated.

He saw them using a pneumatic drill around the pump islands and also a circular saw which was causing a large number of sparks around the petrol pumps. He spoke to the workmen and told them that this was a dangerous practice. They appeared to take very little notice so he then notified the head office of the Company. Petrofina of Leeds. There was no one available to help him and he was advised to obtain help locally.

He therefore complained to the Humberside County Council Trading Standards Department at Scunthorpe upon which a Petroleum Officer visited the station. He found that excavation had taken place using a pneumatic drill around each pump island. A steel band had each pump island had cut away Circular sa,:". He visited the kiosk which was 2.32 metles hom the tank vent pipes and found workmen still using the to excavate the kiosk tloor. Prior consent for the alterations had not been given by the Licensing Authority.

The cover of an electric cable to one ot the pumps had been cut. The men carrying out the work who were sub contractors stopped work on the site. . . .

In explanation the stated that thiS was a national ackage which was being camed out at many other Punch in the United Kingdom.

The Company were charge that on or about 28t!1.0ctober 1986 at Scunthorpe, being the person to whom spmt mber K 18(S) had been granted. did contravene Conchtlon nu I I' 8 of the conditions for the grant ot a petm eum ICCIK'e. m that alterations were made to the premises within 4.3 metres of the storage fittings or associated previous written consent of Chief Officer ot Tradmg Standards. contrary to Section 1(3) ot the. Petroleum Consolidation Act. 1928. as amended. and Sectllm ot The Health and Safety at Work etc. Act. 1974.

The case was dealt with by the Scunthol1ll' Magistrates Court sitting at Brigg on the 2nd .funt'. 1987. Through a solicitor the Companv pleased guilty to the off'encl' and were fined fU)()() and ordered to pay prosecution costs l1t f1'iO

-." For comprehensive safety and vessel servicing which includes all aspects of work. • Nitrogen Inert Foam Inerting • Gas freeing using various Nitrogen purging techniques • Leak testing by all modern techniques • Hot work modif i cations, and repairs, to Lloyds/A.S.M.E. • Bottom i ng , Cleaning , Removal, Slurry Filling • Mothba lli ng • Sprayed Res i n , or Glass Reinforced, Spirit , Solvent, and Chemical Resistant Linin gs , e n g i neered to Lloyds inspectorate of shipping approval. • A b ras i o n t o S.A 3 , Protective Coatings, and Cathodic Protection. P l ea s e Ph o ne (we charge no extra for our knowledge, insurance or e xp e rience) STORAGE TECHNOLOGY FR IA RY MEW S 28 COMMERCI A L ROAD GUILDFORD GU1 4SU TELE X 859535 I NT CO M G FAX 0 4 83 571162 • LONDON / SOUTH EAST AREAS 01 546 2754 • GSOUTHERN / CENTRAL AREAS & TECHNICAL ENQUIRIES UIlDFORD (0483) 222307 • SOUTH WEST AR EA (0822) 2753 • 7 OA Y 24 HOUR EMERGENCY CAl l OUT (All AREAS) G WLfOFORD (0483) 222307

Adencon Draughting Services Ltd.

the preparation of drawings for petrol filling station redevelopments, alterations and tank or installations and obtaining all necessary statutory approvals (i.e. planning permission, building regulation approval, petroleum officer approval etc.) MEMBER A.P.E.A. PHONE 01-739 9538 TUBEFLOW LTO and SOUTHERN PUMP SERVICES "WE COVER LONDON" CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES SUPPLY, AND MAINTENANCE OF FUEL PUMPS, TANKS AND EQUIPMENT ETC. 27=29 TEMPLE STREET, LONDON E2 saa hi

19 PLASHET GROVE ,

LONDON.E61AD Telephone: 01-472 6627/8

Road Tank incident in South Yorkshire

During the afternoon of Wednesday , 17th June 1987 a tractor unit pulling a multi-compartment tanker , constructed of roiled, welded mild steel, containing a tot al of 25,000 litres of liquid was travelling on the M18 Motorway South of Doncaster in South Yorkshire when its driver became aware that a piece of metal had from a high sided lorry containing scrap immedIately In front of him

The metal passed over his cab having ' bounced ' on.the carriageway and hit the tank. As a precaution dnver pulled onto the hard shoulder to inspect his vehIcle and found that the metal had pierced the tank causing a hole from which liquid was discharging.

The emergency services were informed and the PolIce were able to quickly halt traffic and isolate the tanker.

Three fire engines were mobilised by the County FIre Service, one each from Maltby, Edlington and Rotherham

On arrival at the incident the Fire Brigade Officer-inCharge was able to identify the contents of the tanker from the Hazchem sign as toluene and the driver provided the tre?1 card in his possession The compartment of the ta nk whIch had been holed contained about 5,000 litres of th e product

owners of the tank er agree d to the request to prOVIde an adviser a nd a water bowser and decontamination unit were mobilsed by the County Fire Service.

· Firefighters wearing suit able protective clothing Inspected the tanker to assess the extent of the damage and the vo lume of the leak Earth was used to contain the spillage and prevent it entering the drains. A request sa.nd to augment this precaution was made and satisfied WithIn one hour.

As a precaution uncharged lines of hose were laid out to prOVide COver should fire occur.

