Betty is happy to introduce the OPW drip-less nozzle

That

ly.

f Al L-SAfE. In the event of the valve not resetting, it will close during the next fill, preventing a dangerous and costly overfill other valves can fail in the open position. VAPOUR TIGHT. fmco Wheaton have not had to introduce a bottom seal recently, because the A 1100 valve has always been fitted with one . DIPSTICK FRIENDLY. Dipstick can be used whether tank is full or empty. FAST SERVICE. The A1100 is assembled and tested in the UK. Therefore we are able to respond quickly to demands from our two UK stockists. For further information on the Emco Wheaton range of products for Service Stations, please contact Rob Laird at our Margate Office.

® Emco Wheaton Retail Europe Enterprise Road , Westwood Industrial Estate , Margate, Kent, CT9 4JR Telephone: 01843 221555 Fax: 01843 295444

Talking Point

As the HSE contemplate legislation changes within the UK to control petrol filling station s it is clear that politics are beginning to play an important part in what is essentially a public safety issue.

The Government are trying to de-regulate and the wo rd li c ence appears to be no longer in their vo cabulary N i g el Griffith s L ab our 's con sumer affairs spokesman has been quoted sayin g " The reason why there have been so few explosion s or incidents inv o lving petrol is testimony to the effectiveness of the present licen sin g system. Now Mini sters want to throw all thi s away and put the public at ri sk. "

Association : STEP HEN BLANC HARD YO R KS /-llR E & /-! UMB ERS /DE BRAN C /-1 lEDKTORl AL T EAM RO B GREEN

of 2 6 8 9 10 14 16 17 11?/S /-I B RAN C /-1 ANDY BE RRY SOU TH ERN BR ANCH MIKE SILMO N N ORTH EA STER N BR ANCH LI NDSAY LL O YD M IDLA N D S BR ANC/-1 J AM IE THOMP SO N E f)/T O R

STAGE l JAN HI LLI ER S CO Trt S /-1 BRAN C /-1 A D VERTI S ING' SE CR ETA R Y

STEEL PIPE

APEA CONFERENCE 1997

The APEA annual conference and exhibition will be held at the Metropole Hotel in Birmingham on 1Oth and 11 th November 1997.

Please reserve these important dates in your diary.

PETROLEUM EQUIPMENT & TECHNOLOGY MAGAZINE

The Association is including with this issue a free copy of the US based magazine PE&T to all members. The magazine is a technical journal covering the petroleum industry and is based in the US.

Members wishing to subscribe to this journal are invited to fill in the subscription card with its speci a l rates.

The Association has agreed to cooperate more fully with the s taff of PE&T John Hartman and Kally Fraser and we expect to print matters of mutual interest and hope this liai so n will benefit both parties.

I would be interested to hear from any of our reader s on what they think about PE&T.

RISK ASSESSMENT VIDEO

A new video us ing th e lat es t computer si mulation techniques ha s JUSt been produced for a ll indu s try to use as a training aid to und e rsta nd ri sk assessmen t at the fillin g stat ion. It is a lso very beneficial as a cre neral trainin cr aid for all people visiting petrol s tat ion s as and officer:. Th e video ha s bee n produced by BEC Medrn 1n assoc 1at1on with th e APEA , the PRA a nd UKPIA , and 1s fully s upport e d by the HSE. Th e video tak es a uniqu e Journey through a petroleum in sta llation from the fill po int to the dispenser look s und e r the fo reco urt and views th e ha za rd o us zones with 30 clarity. The video defines H azard Ri s k an d Control M eas ure s a nd exp lain s th e risk assessment process 111 a very clear and highly visual way.

:he Yid e_o is a:a ilabl e from the APEA a t a s pec ia l pri ce of U6.44 1nclud1n g VAT/p os t a nd packag in cr M e mb e rs wishing to order a copy of this v id eo ca n Barba ra Ja c ke tt s on tel 01473 828539.

MEMBERSHIP RENEWALS

This yea r we have req ues ted that yo u quote th e renewa l lette r . reie re nce . number w hen pay in g yo ur a nnual s ub sc ripti o n. Thi s you ha ve clon e , a lm ost without except io n, and l would lik e to th a nk yo u for yo ur effo rts , as it mak es m y JOb a lot eas ie r.

There are st ill a numb e r of yo u w ho have not re newed yo ur s ub scr ipti o ns yet fo r 1997. If you w is h to re ne w. co uld I .ask yo u to let m e have yo ur c heq ue/cre dit ca rd s lip wit ho ut dela y pl ease . H yo u have rece ntl y re tired fr om th e indu s try and no lo nge r w is h to be a me mb e r, a note to thi s effec t wo ul d be g rea tl y app rec iate d.

Man y th a nk s

Ba rbara J ack e tts

TRAINING PROGRAMME

The Association has recently run 6 trammg courses covering explosives, electrical , risk assessment, and a very popular two day residential course Petrol Filling Stations Control and Construction. Bri a n and Eileen Taylor have been working on the planning and organisation of these courses and plan others during 1997 , with the first one likely to be the two day course on petrol filling stations.

The Association wishes to record its thanks for those members who have given their time to pass on their knowledge in this way.

The APEA will be running a full training programme for the spring and summer of 1997 , deta il s will be published shortly. If you wish to book a place on the two day Petrol Fillin g Stations Control and Construction course at Hemel Hempstead on 8th/9th April or would like information on other courses run please contact:-

APEA BRANCHES

If members wish to attend branch meetings please contact your branch secretaries, the following county list shows attachment to the branches, however if members wish to attend another branch they may do so.

ALPHABETICAL LIST OF BRANCHES AND AREAS THEY COVER

Eastern Branch

Bedfordshire, Buckinghamshire, Cambridgeshire, Essex, Hertfordshire, Norfolk, Northamptonshire, Oxfordshire, Suffolk

White attended Lubbock High School in Texas Technological College. He is a licensed underground storage tank installer and remover in both Texas and New Mexico. He has been an active member of PEI, serving as treasurer in 1995, and vice president in 1996. He was also elected twice as a district director, and once as district codirector. He also has served as chairman of the Texas Association of Storage Tank Professionals. He has served as co-chairman of the Texas Tank Installers Trust Fund. He was also elected chairman of the Board of Directors of the Tank Dismantlers of the U.S., Inc. White is a member and deacon of the First Baptist Church of Lubbock, a member of the Texas Tech Red Raider Club, and a lifetime member of the American Hereford Association.

White and wife, Sandra, live in Lubbock, and have three sons.

Humberside Branch

Irish Branch

Midland Branch

Humberside, Lincolnshire, Nottinghamshire, North Yorkshire, South Yorkshire, West Yorkshire

The Island of Ireland

NE Branch

NW Branch

Scottish Branch

Southern Branch Wales Branch

Derbyshire, Gloucestershire, Hereford & Worcester, Leicestershire, Shropshire, Staffordshire, Warwickshire, West Midlands Cleveland, Cumbria, Durham, Northumberland, Tyne & Wear

Cheshire, Clwydd, Great Manchester, Gwynedd, Lancashire, Merseyside

Scotland

Avon, Berkshire, Devon, Dorset, Hampshire, Isle of Wight, Kent, Greater London, Somerset, Surrey, East Sussex, West Sussex, Wiltshire, Cornwall

Dyfed, Glamorgan, Gwent, Mid Glamorgan. Powyd, West Glamorgan

NEW PEI PRESIDENT

S Bill R White, president of White's Pump Service and Inc., Lubbock Texas. has been elected to serve as of the Petroleum Equipment Institute (PEI) eurnnrng J·in . . I 1907 W . . ' 0 uai Y , ':I • h1te was elected dunner the Inst1tute's 4fth I e · 1 ,mnua conventron and trade show held recently i o ·I d F . · , . . n r an o, lorrda. More than 4,800 delegates Were in attendance.

PEI is corn · · I 1· · pnsec o more than 1,500 compa111es engaged 1n the rn-ml1l··1ctl1r·· d d' ·b · · · ' ' mg an rstrr utron ol equipment used in ope_rati'.rns. are located_ in all Lites ,md Ill 61 lore1gn countnes. The Institute 's headquarters are located in Tulsa. Oklahoma.

White joined White's Pump Service and Supply in 1960 ''.nd hecame. president in 1973. The company provides sales. idvout design. 111stallation. and service of petroleum hand Ii ng and marketing equipment. It also supplies survey <tlld l."OnsuJt111g services for the applicability of llCW rules .111,J rcµ11J;1t1ons for existinl! and new undemround Jll'ff1 ;J,_·11111 ,11Jr<1µe tanks. ' '

APEA YEAR BOOK

The APEA yearbook has been published and delivered to all _members ready for the new year, the new format is des1gne_d to be more user friendly. We received some from people who were not included, this was mamly due to people not completing the form that was sent out to them in June. The following list of amendments should be noted.

