THE BULLETIN

Journal- of the Association for Petroleum and Explosives Administration

-"'.s;--

VOLU ME 25 No . 1

MABEL CAN DO IT IN 3-2 SE COND S OSEC O.4SEC ........--"---,,,. 2.3SEC ..... COMPLETE FORECOURT ACCESS COVER SYSTEMS DESIGNED WITH SAFETY IN MIND Now you can have access cov:ers for They can be removed or replaced petrol tanks, interceptors, draIns and by all personnel and the petrol tank inspection ducts which have been covers have haunch free frames and specially designed and developed removable s.afety platforms . to conform to health and safety . practIcal, approved and sat regulations. Now available also ID solutIons are only available from e selected colours. Fibresec. Fibxesec Ltd .. The Courtyard' Gay Lane' Otley ' W est Y orkshir e ' LS2 11BR T elephone 0943· 467044

Rapid Response Units on call 24 hours a day for Land or Water Borne incidents. 24 HOUR EMERGENCY TEL: 01-8051856 DEWCO 'PROTECTING THE ENVIRONMENT' FO R DETAIL S OF THI S AND O T H E R OI L RE LA TE D SE RVICES: Co n t a ct : Sa le s a n d Ma rket ing Department, DEWCO SERV I CES LIM i T ED HERTFORD ROAD, WASH, TE L EPHONE : 0 1-804 109 5

MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 01 800 4651 Specialists in Petrol Filling Stations D. S. Leggett (Electrical) Limited ELECTRICAL CONTRACTORS NICEIC APPROVED 181 VICTORIA ROAD, NEW BARN ET, HERTS. 01 =441 3958 SPECIALISTS IN PETROL STATIONS

Once floated on the oil/water surface the bucket filter allows oil into the col-' lection chamber by gravity feed. Water cannot pass through the filter and therefore only water free, reusable or resalable oil is collected. Thus saving on expensive tanker cleaning, and eliminating the possibility of oil overspill into neighbouring watercourses.

Also available:

Surface Samplers for keeping a check on quantity of oil in interceptor. For oil spill recovery larger automatic oil skimmers and absorbent materials are available.

For further information contact:

ENGER OIL RECOVERY For automatic recovery of light oils from ground water pollutions WATER TABLE DEPRESSION OIL WATER SEPARATION The Scavenger recovers oil WATER-FREE and suitable for re-sale or re-use. Scavenger is intrinsically safe and its portability enables it to be used on a site to site basis. THE SCAVENGER BUCKET FOR INTERCEPTOR OIL REMOVAL

Side view of oily water sump: O IL L EV EL O IL LE VEL WAT ER Empty filter bucket is placed in sump OIL WA TER WATER Filter bucket is half full with oil Filter bucket is completely full and alarm signals Unit ready to be emptied FURMANITE Furmanite Eragi01eering Umited Furman House , Shap Road , Kendal , Cumbria LA9 6RU ® Tel (0539) 29009 Tl x : 65 2 6 2

W. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial - Above and Below Ground Supply Test Exchange Service Instal Product Transfer De-Watering Removal Purchase Tank Demolition - Removal - Safety Filling Large Stocks of New and Second hand Petrol and Diesel Pumps, Tanks and Accessories DA YBROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINITY WORKS, BOURNE END LANE, HEMEL HEMPSTEAD 0442 772296 Telephone 021-236 0347 w. J. FINCH (Installations) Ltd. Steaming out and de-gassing petrol tanks; issuing gas free certificates Complete petrol and fuel oil bulk storage tank installations Petrol and fuel oil tank cleaning service Pressure testing tanks and pipe work Heaton House, Camden St., Birmingham BI 3BZ

BRANCH SECRET ARIES

HUMBERSIDE BRANCH R. G. Kitching Humberside County Council,

Honorary Secretary: Mr. B. D. Taylor. Cambridgeshire County Council.

Opinions expressed in this Journal are not necessarily the views of the Association

Talking Point

1987 marks the 25th Anniversary of The Bulletin which was first published some five years after Association was formed. Bob Holdaway was the fIrst Editor and served for a period of Ten years with a break to become Chairman. I am pleased to report that the Editor still receive's Bob's comments and support after all these years!

For the Record the Editors have been.

Bob Holdaway 10 years Jamie Thompson 6 years Stuart Crewe 4 years Bert Thacker 3 years Gerry Edney 2 years

Editor:

Bulletin ISSN 0263 4597

The

VOLUME, 25 Number 1 FEBRUARY 1987 £3.00 (Free to Members) Published by the Association for Petroleum and Explosives Administration

Contents

1

TALKING POINT

NOTES & NEWS 2 PROSECUTIONS 8 LETTERS TO EDITOR 6 NEW MEMBERS 6 AN ALTERNATIVE TO MILD STEEL TANKS 11 APPEAL AGAINST IMPROVEMENT NOTICE 14 PETROL AND OIL INTERCEPTORS THE STATE OF THE ART 17

EASTERN BRANCH F. C. Rason

SOUTHERN BRANCH R. Edwards M.R.B. (Petroleum Services) Ltd

MIDLAND BRANCH Derek Hopkins Warwickshire County Council.

Honorary

Mr. J. A. J. Thompson.

notes & news

1987 SEMINAR DUNSTABLE

The Association is holding the 1987 Petroleum Seminar and Exhibition at Dunstable on Tuesday 13th October 1987. The Council of the Association is firming up speakers with a full day of discussions on topical points. Please note the date for your diaries, exhibitors who wish to advance book space at the seminar may phone Brian Taylor on 0480 57344.

UNSUITABLE PIPE JOINTING COMPOUND

The States of Guernsey Department of Consumer Affairs and Health and Safety at Work recently experienced problems with a pipe thread sealant, kno:v n as La-Co-Slic-Tite, when used on petrol pump suctIOn lines.

The product was used on new lines which were pressure tested in the normal way and found satisfactory.

After the lines had been filled and used for approximately 18 hours, prior to covering with concrete, it was found that every joint was leaking. Once the joints had been remade with tape and another sealant used, no further problems occurred. .

This product is manufactured by the ChemIcal Co .. Chicago. U.S.A. The U.K. dIstnbutors, A. Levermore & Co. Ltd., London SW19 were contacted and they confirmed that this product is recommended for gasoline applications.

For further information contact DICk Leaman, Petroleum Officer. Telephone: 0481 27412.

DRIVER CONTROLLED DELIVERIES

Dangerous Substances (Conveyance Road in Road Tankers and Tank Containers) RegulatIOnS 1981

Having carried out a consultative exercise in 1985 on a draft revision of Schedule 4 to allow driver controlled deliveries, the Health and Safety Executive decided it would be appropriate to allow some trials to be carned out at specific sites under certificates of exemption. The first site chosen was in South Shields and the certificate of exemption has now been issued. Driver controlled deliveries are likely to commence at the end of February 87.

Further sites have been submitted to the HSE anJ are under consideration. Local consultation will be carried out in relation to each specific certificate of exemption. All sites being selected are owned by t.he Oil Companies are spread throughout these compaOles and throughout Great Britain. It is thought that up to ten sites will be selected for trial purposes.

The Road Tanker Regulations are currently being revised. and a first draft is likely to be issued for informal consultation during the next 2 to 3 months. This will include the draft of schedule 4 already t hut a final deCISIon on whether to include dnver (J. trolled deliveries in the revised Regulations will not con I' d ., '11 b h t' ken until the ast mlllute. Such a eClslon WI e b:s:d on the results of the trials: The revised t xlJec ted to he made untlllI.J89 at the earlIest. are no e

SELF SERVICE CONTROL ON FORECOURTS

It is generally accepted by petroleum licensing authorities that the maximum number of pumps that can be safely controlled by one console operator is eight. It is also fair to report that most Oil Companies have been happy with that arrangement as when business is generated to exceed that level, more staff and equipment are needed, as on a motorway site, or some of the very large filling stations. Some confusion is developing as Oil Companies are changing theIr blender pumps for twins, duo or multi product dispensers with up to eight nozzles on one dispenser. In these instances only two hoses can be used at anyone time and therefore a maximum of four dispensers could be used. Industry are introducing interlocks into pump consoles to prevent more than eight pumps being authOrIsed at anyone time as one way around the problem. Petrol Stations however so often differ and petroleum licensing authorities must also consider the other activities now generated at petrol filling statIOns when considering the safe control of pumps eg fast food sales, large retail areas and convenience stores.

NATIONAL HEALTH SERVICE (AMENDMENT) ACT 1986

1. Section 2(1) of this Act reads'"F or the purposes of health and safety legislation (a) a health authority shall not be regarded as the servant or agent of the Crown or as enjoying any status, immunity or privilege of the Crown; and (b) premises used by a health authority shall not be regarded as property of or property held on behalf of the Crown."

2. Health and Safety legislation is defined in Section 2(2) as:(a) the Health and Safety at Work etc., Act 1974 and the regulations, orders and oth er Instruments III force under it; and (b) the enactments specified in the third column of Schedule I to that Act and the regulations orders and other instruments in force unde; those enactments,"

3. Section 2 comes into force (by virtue of Section 8) on 7th February, 1987.

4. From that date therefore. health authority premises such as hospitals. garages and ambulance stations are subject to the licensing requirements of the Petroleum (Regulation) Acts 1928 and 1936. and are covered by all regulations and orders made thereunder.

5. They are also subject to other legislation such as the Explosives Act 1870. the Public Health Act I % I Section 73 and Celluloid and Cinematograph Film Act 1922.

NEW PRICE MARKING ORDER FOR PETROL

A new Order published on 16 January 1987 extends the scope of the Price Marking (Petrol) Order 1980, SI 198011121, by requiring the display of price information for un leaded petrol, whether on the pumps or at the roadside, to be in the same form as that already required for leaded petrol.

