Quarterly Journal of The Association for Petroleum Acts Administration

E. V. BEEBY J. BEER ,J. BIRKS

' J W. FRID H. GRIFFITHS

E. V. BEEBY J. BEER ,J. BIRKS

' J W. FRID H. GRIFFITHS

---,

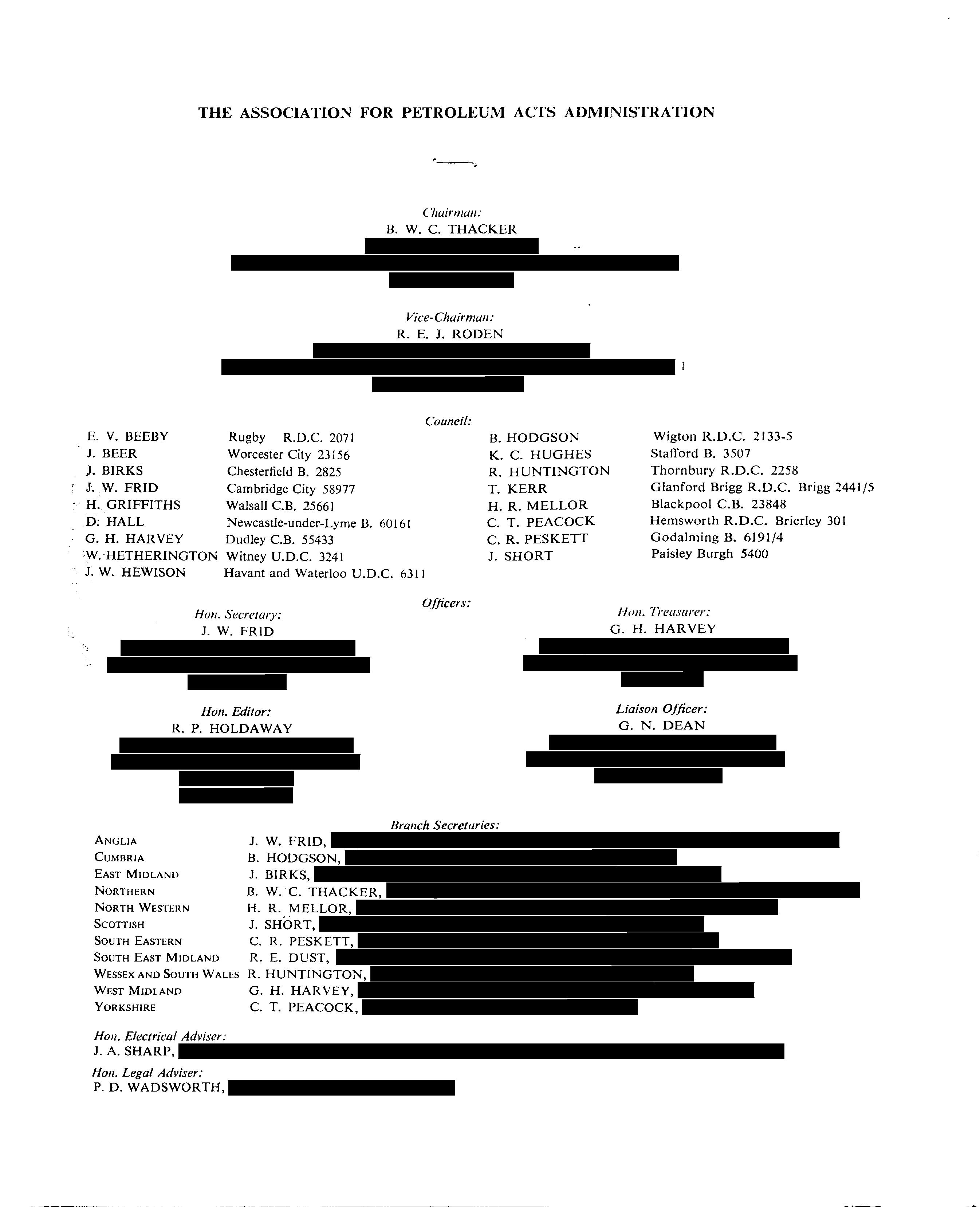

( '/wirman: H. W. C. THACKER Vice-Chairman: R. E. J. RODEN

Rugby R.D.C. 2071

Worcester City 23156

Chesterfield B. 2825

Cambridge City 58977 Walsall C.B. 25661

D; HALL Newcastle-under-Lyme ll. 60161 G. H. HARVEY Dudley C.B. 55433 '.W.·HETHERINGTON Witney U.D.C. 3241

Council: W. HEWISON Havant and Waterloo U.D.C. 6311

Officers:

B. HODGSON K. C. HUGHES R. HUNTINGTON T. KERR H. R. MELLOR C. T. PEACOCK C. R. PESKETT J. SHORT

Wigton R.D.C. 2 I 33-5

Stafford B. 3507

Thornbury R.D.C. 2258

Glanford Brigg R.D.C. Brigg 2441/5 Blackpool C.B. 23848

Hemsworth R.D.C. Brierley 301 Godalming B. 6191/4 Paisley Burgh 5400

Hon. Secretary: J. W. FRID Hon. Editor: R. P. HOLDAWAY

Hon. Treasurer: G. H. HARVEY

Liaison Officer: G. N. DEAN

ANULIA J. W. FRID, CUMBRIA B. HODGSON,

EAST MIDLANU J. BIRKS, NORTHERN B. W. ·C. THACKER, NORTH WESTERN H. R. MELLOR, Scorr1sH J. SHORT,

SOUTH EASTERN C. R. PESKETT, SOUTH EAST MIDLANO R. E. DUST, WESSEX AND SOUTH WALlS R. HUNTINGTON, WEST MIDLAND G. H. HARVEY, YORKSHIRE C. T. PEACOCK,

Hon. Electrical Adviser: J. A. SHARP, Hon. Legal Adviser: P. D. WADSWORTH,

Five years ago L. A. Cave retired from office as Chief Inspector of Weights and Measures to the Corporation of Dudley. The Bulletin published a tribute to the service he rendered to the Council and inhabitants of that town and coupled with it an acknowledgement of his work for this Association as its first Honorary Secretary/Treasurer. Mention was made of the growth in membership of the Association in little more than six years from 28 to 350.

Today on behalf of our 670 members we are privileged to again refer to the retirement of Mr. Cave, this time from the offices he held so illustrously within the Association. In this small tribute we cannot hope, nor is it our intention to eulogise on his many achievements in raising the Association to the present unique position it occupies in the world of petroleum administration. To attempt to do so would embarrass a man who is by nature reserved and who was content to take over a duty and discharge it efficiently and conscientiously.

In thanking Len for his outstanding service we also acknowledge the help and encouragement given to him over the years by his wife. On behalf of all our readers we wish Mr. and Mrs. Cave many happy years of peace and contentment in their new surroundings in Hampshire.

Blackburn CBC Lanes. F Bucklow RDC Cheshire s Chatteris UDC Carobs. s March UDC Carobs. H Orrell UDC Lanes. s Standish with Langtree UDC Lanes. s Warrington RDC Lanes. H Ware RDC Herts. S&H York City Yorks. WM

Mr. J T. C. Davey (Associate), National Benzole Co. Ltd., Bexhill-on-Sea.

Mr. E. R. Ashill, Chief Officer, Hampshire Fire Brigade, after 35 years' service, the last 12 as Chief Officer at Hampshire.

Mr. E. A. Lyne , Surveyor and Public Health Inspector, Warwick R.D.C.

Mr. E. M. Richardson, Engineer and Surveyor, Ramsbottom U D.C.

Mr. R. A. Thomson , Chief Inspector of Weights and Measures , Aberdeen, after 43 years' service with the Council.

Mr. A. A. Wheatcroft (Associate) , Avery-Hardoll Ltd ., Solihull.

Mr. A Elrick , Deputy Chief Inspector of Weights and Measures, Aberdeen, has been promoted Chief Inspector.

Mr. J.C. North, Deputy Engineer and Surveyor, Ramsbottom U.D.C. , has been promoted Engineer and Surveyor.

Mr. W. Qaultrough, Warwick R.D.C., has been promoted Chief Public Health Inspector.

Mr. A Winning, Chief Officer, East Sussex Fire Brigade, has been a ppointed Chief Officer, Hampshire Fire Brigade.

M r. H. John son , Chief Officer, Teesside Fire Brigade, has bee n awa rded the O.B .E.; Mr. F. W Harbidge , Senior

Fire Prevention Officer, Shropshire, the M.B.E., and Mr. H. Griffiths, Chief Officer, Walsall, the Queen's Fire Service Medal, in the New Year's Honours List.

