The •

THIS ISSUE STAGE 2 VAPOUR RECOVERY U.S. SOLUTIONS TO PIPEWORK PROBLEMS FIREWORKS ROAD TANKER INCIDENT VOLUM E 29 No. 1

Journal of the Association for Petroleum and Explosives Administration

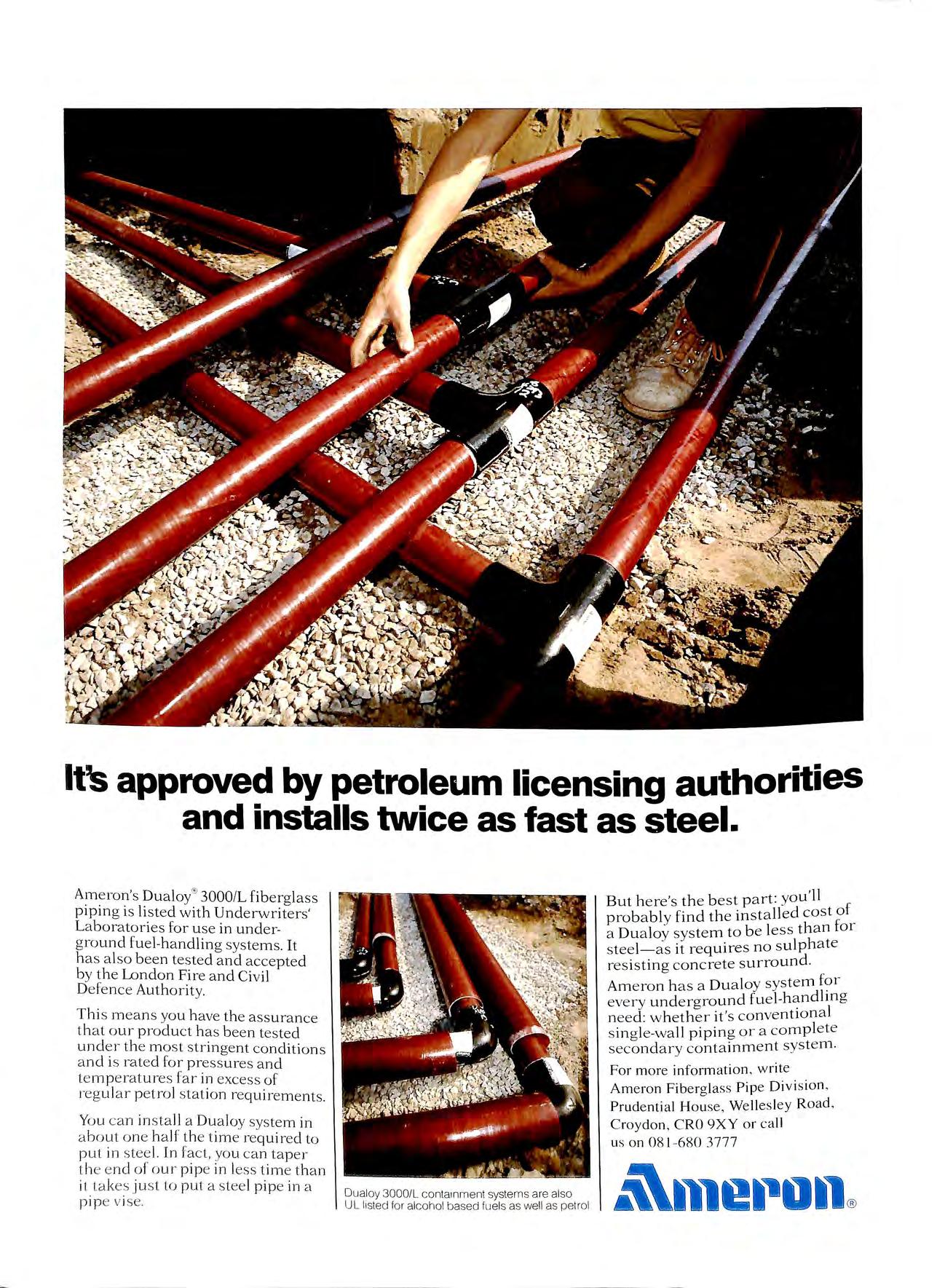

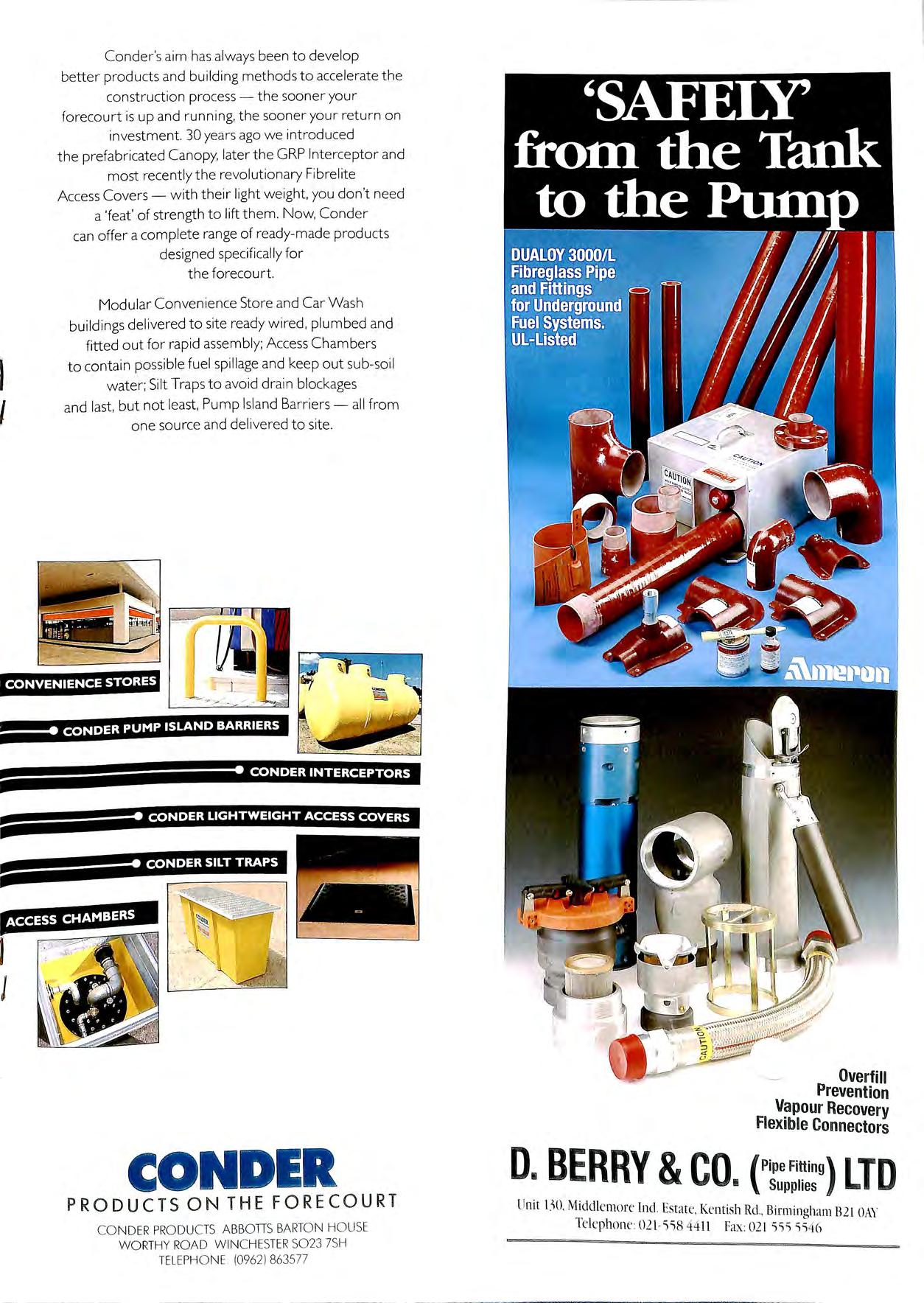

Ameron's Dualoy®3000/L fiberglass piping is li sted w ith Underwriters' Laboratories for use in underground fue l h and lin g sys tems. I t has a lso been tested and accep t ed by the London Fire and Civil Defence Authorit y

Thi s m ea n s yo u have the assurance that our product ha s been te sted und er the mo s t stringent condit ions a nd is rat e d for pre ss ures and t e mp e rature s far in exces s of reg ul a r pe tro l s t at io n requirements.

Yo u can in s ta ll a Dualoy sys tem in a bout o n e h a lf t h e tim e r equired to put in s tee l. In fact, yo u ca n tap er t h e e nd o f our pip e in less time than it Lak e s ju s t to put a s tee l pip e in a p ip e v ise.

But here's the b est part: yo u'll prob ab ly find the inst al led cost ff a Dualoy system to be less than or stee l- as it requires no s ulphate resisting concrete surround.

Ameron has a Dualoy system for every underground need: whether it's convent10 n a l s in g le wa ll piping or a co mpl ete secondary conta inment sys t em

For mo re information, write Ameron Fiberglass Pipe Divi s ion , Prudential House, Wellesley Road, Croydon, CRO 9XY or ca ll us on 081 680 3777

It's approved by petroleum licensing authorities and installs twice as fast as steel.

Dualoy 3000/L containment systems are also UL listed for alcohol based fuels as well as petrol

C p INSTALLATIONS LTD. (Established 1968) Specialists in Petroleum Pipework Installations New and existing Tanks and Lines tested Modifications to existing Installations And all work associated with Forecourt Pipework Ameron approved for Fibre Glass Installations 39 BROOK ROAD, RAYLEIGH WEIR INDUSTRIAL ESTATE RAYLEIGH, ESSEX SS6 7XN Tel: 0268 781184 I 781859 (24 hrs ans) Fax: 0268 776697 PHONE: 071-739 9538 FAX: 071-729 6108 TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET, LONDON E2 6QQ MEMBER A.P.E.A.

l!JiW. LAMB LTD. THE PREMIER PUMP AND TANK COMPANY Forecourt and Commercial Above and Below Ground Supply Test Exchange - Service lnstal Product - Transfer De-Watering Removal Purchase Tank Demolition Removal - Safety Filling Large Stocks of New and Secondhand Petrol and Diesel Pumps, Tanks and Accessories DAVBROOK STREET, SHERWOOD, NOTTINGHAM 0602 621511 + 608084 TRINffV WORKS, BOURNE END LANE, HEMEL HEMPSTEAD WJ FINCH LTD (INSTALLATIONS and CONTRACTORS) Regd. Office: HEATON HOUSE 121 137 CAMDEN STREET BIRMINGHAM Bl 3BZ 0442 872296 Tel: 021 236 0347 Fax: 021 236 8145 OFFERING A TOTAL SERVICE COVERING ALL ASPECTS OF FORECOURT REQUIREMENTS, RANGING FROM CONSTRUCTION & INSTALLATION OF COMPLETE NEW BUILD OR REDEVELOPMENT, WITH FULL DESIGN & BUILD OPTION, TO GENERAL PIPEWORK & PUMP-TANK INSTALLATION & TESTING, IN ADDITION TO OUR GENERAL SITE MAINTENANCE WORKS. ESTABLISHED 1964

_TAMES LuKE ASSOCIATES Safety & Training Consultants to the Petroleum Retail Industry ? l::l:lill!lllllllli i, SALUKI HOUSE 4 BURNT COMMON CLOSE RIPLEY, SURREY GU23 6HH Tel: 0483 222946 - Fax: 0483 211328 }obn •tgfull & 1Ltb. FIRST HANGINGS BLABY ROAD ENDERBY LEICESTER LE9 SAQ Telephone (0533) 862287 Fora Comprehensive service for liquid fuel & LPG installations Consultancy, design, installation, maintenance & decommissioning Gas-free certificates Site surveys LPG vessel 5 & JO year inspections MEMBER APEA, LPGITA DESIGN FUELLED B EXPERIENC Personal attention in design & development for the petroleum retail industry • Principal with over 25 years expenence • Project Management specialists •Progressive & innovative outlook •Consultants for statutory & planning requirements •Comprehensive or tailored se rvice to suit PLANACOURT Planacou1i Limited PO. Rox 27 Billericav Essex CMll 2ES 0277 630868

C·S·STANSFIELD MECHANICAL SPECIALISTS IN FORECOURT PETROLEUM INSTALLATIONS SERVICES Unit 10 Boundary Road Industrial Estate Sturmer, Haverhill Suffolk, CB9 7YH Tel: 0440 712505 Fax: 0440 712506 BELHAN CONSTRUCTION CO LTD Building Contractors (Est 1970) Comprehensive Development and Maintenance Services By Petrol Station Specialists 60 Connaught Gardens 5hoeburyness Essex 553 9LR Tel: 0702 295197

• MANGAN BROS. LTD. Building Contractors 402 Seven Sisters Road, London N4 2LU (REGISTERED OFFICE) Telephone: 071 800 4651 Specialists in Petrol Filling Stations D. & S. Leggett (Electrical) Limited ELECTRICAL CONTRACTORS NICE/C APPROVED 181 ROAD, NEW BARNET, HEATS. Telephone: 081 441 3958 Fax: 081 449 3470 SPECIALISTS IN PETROL STATIONS