The P<?ssibility of providing a su itable plug for hol e was conSidered but dismissed as the tanker could stili not be safe ly move d and it was agreed that this section of the tank neede d to be decanted into another tanker. Co unt y Fire Service used an explosimeter to estab li s h the area of danger and thus e nsure a safe route for the replacement tanker to approac h the incident. Due 5 .mlle On each lane of th e motorway with the e hhood of thiS creating a delay in the arrival of thi S tanker : the Police provided an escort for thi s and th e specJa hst adv ise rs

Upon th' rot . e lr the adv isers put on their own P ect lv e clothIng but needed Fire Serv ice breathIng apparatu h ' h · . s w Ich was worn under close s up e rvi sion . T el r Co nfirm ed that t he tran sfe r of th e toluen e from t e damaged tank s ho uld take place and this was achieved an hYdra uli c pump mounted on the rear of the le place ment tanker. The tran sfer was completed ? prox lmate ly 3 hOurs after t he rece ipt of th e call to the ,0 Unty FIre Se rv ice.

· A lth o ugh the tota l loss of to lu e ne re mained relative ly <; m a ll , the Incident prOvid ed th e ab ili ty of the necessary <;e r VJces to c1 0se l I ' b' . Y la lse and ac hi eve esse ntIal 0 Jec t! ves. rh e 'ie rVlces present in addit ion to t he Fire , Police and A mhu /an ce Serv ices we re the Water A uth orit y and H lt! h wavo., D e partment of th e Loca l A uthorit y

f> 2 DESIGN FUELLED B EXPERIENC Personal attention in design & development for the petroleum retail industry • Principal with ove r 25 years experIence • Project Management specialists • Progress ive & innovative outlook • Consultants for statutory & planning req uirements • Comprehensive or tailored service to suit PLANACOURT Planacourt Limited PO. Box 27 Billericay Essex CMll 2ES 027744016

and Certification of Petrol Metering Pumps

The Role of Standardisation in the process

Mr. F. Wilson, Chairman of the BSI committee on Petrol Pumps

The use of British Standards has long been recognised as a means of increasing efficiency, productivity, and cost effectiveness in Industry, but their importance is not confined to the technical demands of manufacturing. Standardisation influences the goods we buy, the way they are made, assembled, stored, packed, labelled and tested and whether they are safe.

In short British Standards are an important factor in the competitiveness of our major industries, the development of new technology and the safety of consumer products.

BSI this time a fa.mily of standards/codes of practice are bemg created designed to give the up to date guidance necessary to stabalise or extend the degree of that over the the pump industry has built mto the manufacture of ItS most sophisticated product the petrol metering pump.

. Such concern themselves with equipment mstalled. m the hazardous areas of the filling station and NOT with the control/management devices that are installed in non-hazardous areas.

In parallel with this work the appropriate Divisions of the HSE have tackled the enormously difficult task of revising the "Home Office Model Code of Principles of Construction and Licensing Conditions (Part 1) for the Storage of Cans, Drums and other receptacles Petrol Filling Stations".

A bit of a mouthful all that particularly since the relevant phrase "Petrol Filling Stations" is the only heading that counts as far as this paper is concerned. Of course the umbrella legislation for this work is still the "Petroleum (Consolidation) Act 1928.

The inspiration to manufacturers is a need for achieving common requirements across the UK and hopefully into Europe eventually. The standards/codes under discussion go a little way towards achieving this but will only be as good as the backing you give them now and into the future.

The gestation period for the standards/codes has been around seventeen years, far far too long when you consider that the triggers for action were:

(a) The deficiencies (in terms of modern requirements) of the existing Model Code and BASEEFA Certification Standard SFA 3002 : 1971.

(b) The advent of the higher technologies in the 1960's.

(c) The advent and application of the enlightened marketing policies the oil companies.

recall that it was in the L974178 period that representatives of the l.P, LAJAC (before it became LACOTS), GLC, PPMA. HSE and others spent time preparing revisions for the Home Office Model Code. and this work was invaluable when eventually the HSE working party on filling stations was set up.

However work did not address itself specifically to questIon of Electrical Requirements for Filling StatIons. but this has now been amply covered in the HSE proposals shortly to be issued for comment.

I am certain that every effort will now be made to

expedite the completion and issue of the new documents, and this is perhaps an appropriate time for me to list them.

BRITISH STANDARD/lI\'STITUTION COMMITTEE PLC /6

i. BS for Metering Pumps and Dispensers Installed at Filling Stations and used to Dispense Liquid Fuel. Part I Specification for Construction

ii. Ditto Part 2 Guide for the Installation of a Pump onto its foundations.

Ill. Ditto Part 3 Guide for Maintenacne. (incorporating proposals for training).

iv. BS3395: 1980 under revision Specification for Electrically Bonded Hoses and Hose Assemblies for Dispensing petroleum based fuels. Committee RUM/9/5 will shortly consider the revision proposals with a view to issuing the document for public comment.

HEALTH AND SAFETY EXECUTIVE

i. HSE guidance note/booklet "Petrol Filling Station" _ Construction and Operation. Shortly to be issued for public comment.

Obscured amongst the standards are other BS which must be worked to (I expect some of those are also being revised so pervasive is the thrust of to days high technology) and then it must not be forgotten that we are no longer an island and that note has also to be taken of ISO, IEC, CEN, CENELEC, DIN, NBS, AFNOR. lIS and other standards bodies if products are to be marketed world wide (and to survive these days they have to Underbe).UK law (that is to say the Weights and Measures Act) pump manufacturers have to conform to stringent regulations and criteria to achieve pa!tern. approval for their products. in metrology and security of data terms.

