THE BULLETIN

Journal of the Association for ) Petroleum and -_.Explosives Administration

During the pas 2 belt has appea ed t years a different type of drive r on forecou I d· The name is Tab-Link

petr? Ispensers. polyester/poI ure h ' and Its unique this belt to lart at. construction enables minimum of· than conventional times It s easier to service enables the service en .' as one reel ak gmeer to m e up any length of belt to SUit all pump assemblie thereby greatly s, reducing the stock carried

When it comes to the manufacture of pump equipment a design is possible USing Tab-Link, as the tensioning and sliding adjustment systems used with conventional drive belts aren't needed. Tab-Link is in successful use in petrol dispensers throughout Britain, including those serYIced by Pump Maintenance Limited, and built by Avery-Hardoll Ltd., TokheimLtd. and Fen-anti Ltd.

Suprabloc covers h specifically designed been frequent access is re Use where chamber within a to part of a filling station forecourt paved petrol

The system th '. of exposed metal to the e minimum yet provides easy,

The solid bottom Coveg t access. are offered with 300 >< frames section available as recess 11ft-out chequer top which can be fe Or solid or offset over chamber Itted centrally

All units are hot-dip ' gal vanlsed after

manufacture to ensure long-life resistance against corrosion and are fitted with nitrile sealing gaskets.

Published by the Association for Petroleum and Explosives Administration

TALKING POINTS NOTES & NEWS SPILLAGE AT MICHELDEVER

TIRE AT BUNCETIELD INCIDENT TILE SEMINAR REPORT ELECTRICAL INSTALLATIONS CHAIRMAN'S ADDRESS TO YORKS & HUMBERSIDE BRANCH NEW PRODUCT DEVELOPMENT BACK NUMBERS

Opinions expressed in this Joumal are not necessarily the views of the Association 2 3 6 6 8 11 11 14 15 16

Honorary Secretary:

Mr. E. Brown, Cambridgeshire County Council,

Mr. G.A: Edney,

In this issue we welcome 22 new members, which at least equals the record for enrollment over the past few years. This is an encouraging sign. The Association's members should capitalise on this strength, using it to promote the aims of the Association, especially now in the face of some seemingly illconceived, retrograde safety legislation presently being considered. Your Council is spearheading the battle against this; members should do all they can to continue the fight at all levels.

The question of standards and uniformity have often been the plea from the Oil Industry over administration of the Petroleum Acts, and much has been acheived in this area over recent years. Well written and universally accepted codes are available to give guidance to those engaged in developing petrol filling stations. It is therefore with some surprise that the recent embarkation by Esso on a redevelopment programme for their "ERIC" sites (Esso Retail Identification Concept) has brushed with all the recognised codes. The erection of canopies with unusually side staunchions of almost lm wide, has seriously reduced vision from the console position, so that in some sites several pumps cannot be seen. This is now causing concern among Licensing Authorities in the U.K. The Esso ERIC image came from the U.S A. and the order to build the sites in this image throughout the world was made. Planning Laws, Building Regulations and safety requirements

were no doubt considered, but it would appear that the important area of vision of self service pumps was overlooked. Important emphasis is made in all codes concerning public filling stations on the viewing of the pumps and filling area from the console position. The institute of Petroleum Marketing safety code, (which Esso had an input) states (2.2.7.b) "All pumps and dispensers for attended self service should be located so that they are at all times clearly visible from the control point, and so that no obstacle, except for vehicles being fuelled, is liable to be placed or come between the dispensing area and the control point."

Some local authorities are insisting on full visibility in accordance with the code others have compromised and accepted a 50% visibility factor. The company who would appear to be under pressure from the States, have been rigid in approach and unable to change their layout (however SImple) to overcome this problem.

To try and resolve this they are currently examining the use of Closed Circuit Television to view the offending pumps; this however opens a whole new area of problems, reliability of equipment, position of camera and screen, and marching this with Board of Trade approved self service equipment. This however would seem to be a way of appeasement, and it is hoped that the Oil company will move closer to the views of Licensing Authorities and the Codes of Practice and amend their approach to give maximum vision to self service pumps in the interest of public safety.

Membership Fee Increases: As a result of the effect of inflation, which have generally raised costs all round (amongst which the cost of publishing your Bulletin is not least) the Council of the Association has decided to take up the option agreed at last years AGM to increase the membership subSCription by £2 to £ 12 per annum. The council would like to point out that this is the first increase for 5 years, and hope to maintain this level for at least as long. Bulletin only subscription rates are similarly increased.

New Code of Practice: The Association has published a new code of practice for construction and electrical requirements for petrol filling stations and similar private refuelling installations. This code replaces the one first published by the Association in the 1960's. It is the most modem in publication and reflects current practice, and is available to members of the Association at £3. including postage. Non members may also purchase the code, which is available from the Hon. Secretary by sending a remittance of £5 including postage. (I.S.BN. 70-00-2)

N ext Year's Seminar. Following the great success of last year's Seminar (see page 11) the Council has provisionally booked the same venue for Tuesday, 15th October 1985. Members are asked to make a note of this in their diaries. It is suggested that this year the downstairs Main Hall shall be hired, as this is more convenient.

Southern Branch: The inaugural meeting of the Southern BraIlch of the APEA was held on Wednesday 28th November at Heron Service Stations Training Centre at Slough. The meeting, attended by the Association's Chairman, elected Mr. J. Noble as Branch Chairman, Mr. J. A. Simms as ViceChairman, Mr.J. L. Luke as Treasurer and Mr. R. G. Edwards as Branch Secretary.

A lively discussion ensued about plans for the Branch, resulting in numerous offers of speakers and visits for future meetings. The meeting continued with discussions about the current problems of driver controlled deliveries and abolition of licencing.

The Branch Secretary would like to hear from all members in the South of England. Those interested in participating in Branch activities should contact him at Cleansing Service Group Ltd., Grange Road, Botley, Southampton S03 2GD.

Driver Controlled Deliveries: Following the publication of the Draft Code of Practice, the Health & Safety Executive are proposing that the Secretary of State should issue a certificate of exemption to Regulation 20 of the Dangerous Substances (Conveyance by Road in Road Tankers & Tank Containers) Regulations 198 I, allowing driver controlled deliveries on an experimental basis to certain speCified sites for a period. This experiment will be closely monitored by all concerned and the results will influence the decision as to whether such deliveIies can become standard. The proposed Exemption Certificate will state that no site can be used for this experiment unless it is agTeed to by the Licensing Authority of the site concerned.

At a council meeting of the APEA in November, it was decided to ask local authorities NOT to agTee to ANY site being used unlE'ss Regulation 2:1 is ammmded, gTanting to thE' Licensing AuthOlities thE' pOWE'r to enforcE' ALL aspects of thE' ConveyancE' RE'gulations, rather than merE'ly Regulation :W as at prE'sent. It was considE'rE'd that DrivE'r Controlled DelivE'Iies E'ngmdered so man v possiblE' infringE'ments of the

Regulations that the present highly fragmented enforcement would make the whole experiment unregulatable and thus render any results unreliable.

