TH E BUL LETIN

Journal of the Association for Petroleum and Explosive s Administration

liTHE INDEPENDENT -F UEL"

The Self Service Petrol Station is not the "animal" it was when first muted some years ago.

The Oil companies fell over themselves to get approval of this new idea. They agreed to the safety conditions imposed on such sites by the Licensing Authority. Those conditions are generally unchanged but we have a different attitude.

We notice that self service is looked upon as a right whatever conditions the site may be in. The Oil companies now use all available space for the provision of Gas Bars and Supermarket areas to sell products other than those traditionally sold to the motorist for his car.

Large areas of glass overlooking the forecourt are plastered with free offers, special discounts and brightly coloured advertising matter.

The general disquiet among petroleum . fficers of the need to constantly ;emind licensees of the original safety conditions. That the forecourt should be under and that person should have an un1nterupted view of that forecourt.

We hope that the Oil companies and others take note of the need to comply with this important petroleum licence condition.

Honorary Edi tor Mr. J.A.J. Thompson,

The Annual General Mee ti ng will be held at on 29 April thi s y ear A separate no t i fi cation wi ll Oe se n t. Please make the effort to at te n d

In e a c h Bulletin there is an ap plication f o r membership form wit h whic h it is h oped that you will ge t a coll e agu e o r associate to join t h e Associat i on Recruitment is an impo rtant way of k eepi n g the costs do wn • We oft e n her e of new members who were unawar e of t h e Associations ai ms and act i v i t ie s no ws your chance to help i n a pos i tive way. Additio n al forms are availaole from the Hon Sec.

v es A Dang e r ?

Some Local Authoritie s have now oann ed the u se of the angle c h e ck valve whic h is supplied with an all oy cover. The valve s whi ch were normally bronz e , have oeen given an a l l oy cover to the or on ze casting While this has h e lped k eep costs d own it has oeen found to h ave a s i d e effect. With dis simi l ar me tals being invo lve d electro l it ic corr osion occur s espec i al ly in damp manholes or when the v alve i s unde rwater . This has c aused bad pit t in g of th e alloy and has led to lar ge e no ugh holes to cause l eaking petroleum s pirit. It has not ne c ess itated to compl e te r emoval of the valve ocl.y to the replace ment of the cover with one of a bronz e t y p e

Subscri ptions.

The Council of Th e Ass ociation met at Shelf ord on 27 Novemoer and it was r el uctantly agre,ed that du e to increased costs the Annual would increase trom Jan 1st 1981 to Members t8 Associates £9 J3ulletin. SU'becrioers £7 Retired £6

This very heading can ofte n ori u g out a tale fro :!: an experie nced petroleum officer.

The HSE have agreed now tha t 'the Petroleum Spirit (Plas tic VOi.tai.ue rs ) Regulatious and a draft Stan dar d coveriug the use of plas t i c c out ain e E' S for petroleum spirit should g o out for consultation as soou a s poss i ole with a period of three mouthc a ll ow ed for comments.

This publication is expecte d l ater this year.

The HSC will be examining th e comments made on the lat e s t consultative document in J uly last year and the alteratio ns that are proposed. I understand t hat there are no proposed chang es in control of these regulatio ns despite strong overtures ma de by the Local Authorities and t hi s Association. There are h owe v e r o t her minor changes being co n s i de re d and it is unlikely that these Regulations will come in t o force untill later in the year

The HSC had hoped for 1 J an 81 commencing date.

A compr ehensive guide to the HSW Act 1974 has just be en publish e d by the HSC.

The HSC believes that altho ugh the Ac t is n ot d i fficult t o understand t he g ui de i s needed a simple e xplana t i on of its main prOVisi ons and as s ist . manage rs , s afety officers e tc to bette r unde r s tand its Bcope and how i t affe cts th e me

The bookl e t is divid e d i nto eight main section s: Introducti on, The HSC The HSE; Duties under the Act, employers safety policies , Enf orciag Authoritie8 Inspectors; Local Authorities; Improvement and prohibition notices ; Offences, penalties and prosecutioDB, Regulation s and Codes of Practise; Licensing and Appeals against licensing e The Guide ia from HMSO price £2 g75 plus postage

A warning against the extremely .dangerous aad illegal practice of making ammunition in unlicensed premises by drilling live cartridge cases to remove the propellant, is given by the HM Explosives Inspectorate. The problem was bighligted recently when a workman injured his hand as the proppelant ignited, the cartridge exploded, and the bullet wa3 fired On that occaision the dummies were for trials and adjustment of the gun breech mechanisme although the dummy rounds are often prepared in this way for sale to private collectors of replica weapons.

The workmans company was fined a total of £400 for amongst other things, conducting the process known legally as unmaking an explosive in an unsafe manner. The company claimed at the time the practice was "common in the trade"o

Under the Explosives Act 1875 the "unmaking" of an explosive including a cartridge t is deemed " manufacturing" and can only be carried out, therefore in a factory licensed for the purpose by the Health & Safety Executive.