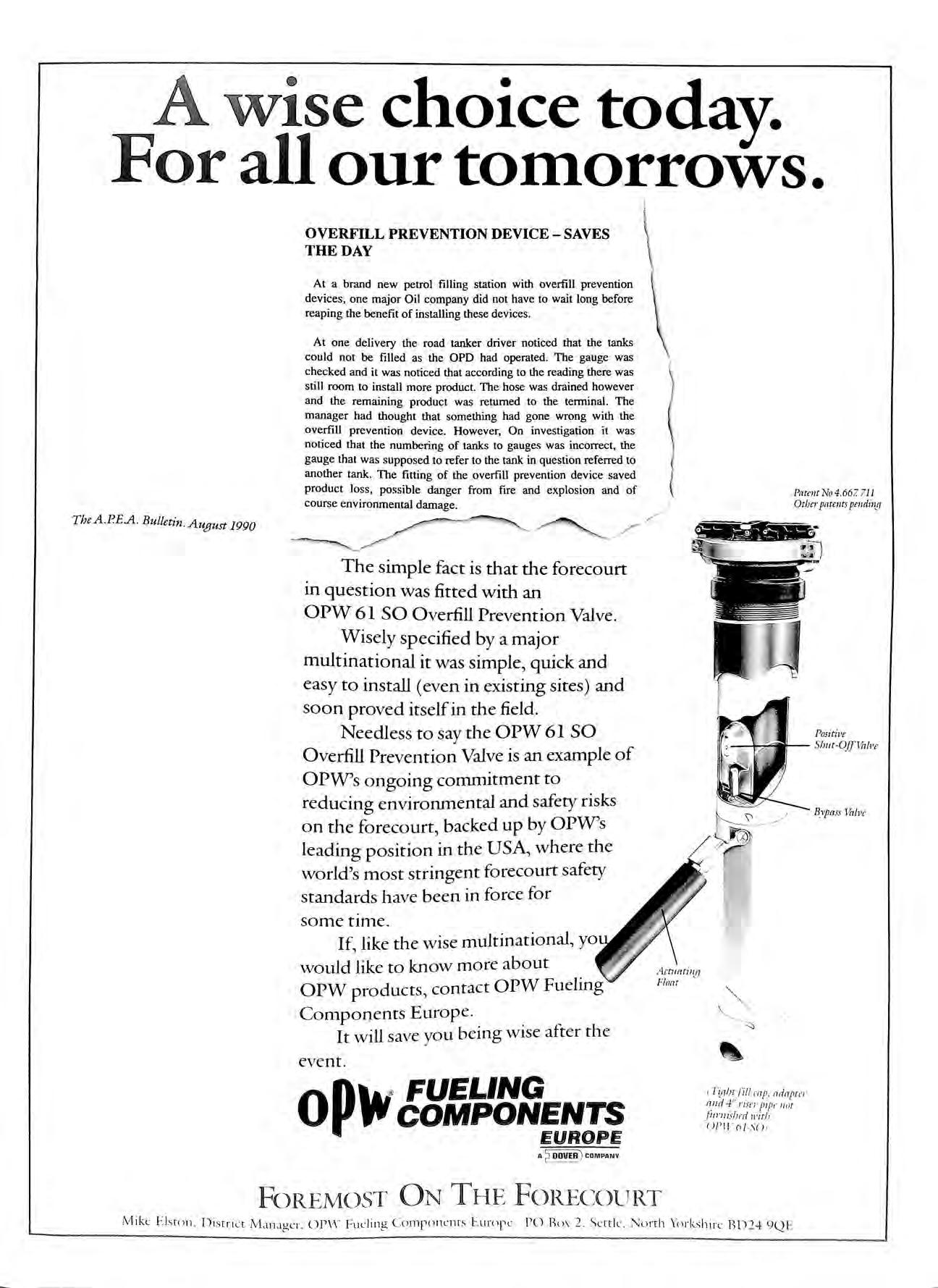

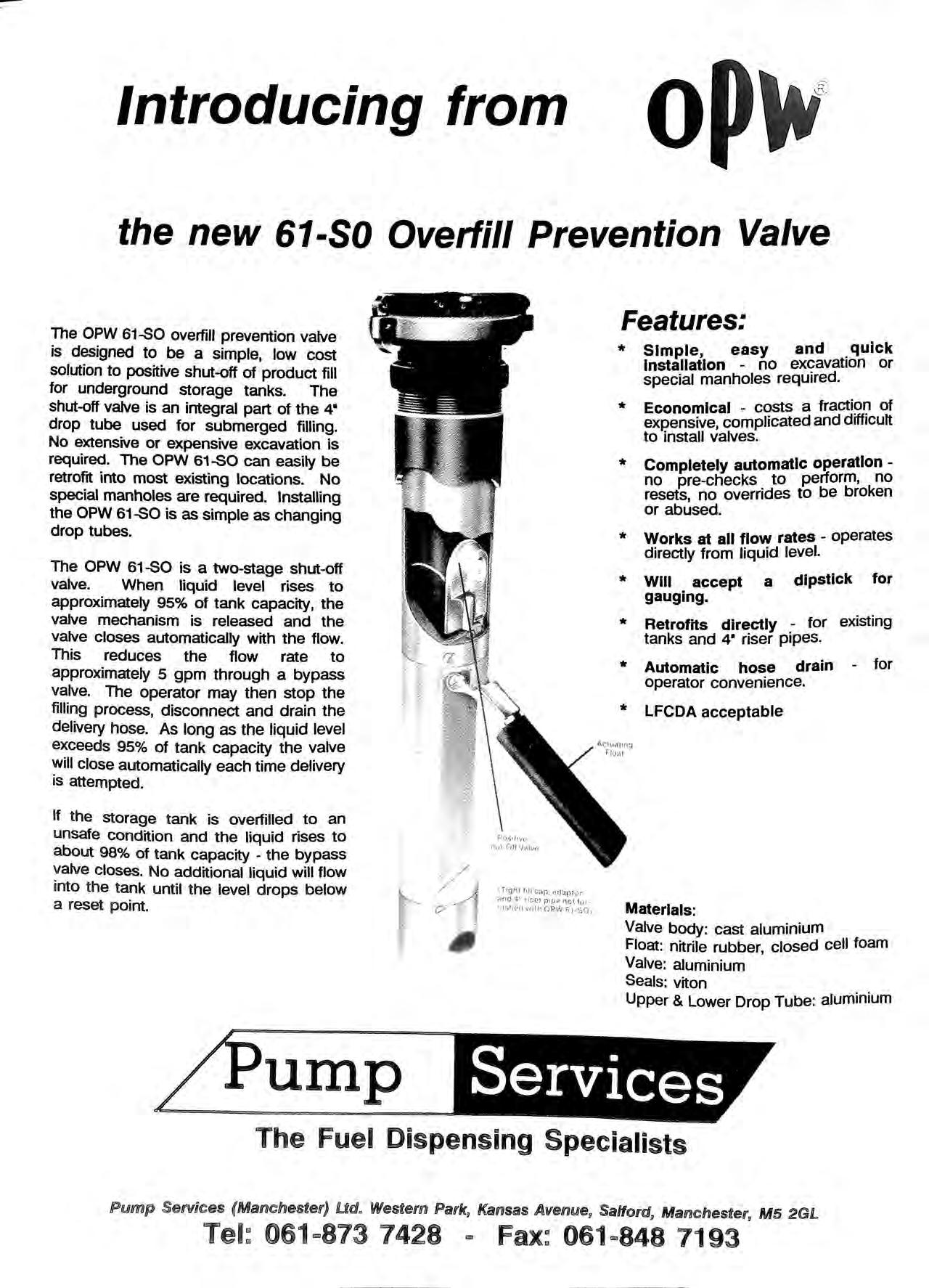

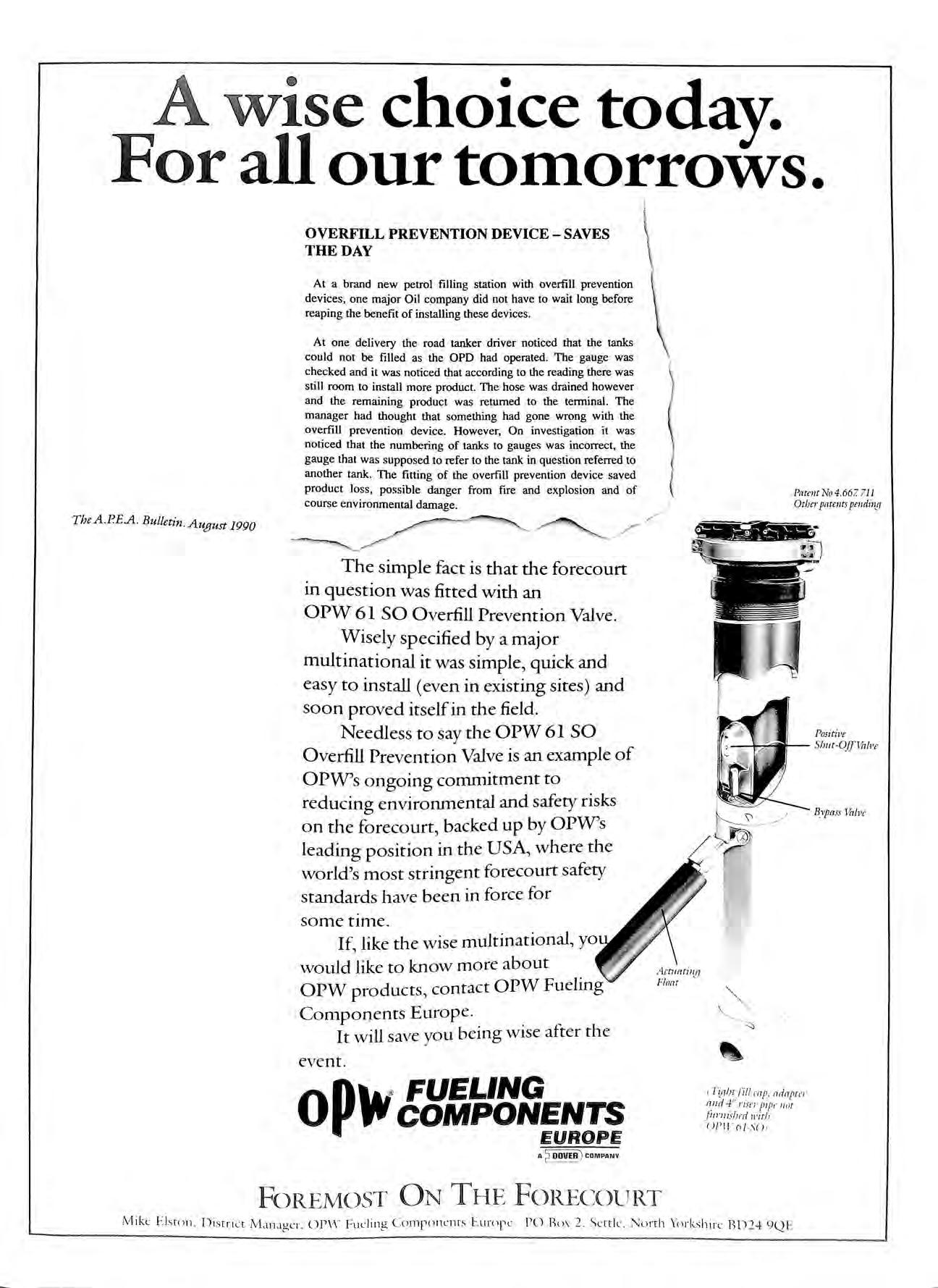

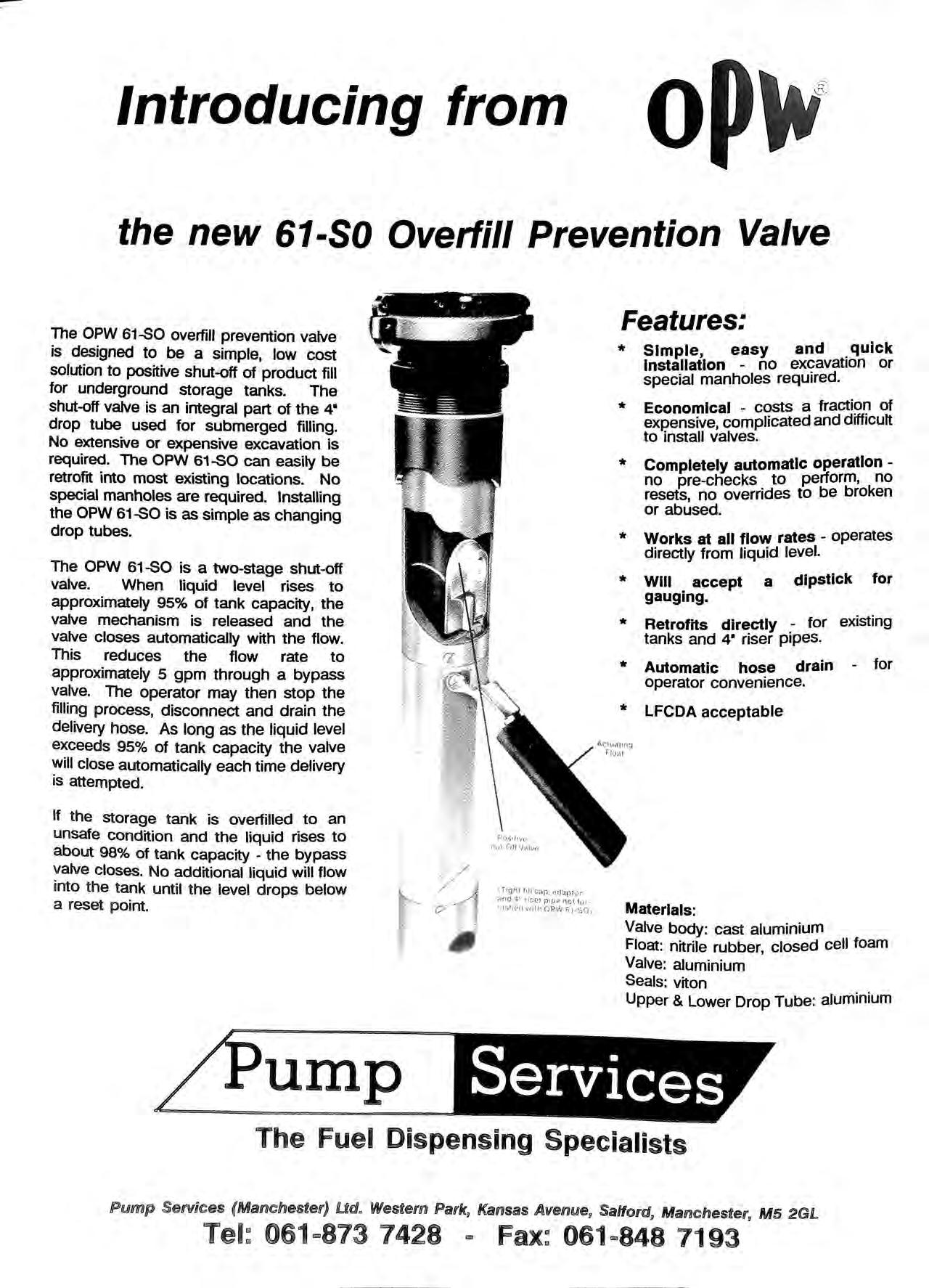

Introducing from the new 61-SO Overfill Prevention Valve

Features:

The OPW 61-SO overfill prevention valve is designed to be a simple, low cost solution to positive shut-off of product fill for underground storage tanks. The shut-off valve is an integral part of the 4" drop tube used for submerged filling. No extensive or expensive excavation is required. The OPW 61-SO can easily be retrofit into most existing locations. No special manholes are required. Installing the OPW 61-SO is as simple as changing drop tubes.

The OPW 61-SO is a two-stage shut-off valve. When liquid level rises to approximately 95% of tank capacity, the valve mechanism is released and the valve closes automatically with the flow. This reduces the flow rate to approximately 5 gpm through a bypass valve. The operator may then stop the filling process, disconnect and drain the delivery hose. As long as the liquid level exceeds 95% of tank capacity the valve will close automatically each time delivery is attempted.

If the storage tank is overfilled to an unsafe condition and the liquid rises to about 98% of tank capacity - the bypass valve closes. No additional liquid will flow into the tank until the level drops below a reset point.

* Simple, easy and quick Installation no excavation or special manholes required.

* Economical costs a of expensive, complicated and difficult to install valves.

* Completely automatic operation no pre-checks to perform, no resets, no overrides to be broken or abused.

* Works at all flow rates operates directly from liquid level.

* Will accept a dipstick for gauging.

* Retrofits directly for existing tanks and 4" riser pipes.

* Automatic hose drain for operator convenience.

* LFCDA acceptable

Materials:

Valve body: cast aluminium

Float: nitrile rubber, closed cell foam

Valve: aluminium Seals: viton

Upper & Lower Drop Tube: aluminium

ump hu\-0f1 V..tivc (Ttght fill cap. nrJ:;pfvr ilfld ,:r· /)!D I? f111. with OP\'; G i SO;

Services The Fuel Dispensing Specialists Pump Services (Manchester) Ud. Western Parle, Kansas Avenue, Salford, Manchester,

2GL 061c873 7428 "' 061=848 7193

M5

Talking Point

One thing is clear in HS(G)41 and that is that pressure testing of petrol tanks and lines using nitrogen is now firmly outlawed by the HSE as a dangerous practise. Most experts have long agreed that such tests are very inaccurate.

The answer to all our test problems in future appear to be "precision testing" of the types being imported from the USA, (Petrotite, Hunter, Tanknology etc). STAGE 2 VAPOUR

PETROL PIPEWORK USA

However users of this equipment must make sure that the equipment used is Baseefa approved, US approval is not acceptable. Operators must be fully trained in the use of the equipment and tank access.

The Association is already preparing leak detection criteria for the Industry after consulting with regulatory Authorities in the USA.

VOLUME, 29 Number 1 FEBRUARY 1991 £5.00 (Free to Members) Contents TALKING POINT NOTES & NEWS NEW MEMBERS LETIERS TO EDITOR The Bulletin Published by the Association for Petroleum and Explosives Administration

company Limited by Guarantee registered in

2261660

Office: Stoughton House, Harborough Road, Oadby, Leicester

4LP ISSN

2 3 4

A

England No.

Reg.

LE2

0263 4597

Opinions expressed in this Journal are not necessarily the views of the Association

RECOVERY 5

PRESSURE

FIREWORKS ROAD TANKER INCIDENT HUMBERSIDE BRANCH J. Horsburgh EASTERN BRANCH R. G. Green Honorary Secretary: Mr. B. D. Taylor. 10 14 18 19 SOUTHERN BRANCH M.Cox Normand Instruments Ltd.,

PIPE SOLUTIONS

MEMBERSHIP SECRETARY B. J. Thompson MIDLAND BRANCH Mr. L. Lloyd CMS Ltd. ADVERTISING SECRETARY J. Luke Honorary Editor: Mr. J. A. J. Thompson.

notes and news

Prosecutions

PETROL SOLD IN 2 LITRE PLASTIC JUICE BOTTLE ON BP SELF SERVICE FORECOURT

Action by Leicester Fire and Rescue Service has resulted in the succesful prosecution of POLYGON RETAILING LTD. (a wholly owned subsidiary of BP Ltd.) following the sale to a member of public of approximately 2 litres of petrol contained in a 2 litre plastic juice bottle.

A Petroleum Officer was passing their site in Groby Road, Leicester on the morning of the 7th March 1989 when he saw a man on the other side of the road pouring petrol into his car from a plastic bottle. When interviewed the man identified the filling station opposite as the supplier.

The bottle was taken as evidence and the gentleman was asked to return to the forecourt as a witness this he did.

On arrival the cashier/attendant was identified by the witness. The cashier/attendant was then cautioned and questioned. Following further investigation the Manageress was also cautioned and statements were taken.

A full site inspection was then carried out which resulted in another 8 charges being made. The case was heard at Leicester City Magistrates Court on the 14th September 1990 which resulted in fines totalling £2,000 and costs of £250 against Polycon Retailing Ltd.

The charges were as follows:-

Offences against conditions of Licence

Condition 12 by allowing petrol to be dispensed into an unauthorised container (2 litre plastic juice bottle) Fine £500

Condition 44 by allowing the customer to fill his own container Fine £500

Note The customer had shown the container to the cashier and had been told to fill it himself.

Condition 56 by failing to display clear operating instructions for customer guidance on petrol pumps 9 & 10 Fine £250

Condition 26 by failing to keep tank manhole chamber No. 4 free from dirt deposits or other obstructions (i.e. 4uantity of paper toweling)

Fine £250

Conditions 66 & 54 failure to display Conditions of Licence relevant to members of forecourt staff in a prominent position

TEXACO FINED £2250 FOR PETROL DELIVERY IRREGULARITIES

Star Service Stations a wholly owned subsidiary of Texaco were prosecuted by the London Fire Brigade at Western Magistrates Court on 8 October 90 followmg contraventions of road tanker delivery regulations.

The company pleaded guilty to to a competant person in charge of the delivery at the site and were fined £1500. They also pleaded guilty to having no sand on the site to deal with the outflow and were fined £500. The London Fire Brigade were awarded £250 costs.

LACK OF VIGILANCE WAS THE MAIN FACTOR LEADING TO THE PETERBOROUGH EXPLOSION

The explosion at Fengate, Peterborough, on 22nd_ 1':1arch 1989, in which a fireman was killed and at least 107 mJured, was due to badly packed fuse heads and rusty used to carry them, concludes a Report on the mc1dent issued by the Health and Safety Executive (HSE). Nobels Explosives Company was fined £250,000.

The Report recommends that explosives manufacturers must tighten up and extend their safety systems to ensure that in future the public are not exposed to such risks.

The incidents began when fusehead combs in the box ignited by the jolting of the vehicle carrying them it passed over a speed ramp as it entered the yard of V1broplant Limited. The fire spread to the rest of the load, and after 12 minutes the cargo of high explosives detonated.

The fuseheads were found to have been carried in authorised and unsafe packages. The method of was unsuitable; it led to a build up of loose material in the rusty metal boxes used thereby increasmg the risk of ignition; and added to that the quantity in each package was excessive.

Following their investigations into the incident HSE 's Explosives Unit made a number of recommendations concerning the transport of explosives:

* operators should develop systems to ensure th_at all activities involved in transporting explosives are safe. and that they meet the requirements of the regulations. These should include proper classification and labelling and correct packing of explosives;

* safety and quality systems should apply not only to ne:-v or modified products but also should include a periodic review of established ones;

Fine £250

Condition 25 for failing to lock the fill cap to tank No. 3 Fine £250

A further three charge were withdrawn

* transport crews should be kept infonned about changes in circumstances such as new products among their load and their training should include measures needed when caJTying specific products and mixed loads;

* all transport of explosives should be pre-planned including measures to ensure that explosives in different compatibility groups are prevented from coming into contact with each other if their packaging is degraded. for example. through fire or minor explosion.

•

2

New Members

The Association welcomes the following new members

Gordon K. Judson WM Morrisons Supermarket pie

Francois Meersseman

FM Consultants

Colin Keith Watson Burmah Petroleum Fuels Ltd. "

Colin Eastlake

Euan J McMurdo Mobil Oil

Peter C. L. Allen Mobil Oil

Philip J. Lambeth Mobil Oil

Roger Marshall Mobil Oil

Barry P. Collison Mobil Oil M.A. Greenwood

Frank Wilfred Oliver Humberside County Council

Michael David Truby Dunclare Dispensers

Patrick Browne Retail Engineering Manager

Richard P Wilson Burmah Castro! pie

D. R. Andrews

William D. Fraser Robert Lewis PM Services Ltd Keith Harrison Total Oil (Great Britain) Ltd

James McPherson Dept of Consumer Protection and Trading Standards

Patrick Browne Retail Engineering Manager

Terry Hedgeland

Mr G. S. George Mobil Oil Compan\ L.td

The Association welcomes the following new members

Gordon K. Judson WM Morrisons Supermarket pie

Francois Meersseman

FM Consultants

Colin Keith Watson Burmah Petroleum Fuels Ltd. "

Colin Eastlake

Euan J McMurdo Mobil Oil

Peter C. L. Allen Mobil Oil

Philip J. Lambeth Mobil Oil

Roger Marshall Mobil Oil

Barry P. Collison Mobil Oil M.A. Greenwood

Frank Wilfred Oliver Humberside County Council

Michael David Truby Dunclare Dispensers

Patrick Browne Retail Engineering Manager

Richard P Wilson Burmah Castro! pie

D. R. Andrews

William D. Fraser Robert Lewis PM Services Ltd Keith Harrison Total Oil (Great Britain) Ltd

James McPherson Dept of Consumer Protection and Trading Standards

Patrick Browne Retail Engineering Manager

Terry Hedgeland

Mr G. S. George Mobil Oil Compan\ L.td

Letters to Editor

Dear Editor,

Reading the Bulletin nearly a decade after my retirement I realise how out of date I am. It is therefore with some trepidation that I comment on the suggestion in Tam Govan 's letter (Bulletin Vol. 28-4) about the fitting of gauze to the vent pipe in the manhole chamber of a 'vapourbalanced' tank.

To be effective as a flame arrester, gauze must be fitted in a vent pipe at the point of discharge to the open air. The gauze will probably also be effective in the pipe within 23 inches of the point of discharge; between 23 inches and 44 inches keep your fingers crossed; but beyond 44 inches do not waste your time!

Many years ago Ken Palmer, carried out a number of experiments at the Fire Research Establishment on flame acceleration in pipes -a number of 'official' papers on the subject were issued in the late 1950's. Ken noted flame speeds of up to 600 feet per second in comparatively short lengths of piping and that gauze is effective up to only 11 feet per second. Reference to this subject and the papers was made in one of the "Through the Pipeline" items in an earlier issue of the "Bulletin".

Yours sincerely W. C.R. Dale

Editorial Comment

Bill Dale an Honorary Member of the Association maybe better known to many as "Otto" and contributed many technical papers to the Bulletin.

Thankyou Bill.

Dear Editor,

At different times the oil companies have been advised to devote more resources to their underground installations.

Your recent Bulletin No. 4 reported damage to tanks occurring on site which adds emphasis to earlier pleas for greater care and attention during installation.

The CEN Standard will comprise two parts one of which is the manufacture of the tanks whilst the second,. and just as important. aspect concerns the 111stallat1on. It is pointless for a manufacturer to take great care in ensurin.g he produces a quality product if similar care and attention is not given during installation. This applies regardless of the material from which the tank is manufactured. Hopefully. contractors will note this concern and respond constructively in the field.

Yours faithfully M. R. (Jriffiths Managing Director Fibre Reinforced Produch Ltd.

