The wrong underground

p1p1ng material could put your entire business in the hole.

If you're rebuilding your station, you're probably in a rush for the pipe to be in the ground and tested so you can get on with your real busi ness of selling fuel.

But don't forget to take a close look at your choice of piping materials.

Here are three things to think about when you choose between 'hard' piping like Dualoy®3000/L and the 'soft' system that's just come on the market.

For starters, there's fluid hammer. Topping off can cause pressure spikes of 20 atm or more. Soft systems use thermoplastic hoses in the primary with safety factors of 3: 1 or less. That's not a lot of margin for failure. With Dualoy 3000/L rigid-wall fiberglass pipe from Ameron yo u get a safety factor of over 1O:1 Second, there's UL-listing. Soft sys tem containment doesn't have it. Wouldn't you want the assurance of a

ril:'\ Underwriters

Inc. @ third party like UL that th e containment can prevent soil contamination in case of a leak? You have that assurance with Dualoy 3000/L.

r / r , r· _)

/ ) '

(.=# k' in

the proven way to move fuels Fibergiass Pipe

1A Christchurch Road Ashford , Kent TN231XB

Tel : 0233 613 928 Fax : 0233 613 884

Prevents overfilling of underground storage tanks. Now also available in 3 inch 0 OPW 104-AOW

MONITORING

NOZZLE

OPW 11-ALD, AUTOMATIC ne lS Mik e Elston , D ist rict Ma nage r UK. OPW Fue lin g C ompon e nts Europ e B.V., T el.: 0729 82 365 'i , Fax:0 72 9H 2 24 24 OPW Fuc lin g Co m pon e n t s E urn µc B. V P.O. Box 11 l, 1160 A C Zwa nc nbur g, T IH: N eth e rland s Te l.: ( l 1). 290 7 S44 2 , Fax: ( l 1 l. 2 9l17- M1H I , Tl' lc x 152 91'

The Keys to Total Fluids Control

over 30 years

has led the field in fluids handling for the transport industry. Now PERMEX moves even further ahead with the introduction of : Fuelfa x the revolutionary touch-screen fuel monitoring system with read-write keys and "Oil Watc h" the automatic oil dispensing system that will boost profits in the workshop. These new systems are designed for easy operation while providing management with data that 's vital to efficiency, economy and profit! Fuelfax , "Oil Watch" and a comprehensive range of Lubrication Equipment set the standards for fluids handling for transport. Get the PERMEX facts TODAY!

I have just heard from Jim Pim the regulator from Suffolk County in New York State, a regular reader of the Bulletin. Many of you will remember his presentation at a past seminar and a paper in the Bulletin on his petrol tank replacement programme. He informs me that the tank replacement programme in his County has now been completed, but like all programmes there were a few remaining outlets that needed to be persuaded to comply.

He informs me that they hit on a novel idea to persuade them, they moved in unannounced, posted an embargo sign and filled the fill pipes with concrete so could take further deliveries! It apparently worked like a charm with the minimum of legal fuss.

AGM

The AGM of the Association will be at Queensway Hall Dunstable on 26 April 1994.

There will be a selection of speakers to talk on petroleum legislation, deregulation and HS(G)41.

Dr Andrew Cottam of the HSE will address the meeting and also Adrian Levett of Warwickshire. It is also hoped to have a speak.er from Industry.

SEMINAR

The APEA has already booked the 1994 seminar and exhibition at the Metropole Hotel in Birmingham for September 26/27th. Please reserve this date in your diaries. We intend to have a full programme and a large exhibition. Watch this space for further announcements.

YEARBOOK

All members should have received just before Xmas a year book, this is the first time the Association has produced such a book and it is hoped that this will be useful to members. It is inevitable that there may be some omissions from the book or mistakes in the information provided, if any member has any comments or suggestions to make as to the contents please write to the Hon Secretary who will pass these on to the committee dealing with it.

IRISH BRANCH SEMINAR

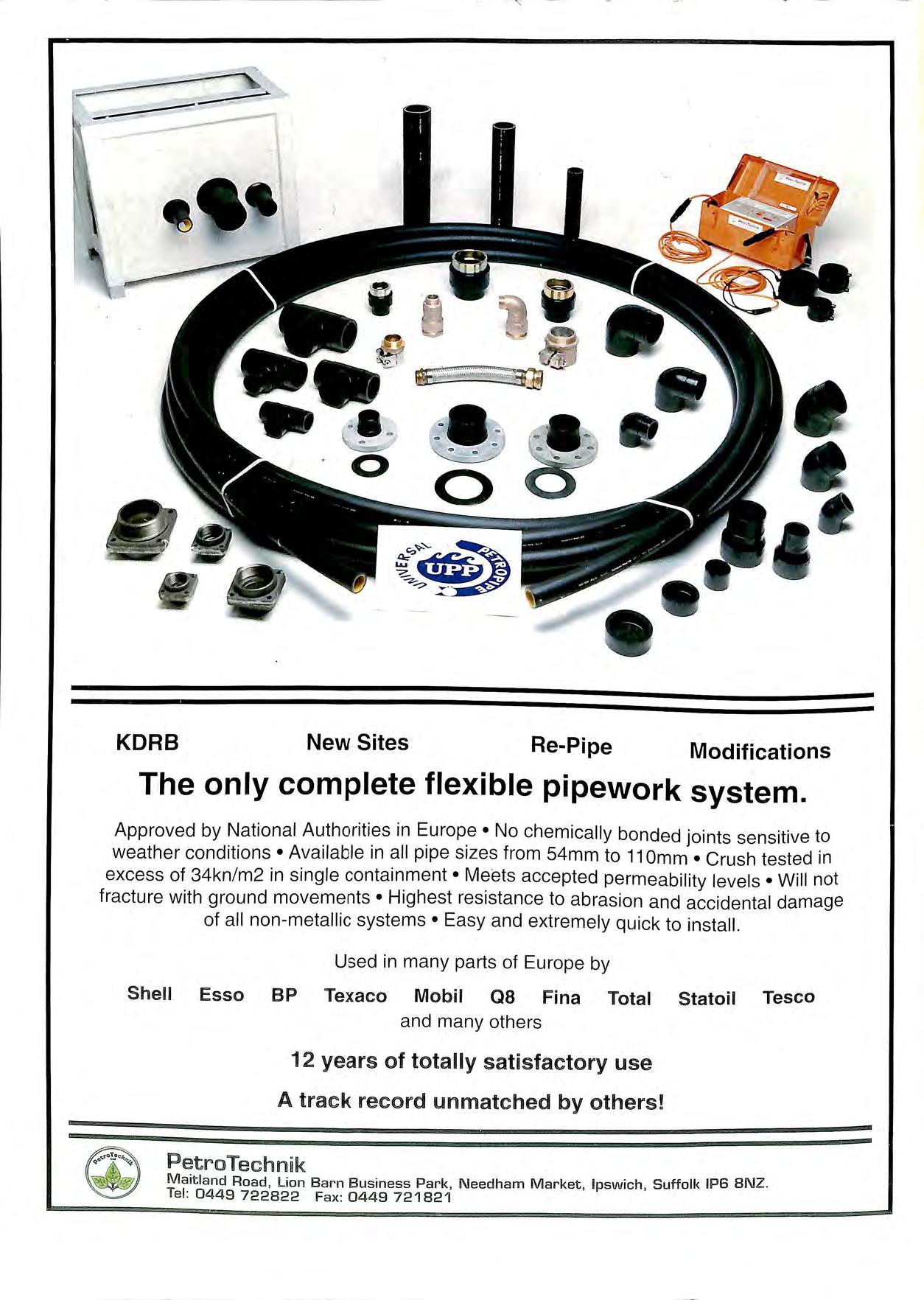

On 11 November at the Spa Hotel, Lucan near Dublin the Irish branch held a very successful seminar and its first AGM. In addition to a very full programme of events which included a number of speakers on pipework the branch was addressed by the minister for Energy Mr Noel Treacy T.D. whose address is reproduced in the Bulletin. The Irish APEA were given the opportunity by the Minister to make suggestions to change petroleum legislation in Ireland. There were a number of exhibition stands taken by manufacturers and the event was well attended by over 120 delegates.

HEALTH AND SAFETY EXECUTIVE

Important announcement

The Health and Safety Executive (HSE) is the arrangements for the sale and distribution of its pubhcatwns. As .a result HSE and HSC publications will no l?nger be available from HMSO Books, by mail order, standmg order or f · rorn its six bookshops.

The new arrangements take effect from 4 October 1993, but in order to organise the transfer of stock HMSO will. not orders for HSE and HSC publications after Fnday September. From that date all orders for HSE and HSC publications and enquiries about the new arrangements should be addressed to:

_HSE Books. PO Box 1999, Sudbury. Suffolk CO I 0 6FS. fel 0787 881165. Fax 0787 313995.

HMSO will. of course. continue to publish and sell regulatory and statutory material on health and safety matters. including hills. acts of Parliament and statutory 1r1s1runients.

FORECOURT CONTRACTORS SAFETY ASSOCIATION

"The inaugural meeting of the FCSA was held at. the West Bromwich Moat House Hotel, near Birmingham on Tuesday, 19th October 1993.

The Founder Members who have been progressing the aims of the Association for the past 18 months received overwhelming endorsement from the delegates present to formally constitute the Association. A further meeting of proposed executive members will shortly be convened to elect the Association Council and provide an open forum for the membership to discuss the aims of the Association.

The aims of the FCSA is to establish and promote good working practices and safety standards and to provide a representative voice and communication source for all building contractors who undertake construction and maintenance work in the Automotive Fuel Retailing Environment. Members will be encouraged to develop uniform and consistent safety strategies according to the requirements of the Institute of Petroleum's Industry Code of Practice.

.one prime objective will be to advance safety and by the provision of training programmes and for companies and to set up a system of and monitoring procedures. A further objective is to provide a central source of information by the pooling of information, experience and research of the potential problems that contractor staff encounter while working at Service/Filling stations.

Whilst safety is the prime objective of the FCSA focus will be _applied to many other legislative and environmental issues that impact on contractors, station operators and the during the undertaking of at Serv1ce/F1llmg stations. The Association will an. of technical developments and Withm the mdustry.and I development w1th111 the Eu_ropean Com!llumty that may impinge upon the progress and 1mplementat10n of Health & Safety standards.

The Associati.on_ will work in parallel to and co-operate with the Assocrnt10n of .Forecourt Contractors, which represents mechamcal and eqmpment contract · · ·11 b d ors Both Assoc1at1ons w1 e represente at the reg 1 · meetings of the Institute of Petroleum's Panel Committee. This will ensure close liaison with h Association of Petroleum and Explosives Administraf t e the of Petroleum and the Health and Executive y

Mr. Geoff Moore, formally with Shell U.K. the Association's Chairman said "the Association is to identification of safety needs, the provision of effective trammg and the implementation of safe workino practices in the service/filling station retailing for the well being of contractors, station operators, their customers and the public."