The co-operation of all local Authorities in this matter is solicited. If you receive any request to participate in the experiment, or if there are any queries, please contact the Secretary of the Association.

HSE to start licensing: From 2nd February 1985, the inspection of premises and issuing of petroleum licences for premises which are notifiable under the N of Installations Handling Hazardous Substances RegulatIOns 1982 will be transferred to the HSE from the petroleum licensing authorities. There will be around 1800. notifiable sites and it is expected that about half these WIll have or require petroleum licences. The HSE around 5? new sites to be licensed each year. The HSE IS at present trymg to set up a licensing procedure to take over the many forms of licence, periods of renewal and to form some sort of hand over procedure from the Local Authorities. It expected offices and inspectors will issue the new hcences and It IS not expected to be carried out centrally.

Revised explosives fees: to the fees charged by local authorities for explOSIves stores and registering premises where explOSIves are kept, are announced in a consultative letter by the Health and Safety Commission.

I t is proposed that the fees for an explosives rise from the current £30 to £36 and for the regIstratIOn of premises from £5 to £6. The fees, which are to cover the full financial costs incurred by local authontJes when d d·· ·ses "'ere last increase Issumg lIcences an regIstenng preml ," in 1983.

Exemption Certificates: Certificate No 6 to the Dangerous Substances (Conveyance by Road in Road Tankers & Tank Containers) Regulations has been granted Caleb Brett Laboratories for the operation of their volumetnc provers and is similar to Certificates Nos 4 & 5 (see The Bulletin for August 1984). Certificate 7 similarly provers operated by local weights & measures authontIes.

Certificate No 8 covers the transportation of underground storage tanks removed from filling stations. Normally tanks are cleaned and purged before they are removed, b.ut it is not possible to do this, the tank is then transported ,;hile It still contains some sludge/liquid/vapour. In Which. cas.e It then qualifies as a "tank container" and the vehicle movmg It come under Regulations 6 & 7 of the Regulations. ,!,lus Certificate exempts such vehicles from these RegulatIOns subject to certain conditions. It also exempts them from the Regulation IS, provided two hazard waming panels are fitted to the vehicle.

Certificate No l:-l revokes the previous Certificate No :·t It has been issued to allow the use of clip-on caps instead of screwcaps on the discharge pipes of petrol tankers which have been constructed or modified for bottom loading only.

Already, Exemption Certificate No 1 has been issued under the nE'W Classification, Packaging and Labelling llfDangerllus Substances Regulations. It covers LPe cylinders and all(l\\s somE' relaxation from the requirement to meet the presnilwd standard of labelling giving some flexibilit \' in roillllling etl'.

The CBI have formed an Explllsiw lndustn l;roup \\ith tlw intention of pro\'iding an industn forum \\ hieh \\ ill devt'iop a consensus \ ie\\ Oil an\ \It'\\ Ill' pn lpllsecliegisiatillll,

both national and international, and be able to represent this view in discussions with the HSE and other authorities.

Anybody interested in joining this Group should contact Mr. D. Watkins at the CBI, 103 New Oxford Street, London WC1A mu.

Shell Research UK has combined forces with a West German manufacturer to develop a system which automatically prevents a customer from overfilling his vehicle autogas tank.

Called AVTOPS (Automatic Vehicle Tank Overfill Protection System) it is a self-contained system within the dispenSing unit and requires no additions or modifications to vehicles. As such, it takes the responsibility of not overfiling out of the customer's hands and limits their ability to fill above required maximum filling ratios. I t is claimed that because It IS on the dispenser it is not subject to the poor maintenance and unauthorised modifications that vehicle-installed safety devices often suffer.

AVTOPS operates by sensing the pressure rise of the product in the tank during refuelling and stops the delivery pump when the pressure rise exceeds a critical value.

The prototype is being commercially produced in Germany, and should be available in this country this year.

Liquefied Petroleum Gas Industry Association N GITA) announce the publication of their Code of Practice 20 ."Automotive LPG Refuelling Facilities". This new f '1: .WIll cover both retail filling stations and privately owned aCIdlbles. It has been developed so as to be compatible with mo e codes f, I fillin conil or petro I . g stations in order to prevent any Ltd Ig The Code is aVailable from William Culross & Son ., oupar Angus, Perthshire, Scotland.

D.I{. PETROLEUM DEMAND LIFTS.

Figures' d b h in! d ISSue y the Institute of Petroleum show t at by for petroleum products in the D.K. increased in 1983 I) dunng the first six months of 1984 compared to that OVer th' The demand for motor spirit showed a rise of 3.3% e corresponding 1983 January June period.

Chief Fire Officer, Derbyshire Fire Service, L. C. Hathaway, Dart Oil Co. Ltd., Mr. D. Walker, Mr. A. B.Johnston, Independent Pumps (Northern) Ltd.,

Mr. D. Whiteley, Independent Pumps (Northern) Ltd., Mr. P.]. Fooks, Mr. D. Rees, Mr. R.]. Reeves, . Mr. G. Hemingway, Pump Maintenance Ltd.,

Chief Fire Officer, Derbyshire Fire Service, L. C. Hathaway, Dart Oil Co. Ltd., Mr. D. Walker, Mr. A. B.Johnston, Independent Pumps (Northern) Ltd.,

Mr. D. Whiteley, Independent Pumps (Northern) Ltd., Mr. P.]. Fooks, Mr. D. Rees, Mr. R.]. Reeves, . Mr. G. Hemingway, Pump Maintenance Ltd.,

Operational weaknesses in rail wagon parking procedures w:re primarily responsible for the events which led up to the spillage of about 90 tonnes of petrol during offloading operations at the Micheldever Oil Terminal near Winchester Hampshire last year, says a report published by the Health and Safety Executive.

There was confusion regarding the allocation of responsibilty between British Railways and the terminal British Pipelines Agency Ltd (BPA) for the safe POSltIonmg of trains on the sidings and despite previous train movements in the depot neither knew t at an unauthorised parking system had allowed to on site, says the report, a detailed investigation of the ent by HM Factory Inspectorate in conjunction with the ill ways Inspectorate.

The incident 0 2 F b ' b . ,n e ruary 1983 occurred while petrol was offloaded from ten rail tank wagons posItIoned in sidin l'd fault ki gs ill on a rising gradient. Because of ap / ng procedures which left handbrakes ineffectively of rh:fl wagons, the train moved, initially rupturing two hoses connecting the wagons to the off-loading , sequent movements severed three more.

About 90 to f says the fines 0 petrol was spilled over a period of time petrol Fortunately no ignition occurred despite yard of g .ooded out from the siding to cover a concrete 10 Centi:p;oXlmately 2,000 square metres to a depth of up to The term·e and to completely surround an office building. ma IS owned by Elf Oil (GB) Ltd.