Although the accident mentioned above involved a company, HM Explosives Inspectorate points out that the legal requirement is also relevant to a person conducting the process of inerting live ammunition for private use.

Two new British Standarde have just been published covering hoses for petrol and chemical applications.

HS 3395 Electrically bonded hose and hose assemblies for fuel dispensers. is a revised specification. A 16 mm hose has been introduced into the size ranges of types and 3 hoses and a semi conducting version of all three types of hose has been incorperated.

BB 5842 ThermoplastiC hose assemblies for dock, road and rail tanker use has been produced to fulfil the requirements of the petroleum industry for hoses made of materials such as polypropolene. It specifies requirements for the design and construction of mandrel-built rough bore hose assemblies suitable for hydrocarbon products and aromatic hydrocarbOns.

BS 2882

Determination of water and sediment in crude petroleum and fuel oils now includee a number of technical improvements, including the use of toluelle in place of benzine; the use of metal heating block as alternative to a liquid bath for heating centrafuge tUbes.

3324

Determination of Vapour Pressure in Liquified Petroleum Gas is used in connection with specifications of LPG oeulg employed to place a limit on the maximum pressure that may develop in cylinders at a selected reference temperature.

'l'he following standards have been revised receutly and all have a bearing on the petroleum industry.

4385

Determination of water in petroleum products.

.oS 4451 Determination of carbon residue in Petroleum Products

4695

Determination of flash and fire points of petroleum products ( vleveland open cup method) 'l'his includes a referel1ce to the use of flash point testers.

ljS 4714 Laboratory determi"atiou of de.usity ot crude petroleum ( hydrometer method)

BS 4282

Determillation of sedimeut in PetroleUDIo

5378 Safety Sigus & volours

As from 1 Jan 81 the provision of an EEC directive on safety signs and colour mandatory in the UK under the Signs Regulations 1980.

'l'bis Regulation is of importance to all concerned with public safety, safety officers, sign manufacturers and suppliers should all be aware of these regulations

Any British Standard is available from Sales Dept 101, Pentonville Road, London N1 9ND.

Kent common with a number of other Local Authorities has a licence condition that underground petrol storage tanks are pre8sure·tested at 20, 25, and 30 years and every 2 years thereafter at the licensees expense. An appeal by a under Section 44 of the Health and Safety at Work Act 1974 was lodged with the Health and Safety Zxecutive and the final outco.ie is still awaited.

A survey of other Local Authorities policy regard to pressure testing and also electrical certification was carried out. 7he results show that out of 54 Local Authorities responsible for petroleum licensing in Zngland and \val·38. 31 have a general policy of mandatJry pressure testing subject to a aispensation in circumstances when ullage .or inventory is al'owedo

A further two insist on at least one pressure test after twenty years, the remaining checks in the usual sequence being ullage. The list which is published here shows that an F indicates that the Fire Authority is responsible for petroleum '....ork

All Authorities except two, \vest Midle.nds and Zast SusseX insist on ::.nitial pressure testing on new tanks.

Greater London and Dorset insist on Inventory records being kept , but 45 Authorities will not allow them.

Greater London, Tyne & Wear, Cleveland, Cumbria snd Durham are the only Authorities who do not insist on electrical certificates, 34 others insist on Annual Certificates, the remainder at differing intervals.

Kent County Council carried out the survey to acquire evidence in an against one of their licence conditions, it has shown they are carrying out a policy common most. It also shows that some authorities are quite pifferent in their approach and although the 1974 Local Government reorganisation has helped provide a more common standard _ it would appear that we still have some way to go for complete uniformityo

·:.nnual Electrical Initial Test Ullage

Greater London F Pressure x 1 x x

Greater Manchester Pressure 1 x 1 1 Merseyside F Pressure x x 1 1 South Yorkshire F Pressure x x 1 2 years 17>"ne & 'dear F Pressure x x 1 x· \'lest Midlands F 1 1 1 1 '.'Jest Yorkshire F Pressure x x 1 2 years

