THE ASSOCIATION FOR PETROLEUM ACTS ADMINISTRATION THE COUNCIL 1966-67

Officers:

Hon.

JANUARY, 1967

Officers:

Hon.

JANUARY, 1967

Published quarterly by the Association for Petroleum Acts Administration

Opinions expressed in this journal are not necessarily the views of the Association

Editor: R. P. HOLDAWAY WEIGHTS AND MEASURES 0EPT GUILDHALL, SHREWSBURY

Subscription: 30s. per annum

TALKING POINT NOTES AND NEWS LETTERS

B.P. ADOPTS THE BLENDER PUMP-G. MAYHEW

SHELL lRUS FLUID 904 NITROGEN PURGING

THE FIBREGLASS UNDERGROUND STORAGE TANK-J. H. B. HORNBY

STOP THAT LEAK WITH CATHODIC PROTECTION-J. H. B. HORNBY

TRENDS IN PETROLEUM SPIRIT DtSPENSING-R. G. SPALDING

NORTH SEA GAS-THE PRESENT SITUATION FLOATING RooF TANKS

BRANCH MEETINGS :

EAST MIDLAND-WORKSOP

SOUTH EAST MIDLAND-BISHOPS STORTFORD

SOUTH EASTERN-REIGATE COUNCIL MEETING-DUDLEY THROUGH THE PIPELINE LEGAL OPINION LEGAL PROCEEDINGS

Chairman: E. V. BEEBY Honorary Secretary/Treasurer: L. A. CAVE

Over the past two years or so there has been a significant advance in methods of distributing petroleum products. The new Conveyance Regulations permit the carriage of a bigger load, the blending pump is now a reality as is attended self-service. A new development is the latched nozzle, which, provided it incorporates a number of special features to ensure safety under all conditions, has much to its use and indeed has been approved with reservat10ns by the Greater London Council.

At its last meeting the Council of the Association at the request of a member authority considered the question of the use of latched nozzles and after due deliberation did not advise acceptance.

To the Petroleum Officer who looks to the Association for in the pursuit of uniformity in administration position must somewhat confusing, so too must 1t appear. to associate members in Industry. The lack of any directive from the Home Office on this and other developments including unattended self-service may well be deliberate policy. It must be remembered that the responsibility for administering the Petroleum Acts is placed squarely on the shoulders of Local Authorities, the Home Office remaining sole arbiter in the event of a dispute or appeal from a dissatisfied individual.

If this Association is to wield the influence expected of 1t by members and to give guidance when asked, the whereby a snap decision is made at a meeting which 1s already overloaded from a time factor with general business is not good enough. It would appear a closer liaison with Industry is called for, a hit and miss procedure dependant on the pride or prejudice of and their officers hardly fits in with our idea of an efficient and productive Britain.

Aylesbury M.B.C. Bucks

Ayr C.C.

Grantham M.B.C. Lines

Hastings C.B. E. Sussex

Heanor U.D.C. Derby

Port of Bristol Authority Gloucestershire

Skelton & Brotton U.D.C. Yorks (N.R.)

Stroud U .D.C. Gloucestershire

J.P. Honour, I.W.M., Slough M.B.C., Bucks.

T. Moore, I.W.M., Slough M.B.C., Bucks.

B. A. C. Sirey, I.W.M., Slough M.B.C., Bucks.

H. W.M. s. W.M. s. H.A. s. H.

G. H. Smallwood, Construction and Maintenance, Shell-Mex & B.P. Ltd., Birmingham 15.

F. Wild, Technical Manager, Penetone Co. Ltd., Egham.

Mr. J. C. Angus, Public Health Inspector, Burnhamon Crouch, has been appointed Senior Public Health Inspector, Bridport.

Mr. M. Gee, a past Chairman of the West Midlands Group, has been promoted Deputy Chief Officer, Wolverhampton Fire and Ambulance Service.

Mr. J. M. Halliday, Deputy Chief Inspector of and Measures, Cambridge, has been appointed Chief Inspector of Weights and Measures, Ipswich.

Mr. K. L. Holland, Chief Fire Officer, Bristol, has been appointed Chief Fire Officer of the West Riding County Fire Service.

We regret to report the death of the following: Mr. A. D. Clarke, Housing Director, Leigh M.B.C. Mr. E. H. Melbourne, Saffron Walden R.D.C., who was the first Chairman of the South East Midland Branch and represented that Branch on the Council.

Mr. A. Leese, Chief Fire Officer, Coventry has _been awarded the Queen's Fire Service Medal for distinguished service in the New Year's Honours List.

H.M. Stationery Office Publications Statutory Instrument No. 1190, Petroleum Spirit (Con- veyance by Road) (Amendment) Regulations, 1966, 5d.

The A.M.C. is represented on the Standing Advisory Committee on Dangerous Substances by Mr. A. Glen, Town Clerk, Southend-on-Sea, Mr. A. Norman Town Clerk, Southampton; Mr. L. 0. Clarke, Chief Officer Swansea; Commander K. N. Hoare, Chief Fire Officer'. Manchester; Mr. J. R. Roberts, Chief Inspector of Weights and Measures, Manchester.

The Dalziel formula printed on page 93 of the last issue 165 of The Bulletin should read 1 (mA) = ---= yT seconds

Two small boys playing with matches near a haulage firm's yard were unhurt recently when a dis11sed 500-gallon petrol tank exploded and threw earth 40ft. in the air.

A fireman said a vapour pocket probably caused the explosion. The tank, at S. Cope Ltd., Hartshill Road, Stoke-on-Trent, was full of water.

Chief Fire Officer, Suffolk and Ipswich Fire Authority, Ipswich.

B. C. Hope, Construction Supervisor, Shell-Mex & B.P. Ltd., Southampton.

Forced air heaters from Jetaire & Co. operating on Propagas Propane supplied by Shell-Mex & B.P. Gases Ltd., were used to provide heat in the foyer of the Grand Hall, Olympia, during the inclement weather prevailing over the period of the recent Public Works Exhibition.

A new method of insulating floating roofs with polyurethane foam has been employed by the Caledonian Mining Co. Ltd., on four crude oil storage tanks at Mobil Oil Company's refinery at Coryton; the surface treated on each tank roof covers an area of 19,000 square feet. The technique employed was to spray a polyurethane application to an average thickness of lin. A particular problem to be overcome was the flexibility of the sheet steel construction of the roofs and also with regard to operational access; however, polyurethane will adhere to any surface and is flexible enough to withstand the slight oscillations of the tank top which often occur during high winds. Contrary to the more conventional methods of insulation, polyurethane is impervious to moisture collecting on the tank top: also, it is very tough and durable and resists attacks by insects, fungi and other plant life. It is thought that it is the first time that this method has been used in the British Isles.

The Shell Refining Company's new refinery at Teesport, due on stream in the early part of 1967 with a processing capacity of 120,000 barrels a day (six million tons a year) will cover 170 acres of land reclaimed over a period of time from the River Tees. It will be one of the most technically advanced complexes of its kind in the United Kingdom. The refinery will manufacture liquid gases? gasolines, (including aviation turbine fuel), gas oil, fuel oil and bitumen to supply the product pattern of the large segment of North-East England that it will serve. All operational control in the refinery will be cen!ralised in one building, which will house a laboratory, mstrumentation, and a computer, and which will adjoin the refinery administration block. The refinery will have one of the most advanced computer control systems of its kind.

·

The economic development of Western Europe will, at !east during the next twenty ye11:rs, depend mainly on imported oil, J. H. Loudon, Chatrman of the Board of the Royal Dutch Petroleum Company, said in a speech at a meeting of the International Chamber of Commerce '

Mr. Loudon said that in the twenty years since the Second World War the demand for energy in all its forms had doubled in the free world and it was expected to double again in the next twenty years.

Nearly ninety per cent of the vast growth in consumption .between 1945 and 1965 was ?1et by increased production of oil and natural gas, which by 1965 accounted for more than two-thirds of the total. By 1985 oil and natural gas were expected to provide nearly three-quarters of the total free world energy.

"In spite of important finds of natural gas in The Netherlands and the North Sea, and in spite of the increasing importance of nuclear energy, the economic development of Western Europe will, at least during the ne.xt twenty years, depend mainly on imported oil", he said.

In his comments in your last issue "Otto" states that "liquid methane is subject to the licensing provisions of the Petroleum Acts".

I would express a doubt whether this is so. To be within these licensing provisions material must be "petroleum spirit". The definition of this is well-known and if we were to attempt to determine the flash-point of liquid methane by the procedure described in part II of the Second Schedule to the Petroleum (Consolidation) Act, 1928, no result would be obtainable, since apart from any other difficulties we would immediately come up against the impossibility of adjusting the temperature of the "oil" to 60°F as required by clause 5 of such part II; s. of the Customs & Excise Act, 1952, also supports this view.

This and other anomalies that result from the exclusion of liquefied petroleum from the of petroleum spirit were discussed m the Petroleum Times, 1951, page 369.

V. BISKE, LL.M., F.R.I.C.

Chester

I read with considerable interest Mr. C. S: McDonald's paper "The Law relating to licences for keel?mg petroleum spirit" in the October issue of the B.ulletm. I however, whether he has not tortured himselfunnecessanly on the question of licensing car parks.