A number of concemin th are made in the report, loading eg . e deSign and construction of rail sidings and offwagon parklpment handling highly flammable liquids, rail and termi lng procedures and the need for British Railways na operator all f I al lllstructions t s gener y to review the issue 0 oc specific site 0 employees concerning working procedures at s.

The recomm d . preVenting th en abons fall into two groups: those aimed at towards mini' e. ?Ccurance of spillage and those directed mlSlllg the B Consquences should one occur. ecauseofth hoses betwee e of the incident, the report says flexible be fitted With: header lines and rail tank cars should before any deakawaycoupling.This device is designed to Inadvertently amage can occur to the hose if the tank car progress. The 70ves away while product transfer is still in halves of each coupling contain valves her the fixed close to prevent loss of product from Brief. Ifold or the tank car. whi aCCOunts of a II have occurr dn.umber of serious fuel spillage incidents le Ieport. "It is of e at other Sidings since 1973 are oiven in IIlve t' note'" d " o- S IgatJon v.' ' It a ds, that during the course of the 1I11rov ' anous 't enanted 111 WI nesses refelTed to previous tllPir' C oveme t f , III ormation ' n s 0 trains within the sidings, but /ormal/ remams d db Y reported, ' anec otal as no incidents ha een pnlcedllres". as Would have been required by company

Such /pedback ' Sugge t d \\1' h 1he safe opera' s e to the HSE that those concerned ( dll,,(,1 ,!I'Ii ,ITj to h(>('tJ on of hazardous goods rail terminals I ,Ome throu h d f '1' 't 'th I JI' !'Ish, III dJl\ v uy. " g every ay ami Jan y Wl If h 'I' (', complacent about the potential injury at

Before operations resumed at the terminal discussions were held between BR and BPA to establish safe braking practice for tank wagons at Micheldever which took account of the gradient of the sidings etc. The division of responsibilities between BR and BPA staff on site for the security of trains was clarified and new instructions and training were given to those involved. Further supervision of both staffs was also introduced. In addition, a number of longer term improvements are being introduced at the site. For instance the operators have just placed an order worth several thousands of pounds with Alpha Process Controls (International) Ltd. for the fitting of 28 of their Fluiseal DryBreak valved couplings.

Hemel Hempstead Magistrate Court heard the permit-towork certificate used by a major oil company in one of its large petroleum installations described as "not worth the paper it was written on".

The Court was hearing evidence from a Senior Chemical Inspector of the HSE in a case brought against the Mobil Oil Company of Hertfordshire County Council following a fire that occurred in the Buncefield Oil Terminal. He continued that the hot-work certificates used were not even in accordance with the industry'S own standard, as laid down in the IP Marketing Safety Code. The company faced four charges of failure to comply with licensing conditions.

InJune 1984, whilst contractors were inside a bund at the terminal carrying out alterations to pipework, there was a spillage of petrol in the bund followed by a fire. Prompt response and action by the fire brigade controlled the fire within 13 minutes, preventing a major disaster.

Investigation revealed that although for this work one item of hot-work had been authorised in a comparatively safe area. this had not been carried out in the area specified. Furthermore, other, unpermitted hot-work had been carried out within the bund in the immediate area of two petrol pipelines. The pipework under alteration, although supposedly dry, contained petrol leaking via a valve on the tank. This had spilled into the bund from a loosely bolted flange and an open drain connection. Vapour was also issuing from an open flange. The bund area had been wetted with water prior to the work, allowing the spilled petrol to float on top.

The fire brigade found that although the generator of an arc-welding set was outside the bund, the leads from it were lying inside, close to the fire area. Evidence was received that leads were lying "apart" (on wet ground) with the generator running prior to the fire. While it was not possible to ascertain the actual source of ignition, it was considered that the most likely cause was an arc from these live leads.

The four counts the company faced were failing to maintain the main tank valve, failing to take due precautions to prevent fire and explosion, failing to maintain a safe area after issuing a hot-work permit and failing to give notice in writing of intention to make alterations. On all but the last count the company pleaded not guilty, claiming that there was no evidence to prove that the valve was defective or not maintained, that the company had taken reasonable precautions and that hot-work certificates were not a requirement of licence but a "peI111issive" condition which could not be breached in law,

B UNCEFIEW Fire damaged pipes to Tank No. 4 Showing flange which leaked.

B UNCEFIEW Fire damaged pipes to Tank No. 4 Showing flange which leaked.

During the case, the court heard that for the alteration work there was little effective liason between the company and the contractors, safety matters being handled purely in verbal discussions. No explosiometers were used on site, the man detailed to issue the hot-work certificate had no training or experience in this work and the company's own safety regulations were only vaguely understood and were not followed.

The court found all the cases proved and imposed fines totalling £5,500 with £500 towards costs.

A petrol filling station closed and when the licence expired it was not renewed. Over the following year correspondence failed to persuade the owner of the site to fill the tanks either permanently or temporarily with water.

Eventually an improvement notice was served on the Limited Company which owned the site with a copy personally delivered to a director of the company. The director requested an extension of the 24 days specified in the notice on the grounds that the filling station was to re-open imminently. An extension was duly granted and when the time limit elapsed an Information was laid before the Court alleging that the company had contravened a requirement of an improvement notice and that the offence was attributable to the neglect of the director.

The matter came before the Sandwich Magistrates' on the 22nd July 19H3 when the director of the company pleaded guilty and was fined .£200 with £75 costs. In addition the Court made an Order under Section 42 of the Health &Safety at Work etc., Act 1974 that the tanks be filled with water

within 28 days unless the filling station was re-opened and a licence issued by the licensing authOrity.

The Licensing Authority refused to issue a licence until a current electrical certificate was produced and despite assurance that the work was in hand the certificate was not forth coming. During the next year the site was re-possessed by a fmance company but was later purchased back by the original Director acting as a Director of a new company. Eventually he was brought back to Sandwich Magistrates Court on the 2nd November 1984 charged with failing to comply with the Court Order. A plea of GUilty was entered and he was fmed a further £600 with £50 costs. The Court was informed that the petroleum station was to be opened in the next few days although the licence had still not at that time been granted.

On the 25thJune 1984 Grimsby & Cleethorpes Magistrates Imposed a £20 fine with £37 costs on Mr. Frederick Taylor, a local petrol pump attendant.

The licensed premises at which Mr. Taylor was employed was visited on the 12th January 1984 by Trading Standards The was fulfilling a Weights and Measures Act appomtment. Whilst on the premises the officer noted that Mr. Taylor,. in his capacity as a petrol pump attendant, was about to dispense petrol into an unmarked container. Mr. Taylor was informed by the officer that it was an offence to do so, but he still proceeded to dispense the fuel.