INAUGURAL MEETING OF THE APEA WELSH BRANCH

The inaugural meeting of the APEA's new branch in Wales took place on the 25th November 1996 in Cardiff. The event was a tremendous success, with 33 new/potential members and a warm, friendly atmosphere.

Phil Monger, the APEA National Chairman, opened the business meeting at I 1.OOam and welcomed members, who came from both industry and the new authorities. Before the commencement of the business meeting, Phil gave a brief resume of the APEA, outlining:

• the different sectors of industry and authorities involved within the Association

• the APEA's representation on the different British and European Standards Committees

• the formulation of the TCB document at the request of the HSE

• and describing some of the Association's activities

Phil went on to thank Sue Meadowcroft, Barrie Gardiner and Barbara Jacketts for their work and enthusiasm in getting the branch off the ground and said that he hoped that this enthusiasm would go through to the officers elected at the meeting.

The following motions were passed/officers elected:

Motion/Officer Proposed Seconded

Motion to fonn the Welsh Branch B Jacketts Gordon Taylor

Branch Representative -B Gardiner S Meadowcroft MTamplin Secretary/Treasurer

-S Meadowcroft B Gardiner P Monger

Chairman -D Holland J D Jones J Irwin Vice/Chairman -G Coles D Holland TWay Committee -B Tierney TWay B Gardiner -G Taylor G Coles S Peters

P. Monger agreed to source a retailer as a possible third member of the committee.

Motions wer.e carried hold branch meetings twice per year and committee meet111gs on a quarterly basis.

Following the business meeting there were three very interesting and well received presentations from:

D Holland of Cardiff City Council

C Anderson of Cookson and Zinn Ltd

INDUSTRY MOVES

Bob Higgs has recently moved from Wayne Autocourt where he was Managing Director for a number of years to Pumptronics, the Norfolk based petrol pump

Rory Hennessy has moved from the London Fire Brigade to Tesco in a "gamekeeper turned poacher" role and he takes over the fire and petroleum position formerly held by Rick Rowswell who retired last year.

OBITUARY

DOUG WHEATLEY, Managing Director, Wheatley Engineering, Hedingham Road, Wethersfield, Essex

One of the petroleum industry's most respected figures, Dauer Wheatley, renowned for his innovative skill in finding solutions to age-old business problems, has died. Doug, who lived with his wife Davinia at Glenmead in Chapel Road, Ridgewell, in Essex, was 51.

His inventiveness as a precision engineer won him a substantial reputation with many of the most prestige UK companies Rol.Is . British Aerospace, . the Engineering Industnes Association who have remamed clients of Wheatley Engineering for more than 20 years.

When a criant oil company asked how to overcome the disruption :nd expense of shutting forecourts to install d vices and service pipes to underground product tanks, Wheatley brought his particular talent and a lifetime's to on a problem which had defeated the industry worldwide.

The result was the of a revolutionary new h · e of drillincr directly mto tanks full of product a tee mqu e method which has earned the approvhal .of the u1K and Safety Executive as well as local aut onty petro eum o 1cers.

0 er Wheatley was an astute businessman who created a ou,,,cr· eerl'ng wing to his business, BORTEC LIMITED, new en,,,m k . 'd' r which today has captured the mar. e1t m prov.1 mgd lsts 1 · ·e1noval fittincr ove1fil prevent10n ev1ces and m fil pipe I , "' d . d . d -'JI' _ without the need to ram .un erground dll'ect 11 mg fill I with water close the forecourt and dispose tanks, 1 t 1em ' of contaminated waste.

on Petroleum licensing and the APEA on Double skin steel fuel tanks

T Foster of Chemsafe Ltd on Fuel tank testing/re-lining

We all wish the newly formed Welsh Branch every success in the future and. hopefully. the APEA will have an important role to play in providing information to the new authorities and industry alike.

I ersonal (ltialities for which Doug Wheatley Among t1e P · 1 · • · • d . b t . nembered. were his corn tesy .in good will be es ie1 t···, cl ·I , h' h 1 -t·iblishcd hte-long 11en s 11ps wit 111 the humour w ic 1 es ' I d I . . d ·t Outside work he p aye a centra role 111 petroleum 111 H.A.T.S. the Hedingham Amateur am·1teur dramatics I f' JI · , ' . S · t _ building a regu ar o owmg tor his Dramatic oc1e y 1·1 I .• cl I ich as "De 1 a 1 . cameo come Y ro es st · t j c1 11 1 ·cti"ii1s Doug and his wife moved from A · con irmel ·' ' · · . s II 8 . nt\"ood in Essex near to the church they R1doewe to 1e ' I "" 1 p, te ·ostal Church. some mont i:-. agu. adopted. Pcn1e en L ·

I I ·. lt)ll'' h·ittlc against cancer Doul!, remained ThroU" 1out 11s e ' '. . . "'b · , , . ·itfiirs and attended church sePdL't's even ·1ct1vc 111 usmess' ' · · ' k . 1 ·Iv enf.O)'ino the choral music. He died at St wee · part1cu ai ; "" S j ' · F ·. H . · " 11 ,.11· BrentwmKI on aturc av. '.'Ith Octoher ranc1s osp1t:t: c, , · · TI f 1 h· s 1.,,l1 tiested donations to (() St. h·ancis s 1e am1 v .1. ·1 • · · • M f · ·d. ·itt"'nded a special scn·1L·c to L'elebrate Douu "s any nen s , , _ ,,. life at Pcniel. Brentw1)od. on Tuesday. I '.'Ith Octuhcr.

Dou" Wheatley leaves his wife and sewn children. s i 111011 Phi Iip. Janws. Cii 11 ian. Lulu. Luma and l'hristuplwr.

OLDCASTLE FORTIFIED VAULTS OFFER THE "ULTIMATE PROTECTION"

FUEL IS SEALED IN WATER IS SEALED OUT!

Oldcastle Precast, Inc. produces the only secured below grade fuel containment vault system on the market today.

These fortified vaults are custom designed to specifications up to a 15,000 gallon capacity and are renowned for their structural design and unique sealing system which offers a lifetime of problem free maintenance. The vaults are tested and proven for reliability in environmentally hazardous areas, and will withstand such disasters as earthquake activity and high water levels.

Oldcastle Precast vaults are classified as (AST's) because fuel storage tanks are located within a vault which allows for easy accessibility and visual inspection. Because of these unique features, insurance costs are greatly reduced, financial responsibility is virtually eliminated and many states are exempt from (UST) clean up taxes.

The UPP system meets all site needs , including Fill, Vent, Pressure, Suction and Vapour Recovery lines and includes a range of Containment Sumps, Tank Access Chambers and lightweight manhole covers.

UPP adheres to the Institute of Petroleum of Great Britain standards and has been approved for use in over 40 countries around the globe. UPP Extra has been tested to UL requirements and recorded a zero permeability level. Full UL listing is expected during 1997.

Using a thermo-fusion welding method, the UPP system can offer joint-free primary and double contained lines that accommodates leak monitoring systems. UPP pipe is robust and rated at 150 psi on pressure lines. The system is now in its l 6th year of use and has not lost one drop of fuel due to product failure. UPP offers the optimum mix of flexibility combined with tensile strength that provides the best solution in environmentally-safe non-metallic systems.

UPP is simple and quick to install. It can withstand extremes of temperature and is insensitive to ground movement.

UPP is used by Shell, Esso, Mobil, BP, Texaco, Caltex and many others who consistently specify UPP as the leading brand available. UPP is the #1 system in Europe and Asia-Pacific and is now available in the USA.

Petro Technik are appointing and training certified di stributors and manufacturer's representatives across the USA in order to make the product available to specifiers and installers nation-wide.

SSL TURN TO TANK TESTING

Solution s Specialist s Limited (SSL) have been appointed UK wide di stributor s for the Piper Precision Leak Det e ction Sy stem used to te st petroleum tanks and pipe-work.

With a growing population of underaround tanks b reachmg the age when annual te sting bec omes mandatory. the Piper System provide a quick , s imple, low co s t method of identifying lea ks in storage tank s and their associated pipe work , without the need to empty the tank s or close down the s ite.

It is es tim ated that the equivalent of 64 full tank e rs of fu e l are di sc harg ed into the ground across th e UK every 3 month s Th e Pip e r Sy ste m pinp o int s eve n th e s mallest le ak. thereby e ns urin g that re me dial ac tion ca n tak e place before th e cost beco mes too hi g h.

Th e bri efc ase s ize d ec1uipm e nt ha v in a be in a put to b ::::. s tre nu o us tes ts in th e UK and in th e USA , is now acc e pte d by fir e a uth o riti e s a nd major o il compani es alike. Using the lat es t in ad va nced mea sure me nt technology. th e s it e op e rator ob tain s co nc lu s ive res ult s minutes a ft e r th e s impl e two ho ur tes t.