Does not the conviction of Grandi show that even if petroleum spirit is kept lawfully by s?meon.e else on a permises, the occupier of those to ensure that any necessary licence is m force if he is to escape liability under Section 1 of the (Condolidation) Act, 1928 ? There is no m the Act that the person keeping petroleum must be the licensee. If there is a keeping the occupier bears an onus.

I think we can agreed that a ma.tor vehicle is no! a "premises" but a car park is. There 1s patently a of petroleum spirit in the fuel tanks of vehicles m a car park. The occupier of the car park 1s the_ person who has the right to decide or. not vehicles can .be parked and under what 1.e. the car pt oproprietor. Since the propnetor 1s not the person mtending to use the petroleum spirit for the purpose of a motor vehicle he cannot claim the benefit of No. 1(1) of the Spirit (Motor Veh.icles, etc.) Regulations, His only recourse therefore 1s to hold a petroleum spmt licence himself.

G.L.C. W. C.R. DALE Geoffery Mayhew, B.P. Retail Market Division, She/1-Mex and B.P. Ltd. writes

Geoffery Mayhew, B.P. Retail Market Division, She/1-Mex and B.P. Ltd. writes

By 1970 some 5,000 of the 16,000 pumps on BP sites covering the United Kingdom will be blending pumps. Most of the BP sites will have one. This major marketing development is particularly advantageous for the BP market in that it offers a much better price and grade flexibility than with the current four grades-BP Super Plus, BP Super, BP Blend and BP Regular.

The introduction of the blending pump means that two more grades can be added immediately to the range without increasing the number of pumps on the filling station.

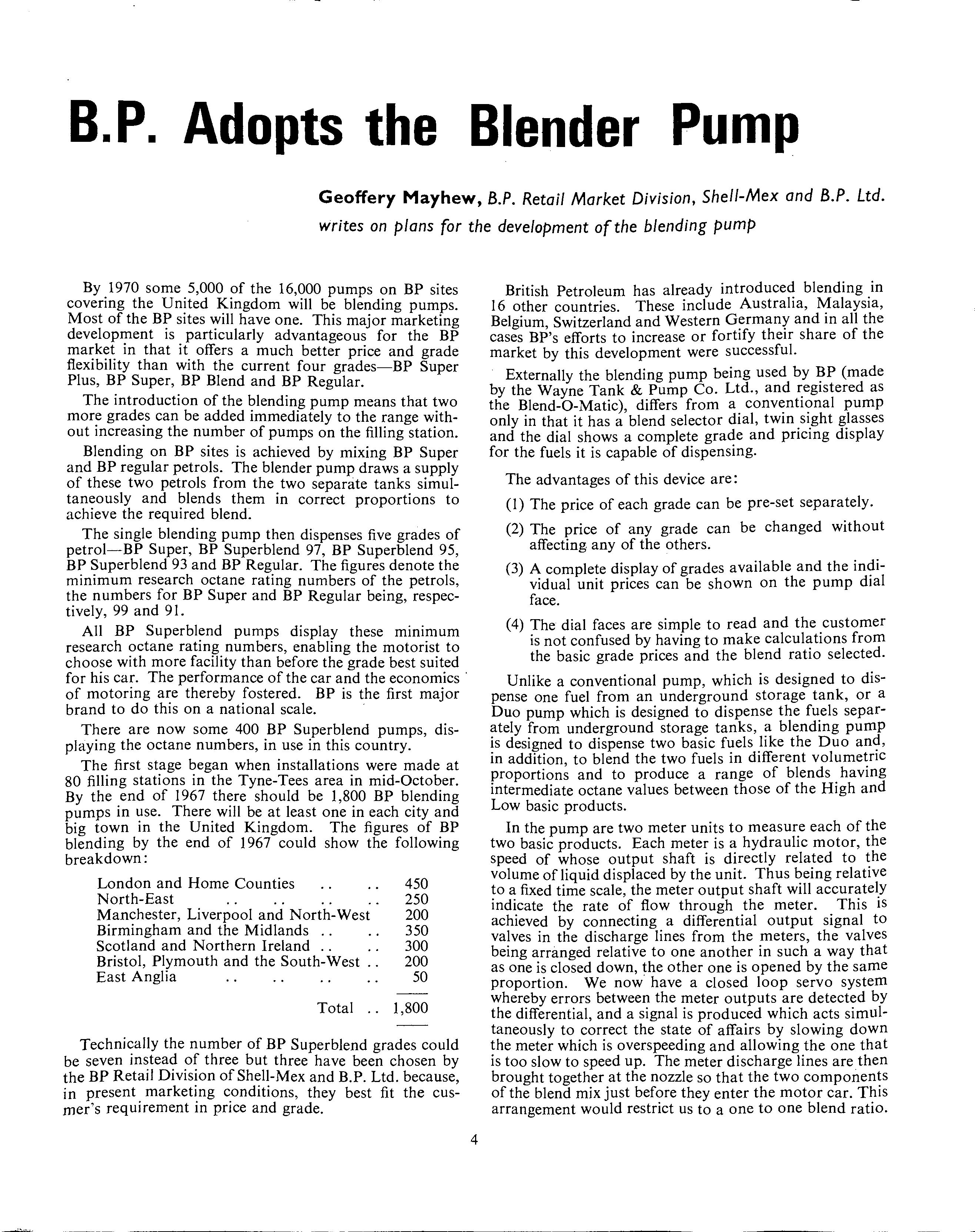

Blending on BP sites is achieved by mixing BP Super and BP regular petrols. The blender pump draws a supply of these two petrols from the two separate tanks simultaneously and blends them in correct proportions to achieve the required blend.

The single blending pump then dispenses five grades of petrol-BP Super, BP Superblend 97, BP Superblend 95, BP Superblend 93 and BP Regular. The figures denote the minimum research octane rating numbers of the petrols, the numbers for BP Super and BP Regular being, respectively, 99 and 91.

All BP Superblend pumps display these minimum research octane rating numbers, enabling the motorist to choose with more facility than before the grade best suited for his car. The performance of the car and the economics · of motoring are thereby fostered. BP is the first major brand to do this on a national scale. ·

There are now some 400 BP Superblend pumps, displaying the octane numbers, in use in this country.

The first stage began when installations were made at 80 filling stations in the Tyne-Tees area in mid-October. By the end of 1967 there should be 1,800 BP blending pumps in use. There will be at least one in each city and big town in the United Kingdom. The figures of BP blending by the end of 1967 could show the following breakdown:

London and Home Counties 450 North-East 250 Manchester, Liverpool and North-West 200 Birmingham and the Midlands 350 Scotland and Northern Ireland 300 Bristol, Plymouth and the South-West . . 200 East Anglia 50

Total 1,800

Technically the number of BP Superblend grades could be seven instead of three but three have been chosen by the BP Retail Division ofShell-Mex and B.P. Ltd. because, in present marketing conditions, they best fit the cusmer's requirement in price and grade.

British Petroleum has already blending _in 16 other countries. These include Australia, J\;lalaysia, Belgium, Switzerland and Western and mall the cases BP's efforts to increase or fortify their share of the market by this development were successful. · Externally the blending pump being used by (made by the Wayne Tank & Pump Co. Ltd., and as the Blend-0-Matic), differs from a. pump only in that it has a blend selector dial, twm .s1.ght g_Iasses and the dial shows a complete grade and pncmg display for the fuels it is capable of dispensing.

The advantages of this device are:

(1) The price of each grade can be pre-set separately.

(2) The price of any grade can be changed without affecting any of the others.

(3) A complete display of grades available and the in?ividual unit prices can be shown on the pump dial face.

(4) The dial faces are simple to read and the _customer is not confused by having to make from the basic grade prices and the blend rat10 selected.

Unlike a conventional pump, which is designed to dispense one fuel from an underground storage tank, or a Duo pump which is designed to dispense the fuels separately from underground storage tanks, blending pump is designed to dispense two basic fuels .hke the Duo an?, in addition to blend the two fuels in different volumetnc proportion; and to produce a range of blends . having intermediate octane values between those of the High and Low basic products.

In the pump are two meter units to measur.e each of the two basic products. Each meter is a hydraulic motor, the speed of whose output shaft is directly to volume of liquid displaced by the unit. Thus relative to a fixed time scale, the meter output shaft will indicate the rate of flow through the meter. This is achieved by connecting a differential output signal to valves in the discharge lines from the meters, the valves being arranged relative to one another in such a way that as one is closed down, the other one is opened by the same proportion. We now· have a closed loop servo system whereby errors between the meter outputs are detected by the differential, and a signal is produced which acts simultaneously to correct the state of affairs by slowing down the meter which is overspeeding and allowing the one that is too slow to speed up. The meter discharge lines are then brought together at the nozzle so that the two componen!s of the blend mix just before they enter the motor car. This arrangement would restrict us to a one to one blend ratio.

It is therefore necessary to include a variable speed gearbox between the meters and the differential, from which one of a number of ratios can be pre-selected before the start of delivery. This gearbox has been designed to provide Blends, apart from the two basic grades, in steps of 121per cent (i.e., Low, 7 : 1, 3 : 1, 5 : 3, 1 : 1, 3 : 5, 1 : 3, 1 : 7, and High). Up to nine grades of fuel are therefore available from two tanks and one pump although the BP Blending pump is dispensing the 3 : 1, 1 : 1 and 1 : 3 blends.