In addition manufacturers have to design their equipment to conform to safety Two robust disciplines both aimed at the petrol metering pump. I am sure you will agree that a pump manufacturers lot is not a happy one.

It is interesting to ponder if an oil company said design us a horse from scratch in accordance with the current standards/code whether they would get a camel or a multi-product pump designed to satisfy just about every requirement in the book... .'

Seriously there is a contmumg need tor mternal UK as well as international effort to try and acJ1l\:.'ve standardisation of requirements for petrol pumps in the safety area.

.'

Internationallv there is an increasmg commonahty ot metrology requii'ements and th!s is still some way to go but at least the light at the end ot the tunnel can be seen.

In the area in spite of efforb by CFCOD (Comite de Fahricants Europeens d' Installation et dt' Distribution dt' PCtro\e) in or thereabout thert.' i" no standarisation dfort currently being umkrtakt.'1l within the EEC. as far as I am Cl\\ are.

Within the EEC and hopefulh EFTA if I \\ en' to bt.' asked to indicak in \\hich particular arl'a tIll' Ihm"t

l)\

standardisation should take place I would say in the hazardous areas of the filling station. By this I mean the zone 2 height and radial spread and the zone definition for the areas of hazard generated by the pump itself. lE Nozzle Boot, Hose Joint, Foundation wells, etc. If this could be achieved then all else would fall into place, as far as manufacturers are concerned I think.

If no sustained effort in this area is made than as Europe becomes Europe with a large E, in the complete sense, it will be weaker because ofthe lack of common safe.ty requirements for petrol pumps and filling stations.

As far as the UK is concerned in due course the BASEEFA Certification Standard SFA 3002: 1971 "Petrol Pumps", and the present Home Office Code wIll be replaced by the new documentation. Subsequently I hope the new documentation can be used by CEN/CENELEC to generate standards for the EEC.

In considering all these matters it is interesting and necessary to retain a perspective on the evolution on the petrol pump and in these closing remarks I list what appears to me to be the most significant factors in the evolution of the pump.

1920's -A STEP CHANGE

The oil companies in conjunction with some far seeing produced continuous flow positive

Isplacement meters (still the heart of the modern pump) which allowed pressure operated systems to be devel?ped. At last the barrel, or 2 gallon can, and the contaIner type dispensers could be left behind.

1930's

The advent of the mechanical computer

At. last it was possible to fill up without needing a umv 3/. ersIty degree to work out the price to pay. (say 10 -lgallons x Is-4V2d per gallon)

Step Change I think in as much that management data to be available and the development of the device gave Impetus to the concept of self-service.

1949 HOME OFFICE CIRCULAR No 218/1949

E Service Pumps: Associated Electrical exqpUIIPI?ent Dr H.E. Watts H.M. chief inspector of OSIves.

1958

The first mo tech I . vement towards the use of electromc step ogy In petrol pumps. This constituted a further contr I ange and had a profound effect on pump and o system design.

it introduced a flexibility into design compute e. the "Rigidity" of the mechanical of the r With Its need to have reasonable juxtaposition meter The . f became '. processIng 0 management data comparatively easy.

1960's

A further st h electron' ,ep c ange. Increasingly the advent of ICS gave imp t h service and for e to t e development of self ward lookmg marketing systems.

1968

Home Office M Filling Stations. odel Code issued for Petrol

J971

BASF FFA Certification Standard SF A 3002: 1971 pt'lrol meterIng pumps".

1974

Local government re-organisation. A new breed of Petroleum Officers entered the licensing field introducing a period of uncertainty for manufacturers, as far as historic safety requirements were concerned.

1974 Onwards

A further Step Change covering the further development of self-service attende? and unattended sites leading to the emergence of hIgh hose pumps, linked to high tech control systems.

Continuing evolution of the petrol pump has led to the production of multi-product dispensers (MPD's).

MPD's are the end result of marketing philosophies which reach out to create high throughout Self-Service Filling Stations having a ground area sufficient to provide at least four through to sixteen or more filling positions. (There are constraints upon how many actual filling operations may take place simultaneously) Such filling stations may also provide space for shops selling a wide range of goods.

All of these developments have advantages and disadvantages but providing considerations for the safety of the public and the employees, and the environment are taken into account then such developments should be encouraged. I have heard it said that the facilities now on offer to the public from some filling stations act to replace the now becoming defunct corner shop. Well there is nothing wrong with that.

CONCLUSIONS

1. The new standards particularly those concerned with maintenance require the need for training to be concerned should pursue that concept WIth VIgOUr.

2. No matter how well the new standards and codes have been formulated and no matter how well manufacturers conform to them (and the spirit of the requirements, and those of the NWMI) conformity has a hollow ring if after installation (and outside shall we say the warranty period) petrol pumps can be serviced repaired, refurbished or moved from A to B by just about anybody without reference to the original manufacturer or the Certification Documents. How then can the conformity of the equipment to the original certification be re-established? There does not at this time appear to be any satisfactory route for this to be achieved, other than, as far as NWML are concerned through Trading Standards Officers who can exercise some legal control in this area.

However as far as safety is concerned there is a gap, and in my view a dangerous gap, existing.

