The •

VOLUME 34 No" 1

Journal of the Association for Petroleum and Explosives Administration

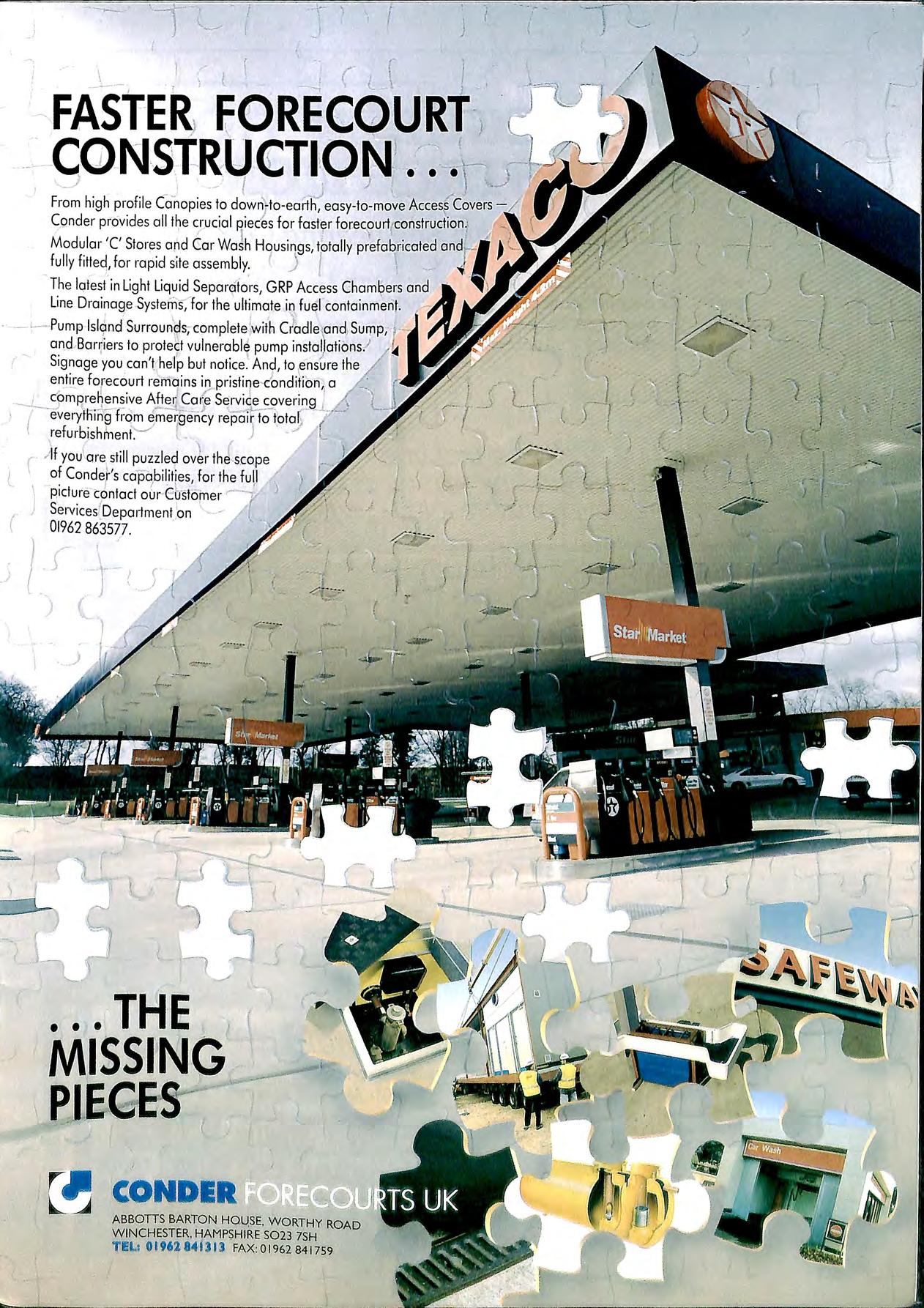

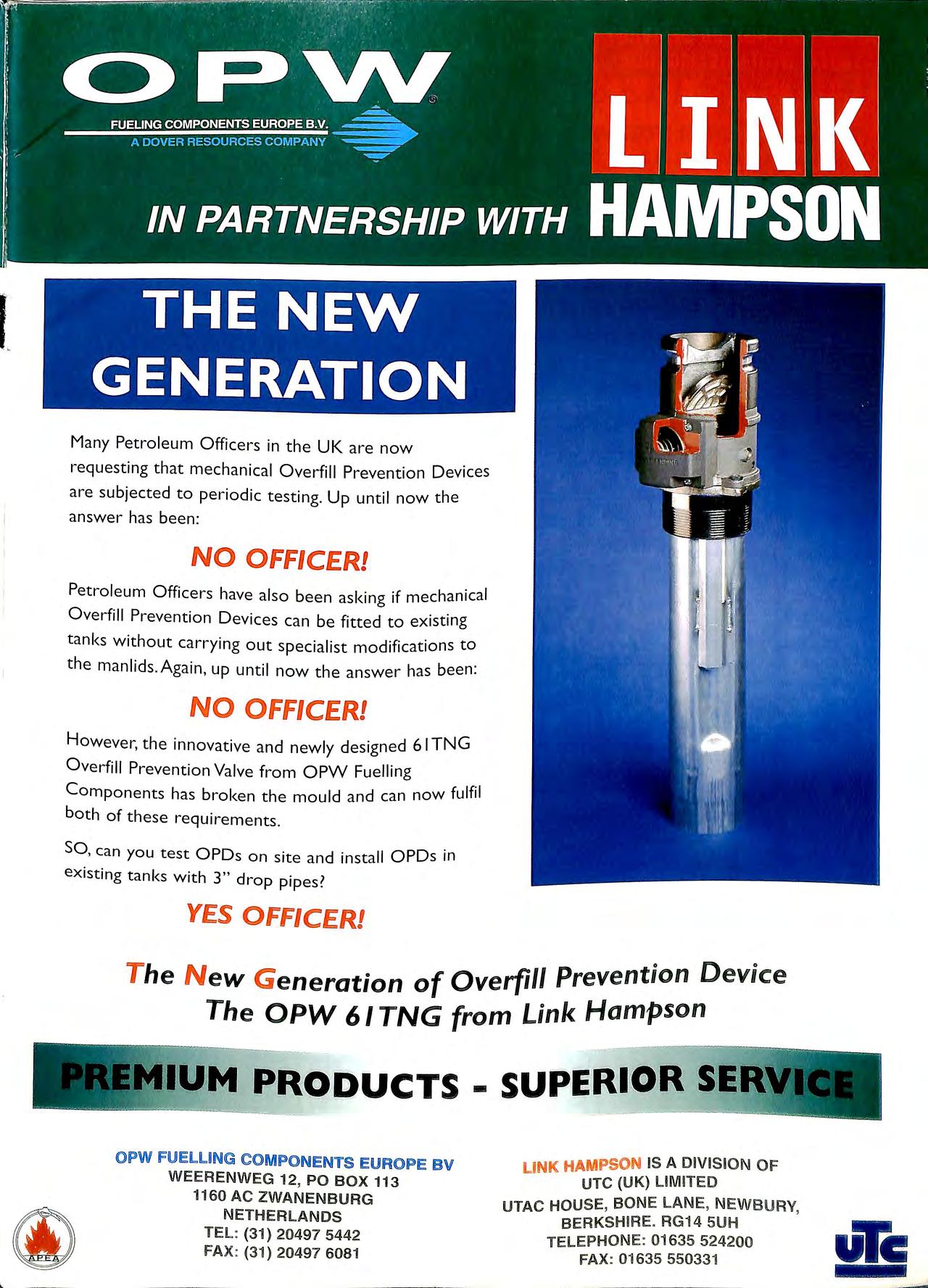

In order to provide the best possible service to their customers , OPW Fueling Components have established a cent ral warehousing facility for the United Kingdom.

This is located at Newbury and is operated by Link Hampson UK Distributo r for OPW Fueling Components.

We can deliver to any location in the UK - OVERNIGHT MIUM PRODUCTS • SUPE RIOR SERVI I I {' OIPW IFll.DlElLUNG COMIPOfNENlf'S IElUlROIPIE BV WEERENWEG 12, PO BOX 113 1160 AC ZWANENBllJRG NETHERLANDS TEL : (31) 20497 5442 FAX : (31) 20497 6081 UNK HAMPSON IS A DIVISION OF UTC (UK) LI MITED UTAC HOUSE, BO NE LANE, NEW B URY, BERKSHIRE RG14 5UH TELEPHONE: 01635 524200 FAX : 01635 550331 uTc

f.

NO OFFICER !

NO OFFICER!

the innovative and newly designed

TNG

Valve

OPW

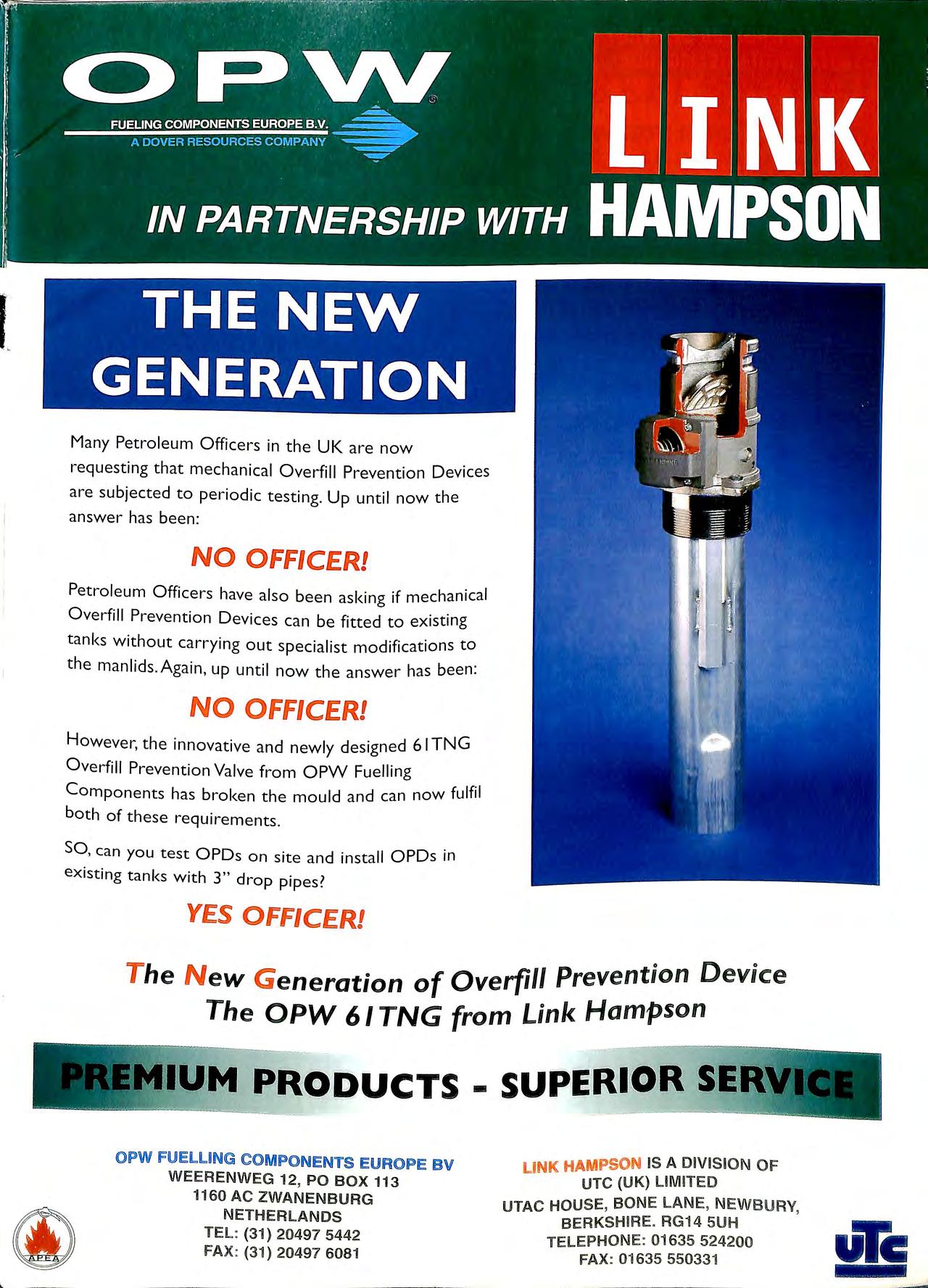

SO, can you test OPDs on site and install OPDs in existing tanks with 3" drop pipes? YES OFF/C R! T he N ew G eneration of Overfill Pre v e nti on Device The OPW 61 TNG from Link Hamps on .. --:--· I \ :'<i ·- ·- __jIUM PRODUCTS - SUPERIOR SE , , I/) I • OPW FlUJElllNG COMPONENTS EUROPE BV WEERENWEG 12, PO BOX 11 3 1160 AC ZWANENBURG NETHERLANDS TEL : (31) 20497 5442 FAX : (31) 20497 6081 ' LINK HAMPSON IS A DIVISION OF UTC (UK) LIMITED UTAC HOUSE, BONE LANE, NEWBURY, BERKSHIRE RG14 SUH TELEPHONE : 01635 524200 FAX : 01635 550331 uTc

Many Petroleum Officers in the UK are now requesting that mechanical Overfill Prevention Devices are subjected to periodic testing. Up until now the answer has been:

Petroleum Officers have also been asking if mechanical Overfill Prevention Devices can be fitted to existing tanks without carrying out specialist modifications to the man lids. Again, up until now the answer has been :

However,

61

Overfill Prevention

from

Fuelling Components has broken the mould and can now fulfil both of these requirements.

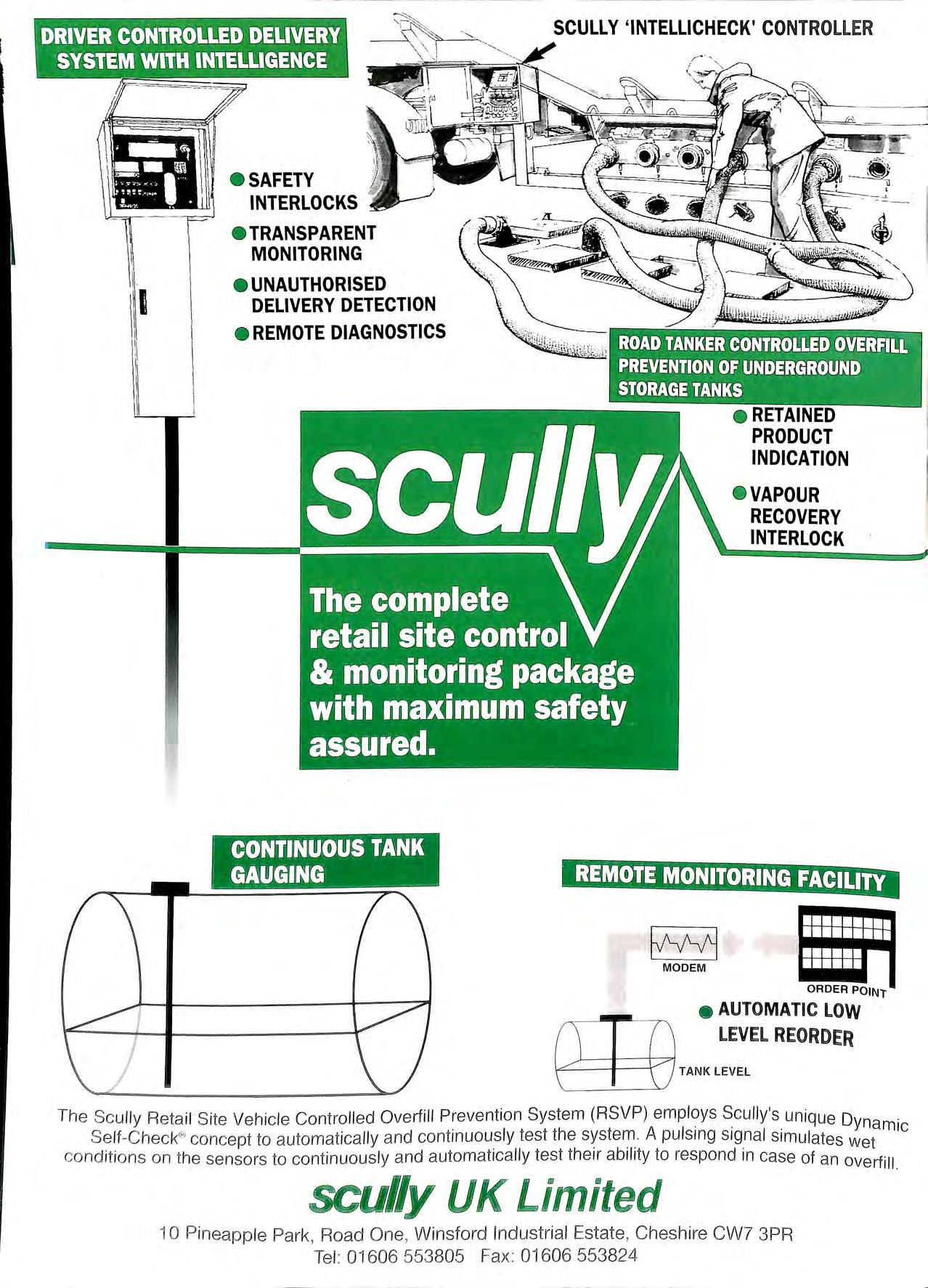

i 1\• l!i I \II i 1 l 'l • SAFETY INTERLOCKS , e TRANSPARENT MONITORING e UNAUTHORISED DELIVERY DETECTION e REMOTE DIAGNOSTICS CONTINUOUS TANK GAUGING _ _ __ SCULLY 'INTELLICHECK' CONTROLLER e RETAINED PRODUCT INDICATION • VAPOUR RECOVERY INTERLOCK Id a 1'it•) iJ1'i(•]:1iL•]d1:tCJ i;X3 i!i•I ORDER POINT • AUTOMATIC LOW LEVEL REORDER TANK LEVEL The Sc ully Retai l Site Vehicle Contro ll ed Overfill Prevention System (RSVP) emp loys Scu lly's un ique Dyn Se lf Check®concept to automaticall y and continuou.sly test the system: A pulsing sig nal simulates we:m ic cond 1t1o ns on the sensors to continuously and automatically test their ab 1l1ty to respond in case of an overfill . scu//y UK Limited 10 Pineapple Park, Road One, Winsford Industrial Estate, Cheshire CW7 3PR Tel : 01606 5538 05 Fax : 01606 553824