It is of course necessary to arrive at a computed price to save the attendant from a multiciplicity of calculations. The unit price of the Low product is set on a computer variator and the unit prices of all the other grades are then individually set in a subsidiary gearbox as increments above the price of the Low product. As each grade is dispensed, the volumetric outputs of the two meters are accumulated by an adding differential mechanism. This volume is then multiplied by the Low product unit price and the increment for the grade being delivered. These two cash volumes are then added together in another adding differential and carried forward for display on the individual sales indications. In this way we arrive at a computed sale price and volume indication for each of the grades being made available.

The attendant's operation demands very little more than the conventional equipment. He is required to:

(1) Select the blend by actioning a lever on side panel and rotating the knob to point to required blend.

(2) Zeroise.

(3) Lift nozzle and operate the motor lever.

(4) Dispense.

The blend selected cannot be changed while the pump motor is running. The pump incorporates all safety precautions incorporated in conventional equipment but in addition has an inter-lock on the blend selector. This means that the motor has to be cut off before the blend can be changed, after which to start the motor it is necessary to zeroise, as on conventional equipment. Attendants who have used the equipment are full of praise for it.

In a relatively short space of time, blending will be P!irt of life for motorists and those who serve the motonst. Our plans are designed t_o the introd ucti_on of this new marketing techmque mvolvmg the measurmg of liquid as efficiently as possible.

A new fire resistant hydraulic fluid, Shell Irus Fluid 904 has been introduced in this country by Shell-Mex & B.P'. _Ltd. The new fluid is the result of the increasing interest m the use of fire resistant fluids in potentially fire hazardous locations which bas led to water-in-oil emulsions being required to operate at higher pressures and speeds than could be obtained with fluids previously available.

Anticipating this trend, work to develop a still further improved Shell lrus Fluid was put in hand at the Thornton Research Centre of 'Shell' Research Ltd., near Chester. The programme is now completed and has resulted in the introduction of Shell Irus Fluid 904.

The main improvement is the greatly enhanced power to reduce wear, thus allowing higher pressures and SJ?eed.s of an order previously uno.btaina?le with emulsions. This is accompamed by improvements m antJcorrosion properties and emulsion stability.

The new Shell Irus Fluid 904 is a stabilised water-in-oil emulsion consisting of micron sized water droplets suspended in a continuous phase of m.ineral oil. presence of water confers excellent fire resistant properties to the fluid.

This article by the British Oxygen Company Ltd., is reproduced with the kind permission of the C.B.M.P.E.

The purging of an industrial installation-whether it consists of storage tanks, pipelines, processing equipment or fixed or transportable containers of any descriptionmay be done for a variety of reasons. All the possible reasons, however, fall under one or other of two main headings: first to prevent fire or explosion where flammable or explosive materials are involved; second, to avoid unwanted reactions between the materials being handled and the atmosphere.

Whatever the ultimate reason for purging, the immediate requirement is to reduce to an acceptable level the concentration of some reactive gas (such as atmospheric oxygen) in the system. The actual level depends on the nature of the industrial process and the final aim in purging. If, for example, the intention is to eliminate the risk of fire on admitting a combustible gas to the system, it is necessary to reduce the concentration of atmospheric oxygen to a level at which it will not support combustion. In this instance, it is not by any means necessary to exclude oxygen completely: it is sufficient to arrive at a level just below the lower level of flammability with the combustible concerned, and in typical cases this permits a small percentage of oxygen to remain.

In the case of a storage container for a foodstuff which is liable to deteriorate in the atmosphere, however, it is necessary to reduce the oxygen level much further, and the permissible oxygen residue in an annealing oven is lower still.

Nitrogen provides an easy, cheap and, in some instances, virtually the only practical way of achieving the object. This gas, which constitutes almost four-fifths of the air we breathe, is odourless, tasteless and non-toxic (though it will not support life or combustion). At the purity at which it is supplied, nitrogen is chemically unreactive and inert towards a very wide range of materials, and is virtually insoluble in a large number of the liquids and other materials commonly used in modern industry.

Apart from its technical suitability for the purpose, nitrogen also possesses the advantages from the user's point of view that it is instantly available in large or small quantities at the required pressure, rate of flow and purity, and further that the nitrogen purging process calls for only simple equipment and procedure, even when demand is subject to wide fluctuations and heavy peak flow rates are involved.

There are three basic ways of purging a system with nitrogen:-

(a) The atmospheric pressure method, (b) the pressure cycle method, and (c) the vacuum cycle method.

With the atmospheric pressure method, is passed continuously into the vessel or system at one and the air or gas being purged leaves from another pomt. The purged gas is normally vented to so that system remains at atmospheric pressure du.rmg the. entire purging operation. The nitrogen performs its function by displacement and/or dilution of the pur&ed gas. In the typical case, both these processes occur simultaneously.

In a long narrow vessel such as a pipe, when nitrogen is passed in at one end and the purged gas leaves the other, the purge may take place almost entirely by displacement and there is little mixing of nitrogen and purged gas at the relatively small interface. In such a case, the amount of nitrogen required to sweep out virtually all the purged gas is the same as the volume of the pipe. In the more general case, when the shape of the vessel does not approximate to that of a pipe, some mixing of nitrogen and ves.sel atmosphere occurs and a reduction of the concentrat10n of any component of the purged gas takes place to a greater or lesser extent by dilution with nitrogen rather than by displacement by it.

If the mixing of the nitrogen and vessel atmosphere were complete throughout the whole purging operation, so that purging was done entirely by dilution, it can be shown mathematically that after passage of one vessel-volume of nitrogen, the concentration of any component of the original vessel atmosphere will have been reduced to _!_ 18 2.7 of its initial concentration (2·718 = e = base of natural Logarithms). After the passage of two vessel-volumes of nitrogen, the initial concentration will be reduced to 1 , and similarly after n vessel-volumes, the concen(2·718)2

tration will reduce to 1 Thus if a vessel of vol(2·718)n ume V ft 3 initially filled with air (0 2 = 21 per cent), is purged with nitrogen which mixes completely on entry and purges by dilution, after passing in V ft. 3 of nitrogen the oxygen concentration in the vessel atmosphere will have been reduced = 7·7percent: after 2Vft3 nitrogen, 2·718 21 to = 2.8 per cent, and so on. 2-718 x 2·718

Obviously, more nitrogen is required for purging down to a given concentration by dilution than by displacement, and in estimating nitrogen quantities for purging tanks and similar equipment it is usual to assume that complete mixing and dilution would take place, since this will usually give a conservative estimate. In actual practice where the typical vessel for purging is a large cylindrical tank with length not greatly different from diameter and with favourably placed inlet and outlet pipes (say, a't top

and bottom), purging normally takes place partly by displacement and partly by dilution, and rather less nitrogen may be required.

In a few untypical cases, more nitrogen than that indicated may be necessary to reduce a concentration to the desired level. This can occur when the inlet and outlet pipes of a large vessel are situated on the same side (for instance, in the lid of a reactor) of a vessel, or when a vessel has a very irregular shape or contains baflles, pipe-coils or other obstructions. In such cases there is some shortcircuiting of nitrogen between inlet and outlet with less than the expected entrainment of the gas being purged. There are no general rules for dealing with these special and each requires individual consideration in estabhshmg a purging programme and nitrogen consumption.

When a system is purged for the first time, it is normally good practice to check by actual analysis of purged gas that the estimated amount of nitrogen has, in fact, reduced the concentration of any component of interest to the desired level. Thereafter, it is usually satisfactory to repeat the successful pr<?cedure without analysis, provided close attentron 1s paid to exact repetition of volumes, rates of flow and other relevant conditions.

The t_ime taken pu.rge a vessel is not a quantity, except msofar as 1t 1s important to keep strictly to timed programmes when these. are based on an original programme set by gas analysis and are to be repeated without analysis. Purging time or-what amounts to the same rate of flow of purged nitrogen, may be decided m case of very large vessels by the maximum flow rate ayaila?le from the nitrogen. supply installation, fixed by pipe sizes, evaporator capacity, and so forth. In the case of smaller vessels when nitr<;>gen supply is adequte for any ?f a range of times of purgmg to be chosen, the selection is made on the basis of what is expedient having regard to au the circumstances.

A very low flow rate (long time of purge) affords time for diffusion and mixing of vessel atmosphere with nitrogen and tends to result in purging mainly by dilution. Similarly a very high flow rate (short time of purge) gives a turbulent jet of nitrogen e?try also towards mixing and purge by. d1lut10n (\n 1!1-termediate flow rate gives less opportumty for m1xmg, mcreases the proportion of purge by displacement, and consequently uses the nitrogen more efficiently. It is not possible, however, to calculate what is the optimum intermediate flow rate for any given system_. This can be found only by with gas analysis or by analogy from experience with similar systems.

In this method the equipment to be purged is pressurised nitrogen, and a period is allowed for complete m1xmg of the nitrogen and origmal vessel atmosphere. The pressure is then released, as a rule to atmosphere.

This method is restricted to equipment which will withstand the necessary pressure. It may be advantageous in cases where pressurisation is also necessary for some other purpose (such as the ejection of liquid, leak testing, etc.), ?r where only one connection is available to serve as both mlet.and outlet. In this method, the amount of nitrogen required to reduce any gas concentration from a known initial level to a desired final level is exactly calculable.

In the typical case, the required purge can be obtained by one or several successive cycles of pressurising and venting, the choice of number being made in any particular case on consideration of time allowable, cost of nitrogen and labour, pressure which the system can withstand, and so on.