Avon F Pressure x x 1 1 Bedfordshire Pressure 1 x 1 2 years tserkshire Pressure 1 x 1 3 years buckinghamshire F Pressure 1 x 1 1 vambridgeshire Pressure 1 x 1 x vheshire F Pressure 1 x 1 2 years L;leveland F Pressure 1 x 1 x t;ornwall F Pressure 1 x 1 1 L;umoria F Pressure x x 1 x Derbyshire F Pr"ssure x x 1 1 Devon F Pressure 1 1 1 1 Dorset Pressure 1 x x 1 Durham F Pressure 1 x 1 x East Sussex F - 1 1 1 1 Essex Pressure 1 x 1 1 Gloucestershire Pressure x x 1 1 Hampshire F Pressure x x 1 1-2 years Hereford & Worcester Prec:sure x 1 1 x Hertfordshire F Pressure x 1 1 x Humoerside Pressure 1 x 1 1 Isle Of \-light Pressure 1 1 1 F x 1 Kent Pressure 1 x 1 Lanca.shire 1 1 F Pressure x x 1 Leicestershire 1 1 1 F Pressure 1 Lincolnshire }t' Pressure x X 1 Norfolk It' Pressure x x 1 1-3 years 1 Northamptonshire F Pressure X x 1 Northumberlaud 1 1 F Pressure x X 1 North Yorkshire F Pressure 1 X 1 1 Nottinghamshire Pressure 1 1 1 Oxfordshire F Pressure x 1 3 years x 1 .shropshire F Pressure x x 1 1 Somerset F Pressure x x 1 Staffordshire F Pressure 1 x 1 3 years Suffolk Pressure 1 1 1 1-3 years 1 Surrey Pressure 1 1 1 Warwickshire Pressure 1 x 1 2-4 years 1 West Sussex Pressure 1 1 1 1 Wiltshire 1" Pressure x x 1

t;lwyd Pressure 1 1 4 years X Dyfed Pressure 1 1 x x Gwent F Pressure 1 1 x X Gwynedd Pressure 1 x 1 5 years 1 IVIid Glamorgan F Pressure x x 1 Pov/ys Pressure 1 x 1 1 South Glamorgan Pressure 1 x 1 5 years ·..Jest Ulamorgan F Pressure x x 1 1