I would like to see a meeting of authoritive people in this area set up so that the matter can be properly (and be seen to be properly) addressed. with a view to policies being formulated and put in place with authority (which must be credible). Some infrastructure systems do exist in other areas of manufacture when faced with the same problems and these could be adapted I think. If after such a meeting all conclude that nothing can be done then we should feel extremely guilty and sorry for the people of the future who may substain injury or worse though our lack of action in this area.

compactable wastes. Also static compactors installed and serviced Skip services FIFTY YEARS OF SERVICE PROGRESS AND EXPERIENCE A modern fleet of tankers for dealing with general and special industrial effluents. Established services for domestic and farm cesspits and gully cleaning. for the professional builder and DI Y enthusiast. tionwide specialist Tank Cleaning Service fda6 Jetting services for , garages and industrial M-=:=and commercial ;/ premises A Hotline' emergency service for the 'out of hours ' unexpected crises. IS WHAT YOU CiET WITH CLEANSING SERVICE GROUP HEAD OFFICE GRANGE ROAD BOTlEY SOUTHAMPTON S032GD BOTlEY 2232 RINGWOOD 2008 BRISTOl552286 NEWBURY 45357 OXFORD 61150 EVESHAM 2620 STONEHOUSE 6116 SEVENOAKS 453175 MAR 26A

B MER TAB-LINK FOR LONGER LIFE EASIER SERVI

During the past 2 years a different type of drive belt appeared on f?recourt petrol dispensers. I he name IS Tab-Link, and its unique po yester/polyurethane construction enables this belt to last a minimum of six times longe: than conventional V-belts.

It s easier to service, as one reel enables the service engineer to make up any length of belt to SUit all pump assemblies thereby greatly , redUcing the stock carried.

When it comes to the manufacture of pump equipment a simpler design is possible using ' Tab Link, as the tensioning and sliding adjustment systems used with conventional drive belts aren't needed. Tab-Link is in successful use in petrol dispensers throughout Britain, including those serviced by Pump Maintenance Limited, and built by Avery-Hardoll Ltd. , Tokheim Ltd. and Ferranti Ltd

BRAItIIItIIER I TAS!ldJ!i:!J/% I So isn't it time you fitted Tab Link you'll fmd yourself in very good company BRAMMER TRANSMISSIONS LTD . Hudson Road , Leeds LS9 7DF Tel (0532) 493486 Telex 556144 The driving force in petrol pump V=Belts! , --

_

c P INSTALLATIONS LTD. (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all Work associated with Forecourt Pipe work 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS67XN Tel: RAYLEIGH (0268) 781184 / 781859 (24 hrs ans.) 3/obn & <!CO. 1Ltb. FIRST HANGINGS' BLABY ROAD ENDERBY . LEICESTER . LE9 5AQ Telephone: Leicester 862287 (STD 0533) For a Comprehensive service for Liquid Fuel & LPG installations Consultancy, design, installation, maintenance & decomrnissioning Gas-free certificates Site surveys LPG vessel 5 & 10 year inspections MEMBER A.P.E.A. L.P.G.LT.A.