Assuming the pressure in the system is initially 1 atma, then pressurisation with nitrogen to P atma will dilute any component of the original atmosphere to _!__ of its'initial p concentration, and on venting the concentration will remain as _!__ of the original value. A second pressurisation p to P atma with more nitrogen will dilute any component to _!__ of the original concentration, and so forth, so that after p2

n cycles of pressurising and venting, any component concentration will be reduced to _!__ of its original level. The P" number of vessel-volumes of nitrogen required per cycle is P-1.

Suppose, for example, that a vessel initially filled with air (0 2 = 21 %) is to be purged by the pressure method to give 0 2 = 1 %. This could be done in any number of ways according to the pressure chosen. If only one cycle of pressurisation is used, the vessel would be required to withstand 21 atma ( = 294 lb./in. 2), the amount of nitrogen required would be a maximum 20 vessel-volull1;es, time and labour would be a rrummum. Alternatively, if four pressure/venting cycles are used, the pressure required is reduced to 4 y'21 = 2· 14 atma ( = 17 lb.fin. 2), and the total nitrogen required is 4 x 1·14 = 4.5 vessel-volumes, while time and labour requirements would be four times the amount for a single cycle.

It will be noted that as the pressure is reduced and the number of cycles required consequently the amount of nitrogen required to reduce an imtial concentration to a given percentage of that value tends toward a limiting value which is equivalent to the same result as with atmosphere purgmg by d1lut10n.

This method is generally similar to the pressure method except that sub-atmospheric pressures used. In this method, the equipment to be purged is and nitrogen is let in to break the vacuum and mix with the residual gas. The method is restricted to systems which can be evacuated and is advantageous where there is only one connection inlet of nitrogen and outlet of purged gas. The method is mainly used for small-scale rel?eti!ion purges of systems such as food packs and electric hght bulbs, etc.

In this method, the degree of vacuum attainable is generally fixed by the nature of the system and the substances within it and by the vacuum pump. Suppose an absolute pressure of P atma can be attained in given circumstances in a system to be purged. Then one cycle of evacuation and refilling with nitrogen to normal pressure would reduce an initial gas concentration from, say C to CP, and n cycles would reduce the concentration to CP". The amount of nitrogen used per cycle would be 1-P vessel-volumes. In

this case the most advantageous purging procedure is to use as good a vacuum as possible with the minimum number of cycles, tending towards the ideal case of perfect evacuation in a single cycle using only one vessel-volume of nitrogen, and reduction of any initial gas concentration to zero.

small quantities of gas concerned, or purgmg is earned out at relatively long intervals, a

cylinder manifold, consisting of an appropriate number of cylinders and equipped with pressure regulating and flow control valves suitable for the demand, can be perfectly adequate.

For larger quantities of gas, or more frequent purging operations, a liquid nitrogen evaporator installation is desirable. For occasional purging operations which do not justify a permanent installation, a road tanker with evaporator can attend for limited periods as required.

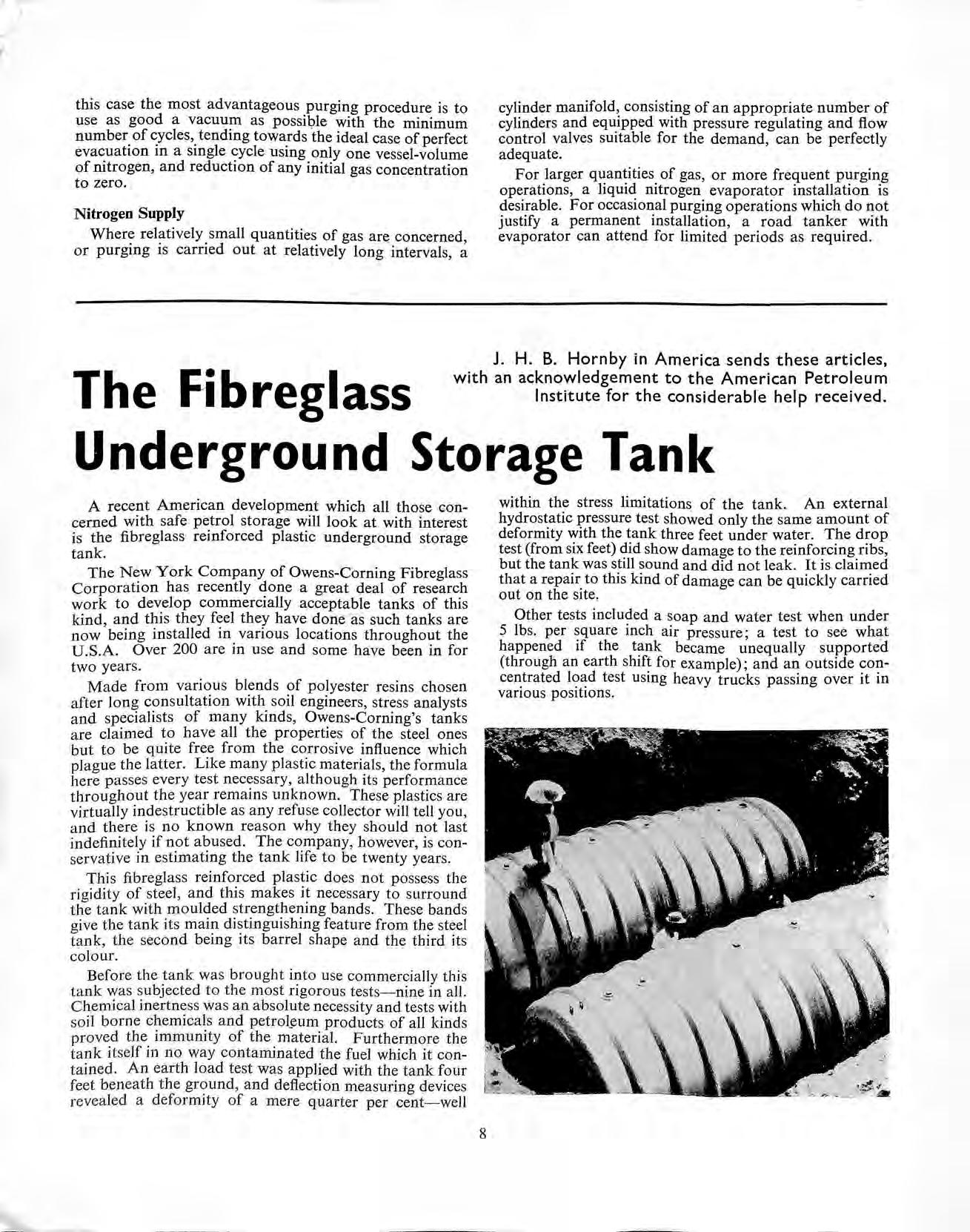

A recent American development which all those G>on cerned with safe petrol storage will look at with interest is the fibreglass reinforced plastic underground storage tank.

The New York Company of Owens-Corning Fibreglass Corporation has recently done a great deal of research work to develop commercially acceptable tanks of this kind, and this they feel they have done as such tanks are now being installed in various locations throughout the U.S.A. Over 200 are in use and some have been in for two years.

Made from various blends of polyester resins chosen after long consultation with soil engineers, stress analysts and specialists of many kinds, Owens-Corning's tanks are claimed to have all the properties of the steel ones but to be quite free from the corrosive influence which plague the latter. Like many plastic materials, the formula here passes every test necessary, although its performance throughout the year remains unknown. These plastics are virtually indestructible as any refuse collector will tell you, and there is no known reason why they should not last indefinitely if not abused The company, however, is conservative in estimating the tank life to be twenty years .

This fibreglass reinforced plastic does not possess the rigidity of steel, and this makes it necessary to surround the tank with moulded strengthening bands. These bands give the tank its main distinguishing feature from the steel tank, the second being its barrel shape and the third its colour.

Before the tank was brought into use commercia ll y this tank was subjected to the most rigorous tests-nine in all. Chemical inertness wa s an absolute necessity and tests with so il borne chemicals and petroi_eum products of a ll kinds proved the immunity of the material. Furthermore the tank itself in no way contaminated the fuel which it contained. An earth load test was applied with the tank four feet beneath the ground, and deflection measuring devices revealed a deformity of a mere quarter per cent-well

within the stress limitations of the tank. An external hydrostatic pressure test showed only the same amount of deformity with the tank three feet under water. The drop test (from six feet) did show damage to the reinforcing ribs, but the tank was still sound and did not leak. It is claimed that a repair to this kind of damage can be quickly carried out on the site.

Other tests included a soap and water test when under 5 lbs. per square inch air pressure; a test to see happened if the tank became unequally supported (through an earth shift for example); and an outside conce°:trated test using heavy trucks passing over it in vanous positions.

J. in America sends these articles, with an acknowledgement to the American Petroleum Institute for the considerable help received.The final tests were to do with the pipe fitting problems. In both the torque and strength tests the unions withstood all that was required of them.

It seems, then, that the future for this kind of installation is very bright indeed, and the Underwriter's Laboratories of the American Insurance Association are very satisfied with it from their point of view. From ours, as the safety people, it also looks good, because it should not leak in normal use, even over a long period of time. Its outstanding feature as I see it is that it just is not subject to corrosion or deterioration of any significant kind when below ground.