Mr. B. W. C. Thacker, Senior Fire Prevention Officer, Teesside Fire Brigade, and Chairman of this Association , has been appointed to represent the A.M.C. on the Technical Sub-Committee of the Central Fire Brigades Advisory Councils Joint Fire Prevention Committee, dealing with petroleum spirit storage.

We regret to report the death of Mr. J. S. Bates, Borough Surveyor, Loughborough.

Programme for metric change in the United KingdomPetroleum Industry. Available from the Institute of Petroleum ,

A nomination for Office or for Membership of the Council is enclosed with this copy of the Bulletin Completed forms to be returned to the Hon. Secretary not later than the lst March, 1970. Any Notice of Motion must be received by the Hon. Secretary not later than 28 days before the date of the A.G.M., which will be held sometime in April, 1970.

The Association Codes of Practice are now out of print. A re-print has been ordered. Applications for copies , together with cheque or postal order (6/- per copy including postage) to be sent to the Hon. Editor, R. P Holdaway, Shrewsbury.

Members are invited to submit to the Hon. Editor suggestions and designs for an appropriate symbol for the Association. The design to be suitable for incorporation in a badge of office for the Chairman.

Three courses of instruction for petroleum officers have been arranged for the year 1970. The courses are to be held at the University of York, Shropshire Adult College , Attingham Park, Shrewsbury, and the University of Surrey. Requests for provisional reservation to be addressed to Messrs. B. W. C. Thacker, J. W. Frid and C. R. Peskett respectively.

Would members please inform the Hon. Secretary of any change of their address or telephone number over the past twelve months .

In his letter published in the Bulletin of October 1969 Mr. D. comments about the future of' leum admm1strat10n and this Association after local government reorganisation. As pinpointed in Mr. Hall's letter. any is doubtless going to cause a drastic reduct10n m the number of authorities administering petroleulll: legislatioi:i and consequently there will be a sharp drop m those eligible for membership.

However, I feel that the reduction in numbers will not be so great as first Even if the majority recomendat1ons were to be implemented "in toto", there would appear to. be provision for 78 petroleum authorities in England (i.e. 58 unitary authorities and 20 metropolitan district councils). In addition we must not forget the petroleum authorities which would be established after local government reorganisation in Scotland and Wales. It would certainly seem that at least one hundred petroleum authorities would remain in Great Britain, even after the most radical reform. If Mr. Senior's two tier system were to be adopted, then there would be 148 district authorities in England alone, responsible for all licensing functions. It should be noted that the C.C.A., U.D .C A and R.D.C.A. have, in their submissions to the Minister of Housing and Local Government, supported a two tier organisation ; whilst the A.M.C. has proposed a very substantial increase in the number of unitary authorities to a figure closer to the 140 coherent socio-geographic units discovered by research.

Mr. Hall rightly fears that more specialisation will result in a loss of the present multi-disciplinary approach to problems of petroleum administration. With more centralisation, more specialisation seems inevitable, but we can perhaps console ourselves with the thought that the present expertise has been built on a foundation of many professions and we must therefore ensure that this expertise is never lost but ha nded on to the future specialist officers

The present uncertainty as to the future structure of local government makes prognostication a vague venture. Possibly we shall all be better able to gauge the effects of local government reform after the Government White Paper on the subject is published early in 1970.

RoyalTunbridge Wells C. A . How ARD-LUCK

I am writing on behalf of members of the Yorkshire Branch to query certain parts of conditions contained in the Codes of Practice published by the Associa tion in July , 1969 . T refer to Appendix 4 , page 18 ,

paragraph 9 (control of circuits) part (b) (pump circuits), which has a reference to the Home Office Code of 2.3.8. The Home Office Code under paragraph 2 3.8 , page 16, reads as follows: "The supply circuits of each pump should be separately protected by fuse or circuit-breakers set to operate when the current in the circuit so exceeds the rate of current for such a period of time as to involve danger".

An extract from the Electrical Contractor and Retailer deals with the previous Code which was published in January, 1960, and part (h) of the extract is worded as follows: "The supply circuits of each pump shall be separ- ately protected by fuses or circuit-breakers set to operate at a current value as near as practicable to the normal current taken by the apparatus". Many members of the Yorkshire Branch have had a running battle with electrical contractors to obtain separate circuits for motor an_d lighting to each pump. Thus the article has helped this battle by interpreting the original condition to mean separate circuits for lights and pump motor.

The new Home Office Model Code paragraph 2 3.8 is similar to the old Code and the interpretation by most members of the Yorkshire Branch is that this still means separate circuits for lighting and pump motor to ea ch pump. We found , however, that in Appendix 4, paragraph 9(b)(i), it is suggested that we have only a single circuit to each pump and in paragraph 9(b)(ii) we should have a single circuit to a blender pump and in p a ragraph 9(b)(iii) we should have three circuits to a du a l delivery pump. Only paragraph 9(b)(iii) satisfies our interpretation of paragraph 2.3.8 of the Home Office Code and we think that paragraph 9(b)(i) and (ii) of Appendix 4 should demand dual circuits to ea ch pump , one for lighting and one for pump motors

In practice the pump is used during the day without the pump lighting being ignited , so that for conveni ence sake dual circuits are very often provided. We are worried , however, that with a single circuit to an ordina ry pump and particularly to a blender pump , when the lighting is on alone and no motors a re running, the system is fus ed to take the current of the lighting plus in the case of a blender two pump motors and dangerous overhea ting could occur without the fuse ope ra ting.

We consider the new Code is , therefore , a retrogade ste p from a safety angle, from the interpretation placed on the old Code and the conditions at present demanded by most members of the Yorkshire Branch.

The idea of the n ew Code is that all members should adopt it on a national basis and many membe rs of the Yorkshire Branch feel reluctant to adopt the cond itions se t out in Appendix 4 , pa ra graph 9(b)

Sheffi eld S. GAS COI BROWN,

BROWN,

Although in this country there is, in general, no legal requirement that the user of electrical instrumentationin atmospheres employs only certified equipment, m pi:actice many users wish to have written assurance that their instrumentation will not constitute an explosion hazard. In some countries such assurance by a government or other independent organisation is mandatory. It that any discussion of progress in the United Kingdom in this area must deal with the development of the British Approvals Service for Electrical Equipment in Flammable Atmospheres (the organisation recently set up by the Ministry of Technology to handle all non-mining applications) and the work of the British Standards Institution on relevant standards

At the beginning of 1969 BASEEFA took over the handling of applications for the certification of flameproof enclosures . It will also be ready to deal with applications for "e" type and "N" type equipment as Bntish Standards for these become available.

It was a source of great frustration and disappointment that in the area where improvement is most needed (and '."'hich is of greatest interest to manufacturers and users of mstrumentation) , i.e. intrinsic safety, there was a long in recruiting a man to head a small team engaged this work. However, the man appointed started work in October , 1969 , and in the same month BASEEFA took responsibility for intrinsic safety approvals for a changeover period of some months. BASEEFA: will be assisted by H. M. Factory Inspectorate staff who formerly carried out thi s duty.

In common with the certificates which have been issued by other government departments under the earlier arrangements, BASEEFA certificates will declare conformity to a Standard rather than state that the equipment in question is safe. Generally the Standard will be issued by the BSI and therefore a certificate will be based on the knowledge and experience which this organisation obtains from the participation of experts in all aspects of the subject during the preparation of standards.

In order not to impede new developments and to assist exports, BASEEFA will also produce its own standards. These may arise from new concepts or be based on foreign standards. An essential feature will be that every such internal standard will be freely available so that the criteria on which it is based will be generally known. Any applicant may request certification to any BASEEFA standard which has been issued. In certifying that equipment complies with a foreign standard, BASEEFA will, of course, have to be satisfied that the standard is of adequate quality. Failure to do this would put at risk the high reputation which British certification holds.

BASEEFA considers that in order to justify continued reliance on the safety of a design it is necessary to continue and develop the surveillance procedure, which is not widely used at present. In the certification of foreign equipment acco unt will be taken of any inspection procedures in the country of origin.

One aim of BASEEFA is to promote the reciprocal acceptance of Certificates by various National Authorities. This task will clearly be easier when the stand ar ds of the countries concerned are based on IEC recommendations. Work in the international field will be a continuing process for many years. As an interim measure it is hoped to arrange bilateral agreements with other testing authorities whereby certificates will be issued by one authority based on test reports and documents produced by the other.

At present it is not possible for a piece of composite equipment containing separate parts to be certified as a complete unit. All that is possible is that the components can be certified separately. BASEEFA intends to issue certificates for composite equipment and proposes to publish shortly a standard for pumps which includes the use of several different concepts.