The amendments stem from the implementation of an EC Directive which requires that premium grade un leaded petrol be made available throughout the Community from 1 October 1989. It is already starting to appear in the UK and the new Order will ensure that purchasers will be informed of the price clearly, to avoid confusion on multi-product sites.

PETROL RETAILERS ASSOCIATION

In January 1986 the Motor Agents Association set up a party under the chairmanship of the then MAA PresIdent, Dr Bernard Smith, to consider the establishment of a separate and semi-autonomous association for petrol retailers, under the umbrella of the MAA. The working party's recommendation that the PRA be formed was approved by the MAA National Council in July 1986.

PRA Purpose and Objectives

The purpose of the PRA is to provide an executive trade association for petrol retailers within the MAA, one that will inspire and retain members' confidence because it is dedicated to petrol retailers and will as its objective, promote the interests of retaIlers to government, the oil companies and the public.

The PRA will determine its own policy on behalf of PRA r,nem?ers, except where policy decisions come Into conflIct WIth other classes of MAA memberships. All MAA members involved in petrol retailing will automatically, be attached to, and be members of, the are also engaged in other qualIfyIng tradIng actIvities will be dual MAAlPRA members.

PRA Organisation and Constitution

The PRA's c?mmittee structure is as follows:

1. An committee of up to 14 members comprIsIng:

(i) four honorary officers President and th' 'd lee vlce-presl ents.

(ii) eight chairman of the PRA regional committees.

(iii) any members who may need to be appoInted at a PRA Annual General Meeting to ensure balance of representation Independents, tenants. licensee and the varIOUS petrol brands.

2. Eight regional committees based on. and evolved from. the present MAA regional petrol committ, MAA U I I " ees. the ster petro dIVIsion and the SMT A petrol commIttee.

3. Brand councils. whose membership will be confined to members and which will be concerned with a partIcular petrol brand. These councils will facilitate substantial discussion between individual oil companies and their petrol retailers.

PRA EXECUTIVE COMMITTEE

President P J H Lowe

Vice-President -D B A Davis Vice-President -K I Oakerbee

PRA HEAD OFFICE STAFF

Director -C K B Petter

Deputy Director and Secretary -C H Ainsley

Staff Secretary Mrs D L Adsley

PRA Corporate Identity

The PRA will have its own logo which will be a petrol pump nozzle in a vertical position, being white on a blue background.

PRA Newsletter 'Forecourt'

The PRA will produce a monthly newsletter edited by Peter Noble. This will give comment, advice and news of technical trends and will be in addition to the regular petrol column. written by Peter Noble. in the MAA magazine, Motor Trade Executive.

WHAT IS BAFE? AN OUTLINE Concept

BAFE (British Approvals for Fire Equipment) is the Government recognised. National organisation, which, in relation to fire protection equipment and related services, selects criteria as National criteria and adopts schemes regulated by these criteria as National schemes. It owns and controls quality markings for use in conjunction with such schemes.

Aim

The Aim of BAFE is to ensure the quality of all fire protection equipment and related services.

In furtherence of this Aim. BAFE seeks. among other things to:_ promote the establishment of National to ensure quality over the whole range of fIre protection: adopt suitable as own and control uI11fymg qualIty markmgs for use in conjunction with adopted schemes: promote the of approp:iate reciprocal arrangements WIth other countrIes.

Who Runs BAFE?

The controlling and decision making body of BAFE is BAFE Council which is constituted in such a way that: all interests are represented (directl\, or indirectly): no one interest predominates:

There are five groups of interests. each rep.resented by a panel. each panel appointing a number ot CouncIl members as follows:-

RegulatoQ' Authorities: .+ Members frum: . Home Office Health and Safety Executiw Chief and As'sistant Chief Fire Offil'ers Association Local Authorities supportt.'li and briefed h\ a panel

organisatinns

\h

..,

Users and Consumers: 3 Members from:-

Confederation of British Industry The Retail Consortium supported and briefed by a panel representing 24 organisations.

The Fire Trade: 2 Members from:-

British Automatic Spinkler Association B.ritish Fire Protection Systems Association FIre Extinguishing Trades Association

The National Federation of Building Materials Producers by trade association representing some 120 fire protection companies as well as wide coverage in the building industry.

Certification Bodies: 2 Members from'-

The British Standards Institution

The Loss Prevention Certification Board Ltd (formerly FOC)

-Test Houses: 1 Member from:-

The Technical Centre of the LP CB (formerly FIRTO) representing LPCB, BSI Test Houses, NAMAS.

Method of Operation

In areas of fire pt' BAFE ro ectlOn covered by existing schemes neces adfPts schemes whose criteria (modified where BAsFary .are acceptable as National criteria E Id 'f' sche entI les area of fire protection where mes are requ' d d promot h an where none exist and t establishment of National criteria for such an adopts them as BAFE Schemes.

In all instances BAFE Sch emes:-

specifications which are verified y testIng:

ongoing quality control to BS 5750 to P sUdre consistent and ongoing compliance with ro uct sp 'f' rei t d eCI IcatlOns or codes of practice a e . t? activities (e.g. maintenance)' Bnhsh Standards where available.' Where are not ava'l bl BAF measure I a e E may. as an interim of other convers t' ns will be offered to BSI for a Ion In d " Standards; ue course Into Bntish use only Certif' , accredited b Icatlon (where available) Council for Cy ,NatIOnal Accreditation use I ertl IcatlOn Bodies (NACCB)' , on y Test Lab' • accredited b oratOrIes (where available) Accreditation ys National Measurement ervlce (NAMAS),

BAFE Schemes may b f ' _ product cert'f' e? varIOUS types:, , I Icatlon: registration of COl ' , " npames to perform various actIvItIes such as:dt:sign installation maintenance ccrtification of discrt:te systems,

Detaile? testing and surveillance for BAFE adopted IS undertaken against the agreed National cntena by agreed NATLAS Accredited Certification Bodies such as BSI or LPCB. This is recognised by the award of appropriate Certification Body mark (e.g. the BSI Kltemark), In recognition of the certification being against BAFE scheme National criteria the Certification Body mark is enclosed by the BAFE annulus, each BAFE adopted National scheme. no matter Certification Body undertakes detailed surveillance, there is but one set of National criteria,

H.S.E STATEMENT ON HOSES

PETROL FILLING STATION LICENSED UNDER THE PETROLEUM (CONSOLIDATION) ACT 1928: GOODYEAR/BARROW HEPBURN INDUSTRIES PETROL PUMP HOSE ASSEMBLIES

The Health and Safety Executive's attention has been drawn to failures in service of Goodyear Yx" petrol pump hoses and couplings assembled and distributed by Barrow Hepburn Industries Ltd (BHI),

As a result of a number of failures (eg swelling or splitting of the hose adjacent to the end fitting. occasionally leading to complete separation of the hose from the end fitting), Goodyear and BHI established that W' hose lengths assembled and supplIed between October 1984 and October 1986 may be defective, They have therefore decided to replace at their own expense all those hose assemblies (some 34,500 hose lengths and couplings on current estimates) with assemblies not subject to such defects, They have also agreed an action plan for carrying out the replacements with the industry, , Currently. Goodyear and BHI are assembling and testing replacement assemblIes are supplying them to the industry as they become Petrol pump manufacturers and maintenace compalll es have already started on a programme of replacement of relevant hose assemblies. using their records of supply and servicing as a basis for the programme, O,n current plans. Goodyear and BHI will complete their part of the exercise during March 987 an? the manufacturers and maintenance compallles their part as soon as possible thereafter.

, A copy of an illustration which should help licensing officers to identify the hose asseI?blIes, are to be replaced, It is anticipated will Wish to look out for any of these assemblIes the normal course of their duties and inform oCCUpiers that th,e assemblies will be replaced. without cost. theIr maintenance companies as soo as possible, If IS a,lso anticipated that they will wish to take any other actIOn they consider necessary in the interests of , Officers will also wish to know that. if they IdentIfy occupiers who have hose assemblies which need replacement hut who do not have a service contract with a petrol pump maintenance company. M,r Wilson of the Petrol Pump Manufacturers ASSOCIatIon. 30 Norton Drive. Fareham. Hampshire POlo 7PZ. should be informed, Mr Wilson is co-ordinating the replacement programme on behalf of Goodyear. BHI. petrol pump manufacturers and maintenance compalll es and will ensure that any occupiers identified in this way are Included in that programme.

N 2 CRIMP MARKS '---In ___ ---J N a CRIMP MARKS ___ --J JIF "'1-a-C-R-IM-P---f MARKS H.OSE RECOGNITION NOT FOR REPLACEMENT seT SR 2083 NOT FOR REPLACEMENT fi,OOD/i'EAII 5/8" HARDWALL PETROL HOSE BS 3395 TYPE 3 11/86 SUSPECT - TO BE REPLACED WHERE 4th FIGURE IS 4, 5 OR 6 GOODfiEAIl SeT SR 1536 BLACK, BLUE, RED & YELLOW HOSES

Letters to Editor

Dear Editor

re: DIESEL WAXING

As the manufacturers of Fuel Storage and Dispensing Units it is quite conceivable to overcome the annual problem of Diesel Waxing by fitting electrical heating devices in the storage tank and around the suction pipe but this still leaves the pump which is probably not used through the night when the temperature is at its lowest.

There are also a very large number of installations on Farms and on Building Sites where power supply is not available.

There is also the waxing in the tank on the vehicle.

Why should industry spend thousands of pounds on equipment that can only overcome part of the trouble. "Yes additives are available" but transport does not always take on fuel at the same location.

The answer is with the Fuel Supplier, the Oil Company.

Comment from the Oil Companies would be welcome.

Yours faithfully for E.W. Taylor Fuel Control Ltd. E.W. Taylor Managing Director.