What then of the garage proprietor-the man who foots the bill ? Well, it must be bought, delivered and installed, and that should be the end of it. Purchase price is high but installation costs are less because no concrete vault or special backfill is needed.

In theory at any rate there will be no costs such as removal or replacement with the accompanying loss of sales, customers, good public relations and so on. Anxiety too should go-and who can assess the value of that ?

The plastic underground tank just had to come, as has the plastic bucket and the plastic toy. It looks very much as if this is it.

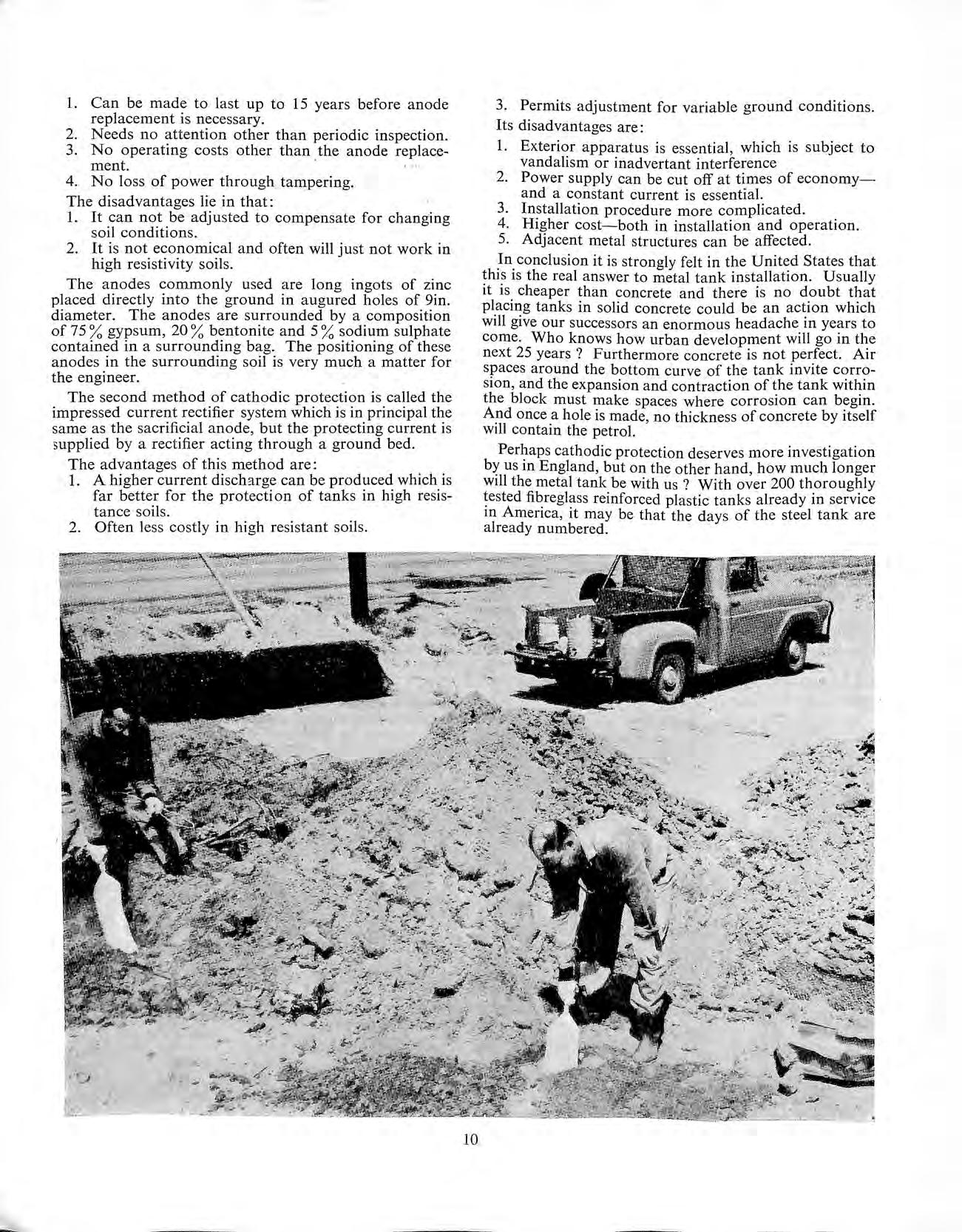

Controversy over the best method of tank installation rages on this side of the Atlantic just as much as it does in England. Concrete has its advocates and so has the vault-but here there are many knowing people who say th.at you cannot beat J?Utting tanks straight into the ground with cathodic protect10n.

In nine cases out of ten it is corrosion of the tank over the years which causes a leak, and stopping the corrosion would stop the leak. To stop the corrosion is the point of cathodic protection.

It is well appreciated t.hat corrosion of a tank takes place because of direct electrical current which removes metal from the surface of the tank and deposits it elsewhere the currents often being set up by the chemical action of stances in the soil-a sort of accidental dry cell batteryand once the flow of current is established and measured it is t<?o of a J?roblem,. Establishing 1t, however, is a speciahst Job mvolvmg findmg the makeup of the soil in which the tanks are to be sunk, as well as its resistivity to electrical currents.

This is determined by one of two methods, using electronic instruments: First, by on the.site? using an an earth resistivity meter. This device, which 1s used in conjunction with metal rods forced down into the earth indicates soil resistivity in ohms per cubic centimetre. each site a number of readings are taken at different places and depths. The second is to remove soil samples from various depths and locat10ns and send these to a central testing laboratory. Both these procedures are best left to a company specialising in cathodic engineering.

If these tests reveal a resistivity below 3000 ohms per c.c. then enough corrosion can be expected to justify the cost of installing cathodic protection. If the value is below l OOO ohms very serious corrosion can be expected, and if

above 5000 this type of protection will be unecomical and unnecessary anyway.

What then are the mechanics of this type of protection ? Before the cathodic method is looked at it is as well to remember that re-filling the hole containing the tank with washed and dry sand only provides temporary protection against electrolytic action because it will absorb ions from the surrounding soil and become corrosive itself.

Tank coatings of course help to keep corrosion down, and such bituminous coatings are required as a point of licence and installation condition as in England. In the U.S.A. there are five basic types of coating (for underground tanks and pipework) and they are listed here in increasing order of cost:

Cold applied mastic coatings

Hot applied pipeline coatings

Plastic tapes

Thin film plastics

Solvent or heat applied enamel pipeline tapes

The great weakness of all is that !hey are subject to damage during the handlmg mstallatJon of the tank and when damage occurs corros10n starts at that place. Coating should be touched up wherever possible right up to the last moment of exposure. This point is of paramount importance in tank installation of all kinds.

Returning now to the cathodic protection methods, two can be applied, and each has advantages and disadvantages. The first, using sacrificial anodes is the one often seen on the hulls of boats when they are hauled out for repainting. Plates made of zinc or magnesium can be seen screwed to the rudder, propeller shafts and hull of the vessel for the express purpose of being eaten away by the electrolytic action encountered in salt water. The principle is identical in our case. The advantages of the system are:

I. Can be made to last up to 15 years before anode replacement is necessary.

2. Needs no attention other than periodic inspection.

3

. No operating costs other than .the anode replacement.

4. No loss of power through tampering.

The disadvantages lie in th a t:

1. It can not be adjusted to compen sa te for changing soil conditions.

2. It is not economical and often will just not work in high resistivity soils.

The anodes commonly used are long ingots of zinc placed directly into the ground in augured holes of. diameter. The anodes are surrounded by a compos1t1on of 75 % gypsum, 20 % and 5 % sulphate contained in a s urroundmg bag. The pos1t10nmg of these anodes in the surrounding soil is very much a matter for the engineer.

The second method of cathodic protection is called the impressed current rectifier system which is inyrincipal same as the sacrificial anode, but the protectmg current is supplied by a rectifier acting through a ground bed.

The advantages of this method are:

I. A higher current dischg_rge can be wh1ch_ 1s far better for the protection of tanks m high resistance soils.

2. Often le ss costly in high resistant soils .

3. Permits adjustment for variable ground conditions.

Its disadvantages are:

1. Exterior apparatus is essential, which is subject to vandalism or inadvertant interference

2. Power supply can be cut off at times of economyand a constant current is essential.

3. Installation procedure more complicated.

4. Higher cost-both in installation and operation.

5. Adjacent metal structures can be affected.

In conclusion it is strongly felt in the United States that this is the real answer to metal t a nk installation. Usually it is cheaper than concrete and there is no doubt that placing tanks in solid concrete could be an action which will give our successors an enormous headache in years to come. Who knows how urban development will go in the next 25 years ? Furthermore concrete is not perfect. Air spaces around the bottom curve of the tank invite corrosion, and the expansion and contraction of the tank within the block must make spaces where corrosion can begin. And once a hole is made, no thickness of concrete by itself will contain the petrol.

Perhaps cathodic protection deserves more investigation by us in England, but on the other hand, how much longer will the metal tank be with us ? With over 200 thoroughly tested fibreglass reinforced plastic tanks already in service in America, it may be that the day s of the steel tank are already numbered.

The Model Code of Principles of Construction and _Licensing Conditions referring to spring controlled nozzles m power operated pumps states that no stop or catch should be provided on the nozzle attached to the delivery hose which would enable the valve to be kept open and thus eliminate manual control.