Action was brought under Section 7(b) of the Health and at etc. Act 1974 for failing to comply with a duty Imposed on his employer by virtue of a licence condition.

Proceedings were instituted against a large local petrol retailer for failing to comply with two licence conditions and also contravening paragraph 5 ofSchedule 4 of the Dangerous Substances (Conveyance by Road in Road Tankers and Tank Containers) Regulations 1981.

The premises of a Hull licensee, were visited on the 26th March 1984 by a departmental Enforcement Officer. Observation on the forecourt by the officer indicated that a delivery of fuel was taking place from a tanker into underground storage tanks. Two delivery hoses were connected from the tanker outlets to the fill pipes oftwo ofthe tanks. No warning sign or person supervising the delivery was noted.

The defendant company pleaded guilty to the following three charges:-

1. Failing to display a warning notice prior to an underground cover plate being removed. (Licence Condition)

2. Permitting the delivery from more than one tanker compartment when permission for more than one simultaneous delivery had not been given by the licensing authority. (Licence Condition)

3. Failing .to ensure a competent person was in charge during the dehvery. (1981 Regulations) and were fined £50 in each case with costs of £53.

pipe, owing to insufficient ullage in the underground tank.

At the court hearing the company entered a guilty plea and were fined £400 with £121.78 costs. (note the variation in fines imposed in these three cases Editor).

The Petroleum Branch of the London Fire Brigade were notified of petroleum spirit being found on a River one Sunday evening in the Romford area. The River emerged from a culvert which ran under the busy A12/A127 interchange at Gallows Corner. Petrol was traced back to one of the numerous sites in that area. Petrol was found in several manholes including the petrol interceptor, examination was made and it was found that one of the tanks was being pressurised, and petrol w,,:, flowing out of the. ground off set pipe, even though rt was capped. The Imtlal problem was resolved by having a tankwagon and guIley cleanser remove petrol and prevent further outflow to the river. Later product was uplifted from the the three year old installation was tested and the followmg proved.

The gauges installed are the type which the levels are taken using a small compressor these are then transferred int.o electrical readings and ticket printer in the console area. gauge proved to be inaccurate and read 800 litres too low. FlV.e days before the incident this tank was overfilled, due to this low reading. It was also found that the tank vent had an "adverse fall" and therefore petrol within the vent did not fall back into the tank.

A petrol tanker in Kent was seen on licensed premises with hoses coup!ed to under-ground tanks but no persons apparently m attendance. The officer on closer inspection fou?,d that the drivers was in his cab smoking whilst the delIvery was taking place. There was no one in attendance representing the licensee of the premises.

The offence committed by the driver falls under regulations 11 of the Dangerous (Conveyance by Road in Road Tankers and Tank Contamers) Regulations 1981 which is enforced by either the H & SE or local EHO and therefore the only contravention which could be prosecuted by the Trading Standards Department was that of non attendance by the licensee. the H & SE agreed to lay an information based on the eVidence of the Department's officer and both prosecutions were undertaken in Court by the Department with an H & SE present. The tanker driver and licensee were fmed £250 each.

Further proceedings were instituted for failing to comply with the Dangerous Substances (Conveyance by Road Tankers and Tank Containers) Regulations 1981 against a licensee in Scunthorpe for failing to ensure that a competent person was in charge during a delivery to an underground storage tank.

The incident occured on the 11thMay 1984 when a delivery of 2000 litres of 4 star petrol was being made to the premises. A young office girl made out and sig11ed the statutory certificate indicating the tank would hold :WOO litres, although she had no knowledge that there was sufficient ullage.

Throughout the delivery no one from the company was in attendance and because the compartment on the road tanker contained :-l,4000 litres of petrol the driver had to control the delivery from the top of the tanker.

During the delivery approximately -W gallons of petrol escaped from the joint between the tanker hose and tanker fill

The compressor feeding the was pumping .around 4.5 psi into the tank, this in normal CIrcumstances dIsperses through the vent pipe. In this case with the vent full of petrol pressurisation of the tank occured and petrol flowed out of the offset fill pipe, into the ground through the porous manh:;t was proved that over 4000 litres came out of the tank d g this period and was not recovered.

. . I hr Id had the GRP

The mstallatIOn, on y t ee years 0 , . I d 't found to have two petroleum mterceptor rep ace as 1 was d d large holes in it. New vent pipes to the tanks were ru:. . '1 emed is reviewmg Its It IS understood the 01 company conc policy on tank gauge suppliers.

As the result of a change in occupancy. of a site, the licensee eventually vacated, leavmg the SIte Subsequently, parts of the site were o,:cupied by van?us traders, resulting in the forecourt area bemg used for vehicle maintenance, storage, access to buildings etc.

Follmving some lengthy the new licensee (the Petroleum Licence stilI bemg 111 force) and eventually serving summonses on him, the case came to court in September 1984.

The case was somewhat confused by the fact that the present licensee had only taken over the inJuly, and that the previous licensee was still employed by the company. Despite the absence of the previous licensee, the case proceeded. The present licensee pleaded guilty to charges of failing to notify transfer of occupancy, failing to make tanks safe, failing to keep fill pipes locked etc and failing to give notice of discontinuing the use of the tanks, and \vas fined a total of ,i:500 plus ,CH) costs.

In the meantime, and as a result of the proceedings, six underground tanks were made temporarih safe b\ blanking off connections, filling manhole chambers \\'ith sand and cement se reed and tht' isolation of all l'iectlirs. It is ant icil la led that this site will ewntuallv be bnlllght back into ust'

Following a telephone call that a person was storing petroleum in a private terraced house, the .Officer accompanied by another Officer of the Fire Service VlSl ted the premises. Unable to obtain an answer, the Officers proceeded to the rear of the premises and saw approximately 50 gallons of petrol in 5 gallon plastic containers stacked against the rear of the house.

Proceedings were initiated by West Glamorgan County Council, there being two charges as follows:-

(1) Keeping Petroleum Spirit without the requisite licence in contravention of Section 1(1) of the Petroleum (Consolidation) Act 1928.

(ii) Keeping petroleum spirit to which no warning label was attached contrary to Section 5 of the Petroleum (Consolidation) Act 1928.

Subsequently the hearing was held in the Magistrates Court in October 1984, the Plaintiff pleading guilty on both charges.

Being a guilty charge, no evidence was required. Nevertheless the Court awarded a conditional discharge; costs of £45.53 (independant analYSis of petroleum samples) were awarded in favour of West Glamorgan County Council.

Over a period of months a number of anonymous complaints were made to the Department alleging that inflammable liquids were being kept at a private house in Gravesend. It was imposssible to verify this information by observation, and informal contact resulted in a denial by the occupier that any such liquids were being kept. A complaint was eventually received from a neighbour, which gave sufficient grounds to apply to a Magistrates Court for a warrant under Section 18 of the Petroleum (Consolidation) Act 1928. When the warrant was executed a total of 110 cans of varying sizes from 1112 to 2112 litres were seized. A number of the cans were sent to the County Analyst to confIrm that the contents which were paints and thinners were in fact petroleum mixtures.