Dear Editor

The Bulletin Volume 24. No23 Notes & News

I . :-vas niterested to read the article headed SCREW U.p In above mentioned volume. Having had to deal w h Ith qUite a few of these cases where internal fill pipes ave come uns d T h th crewe. welve cases III all throug out e country. The fOllowing facts were common to all cases:

The internals I'" Th were a umIlllUm III all cases.

I e threaded end in all cases had gone oval. n the case of direct fills the tanker drivers had reported the fault d . h d an In the case of offset fills the fault a come to light 'th d . · el er unng redevelopment or as In one case where f I' ' t k ue was comIng from the vent dunng an er offloading.

It 'is our " '. · OpInIOn that dunng Installation of these Illternal fIlls a p' th I ..' Ipe wrench had been used to tighten e a umInlUm thread ." · '. CausIllg It to mlshape glvIllg the

.It was tight. Of course this was not the case and Vibration cau d d . se urIng tanker offloading soon unwound the fill Th' Id " , : wou of course be all the qUicker a hrass dip IS left in the internal. If dip sticks al e to be left III offset fill internals for any reason. Carhon fibre dip sticks should be used.

Yours faithfully Roy Hammond petroleum Pipework Specialist

New Members

c. V. Page

WaIter Page (Safeways) Ltd. J. A. Hull, Gordon White & Hood, P. O. Steven, Trading Standards Department, Lothian Regional Council, N. Payne, Sunny Heights, A. E. Gass, T. G. Crosbie, J. A. Hull, Gordon White & Hood, M. G. Randall, P. BaIchin, G. M. Ewart.

The Association welcomes the following new members

P. K. Beavon, B. H. Gallagher, Tri-Scan, S.D.S. Gregory, Turnkey Design Partnership Ltd., , D. J. Duckworth, Turnkey Design Partnership Ltd., G. P. Peart, R. I. Edge. Country Trading Standards Officer, Clwyd County Council, W. Cunningham, Fuel Management Systems. W. G. Cowburn Cowburn, Bers and Co Ltd., Mr. 1. Bers. Cowburn, Bers and Co. Ltd.,

1. Hornbv. Cowburn'. Bers and Co. Ltd ..

Belhan Construction Ltd

S.' P. Bulgen, Trading Standards Department, Dorset County Council A. J. Chappell,

S. Crone. Swains Park Industrial Estate. R. N. Gibson, B. Mincher. D. J. Minogue, Highfields, M. Nicholas.

p.Oglesby. lan Stephen.

N. Thomson. Maritime Industrial Group. L.H.P. Wood.

P. K. Beavon, B. H. Gallagher, Tri-Scan, S.D.S. Gregory, Turnkey Design Partnership Ltd., , D. J. Duckworth, Turnkey Design Partnership Ltd., G. P. Peart, R. I. Edge. Country Trading Standards Officer, Clwyd County Council, W. Cunningham, Fuel Management Systems. W. G. Cowburn Cowburn, Bers and Co Ltd., Mr. 1. Bers. Cowburn, Bers and Co. Ltd.,

1. Hornbv. Cowburn'. Bers and Co. Ltd ..

Belhan Construction Ltd

S.' P. Bulgen, Trading Standards Department, Dorset County Council A. J. Chappell,

S. Crone. Swains Park Industrial Estate. R. N. Gibson, B. Mincher. D. J. Minogue, Highfields, M. Nicholas.

p.Oglesby. lan Stephen.

N. Thomson. Maritime Industrial Group. L.H.P. Wood.

West Yorkshire Fire Service PROSECUTIONS

PETROLEUM (REGULATIONS) ACTS 1928 AND 1936

1 For not renewing their Licence ie keeping mixtures without a Licence at Leeds Magistrates Court on 7 October 1986.

Three defendants pleaded guilty, each was conditionally discharged for two years. Costs against defendants were awarded in one instance of £50 and two instances £25 each.

NB In each of the above cases early application was made for Licence renewal for 1987!

DANGEROUS SUBSTANCES (CONVEYANCE BY ROAD IN TANKERS AND TANK CONTAINERS) REGS.1981

2 On 11 December 1986, Leeds Magistrates imposed a £200 fine, £100 costs to the Fire Service and £30 fee on Henry Kordowcza, a garage hcensee.

An Officer visited the garage on 15 September 1986 When a petrol tanker was at the garage delivering petrol. The Officer noted that there was no-one from the garage in attendance at the tanks with the tanker Further enquiries ascertained that the lIcensee himself, being Mr Kordowicz had been with the tanker driver but had been called away from the to another garage of which he was also the LIcensee.

It was also noted that the delivery certificate had been signed for Tank No 3 but the delivery hose had not yet been connected to No 3 tank. This case may not have come to court had Mr Kordowizc's attitude been reasonable, but when advised that these matters were serious and action may be taken he inferred that "Well! Everyone !t!" I thought you would just "slap my wrist!" ThIS IS the first instance in West Yorkshire that costs been awarded separately and directly to the Fire Service, which we feel now sets a precedent. Actual offences charged detailed attached.

DEFENCE

CHARGED: Henry Kordowicza

1) !hat on the 15 September 1986, being the person III charge of petroleum-spirit storage tank No. 3. at the Lawnswood Service Station Otley Road, Leeds, did sign your name on the certificate specified in Schedule 4 Part 11 of the Dangerous Substances (Conveyance by Road in Road Tankers & Tank Containers) Regulations 1981 before the connecting hose through which petroleum-spirit was to be delivered was connected to the filling point of that tank contrary to Regulations 20 and Paragraph 6 of Schedule 4 of the Dangerous Suhstances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 (made under Sections 15 and 82 of the Health & Safety at Work etc Act 1<)74). Section 33 (1) (c) of the Health & Safety at Work etc .. Act 1974 and ( riminal Law Act 1977.

Fined £50.00

2) That on the 15 September 1986, being the person in charge of petroleum-spirit storage tank No. 1. at the Lawnswood Service Station, Otley Road, Leeds did fail to keep a constant watch thereon during the whole time of delivery into that storage tank contrary to Regulation 20 and Paragraph 8 of Schedule 4 of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 (made under Section 15 and 82 of the Health & Safety at Work etc., Act 1974), Section 33 (1) (c) of the Health & Safety at Work etc., Act 1974 and Criminal Law Act 1977.

Fined £50.00

3) That on the 15 September 1986, being the person in charge of petroleum-spirit storage tank No. 2. at the Lawnswood Service Station ,Otley Road, Leeds, did fail to keep a constant watch thereon during the whole time of delivery into that storage tank contrary to Regulations 20 and Paragraph 8 of Schedule 4 of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 (made under Sections 15 and 82 of the Health & Safety at Work etc., Act 1974), Section 33 (1) (c) of the Health & Safety at Work etc., Act 1974 and Criminal Law Act 1977.

Fined £50.00

4) That on the 15 September 1986, being the person in charge of petroleum-spirit storage tank No. 4. at the Lawnswood Service Station ,Otley Road, Leeds, did fail to keep a constant watch thereon during the whole time of delivery into that storage tank contrary to Regulations 20 and Paragraph 8 of Schedule 4 of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981 (made under Sections 15 and 82 of the Health & Safety at Work etc., Act 1974), Section 33 (1) (c) of the Health & Safety at Work etc., Act 1974 and Criminal Law Act 1977.

Fined £50.00

LEGAL CAUTION PROCEDURE

West Yorkshire have also introduced a new Legal Caution Procedure which is as effective as instigating proceedings and may be used instead of proceedings if a person or a firm will admit an offence or offences. They are required to sign two identical caution forms ie admit the offence or offences. They keep one copy and the other copy is retained by the Fire Service. They are advised that should similar contravention occur in the future, they will be prosecuted and that the caution can be cited in evidence.

The procedure is used by Authorised Officers only at Fire Service Headquarters and in most cases the offender is required to attend Headquarters to sign.

The main purpose of the use of the forms is:

A To let the offender know that:

1 The offences committed are serious: where petroleum/explosives matters are concerned they are Criminal Offences.

2 The form, having been signed ie he/she admits the offence, the caution may be cited should further action be necessary.

3 The fact that the form has been signed should ensure that more attention is paid by the Offender to their responsibilities.

4 That the alternative to signing the form and admitting the offence(s) is the possibility of prosecu ti on.

B For the Department:

1 A record of acknowledged offence(s) is maintained in the file.

2 It is advantageous to have an effective stage between the latter in the file and outright prosecution.

3 The satisfaction that it is possible to offer an effective alternative to proceedings.

4 The offender has admitted the offence(s) and the likelihood that much more care wiII be taken in the future.

S It is not necessary, at the time of using the caution, to have every document relating to the case finalised as would be the case for a prosecution, only the relative facts are required at this stage.

The procedure has now been used in three instances:

1 A firm admitted permitting petroleum spirit to be dispersed into non-approval containers. Of concern, but not related to the actual container offences, was that this happened twice at the same garage and the person who purchased the petrol in one instance poured it over himself and set himself on fire he subsequently died and the other opened the container in the living room of his house, with consequent horrific results.

2 A tanker driver admitted delivering petrol into an underground tank before the person in charge signed the delivery certificate.

3 A person did not keep a constant watch on tanks. enter tank number and quantities to be delivered and did not sign the certificate after the hose had been connected and before delivery.

Prosecutions

Murco Petroleum Limited, Winston House, Dollis Park, .London

A petroleum company operatlOg and act 109 as lIcensee for a national chain of petrol service stations was prosecuted for a contravention of licence conditions in that the fill pipes of underground petrol storage tanks were not kept securely locked despite a written warning sent three weeks prior to the date of the actual offence. The company was fined £20n with £50 costs.