This article, which has been revised by Mr. Brown, is reproduced by courtesy of the Council of British Manufacturers of Petroleum Equipment A talk by K. J. B.S.c. (Eng.), M.1.E.E., M.lnst.M.C., Foxboro Yoxall Limited of the_Intrinsically Safe and Flameproof Instruments Section of BIMCAM to The Contractors' Committee. on Instrumentation, June, 1969It should be appreciated that the setting up of BASEEFA in no way affects the responsibility of H.M. Factory Inspectorate to inspect industrial premises and make recommendations to occupiers where necessary. The Factory Inspectorate is represented on the Advisory Council of BASEEFA and it is expected, of course, that it will normally accept BASEEFA certification as evidence that the occupier of the premises is taking all reasonable care. However, it has the right to take action in any circumstance which it considers might make the use of equipment covered by routine certification unsafe.

BSI have recently been reorgam_sed m to brmg them mto line with IEC work. Techmcal Committee ELE/83 and all its sub-committees have ?een re-nu1:11bered. main change is that the Code Draftmg Committee (for which the Institution of Electrical Engineers formerly provided the Secretariat) is now a sub-committee of Technical Committee ELE/ELCP/4 (formerly ELE/83).

A which relates to all concepts of protection is the classification of hazardous areas. A recent international meeting agreed to publish a document classifying three areas of risk, to be named Zone 0, Zone 1 and Zone 2. These broadly follow the lines of the division definitions laid down in CP 1003, Part 1.

An recommendation on constructional requireme1:1ts 1s about to be published. This has good international agreement and the new British Standard which is in course of preparation will follow it quite closely.

An IEC recommendation dealing with tests is also to be published but its _has been rather poor, partly on the that It contams two methods for testing have not sho'"'.n to be compatible. In the Umted Kmgd<?m there is also disagreement with the factor of !·5 by wluch the routine test pressure on the is related to the explosion pressure. It 1s likely that the new British Standard will retain the routine test pressure specified in B.S. 229.

A draft _of a British. for "N" type equipment has been issued. is a general one which will be followed by parts to specific types of apparatus and necessary rev1s1ons. to the Code of Practice (CP 1003, Part The c?ncept one of good class industrial products with features and its usage is intended be m D1v1sion 2 areas. The issue of the Standard will enable BASEEFA to certify such equipment The of type equipment has had a mixed reception some countries feeling that the "e".type specification should be _used. However, "e" type eqmpment may ?e. unnecessarily expensive for use in Divisio!12 are3:s-1t _is design that in some countries its use is permitted m D1v1s10n 1 areas.

There is no doubt that a British Standard will be issued based on the IEC recommendation for this. The main use of this Standard will probably be to facilitate exports rather than to serve the home market.

The use of IEC type of break-flash apparatus (based on that originated _in Germany) has now internationally. A disc electrode made of cadmmm will be used for all testing except where it can be shown not only that there is no risk of a cadmium spark in the equipment as tested, but that it is unlikely that during the life of the equipment cadmium will be added, e.g. by the of cadmium plated screws to replace ones lost from panels. Where cadmium ex?luded, use of a tm is permissible. In. circmt the cadmmm disc will produce 1gmtion at a energy level than the tin disc. The exclusion of cadmmm may therefore be crucial in equipment working at levels which are marginally safe.

In the United Kingdom a Drafting Panel of S1;1bCommittee ELE/ELCP/4/2 (Intrinsic Safety) is on a draft British Standard based on an IEC workmg group document. This will cover construction testing procedures and it will be very much more than the existing BS 1259 which _it _will replace_. As far as mentation is concerned, this is the most important act1v1ty at the present time.

Standardisation work will lay down the criteria. Instrument and system designers will work the framework of these criteria to provide the most flexible arrangements which are consistent with the maintenance of safety.

Within the last few years the complexity of instrumentation schemes has increased very greatly. Almost of the complexity is in the safe area, where computat10!1 by analogue instruments or by separate (but connected) digital place. It seems certam that to facilitate initial and to that plants are not made unsafe by 11!-Istakes from over-complication, of safe couplmg of safe area equipment with that m the hazardous area will be developed and expanded.

Coupling devices have been used for decades but need for their widespread use has becc;>me appa_rant only m the last five years or so. The Zener provides an economic and very satisfactory solution m some Concepts such as the magnetic amplifier and the transistor amplifier having a high impedance between the safe area circuit and the field circuit can be used. Other methods, such as optical ones, are BASEEFA, Factory Inspectorate and the tion are all well aware of the of procedures made possible by the use of couplmg devices:

British Standard 229: 1957. Flameproof Enclosure of Electrical 1259: 1958. Intrinsically Safe Electrical Apparatus and Circuits.

· I A . / B .-1 · J Standard Code of Practice CP 1003. Electnca ppaiatus a1u 1 A 1 is 1 • fed Ec.1uipment for use in Explosive Atmospheres of Gas or SSOC/Q A /' Va our other than Mining pp 1cat1ons.

I. Choice, installation qnd maintenance of flamepruof and intrinsically safe eq111pment.

Part 3. Division 2 areas.

Br 'fish Standards Institution Techmcal Comm1ttee ELE/ELCP(4Electrical Apparatus for Explosfre Atmospheres. ELE/ELCP/4/l-Flameproof Enclosures. S11b-Com1111ttee ELCP/4/2-111tri11sically Safe Apparatus.

Code of Practice 011 Zener Barriers-BI MC AM.

Automation in the Marketing side of the Oil Industry may be said to have developed at an increasing rate over the past 12-15 years from about the middle of the 1950's. The main emphasis of this development has taken place in two main spheres within plants.

Tankage and pumping Ro a d loading racks

Automation in tanks has been concentrated on automatic tank gauging and temperature indication. Special sensing heads within tanks supply power to servomechanisms which cause remote electronic readout to indicate the depth of product within tankage accurately to within l / lOin. Working through the same system of transmission, long probes, extending to the bottom of the tankage, give an indication of the average temperature of the product. Such systems can also provide high level and low level alarms to ensure safety and good operations.

Product was moved from tankage in earlier days by means of steam driven ram pumps and some of these may still exist in remote parts of the country. Or they may be retained as standby units. In general, however, these sets were soon replaced by the electric motor driven pump. The practice among most oil companies is to install between one and four electrically driven pumps for each product grade. The demand at the loading rack determines the number of pumps operating at any one time. Under these conditions, it is obvious that the flow rate through the main pipe line varies considerably, but flow controllers in each line restrict the outlet flow so that it has a linear ve locity of the order of fifteen feet per second. This velocity is se t to limit the problems of static electricity. Automatic control of such pumps can be achieved by a number of ways but a simple and efficient method is by means of mercury sw itches on the loading arms. As the driver pulls the loading arm down into the vehicle, the mercury sw itch is operated an d the ap propriate pump is swi tched on. Additional pumps are then brought in as required as further ar ms are used, by means of a simple device which reads the amount of current flowing through the arm-meters of the pump motors.

It is at the road lo adi ng racks, however, that the greatest development has occurred within automation. Well before 1960 Esso had intro duced the use of interlocks to prevent prod uct flow into a vehicle until the vehicle was properly connected to earth. The system of connection between loading rack and vehicle which provide this ear th interlock has been developed by Esso to a simple yet very effective plug an d socket which is now u sed almost universally throughout the oil industry. The successful operation

of these earth interlocks depend upon automatic valves which close or "fail safe" under fault conditions. Earlier patterns of this valve were air operated but the current type of valve is electrical/hydraulic

The approach to further automation to the loading racks has three main aims : Safety Security Efficiency

To this end, Esso have steadily progressed to the stage when, in 1964, our plant at Aberdeen was equipped with full automation. This system prohibited loading except by those in possession of special coded keys. The use of such keys identified the operator who was then able to load products through two loading arms simultaneously, provided that earthing and "correct arm" interlocks had been completed. On completion of the loading full details of the operation are recorded by removal of the coded key. This system, which was commissioned during Easter, 1964, has been working successfully since that time. It is the basis from which the existing automation at West London Terminal, and four other major Esso terminals, has been developed.

The automation at these plants has been built by Westinghouse Limited of Chippenham against a specification written by Esso engineers. The main part of the circuitry has been built against " Intrinsically Safe" standards. This ensures that even if sparks occur at the loading rack areas , these sparks are not capable of producing sufficient energy to cause ignition. Other equipment is of certified F.L.P. pattern or is positioned in a remote SAFE area.