Those persons or companies who would like to apply for membership of the Association should write to: The Secretary Forecourt Contractors Safety Association

FIRE SERVICE JOINS FIGHT AGAINST POLLUTION

The NRA (National Rivers Authority) has signed an official agreement with the Fire Service to ensure cooperation when dealing with fires or spillages which pose a pollution threat to rivers or watercourses.

Pollution of the water environment can occur at some fires or accident sites as fuel or chemicals are washed into drains, sewers or watercourses with water which is used to extinguish the fire. The new agreement will build on the working relationship already established between the NRA and the Fire Service to minimise the environmental hazard from emergency firefighting action.

The Memorandum of Understanding was signed today by NRA Chief Executive, Ed Gallagher, and Graham Edwards, of the Chief & Assistant Chief Fire Officers Association (CACFOA).

Ed Gallagher commented:

"I very much welcome the co-operation of the Fire Service in helping the NRA to protect the water environment. We fully appreciate that the fire brigade's first task is to save lives and extinguish fires. However, crews can take simple pollution prevention measures which will help to prevent contaminants entering rivers."

The document sets out ways in which the NRA and the Fire Services can co-operate when dealing with incidents, and covers important areas of mutual interest including methods of decontamination, using the skills of the Fire Service in NRA contract work and pollution prevention training for fire brigade staff.

The NRA has always worked closely with the fire brigade, encouraging them to take action to contain spills wherever possible, in preference to dilution aqd dispersion may cause pollution. The NRA is issuing an mcreasing number of anti-pollution packs to the Fire and Rescue Services in an effort to reduce the number of oil pollution incidents caused by accidents particularly those mvolving road vehicles. These packs contain various absorbent materials with which the Fire and Rescue Services invariably the first to arrive at the scene of the accident can absorb spillages and prevent oil and other pollutants from entering rivers and streams.

The NRA is cmTently devising instruction manuals on how to treat spills and contain harmful substances during the firefighting operation.

GLOBAL-MS! pie

On 20th Septe'.11ber 1993 the merger of Global Canopies Ltd. and MSI-F01ecourt Structures Ltd. to form Global-MS! pie was The new company is one of the top three supphers of Forecourt Products i 1 E . . d will b , h UK, 1 lllope, an ecome t . . s p1e1111er supplier for Forecourt Canopies and Associated Products.

Global Canopies Ltd. a stib ··d· t' p . . . . s1 1ary o rn"tman Internat1onal Sec_unt1es Ltd., has been a leading supplier of Forecourt for over 25 years. and in the last 2 years has successfully mstalled canopies throuohout th EEC Central Europe and the former Eastern Block countri:s. '

MSI-Forecourt Structures Ltd. a subsidiary of MS International pie. evolved out of Turner Bros. ( Kingswood)

Ltd. and the Canopies Division of Mech Construction Ltd. to concentrate on the development and introduction of forecourt products. Over the past three years they have introduced a whole range of new products including, Integrated Pump Island Units, the MSI-Chamber Liner, and the MSI-Superceptor Forecourt Interceptor. In addition, an improved range of Pump Island Surrounds, Standard Access Covers and the MSI-Easilift Cover has been enthusiastically received by the market.

Global-MSI pie will therefore have the largest, most diverse and comprehensive range of Products and Services in the U.K. forecourt market. The complementary strengths and product ranges of the two companies will brino positive benefits to both existing -and new customers. In addition, the !arger of Global-MSI pie and the corresponding mcrease m management resources wiII lead to a much higher level of customer service.

Global-MSI pie will operate from all of its present locations, Tonbridge, Doncaster, Madrid, Utrecht, Vienna, Prague and Budapest in order to provide full European coverage and capitalise on the existing expertise.

The company will be able to provide a comprehensive package for major oil companies, or the smallest dealer, irrespective of their size or location. Feedback from our customers at the recent launch confirmed our perception that this 'one stop shop' approach is exactly what the industry is looking for.

At the recent APEA Seminar and Exhibition in Birmingham, Global-MS! pie was enthusiastically received by all sectors of the forecourt industry.

Executive Board Members of Global-MS! pie, Chris Ball, Malcolm Froud, Alex Galanis, Trevor Femley, have their respective companies through the recess10n_ industry has ever known and have the JOmt venture to develop Global-MS! pie as the premier forecourt company in Europe.

LONDON PROSECUTIONS

At Richmond Magistrates court 01: 9 September Mr A th ny Padoet a road tanker dnver employe.d by n 0 0 14 b j' ? CONOCO pleaded guilty to o part_ f . hedule 4 of the Road Trathc (Cam age of Dangerous 0 SC d T k c . Substances in Road Tanker an an· ?ntamers) Regulations 1992. The inci?ent had occmTed on, Ma 1993 when during dehvery Mi: Padget lll:d1d_ the otf_set f··11 y 011 co11 nector of a hose which was still d1scharg111g 1 snap d k A ·11 f petroleum spirit into the undergroun tan ·s.. _o. around 60 litres was caused the busy Sa111sbu1ys l rket site Emergency services were called to deal 1ype1 ma , · £ 1, 6 () cl £7 ) with the spillage. Mr Padget was hned an ( 0 costs.

1 )ther prosecution a company. Truckpoint Vehicle n an( 1· cl k . . Hire Ltd was prosecuted for un 1cense ·eepmg I 11 111 underoround storage tanks at their petro em . e· s in Borouoh Hioh Street SE I. The site 1s situated premise. e 0 . the Northern Lme underground system and the ove1 cl 1 occupiers had not responde requests ·or improvements on the site. originally made m 1989. The company were informed that the would not be at the end of 1992. As the storage ol petrol contmued after the hl·ence ran out. a summons was brought for unlil·ensed keeping. Despite mitigation by the _as tl1 financial difficulties the company wen.' tmed { 1.:'100 plus f:'l00 costs.

ANNUAL GENERAL MEETING MOONRAKERS,

SWINDON -17 FEBRUARY 1993

47 members attended this meeting including two representatives from the Irish Branch. The morning session was spent dealing with Branch business and the election of Branch officers. Mike Sewell, Jim Luke and Rory Hennessy were re-elected as Chairman/Representative to Council, Secretary and Treasurer respectively. Other Branch committee members elected were Chris Prior, Ray Wilson and Richard Graham.

The afternoon session covered the subject of safe working practices on petrol station forecourts and presentations were given by Mac Cox of Veeder-Root, Alistair Clarke of Lectronic Specialists and Dennis Fox of the Association for Forecourt Systems Contractors.

MEETING ON STAGE 2 VAPOUR BALANCING VERBEER MANOR, CULLOMPTON 19 MAY 1993

Another well attended meeting covering a subject very much on the minds of site operators, designers and developers. The morning session presentations were given by Rory Hennessy of the LFCDA who gave an update on legislative developments and Jim Luke of James Luke & Associates who spoke about the way Stage 2 practical matters are being addressed on redevelopment sites in advance of the implementation of full Stage 2 requirements.

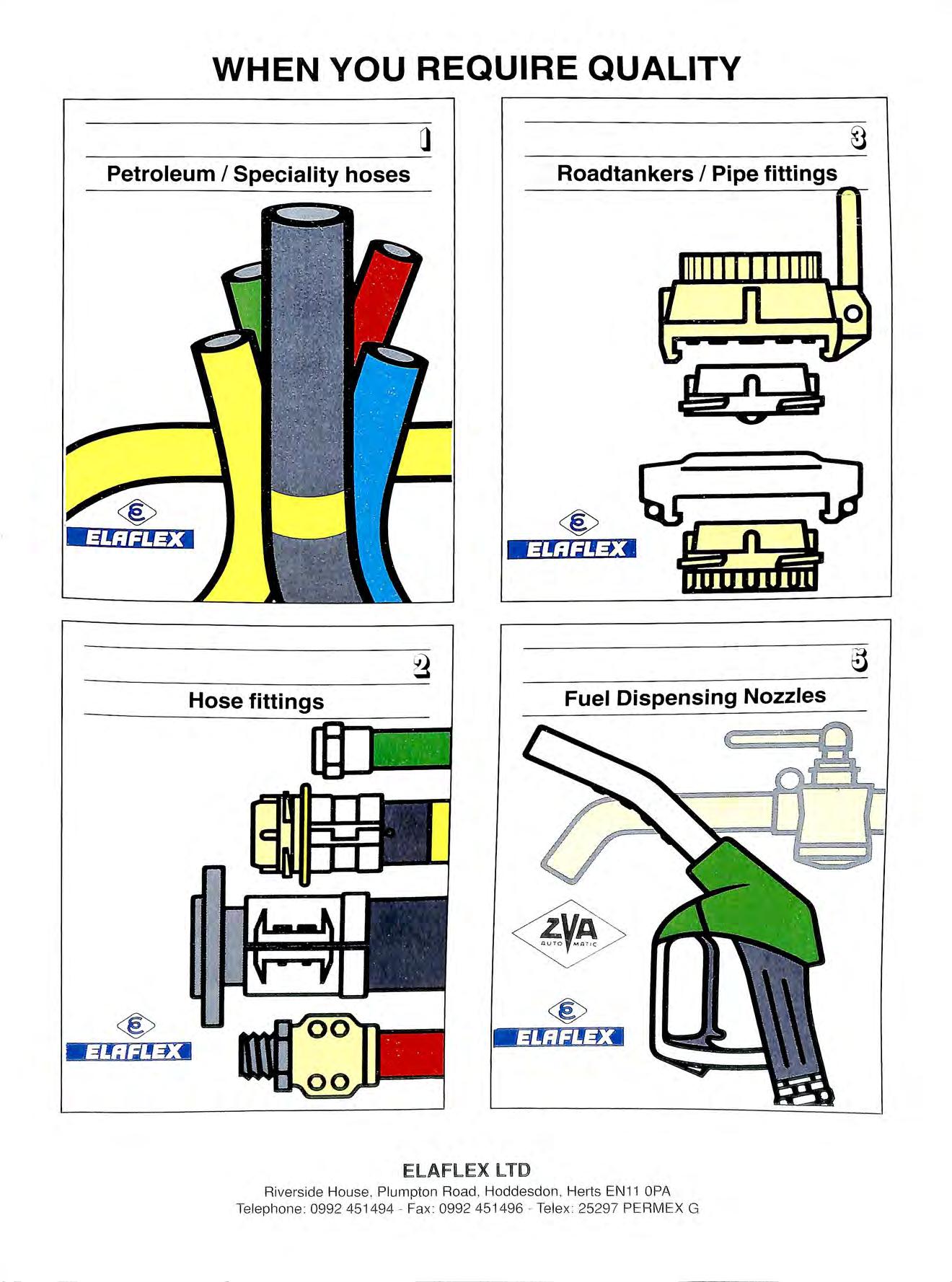

Th_e afternoon was in the domain of the equipment suppliers and presentations covering the relevant technical aspects of Stage 2 equipment were given by Ged Norris of Emco-Wheaton and Anton Martinuissen of Elaflex.