2 Peter Oates T/A Auto Buyers (Margate).

A former small filling station had stopped retailing petrol some five years previous but the licence had been renewed annually for the purposes of the car sales business which was run from the premises. On the 31st December, 1985 the licence expired and all efforts to encourage the licensee to either relicence or dispose of the product in the tanks was in vain. Eventually on 9th July. 1986 the two tanks were dipped by a Petroleum Officer who found that they contained a total of 193 gallons. As the petrol pump had been disconnected a sample was taken direct from the tank. The sample was subsequently confirmed as petroleum spirit and the occupier of the premises was prosecuted on 7th October 1986 at Margate Magistrates Court where he was fined £100 with £55 costs. .

Prosecution under the Explosives Act 1875

Following an incident, involving fireworks, during which a boy lost the greater part of his right an Officer of the Oxfordshire Fire Service accompanied Police to a reported break-in and theft of fireworks from an address in Oxford.

Upon arrival the Officer discovered that the occupier kept a large quantity of display t.ype fireworks in a garden shed. Youths had broken IOta the shed and had stolen a quantity of these fireworks. one of which. it is believed. caused the injury to the boy. The shed itself was constructed of timber, provided with glass windows and the door was secured by smaII padlock on a hasp and staple. the retaining screws of which were expos.ed. It that entry was gained by simply removlOg the SCI ews. The shed was not licensed or registered as a place for explosives and its design, .constructIO? and location was such that it was ObVIOusly unSUItable for that purpose. Therefore the remaining fireworks were removed and transferred to the. explosive store and proceedings were 1l1ltJated against the occupier. On the 10th February. 1987 at the East Oxfordshire Magistrates' Court the occupier pleaded guilty to the charge that hc:-

did keep a quantity of mixed namely 182 kilograms or thereabouts of .. . I . :\ I COl1tnrt v to Section .5. 10 an unaut10nsel pace. < J Explosives Act 1875 and Section 3.3 (3) Health and Safety at Work etc. Act. 1974."

He' was fined £200 plus £50 costs. and t· t "'s lIcensed to return the firworks to the manu HC Ule). store. which he subsequently did.

l)

...,

FIFTY YEARS OF SERVICE PROCRESS AND EXPERIENCE A modern fleet of tankers for dealing with general and special industrial effluents. compactable wastes. Also static compactors installed and serviced. Skip services for the professional builder and 01 Y enthusiast. tionwide specialist Tank Cleaning Service. Established services for domestic and farm cesspits and gully cleaning. Jetting services for garages and industrial • commercial:;/ premises. A 'Hotline' emergency service for the 'out of hours' unexpected crises. IS WHAT YOU GET WITH CLEANSING SERVICE GROUP HEAD GRANGE ROAD BOTLEY SOUTHAMPTON S032GD BOTLEY 2232 RINGWOOD 2008 552286 NEWBURY 45357 OXFORD 61150 EVESHAM 2620 STONEHOUSE 6116 SEVENOAKS 453175 MAR 26A

Underground Petroleum Storage, an alternative to mild steel

by Geoffrey Ashton Ferranti Resin Ltd.

by Geoffrey Ashton Ferranti Resin Ltd.

in Britain ar e protected by legIslatIon aImed at pr e venting corrosion in the mIld steel tanks exclusively used in British forecourts. However the exclusive us e of mild steel in underground petroleum storage has resulted in several restrictions being placed on the operators.

Tl: e restrictions stem from additional protection to prevent corrosion and stop potentially leaks To explain th e re s trictions it is necessar y to IdentIfy the causes of corro s ion External sources can b e a majo.r fac.tor , e lectrical currents , ox yge n concentratIOns 111 the soIl , the chemical constituents of th e so il , all contribute to th e d eg radation of a tank

Thi s d eg radation is further e nhanced since th e cOI:rosion is usually confin e d t o a point r a th e r than b e ing ul1lformly spread over the t a nk. This concentrates the effect and will cause lea ks far quick e r than uniform corrosion To provide prot e ction , a ll UK installations of und e rground mild steel tank s h ave to b e enca se d in a laye r o f s ulphat e resi s tant concrete at least 150mm thick.

Th e use of concrete dra s ticall y increases not only th e cost of 1I1 s t a ll a tlOn , but th e cost o f clo s ina down a s it e This is b eca use once a s it e is closed the ex is tin g taJ:k .must e Ith er b e r e moved or completely fIlled 111 wIth concrete s lurr y t o pr eve nt th e ri sk of fire and e xplosion.

R e m ova l of a concrete e nca se d tank is expensive. s inc e th e tank cannot b e re-used without ex t e n s iv e r ef urbI s hm e nt and tes tIn g. But unl ess th e t a nk re moved th e n th e s it e becomes un at tra c tiv e pr ospec tI ve use rs, a nd un eco no mI C as a petrol o utl e t

Apa rt tram con c re te cas In g. a n ex t e ri o r coating a nd cat hod IC prot ec tIon are ava Il ab le as furth e r of In c reas ll1 g pr otec tIon a nd In s ta ll a ti o n cos ts.

Cathodic Protection

The cathodic prot ec ti o n is particularl y important bec a use the action of e lec tro-chemical and e lec trIc a l currents in the soi l are two of the major promot e r s of corrosion The El ec tro chemical action is kn ow n as galvanic corrosion and can be compared to th e that takes place insid e a dry ce ll battery. Both a rustmg s t ee l tank and the dry cell are undergomg an e lec tromechanic a l oxidation r e duction r ea ctIon. Th e z inc case of the batt e r y a nd the steel exterior of th e t a nk both serve as th e n ega tiv e electrode or anode, g iv in g up m e tal ion s that a r e drawn throu g h so Il t ? the po s itive e lectrode or ca th o d e The end r es ult o t thI S r eac tion is a dir ec t e lec trI ca l current 111 the case of th e dr y cell and a rust y exterior in th e cas e of th e s t ee l t a n k.

When con s iderin g a st r ay e lectrIcal curren,t f\Om poorly installed e lec trical e quipment th e e tt ec t is exace rbated b y the m o r e powerful curr e nt.

To complicate th e pi c tur e und e rground s t o r age t a nk s a lso s uffer from int e rn a l co rro s ion Th e AmerIcan P e trol e um Institut e co n c lud e d that in 198 1 nin e p erce nt of all lea k s were th e r es ult of int e rn a l co rro s io n a nd th a t was in a co untr y w h e r e co ncr e t e casing h as n o t b ee n a dopted to minimi se e xterna l corrOSIOn.

The elements th a t co ntribut e to co rrO SIon on th e in s id e of tank s includ e water. oxyge n b ac t e ri a a nd s ludg e d e po s it s. Oth e r ca u ses ca n b e a ttribut ed to th e in sta llation a nd frequency of u se.

Wat e r is an e lect r o lyte. w hi c h promot es CO !TLl SIOn throu gh c h e mi ca l reac tion s. It ca n be Introdu ced to t a nk s bv pre c ipit at io n fr om th e pruc\uct 111 th e t a nk So m e p e tr o le um a dditi ves und e r cons Id e ratlun s u c h a s m et h a n o l h o ld hi g h e r leve ls ut" \\ a t e r a nd cLl uld lea d t o in c rease d pr ec ip it a ti o n

I1

Alternately as relatively humid air enters the tank, contact with the cooler tank walls promotes condensation to introduce water. Airborne pollutants such as sulphur dioxide in this air will induce the accumulation of sulphuric acid deposits to further increase the likelihood of internal corrosion.

Typically oxygen is drawn into the tank through vents as the product is removed , completing the list of elements required for corrosion. Other than corrosion water-soluble oxygen also supports the growth of bacteria. From this bacterial activity, the metabolic waste products bring localised corrosive conditions.

In operation the garage operators must keep an accurate stock inventory, generally using standard guaging sticks. The repeated impact of the stick on the tank bottom can lead to the breakdown of protective layers. Eventually with the bright metal exposed , concentrated point corrosion , exacerbated by the constant friction of incoming fuel , will occur.

The probability of internal corrosion is also related to tank use. A high turnover will lead to greater volumes of oxygen and water being introduced. Irregularities in the floor of the tank will lead to the collection and concentration of impurities again promoting point corrosion.

However twenty years ago the Americans adopted a new approach to this problem Instead of examining means of improving the protection available on mild steel tanks , steps were taken to develop a non-corrosive material to replace steel with an inert and nonconductive material. The choice of replacement material was Glass Reinforced Plastic (GRP).

The underlying motivation was to remove the problem of maintenance install it then forget it! The success of the introduction is now well-documented following reports presented by Texaco , Shell and Exxon at the 1982 meeting of the marketing division of the American Petroleum Institute.

Texaco announced a ten-year programme replacing mild stee l tanks with GRP tanks. Until the changeover is complete , leak detectors have been retrofitted throughout Texaco ' s retail outfits and operators are obliged to keep daily inventory records.

Shell in 1977 had initiated a ten-year replacement programme, and four years ago Exxon had replaced over two thirds of its 8000 mild steel underground tanks with th e GRP alternative.

Inv es tment on this scale r e quire d hard economic evidence and a highly functional product. The economic ev id e nce was provided from several so urces. Having studi ed the problem Warren Roger s Associates of New port , Rhode Island devised a formula to predict tank failure. This is based on m eas urements , made on eac h sit e , to cover the soil acidity, resistivity, moisture content a nd the presence or absence of sulphides.

O n e documented case of a leak occurred at an Exxon serv ice stat io n in East Meadow , New Jersey in 1978. Loca l so ur ces claim a cummulative total of 30,000 ga ll o n s escaped.

Twenty seve n families in the loc a l re sid e ntial n e ig hbourhood were affected , to date so urce s estimate Exxo n ha s s pent between $5M a nd $lOM 111 cleanng up t hi s o n e lea k [ n De nve r a simil ar leak in 1980 was ce d to a C hev ron station. tfaj n d e n y ing the leak cost $200 milli on to r eso lve, a , _ n s pok es man said figur es betwe e n $10 millIon

f' "

par< Igur es.