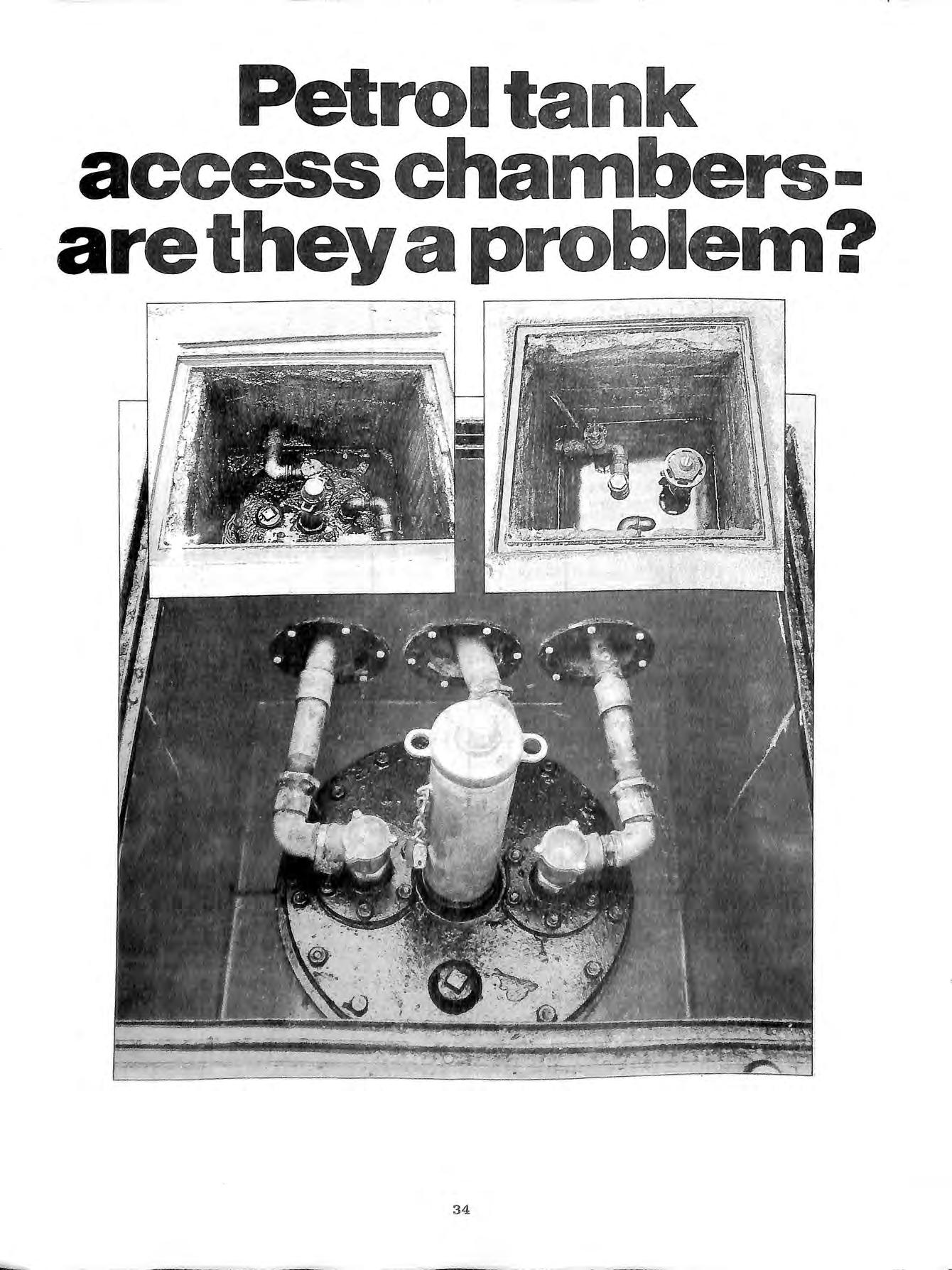

Fioresec Marketing ' Ltd 12, Station Road Cullingworth Bradford (0535) 273091 ' are selling what they claim is an underground revolution for petrol tank maaholes. This prefabricated section is in . two hal v es and forms in-situ shuttering for the tank manhole. There is a vertical gasket of rubber with r.ubber sealant where the neck is and where the manhole is jOined. The entries for suction, vent and offset fill pipes are cut out of impressions preformed ill the manhole. These are then protected using nitrile rubber sleeves and polypropolene locating rings. Provision can be made for future suction lines without disturbing the manhole. On.e installed the c,bamber keeps out water and retains spillages w.Lthin the manhole which is easily cleaned ceing GRP. The manhole looks attractive·and one I . saw iDstalled proved quite simple, it was enthused aoout oy two experienced Pump Maintenance fitters and after two months use is still COne dry despite a high water taDle. Petroleum Officers or other interested p ersons should contact the company for furthur information.

Fibresec have a new answer to the old problem of inefficient manhole units -a unit that is unique in design, simple yet very effective in ke/epin g tank chamb ers fr e e fr om w at er .

vast improvemen t In traditional design and str ucture was far from

It was developed by

specialists with fi rst - hand

A. company moved to new premises "/here it was intended to trade, among other things as vehicle refinishers. A licence was duly applied was granted to store not exc··::.'ding 15 gallon3 in &. metal cabinet \-!ithin the premises. After storing petroleum s::il:'::.t and mixt,:.rcs in excess of that quantity 1:ly licence Rnd in conditions nnacceptable to the authority, the licensee \..ras informed that a rene'.r,al would be

At this point he 'Nas informed of his vption as to the right of appeal which he did not take up. The stor3ge of petroleum mixtures continued after expiry of the licence and a prosecution brought Penryn Court on 10 December 80. The company pleaded guilty to a charge of unlicensed keeping as did the director. The company were fined £120:00 with £40 costs and the director fined an additional £20. The magistrates ordered that either the metal cabinet complying with the huthorities guidance be provided or storage be remov3d within, three weeks.

Proceedings were instituted against the Vanwil Oil Company Ltd of Gaernarfon Gwynedd and an employee as a result of a petroleum officer noticing that the filling covers of the tank wagon were not propoerly closed. The vehicle was followed and the driver approached as soon as opportunity :1resented itself. The vehicle was inspected and it was found that the dipping tube cap and manlid cover of a compartment containing 550 gallons of petroleum spirit were not closed. A further inspection revealed that inadequate fire extinguishers were carried and that the fire screen did not extend to within 12 inches of the ground, neither was the window in this screen fitted in a fire resistant surround. copy of the Regulations were available. The company pleaded guilty to three charges at Magistrates of:1) Failing to provide copy of the Regulations Fined £50 2) Operating a tank wagon which did not comply with the regulations Fined £100 3) Having inadequate fire extinguishers Fined £150

The driver pleaded to failing to close the manlid and dipping tubes, he was fined £100 on each charge and for starting the engine of a tankwagon oefore closing these openings he "'!a6 fined an additional £50.

A man 'who worked at a Hull scrap metal yard received serious hand injuries when a 45 gallon metal drum exploded. He was cutting the drum with a torc? when the explosion ha}:pened and the force of the blast sent the drum ll.d flYl.ng 20 yards through the air, Hull Magistrates heard. Albert Draper & Sons Ltd pleaded guilty to contravening the 1961 Factorip.s Act oy not taking suitable precautions the torch cutting of metal containers The were fined £200 and ordered to pay £20 costs. Mr Eaton prosecuting on oehalf of the HSE said that 18 years ago at the same time premises a man had been killed in a similar accident when he was using a torch on a petrol cylinder. He explained that there was uOW a wealth of posters and advice on how to tackle this task in a correct manner including st'eam cleaning or filling with cold water. '

In this caee he said traces of liquid iu drums of the same as the oue that exploded were found to De of highly flammaule miAture. fllT Storrs-Fox defendiug explained that the had oeeu EI.ware of the dangers since the previous accident. Th3Y educated their employees to eusure that all drums were free from flammaule mixtures. He said that the i"jured man had tell years c perience iu the jOD aud had Drought the accideut upon himself. The comp3!JY will 1101011 dispose of drums uy orushiug il1stcad ot'