SEALED PAVING SYSTEM REDUCES FORECOURT FIRE RISK

Growing concern about th hydroc a rbon residue s d e potential build up of 1 un e1 petrol fo 1qu1d co ntamin a nt s percolaf 1ecourt areas and the d eve lopment of 1 _ m g mto the s ub so il has led to f II ' w Mt is believed to b I u y sea led pa vino system_ p . e, t l e UK ' s first b et 1apave.

Th e u se of sealed pavmo sys te commonplace across many Euro b · · m s 1s already 2 million squa re metres of lpean countries. Smee 1988. I . I cl sea ed block aic an m sta ll ed 0 11 pet. 1 f . pavmg h as been I G 10 01ecourts I anc e rm a ny alone. · 111 t le N e therlands

This grow in g trend h as cl 1 · · eve oped t II · m many European countries h. 1 0 owing leg isl at io n .· k f . . w ic l dictates th I is a 11s o toxic liquid s or s b _ c at w l e re there · u s ta nc es p II · 01 uncl e rlym g ground 1 se 1 1 : 0 utmg local water · ' c a ec su rJ · mstallecl with clrainaoe a nd • t 1 ace material mu st b e b c Ccl Cl pits p. · j accidental s pillage 1 ov 1c eel to deal with

Barring the in oress ot· p t. 1 b e 1o eu 111 b cl . prevent a n y pos s ibility of b 1cl ase fuels will also cl u1 UJJ of un e rn eat h the s urfa ce so 51·0 1 '" petrol vapour ·· · b n1 icantly · cl · tire or exp lo s io n. i e uc111g the ri s k of

Petrapave, dev e loped bv 1 1 J eac 1n a b ·11 manufacturer Marsh a ll s 1 1 • 15 b n b ui c 111 g m ate ri a ls c ee n Ill trod cl ant1 c 1pat1 0 11 ot more s trinoe t . . u ce 111 th e UK 1n E n viron m e nt Agency from the I b e u se of sea l cl sys te m s 111 t lJ S co untry · · c e pa v in g

Three years of in_-depth rese·li·cl 1 I ' l anc n ooro t . e el to th e la un c h of this hi uh d e n s ·t· 0 us est 1n g ha s I I '°' I y co n c ret e bi k w ll C l wo rk s 111 co njun c tion w it h a i · I· oc pav111g joint sea la nt. 1 e as ti c polysulphicl e

Th e sea lant u sed in co njunction with Petrapave is a hi gh s pecification , two part polysulphide compound which ha s been dev e loped to re s ist more than I 00 different c hemical s .

When correctly applied, it preve nt s p e netration of, and ha s lon g te rm resi sta nce to, petrol , diesel and mineral o il s It will also with s ta nd extre m e c limatic co ndition s a nd can accommodate seve re deflections in the pavem e nt w ith o ut losi ng integ rit y of th e sea led j o int as in trafficked s ur faces

Anoth e r advan tage of th e sea la nt is its ability to 'k nit ' s h o uld repa ir be necessary. If Petrapave blocks h ave to be uplift ed to acc ess und e rl y in g piping or se r v ices the new ly app li ed sea lant w ill ' knit' wit h th e ex ist in g mat e ri a l eliminating weak poi11ts in th e sea le d j o int.

Th e se alant qualifi ed to th e KIWA CSO spec ifi cat ion und e r cert ifi cate K7462 (a E uropean Ce rtifi cat ion Stand a rd ). is solv e nt fre e a nd se lf leve llin g It is in sta ll ed b y spec iali s t sea la nt app li cat ion co mparn es us111g s pec iali sed. co mput e r co ntro ll e d g unnin g sys te m s w hi c h ha ve b ee n d eve lop e d to e n su re pre ci se compon e nt 1111 x 1n g. co n s tant te mp e rat ure and uniform flo ws

Guara nt ees of th e System s pe rfurman ce a re also availabl e from Mars ha lls appro ve d in stallatiun n111trnctor s.

Th e Pe trapa vt' system is crem in g growing interes t fr) b I I cl. \ 111 .t num e r o · parti es 111 c u 111 g p e trol s tations 1 1-1-t iLit 11 -· · ' · ' llllllC S and s up e rm a rk e t cha in s. It has alre a d y bee n in sta lled 0 11

two UK petrol forecourts the first in St Helen s, Lancashire , and the second in Leed s, West Yorkshire The two s ites total appro x imately 1,200 square metres of the Petrapave sealed paving sys tem

Petrapave's physical properties are complemented by its hexagonal shape and nine colour options to suit a variety of applications and which help to disguise spillage stains. P e trapave also offers the advantages of traditional concrete block paving It is quick to lay which is particularly beneficial for large applications and can be trafficked within 24 hours The multi directional interlock gives excellent load bearing characteri s tic s.

Not only is Petrapave se t to have s ignificant effect on th e s p ec ification of surfacing materials for petrol forecourt s. It a l so has the potential to be in s talled in refineries, chemic a l plants , diary and brewery applications, tanker parks and wa ste management depots.

Further technical information re g arding the Petrapave S ealed Paving System , its specification and installation is available through Mars h a ll s Te chnical and Advi so ry D e partment on telephone 01422 306300 .

PETROL STATION PERFORMANCE MONITORING

(Petro l Station s, Supe rm ark ets, M o to rwa y Service Area s etc.)

Four companies h ave go t together to pro v ide a monit o rin g sys tem in a Mobil/Bud ge ns s uperm a rket pe trol statio n s ite at Milton Ke y n es. Thi s in stallation ha s bee n in st a ll e d to demon s trate th e ad va ntao e s of el ec tronic fac iliti es monitoring Th e M a in Elect;ical Control a nd Di s tributi o n Panel manufa c turer ' s Control Sy s tem s a nd Eq.u1pment, of Bourn e End Bu ckin g hamshire , main pan e l build e rs to Mobil R e ta il , h ave ad diti o nall y in co rporate d temperature, e n e rgy co ns umpti o n and line lea k aoe b m o nitorin g into the main pan e l durin g manufacture.

This ha s been the brain c hild of Mobil 's former ret a il e_ lect ri ca l engineer To ny T om ly n To n y says th a t for the fir s t time we ca n s ee clearly w h e re the e n e rgy i s b e in g use d and h ow e quipm e nt is pe rform in g . Toge th e r with th e te mp e ra ture monit o rin g a ppli e d to th e cold ca bin ets th e s y s tem wi ll be ca p a bl e of ca llin g th e s pec ific repa ir co ntra c to r thu s remov in g th e tediou s ta s k s fro m th e staff a nd imp rov in g ca ll o ut p rocedu re s Th e co ntra c to r w ill be ab le to diagno se th e exact fa ult before oo in o o n s ite thu s preparing him for th e e x act ta s k. Th e co mp a ny w ill obta in a n accountability reco rd thu s also d e ta ilin o th e pe r fo rm a n ce of the repa ir co ntr acto r. A useful to o l a ny maint e n a n ce burea u a nd o pe ra tin g compa n y

M o bil h a ve a lway s m a int a in e d a oo o d c usto m e r se rv ice re la tion s hip c o upl ed es pe c ia ll y w it h 0 safe ty and ca re, thi s sy s te m w ill e n ab le th e m to furth e r e nh a nc e thi s a nd at the s am e ti m e a ll o w s taff m o re t im e fo r th e c us tom e r.

Th e se c o s t e ffec ti ve inno va ti o ns prov id e a not he r leve l o f \ al e ty a nd c are

T hi \ initi a l in s ta ll at io n is m e re ly a cl e mon strali o n of lll c>n11 o nn g c apabi liti es . T h e sy s te m is a lm o s t infin ite ly L'X ]X1nd a hle lo c o ve r w h a teve r a ny o pe ratin g c ompan y ma y n: q 1.11re. T h e sys te m a lre a d y pro v id es h is tori c a l a nd c urre nt l\' l '1 rd \ w h ic h c a n he in te rroga te d a t a n y lo c ation us in g <I PC p l11 .i2µL'l l 111 lo <1 te le ph o ne lin e T h e te mp e rature m oni to ri ng

alone provides a useful service eliminating the need for s taff to continually log the temperature of each cabinet. Accurate food hygiene record s are a m a ndatory requirement.

It is expected that the condition monitoring will reduce the downtime during a nnual testing as well as anticipating and eliminating some electrical breakdowns. The system is also two way and certain parameters can be set from a remote location. The system controls the switching of all external lights again providing a significant energy saving facility.