We've proved that our techniques can remediate soils during a Scottish winter in as little as one month. bio-logic REMEDIATION WORKS LTD. FestivalllvsinessCentre, lDH Tel: Ol413140021Fax: Ol413140026 NATIONWIDE FORECOURT DRAINAGE & INTERCEPTOR SERVICE Cleaning & Removal of Silt & Debris from Interceptors Catch Pits Tank Tops Bucket Traps Surface Drainage Channels Car & Jet Wash Pits Water for tank testing plus treatment & disposal of the contaminated water. Forecourt Division : 125 Pershore Road Evesham WR11 6LZ if EVESHAM (01386) 47190 Petrol, Oil & Solvent Tanks Cleaned to OCTEL and Petroleum Industry Specifications. Tank Cleaning Division : Grange Road , Batley, Southampton. S030 2GD ill BOTLEV (01489) 783462 WASTE l'A' DJ MANAGEMENT 0 Head Office : Grange Road , Batley, Southampton , 8030 2GD Tel (01489) 782232/6 Fax: (01489) 789821 CLEANSING SERVICE GROUP LTD TUBEFLOW LTD SPECIALISTS IN PETROL PUMP, TANK AND PIPEWORK INSTALLATIONS AND ASSOCIATED WORKS APPROVED CONTRACTORS TO THE PETROLEUM INDUSTRY AND LOCAL GOVERNMENT AUTHORITIES 29 TEMPLE STREET LONDON E2 6QQ Tel: 071-739 9538 Fax: 071-729 6108 MEMBER A.P.E.A. D DC BUILDERS LTD FOR SERVICE QUALITY & RELIABILITY WE OFFER A COMPLETE SERVICE ON MAINTENANCE AND IMPROVEMENT WORKS TO THE PETROLEUM RETAIL MARKET D D C BUILDERS LTD 7 ST CLAIR CLOSE CLAYHALL ILFORD ESSEX IGS OPA Teh 08lc550 5216 Faxg 081 c550 6095

SHORT COURSES

• Electrical requirements for Petrol rilling Stations (New HSE code HS(G) 41) ONS

• 16th EDITION IEE WIRING REGULA TI

• Electricity at Work Regulations 1989

• Insp ection and Testing of Electrical Installations l'rcsc11tcr: TERRY HEDGELAND BA. FIEIE. MIOA Original author of the highly IEE 15th Edition 2-day short course Phone: 0737 553328

PETROL FILLING STATIONS: e CERTIFICATES OF ELECTRICAL INSPECTION & TESTING to HS(G) 41 & LACOTS requirements EMERGENCY LIGHTING : e COMPLETION CERTIFICATES based on model in BS 5266: Part 1: 1988

PERIODIC INSPECTION AND TEST CERTIFICATES

CIVIL ENGINEERING CONTRACTORS TO THE OIL COMPANIES FOR 24 YEARS C.R. RICHARDSON (CONTRACTORS) LTD DESIGN & BUILD COMPLETE REDEVELOPMENTS MAINTENANCE & REPAIRS Anerley Court, Half Moon Lane, Tel: 01732 838608 Hildenborough, KentTN11 9HU Fax: 01732 838064 TANKSAFE LIMITED 4rh Floor, Bell Courr H ouse, I I Blom fi eld St. London, EC2M 7AY Te l: 07 1 628 5695 or 071 628 485 1, Mobile: 0850 842828, Fax: 07 1 374 0408 UK Applicator of water based, variable dens!ty, hard foams for injection and all void filling requirements. NEUTRATANK H ydroca rb on absorb in g fill er fo r tanks and pipelines •!• Light weight and hi gh load bear in g •!• Environm entally sou nd •!• Fas t clean appli ca tion RG22 fo r pe rm anent rank aba nd onm en t RG8 c · I rm neutrali sat io n 1or safe r rank excavano n ors 1on re THERMOTANK. RC.30 the modern backfi ll materia l for new rank in sta llations •!• H igh superimposed load capab ili ry •:• High in sulation fo cror for low producr shrinkagt •!• H igh rigidiry and co hes ion •!• Reta in s hydro carbons Fnr fio-ther information and a quota ti on , ca ll Charles Hudfeston

arrangements to meet your requirements at competitive rates

TRAINING IN-COMPANY

Flexible

based on

FIRE

e INSTALLATION &

based on model

1988 e

based on

£9 .87 [

+VAT per pad e PRACTICAL GUIDE TO ELECTRICAL INSTALLATION TESTING £16.95 Prices include p&p Order with cheque payable to: UNEEDA PUBLICATIONS, 5 HIGHWOLD, CHIPSTEAD, SURREY CR5 3LG IF YOU WISH TO PURCHASE EXTRA COPIES OF THE BULLETIN OR YEAR BOOK , PLEASE CONTACT : BARBAR.A JACKETTS ON 01473 828539 ALSO AVAILABLE ARE APEA TIES (I N BURGUNDY OR BLUE) AND THE FOLLOWIN G APEA PUBLICATIONS : MODEL CONSTRUCTION REQUIREMENT S FOR PETROLEUM SPIRIT CAN + DRUM STORES AND CODE OF PRACTI C'E FOR GROUND FLOO R, MULTT ST OREY " UNDER GROUN D CAR PAR KS

e

model in BS 5266: Part l: 1988

ALARM SYSTEMS:

COMMISSIONING CERTIFICATES

in BS 5839: Part l:

CERTIFICATES OF TESTING

model in BS 5839: Part 1: 1988

£8.40]

A . J. Bayliss (Stourport) Ltd U n tn at s o FM 27512 Petroleum Engineers Petrol, Fuel Oil and Electrical Installations 11/12 HODFAR ROAD, SANDY LANE INDUSTRIAL ESTATE, STOURPORT-ON-SEVERN DY13 9QB TELEPHONE: 01299 824541-2-3 FAX: 01299 827638 SPECIALISING IN ALL ASPECTS OF FORECOURT PETROLEUM INSTALLATIONS AND SERVICING FULLY ACCREDITED TO BS EN ISO 9002: 1994 LZ BS 5750 Part 1/ISO 900 1 Approved • ti t-1 ;1 a=1 • ! =t1., ... =I• a-1 We do not compromise on quality where environmental issues are concerned. Internal pipework and overflow prevention valves can be supplied, fitted and tested at our works t o ensure the integrity of the system. Station Road Works Hadleigh , Suffolk, I P7 SPN tel : 01473 823061 fax : 01473 824 1 64

Emco Wheaton Retail Europe Enterprise Road , Westwood Industrial Estate, Margate, Kent, CT9 4JR \I ' Telephone 01843 221555 Fax: 01843 295444

Wheaton Gold Valve?

market

Valve

DIPSTICK

FAST SERVICE. The

to respond

our

EMCD

Emco

That will do nicely. The Emco Wheaton A1100 OPS is fast becoming the

leader Overfill Prevention

VERSATILE. Can be installed in any position within a full 360 degree rotation, without any risk of fouling suction pipes etc simply the best valve all round! DURABLE. Floats are internal and protected by a metal shroud which prevents damage during installation or inspection. FAIL-SAFE. In the event of the valve not resetting, it will close during the next fill, preventing a dangerous and costly overfill - other valves can fail in the open position. VAPOUR TIGHT. Emco Wheaton have not had to introduce a bottom seal recently, because the A 1100 valve has always been fitted with one.

FRIENDLY• Dipstick can be used whether tank is full or empty.

A1100 is assembled and tested in the UK. Therefore we are able

quickly to demands from

two UK stockists For further information on the Emco Wheaton range of products for Service Stations, please contact Rob Laird at our Margate Office.

'-

N as h & Pa rtn e rs ha ve bee n wo r k in g in partn e rs hip w ith th e Re ta il Pe trol e um indu s tr y fo r a lm os t thir ty ye a rs, pl a nnin g and d eve lo p in g re tail ins ta ll a t io ns from a s t rai g ht for wa rd p ump c h a n ge to Europ e ' s la rges t fi llin g s ta ti o n Eve ry s te p of t he way, fr o m fe as ibil ity s tud ies a nd s ur vey in g, pro ject m a n age m e nt a nd commi ss io nin g, w e ta ke ca re o f e ve ry d e ta il. W he t h e r a m a jor o il co mpan y or a n indi v idu a l d e a le r, o ur c li e nts a re a ss ur e d nf th e Na s h co mmitm e n t to q u a lity a n d ad h e re n ce to BS5750, bac ke d b y up to th e minute tec hn o logy, inn o v atio n a n d ex p e r tise From a g re e n fie ld s ite to a full y o pe ra tio n a l in s tal lat io n, Nas h & Pa i·tne r s d e li ve r neat ive ye t hi g hl y p rac t ica l s o lu tio ns + A RC HI T ECTS * SU RVEYO RS + TOWN l' LANNE 16 + J''R OJJ::C I MANACF: W:i • l' JmP u ny ( ON'-lU l I AN rs

GCS G c s a rage onsult ancy ervices Ltd Cert No. FM 23290 NationallnspectionCouncillOf 89c:tricallnstallalionConl:rading • •111: E1c APPROVED CONTRACTOR UNIT 10 MERTHYR TYDFIL INDUSTRIAL PARK PENTREBACH MERTHYR TYDFIL MID GLAMORGAN CF48 4DR TELEPHONE (0443) 692008 FAX (0443) 692159 FUEL PUMPS AND TANKS FUEL MONITORING AND METERING EQUIPMENT PROJECT MANAGERS/ENGINEERS We are delighted to inform you that the British Standards Institution has approved our Quality Management System and awarded us BS5750 Part 2 Creditation. ·-·-··-·-·-· We shall continue to assess and inspect our Quality System to ensure that we meet the rigorous demands of our industry 1973 2 1 YEARS OF SERVICE TO THE PETRO LEUM INDUSTRY 1994

ED WARDS (Tank Removal) Ltd THE COMPLETE FUEL TANK SPECIALISTS PETROL · OIL · CHEMICAL · STORAGE TANKS ABOVE OR BELOW GROUND CLEANED·GASFREED·REMOVED SERVICES INCLUDE: • Gas Free Certification • Tan k Rem oval - Disposal • Cold Cu tting • H o t Cutting • Bulk Fuel Up lifting • Slur ry Fi lli ng • Ga r age Demolition • Battle Plate Cutting • Basement Tan k Removal • Foam lnerting ALL WORK IN S TRICT ACCORDANCE WITH CURRENT HSE AND PETROLEUM REGULATIONS We specialise in the removal by cold cutting of solid filled tanks an d disposal of these tanks from site . EDWARDS (Tallllk Removall) LTD li28- 130 CH1URCH §TREET9 CROYDON9 SURREY9 CRO lRF 08 1 6869775 0816801890

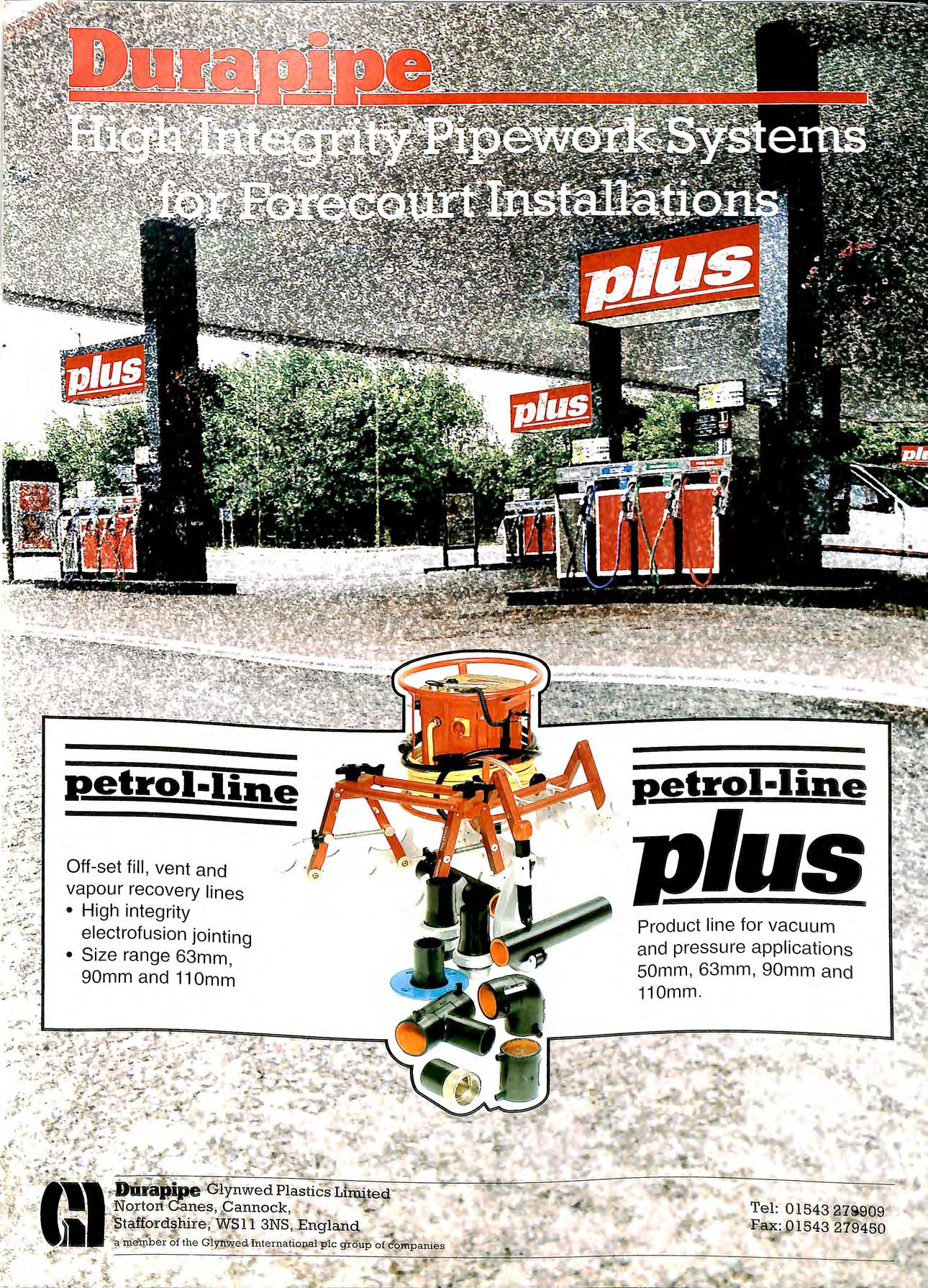

PETROLaLINE: Por ofifset-fill, vent and recovery. Robust and easy to use, this petrol and additiv® resistant system 1s .based on Durapip@'s patented electrofus1on jointing method.

NEW fr om and

from TOTAL C ONTAINMENT INC.

fuel

1 d . e 1very

ary

. ..

suction

.

. . .

ENVIROFLEX: For

d

Total secon

containment for

pressure s t

or

ys ems, or Monotlex for direct bunal suction systems Ea t .