Insurance companies introduced premiums weighted against operators with ageing mild steel tanks, Premiums have been set on a rising scale to account for the ageing of the tank, Use of GRP tank is covered by a flat rate premium simplifying cash-flow. However it is unlikely that British insurance companies will offer a similar scheme of positive discrimination in favour of the GRP product.

NEW MATERIALS

The availability of an established product on the market was perhaps th e deciding factor in the adoption of a n ew material for tank construction. During the 1960 ' s the Owens Corning Foundation was asked by petrol r e tailers to develop an underground GRP tank , This was performed in conjunction with a tight functional specification ASTM 4021 to monitor both the quality of the product as well as the procedures governing the installation.

installation proc e dure has important ramifIcatIons for the British market impregnated concrete IS not required as th e re is no corrosion problem , and since pea grav e l is se lf-packing it provides an exce llent packl11g medium.

Thi s provides great freedom in installation , and through ca r e ful e ngine e ring great strength. An exa mpl e of the strength is that o ne in stalled GRP tank S with a of 3ft backfill cover can support co nst ant trafhc from the h eav ies t over-the-road vehicle. ( H-20 ax le loads 32 ,000 Ib).

( h eY

Q

a nu 0 12

' () " d b II I

' 12 million we re goo a

Another area where these tanks have opened up new application areas is in locations with extremely high water tables. An empty tank can be installed with 3ft of water over the tank top with a 3: 1 safety factor against external hydrostatic pressure. Where necessary fibreglass hold-down straps are used to secure the tanks. Particular installations are catered for by up to three methods of securing the anchor straps.

It must be asked given the practical advantages of using a material better suited to the task, why have GRP tanks not gained acceptance within Britain.

Other countries such as Canada and Norway have readily adopted the new tanks. In Norway a government led initiative aims to replace some 2000 metal tanks with GRP during the next five years.

In Britain during the 1960's a GRP product was evaluated at a trial site, but the poor design, indifferent quality of the product and a lack of supervision during installation meant the trial was unsuccessful.

But in 1985 a specification was drawn up using the combined knowledge of the London Fire Brigade and the Polymer Chemistry Group of the former GLC for GRP underground petroleum storage tanks. The specification owes much to the ASTM 4021 used by

Americans in that it is highly functional and covers the product and its installation. The most important provision is allowing the burial of the tank in pea gravel and not concrete.

,This provision offsets the cost premium of the GRP product, since installation costs are slashed with pea gravel costing one third the price of concrete. The absence of a suitable product in Britain can no longer be cited as a cause for its lack of acceptance. In June 1986, Ferranti Resin of Peterlee acquired the exclusive rights from the Owens-Corning Fibreglass Corporation via the wholly owned Norwegian subsidiary Veroc Technology AlS.

In January the first tanks were produced by Ferranti Resin using the computerised production process. Lloyds Industrial Services visited the factory to witness the statutory performance tests as laid down by the London Fire Brigade. The GRP tank passed all tests successfully and now the next stage is to await the official launch and obtain a thorough evaluation of the product.

This article first appeared in Petroleum Review th official magazine of the

of

C P_I_NS_TA_LL_AT_IO_NS__LT_D. (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all work associated with Forecourt Pipework 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS67XN Tel: RAYLEIGH (0268) 781184 I 781859 (24 hrs ansa)

Institute

Petroleum. e

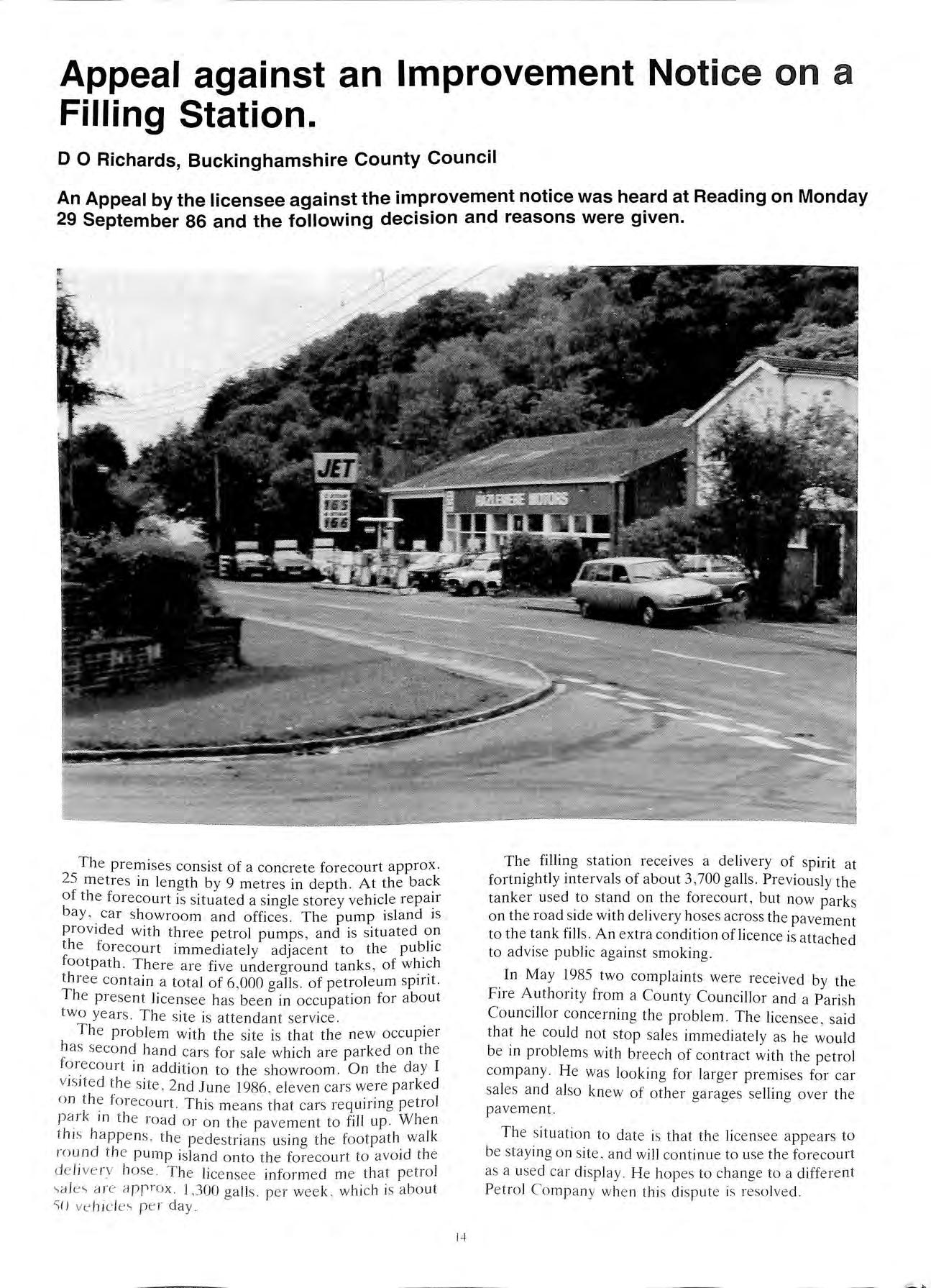

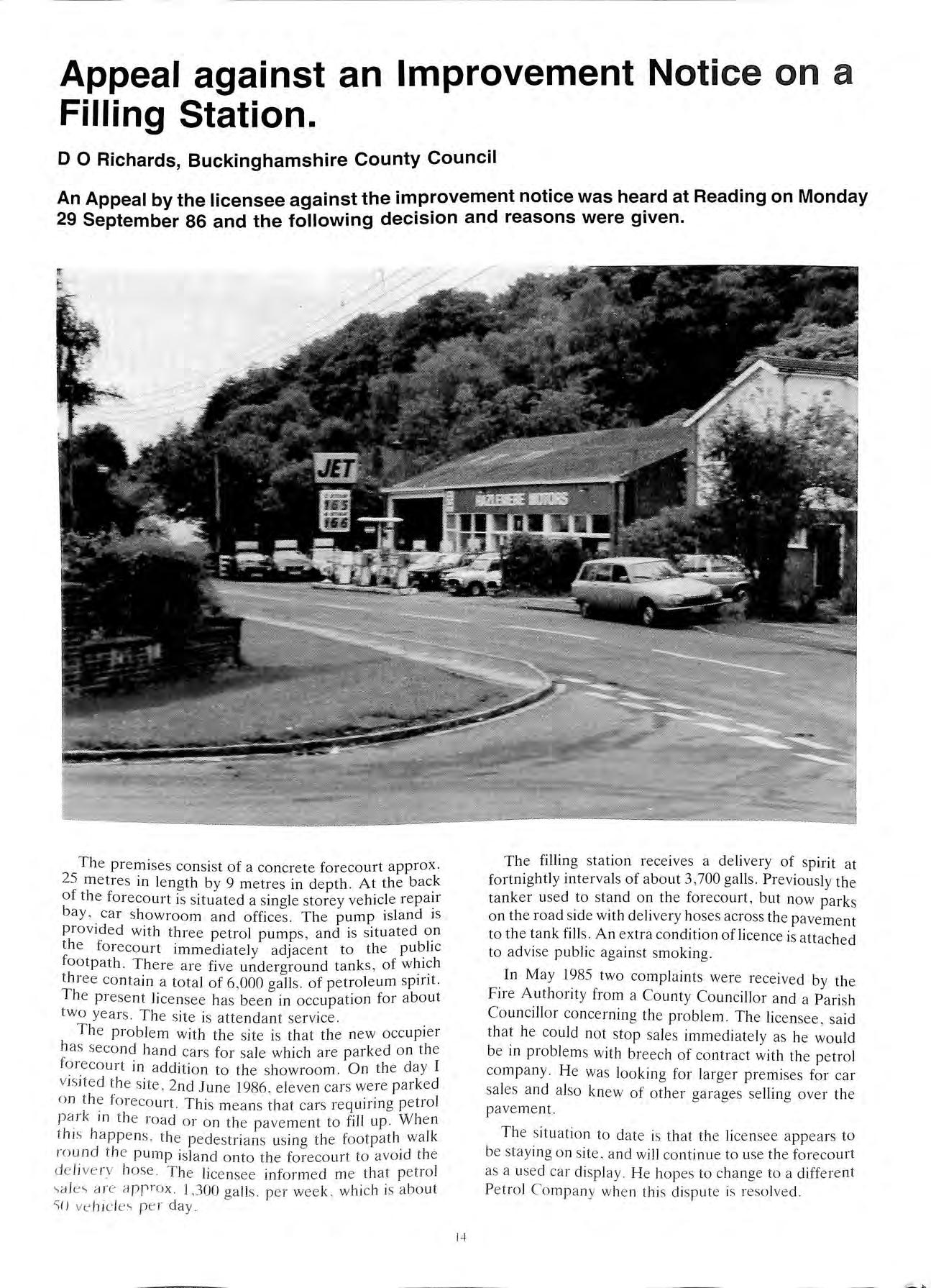

Appeal against an Improvement Notice on a Filling Station.