On the 3rd October 1984 the occupier entered a plea of guilty and the Magistrates accordingly convicted but awarded a conditional discharge for six months. All of the seized cans were ordered to be forfeited . Aagh! Corner

an HSE Inspector visited a company, he found that theIr records regarding their keeping of explosives and detonators did not quite add-up. A total of 293 kg of explosives and 119 detonators could not be accounted for. Further investigation revealed that the missing items were, in fact, stored in (a) a hotel bedroom, (b) the car park of this hotel and (c) an unlockable box in a van which was in general use.

Proceedings were instituted against the company and they were subsequently fined a total of £500 plus costs.

A total of 153 members and guests attended last years Seminar held at the Queensway Hall in Dunstable on October 16th. All who attended agreed that this was one of the most effective and interesting events of its type ever held. Congratulations are due to all involved in arranging and orgallising the Seminar.

Delegate registered at 10 o'clock and after a reviving cup of coffee (sorely needed by those who had just braved the roadworks on the M 1) they were ushered into the lecture hall to be welcomed by Jamie Thompson . He then introduced the first two speakers, BIian Webster of the NICEIC and Pat Lloyd of the HSE. The text ofMr. Websters talk is given in this edition, we hope to have Mr. Lloyds available in our next. As might be expected, these gave rise to considerable discussion afterwards, especially Pat's when he faced some quite hostile questioning.

After this, an excellent launch was served at which the discussions continued, heatedly in some case's. After lunch, there was a very comprehensive trade exhibition to be visited, where the exhibits engendered considerable interest, including the new DCD control box unit.

was given over to a joint presentation by Martm SImpson of UK PIA and Mike Sewell of the HSE on Driver Controlled Deliveries. It maillly consisted of a slide/ tape presentation produced by the .Road Tranport Comrmttee of the UKPIA. After a short introduction by both presenters, the slide/tape was shown, followed by a lengthy questIOn and answer penod, when the presenters were quizzed over the effects of DCD. The Bulletm WIll undoubtedly be returning to this sub'ect in the very near future.

Mr. Webster is an Inspecting Engineer with the NICEIC. The views expressed in this article are his own and are not necessarily those of the Council.

The National Inspection Council for Electrical Contracting (NICEIC) is a non-profit making consumer organisation set up in the mid 1950's. Its aims and objects are protect consumers of electricity agaillst faulty or otherw1se unsafe installations, this duty being fulfilled by carrying out regular inspections of some 9 to 10,000 electrical contractors, Electricity Board Contracting Departments and Drrect Labour Departments of Local Authorities. The NICEIC publishes a roll armually of commercial or Approved Contractors. To be on this roll, the busmess must satisfy the National Inspection Board of Its tec.hnical competence, prove its ability in respect of workmanship and be a commercially sound business of some 2 to ? years standing. However not all of these businesses are eqmpped to cany out work on petroleum installations or issues Petroleum Certificates. In the NICEIC News Letter No 61, we adVIse that if a contractor is not conversant with the relevant Codes of Practice for petroleum installations, then he must not. carry out such work, as the legal implications are so great m the event of signing a Certificate for a faulty installation. We have specialist contractors in each area, who carry out forecourt installations and certification and your local NICEIC Inspector is a ware which films are capable of this class of work and would be pleased to give advice.

The NICEIC requires each contractor to possess the current copy of the lEE Regulations, the 15th Edition of which was published in 1981 with ammendments dated January 1983 and May 1984. This publication comes into full :ffect ;n January 1985. The statutory requirements of the 193/ Supp y Regulations and the 1983 P.M.E. Regulations must also be complied with in order to obtain a supply from the Electl1Clty Boards. The ElectIicity Council have issued two Engineenng Recommendations which give the design mfol1natlOn required by the 15th Edition P.2 3 which gives the values of Ze (external earth loop impedence values) al1d P.25 glVes values of P.S.C.C.'s (prospective short for consumers with service lenoths of up to c)O metles. Bo these Recommendations are services up to 100 amps It must be stressed these are for guidance onl y al1d may not apply in the London El ec tIicit y Board areas or other Ctt y centres where th ere are parallel distribution cabl es and large supply tra.nsf0Il11ers

The relevant Codes of Practi ce appl ying to p etrol eum installation s in us e today are th e APEA Cod e the 1%9 H o m e Offi ce Mod el C ode and th e NICEIC El ectnClan s Handbook No 3 (wh.i ch is no w Ullfo rtun a tely out of ptint ). I und erstand that th e H SE are to brin g out a re vised Co d e of Practi ce of th e ir ovvn.

vVh en carrying o ut a foreco urt insp ecti o n, th e foll owin g point s lllu st be co nsid e red and examin ed:

This is usually provided by the Electricity Board supply cable sheath or overhead earth, which is now referred to as TN.S. or Terra Neutral at the sub station and separate in distribution. If this is not available, the alternative is to us e Current Balance E.L.C.B.'s which are now called R.CD.'s or R C C.B .'s (Residual Current Devices or Circuit Breakers). If only one of these devices is us ed at th e main intake it is not suitable from safety or security standpoints, as it could operate while petrol is being dispens ed, thus breaching Regulation 3 14 1 (i) which requires that the operation of a device will not cause danger or inconvenience So ifR.C.D protection is to be employed, then more than one device will be required These will have to b e so arranged and co-ordinated so that discrimination is obtained between devices, to prevent the loss of (for example) the 100 lux level of illumination at the pumps or the delivery read-out (although, no doubt, read-outs can b e fitted with memories). Without such discrimination, a faulty appliance in the showroom would have disastrous results on the forecourt b y totally cutting off the supply. Discrimination can be achieved by installing a larger device device (say 300 mAl at the supply and smaller devices (say 30mA) to protect parts of the installation. A factor that must not be overlooked is the disconnection times for the various R.CD .'s; the d evice a t the supply must have a slower disconn ection time than the individual parts d evices. W e may find increasing use of this method of protection, as I understand that some Electricity Boards will not provide TN.C. S or P M.E terminals for petroleum installations in some areas. Th ey are concerned that either earth circuits could return to their network via the petrol storage tank on one ext rem e or, in the event of a non earthed tank, the whole of the

forecourt becoming above true earth potential under distribution fault conditions.