I. volume 18 number 4 The Bulletin published a paper on the lining of underground petrol tanks. The writer made some valid points in his'discussion but I felt had not considered enough the problems that the Local Authority have to consider when deciding whether or not to approve this system of lining. There is certainly no mention in the now outdated Home Office Code of such a system and it is up to each individual Local Authority in discussion,comparison and experiment with industry to come to its own conclusion ; and certainly because one Authority accepts such a system does not mean that it is duty bound on all. I would first warn Industry not to expect "carte blanche" approval for such a system. The complexity of the types of premises we licence would mean that no such blanket approval could be given. Many unsatisfactory installations throughout the country range from the bad to the dangerous, and while the licensing authorities use the various methods within their power to try and rid themselves, or improve these premises it is unlikely that if a tank leaks at such an installation that approval would be given to perpetuate its life. I undorstand that some Authorities have asked the H.S.E.petroleum liason·officer his viewc on this subject. I would point out that petroleum licensing is such a specialised subject that in most cases the officer has far less experience than the Petroleum Officer. A factor to be considered is that the local authority often waits for the development of a site to require those safety factors common on most installations; for example the provision of a petroleum interceptor. The authority may feel that by approving the lining of a tank they will lose the opportunity of bringing such an installation up to date. I can see the argument put forward on the lining of a tank on cost grounds, a site owner or Oil company must look at this option to oostly replacement and associated ground work it involves. I am sure that we will see an inorease in applications over the next few years to line leaking tanks. I do not believe however there will be a flood of applicatiOns. The Oil companys who own the majority of installations in the country are still convinced on the merits of tank replacement, only in exceptional cases have shown an interest in this system of repair. The market tor this system will I teel be with the private installation, and those where the cost of replacement is prohibitive and unfortunately these installations are often the unsatistactory ones refered to above. I have had some personal experience in tank linings and the G.L.U. has conducted some research in this field. In 1972 an 18 month old tank was found to be leaking atter water had entered the tank, a fault was found in an upper weld. Atter much deliberation a GRP lining was allowed and a four year guarantee given. The tank was re-tested and put Dack into use. It was disoovered three months after the guarantee ran out that the tank was faulty, a test revealed a leak and the tank was tilled with ooncrete. This was an early experiment and the knowledge of tank lining was nebt as advanced as it is today. More reoently applioations were made tor approval of a tank lining usi-ng the ItMatcote lt system and in 1978 officers from rrr'J department along with officers from the Soientifio seotion were invited to view the GRP lining ot two 500 gallon tanks at an installation outside Londou. The interiors were shot ulasted after the cleaning and safety proceedure had ueen &dopte!. They were seen to De quite clean and must be treated within 2 hours it rusting is to be prevented. A two part epoxy primer paint diluted to a wash was applied to protect the steel. The repairs found neoessary were at the base of the tank where small holes and pitting had occured. These were repaired using an epoxy filler paste and after curing a steel plate was embedded, then coated using the epoxy resin oompound. These two tanks were too small to use the Automatic

spray equipment and the lining was hand mixed and rolled onto the interior using a hand roller. A single sheet of chopped strand mat was embedded into the resin One aspect of the lining using a hand layup in this case was that the quantities of the resin components were not measured or metered with any accuracy and as a result differing cure rates were acheived for different batches.

In 1979 an application was made to repair a larger tank within the Greater London area using the automaticspray plant which meters, mixes and applies chopped strand. The tank was installed in a site which made replacement very difficult and it was decided that approval would be given for this "one off". The normal safety proceedure was carried out and an inspection revealed that the leak had occured from a hole under the striker plate. The plate was removed and the repair was made using a proprietary brand- of epoxy resin. The steel was shot blasted and after this the first stage of a two stage system of epoxy resin was sprayed onto the interior. This was followed by a spray coat of chopped glass ro rovings; the process was repeated untill the desired thickness was reached. This was determined by the uniform blue colour of the coating. Due to the low viscosity of the GRP epoxy resin coating , hand rolling was necessary to prevent sagging. Five days after,the lining was inspected and although the resin had gelled it had not cured and no readings were obtained on the tlarcol Hardener Tester. The thickness varied from fractions of millimeters at the top to several millimeters at the bottom.

It was felt that at this site the viscosity of the resin was too low when first applied and this meant that it started to flow and slumped , so thickness could not be properly controlled. The cure rate was far too slow and it was necessary to introduce a fan heater to get it cured within ten days. With shot blasting difficulties and this prOblem the whole operation took 16 days. The lessons to be learnt that it is almost impossible to obtain factory controlled conditions and finishes on site. There needs to be strict control of materials , with correct mixing, and batching of resins and a very high standard of skill by installers. There also needs to be a high degree of inspection of the process which takes up many man hours. The guarantee issued with the lining is of course given in good faith, but as has been seen recently is of no value if the company goes out of business.

The Local Authority before considering such a repair should therefore decide if the installation meets all aspects of their code. It should then decide on the merits of system of lining, and if offi?ers are in their knowledge of plastics to supervise such a In this perhaps the British Plastics Federation could help by being an approving

In conclusion I would support the comments made by Mr Fowles Smith in his paper in the same that we should be looking for oetter protection of the steel before the tank is installed. Are we not in danger when we repair a few small holes in a tank shell of dealing with the symptons rather than curing the disease ?