o 0 Richards, Buckinghamshire County Council

An Appeal by the licensee against the improvement notice was heard at Reading on Monday 29 September 86 and the following decision and reasons were given.

The premises consist of a concrete forecourt approx. 25 metres in lengt h by 9 metres in depth. At the bac.k of the forecourt is situated a single storey vehicle repair bay , car showroom and offices. The pump island IS provided with three petrol pumps , and is s ituat ed o.n the forecourt immediately ad jacent to the publIc footpath There are five underground tanks , of which three conta in a total of 6,000 galls. of petroleum spirit. The pre se nt licensee has been in occupation for about two year s The s ite is attendant service.

The problem with the site is that the new occupier ha s seco nd hand cars for sale which are parked on the fo r ec ourt in addition to the showroom On th e day I vis ited t h e s ite , 2nd June 1986 , eleven cars were parked o n the fo recourt. T hi s m eans that cars requiring petrol park 111 th e road o r on th e pavement to fi ll up When t hi s happ e n s , the pede s trians us ing the foot path walk round t h e p ump island onto the forecourt to avoid the de li ve r y h ose . Th e li censee informe d m e that p e trol '> ale " ar e ap rr o x 1 ,3 00 g all s p e r wee k , whi c h is a bout 'i f ) ve hi c le s p e r clay.

The filling station receives a delivery of SpIrIt at fortnightly int erva ls of about 3,700 galls. Previously the tanker used to stand on the forecourt, but now parks on the road side with delivery hoses across the pavement to the tank fills. An extra condition of licence is attached to advise public against

smoking

In May 1985 two complaints were received by the Fire Authonty from a County Councillor and a Parish Council lor concerning the problem. The lic ensee, said that he cou ld not stop sales immediately as he would be in problems with breech of contract with the petrol company. He was looking for larger premises for car sales and also knew of other garages se llin g over the pav e ment.

The s ituation to date is that the li censee appears to be stay ing on s it e, and will continue to use the forecourt a s a lI se d ca r di s pla y. He hop es to change to a diffe rent P e trol Co mp any wh e n thi s disput e is reso lved.

14

It was necessary to serve a Prohibition Notice under the H .A. S .W.A., to prohibit the display of cars on the forecourt , or refuse to li ce nce the site.

I visited the site and consider th a t the forecourt should be cleared of cars and used as a filling station or sales of petrol be stopped. My reasons are as follows:-

1. Over the pathway petrol sales ca uses the public to use the forecourt as a footpath. There is no way the no smoking condition can be enforced.

2. Although the pump isl a nd is adjacent to th e footpath, cars could at lea st pull onto a proper forecourt to fill up

3. Th e footpath is tarmac and is showing signs of deterioration , probably due to petroleum spirit.

4. The other filling stations th a t the licensee cites as filling over the pavement have never had a forecourt and have been working this way for over 15 years This garage is provided with a forecourt which was in use for refuelling until abo ut two yea rs ago.

5. Th e tanker parks on th e roadway to discharge This is just before a right hand bend in the road which could cause a traffic accident, also any spillage would be above surface water dr a in s .

6. The site is obviously not larg e enough to serve petrol a nd display cars to the pr ese nt extent. If this site is a llowed to continue in it s present form it would prove difficult to stop other small filling stations doing the same thing

7. If the licensee signs a contract with another Petrol Co mpan y, the y may introduc e promotions which could result in incr ease d pe trol sa les. 4th June , 1986

0.0. Richards

FULL REASONS

1 Thi s is an appeal by th e lic e ns e against an improv e m e nt notice No 2/86 dat e d 9 Jul y 1986 and served by the Buckingh a mshir e Fire Brigade upon th e appe ll a nt s The notice was se rv ed under the provisions of th e Health and Safety a t Work e tc. , Act 1974. It st a t ed th a t Section 4(2) of the 1974 Act had been contravened. Section 4(2) reads as fo llows :" It sh a ll be th e duty of eac h person who has , to a n y ex t e nt , control of premises to which this sectio n applies or of th e m eans of access th e r eto or egress ther efrom of a ny plant or s ub sta nce in suc h premi ses t o t ake s uch meas ur es as it is reaso nabl e for a person in hi s position to t a ke to ens ur e , so far as is reaso nabl y practicabl e, t hat th e premises , o r m ea ns of access thereto or egress th e refro m avai labl e for use by persons us ing the premis es, and any plant or s ub stance in the pre mise s or. as t he case may b e, provid e d for us e there. is or a re s afe a nd wit hout r isks to hea lth

DESIGN FUELLED B EXPERIENC Personal attention in design & development for th e petroleum retail industry • Principal with over 25 years expenence • Project Manage me nt specialists • Progressiv e & inn ovativ e outlook • Consultants for statutory & planning req uire me nts • Comprehensive or tail o re d service to suit PLAN ACOU RT Planaco Ult Limited Po. Box 27 Bill eli cay Essex CM ll 2ES 027744011:1

2 The notice stated that the reason for the opinion that the Section had been contravened was:

"The dispensing of petroleum spirit across a public thoroughfare which constitutes a danger to members of the public."

The notice required that the contravention should be remedied by 6 August 1986, and the Schedule said: "The forecourt to be cleared of motor vehicles to enable sufficient room to dispense petroleum spirit to vehicles on the licensed forecourt."

3 By Notice of Appeal received at Central Office of the Industrial Tribunals on 6 August 1986, the appellants said that it was impossible to clear the forecourt, as car sales were the main focus of their business, that other busier garages carried out the same practice, that the enforcement of the Schedule would involve staff redundancies and cause embarrasement to their petrol company, that attended service was a valuable contribution to the wen being of the community, that petrol had been served in that manner for 50 years, and that the volume of petrol sales was low.

4. We first dealt with the question of the notice of appeal being out of time. Paragraph 2 of the Rules of Procedure contained in the Industrial Tribunals (Improvement and Prohibition Notices Appeals) Regulations 1974 provides that a Notice of Appeal shall be sent to the Secretary of the Tribunals within 21 days from the date of service of the notice appealed against on the appellant, but that a tribunal may extend the time where it is satisfied on an application made in writing, that it was not reasonably practicable for an appeal to be brought within that time. One of the partners in the appellant firm, and who appeared on behalf of the appellants, said that he was away on holiday for 3 weeks, returning to work on 21 July. He then had to deal with a pile of correspondence. He saw the improvement notice and observed that he was to remedy the contraventions by 6 August, but did not appreciate until later that there was a time for making the appeal. When he wrote to the Tribunal on 4 August he apologised for delay, and impledily asked for an extension.

5. The Tribunal was satisfied that it was not reasonably practicable for the notice of appeal to be entered within the prescribed time, and accordingly extended the time. 6. We heard evidence from the partner himself, and from Mr Richards the Assistant Senior Fire Prevention Office. Mr Thomas, solicitor represented the County Council.

7. The appellant firm acquired the premises at Hazlemere, Wycombe, in February 1984. On the land is a small service garage, with 3 petrol pumps and car sales. When the appellants acquired the premises the number of cars for sale was small. Although there was access for cars to pull off the road onto the forecourt in order to be served with petrol (petrol was at all times served by an attendant) it was the practice for a number of people to stop on the highway or pull onto the footpath to purchase petrol. The principal business of the appellants is the sale of second-hand cars. so they filled the forecourt with cars. When their attention was drawn to the difficulties raised by this. they left what was in effect a footpath on the forecourt land so that when cars were pulled up and the pavement of the

public highway was obstructed, foot passengers could walk on the forecourt. The amount of land available to the appellants is small, and if the improvement notice is brought into effect, they will have to reduce very substantially the number of cars held of give up the sale of petrol.

8. The County Council produced a bundle of documents. The problems at these premises began in 1960 when it was noticed that tankers were offloading petrol direct from the highway, and it was required that warning notices should be put up when such offloading took place.

9. In 1985 there had been a complaint by a parish councillor and the fire brigade visited the premises. They sent an informal letter to the appellant on 8. May 1985 requiring that within the maximum period of a years measures should be taken to ensure that the licensed forecourt was the only position from which petroleum spirit be dispensed. Apart from moving the cars back so that there was a passage behind the petrol pumps, (as stated above), the appellants took no action.