MEETING ON TRAINING

WILTSHIRE FIRE BRIGADE, DEVIZES 25 NOVEMBER 1993

final 1993 meeting covered the various aspects of trammg forecourt staff and contractors working on The first presentation was by John Harper of Fire Brigade who outlined the licensing authority viewpoint on the training requirements for those involved in forecourt operations. This was followed by John Fuller of the Petroleum Employers Skill Council who explained the of the National Vocational Qualification rammg system for forecourt staff and Tony Palmer of the Petroleum Training Federation who dealt with the actual process of training of staff and all of the practical difficulties that go with it.

The afternoon session opened on the trammg of and the speakers were John Smith of Lectronic who gave an insight into the way his company h addressed the training of its staff, and Terry Hedgeland w o dealt w'th h · · h 1 t e standard of competence of electncians w o work m the t I " pe ro 1orecourt envmmment.

quality of the presentations; thanks are therefore extended to all of those who have contributed to this success during 1993.

An active programme of events is being planned for 1994, commencing with the Branch AGM which is to be held in Swindon on 16 February 1994. The details of this and future meetings will be circulated to Branch members.

Any offers or suggestions for future venues and/or presentations will be gratefully received by the Branch Secretary for consideration by the Branch committee.

In addition to the main meetings, the Branch Executive Committee meets regularly, under the chairmanship of Mike Sewell, to carry out general management of the Branch including the arrangement of meetings and the exchange of information between the Branch and the APEA Council.

Members in the Branch area should be receiving details from the Branch Secretary of all events. If any member is concerned that details are not being received then the Branch Secretary, Jim Luke, should be contacted at the address shown on the lead page of the Bulletin. A number of members outside the normal Branch catchment area have requested to be placed on the mailing list so that they can have the opportunity of attending meetings, and the Branch Secretary will be happy to include other members names upon request.

YORKSHIRE AND HUMBERSIDE BRANCH MEETING

Twenty five members attended the autumn meeting of the above Branch at the Red Hart, Blyth, on the 6th Octob 1993. er

The National Chairman, Mr Mike Lugg was welcomed t our meeting an. address on his hopes for Association dunng his year m office.

The second presentation of was. given by Mr Chris Cooper of Services Limited on the implications for a business acqumng BS 5750.

After lunch Mike Lugg and John Dallimore represent' the Mechanical and Electrical Working Groups for revision of HS(G)41 addressed the meeting on the chan e proposed for the second edition of this booklet with the Health & Safety Executive. y

· · B · · d

ose With a tour of the Wiltshlfe Fife nga e Trammg Centre h' h · · · f . w 1c mcluded a practical demonstrat10n o dealing with flamm bi l' · · · h' h mbers . . a e 1qu1d f1res dunng w 1c me · to in the putting out of a 1<>ad tank.er fire. Appreciation for this interestmg demonstration is extended to Steve Norton of Wiltshire Fire Bngade.

The day cl · d ·

1994 AND BEYOND

'louthern Branch meetings continue to be well supported and lhe success of the meetings is due principally to the

On Wednesday 13th October 1993 a dozen branch had a very enjoyable visit to Wefco Group Limited at Gamsborough. The members were shown around the various work sites and informed as to the processes involved in the manufacture of a double skin tank.

Letters to Editor

Dear Editor

In the August issue of Bulletin 'Talking Point' accused HSE of "dithering" over issuing revised guidance on petrol filling stations.

There is a major problem with HS(G)41 the fact is that the current guidance is being used in some quarters as if it is prescribed legal standards. The standards asked for at both new and existing filling stations should be commensurate with the risk. Before proceeding further with revised guidance we must review the application of the current document and consider how adequate safety standards can be achieved whilst avoiding unnecessary costs to industry.

This is not dithering. It is facing up to the realities of problems caused by current interpretation and practices in the use of HS(G)41. As part of the process of overcoming these problems, I am talking with Petroleum Licensing Authorities and bodies such as APEA as we value their input to the development of pragmatic and flexible guidance relevant to all petrol filling stations.

Yours sincerely

DRANCOTTAM Head, Flammable Liquids Policy Section Safety Policy Division HSEEditors note

It is nice to know the HSE read the Bulletin! Thank you for your response, Association members will be able to listen to Dr Cottam who has kindly agreed to address the AGM at Dunstable on April 29th.

would be se-?Tegated from the PME system; only where the fillmg stat10n was part of a larger site fed from a PM_E would it be necessary to segregate the filling stauon earthmg system from the earthing system serving the remainder of the site.

May I also add a comment to Tony's remarks concemincr PME and Cathodic protection. 0

The HS(G)41 Working Group were also concerned at the possible harmful effects on intrinsically safe instrumentation of using impressed current cathodic protection for tartks and pipework. It was hoped to form a small working group, with manufacturers represented, in order to investicrate the 0 general question of compatibility between various types of instrumentation used at filling stations and in particular the effects of impressed current cathodic protection on I.S. systems.

Unfortunately, with the retirement of Neil Povall of HSE and the completion of the work on the revised edition of HS(G)41 the driving force was gone.

Perhaps this is an issue that Tony Tomlyn could pursue through one of the I.P. Committees.

Yours sincerely JOHN DALLIMORE

Dear Editor,

PME AT PETROL FILLING STATIONS

I read interest Tony Tomlyn's article on PME which appeared m The Bulletin, Volume i 1 N b _, , um e1 _,_

I would like to correct th . e reference m the fourth paragraph regardmg the statement in HS(G)41 that PME should not be used for earthing on p t 1 F. 11 S , , . e ro 1 mg tat10n hazardous area sites. Clause 174 of HS(G) 4 I , . . 11 d "Th fill. · <1ctucl Y rea s e 1 mg station area shottld be ti· t d t · ea e as a separa e system not be supplied by means (of a PME system)

The wording_ of this was chosen carefully by the Workmg .Group as 1t was considered to be totally 1mpract1cable to safely segregate only the hazardous areas of the filling station from the PME system.

It was intended that in practice most filling station sites

Dear Sir,

your recent edition of The Bulletin under heading "Ripping Yarn" showed a picture of a Texaco site at Luton I our company has recently completed the w1e1e redevelopment of the petrol filhng stat10n.

Mangan Bros. has in cl r 31 years durma which time we have p1obably 111 ustry ior e- • 00 · · 11· k d 0111ethina 111 the rea1on of 5 sites 111st<1 mg wor e on s e_ e- •. d 11 a a vast number of new and old tanks. an remov1 e-

Not once during this pe1iod has any claim been made -1 111p·my nor to my knowledge has there ever aaamst t 1e co ' _ . . _ . . e- ·c1ent on site The recotd ol M,mgan B1os. 111 been any acc1 · · 11 d t"ety nritters 1s second to none. hea t 1 an sa ' ·

Y t -·ibtitoi· i's riaht in assuming where any job is our con 1 · c- • -·· d tlttt by Mannan Bros. that proper prncedures bemg cau 1e cbeen adopted, and adhered to.

Yours faithfully for and on behalf nf Mangan Brothers Contractors Ltd

JAMES MANGAN DirectnrTHE BRANCH STRUCTURE AND THE NEW BRANCH REPRESENTATIVES COMMITTEE

By Mike Sewell, Chairman of the Branch Representatives Committee and Chairman of the Southern Branch.Branch Structure

As most members will know the APEA has a number of Branches spread around the country, although not all of Great Britain is presently covered by this Branch structure. These Branches are listed, together with the names and addresses of the Branch Secretaries, at the front of each edition of The Bulletin.

These Branches obtain their funds from the APEA on a capitation basis, ie so much per member per year. In this way members can meet on a local and informal basis to hear speakers on topics of special interest to members. A lively discussion can often be generated which is not usually the case at the two main APEA meetings held each year.

:he APEA is concerned by Council whose Officers and ordmary members are elected at the AGM in April each year. In addition to these 12 posts each Branch sends a representative to Council. These Representatives are elected by each Branch at its own AGM and serve on Council for a year at a time just like the other members of Council.

Branch Representatives Committee

In previous editions of The Bulletin you will have read of the changing structure of Council and the formation of a number of Committees reporting to Council. One such is the Branch Representatives Committee which compnses the seven Branch Representatives. In five cases the Branch Representative is the Branch Secretary, but in the case of the Southern Branch (myself) and the North Eastern Branch (Mike Silman) it is not.

The main purpose of this Committee is to formulate a con_imon view of all Branches for representation on the Policy and Finance Committee or Council and it is responsible for appointing a Representative to each of the other. Committees. In particular, it will be responsible for the members' voice is heard in the administration .APEA. It will also be responsible for coordinating the activities of the APEA as it moves into establishing a position in Europe. The Committee is likely to meet two or three t.1mes per year.

. The first meeting of the Branch Representatives Com · , mittee Was held on 20 January J993 and there have since been · f h · t ·cs of .1· a lll1 er two meetings. The malll opi · u1scuss1on hav h d how h . e een the new committee structure an t e ( ommittee c· h I · · f. h APEA and k an e p lu11her the o · t e eep lllemh· · · I' ers 111 onned of what is going on.

The first task of the Committee was to appoint to each of the other Committees as follows.

P1Jl 1n. and Finance Committee

I 1;11;1111µ <'ummittee

Seminar and AGM Committee

Committee

Publications and Advertising Committee

Council and the new Committee Structure

The main reason for the setting up of the new committee structure of Council was because the Council had become too large. With 19 members it had not always been possible to complete the business of Council at its meetings.

The Branch Representatives Committee has kept the new committee structure under review and, following its first meeting, it made some recommendations to the Policy and Finance Committee for reducing the size of Council. These were rejected by both the Policy Committee and at a subsequent meeting of Council. It was recognised, however, that there may well be a case for reducing the size of Council after, say, a year once the new committee structure has settled down. It is likely the Branch Representatives Committee will make some further recommendations to Council at its meeting in February 1994.

What the Committee is doing for you

In relation to keeping members more informed there were three things the Committee agreed could be done. Branches will let other Branches have details of their open meetings so that information concerning subject matter and speakers can be disseminated. Branches will publish notes of their meetings in The Bulletin in order to let the membership as a whole know what is going on in other parts of the country. Thirdly, Branches will seek more articles from members especially from local authorities, for publication in Bulletin. Details of incidents, prosecutions and local problems are always welcomed by the Editor.

The Branch Representatives Committee is charged with the fostering of the Branch structure, ie the setting up of new Branches. Three new Branches have been set up in the last three years, ie the North East, the North West and the Irish Branches, but there are still areas of Great Britain not catered for by a Branch. The two main areas are Wales and Scotland. It is hoped that Branches can be set up in these areas and I will be writing shortly to all members in Wales and Scotland to see what can be done in this respect.

In this way the whole of the British Isles will be covered but the APEA is not content with remaining isolated from rest of Europe. An initiative to set up a European Branch ha been on the go for some while and this has now been takes over by the Branch Representatives Committee. There already a number of ?n the mainland of Europe and there are also a number of Bnt1sh members working there.