Tony says that thi s is undoubtedly the way in the future , ' to be able to analy se and fine tune the installation a nd therefore fully support safe reliable efficient retailing '

TANK CUTTING

Dave Abbot of Abbott Power

It appears inherent in our Industry that we mu s t have photographic evidence of ju st about everything that goes on. Don't get me wrong , I think its great and to tho se e nd s I s ubmit a photograph which I feel a bit different but still very much akin to our Industry albeit the demolition s ide

The feature the demolition of an 8 million litre die se l oil storage tank which I witne ssed.

After the tank w as gas freed and certification issu ed a large hole was cut in th e sid e of the tank for m a n a nd winch access. There is no central support for the roof, it being ca ntilevered from th e sid es. Th e roof is oxy-acetyl e ne cut appro x imately I metre from the outer edoe (to re tain ri g idity of the tank ) for th e full diameter of th ; tank. Whil s t cutting the roof of th e ta nk the und e r s id e ca ntil eve r s upport s are also cut. All th e cantilever s upport s b a r three a re severed Th e photograph shows the nea r co mpl e te d flam e cutting operation from inside the tank. Wh e n this operation is complete the area is cleared of pe rs o nn e l. W111c_h .cables which were previou s ly attached to th e three rem a111111g s upport s ta ke up the strain and as th e re is 80 to nne s plu s we ig ht on th e roof the remainin g cantilevers she a r and the roof falls in. Thi s is then c ut int o s rnall e r re mo va l a nd th e s ide s s liced up with hy dra uli c sc issors . Easy when yo u know how !11

Letters to the Editor

PETROL SPILLAGE ON ISLE OF

Edward Kenna Petroleum Officer Isle of AngleseyANGLESEY

T?e following details of a petrol spillage, have a bearmg on the debate concerning stage I b vapour recovery, overfill protection and the fitting of pressure/vacuum valves on vent pipes. It is from this experience that I hope other petroleum officers and site designers will re examine the trend of beino lulled into a false sense of security when they 0accept cross contamination valves on vent pipes connected to a vapour recovery system.

recently oversaw the installation of a new underground petrol storage tank with four separate compartments. The tank was double skinned and fitted with air operated (pneumatic) contents gauges.

The tank was filled by means of offset fill pipes which were correctly marked with the reduced safe workino capacity of each compartment. Each compartment vented by means of low level manifolded vapour recovery system fitted with valv t . · · es o p1event cross contammat10n. 1:hese vents were manifolded and vented using two nsers fitted with pressure vacuum valves.

The licensee for some i·e . h d · ason w1s e to fill his tanks to maximum capacity He 1 . . · correct y read the contents of each tank but mcorrectly determined the ull a b reference to the aoe space y total capacity on each gauoe ·1nd not to the safe ·k· a · 0 < wo1 mo capacity mdicated on each offset fill pipe. ·

fuel was delivered to the tank from the road tanker <1n. kecause of the error in determining the ullao-e space qu1c ly exceeded the · 0 maximum capacity of the tank which caused a problem.

The fuel travelled up the vent stack and came into contact with the b· II 1 co a va ves to prevent cross ntammat1on. however because of· th d"l"I' . f. I he· h · e 1 erence 111 ue ig t the petrol tanker and the vent stack, the fuel contmued t ) . . l exe1 t pressure and was only relieved when It travelled along the suction lines. lifted the underpump check v· J d · · d ve an streamed out ot the vent tor the air separator of several pumps.

The driver ·ind th 1 ' e 1censee were unaware ot the problem until 1 n b . 1 1 < lem e1 o the public attemptrna to retuel <1c v1sed them of tl . . 0 :I le petrol streammn all over the c 1spens111g area. ""

The moral of this st 1·· · · 01 Y 1om my v1ewpo111t 1s that two valves are always bctt tl · e1 1<1n one but this 111c1dent would not lnve occurred if th I ••• < • e one va ve had been placed in the c011 ect pos1t1on 1ns1de the tank. an overfi II prevention valve.

Dear Editor

Carriage of Dangerous Goods by Road Regulations 1996 Regulation ll(l)(a) and Schedule 3

I am writing to ask that you make your members aware of the contents of this letter. In particular that you ensure, as far as you are able, that your members realise that they must carry out their obligations under the above legislation.

Following a roll-over incident involving road tanker carrying petrol it was found that product had been released from the fire engulfment relief valve (fe valve) (also known as the fill lid). The requirements relating to the performance of the fe valve have always been interpreted as allowing a release product due to the initial shock loading but the valve should immediately reseat and reseal. In this incident a number of the fe valves did not reseal. The reason for this has been found to be a deterioration of the spring performance. In one case the spring was so badly corroded that it was completely inoperative. Additionally it was found that the sealing gasket on some of the "lids" had also deteriorated so as to not provide a seal.

All operators of road tankers should take note of the circumstances described above and should note that the circumstances may describe a contravention of the requirements of the above mentioned regulations.

All operators are advised to ensure that the maintenance schedules of their tanks include a regular examination, and testing where necessary. to ensure c01Tect functioning of all safety relief valves and a leak test of fittings.

When a safety valve, such as the fe valves on this road tanker, is designed to allow maintenance and by persons other than the manufacturer, the instructions given by the manufacturer should be and the maintenance and adjustment should be earned out by persons who are competent to do so.

Where a safety valve is not intended be subjected to maintenance etc other than by the manufacturer, t.hen the valve should be returned to the manufacturer or his agent for attention when this is necessary.

The Carriage of Dangerous Goods by_ Ro'.1d 1996 also require that the periodic and · · d t by 1 coinpetent person 111 accordance with a 1s carne ou , · · I All C)perators should ensure that the wntten written sc leme. ' · · I t · tl1e11 · ta 11 ks a11d fittin"s mclude the satet"· sc lemes 01 < • "" • .J . I , It ·. my OJJinion that the written scheme should Vd \eS. IS · I d t 11 1y .1 vistnl examination but also tcstmg of the rnc u e no o ' · ' I I :tete1·1·{)l"'ltion of pertormance 1s suspected. vavew1e1ec <

Competent persons who carry out the and testing should also ensure that they mclude a.I I. tl!lmgs which could effect safety in transp.ort. It 1s my that I · )di'city of such examinations should. m part. be t le pern · decided upon in the light of the maintenance schedule

Competent persons arc remi1.1ded that R.egu.latinn 6k l places a duty upon them in relation to exammatmn. testing and certification of any tanks.

Yours sincerely

PG Castle HSE. Bootk. Merseyside

Prosecutions

POOR CONTROL BY LICENSEE LEADS TO £10,000 FINE

A West Sussex licensee, Mr Gopalakrishnan, a s?le trader, was fined £10,000 plus £297 costs for not complymg with the conditions of his petroleum licence on lst 1996. The site, Crawley Autopoint is a small scale retail site in a residential area of Crawley, West Sussex. The court case was the culmination of three visits to the site.

The first visit came after petroleum was discovered outside the site in an excavation for a new water main. This incident led to the closure of the local road for some hours. Inspection of the site revealed petroleum in several storage tank manholes. The tanks and lines of the site were tested but no leaks were found. Investigation showed large discrepancies in the stock reconciliation records. It appeared the storage tanks had been over filled on several occasions. The management control over the site and training of employees on the site was poor. Mr Gopalakrishnan was interviewed and advised on how to comply with his licence conditions.

Two further inspections of the site revealed further spilled petroleum in the storage tank manholes as well as other continuing breaches of licence conditions previously discovered on the initial inspection. The site was advised each time on the requirements of the licence.

Mr Gopalakrishnan's Counsel plea bargained and as a result the original 23 summonses were reduced to I0 to which Mr pleaded guilty. The Magistrates clearly took account the danger to the local residents and the failure of the licensee to rectify the situation after the first visit.

Mr Gopalakrishnan has now left the site and a new has taken over. He is also appealing against the seventy of his sentence.

At the insistence of the PO, the licensee in

specialist pipe fitter to carry out emergency This was achieved by cutting off the damaged and erecting a temporary stack as a safety measure for the duration of the Christmas holidays. The tanks connected to the three damaged vent lines were dipped using a water detecting paste to determine their water co?tent. Alt?ough. the construction work had taken place dunng a penod of dry weather, the site is located in an known to have a high water table so it was not that water content of the individual tanks was I00 litres, 800 lttres and 4000 litres respectively. In the latter case there was no ullage space left in the tank and it is possible some displacement had

The circumstances giving rise to the incident :-ve1:e investigated by the PO and during the course his investigation it soon became apparent that the add1t10n to contraventions of the Conditions of Licence' there were also possible infringements of the Health and Safety. at Work etc Act 1974 (HSWA) and the Construction (Design & Management) Regulations 1994 (COM Regulations).

In accordance with inter-agency liaison procedure, the PO notified the Health and Safety Executive (HSE) as a matter of evident concern. Initially the PO and the (Construction Group) Inspector carried out a JOil1t investigation by interviewing the proprietor, the construction contractor, who had not worked on a petrol station before, and their employees.