Shock protection measures given in the 15th Edition will require the bonding of earthed services within the consumer's premises to the main earth terminal, so as to create a Faraday Cage situation. This will involve the bonding of gas, water, oil and air lines together with any structural metal work connected to the general mass of earth and such things as the flow to and return from a central heating boiler. The size of this main bonding conductor is determined by the use of the Adiabatic equation found in Regulation 543-2 For simpler calculations, Table 54F which gives the relationship between conductor and bonding cables Can be used:

Phase Conductor cross section Protective Conductor crosS mrn 2 section mm 2 up to 16 equal size 25 & 35 16 over 35 50% of conductor size

One aspect?f 15th Edition is the emphasis on protection from short rather overload. The regulations adaquate consIderation be given to the shortClTcwt capability of equipment. Protective devices or M.C.B.'s must b e capable of clearing or breaking the maximum fault current without damage The fault level or short-circuit current varies with the distance the equipment is from the supply source (transformer or alternator) and is at its

maximum the nearer the installation is to the source. The Electricity Council's Engineering Recommendation P.25 gives fault levels for consumers with up to 100 amp supply related to service lengths from 1 to 50 metres.

Service Length P.S.C.c. Device Required metres kA

zero 16

Cartridge Fuse 8 8.8

Cartridge or M9 MCB 1.') 6.0 Cartridge or Mli MCB 26 3.9 Cartridge or M4 MCB or S4 semi·enclosed

SO 2.2

Cartridge or M2 MCB or S2 semi-enclosed

This in effect means that the 250v S2-type semi-enclosed fuse and the Ml and M2 M.C.B.'s would only comply with the Regulations if they are supplied from a service which is terminated some 50 metres from the consumers premises.

The code letters Ml to M9 refer to B.S.3871 M.C.B.'s types to .3, rated between one and nine thousand amperes, short CIrcUIt. Type 1 have the maximum magnetic cut-off of 4 x the rated current are the most sensitive. Type 2 have a cut-off of7 x, and type 3 have acutoff ofl0x the rated current and are progressively less sensitive.

The code letters SI to S4 refer to B S 3036 se' 1 d ml-enc ose fuses, rated between one and four thousand h circuit. amperes, sort

Cartridges are either B.S.88 part 2 rated at 80 kA h circuit and .cod.ed AC 80 or BS 1361, which are rated at\ kA, short CIrCUIt. )..

Thus use of P.25 enables us to determine th 't b'l' h · . d . e SUI a I Ity of t e maIn protectIve eVlce in respect of sh t. or CIrCUIt current. Shock protectIon measures o-iven in th 1 t: h di '. o' e at EdItIon reqUIre sconnectIon tImes of 0 4 seco d c . d t: d . n s lor portable eqUIpment an "secon s for fixed equI' d b 1· h 1 pment. This IS acheive y ImltIng t e va ues of Zs to withi h aiveninTables41Al or41A2respectively Z t edfiblgures o· '" A . SIS lOun y the use of the equatIOn gIven In ppendix 8 of th RI' Zs = Ze + RI Rs e egu atlOns: where Ze is the earth loop impedence at the origin of I (the meter position) supp y

R is the resistance of the conductor I is the resistance of the C.P.C. (or earth wire) giving Zs the earth loop at the furthest point on the circuit.

Ze is determined by making an earth loop impedence test at a safe and convenient point as near as possible to the mains position. This can be used as a reference point. On no account must the Earth Loop Impedence Tester be used in Division I or II areas as it is not an intrinsically safe instrument, and it passses a heavy current for a of a Earth loop impedence tests should be made WIth the maIn bonding NOT in circuit using the link required by Regulation 542- 20, if at all practicable.

It is now possible to proceed with the visual inspection of the site, checking that such things as lay-out, separation distances etc conform to the requirements. Provision of notices, fire equipment etc must also be examined. It is also important to be on the lookout for glaring errors it has not been unkno\\11

for tank vent pipes to be used as masts for telephone wires etc! Lighting must be inspected too. The 100 lux standard of illumination at the discharge point is an important factor; and if the discharge point is below the canopy, a tanker must have clearance of 1.25 metres. or else the lighting has to be of Division I standard:

Before attempting to carry out electrical tests on pumps, the covers must be removed to allow the vapour to escape. All equipment within the pump must comply with the relevant BASEEFA or equivalent standards. All cable glands must be tight it is not uncommon to find one in ten loose, even on a otherwise good installation. Glands should be coded BAS 112U ExIlb, the olive type (not wedge-type), with five threads (if metric) or one inch of thread (if imperial). It is important to check that the glands are in the correct threads espeCially if imported pumps are installed.

Using the "reference point" mentioned above, it is possible to carry out earth continuity measurements to determine the values of R2 in the equation given in Appendix 8. The instrument used in such measurements must be capable of measuring one ohm over a wide portion of the scale. Multirange instruments do not usually have such a scale so the test should be made with an Insulation Continuity Instrument. If this meter is not intrinsically safe it must be held over 1.25 metres from the ground when near the pumps. Loose or damaged pump housings (due to impact, vandalism etc) must be especially considered and their continuity checked. The reading to be expected must be less than Ih ohm both the motor and pump housing. Readings greater than must be considered suspect as it is possible to obtain low readmgs of an earthed petrol tank on its own. Earth continuity tests. must also be made on the Fireman's Switch and the control SWItches within the kiosk. While testing the Fireman's Switch, it is advisable for non-corrosive fixings and any unused holes being blanked to prevent the ingress of moisture.

Circuit arrangements should be such that each pump is on its own circuit, and the isolator switch not only isolates the pump but the pump light as well. The isolator switch must be clearly marked as it is possible the wrong box could be opened exposing live terminations. For the same reason joint boxes should be avoided. The isolator for a single phase pump must be of the double-pole type, breaking both the live and neutral COlU1ections as an inbalance in the supply netwolk may pelmit small voltages to be present in the neutral conductor, which, while not presenting a shock hazard, could result in a spark.

The 15th Edition now requires isolation for three reasons.Functional SWitching (i.e. at the pump and in the kiosk): Mechanical Maintenance (i.e. either by the control panel or opening the s SvV1tch) Emergency Switching (i.e. the FiremaIl's S\\1tch or a Ice under the control of the person in the kiosk). As mentIOned before, mechanical maintenance switching must isolate both motor and light.

Finally, all other considerations having been checked, it is now possible to proceed to make the insulation test. TillS should be done with the main switch off, solid state deVIces isolated, neutral link detached in the case of three-phase ,iI:stallations and pump motor s\\'itches in the "off' 111(' test should be made at twice the R.M.s. voltage e.g. 2 " 2,SO volts, which means a .'lOO volt D.e. test in most cases. Thl' minimum reading should be :)0 megohms di\'icied by tht'

number of points but in no case should it be less than 1 megohm. For the 1937 supply regulations, the leaking current must not be greater than one ten thousandth part of the maximum demand. IfR.CD.'s are installed, they must be tested with an instrument complying with the specification laid down in Appendix 15 Item 6.1, May 1984 Edition.

With effect fromJanuary 1985, allJ.I.B. graded electricians will be required to hold the Certificate awarded at the end of a "15th Edition Assessment" course, which is run by most Technical Colleges. Although mandatory for electricians, it is strongly recommended for all who have an interest in the subject and past courses have been attended by Petroleum Officers, architects etc.