In the Debate on Motion for Adjournment in the House of Commons on the 29th July, 1966, the Hon. Member for Twickenham once again urged the Home Office to amend the Model Code to permit the use of latched automatic nozzles. He further urged that local authorities be recommended to follow the amended code and that this should lead to more self stations including those of the unattended type.

In reply, the Minister of State, Home Office, said that the question of latched automatic nozzles was being given speedy attention but it could not be dealt with in isolation, from the rest of the code. A revised draft code has been submitted to the Standing Advisory Committee on Dangerous Substances and a special sub-committee is making a detailed study of this.

The use of these dispensing pumps is extending. Such u_nits can deliver up to nine separate grades of fuel from a single hose outlet by dispe!1sing of two base alone (these being of rel.atJvely high and I.ow octane.rating) or blending them in volumet.nc proport10ns. to produce fuels of intermediate octane rating. Each blending pump has two pumping units driven by separate motors.

The Model Code recommends that the supply circuits o_f pump shall be separately protected by fuses or circuit breakers.

Local Authorities incluoing the Greater London Council have accepted that in the Home Office recommendation, the term pump should mean dispenser so that the. two motors of the blending pump can be protected by a single fuse. The Home Office have confirmed that this interpretation is correct.

(I) Attended

There is no model code of requirements for self service stations. There are however, already a substantial number of stations of the service in existe!1ce and a typical set of add1t10nal licence cond1t10ns relatmg to these is as follows:

1. Self-serve dispensing units shall not be used for delivering petroleum spirit except into the ?f a motor vehicle. Deliveries of petroleum spmt into cans, etc., as prescribed shall only be made by authorised employees.

2. The licensee shall ensure that thfie11 .control. _is manned at all times when the mg is in operation. In the event of in charge of the control room leaving this pos1t10n, and the control room is unmanned for any reason .whatsoever, all the self-serve on the station be de-activated and made of operat10n within the control room. If the cont.rot room have to be abandoned at any time the switch on the exit wall shall be moved to off .

3. There shall be provided on self-servet in?trument, including . s, m. a conspicuous '1: notice full operatmg instructions mcludmg, 1f appropriate, the use of the speaker unit to control room.

4. In the event of any untoward <?ccurring at or in the vicinity of any measunng mstruments which has created or is likely to create .a hazard., the person in charge of the control room will de-activate all instruments, set the isolating switch to the "off" position and set off the electrical alarm bell system.

5. If any is observed to .spill petrol putting pet:ol mto a mot?r vehicle from any dispensing umt, the person m charge of the control room should de-activate the measuring instrument being used, summon other staff to deal with this and take such action or give orders to deal with such.

6. In the event of any incident or circumstance whereby any fire or explosion takes place on the filling station area, the person in charge of the control room shall also inform the private branch telephone exchange operator who will originate immediately a "999" call to the Local Station of the Fire Brigade. Alternatively, the person in charge of the control room shall originate such a call direct.

7. The person in charge of the control room shall not re-activate the measuring instrument until a customer has completed a self-serve delivery of petrol and paid or accounted for the sale.

8. The person in charge of the control room shall request over the measuring instruments speaker system any person leaving a motor vehicle smoking, or, having left a vehicle, commencing to smoke, to to stop smoking before preparing an instrument for use by that person and will de-activate the unit if request not complied with.

9. The licensee shall provide at least one one-gallon foam fire extinguisher and a quantity of sand at each self-serve dispensing point. There shall be attached thereto or nearby a notice indicating that the extingguisher and sand may be used by any person in the event of a fire or explosion occurring at that point.

10. No vehicles shall be parked permanently on the filling station area except for the area reserved especially for this purpose.

11. The licensee shall maintain in effective condition the ringing alarm bell system and carry out and record checks made on the system at least once every three months. This record to be kept in the control room for inspection purposes by a Petroleum Officer of the Council.

12. All employees engaged in dispensing petroleum spirit from the measuring instruments on the shall be advised of the electrical arrangements msofar as, if applicable, failure of the individual pump units will cause cessation of deliveries. No unauthorised or other than competent employee or agent is to be allowed to investigate a breakdown of the pumping units. Jn the event of any unusual breakdown of pumping operation on any units, the petrol pumps' master switch shall be put to the "off" position as a precautionary measure and the appropriate fuses removed, before that unit master switch is again switched on.

13. Each pumping unit fuse and distribution switch shall be marked with the number of the pump or brand of spirit as appropriate.

(a) The instrument shall be of a design approved by the Council and shall not be adapted or altered in any way without the prior approval in writing of the Council.

(b) The instrument shall only be used when the licensed premises are fully occupied and appropriate staff can exercise reasonable surveillance over the instrument and its operation. At all other times the instrument shall be kept locked so that coins cannot be inserted or the instrument used in any other way.

(c) Operating instructions shall be preceded by the words 'Stop Engine-No Smoking or Naked Lights' in It inch red lettering on a white background and clearly legible. The operating instructions for the proper and safe operation of the instrument shall be clearly marked on the instrument.

(d) The instrument shall not be used except to deliver petrol or petrol/oil mixtures into the tank of a motor vehicle.

The Standard Weights and Measures Department of the Board of Trade have drawn up a standardised set of ininstructions for petrol service pumps used on these stations and the Home Office have recommended that these be preceded by an instruction reading:

All Licensing Authorities have required the use of automatic nozzles without latch on these pumps but the Greater London Council have in addition specified that such devices should prevent (a) delivery of petrol until the nozzle is properly located in the fuel tank orifice, and (b) overfilling of a fuel tank.

In the reply in the House of Commons, on the 29th July, the Minister of State, Home Office, referred to both attended and unattended self service stations. She stated that both of these types of installation are touched on in the draft of the revised Model Code.

Some unattended installations are already in operation in England, using either coin-operated or bank-note operated equipment.

Such installations are few and of an experimental nature and largely because of this detailed regulations of the type used for attended installations have not yet been developed.

The Local Authorities concerned have granted a licence only for the installation of a particular approved type of equipment and some additional requirements have included the provision of flood lighting, adequate fire precautions, position on the forecourt with suitable interception to collect any spillage that might occur and an alarm bell to ring in the owner's house. '

Note acceptor cabinets and electrically operated multicoin devices are difficult to flameproof. They are usually mounted in a separate housing from the pumps and inremo!elY from them in an approved location, with mterconnect10n by approved wiring.

The Home Office when approached have said that it may be helpful to consider the following observations: l. Approval, of course, would lie with the local authority; there is no existing veto against such devices in the Home Office.

2. There should be shown to be a real demand for them.

3. Adequate safeguards should be incorporated and should include the following features:

(a) Children or young persons should not be able to obtain petroleum spirit from the devices.

(b) The device should be so sited as to create a minimim hazard in the event of a spill, which should run away to an interceptor of suitable design.

(c) The device should only be operable by use of a special key. This could be R.A.C. or A.A. but in any case should be oversize from the normal Yale key in order to prevent home manufacture. The device should only be capable of taking one kind of coin, say a half-a-crown, and the amount of petroleum spirit obtainable at one time should not exceed one gallon; the question of accepting banknotes would need special consideration with regard to the sensing arrangements.

(d) A safety device should be incorporated to prevent petroleum spirit being delivered until the nozzle was in the fillpipe of the vehicle.

(e) The nozzle itself should be so designed that it can be grasped without at the same time grasping the trigger, and a shroud on the nozzle holster should also be provided to serve the same purpose.

(f) There should be incorporated means to prevent the hose and nozzle being left on the ground after use.

(g) There should be provision for adequate inspection and maintenance of the device which, until experience has been gained at any rate, should be restricted to one per garage.

(h) There should be ready access to a telephone to notify the Fire Service in case of an accident.

requirements would the installation of any equipment that is at present available for trial and in fact some of the requirements are probably impracticable.

Meanwhile, the number of unattended self service installations in Europe is increasing rapidly and the experience with large numbers of these commercial installations has been excellent.

Mr. S. M. Carruthers (Belper R.D.C.) asked what would happen if a customer could not get all the petrol he had paid for into his car tank. Mr. Spalding replied that the next customer would receive this surplus petrol if he came along within three minutes but when the pump shut off the petrol was lost to the public.

Mr. J. T. Ainsworth (Skegness U.D.C.) said that he did not like unmanned stations for there was always the maniac who might come along and spray petrol all over the place and be a hazard to the community. Mr. Spalding replied that there is always the problem of the maniac who might act anywhere and quoted as an example arson in a timberyard. He said that to prohibit self-service stations on such grounds seems wrong while the rest of the world goes ahead and reminded members that he was not trying to promote self service stations. He said that his work was to create exclusive designs and provide good technical equipment for the market.

Mr. Crowe thought there was a possible hazard if a car was not safely positioned before a sale and a spillage occurred. Mr. Spalding replied that car detectors and electronic nozzles might be employed but since they sent most of their products abroad they were governed to some extent by the requirements of their foreign buyers.

Mr. Coleman said he did not like payment to be made inside the kiosk and preferred the original idea of payment being made outside the kiosk .. Mr. Spalding replied that it was a matter for local plannmg.

The Chairman, Mr. E. T. Crowe, opened the discussion by saying that obviously lots of research and technical know-how had gone into the design of self service stations. He said he felt that such stations were bound to come and the new selective employment tax would tend to encourage them. Mr. G. C. Cartwright said that his committee had recently approved the use of coin-operated pumps in Nottingham and questioned the efficiency of inertia nozzles when inserted in the tanks of certain cars.