· sy o install and ma1nta1n, compatible with all f I d dd'. ues an a 1t1ves currently on the market. UL listed.

by Du1apipe SUPPLIED BY THE OFFICIAL DISTRIBUTORS - for further information on either, or both, of these products call 2 FORECOU RT EQUIPMENT SPECIALISTS PURFLEET COMMERCIALS LIMITED 520 London Road West Thurrock Essex RM16 1BE. Tel: (0708) 863931 Fax: (0708) 868226

I \ \ I \ ' -J ° F J ) • I SL f" r f1 _I f 'I\. l ' ----_ -_:=- -- p ·. - R·--. 0- T; ··- E _·-c ·--T - -1- '\ - - - : - =- :. ; _:. ' :: c = THE ·--. _, ENVIRONMENT For furth e r information please ring:Petro I/end Petro Vend {Europe) Limited 7 6 6 Leeds RoadK Newton Bara Wakefield WF1 2QF Tel : (01924) 291919 Fax : (01924) 376511

Retrol·line Off-set fill , vent and vapour recovery lines • High integrity electrofusion jointing • Size range 63mm ' 90mm and 110mm eetrol·line .,,_lus Product line for vacuum and pressure applications somm , 63mm , 90mm and 110mm

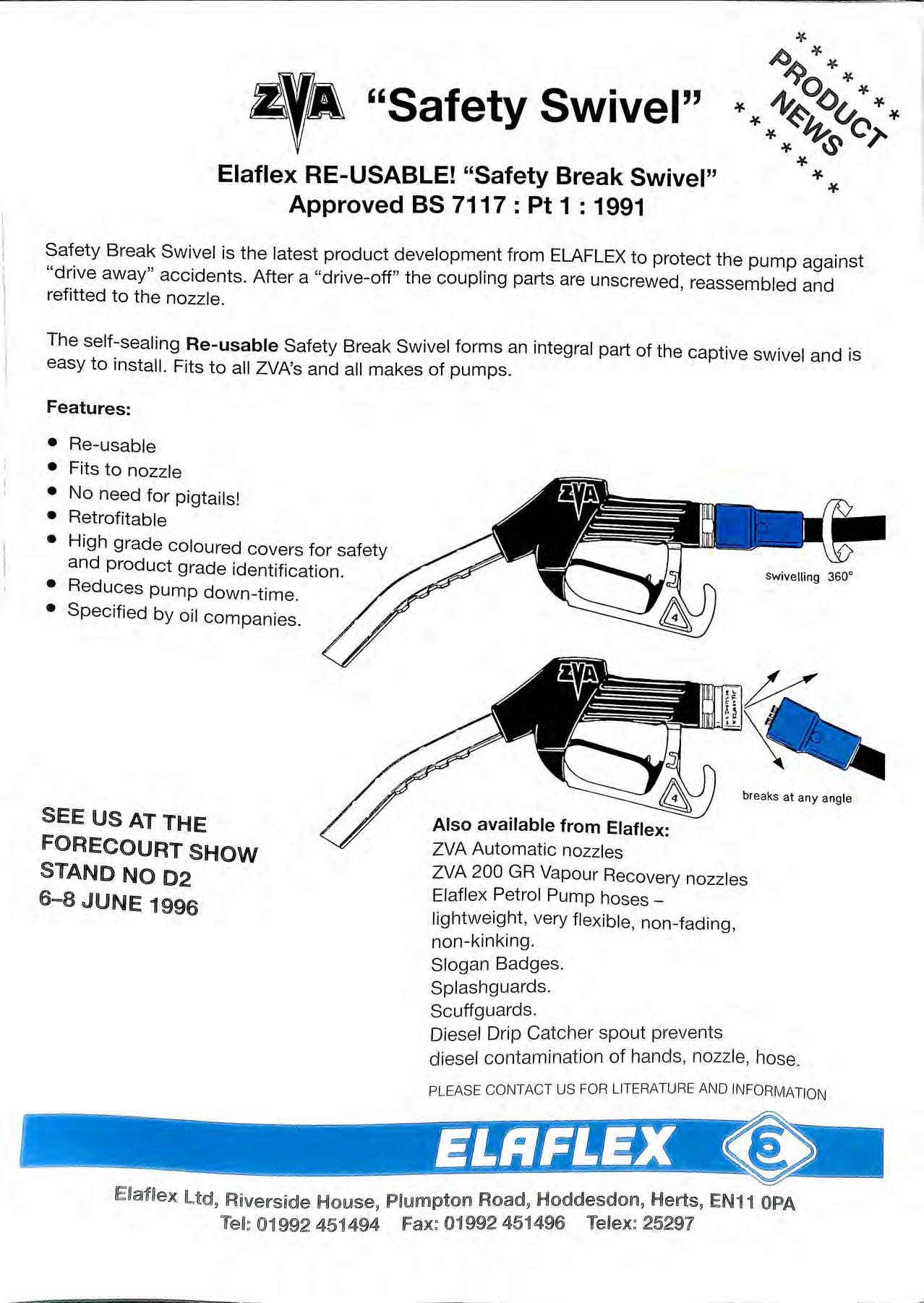

• "Safety Swivel" Elaflex RE-USABLE! "Safety Break Swivel" Approved BS 7117 : Pt 1 : 1991 Safety Break Swivel is the latest product development from ELAFLEX to protect the pump against " drive away" accidents. After a " drive-off" the coupling parts are unscrewed , reassembled and refitted to the nozzle. The self-sealing Re-usable Safety Break Swivel forms an integral part of the captive swivel and is easy to install. Fits to all ZVA's and all makes of pumps. Features: • Re-usable • Fits to nozzle • No need for pigtails! • Retrofitable • High grade coloured covers fo r safety and product grade identification. • Reduces pump down-time. • Specified by oil companies. SEE US AT THE FORECOURT SHOW STAND NO 02 6-8 JUNE 1996 breaks at any angle Also available from Elaflex: ZVA Automatic nozzles ZVA 200 GR Vapour Recovery nozzles Elaflex Petrol Pump hoses lightweight, very flexible , non-fading, non-kinking Slogan Badges Splashguards Scuffguards Di esel Drip Catche r spout prevents di esel contami nation of hands , nozz le , hose PLEASE CONTACT US FOR LITERATURE AN O INFORMATION lt<dl 9 fRoverside 1Hl on.nse 9 Roaid9 HoddesdO U1 i H e rts, EN11 OPA Oi992 45i494 Fax: 01992 451496 25297

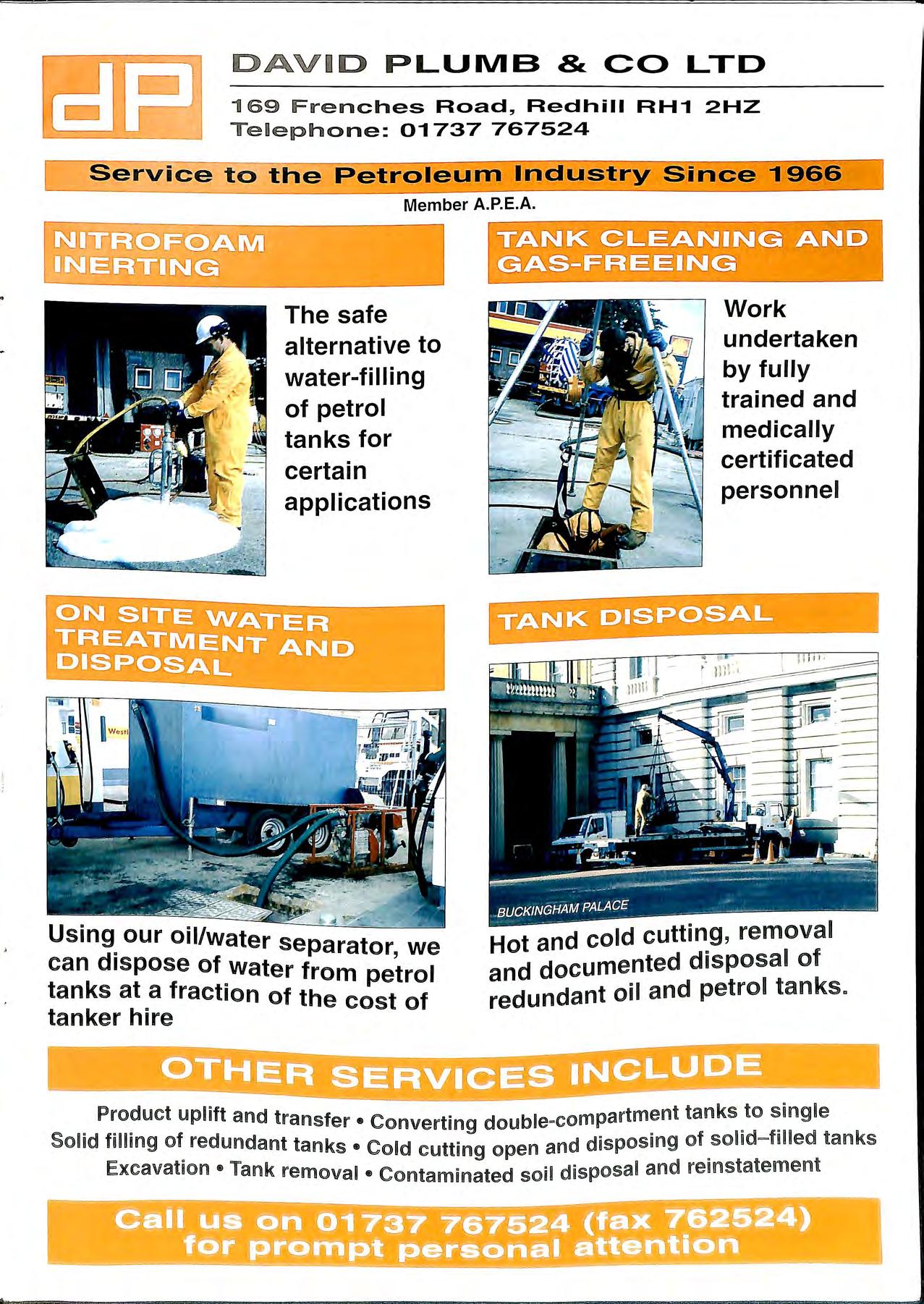

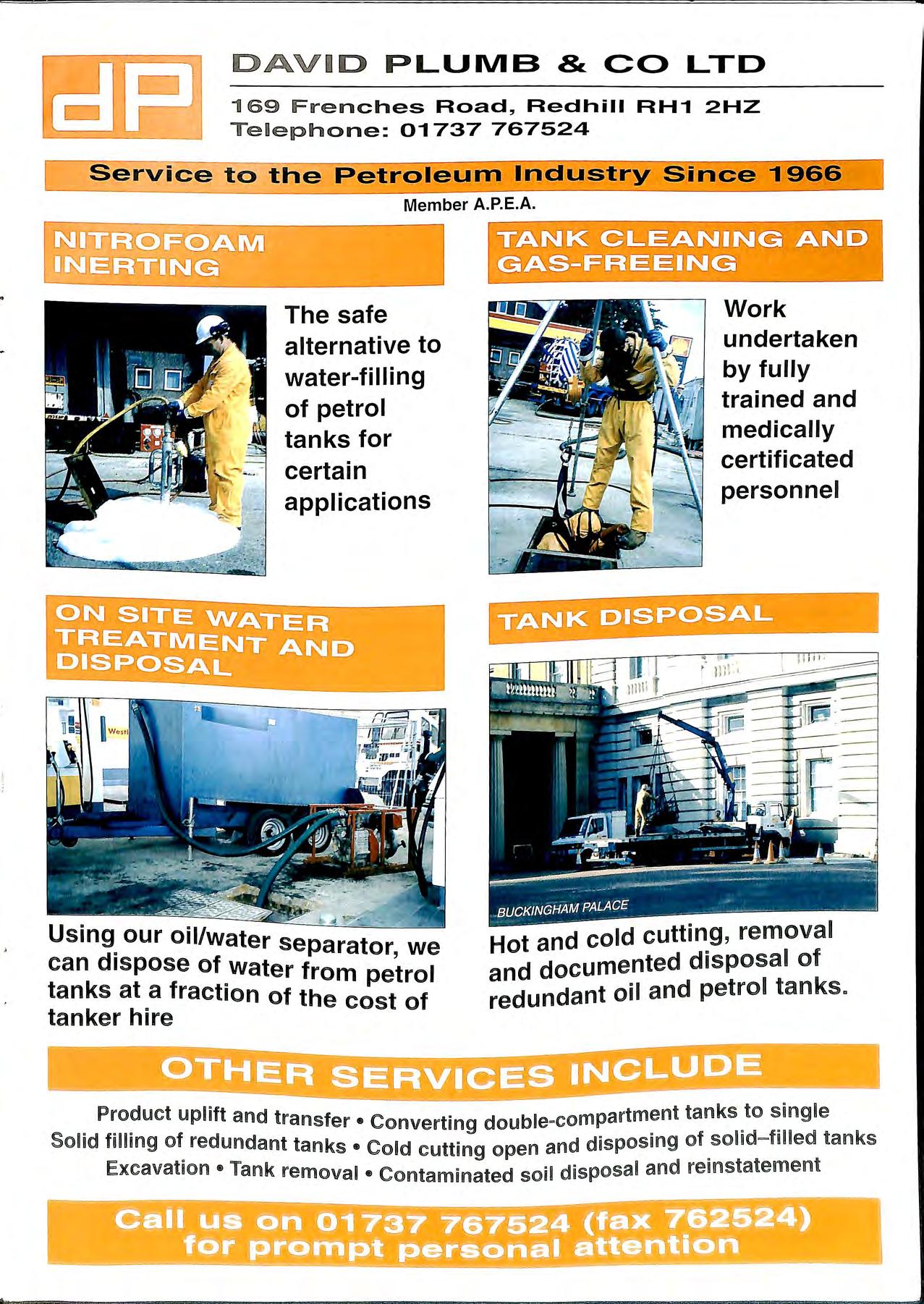

D VID P LUMB & CO LTD 169 Fren ches Road, Redhill RH1 2HZ Te l eph one: 01737 767524 Service to the Petroleum Industry Since 1966 Member A.P.E.A. The safe alternative to water-filling of petrol tanks for certain applications Us ing_ our oil/water we can di s pos e of water from petrol tanks at _a fra ction of the cost of tanker hire Work undertaken by fully trained and medically certificated personnel Hot and co ld cutting, rem oval and doc umented di s p osal o f redundant o il and p etrol t an k s . up li ft and transfer • Converting ta n ks .to So li d f 1ll mg of. redunda nt tanks. Cold cutt ing open and dispos mg of .solid-filled ta n ks Excavat ion •Ta n k removal • Contam inated so il disposa l and remstatement

Talking Point Contents

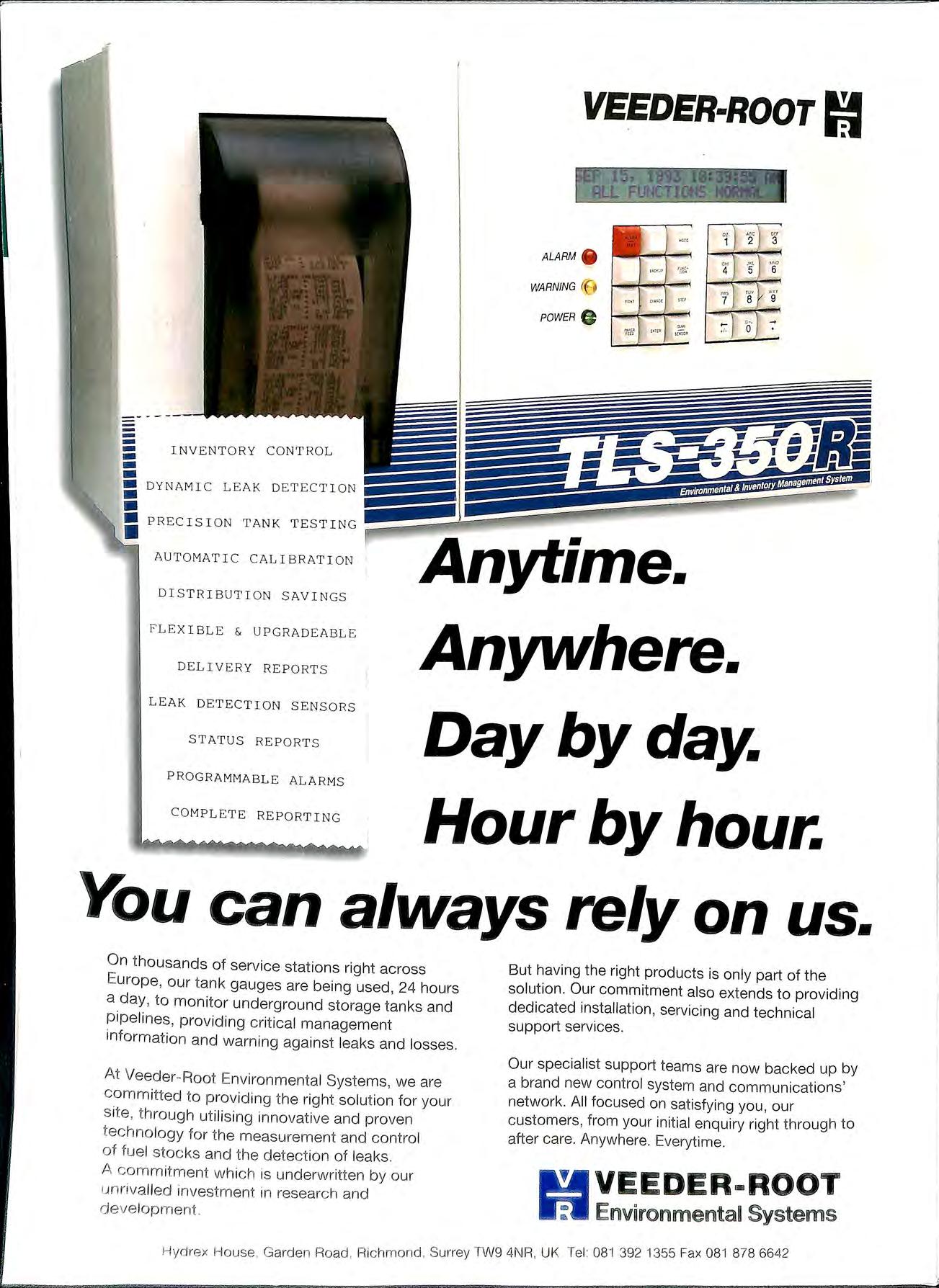

The introduction of leak detection leak into this industry has enabled designers to build service stations in places where prior to their introduction, the site may not have been built or the costs would have been prohibitive. It has given piece of mind to both regulators and service station owners and we hear the phrase "there should be no problem we have leak detection fitted." PROSECUTIONS

Its introduction as one of the control measures in the HSE risk assessment document is a fu11her sign of its prominence in the market.