The equipment is best described by driver operation :

The driver pulls into the loading rack, after being issued with loading document, and turns "off" his vehicle safety switch He then climbs on to the vehicle and inserts his "driver code" card into the card drawer at the pre-set head on the handrail. This is INTERLOCK No. l and unless this and other interlocks are completed properly no product can be obtained.

The vehicle is connected to a good earth by means of the two socket outlets connected to extensible cables, existing at the handrail of each loading bay. INTERLOCK No. 2.

The lo3;ding arm product to be taken in is pulled into vehicle manhole. A mercury switch, w1tl_1 three separate contacts on the loading arm is operated. INTERLOCK No. 3. This ensures that the pump is running and that the correct arm has been selected. The driver then checks that the compartment is empty and that its size is correct for the quantity to be loaded.

The manual loading valve on the loading arm is opened into the "latch" position. It stays in this "latch" position until the loading arm is raised, when the valve is closed automatically. INTERLOCK No. 4.

The driver then presets the quantity and grade of product to be taken from the preset head. This will not allow product if Jess than 35 gallons or more than 1,999 gallons are selected; nor will it allow product unless the grade is the same as that of the loading arm in the vehicle.

INTERLOCK No. 5.

The "ready" button on the preset head can then be pressed to accept product. INTERLOCK No. 6. If all the interlocks have been satisfied properly and the drivers l<?ading card has not been "locked out" a signal will be g1yen to open the automatic valve in the line and product will flow. As this takes place, the product meter will drive a pulse transmitter, causing a steady stream of pulses to be sent back to the control position in order to give the "shut off" position at completion. If some mechamcal ?r electrical fault has affected the drive to the pulse and signals are not being received, a sending cucmt associated with a flow switch operates and stops flow. INTERLOCK No. 7.

;Afte! flow has commenced on the first loading arm, the dnver 1s free to move about the top of the vehicle, prepare the next loading arm and continue loading with other prod1:1cts, up to a maximum of five at any one time. In p_ractice, four arms appear to be the maximum used but loading of three arms at one time is achieved quite frequently as the loading authority permits.

h During this operation, should the driver consider that e wants to stop flow for any reason, he has ready access "trip" wire which runs the full length of the handrail. s flow on the whole of his loading bay without other drivers' operation. Re-instatement of loadmg .takes place by pressing a "reset" button on the presettmg head when the driver has dealt with the reason for "trip".

1 Odi:i completion of vehicle loading, the driver parks his oa mg arm, closes and locks his vehicle manlids and removes his coded key from the key card drawer.

As the loading arm is lifted from the compartment a simple wire strop ensures that the manual valve is close. Another wire strop provides a parking position or the drop tube to ensure that this does not suffer or mechan}cal damage. Removal of the coded key from t e drawer gives a signal to logic circuits in the control the typewriter to print the following mformat1on:

Date Meter No. Time Product Loader Driver Code Quantity

Bay No. Product temperature where necessary

If the product delivery is less or greater by a defined than that preset by the driver the information is in red with a negative or sign and an audible alarm draws this to the attention of a supervisor.

A simple MIMIC diagram positioned at the control centre of the whole loading arrangement ;h1le audible and visual signals provide simple but effecive fault finding features.

The whole system is designed on "Fail Safe" principles so that in the event of fault conditions the equipment is designed to "shut down" and deny product to some or all of the bays dependent on the fault. Under such conditions the plant could be shut down for the period until the fault had been found and cleared. This could be hours or even days dependent on the severity of the fault and the availability of suitable engineering staff. For this reason, the equipment has been designed to incorporate a "Remote Manual Override" which, when implemented, would allow driver loading without use of the coded key and automatic preset and without details of the load being recorded at the remote position. Drivers would load using one arm at a time under these conditions but the earthing interlock would still be retained.

Experience has shown the need for logical interlocks to ensure that changeover from an Automatic to Manual condition is carried out with positive safety. These interlocks are incorporated in a system of keys and switches in such a manner as to make it impossible to make the changeover without complete safety. The operation is restricted to named and authorised supervisory staff who, alone, possess the keys giving access to changeover equipment.

Considerable effort has been expended on training. Drivers are not issued with "coded keys" for which they have to sign until they have been trained on a minimum number of occasions and demonstrated their ability to a number of trainers. Drivers also have to sign that they consider that their training has been adequate or that they require further training. Comprehensive Operating Manuals are being continually updated, have been prepared and are issued to all supervisory staff with responsibilities in automation. Each operating manual lists the names of individuals with responsibilities for different areas of work. These supervisors are all subject to intensive training and simulated fault condition and fault finding routines. Each individual, whether supervisor or operator, is logged by in books subsequently held by the plants, which md1cate the length and type of training, by whom and whether or not they have satisfied the final examiner.

Simple maintenance can be achieved up to a certain level by plant staff but a maintenance contract is placed with the manufacturer for scheduled and breakdown service. This ensures that fully qualified electronic engineers are on site within 48 oours of a service call being made.

The system has been operating in principle at Aberdeen smce 1964. In its final form it has been in operation at Hythe Terminal since January, 1968. It is also working in this form at:

Tynemouth near Newcastle Avonmouth-Bristol

The Company is not resting on its laurels as can be expected. It feels it has achieved a major breakthrough towards achieving the aims of :

Already, plans are in being for a further step forward to keep Esso ahead in the technological field of operation.

This is into two parts-the first deals with Petrol F1llmg Statton development currently being carried out in the No_rth West of England, and the second deals with changes m the pattern of Self-Service Petrol retailing likely t? evolve from developments as a result of evaluations currently bemg undertaken by our Company in various parts of the Country.

Let us by asking "Why Self-Service ?" There are three pnnc1pal reasons:

(a) !he general trend tow:irds larger, more economic units m all branches of busmess; this trend is to some extent Government and is being accelerated by the present economic climate.

(b) .T?-e rising cost o! utilities (like clectnc1ty). to 1t 1s mterestmg to note that it now costs a filling stat10i;i employer more £3 10s. Od. per week for each full-time male employee m taxes and other charges before the employee even starts to work.

(c) The rising population will make it essential that these new large efficiently with a minimum of staff; the Umted Kmgdom car population doubled between 1957. and 19?5 according to Ministry of Transport estimates, 1s hkely to nearly double again between and 197?, reaching then a total of 16,900 OOO registered private vehicles. '

Let us !1<?w look. at what are the basic needs of a SelfService F1llmg Stat10n.

Essentially they requir.e: a .covered refuelling area a cov.ered route to the well-spaced refuelling positions, good forecourt no forecourt obstructions such as cars over-sp1llmg from a workshop d preferably a .modern accessory shop. ' an

It is possible to provide no less than eight f tr positions by .the use .of blender pumps-whiche :n designed t<? dispense six grades of petrol (from 91 to 101 octane from the one pump; the traffic flow is of eight , the bottom serving the refuelling positwns t?P half servmg the coin-operated car wash; the hghtmg is suspended on the underside of the canopies. Of c?urse, can be added-such as temporary ba;Ys to coin-operated canned oil vending machmes m the v1cm1ty of the control building.

You may "Yell at this point, "This is all very well at sites with but what about the small site ? " Well, how hm1tmg this questi.on of space ? Here are plans of three more projects for which conversion pro-

posals have been prepared. The site dimensions in these three cases are, respectively, 50ft. (depth) by 170 ft. (frontage), 96ft. (depth) by 120ft. (frontage) and 52ft. (depth) by 84ft. (frontage).

As you can see, the basic plan has been i? e:ich case to cater for the size restriction-but the basic prmc1ple remains the same. (At this point slides were shown illustrating the effect of applying these principles to a site, and the sequence of steps undertaken by a motro1st visiting the site was demonstrated).

So far I have dealt only with POST-PAYMENT SELFSERVICE. To end, I want briefly to mention SELF-SERVICE. This system is now becoming comparat1v.ely common at a number of our filling stations for use durmg the night when the station is unmanned.

Over the past eighteen months the Company has been carrying out evaluation exercises at completely filling stations where this type of equipment h:is •? use throughout the day. From these investlgat10ns it would seem that this type of self-service may have a useful part to play in the development of the smaller throughput filling station. One of our dealers hopes shortly to be applying for local authority consent to the development of the first such filling station in the n<?rth west and these slides show the sort of eqmpment which such a site may be using.

This brief mention of the unmanned filling station brings me to the point where the future commences, and at this point I would like to hand over to my. Mr. J. Bridger from our Head Office-who will be talkmg about what we may see on the filling stations of the future.

Gentlemen, I have been invited to talk to.you th!s afternoon on developments in self-service refuelling eqmpment. My colleague has already spoken to you the philosophy behind the two types of self-service, pre-and post-payment.