It was decided that the risk to employee and public safety arising from the incident was such that one of the agencies should take enforcement action against the offending parties. With there being possible offences contrary to the HSWA and the COM Regulations the HSE continued the investigation which culminated in the proprietor being charged with the following offence:-

, This case came to light on 22 Oecemher 1995 when an call was made to the Fire Service by the of a West Yorkshire vehicle repair/petrol filling st<1t1on hus· ' . . f h · mess say111g that petrol was leak111g rorn t e storage tanks.

p In response to the 999 call a fire appliance and etrott:uin Officer <PO) were mobilised to the incident.

f On arrival at the premises the Fire Service personnel petrol floating on 101J of water sittino in an excavation dt Jacent t . 1:· 0 <>ne of the undernround storaoe tanks. It was cont 1rn1ed h I 1:- 1:- h Y l 1e proprietor that the excavation had een n1acte to ex I P1Jse I le buncd vent Imes pnor to their relocation d\ Part of , · extension work to an MOT hay.

After th, · h, t: f 11 e appl 1ance crew had removed t e pi·trol/watcr fro111 the excavation. ii could be seen that three , ii t hl' ex I k P11 se( Vent lines had numerous puncture mar s. 1'·'' 1 1 >f Which Were hel()\A the v,ater level. A closer · 111 llll<ltion of tl · I 1· I ·tL1 ··s le pipework n:·vealc( two urt icr punt 1e. 1 f," Ii had i)e, · I I · 'th ·1 1··1b1..1L· tn rcpa1ret 1} wrapping w1 ' ' · 11111 "'" !\Ii the puncture marks were consistent with the "'"'"· · 11 1 11 l'(tJJ he v;iu..,cd hv "pneumatic chisd.

"Contravened Section 3( I) of the HSWA in that failed to conduct their undertaking, mainly the of a petrol filling station, in such a way to ensure so Jar as is reasonably practicable that the building contractor members of the public were not exposed to risks to theu safety from the ignition of petrol or it"s vapours works arranged by them to excavate fuel tanks vent were neither undertaken by a competent contractor nm were they under the direct supervision or adequate control of a competent person".

The defendant pleased guilty to the charge at a Hearing before the Leeds Magistrates on 4 November 1996 when a fine of £7,5004 was imposed with £500 costs being awarded to the HSE.

There was insufficient evidence available for action to be taken against any of the parties involved under the COM Regulations.

The appeal was Heard on 10 January 1997 when tie Ul 1:- l J i"e dismissed the appeal saying that the level of fine was exactly right for the seriousness of the matter. The appellant was also ordered to pay the HSEs costs for attending the appeal.

Roger Marris

Yorkshire fire and Civil Defence Authority

MAGISTRATES IMPOSE A HEAVY FINE AFTER CONTRACTORS DAMAGE VENT PIPES

THE EFFECTS OF STAGE 1 B VAPOUR RECOVERY ON HYDROSTATIC GAUGES

By Mac Cox Technical Services Manager, Veeder RootHand Pump

Balance Chamber >

All at Normal Atmospheric Pressure I

I

FIG 1 : HYDROSTATIC GAUGE, NO STAGE 1 B

Introduction

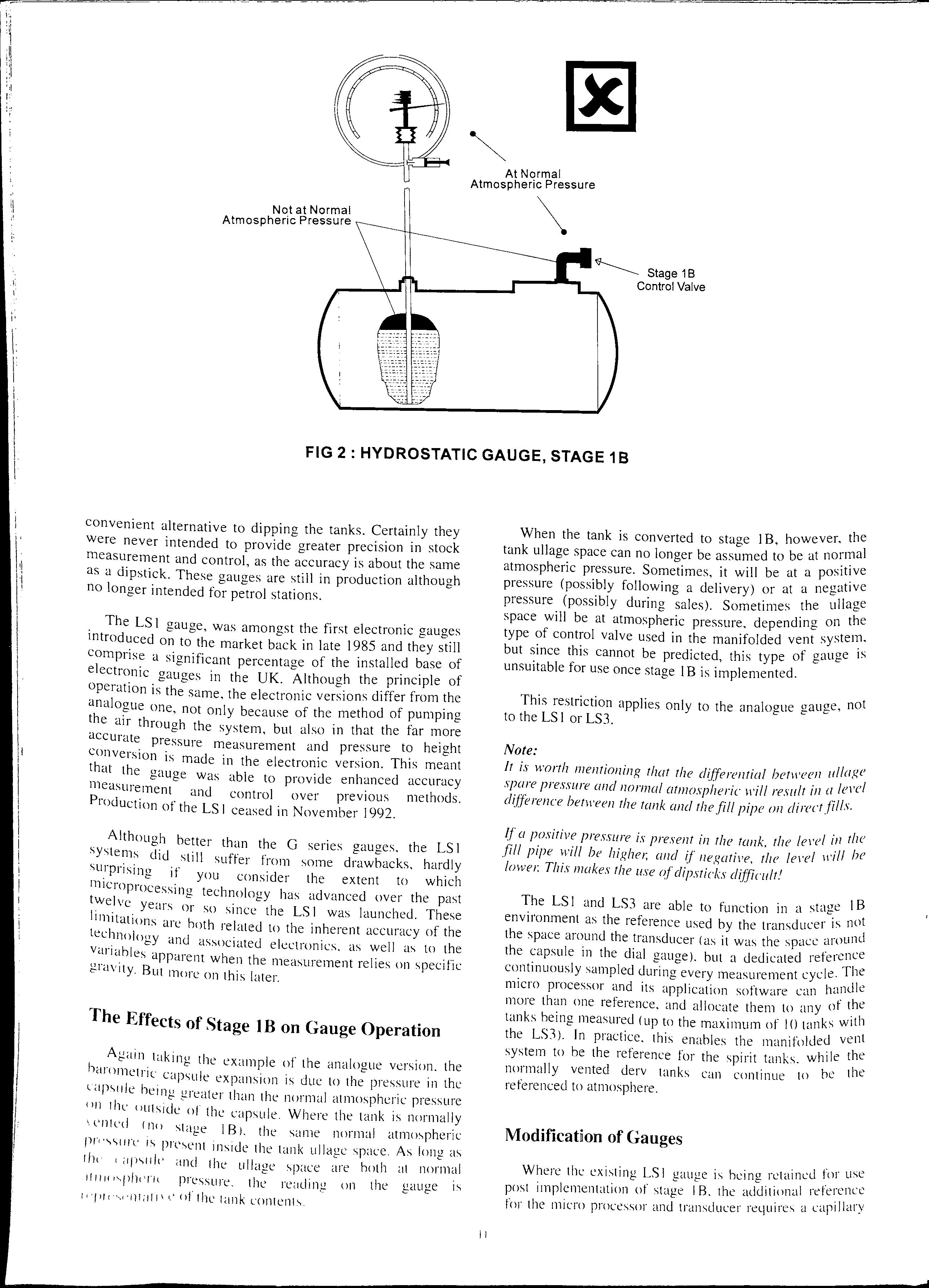

. A of tank gauging systems are still on hlhng stations in the UK. both electronic and_ an .analogue versions of the product. Stage I B has a on the operation of hydrostatic systems which were mstalled prior to tile si'te b · · emg vapour and the gauges will either need to be modified to cope the new venting arrangement on the site or, in the case of analogue gau<>es repl·1ced as 11 d · o · ' • o up(Tra c 1s possible. 0

The purpose of this pape1· '1s to t· · I · · exp <lll1 t 1e reasons why mod1t.1cat1ons or. are necessary. what is mvolved 111 the modifications and wt1 1t l}ptl.l>Il , · ' s are open whe1e _is Before doing this a brief look at the h1st01 y of hydrostatic "'lll""'S 1 ·s 'l])pl· · 1 o' b'"' • ' opna e.

Hydrostatic Gauges How they Work

The gauges, both analogue and electronic v,." ·k ' I . e1sions. WOI by measuring t le static head of p1·essti1.., ()f. tl 1· · I · , :- · · · '" le iquil 111 a tank with stc1nd,u dised i eterenc" 'lilt! Ill · 1 . . . '"· ' en usino t ll' resultant readmg lo mter height wl1i"·t1 1 ·s th"il 01 1 -. -. conver Cl to volume.

. In the analogue .version a small hand pump is inteoral the .dial. and the system is primed ;ith a tev.· strokes. a1.r 1s passed. \'Ia a restrictur (lo aid stability) through the capillary lme lo the vertirnl tube in the lank. This air "purges" the product from within the tube until a few of air emerging from the slot at the bottom end indicates that the air pressure in the has created a "balance" v.ith the static head of till' 1;roduct in

the tank, this is the reason why this tube is refeITed to as the "balance chamber". This pressure balance is seen at the gauge as a repeatable reading between pump strokes. umige measurement being made as the pressure expandmg 0 · t'b · t d ·prun<> pre- the "barometric capsule aga111st a ea 1 ia e · s o 1 · t . to rot·1te around the loaded mechamsm causes t le po111 e1 ' scale. The indicating scale is marked up in litres, equivalent to the product height that the measured pressure equates to.