The ability to measure fuels in underground storage tanks to the nearest pint rather than gallons is contained in advanced equipment being marketed by Contents Measuring Systems Ltd., a new subsidiary of Smiths Industries. Although the measuring technique is applicable in almost all circumstances where an accurate check on deliveries and usage of fluid in storage tanks is necessary, the system is of immediate benefit to petrol distributors

monitoring of levels of increasingly costly stock is becoming ever more important.

The CMS 2000 is a microprocessor-controlled contents gauge which uses a capacitive transducer. The transducer measures the height of the liquid in a tank and the microprocessor instantly converts this into volume.

The system enables stock to be checked at all times whatever the weather conditions, for it reads the volume in the tank irrespective of changes in temperature or specific gravity, and takes just! second to do calculations for each tank. The equipment can be married to present electronic forecourt management systems, for example consoles and cash registers, and a printer can be attached to provide a permanent record of tank reading s. An optional warning device can be incorporated to warn of overfill changes or recording level. One great advantage of the eMS 2000 is that it warns, and detects

approved barrier

11(\- '--

Microprocessor control system converts signals f rom the probe and presents them as an easily read digital display in litres.

n

IIn. "''''11 (1111" I betw.... the electronics unit and the probe ensur• .s that excessive , electri cal .nergy cannot reach the tanks.

Capacitive tank probe, .Ill installed, measures product to a very high degree of accuracy. Build up of water in the tank is also indicated.

Line Dra.wing of the GMS 2 000 microprocessor oascd tank gauging sy s t em

build-up, of excessive water in the tanks before it i·s drawn into the pumps, and thence into a vehicle t s tank. It has a measurement capability o:f accurate information to within 20 litres when tank contents are varied for example by 10,000 litres.

Hitherto a major problem with all tank contents measuring systems has been to establish the·exact relationship between the height of the liquid in a tank and its corresponding volume especially in underground storage tanks. The eMS 2000 system utilizes a newly developed system to overcome this problem.

The greatest challenge in the development of the unit was in the analogue design, where a voltage had to be obtained which was'related very precisely to the height of the· liquid in the tank. The adaition of the microprocessor-has allowed great flexibility in the design, so that conversions to and from litres/ gallons, high and low warning, data transmission, error checking and self-testing can be incorporated. The unit does not have to be re-calibrated if the product being gauged is changed.

The system has been tested and approved by the

British Approval Service for Certification of Electrical Equipment in Flammable Atmospheres for use in hazardous areas such as garage forpcourts. To ensure there is no risk of explosion, a voltage limiting capacitive barrier unit is interposed between the electronics unit and the probeo

Using telephone land lines, it is possible for an oil company headquarters computer to interrogate each garageis system , that delivery services can be opera t ed more economically. In addition to better stock cont r ol there a r e also environmental benefits, for example tankers could avoid rush hours in urban are as.

GKS 2000 tamk gauging system.

Further information is aTailable from UMS Ltd KLG Works

Putney Vale g London SW 15 0 1- 452 3333

Jo hn Owen, Assistant Techn i c al Sales Manager , an d Tim Gil es Pro duct Manager shown with the demonstration mo de l of t h etaDk ventilating pipes at a petrol filling station in Hounslow passed through the wall of a store at a-laundrette next door and were then taken up in a concrete to discharge to the open air.

During a delivery of petrol from a tank wagon flames were see issuin. from an air brick in the wall of the laundrette store. Delivery was stopped and the brigade called. Aa soon as the fire was extinguished and delivery was started t reignition of the vapour occurred. The inspector prohibited any further deliveries of petrol until the soundness of the ventilating pipes had been checked. However the oil company operating the site promtly installed new pipes outside the laundrette store to enable the filling station to operate. The Inspector was not able to carry out a full inspection on the old pipes but he was able to see that there wasno£etfective seal between the pipes and the wali cavity and that the gauzes on top of the pipes were partiy blocked. These two factors together with the leaking pipe could have caused the release of vapour during delivery The proprietor of the laundrette said that he had always noticed a smell of petrol • in his premises during tank wagon deliveries • Unfortunately he bad never told anyone.

A IIIaJl minor burns when a disused petrol suction line he was cutting with a disc-cutter burst into flames at premises in Wimbledon. The fire was extinguished b the brigade and damage was confimed to the disc cutter which was completely burnt oY t A section of the pipe between the cut and the storage tank was found to contain i This emphasises the need to ensure that a disused suction line is drained and • through with water.