Taking pre-payment first the equipment currently <?n the United Kingdom consists of two types: corn or note operated.

Various manufacturers are developing units incorporating coin accumulating w ic can accept multiples of 20p (2/-) .or. 50p (10/-) I.n cases where the space available w1th111 the pump casmg is sufficient, the coin acceptor may be pump mounted and

B.P. Retail Head Office, Shell-Mex and B.P. Ltd.

the cash value of petrol dispensed controlled by a proprietary cash pre-set mechanism. In other cases such as blender pumps, where the blend control systems and cremental gear box take up so much space that there 1s no longer room for a coin mechanism, some kind of remote cash accepting unit must be considered. Several manufacturers have developed a remote coin and note acceptor combined, which is available either free standing or as a wall mounted unit. In these cases, the coins inserted by the motorist are counted on relays within the cabinet. Electrical pulses, sent between the pump and the coin/note acceptor count the cash units dispensed by the pump, and cut the pump delivery at the appropriate moment.

Bank note validators have been undergoing a great deal of development recently,and several different techniques of bank note verification are now being evaluated. Adverse climatic conditions, condensation, humidity, customer mis-use and vandalism are all factors that have influenced the design of note acceptors. However, there is no doubt that they are now becoming reliable, and my Company hopes to have over 200 installed by mid 1970.

The siting of a pre-payment unit, whether coin or acceptor, is of great importance. In this context, air purging of the unit is a very obvious advantage as it allows its installation within division two areas, thus making possible an easy identification of the coin note acceptor with the pump which it is serving.

Manufacturers have available pre-payment units which can be linked to as many as six different pumps. When credit is established on a particular pump, the pre-payment unit is immediately released ready to accept credit on another pump.

Looking further into the future, the days of automatic credit card systems may not be far ahead. These are already on evaluation in Sweden, and consist of a combined console which includes coin acceptor, note acceptor and a credit card acceptor. For credit card operation, the motorist inserts his card, selects a personal code on a sm.all panel of press buttons, presets his required gallonage with a further button and serves himself. His purchased quantity together with his account number is then transmitted to a punched tape within the service station building. Periodically the tape is sent to a central data processing centre for the production of accounts.

Turning now to post-payment equipment, you are probably all familiar with this system, where the motorist serves himself then visits a central control point to pay for his purchase. This form of self-service is now in widespread use in the United Kingdom.

Basically there are two methods of transmitting information from the pump to the control point or console. The first operates electro mechanically. Pulse generators mounted on the cash and volume shafts of the pump computer head, send impulses to the console. The pulses are then counted by drive resettable mechanical counters in the console.

. The seco!ld common system operates entirely electronically. Agam pulses from generators in the computer head are sent to the console, but in this case, the information is registered as an electronic display.

This latter is a more flexible system and one manufacturer is already incorporating 'memory circuits' in the console which store up information until released by the

cashier. This could lead to faster operation, as a customer would not need to wait while a previous sale from the pump he had selected was cleared. He would be free to fuel his car, whilst his cash/volume would totahse in the memory store until released by the cashier when the the previous sale had been cleared.

Memory circuits could logically be developed for longer term applications, providing daily or even totals of spirit sold or cash taken for use in accountmg or stock taking.

Alternatively, electronic impulses from the pump can be used to drive a ticket printer in the kiosk or control point. Again, this should theoretically be a fast systen:i, since a ticket is printed automatically when !1- pump switched off, obviating the need for the cashier to wait until the customer has walked to the control point and seen his sale displayed on the console. Immediately the ticket is printed the pump can be cleared for a subsequent customer.

As a low cost solution to post-payment, some manufacturers are developing pump mounted ticket printers. These obviate the need for a console, as each customer carries his receipt to the cash desk.

A further post-payment type system that is being offered by some manufacturers is the key operated pump. This system consists of a pump, the head of which contains an array of maybe fifty key slots. Selected account customers, or perhaps drivers from a transport fleet are issued with a key corresponding to a particular slot. The insertion of the key releases the pump for delivery, and the volume taken by the key holder is recorded on a totaliser. Every so often, as required for accounting or billing purposes, the totalisers can be read.

Now, what of the pump itself? Self-service has less accelerated pump development, and brought m its wake many improvements. The burden has now been placed on pump manufacturers to produce that is designed for use by an unversed public. Lightweight radial arms are re-appearing on the scene, and one manufacturer is now offering flexible twin hoses for blender pumps, coupled with single knob grade selection and automatic on/off switching.

It is conceivable that in the long term we shall see the disappearance of the petrol pump as we know it now. Equipment is already being evaluated in Sweden by my Company that features a remote pumping unit, a small stanchion or wall mounted control unit with push button preset price controls and a lightweight nozzle with electronic display readout mounted actually on the nozzle itself. The nozzle display may be selected to read in either price or volume by means of a push button on the control panel. The unit operates on a post-payment system during the day and on a note acceptor system by night. You may have seen also our installation in Birmingham; the first pumpless petrol station, where hoses descend from the roof to fuel cars standing on a pumpless forecourt. These are developments we may see more of before too long.

As you will have judged, petrol refuelling equipment is at a particularly rapid and interesting stage of development just now. The advent of new manufacturers into the United Kingdom market is doing much to stimulate new ideas and to provide the oil companies, and increasingly the public, with modern well designed equipment.

When the new Teesside County Borough was formed some eighteen months ago it was decided to provide authorised parking areas for petroleum tank wagons and the tanker traffic in the area is of major proportions, 1t was agreed that three sites should be chosen.

It apparent during preliminary work that these parkmg are3:s should be adjacent to known tanker routes, close to mam roads, and should also take into account improvei:ient plans. This led to exploring the possib1hty of keepmg tankers onto specified roadways which would pass authorised parking sites and at the same time keep clear of highly congested areas. ' '

The police, because of their interest, were enthusiastic from the commencement of this exercise and after a certain amount of exploratory work a meeting was called on 24th 1969 between the Police, the Fire Brigade, the Highways Department and fifteen representatives of tanker fleet operators. At this meeting the police stressed the need for a voluntary system of co-ordinated routes for vehicles carrying dangerous loads and asked for co-operation from all concerned.

The Service emphasised the need for pre-determined routes m o!der to enable the special services required, to locate and isolate any accident involving a vehicle carrying a dangerous load. It was obvious that such loads were much more in densely populated and congested areas than m rural areas and if an accident involved materials, 'the emergency services would reqmre as much workmg space as possible.

The meeting defined dangerous loads for this particular purpose as follows:

Any petroleum solution or mixture giving off an inflammable vapour.at a t.emperature below 73°F. and any other substance which gives off an inflammable vapour at a temperature bel?w /3°F. and coming within the Petroleum (Inflammable L1qu1ds) Order, 1968.

.Loads of ammonia, chlorine, phenol substances, or any mixture of such substances (this definition to be classified and further added to).

Loads of toxic material and inflammable gases carried under pressure.

Routing of these tankers was discussed and agreement was reached on the roadways which would be used by these vehicles and it was decided that the new routes should operate from lst January, 1970, and that the Highways Committee should be so informed.

A member authority is concerned about the standards of safety which apply when are being moved.by rail. Under present regulat10ns .railway wagons carrymg military explosives are only to a S,!Ilall indicating the nature of the explosives bemg earned. Wh1.le it is desirable that, in the event of a fire, the .officer m charge should be aware of the type <?f exl?los1ve it is appreciated that more readily identifiable markmgs could cause alarm for railway workers and the _general public raise difficulties from vandals, and be obliterated by or fire. We feel, therefore, that the method of dealing with the problem is for advance notice of the movement by rail of abno!mal loads to be given to local fire and pohce authorities, and taken the matter up with the Home Office and the Mimstry of Transport.

Municipal Review Supplement, December, 1969

Continued from page 18

A site visit was then to the to see self-service in operat!on. _The method of oper- by Shell-Mex as an evaluat10n site. e ation on this site is as follows: . (a) The motorist can use the pumps following thd pr:nted instructions and then pay the forecourt atten an · (b) The forecourt attendant can are not sure of.the be trained to use time all motorists usmg the site wt these pumps with care. d d . th . to collect monev an see The forecourt war en ts eie · "e carried that the general forecourt licence condttwns ar out. · h d

At night-time one of blender pumps is switc e over to note accepter self-service.

The operation of change-over on this site is by means of two switches and is very simple and safe to use.

Messrs. B. W. C. Thacker (Chairman), E. V. J. Beer, L. A. Cave (Secretary), G. N. Dean, J. W. D Hall, G. H. Harvey, W. Hetherington, J. W. Hew1son, B.° Hodgson, R. P. Holdaway (Editor), K. C. Hughes, R Huntington, T. Kerr, H. R. Mellor, C. T. Peacock, c: R. Peskett, R. E. J. Roden and J. Short.