Now that we are becoming more and more under the influence of the EC as far as legislation is concerned. it makes sense to have some form of organisation within the EC area. The problem is that in the other European countries there is the same_ rapport/cooperation between industry and the legislators/enforcers and, as far as the APEA knows. there is no such body elsewhere in Europe which matches the APEA. ft therefore makes sense to spread the APEA machine into Europe.

How you can help the APEA

Mike Sewell

Brian Taylor

The Branch Representatives are your means of contact with the administration of the APEA. If you have problems or wish to make suggestions for the hetter organisation of the APEA. please contact your Branch Representative. He/she can then take the matter to the Branch Representatives Committee or. where appropriate. direct to Council. Please make use of your Representatives. They are there to help you.

Philip Lusmore Technical Lindsay Lloyd Harry ReidTHE DESIGN OF OBSERVATION AND MONITORING WELLS

M. A. Park, DemeoBackground

Estimates of fuel leaks from underground tanks and pipelines vary considerably, however it is likely that at least 10% of the 85,000 or so tank installations in the U.K. could be leaking posing a major groundwater pollution risk. The Health and Safety Executive guideline bulletin (HSG4 l) makes reference to leak monitoring, but without the degree of detail required by the operator, installer, designer or petroleum officer. On most new sites in the UK, and many older sites, leak detection wells are now being installed but in the absence of published specifications the construction of these wells is often left to interpretation on site where due consideration is not always given to the design requirements. This can lead to the use of materials which are unsatisfactory as regards strength, corrosion resistance or longevity and which do not have a slotted or screen section designed to allow precise level monitoring and facilitate the recovery of a thin film of product. It is hoped that the following notes will take some of the mystery out of observation well design.

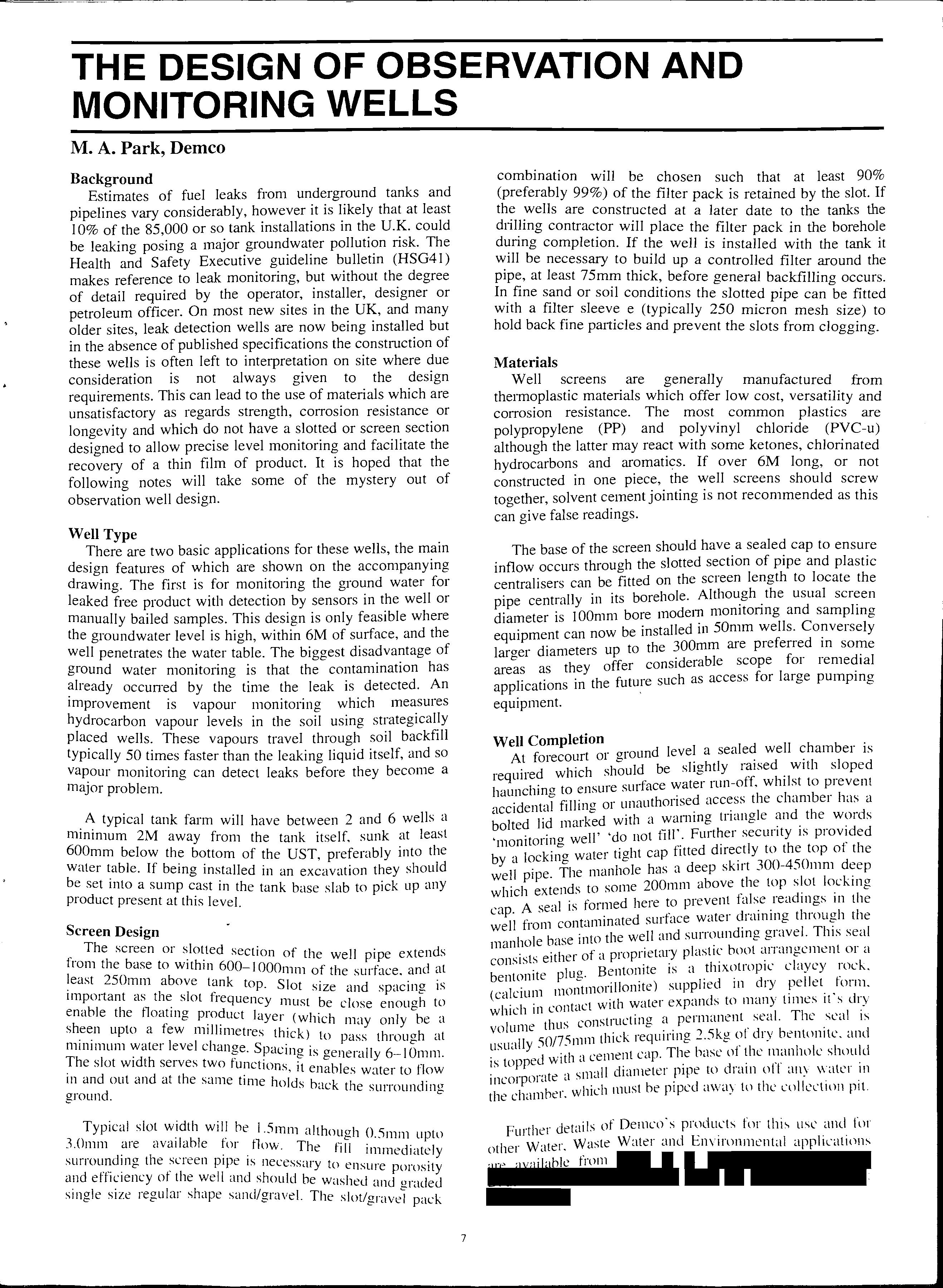

Well Type

There are two basic applications for these wells, the main design features of which are shown on the accompanying drawing. The first is for monitoring the ground water for leaked free product with detection by sensors in the well or manually bailed samples. This design is only feasible where the groundwater level is high, within 6M of surface, and the well penetrates the water table. The biggest disadvantage of ground water monitoring is that the contamination has already occun-ed by the time the leak is detected. An improvement is vapour monitoring which measures hydrocarbon vapour levels in the soil using strategically placed wells. These vapours travel through soil backfill typically 50 times faster than the leaking liquid itself, and so vapour monitoring can detect leaks before they become a major problem.

A typical tank farm will have between 2 and 6 wells a minimum 2M away from the tank itself, sunk at least 600mm below the bottom of the UST, preferably into the water table. If being installed in an excavation they should be set into a sump cast in the tank base slab to pick up any product present at this level.

Screen Design

.. The screen or section of the well pipe extends f10m the base to w1th111 600- I000111111 of the swface, and at least 250mm above tank top Slot . d . . · size an spacmg 1s unpo11ant as the slot frequency must b 1 h to enable the floating product layer eh c ose eno, ugb ·h 11c may on y e a s een upto a few milhmet1·es thi"ck) t h h t , · . o pass t roug a m1111mu111 wate1 level change Spacma · 11 6 10 Th . . . · . ,,, is genera y - mm. e slot width serves two functions 1·t e bi tl · , na es water to ow m and out and at the same time holds b·t k tl d" d L c 1e smToun mg groun .

Typical slot width will be I Smm alth<)li"h () c • •• < ••1111111 upto 3.0111111 are available for flow The t·1·11 · d" I . _ . . .. . . · 1111111e mte y sun the :ueen pipe 1s necessary to ensure porosity of the well and should be washed and graded smgle size regular shape sand/gravel. The slot/gravel pack

combination will be chosen such that at least 90% (preferably 99%) of the filter pack is retained by the slot. If the wells are constructed at a later date to the tanks the drilling contractor will place the filter pack in the borehole during completion. If the well is installed with the tank it will be necessary to build up a controlled filter around the pipe, at least 75mm thick, before general backfilling occurs. In_ fine sand or soil conditions the slotted pipe can be fitted with a filter sleeve e (typically 250 micron mesh size) to hold back fine particles and prevent the slots from clogging.

Materials

Well screens are generally manufactured from thermoplastic materials which offer low cost, versatility and corrosion resistance. The most common plastics are polypropylene (PP) and polyvinyl chloride (PVC-u) although the latter may react with some ketones, chlorinated hydrocarbons and aromatics. If over 6M long, or not constructed in one piece, the well screens should screw together, solvent cement jointing is not recommended as this can give false readings.

The base of the screen should have a sealed cap to ensure inflow occurs through the slotted section of pipe and plastic centralisers can be fitted on the screen length to locate the pipe centrally in its borehole. the usual diameter is 100111111 bore modem momtonng and samphng equipment can now be installed in 50mm wells. Co?versely larger diameters up to the 300111111 are preferred m so1!1e areas as they offer considerable scope for applications in the such as access for large pumpmg equipment.

Well Completion

.

At " ourt or around level a sealed well chamber is i01ec o d . h I d · d h"ch should be slightly raise wit s ope reqmre w 1 · · _ haunching to ensure smface wate1 nm-off, whilst to p1event accidental filling or unauthorise? the chamber has a b I d I 'd inarked with a wammg tnangle and the words O te I · · "d d • ·t · g well' 'do not fill' Fwther security 1s prov1 e mom orm · by a locking water tight cap fitted to the top of the II · The manhole has a deep skirt 300-450mm deep we pipe. I I k. h I t 1ds to some 200mm above the top s ot oc ·mg w 1c1 ex e1 . . . A I 1 ·s "ormed here to prevent false readmgs m the cap. sea l' well from contaminated surface water throu-?h the I I b ·e 111to the well and surroundmg gravel. This seal man 10 e as .·. , "tl er of a proprietary plastic boot all"angement or a consists e1 1 · I k b ·t pltw Bentonite is a th1xotropll' c ayey roe ·. ento111 e ,,,. · d II 1· .. 1 · 1ntmorillonite) supplied 111 ry pe et cmn. (ea c1um mt · · · d I · 1 · • 1tact with water expand.s to many tunes 1t s ry W UC 1 111 l 01

I th ,.0 nstructin<> a permanent. seal. The seal 1s vo ume us " · "' II co/7'imm thick requmng 2.5kg ol dry bento111te. and usua y -' " i with a cement cap. The base ot the manhole should 1s toppel . d . 11 .' ··ite .1 s111·tll diameter 11rne to ram o anv water 111 111corpo1, < • ' • t • the chamber. which must be piped away to the collect1011 pit.

Further details of De1m:o·s produl'ts for this use and for other Water. Waste Water and Environmental appliuttions are available from

TANKER DRIVER ENGULFED IN FLAMES WHEN LOADING GAS OIL

Roger Marris West Yorkshire Fire & Civil Defence AuthorityWhat started as a routine loading procedure for a tanker driver turned out to be a terrifying experience, leaving him in a state of shock with bums to his head and legs.

On the morning of 18 August 1993 at around 0645, the driver, employed by Floyd Oil, was alone in the Pontefract depot and had commenced to fill two of the five compartments of his road tanker with gas oil and derv. The previous days delivery was a full load of motor spirit. With the exception of compartments No.2 and No.3 the lids of the remaining three compartments were left unlocked but in the closed position.