The elderly lady occupier of a first floor flat in a semi detached house in Hounslow suftered burns to her face , hands , arms and back and was removed to hospital h h f " w en a fire started in her kitchen. The fire spread throughout t e 1rst floor and d t second floor. The orough Surveyor served a " Dangerous Structure Notice" fOlloJ: he the fire. g It was alleged b,y a neighbour that the woman used petrol to elean Clothes. If this was the case , the pilot jet of a gas operated refrigerator could have ignited th petrol vapour. However t the victim when interviewed denied this and blamed the e fire on a gas explosion.-

A mechaaic engaged in cutting a torsion bar with oxy-acetylene equipment at the r of a car in a small lcok up garage in Wimbledon was startled when a fire started floor underaeath the car. An attempt to extinguish the fire with an extinguisher was un unsuccestul and the tire quickly spread to oxygen and acetylene cylinders. _An Acetylene cylinder exploded and was projected onto a private garage at the rear of the prpperty in another road. The causeoof the tire was attributed to the melting of the fuel supply line aDd the release of petrol.

Luckily was hurt, but the garage was extensively damaged. The mechanic was cautioned for the breach of No 9 of the Petroleum Spirit (motor vehicles ete) Regulatioas 1929.

When an inspecto;, visited a petrol filling station ill Ealiug he fouud that the fire extiuguishers usually kept Dy the pumps had Deen mOTed to another location. lie vas told that this was due to the fact that two female drivers having tried to inflate their tyres from a dry powder extinguisher had complained to the manager that the "air hose" was UllserviceaDle. :

The petroleum licence for a sub-standard petrol filling station in Sutton expires ou 1 April 1981 • The premises are so that it is doubtful if any worthwhile improvement could oe made without complete redevelopmeut of the site. Wheu the liceusee died earlier this year i is widow applied for transfer • The council's policy regarding premises of this nature was explained and she was told that a report would be submitted to the Public Services and Safety Committee recommending that the Council should refuse to renew the licence. In order to preserve the status quo in the interim , transfer of the current licence was agreed.

When the report was considered the lady appeared by invitation before the Committee to state her case for having the licence renewed in her name. Having heard the case and questioned the applicant , the committee decided (a) that the Council will not renew the licence when it expired; and (b) in the event of an appeal being lodged with the Secretary of State under Section 44 of the Health & Safety at Work etc Act 1974 the Chief Officer may be authorised to grant a licence for six months from 1 April 81 or such longer period as may be necessary to maintain staus quo while the appeal is being heard.

A licence transferred to the occupier of licensed premises in Goulsdon ,,'as by post in 1967. The postal packet was not delivered and thirteen :t was eventially returned to the sender after cojourning in various the London area.

A firm was fined £200 with £174 costs at Tottenham Magistartes Court for. keeping about 40 gallons of petroleum mixtures without a licence in a.box The trailer was parked near a window of a staff canteen and its inter10r was not suitable for a flammable atmosphere. The petroleum mixture was being kept for use in printing machines in the premises.

A firm engaged in the transport of petroleum fuels was fined £250 for each of breaches of Regulation 11 of the Petroleum Spirit ( Conveyance by Road) at Bow street magistrates court. Cost of £50 were awarded. Filling openings caps, a manlid gasket and a ventilating opening gauze on the tank wagon were defective. At the same court the driver of the tank wagon was fined £15 on each of three infringements of Regulation 12 (2) (unlocked filling openings) with £50 costs.

A firm were fined £150 on each of two infringements of the Gorrosive Substances (Conveyance by Road) Regulations at Kingston Magistrates Court £50 costs were awarded. The offences of not displaying a prescribed notice ( Regulation 3) and not carrying a fire extinguisher ( Regulation 7) came to light as a result of a spillage of the corrosive powder from plastic sacks which had been damaged when the vehicle was loaded.

26th APRIL, 1980.

The Chairman, Mr. J.W. Frid, opened the meeting and welcomed the 19 members who had made the effort to attend.

1. There were 19 apologies of absence.

2. The minutes of the A.G.M. held 25th April 1979 were put to the meeting and unanimously accepted.

3. There were no matters arising.

The Chairman at this point in the meeting thanked the Treasurer Mr. C. Peacock, who was not puting up for re-election, for the many years of loyal and concientous service to the Association. He than made a token presentation of camping equipment to Mr. Peacock as it' had not arrived on time.

Mr. Peacock then thanked the Association in.his usual yorkshire way.

4. The Chairman presented his report on his year in office. He made reference to the two revitalised branches in the Midlands and South East and also the forthcoming Seminar on the Conveyance of Hazardous He then called upon Leach Branch Secretary to say a few words about the activities of their Branches.

5. The Secretary presented his report in which he mentioned the increase in membership which had been due mainly to the Editor's recruitment drive. The Council of the Association had met twice when the main topic of discussion was the forthcoming Seminar.

There had been a steady request for information and advice and it was clear that there was scope for development and increase in membership. He then made a plea to the membership to come forward with suggestions of what they wanted from the Association.

6. The Treasurer submitted his report which was accepted by the meeting.

7. The Editor presented his report in which he said that the Bulletins had been produced at regular intervals. He had initiated a recruitment drive via the Bulletin which had proved succBsful. He then made the usual plea for information and material to be published.