Report on the Address given by Mr. B. O. Lowe Chainnan of the APEA, to the AGM of the Yorkshire and Humberside Branch on 22nd March 1984.

Mr. Lowe thanked the branch for the invitation to attend the meeting and expressed his pleasure in being afforded the opportunity of wearing the National Chairmans badge of office.

He outlined the struggle which ensued from 1974 local government re-organisation to keep the Association viable, however he reported that the finances had vastly improved due in the main to income from the seminars.

Generally the situation regarding the branches was very good but concern was expressed by him with regard to the South Eastern branch. Attempts were to be made to reform it again.

Mr. Lowe informed the meeting that regular meetings of the national council were being held from which good ideas and material were being produced including the revision of the existing A.P.EA. code and a further seminar in the Autumn.

The 'old chestnut' of licensing regulations had been a topic for discussion and although the Health & Safety Executive were looking towards regulations the industry had advised that there are advantages in the licensing system. In particular they like the seal of approval from local authorities.

The national chairman also reported that the Association had been invited by the Health & Safety Executive to discuss the position regarding the enforcement of regulations relating to tankers. The opportunity was taken to outline the lack of enforcement in this area and the resultant problems.

He went on to say that the opening up of the Association to industry and commerce had proved to be a great success with the injection of new ideas and support. However he expressed concern that standards are maintained. He was not against change but was concerned in particular with regard to a code of practice drafted by industry, submitted to the Health & Safety Executive without any input from the Association.

He concluded by expressing his thanks to the branch for his invitation to attend and address the meeting.

A new lamp unit for general purpose illumination in Zone 1 hazardous areas has been introduced Known as the Tubolight 44, it is designed to be used to light gangways, bays and storage tanks where the hazardous nature of the environment prohibits conventional lighting.

Further details from: The Wolf Safety Lamp Co. Ltd., Saxon Road Works, Sheffield, S. Yorks S8 OYA

A new range of smaller oily water separators has been introduced, designed for the smaller industrial application. as the Mini Skim TKS range, there are three models g1Vmg treatment capacities from up to It is claimed that they can .treat wastes to below local authority reqwrements. Each umt has a built-in storage corn t t par men, gIvu:g high storage for separated oil, thus reducing on-sIte costs. The uruts can be operated both above and underground

Further details from: Skimovex (U.K.) Ltd., Highway House, 17 London End Beaconsfield. Bucks HP9 2HN. '

A range of storage cabinets for flammable liquids and similar dangerous chemicals which incorporate an alarm has been introduced The alarm gives a warning if the door of the cabinet remains open for longer then 15 seconds. It is designed to give sufficient period of time for authorised access before sounding and will deactivate when the door is properly closed.

Further details from: Swift-Act Tools Ltd., Oakfield Road, Kingswood, Bristol BS15 2LT.

A vertical double-walled tank intended for the storage of autogas at service stations has been developed It has perlite insulation in the vacuum space between the two walls, which affords extra insulating properties in the event of fire engulfment. It is claimed it can withstand fire for extremely long periods without the inner tank rupturing, which reduces its risks as compared to conventionally designed tanks The vertical orientation not only reduces the need for space, but serves to stabilise the liquid temperature thus increasing accuracy in measurement.

Further det ails from: AGA-Gryo A.B., Box 8887, S-402 72, Gothenburg, Sweden.

Your editor has a quantity of back numbers of the Bulletin going back to Volume 8 (1969) _Appended is an index of the major articles appearing over the past 15 years some of which are defInitive on their subject, others, of great Historical interest-

If you require any of these issues they are available at a cost of SOp per issue (inclusive of post & package) from the EditorCheques made payable to the Association please_

Bund Walls on Petroleum Installations

Diesel Engines Safeguards for use of in Flammable Atmospheres

Dipsticks Testing of and Static Electricity

Driver Controlled Deliveries

Electrical Equipment in Flammable & Explosive Atmospheres Standards & Safety Areas in Storage Safety in Dangerous Areas Instrumentation for use in Hazardous Areas Requirements in the Oil Industry Recommendations Home Office Codes etc

Emergency Procedures

Equipment, Filling Station Automation in Belt Drives for Concrete Blocks on Forecourt Pumping New Developments in (i!l7:{) Prp-Payment Petrol Vending Offset Fill Box Incorporating Gauges

21·4 10·1 10·4 17·4 20·2 22·2

15·2,18·1,21·2 8·3 9·2 9·1 11·2 13·1 9·3,11·4,14·1 9.1 20·3,20·4 20·4 11·4 12·4 15·2 17·1

Pumps, maximum horizontal & suction lift Remote Contents Gauges

Remote Pumping Systems, Installation of Self-Service, Development of Recyling of pumps

Explosives

Fire

Safe Practice & Storage Sale of and its Prevention Portable Extinquishers

Hazardous Chemicals New Regulations for Packaging

Hydrant Fuelling Systems

Incidents

Explosion & Fire at Polythene Plant, Wilton Fire at Teeside Refinery Fire at Conoco, Plymouth Petrol Spillage at N orthhoIt

Tanker Accident at Audley End Over turned Tanker at Erdington Tanker Accident in Suffolk Tanker Accident at Westoning, Beds Filling Station Leak, Bucks Chemical Fire at Barking Spanish Camp Site LPG Disaster Cross Over of Petrol and Heating Oil Tank Explosion on Humberside

Compressor Causes Explosion after Petrol Delivery Exploding Propane Cylinder Damages Garage Propane Leak at Wealdstone Spillage at Micheldever

Interceptors

Plastic Tanks for

Hi·2 13·2 12·2

9·1,22·2 22·4 17·3 13·2 14·1 13·2 14·1,14·2,16·1 12·3 22·3 8·1 8·3 10·2 10·1 14·2 15·2 15·2 lfi·2 Hi· 1 Hi·1 18·4 IS·1 19-:-1 19·3 20·2 20·1 20·1 22·4

Legis lation (Ge neral)

R eo rgani sa ti on of LA's and Pe tro leu m

Planning & the Petroleum Office r Politics of Health & Safety Serving a Petroleum No ti ce (Case Study)

of Car Parks & Garages

petrol marinas

Major Installations & Depots

Petroleum Spirit Installations Administration in

Storage & Transport of Petroleum, LA Re sponsibilities in Professional Responsibility in

New Standards Required?