Mr Anthony Lambert Shell UK Oil

Wendy Griffin

Broadway Malyan Architects

Stuart Gordon Cooper Clarke Southern Ltd

Robert Weaver Texaco Ltd

Mr A. T. Jenner Forecourt Engineering Ltd

C. J. Cunliffe Avis Rent A Car

Daniel Conway Cameron Technical Services

6

f·rank Atkinson W 111 Morrisons Supermarket pie 4

Derek Ronald Middleton Cameron Technical Services Ltd

R. L. Weeks Texaco Ltd Peter .I. Beeclen Apex Service Station Ltd

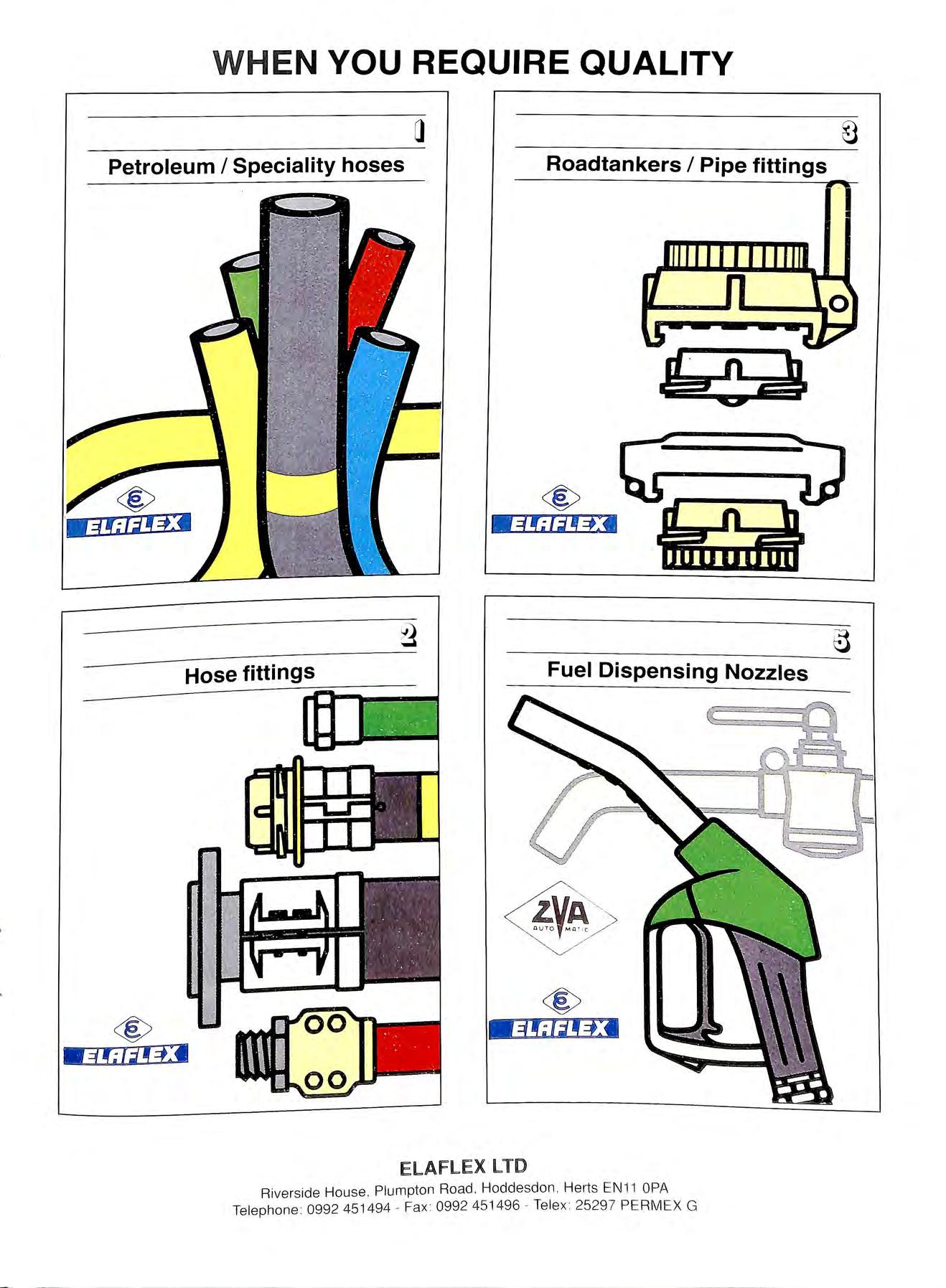

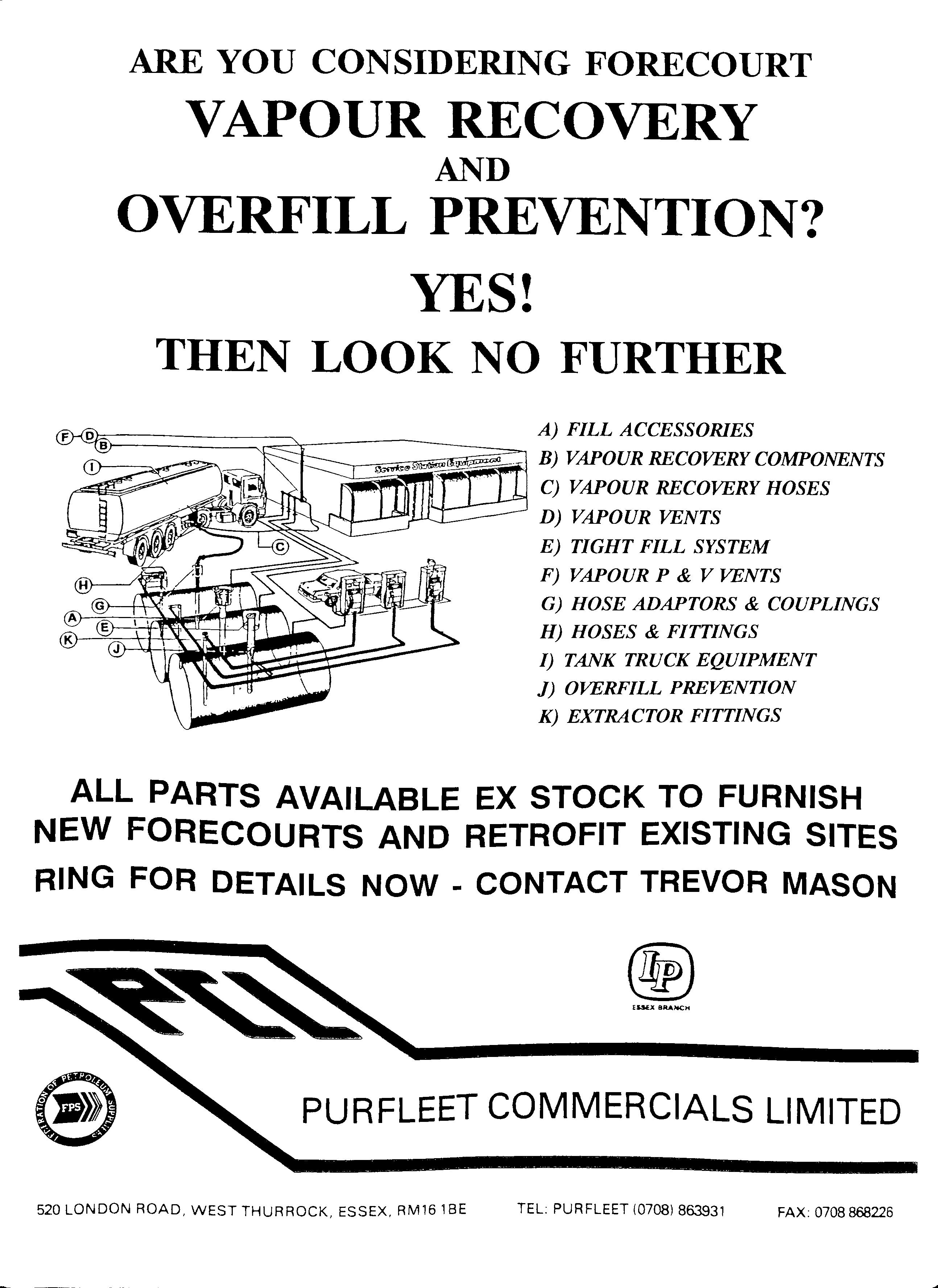

STAGE II VAPOUR RECOVERY SYSTEMS IN USA AND EUROPE

By Dr. Harald Falckenberg, Elaflex

1. US Stage II Systems

In the United States there is a domination of the passive (balance) Stage II systems. Th e clear market leader is Emco-Wheaton followed by OPW. The active systems, eg Healy (hybrid) and Has s tech (vacuum assist) hav e won only a s mall mark et share. The main reasons are regarded to be: Higher cos ts of active s ys tem s Repair s of active sy stems generally require skilled m ec harnc s Failures are not alway s apparent. Although te s ts ha ve proved that the in-u se effic ien? of __ active is be tt er. the legal requirem e nt of 9:i %• e ft1c1 e nc y ha s torc e d activ e syste m s to use rath e r s trong vac uum pump s which s uck by-pas s air into the vapour lin e a nd. so produce vapour/air excess ret urn. The calibration ot th e vapo ur vo lume is difficult w ith s trong vacuum pumps. II th e excess is to o hi g h , some form of sec ondary pro cessing (incinerator, co nd e n sato r or abso rpti o n) is required.

We be li e ve that none of th ese a rg um e nt s re main va lid. if you re quire rea li s ti c rates of e ffici e ncy a nd furth e rmore t<Lk e full adva ntage of th e fact that active syste m s do not necess arily nee d rubb e r be ll ows for th e no zz le The no zz les of th e act ive sys te m s in th e US a ll ha ve s uc h rubb e r be ll ows and th e re fore have th e sa m e handlin g a nd mainte nanc e probl e m s as th e no zz les of th e pa ss ive sys te m s .

The US Environmental Protection Agency (EPA) have carried out long tests with the Stage II vapour recovery systems and found out that the practical in-use efficiency of Stage II vapour recovery systems is around 70 % hydrocarbon return (60% and under if you additionally regard the times of non-compliance). The EPA therefore favoured the on-board control and, still in the Reagan era , m ad e a draft for a law requiring on-board for all cars from 1993 on.

At the end of 1990 finally the long expected law (modification of the Clean Air Act) ha s been passed. By this law Stage II syste ms are required for all extreme, severe , serious and moderate ozone nonattainment areas. Each state mu st submit until November 1992 a State Implementation Plan (SIP) to the federal EPA for approval. The retro-fitting of the stations has to t ake place until 1995. Regarding on-board sys tem s EPA w ill make a regulation , provided that consultation s of the EPA with the Depart ment of Transportation clear the safety issues regarding on-board canisters in case of accidents. If on-board sys tems are found safe and the regulation is promulgated, Stage II in moderate nonattainment areas will no longer be nece ssa ry . Stage II requirements in the other nonattainment a re as may be waived late r if onboard systems are in wide s pread use.

Both partie s involved , c ar industry <me! oil industry, claim the law as a victory for their position.

2. Situation in Europe

The s ituation in Europe is different because a Ja w regarding onboard _control systems has to be decided by the EC. Thi s 1s a difficult procedure and one expects that the making of such a law will re quire ap pro x. 3 to 5 ye ars with a subseq uent furth e r l 0 yea rs to phase out ex ist in g cars. On the other ha nd , Stage II sys tems can be required by the lo ca l authont1e s w 1th111 a s hort tim e TJ1at· · . 1 · c IS t 1e way th111g s happe n 111 Europ e

At first in Gotenborg. Swe den. then in so S · m e w 1ss Ca ntons and la te r 111 Mu111ch a nd Bad e n W . ue 1ttembe ro local authoritie s h ave re quire d Staa e II 1 S · "' , "' · n w tt ze rl a nd and 111 G e t man y the Fe d e ral Govern m e 1 , · n s consider th e genera l mtroduct1on o t Stage 11 Dr·ift 1 · · ' s o 1es p ec t1 ve re gu la tion s have a lre ady bee n IJubl 1 , d T . · . . . is 1e · he onl y qu es tion see ms to be w hat effic ie 1 · " 1 LY 1e ga rcl111 g th e h ydt oc a 1bon 1ecove ry and wh ic h f. t· , cl · · ll S c\11 s ubs e qu e nt tes ts w ill be 1e qu1re d (s ee 7 be lo w ) T I _ 1 , . , . . · 1e 11 s t E u rop e ;111 co unt1 y '-" 1th a law re qutrtno St·ioe · I I · , S 1 "' 'c- is wee e n. T he la w hct s .iust bee n pass e d o n November I "i 199() ,, _ , be lo w). (se e 8.

T he re_ are some cou ntri es. l1ke De nm a rk th e Net he rl a nd s A ust ri a a ncl Lu xe rnburg. wa it in g for th e final dec isions be mad e 111 th e a bove co untri es.

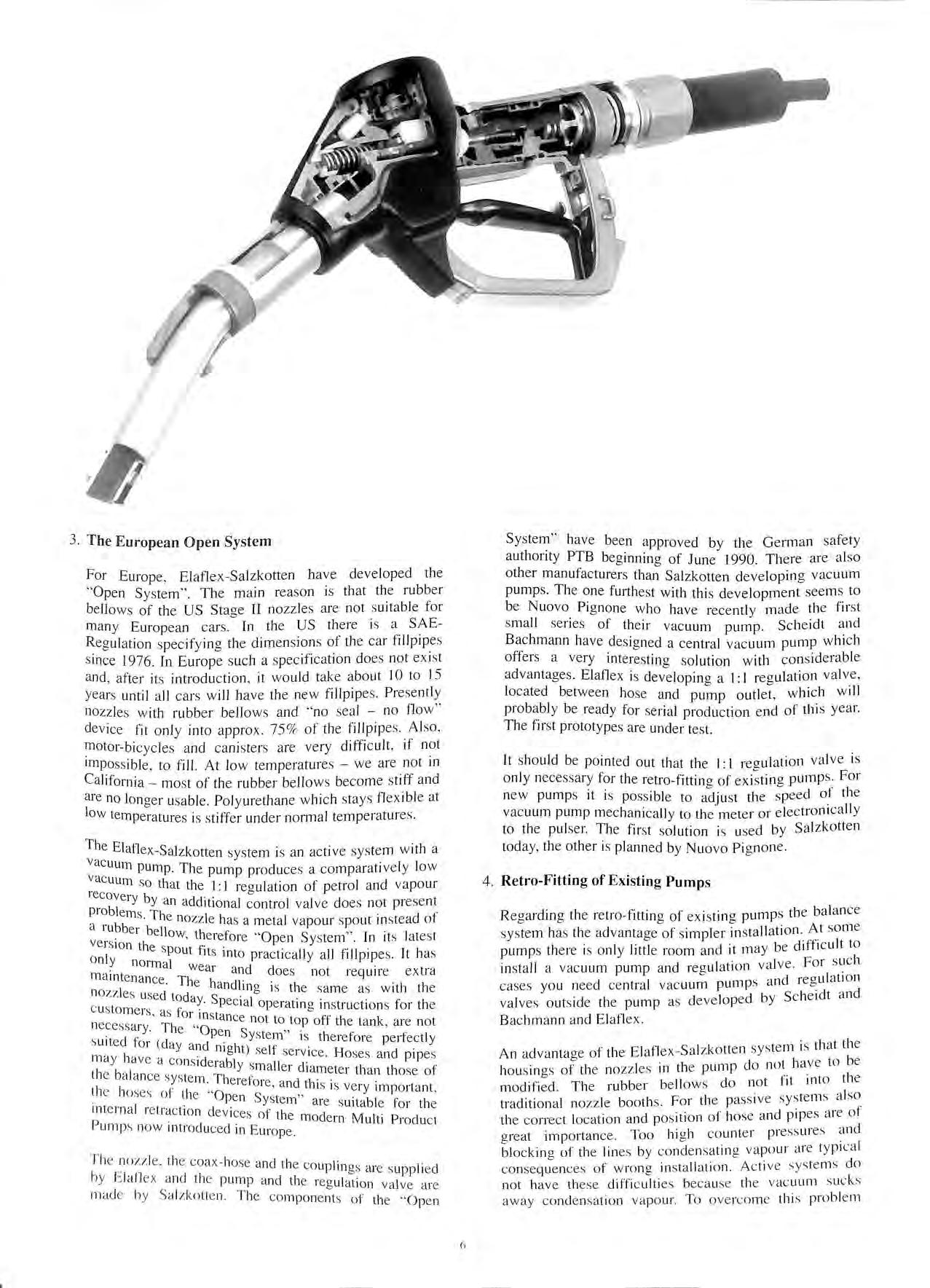

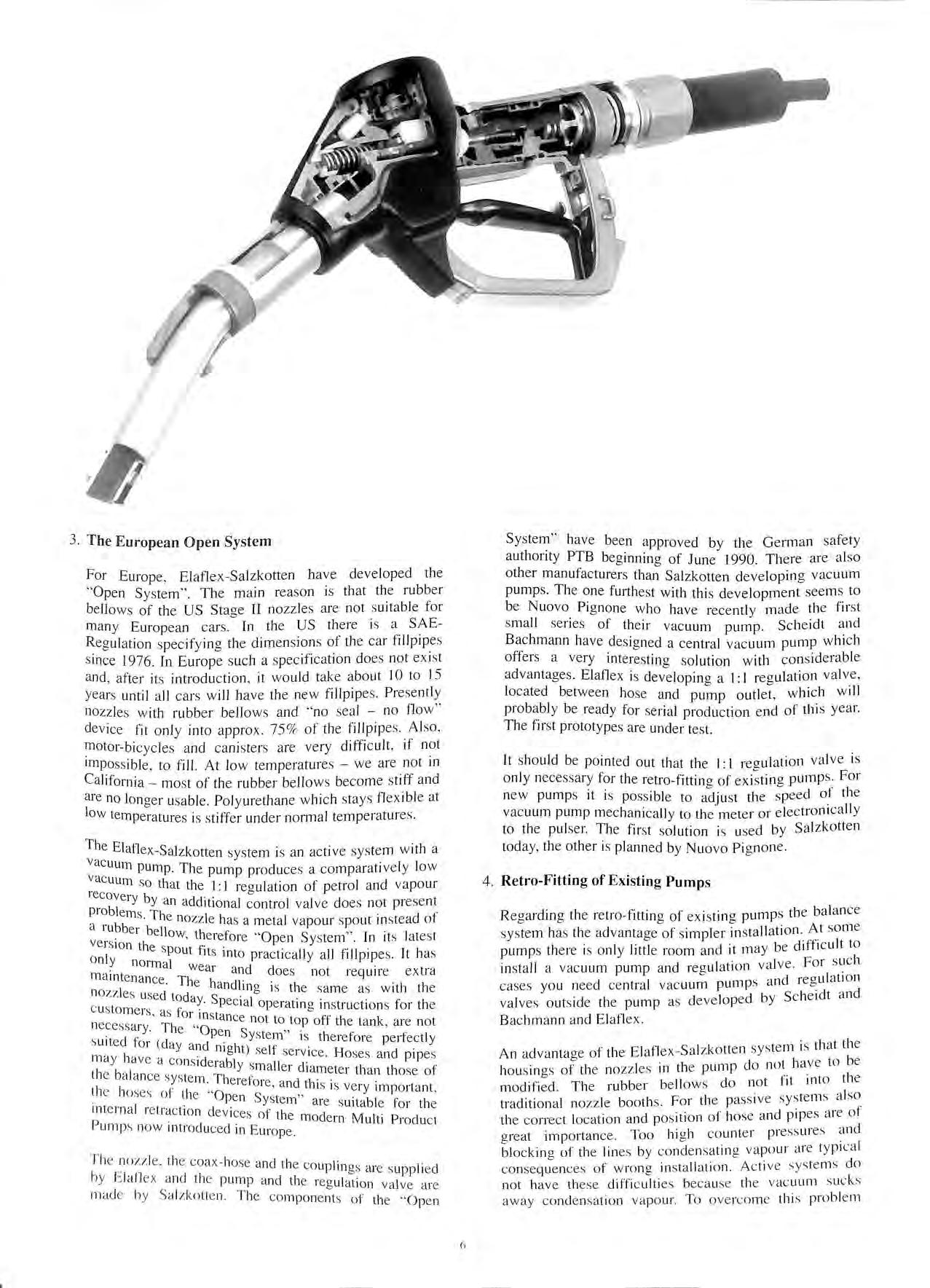

3. The Europ ean Open System

For Eu rop e, Elafle x S a lz kotten have developed the " Open Sy stem". The main reaso n is that the rubb e r bell ow s of the US Stage II no zz le s are not s uitabl e for ma n y E urop ea n ca rs. In the US th e re is a SAEReg ul at ion s pecifying th e dimen s io ns of the car fillpipe s s inc e 1976 Jn Europe s uc h a s pec ifi cati o n doe s not e x is t and , afte r its introdu c ti o n , it wo uld take a bout I0 to I5 yea rs until a ll cars w ill have th e new fillpipes. Pre se n t ly no zz le s w ith rubb e r bellows and " no sea l - no flow " dev ic e f it only into a pprox. 75 % of the fillpip es Al so, motor-bicycles and c a ni s ters are ve ry difficult , if no t imp oss ibl e , to fill. At low temp era ture s we are not in Ca li forn ia mo s t of th e rub ber be ll ows become s tiff a nd are no lo n ge r usable. Pol y ure thane w hi c h stays fle x ibl e a t low temp era tures is s tiffer und e r no rm a l temperature s.

The Elatl ex -Sal zkotten sys tem is a n act iv e sys te m w ith a pump. Th e pump produ ces a co mparati ve ly low acuum so that th e I :I reg ul a tion of petro l and vapour by an additional co ntrol va lve do es not prese nt P1o e ms TI f a bb · l e no zz le ha s a m e tal vapo ur spo ut in s tea d o Ill e r bello h ve i·s· h w, t e refo re " Open Sy stem". In its latest io n t e spo t f' " o nly · u its mto pract ic a ll y a ll fillp1pe s. It has · normal wear and doe s not req uire extra mainte nanc e Th h no zz les used todae and lm g is th e sam e a s w ith the c usto me rs a f y Spec ia l ope ra t111 g mstru ct1ons fo r th e ' s o1 mstan ce no t t t ff h necess ary Th e " O e o,, o.p o t e ta nk , are no t s ui te d fo r (da dp .n Syste m is th e refo re perfec tl y m · 1, Y an mght) se lf se rv ice Hose s and pipe s a y la ve a co nsid e rabl II th e b· I· Y sm a e i chame te r than th o se of a <t nce sys te m. There fo re, and thi s i th e hoses of th " O · s ve1y 1mpo1ta nt , · · · e pen Sys te m" are s uitabl e for th e mte 1na l re tra ctio n dev ices of the 1 p . · moc e rn Multi Prod uc t ump s now in trod uced Ill E ur ope.

T he no zz le. the coax- hose a nd the co uplin os a 1· l b E l f'J "' re s up p 1ec Y a ex and t he pump a nd the reo L1l a·r10 I ,, n va ve are mad e h y S a lz kotte n Th e co mpon e nt s of th e " Ope n

System" have bee n approved by the G e rm an safety authonty PTB be g innin g of June J990. Th ere a re a lso other manufacturers than Salzkotten developin g vac uum pumps. The one furth es t w ith thi s de ve lopm e nt see m s to be Nuovo Pi gno ne who have rece ntl y m ade th e fir s t s mall series of the ir vac uum pump . Sc he idt a nd B ac hmann have de s ig ned a ce ntral vac uum pump w hi c h offe rs a very interest in g so lution with co n s iderable adva ntages Elaflex is de veloping a I: I reg ul a ti o n va lve, lo ca ted bet ween hose a nd pump outlet, w hi c h w ill proba_bly be ready for se ri a l production e nd of thi s year. Th e fir st prototypes are und e r test.

It should be pointed o ut that th e I: I regul at io n valve is only nec essary for the retro-fi ttin o of existino pump s. For b 0 new pump s it is poss ible to adj ust the speed o.f the vac uum pump m ec ha ni ca ll y to th e m e te r or e lec trorn ca ll y to the pul se r. The fir st so luti o n is use d b y Sal z kotte n tod ay, the other is planned by Nuovo Pi g non e.

4. Retro-Fitting of Existing Pumps

Rega rding the re tro-fittin g of ex isting pumps th e bal a nce sys tem ha s the adv a nt age of s impl e r in stallation so m e pump s th e re is only littl e room a nd it may be d1ft1cult to in s tall a vac uum pump a nd reg ulation va lve. Fo r s uc h d reou lat 1o n cases yo u need ce ntral vac uum pumps a n "' va lves outs id e th e pump a s d eve lo ped by Sc he idt a nd Bachmann a nd Elafl ex

A n aclvanta oe of th e E laflex Sa lzkotte n syste m is that th e "' d · h to be hous in gs of th e noz z les 111 the pump o not a.v e modified. Th e rubb e r be ll ows do not fit 11110 th e traditional nozz le booth s For th e pass iv e sys te m s a lso _ the co rrec t locatio n a nd pos iti o n of ho se and pipes a re o f g rea t importance. Too hi g h c ou nte r press ure s and b loc kin g of the lin es by co nd e n sat in g va pour a re ty pi ca l co nsequen ce s o f wro n g in sta ll at io n. Act ive sys te m s do not have th ese diffi c ulti es beca use th e va c uum s uc ks away c onden sat io n va po ur. To ove rc om e t hi s prob le m

6

most of the coax-hoses of the balance systems include today a venturi-system but it should be said that this only helps to reduce the blockings but not to eliminate them. Therefore, one has to carefully check the conditions when retro-fitting old pumps.