· f the hydrost·1tic The same method if implemental!on o . . ' I d with the LS I and LS.3 electromc gauge pnnc1p e 1s use · 1 , ., TI ·e 1 f'ew ·idded soph1st1ca11ons 10we\e1. systems. lei e a1 ' ' , , TI I d pump is replaced with a small comp1ess01. the 1e 1<1n · · t ·dt1 ·er ·md I· "·I w1'th a hi"h •xec1s10n rans e ' dial nauoe IS 1ep ,ieel c- t 0 0 01 to me·isure the pressure and convert 1t to micro process '· 1 • · • I TI led I nventory 1s avatlab e on ,m 111teg1 a volume. 1e compu Ti"J 1· k d I· b Il i's.· typically transm1tted us mg .tn RS-._ Ill 1sp ,1y. l f" ·t ol ·1 lns1 · the POS or Pump Controller o ten as pai ' '. c: wetstock control package.

History of Hydrostatic Gauges in the UK

I I · tli, systems were supplied by Normond n t ie mam c · · · I ·it"' most commonly recog111sablc under the Instruments anl ' '" · I. d 11· Nl11·111ond LS I and the Nonnond (I 1ran names l '" S · I ti' "'tuoes Normond mstrumc:nt;. was acquired c c:nes ana og 1: c-' o · · by Veeder-Root in January J l)lJ2. but tllL' systems where still sZ>ld under the Nornwnd name.

The analogue gauges ha\'e been. in use in hllth the rt'tail petroleum and industrial markets sinl·e thl'tr intrndut·tillll in 1945. In the retail pt·trokum industry they \\ere \\'idt'I) used as the solution tll prll\ iding a remote l"l'ading tan" gauge when rc:mPtl' fills were used. Pr often simpl) a

Not at Normal Atmospheric Pressure

At Normal Atmospheric Pressure

FIG 2 : HYDROSTATIC GAUGE, STAGE 1 B

convenient alternative to dipping the tanks. Certainly they were never intended to provide greater precision in stock measurement and control, as the accuracy is about the same as a dipstick. These gauges are still in production although no longer intended for petrol stations.

The LS I gauge, was amongst the first electronic gauges Introduced on to the market back in late 1985 and they still comprise a significant percentage of the installed base of electronic gauges in the UK. Although the principle of operation is the same, the electronic versions differ from the one, not only because of the method of pumping the alf through the system, but also in that the far more accurate pressure measurement and pressure to height conversion is made in the electronic version. This meant that the gauge was able to provide enhanced accuracy measurement and control over previous methods. Pr d · 0 uctmn of the LS 1 ceased in November 1992.

Although better than the G series gauges, the LS I systems did still suffer from some drawbacks. hardly su.rprising if you consider the extent to which microprocessing technology has advanced over the past twelve years or so since the LS I was launched. These lnnitations are both related to the inherent accuracy of the technology and associated electronics. as well as to the variables apparent when the measurement relies on specific gravity. But more on this later.

The Effects of Stage I B on Gauge Operation

Again taking the example of the analogue version. the harornetric capsule expansion is due to the pressure in the l apsille being greater than the normal atmospheric pressure 11 11 1lw outside of the capsule. Where the tank is normally 'l'llft•d <ll< 1 stage I B l. the same normal atmospheric Jlr•·..,s11rl' is pre-.ent inside the tank ullage space. As long as lh1· 1 ;q1..,tile and the ullage space are hoth at normal ""''''·Jlh<Tll pressure. the reading on the gauge is ,. of the lank contenls.

When the tank is converted to stage I 8, however, the tank ullage space can no longer be assumed to be at atmospheric pressure. Sometimes, it will be at a pressure (possibly following a delivery) or at a negative pressure (possibly during sales). Sometimes the ullage space will be at atmospheric pressure, depending on the type of control valve used in the manifolded vent systen:i, but since this cannot be predicted, this type of gauge is unsuitable for use once stage 18 is implemented.

This restriction applies only to the analogue gauge, not to the LS I or LS3.

Note:

It is worth mentioninR that the d(fferential between 11/lage spare pressure and normal atmo.1pheric will result in a level difference between the tank and the fill pipe on direct.fills.

If a positive pressure is present in the tank, the lel'el in the fill pipe will be highe1; and (f nef?ative, the le1·el !l'ill he lowei: This makes the use dipsticks difficult!

The LS I and LS3 are able to function in a stage I B envi1·onment as the reference used by the transducer is not the space around the transducer (as it was the space around the capsule in the dial gauge). but a dedicated reference continuously sampled during every measurement cycle. The micro processor and its application software can handle more than one reference, and allocate them to any of the tanks being measured (up to the maximum of IO tanks with the LS3 ). In practice. this enables the manifolded vent system to he the reference for the spirit tanks. while the normally vented derv tanks can continue to he the referenced to atmosphere.

Modification of Gauges

Where the existing LS I gauge is hcing retained for use post implementation of stage IB. the additional refe1_·ence for the micro processor and transducer requires a capillary

All at the same Variable Pressure (Not Normal Atmospheric)

Reference \ Stage 1B Control Valve

Vent

FIG 3: LS1/3 GAUGE, WITH STAGE 18 IMPLEMENTED

to be run to an access point on the manifolded vent system. This access is typically via a special riser fitted to the existing balance chamber entry on the tank lid, or the point at which the individual vent lines are manifolded if more convenient for ducting back to the LS I position. The LS I will need to be re-programmed to sample the new spmt reference and to allocate the measured parameter to those tanks, (and only those tanks) that are connected to the ma_nifolded vent. This is accomplished using custom PC software and an EPROM programmer on site to endure the data matches the site configuration.

Planning is vital when considering conversion to s taae 1B, ensure part of thi s is checking the type of aauaes fitt;d and their suitability. b b

It is that a qualified contractor is e ntru s ted with this work to ensure gauge accuracy is maintained Veeder Root are able to offer complete support for the whole LS product range from informal advice to on s ite conversion by our national Service Engin ee ring Team

Upgrading Hydrostatic Gauges - The Options

Wh e re Stage I B has been impl e mented on a s ite with analogue ga ug es, they have to b e re pla ced with a nother tank gauge.

The be s t. option would b e to rep lace it with a mod e rn sys te m u s ing s tat e of th e art tec hnolo gy lik e rn ag ne tos tn ct 1ve probes which are a bl e to provide hi g hl y accurate m eas ure m e nt an d s tock co ntrol , a s well as a h os t of other imp o rtant benefits. s u c h as the ability to test the tanks for leaks to the req uire d sta ndard s w ith o ut the nee d o r e_xpe nse of u s in g a m ob il e tes t. Thi s is espec ia ll y tru e in I 1g ht o1 the 1act that th e eq uipm e nt cost of s u c h a new sys tem is not s ig nifi cant ly greater than the a lte rn at i ve d e tail e d belo w.

Ho wever it was recog ni sed th at th e re wu ulcl be s ign ifi can t cost sav in g to th e s tation ow ne r if th e ex is tin g

balance chambers and nylons could be used for the new systems as this would obviate the need for modifying the tank lid to accommodate a new probe or to lay down new underaround ductina for the cables The need for a cost b b effective system was even more important when it is considered that the majority of sites which have analogue gauges are not generally slated for extensive inve s tment or upgrading With this in mind , Veeder-Root to launch the LS3 , a significantly improved vers10n of th e LSI.

The LS3 operates on the sa me principles as th e LS 1, however th e following improvements have b ee n made.

• Improved pneumatic controls displace far les s ai_r than the original LS I _ in fact only l % aga111st the 011g111al sys tem!

• Current electronics hardware a nd software en han ce tran sducer accuracy.

• Inbuilt diagnostic software and " hi s tory log " allow service te c hni c ian s to check on the r easo n 1or malfun c ti o ns well after th ey occ urred g 1v1ng quicker, more re liabl e fix es .

Th e LS3 can be in s tall ed with minimum on site work bes or m od ifi ca tions and m1n1111 a l n ew c ablin g no ne w p10 · 1 b I 1ak ina it the most cost eHec t1 ve route avai a le or ny ons n < "' • for up g radin g th e a na lo g u e ga uge.