Mr. Spalding replied that the inertia nozzles operated horizontally and even upside down but his company were aware of new car designs where the nozzle had to be used sideways. Mr. D. Barnes (Chesterfield R.D.C.) said that when storage tanks became dry, the customer would not receive his full amount of petrol. Mr. Spalding said that it was a question of good house-keeping on the part of the proprietor, otherwise the customer would lose his money.

• Mr. K. Coleman (Leicester) said that it would be better to have a coin operated pump capable of receiving a 10/note and giving change. Mr. Spalding said such a pump could be constructed but giving change was not favoured.

Mr. J. Norris (Chesterfield) referred to attended stations and said that when the nozzle is hung up on such stations the pump is de-energised and the controller would not re-activate the pump unless all is clear, but <;>n unmanned stations this would not apply and there might be some hazard when the pump is operated. He thought that licensing conditions should require the use of automatic cutoff nozzles to prevent the over-filling of car. tanks and pumps should also have _a pre-set mecha111sm. Mr. Spalding referred Mr. Norn_s to 8 ?f model of requirements for self service stations 111 his paper which enabled an operator to de-activate the pump if customer was smoking and agreed that unmanned stations had their own particular problems.

Mr. Cartwright said that hazards do exi.st unattended stations and the question is whether this 1s acceptable. Nottingham believes there is little. risk and has been no serious vandalism on open stat10ns or on pumps. His committee now accepte.d self service pumps after suitable and approved planning. He wondered whether girl attendants wot!ld hear the custome! over microphone when car were left runnmg. M1. Spalding replied that girl attendants should . hear the customer and in any case they should be fully mstructed to deal with all possible problems.

Mr. w. H. Matthews (Derby) wondered what steps had been taken regarding othe! services as topping up batteries engine oil, and air. Mr. Spaldmg replied that 1t depended on the standard of petrol station. Some stations were provided with oil cabinets in contact with the kiosk and the operator on a button could and account for a can of 011. There were the usual a1r-lmes, distilled water bottles and cans of water and in fact all the normal facilities.

Only a short time ago, gas from the North Sea seemed a distant prospect to most people. In 1962, exploration of the area had begun, using seismic techniques to provide an indication of the sorts of geological structures underlying the sea. The first exploration and production licences had been granted in 1964 and the first well drilled at the end of that year.

But it has been the gas strikes of the last year which have really caught the public imagination. Gas from these should be flowing into the country in the next two or three years and another fuel will have become available to energy consumers in Britain.

The story of the North Sea is a many-sided one about which a great deal could be written-about the geological history of the area which has led to the accumulation of gas in porous sandstone thousands of feet below the bottom of the sea; about the costly research and development efforts of the oil companies which were necessary before exploration and production could begin in such a difficult area; about the actual drilling operations and the weather and other hazards which have accompanied these.

The purpose of this article is, however, more limited. It is to look at the impact of North Sea gas on the British fuel economy-in particular to discuss the quantities which may be available, how these should be used, and the ideas which should govern the price of North Sea gas. On all these matters there has been considerable speculation, mostly well wide of the mark, and it is hoped to give a more considered view in this article.

Views expressed in public about the potential of the North Sea have varied enormously with drilling successes and failures. In the middle of this year, when a number of commercial discoveries were made, some of the newspaper stories published rose to extremes of optimism, giving the impression that there is a huge pool of gas filling the area between Holland and Britain, just waiting to be tapped by anyone who cares to drill a hole. It was suggested that the English waters of the North Sea are bound to contain reserv_es several times the size of the large field at Slochteren m the Netherlands. Then, the mounting number of 'dry holes' led to some tempering of this view. More recently, several finds have brought another surge of optimism. What is the truth of the matter ?

At the present stage, all that can be said with authority is that the potential of the North Sea is still unknown. The presence ?f gas has been definitely established in several fields-it appears that six or seven areas have now been found to significant quantities of gas, though there has been msufficient drilling to prove the extent of the reserves and whether or not all the fields are commercially But because this has happened in an to Holland it does not necessarily mean that Britain can count on very large reserves. Any estimates of total North Sea reserves which are made at this time can

only be speculative. Though the area has been extensively explored by seismic methods, this can only indicate where there are structures which may contain oil or gas. The only way to find out whether or not anything is there is by drilling holes.

As drilling gets under way, it is quite erroneous to start drawing conclusions about the area's ultimate potential based on the early ratio of successes to 'dry holes'. It cannot be assumed that the wells drilled early in the explor- ation of an area are tapping a representative sample of that area. In fact, it is likely that they are not, since it will usually be those structures which appear most promising which are drilled first. For this reason, it is quite common for the proportion of successes to be relatively high in the early stages of development of a new field. In the North Sea so far, twenty-five exploratory wells have been drilled and six or seven have encountered some gas; but in the end the success ratio may well settle down at something nearer the world wide average for the oil industry of three commercial finds in every hundred exploratory wells drilled.

There are two further important points about the size of North Sea reserves. One is that it seems to have been generally assumed that these will be located in a large field like Slochteren or possibly in a number of such fields. However, the evidence so far available suggests that it is more likely that such gas as is found will be in relatively small structures. Even if reserves comparable to Slochteren are eventually discovered finding them will be difficult and expensive and may a considerable time.

The second point is that the amount of gas which is eventually recovered from the North Sea will depend not only on the quantity of gas which is in place and on the techniques available for extracting it. As with any other !latural lying under the ground, the amount which 1s produced will also be a function of the economic incentive given. to the other words, it will depend on the pnce that 1s paid for the gas.

With any given supply of gas available for the market, the question arises of the use to which this should be put.

To understand how this problem applies in the U.K. one has to look at the nature of the gas industry in this country. The British gas industry meets only a small part of the country's energy requirements-about 6 per cent. compared, for example, with around 33 per cent. in the U.S. Its sales are concentrated on those consumers who can _take ad_v!intage of, and are willing to pay for, the special qualtttes of gas-domestic customers and limited numbers of industrial and commercial concerns. At the present time gas is not a competitor in the very large "bulk heat' market-where fuel is burnt under industrial (including power station) boilers and its value reflects only the number of B.Th.U's it contains.

Given this background, how should natural gas be used? First, it should be noted that because the gas industry in this country is small volumes of natural gas which are

modest in relation to the energy market as a whole are apt to large compared with gas sales. For example, gas mdustry to be basing its long term planmng on the assumpt10n that by 1980 about 4 OOO million c.f.d: fee_t per day) of North Sea gas will be available -this 1s four times the present output of the gas industry and therefore sounds large. 4,000 million c.f.d. would, however, represent only about 12 per cent. of probable _l.J.K. demand in 1?80. This is an important point m seemg North Sea gas m perspective because it means that even these apparently large volumes would not give us access to unlimited quantities of gas. The U.K. energy m_arket is_ a large one and it probable that natural gas will remam a scarce resource m relation to this market.

If natural gas supplies are likely to be limited in relation to their potential market, it becomes necessary to examine !he use to which they are put. Natural gas is a high-quality fuel, easy to control, low in sulphur and ash and needing no storage by the consumer-an ideal fuel for sorts of markets at present being served by the gas mdustry. Sales to these consumers are already expanding fast-at about 10 per cent. per annum-and a continuation of this rate of increase would be sufficient, by 1980 to absorb a supply of 4,000 million c.f.d. There may be a for some gas sales outside this traditional market-for ex3:mple, to industry if !latural_ gas supplies temporarily outstnp demand, or mdustnal sales during the Summer when heating is But, unless very large reserves are found, 1t would be highly undesirable to sell natural gas on a long-term basis into bulk fuel markets to ab_ou_t i;nillion c.f.d. of natural gassmce this could d1ss1pate limited resources very quickly.

It must be stressed that this argument about the need for natural gas to move first into the 'traditional' markets of the gas industry is not special pleading based on fear of what an oil company might lose if natural gas were to compete with oil for bulk fuel sales. In fact, oil sales will be affected adversely wherever natural gas goes-the present expansion of manufactured gas industry is, after all, being fed by 011 feedstocks.

The only independent test of the use to which natural gas should be put is not what an oil company thinks, or what the Gas Council or the Government thinks. This test is quite simply what would have happened to the gas in a competitive market in which a number of buyers of gas were faced by a number of sellers. In such a market gas would move first to those buyers who placed most value on it-by definition, those able to make best use of its special qualities and therefore those prepared to pay most for it. Only if reserves turned out to be very large, or if there were temporary surpluses, would natural gas be sold for burning under boilers.

In this country we do not have a truly competitive market for natural gas. There is competition between producers to supply gas, but there is effectively only one buyer. As usual when we move away from competitive conditions, problems are created. In this case, because the is not fully competitive, it will not automatically provide the right answer, so that a conscious decision become_s necessary on the use to which the gas should be put. It 1s our opinion that the interests of the economy will be be_st served if a decision is taken quickly to bring about the situation which would have occurred naturally in a competitive market. Once this decision has been made,

the be clear for a planned programme of convertmg to _natural gas, as rapidly as can be managed w1thm the hm1ts of available reserves.

The aspect of North Sea gas on which there has been most public speculation is price. This is not the time to to this by setting out more figures on what the price will or should be. However, it is worth a few words on the factors which should determine price.

There appears to be a general belief that the lower the price of North Sea gas, the greater will its benefit be to the British economy. This idea is implicit in most of what has been written about the North Sea.