It is only as good however as the people who monitor it and understand what to do when the alarms sound. Too often in recent years either the operator or the manufacturer have turned off alarms, chosen to ignore what the systems are telling them, and in one case recently one supplier of equipment carried out a criminal act by deliberately bypassmg the system because the alarm kept sounding!

If leak detection is to preserve the credibility it deserves then manufacturers. Oil companies and service station MUST ensure that everyone dealing with the equipment fully understands it and calls out the regulators when the alarms sound.

CLOSURE OF FILLING

VOLUME34 Number 1 FEBRUARY 1996

Bulletin Published by the Association for Petroleum and Explosives Administration

company

Guarantee registered in

No. 2261660

(Free

Members)

this Journal are

the

The

A

Limited by

England

Administrator: Mrs Barbara Jacketts £8.00

to

ISSN 0263 4597 Opinions expressed in

not necessarily the views of

Association

5

NOTES &NEWS LETTER TO EDITOR

7 & 10

STATION

PETROL PUMP REPAIR SCHEME NEW OVERFILL PREVENTION DEVICE CALL OUT REPORT

APEA BRANCHES NAT McCOY lc-t r;i)ILC:- Oli-02 5'2..0 b 11 12 13 15 16 17 !RISH BRANCH SECRF:TARY (ANDY BERRY SOUTHERN BRANCH SECRETARY MIKE SILMON NORTH EASTERN BRANCH CHRIS DAY MmtANfJS BRANCH IAMll· f"HOMPSON FIJITOR HARRY REID NORTH WESTERN BRANCH EDITORIAL TEAM ROR GREEN REPRESENTATIVE !AN HILLIER SCOTTISH BRANCH Al>l/f.RTISIN<; SI·< RF7AR>

INSPECT YOUR HOSES CCTV ON SELF SERVICE SITES

NEW TANK FAILURES CAUSE CONCERN IN THE INDUSTRY

Steel

A double skin steel tank manufactured by Wefco has recently failed in Kent after only four years of use. The tank leak detection system detected a leak in the outer skin of the tank. The tank was excavated, removed from the ground and a new replacement tank was installed in its place.

in the vicinity of a weld and an 1s being carried out as to the cause of the failure.

Ob · · servat10ns by those mvolved in the tank removal also concerned the state of the tank coating which in places did not appear to have adhered to the steel surface. This tank had not been shot bi t d b f . as e e ore coatmu, but had been chemically w·1sh d TI · · e h < e · 11s is a practise the company state t ey no longer use. ·

Althouah prem·1ture t· k f . . • 0 < an ailure 1s of concern it must be 1emembered that n I . f 0 oss o product had occurred the area a1 ound the mstallation ' up was needed In _safe and no environmental clean .· d . · add1t1on the tank retJlacement was ca111e out with the mi · · II d · nimum ot disruption as the tank was 111sta e 111 pea sh 111gle.

Investigations are bein c installations where 1 k g amed out at two other WEFCO ea alarms a. · d' · · Essex and anothe1·. w·1 . . <le 111 Icatmg losses. one 111 111 1 tsh1re.

GRP

In London late last manufactured by Kl · yem a smgle skin GRP tank mgester was fo d I baffle between the tw · un to iave tailed as the o compartment. f h k I d 1· m1x111a derv and petrol TI . s o t e tan · la sp 1t from the t·mk b. 1.e did not lose any < , ut 111vest1 u·1t1 . . I d I I tanks had deflected in tl f · e< ons 1evea e t iat t le installed. In this case 11e1 hour year period they had been • • c1 t ree t k. replaced with new tank . d s were removed and carefully with internal an the ll1stallation was checked c I<1meters check d II TI site is operational acrain Th · e at a stages. 1e . e . e remov·tl of tl . . k and their replacement wa. . d <. le ex1st111g tan ·s <s m<1 e easier h I I · I surround. · Y t le pea s llllg e

In addition it has hcen rep t 1 • this time all double w·ill t· 101 Cl that other GRP tanks. < dn have ·1!. 1· ·1 I II installations being on < so ai Cl. a three mot01 way ser · London Berkshire ·md St· 11 d . · vice stations. 111 . ' < d or shire. I L I , skm t·mks leak detecti· h 1 n one on tht: douhle . ' . < on ac "one off . . . . which the O]Jerators chos e · md1cat111g a leak. .enottobel1'v• 1· I . I . ·cr· · . . t: e anl ignore tor six mont 1s. nvest1e<1t1ons have found I" . . and further checks are beino mad a sp It In 111ner tank of the failure. e e to try and fmd the cause

In Berkshire two tanks on either SI.ll' 1 th · e o e motorway. <1nd <1nothe1 l<1nk 111 a new motorw· · II · : S <1y msta at1on 111 • tattorclshire are being 1nvesti<rated ·is I k 1 , .__ · ". ea a arn1s are 111d1catmg tank failure.

NRA GUIDANCE ON FILLING STATIONS

The National Rivers Authority has commissioned Groundwater Technology International Ltd to prepare a Guidance Manual on Underground Fuel Storage Installations. Estimates suggest that a third of petrol filling stations have contamination problems to a greater or lesser extent. The objective of the manual will be to assist NRA staff to understand the components of these installations and the associated risks to water resources in order to formulate a consistent national approach for the NRA's response to UST planning applications.

Groundwater Technology International will be accumulating data from a range of sources including national fuel suppliers, design consultants and relevant equipment manufacturers in order to provide information on the engineeiing options relating to petrol filling stations and similar sites. A hazard ranking methodology will be incorporated into the guidance manual to assist in the assessment of risk associated with an underground storage of fuels.

Groundwater Technology is one of the world's largest environmental consulting, engineering and remediation firms. The firm has 1600 employees and over 50 offices in Europe, North America and Australia.

For further information, contact Colin Green or John Waters on

INSTITUTE OF

PETROLEUM LAUNCH

UNDERGROUND PIPEWORK SPECIFICATION

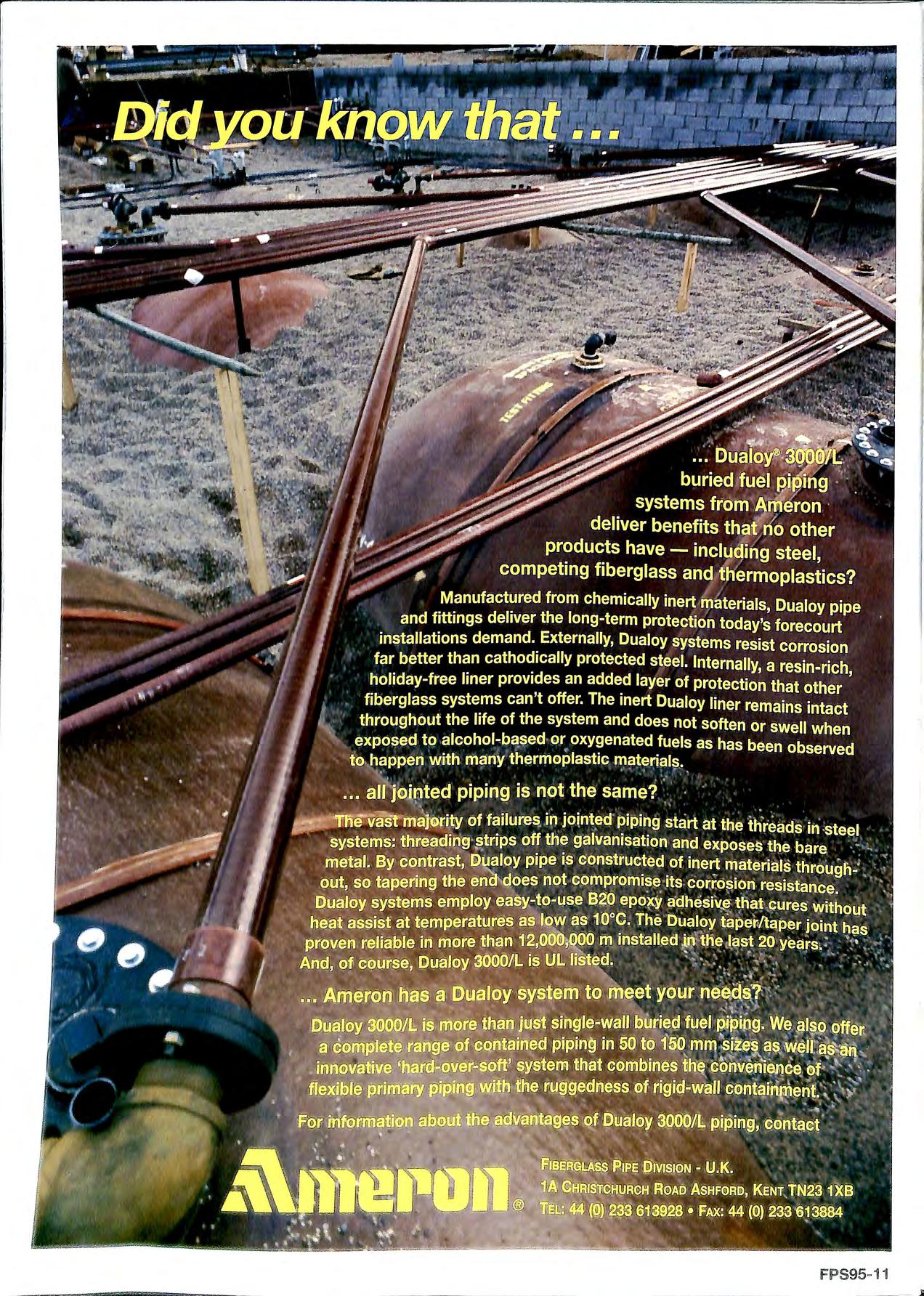

The IP launched its long awaited specification for de raround pipework in the week before Xmas. The un e t' document is a performance spec1hcat1on or pipework and was prepared with assistance from ERA Technology.

o e of the benefits from the specification is that it all types of pipework including the. many recent additions that industry has seen over the past Jew years.

One of the most helpful moves the in . d .· " leaks from pipes is that the pertormance criteria ie UCll1e · · TI · ·11 1·1· · I fl1wn 1 thirt)' year hte-span. lIS w1 e ect1velv now <1ys l ' , , . , , • ll , w wtl\'aI1!Sed steel p1pe\\·OI k t01 ne\\ 111st<1lbt1ons now OU ,\ e< < · , t · 1te 111 ) The performance requirements tor (see nex · l ·1·t)' 11·e 1110re stmrnent than the USA UL. standards permea 11 1 < · · cl "SSeLI ·1s ..steady state permeation rates. an are exp1t:. · <· ·

The code states that the maximum rates fo_r penneatinn j II 1·1· ·et 1·1·11 suction and Yent Imes as bein" or a o s · · · t e 2g!m 2 day.

With secondary containment pipe\vork being per day.

The standard covers all nther _performance requirements and indicates the tests needed lnr the type or pipe lll he used.

The code is a\·ailahle from the Institute or Pctrnlcum o171 ..J.67 71 ()() at a cnst of C.:J..

notes & news

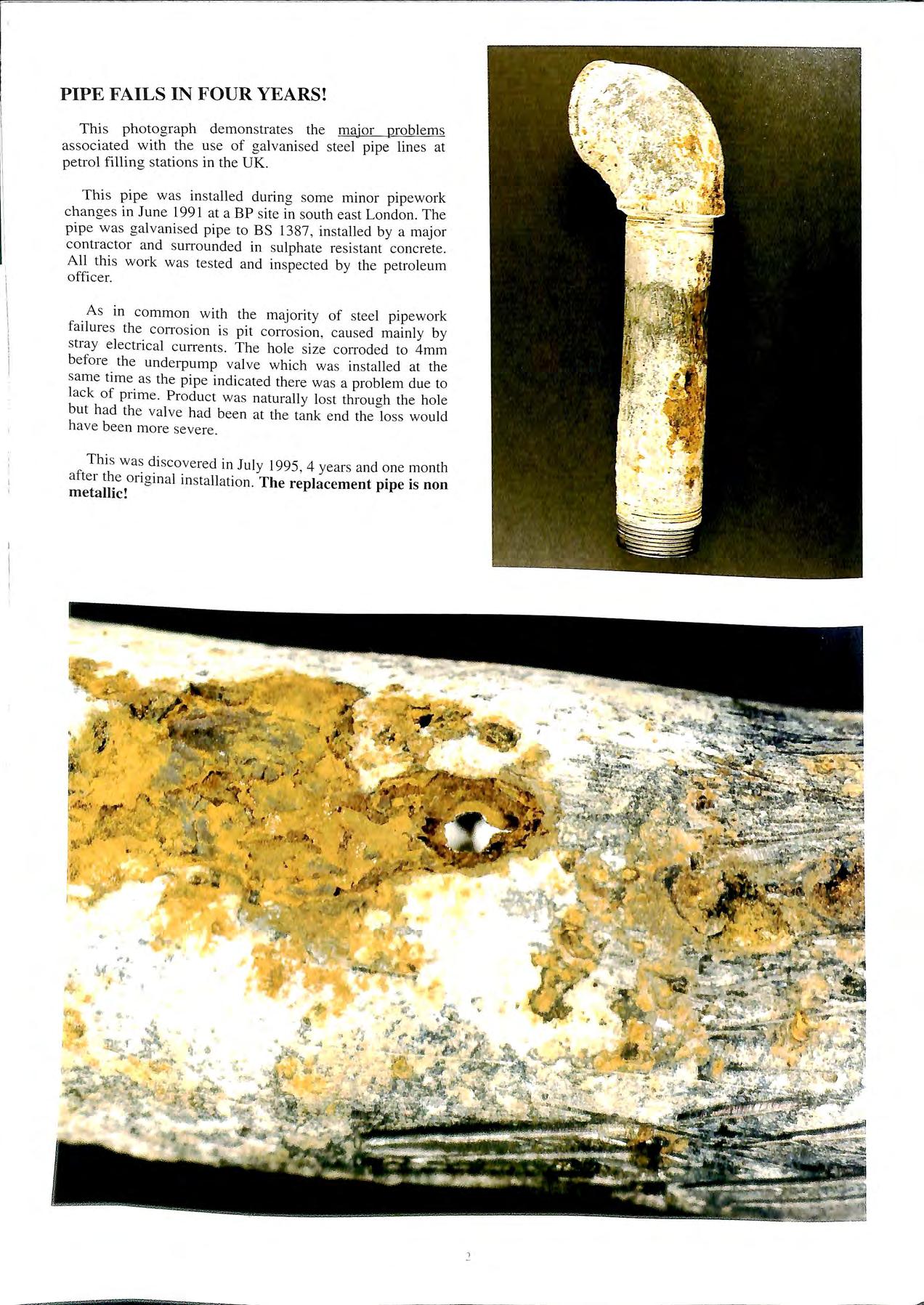

PIPE

FAILS

IN FOUR YEARS!

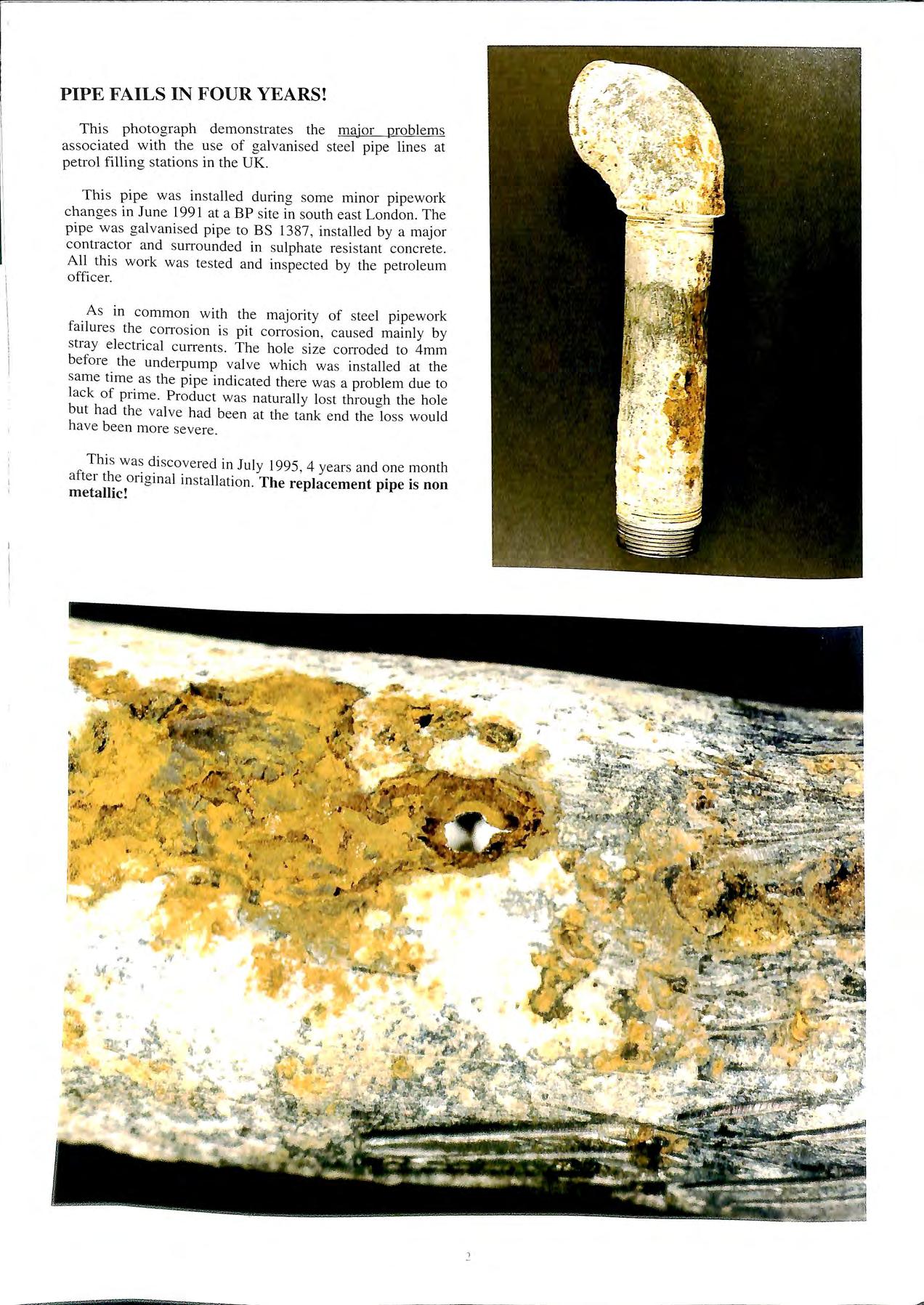

This photograph demonstrates the major problems associated with the use of galvanised steel pipe lines at petrol filling station s in the UK.