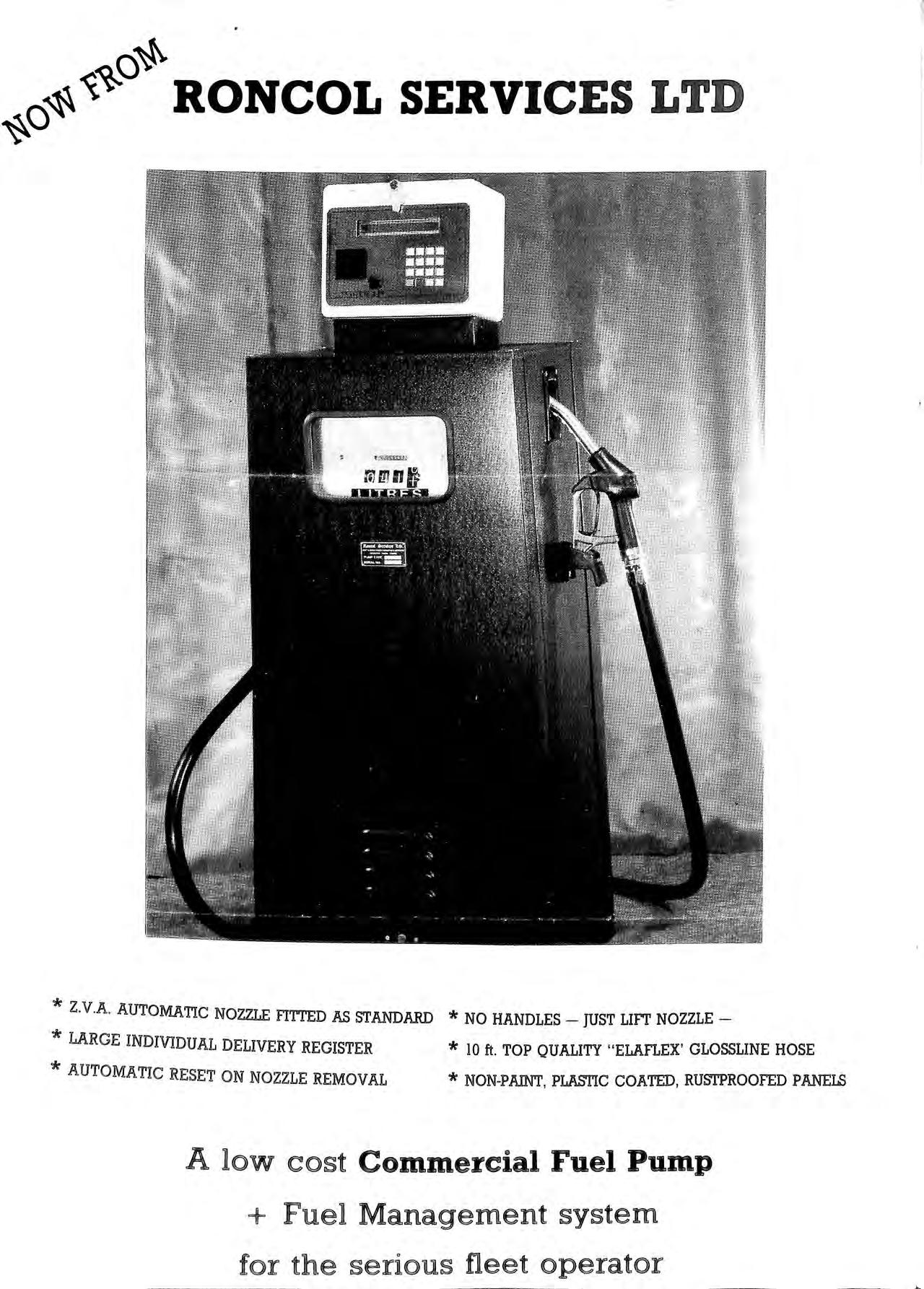

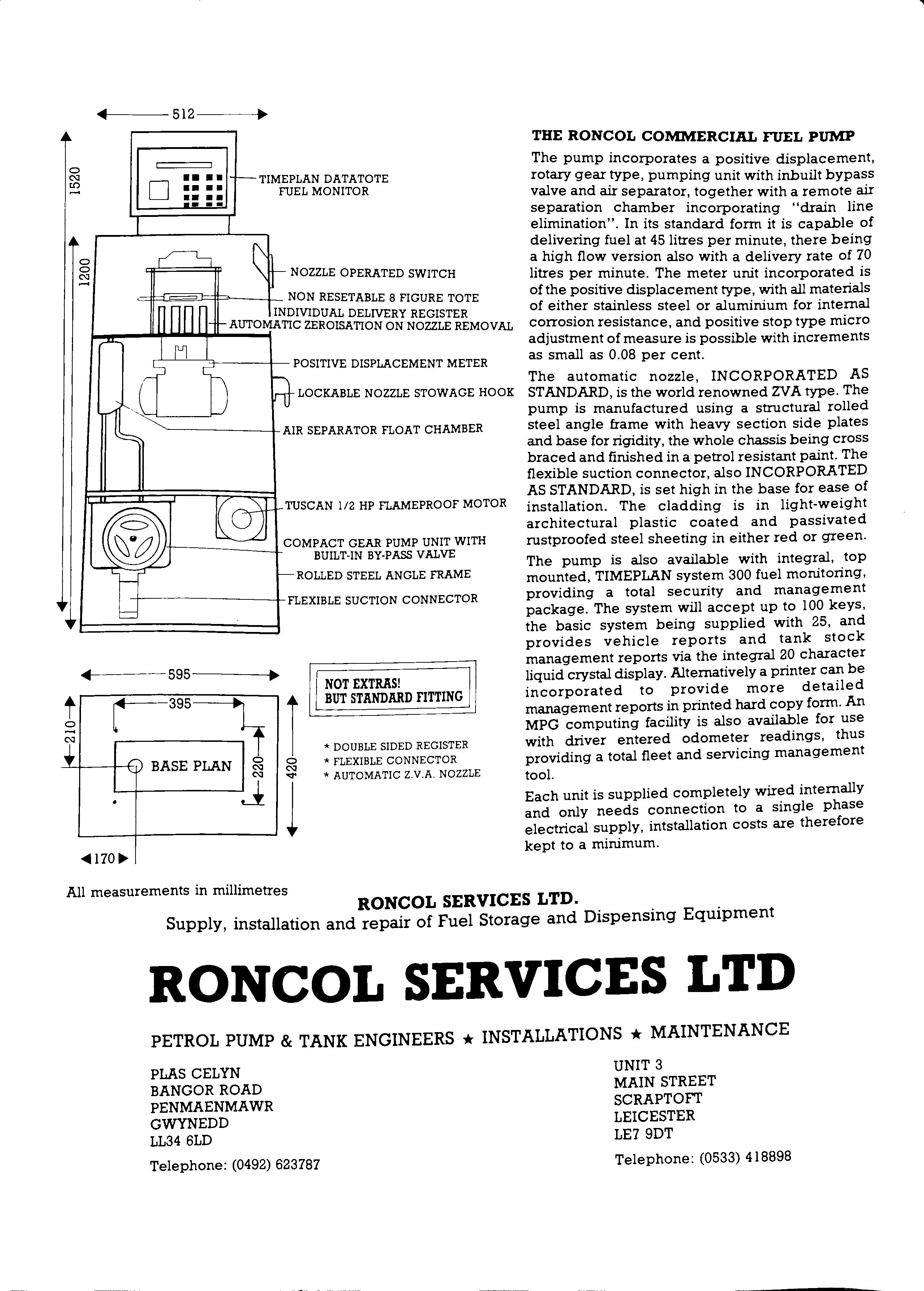

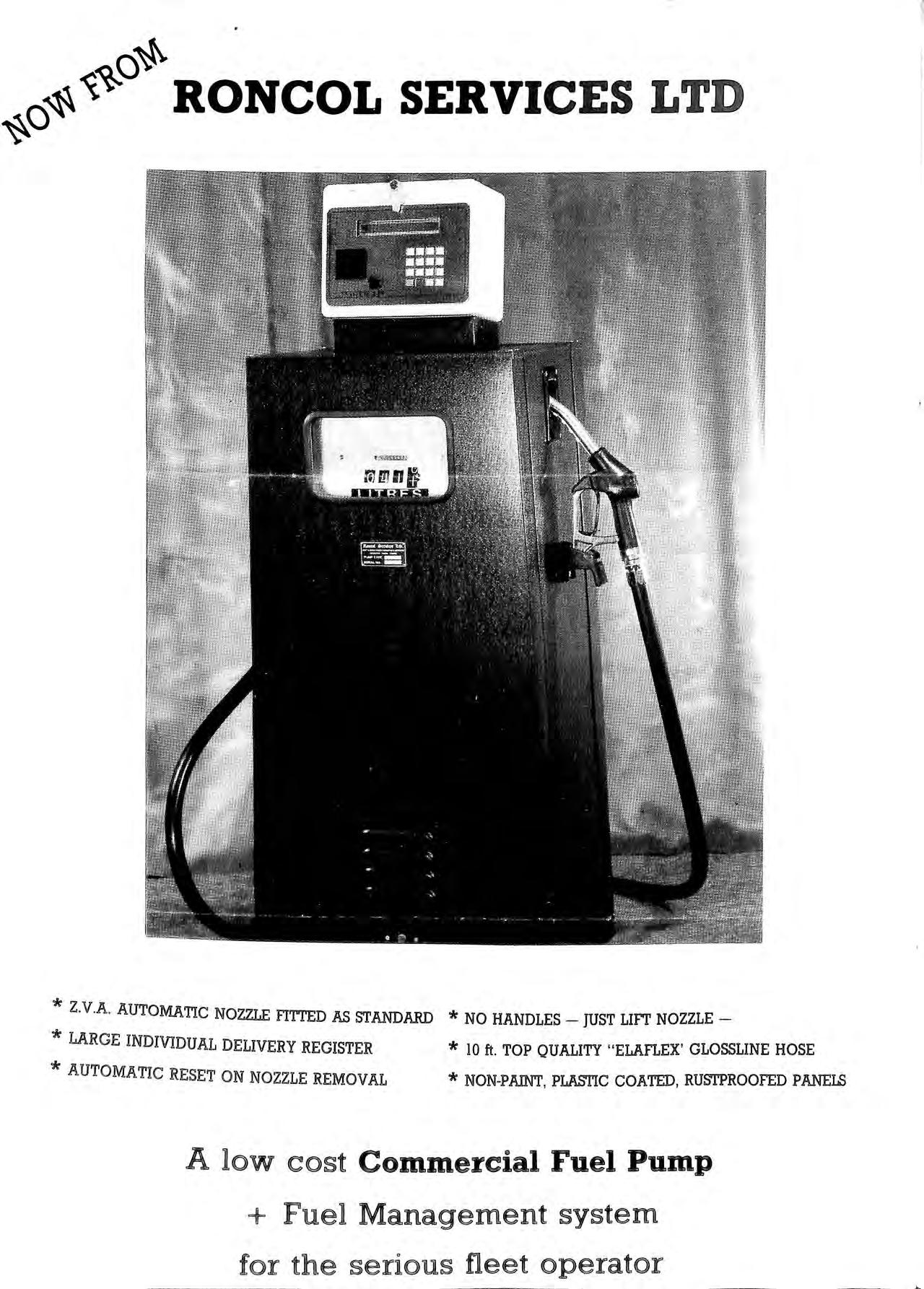

RONCOL SERVICES LTD * Z.V.A. AUTOMATIC NOZZLE FITTED AS STANDARD * NO HANDLES JUST LIFT NOZZLE* LARGE INDIVIDUAL DELIVERY REGISTER * 10 ft. TOP QUALITY "ELAFLEX' GLOSSLINE HOSE * AUTOMATIC RESET ON NOZZLE REMOVAL * NON-PAINT, PLAS'I'lC COATED, RUSTPROOFED PANEU5 A low cost Commercial Fuel Pump + Fuel Management system for the serious fleet operator