After isolating the road tanker main switch and connecting the earthing system, the driver first positioned the flexible loading hose into compartment No.3 to fill with 1,300 litres of gas oil. It was the practice of the driver when loading at this particular depot to insert only about one metre of the loading hose into the compartment, close the lid on the hose and secure the hose in that position with his foot. The purpose of this practice was to prevent the flexible hose thrashing around in the compartment which according to the d1iver occurs if sufficient hose is passed through the opening to reach the bottom of the compartment.

Whilst compartment No.3 was filling, the driver carried out the same procedure to fill compartment No.2 with 5,000 litres of derv. Only this time he left the derv pump on a slow fill knowing that he would shortly have to attend the completed I ,300 litre fill of compartment No.3. At this point the driver was on top of the tanker astride the two compartments holding the hoses in position with his feet.

When the gas oil pump had closed down the d1iver opened the lid of the compartment and in one movement grabbed and pulled the end of the flexible hose to the lip of opening. At the same time he noticed a lazy blue flame No. 3 compartment. This immediately flashed up in his face and engulfed him in a ball of flame.

The driver was aware he had been burnt but did not real!se that his clothing (probably his trousers) were on fire. and in a state of shock, he evacuated the vehicle by moving onto the roof of the cab, sliding his body the edge and dropping to the floor. He cannot recall. ut presumes he suspended himself from the cab by gripping gutter before droppino to the ground. His nonnal egress rom th 0 th fi e tanker by the rear bulk head ladder was impeded by e ire.

his'i::.,n °_n the felt a sensation on e·' ieahsmg his clothmo was on hre rolled on the ground to extinguish the flame;

recovered from the initial shock it was apparent to the dnver that the diesel pump was still running (albeit

slowly) thereby displacing petrol vapour from No.2 compartment. The fire appeared to be still burning on the roof of the tanker.

down the pump at the emergency switch the dnver faced the dilemma of either tackling what appeared to be a small fire or telephoning for the Fire Service. His immediate response was to tackle the fire. He did this by climbing the cat ladder at the rear of the tariker where he found a slow burning vapour fire in the valance area of compartment No.3. Using a 9kg dry powder extinguisher he advanced with a sweeping action until he noticed a sudden burst of flame over the partly filled No.2 compartment (it was estimated that the 5,000 litre compartment held approximately 800 litres of derv) at the same time the extinguisher had fully discharged it's contents. Believing himself to be in danger the driver withdrew and telephoned for the Fire Service.

When the Fire Service responded some four minutes later they found the fire to be out on arrival. It is not known whether the fire had burnt itself out by consuming all the available petrol vapour or whether the driver had in fact been successful with the extinguisher.

In view of the unusual nature of the incident, the investi oation into the cause of the fire was undertaken by the e Health and Safety Executive.

The weather protected loading gantry is of a_ design without a platfo1m for the driver to work from. With _only Class III petroleum products being loaded, the associated electrical fittings ai·e not to Zones One or Two standards.

All aspects of the unloading fixed_ sources of ionition were taken into cons1derat10n dunng the · 0t· t·011 In the end the HSE concluded that the most mves 1ga 1 . · d probable cause was a static discharge from the bo y igniting the residual motor spirit vapours: The _dnver_ was · · Jati"na boots and gloves at the tune of the foe. wearing msu e "

Although in this pm·ticular the_ probable tt ibuted to the failure to use ant1-stat1c or conductive was a I t· d" I d f. t ear the possibility of accidental 1g111t10n o tsp ace oow. ., , r petrol vapour cannot be where l oat mg takes place at gant1ies not designed and mamtamed to Class I product standard.

Fortunately on this occasion the fire. possibly due to the prompt and courageous action of the driver. was confined to the burning of displaced vapours.

The HSE are now actively looking into this incident with a view to establishing an agreed standard to he accepted by all parties within the industry after consultation with thl' appropriate trade associations.

DRILLING LIVE PETROL TANKS

By D. WheatleyIn May 1991 you were introduced through 'Bulletin' to an hydraulically driven system for the extraction of internal fill pipes. The introduction of this method revolutionised the industry as increasing legislation and recommendations have placed greater burdens of responsibility on the forecourt operators For those readers who may have missed this article, let me quickly re-cap and then show how this system for 'LIVE ' tank access has been fmther developed.

Since overfill prevention has become mandatory in an increasing number of authorities, a system was developed to remove 4" aluminium fill pipes in order to facilitate the retro-fitting of mechanical overfill prevention valves. The aim was to complete this modification causing no inconvenience to customers and no loss of revenue to the services station. Prior to the introduction of this system, the usual method of fill pipe removal created great upheaval on the forecourt which in many cases included breaking up forecourt surfaces to give sufficient working space for such work to be undertaken.

The BORTEC rig was developed on the lines of a demountable trailer which, when erected directly over the access chamber, was equipped with an isolating system which was lowered into the fill pipe so that the cutting process would be completed in a vapour controlled environment. The motive power is supplied by a diesel hydraulic pump which incorporates a flame arrestor and is positioned approximately forty feet away from the working arena. The cutter, guided by the isolating unit, bores the hexagon nipple under the ' T' piece to allow the fill pipe to be removed upwards and be replaced by a new fill pipe which is fitted with·an overfill prevention valve

Further developments from this basic principle now embrace the wider issues of 'LIVE' tank access as the demand for electronic 0 P D.s, wet stock gauges, vapour recovery systems, tank testing equipment and additional suction lines increases. For the inclusion of these ancilliary devices it is necessary in many cases to create threaded entries into the tank lid and the process is as follows.

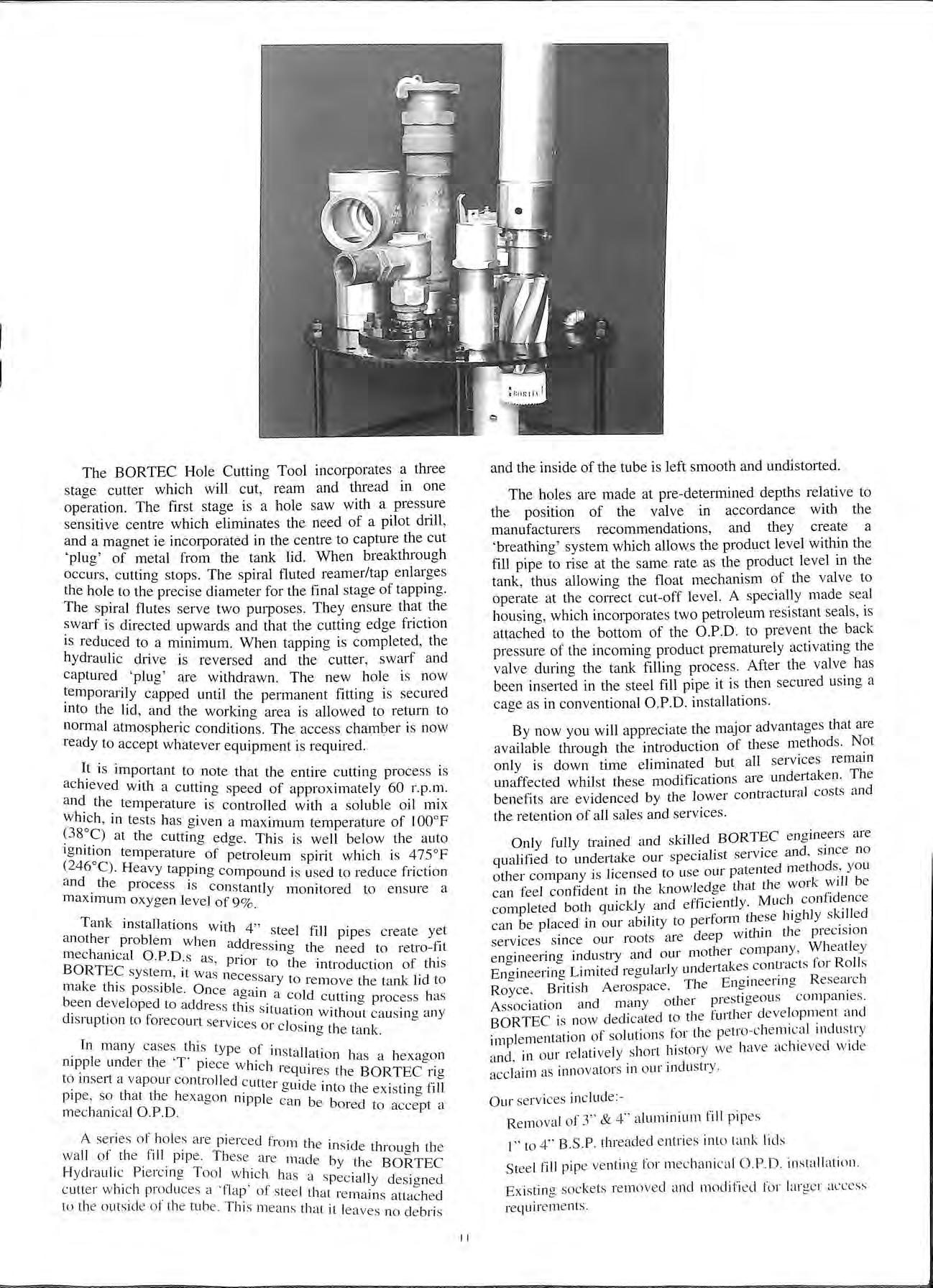

The BORTEC hole cutting system is a two-man operation for cuttmg and tappmg threaded holes directly into 'live ' product tank lids without closing the tank or affectina its use during the modification process . b

Our initial survey ensures the suitability of the tank lid for the introduction of additional holes and that such work can be conducted in a totally safe environment. Before such work can commence to make holes of l" to 4" B.S.P , we first ensure that there is sufficient space for our equipment to function conectly allow ing ample room for the erection of ba.iTiers and cones to prevent public intrnsion, and that th tank hd is a minimum of 3/s" thick i.n .order to approximately 4 1h threads 111 the hd. Thi s is sufficient t achieve a ga s- tight seal. for the incoming equipment. assured, the proce ss 1s undertaken acknowledging the stringent safety regulations which must be addre ssed.

The sam e BORTEC rig is utili sed as with the other system but the cutter assembly and isolation unit s di.ffe. 1 as thi s process addre sses the need to create new hole s dire tl into the lids of ' live ' product tank s c Y

Ha vin g cl ea.ned th e acce ss chamber, the BORTEC rig is accurate ly positioned and levelled as required. Before the c utin g equipm ent is low ered , an adju stable shroud is pos iti o ned at th e cutting a.i·ea and nitrog en is introdu ced in o rd er to create an oxyge n fre e environm ent. Thi s s hroud incorp orates four hoses two for th e injection of nitrog en and . th e oth ers for coolant/lubri cant and an ox yge n mo 111tonn g ga uge The shro ud co mpl etely e nvel opes th e area to be c ut and th e oxyge n leve l is monitored throu g hout th e c uttin g pro cess. T wo ind epend e nt nitroge n bo ttl es are used to ens ure co mpl ete safety O ne bottl e is used to pro v id e a co nsta nt tri c kl e of nitroge n whil st th e o th e r g ives a hi ghpress ure purge to c lear away th e swarf fr o m th e c utter and s urrou ndin g area and a lso q ui ckl y red ress the in e rt en viro nm e nt sho ul d a flu ct uati o n occ ur.