This pipe was installed during some minor pipework changes in June 1991 at a BP site in south east London The pip e was galvanised pipe to BS 1387, installed by a major contractor and surrounded in sulphate resi stant concrete. All this work was te sted and inspected by the petroleum officer.

As in common with the majority of steel pipework failures the corrosion is pit corrosion , caused mainly by stray electrical currents. The hole size cmTod ed to 4mm before the underpump valve which was installed at the same time as the pipe indicated there was a problem due to lack of prime Product was naturally lost through the hole but had the valve had been at the tank end the loss would have been more severe.

Thi s was di scovered in July 1995 , 4 years and one month after the original installation. The replacement pipe is non metallic!

,., ., . ' .

DATES FOR YOUR DIARY

The AGM, April 25th, Queensway Hall , Dunstable.

APEA Conference at the European Petroleum Exhibition, Amsterdam , May 6th , 7th & 8th.

APEA Conference and Exhibition , Metropole , Birmingham, September 23rd & 24th.

Further details from Barbara Jacketts 01473 828539.

THE SAFE STORAGE AND DISPENSING OF PETROL - THE NEW RISK ASSESSMENT GUIDANCE

Dr Andrew Cottam & Alan Roberts Flammable

Substances Policy

Section Health and Safety Executive

The Health and Safety Executive ' s (HSE) new risk assessment guidance was launched at the APEA Conference in September 1995. Following the successful completion of the pilot exercise , publication of the new document HS(G) 146 is expected from the end of January.

The guidance, which has been widely debated , was prepared by a working party consisting of representatives of HSE, the petroleum industry and petroleum licensmg authorities.

The objectives of the new guidance are to:-

• promote a risk based approach to the setting of safety standards;

• allow flexibility in the selection of control measures in light of the circumstances at individual sites;

• seek consistency in enforcement across Great Britain.

HS(G)l46 applies to all new and existino sites where petrol is stored and dispensed as fuel for moto; vehicles and similar machinery. This includes petrol filling stations, private businesses, farms, etc. It is not prescriptive but aims to make those responsible , at both retail and non-retail sites, aware o'. the hazards, and enable them to adopt a practice of 1dent1fy111g, assessmg and controllino risks. Durino the pilot exercise, which involved more than °1 OO s ite s in areas, operators found the "five steps" to risk assessment straightforward.

Until APEA and IP publish their detailed technical guidance in Summer l 996, HS(G)4 l should continue to be use d for guidance on building a new site or major redevelopment. Following the publication of the industry guidance HS(G)41 will be withdrawn.

The ri sk assessment guidance HS(G) 146 , Dispensing P etrol: Assessing and controlling th e risk of fire and exp losion at sites where petrol is stored and dispensed as a ji1 e ! (ISBN 07176 1048 9) will be available from HSE Books price £7.50 The address is: PO Box 1999 , Sudbury, Suffolk , COlO 6FS Tel: 01787 88 1165. Fax: 01787 313995.

VENT FIRE ON VAPOUR BALANCED SYSTEM

· 1 d taken a delivery of petrol and the s ite had A BP site rn f'.tted The delivery was at I 0:30 and had our balanc11rn 1 · vap ' by I 0:45. The tanks still had plenty of been comp _ 11 .20 durino a thunderstorm the vents l!aoe At app1ox o d u ' 0 · kb 1 ohtenino and the vapour 1gn1te were stl uc Y 1o 0

· ed the alarm the site was closed and the A eiohbour ra1s ' ' n. 0 : d some IO mmutes later. The fire was f bnoade allJ\e . I f' I ire o' a di·y powder extingu1s 1er rom t 1e site · · I ed usm 0 extmguis 1 0 ctor called at the site at approx 13 :00 TI etroleum rnspe ' · 1 e P . eel vapour discharge irom the vents. 1 still witness ' 1ou1 s. · f 1 site by BP has not thrown any light on Examrnat1on o tie this phenomena.

NEW GENERATION PIPE & JOINTS LAUNCHED AT APEA EXHIBITION

·ation of polyethylene coa ted steel pipe and A new aene1, f . 0 1 · ts for the pet1 ol sta tion 0 1eco u1 t mark e t mechan 1ca JOll1 1T b o p· d y· · 1 cl by British Stee u es ex 1pe s dn 1ctaulic was Jmmc 1e Systems.

U _. 0 th e brand names "Securipipe" and "Victual ic ". sm 0 at· tlie APEA Ex hibiti on 1995. al the Me tropol e were see n Hote l, NEC Birmingham. o n Septembe r 25/26.

Kris Jessiman, British Steel Tubes & Pipes' Senior Market Analyst, says, "a number of pilot projects have already been successfully carried out, confirming that both pipe and joints have enormous potential in the forecourt and related sectors."

Securipipe, British Steel's proven polyethylene coated steel pipe, can be used with specially developed Victaulic joints and a range of joint protection products to give costeffective solutions for underground pipework.

This unique combination gives Securipipe the advantages of strength and speed, which come from robust steel pipe with full corrosion protection, allied to an extremely fast installation procedure using Victaulic joints. Both provide technical and commercial benefits which appeal to oil companies, contractors and licensing authorities.

"Victaulic joints have a great track record, dating back to the 1920s, in a wide variety of industries, including fuel lines for the MOD," adds Bob Dunn, Product Manager at Victaulic Systems, "and with the new Viton B gaskets developed specially for this application we are confident we have a winner on our hands."

. With its inheren.t mechanical properties, coated steel pipe is easy to work ':"Ith on site and is impermeable to a wide range of fuels, mcluding lead free and diesel. Also, the coating, together with a range of joint protect10n products, gives vital continuous anti-corrosion protection.

DURAPIPE

PETROL-LINE PLUS

Nove.mber I 6th, not only saw the first of the 'Beaujolais Noveau but was th d . . ' . · e ay chosen by Durap1pe to launch the11 new pipe, Petrol-Line Plus.

For the past two ye D . p t. 1 L" · ais, urap1pe have been promotmg et. 10 .t the garage forecourt industry for a number o spec1 1c uties Pr h b the lack of: · · ogress t ough has been restricted y

<i > UK performance specification for underground pipework

<ii) Confidence in A .· me11can/Swed1sh spec1flcat1ons.

However, durino tl 1 · <=- 11s t11ne Durapipe's reputation lor supp ymg a quality p. d d · 10 uct. service and trammlT has grown <111 111 1esponse to 1 k <=· 1iar et demand for a British product and env11 on mental con , · Petrol-I in PI ceins over ground water pollut1on. , e us evolved.

Petrol-1.ine Pius is tl . . . development . :. · le result ot an extensive mternal TI · , piogi<1mnie and utilises the latest technology. · le pipes unique douhll'. bond 'cl composite structure incorporates a niet·ilr h· · e benefits over e '. ic di 11er layer and of lers a host of cxcep11onal r· systems. not the least being its l l esis_t<1iKe lo permeation. Durino the products t C\e ''Pl1lent peruid l'f cl. l . . · 1 , <1mended its standard and method , > l t'IL'l llllllJJlnftfU'tlif\,· · · · I I 1 _,,._ ' .Ying permeation and their rensel .f;iJJt "" -.p1:c1l1es 1 · · · . ' lllaximum 4 o/m·' per day of pipe 111l.1<1 .111 .t flw In.., 1 1 <=- 1 1 Ute oJ Petroleum has also recent Y , ,11, d Jf• at 1 0 .• I· l i=-1 dill mes per square llll'lre pe1 <. <1y / 11 /, p,.,,,,J 11w Plus I· I I · l<1s ken independently tested h\· t 1e I< 111d ;i/1 iil<1r111" a1·1,,1· I I . 1· . :.,.,1·,. .- seal) -;talc nim 1t1ons .. "r 1, .1 ,, !,,. , ,1111,c:'111 perda\

It is this feature which makes Petrol-Line Plus particularly suitable for permanently filled fuel lines, while the materials inherent strength and robustness allow it to be used under vacuum and pressure conditions.

The system utilises Durapipe's range of electrofusion fittings and ancillary equipment, which conform to the exacting standards demanded by British Gas and includes eleetrofusion tees and elbows. These products not only lead to reduced installation time, but also reduce the number of joint surfaces.

Durapipe is a well established UK manufacturer of thermoplastic pipe and fittings and the first to achieve BS EN ISO 900 l accreditation.

Durapipe's Petrol-Line systems are available in the UK through an established distributor network but further training and literature requests 'can be made dtrect with Durapipe in Norton Canes Cannock, Staffordshire, WS 11 3NS. '

LUCKY ESCAPE

scenario is a busy London hypermarket site, in the evenmg and a Mercedes pulls up to one of the pumps and the lady the hose to fill up on the far side of the car. pump is authorised and as she starts to fill the car the swivel between the hose and the nozzle parts and petrol is pumped over the forecourt.

1:he _lady then to the kiosk, nozzle in hand to report the the pump is still pumping product, membe1 s. of the. pubhc. on tip toe trying not to get their feet wet, and dnvers dnvmg through it. The lady has to wait her turn to report the incident, by the time the control operator has .realised what has happened, the pump has stopped on its. own as a limiting device (set at £50) The ftre brigade is called and the site closed and peliol 1s washed to the separator and then disposed of.

The it was late and it was clear tha_t_ sup.e1 v1s10'.1 is still a cursory nature by the competent pe1 son the Kiosk. The site was extremely lucky not Lo h,ive had a fire wh· h 1 cl 1c resu te 1n lllJUry or death to the1r customers.

ELAFLEX SAFETY-BREAK COUPLINGS

Background

One of the safety requirements in BS 7117 Part I. the standard for metering pumps and dispensers, is !he provision of a break coupling device the pump and the no;:zle. The device should break With a pullino force between and 1200 Newtons in such a way any release ol fuel 1s restricted and the hose ends are sealed. This requirement was included to any liquid fuel release and/or damage to the petrol dispenser in the event of a vehicle moving with the nouk spout in the filling pipe.

The Elaflex safety break coupling. is situated at the noule end of !he hose and is approvt.:d as one of the desi!!.ns that pump n1anufac1urer..; can u-;e lo conform to BS 7117.-

The Problem

There have been a number of incidents reported over the past 12 months where members of the public using dispensers with the Elatlex safety break coupling have been sprayed with petrol, fortunately so far there have been no associated fires, but on at least three occasions those affected have ended up in hospital. Investigations indicate that cars hitting the nozzle or hose have caused the safety break coupling to separate. In some cases damage has been caused to the safety break coupling and/or the nozzle and/or the nozzle housing. Although the Elaflex safety break coupling is designed to be re-assembled this should only be CatTied out by qualified service engineers using a vice and following the manufacturer's instructions. Some incidents happened when attempts were made to re-assemble the coupling by either forecourt staff or customers while the dispenser was still in use with the result that petrol was pumped during the attempt. Other incidents occuITed following separation and incoITect partial re-assembly when the dispenser was subsequently taken into use by an unsuspecting person.

Incidents continue to occur despite the pump supplier the couplings and in providing additional warning nol!ces advising not to try to remake any parted units.

The Elatlex n_ozzle-end safety break coupling has been used ?n.d1spensers with retractable hoses, such as the lbaico Emolme, but other pump manufacturers have also used coupling. ?ther nozzle end safety break couplings are available fro.m different manufacturers and although they have not been fitted as extensively as the Elatlex couplings have no safety reports associated with Some ol these umts are, however, prone to damage car pamt work.

For reasons of public safety the manufacturers of Elatlex safety break couplino will replace the couplinos With a different unit. The has redesigned the unit to overcome the problems associated with re-;ssembly by untrained persons and it is hoped that the new design will be as a replacement in approximately 4 weeks after and trials have been caITied out. Additional 111:Pr?vements are also being made at the same time to piovide to the poppet valve that becomes exposed when a coupling separates.

Recommendations

1. Existing Disnensei·s WI fi ., · · 1e1 e 1tted, Elatlex safety break couplmos should be I· d b e 1ep .ice y the supplier with modd1ed tu11ts that co 1 · h · ' mp Y wit BS 7117 and that prevent pet1ol bemo released ·t· d . . , .e · 1 palle umts are 111correctly re- <1ssembled 111-s1tu.

2. New Disgensers All d" . h " new 1spensers should be supplied wit sa1ety break co I" · · BS 7117 Wh . . up mgs 111 order to comply fully with e1e d nozzle end safety h k t" d . should be of. d .· ie<1 is itte it : . . d that prevents petrol beino released 1f pai ted umts are mcorrectly i·e-·isse 11 1 · .e < · · m 1 Cl 111-SltU.

HSE Recommended Action by Petrole L . · A th · · um 1censmg u onhes

1. Petroleum Licensing Authorities ·ii·e ·k :I ,· ._ , · ' as Cl to co-operate v. 1th the mc1nufadu1e1s prl)"1··1111 ()1· 1., 1 · El 1·1 e ' ep acmo , a ex safety break couplmg on existinu di'spei1s ,1 ·tel tl · e · e s w1·1 1e new modified umts.

1 At sites _new dispensers are being installed. Petroleum L1cens111g Authorities should continue to seek

that all dispensers, with or without retractable hoses, are fitted with safety break couplings in order to meet the full requirements of BS 7117.

Further Information

There are a large number of Elaflex safety break couplings cmTently use and it is estimated that it will take approximately 6 months (ie. until August 1996) to replace all the units once the modified version has been re-certified by BASEEFA.

Letter to the Editor

Dear Sir, Petroleum Deregulation and Guidance Review

I have been employed as a Petroleum Licensing Officer for around ten years and feel that some comment must be made with recrard to the cmTent proposed changes to e regulation and guidance.

It appears to me that the only reason for the proposed changes is political and to take control of yet an?ther local authority function away from the local authonty and to create yet another quango to tow the government's pai1y line.

Part of the reason for these changes is due to some enforcement authorities having the out-dated idea that the only reason they are there is to prevent development and _be as objectionable as possible and not accept best technologies for pai1icular developments.

1 1 0 been 111 ade by the trade of Great cnt1c1sm ms a s ' . . t t ·oach from different authont1es. It amazes 111cons1s en app1 . . th 't h· . me that no representative of an au on y as d h I b d to 11appen as different developments state t at t 11s 1s oun .. . 1 . WC)tild require different approaches 111 t 1e same aiea depending on many factors.

The latest proposals in my op1111on. make no advancements to the of population. if t ·1ous accidents by anythina make a blue print 01: se1 " , e 'd 1 t ,, I e·1pest IS best encouraging the 1 ea t 1<1 c 1 ' · · · ·

C Cel1tly addressed the Scottish branch of Dr ottam re ' · A :I de the followinn strange contradictory APE anl ma e statements:-

· 11c)t 1·ec1uired as it is too strong an I. Licensing 1s enforcement tool. .., Strong enforcement is a definite requirement.

It is a pity that HSC' seem to he convinced that the · · 1s t)f. ()l1t:' 11erson are all that matters. l know that other op111101 t · · · 111 s 11.,, l"tlled for in a consultation process hut these arc op1111l , ' · always ignored by arrogant know-alls.

Yours faithfully.