Mr. J. Birks.

Of the previous meeting held on 2nd June, 1?69, havmg been already circulated, were confirmed and signed.

Re alia: An ad hoe C<?mmittee this g d th Council decided to pubhsh an item m the matter an e · "d d d · f Bulletin inviting Members to submit t eas ai:i es1gns or a suitable symbol as the mark of the Assoc1at1on.

The Chairman had circularised members of. Comd th finances of the Assoc1at10n an holding Committee and Council part1<?ularl\ t e c gested that it was now necessary to Meetmgs. .t was :ug over a two day period in order to hold Council M.ee deal with the business under disgive. out that this would :ostof such meetings and .would se in the subscription rate and it an mcrea b rs of the Council would find 1t difficult, 1f not some te be away from their Authorities for two day imposs1 e, 0 h Id" C "tt M t · d The present method of o mg om_nu ee ee perio. s. h rly morning prior to the Council Meetmg at mgs 10 t e e: felt to be a helpful solution and provided l l wlameeting time and kept costs within reasonable ad 1t10na · th" b · b . · s The Council decided to contmue on 1s as1s ut hmitd. the Committee to examine the. cost of t_wo day aske. and also look into the question of an mcrease meetmgs, in the subscriptwn rates.

The Treasurer reported a credit balance of £427/19/11 in the general account. It reported that the cost of · ting the Codes of Practice was £227/2/6; to date the prm nt realised by the sale of Codes amounted to A free copy had supplied to all members and all copies had been post The Com"ttee responsible for compiling and pubhshmg the Codes mi congratulated on the successful conclusion, both and financially, of what had been a very long

and complicated task. The Codes had been very well received in all quarters.

. A Report of the Committee, amended following a meetof the Committee earlier in the morning, was circulated pnor to the Council Meeting. It was unanimously agreed to susl?end Standing Orders and discuss the report in Committee. On resumption, the Committee's Amended Report giving details of changes in the constitution and rules to be considered at the next Annual General Meeting was received and adopted.

It was noted that Residential Courses were proposed in three centres and it was agreed that the Association would guarantee these courses against any loss or receive any profit made. The recent Course at Attingham had proved again to be a success with 59 present; financial details were not yet finalised. The Council again discussed the question of organising Courses at different levels and it was suggested that ordinary Courses could be run at new venues, retaining Attingham for Advanced Courses only.

The Committee had been dealing with various quer· from members, and at a meeting immediately prior to ths Council Meeting had agreed a procedure to deal ex d"e tiously with queries from members; details in qu land answer form would be published annually .es Bullefin. The Report, circulated the meetmg was received and adopted. The Chairma a t e that the Committee should look at the form of enl ·11 · h c d · · ec nca cert1 cate m t e o e m particular reference to ·t r cation and use for existing premises. 1 s app 1

Following representations to the Home Offi.c letter had n_ow been receiyed regarding membershie, aof the Sub-Committee of the Standing Advisgry Committee on Dangerous Substances (Sub-Com "ttee 4). \Yhilst the Association would have the examimng documents relating to Petroleum matters and thereon, representation on the Committee still not available on the grounds that Local Authority was already adequately catered for. The Council decided to ask the Chairman Officers. to a suitable reply and in so doing reiterate the v_1ew prev10usly expressed, that the Association should be directly represented on the Committee.

There were now 557 Local Authority and 108 Associate Members of the Association.

I

The Council confirmed that members were free to reproduce such parts of the Codes as they required. There would be no objection to extracts of the Codes being re-produced in bona-fide journals provided suitable acknowledgements were made. The Education and Publications Committee were asked to look into the question of copy-right and the cost of re-printing additional copies.

The Chairman announced he had received a letter of resignation from Mr. L. A. Cave, who was moving to Gosport shortly. Mr. Cave had carefully considered all the implications and had reluctantly decided that he could no longer carry out his duties. The Council had no altf'.rnative but t? accept, 'Yith very real regret, the resignat10n, and unammously wished to place on record sincere and for all the thought, time and work given by Mr. Cave smce the very first days of the Association. The Chairman in wishing Mr. Cave a happy and success.fol move stated that his services would be duly recogmsed at the next Annual General Meeting and proposed from the chair that Mr. L. A. Cave be recommended by the Council to be the Association's first Vice-President; this proposal was unanimously carried.

The Council considered action necessary to effectively deal with the administration and finances of the Associa-

tion and unanimously agreed that it was necessary to appoint a separate Secretary and Treasurer.

It was proposed by Mr. Holdaway, seconded by Mr. Peskett and agreed that Mr. J. W. Frid of Cambridge be appointed to act as Secretary and it was proposed by Mr. Hewison, seconded by Mr. Roden that Mr. G. H. Harvey of Dudley be appointed to act as Treasurer. Both Mr. Frid and Mr. Harvey were thanked for taking on these posts.

Council members receiving invitations to Branch Meetings would be expected to pay their own expens.es unless officially attending on of the Council of the Association.

The Scottish Branch Representative raised the quest.ion of representations regarc;li';lg effect of any re-<;>rgam.sation on Petroleum Admmistration. After some discuss10n the Council decided the Association was not competent to make such representations, and suggested that the Scottish Branch should, if they so desired, make representation direct in respect of Scotland.

A vote of thanks to the Birmingham City Council and Mr. Roden for the hospitality and arrangements made, was carried unanimously.

A meeting of the Branch was held at Fire Brigade Headquarters, Park Road South Middlesbrough Teesside, 29th September, 1969. ' '

Thirteen representatives of Licensing Authorities were present as well as two trade visitors.

Apologies for absence were submitted on of Whitley Bay Borough Council and Darlington County Borough Council.

The minutes of the meeting held on the 11 th March, 1969, were accepted as a true record.

Item 4. Notification had been received that the two petroleum courses for this year had been over subscribed.

Item 5. The Association's Model Code had been published and this had been dispatched with the Bulletin. Additional copies were available from the Hon. Secretary of the Association at five shillings each.

Item 6. In view of the number of queries received by Reference and Legal Committee, the Council had agreed to publish these, with replies in the Bulletin.

The Secretary reported that moves may be under way to make legislation to control the storage of liquefied petroleum gas cylinders. This with many other substances would be covered by the Flammable Liquids Regulations.

Mr. A. F. Brunner stated that the conditions in the Model Code compared with those of his own Authority and he was prepared to recommend the adoption of the Association's Code in the County Borough if other Authorities in the area would follow suit. The Hon. Secretary reported that Teesside County Borough would probably follow suit when next the licensing conditions were It was agreed that this uniformity was necessary m the mterests of petroleum administration.

The Secretary pointed out that the Association's Model Code had been published for the guidance and information of members and planned and designed as a supplement to the Home Office Model Code. The meeting welcomed this publication and expressed appreciation with the final document.

A query was raised regarding the division hazard area around dispensing pumps. It was generally that the hazard area was defined as being from the pump itself. However, it must be admitted that the nozzle, when at the f!-lll. extent of the dispensing hose must at times be on the hm1t of the hazard area. In some cases this was 12ft.-14ft. and in other cases 20ft.

A member asked if it was common to require the provision of sand on the forecourt as well as extinguishers. It was agreed that both should be provided as their purposes were not the same.

A member asked whether or not the requirement of 2 x _5 lb. dry powder extinguishers on unattended selfserv1ce forecourts was in place of, or supplementary t_o other fire equipment required. It was agreed that this should be interpreted as supplementary.

Mr. Brunner referred to page ten, section three of the Model regarding the requirements for control rooms on self-service forecourts in division one and two areas. He raised a query as to what requirements should be made when the control room was outside these areas. The said he would bring this to the notice of the Association but felt that it should be the same regardless of the setting of the control room.

A 9uestion was raised regarding the wording of notices it. was agreed the exact wording should be at the d1scret10n of the Authority concerned.

.It was planned to hold two schools next year and for this purpose the country had been split into two areas. fn the case of the Northern area the venue was York .University, which had been visited by the Secretary and it was regarded as quite suitable. The dates of the school were 6th, 7th and 8th July, 1970, and the fees were £9 9s. Od. for residential students and £4 10s. Od. for day students. Provisional bookings should be made with the but it was intended to limit the number of applications from each Authority.

The reported on a fire and explosion at a garage m Lmthorpe Road, Middlesbrough, Teesside, in _May, 1969. Prosecutions arising from this case resulted m the ?wner of the premises being fined £100, the attendant bemg fined £5 and the tanker driver being fined £10.