H oweve r, it s ho uld st ill be recog rnsecl that h yd ro s tatic syste m s. n o m a tt e r h ow modern._ do s.t '.11 lro'.11 some I 11 ·t·' ti o ns primarily that th e 11 <1ccu1 c1cy vc1 11 es w ith II I « d TI c h a nges in spec i fic grav it y of th e pro uct 11 s 1s important particularly as load o n load va ri ances ol" th e sa m e grade are no t un co mm on

We wo uld th e re fore reco m m e ncl that se ri o u s con s id e ration is alwa ys given tu up grnd in g tl) a c urr e nt ledinolo gy as thi s ma y we ll b e mon:' cust e llcc l1\ 'L ' in th e lon g te rm.

THE WORK OF THE TECHNICAL COORDINATING BODY

By Michael LuggBackground

The issue of the draft TCB guidance (APEA/IP Code) for consultation last year produced a very good response which confirmed the great interest in this work that exists within the industry and amongst enforcers. The various working groups have been busy assimilating and reviewing the comments received to see how best to accommodate the details and principles raised and to make the final document relevant, helpful and user friendly.

New developments

Since the issue of that draft and receipt of comments. significant changes have occurred which have a direct effect on this work and will influence the final output, in particular in how it is constituted and presented. New petroleum legislation currently being drafted and coming into force next year will reflect a sea change to the basic philosophy underlying how health and safety at petrol filling stations will be administered and controlled in the future. This has crystallized many of the concerns raised in the consultation process and the way forward has suddenly become clearer. Importantly, the HSE has recognised that the away from the traditional licensing regime will reqmre clear supporting guidance if confusion is to be avoided.

The way forward

The HSE will now produce new guidance to address all ?perat!onal in light of the new legislation and mcludmg experience gamed to date in the use of HS(G) 146. As_ a consequence, sections drafted for the TCB guidance concerned with operational matters will be taken out of the and incorporated into the new HSE operat1ona.1 t.ogether with an expanded risk assessment sect10n. This will leave the TCB · I· , t gUI( dlH.:e 0 deal with the technical aspects of th; design and construction of both new and redeveloped filliil r ·t· t' ... II h d 'f' · g s " ions .is we as t e mo 1 1cat10n of existing ones.

The result of this revised approach is that there will now be two separate but closely rehted sets t)f. 'd t' • • • • 0 u1 ance or petrol f1 II mg stat10ns: e

I. The HSE operational guidance to be bi' -1 I b h HSE d . , pu is 1ec y t e an directed prinnrily at .·t oivino advice on wh· ·h • , s1 e operators, c "' .'1t. s ould be done to ensure the sale operation of a 11111110 st·ition ·rnd t I · 1 relevant le 0 islation J ":I' '· • 0 comp Y wit 1 c '. · t wi I give guidance on control measure options (both 01Je1 1t1't)ll"ll p. I d t ' ' 1ocec ures an hardware solutions) to reduce the r1 · ·k . , . . , " I I s s ,\SSOCldkl wit 1 vanous 1dent1hed hazards to ·111 ·ippr .· t I I · ' • op11a e eve 111 the light of the test ot reasonable Pl"lct'i .. b'l't . d II ·i , c.1 1 1 y. .in gene1:a y w1 I give guidance on good operational practice.

2. The TCB technic.al guidance. to be published by APEA/IP and directed primarily at designers. contractors and mstallers. describing various cZrntrol measures options identified from the risk assessment

section of the HSE operational guidance and giving advice on how to construct or install them. It will describe good accepted practice in the construction of new or the redevelopment and modification of existing sites and will be neither exclusive nor prescriptive.

For the first time, the principle of reasonable practicability and the differences in its application between new and existing sites will be addressed in the HSE operational guidance. This should clarify what has, for many years, been a source of much misunderstanding between operators, developers and enforcers. It will also enable the TCB guidance to be more clearly focused and directed so helping to overcome any possibility of its recommendations being interpreted as prescriptive.

The radical new approach by the HSE is being led by Dr Steve Rooker who was appointed at the end of last year to the position vacated earlier by Dr Andrew Cottam. Fresh from the task of overseeing the regulation of the newly privatized gas industry, Dr Rooker comes with a reputation for cutting through bureaucracy and getting things done, a refreshingly welcome approach!

Control

The HSE Steering Group, which has responsibility !or directing and coordinating the work of all the bodies has set up a Publications Sub Group _to . d · f tl ·e two sets of 0 wdance. and coordmate the pro uction o 1es ·. · c This "roup is comprised of representatives from PRA "'UKPIA and HSF and is particularly responsible tor ' · f. b t the TCB and the HSE managmg the mter ace e ween guidance documents.

Q I A.. ce reviews will b.e undertaken ua 1ty sswan · 1 . d' II d .· the development of the operat1ona perlO tea y mmg ' d 'd cl .· to wider consultation with en101ce1 s <1n gw ance an p1101 · f . f . the industry to ensure qualtty. c!anty and_ ot TI QA Panel will be chaired by D1 Rooke1 and purpose. 1e ' cl · I ·I f' I' independent from those pro uc111g t 1e be mace up o peop e .• ,. , d f TI I wi'Il ct)ns1st ot HSE (2), Enfrncets (\ 1.1 n ts. 1e pane · · APEA) (4 ), IP (2 ), Supermarkets (I), Trades U111ons (2). PRA (2) and UKPIA (2).

The QA of the TCB guidance will remain with. the · s t \''111·c11 11·1ve drafted the elements ot the vanous ec 01 s ·• ' document.

Timetable

The target timetable for the of HSE operational guidance is w1tl.1 the issue of the Health and Safety Comm1ss1on s cnnsultat1on document on proposals for new petroleum safety regulations planned for June. The target 1111lestones are:

first draft to QA panel end Feb revised draft to QA panel mid April issue fm consultation mid June

·,

It is the intention that the production of the TCB guidance should, so far as is reasonably practical , follow a similar timetable so that the two documents can be issued for formal consultation at the same time.

Some final thoughts

An enormous amount of time and effort has been put into the work of drafting the TCB document against a background of existing guidance which was outdated and application which was variable and often unnecessarily and onerously prescriptive This work has been undertaken in the main by APEA members, largely in their own time, and often against a background of promised support which never materialized (one Sector has had four Leaders and currently has none), criticism without contribution and powerful vested interests bringing political pressure to bear, to mention moving goal posts and the pressures of ever increasing personal workloads.

This has undoubtedly extended the time originally anticipated for this work. Notwithstanding all that, a clear

view of the road to the final destination is now appearing from the mists and I am confident that, encouraged by the fresh approach from the HSE and with the continued commitment of the Sector Leaders and their working groups, the APEA and the IP jointly will this year publish the good solid Technical Guidance so long awaited by the industry. It will not be ' best practice' nor ' minimum standards ' neither term being appropriate. It will represent good accepted industry practice as befits any proper guidance. The standard appropriate to any particular circumstance will be determined from an assessment of the risks as described in HSG146.

It is in the best interests of all , industry and enforcers alike, that when the HSC consultant document, as well as the revised TCB guidance, is published comment is made by as wide a spectrum as possible to ensure that the fina l result is the best that can be achieved Members should , therefore , be prepared to make constructive comment on these documents when they are published in the summer.

TESTING TIMES FOR WAYNE

With cost saving and environmental iss ues at th e fore _ th e centre point of Wayne Dre sse r ' s display at this year's APEA show was th e ir Prec isio n Tank and Lin e T est in g Sy s te m.

The leadin g UK pump manu fact urer. also exhibited th e ir la te s t product la un c h ; ISM Nu c le us ; combined point of sa le and forecourt control system.

lain Ma c leod , Wayne 's in s tallation m a n age r. says, " an es timat e d 2 % of UK underground pe trol ta nk s are leaking , this prese nt s considerable co s t s both to th e environm e nt and to profit s. Unfortun a tely, in the pa s t leak detection h as bee n mi stake nly g ive n a low priority by s it e ow ne rs and they have s uffered fin a nciall y when leaks h ave s prung. Only th e n h as th e fa lse eco no m y of n ot testing beco m e appare nt.

In __ today 's m a rk e t , petrol re ta il e rs s imply ca nn ot afford th e f 111 es, c lea n up/ s hutd ow n cos ts a nd im m:e dam a ge cau sed by a leak. Pre ve nti o n a nd ea rl y wa rnin g a re t h a n c ure Fo rtun a te ly, W ay ne offer a quick a nd foo lproof m e th od of le ak. d e tect io n , w h e re by lea ks ca n b e stopped 1mm e d1ately until product uplift h as been arra nged.

E sse nti a ll y th e s ystem wo rk s b y tes ting tank s a nd a ll a ssoc iated lin es a t t he s am e tim e u s in g low press ure ( 1.5 p s i ) 111 e rt nitro ge n ba la nced through a ve nt lin e Th e sys te m ope rates o n bot h press ure a nd v ac uum to pro v id e acc urat e rea din gs o n ta nk and lin e c o ndi t ions so th e re is no nee d for a bu sy pe tro l s tati o n to c lo se clo w n ' T hi s is ce rt a inl y a n imp o rtant co ns id e ration fo r s it e o w ne rs.