Graham Shand

·•

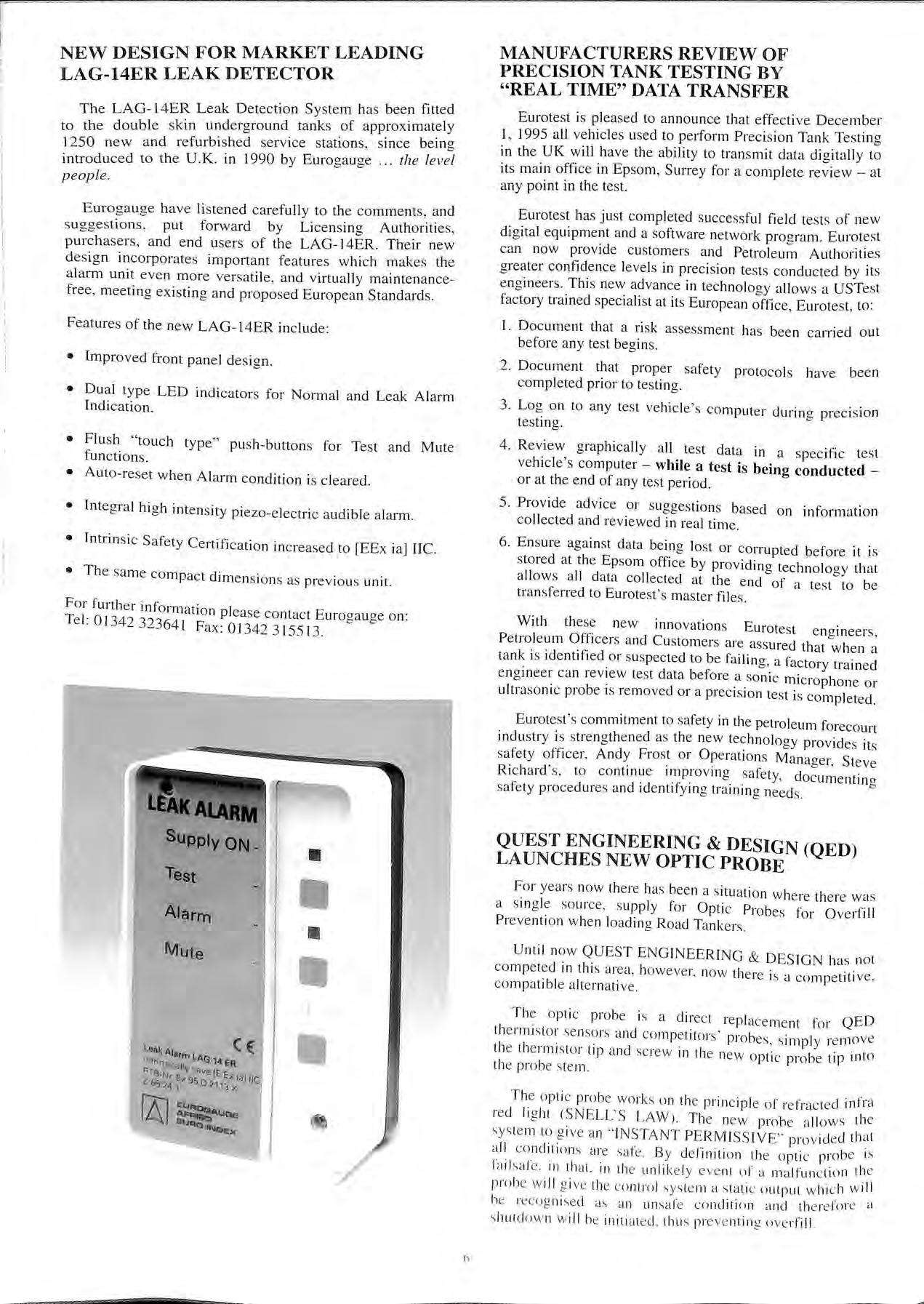

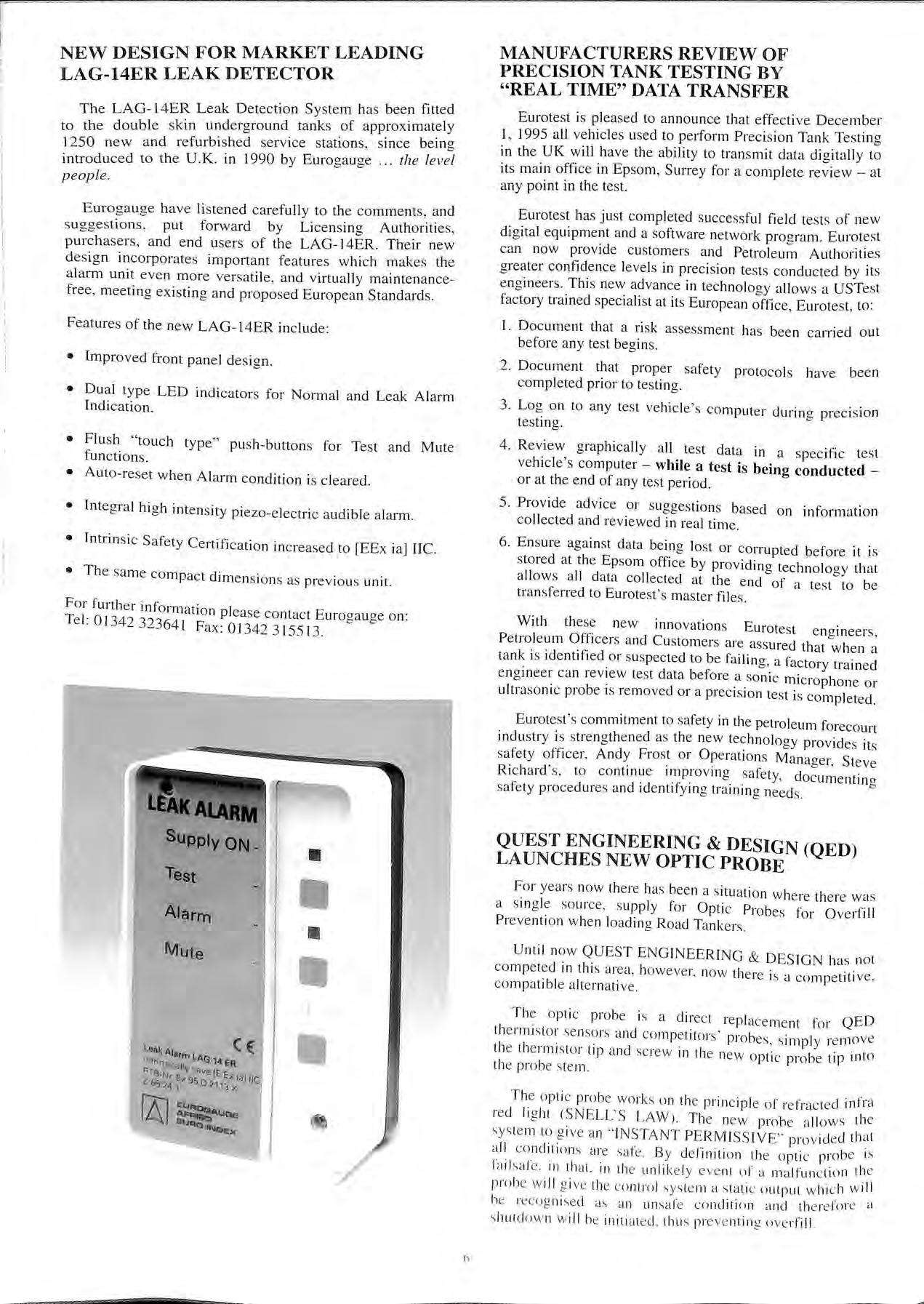

NEW DESIGN FOR MARKET LEADING LAG-14ER LEAK DETECTOR

Th e LAG- l4ER Leak D etec ti o n Sy stem ha s bee n fitted to the double skin underground tanks of approximately 12 50 n ew and refurbi shed se rvice station s, since bei ng introduced to the U .K in 1990 b y Eurogauge the leve l people.

Eurogauge have li stened carefully to the co mm ents, and s u ggestion s, put fo rward by Licensin g Authorities, purchaser s, a nd end us e rs of the LAG- I4 ER Their new des ign incorporates important features which make s the alarm unit even more versatile, and virtually maintenancefree , meeting existin g and propo sed European Standards.

Features of the new LAG-1 4ER include:

• Improved fro nt panel de sign

• Dual ty pe LED indi cators for Normal and Leak Alarm Indi cation

• Flush " to uch type" pu sh-button s for Test and Mute functions

• Auto-reset w hen A larm condition is cleared.

• Integra l hi g h intensity piezo-electric au dibl e alarm.

• Intrinsic Safety Certification increased to [EEx ia] II C.

• The same compact dim e nsio ns as previou s uni t.

For furth er in fo rm ati o n pl ease contact Euroga uge o n: Te l: 01342 32364 1 Fax: 01 342 3 1551 3.

MANUFACTURERS REVIEW OF PRECISION TANK TESTING BY "REAL TIME" DATA TRANSFER

Eurotest is pl eased to announce that e ffect ive Dece mber I , 1995 all vehicles used to perform Preci sion Tank Testin g in the UK will have the ability to trans mit data di g ita ll y to its main office in Epso m, Surrey for a co mpl ete rev iew at any point in the test.

Eurotest has just completed successfu l field test s of new di gital equipment and a so ftware network program. Eurotest can now provide cu stomers and Petrol eum Authorities greater co nfidence levels in preci sion tests conducted by its eng ineers Thi s new advance in technol ogy allows a USTest fac tory train ed specialist at its European office , Eurotest, to:

I Document th at a risk assessment has bee n carried out befo re any test begins.

2. Document th at proper safe ty protoco ls have bee n completed prior to tes tin g

3. Log on to any te st vehicl e's co mputer durin g precision testing.

4. Review graphically all tes t data in a spec ifi c test vehicle's computer while a test is being conducted or at the end of any test period.

5. Provide advic e or sugges tion s based on information collected and rev iewed in real time

6. Ensure against data being lost or corrupted before it is stored at th e Epsom office by prov iding tec hno logy th at a ll o ws all data collected at the end of a tes t to be tran sfe rred to Eurotest's master file s

With new innovat io ns Eurotest eng in ee rs, Petroleum Officers and Customers are assured th at when a tank is id entifi ed or suspected to be failing, a factory trained eng in eer can review test data before a so ni c mi crophone or ultraso ni c probe is re moved or a prec ision test is completed.

Eurotest's commitment to safety in the petroleum forecourt indu stry is stre ngth ened as th e new tec hnol ogy provides its safety officer, Andy Frost or Operations M anage r, Steve Ri c hard 's, to continue impro ving safety, documentin o- safe ty proced ures and ide ntifying trainin g needs . 0

QUEST ENGINEERING & DESIGN (QED) LAUNCHES NEW OPTIC PROBE

For ye ars now th ere has bee n a situ at io n where there was a sin g le so urce, suppl y for Optic Probes for Overfill Prev e nti on whe n load in g Road Tanke rs

Until now QUEST ENG INEER ING & DESIGN ha s not competed in thi s area , however, now there is a co mpetiti ve , compatibl e alte rn at ive .

T he opt ic probe is a d irec t re placeme nt fo r QED th e rmi stor sensors and competitors' probe s. si mpl y remove th e th ermistor tip and screw in the new optic probe tip into th e pro be stem

Th e opt ic probe work s o n th e princ ipl e o f refract ed infra reel li g ht (SNELL' S LAW). T he ne w probe a ll ows the sy ste m to g ive an ' INSTA NT PERM ISS IV E" provided that all co nditi o ns are sa fe . By defin iti on the opt ic probe is fa il sa re in th at. in the unlik e ly eve n\ o f a malfunction th e pro be will g ive th e co nt ro l sys te m a stat ic o utput whi c h w ill he rec ugni secl as an un safe co ndit io n and therefo re a s hutcl ow n w ill be ini tiated . thu s pre ve ntin g. o ve rfill

Supply ON• Test • Alarrn • Mute • •

TEXACO FINED FOR CONTINUALLY IGNORING SAFETY REQUIREMENTS

The London Fire Brigade pro se cuted Texaco Ltd at th e South We stern Magi strates Court on 18 Se ptemb er 1995.

The pro sec ution stemm ed from an in spection carried out on 24 Octob er_ 1994. 40 x ISkg bags of wooden logs were stac ked up aga 111 st th e petrol pump s The magistrate s heard that the petroleum in spec to r Mr Andy Be rry had on pre vious occasmns wa rn ed th e company aga in st this practise. whi c h mc lucl111 g th e stac kin g of bag s 0 1·coal.

Texaco Ltd we re subs eq ue ntl y wa rn ed in w riting that thi s infrin ged a li ce nce condition. but took no action to re mo ve th e lo gs.

When th e infrin geme nt was re port ed it was di scove recl that Texaco hacl tran s ferred occupanc y of th e pre mi ses without giv in g th e writte n noti ce to th e Lonclun Fire Brigad e as 1·equirecl by con dition 17 nf th e li ce nce. In

. t tlie storage of th e lo gs · lernn a O · addition to the summons ie 0 5 also clirectecl against , summons wa next to th e pump , a · f 1 chanae 111 occupation. Tex aco for failing to notify them o ' "'

t cl to ha ve th e summons 1· ·t s atternpe '

The clet-enc e so JCI o1. b arauina that Texaco had I a withdrawn Y ' 0 0 relatma to the o"'s to th e need to aclhe1 e to 0 · attention · · drawn th e occupiei 5 01 checks or other poliung cl · S1nce no sp lice nc e con it1 ons. . lei be nisecl. cl clelence cou ' meas ures ex 1ste , no

1 to bot h summon ses and 1n

Texaco pl eaded gui ty upi er had bee n told to co mpl y cl tint the occ · ·1 mit1 gat 1on S<U ' 1 _. 1 li ce nce and blamed th e la1 m e lo I I ·ov1s1on s o t ie I wit l tie P 1 DA of the tran s fer 0 1· occupation ol t 1c Silt' 1ni orm th e LFC. isat io n within Tex aco. on a large sca le I eo1ga n

I Te x·1cn { 1000 fur t"ail1ng lo nntil\1 TI i1 1aistrates lil t: L " i e 1 · 1 .·ty 1t1out the o l uccup1er ol th e I·. sin aa ut1 011 ' th e ice n c 1 ivoocl ioa in st the pe trol pumps attra cted · TI storage o · 'c s ite. ie. ind cos ts 0 1 · £700 we re awa rd ed to th e a !me o f t:_ ' London Fire Br igade.

LONDON PROSE CUTION

7

NEW UPP PIPE FROM PETROTECHNIK

Improved flow rates, lowest permeability (O.Sgr/sq m./day or less with standard leaded and unleaded fuels) and ven areater flexibility are the latest developments of Petro UPP pipe for petrol stations the result of 2 112 years of intensive re search and development work by the UK based company.

Production has been switched to a new British manufacturing plant to take advantage of technology that will monitor every millimetre of the hned polyethylene pipe as it is extruded. The process guarantees an even higher quality product and permits the use of a new formulation for the liner baITier.

UPP pipe, with its advanced range of fittings, is a complete pipework system which offers clients significant operational benefits over other pipe materi als such as steel , glass fibre, nylon and aluminium layer polyethylene The pipe 's flexibility can eliminate the need for many fitting s associated with other syste ms, and also re sists fracture through ground mo ve ment.

Speed of installation up to half the time required by other materials also ensure s UPP in stall ers spend less time on site, reducing labour costs while its corrosion re sistance provides longer economic life, exceeding the site's norm al lifespan.

For the in staller, the pipe is pleasant to handle and offers fa st, simpl e in stall ation regard less of weather conditions. Using the UPP sys te m require s a minimum of capital equipment and the pro ven tec hnique of e lectro-fu sion weldin g has been even further refined w ith a range of clamps and scrapers conceived to minimi se the ri sk of bad joints through incorrect operator practice.

"With our enhanced pn»duction facilities, " says PetroTechnik' s Norman Allen, " we can maintain stricter control over quality, but more important is th e better product we can deliver through our investment 111 re search and development as well as new technology

"This is the new generation of UPP. Our testing on the new pipe and it's an evolutionary step, not a radical product will give clients the same confidence. And, with many service stations being redeveloped at regular intervals, there are potential long term savings new UPP pipe, as the pipe can be re-used tune and aga111.

This major new investment by PetroTechnik further enhances UPP 's market leading position As John Boudry, PetroTechnik's managing director, says , " UPP is by far the highest selling non metallic pipework syste m available in Britain today, a position we have achieved and maintained by a programme of continual research by our own development engineers. We are still the only manufacturer to offer a complete range of lined pipework, and, unlike our competitors, we offer not only straight lengths but long runs of coiled pipe as well."

Continued growth in the UK and rapidly expanding sales across the globe bear witness to PetroTechnik's policy or continual product development.

" We have always been committed to product development," says Boudry, "and when the re sult is a liner almost as smooth as glass through a combination of state of the art extru sion processes and pol ymer resea rch , the commitment is rewarded. UPP can deliver better flow rates and permits smaller diameter, more flexible pipes to be used in comparison with steel. Permeability has been reduced to virtually nothing

I \ \ I I \ I I I I I

Even more_

PetroTechnika ly s per I .. --·UPP underground service station pipe·work has long been recognised as the best available. But just because it's the 0 best doesn't mean we can't improve it . And we have ...

systems

PetroTechnik Ltd , Maitland Road, Lion Barn Business Park, Need ham Market, Ipswich , Suffolk, IP6 8NZ Tel: 01449 722822 Fax: 01449 721821.

" We now produce the near perfect pipe with every millime tre quality checked to en s ure con sta nt pipe wall and lin e r thi c kness as we ll as e limin a tin g out of roundne ss and o vality.

is now in use in over 4000 installation s in 30 countries by most major oil companies, supermarket

s

independents alike "

"UPP pipework

chain

and

T

p P E 0 P L E

John Baudry, PetroTechnik's Managing Director with a coil of new UPP pipe.

.• I UPP. ..

H E u p

TEXACO COMPANY FINED £8000 FOR "GROSS NEGLIGENCE"

Star Service Station Ltd a subsidiary of Texaco was prosecuted by the London Fire Brigade following a serious incident which involved an Elaflex safety break coupling and people being drenched in petrol.

The incidents occmTed at the Texaco "flagship' site near the Tower of London St Katherines EI.

On 2 February Mr Duncan McKenzie a customer was doused in petrol as the coupling parted, petrol spraying all over his car and his clothes. Mr McKenzie complained to the London Fire Brigade following the incident as he felt his complaints to Texaco were not treated seriously.

The following day the Petroleum Inspector Mr Terry Howes called to investigate the incident and along with the deputy manageress of the site went to the pump. During the inspection an employee who was at the control console authorised the pump, the fitting sprayed out gallons of petrol onto the forecourt over the inspector, who had to attend Moorfields eye hospital for treatment as petrol had gone into his eyes.