The BORTEC Hole Cutting Tool incorporates a three stage cutter which will cut, re am and thread in one The first stage is a hole saw with a pressure sens1t1ve centre which eliminates the need of a pilot drill , a, magnet ie incorporated in the centre to capture the cut plug of metal from the tank lid . When breakthrough occurs, cuttmg stops. The spiral fluted reamer/tap enlarge s _to the preci se diameter for the final stage of tapping he flute s serve two purposes. They en sure that the is directed upwards and that the cuttin o edoe friction IS red d . . "' "' h . a m1111mum. When tapping is completed, the ydiauhc d11ve 1s reversed and the cutter, swaif and captured . ' plug ' are withdrawn. The new hole is now c a pped until the permanent fittino is secured the lid, and the working area is allowed 0 to return to noimal atmospheri d . · d c con 1t10ns . The acces s chambe r is now rea y to accept whatever equipment is required.

It is impo1tant to t h · a h no e t at the entire cuttmg proce ss is < c 1eved with a tf and th cu mg speed of appro xim a te ly 60 r.p.m. wh· h e _ tempernture is controlled with a so luble oil mix IC , lI1 te sts has oi · (3 8oC) ."' ven a m a ximum temperature of J00 °F ionition att the edge This is well be low th e auto "' empe1 atu re of pet. 1 (246 °C ) H . 1 0 eum spmt which 1s 475 °F . e a vy ta ppma com d . a nd the "' poun is used to redu ce friction proce ss 1s con st 1 ma xim ant Y mo mtored to en sure a um oxygen le vel of 9 %

T a nk in stall ati o ns with 4 ,, ano ther proble m wl steel fill pip es c reate ye t 1e n addre rne ch a nj caJ O P D. s as, rior ss mg th.e nee d .to re t!·o-fi t BORTEC sy stem , it was : th e mtrodu c tton of thi s make thi s poss ibl e o e ces_saiy to re mov e th e ta nk lid to b . nee a oa m a Id ee n de veloped to addres s th"': .. . co c uttin g pro cess ha s d · J S Sllu at · 1srupt1 o n to fo reco urt se. . ion without ca us in o a ny I vices o r c lo s in g th e ta nk "'

In ma ny cases thi s ty pe f nippl e und e r th e 'T' p iece h 0 lm s tall a ti o n has a he xa ao n w ic l requ. 1 "' . to mse rt a vapo ur co ntroll ed n es t 1e BORTEC n a c utte r ouicl · o pip e, so th at the hexaoo n nip 1 "' e int o th e ex 1stm g till I o p e can be b cl mec i a mca l O .P .D. o re to acce pt a

A se ri es of ho les are pie rc ed f ro m the in · 1 h wa l1 of the fill pi pe T hese 31 s ic e t rn ug h th e H . . . e mad e bv th BO RTEC ydra ul! c P 1e rc mg Too l whi c h has a s J e c utt e r whi c h prod uces a fl ap ' of st 1 h pec iaJl y des ig ne d . e e t at re nn m s tt l l to the o uts ide o f the tube T hi s , tJ < a ac i ec me a ns 1a t It lea ves no de bri s

and the inside of the tube is left smooth and undi stmted.

The holes are made at pre-determined depths relative to the position of the valve in accordance with the manufacturers recommendations, and they create a ' breathing' system which allows the product level within the fill pipe to rise at the same rate as the product level in the tank , thus allowing the flo at mechanism of the valve to operate at the correct cut-off level. A specially made seal housing, which incorporates two petroleum res istant seal s , is attached to the bottom of the O.P.D. to prevent the back pressure of the incoming product prematurely activating th e valve during the tank filling proce ss After th e valve has been in serted in the steel fill pipe it is then secured using a ca ge as in convention a l O.P.D. in stallation s .

By now you will appreci ate the m ajor advant age s th at are available through the introduction of thes e method s Not onl y is down time elimina ted but all servic es remain unaffe cted whil st these modification s are undertake n Th e be nefit s are e viden c ed by th e lower contrac tural cos ts a nd the retention of all sale s and servi ces

Only fully train ed and skill ed BORTEC eng ine ers me qualified to undertake our spe ciali st se rvi ce and , sin ce no other c o mp any is li cen sed to use o ur pate nted me thod s, you c an fe el co nfid e nt in th e kn o wl edge th a t tl1 e work will be completed bo th qui ckly a nd effi cie ntl y Mu ch confid e nce ca n be pl ace d in our ability to per fo rm th ese hi g hl y skill e d se rvi ce s sin ce our roots are dee p withln the prec is io n e ng in eerin g indu stry a nd our mother co mp a ny, Wh ea tl ey E ngin ee rin g Limited reg ul arl y und e rtakes co ntrac ts fo r Ro ll s Ro yce, Briti sh Ae ro space , Th e En g in ee rin g Researc h Assoc iatio n and ma ny o th e r pres ti geo us com pa ni es . BORTEC is now dedica ted to th e f urthe r de ve lo pm e nt a nd impl e me ntati o n of so lu tio ns fo r tJ1 e pe tro c he rni ca l indu stry and , in o ur re lative ly sho rt hi sto ry we hav e ac hi ev e d w id e acc laim as inn ovato rs in o ur indu stry

Our ser vices inclu de:-

Re mova l of 3'" & 4" a luminiu m fill p ipes

L" to 4" B. S. P. thr eaded e ntr ies int o tank li d s S tee l fill pip e ve nting fo r me c ha ni c a l 0 .P D in s ta ll ati o n

Ex istin g socke ts re mo ve d a nd mod ifi e d fo r lar ge r acc ess req uire me nt s .

FOR ENERGY, MR. NOEL TREACY, T.D., TO THE ASSOCIATION FOR PETROLEUM AND EXPLOSIVES ADMINISTRATION.

SPA HOTEL, LUCAN THURSDAY, 1NOVEMBER1993

Ladies and Gentlemen,

Thank you for inviting me to address your Seminar on the occasion of the inaugural Annual General Meeting of the Irish Branch of your Association.

First and foremost I would like to congratulate you on the formation of an Irish Branch of the Association for Petroleum and Explosives Administration. Your Association's concern with recognising the hazards associated with the Retail Oil Industry, is very welcome and the objectives of minimising the risks and achieving cost effective Environmental Protection, are very worthwhile. Environmental hazards are of concern to us all and are increasingly the focus of Public scrutiny and rightly so. Whatever the demands of economic progress, sight must not be lost of the value of the Environment as a National Asset, which contributes to the quality of life in general and yields indirect benefits particularly in relation to Tourism.

Free competition is generally regarded as the best mechanism to ensure downward pressure on prices, a high level of service and in general a good deal for the Consumer. I fully support the promotion of Competition in the downstream Oil Industry. However, there is no reason why an industry cannot, within a competitive framework, cooperate in areas of common interest. The delivery of Petroleum Products to final Consumers, operates under two major influences the demands of Consumers for wide availability and efficient delivery of products and the regulatory framework, which is necessary to ensure, that adequate standards are in place for the safety and protection the Environment. It is a process which directly invol:'es 011 Companies, Equipment Manufacturers and Supphers and the Regulatory Authorities and it is approp1iate that these different interests, make a concerted effort to minimise hazards, in the first instance and to develop systems to respond quickly and effectively, where hazards do occur.

I am confident that your Association will provide a forum, which will act as a catalyst, towards the Technological changes which will not only contribute to the achievement of cost effective solutions to, Environmental threats, but to the arrival at those solutions in the most efficient way possible. Indeed, I note from your Programme, that you have already this morning examined a wide range of relevant issues including pipework systems and tankage, responses to oil emissions and legislative requirements. I am sure that these discussions have been fruitful and through highlighting issues of common concern will provide a sound basis for the development of your Association in Ireland.

The administration of legislation in relation to dangerous -;uhstances is primarily a matter for my colleague the Minister for Enterprise and Employment.

l am -.;ure that he will welcome any views which your Associal ion wish to put forward regarding the regulatory re4u1re111ents for the storage and transport of Petroleum Prnduus.

l\o., lhe Mimster with responsihility for Energy matters.

my primary concern in relation to Retail_ Oil is the high level of petrol and auto diesel pnces m Indeed Ireland has the undesirable distinction of havmg the highest prices for motor fuels in the European The Fair Trade Commission, which conducted an enqmry m 1990, into the supply and distribution of fuels, attributed the high prices in Ireland to high distribution costs and low throughput, at Retail Outlets. Some particularly striking points, which emerge from the Report, include the fact, that we have four times as many Retail Outlets per 1,000 cars, as our European Partners and a much lower proportion of Self Service Sales.

A process of rationalisation and development of the Industry, is therefore inevitable. This process will gain increased impetus through competitive forces, through investment needs to meet emerging environmental requirements and through the 1999 deadline, for compliance with the 1988 Regulations, under the Da.ngerous Substances Act. All of these factors, will combine to undermine the economics of marginal Retail Outlets and, indeed, the 1999 deadline, will demand the closure of Roadside Petrol Pumps and of Forecourts with space limitations. A smaller number of outlets with higher throughput, enhanced environmental requirements and greater emphasis on cost control, will demand the development of more efficient fuel storage, delivery and dispensing techniques.

With regard to environmental requirements, controls concerning constraints on emissions to the atmosphere of petroleum vapours, are in the process of preparation at EC level. The initial requirements will relate to the installation of closed loop vapour systems, between Supply Terminals and Service Stations. Further measures are planned to capture vapour en:iissions'. during Vehicle Refuelling Operations, on Service Station Forecourts. The manner in which these proposals will develop and how they will impact on retailing techniques, remains to be determined.

A further area, in which I see a role for your Organisation results from the move towards Unleaded Petrol. There are two grades of Unleaded Petrol Super 98 and the cheaper Euro 95. The consumption of Euro Unleaded Petrol, which is adequate for virtually all Cars, accounts for only 12% of the Irish Market, compared with 50% in the UK. The Automobile Association recently ran an information campaign, promoting the use of Euro Unleaded Petrol.

The campaign revealed, that only one in four Petrol Stations in Dublin and only one in five elsewhere, actually stock the cheaper grade of Petrol. I am confident that the increasing Consumer awareness, of the acceptability of the Euro grade Petrol, will bring pressure to bear on a much greater proportion of Retail Outlets, to stock both grades of Unleaded Petrol, as well as Leaded. The question of how Smaller Stations will respond to this need. will have to be addressed.

In conclusion. I would like once again. to congratulate you on the formation of this Association and wish you every success in your future endeavours.