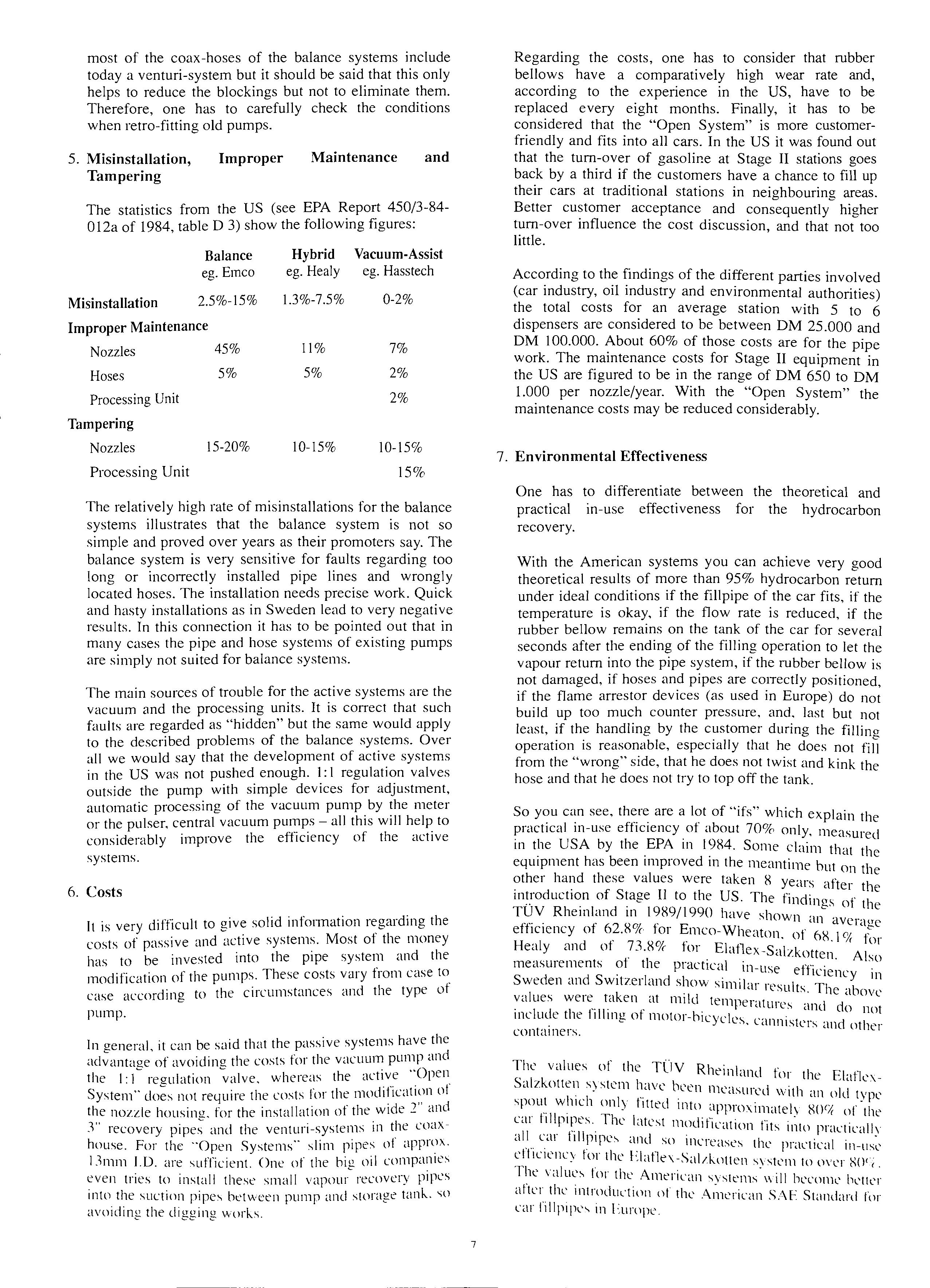

5. Misinstallation, Tampering Improper Maintenance and

The statistics from the US (see EPA Report 450/3-84012a of 1984, table D 3) show the following figures:

Misinstallation

Balance eg. Emco 2.5%-15%

Improper Maintenance

Nozzles 45% Hoses 5%

Processing Unit Tampering

Nozzles 15-20%

Processing Unit

Hybrid eg. Healy 1.3%-7.5% 11% 5% 10-15%

Vacuum-Assist eg. Hasstech 0-2% 7% 2% 2% 10-15% 15%

The relatively high rate of misinstallations for the balance systems illustrates that the balance system is not so simple and proved over years as their promoters say. The balance system is very sensitive for faults regarding too long or incorrectly installed pipe lines and wrongly located hoses. The installation needs precise work. Quick and hasty installations as in Sweden lead to very negative results. In this connection it has to be pointed out that in many cases the pipe and hose systems of existing pumps are simply not suited for balance systems.

The main sources of trouble for the active systems are the vacuum and the processing units. It is correct that such faults are regarded as "hidden" but the same would apply to the described problems of the balance systems. Over all we would say that the development of active systems in the US was not pushed enough. I: I regulation valves outside the pump with simple devices for adjustment, automatic processing of the vacuum pump by the meter or the pulser, central vacuum all this will to considerably improve the efficiency of the active systems.

6. Costs

It is very difficult to give solid infonnation regarding the costs of passive and ac_tive system?. Most of the money has to be invested mto the pipe syste1:n and the modification of the pumps. These costs vary from case to case according to the circumstances and the type of pump.

In general. it can be said that the passive systems have the of avoidino the costs for the vacuum pump and "' · ..() en the I: I regulation valve, whereas the active P System" not require the costs for the modification ot the nozzle housing. for the installation of the wide 2" and T' recovery pipes and the venturi-systems in the coaxhouse. For the Open Systems slim pipes of 13mm l.D. are sufficient. One of the hig oil compa111es even tries to install these small vapour recovery pipes into the suction pipes between pump and storage tank. so avoiding the digging works.

Regarding the costs, one has to consider that rubber bellows have a comparatively high wear rate and, according to the experience in the US, have to be replaced every eight months. Finally, it has to be considered that the "Open System" is more customerfriendly and fits into all cars. In the US it was found out that the tum-over of gasolir.e at Stage II stations goes back by a third if the customers have a chance to fill up their cars at traditional stations in neighbouring areas. Better customer acceptance and consequently higher tum-over influence the cost discussion, and that not too little.

According to the findings of the different parties involved (car industry, oil industry and environmental authorities) the total costs for an average station with 5 to 6 dispensers are considered to be between DM 25.000 and DM 100.000. About 60% of those costs are for the pipe work. The maintenance costs for Stage II equipment in the US are figured to be in the range of DM 650 to DM I.OOO per nozzle/year. With the "Open System" the maintenance costs may be reduced considerably.

7. Environmental Effectiveness

One has to differentiate between the theoretical and practical in-use effectiveness for the hydrocarbon recovery.

With the American systems you can achieve very good theoretical results of more than 95% hydrocarbon return under ideal conditions if the fillpipe of the car fits, if the temperature is okay, if the flow rate is reduced, if the rubber bellow remains on the tank of the car for several seconds after the ending of the filling operation to let the vapour return into the pipe system, if the rubber bellow is not damaged, if hoses and pipes are correctly positioned, if the flame arrestor devices (as used in Europe) do not build up too much counter pressure, and, last but not least, if the handling by the customer during the filling operation is reasonable, especially that he does not fill from the "wrong" side, that he does not twist and kink the hose and that he does not try to top off the tank.

So you can see, there are a lot of "ifs" which explain the practical in-use efficiency of about 70% only, measured in the USA by the EPA in 1984. Some claim that th equipment has been improved in the meantime but on th: other hand these values were taken 8 years after th of Stage II to the US. The findings of TUY Rheinland in 1989/1990 have sl1ow 11 · ' aver·1ue efficiency of 62.8% for Emco-Wheaton. of 68 I 01 ' 1?. H · I d t· 7., 8('/ · · · 1< 01 ea y an o . -'· 1c t01 Elaflex-Salzkotten. Also measurements of the practical in-use eff· · , · 1uency 111 Sweden and Sw1tzeiland show s1m1hr restilts TI b . ' · ·. 1e a ove values were taken at mild temperatures I cl ·I i h t'"IJ" f . dnt o not me ut e t e 1 mg o motor-h1cycles L"t 11111· ·t cl · · ' s e1s an other contamers.

The values of the TOV Rheinland for the ElaflexSalzkotten system have hcen 111e·1s111·e I \\".tl 11 • •. '. L •1 1 an o t type w!11ch only fitted mto approximately 8()<'4 of the car The latest modification fits into practicallv al·l·· car hll!11pes and so increases the practical dhnency tor the Elatlex-Salt.kotten svstt·m to over 8()<;;. The values for the American svstems. will become betk•r after the introduction of the A1;1erican SAE Standard for rnr fillpipes in Europe.

7

According to the law in Sweden and the drafts of the regulations in Germany and Switzerland the following efficiency rates are required:

Germany No specific rate required; efficiency must be to present state of technology ("Stand der Technik");

Sweden 85% under optimized conditions for cars with SAE fillpipe and 70% measured under practical conditions;

Switzerland 90% for cars with SAE fillpipes.

It is not yet clear what test procedures will be adopted and therefore one can not yet say, whether the systems in the market will fulfill the required values. In Switzerland the CARB (Californian Air Resources Board) approval will probably be accepted, whereas in Germany this will definitely not be the case. Sweden accepts the CARB approval but additionally requires that the CARB approved systems fulfill the above efficiency rates according to the TOv test method. There is a common opinion in Europe that the CARB test procedure is too complicated and questionable. The tendency is to carry out hydrocarbon tests only for the type approval and to make the regular follow-up tests on the basis of volumetric measurements.

A new test procedure for the hydrocarbon test has been agreed between the environmental authorities of Sweden, Denmark, Switzerland, Netherland and Germany. First tests according to this method which is much than the CARB test will be carried out by the TUY Rheinland in March/April 1991.

There is little doubt that in the long run the on-board systems with the laroe canisters are the more efficient 0 solution under environmental aspects. If the authont1es nevertheless decide in favour of Stage II in order to have a solution without the need of EC laws, they should make reasonable requirements based on the practical i?-use efficiency. The requirement of 95% or 90% under ideal conditions could outrule systems which provide clearly according to the existing data 20% to 25 % - a better environmental effectiveness under practical aspects.

Customer-friendly uncomplicated handling under and winter conditions, the filling of motorbicycles and canisters, the wear of equipment all this be regarded. In addition to that there will be a introduction phase taking several years until all cars S Edurope will be equipped with fillpipes to the SAE tan ard and fl 11 11 Sh 1 un 1 a stations will be converted to Stage · ou d the authorities decide on unrealistic rest procedures not co ·d h · ns1 enng the m-use efficiency they will ave to answer the f II , . o owmg questions: What 1s gomg to happen with app · fi rox1mately 25% of cars having non.1.tt1?.g What with motor-bicycles? What with c<1nisters · Today the customers still have alternatives.

As the active closed systems have hetter eff1c1ency values under ideal conditions active closed system has better practical in-use elfic1ency values. it would also be possible to make a compromise that systems may be approved with %, under ideal conditions or % under practical in-use conditions.

Perhaps the German solution is preferable. The requirement of efficiency according to the present state of technology leaves the final decision up to the authorities and so is very flexible. It is expected that the draft will become law in Germany within the next six months. The original plan to send the draft to the EC (Brussels) for approval has been given up. The draft is split into one part regarding Stage I and a second part regarding Stage II. Only the Stage I part will be sent to Brussels for coordination in the EC.

8. The Swedish Law on Stage II

The Swedish law of November 15, 1990 requires 85% under controlled conditions and 70% for a vehicle stock representative for Sweden and operated by "normal customers". The measurement method is the one used by the TUY Rheinland.

A very important point of the Swedish law is that all systems already introduced into the market are regarded as approved but January 1, 1995 at the latest sue? systems must be covered by a certificate. So 011 companies making their decision in favour of a system run the risk that it will not fulfill the reqmred efficiency values and later will have to be replaced. But also the CARB approved US systems are not on the safe side. Although the CARB approval is accepted as certificate, the US systems nevertheless have to fulfill 70% and 85% efficiency rates according to the TUY Rheinland method, if they are controlled by spot tests during the regular inspections. Having in mind that the EPA measured an average efficiency of 70% in the US for cars with SAE fillpipes and considering that European tanks must have flame arrestors causing counter pressure, it is not at all clear that this value is reached in Europe. On the other hand, they have to decide because according to the Swedish law until January 1, 1992 25% of all petrol stations including all stations in the. city areas Stockholm/Uppsala, Gotenborg and Malmo will have to be equipped with Stage II systems. Until January 1, 1995 all stations must be retro-fitted.

The installation of the systems shall be by authorized companies and the regular inspectmn and maintenance will be controlled by spot tests by a National Test Agency. This means that different from the · . . tensi·ve control s1tuat1on m the US, where an ex bureaucracy has been built up, the control of the Stage · . . f t J by the 011 m Sweden will be mamly sel -con ro companies. If they do their job correctly, the costly ·ll be earned out controls of the National Test Agency wi only in exceptions.

.t I aves room for the

The Swedish solution is falf as 1 e · E ·bi ·ystem for urope. development of the best poss1 e s ·

9. Result

US 'ticism of the active All in all we conclude that the en ·h ort is not systems described in the introductmn.of t th··t the valid for the "Open System". The i:nam a In k with ru e1 e ows. active systems in the US wor Eur h h . SAE Standard tor car hllp1pes. , ope. w ere t ere 1s no " we are forced to think about alternatives.

8

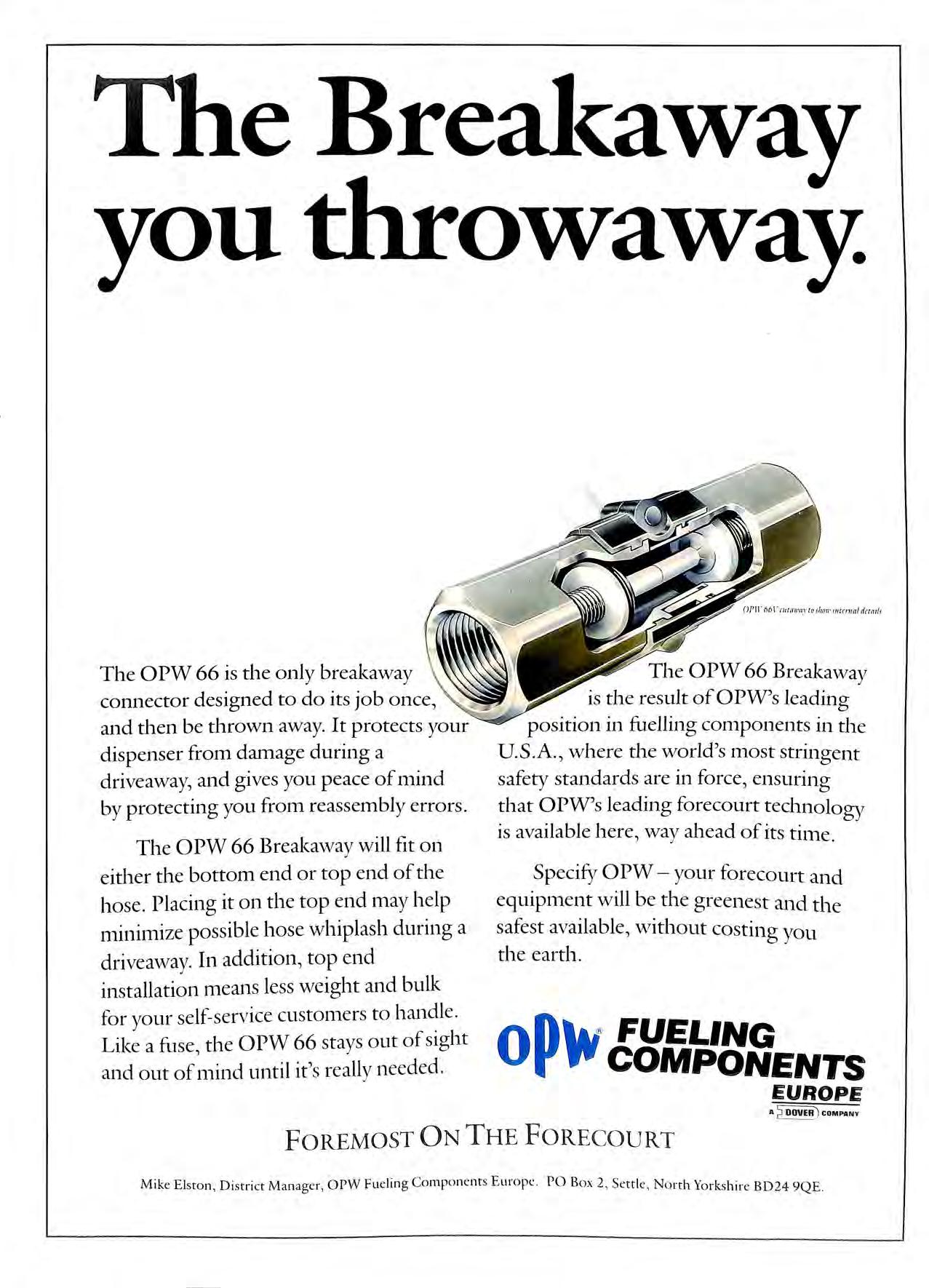

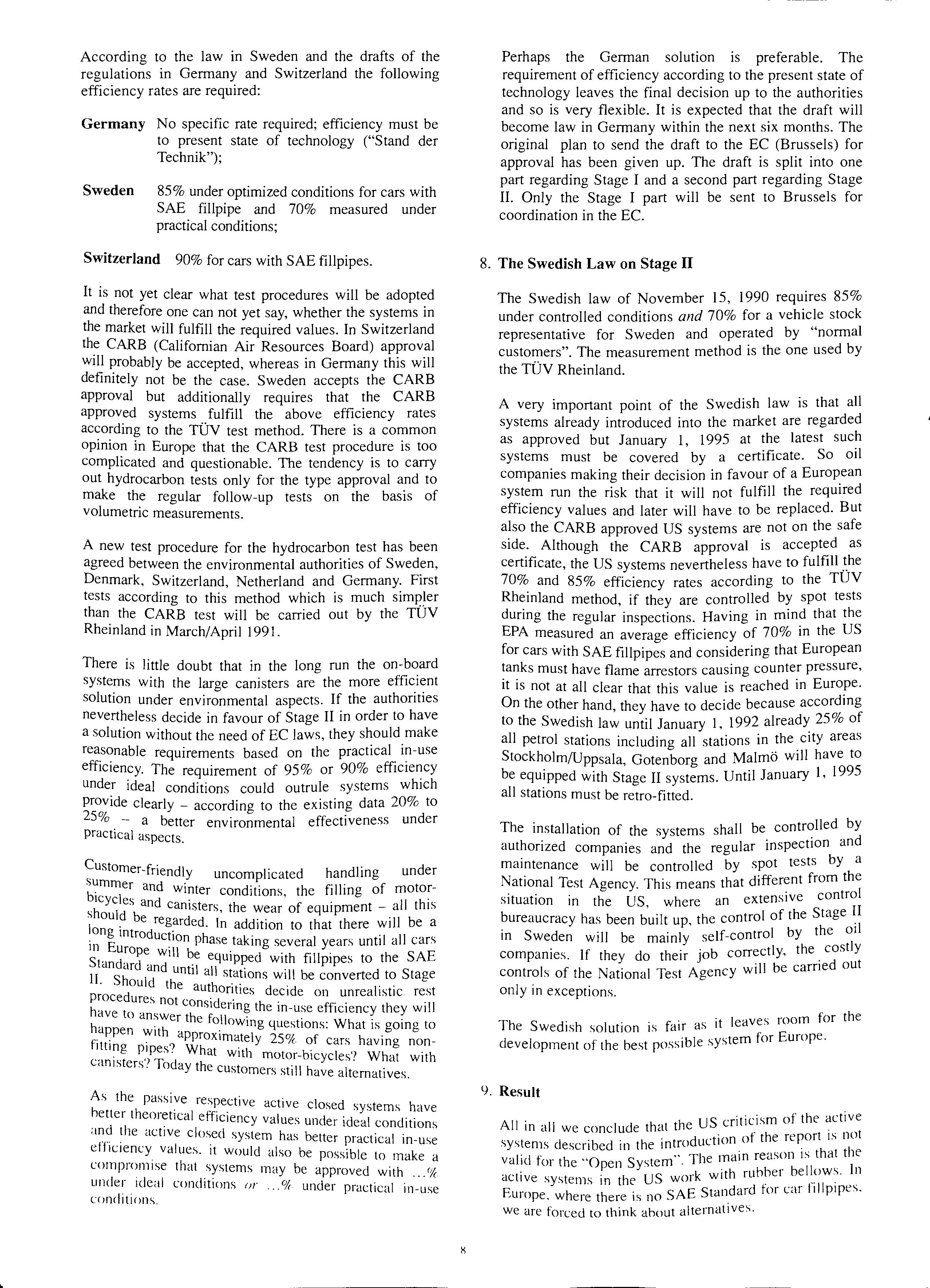

The Breal{away you owaway.

The OPW 66 is the only breakaway connector designed to do its job once, and then be thrown away. It protects your dispenser fr01n dan1age during a driveaway, and gives you peace of n1ind by protecting you fron1 reassen1bly errors.

The OPW 66 Breakaway will fit on either the bottom end or top end of the hose. Placing it on the top end inay help 1ninin1ize possible hose whiplash during a driveaway. In addition, top end installation means less weight and bulk for your self-service customers to handle Like a fuse, the OPW 66 stays out of sight and out of mind until it's really needed.

The OPW 66 Breakaway is the result of OPW's leading position in fuelling con1ponents in the U.S.A., where the world's n1ost stringent safety standards are in force, ensuring that OPW's leading forecourt technology is available here, way ahead of its tin1e.

Specify OPW -your forecourt and equipn1ei1t will be the greenest and the safest available, without costing you the earth.

FOREMOST ON THE FORE COU RT

Op hl FUELING P COMPONENTS EUROPE A 2DOVER ) COMPANY

Mike Elston, District Manager, OPW Fue ling Components Europe PO Box 2 , Settle , North Yorkshire BD 24 9QE

PETROLEUM PIPEWORK: THE U.S. EXPERIENCE

By Don Bragg

The evolution of undero-round storage tank systems in the U.S. ha s been greatly in the last five years The 1988 EPA Regulation, and the growing concern for public safety and protection of the environment has_ dramatic changes in both technology and mstallation procedure. According to studies by the US Environmental Protection Agency, pipin g ha s been the major cause of leaks. Thu s, va st improvements have been made 111 available products

During the post-war years of the fifties, when the U.S. highway sy stem was rapidly growing, many thousand s of bare steel tanks and galvanized pipes we re in stalled as new service stations were built. This presented a number of problem s, unknown at the time, that began to show up m the seventies.