THE RONCOL COMMERCIAL FUEL PUMP

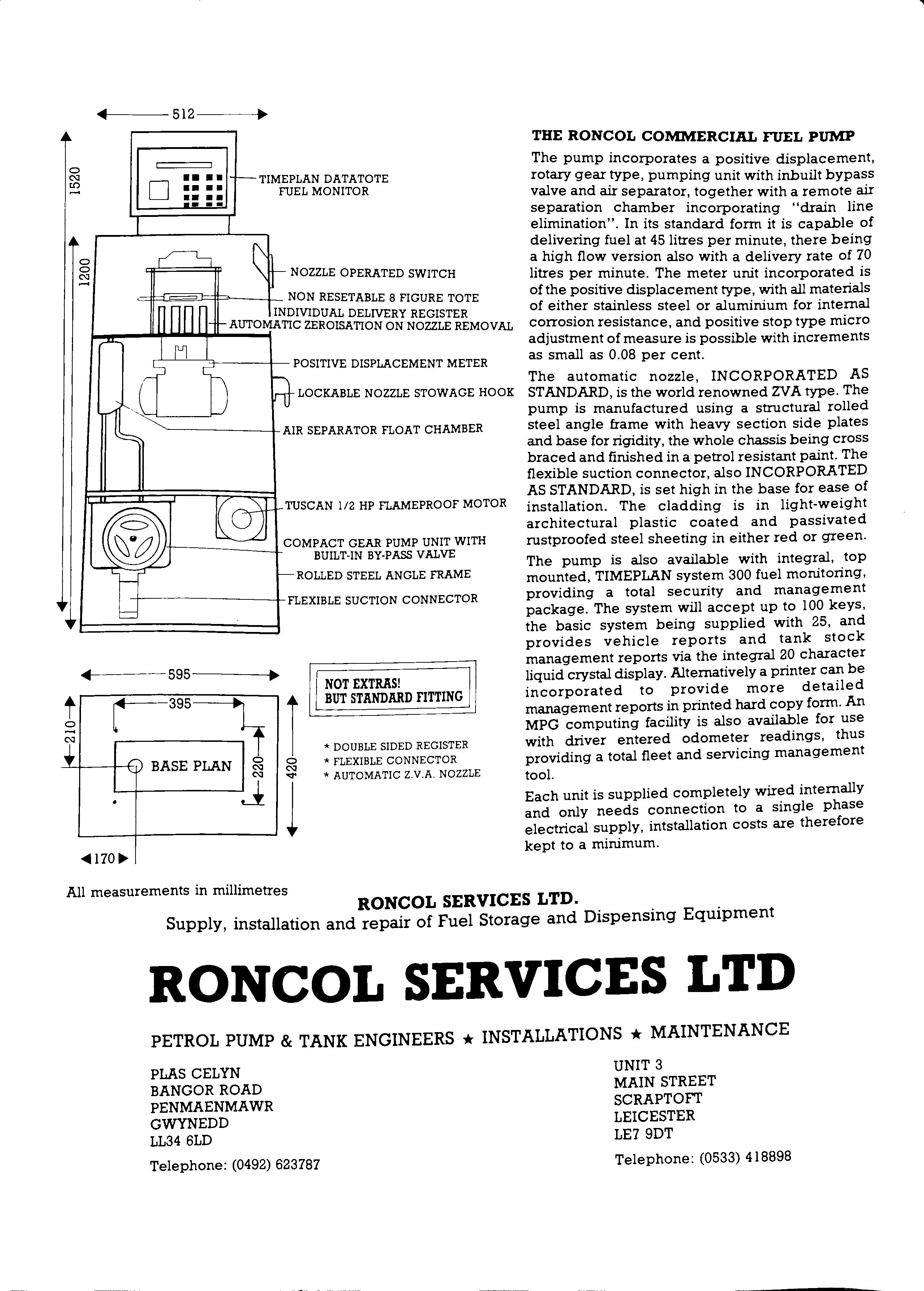

The pump incorporates a positive displacement, rotary gear type, pumping unit with inbuilt bypass valve and air separator, together with a remote air separation chamber incorporating "drain line elimination". In its standard fonn it is capable of delivering fuel at 45 litres per minute, there being a high flow version also with a delivery rate of 70 litres per minute. The meter unit incorporated is ofthe positive displacement type, with all materials of either stainless steel or aluminium for internal corrosion resistance, and positive stop type micro adjustment of measure is possible with increments as small as 0.08 per cent.

The automatic nozzle, INCORPORATED AS STANDARD, is the world renowned ZVA type. The pump is manufactured using a structural rolled steel angle frame with heavy section side plates and base for rigidity, the whole chassis being cross braced and finished in a petrol resistant paint. The flexible suction connector, also INCORPORATED AS STANDARD, is set high in the base for ease of installation. The cladding is in light-weight architectural plastic coated and passivated rustproofed steel sheeting in either red or green.

The pump is also available with integral, top mounted, TIMEPLAN system 300 fuel monitoring, providing a total security and management package. The system will accept up to 100 keys, the basic system being supplied with 25, and provides vehicle reports and tank stock management reports via the integral 20 character liquid crystal display. Alternatively a printer can be incorporated to provide more detailed management reports in printed hard copy fonn. An MPG computing facility is also available for use with driver entered odometer readings, thus providing a total fleet and servicing

Each unit is supplied completely wired internally and only needs connection to a single phase electrical supply, intstallation costs are therefore kept to a minimum.

o N [()o o N 1---o •••• •••• •••• •• TIME PLAN DATATOTE FUEL MONITOR NOZZLE OPERATED SWITCH NON RESETABLE 8 FIGURE TOTE INDIVIDUAL DELIVERY REGISTER 1-......_....",.,.......................A_UT_O..jMATIC ZEROISATION ON NOZZLE REMOVAL POSITIVE DISPLACEMENT METER LOCKABLE NOZZLE STOWAGE HOOK '------_.L AIR SEPARATOR FLOAT CHAMBER 1/2 HP FLAMEPROOF MOTOR 1t-____ iCOMPACT GEAR PUMP UNIT WITH BUILT-IN BY-PASS VALVE ROLLED STEEL ANGLE FRAME -t----------l- FLEXIBLE SUCTION CONNECTOR

1----r NOT EXTRAS! j

t 0BASE PLAN 0 N N . t BUT STANDARD FITTING I * DOUBLE SIDED REGISTER * FLEXIBLE CONNECTOR o N ..,. 1 * AUTOMATIC Z.V.A. NOZZLE tool.