8. Mr. S. Worsfold was elected as Chairman for the coming year.

It was agreed not to elect a Vice Chairman.

Mr. E. Brown was elected Secretary.

Mr. R. Jones was elected Treasurer.

Mr. Jo Thompson was elected Editor.

It was agreed not to elect a Liason Officer and Legal Advisor. The Hon. Auditor to be nominated by the Treasurer and approved by Council.

9. The following, additional members were elected to Council: Mr. B. Thompson, Mr. Bo Lowe.

10. The following motion was unanimously accepted by the meeting: "That if in the opinion of the Council of the Association it became necessary to increase membership subscriptions in 1981, an increase of upto £2 on all subscriptions shall be implemented from January 1981."

The testing of tanks and pipelines by persons other than petroleum officers was discussed at length and it was agreed that it should be discouraged.

A short discussion followed on the relining of tanks.

A letter received from B. Thacker was read to the meeting in which he thanked them for electing him an Honorary Member.

The meeting closed at 12.50am.

The afternoon session was taken up by an informative talk by Mr. J.M. Adams, Deputy Director of B.A.5.E.E.F.A. He explained how the organisation had come about and what they did from day to day.

The Chairman thanked Mr. for his time and apologised for the small attendance at the meeting.

I would like to thank members of the !.ssociation for their of confidence in electing me as the Chairman for the year, a year which recurring signs of change promise to be as testing as any in the past. enthusiasm and resolve of its be more than to meet the aims of its founders to upde.ting information and. as a

Despite this I am sure that through the Branches the ,\ssociation will prosper and the needs of its members, and to continue be a forum for the exchange of views; for reference point for all disciplines.

I am proud to be elected as your Chairman and intend to futher the aims of the Association in every way possiol e •

Mr S Worsfold.

fer Association of Petroleum Explosives Administration Senior Petroleum Inspector Greater London vouncil.

1. Conforms to Highly Flammable and Liquefied Petroleum Gas Regulations 1972 and the Health and Safety at Work etc. Act 1974. 2. Fire check door (112 hour or 1 hour)

Insulated to maintain cool temperature with in store

The walls and roof are well insulated and the roof is fitted with a heat·reflecting surface to maintain a cool within store. The exterior has bonded vinyl steel sheetlng and is fitted with red. fire check door containing intumescent strips a which expand and seal the door in the event of fire There is also a mortice lock with internal override, manually operated Opening and closing vents are also fitted to allow free passage of air.

The " Arrestof l ame " Lightweight Hazardous Goods Store is designed for the storage of bulk flammable liquids , petroleum and mix t ures and all hazardous goods In complete safety . The store is ready for instant use and is weatherproof , durable and maint enance free

Flameproof lighting is standard complete with a door operated switch Facilities are provided for the provision of thermotube heating, extrac tor fan , etc ., if required

Details may be obtained from Flametamers International Ltd Ameeco House nasildon Esse x (0268) 284361

This, the eighth "I n tema tion al Fire, Security and S afety Exhibition and Conference ", w ill ag a in be the largest eve r staged with more than 600 co mpanie s from all over the world exhibiting an international and com pre hen sive range of equi pme nt , materia ls and se rvices Included amongst the produ cts and services on di splay will be :-

m IiglTtng IlQIiIJme!rt Fire and laddaf s VIP protectiJo Emefllel1cv anrl reSCl'e Breathing app aratus lightin g eqlL;pmenl Exp losion protection systems Safety sig ns Vetritles Resea rch and testing Safety equipTTK! nt Fire detectin n eq uipm ent inform ation Health & hygiene products Fire system s Techni cal Publications Machinery protection Structural fire pre cautions Compute r based systems Belts anrl harnesses Un ifo rm s Access control Detection aod test equipment Protective dlJ th ing Commercial securit y Face anrl head protectio n fiRed, portable and mobile fire Closed circuit televis ion FaM arrest equipment extinguishers Intrude r alarm systems Protective footwear Comm unications sy ste ms Int ru ne r detec tors Safety gloves Emeryemy lijjhting locks and lacking devices Safety containers Stf!f1dhy powe r Safes, security cabinets ann Construction site safety fire l!!arm systEms strongrooms Safety analytical equipmef1t Sprinkler systems Grilles, shutters and barriers Monitoring systems Gas detect ion equipme nt Static and patro l guards Safety consultallCY s8fVices Fire doors 8fld shutters Cash and villuil!Jles in trans it Safety training ami education !lour panic hardw are Retai l securit y prodl!l:ts EnvironlTll!f1tal equipment

FIf!! retard!!nt rrurtllfials Security ami safety Sound att8llJ8tiln pnKU:ts Fire resistllllt sales 8fld SignaMing syste ms Floor safety products Cllbinets Vehitle security systems

The a bove is just an outline 0 1 th e va s t am oun t of equipment and services which will b e se e n at IFSSEC '81