A te s t can be carried out Ill 2-3 hours a nd 2 b test·ecl a t the one tim e causing comp artment s can e minimum disruption.

Thi s co mp ac t kit e nh a nce s o ur cu s to m e rs ' profitability and a ll ows them to s ig nal to th e ir own cus to m e rs a to the e n v ironm e nt. Now adays , s it e own e rs really do need to take a more proa_ct1ve app roac h to e n v ironm e nt a l iss u es no t ju s t as a soc ial duty but al so to keep their bu s in esses aliv e co nsid e rin g thi s, It IS in c red ibl e to think th at many _a re s till r e lyin g o n a traditional dip-stick method fo r then· ta nk tes tin g.

Ne ve rth e less, T a m confident that t hi s a rea of wo rk w iII a ea te r import a nce in th e near futur e, Wayn e h ave assume ,,, 1 < b · ·atecl b a ·eel them se lves up to take on us m ess ge ne 1' y ,,,eai d. lea is lati o n 0 11 ta nk and pump te st in g 111 th e 1mpen m g new "' ' .· W 1 cl e loped a pa rticu lar ex pe 1ti se 1n e n s u1 rn g UK. e 1ave ev · · II r· s 'U"e ass ure d to the hi g hes t sa le ty and all that m s ta a io n ' < • · f · t· 011 s and l be li eve that o u1 ta nk tes trn g qu a lit y s pec 1 1ca 1 c sy s te m is th e bes t on th e m a rke t.

All of thi s is ju s t a part of Wa y ne's multi fa ce te d , h t· 1·oreco urt req uire m e nt s W ay ne w ill und e rt ake app 1oac o 1 .- I · I · 111 d builclin o fo r a il types o p e tio s ta tion th e ces 1° n ' "' · 1 1 "' 1 .- II 111 waa e m e nt fo r turnk ey ope r a ti o n s nn 1n c uc 1n g u ''"' 1 lei s ite s We· 11 se lec t co nt ractor s and s ub1111 t 01ee n 1e 1 0 1 · lJli clt io ns in s hort. sa tl s ')' a c u s tom e r s p1TlJ e c t p an rnn g ap ' ; needs fr o m s tart to t1rn s h

O n th e ex hibi tion overa ll , la in MacLe ocl says. ' ·thi s s h o w is th e id e a l ve hicl e to d e rnon s trnk Olli in s tallati o n ex pertis e w hil s t a lso offe rin g us t he opportu n it y tu prn v ick inform a ti o n o n o ur na ti o n w id e se r v ic e prn v is it)n a nd r;1n ge of fo re co urt e quipm e n t."

PIPEWORK AND FITTINGS

BRITISH STEEL and VICTAULIC SYSTEMS (a GLYNWED INTERNATIONAL COMPANY) have combined their considerable resources to introduce their high quality pipes and fittings to the petroleum market for above and below ground applications in petrol station forecourts.

Ask any self respecting installation engineer and he will tell you bluntly that "steel pipework is effective provided it is installed correctly ".

BRITISH STEEL and VICTUALIC SYSTEMS have developed a solution which can be installed simply, efficiently and quickly, giving you leakfree pipework and peace of mind.

SECURIPIPE steel pipe with a polyethylene coating for built-in protection against corrosion , is used with specially developed VICTAULIC joints (now incorporating Viton B gaskets) and a range of joint protection products to give cost effective solutions for petrol station pipework.

This unique combination gives SECURIPIPE the advantages of strength allied to an extremely fast installation procedure , offering a range of technical and commercial benefits including:-

• speed and ease of installation

• versatility for both new and refurbished projects

• the inherent strength of steel pipe

• lasting protection against corrosion

• joints can be dismantled for modification s

• allowance for controlled pipe movement

• training and technic al back up

The features and properties of SECURIPIPE and VICTAULIC joints and fittings are shown in Figure I.

The VICTAULIC pipe jointing system has a successful track record stretching back 75 years and are used in a wide variety of applications.

BRITISH STEEL TUBES & PIPES is the UK's largest manufacturer of welded steel tubes , including BS 1387 General Purpose tubes which have a 70 years plus track record in petrol station forecourts

As leaders in their respective fields, BRITISH STEEL & VICTAULIC SYSTEMS have the experience and knowhow to offer an effective solution for petrol station pipework.

For more information or brochures on SECURIPIPE and VICTAULIC SYSTEMS contact:-

Frank Hare Operations Consultant to both companies on 01886 880081 or fax 0 I 886 880082.

Figure 1.

SECURIPIPE AND VICTAULIC

Housing Finish Gasket

Ductile iron conforming to BS 2789: Grade 420/12

Primer paint as standard or hot dip galvanised conforming to BS 729

Grade 'O' Viton B

Metric Bolts Heat treated carbon steel, track-head conform ing to physical properties of ASTM A-182 9

Finish Metric bolts are zinc plated, gold chromate colour coded

Fittings Malleable cast iron to BS 6681 or Ductile iron to BS 2789

Finish Primer paint as standard or hot dip galvanised conforming to BS 729

Coating 1.2mm nominal, 1.0mm minimum Thickness

Adnesion Typical value 50 seconds to peel a25mm wide strip over alength of 25mm wh ile applying atangential pull of 22N at 15' C

Freedom from 100% pass using a1OkV detector Holidays Oe coating discontinuities)

Strength of Typical value 16N/sq.mm whentested in accordance with BS 2782, Polyethylene ie. total strength increases with cross sectional area and coating thickness

Impact Typical value 5-6.SJ when tested in accordance with DIN 30670 Resistance

Penetration/ Approx 9.5% under acompressive stress of 21 N/sq.mm at Indentation 50°Cfor 200,000 hours

Operating -20'Cto +30' C. Above this Temperature temperature care should be taken in Range product handling, transportation and storage 'Applied to self colour/galvanised steel pipe

Standard Welded steel pipe to BS 1387, medium gauge, ends plain, self colour, Product alternatively galvanised

Sizes 50mm, 80mm and 100mm NB as required

Options Light/heavygauge

LEAK DETECTION SYSTEMS FOR DOUBLE SKIN TANKS.

LEAK DETECTION SYSTEMS FOR DOUBLE CONTAINMENT PIPES AND DISPENSER SUMPS.

TYPE 2000 INTELLIGENT TANK CONTENTS GAUGING SYSTEM.

INTERCEPTOR LEVEL ALARMS.

*BS 5750 Part 1 quality assurance

*All systems meet relevant safety standards (EEx ia /IC for Zone o & EEx ib /IC for Zones 1 or 2)

*Systems approved by LFCDA.

TALK TO THE EXPERTS on: 0342-323641 Fax: 0342-315513

Northern Sales: Tel & Fax: 0706-370695

FASTER) FORECOURTi _1

.: From high profile Canopies to dow ryto-earth, easy-to-move Acces;; Covers / Conder provides all the P.ieces for forecourt rconstruction i fully fitted,, for rapid site assembly: i ) / 1 Modular 'C' ard Car Wash Housings, totally prefab r-ieated enEllJ' f The lqtest ,in Light Liquid Separators, GRP Access Chaml;Jers and l Line Drainage Syste rr15, for the ultimate _i n fuel containme nt. \

·--Pump Island Cradle,and; Suryip 11 and to pump insta!J a iA tions ! Signage you can \ help but notice. And, to ,ensure the entire fo recouri remains in pristine e:onditfon,, a _ [ • Lt • Aft c r s ·l · ·

__a_:)e .c. \ ...J .: . e verytnm'g frqm eme1igency to t.otal, r' I refurbishment:--- ' . j _, ' · \ \ ( .- ./If you1are still puzzled over the·-sco,pe/ • 1 of Condeh ca pa1bilities, for the fu [I I_ \ picture t pntact our Eb st6rner ---y Sei:vices 1Deprniment .on J / (

Take the right road and gear up for the future with Veeder-Root.

In the current economic climate only the strongest will survive.

Some businesses that are trading successfully today may not be around tomorrow That's so often the case nowadays with technology, or indeed, manufacturers.

Not with Veeder-Root. Our tank gauging and environmental systems are entirely future proof

The reason? By designing a unique modula r system, we can upgrade your eq uipm e nt quickly and easily whe never you choose to enhance your system.

Which is ju st as we ll. Be ca use our

on-going investment in the future means we are continually developing new ways in which our tank gauges and leak detection systems can be used to help you run your business .

It's no real surprise that more than 250,000 underground tanks around the world already have our systems in place.

But it's not only our technology which is future proof , so is Veeder-Root. We have the resources to support you and your investment, both now, and into the future.

Veeder Root. The secure way to gear up for your future