All measurements in millimetres RONCOL SERVICES LTD. Supply, installation and repair of Fuel Storage and Dispensing Equipment RONCOL SERVICES LTD PETROL PUMP & TANK ENGINEERS * INSTALLATIONS * MAINTENANCE PLAS CELYN BANGOR ROAD PENMAENMAWR GWYNEDD LL346LD Telephone: (0492) 623787 UNIT 3 MAIN STREET SCRAPTOFT LEICESTER LE79DT Telephone: (0533) 418898

management

Illustrated

The pump illustrated is a KS key controlled unit.

A full RANGE of fuel control units with or without tank installations.

Illu strated below 1800 gal. unit complete with Gasboy model 1820. Automatic Nozzle and 12' x %" hose.

Throu gh put 8· 10 G.P'M. ca librated in imp. ga l. or litre measure to c ustomers requireme nts

Automatically CONTROL MOTOR FUEL USE! * A STEEL CATCH PIT IS MORE FLEXIBLE THAN A BRICK BUND * ALL PIPEWORK FROM TANK TO PUMP IS COMPLETEL Y ENCLOSED * PUMP IS WIRED TO JUNCTION BOX READY TO CONNECT TO MAINS ELECTRICITY * NORMALLY NO PLANNING PERMISSION REQUIRED * AS SUPPLI EO TO THE GREATER LONDON COUNCIL AND OTHER LOCAL AUTHORITIES * NO BUILDING WORK REQUIRED * TANKS CONSTRUCTED IN 6mm ( % ") THICK MI LD STEEL PLATE AND STAYED INTERNALLY * STORAGE TANK AND BUND WALL REST ON 3" x 2" x %" STEEL CHANNEL * PAINTED RED OXIDE

1800 gal. unit complete with Gasboy model 390 Fuel Control K20 unit Automatic Nozzle and 12' x *''' hose. Throughput 8· lOG P M. ca librated in imp. gal. litre measure to customers requirements

TANK HOU SE D WITHIN A TANK, OUTER TANK HOLDS 10% MORE THAN THE DERV STORAGE TANK TO COMPL Y WITH REGULA TlONS OPTIONAL EXTRAS HIGH SPEED PUMPS 18 20 G P M. AND OTHER FUEL CONTROL UNITS Camplete range ef Tanks, rectangular er cylindrical, available fram 600 to 12000 galls. capacity. A /I installations can be supplied less catch pit to meet individual customers requirements. Spec ialist in equipment allied to the Petroleum & Chemica l Indu stry Tank and Pu mp in sta ll ations RiVERSIDE WORKS, CAMBRIDGE ROAD, HARLO W, ESSEX CM20 2ET. TH: HARLOW (02 79 ) 38727

LAFON SAFETY FILLING LIMITERS

For or underground tank storage of petrol and diesel, gravity or pump fed.

forecOurt safety in mind, the Lafon Filling ensure no overfills, no pollution or environmental damage.

With deliveries out of hours no errors in filling can take place.

Full protection against product overfills, damage and Pollution costs.

LAFON Filling Limiters require no maintenance, are used internationally, and do not rely on extraneous products such as electricity.

.'

I.F.L. Ltd.

160 Abbey Street, Derby DE3 3SS

Tel: 0332 36 96 14

Telex: 377106 (IFL)

(Forecourt Safety at its Best)

EASTERN COUNTIES TANK CLEANERS LTD. St. Margarets Wharf STANSTED ABBOTTS, Ware, Herts. 5, Brinell Way, Harfreys Industrial Est. GREATYARMOUTH, Norfolk. TANK CLEANING, GENERAL CLEANING and 24 HOUR EMERGENCY OIL SPILLAGE ANTI-POLLUTION SERVICE TANKS Oil . Spirit· Chemical . Pharmaceutical . Water· Petrol Aviation Fuel· Tank Painting· Tank Removal Descaling of Pressure or Condensate Tanks Pressure testing of Tanks and Pipes Interceptor Pit clearance· Oil spillages Also rehabilitation of below ground Service Station Tanks. Waste Oil Collection and Recycling. Telephone: Ware (0920) 870343 Telex: 817535 Gt. Yarmouth (0493) 602848 Telex: 975422 EASTERN COUNTIES TANKCL£ANERS Puhlished by the Association for Petroleum and Explosives Administration and Printed by Miro Press, Bury St. Edmunds.

D. E. J. Ashby

Total Oil (Great Britain) Ltd

L. M. Lombardo Hollydene

Edward A. Cairns Tokheim Limited

Roger Davidge

Gordon Christopher Kinnear

L. G. Treliving

R. M. Rumbold

M. D. Mulvana

Total Oil (Great Brit a in) Ltd

Thomas F Mitchell clo John Ward & Associates Ltd

A. M. Bearman

Total Oil (Great Britain) Ltd

Jeffrey Attwood

Total Oil (Great Britain) Ltd

D. E. J. Ashby

Total Oil (Great Britain) Ltd

L. M. Lombardo Hollydene

Edward A. Cairns Tokheim Limited

Roger Davidge

Gordon Christopher Kinnear

L. G. Treliving

R. M. Rumbold

M. D. Mulvana

Total Oil (Great Brit a in) Ltd

Thomas F Mitchell clo John Ward & Associates Ltd

A. M. Bearman

Total Oil (Great Britain) Ltd

Jeffrey Attwood

Total Oil (Great Britain) Ltd