In consequence of this incident two summons were directed against Star Service Stations. It was alleged that Condition 11 C of Part A of the licence was contravened by the failure to take all practical steps to prevent the escape of petrol from pump 5 which was known to be defective because of the incident that had occuITed the day before. The other summons was against the failure to have a person supervising the dispensing of petroleum spint from pump 5.

Cooper Whiteman solicitors for Star Service Stations Ltd indicated that they were minded to advise their client to plead guilty to the first summons as the pump should have been secured by means of a padlock. They served notice that on the second matter they would contest this. as the who had authorised the pump was under training from another. However on the day of the court appearance on 11 January 96 the company chanoed their mind and pleaded guilty to the two counts. In mitigation they explamed the company training programme and produced tra1rnng manuals.

The Metropolitan Stipendiary Magistrate Mr Kelly did not accept that the company had done everything that should have been done to prevent this accident. He stated that It was unacceptable that an accident to the Texaco rn-.tomer which had heen had enough. was repeated the foll 11 w1ng day He accused the company of gross negligence ;11Hl t 1ncd the rnmpany UOOO for fai Ii ng to take all practical ... rep' lo prevent the e"cape or petroleum spirit. He then 1n1pmL'd a finl' of f2000 for failure to have a competent pn,on \t1pl'n 1\e rhc dispensing or petrol.

< ''""" .,f litJl"i WtTl' to the London Fire 1;11 :_·.id1.

£3000 FOR OVERFILL

The London Fire Brigade prosecuted Thames Service Stations Ltd for contraventions of the petroleum licence covering the premises, and provisions in the Road Traffic (CmTiage of Dangerous Substances in Road Tankers and Tank Containers) Regulations 1992; the case was heard at South Western Magistrates Court on 17 November 1995.

The prosecution was in consequence of an investigation which followed the spillage of petrol during the course of a delivery from a 1:anker. When he attended the site Petroleum Inspector Andrew BeITy found that four tanks were outnumbered, and that they were not marked with their maximum working capacity, contrary to the abovementioned 1992 Regulations. Moreover, the gauges for measuring the contents of storage tanks 1 and 6 were not working satisfactorily, contrary to a condition of the licence; and the contents of tanks I, 6 and 8 had not been ascertained immediately prior to the delivery of the petrol, contrary to the 1992 Regulations. Five summonses were directed against the company in respect of these offences.

The solicitors for the defence, indicated as late as 23 October that a guilty plea might be entered to the charae of failing to ascertain the contents of the tanks before that "Insofar as the other allegations are concerned our chen.ts are determined to maintain their Not Guilty pleas in to those allegations." They argued that the remammg four summonses should be withdrawn because the company had instructed contractors to rectify the defective gauges and that the labels for tanks had been but. had gone astray. Scrutiny of the documents support, however, showed that no due existed because instructions to rectify the gauges were given to the contractor on 21 November 1994 and that when revisited on 2 December 1994 a fault was found. No evidence existed that this was rectified between 2 and .M1:. inspection on 28 February 1995. The alleeed m1sdirect1on of the tank labels did not raise a defen.ce .to the presence of defectively labelled tanks in a funct1on111g service station on the date of the inspection.

The defence was consequently notified that the would proceed; and on 9 November they not1f1ed the Authority that guilty pleas would be entered to all five summonses.

At the hearing the Statement of Facts put before the Magistrate stressed the dangers of delivery into wrono tanks and spillage when tanks are not properly lahelleLl their capacity not ascertained hefore delivery. and their gauges are not functioning fully. In mitigation it was said that the defendant had pleaded guilty and de..,erved the one third reduction of hi' sentence required hy criminal procedure; and that he had now instructed all forecourt managers to inform him immediately if pumps. tanks or gauges developed faults. The fined the company f.2.000 and awarded f 1.280 cost".

LONDON PROSECUTIONS

Iii

e r Marris, West Yor k shire Fire Brigade

The Licen see of a f1·111·110 t t' · h · · b s a ion 111 t e touri s t village of Hawo1th f111ally acquiesced the in e vi'tab ' l ' t f f 1 1 y o e n orcement action and cl o sed the petrol reta ilino s 'd 1· 1 · b · · J 1 b , 1 e o 11 s us me ss 111 anu a ry t 11 s year.

Bridge hou se Gara oe is s omewl . t . f 1 b M uniqu e or a 111 e t1 o po 1tan a 1e a 111 that the road t ii1k 1 d f ' ' e1 un o a s rom a pos 1t1on on the public hi o hway with tl1e d 1 1 1 .d 1 _ . . b e 1very 1ose a 1 a c1o ss t 1e tootpath. D1 s pe n s1110 is by w a ft 1 d d b • ' y o wo p e tro an on e 1ese l pump ad a pte d with m e cl1a . 1 d' 1 n1ca 1a ia arm s to re tu e l ve hicl es a lso parke d on th e hi o l D · b 1wc1 y. ep e nd111 0 o n which way a ve hicl e parked 1t w as of'te tl 1 ° ' ' n i e case w i e re th e a ttend a nt had to s tand 111 th e bu sy ro ad t d. · ' o 1s pe ns e pe trol.

Th e Li ce n s in g Authority b e c·ime in c i·e 1 ' as 111 g y c on ce rn e d a t th e 111 a cl e qu ac 1es o f th e s it e so 111 1 I · ' , uc l so t iat It was cl ec 1cle d to carry o ut a full ri s k a ssess in e i1t ·tl · · . . , · ·. w1 l a v iew to ta k111g e nfo rce m e nt ac ti o n.

As e xpec te d th e ass ess m e nt found th at th e abse nce o f a n y c ontrol me as ures to co nta in a Sl) ill aoe t 1 1 . f o 0 1 o exc uc e so urces o f ig niti o n rom t he ha z ard o u s a rea s pl ac e d th e publi c a nd e mpl oy e es to a n un acce pt a bl e ri s k of injury fr o m lire o r ex pl os io n.

Afte r tak in g le ga l a d v ice. t wo se p a rate P ro hibiti o n No ti c es we re d e fe rre d un til 3 1 De c e m be r 1994 w e re s e rve d on th e L ice ns ee o n 9 Ma y 1994 (W ith th e L ice n s in o A uth o ri ty ha vin g add iti o na l pow e rs d urin g a d e li ve r; c o nf us io n o ve r the re lev a nt le g is lat io n c oul d hav e ar ise n

h a d one ov e rall Noti c e be en se rved).

The fi rs t Notice d e alt w ith the road d e li ve ry in · f t. 1( 3) ot the Pe trol e um re s pect of contra ve ntion s o sec ion (Con so lidation ) Act 192 8 (P(C )A ) a nd S ec tion s 2( 1) and 3( I) o f th e He alth a nd S afe ty a t Wo rk e tc A c t 1974 (HSWA ) Wh e reas th e seco nd N o ti ce cove re d contra ve ntion s of S ec ti o n I (3) of th e P(C) A w he n petro l is d. 1 1 ac h c ase th e N o ti ces ha d a ttac he d a be m g 1spe nsec . n e, ' bi b d I f ·k to b1111 a the s ite up to an acce pt a e , ut sc he u e o wo1 s o no t nece ssaril y a n HS (G )4 l. sta ndard

cl bi tl Li·censee Io d uecl a n a ppea l '1ga in s t bo th Pre 1cta y i e c N tl e 010 L111 c1s th a t " th e o pe rati o n o l th e g ai age o t1 ces o n i o 1 1· · I f " e·i so n abl y prac ti cab e co mp 1a nce w it 1 e nsures so ai as is 1 ' , ' · C) A cl tl HSWA a nd d e m e cl th e d1 s pe ns 111 g o1 th e P ( a n 1e .· I I tI e s ite in vo lves a n s k o t se 11 o us pe1so nal pe tro Tom 1 · · injury' ·.

T he Indu s tri a l Tribun a l hearin g was se t fo r 2:1 Nove m be r 1994 d r· th e ''e le ve nth ho ur" the ap pe llant c han ge d th e a n a 1 I f 111s ap i) ea l to that o f a n 1n s ut iL 1e nt lim e pe ri od g roun c s 0 1 . ' [0 pro v id e th e co nt ro l m e as ures ln do in g so h e ta C1 tl y a dmitt e d that the o pe ra tio n o f hi s s ite w as p re.1u cl 1c 1<1l to publi c/e mpl o yee safe ty.

Afte r see in g a n ou tlin e p la n th e T ribun a l acc e pt e d th at th e Ap e ll a nl in te nd e d to re deve lop th e s it e a nd w ith the re s po nd e nt 's (fh e / 11 sp ec /or 11 /1 0 is s u e d Ili c Pm lii hi t i1111 N o1 ices ) co nse nt d e te rmin e d th at :

Prohibition N otice s Close Filling Station

LL.. ----:-=n· . . --... . - ·

Rog

11

The appeal be adjourned sine die with both parties at liberty to reinstate/apply for further directions at any time.

11 That the operation of the Prohibition Notices be suspended pending further Order of the Tribunal or until the withdrawal of the appeal.

Plans were indeed submitted to the District Council to carry out a full development including the purchase of, and alterations to, an area of the unusually wide road junction on which the site lies.

When it became apparent some eleven months later that the Licensee was encountering difficulties in obtaining planning consent, the Licensing Authority were of the opinion that further action was needed to expedite the matter. This was done by giving the Licensee three months written notification of the refusal to renew the petroleum

licence when it expired on 31 December 1995 and making application to the Tribunal to reinstate the appeal proceedings specifically in order to lift the suspension of the Prohibition Notices.

Proceedings were reinstated on 18 December 1995 and with the appellant's and respondent's agreement the decision of the Tribunal was to dispose of the appeal in the following terms:-

That the appeals be withdrawn; and

11 That the suspension of the Prohibition Notices be continued until I January 1996.

This decision together with the refusal to renew the Petroleum Licence effectively closed the site as a petrol filling station on I January 1996.

Petrol Pump Repair Licence Scheme

for Repairers of Explosion Protected Ex Electrical Equipment

Electrical equipment used in hazardous areas including pet'.ol must be designed, manufactured, installed and mamtamed in accordance with the explosion protection standards. BASEEFA certification helps manufacturers to t?e .first two items, while the operator of the mstallation Is responsible for the other two.

When it r .· . . . comes to repair and overhaul, the esponsib1ht1es are less clear. The EECS Repair Licence Scheme .helps to define the responsibilities of the owner and the repairer of the equipment and provides a means for each to demonstrate that they have fulfilled their obligations.

l_'he Scheme is applicable to non-mining (Group II) It uses as its basis the EECS document "Repair and Overhaul f C .f. p bi" . 0 ert1 1ed Products". supplemented by IEC ubl!cat!on 79-19, ISO 9002 and other relevant pu 1cat1ons.

While intended · .1 . . . Schen , · Y for repair compames, the le is also avallable to manufacturers of certified equipment who ·h c , Wis to have their repair and overhaul ope1 dt1ons covered b . operations Y an EECS Repair Licence. The repairers mclude strategically positioned, authorised Licence. w ldnd th.e World, for whom an EECS Repair ou provide · d a emonstration of competence.

The EECS R · . , epa1r Licence Scheme

• allows license I . . . · c repairers to claim that their systems die <1ppropn·tte t lh ' 0 e needs of certified equipment.

• ht:lps

coin owners and users of equipment to select petent repairers.

The FI-CS J · , , · ,icensed Repair Markis)

• will he require l. l. c <1nc under cons1deral1on.

Ho\1- the EE{ 'S re . . . Patr Licence Scheme works

I I < \ J ·11·. I . h. I · · ' e to companies w 1c 1:

• /J;ll i· d qu·tJ I

· ' 1 \ n1anul,!en1en1 <.;y-;tcm certified to ISO

900 I or ISO 9002 by a recognised certification body,

• meet the requirements of EECS document "Repair and overhaul of certified equipment",

• with the appropriate industry codes of practice such as IEC Publication 79- I9 "Repair and overhaul for apparatus used in explosive atmospheres"

• are a.ssessed by EECS for conformity with the Scheme reqmrements,

• are to periodic auditing by EECS to confirm contmumg compliance.

BASEEFA Repair Licence relates to a particular company at a specified site. The scope of the licence is stated in terms of:

• Group I (mining, Group II (non-mining) or both

• Explosion protection concepts (e.g. Flameproof Ex d)

• Equipment types (e.g. motors)

The has a three-year term and is renewed subject to contmumg compliance with the requirements of the Scheme.

A licensed repairer may affix the appropriate BASEEFA repair mark to the apparatus following repair and final inspection.

When an item needs repairing. the owner or user should select the repairer with the same care that they used when specifying the equipment in the first place. The original manufacturer is the obvious first choice. but there are circumstances when that option will not be feasible. Selection of an EECS licensed repairer provides assurance that the are being performed by a company which understands the partirnlar requirements for certified. explosion protected equipment.

For further information, contact Roger Turton on 14410129828000

I·'

CUT OUT THE MIDDLE MAN

A guide to The New Generation of Overfill Prevention Devices

By Ged Norris of Link Hampson

Introduction:

It is often said that "the prevention is better than the cure". In the case of environmental clean-ups. it can also be considerably less expensive. During recent years, we have become accustomed to the concept of fitting Overfill Prevention Devices (OPDs) into underground storage tanks at service stations. Originally designed and sold standalone safety devices. OPDs seem to have become inextricably linked to Stage IB Vapour Recovery in most people's minds. since the publication of HS(G) 41. If manifolding below ground, or at low level above ground. an OPD is usually fitted to prevent crossover of product into adjoining tanks. Obviously, OPDs are still a valuable safety feature on sites as stand-alone units. Prevention of spillage has immediate environmental benefits. However, the next three years the industry focus for OPDs is likely to be on Stage IB Vapour Recovery sites.

Legislation:

We are all aware that Stage I of the European Parliament Directive has been adopted into the UK's leg1slat1on. The first phase of implementation, which lasts for three years, has already started. This means that converting to Stage IB is a legal requirement and be with, if the annual throughput of a se1 vice stat10n exceeds IOOO cubic metres. We know that the ave.rage annual throughput of a UK service station was approximately 1750 cubic metres in 1994 (S UK PIA) Th f ource ere ore, although there a1·e 110 pt1bl" h cl t·· 1s e 1gures as to many exceed the initial throughput we can see th<1t a larne numbei· of· s"t 11 h b i: 1 es w1 ave to e converted durmg the first phase 111 dd"t" · · a 1 ion, some sites with lower throughputs which 11.e 1 t cl , ' oca e m sens1live areas. will also have to be modified in the first phase.

Retrofitting:

In recent years, a number of Ret· 1 ··t . h been converted to Stane IB "·tpl)U es ave ]already_ i: v, 1 ecovery a 1ead ol leg1slat1on. There has also been ,1 • , d •1 • ., I· d . ' g1e<1t ea of press cove1 <1ge 1e ate to the cost ot sucl1 · ·t· II· . . , · ms d dl1ons. Some ol these estimates have seemed to b "]di · e w1 y exa'"'erated particularly II we simply add up th t. 00 · d · e cost o the fltt111<>s comb111e with an estimate for Jabt)ll. , H i:· I · 1 costs. owever on c oser exam111at1on. 1t appears tint tl1e t t· 1 . . ' . · · s ' o a cost mcurred 111 111stall111g tage IB may be hioher thai .· · 11 some sites. This may be wh"'ere ex1· ·1t_011g111ak y !thought on · s mg tan s rnve to be mochlled 111 order to flt OPDs. '

On modern service station sites .1. · , · , · • ulOp pipes have been mstalled Ill t,mks 111 such a way tli·it lll, , b 1 , ' cy can e east y removed. Ne\,ertheless. the ma 1 ·ority lll. ·. · k ex1st111g tan ·s are t1ttecl with olcle1 styles ot drn1J pipes wl · 1 1 l " 11c l are aslenec from uncle1 ne<1th the manhd, Consecluentl . . . , II· , . 1 · y. lnSld d[IOll OI an OPD ms necess!lated the tank dr·11 11 1, l 1 · ' 'be am remova of the rnanhd lrom the tank. an ex1Je11s 1 ·,,., Sl)ILtt' · · · · · 1011. g1v111a nsc to potential safety and logistical IJl"ll le 111 s A "' · • c u n a ternal1ve solution was cle\'eloped to carrv out s1Je'ci"tli'st 111 1· 1.. 1· . . · · , . oc 1 tea ions to the tanks. w1t?out renwving the manlids or draining the tanks. This solution has ht'come commonplace over last

few years, and is considerably less expensive than the old method. However, when we examine the total cost of the conversion of a site to Stage IB Vapour Recovery, including equipment, labour and specialist modification procedure, it seems to have exceeded the industry's original estimates. As the conversion work canied out before this year has been implemented on a voluntary basis, some projects have been delayed due to budget restrictions. A number of people have also been asking if mechanical OPDs can be fitted to existing tanks, without caiTying out specialist modifications to the manlids. All of the world's manufacturers, of OPDs and Stage IB equipment. have been looking at this situation and attempting to find a solution. OPW Fueling Components, the leading company in this field. have recently introduced the 61 TNG Overfill Prevention Device. According to Mike Elston of OPW, this is a completely different type of mechanical OPD. Originally designed for direct-drop sites, it can also be installed in a number of offset-fill applications. A modified version of the TNG has been designed so that it can be installed in existing drop pipes. regardless of size. Previous innovations have enabled OPDs to be installed inside existing 4" drop pipes but. until now. tanks. with existing drop pipes of smaller diameter specialist modification work to remove the drop pipe.

Operating Principle:

. . .