Some Current Problems (1978) Requirements for Unattended Self S e rvice and Fi ll ing Station Planning Appeal Rejected for Over-Pavement Pumps Practical Application of Part II , Model Code

LPG

ExplOSions & Fire H azard of Taxi Fuel of the Future on Service Stations in Holland Safety Training for Danish Service Station Code for Maintenance and Testing of Install a tions

Pe trol Cans Plas ti c

Petroleum in Germany

Pro perties, Planning Prevention & People Production & Movement, 100 years in A Simple Approach to Conv eyance & Delivery of

12- 3 Hi- I 19-4 20-2 11-1 12- 1 18- 2 13-2

17-2, 17-3 14- 1 16-2 17- 3 17-2 19-4 12- 1 17-2 10- 2

11 -2,14-1 , 14- 2 18- 3,20-1 9-:3 2 1-4 21 3 22-3 22-3 19-3,2 1-3 22-4 11-2 11 -3 16-2 22-2

Pipework & Services

Airlocks & "Spitting" Dunng DIscharge

Drain Line Leakages PTFETape Sealing Ducts on Garage Foreco urts Corrosion of

Radar Ignitions by Safety (General) In Marketing Operations In Handli ng Petroleum a t Di stribution Depots Training & Health on the Forecourt

Static Electicity and Dip rods

Stocks

Control of

Storage Tanks Installation of, Underground Glass fibre Gas Freeing & Purging of Demolition of Disused, Safety Precautions Movement of, Underground Fires and Exp losi ves in Sq uare __ Testing, New & EXl stmg Corrosion of Leaking, Rehabilitation of Pressure Testing G_R_P_ Repair to

Tankers

New Design for Hazardous Substances Loading Systems

I S-I 12-1 19-4 20-3 19- 3 19-1 8-4 10- 4 2 1- 2 21-3

8-2, 12-4, 22- 1 20- 2 20-4 22- 1 8-4,9-3, 14- 1 ll- 3, 14 1, 17-1 10 -2, 19-4 10-4, 18-2 10- 3 11- 4,20 -2 11- 3 12-1 9-3, 15-2 18-4 18-4, 19-2 19-2, 20-2 22-2 17-4 21 2

Illustrated

The pump illustrated is a K5 key controlled unit.

A

Illustrated belo W 1800 gal. unit complete with Gasbov model 1820. Automatic Nozzle and 12' x W' hose.

Throughput 8 lOG. P. M. calibrated in imp. gal. or litre measure to customers reqUirements.

ELTRA GAS LIMITED STATION DRIVE THORNHILL ROAD STREETLY, ' SUDON COLDFIELD WEST MIDLANDS. ' Tel. No 021-353 6288/ 9

Eltra Gas offer a complete service for industrial and domestic fuel supplies of Liquified Petroleum Gas.

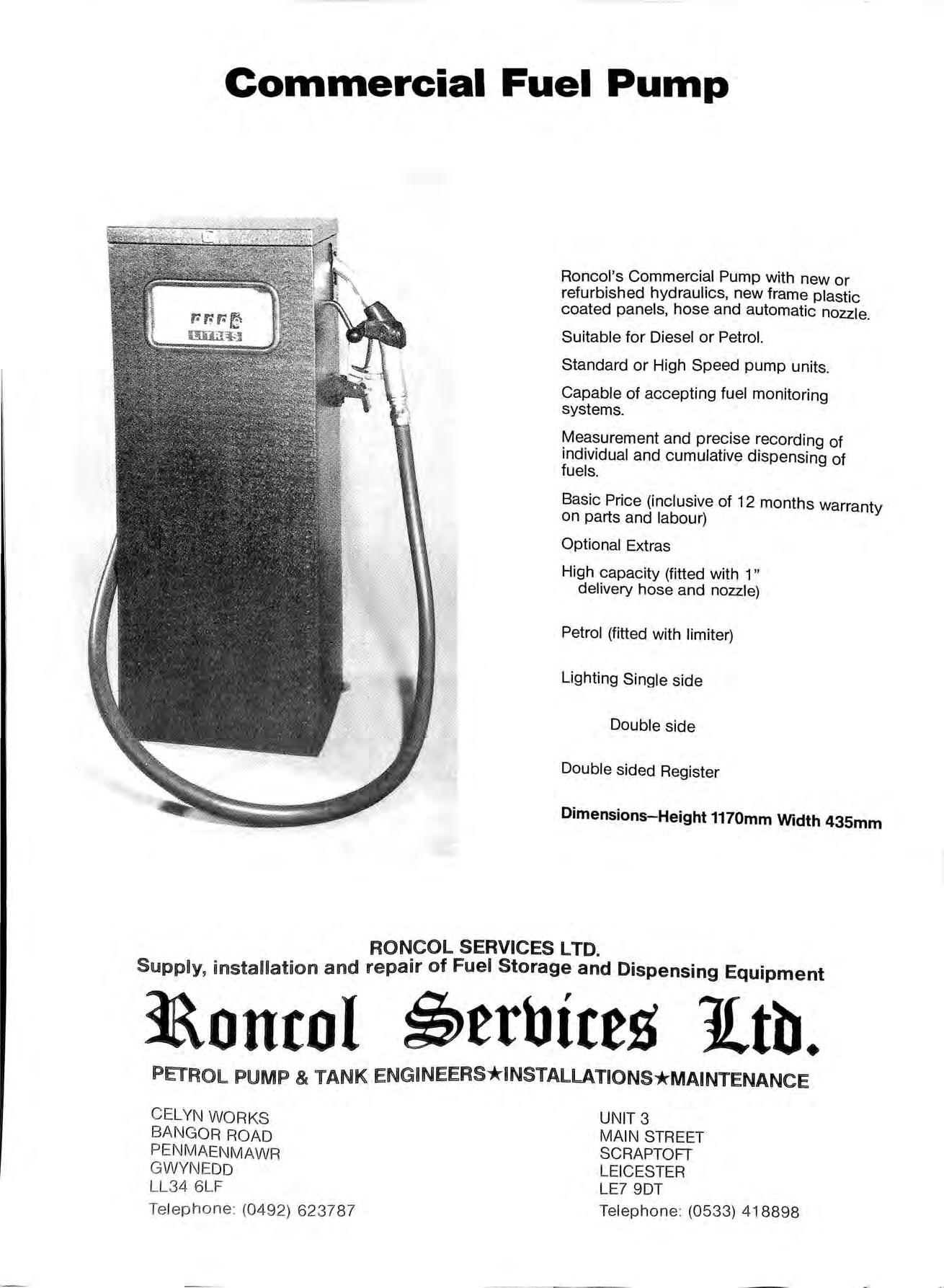

Roncol's Commercial Pump with new or refurbished hydraulics, new frame plastic coated panels, hose and automatic nozzle.

Suitable for Diesel or Petrol.

Standard or High Speed pump units. Capable of accepting fuel monitoring systems.

Measurement

Basic

Optional Extras

High capacity (fitted with 1" delivery hose and nozzle)

Petrol (fitted with limiter)

(Petroleum & Civil Division)

Members of the Association for Petroleum & Explosives Administration

Southern Bay Premises, Alton House Estate, Gatehouse Way, Aylesbury, Bucks.

Telephone: Aylesbury (0296) 22039 & 34481