UNDERGROUND LEAKS IN PRESSURIZED PIPING SYSTEMS AS A RESULT OF HYDRAULIC LINE SHOCK

Daniel M. SingletonThe Environmental Protection Agency has established that the majority of the underground product leaks result from product loss at the piping systems rather than the tanks. Leaks from pressurized piping systems are more of an ecological concern than those from suction systems.

Pressurized piping systems became common to retail fueling sites in the I 950' s. These systems with remote pumps were brought about due to the increase in vapor pressures of the gasolines available at that time. The higher vapor pressures made suction pumping systems different to use especially in warmer climatic areas and areas of higher elevations. Other factors also influenced the need for remote pumping systems such as larger diameter tanks and long piping runs.

. A pressurized piping system utilized a remote pump mstalled in the tank or in the immediate area above the tank. The fuel is then pushed from the tank to the dispensing units.

Numerous articles have been written with reference to underground storage tank leaks related to piping system losses. These product releases were concluded as losses resulting from loose swing joints and fittings, corrosion, poor workmanship and the materials used in the manufacturing of some of these piping system components. Little if any data has been published with reference to HYDRAULIC LINE SHOCK which can cause or contribute to the failure of any of the system components.

Hydraulic shock, which is also referred to as water hammer, surge pressure, line spikes, shock load or waves, is produced by the abrupt change in direction of a liquid traveling through a piping system. A moving column of liquid has momentum or inertia that is proportional to its weight and velocity. When flow is stopped suddenly as by a quick closing valve within the system, this momentum is converted to a shock load. The longer the system piping and the hiaher the velocity, the greater the shock load will be.

b

The shock wave stm·t as soon as the valve begins to within the system. It travels upstream at m excess of 4,000 ft./sec. The kinetic energy of this movmg fluid is chanaed to pressure energy within the shock wave and will continue to cycle until all of its energy is The American Petroleum Institute states that the osc11latmg peak pressure of the shock wave when in milliseconds can rise to many times the system s nomrnl operatin,g pressure. These shock loads can be of sufficient force to hurst pipe and break piping system components.

Engineering data published by system component manufacturers state that to minimize hydraulic shock, only valves that will not allow instantaneous closure be used. If a valve can be closed by the end of the first cycle of the shock wave, the maximum change in liquid velocity is realized and the system experiences this as maximum shock pressure. If the valve is not closed by the end of the first cycle, the change in velocity is inversely proportional to the closing time and the actual shock pressure developed will also be inversely proportional to the closing time.

Technical publications dealing with fluid mechanics and hydraulics are available to provide formulas and equations for the calculation of pressure surges as a result of a single valve closure in a simple piping system. Sophisticated computer programs that detail fluid transients of hydraulic shock within a multiple branch piping facility are also available. An example of a multiple branch piping system might be one of today's retail marketing facilities.

When designing these type piping systems, prudent engineering principals would preclude the of any instantaneous closing valve that cause hydraulic shock. Unfortunately the automatic nozzle valve currently at most retail refueling facilities is an instantaneous closmg device. Hydraulic shock is most prevalent in the post-pay format of marketing.

The patent for the automatic nozzle valve was applied for in 1959 which was before the self service came of age. The nozzle was designed to trip closed automatically when the fluid filing the container reached a predetermined level. This allowed the attendants to release their manual handling of the nozzle and fulfill other functions such as checking the vehicle's vital fluid levels and tire air pressure. Today with the advent of self service, the customer experiences instantaneous closure of the nozzle when the predetermined fluid level is reached causing a shock wave. This instantaneous closure also happens with each click of the nozzle as an attempt by the customer to topoff their tank or reach an even monetary amount on the computer register. Each successive trip of the nozzle magnifies the surge pressures.

Good engineering design would also eliminate the use or a system that did not have working pressure ratmg compallble with the maximum operating pressure of the system. In addition, the cyclical life of each system component should be examined.

Where justification of the return on investment is a requirement, life expectancies of the facilities is a parameter for consideration. Since 30 year warranties are available for pipe and tanks, 30 years is accepted by many as the useful life of the piping system. With the petroleum product sold at these sites typically generating the most gross revenues, monthly throughput, the gallonage, must also be estimated.

An example site might be one of very low volume, say 20,000 gallons of one particular product per month. Establishing 30 years as the useful life of the facility, some 7 ,200 ,000 gallons would be sold through this one product system If this volume were dispensed in average increments of 10 gallons per sale , and the customer only topped off their tanks once during the transaction, then the cycles experienced by the piping systems components would be 1,440,000 cycles.

By calculating the peak pressure, which is the shock pressure plus the operating pressure, it is recommended that under no conditions should the peak pressure exceed the cyclic pressure rating of the system components. A manufacturer of piping components indicates if peak pressures occur more than 10,000 cycles during the design life and are greater than allowable, the manufacturer should be consulted.

Recently a client was experiencing an extremely high rate of leaks from the dispenser ' s spin-on filters. At the facility selected to determine the amount of hydraulic shock in the pipmg system, the submerged remote pump was located approximately 150 ft. from the furthest dispenser and all of the dispensers were fitted with standard automatic nozzles. filter was removed from a dispenser and was replaced with a pressure gauge with a deadman pointer. The pump was started, without any product being dispensed the systems pres sure of 28psi wa s recorded. The pump was stopped , where the relief valve was reduced and held the system pre ss ure at 16psi.

With the pump restarted and one nozzle full open, flow was recorded at 18gpm The nozzle closed automatically and the surge pressure recorded was l 48psi, with subsequent closures of the nozzle 215psi was recorded. With two nozzles on the same system flowing fully open, the system pressure was recorded as 20psi and subsequent closures of each nozzle allowed the pressure gauge to read 290psi. Adding the operating pressure of 20psi to the surge wave pressure of 290psi, the peak pressure in the system manifold was 31 Ops i If four nozzles could have been operating at one time during this test, the peak pressure would have exceeded 400psi. Flow rate is directly proportional to velocity and also directly proportional to the hydraulic shock. As flow rate increases as more are used simultaneously within the system, so will the shock load.

Air or vapor in the piping system magnify hydraulic shock pressure, therefore 116 cubic inches of liquid were removed from the test system to induce air into the manifold. The system was energized, with one nozzle flowing full open, automatic closure of the valve a shock pressure of 290psi was noted. The resilience of this air pocket caused a difference of 75psi in the system.

Other instances of hydraulic line shock can be documented such as a prominent component manufacturer marketing safe-break hose couplings This manufacturer experienced premature separation of the device and investigated problem at the of the major oil company that had the complamt. With a single automatic flowmg full open and normal closure in conjunction with repeated mstantaneous closures in order to top-off th line shock wave was recorded at 280psi. The peak load in excess of 300psi can be calculated.

As long as automatic nozzle valves that are of the mstantaneous closure type are used, hydraulic line sh k ·11 h oc w1 contmue to en ance piping system leaks.

Respectfully submitted,

POLLUTION PREVENTION IN FORECOURT REFURBISHMENT

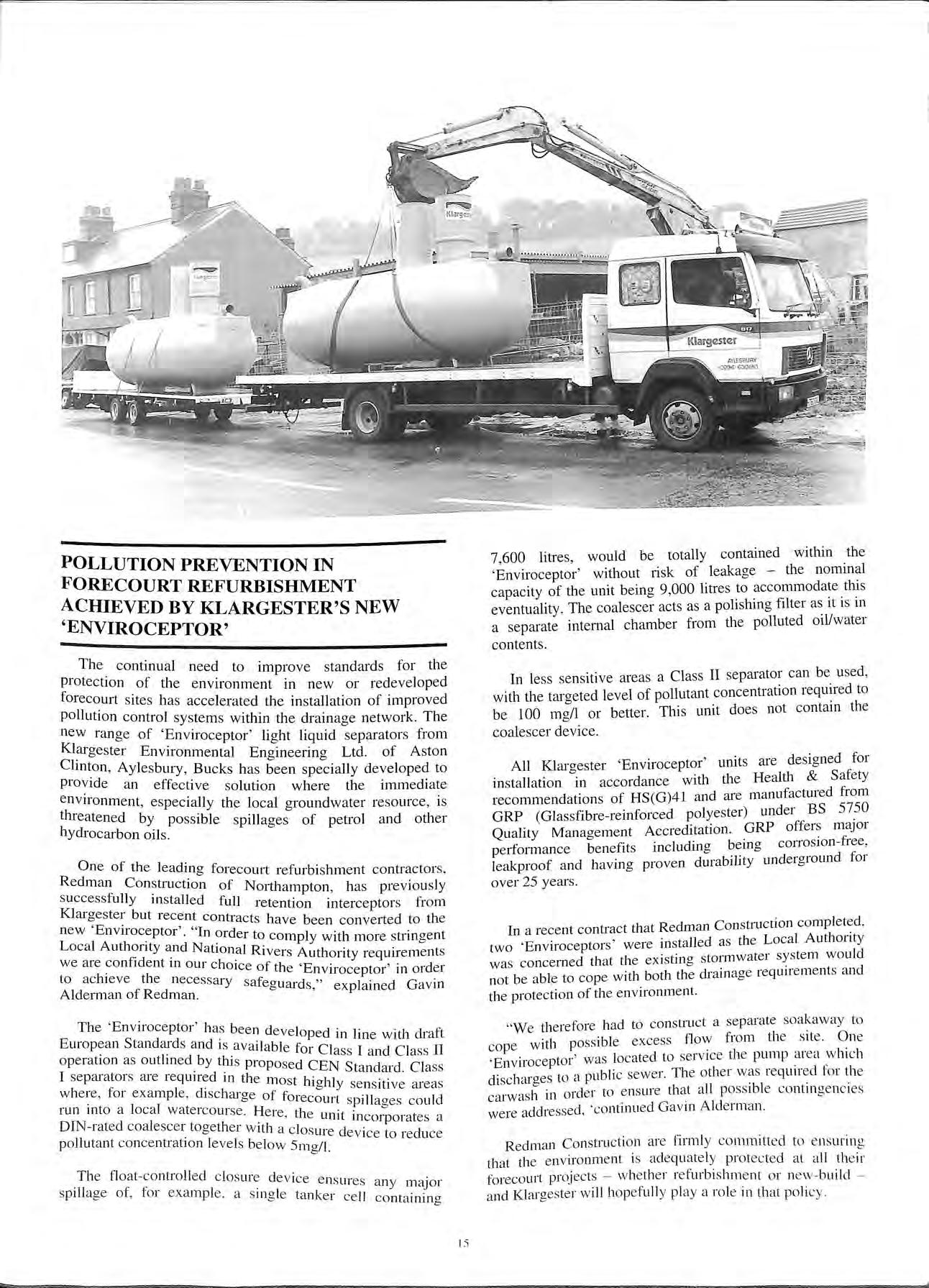

ACHIEVED BY KLARGESTER'S NEW 'ENVIROCEPTOR'The continual need to improve standards for the protection of the environment in new or redeveloped sites has accelerated the installation of improved pollution control systems within the drainage network. The new range of 'Enviroceptor ' light liquid separators from Environmental Enginee1ing Ltd. of Aston Aylesbury, Bucks has been specially developed to provide an effective solution where the immediate especially the local groundwater resource, is hreatened by possible spillages of petrol and other hydrocarbon oils.