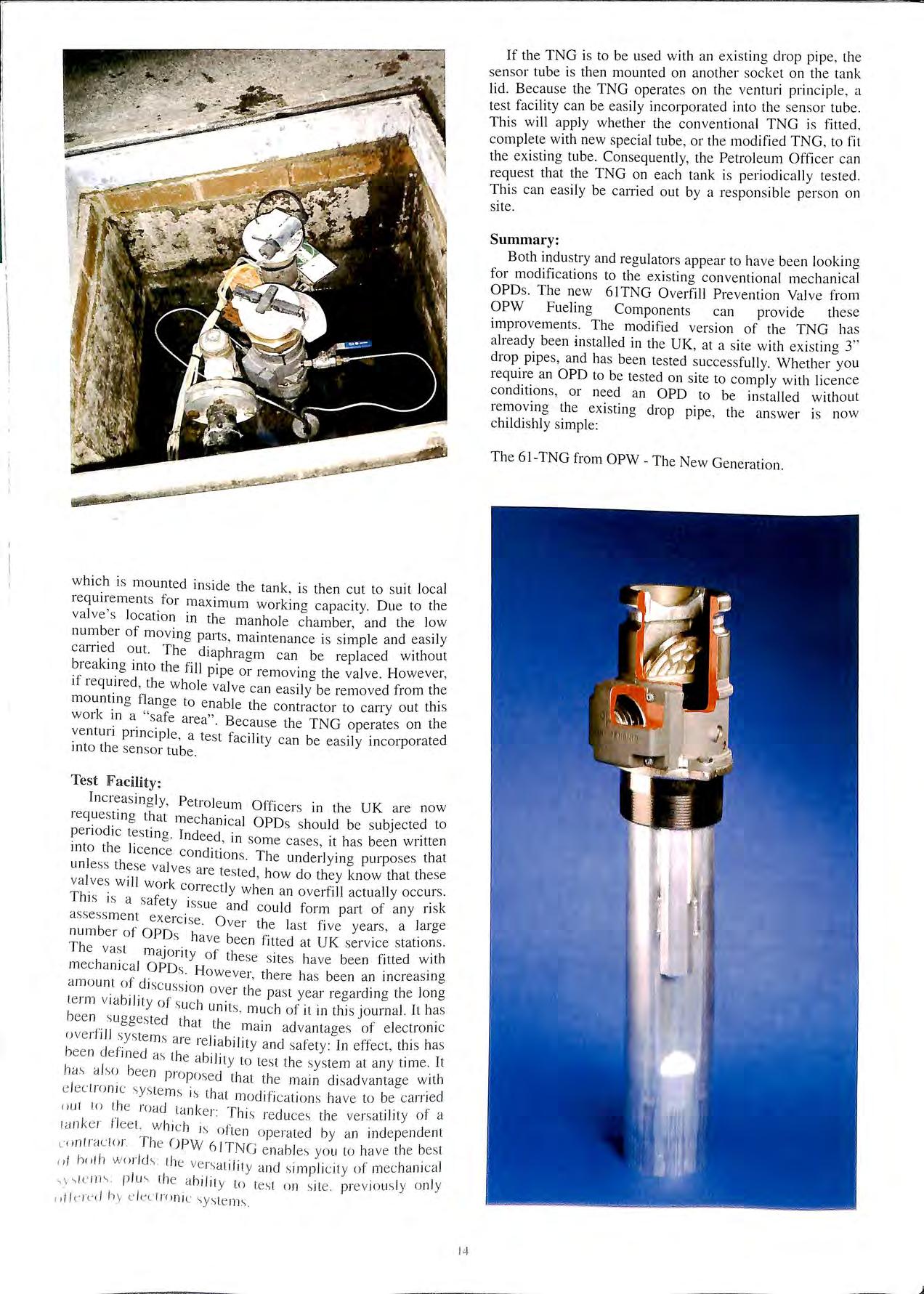

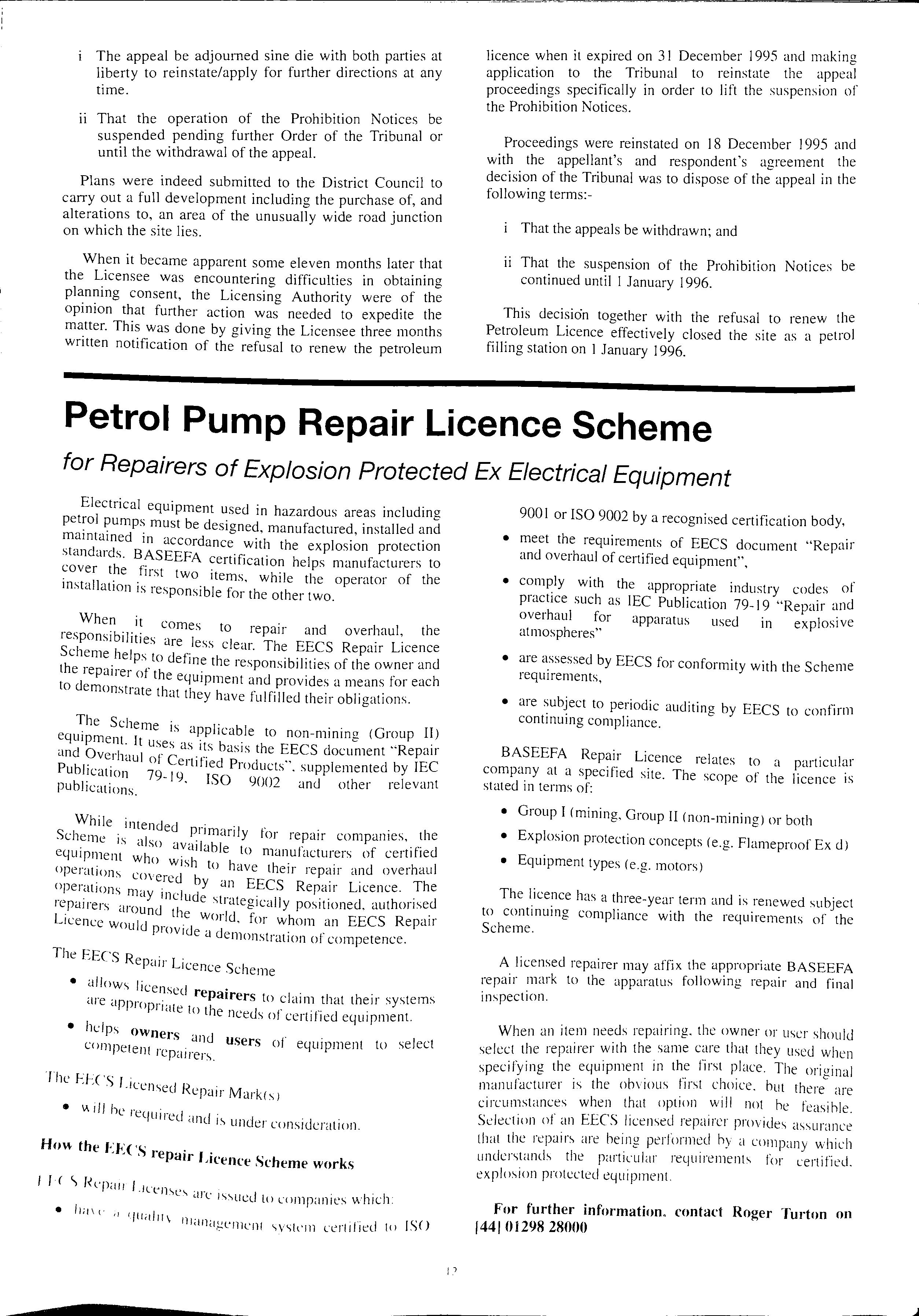

For new tanks the TNG is usually supplied with its own special drop pipe, as with OPDs, 61 TNG uses a venturi mechamsm. s11mlar to an automatic nozzle. The product flow through the suction tube_creales a vacuum. This vacuum, which would pull the diaphragm closed. is relieved by the sensor tube. Once the product level reaches the bottom of the sensor tube. at a delennined shut-off level. the vacuum is n'.1 longer bemg relie\'ed and exerts a direct pull on the diaphragm. The diaphragm in turn operates a cam that moves th: · I · d l tlo•v st·1·eam The product flow then closes mto t 1e p10 UC ' • . ' . '.. ., 1 t hi ']1 stays closed until the head p1cssllle 1s t 1e poppe w c . ' · relieved. After shut-off. the valve 1s held closed by the head f tl pi·tidtict 011c'e' the outlet valve on the road pressure o 1e ., , . , ., ., , , , k · I , ·iiid tile' 11e·1d pressllle 1s thctdiv 1eh1::v1::d. tan er 1s c oseo. , ' · · I l Pells 'lLill1111·1tieallv Tlus then _allows _h_1st t 1e poppe re-o . ' ' : , · p·ii·ed to the s1,1ml 1cantly reduced !low onunage com , · "' lhrougli drain ports 011 other mechamcal 61 Tr-:G · · II -1 , tll"' 111·11111t1le chamber and 1s therefore east!\· 1s msla Cl 111 ' • accessihlc, As the complete valve not hm_·e lo pass through the nipple into the tank. the P'.trl ot the valve has bL'Cn positioned_ ol the thus optimising 110\V rates. Flow restnct1on 1s less than with other mechanical OPD on the market today. allowmg ,·irtuallv full-bore delivery. These ft'atures allo\\ the driver to com;11ete his achie\ ing cconomiL'S for the operator and m1111m1_s111g 111L'On\l'nlenl·L' l\) the -.itc. The 61 TNG is supplit'd wllh own butlt-111 adaptm \\'hich threads onto the nipple in the manhok L·hamhcr. This adaptor then pnn·idcs a flanged joint for mounting the TNli holh'. Tht' sL·nsor whc then connL'l'll'd tP a nominated spai:e entry nn thL' manlid. Tht' last pan of the '-t'nsur tube.

I

which is mounted inside the tank is then cut to suit local requirements for maximum working capacity. Due to the valve 's location in the manhole chamber, and the low number of moving parts, maintenance is simple and easily carried out. The diaphragm can be replaced without breaking into the fill pipe or removing the valve. However, if required , the whole valve can easily be removed from the mounting flange to enable the contractor to carry out this work in a "safe area". Because the TNG operates on the venturi principle, a test facility can be easily incorporated into the se nsor tube.

Test Facility:

Increasingly, Petroleum Officers in the UK are now requesting that mechanical OPDs should be subjected to periodic te sting. Indeed , in so me cases, it has been written into the licence conditions. The underlying purpo ses that unle ss the se valves are te sted, how do they know that the se valves will work correctly when an overfill actually occurs. This is a safety iss ue and could form part of any risk assess ment exercise. Over the la st five years, a large number of OPDs have been fitted at UK service stations. The vast majority of the se site s have been fitted with mech a ni ca l OPDs. Howe ve r, there has been an increasing amo unt of di sc uss io n over the past year regarding the long term v1ab i1Jly of s uc h units , mu ch of it in this journal. It has been .. s ugge s ted that the main advantages of electronic ove rfill sy stem s are re liability and safe ty: Jn effect , thi s has be en de fined as the ability to test the system at any time. It ha s a lso bee n proposed that the main di sad va ntage with e lec tron ic syste m s is that modifications ha ve to be c arried o u t to the road tank e r T hi s reduce s the ve rsat ility of a ta nk e r fl ee t, w hi ch 1s often operated by an ind epe nd e nt l on tra ct o r T he O PW 6 J TN G e nab le s yo u to ha ve the bes t r ii h()t h th e ve rsat i/it y and s impli city of mec hani ca l ,y, re 1m plu , th e abi lity to tes t o n site pre viou sly on ly 1 ,·f/e re d hy e le c troni c sys te m s

If the TNG is to be used with an existing drop pipe , the sensor tube is then mounted on another socket on the tank lid. Because the TNG operates on the venturi principle, a test facility can be easily incorporated into the tube. This will apply whether the conventional TNG 1s fitte?. , complete with new special tube, or the modified TN_G, to flt the existing tube Consequently, the Petroleum Officer can request that the TNG on each tank is periodically tested. This can easily be carried out by a responsible person on site

Summary:

Both industry and regulators appear to have been looking for modifications to the existing conventional mechanical OPDs. The new 61TNG Overfill Prevention Valve from OPW Fueling Components can provide these improvements. The modified version of the TNG has already been installed in the UK, at a site with existing 3" drop pipes, and has been tested successfully. Whether you require an OPD to be tested on site to comply with licence conditions, or need an OPD to be installed without removing the existing drop pipe, the answer is now childishly simple:

The 61-TNG from OPW -The New Generation.

I l I I l t '

14

Petroleum Inspectors Call Out Report

By Ray Stenson, London Fire Brigade

PREMISES:-

MOTOR SERVICES, 308 WEST GREEN ROAD, NlS SUPPOSED CAUSE:PETROLEUM SPIRIT LEAKING INTO THE GROUND FROM A STEEL SUCTION LINE

DATE OF INCIDENT: 18/9/95

On 18 September 1995 LFCDA petroleum inspector Ron Young was alerted to attend an incident at Langham Road School N 15 where London Fire Brigade appliances had been called to attend to a strong smell of petrol in the girls' changing room in the gymnasium emanating from the drainage gully in the floor.

What occmTed thereafter was a series of events lasting over one month which had resource implications for the LFCDA, the local authority drainage specialist, Thames Water Utilities (TWU) and Mobil oil company, and affected the day to day lives of school pupils and staff. as well as patrons and staff of a nearby public house and filling station.

On arrival at the scene, Mr Young's first action was to take an explosimeter reading and, as a high reading was recorded on the apparatus when placed adjacent to the !=Sully, he adv_ise? that windows and doors be opened to mcre?se He then visited nearby commercial attempt to ascertain the cause of the smell. His first v1s1t was to K. K. McCools public house which had been the scene of a previous incident on 15 September I when petr?I smells had been noted in the ladies tmlets. On entermg the premises ·i sm II f I ·d · · ' · e o petro was ev1. ent; a further explosimeter test carried out in the toilet registered another high readino and th · d · d b• e mspector a v1se that the door be left open to inci·ease t"I . h ven 1 at10n as t ere were. no wmdows m the toilet. A subsequent tour of the premises revealed no smell of petrol 1 · th b II n e pu ce ar.

The inspector's next port of call w·is to th M b"l . . '" G · R d ' e o 1 site m vvest 1een oa , some 150 metres f" 1 h · ·d · dW.ty 1om t le pub on t e s1 of the road. The manager gave details of the mc1dent which occurred on 15 S t h 19 · ep em er 95 and stated that TWU had mvestioated th d. · · · • b e rnmage. mcludmo the mterceptor. and found nothino ui1t ·d Th b "' h · . . b owm . e manhole cove1 s to t e offset fills were then 1,.f·t d d 3 e an revealed that tank no. supe1 unleaded· and tm1k 11 4 1 d . . . • o un ea ed· were heavily contammated with spirit and . ·d · ' · d · .tn I ent1cal aronn to that faun m the school and pub was t d T k ' '.l (4*) were only T h I " no _e an s no. I and :- · ig t Y contammated. The basic mstallat1on at this site 1s 23 years old . d 1 . d · .tn t 1e suction lme runs me ex ten ed to the pumps furthe. . 1-. 'most 10m the tanks so that many a1e. chopped Imes A rer)l·i. 11 · II · · • 'cement o set till had been msta ed the previous ye·ir A · . d · ' · n 111spcct1on ol the site recor s revealed losses in the ma1·11 t ) h . . , () , h l e aIOUill1 1c/r but over t e pre\'lous few days t·ink no I t" d. ··I d . 1c1 • • ee mg pumps 5 and 6 s 10we a 1c loss. Mr You no im 111 ,d· t 1 1 1 d I b e Ja e y c osec these pumps an t 1ereafter closed the sit, I f' 1 1 · t Lown or t 1e cay at 1700 hours pendmg the visit of the oil t · company Itters the lollowmg day. He then made retun1 ,, 1 ·s,·ts t tl I I · · 0 1e SC 100 a1_1d pub where explos1meter readings remained constantly high His next \1s1t wa_s .to a neighbouring premises whici1 dealt 111 tyres and repairing carburettors. He was informed

by the manager that the company had only been in the premises for four months and did not pursue the carburettor side of the business. The tyre bay workshop floor was cleaned every week and Mr Young concluded that these premises were not a contributing factor. No contamination was found in the interceptor and a check of the foul drain and the outlet side of the interceptor revealed no trace of petroleum spirit. Due to the nature of the incident the local authority had to be notified. Accordingly, Mr Young advised the London Borough of Haringey's drainage specialist team who in turn passed the information to TWU. A joint inspection of the nearby sewer then ensued.

The following day the Mobil fitter duly on site and was instructed to test all pipework. The mspector then made a series of visits to the premises affected by the smell of petrol the previous day. There was no smell in the pub at 0900 hours but an explosimeter reading in the sch?ol showed a rise from the previous day. As smTmmdmg ground contamination was seen to be seeping_ into inspection wells, these were investigated to ascertam the level of contamination as the site had problems over the previous year. At a return visit to the school _some three hours later, with a hose having been turned 111 gully on Mr Youncr's instructions since his earlier v1s1t that morning. the reading had fallen The smell in the pub had by now abated and a ml readmg obtained. Back at the Mobil site all pipework was found to be sound except that to pumps 5 and 6 trom No I which had been leaking and capped o_ff. mspector 00 ted a 111eetincr of all interested parties to 11nprove the subbes L e f 1 f t tl site and called for a tank inspection m view o t le ac 1at the installation was 23 years old.