10. The fire brigade had in mind the model code of principles to petrol filling stations issued by the Home Office 10 1968. Among these principles are a requirement that precautions should be taken to prevent the escape petrol into a public drain or sewer, and that all practicable steps should be taken to ensure that no naked light fire or flame or smoking should b permitted within 4 feet of a petrol pump or the of a petrol storage tank. There was a possibility in this case foot passengers passing to and from might light a cigarette within that 14 feet. Furthermore there was some danger to the public from petrol pipes lying across the footpath of the highway.

11. The evidence was that the forecourt is completely block.ed by parked cars for sale, and that the only practicable way of serving petrol is over the pub!" highway. On the other hand if some of the sale were removed, cars requiring petrol could pull onto the forecourt.

CONCLUSIONS

12. The tribunal was satisfied that the arrangements in the past had been that cars requiring petrol Would pull off the road onto the forecourt. This is the primary purpose of a forecourt. It was also satisfied that there was risk to safety or health by allowing cars as a regular occurrence to be parked in a road where there is somewhat of a bend, that there was risk of foot passengers tripping over a petrol hose if they were s ill-advised as to walk on the footpath of the highw 0 h 'l b' f' ay w I e cars were emg died, and that there was s risk of fire if people over whom, the appellants no control were to walk on the appellants' land wlthm 14 feet of the petrol pumps.

13. .The tr!bunal considers that it is reasonably (m words of Section 4( 2) of the 1974 Act) for the. Improvement notice to be complied with. the tribunal affirms the order. subject to It takll1g effect on 2R October.

III

Petrol and Oil Interceptors The State of the Art

by Roger Davidge, Market Development Manager, Conder Pollution Control.

In the early part of this century when petrol driven vehicles were emerging as an acceptable form of transport, drivers purchased supplies of petrol in cans from hardware stores. Mechanical breakdowns were frequent but more people became stranded probably through running out of fuel than for any other single reason. The stranded motorist, if he was a member of the newly-formed Automobile Association, could usually rely on an AA patrolman to bring him a can of petrol, but whilst the patrolman was thus engaged, he did not have very much time to deal with genuine breakdowns.

In order to overcome this problem, the Automobile Association stockpiled supplies of petrol at convenient locations around the countryside for re-sale to the motorist. These stocks were eventually stored in underground tanks and dispensed by means of handcranked pumps. The first of the AA Petrol Stations as they were called, was opened in November 1919 at Aldermaston in Berkshire.

The AA continued to develop petrol stations up until 1932. They then relinquished control of that side of their business in order to concentrate more on the mobile services that they were providing for their members; no doubt they thought that it was a good idea at the time.

During the 1920's, legislation to control the licensing of garages and filling stations was introduced, and later in 1936 Section 27 of the Public Health Act made it an offence to allow petroleum spirit to enter a public sewer.

The London County Council, anticipating this in the years between 1925 and 1930, designed and introduced the first petrol interceptor. This interceptor (see 1) consisted of 3 separate chambers by dlppipes, and working on the principle of flotatIOn. separate and retain petrol from the forecourt dramage system, thus allowing only surface water to enter the public sewer.

NOTE.-The ventilating pipes from the chambers must not be joined together below the level of the lowest gully connected to the interceptor.

All pipes within the chambers through which liquid passes should be of iron, and all brickwork should be rendered with cement mortar, unless engineering bricks arc used.

LONGI TUDINAL

SEQ,TJON

Figure 1. L. C. C. Pattern Petrol Interceptor.

C. =--r; --=::.: ,'NO-t- -;-r- -.::!) .-,.- __.,.w 0I1UTS[QTIONAL flAN AB.

The traditional interceptor as described above suffered from one major drawback being constructed from rendered engineering brick and incorporating cast iron pipework, it was both expensive and labour intensive to build.

However, in 1972 all of this changed. CONDER HARDW ARE LTD of Winchester revolutionised the interceptor scene by introducing a pre-fabricated 3chamber interceptor, manufactured from glass reinforced polyester (GRP) and utilising lightweight uPVC pipework.

See Figure 2.

The 3-chamber Conder interceptor was modelled closely on the LCC unit but was built under strict factory-controlled conditions. It was tested and supplied to site in one complete assembly, thus allowing the builder or contractor to complete the entire installation in one day. Accepted for installation throughout the United Kingdom, and having the approval of the LFCDA, the Conder interceptor is preferred because its unique design allows the placing of concrete backfill between the chambers which enhances the structural integrity of the interceptor.

Figure 2. Three Chamber Conder Interceptor.

Over the 60 years or so since this design of interceptor was introduced, it has been known variously as the LCC Pattern, the London Fire Brigade interceptor, the GLC unit and even the Code of Practice interceptor, but regardless of the name, it remains the same unit and is still the only design permitted in London by the LFCDA for filling station development. It is also approved by all ofthe Local Authorities within the United Kingdom.

The Pollution Control Division of Conder Products and Systems Ltd, as the Company is now known, has maintained a comprehensive development and testing programme over the years and, as market leader, it is now able to offer a wide range of interceptors for use as sedimentation units, for use with washdowns, Bypass interceptors and a new range of 2-chamber oil interceptors that conform to the latest BS 8301 requirements.

Oil Interceptors

The function of an oil interceptor differs from that of a petrol interceptor and it has been accepted that the 3-chamber design is not the most efficient for separating oil.

I n order for such an interceptor to work efficiently, it is necessary to restrict the surface water generated by a forecourt to a minimum; failure to do this may result in turbulence being caused within the interceptor chambers and the already separated contaminents may be re-entrained and subsequently flushed out from the unit. Normally, only the road tanker unloading stand and the area immediately in the vicinity of the pump island are drained through the interceptor. It is undesirable to allow roof or canopy drainage to be con nectcd to the same system and. likewise, under no is the effluent from a carwash to be introduced to the pt:trol interceptor.

The Hydraulics Research Institute at Wallingford have recently carried out a series of tests on petrol and oil interceptors for the Department of the Environment. findings are contained in a separate report, but their recommendations regarding the design of a 2chamber interceptor have been incorporated in British Standard 8301. There is, however, some dicussion on this subject because, as is stated above, it is generlly held that the 3-chamber interceptor is not right for use as an oil interceptor and, conversely. in some circles it is held that a 2-chamber unit is not acceptable as a petrol interceptor. Certainly. the 2-chamber interceptor as shown in BS R301 is not acceptable to the LFCDA Petroleum Inspectorate.

, , , . . , , " ' .. - -...a-', ' • • • • rI '.' .. ' , . , I , ,

J) " .' ... , , . . , r , ' . .,.I ' • 11 '. .' ,- ., =-.. " \.- ------ --.J.:, :.l'--__ . : " , . ,

" IX .. ' .. . ' . , "

To return to the subject of an oil interceptor, the first chamber should be half the capacity of the second and it should incorporate a submerged inlet, although not necessarily a surchaged inlet. The submerged inlet is to reduce turbulence. The chambers are connected by means of a wide horizontal submerged slot; this again is to reduce turbulence and to ensure the steady transfer of liquid between chambers. The second chamber offers oil particles a long steady flow-path in which they can coalesce and rise to the surface. The final outlet can either be a straight pipe protected by a baffle board or a large diameter dip-pipe.

Bypass Interceptors

Bypass interceptors are relatively new to the scene when compared to the history of the LCC interceptor. They are definitely not suitable for use on filling stations or any other type of installation where bulk fuel storage is held.

The Bypass interceptor is intended for areas where large run-off rates would be expected but with low contamination factors. The ideal situation would be on a large car parking area where the only expected contaminents would be oil and rubber residue. The Bypass is designed to accept only 10% of the total designed flow rate, the remainder of the flow, as the storm intensity builds up, is allowed by means of weirs to bypass the interceptor element of the unit. Because the Bypass interceptor only accepts 10% of the total flow rate, the entrained contaminents cannot be flushed out of the unit under storm conditions.

3. Two Chamber Conder Oil Interceptor to British Standard 8301 requirements.

Apart from the types of interceptors described above, there are many other variations on the main theme, but it would be confusing to attempt to document them all here. The Pollution Control Division of Conder Products & Systems Ltd has a friendly and efficient Customer Service Department who would be pleased to answer any queries. They can be contacted on Winchester (0962) 63577. --9 ..

See Figure

3.

1'1

Figure

...

B MER TAB-LINK FOR LONGER LIFE EASIER SERVI

During the past 2 years a different type of drive belt has appeared on forecourt petrol dispensers The name is Tab Link, and its unique polyester/polyurethane construction enables this belt to last a minimum of si x times longer than conventional V-belts It' s easier to service , as one reel enables the service engineer to make up any length of belt to suit all pump assemblies , t hereby greatly reducing the stock carried.

When it comes to the nnanufacture of pump equipment a simpler design is possible using Tab Link, as the tensioning and sliding adjustment systems used with conventional drive belts aren't needed. , Tab-Link is in successful use in petrol dispensers throughout Britain , including those serviced by Pump Maintenance Limited, and built by Avery-Hardoll Ltd , TokheimLtd and Ferranti Ltd.

BRANlNlER So isn't it ti me you fitted Tab-L ink _ you' ll find yourself in ve ry good company. I TARflllfiYlf% I BRA MME R T RANS MI SSIO N S LTD. Hudson Road , Leeds LS9 7DF Tel (0532) 493486 Telex 556144 T he driving f orce in p etr o l p u mp V=B e lts!