The origin of these ideas is not difficult to see. We have lived in an inflationary economy for a long time and this encourages the belief that keeping down prices is in itself a good thing, especially at a time of Government price and income restrictions. Then along comes a new source of energy which promises to be cheaper than manufactured gas. A few superficial comparisons are made with natural gas prices in the Gulf of Mexico and suddenly prices of the order of 2d. a therm appear.

It can easily be shown that this kind of comparison with the Gulf is superficial and misleading. It is economic nonsense to talk about prices like this without taking into account energy supply and demand conditions in the U.K. and the amount of gas which may be produced from under the North Sea. It would be pointless to try to force the price of natural gas here down to the level which exists in the U.S.-where natural gas supplies about one third of the energy market-when it appears that a relatively small part of Britain's future energy requirements will come from the North Sea.

What is so easily forgotten in discussions about North Sea gas pricing is _th<:t price is an economic mechanism for bnngmg supply and demand mto balance -and any attempt to manipulate it will affect this supplydemand balance. It has already been pointed out that on the evidence so far available, natural gas is likely to remain in limited supply. If this is and if for some the price is reduced below wh<:t 1t would have been m competitive conditions, there will be a double effect-demand will be stimulated by the low price and supply will be restricted because of the reduced incentive given to those engaged in the risky business of finding and producing gas. (In effect, to try to a low price is to producers to bear the nsk of North Sea exploration, without offering them the if they are to _do so). In the end this will result m a shortage of supplies and probably the price of North Sea gas being higher than it need have been. There is no escape from this market mechanism. If it turns out that supplies from the North Sea are very large the price will fall as a result of the market mechanism and this will be to the benefit of the economy. But to try to achieve this effect in the absence of such supplies can lead only to wasteful use of the gas, to a reduction of incentives to look for further suppliesin fact, to the usual distortions which result from trying to defy market forces.

One reason behind this concept of trying to push the price down as far as possible is therefore probably a failure to appreciate the economic consequences of such action.

Another reason is perhaps that people fear the producers will make a lot of money out of the North Sea if something is not done to stop them. A little thought will show that there are no grounds for this fear. It has already been pointed out that the Gas Council has been placed in virtually a monopoly buying position and that a number of producers are competing to supply it. The Government will take about 50 per cent. of any profits made by the producers, who have borne all the risks of exploration. And finally, natural gas will have to compete in the U.K. market against alternative fuels. In these circumstances, the North Sea producers could not exploit the market, even supposing that they wanted to do so.

This article has been concerned to point out three things. First, that the potential of the North Sea is still unknown but that evidence so far suggests it will be by no means a 'bonanza'. Second, that in such circumstances there is no sense in trying to carve out a permanent market for the gas in low-value applications. Third, that it would be economically unsound to attempt to price North Sea gas on the assumption of virtually unlimited reserves. The last is the key point: and the one that has been most neglected in public discussion.

Produced as a Supplement to Essa Magazine, Autumn 1966

One of the main features of a floating roof tank is the fact that it practically eliminates vapour space. Such space is found only in the peripheral area between the edge of the roof and the tank shell.

. While this design greatly reduces the fire hazard, it also mcreases the difficulty of reaching the reduced vap?ur space where the majority of fires occur. Positive apphcat10n. of foam into this space is impossible with most pr<;>tect1on systems, which are not able to penetrate the fabnc seal and its protective weather shield.

A recent development by National Foam Ii;ic. of Pennsylvania, U .S.A., is stated to overcome this with a system that places foam applicators directly into the vapour space. Such a system has been tried out on a tank of a chemical company in New Jersey. A PIJ?e was mstalled up the side of the tank to the platform, runnmg over the platform and into a flexible hose catenary. The lower end is connected to a circle of pipe mounted directly on the roof.

. At various intervals along the pipe, foam make!s are mserted through the floating roof and pontoon, directly _the vapour space beneath the seal. This provides positive foam application if a fire occurs.

The flexibility of the system enables it to operate at peak efficiency regardless of the roof level. It also eliminates the use of.the tank drain hose as part of the protection system. A dram hose cannot be periodically inspected and could burst under the pressure of foam application during a fire.

On the floating roof tanks of modern design, the fire almost always occurs in the seal. For this reason, many large refineries rely on the mobility of their fire departments to protect these tanks. However, where personnel are not readily available, this new National Aer-0-Foam system is said to give positive foam application quickly and directly onto the fire.

In some confined areas, the application of high expansion foam can be considered as an improved "ventilating"

technique. The function of the foam is to displace the heated air and gases of combustion. To accomplish this, the area must be ventilated at a high point, preferably opposite the foam entrance point.

High expansion foam-being slightly heavier than the heated gases-will cling together and settle to the lower part of the area. This displaces the heated gases volumefor-volume with the amount of foam introduced.

. The advantage of. high expansion foam over a smoke ejector becomes obvious, say the company. The air from a smoke ejector is introduced at a much higher velocity than the foam. This air stream, almost the same weight as the gases, tends to mix with the heated gases. Under conditions.this can actually cause the fire to rise in mtensity, due to mcreased oxygen supply. Even if this does not happen, the mixture may be such that a 5,000 c.f.m. smoke ejector is actually evacuating less than 2,500 c.f.m.of heated gases.

From the viewpoint of removing heated gases and smoke, th_e. use of high expansion foam offers a much more pos1t1ve and efficient means of ventilation it is claimed. '

In _addition to _superior ventilation, high expansion foam a bar!1er to radiant heat. This prevents areas which are not mvolved from reaching the ignition point.

The _water in the foam also cools burning areas by absorbmg to produce steam and provide an inert atmosphere directly at the source of the flame. While the t<;>tal amount of is small, the application of water directly to the flame 1s much greater than it would seem. The reason is that the bubbles contact the flame and burst while turni!1g into. steam. These are replaced by other bubbles which contmue the process until the area has been cooled and wetted to the point where the succeeding bubbles do not break. In effect an automatic flow of bubbles and water directly to source of the flame is set up.

The inaugural meeting of the East Midland Branch was held at the Town Hall, Worksop, on Thursday, 29th September, 1966.

Present were the Chairman Mr. E. T. Crowe, Mansfield and 26 members; 17 apologies were received.

The meeting was welcomed by His Worship the Mayor of Worksop, Alderman H. B. Taylor, who outlined the various industries, amenities and historical aspects of Worksop. The Chairman thanked the Mayor for finding the time to open the meeting and expressed his interest at the many things Worksop had to offer. Alderman Taylor then wished the meeting well and left the Council Chamber. Mr. Crowe, in extending his own welcome to those present, expressed his pleasure at seeing Messrs. C. T. Peacock (Hemsworth R.D.C.) and B. W. C. Thacker (Middlesbrough), members of the Council of the Association who were attending as visitors.

The meeting agreed that the Chairman and the ViceChairman of the proposed Branch be Messrs. E. T. Crowe and G. C. Cartwright (Nottingham), Mr. J. Birks (Chesterfield) was appointed Honorary Secretary/Treasurer.

Suggested Branch rules and constitution were then considered and the boundaries of the Branch defined as comprising the geograph!cal area Derbyshire, Leicestershire Lincolnshire, Nottmghamshire and Rutland. Classes of were then thoroughly discussed and it was eventually moved that Rule 3 be amended as follows:

"In addition any person employed in the administration of the Petroleum Acts shall be eligible for membership of the Branch provided his Local Authority or any one of its officers is in membership of the Association as provided above".

Questions of subscriptions to the Branch were also considered, and a fee of 5/- per branch member was agreed.

It was agreed that in addition to the election of officers already confirmed, a Caretaker Committee be formed, to act until the first Annual General Meeting. The following were then elected to form this Committee:

Mr. K. Coleman (Leicester City Fire Brigade)

Mr. W. H. Matthews (Derby County Borough)

Mr. G. Popplewell (East Kesteven R.D.C.)

Mr. J. Staddon (Essa Petroleum Company, Limited)

This was left in the hands of the Chairman and Secretary. Mr. Matthews said that general licensing conditions might be discussed at the next meeting and Mr. G. C. Cartwright said that some person concerned in the drafting

of the Model Code of Licensing Conditions might be invited to initiate a general discussion.

Mr. F. M. Bucknall (Grimsby) said that the meeting should not necessarily discuss petroleum products for there was a wide field of other dangerous substances found in schools, factories and shops. He said that his experience was that flammable substances in the retail and wholesale factories were often ignored.

Mr. Matthews said he had a problem regarding the safe storage of liquid methane by the Gas Board in Derby. He understood that the Home Office should have informed him of the presence of the liquid methane and the sa.fety precautions to be taken. He stated that he had rece!ved no communication from the Home Office and had wntten to the Gas Board but received no reply. Mr. Coleman said that in Leicester they had a one ton cylinder of liquid methane used for the North Sea Gas experiments which was on a temporary stor!'lge basis for period of twelve months. He said that it had been licensed the Methane Order and common sense used regardmg safe storage conditions.

The business meeting was then and adjourned for lunch. In the sess10n, the man introduced Mr. R. G. Spaldmg, M.I.Mech.E., Chief Engineer of Wayne Tank and Pump C?mpany, who presented an interesting and informative paper t!1e help of slides entitled "Trends in Dispensing'', which dealt with the plannmg. an.d code of requirements of self-service stations. This is reported on page 11.