First, the galv anized pipe, being electrically more active than the steel tanks, tended to 'sacrifice ' itself and corrode. Second, in order to allow for ground shifts and seasonal tank movem e nt , a serie s of short pipe s and elbows (known as a s win g joint) was in stalled at the tank and di spen ser end s of the pipework. Although the intention wa s good , by th e very nature of its con s tru c tion a sw ing joint is un safe and diffi c ult to in s tall. An enginee ring s tudy done some years ago, c oncerning movement in swing joints, revealed some importa nt fa c ts whi c h have contributed to the leaking probl e m s

Th e s w in g j o int re quire s a minimum of two separate joints in e ac h o f three plan es in order to allow a full rang e of mo ve m e nt. Thi s requires that the s wing joint be mad e of at le a s t fi ve e lb ows and that th e e nds are part of th e s win g m ov e m e nt. Us uall y fe we r e lbo ws are used , how eve r thi s limits po te nti a l mo ve me nt to fe we r pl a nes Ev e n with fi ve e lb ow s, m ov e m e nt is limited to an arc a bout th e pipes a nd

elbows perpendicular to the movement path. In oth e r word s, the swing joint is required to follow the outside lines of a hollow shape. Movement inside or outside of this line cannot be accomplished without forcing the end fittings out of their perpendicular position. While this may all seem acceptable, even desirable, in order to allow the s wing joint to function, this is where the real problems li e.

Any movement in a single plane requires at least two joints to move. One must loosen and the other tighten. If movement is in two planes, then fou r must move and so forth. This is the only way that movement can be accomplished with a swing joint , or for that matte r, with any type of hard piping. This automatically open s one or more leak paths at the threaded joint. Another flaw in this logi c is that in order to move a threaded connection in a properly in stalled swing joint, a force greater than the torqu e used to couple the elbow s and pipe nipple s must be used Obvious ly, this will seldom if ever happen. Thus the statement that swing joints don ' t swing is mo st appropriate In actual practice, any movement sets up stresses in the piping that may be relieved catastrophica ll y at some future time. In a s ystem using fiberglas s pipe and pea shingle , the GRP pipe wi ll give before the metal swing joint. For this reason fiberglass pipe manufacturers recommend the use of flexible connectors, and the EPA regulation recommends their use where turns are less than four feet apart.

Flexible connectors are short lengths (usua ll y 24" or 30" long) of PTFE hose, braided with stain le ss steel wire or a non-corroding material, and coupled with various end '.inmgs. None of the aforementioned problem s with swing J0111ts are characteristic of flexible connectors While a swing joint may have from four to ten threaded joints , a fle xible connector has only two. Furthennore these threaded joints wi ll not unscrew with movement: The flexible connector can move anywhere and follow any path within its area of movement, limited only by the bend radius and length of the particular connector. The force to move the flexible connector is minimal and no stresses are built up to cause potential problems.

Ev_en from the practical standpoint of installation, a flexible connector, along with GRP pipe, is far Jess difficult and time consum111g to use. Of course a certain amount of care is required to handle and install' a flexible connector s ince flexible piping can be as rugged as so lid steel. Unquestionably though, there are obvious inherent risks in using s wing joints or connecting GRP pipe directly to steel e lb ow s Even where frost is not a factor o-round water and cha_nges in tank weight and traffic can stress on a p1p111g system Such movement is absorbed by flexible connectors. Furthermore, flexible connectors are designed for underground service, tested and listed to industry specifications and backed by the manufacturer.

After the San Franci sco earthquake of October 1989, an exam111at1on of hundreds of in stallations utili z ing flexible c?nnectors and GRP showed no damage or leaks in the pipework. The reason given by one oi l company engineer wa s that their UST system s are " bedded in sand or a g rav e l material and are independent of anything and hav e fl e xib le J0111t s and connectors They move when the ground moves. The flexibility is built in. " Suc h dramati c evidence, although not pl easant to expe rience , is proof that flexibl e connector: are th e e nvironmentally safe solution. Non me tall1c fl ex ibl e connectors, whe n used with GRP, solve both th e probl e m of movement and corros ion and are rapidly beco ming the tec hnology of c hoi ce .

10

II

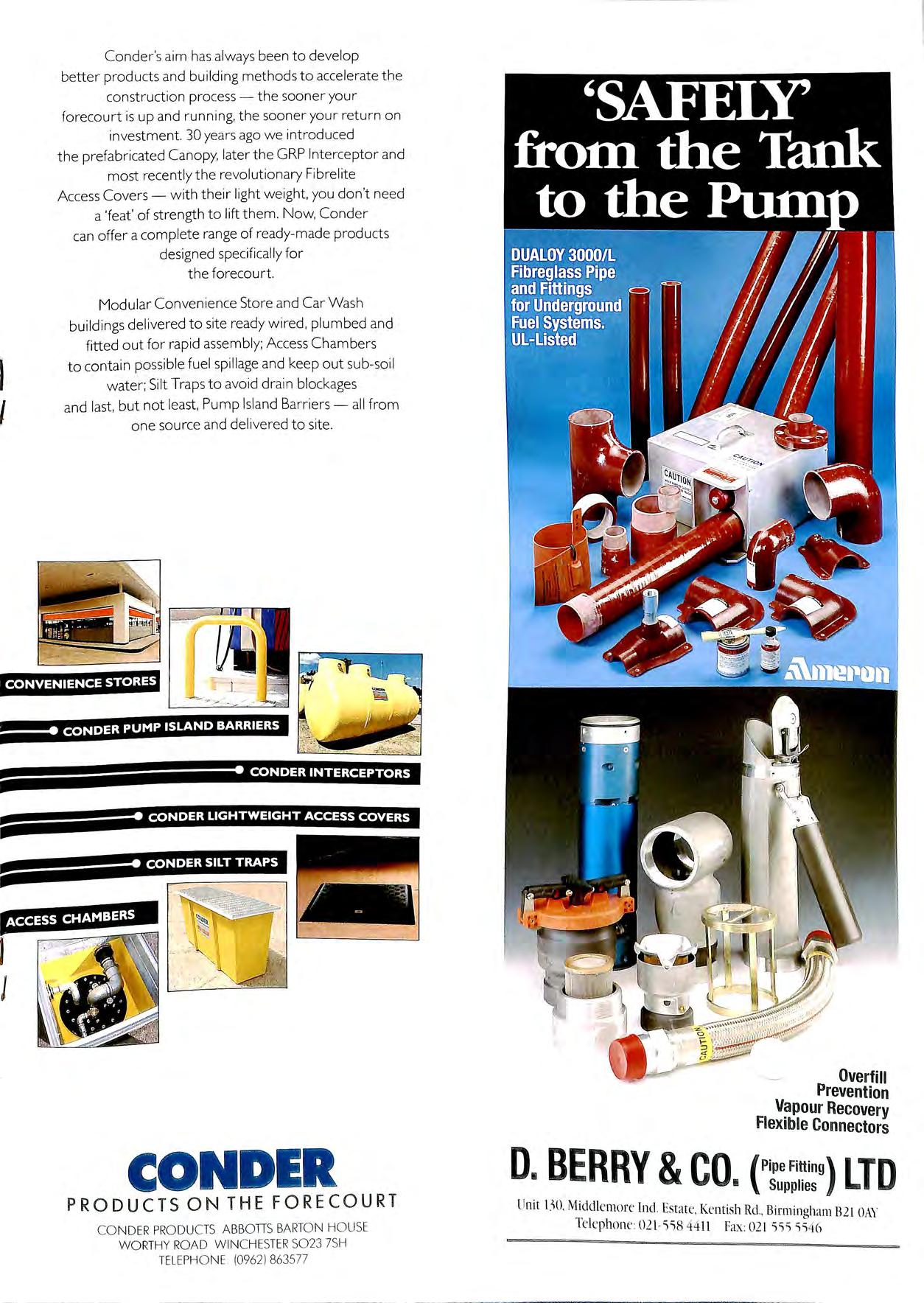

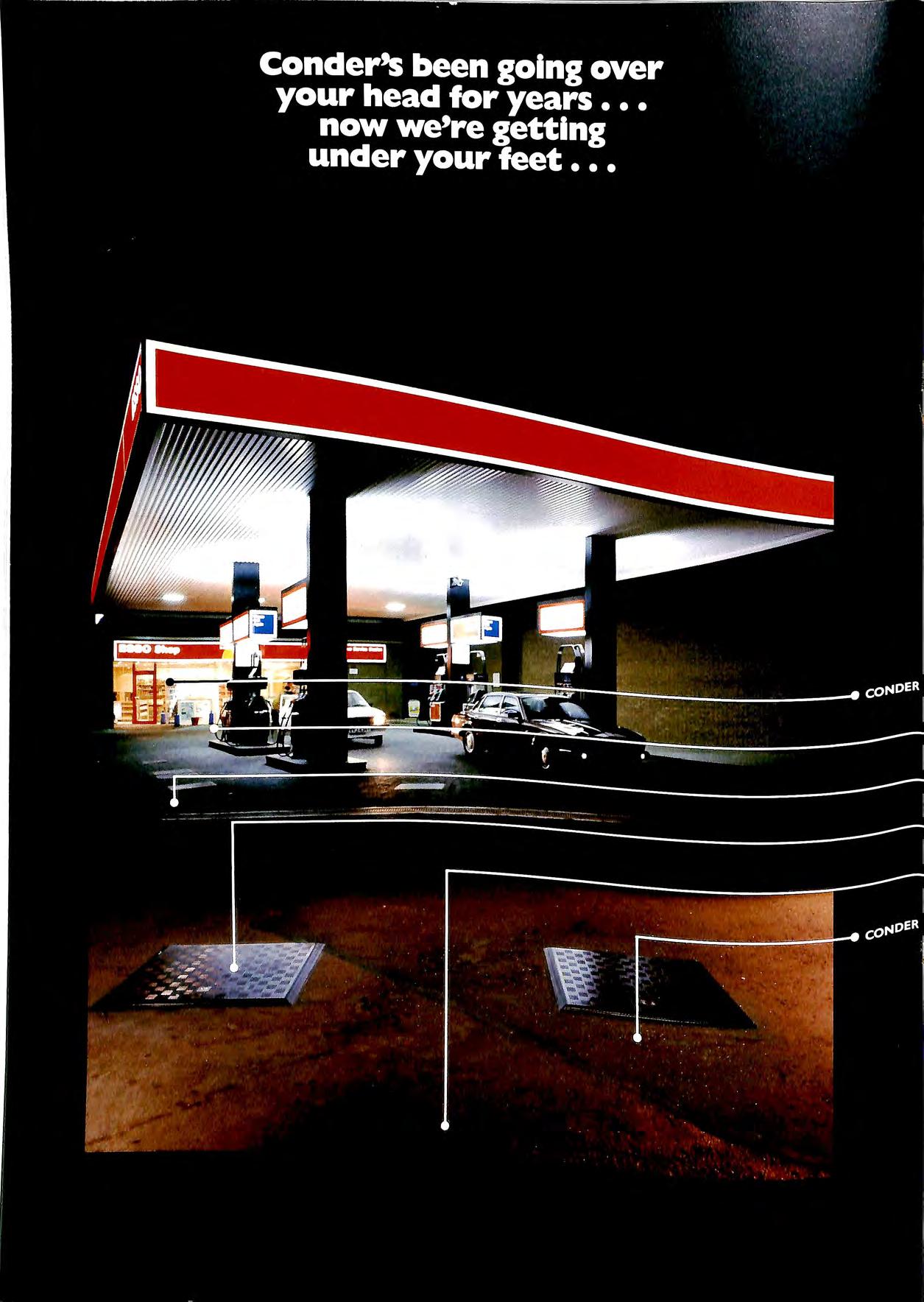

Conder's aim has always been to develop better products and building methods to accelerate the construction process the sooner your forecourt is up and running. the sooner your return on investment. 30 years ago we introduced the prefabricated Canopy. later the GRPInterceptor and most recently the revolutionary Fibrelite Access Covers with their light weight, you don't need a 'feat' of strength to lift them. Now, Conder can offer acomplete range of ready-made products designed specifically for t he forecourt.

Modular Convenience Store and Car Wash buildings delivered to site ready w ired, plumbed and fitted out for rapid assembly; Access Chambers to contain possible fuel spillage and keep out sub-soil water: Silt Trapsto avoid drain blockages and last. but not least, Pump Island Barriers all from one source and delivered to site.

I I

CONVENIENCE STORES CONDER PUMP ISLAND BARRIERS CONDER INTERCEPTORS CONDER PRODUCTS ON THE FORECOURT CONDER PRODUCTS ABBOTISBARTON HOUSE WORTHYROAD WINCHESTERS023 7SH TELEPHONE (0962) 863577 D. BERRY & CO. Overfill Prevention Vapou r Recovery Flexible Connectors ( Pipe I 'JD Supplies L Unit l.'>0 Middlemore Ind Es tat e Kentish Rd ., Birmingham B2l OAY Telephone 021 558 44 11 fa'\: 021 .:;.:;.:; 5546

PRESSURE PIPE CONCERNS

- A WAY FORWARD

and Mr. Rory Hennessey of the LFCDA, who's jurisdiction includes the Hounslow site. Their willingness to investigate new technologies in regard to environmental protection of retail petrol outlets played a major role in the development of this system.

First, some background

The Houn slow si te is formally known as Mobil Oil Limited, Moons Filling Station, Cranford Roundabout, Hounslow, Middlesex. It is a complete "knockdown, rebuild" of an existing s uction system. It consists of 6 islands, six nozzles per isl a nd, kiosk between the 2nd and 3rd islands, a car wash and remote tank fa1m. Th e tank s have 3;4 HP Red Jacket s ubmersible pumps, and each product line is traced with Gore Tex hydrocarbon leak detection cable specially manufactured for Red Jacket. Each submersible pump has a press ure kit installed, utili z ing the pressure sensing capabilities of the system. New ta nk s were in stalled with vapor probes ( 1 at each corner of the tank farm) providing detection for the tank fann. Tank s and product distribution lines a re glass re-enforced polymer (GRP).

Now, the system

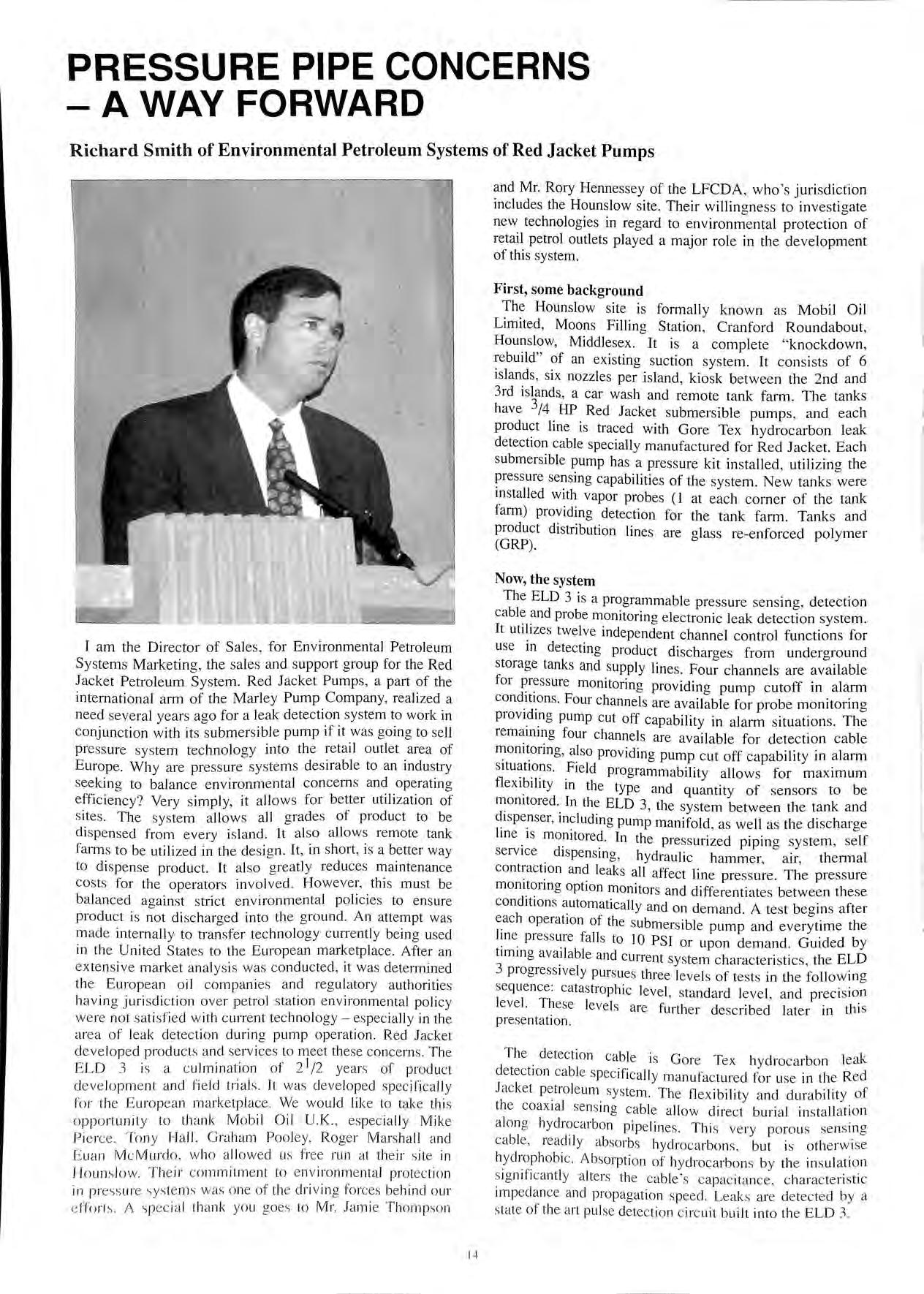

I am the Director of Sales , for Environmental Petroleum Sy stems Marketing, the sales and s upport gro up for the Red Jacket Petroleum System. Red Jacket Pumps, a part of the international arm of the Marley Pump Company, realized a need se veral years ago for a leak detection system to work in conjunction with its s ubmers ibl e pump if it was going to se ll press ure syste m technology into the retail outlet area of Europe. Why are pressure systems desirable to an industry seeking to balance environmental concerns .operating efficie nc y? Very sim pl y, it a ll ows for better ut1!J zat1on of s ites. The sy stem allow s a ll g rade s of product to be di spen sed from every is land . It a ls o allows remote tank farm s to be utilized in the de s ig n. It , in s hort , is a better way to di s pe nse product. It al so g reatly reduces mainte na nce cos ts for the operators in vo lv ed. However, this mu st be balanced agai nst strict environm e ntal policies to en s ure product is not di scharged into the gro und. An attempt was mad e internally to tran sfer technology c urrently being used in th e United State s to the European marketplace. After a n ex te ns iv e market analy s is was co nducted , it was determined th e Eu ropea n oil co mpani es and reg ul atory authorities havin g juri s diction over pe trol sta tion e nvironmental policy we re not sa ti sfied w ith c urre nt tec hnology e specially in th e are a of lea k detec ti o n durin g pump operat ion Reel Jac ke t deve lo ped products and se rv ices to mee t th e se con ce rn s. Th e E LD 3 is a c ulmination of 2 1/2 yea rs of produ ct d e ve lo pm e nt and fie ld tri a ls It was deve loped spec ifi ca ll y fo r the E urop ea n mark e tpla ce. We wo uld lik e to tak e thi s op po rtunit y to thank Mo bil O il U.K., es pec ia ll y Mik e P ie rce , To ny Hall , G ra ham Poo ley, Roge r Mars hall and E uan McMurdo , w ho a ll owed us fr ee run at th e ir s ite in Houn s lo w. Th e ir co mmitm e nt to e nv ironm e ntal protec ti o n in press ure sy s te m s wa s o ne of t he dri vin g forces be hind our e ffort s A s pec ial thank yo u go es to Mr. Jam ie Thompso n

The ELD 3 is a programmable pressure sensing, detection cable and probe monitorin g e lectro nic leak detection system. It utilizes twelve independent channel control function s for use in detecting product di sc ha rges from underground storage tanks and suppl y lines. Four channels are available for monitoring providing pump cutoff in alann cond.1t1.ons. Four channels are available for probe monitorin g prov1.d111g pump cut off capability in ala1m situations. The remammg four channels are available for detection cable also providing pump cut off capability in a larm field programmability allows for m ax imum flex1b1hty 111 th e typ e and quantity of sensors to be momtored'. In the ELD 3, th e syste m between the tank a nd d1 spe nser, mcludin g pump manifold , as well as the discharge lme . is mo nitored In the pressurized pipin g sys tem, se lf service di spe nsin g, hydra uli c hammer, air, thennal cont1.·act!on and leak s all affect line press ure Th e pressure momtonng option monitors and differentiates between these conditions automatically and on demand. A test beg in s after e.ac h operation of th e s ubm e rs ible pump and everytime the lm e. falls to l 0 PSI or upon demand . Guided by t11rnng available and current sys tem characteristic s, the ELD 3 progressively pursu es three leve ls of te sts in the following sequence: catastrophic lev e l, standard level , a nd prec1s1on leve l. These leve ls a re further de sc rib ed later in this prese nta tion.