The tanker driver pleaded guilty but had said in a letter to the court that very certi.ficates completed in the area at fillmg stat10ns and this practice was with the kno"':'ledge of the petroleum companies. The C_hairm.an had written to the yetroleum companies regardmg this matter and three replies received so far had expressed surprise at this statement. It was felt that all petroleum officers present would be interested in the allegations made.

A meeting of the Branch was held at the c .1 Chamber, Amersham, on Thursday, 16th

36 members were present. Apologies for abse · d f M R H M nee were rom essrs. Letchworth B G Willis, Baldock, A. L. Good, Bishops Stortfo 'd · · K. H. Marsden, Watford. r ' and

The minutes of the meeting held at the Council Offi Witney, on 22nd April, 1969, were confirmed. ces,

A question was asked whether the definition of'orct· member' had yet been finalised. The Hon. Sec/nary reported that he had recently seen a draft of proposedetary rules of the Association which would be submitted t new Council in the near future. These rules included 0 the definition of the term 'ordinary member'. a new

The Secretary read a letter he had received f Secretary of the South Eastern Branch giving drorn the the School of Instruction which he was Pro of organise at The Manor House, Farmcornbe Po.sing to Hall of Residence of the Surrey University' is a middle of April, 1970. Of the 36 members p;eseunn& the cated that they would be prepared to support nt 9 mditary level training Course and 3 an advanced le a1 elemenThe Secretary was instructed to write to the Course . indicating that the wishes of the meeting were e iouncil tary mid-week Courses. or lemen-

The Secretary also gave details of a report of he had received from the Chief Inspector incident Borough. A driver, having received a deliver at Slough drove off with the nozzle still in the filling 0°lif.etrol, The Nozzle of the O.P.W. type did not shear as . is car. Intended.

A long discussion took place on both the H and Model Code of Office Conditions of Licence, the following being thnts points made: e mam

1. Stores under 50 gallons should usually be sited outside a building. If inside, kept to a minimum of 5 gallons only, i.e. sufficient for one day's use. Ventilation of container considered essential.

2. A light roof rather than a 2in. concrete roof was considered desirable so as to lessen the explosive effect of an ignition in the store. Vents should never be allowed to vent on to other people's property. If concrete roof considered necessary allow explosion vents of say half square foot for each 10 cubic foot of the store.

3. Empty Cans. Empty cans should be stored only in an approved place and with the caps on. As soon as possible they should be sent to a crushing plant.

l. Non-metallic containers. Mr. W. C. R. Dale expressed the view that the only suitable such containers were those constructed of reinforced glass polyester resin. Such tanks need metal guards to prevent impact damage. Extensive experiments are proceeding in the U.S.A. with regard to these tanks. The outcome will not be known for a few years yet.

2. Dis-used Tanks. A view was expressed that the provisions of the Public Health Act relating to dis-used tanks were inadequate. One of the big problems was what to do with them when they have been excavated. The view was also expressed that the lead content in the sludge might also be dangerous if left lying in places to which unauthorised persons had access. Mr. Dale sa!d that experiments were being made as to whether this could be rendered harmless by treating with potassmm manganate but details were not yet to hand.

'\ disc!-lssion took place with regard to the cond1t10ns relatmg to electrical requirements. The meeting appeared to be equally divided as to whether the tests to be applied, and the results of those tests should be included in the certificate to be called for whether the should cc_mtain merely a statement that the mstallation was satisfactory with no details at all. 'Yith. regard to doublt; pole switches in the lighting circmt, _Mr: Dale explamed that frequently in complicated circmts the neutral or. earth wire could carry a voltage of ".olts and it was not sufficient merely to break wire. double pole switches should be ms1sted upon m all circuits and he would consider each pump motor of a duo-pump as separate pumps each to be controlled by a double poled switch.

Mr. E. L. F. Welch of St. Albans proposed a vote of thanks to Mr. Dale of the Greater London Council for coming along to the meeting and giving the meeting the benefit of his undoubtedly great experience in the general administration of the Petroleum Acts. This was received with acclammation.

The Chairman also thanked Amersham Rural District Council for providing the means to hold the meeting and for their very generous hospitality before and after.

The Annual General Meeting of the Branch was held at Blackpool on 2lst October, 1969.

The Branch Chairman, Mr. J. R. Roberts of Manchester, presided and there was an attendance of 49 members.

An official welcome was extended by Councillor C. Lowe, A.C.C.S., Chairman of Blackpool Public Safety Committee, the Branch Chairman responding on behalf of the members.

The meeting approved the minutes oft.he last Branch meeting held on 16th October, 1968, received the report of the Hon. Secretary and Branch Represel?-tative and adopted the Statement of Income and Expenditure.

Under items of correspondence, the noted that the former practice of one local . to grant a licence which excluded powers of mspect1on, a large bulk had now been discontinued. The meetmg sidered a suggestion from a member that the Branch might compile a list of who. would be for the issue of electrical mstallat10n test but decided not to pursue the quest10n of the validity of charging proport10nate licence fees on a quarterly basis for unexpired parts of year where all licences expired on the same date was dtscusse.d. Sever1:1l members stated that this was the present practice of their local authorities.

The following were elected to serve until the next Annual General Meeting: Chairman: J. R. Roberts, Manchester C.B.C. Vice-Chairman: F. Kenniford, Accrington M.B.C. Hon. Secretary, Treasurer and Branch Representative: H. R. Mellor, Blackpool C.B.C. Executive Committee: T. Broster, Birkenhead C.B.C. A Hewitt Liverpool C.B.C. c: Savage'. Poulton-le-Fylde U.D.C. N. K. Whitehead, Blackpool C.B.C. K. Williams, Cheadle & Gatley U.D.C.

Hon. Auditors: c T. A. Alexander, Morecambe & Heysham M.B .. D. Nield, Lancaster M.B.C.

The best thanks of the meeting were extende_d to Mr. G. H. Lancaster (formerly Wilms.low, now _retired) and Mr. E. G. Newton (Chester) for their past services as m.embcrs of the Executive Commi.ttee and to Mr. A. (Lancaster) for his past services as a Branch Aud1to1.

Under the Branch Rules it is a that. the Annual General Meeting should, from time to. t1_me, determine the amount of the Branch annual subscnpt10n., After hearing the Branch Treasurer report on the state ot

the Branch Finances, and on his recommendation, it was Resolved that for the years 1969 and 1970 no annual subscription be collected except from new cants for Branch membership who shall pay a subscnpt10n of 5s. Od. at the time of their application.

The meeting welcomed the formation of their new neighbour, the Cumbrian Branch, and upon the inclusion of the County of Westmorland within the Cumbrian Branch boundaries, resolved that Westmorland be deleted from Branch Rule 6 which defines the North Western Branch area.

The Hon. Secretary reported the receipt of an invitation from Shell-Mex and B.P. Ltd. to visit the Haydock Terminal on the occasion of the 1970 Spring Meeting. It was Resolved that the invitation be accepted with appreciation and that the making of the arrangements with the Company be referred to the Executive Committee.

On the conclusion of the business meeting, the Chairman invited Mr. F. G. Ashley, Liaison Engineer, Wayne Tank and Pump Co. Ltd., to address the members on the Bank Note Acceptor Unit. Following a most interesting talk, Mr. Ashley answered questions dealing with the method of pressurising the unit so that it could be installed within a Division 2 area and also on the provision of telephone facilities for the emergency contacting of the Fire Brigade. members then visited an adjoining filling station at a Note Acceptor Unit was operating in conwith a Blender Pump where Mr. Ashley gave a practical demonstration of the equipment.

Electrical Requirements-Mr. J. A. Sharp

the meeting after the luncheon break, the called upon Mr. J. A. Sharp, A.I.E.E., Senior Assistant Engineer (Commercial), Midlands Electricity Board and Honorary Electrical Adviser to the Association, who gave a detailed talk on the Electrical Requirements of Association's Codes of Practice. Following the talk, which f'1r. Sharp had illustrated with sketch diagrams, the Chairman invited discussion and questions.

Replying to the points raised, Mr. Sharp said that where the tanker stand at a petrol filling station was covered by a approximately 4 feet above tanker height he considered that electric lighting on the underside of the cai:opy roof would be satisfactory if totally enclosed fittm_gs "".ere _use.d. Flameproof fittings would not be req mred m this situation.

On to kiosks and other buildings with entn.mces w1thm D1v1s1on 2 areas, he said that infra red heatmg not be permitted within the kiosk, even above height of 4 feet. Whilst the Association's Codes of Practice were more permissive than the Model Code in such matters as the installation above 4 feet of electric cash registers and telephones, open type of heater could be satisfactory. Only fl.ameproof heaters should be used.