Now you can dispense, meter or transfer using our unique portable battery operated pump which delivers up to 10 GPM -12 and 24 volt D.e. pumps Mechanical and Electronic digital flow meter Pump Services (U.K.) Ltd. Western Park, Kansas Avenue , Salford , Manchester M5 2GL. Tel : 061·873 7428 Tel ex: 667834 THE FUEL DISPENSING SPECIALISTS Jobn &: (!CO. l£tb. FIRST HANGINGS· BLABY ROAD ENDERBY LEICESTER· LE9 5AQ Telephone: Leicester 862287 (STD 0533) For a Comprehensive service for Liquid Fuel & LPG installations Consultancy, design, installation, maintenanc e & deCOlnnlissioning Gas-free certificates Site surveys LPG vessel 5 & 10 year inspections MEMBER A,P,KA, LP,G,LT.A,

r-. RONCOL SERVICES LT D * Z.V.A. AUTOMATIC NOZZLE F1'ITED AS STANDARD * NO HANDLES JUST LIFT NOZZLE * LARGE INDIVIDUAL DELIVERY REGISTER * AUTOMATIC RESET ON NOZZLE REMOVAL * 10 ft. TOP QUALITY "ELAFLEX' GLOSSLINE HOSE * NON-PAINT, PLASTIC COATED, RUSTPROOFED PANELS A low cost Commercial Fuel Pump + Fuel Management system for the serious fleet operator

THE RONCOL COMMERCIAL FUEL PUMP

The pump incorporates a positive displacement, rotary gear type, pumping unit with inbuilt bypass valve and air separator, together with a remote air separation chamber incorporating "drain line elimination". In its standard form it is capable of delivering fuel at 45 litres per minute, there being a high flow version also with a delivery rate of 10 litres per minute. The meter unit incorporated is of the positive displacement type, with all materials of either stainless steel or aluminium for internal corrosion resistance, and positive stop type micro adjustment of measure is possible with increments as small as 0.08 per cent.

The automatic nozzle, INCORPORATED AS STANDARD, is the world renowned ZVA type. The pump is manufactured using a structural rolled steel angle frame with heavy section side plates and base for rigidity, the whole chassis being cross braced and finished in a petrol resistant paint. The flexible suction connector, also INCORPORATED AS STANDARD, is set high in the base for ease of installation. The cladding is in light-weight architectural plastic coated and passivated rustproofed steel sheeting in either red or green.

The pump is also available with integral, top mounted, TIMEPLAN system 300 fuel monitoring, providing a total security and management package. The system will accept up to 100 keys, the basic system being supplied with 25, and provides vehicle reports and tank stock management reports via the integral 20 character liquid crystal display. Alternatively a printer can be incorporated to provide more detailed management reports in printed hard copy form. An MPG computing facility is also available for use with driver entered odometer readings, thus providing a total fleet and servicing management tool.

Each unit is supplied completely wired internally and only needs connection to a single phase electrical supply, intstallation costs are therefore kept to a minimum.

r o C"I too o C"I512--o •••• •••• •••• • TIMEPLAN DATATOTE FUEL MONITOR NOZZLE OPERATED SWITCH NON RESETABLE 8 FIGURE TOTE INDMDUAL DELIVERY REGISTER .w.oIo4-lL..,;;,A;;.;UT..;;..;,O;;.jMATIC ZEROISATION ON NOZZLE REMOVAL __---!_ POSITIVE DISPLACEMENT METER LOCKABLE NOZZLE STOWAGE HOOK '--------J-AIR SEPARATOR FLOAT CHAMBER TUSCAN 1/2 HP FLAMEPROOF MOTOR J+_____ -I-COMPACT GEAR PUMP UNIT WITH BUILT-IN BY-PASS VALVE ROLLED STEEL ANGLE FRAME -+---------I-FLEXIBLE SUCTION CONNECTOR t 0 BASE PLAN 0 '- C"I C"I INOT EXTRAS! I i BUT STANDARD FInING I * DOUBLE SIDED REGISTER * FLEXIBLE CONNECTOR oqo * AUTOMATIC Z.V.A. NOZZLE . !1 1

All measurements in millimetres RONCOL SERVICES LTD. Supply, installation and repair of Fuel Storage and Dispensing Equipment RONCOL SERVICES LTD PETROL PUMP & TANK ENGINEERS * INSTALLATIONS * MAINTENANCE PLAS CELYN BANGOR ROAD PENMAENMAWR GWYNEDD LL346LD Telephone: (0492) 623787 UNIT 3 MAIN STREET SCRAPTOFT LEICESTER LE79DT Telephone: (0533) 418898 ...,

Illustrated 1800 gal. unit complete with Gasboy model 390 Fuel Control K20 unit.

Automatic Nozzle and 12' x '%" hose.

Throughput 8 - 10 G.P M. calibrated in imp. gal. litre measure to customers requirements.

The pump illustrated is a K5 key controlled unit.

A full RANGE of fuel control units with or without tank installations.

Illustrated below 1800 gal unit complete with Gasboy model 1820. Automatic Nozzle and 12' x '%" hose.

Throughput 8 10 G.P.M. calibrated in imp. gal. or litre measure to customers requirements.

* A STEEL CATCH PIT IS MORE FLEXIBLE THAN A BRICK BUND * ALL PIPEWORK FROM TANK TO PUMP IS COMPLETEL Y ENCLOSED * PUMP IS WIRED TO JUNCTION BOX READY TO CONNECT TO MAINS ELECTRICITY * NORMALLY NO PLANNING PERMISSION REOUIRED * AS SUPPLIED TO THE GREATER LONDON COUNCIL AND OTHER LOCAL AUTHORITIES * NO BUILDING WORK REQUIRED * TANKS CONSTRUCTED IN 6mm ('la") THICK MILD STEEL PLATE AND STAYED INTERNALLY * STORAGE TANK AND BUND WALL REST ON 3" x 2" x 'la" STEEL CHANNEL • PAINTED REO OXIDE

TANK HOUSED WITHIN A TANK OUTER TANK HOLDS 10% MORE THAN THE DERV STORAGE TANK TO COMPL Y WITH REGULA TlONS. OPTIONAL EXTRAS HIGH SPEED PUMPS 18-20 G.P.M. AND OTHER FUEL CONTROL UNITS Cemplete range ef Tanks, rectangular or cylindrical, available from 600 te 12000 galls. capacity. All Installations can be supplied less catch pit to meet individual customers requirements. RIVERSiDE WORKS CAMBRIDGE ROAD' HARILOW. ESSEX CM20 ZET IH: HARU1W (0279) 38727 Specialis t in equipment allied to the Petroleum & Chemical Industry Ta nl < and Pu mp ins ta ll ati ons

LAFON SAFETY FILLING LIMITERS

For above or underground tank storage of petrol and diesel, gravity or pump fed.

With forecourt safety in mind, the Lafon Filling Limiters ensure no overfills, no pollution or environmental damage.

With deliveries out of hours no errors in filling can take piace

Full protection against product overfills , damage and pollution costs.

The LAFON Filling Limiters require no maintenance, are used internationally, and do not rely on extraneous products such as electricity

Safety at its Best)

Ltd.

-on (Forecourt

I.F.L.

160 Abbey Street , Derby DE3 3SS Tel: 0332 36 96 14 Te lex : 377106 (IFL)

EASTERN COUNTIES TANK CLEANERS LTD. St. Margarets Wharf STANSTED ASSOrTS, Ware, Herts. 5, Brinell Way, Hal1reys Industrial Est. GREATVARMOUTH, Norfolk. TANK CLEANING, GENERAL CLEANING and 24 HOUR EMERGENCY OIL SPILLAGE ANTI-POLLUTION SERVICE TANKS Oil · Spirit· Chemical· Pharmaceutical· Water · Petrol Aviation' Fuel· Tank Painting · Tank Removal Descaling of Pressure or Condensate Tanks Pressure testing of Tanks and Pipes Interceptor Pit clearance· Oil spillages Also rehabilitation of below ground Service Station Tanks. Waste Oil Collection and Recycling. Telephone: Ware (0920) 870343 Telex: 817535 Gt. Yarmouth (0493) 602848 Telex: 975422 tASTE RN CDUNlIES TANKCL£ANERS Published by the Association for Petroleum and Explosives Administration and Printed by Miro Press, Bury St, Edmunds,

P. K. Beavon, B. H. Gallagher, Tri-Scan, S.D.S. Gregory, Turnkey Design Partnership Ltd., , D. J. Duckworth, Turnkey Design Partnership Ltd., G. P. Peart, R. I. Edge. Country Trading Standards Officer, Clwyd County Council, W. Cunningham, Fuel Management Systems. W. G. Cowburn Cowburn, Bers and Co Ltd., Mr. 1. Bers. Cowburn, Bers and Co. Ltd.,

1. Hornbv. Cowburn'. Bers and Co. Ltd ..

Belhan Construction Ltd

S.' P. Bulgen, Trading Standards Department, Dorset County Council A. J. Chappell,

S. Crone. Swains Park Industrial Estate. R. N. Gibson, B. Mincher. D. J. Minogue, Highfields, M. Nicholas.

p.Oglesby. lan Stephen.

N. Thomson. Maritime Industrial Group. L.H.P. Wood.

P. K. Beavon, B. H. Gallagher, Tri-Scan, S.D.S. Gregory, Turnkey Design Partnership Ltd., , D. J. Duckworth, Turnkey Design Partnership Ltd., G. P. Peart, R. I. Edge. Country Trading Standards Officer, Clwyd County Council, W. Cunningham, Fuel Management Systems. W. G. Cowburn Cowburn, Bers and Co Ltd., Mr. 1. Bers. Cowburn, Bers and Co. Ltd.,

1. Hornbv. Cowburn'. Bers and Co. Ltd ..

Belhan Construction Ltd

S.' P. Bulgen, Trading Standards Department, Dorset County Council A. J. Chappell,

S. Crone. Swains Park Industrial Estate. R. N. Gibson, B. Mincher. D. J. Minogue, Highfields, M. Nicholas.

p.Oglesby. lan Stephen.

N. Thomson. Maritime Industrial Group. L.H.P. Wood.

by Geoffrey Ashton Ferranti Resin Ltd.

by Geoffrey Ashton Ferranti Resin Ltd.