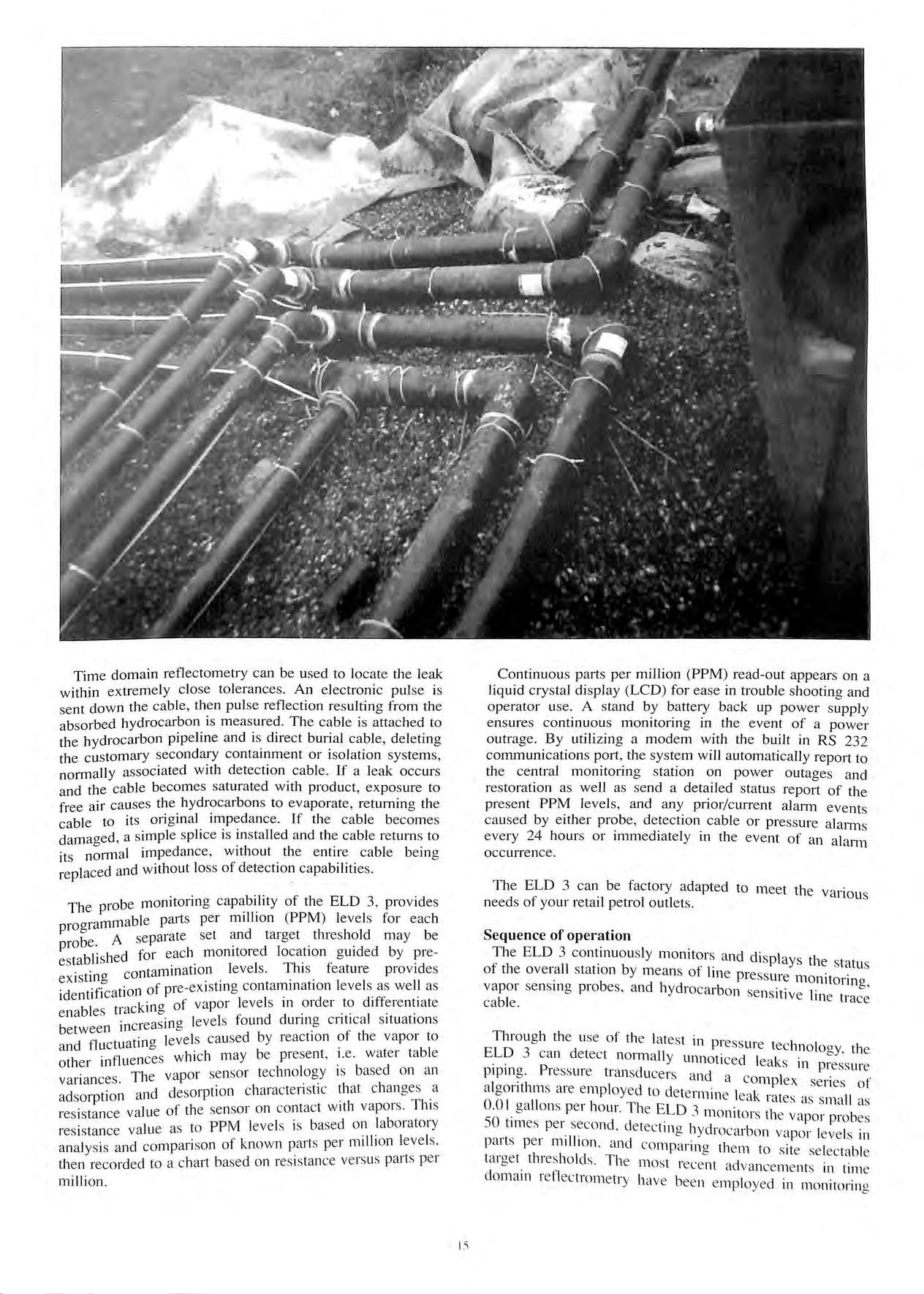

Th e detection ca bl e is Gore Tex hydrocarb on le ak de tect10n cab le spec ifi cally manufactured for use in the Re d Jacket petroleum sys te m. The flexibility and durability of the coaxia l se ns in g cabl e a ll ow direct burial in s ta ll a tion a lo ng hydroca rbon pipelin es This very porou s se ns in g ca bl e, read il y ab so rb s hyd roca rbon s, but is ot herw ise hydrophobic. Ab sorpt io n of hydrocarbon s by th e in s ul ation s ig nifi ca ntl y alte rs th e ca bl e 's ca pacitance, c harac te ri s tic impedan ce a nd propaga ti o n s peed. Leaks are de tec te d by a sta te of th e a rt pul se de tec ti o n c irc uit built into th e ELD 3.

Richard Smith of Environmental Petroleum Systems of Red Jacket Pumps

14

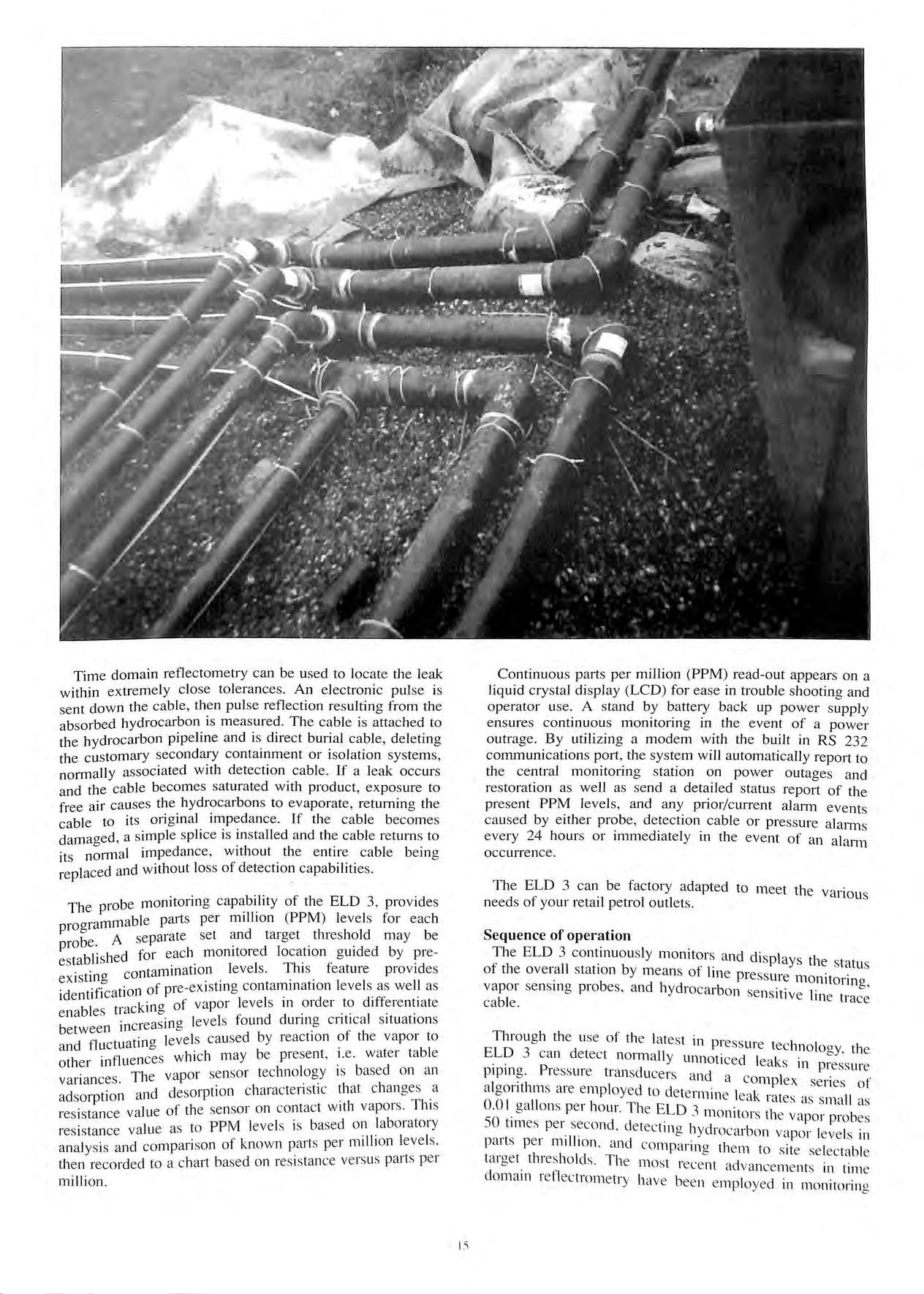

Time domain reflectometry can be used to locate the leak within extremely close tolerances An electronic pul se is sent down the cable, then pulse reflection resulting from the absorbed hydrocarbon is mea s ured. The cable is attached to the hydrocarbon pipeline and is direct burial cable, deleting the customary secondary containment or isolation systems, nonnally associated with detection cable. If a leak occurs and the cable becomes saturated with product, exposure to free air causes the hydrocarbon s to evaporate , returning the cable to its original impeda nce If the cable becomes damaoed , a s imple splice is insta lled and the cable returns to its impedance , without the entire cable bei ng replaced and without los s of capabilities.

The probe monitoring of the ELD 3, provides ro rammable parts per million (PPM) levels for each p. gb A separate set and target threshold may be pio e. · d I . 'd d b bi hed for each momtore ocat1on gu1 e y pre- esta is I I Th' f .d . · contamination eve s. 1s eature prov1 es ex1st111g identification of pre-ex1stm g well as e nabl es tracking of vapor !eve s dm _o r er _to 1 1 erent1ate · easina level s found unn g cnt1ca s1tuat1ons between 1nc1 "' f] t ·na levels caused by reac tion of the vapor to and uctua 1 o · fl ces which may be prese nt, i.e . water table other 111 uen . ,

· The vapor se nso r tec hnolo gy 1s based on c1n vai 1an ces. · · I I d t . 1 ,111 d de so rption chara cte n st1c t iat c 1anges a a so rp 101 ' · Th.

· t value of the senso r on con tac t with vapo1s. is res1s ance . I . b d n laboratory res istance value as to PPM !eve s 1s ase o. analy sis and comparison of known parts per million I_eve ls,_ then recorded to a chai1 based on resis tan ce versus pa1 ts pe1 million .

Continuous parts per million (PPM) read-out appears on a liquid crystal display (LC D) for ease in trouble shooting and operator use. A stand by battery back up power s upply ensures continuous monitoring in the event of a power outrage. By utili z ing a modem with the built in RS 232 communications port, the system will automatically report to the central monitoring station on power outages and restoration as well as send a detailed status report of the present PPM levels, and any prior/c un-ent alam1 events caused by either probe , detection cable or pressure alanns every 24 hours or immediate ly in the event of an alann OCCUITence.

The ELD 3 can be factory adapted to n1eet tJ1e · vanous needs of your retail petrol outlets.

Sequence of operation

The ELD 3 continuously monitors and displa . tl f I II ys 1e statu s o t1e overa station by means of lin e pre ss tii·e · . . mon1tonn o vapor se nsmg probes, and hydro carbon sens·f 1. "'' ca bl e 1 iv e 111e trace

Through the use of th e lates t in pressure t , 1 1 ELD 3 d ec 1110 ooy, th e ca n etect nonnal ly unnoti ced I k · "" · · ea s 111 press ure p1p111 g. P1 ess u1 e transducers and a c 1 0 .· omp ex se n es ot al 0 011thms aie employed to dete rmin e 1 ak oo cr I _ e, 1ates as s ma ll as I ""a Ion s pe1 hoL11. The ELD 1 rno111·101·s tl1 t 50 · · · e vapor pro 1es tim es. per second. detecting h ydrocarbon vapor leve ls i;1 pe 1_ i:11!11on. and compar in g th em to s ite se lectab le ta1 0 et th1eshold s. The mo st rece ilt ad d · fl · va nc eme nt s 111 tun e omam re · ectro me t1y I b . 1ave ee n e mplo yed 111 mo111tonng

II STREETS AHEAD LEADERS IN FORECOURT AND PETROLEUM INDUSTRY SAFETY MANUFACTURERS AND DISTRIBUTORS OF PROMOTIONAL SIGNS AND SAFETY EQUIPMENT. SUPPLYING: POLICE EMERGENCY SERVICES * UTILITIES * MARINE AND AVIATION * ADVERTISING * PROMOTION INDUSTRIES ROLL UP REFLECTIVE SIGNS HIGH VISIBILITY CLOTHING AND REFLECTIVE BADGES 1;a1:J:1 ) / F\RE 111m·Jm RESCUE ...... Fiksr AID Si Jill-IN /\MIJUl /\Nci: ******************* c,oe.N1' ******** \S NO AC ******* SAfE-rl *********** ********* 0 GUARDIAN 11 FREE STANDING BARRIER 11 GUARDIAN° REFLECTIVE STRIP OTHER PRODUCTS AVAILABLE: RIGID SIGNS, CONES, FLASHING LAMPS, MANHOLE GUARDS, BARRIER BOARDS, WINDOW STICKERS, CYCLE AND EQUESTRIAN SAFElY Special signs made to order STREETS AHEAD (JJ) LTD, Unit s, Uss Business Centre, Station Road, Uss, Hants, GU33 7SD Tel: 0730 894333 Fax: 0622 743289

the leak detection and location cable. The cable remains non-reactive until coming in contact with free hydrocarbon molecules. The ELD 3 reports to the central monitoring computer via telephone at a pre selected time each day, downloading its current status. These reports are maintained in archival storage at the monitoring company, and will be forwarded to appropriate regulatory authority at their discretion. The ELD 3 provides positive shutdown of the pump in the line or tank which fails, and sounds an alarm for the attendant at the kiosk. As stated before, the computer immediately contacts the monitoring companies computer and signals an incident has occurred. The ELD 3 's software data acquisition package displays the station identification, type of alarm, and action taken. (i.e. pump shut down) The monitoring company immediately contacts the spill response unit of the oil company involved, and dispatches its own engineering personal to assist the oil companies efforts in dealing with the incident. Once a pump has been shut down due to a suspected leak, it cannot be re started until the incident has been investigated by the oil company involved. All reports of that incident will be forwarded to the local regulatory authority having jurisdiction over the station in question.

During an alarm condition on one or more product lines, the system continues to monitor the other products, allowing the non-affected products to be dispensed as normal. Only the product involved will be interrupted.

Leak detection by pressure management

Three modes of line leak detection are built into the circuitry of the ELD 3 's pressure monitoring system. The first mode is the catastrophic leak detection which detects a leak rate of approximately JO gallons per hour in 8 seconds. The standard leak detection mode detects a leak rate of approximately 0.1 gallons per hour in a time frame ranging between 30 seconds to 30 minutes. The precision leak detection mode detects a leak rate of 0.01 gallons per hour in a time frame of 30 to 90 minutes after the delivery system has been at rest for 45 minutes. This test is initiated everytime the pump stops. If the pump is operated during this time, the ELD 3 automatically resets and prepares for the next precision lea_k test. benefit of the pressure agement system 1s the availab1hty of current operational man h 1 U res of the system to t e centra momtonng computer. press · ff This allows the momtormg sta to the operational status of real t1fme prov1dmg 1 , ble "trouble shootmg too m case o pump, check a va ua p·icker manifold failure. At Moons, we have valve or ' . d precision tests for all 4 grades of product daily. achieve ·

k

detection by vapor probe

Lea 1 ak is detected by a vapor probe, the computer Once a e · d 1 · Of several courses, depen ant upon t 1e option will take one . .. I' d Th . . selected when the station 1s. m1t1a 1ze . e mm1m1u1m 1s tod · 1 at the kiosk for the attendant, as we as sen sound an a ann · h h 1 1 · ·tl to the monitonng company t ru t e te ep 10ne the sign< dd. ally the ELD 3 can be programmed to shut modem. A 1t1on · d h h bme rsible pump which correspon s to t e clown t e su · suspected leaking tank.

Leak detection and location by hydrocarbon detection cable 1 .

The detection cable remains non-reactive unt1 11 comes m contact with free hydro carbon products. Once tlw cahle is sufficiently "'wet" its capacitance and imped1enn' is changed. electrically surpassing predete1111ined thresholds.

The ELD 3 then locks out the corresponding pump serving that channel. With the use of the latest in time domain reflectrometry, the monitoring company's engineering staff can identify the source and the location of the leak.

Upon arriving at the site, the monitoring company personel connect the suspected cable channel to a TDR (time domain reflectrometer). It identifies where, in feet, the incident occurred along that particular channel. Once it has been located and repaired, the cable returns to its original detection capabilities, without any loss of sensitivity. If the cable becomes damaged, that portion of the cable may be replaced and the cable returns to normal usage. This precludes the necessity of the entire cable being replaced.

Non leak faults at the site

Upon a power failure at the ELD 3, all pumps are locked out until power is restored and the ELD 3 automatically resets.

If the phone line is damaged, the ELD 3 will continue to operate as normal. In the event of an alarm, the particular pump involved will lock out and the ELD 3 will attempt to call the monitoring company's computer. If the monitoring company's computer does not receive a status report from that particular site within 24 hours, the computer will alert the monitoring company's staff of a possible problem and will notify appropriate oil company personnel. Upon their investigation and report, the other response steps are taken as necessary.

In conclusion, I would like to thank the association for petroleum and explosives administrative for the opportunity to address their conference today.

Along with our distributors in the United Kingdom, Normand Environmental Services, we look forward to discussing with you your specific environmental concerns and how our system can assist you in addressing those concerns.

To summarize

We believe the petroleum industry, both oil companies and regulatory authorities are looking for active leak detection systems. The ELD 3 is a pro-active system not a reactive system. Systems such as secondary containment systems react to product discharges. That is, when a leak occurs sufficient product must enter the mterst1tial space, m1-?rate to the detection apparatus, and set off the alarm. Ce11am systems do employ detection 'l\ the interstitial space however, it can take up to I o h < ong o ours to detect a leak. Because of the 3 's response times. we can detect extremely small quantities of product 1 " 1 · 1 n smgu ar mmutes, e 11111nat111g the need for any type of , containment. We believe the ELD 3 is the . It · d e111at1ve to secondary contamment for underground 11 · · 0 ·tpmg systems ur system can be utilized on both pressLii·e . 1 . '· · · , i · ·· dnc suction systems. anc we look forward to answerino you may have. '=' any questions

\ 7

FIREWORKS

By Philip Rose DCA. MITSA Chief Trading Standards Officer London Borough of Islington

I read with interest the article written by the Revd. Lancaster in issue 3 of the Bulletin. There are indeed problems with fireworks and the consumer end of the explosives industry, in fact far more than the article suggests.

We currently have:-

(i) preliminary legislation that dates back to 1875, is archaic language and is a nightmare to work through with its multitude of Orders in Council.

(ii) a British Standard that has a number of defects but cannot effectively be updated because of the work on the CEN standard (not likely to be available in its full form until 1996), and

(iii) a set of safety regulations that are very difficult to enforce without using very young children to make purchases and that appear to ban the sale of such basics as caps and Christmas crackers to under 16's.

I mentioned Christmas crackers above and the problem regarding sales to under 16 's. Cracker snaps are subject to the controls of the Act and sensibly so when many thousands might be stored in one place. But the situation doesn't change when incorporated in wrapping to form a cracker. Should shops who only sell Christmas crackers seek registration for storing explosives, and more importantly should the thousands of outworkers who put the crackers together be registered? Legally the answer appears to be yes. I quote this example to show that I fully sympathise with Lancaster regarding the nonsense of treating fireworks and other consumer explosives in the same way as mainstream explosives. I would not however support the continued availability of what I would consider none consumer products such as display fireworks to the general I think the days of calling out the Army Bomb Disposal Unit to deal with such failed fireworks in back gardens should be a thing of the past.

'W_e also have the nonsense whereby manufacturers who claim compliance with BS7114 in their labelling could be in breach of the Tracie Descriptions Act 1968 should they wish to acid more safety information to fireworks than specified in the Standard as the labelling will then no longer comply with the requirements of the Standard.

Should Trading Standards Officers wish to carry out any satety checks on fireworks at retail level then they face 111 ',llor difficulties. The sampling system laid down in BS7 I I4 is clearly designed for testing in a factory situation ;md almost impossible to apply to supplier at retail level. h·en then should a TSO decide to take samples for testing thn must en..,ure they do not fall foul of the Road Traffic r< a1T1a12c llf Fxplmives) Regulations 1989. These

regulations allow fireworks to be transported from a retailer to a test house if under 50kg however this does not apply to transportation from a non-retailer because of the need to be a registered carrier.

The above few examples are given to indicate the difficulties that the various legislative requirements cause both industry and enforcement officers. There are many more examples that could be related but they would only reemphasize the above. The important thing is that the various groups involved have started to work towards resolving the difficulties. Standard Fireworks and the Institute of Trading Standards have recently run a series of joint seminars throughout the UK to improve understanding of the requirements, the HSE are looking at revision of the 1875 Act and the DTI are considering revision of the regulations controlling sales to under 16 's.

A lot of work needs to be done and hopefully we will see major improvements in the not too distant future.

I could not finish this article without a reference to firework related accidents, the crux of why it is necessary to ensure fireworks are both manufactured, stored and used safely. For years the DTI have produced national statistics that show some 800 firework related accidents in Great Britain per annum. After November 5th last year twelve London boroughs carried out surveys involving over 12,000 school children to determine an accurate picture of the level of firework related accidents. The survey reveal that 308 children had had an accident and 119 of those had required treatment from a hospital or a GP. Quite clearly the national figures supplied by the DTI appear to be a gross understatement of the accidents that are occurring. It is again pleasing to report that the DTI have closely co-operated with the London Trading Standards Departments to jointly organise a 1990 survey across London such that the full picture can be gained.

With Govemi_nent Departments, Industry, and Trading Standards closely closely together it is to be hoped that these accidents will decrease and fireworks become something to enjoy in safety.