One of the leading forecourt refurbishment contractors, Redman Construction of Northampton has previously successfully installed f 11 .' u retention mterceptors from Klargester but recent c h , onuacts ave been converted to the new Env1roceptor' "In d · · · or er to comply with more stnnaent Local Authonty and Natio J R. · · ""' _ na 1vers Authonty requirements we are confident m our choice of tl 'E , . d _ ie nv1roceptor m or e1 to achieve the necessary safeaL ard ,, 1 . d G . Alderman of Redman. ""' ' s, exp arne avm

The 'Enviroceptor ' has been develo d . 1. . d f E · s . d d pe m me with ra t tan ar s and IS _avail a ble for Class I and Class n opeiat10n as outlined by this proposed CEN S · I · t · · d · tandaid. Class sepai a 01 s ai e 1eqmre 111 the most hi ah! _ where , for example, di sc hai·ae ""' y sens1t1ve aieas · 0 of foiecourt spillaaes co uld run mto a local waterco urse Here th · · ""' · DIN d l ' e un1t mcorporate s a -rate coa escer together with a clos L . d < 11 e evice to reduc e polluta nt concentration leve ls below Smg!I.

The float-controlled c los ure dev ice e ii s · ure s any major sp ill age of, for example, a s in g le tanker ce ll conta ining

7 ,600 litres, would be totally contained within the 'Enviroceptor' without 1isk of leakage the nominal capacity of the unit being 9,000 litres to accommodate this eventuality. The coalescer acts as a polishing filter as it is in a separate internal chamber from the polluted oil/water contents.

In less sensitive areas a Class II separator can be used, with the taraeted le vel of pollutant concentration required to be 100 m;/l or better. This unit does not contain the coalescer device.

All Klargester 'Enviroceptor' units are designed for installation in accordance with the Health & Safety reconm1endations of HS(G)41 and are manufactured from GRP (Glassfibre-reinforced polyester) under BS 5750 Quality Management Accreditation. GRP major performance benefits including being conos10n-free, leakproof and having proven durability underground for over 25 yeai·s.

In a recent contract that Redmai1 Construction completed , two 'Enviroceptors' were installed as the Local Authority was concerned that the e xisting stormwater system would not be ab le to cope with both the drainag e requireme nt s and the protection of the e nvironment.

"We th erefore had to construct a sepai·ate soak.away to cope with possible excess flow from the site One ' Enviroceptor ' was lo ca ted to service the pump area wh ic h di sc hai·aes to a public sewer. The other was requ1red tor th e in order to e nsure that all po ss ibl e co ntin ge nc ies were addressed , ' co ntinu ed Gavin Alderman

Red man Construction are firml y com mitted to ensur in g that th e e nvironm e nt is adeq uate ly prot ected at all their forecourt proj ec ts wh e th er refurb is hm e nt or ne w-b uild a nd K laTgester will hop efu ll y play a role in that policy

MAKING A SPLASH IN EUROPE ....

ENTEC (POLLUTION CONTROL) LIMITED HAYING SECURED AGREMENT CERTIFICATION FOR THEIR RANGE OF SEPTIC TANKS AND CESSPOOLS, TOGETHER WITH BS.5750 QUALITY ASSURANCE, HAVE TAKEN THE PLUNGE AND SUBMITTED THEIR PETROL INTERCEPTOR TO GERMAN DIN ASSESSMENT, RETURNING WITH WHAT ARE CLAIMED TO BE THE BEST RESULTS TO DATE

In advance of Common European (CEN) Standards for Light Oil Separators, ENTEC (POLLUTION CONTROL) LIMITED has successfully tested a range of Petrol Interceptors to the process requirements of DIN 1999 at LGA WURZBURG, the approved DIN testing house in Germany.

DIN 1999 forms the basis of the process performance of the Proposed European Standards· (PrEN 858-1) for Light Oil Separators. The specific requirements being that, under test conditions, Class 2 Interceptors (where discharge is to foul sewer), should achieve less than 100 mg/litre, and Class 1 (where discharge is to surface water), less than 5 mg/litre total oil content.

For testing purposes ENTEC used an 11,000 litre FORECOURT INTERCEPTOR fitted with a closure device to a_chieve Class 2, and with coalescing filter to achieve Class I discharge.

The ENTEC FORECOURT INTERCEPTOR was successfully tested to the requirements of DIN 1999 at flow rates of up to 25 litres per second, and dosed consistently the test period with oil (SG 0.85) at a concentration of 5000 mg/litre as specified in DIN 1999.

Analysis by solvent extraction of the resulting discharge from the Class 2 ENTEC Interceptor by LGA confirmed an

oil content of 87 mg/litre, ensuring compliance with the DIN requirement.

With the addition of a coalescing filter, a Class 1 discharge of 4.3 mg/litre was achieved at a flow fo 25 litres per second with 0.9 mg/litre being subsequently achieved at 20 litres per second. LGA commented this latter result was the best result to date at this flow rate of any European Interceptor tested by the DIN testing house.

A typical forecourt incidentally, is likely to generate flows of less than half the above flow rates used for testing the ENTEC Interceptor.

Both a requirement of DIN 1999 and the PrEN 858-1 document, the ENTEC closure device was successfully tested by LGA and is claimed to be the first such device to be assessed by a DIN testing house.

To ensure adequate warning is given of oil levels within Forecourt Interceptors, ENTEC already markets an alarm to approved BASEEFA standards which meets all relevant European Standards.

Class 1 and 2 Petrol/Oil Interceptors are already mandatory on new forecourt applications within the London area, and many Petrol Companies are adoptina such standards throughout the United Kingdom in anticip:tion of future legislation.

ENTEC (POLLUTION CONTROL) LIMITED can offer a range of .both Full Retention and Bypass Interceptors , the 11,000 litre Forecourt Interceptor descnbed m the text, together with Closure Device Coalescing Filter and Alarm to ensure F t' ' orecour Developers mstall products in accordance with foithcomina European Standards. 0

All ENTEC products are manufactures to BS.5750 Quality Assurance Certification.

HSE MEETING

Roger MarisThe West Yorkshire Fire Service Headquarters at Bradford, was the venue, on 13 October 1993, of an informal meeting between Dr Andrew Cottam of the Health and Safety Executive and Officers representing 12 Petroleum Licensing Authorities from the North of England.

Dr Cottam is the head of Flammable Liquids Policy Section and has recently taken over responsibility for the revision of HS(G)41.

The meeting was arranged as a "getting to know you session" with a view to promoting a better understanding of the respective roles of the HSE and PLA's.

After explaining how the various branches of the HSE function, Dr Cottam clarified the current position of the revision of HS(G)41 and dispelled some of the rumours that are in circulation regarding it's delay in publication.

There was then a general open discussion, for the benefit of Dr Cottam, where Officers aired their views of the current problems encountered by PLA's in administering the (Consolidation) Act 1928 as far as petrol filling stations are concerned.

Amongst the items discussed were:-

• The adequacy of liaison with the HSE (as if to emphasise this point it was apparent during the course of discussions that only a small number of the Officers present were aware of the consultative document in circulation concerning the proposed revision of the 1929 Petroleum Spirit (Motor Vehicles etc) Regulations and the HEPOL (F) form for reporting contraventions of the 1992 Road Tanker Regulations).

• The difficulties created by continued absence of an up to date code of practice for the construction and maintenance of a petrol filling station.

• Precision tank and pipework testing.

• The performance of traditional and innovative tank and pipework systems.

The debate raised some worthwhile ideas which deserve to be put forward to a w1·d d" · er au 1ence for comment. With this m mmd I have appended be! h ht, h . h · · · 1 ow my own t oug s w 1c , m prmc1p e, accord with the co f · · f . nsensus o op1mon o the PLA Officers attendmg.

I would welcome any comments sup ·t· h · . . . · pm 1ve or ot erw1se as to the need and feas1b1hty of introduci·n · h f h I g e1t er o t e two proposa s.

Should it transpire there is general aor · f f o eement m avour o one or both of the schemes perhaps ·t Id b . . . ' · 1 wou then e appropnate to raise as an 1tem(s) for disct · h AGM of the APEA. · tssion at t e next

Comments can be made directly to If " II · dd · myse at the 10 owmg a ress or 1f the editor agrees thro h bi" · in the Bulletin. · ' ug pu 1cat10n

PETROL FILLING STATIONS CENTRAL INFORMATION SERVICE TO COLLATE THE PERFORMANCE OF BOTH TRADIDONAL SINGLE SKIN STEEL TANKS AND PIPEWORK AND THE INNOVATIVE TANK AND PIPEWORK SYSTEMS

The performance and failings of traditional single skin steel tanks and associated galvanised pipework is somewhat anecdotal.

Numerous leaks have occurred over the years and there is a general concensus of opinion that steel pipework is more susceptible to leaks than steel tanks and defective pipework joints result in a greater number of leaks than pipework penetration due to corrosion.

Considering that a corrodible storage and transfer system for a highly flammable and explosive product is buried underground (out of sight out of mind), it is perhaps remiss of PLA's and the industry not to closely monitor the performance or known weaknesses of such installations.

This, sadly, has been the case and no doubt the absence of any national or local data on the number and frequency of leaks has contributed to the continued use of a system prone to failure through corrosion and/or bad workmanship.

With the introduction of double skin steel tanks, GRP tanks and many new types of 'plastic' pipework, it is important, even imperative, that any failings for whatever reason in these new vessels and materials are closely monitored.

In this way it will be possible to build up a picture of any possible inherent matenal or constructional/method of installation defects.

There would, of course, need to be a central co-ordinating body and data base to receive and collate the information submitted by PLA's. The information would only to be brief details of the leaking system and could be submitted on a profornrn on something like a quarterly basis.

Information needed to pinpoint or establish any worrying or unacceptable trends on a particular system would be:-

i) Construction of vessel in the case of tanks.

ii) Type of material (trade name) in the case of pipework.

iii) Date of installation.

iv) Use of pipework suction/pressure/vent or off-set fill.

v) Reasons for failure (if joint in pipework type of joint).

vi) How the leak was detected.

vii) Grade of product stored/transferred.

viii) Failure of any detection equipment to operate. if installed.

ix) Approximate quantity of product lost.

In addition to monitoring the pe1t'o11nance of innovative systems this scheme. were it .adopted would either reinforce or dispel the doubts that exist m some quarters as to the suitability of the traditional single skin steel tank and pipework systems.

PETROL FILLING STATIONS AND OTHER

LICENSED PREMISES UTILISING UNDERGROUND STORAGE TANKS PRECISION TANK TESTING SYSTEMS CO-ORDINATING BODY

There is general concern both within the industry and amonast Petroleum Officers of the present procedure where it is ;ecessary for manufacturers/franchisees of equipment such as precision testing systems to approach each individual PLA for acceptance of their equipment.