At attended self-service stations where the control consoles had been installed in a kiosk which was itself within a Division 2 area, provided the consoles were provided with encapsolated switches (which though not fl.ameproof were sparkless) there would be no objection. This type of switch, built within a sealed glass tube, had one fixed and one oscillating contact. The switch was operated by means of a magnet fitted externally to the glass and therefore any sparks were enclosed within the glass. The same type of switch could be used on bank note acceptors installed in Division 2 areas.

In the case of ancillary buildings with entrances just within the Division 2 distance (e.g. 13 feet from a pump) where the area was not enclosed or restricted by a canopy or other buildings, the provision of a 6in. sill across the doorway could justify the treating of the building as outside the Division 2 area.

Answering a question relating to filling stations where new installations or alterations were to be made, Mr. Sharp said that it would be desirable to bring the premises into compliance with the new Code. In many cases this would not present too great a problem since the new Code was a relaxation from the old Code in the matter of safety distances which had been reduced from 20 feet to 14 feet.

Replying to a query on the lighting of large can stores, Mr. Sharp suggested that an alternative to the provision of fl.ameproof equipment would be to light the store from the outside through armour plated glass. This method might even prove cheaper.

Speaking on the acceptance of electrical installation test certificates, Mr. Sharp emphasised that the signature must be that of the employer or Company who would be members of the approved bodies and must take the responsibility for certifying the results of the tests. The signature of the employee who had carried out the tests would not suffice. It had been said that one Electricity Board would not undertake this work but he had found that most would do so but only on payment. They could not be expected to provide the service free of charge.

Asked about the depth of 18 inches at which unprotected electrical cables were required to be laid, Mr. Sharp said that this was a standard electrical requirement and was to ensure that they were well below a spade depth. Where cables were run through specially laid ducts, however, a depth of 6 inches could well be adequate.

In concluding his replies Mr. Sharp admitted that there was a direct conflict between the Model and Association Codes in the positioning of the Master Switch. Pointing out that this was in respect of attended stations, he said that the Association preference for the master switch to be visible to the public and within easy reach was because the act of switching off would not create any danger.

The meeting then considered a question posed by a member in respect of a petrol station at which a tea and coffee blending machine had been installed on the forecourt but in a "safe area". When the petrol station closed at night the forecourt was used as an all-night coffee bar with persons leaning on the petrol pumps and smoking. Residents in the area had complained of the danger but the licensee was not prepared to co-operate by closing the vending machine at the same time as the petrol station. It had already been ascertained that no action could be

taken under Town Planning requirements. Although the matter was discussed in some detail, the meeting was unable to suggest any practicable method of preventing the practice.

The meeting concluded after votes of thanks had been expressed to Mr. Ashley and Mr. Sharp for their respective informative talks, to the Chairman of Blackpool Public Safety Committee for the provision of the accommodation, to the Chief Inspector and staff of the Blackpool Weights and Measures Department for their assistance in the making of the arrangements and to the Branch Chairman for his able conduct of the meeting.

After light refreshments, members were invited to tour what is reputed to be the greatest free show of safe area electrical equipment on earth-the Blackpool Illuminations.

An Ordinary General Meeting of the Branch was held at the Guildhall, Nottingham, on Monday, 3rd November, 1969.

The Chairman, Mr. J. Bantoft, and 34 members. Thirteen apologies were received.

The Minutes of the Annual General Meeting held at Derby on the 12th May, 1969, were confirmed.

There were four applications for membership and two for associate membership which were submitted and approved.

The Secretary confirmed that the North Region Education Committee had arranged a Course of Instruction for Petroleum Officers to be held at York University on 6th, 7th and 8th July, 1970. Final details were to be circulated later and members were advised, because of the popularity of such courses, to make provisional bookings to Mr. B. W. C. Thacker, Senior Fire Prevention Officer, Fire Brigade Headquarters, Park Road South, Middlesbrough, Teesside. The fee was £9 9s. Od. for residential students and £4 10s. Od. for day students including lunch. No fee to be sent at this stage. _

Members were invited to submit any unusual licensing experiences and problems of particular interest. Mr. G. c. Cartwright opened the discussion and referred to the problem of licensing where a forecourt of a garage had been let to a petrol company but the underground storage was located in the garage area retained by the proprietor in pursuance of his own business. Mr. L. F. Lightfoot had a similar problem but .in his case the proprietor retained the forecourt and let his garage.

Mr. c. W. Howkins said his problem concerned the correct licensing of a petrol station located on land owned by a brewery company and adjoining a public house.

A manager was in charge of the petrol station and another manager was in charge of the public house. The manager of the public house allowed a mobile fish and chip shop to stand in his car park at a location within 14 feet of the petrol pumps. A number of members thought that it was wrong to issue joint licences and that the only satisfactory course to adopt was to issue two separate licences where practicable.

Mr. W. E. Sendall brought the attention of members to a new coin-operated petrol pump in his area which did not have a limiting device of up to ten gallons in addition to the money pre-set and wondered whether members though• that the money pre-set limit was sufficient. Mr. J. D. D. Bates, Premier Pump and Tank Co. Ltd., said that if the petrol pumps could be used as an ordinary petrol pump then it must be provided with a limiting device as recommended in the Codes of Practice.

Mr. R. E. Clarke, Leicester City Fire Brigade, sought the opinion of members regarding a request by a petrol company who wished to provide their tanker drivers with portable battery hand-lamps for use in the hours of darkness where the standard of lighting on the petrol station is inadequate. The idea had been rejected by his authority and after some discussion it was decided to refer the matter to the Reference and Legal Committee of the Association. Mr. H. Litchfield was concerned over the keeping of petrol and re-fuelling of cars on a racing circuit in his area. Mr. J. Birks informed him that this problem had been considered by the Reference and Legal Committee but unfortunately it had not been the practice to publish their opinions in The Bulletin. The Council had recently decided that all such opinions should be published in the future.

Mr. Cartwright related his experiences in dealingwith a leaking petrol road tanker on the public highway and wondered who was really responsible for su_ch road tankers safe. Mr. Clarke said that the Leicester City Fire Brigade dealt with such hazards although wondered who was really responsible. Mr. Sendall said that his authority stored 500 gallons of Slix for such emergencies and when any was used on a petrol road tanker then a charge was made to the appropriate petrol company for its use.

The Secretary reported that the Yorkshire Branch had decided to invite the Chairman and Secretary of the East Midland Branch to all their branch meetings with a view to a mutually beneficial exchange of ideas. It was .agreed that the East Midland Branch should have a reciprocal arrangement.

Jn the afternoon a discussion on the Association's Codes of Practice took place. Attention was focused on the method of installing underground petrol tanks by back filling with sand. Members generally .this method has its advantages and under stutable cond1t1ons is an acceptable alternative to a concrete surround. There was some doubt, however, that the manhole might not be adequately supported to withstand surface loads. Some members thought that a concrete surround had its disadvantages especially if the concrete was not placed uniformly around the tank. Mr. E. Stainforth said that the concrete should always be vibrated in to avoid air locks

but as regards future removal of tanks he thought that there was something to be said for the method of back filling with sand. Mr. P. J. Henze discussed the use of steel pit wire to prevent tanks floating in a concrete mix. Mr. Birks said the idea was alright but considered that flat steel straps were to be preferred to round steel pit wire which could penetrate the protective coating under extreme pressures.

Mr. Howkins wondered what the opinion of members was regarding the use of non ferrous metal such as aluminium for the construction of underground tanks. Mr. R. J. Reeves of Shell-Mex and B.P. Ltd. said that it was a question of economics for such metals were normally expensive and steel tanks generally lasted for twenty to thirty years, which was adequate. Mr. Stainforth suggested the use of plastic coated steel tanks but Mr. Reeves said that there was always the chance of the resin being scratched and destroying the protection. Mr. Cartwright thought there was no reason why tanks could not be made of steel greater than a quarter of an inch thickness. Mr. Reeves but said that petrol companies simply met the requirements of local authorities who were satisfied with quarter of an inch thickness.

The meth_od of applying a pressure test to underground tanks was discussed. Mr. Stainforth said that when testing double compartment tanks a petroleum officer was only concerned with the soundness of the outer shell and not the individual compartments. Mr. Litchfield thought that the separate compartments should be individually tested and other members agreed. Mr. Cartwright said he a soap test on the seams of the tank made prior to ins_ertion in the ground. Mr. S. M. Carruthers this test also but members discussed the possibilitle_s of to !he tank on insertion. Mr. Cartwright said that the msertion of the tank should be carried out in the presence of the petroleum officer.