18

.-1

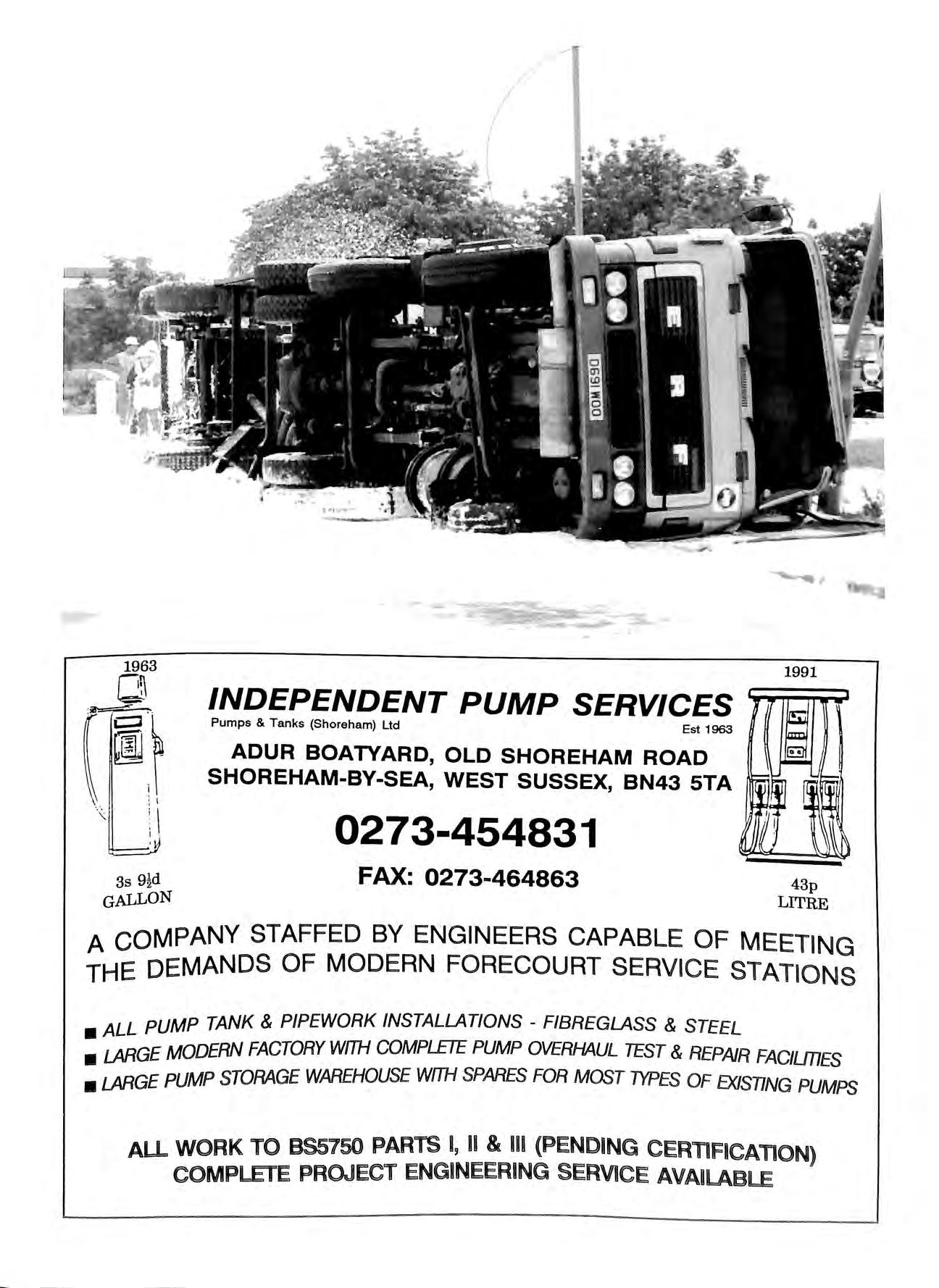

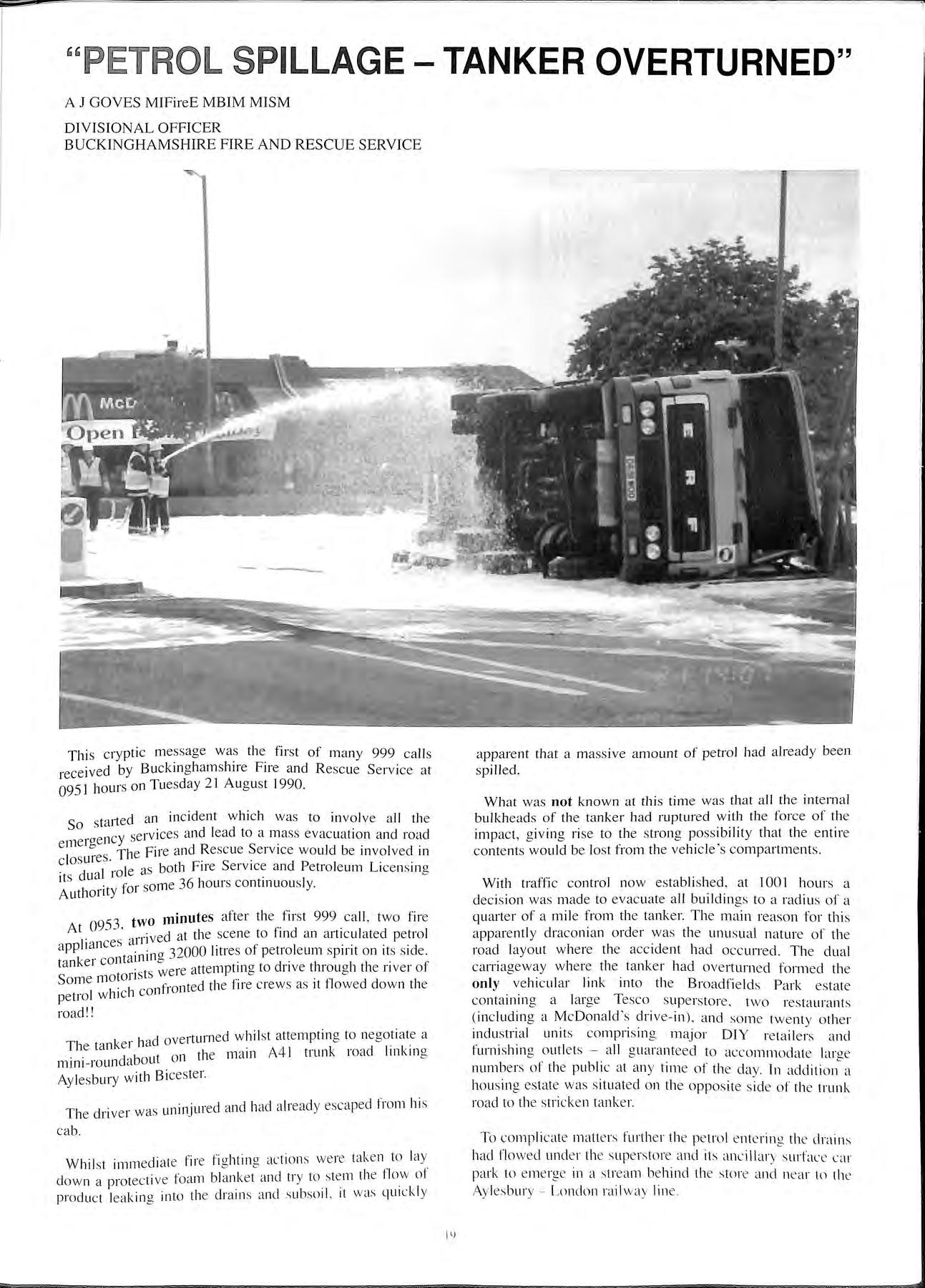

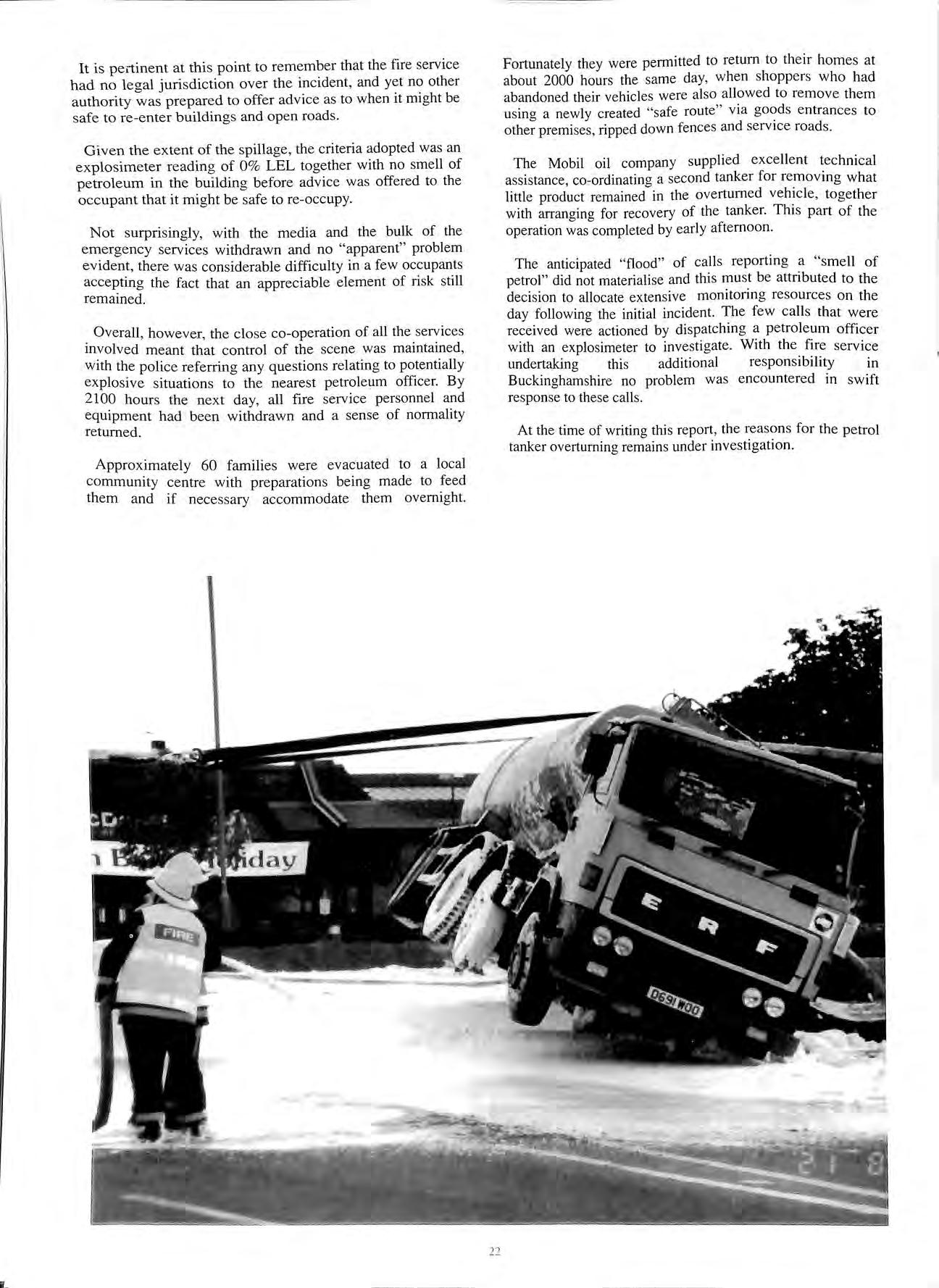

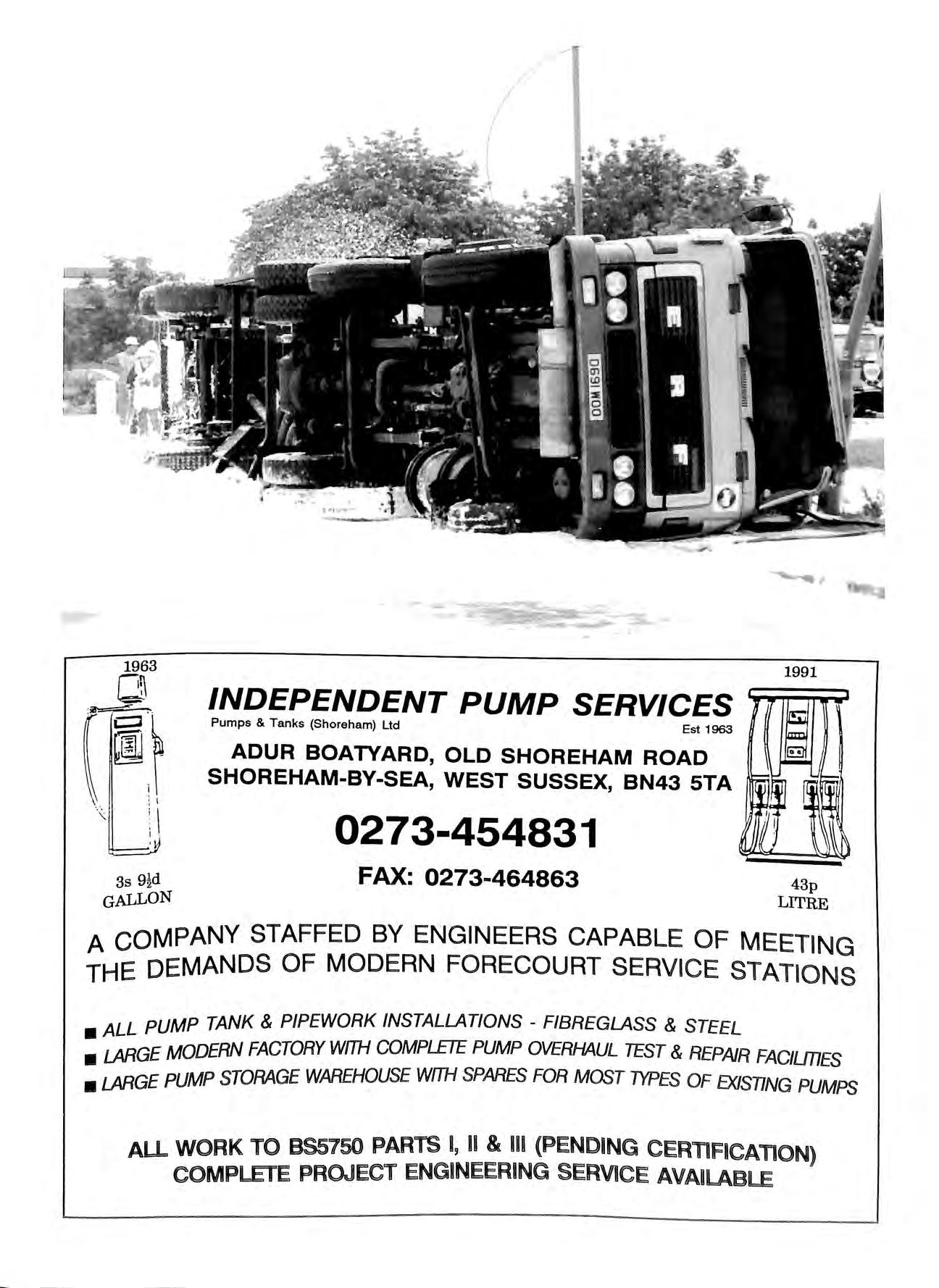

A J GOVES MIFireE MBIM MISM DIVISIONAL OFFICER BUCKINGHAMSHIRE FIRE AND RESCUE SERVICE

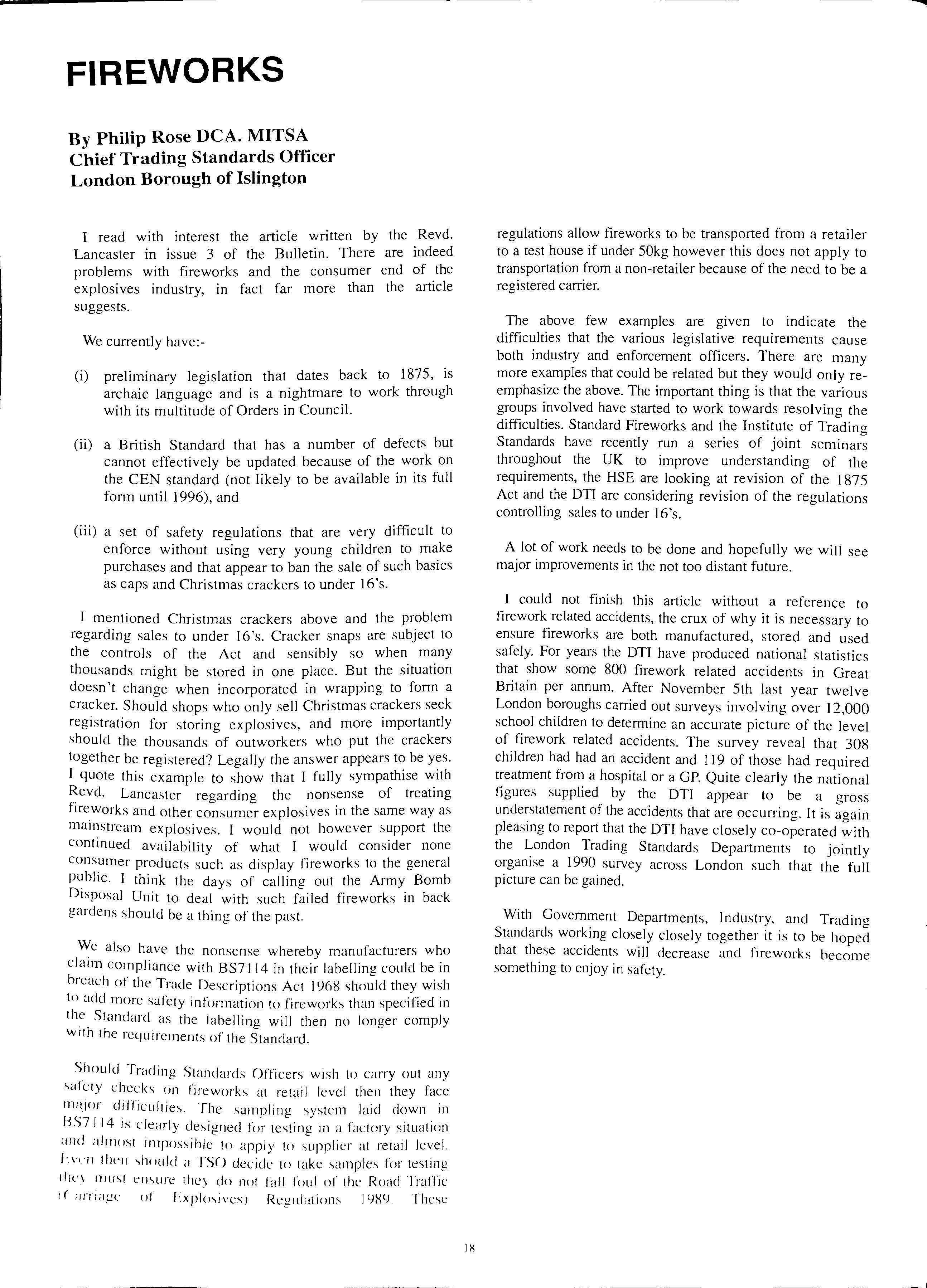

This cryptic message was the first of many 999 calls received by Buckin g hamshire Fire and Re scue S e rvic e at 0951 hours on Tuesday 21 August 1990.

So s tarte d an. incident whi c h w as to involv e all th e en c y se rvic es and lead to a m ass evacuation a nd ro a d e m e ig I R S Id b . I d . clos ure s Th e Fire anc essc ue erv1c e 1 wou e rnvo ve rn . d 1 ·ole as both Fire e rv1c e anc Petroleum L1 ce ns m g ua 1 for some 36 hours contrnuou s ly.

Authority

953 two minutes afte r th e fir s t 999 c a ll. two fir e

At. O ' JTived at the scene to find a n arti c ulated pe trol 'tpp!Iance s a . f I .d c · ino 3 2000 !Itres o · petro eum spmt on its s 1 e. tanker contam "' · d · I I I · t' · ts w e re att e mptmg to nve t 1rou g 1 t 1e nv e r o Som e motoi is · · · · fl d I . h onfronte d th e fII e c 1ew s as 1t o we down t 1e pe trol wh1c c ro a d!!

h ' d o ve rturn e d whil s t attemptin g to ne g oti a te a Th e tank e 1 d · · d ' b t 011 th e m a m A4 1 trunk ro ad lmk1n g m1111 roun c1 ou Ayle s bury with Bi ces ter.

Th e driv e r wa s uninjured and had a lre ad y esc ap ed fr o m hi s ca b.

Whil s t imm e di a te fir e fi g htin g act io ns we re ta ke n _ to lay. d ow n a protec ti ve foa m bl a nk e t and tr y to ste m th e llo.w of produ c t lea kin g into t he drain s a nd s ub s01L 1t was qui c kl y

app a re nt th a t a ma ssi ve amount of p e trol had alre a d y be en spilled

Wh a t w as not known a t thi s tim e was that all th e inte rnal bulkh ead s of th e ta nk e r ha d rupture d with th e force o f th e impa c t, g iving ri se to th e s tron g poss ibility that th e e ntire conte nt s would be lo s t from th e ve hi c le 's c ompa rtm e nt s

With tra ffic control no w es ta bli s he d , at I 00 I hour s a deci s ion was made to e v ac ua te all buildin gs to a radiu s of a quarte r of a mil e from th e tank e r. Th e m a in reas on for thi s appare ntl y dra c oni a n orde r wa s th e unu s ua l n a ture o f th e road la yout wh e re th e accide nt h a d o c curre d. Th e dual c arria ge w a y w here th e ta nk e r had ove rturn e d form e d th e only vehi c ular link into th e B roa dfi e ld s P a rk es tate co ntainin g a large Tesc o s up e rs tore . t wo res taurant s ( includin g a M c Don a ld 's dri ve -in ), a nd so m e twe nt y o th e r indu s tri a l unit s co mpri s in g major DI Y re ta il e rs a nd furni s hin g o utl e ts a ll g uarant e e d to acco mm o d a te la rge numb e rs of th e publi c a t a n y tim e of th e d a y In a ho us in g e sta te w as s itu a te d on th e op pos ite s ide o f th e trunk ro a d to th e s tri c ke n ta nk e r.

To compli c at e m a tt e rs furth e r th e petro l e nt e rin g th e drain s ha d flo we d und e r th e s upe rs to re a nd it s a nc ill a ry s urfa c e ca r pa rk to e m e rge in a s tre a m be hin d th e store a nd ne a r to th e Ay les bur y Lon d on ra il wa y lin e.

,'' ETROL

SP ILLAGE - TANKER OVERTURNED"

i'J

L

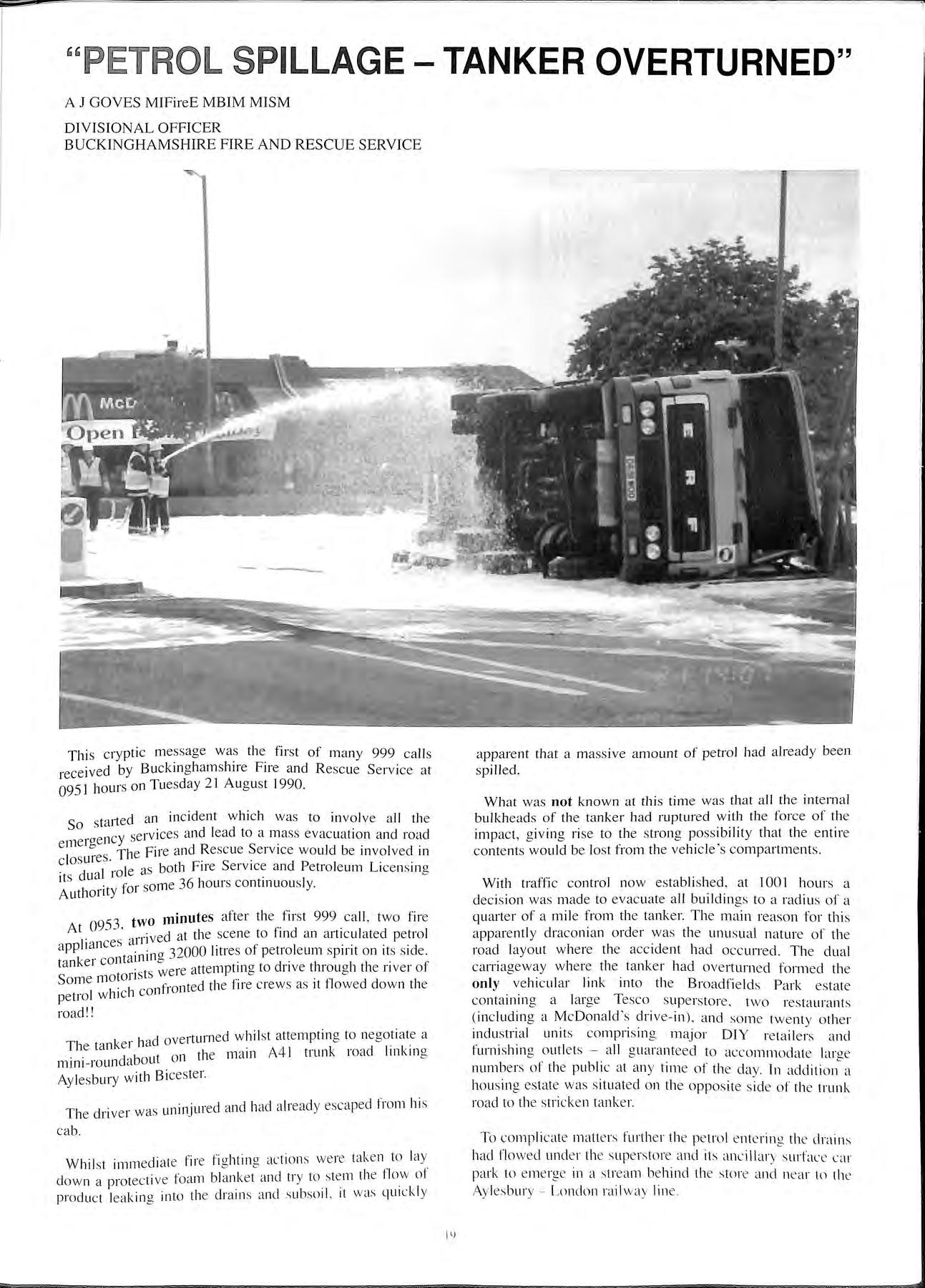

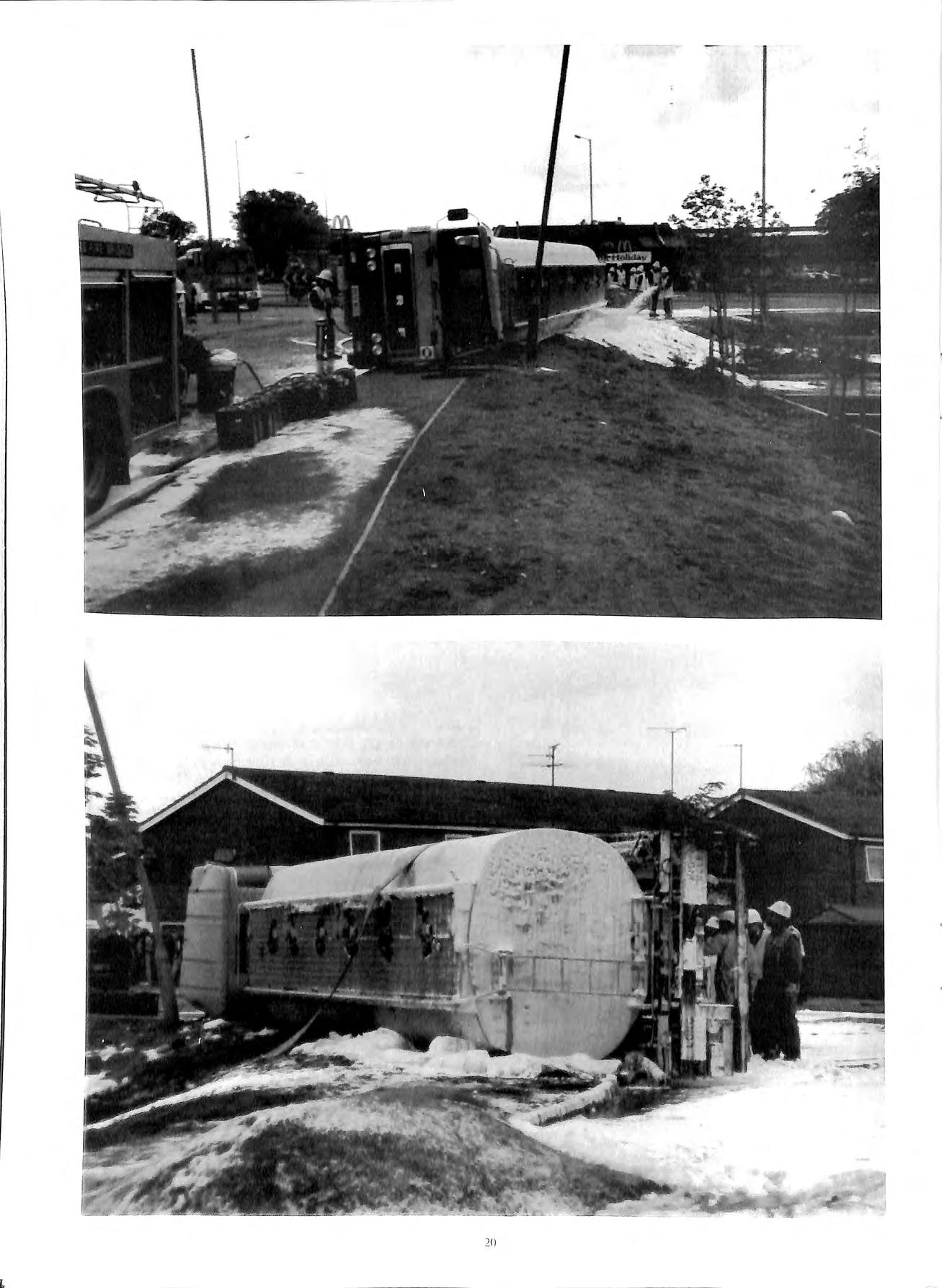

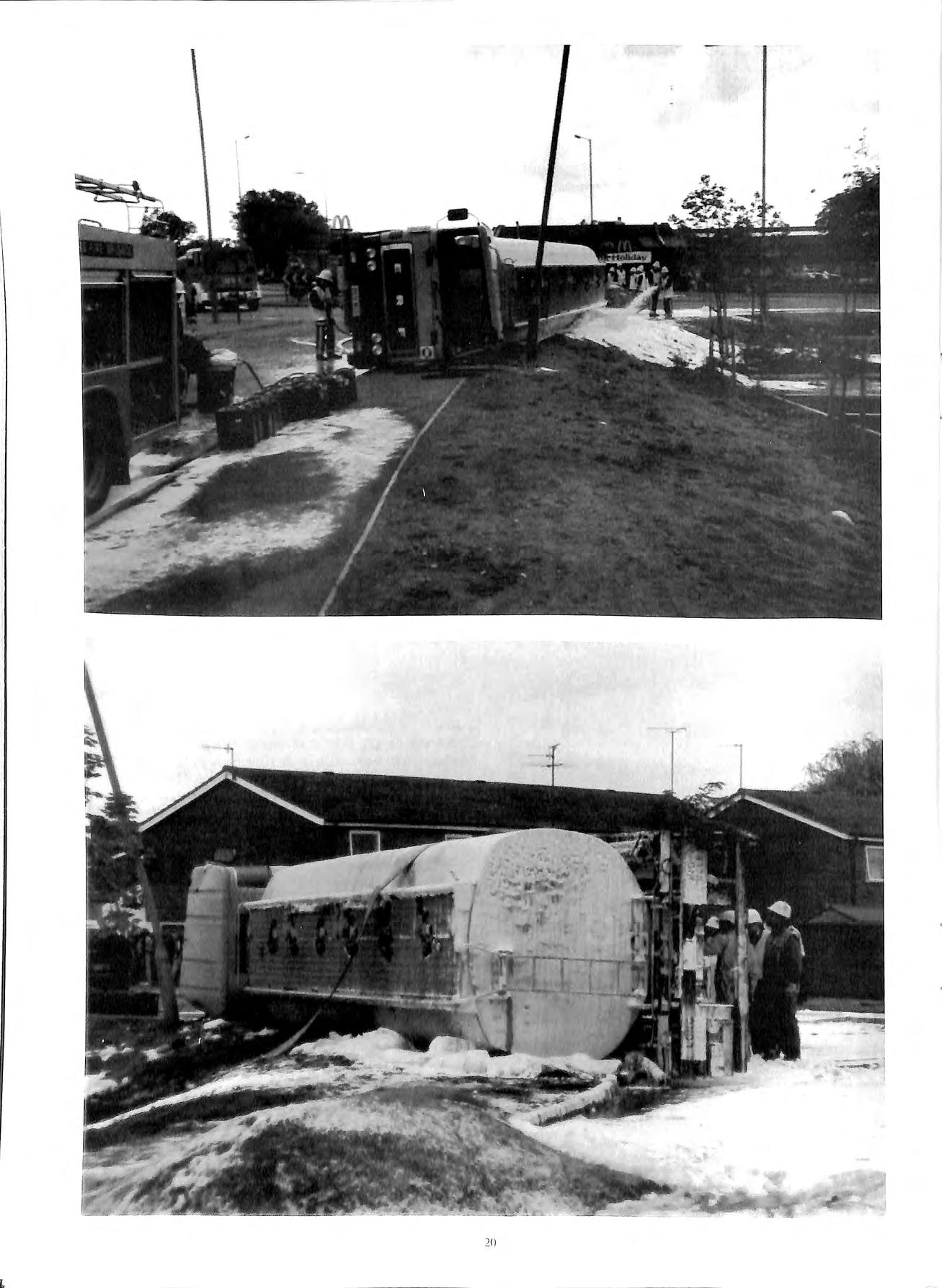

Appro ximately 30000 litres of petroleum spirit were still unaccounted for upon righting the tanker.

The bulk of contamination to the open water course was contained by booms supplied and installed by the National Rivers Authority.

Two tankers supplied by Leigh Environmental arrived at the scene at 1830 and 1930 hours with a police escort with the express intention of uplifting the petrol in water courses, drains and any other depressions. With this facility now available it was possible to plan ahead and consider flushing the drains to eradicate the remaining petrol. This operation continued all through the night and until the following day.

The enormity of the "monitoring task" became apparent as the area was reassessed on the following morning, some 24 hours after the initial incident. Apart from the drains and roads where clearing operations continued, the area affected comprised some 24 buildings, nearly all of which had not been occupied by anyone for many hours.

In order to avert a flood of calls for help which would inevitably happen when occupants returned, the decision was made to commit fire service resources to the area to monitor and record each building with explosimeters so that an accurate record could be maintained and appropriate advice to the many businesses involved.

Gas, electricity and telephone supplies to the affected area were shut down, and fire service petroleum officers began monitoring with explosimeters to confirm the area needed for evacuation, with a view to extending it if necessary.

Over 100 drains, some 3000 metres of drainage system, and approximately three quarters of a mile of open stream (which in places passed under buildings) were surveyed by officers using six MSA Combustible Gas Indicators (Models 5 and 40).

Accordingly, a mass evacuation began, co-ordinated by the police, utilising a pobce helicopter hovering overhead to broadcast messages to the public.

Over 300 people left the superstore but many had to be "persuaded" to abandon their vehicles and walk away through adjacent gardens to reach safety. It was a very difficult operation, underlining the need for firmness and authority on the part of those arranging the evacuation (which included Tesco staff) coupled with good communication skills, since people could not see the tanker or smell the petrol until they had traversed several hundred metres. In consequence many were reluctant to leave the scene in the early stages of the evacuation.

21

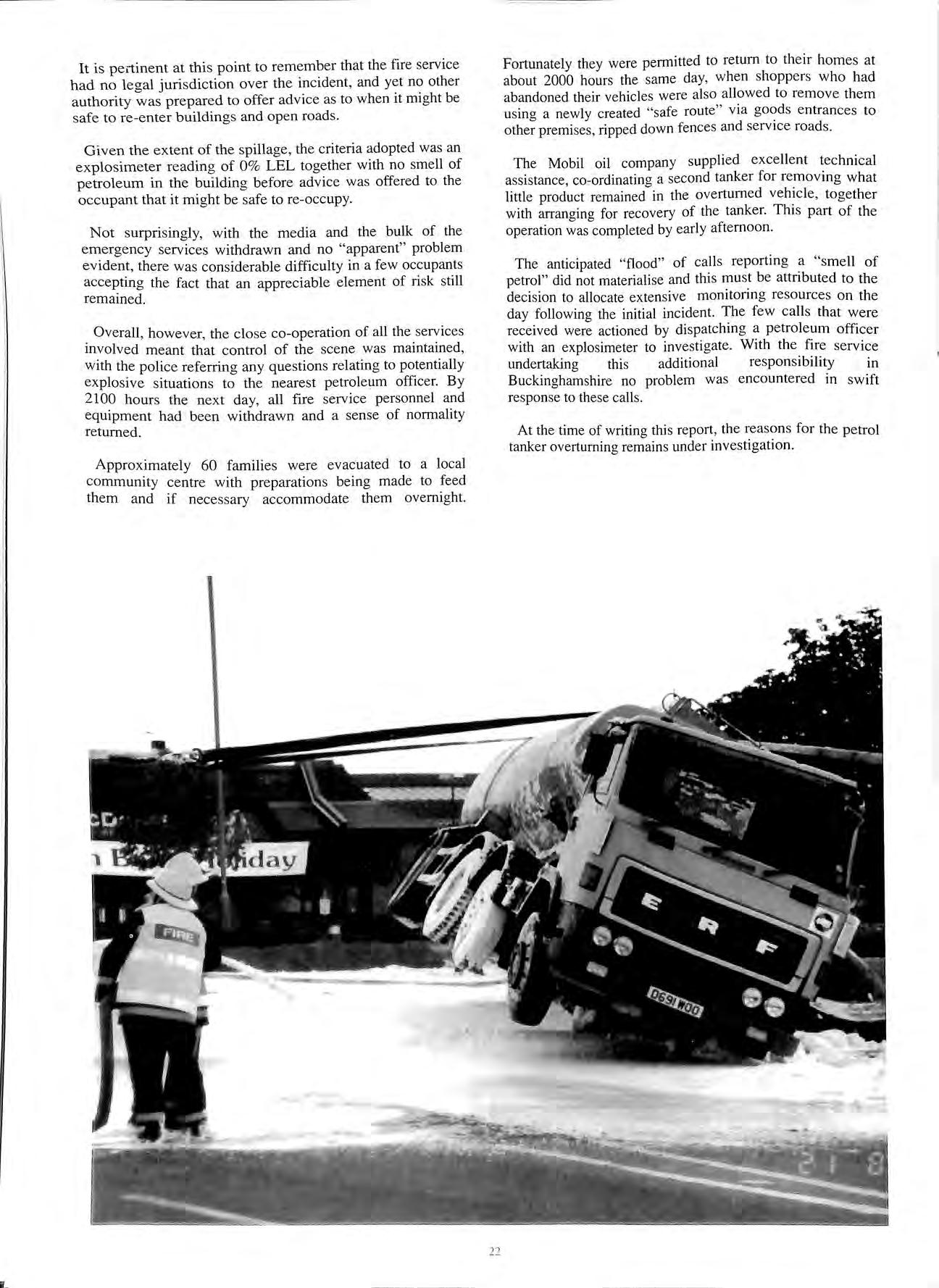

It is pertinent at this point to remember that the fire service had no legal jurisdiction over the incident, and yet no other authority was prepared to offer advice as to when it might be safe to re-enter buildings and open roads .

Given the ex tent of the spillage, the criteria adopted was an explosimeter reading of 0 % LEL together with no smell of petroleum in the building before advice was offered to the occupant that it might be safe to re-occupy.

Not surprisingly, with the media and the bulk of the emergency services withdrawn and no "apparent" problem evident, there was considerable difficulty in a few occupants accepting the fact that an appreciable element of risk still remained.

Overall, however, the close co-operation of all the services involved meant that control of the scene was maintained , with the police referring any questions relating to potentially ex plosive situations to the nearest petroleum officer. By 2100 hours the next day, all fire service personnel and equipment had been withdrawn and a sense of normality returned.

Approximately 60 families were evacuated to a local community centre with preparations being made to feed them and if neces sary accommodate them overnight.

Fortunately they were permitted to return to their homes at about 2000 hours the same day, when shoppers who had abandoned their vehicles were also allowed to remove them using a newly created "safe route" via goods entrances to other premises, ripped down fences and service road s.

The Mobil oil company supplied excellent tec hnical assistance, co-ordinating a second tanker for removing what little product remained in the overturned vehicle, together with arranging for recovery of the tanker. This part of the operation was completed by early afternoon.

The anticipated "flood" of calls reporting a "smell of petrol " did not materialise and thi s must be attributed to the decision to allocate extensive monitoring resources on the day following the initial incident. The few calls that were received were actioned by dispatching a petroleum officer with an explosimeter to investigate. With the fire service undertaking this additional responsibility in Buckinghamshire no problem was encountered in swift response to the se calls.

At the time of writing this report, the reasons for the petrol tanker overturning remains under investigation.

L

22

1963 0 (i:t \ :1 I 3s a.ALLON / I INDEPENDENT PUMP SERVICES Pumps & Tanks (Shoreham) Ltd Est 1963 ADUR BOATYARD, OLD SHOREHAM ROAD SHOREHAM-BY-SEA, WEST SUSSEX, BN43 5TA 0273-454831 FAX: 0273-464863 I • 1991 43p LITRE A COMPANY STAFFED BY ENGINEERS CAPABLE OF MEETING THE DEMANDS OF MODERN FORECOURT SERVICE STATIONS •ALL PUMP TANK & PIPEWORK INSTALLATIONS - FIBREGLASS & STEEL • LARGE MODERN FACTORY WITH COMPLETE PUMP OVERHAUL TEST & REPAIR FAClunEs • LARGE PUMP STORAGE WAREHOUSE WITH SPARES FOR MOST TYPES OF EXISTING PUMPS ALL WORK TO BS5750 PARTS I, II & Ill (PENDING CERTIFICATION) COMPLETE PROJECT ENGINEERING SERVICE AVAILABLE

• RAVENA CONSTRUCTION LTD Building & Civil Engineering Contractors Specialists in all forms of forecourt petroleum installations FOR FREE QUOTE TELEPHONE: 0926 624489 (Office) or 0831 461061 (Mobile) The Willow Tree, Wasperton, Barford, Warwick, CV35 SEB D.M. PETROLEUM SERVICES Proprietor:- D. B. MAJOR Telephone: 0462 732418 Forecourt and Commercial PetrolDiesel Installations 25 Brook Street, Stotfold Hatch in Hertfordshire SG54LA ---·-----------------------------_1

DO YO U HAVE COMPLETE CONTROL OF YOUR LIQUID ASSETS?

In today's financial and environmental climate the forecourt operator must have complete control of his wet stock.

No one can afford to allow wet stock losses to go undetected particularly as the new Health and Safety guidelines, HS(G)4 l, require all petroleum retailers to make daily stock reconciliation checks.

Normand has the products that can deliver the control you need to counter any problems you may experience in the area of oil loss.

And the ability to offer you practical advice on the most appropriate package for your service station.

We made our name specialising in supplying the oil industry with

the most successful range of tank gauges in Europe, with complete servicing back-up and calibration expertise.

Together with CMS we helped to develop and perfect Driver Controlled Delivery.

And we' re now in the business of protecting you and the environment with a superb range of leak detectors and monitors, as well as consultancy, advisory and risk assessment services from our Environmental Systems division.

We know our range of products will give you both complete performance and peace of mind.

Call us for more information now before you experience any form of stock loss.

Normond limited

Hydrex House, Garden Road, Richmond, Surrey TW9 4NR, UK Tel: 081 392 1355 Telex 919193 Fax: 081 878 6642

Nonnoncl

CAPITAL DEMOLITION <NHEJ LTD Specialist removal of feel tanks General demolition Concrete breaking BYFLEET (09323) 46222 41525 46005 C & S STANSFIELD LIMITED AMERON APPROVED INSTALLER FOR FIBERGLASS PETROLEUM INSTALLATIONS Unit 10 Boundary Road Industrial Estate Sturmer, Haverhm CB9 7YH 0440 712505 Fax: 0440 712506